Page 1

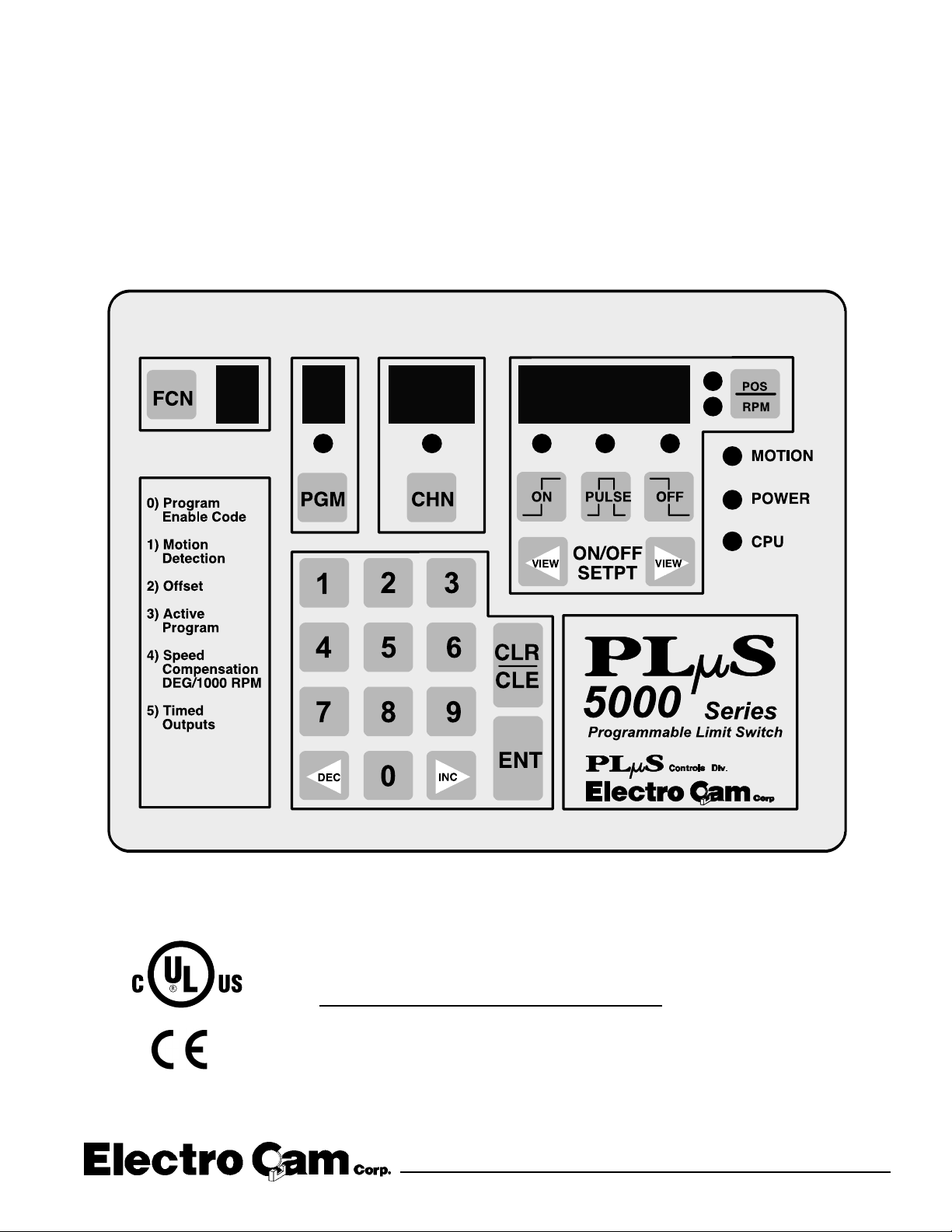

PLµS® PS-5000 Series

Programmable Limit Switch

Programming &

Installation Manual

October 2001

13647 Metric Rd • Roscoe, IL 61073 USA • 815/389-2620 • FAX 815/389-3304 • 800-228-5487 (U.S.A. and Canada)

Page 2

Copyright © 2001

All Rights Reserved

Neither this document nor any part may be reproduced or transmitted in

any form or by any means without permission in writing from the publisher.

®

, PLµS®, SLIMLINE®, and PLµSNET® are all registered trademarks of

Page 3

Table of Contents

Section—Introduction

Basic Cam Switch Operation . . . . . . . . . . . . . . . . . . . . . 1-1

Standard Features . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Optional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Model Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Section 2—Dimensions & Component Locations

Controllers with External I/O Module Rack

5001, 5101, 5004, 5104, 5034, 5134 . . . . . . . . . . . . 2-1

Controllers with I/O Modules on Controller Back

5021, 5121, 5024, 5124 . . . . . . . . . . . . . . . . . . . . . . 2-2

Controllers with Built-In Transistor I/O Chips

5011, 5111 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Section 3—Wiring

Logic Terminal Strip Wiring . . . . . . . . . . . . . . . . . . . . . . 3-1

External I/O Racks (5001, 5101, 5004, 5104)

16 Module I/O Rack—Standard . . . . . . . . . . . . . . . . 3-2

16 Module I/O Rack—Analog . . . . . . . . . . . . . . . . . . 3-2

16 Module I/O Rack—M16 Slimline . . . . . . . . . . . . . 3-2

24 & 48 I/O Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

I/O Modules on Controller (5021, 5121, 5024, 5124) . . 3-4

Module Wiring, Outputs . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Sinking/Sourcing Defined . . . . . . . . . . . . . . . . . . . . . . . 3-5

Module Wiring, Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Input Wiring, 3-Wire Sensors . . . . . . . . . . . . . . . . . . . . . 3-5

Built-In Transistor I/O Chips (5011, 5111)

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Output Wiring, Sourcing . . . . . . . . . . . . . . . . . . . . . . 3-7

Output Wiring, Sinking . . . . . . . . . . . . . . . . . . . . . . . 3-8

Output Wiring to PLC . . . . . . . . . . . . . . . . . . . . . . . . 3-9

PS-5X34 Controller & 32 DC Output Rack . . . . . . . 3-10

PS-5X34 Output Rack Layout . . . . . . . . . . . . . . . . 3-11

PS-5X34 Wiring to PLC's . . . . . . . . . . . . . . . . . . . . 3-12

PS-5X34 Output Rack Transistor Array Chips . . . . 3-13

Resolver Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Cable for Stainless Steel Resolver . . . . . . . . . . . . . . . 3-15

Encoder Cable Installation . . . . . . . . . . . . . . . . . . . . . . 3-16

Section 4—Programming, Standard Features

Access Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Keyboard Description . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Output Setpoint Programming . . . . . . . . . . . . . . . . . . . . 4-3

Master Level Programming

FCN 0 Programming Enable . . . . . . . . . . . . . . . 4-4

dr Direction of Rotation . . . . . . . . . . . . . . . . 4-4

SF Scale Factor . . . . . . . . . . . . . . . . . . . . . . 4-4

P1 & P2 Keyboard Enable . . . . . . . . . . . . . . . . . . 4-4

tb Time Base for Output Timing . . . . . . . . . 4-5

Enhanced Position/RPM Display Logic . . . . . . . . . . 4-5

dd Display Default . . . . . . . . . . . . . . . . . . . . 4-5

tr Toggle RPM . . . . . . . . . . . . . . . . . . . . . . 4-5

rU rPM Display Update Frequency . . . . . . . 4-6

ct, cS, cA Communications Parameters . . . . . . . . . . 4-6

FCN 6 Output Channel Access . . . . . . . . . . . . . 4-7

FCN 7 Motion ANDing . . . . . . . . . . . . . . . . . . . . 4-8

FCN 8 Subdividing Outputs . . . . . . . . . . . . . . . . 4-9

FCN 9 Enable Inputs and Modes . . . . . . . . . . . 4-9

Setup Level Programming

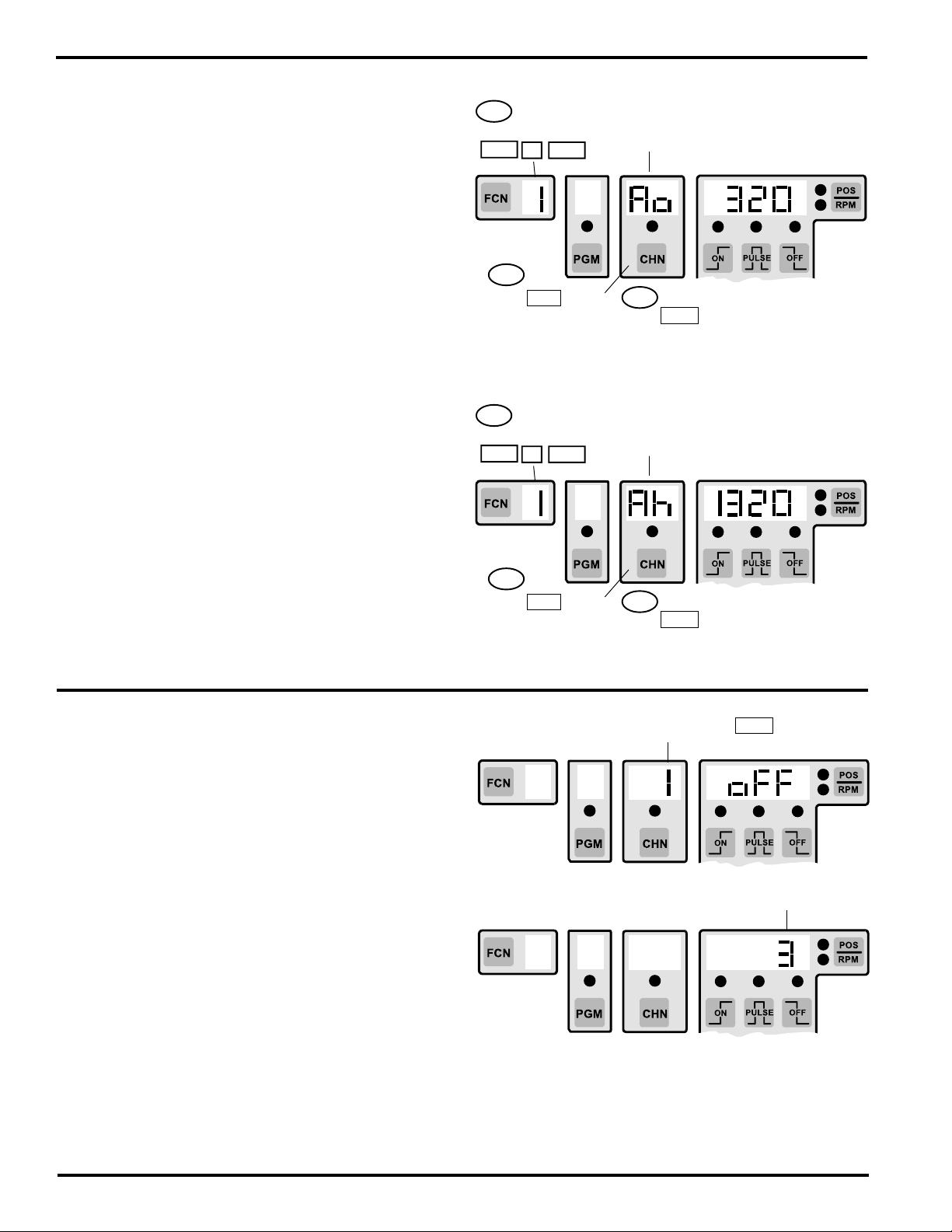

FCN 1 Motion Setpoints . . . . . . . . . . . . . . . . . . 4-10

FCN 2 Offset . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

FCN 3 Program Number . . . . . . . . . . . . . . . . . 4-10

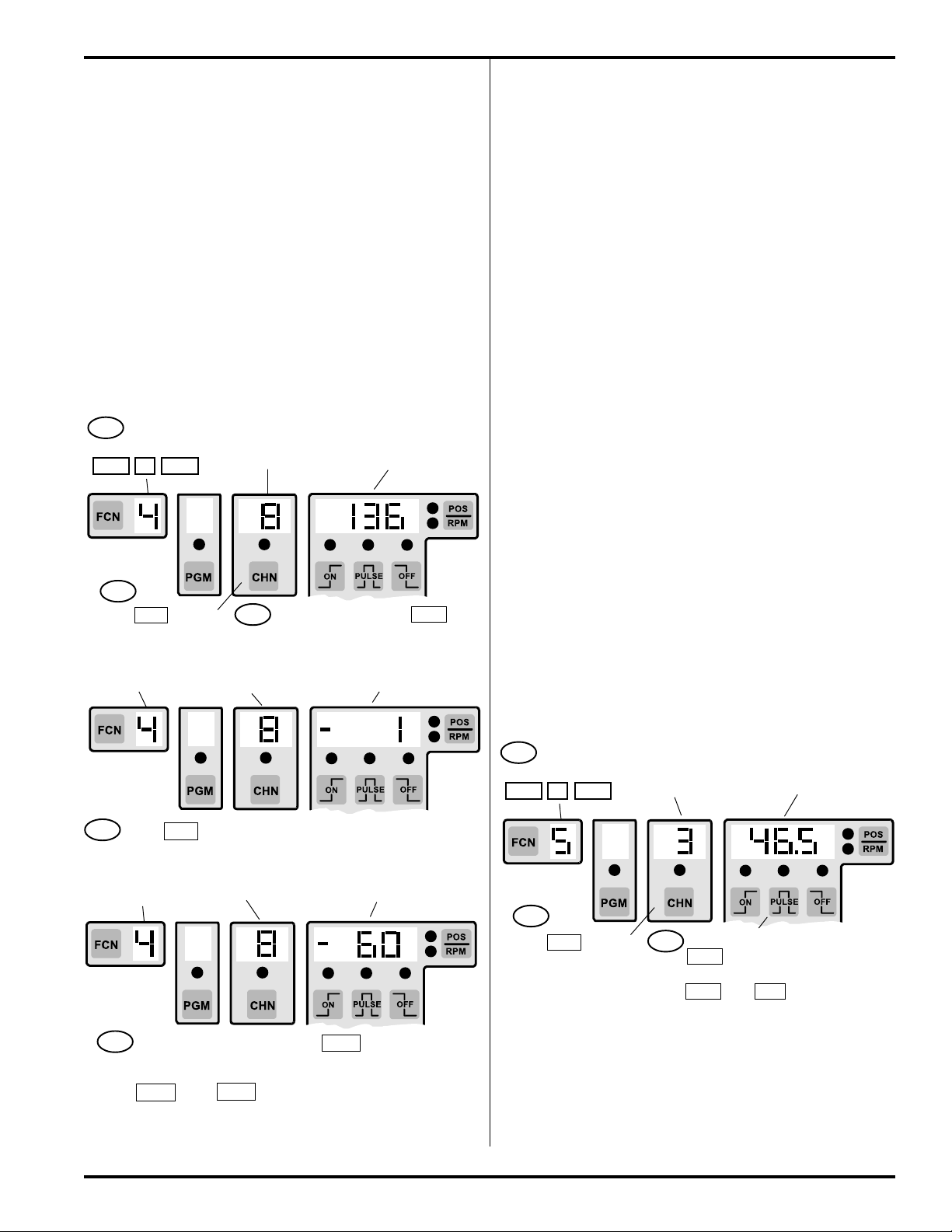

FCN 4 Speed Compensation, Standard . . . . . 4-12

Speed Compensation, Negative . . . . . 4-12

FCN 5 Timed Outputs . . . . . . . . . . . . . . . . . . . 4-13

Section 5—Programming, Optional Features

Leading Trailing Speed Comp (“-L”)

FCN 0 Speed Comp Type . . . . . . . . . . . . . . . . . 5-1

FCN 4 Leading/Trailing Speed Comp . . . . . . . . 5-1

Analog Output (“-A”)

FCN 1 Analog Offset & High RPM . . . . . . . . . . . 5-2

Outputs Based on Direction of Rotation (“-D”)

Direction ANDing . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Direction Hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Gray Code Output (“-G”)

Gray Code Conversion Ladder . . . . . . . . . . . . . . . . . 5-3

FCN 4 Gray Code Speed Comp . . . . . . . . . . . . 5-3

Extra Program Storage (“-F”)

Pulses/Programs Available . . . . . . . . . . . . . . . . . . . 5-4

Program Number Displays . . . . . . . . . . . . . . . . . . . . 5-4

FCN 3 Program Number Changes . . . . . . . . . . 5-5

Viewing/Editing Program . . . . . . . . . . . . . . . . . . . . . 5-6

Phase Mark Registration (“-P”)

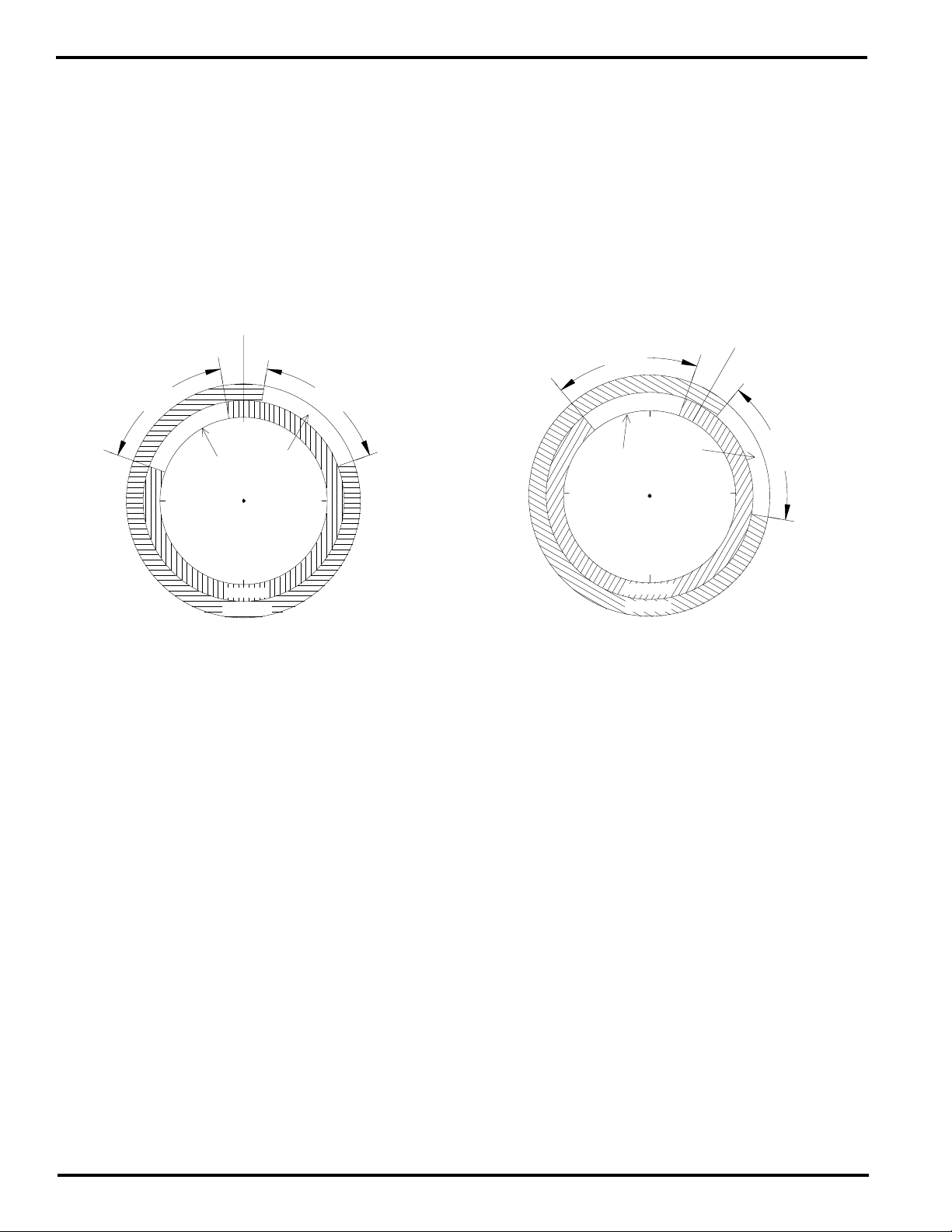

Examples and Adjustment Methods . . . . . . . . . . . . . 5-7

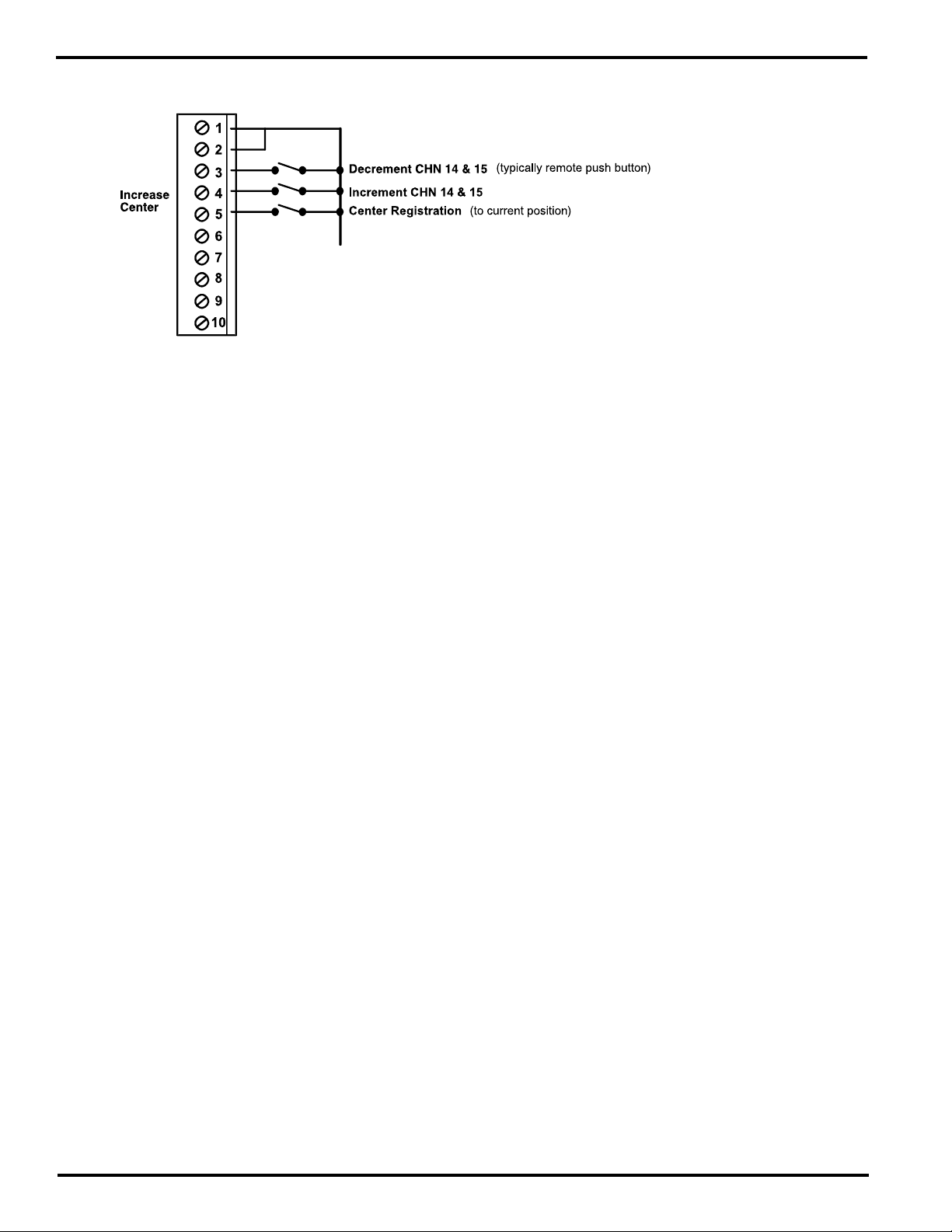

Input Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

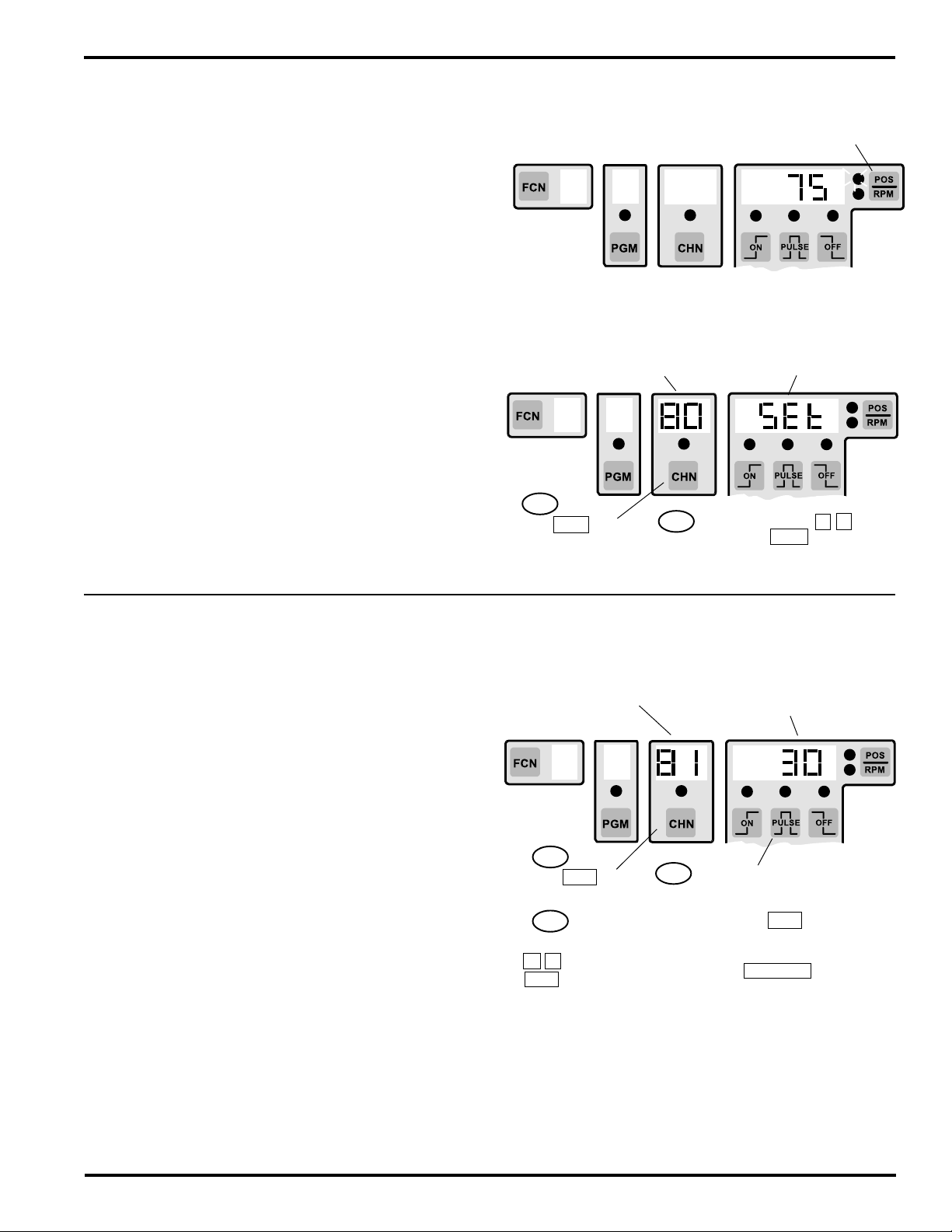

CHN 80 Auto-Center Registration . . . . . . . . . . . . 5-9

CHN 81 Adjust Registration Center . . . . . . . . . . . 5-9

Reversal of Centering Logic . . . . . . . . . . . . . . . . . . 5-10

“OFF” Logic Examples . . . . . . . . . . . . . . . . . . . . . . 5-10

Appendix

Output Grouping & Modes

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Configuration Examples . . . . . . . . . . . . . . . . . . . . . . A-2

Mode 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Mode 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Mode 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Mode 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Mode 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

Communication Port Wiring . . . . . . . . . . . . . . . . . . . . . A-14

Encoder Position vs. Degrees . . . . . . . . . . . . . . . . . . . A-15

60 Pulse Disc—Position vs. Degrees . . . . . . . . . . . . . A-15

Alternate Functions . . . . . . . . . . . . . . . . . . . . . . . . . . A-16

Alt Fcn 1 Transducer Position

Alt Fcn 2 Logic Input Status

Alt Fcn 3 Offset Value

Alt Fcn 4 60 Pulse Disc

Alt Fcn 1002 Keyboard Test

Alt Fcn 1003 LED Display Test

Alt Fcn 1004 Watchdog Timer Test

Alt Fcn 1005 Control Model Info

Alt Fcn 1006 Options & Rev. #

Alt Fcn 7000 Restore Defaults

Alt Fcn 7001 Clear Setpoints

Alt Fcn 7999 EEPROM Test

Remote Display Installation . . . . . . . . . . . . . . . . . . . . . A-17

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . A-18

Index

Page 4

WARRANTY

1. Electro Cam Corp. warrants that for a period of twelve (12) months from the date of shipment to

the original purchaser, its ne w product to be free from defects in material and workmanship and

that the product conforms to applicable drawings and specifications approved by the Manufacturer. This warranty period will be extended on Distributor or OEM orders to a maximum of

eighteen months to take into consideration Distributor or OEM shelf time.

2. The remedy obligations of Electro Cam Corp. under this w arranty are exclusiv e and are limited to

the repair, or at its option, the replacement or refund of the original purchase price of any new

apparatus which proves def ective or not in conf ormity with the drawings and specifications. Shipment of the claimed defectiv e product to Electro Cam Corp. shall be at the cost of the consumer .

Shipment of the repaired or replacement product to the consumer shall be at the cost of Electro

Cam Corp. All claims must be made in writing to Electro Cam Corp., 13647 Metric Road, Roscoe,

IL 61073 USA.

3. In no event, and under no circumstances, shall Electro Cam Corp. be liable for:

a. Any product damaged or lost in shipment. Inspection for damage should be made before

acceptance or signing any delivery documents releasing responsibility of the delivering carrier.

b. Product failure or damages due to misuse abuse, improper installation or abnormal condi-

tions of temperature, dirt or other contaminants as determined at the sole discretion of Electro

Cam Corp.

c. Product failures due to operation, intentional or otherwise, above rated capacities as deter-

mined at the sole discretion of Electro Cam Corp.

d. Non-authorized expenses for removal, inspection, transportation, repair or rework. Nor shall

the manufacturer ever be liable for consequential and incidental damages, or in any amount

greater than the purchase price of the equipment.

4. There are no warranties which extend be yond the description on the f ace hereof. This warranty is

in LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED INCLUDING (BUT NOT

LIMITED T O) ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ALL OF WHICH ARE EXPRESSLY DISCLAIMED. Any legal proceeding

arising out of the sale or use of this apparatus must be commenced within (18) months of the date

of shipment from the manufacturer.

Page 5

Introduction

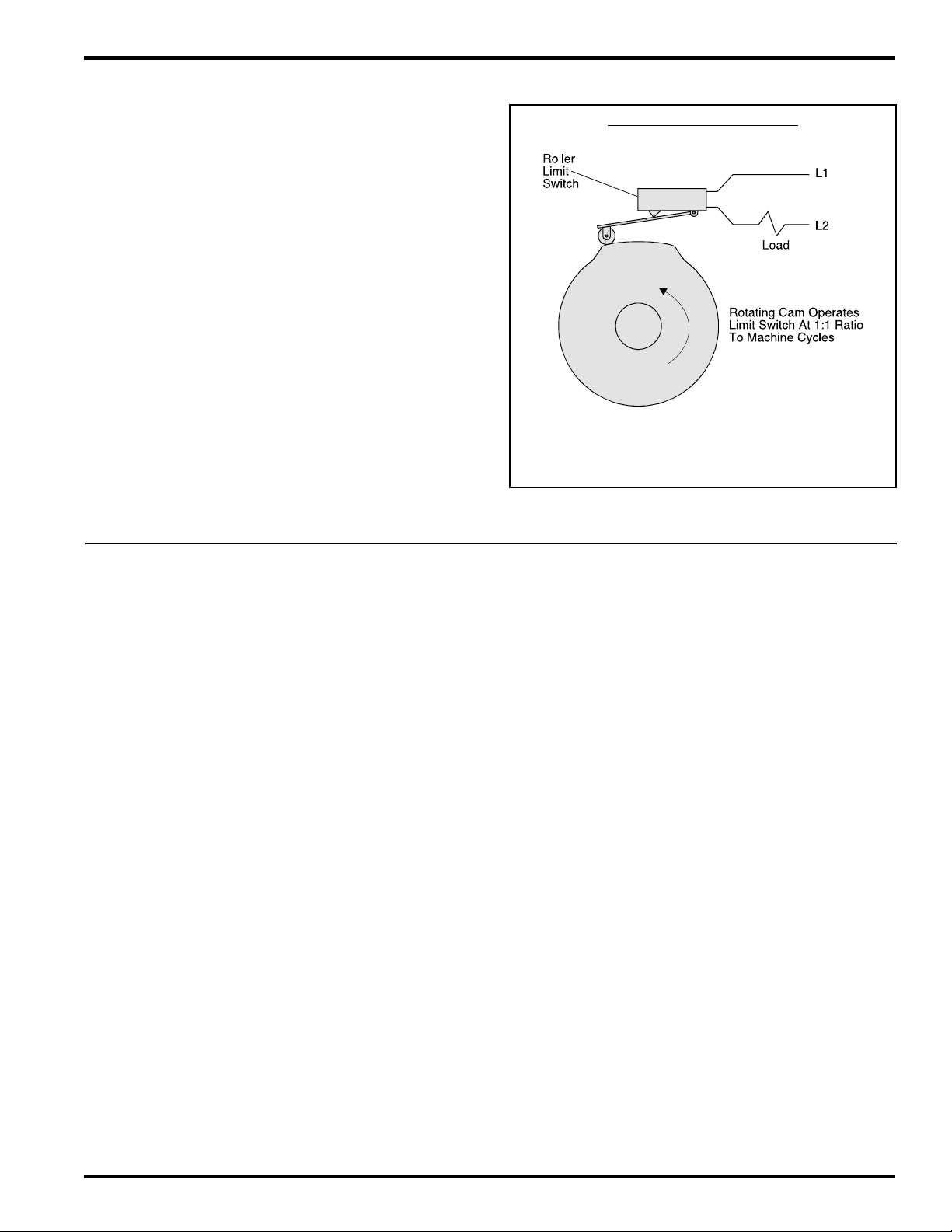

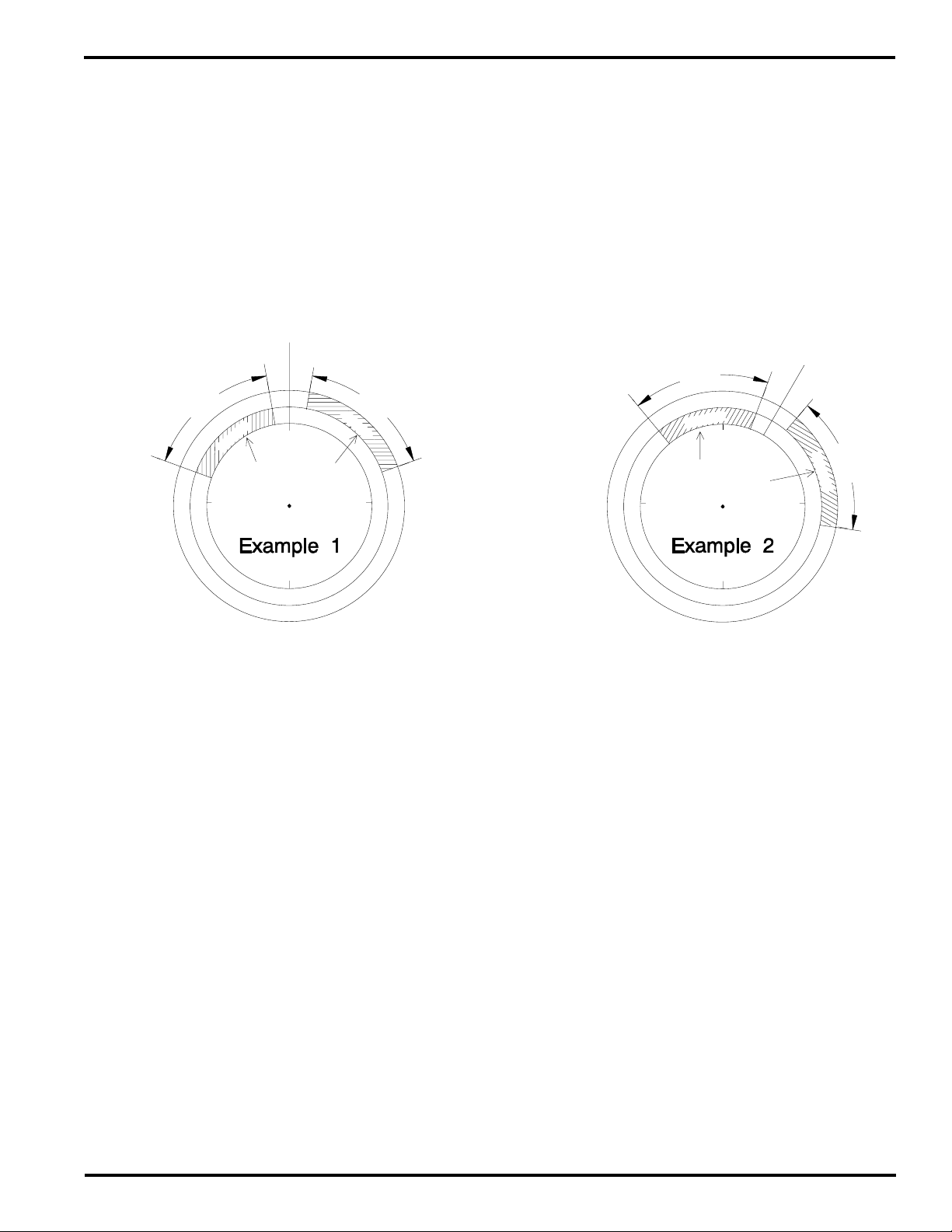

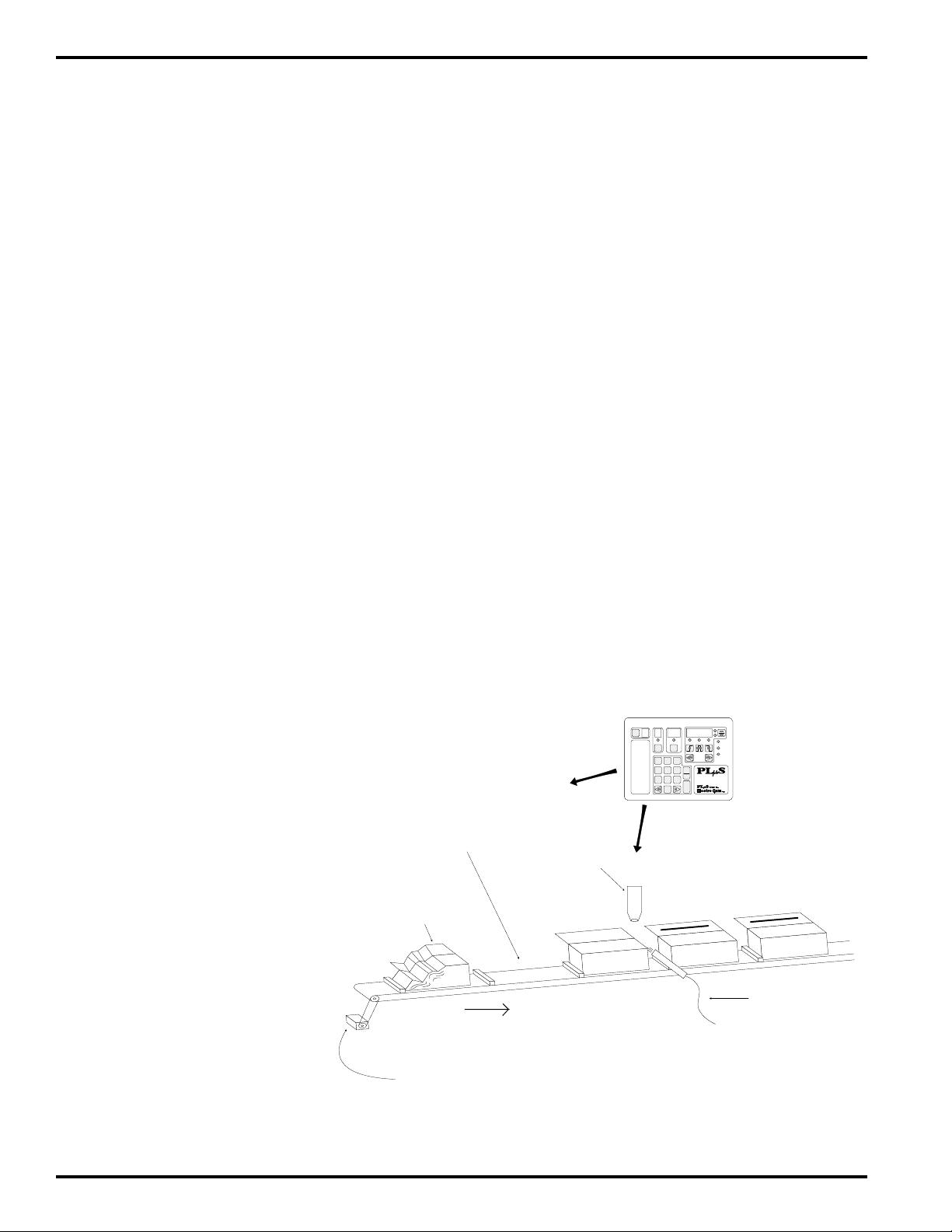

Basic Cam Switch Operation

A PLµS control’s main purpose is to operate outputs in a

manner that simulates cam switches. The drawing to the

right illustrates the operation of a cam switch. Its function is

to switch the load on and off at the same rotary positions of

the cam shaft during each revolution of that cam shaft. The

rotating cam shaft is driven by a machine at a 1:1 ratio, so

that the on / off positions of the cam switch always match

specific positions in the machine cycle. However, cam limit

switches have the following disadvantages: unreliable

(wear), hard to adjust (machine must be stopped during

adjustment), and they cannot run at high speeds because

of contact bounce and excessive mechanical wear.

PLµS controls overcome these basic cam switch problems.

They have no moving wear parts, they are easy to adjust

from the keyboard with the machine running or stopped,

and they can operate at speeds up to 3000 RPM. They also

add many capabilities far beyond simple cam switch logic.

Standard Product Features

Basic Cam Switch Operation

The limit switch will turn on and off at

the same cam degree positions every

cam revolution (every machine cycle)

Keyboard/Controller

The keyboard controller is the main component of the PLµS

system. The front keypad and displays provide a complete

user interface from which every aspect of the control’s

operation can be monitored and programmed. When

properly mounted with the gasket provided, the keyboard

meets NEMA 4 standards. A clear silicon rubber boot

assembly is available to provide NEMA 4X protection for

installations where harsh washdown chemicals are used.

Ease of Setup

All output position setpoint values are simply entered

through the numeric keypad. These setpoints can be

adjusted while the machine is running or stopped by using

the increment, decrement, or numeric keys. The keyboard

is also used to synchronize the control’s position to the

machine, eliminating the need to mechanically adjust the

resolver’s shaft position.

Multiple Programs

Depending on the model ordered, up to 64 different

programs, or “job recipes” can be stored in the control’s

memory. This minimizes down time for job change over

because simply changing program numbers makes all of

the output setting changes required. Program numbers can

be changed by mechanical switches; PLC’s (using the

hardware program select inputs); the keypad; or serial

communication messages.

Output Speed Compensation

Speed compensation allows outputs to compensate for the

response time of the controlled devices by turning on earlier

as machine speeds increase. This eliminates the need to

adjust output settings whenever machine speeds are

changed. Using speed compensation often allows higher

production speeds and eliminates the need for output

adjustments.

Motion ANDing

A speed range can be programmed into the controller, and

outputs can then be ANDed with the speed range so that

they will be disabled unless the machine speed is within the

range. This can be used to turn off outputs if the machine

stops; disable outputs until the machine reaches a minimum

speed; or disable outputs if the machine goes above a

specified maximum speed. A common use for this feature

is disabling outputs to glue valves so the flow of glue turns

off if the machine stops.

Timed Outputs

Outputs can be programmed to turn on at the programmed

“on” position and turn off when the specified time elapses,

rather than staying on until an “off” position is reached. The

result is a constant output duration, regardless of machine

speed. The output will turn off when the “off” position is

reached if it hasn’t already timed out. Timed outputs are

used to drive devices which require a fixed time to perform

a task, regardless of machine speed.

1-1 Introduction

Page 6

Standard Product Features (continued)

Selectable Scale Factor (resolvers only)

The number of increments per revolution (Scale Factor) is

programmed by the user. Standard controls have a

maximum of 1024 increments per revolution and “-H” option

(high resolution) controls have a maximum of 4096

increments per revolution. To make the control operate and

program in degrees, a Scale Factor of 360 is used. In some

applications it is desirable to use a Scale Factor that defines

each increment as a specific distance in engineering units

(ex: 1 inc = .1" of travel).

Output Grouping and Modes of Operation

Outputs can be subdivided into groups and each group

can be associated with an input device. There are five

different modes of operation that can be selected for each

group. For example, some modes allow the group to activate

only when the corresponding input has signaled that product

is present. Glue control is a typical place where outputs

are disabled until product is sensed as being present. For

details, see page A-1.

Optional Product Features

Analog Output, “-A”

Units with this option can output an analog signal that is

linearly proportional to RPM. The analog signal level at

zero RPM can be programmed through the keyboard, as

well as the RPM that corresponds to maximum signal. No

measuring equipment is required for initial setup, and

calibration is not needed. Typical uses are control of glue

pressure as machine speed changes, and speed matching

of other equipment to the machine being controlled.

Outputs Based On Rotation Direction, “-D”

In standard PLµS controllers, outputs will turn ON/OFF

based on resolver position, regardless of which way the

resolver is turning. With the "-D" option, outputs can be

based on resolver rotation direction.

Large Program Memory, “-F”

Depending on the number of outputs ordered, standard

controls can store up to 64 programs consisting of not more

than 1258 output pulses total. Controls with the “-F” option

increase this capacity by storing up to 256 programs

consisting of not more than 4589 output pulses total.

Gray Code Position Output, “-G”

The “-G” option provides eight bits of position information

on the last eight outputs. This “gray code” output can be

connected to a PLC or other electronic control device,

eliminating the need for expensive accessory cards. The

PLC can then make control decisions that do not demand

a fast response, while other PLµS outputs directly control

devices that must operate quickly and consistently.

High Resolution, “-H” (resolvers only)

Controls with this option can divide the resolver shaft

Serial Communication

Serial communication provides an RS-232 and an RS-485

communication port. Using PLµSNET software for IBM

compatible computers, available from Electro Cam Corp.,

the control’s entire program can be saved from the control

to a disk file or loaded from a disk file to the control. The

program can be printed or edited using the computer. It is

also possible to send individual communication commands

to the control, while running, to change settings in the

program. The user must write appropriate software to

communicate at the individual command level.

Expanded Operator Access

This feature gives the operator access to motion detection

settings, offset, active program number, and speed

compensation.

NOTE: Serial Communication and Expanded Operator

Access were "-C" and "-E" options prior to date code

9740.

rotation into as many as 4096 increments. Standard

controls have a maximum of 1024 increments.

Leading/Trailing Edge Speed Comp, “-L”

This option allows the “on” and “off” edges of output pulses

to be speed compensated by different amounts. High speed

gluing is a common application where the “on” and “off”

edges of the output signal have to be compensated by

different amounts.

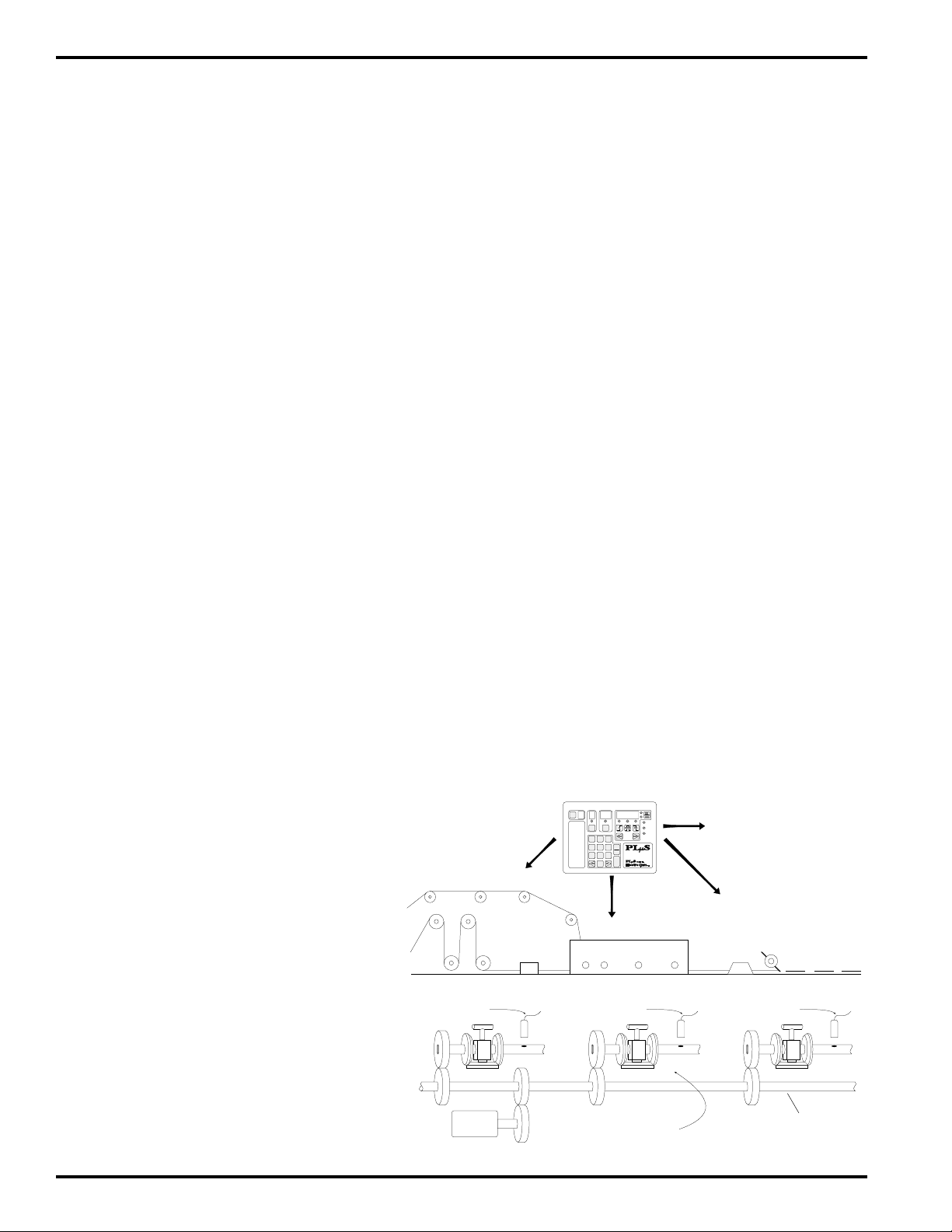

Phase Mark Registration, “-P”

Phase mark registration allows the PLµS control to

determine if a product appears before or after a

programmed timing window. If mis-registration occurs, the

product’s timing can be adjusted manually, or by a PLC or

similar controller interfaced to the PLuS control.

Caustic Washdown Boot, “-W”

The face of the keyboard is rated NEMA 4X (meets NEMA

1, 4, 4X, and 12). For additional protection against caustic

washdown, grease, oil, dirt, and normal wear, a clear

silicone rubber boot is available that fits over and around

the keyboard. The back of the boot provides a good seal

between the back of the keyboard and the control panel.

The boot is transparent and pliable, allowing the keyboard

to be viewed and operated through it. Controls ordered

with the “-W” option are shipped with the boot fitted over

the keyboard. Boots may also be ordered separately and

installed in the field (#PS-4904-99-001).

Remote Display

A remote display which connects to the RS-485 port is

available for units ordered with both the “-C” and “-E”

options. This allows position and RPM information to be

displayed up to 1000 feet away from the controller.

1-2 Introduction

Page 7

PS-5000 Series Model Summary

PS-5011

PS-5111

Key To Option Selection

PS-5001

PS-5101

PS-5004

PS-5104

PS-5034

PS-5134

Model Output Type Transducer Outputs Programs Modes? Options

PS-5001-10-016 Module Rack Encoder 16 64 no A, F, G, L, P, V, W, 20, 24

PS-5101-10-016 Module Rack Resolver 16 64 no A, F, G, H, L, P, V, W, 20, 24

PS-5001-10-024 Module Rack Encoder 24 48 no F, G, L, V, W, 20, 24

PS-5101-10-024 Module Rack Resolver 24 48 no F, G, H, L, V, W, 20, 24

PS-5001-10-048 Module Rack Encoder 48 24 no F, G, L, V, W, 20, 24

PS-5101-10-048 Module Rack Resolver 48 24 no F, G, H, L, V, W, 20, 24

PS-5004-10-016 Module Rack Encoder 16 64 yes A, F, G, L, P, V, W, 20, 24

PS-5104-10-016 Module Rack Resolver 16 64 yes A, F, G, H, L, P, V, W, 20, 24

PS-5004-10-024 Module Rack Encoder 24 48 yes F, G, L, V, W, 20, 24

PS-5104-10-024 Module Rack Resolver 24 48 yes F, G, H, L, V, W, 20, 24

PS-5004-10-048 Module Rack Encoder 48 24 yes F, G, L, V, W, 20, 24

PS-5104-10-048 Module Rack Resolver 48 24 yes F, G, H, L, V, W, 20, 24

These Models

Use External

I/O Module Racks

20-240 VAC: Change “-10-” to “-20-”.

24-24 VDC: Change “-10-” to “-24-”.

A Analog output proportional to speed

F Additional setpoint/program storage

G Gray code position output

H High resolution, resolver only

L Individual leading/trailing edge speed compensation

P Register mark phasing

U CE mark - requires 24VDC input

V Vibration protective coating

W Washdown Boot

These Models

Use Built-In

I/O Transistor Chips

# of # of Output

PS-5021

PS-5121

PS-5024

PS-5124

These Models

Have I/O Modules

On Controller Back

PS-5011-10-N08 Transistor, Sinking Encoder 8 64 no F, L, V, W, 20, 24

PS-5111-10-N08 Transistor, Sinking Resolver 8 64 no F, H, L, V, W, 20, 24

PS-5011-10-N16 Transistor, Sinking Encoder 16 64 no F, G, L, P, V, W, 20, 24

PS-5111-10-N16 Transistor, Sinking Resolver 16 64 no F, G, H, L, P, V, W, 20, 24

PS-5011-10-P08 Transistor, Sourcing Encoder 8 64 no F, L, V, W, 20, 24

PS-5111-10-P08 Transistor, Sourcing Resolver 8 64 no F, H, L, V, W, 20, 24

PS-5011-10-P16 Transistor, Sourcing Encoder 16 64 no F, G, L, P, V, W, 20, 24

PS-5111-10-P16 Transistor, Sourcing Resolver 16 64 no F, G, H, L, P, V, W, 20, 24

PS-5034-10-032 Transistor, Ext. Rack Encoder 32 32 yes F, G, L, V, W, 20, 24

PS-5134-10-032 Transistor, Ext. Rack Resolver 32 32 yes F, G, H, L, U, V, W, 24

PS-5034-10-064 Transistor, Ext. Rack Encoder 64 16 yes F, G, L, V, W, 20, 24

PS-5134-10-064 Transistor, Ext. Rack Resolver 64 16 yes F, G, H, L, U, V, W, 24

PS-5021-10-M09 Modules on Back Encoder 9 64 no A, F, L, V, W, 20, 24

PS-5121-10-M09 Modules on Back Resolver 9 64 no A, F, H, L, P, U, V, W, 20, 24

PS-5024-10-M09 Modules on Back Encoder 9 64 yes A, F, L, V, W, 20, 24

PS-5124-10-M09 Modules on Back Resolver 9 64 yes A, F, H, L, P, U, V, W, 20, 24

1-3 Introduction

Page 8

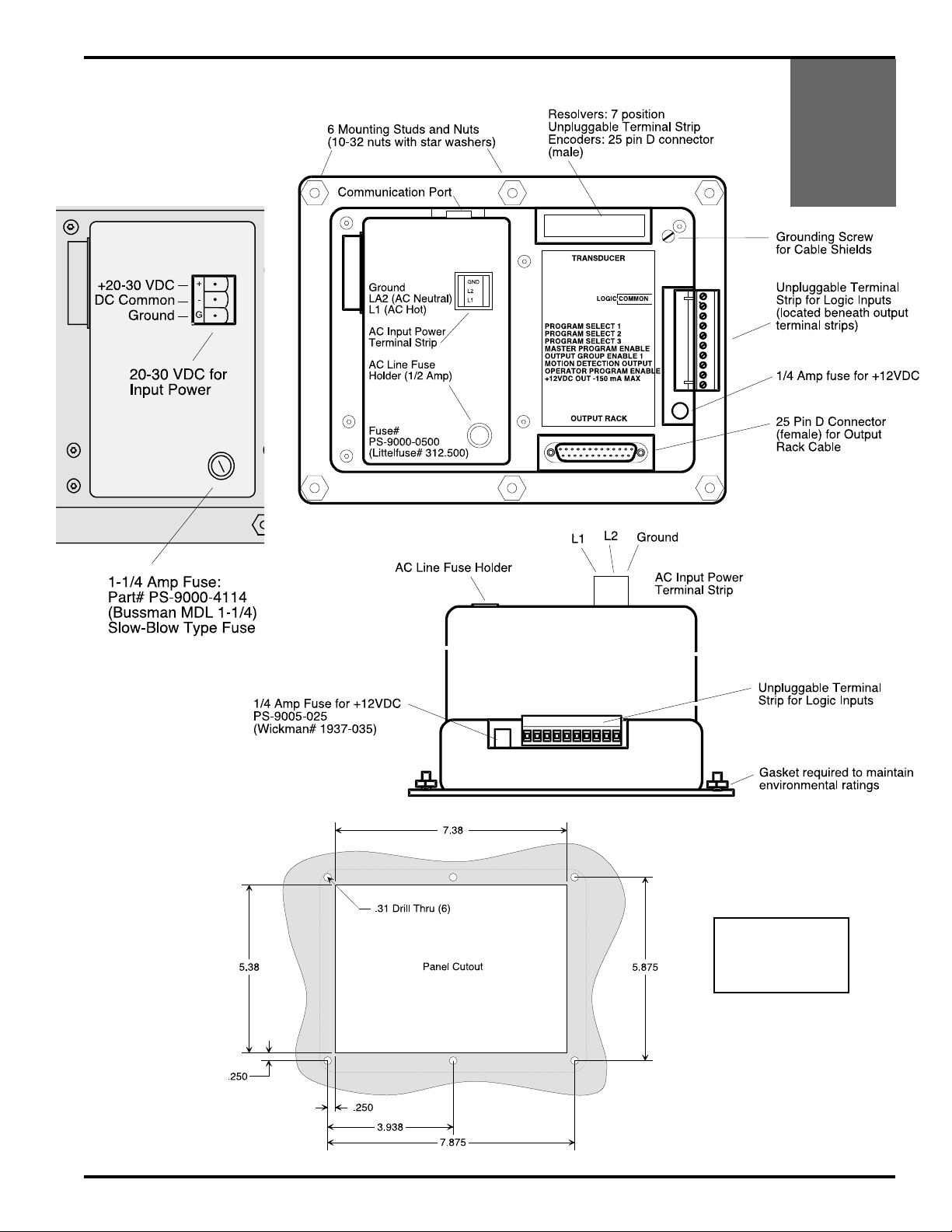

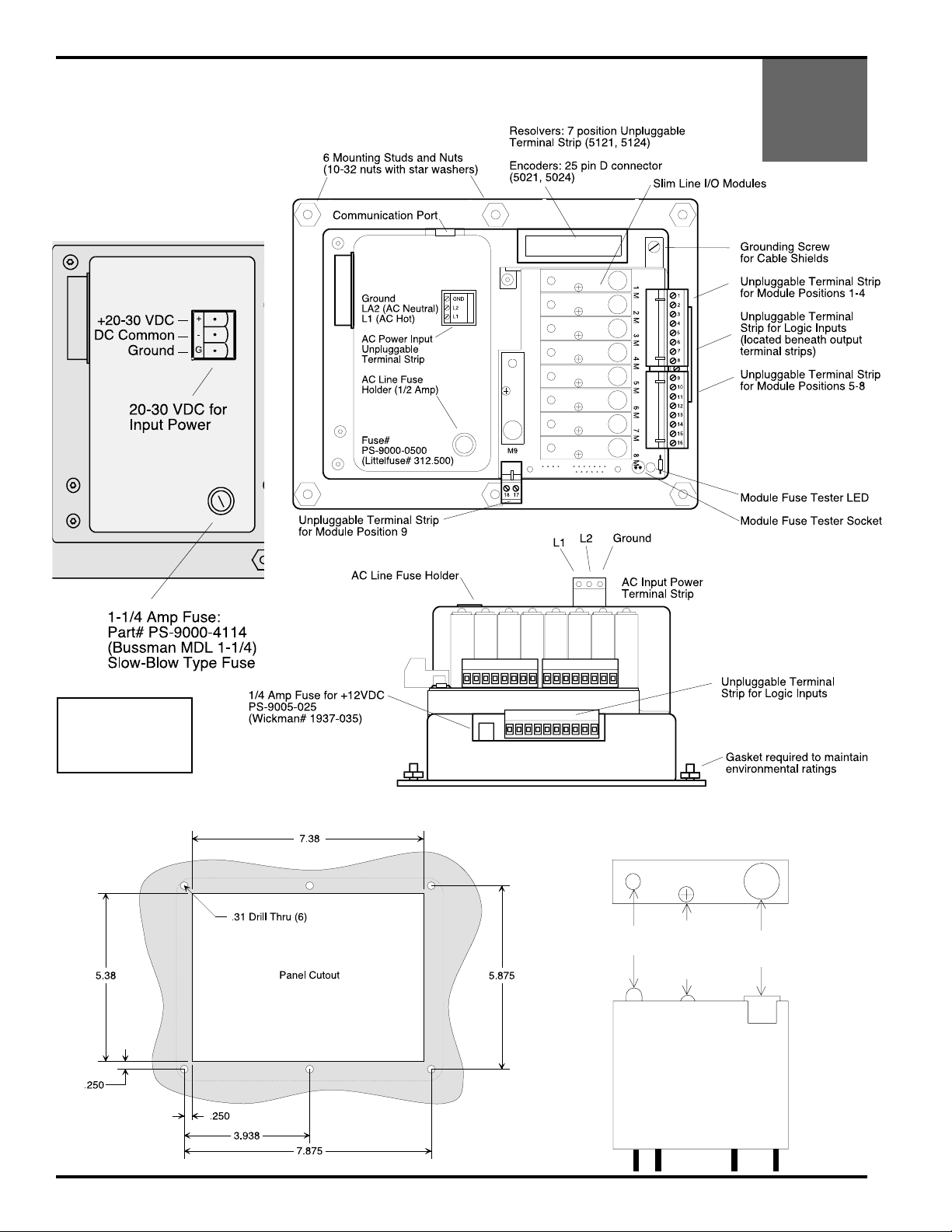

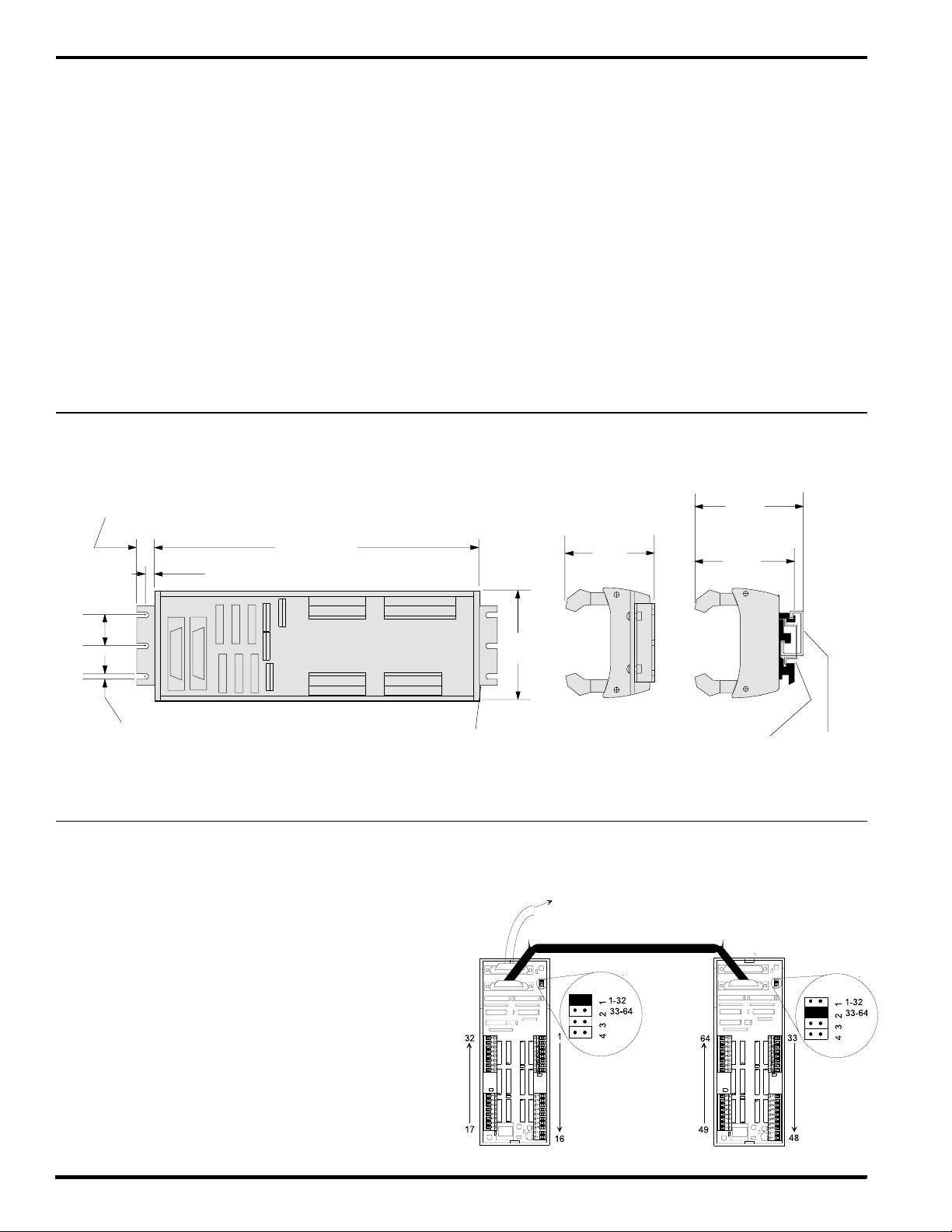

Detailed View of

24 VDC Version

Controllers w/ External I/O Module Rack

PS-5001

PS-5101

PS-5004

PS-5104

PS-5034

PS-5134

2-1 Dimensions & Component Locations

See Page 2-4

for Controller

Dimensions

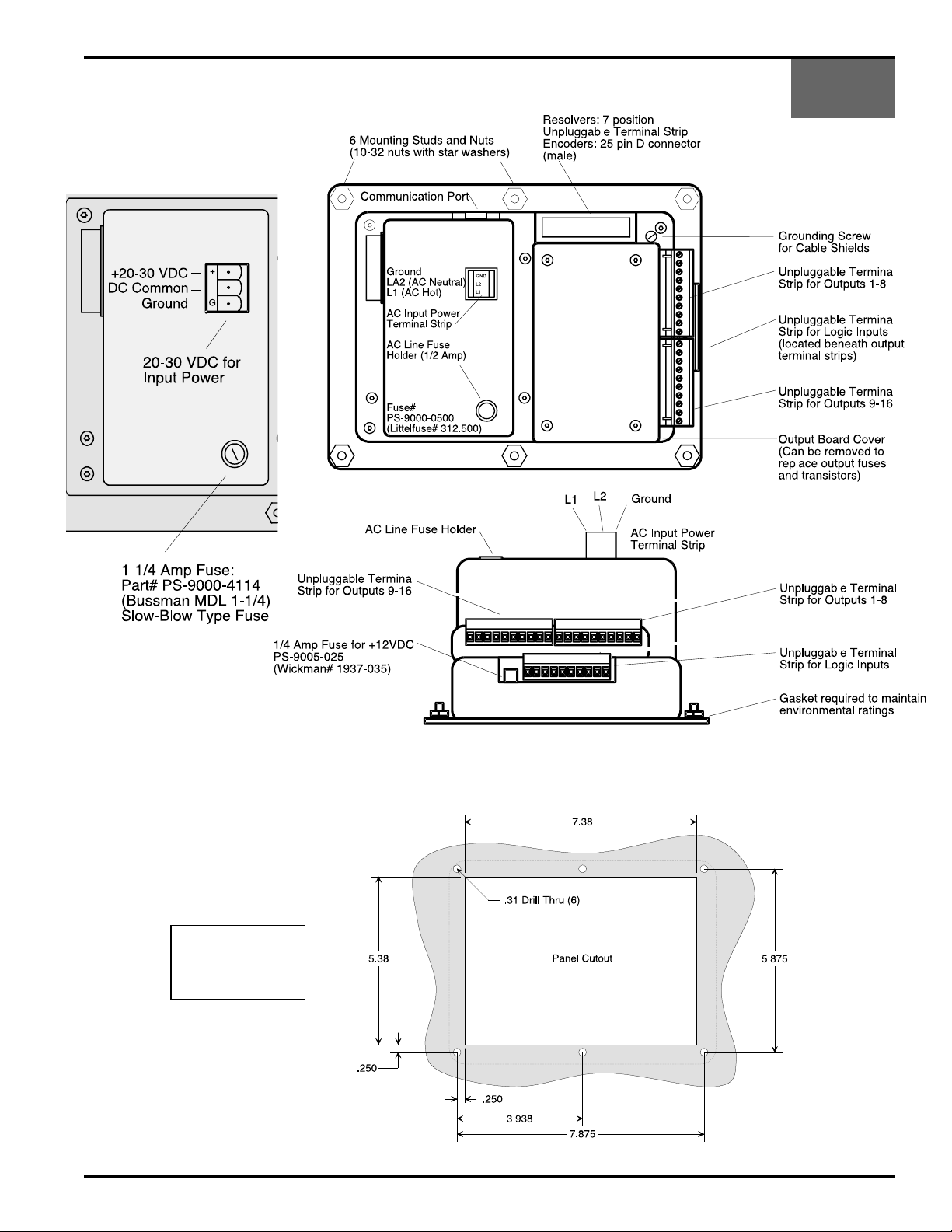

Page 9

Controllers w/ I/O Modules on Controller Back

LED

HOLD

DOWN

SCREW

FUSE

4A

Detailed View of

24 VDC Version

PS-5021

PS-5121

PS-5024

PS-5124

See Page 2-4

for Controller

Dimensions

Slimline Modules

TOP

2-2 Dimensions & Component Locations

Page 10

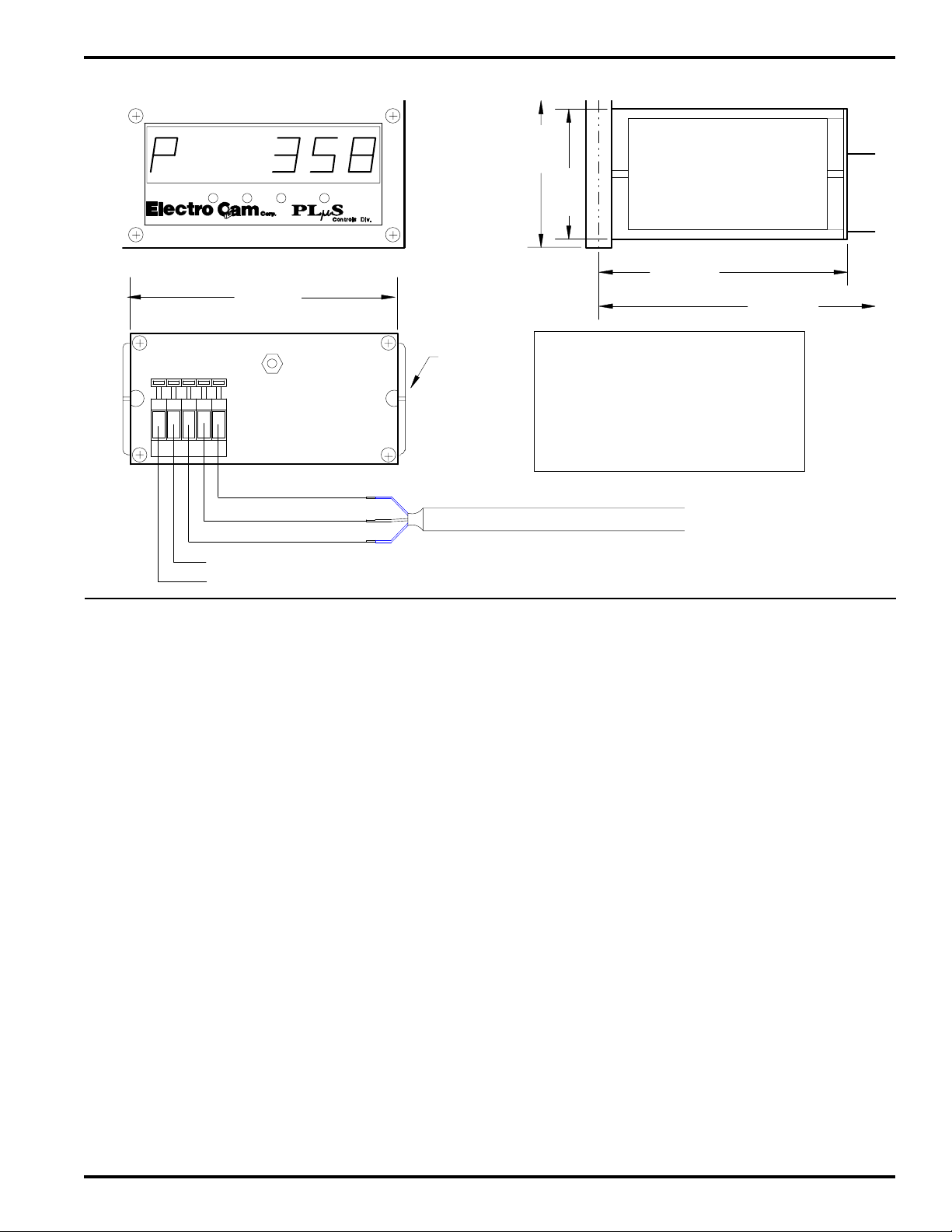

Detailed View of

24 VDC Version

Controllers with Built-In Transistor I/O Chips

PS-5011

PS-5111

See page 2-5

for Controller

Dimensions

2-3 Dimensions & Component Locations

Page 11

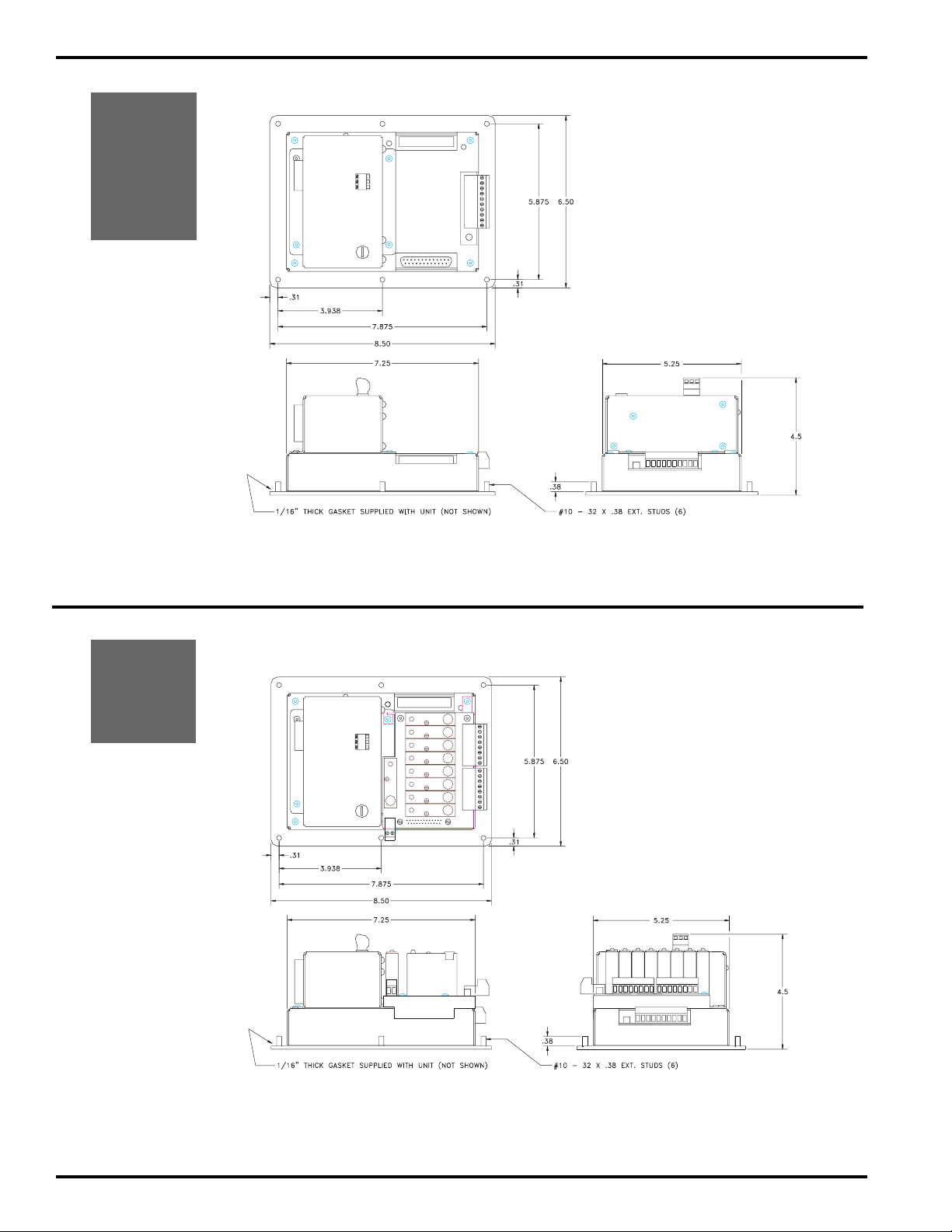

PS-5001

PS-5101

PS-5004

PS-5104

PS-5034

PS-5134

Controller Dimensions

PS-5021

PS-5121

PS-5024

PS-5124

2-4 Dimensions & Component Locations

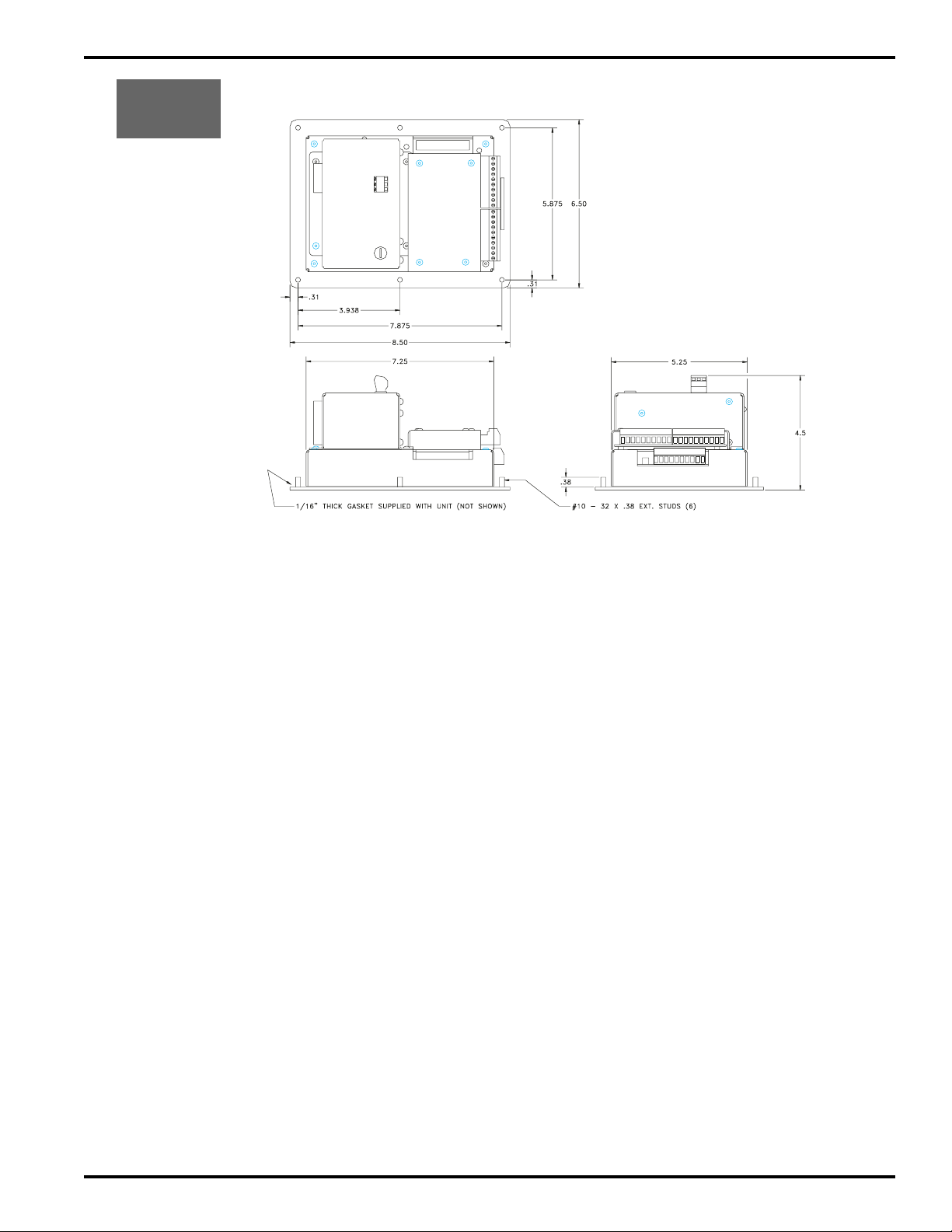

Page 12

PS-5011

PS-5111

Controller Dimensions

2-5 Dimensions & Component Locations

Page 13

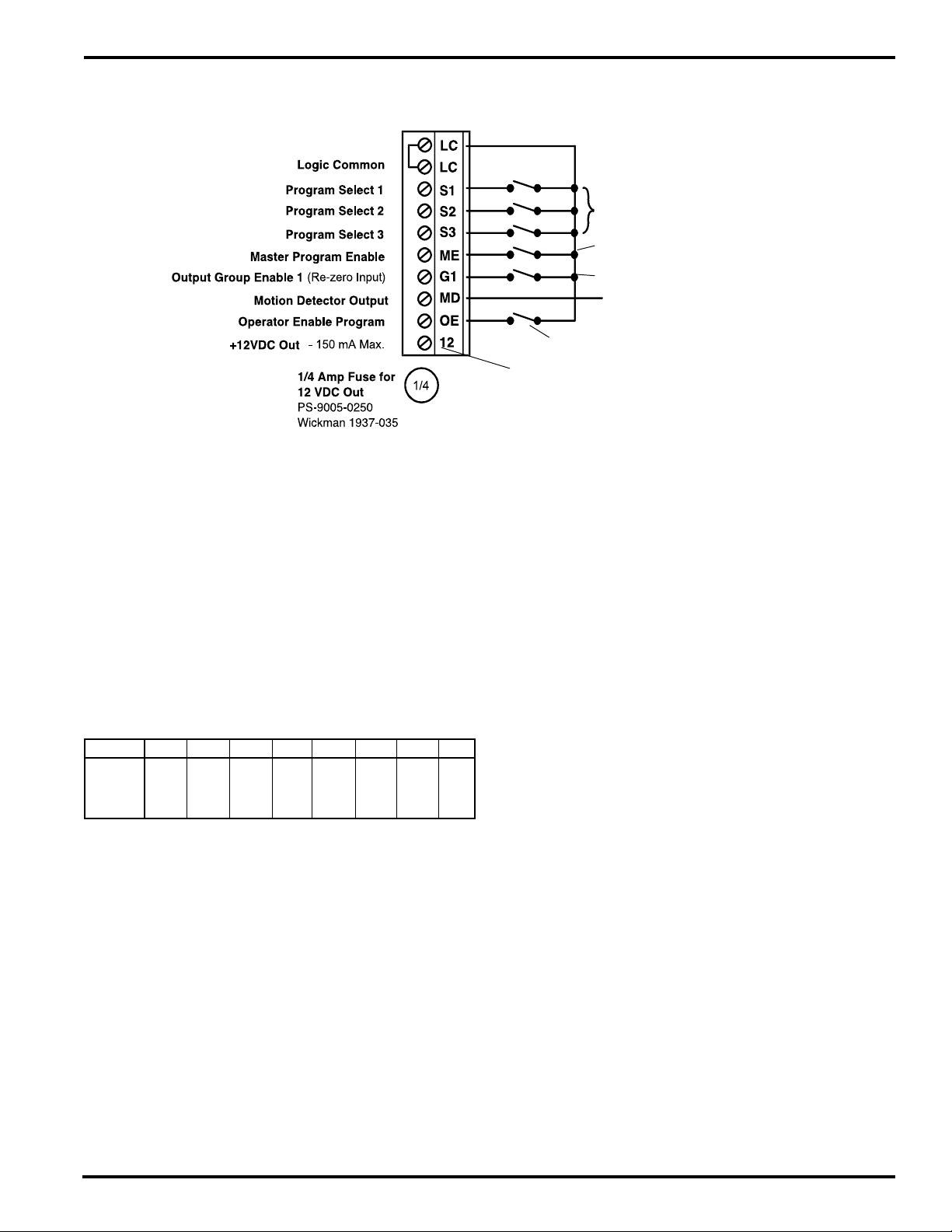

Logic Terminal Strip Wiring—Standard Controller

Logic Terminal Strip

(see pp. 2-1 thru 2-3 for location)

General Logic Input Information

The logic inputs, Terminals 2-7 & 9, are switched by a

current sinking path to Logic Common. They can be switched

by mechanical switches, relays, or NPN transistor outputs.

Logic input terminal voltage is approximately 12 VDC, and

4 mA of current are conducted through the switch to Logic

Common.

Program Select Inputs (Terminals 3, 4, and 5)

These inputs determine which program in the current

program bank is controlling the outputs. When any of these

inputs are connected to Logic Common, they take priority

over the keyboard selected active program (FCN 3). If these

inputs are being used, make sure that the FCN 3 active

program is set to 1. Input combinations are:

PRG # 1 2 3 4 5 6 7 8

SEL 1 off on on off off on on off

SEL 2 off off o n on on on off off

SEL 3 off off off off on on on on

Master Program Enable (Terminal 6)

When the Master Program Enable input is switched to Logic

Common, all programming operations are accessible. A

key switch is commonly used for this input to prevent

unauthorized personnel from accessing the more

complicated features of the control. A temporary jumper can

also be installed for initial programming at the master level,

and then removed when this programming is completed.

Output Group 1 Enable (Re-Zero Input) (Terminal 7)

On standard 5XX1 controls, switching this input to Logic

Common instantly changes the control's position to zero

degrees. The position re-zeroes off of the leading edge of

the signal, but is not held at zero while the input is energized.

When the controller is de-energized, the controller position

will revert to the offset value programmed in FCN 2.

Program Select Switch and Cable:

Pt# PS-4901-01-XXX (XXX=FT)

Program Enable key switch and cable:

PS-4902-01-XXX (XXX=FT)

Input from photo sensor typically

To PLC or other electronic input

Program Enable key switch and cable:

PS-4902-01-XXX (XXX=FT)

DC power for accessories, typically photo sensors.

Terminals 1 and 2 are negative side of this supply

On models PS-5004, 5104, 5024, and 5124 this input is the

enable input for output Group 1. There are four programmable

modes of operation available for enable inputs. For more

information see the Output Grouping and Enable Modes

section in the Appendix.

Motion Detection Output (Terminal 8)

This is a sourcing output signal that is on whenever the

current machine speed is within or equal to the Low and

High RPM setpoints (FCN 1, page 4-7). The circuit is

basically a 12 VDC supply being sourced through a 470

ohm resistor. It is typically connected to PLC inputs or

external solid state output modules. Because the 5000

Series controls have Motion ANDing, any of the standard

outputs can be programmed to be on whenever the motion

logic is on. This is an alternative to the Motion Output when

it is not compatible with an input circuit or if a higher voltage

or current needs to be controlled.

Operator Program Enable (Terminal 9)

When this terminal is switched to Logic Common, access to

programming at the Operator level is enabled. A key switch

can be used to control who can make program changes at

the Operator level. Operator access can also be enabled

through a keyboard enable code number.

12 VDC Power Output (Terminal 10)

The 12 VDC accessory power supply is regulated and

capable of supplying up to 150 mA. It is protected by a 1/4

amp fuse which is located just below the Logic Terminal

strip. This supply is intended to be used for electronic

sensors or other electronic circuitry. It should not be used to

power relays or any other inductive devices. Logic Common

(terminals 1 or 2) is the negative side of this 12 VDC supply.

3-1 Wiring

Page 14

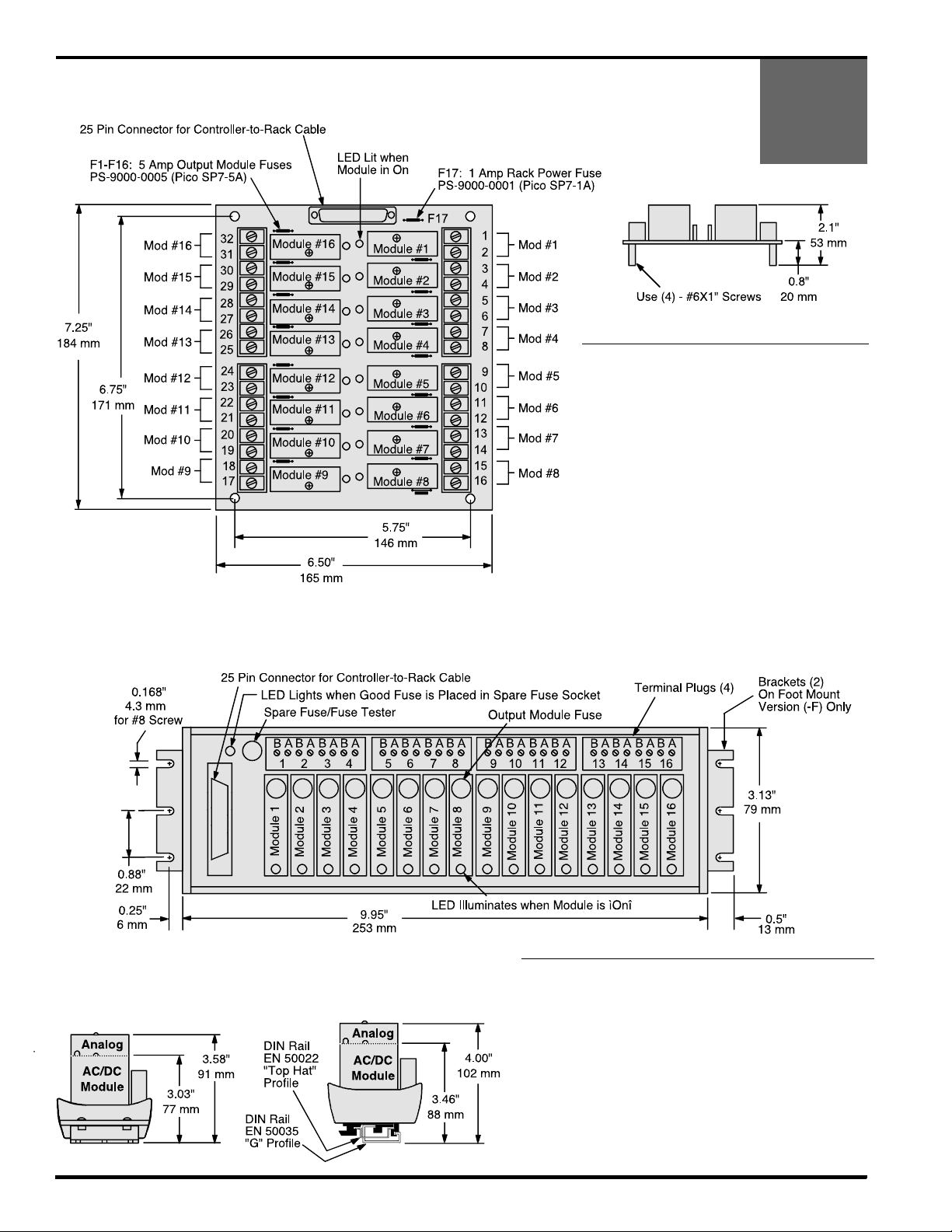

External 16 Module I/O Racks: Dimensions & Specifications

Standard 16 Rack: PS-4100-11-216

Analog 16 Rack: PS-4100-11-316-A (for “-A” Option Only)

PS-5001

PS-5101

PS-5004

PS-5104

End View

Notes:

•A Standard module is required for each Input or

Output used. See Appendix for module specs.

• AC and DC modules can be mixed as needed.

• Input modules can be used only with 5004 and 5104

units.

• Output modules act like switches; they do not

supply power to loads.

• Position 16 of Analog racks is dedicated to analog

output and will not work with other modules. If an

analog module is used, it must be installed in

position 16.

• Odd Terminals: (+) or hot

Even Terminals: (-) or load

Slimline M16 Rack

Foot Mount Rack: PS-4100-11-M16-F

DIN Rail Rack: PS-4100-11-M16-D

End Views

Foot Mount (-F)

DIN Rail (-D)

Notes:

•A Slimline module is required for each Input or Output used.

See Appendix for module specs.

• AC and DC modules can be mixed as needed.

• Input modules can be used only with 5004 and 5104 units.

• Output modules act like switches; they do not supply

power to loads.

• Analog modules may be installed in position 16 only.

• Module Fuses: 4 Amp, #PS-9005-0004

(Wickman 19370-K)

• “A” Terminals: (-) or load

“B” Terminals: (+)or hot

3-2 Wiring

Page 15

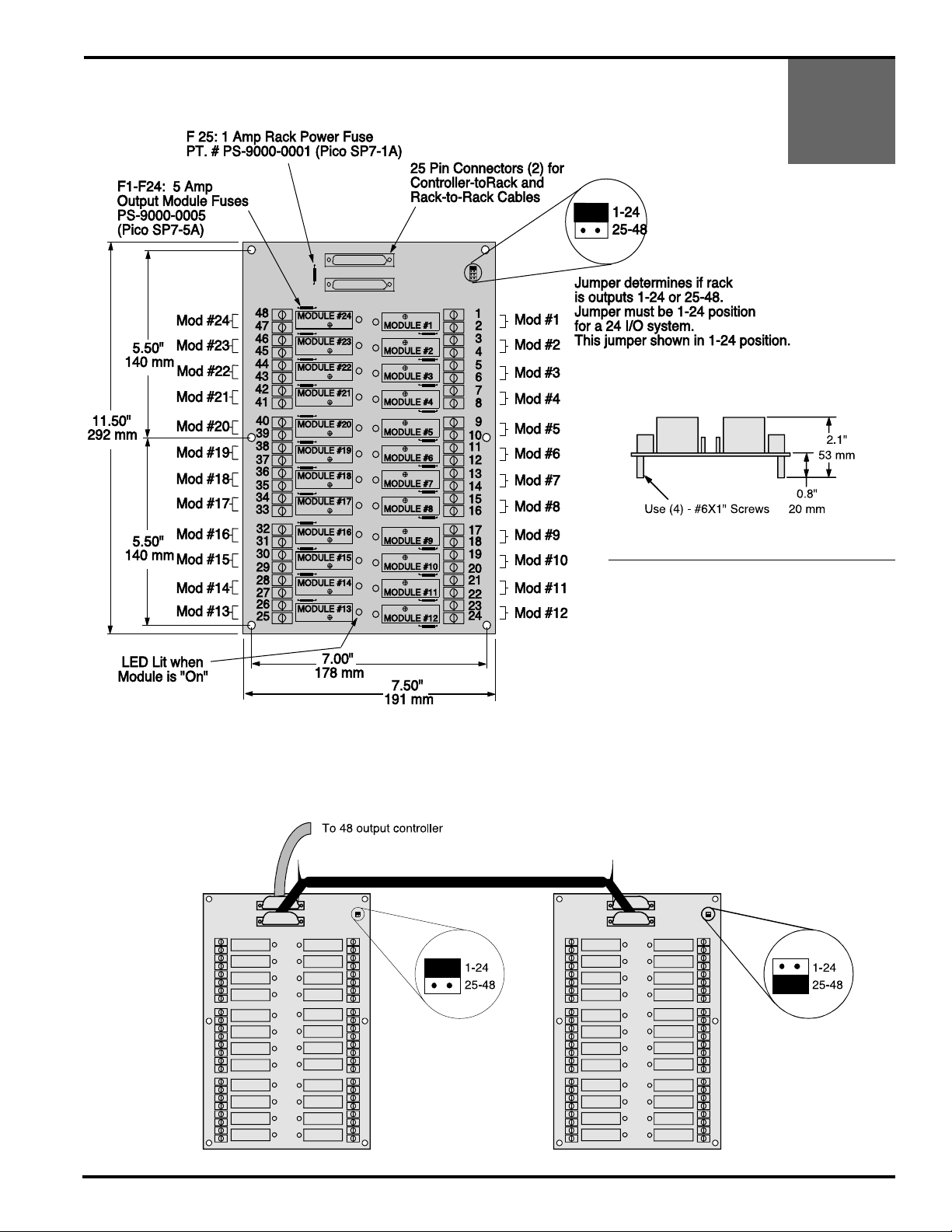

External 24 & 48 Module I/O Racks: Dimensions & Specifications

Standard 24 Rack: PS-4100-12-224

PS-5001

PS-5101

PS-5004

PS-5104

End View

Configuration for 48 I/O System

Notes:

•A Standard module is required for each Input or

Output used. See Appendix for module specs.

• AC and DC modules can be mixed as needed.

• Input modules can be used only with 5004 and 5104

units.

• Output modules act like switches; they do not

supply power to loads.

• Either 25 pin connector can be used to connect the

rack to the controller. The other connector ties to a

second rack for 48 I/O as shown below.

• Odd Terminals: (+) or hot

Even Terminals: (-) or load

3-3 Wiring

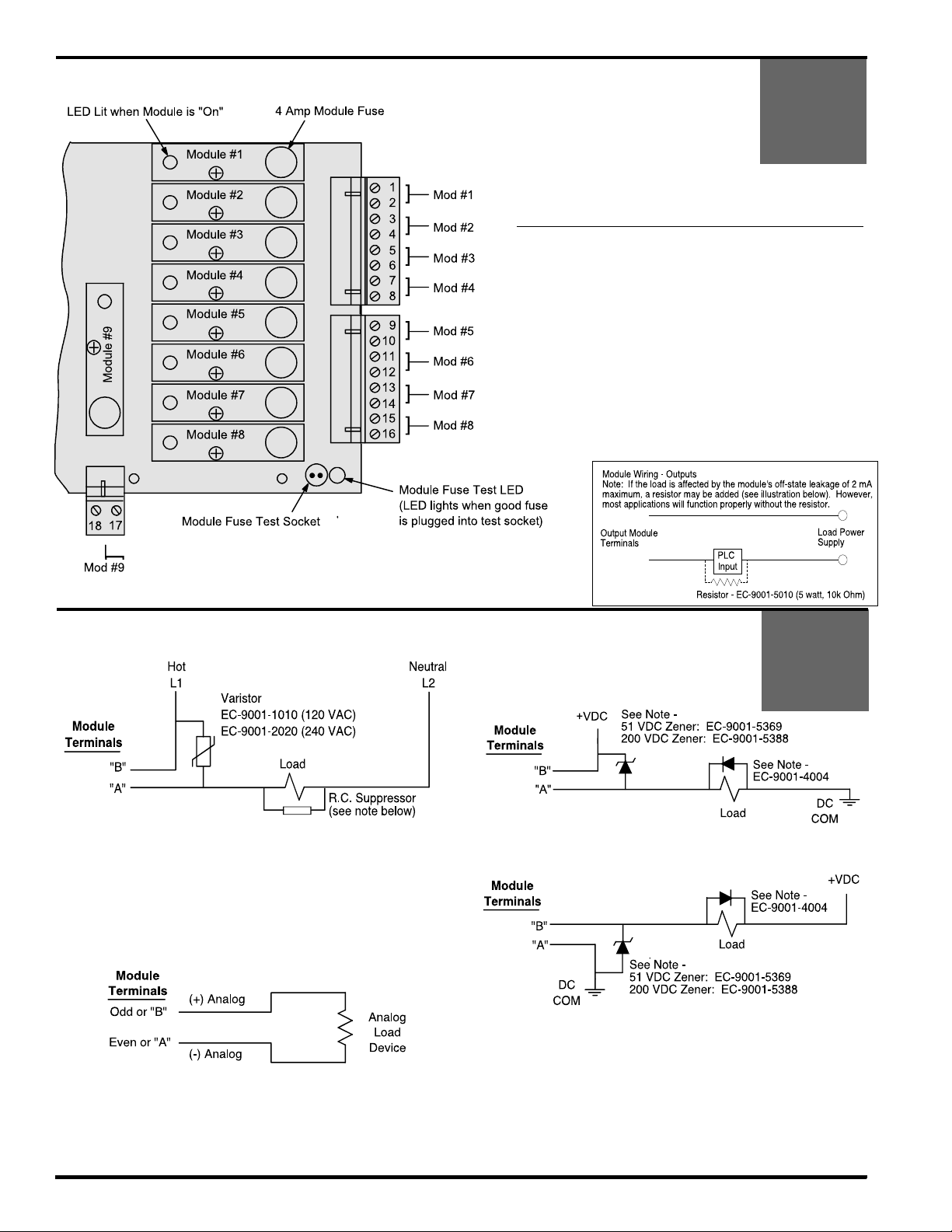

Page 16

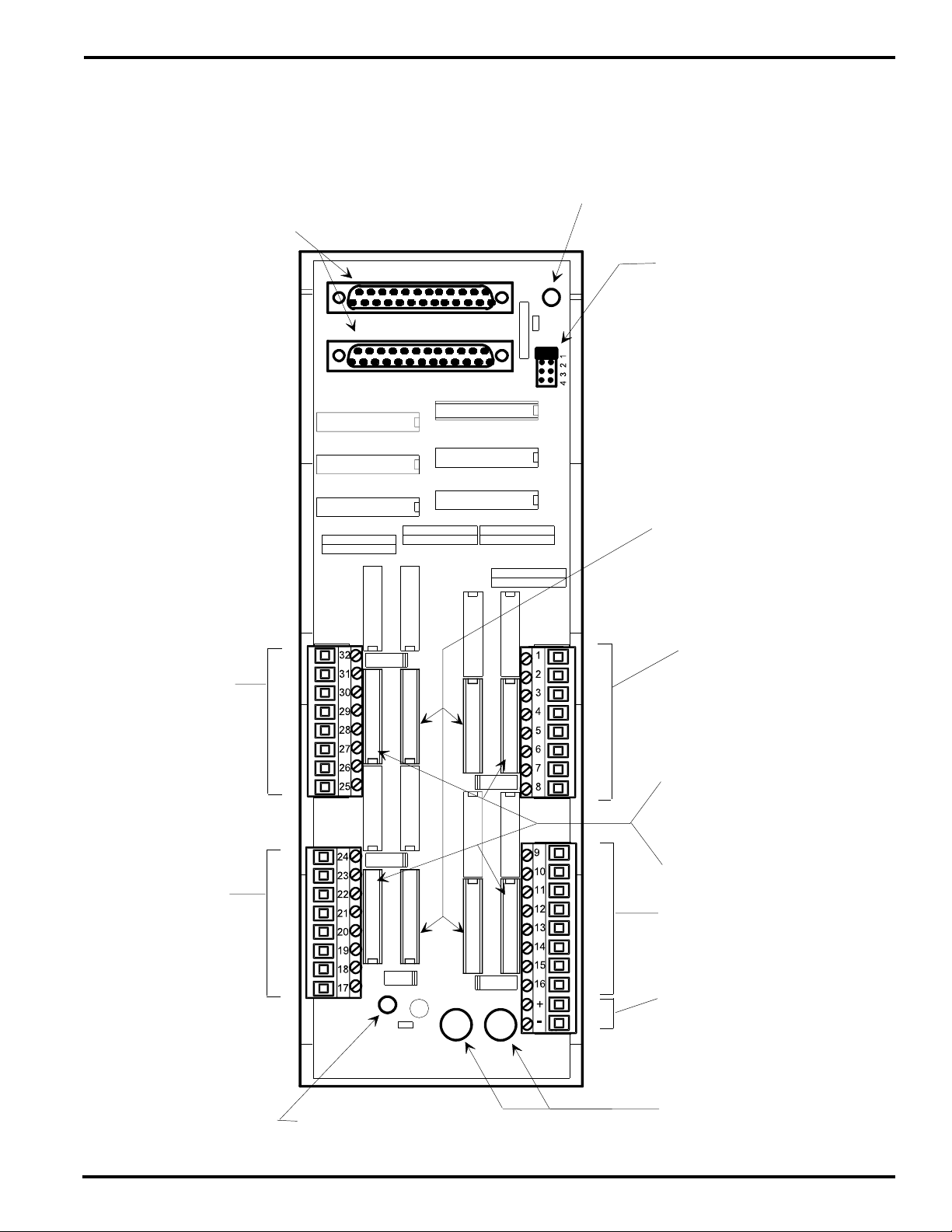

Slimline I/O Modules on Controller Back: Specifications

Back View of Controller Body

PS-5021

PS-5121

PS-5024

PS-5124

Notes:

• A module is required for each Input or Output used. See

Appendix for module specs.

• AC and DC modules can be mixed as needed.

• Input modules can be used only with 5024 and 5124 units.

• Output modules act like switches; they do not supply power

to loads.

• Analog modules may be installed in Position 9 only, and

only on units ordered with option “-A”.

• Module Fuses: 4 Amp, #PS-9005-0004 (Wickman 19370-K)

• Odd Terminals: (+) or hot

Even Terminals: (-) or load

Module Wiring - Outputs

AC Output

Odd or

Even or

• Most applications will not need the varistor or R-C suppressor shown

above. However, when other switching devices are in series or parallel

with the AC module, voltage spikes may damage the module. Use one

of the following two methods to suppress voltage spikes.

• For infrequent switching, connect a varistor (MOV) across the terminals.

• For continuous switching, wire an R-C suppressor in parallel with the

load.

Analog Output

• Control must have Option “-A” to use analog output module.

• Analog output modules source the analog signal.

• Analog output signals are isolated.

• Caution: Do not apply external voltage to an analog module or you will

damage it.

DC Output

Sourcing

PS-5X04

PS-5X21

PS-5X24

Odd or

Even or

Sinking

Odd or

Even or

• Most applications will not need the diodes shown above. However,

highly inductive DC loads may damage modules by generating voltage

spikes when switched off. Suppress these loads using one of these two

methods:

• Connect a Zener diode across the terminals. This will not significantly

increase the load turn off time. Voltage rating of the diode must be

greater than the normal circuit voltage.

• Connect a reverse-biased diode across the load. This may increase the

load turn off time.

PS-5X01

3-4 Wiring

Page 17

Sinking or Sourcing (as pertaining to Electro Cam Corp. products)

Sinking means that when the logic is true and the output (or input device) is ON, the output (or input device)

is providing a DC common or ground to the connected device.

Sourcing means that when the logic is true and the output (or input device) is ON, the output (or input device)

is providing a +DC voltage to the connected device.

This information is important when interfacing an Electro Cam Corp. product with another electronic device. If you are using an Electro Cam Corp. product

input to an Allen-Bradley 1746-IN16 “sinking” input card* or similar A-B device, you have to supply a +DC voltage (Electro Cam Corp.

to this card, NOT a DC common or ground. In these cases,

*Other manufacturers include, but not limited to: Koyo (formerly GE Series 1, Texas Instruments, or Siemens SIMATIC PLS’s) that use descriptions

similar to Allen-Bradley.

Sinking

is what the card does with the input voltage; sinks it to common or ground.

Sourcing

output)

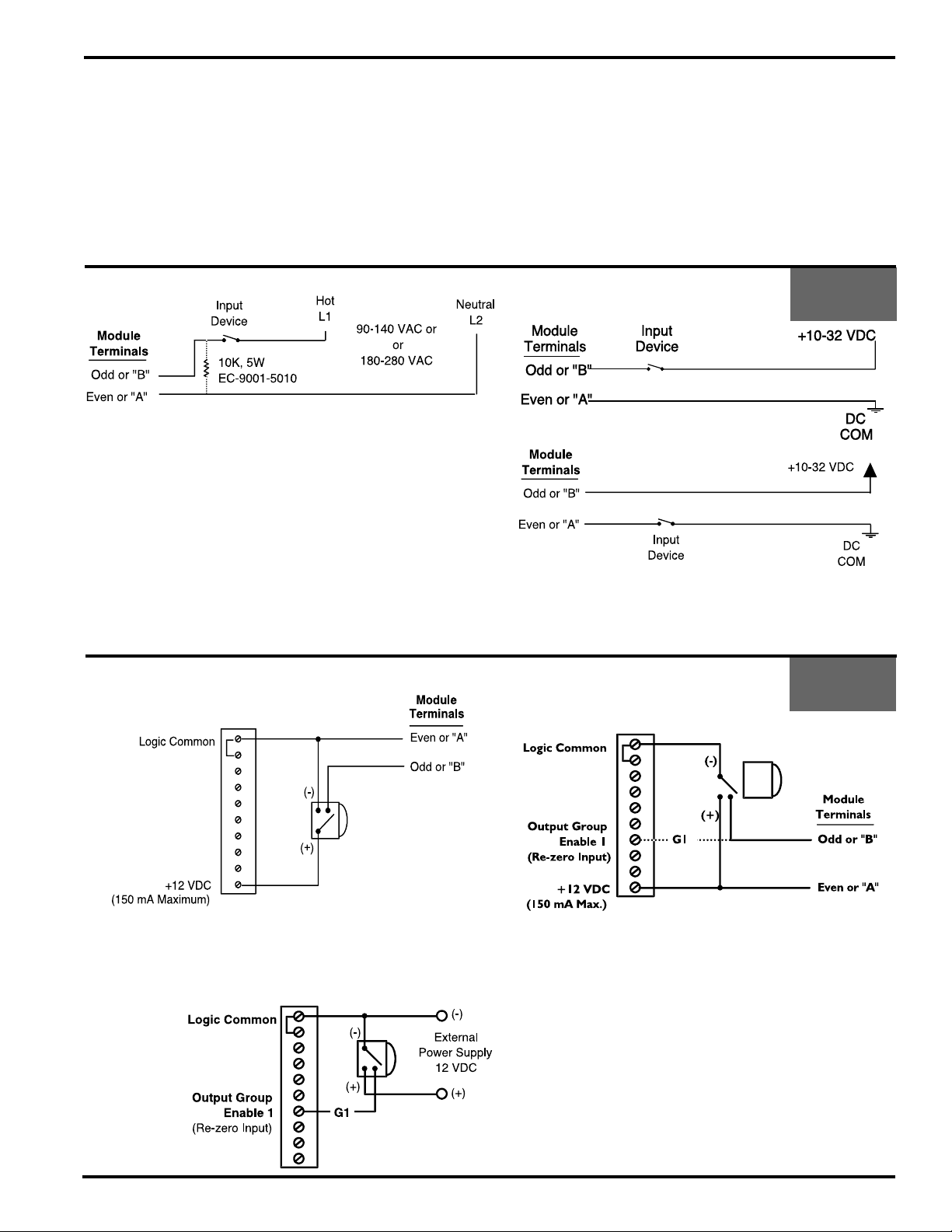

Module Wiring—Inputs

AC Input

• Input devices can be mechanical contacts or solid state.

• The load 10K load resistor shown may be needed if the AC input device

has off-state leakage, such as a solid state triac.

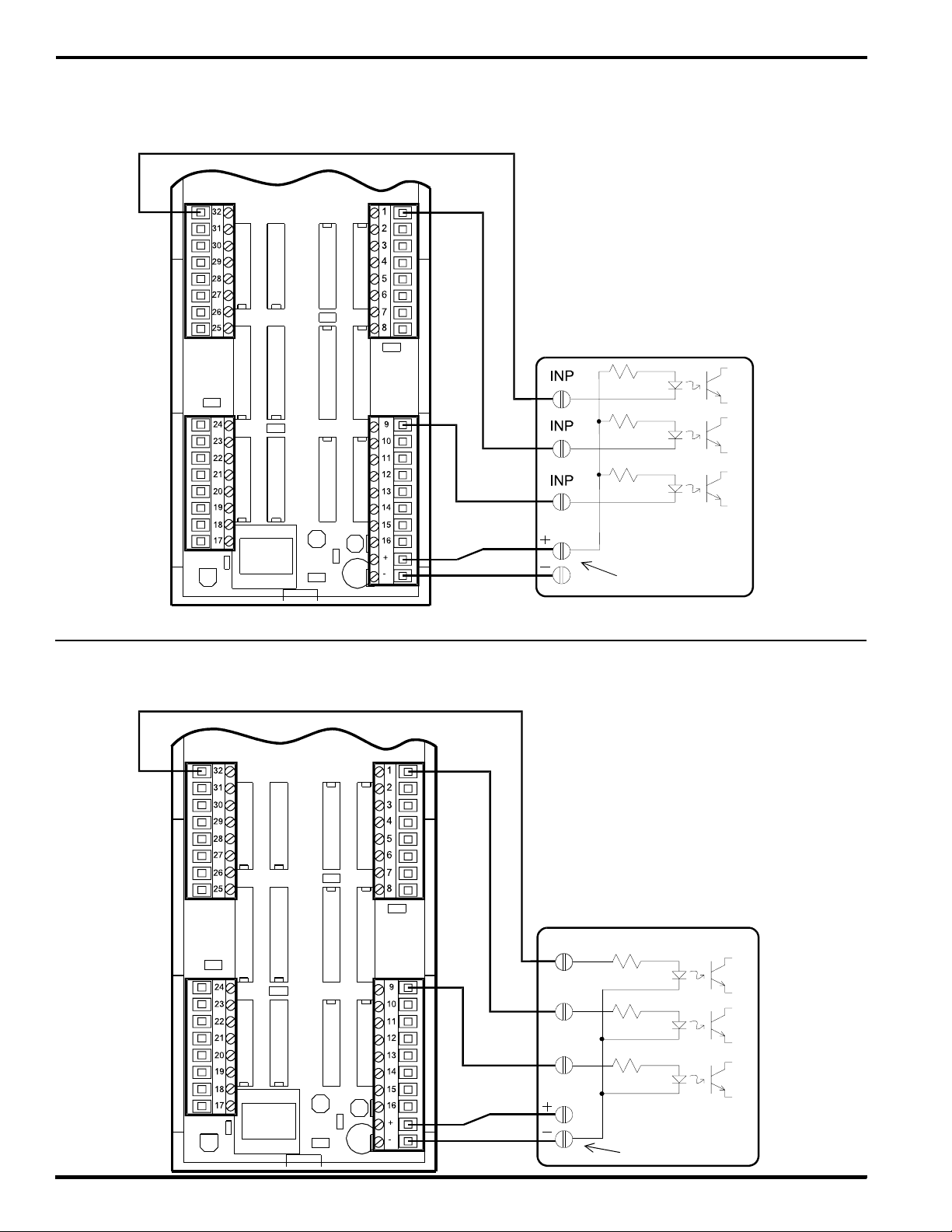

Input Wiring, 3-Wire Sensors

Using Logic Terminal Strip Power Supply (pg. 3-1)

Sourcing

DC Input

Sourcing

PS-5024

PS-5124

Sinking

• Input devices can be mechanical contacts or solid state.

• 12 VDC power is available from the controller’s logic terminal strip. See

page 3-1 for details.

Various

Sinking

Models

• For controllers using input/output modules.

Using External Power Supply & Terminal 7

• Module wiring applies only to controllers using input/output modules.

• Using sensor to switch terminal 7 can be done for any PS-5000 Series

controller. See page 3-1 for details.

• Using sensor to switch terminal 7 can be done for any PS-5000 Series

controller. See page 3-1 for details.

3-5 Wiring

Page 18

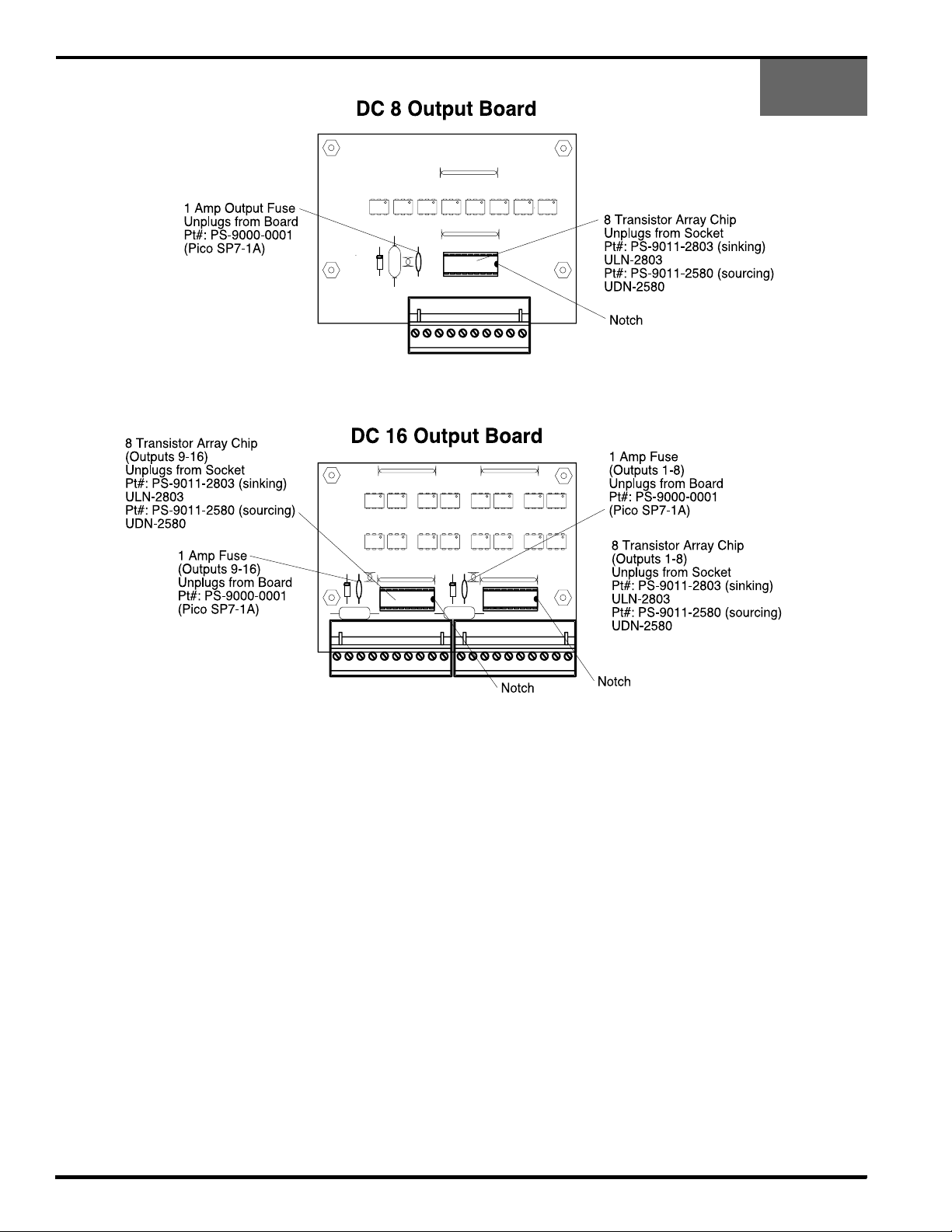

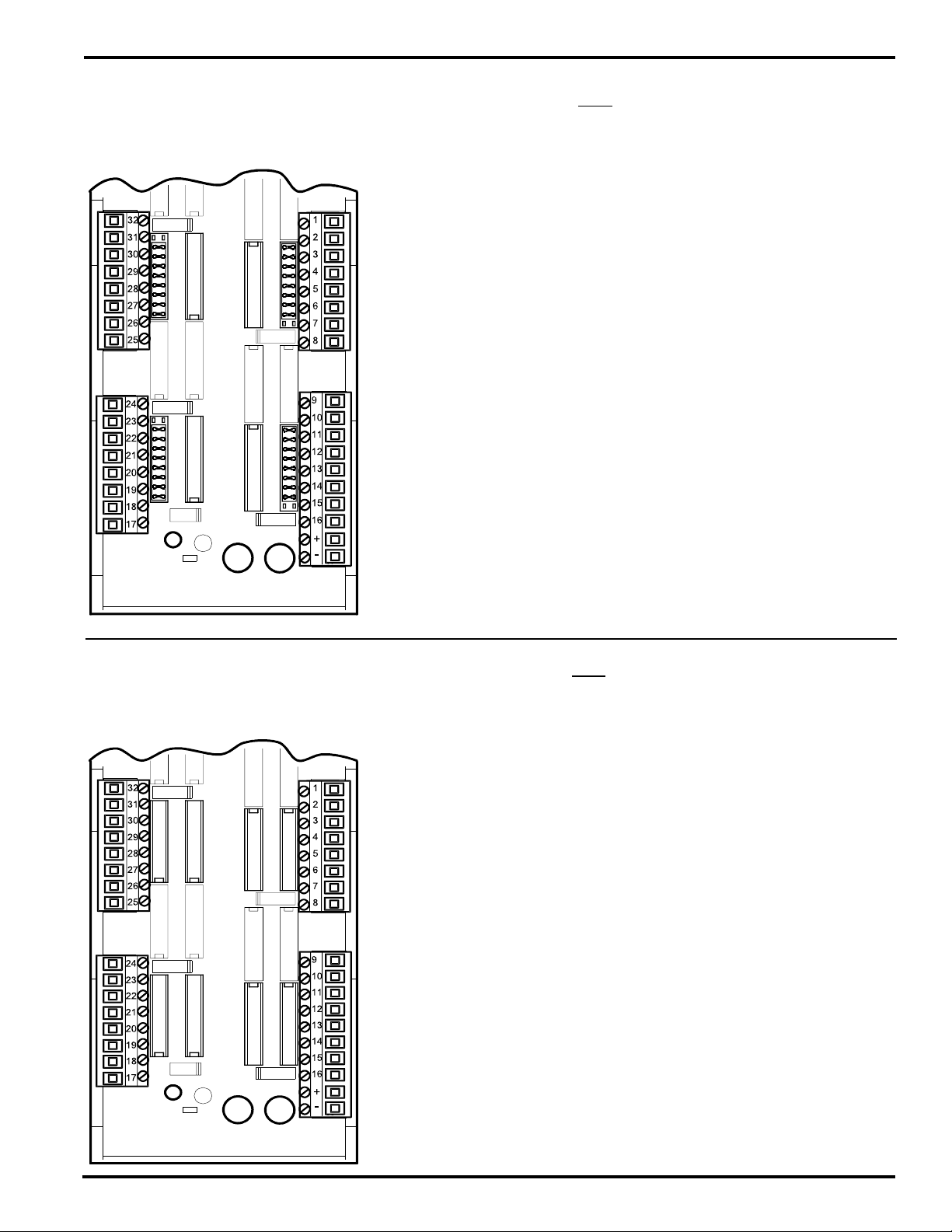

Built-In Transistor I/O Chips: Specifications

PS-5011

PS-5111

The output board which contains the output transistor array

chips and the fuse(s) is located under the output board

cover. The pluggable output terminal strips plug into receptacles that are mounted to the output board The only time

it will be necessary to remove the output board cover is

when an output fuse is blown or a transistor array chip is

damaged.

Output Transistor Array Chips:

Each group of 8 output transistors is contained in a single 18

pin transistor array chip. If one or more of these transistors

becomes damaged, the chip can simply be unplugged from

the socket and replaced. Note that Sinking and Sourcing

output boards do not use the same transistor array chip.

Output Fuses:

Each group of 8 outputs (1 transistor array chip) is protected

by a 1 Amp plug in fuse. This fuse will blow if the DC power

polarity is incorrectly wired to the “+” and “-” terminals on the

output terminal strip. On the sourcing output versions this

fuse will also blow if the total amount of current being

3-6 Wiring

conducted by that group of 8 outputs exceeds 1 Amp. If a

fuse blows, all 8 of the outputs in that group will be inoperative until the fuse is replaced.

Output Cables:

Pluggable screw terminal strips are used to connect the

transistor outputs to the load device. Therefore, no special

connectors are needed for output wiring. However, shielded

cable is recommended (Electro Cam part #: PS-4300-04XXX, 2 cables required for systems with more than 8

outputs) to maximize immunity to electrical noise. The

shield should be connected to the grounding screw located

on the back panel just above the output terminal strips. The

shield should be unconnected at the load end of the cable.

Also, the cable should be kept away from other electrical

wiring, especially control wiring involving solenoids, relays,

contactors, and motors.

Page 19

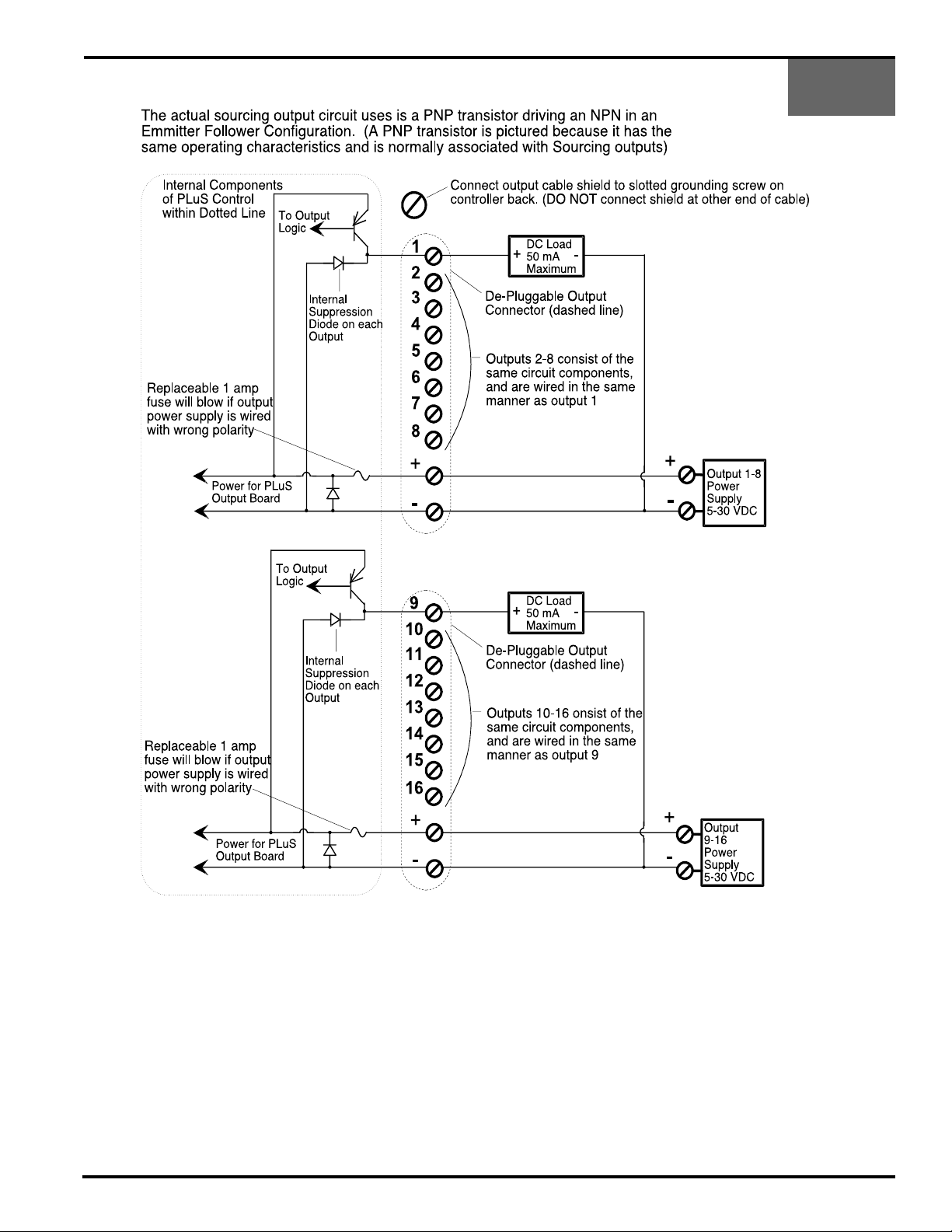

Built-In Transistor I/O Chips: Output Wiring, Sourcing

PS-5011

PS-5111

The output power supplies shown can be internal to the

load device being driven. This will normally be the case

when connecting to PLC's.

The loads connected to outputs 1-8 must all be powered

from the same power supply.

The loads connected to outputs 9-16 must all be powered

from the same power supply.

The same power supply can be used to power all 16 outputs

by paralleling the wiring between the “+” and “-” terminals

on the PLµS output terminal strips.

3-7 Wiring

The load power supply must be connected to both the “+”

and “-” terminals on the output terminal strip(s).

The unpluggable output terminal strips are keyed so they

can only be plugged into the correct receptacle.

Use shielded cable(s) for output wiring. Electro Cam 10

conductor cable part number PS-4300-04-XXX (XXX=length

in feet) is recommended. Two cables required for 16 output

units.

Page 20

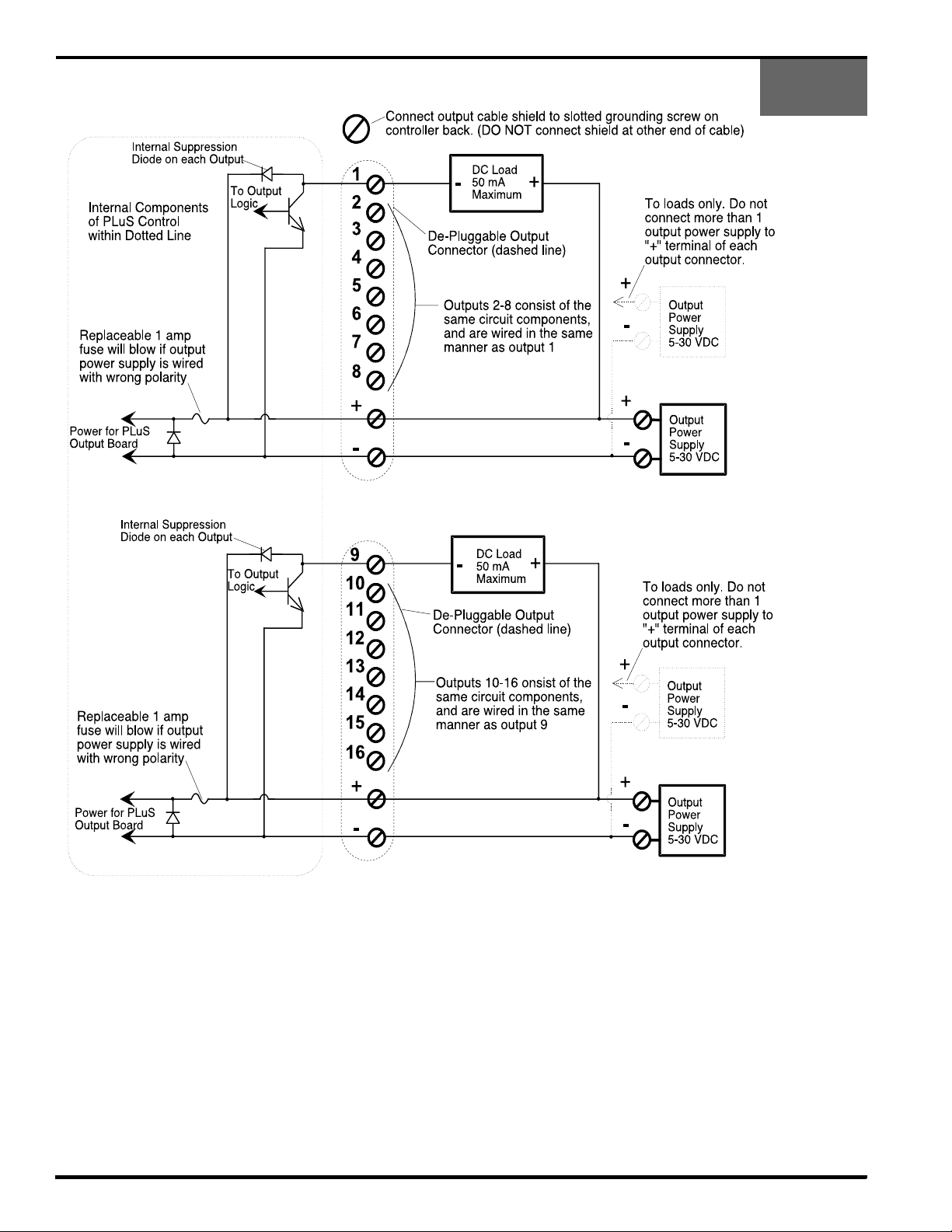

Built-In Transistor I/O Chips: Output Wiring, Sinking

PS-5011

PS-5111

The output power supplies shown can be internal to the load

device being driven. This will normally be the case when

connecting to PLC's.

More than 1 power supply can be used to power loads within

each group of 8 outputs. Only one of the power supplies

used within the group can have its positive side connected

to the “+” terminal of the corresponding 5011 output terminal

strip. The common of each power supply used within a

group of 8 outputs must be connected to the “-” terminal of

the output terminal strip.

3-8 Wiring

The same power supply can be used to power all 16 outputs

by paralleling the wiring between the “+” and “-” terminals on

the 5011 output terminal strips.

Both the “+” and “-” terminals on the output terminal strip(s)

must be connected to a load power supply.

The unpluggable output terminal strips are keyed so they

can only be plugged into the correct receptacle. Do not force

when plugging them in.

Use shielded cable(s) for output wiring. Electro Cam 10

conductor cable part# PS-4300-XXX (XXX=length in feet) is

recommended. Two cables required for 16 output units.

Page 21

Built-In Transistor I/O Chips: Output Wiring to PLC

PS-5011

PS-5111

PS-5X11 with

Sinking Outputs

PLC with Sinking Inputs

(A.B. calls these sourcing inputs)

Power Supply can be

external from the PLC.

PS-5X11 with

Sourcing Outputs

PLC with Sourcing Inputs

(A.B. calls these sinking inputs)

Power Supply can be

external from the PLC.

3-9 Wiring

Page 22

PS-5X34 Controller & 32 DC Output Rack

Introduction

The PS-5X34 system is available with either 32 or 64 low

current transistor outputs. These systems are intended to

be interfaced directly to PLCs or other control devices with

low level DC inputs.

The 32 transistor output rack(s) used with PS-5X34 controls

can be DIN rail mounted (-D) or foot mounted (-F) and are

available with Sinking or Sourcing outputs.

Systems that require 32 or fewer outputs will only need one

of the transistor output racks. Systems requiring more than

32 outputs need two transistor output racks daisy chained

together (see rack configuration section below).

PS-4100-12-X32-X Dimensioned Drawing

1/2" (13mm)

9"

(229mm)

7/8"

(22mm)

1/4" (6mm)

The PS-5X34 controller incorporates the same keyboard

and features that other PS-5000 controls use. Because of

the large number of outputs being controlled, the number of

programs stored in a 32 output controller is 32, and the

number of programs in a 64 output controller is 16.

This control has PS-5XX4 capabilities (output grouping and

modes) and includes an RS-232/485 communications port.

Outputs can be subdivided into as many as 8 groups, and

the position of each of these groups can be offset individually.

Because the rack transistor outputs cannot be configured

as inputs, the only enable input available is the "Output

Group Enable 1" input located on the logic strip. Output

Group 1 can operate in any output mode, all other groups

must operate in Mode 0 only.

DIN Rail Mount*

Foot Mount

2-1/2"

(64mm)

3"

(76mm)

2-13/16"

(72mm)

C

L

0.168" (4.3mm)

For #8 Screw

*DIN Rails must be ordered separately

Brackets (2) on

Foot Mount Version (-F) Only

Output Rack Configuration

Control systems requiring 32 or fewer outputs will need only

1 PS-4100-12-X32 transistor output rack. The "Rack

Address Jumper" must be plugged into position 1. This will

configure the outputs to be channels 1-32. 1 rack cable (Pt#

PS-4300-02-XXX) will be needed to connect the rack to the

controller.

Control systems requiring more than 32 outputs will need 2

PS-4100-12-X32 transistor output racks. The "Rack Address

Jumpers" must be plugged into position 1 on one of the

racks, and position 2 on the other. Output channel numbers

will be assigned as shown in the illustration to the right. 2

rack cables (Pt# PS-4300-02-XXX) will be needed: one to

connect the controller to the first rack and the other to

connect the two racks.

3-1/8"

(79mm)

DIN Rail

EN 50022

To PS-5X34 Control

DIN Rail

EN 50035

3-10 Wiring

Page 23

PS-5X34 System: Output Rack Layout

Sinking Output Rack Pt#: PS-4100-12-N32 Sourcing Output Rack Pt#: PS-4100-12-P32

Each Output can Source 10-30 VDC, 100 mA MaxEach Output can Sink 3-30 VDC, 100 mA Max

DB 25 Connectors (Female)

Connect to PLuS controller or another rack

(these connectors can be used interchangeably)

Output Terminals

25-32

E.C. Pt#: PS-9006-0014

(unpluggable)

PLµS Power LED

On when PLµS control is powered up

and connected to rack

Rack Address Jumper

1: Channels 1-32

2: Channels 33-64

3: Unused

4: Unused

(Jumper shown in position 1)

Transistor Array Chips

(socketed for field replacement)

X

E.C. Pt#: PS-9011-2803

Generic Pt#: ULN-2803

Output Terminals 1-8

E.C. Pt#: PS-9006-0011

(unpluggable)

Transistor Array Chips on

Y

X

Y

X

Sourcing Output Racks

(socketed for field replacement)

E.C. Pt#: PS-9011-2580

Generic Pt#: UDN-2580

Output Terminals

17-24

E.C. Pt#: PS-9006-0013

(unpluggable)

F1

X

Y

F2

Y

X

User Power LED

On when user power applied to rack

(will NOT be on if user power fuse is blown)

3-11 Wiring

Y

OR

Dip Jumper Blocks on

Sinking Output Racks

E.C. Pt#: PS-9006-0015

Output Terminals 9-16

E.C. Pt#: PS-9006-0012

(unpluggable)

User DC Power Input

10 - 30 VDC, 4 Amp Max

(Sinking outputs switch "-")

(Sourcing outputs switch "+")

User DC Power Fuses

4 Amps (F1= "+", F2="-")

E.C. Pt#: PS-9005-0004

Wickman Pt#: 19370-K

Page 24

PS-5X34 System: Wiring to PLCs

Wiring to a PLC with Sinking Inputs

(A.B. calls these Sourcing Inputs)

PS-4100-12-N32

Note: PLµS transistor output

rack and PLC MUST

both be connected to

the same DC positive.

PLC

Power Supply can be

external from the PLC

Wiring to a PLC with Sourcing Inputs

PS-4100-12-P32

(A.B. calls these Sinking Inputs)

Note: PLµS transistor output

rack and PLC MUST

both be connected to

the same DC common.

PLC

3-12 Wiring

Power Supply can be

external from the PLC

Page 25

PS-5X34 System: Output Rack Transistor Array Chips

Transistor Array Chip Layout on PS-4100-12-N32 Sinking Output Rack

PS-4100-12-N32

ULN-2813

ULN-2813ULN-2813

ULN-2813

The output circuits of the Sinking and Sourcing output boards are powered

through the "User Power Fuses." If the outputs on these boards are

malfunctioning, check that both fuses are good before investigating

the transistor array chips. If the fuses are good, the "User Power LED"

will be lit. When either fuse is blown, the LED will not light and all 32 outputs

will be dead. Verify that "User DC Power" is present.

The transistor array chips and jumper blocks used on the Sinking board are

socketed for field replacement. In the event of a wiring error or accidental

short circuit, it is possible to damage one or more array chip. In these

situations, replacing the ULN-2813 chip(s) will usually correct the problem.

The orientation of the these chips is critical with respect to their notched

ends. Insure that all chips are oriented in the direction shown in the

illustration to the left.

The jumper blocks installed in the sockets next to the terminal strips do NOT

short together all 9 sets of parallel socket holes - one set is left open. Insure

that the open set of holes is at the correct end of the corresponding socket

as pictured in the illustration to the left. A connection between these two

holes will short out the "User DC Power" supply and cause one of the

"User DC Power Fuses" to blow.

Part Numbers

Sinking Transistor Array Chip: E.C. PT# PS-9011-2803

Generic PT# ULN - 2803

16 Pin Dip Jumper Block: E.C. PT# PS-9006-0015

Transistor Array Chip Layout on PS-4100-12-P32 Sourcing Output Rack

PS-4100-12-P32

ULN-2813 ULN-2813

UDN-2580

ULN-2813

UDN-2580

UDN-2580

The output circuits of the Sinking and Sourcing output boards are powered

through the "User Power Fuses." If the outputs on these boards are

malfunctioning, check that both fuses are good before investigating

the transistor array chips. If the fuses are good, the "User Power LED"

will be lit. When either fuse is blown, the LED will not light and all 32 outputs

will be dead. Verify that "User DC Power" is present.

Two types or transistor array chips are used on the Sourcing board. They

are all socketed for field replacement. In the event of a wiring error or

accidental short circuit, it is possible to damage one or more array chip. In

these situations, replacing the UDN-2580 chip(s) will usually correct the

problem. The orientation of the array chips is critical with respect to the

notched end of the chips. Insure that all chips are oriented as shown in

the illustration to the left.

Part Numbers

ULN-2813

UDN-2580

Sourcing Transistor Array Chip: E.C. PT# PS-9011-2580

Generic PT# UDN-2580

Sinking Transistor Array Chip: E.C. PT# PS-9011-2803

Generic PT# ULN - 2803

3-13 Wiring

Page 26

Resolver Wiring and Dimensions

STANDARD RESOLVER CABLES

PT# PS-5300-01-XXX (XXX = LENGTH IN FEET)

Connector - Controller End

PT# PS-5300-01-TER

(Weidmuller # BLA7 12822.6)

Cable Type:

Connector - Resolver End

PT# PS-5300-01-MSC

(ITT Cannon # KPT-06-F-12-10-S)

3 individually shielded pairs, 22 gauge

S2

Green

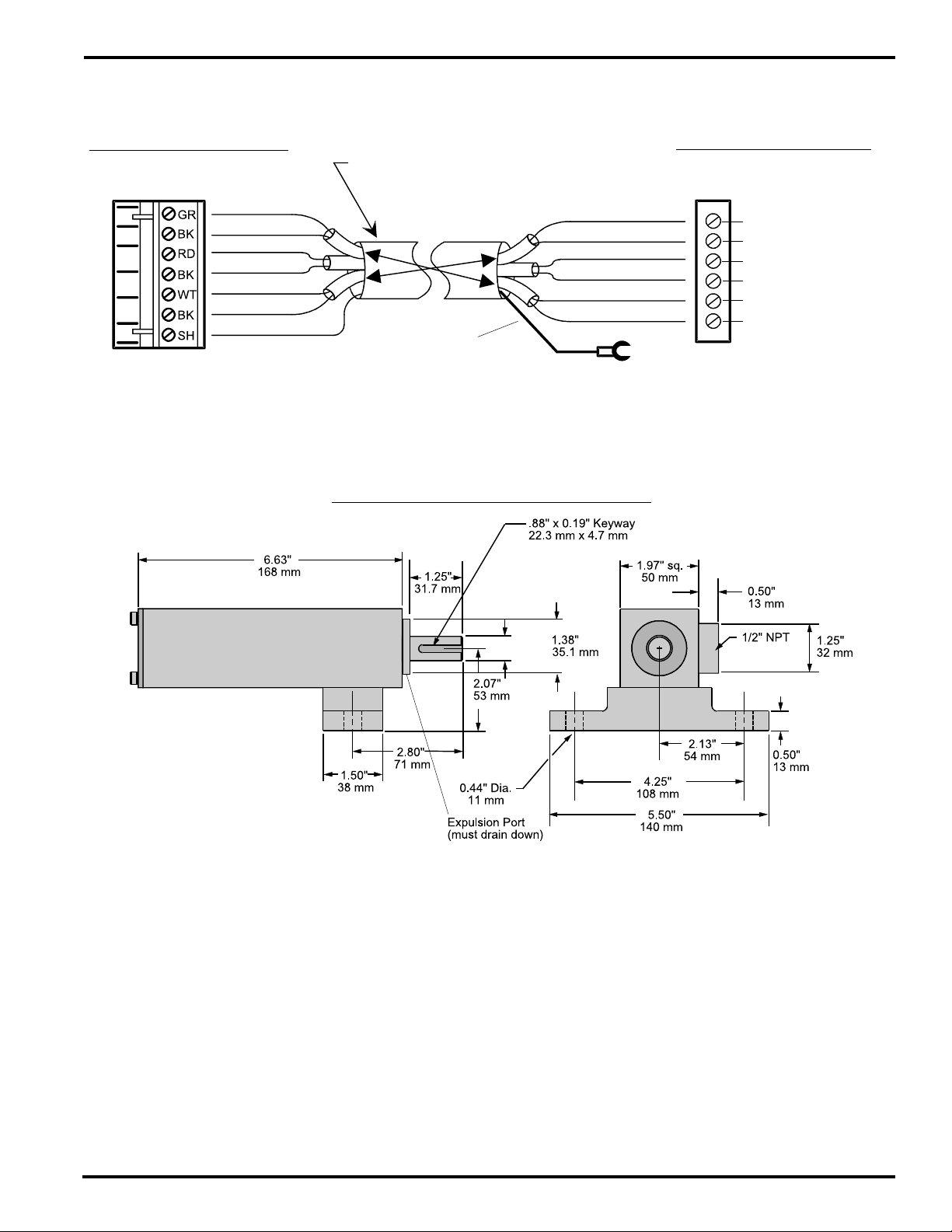

Black

Red

Black

White

Black

Shield

S4

S1

S3

R1

R2

Shield

(see note below)

Pin B - Green

Pin A - Black

Pin D - Red

Pin C - Black

Pin F - White

Pin E - Black

Shield

Shielding Note: Resolver cables made after 3-2-93 have a ring lug on a black shield wire at

the resolver end. The ring lug should be attached to one of the resolver connector strain relief

screws to protect against static discharge through the resolver cable. In some installations, it

may be advisable to disconnect the ring lug to prevent ground loops through the cable shield.

Consult Electro Cam if electrical noise problems are suspected.

RESOLVER DIMENSIONS

Foot Mount Resolver - 3/4" Shaft

Front View

(pin out)

= Not Used

With Rear Connector (shown):

PS-5275-11-ADR

With Side Connector:

PS-5275-11-ADS

Cable:

PS-5300-01-XXX where “XXX” is length in feet.

With Rear Connector (shown):

PS-5238-11-ADR

With Side Connector:

PS-5238-11-ADS

Cable:

PS-5300-01-XXX where “XXX” is length in feet.

0.749/

0.747"

19.02/

18.97 mm

Flange Mount Resolver - 3/8" Shaft

0.375/

0.374"

9.53/

9.50 mm

3-14 Wiring

Page 27

Resolver Wiring and Dimensions

STAINLESS STEEL RESOLVER

Cable for Stainless Steel Resolver with Terminal Strip Connections

Connector - Controller End

PT# PS-5300-01-TER

(Weidmuller # BLA7 12822.6)

Green

Black

Red

Black

White

Black

Shield

PT# PS-5300-02-XXX (XXX = Length in Feet)

Cable Type:

3 individually shielded pairs, 22 guage

White

Black

Black

Red

Black

Green

Shield

Shield

(see note below)

Shielding Note: This type of resolver cable will have a spade lug connected to the shield at the resolver end. The lug should

be attached to the grounding stud on the cover plate of the resolver. In some installations, it may be advisable to disconnect

the lug to prevent ground loops through the cable shield. Consult Electro Cam if electrical noise problems are suspected.

Connector Inside Resolver

(cable is stripped and tinned at

both ends)

WHITE

BLK (P/W) WHITE

BLK (P/W) RED

RED

BLK (P/W) GREEN

GREEN

Stainless Steel Foot Mount Resolver - 5/8" Shaft

Horizontal Mount

(shown) PS-5262-11-CTG (with right connector)

PS-5262-11-CTL (with left connector)

Vertical Mount (Shaft Up)

PS-5262-11-CTG-V (with right connector)

PS-5262-11-CTL-V (with left connector)

Cable: PS-5300-02-XXX where “XXX” is length in feet.

.625/

.624" dia.

15.88/

15.85 mm

For horizontal applications

3-15 Wiring

Page 28

Encoder Cable Installation

Encoder cable receptacle (male)

connectors are keyed to plug in

one way only

NON-TERM

TERM

Plug shield spade connector onto

NON-TERM lug if encoder is grounded

to the machine

Plug shield spade connector onto

TERM lug if encoder is not grounded to

the machine

Encoder compression

seal fitting

Spade connector for

cable shield

Connector for

encoder (female)

Turn it parallel to the

cable as shown to

slide it through the

encoder fitting

Split rubber sealing

grommet

Split nylon washer

Knurled compression

nut (threaded end

toward encoder)

Note: The encoder cable can be pulled through 3/4" or

larger conduit. Pull the cable from the controller to the

encoder. Turn the encoder connector (rectangular) parallel

to the cable (as pictured to the left) and tape it in this position

while it is being pulled. Pull the connector through conduit

before following the cable installation steps below.

A bulkhead connector assembly (PS-4300-09-XXX) is

available for installations where it is desirable to unplug the

encoder cable from the control enclosure.

Installation Procedure

1. Turn encoder connector (rectangular) parallel to cable

and slide knurled compression nut over it. Threaded end

of nut must face encoder connector.

2. Slip the nylon friction washer and the rubber sealing

grommet onto the cable by opening up the splits.

3. Turn encoder connector parallel to the cable and slide it

through the encoder compression seal fitting.

4. Plug encoder connector into the receptacle, making sure

that raised key on connector mates with the key slot in

the receptacle.

25 pin DB connector

(female)

Retainer screws must

be securely tightened

to insure proper

cable grounding

5. Plug the shield spade connector onto the “NON-TERM”

spade lug if the encoder is grounded to the machine, or

onto the “TERM” lug if the encoder is not grounded.

6. Slide the rubber grommet, nylon washer, and

compression nut up to the compression fitting. Thread

on the compression nut. Push a small amount of cable

into the encoder to insure that it isn’t pulling on the

connector as the compression nut is tightened.

7. Put lid back on encoder. Operating without the lid can

allow dust and other contamination to affect proper

operation of the encoder.

3-16 Wiring

Page 29

Programming Access Levels

Levels of Programming Access

The 5000 Series of controls have three levels of programming

access. Entry into these levels of programming is

accomplished through dedicated hardware inputs and/or

programmable enable codes entered through the keyboard.

Master Level—Accesses all programmable features. In

addition to all setpoints and functions, the Master Level also

establishes the keyboard entry codes for the “Setup” and

“Operator” access levels. Master Level programming also

determines which outputs are accessible to the operator.

NOTE: On units prior to date code 9740, operator access

was limited to setpoints and timed output values, unless

equipped with the Expanded Operator Access (-E) option.

Setup Level—Accesses all output setpoints and the

functions listed on the keyboard. These are control aspects

that may need occasional adjustment, but go beyond normal

operator responsibilities.

Operator Level—Functions available as specified in Master

Level programming. The operator is allowed to change the

following settings for output channels designated in FCN 6:

• Setpoints • Offset

• Timeouts • Active Program Number

• Motion Detection Settings • Speed Comp Settings

The table below details which functions and set points can

be changed at the three levels of programming access. It

also indicates if the programming access levels can be

accessed by hardware input and/or keyboard enable code.

FEATURE MASTER SET UP OPERATOR

Enable Method hardware code hardware / code

Output Set Points All All Selected

Output Time Out Values All All Selected

Motion Set Points Yes Yes Selected

Offset Yes Yes Selected

Active Program Yes Yes Selected

Speed Compensation Yes Yes Selected

Direction of Rotation Yes No No

Scale Factor Yes No No

Set Up Enable Code Yes No No

Operator Enable Code Yes No No

Time Base Selection Ye s No No

Motion ANDed Outputs Y e s No No

Select Operator Outputs Y es No No

Output Enable Modes Yes No No

OPTIONAL FEATURES:

Lead/Trail Speed Comp Yes No No

Communication Setup Ye s No No

Analog Setup Yes Yes Selected

Logic Terminal Strip

LOGIC COMMON

PROGRAM SELECT 1

PROGRAM SELECT 2

PROGRAM SELECT 3

MASTER PROGRAM ENABLE

OUTPUT GROUP ENABLE 1

MOTION DETECTION OUTPUT

OPERATOR PROGRAM ENABLE

+12VDC OUT - 150 mA MAX

Hardware Program Enable Circuits

1

2

3

4

5

6

7

8

9

10

Master Programming is enabled when terminal 6 is connected

to terminal 1 or 2. The Master Level can only be accessed by

energizing this input.

Operator Programming is enabled when terminal 9 is connected

to terminal 1 or 2. The Operator Level can also be accessed

through a keyboard enable code.

Keyboard Enable Codes for Setup and Operator Access

Either the Setup or Operator programming levels can be accessed by

entering the corresponding program enable code through the keyboard.

These codes can be 1, 2, 3, or 4 digit numbers and are established

during Master Level programming.

To Enter a program enable code number press:

FCN 0 ENT 1st digit 2nd digit 3rd digit 4th digit ENT

The PE codE message will disappear when a valid enable code is

entered.

The level of access gained depends upon which code number is

entered.

Programming access will time-out approximately 5 minutes after the

last keystroke. To cancel access before the 5 minute time-out press:

FCN 0 ENT CLR/CLE ENT

4-1 Programming, Standard Features

Page 30

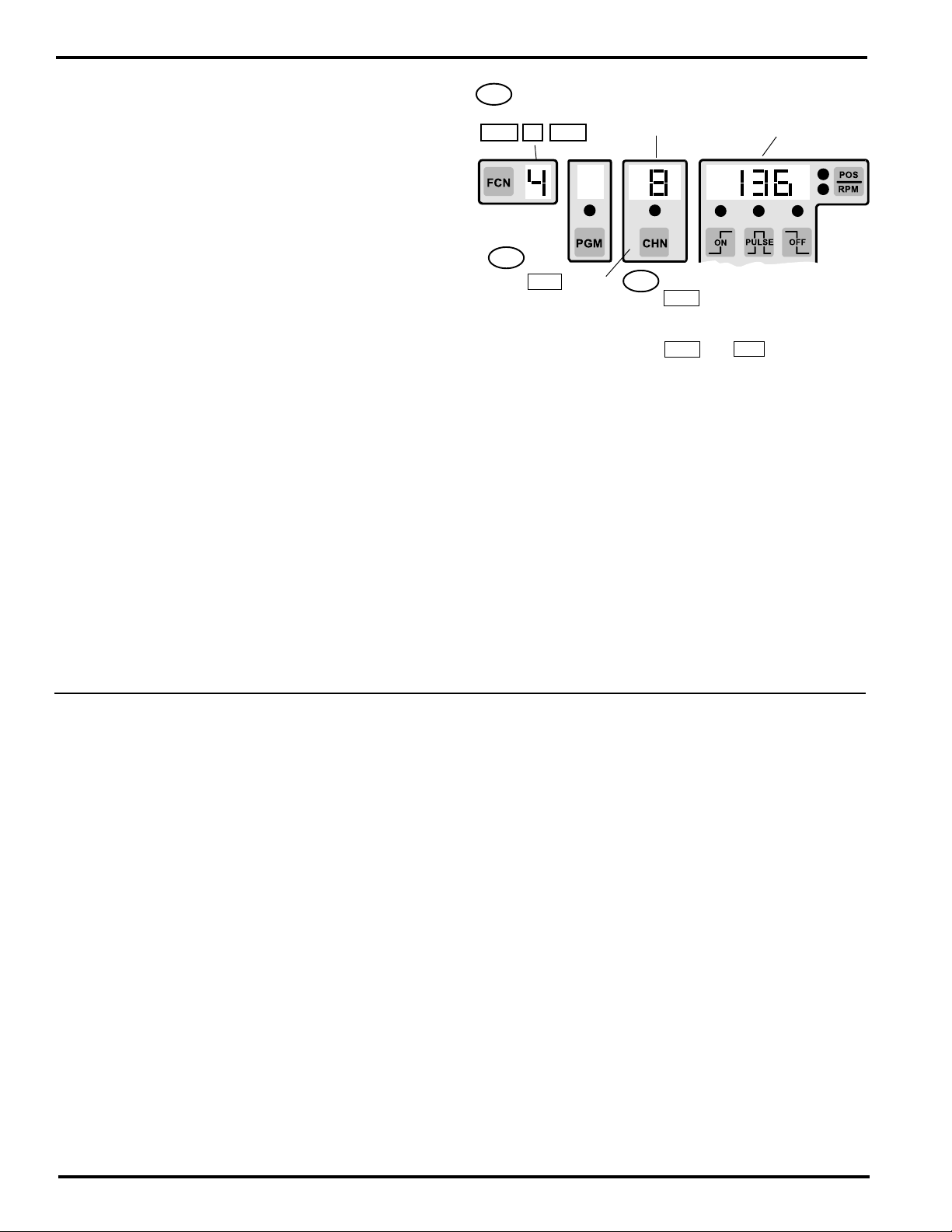

Keyboard Layout, Keys and Indicators

2

1

1 - Function Key and Display

The FCN Key is used to access the controls functions. The

FCN number accessed will be displayed in the display next

to the FCN key.

2 - Program Key, LED and Display

The PGM key allows programs other than the current active

program to be viewed and or edited. The program number

selected for viewing/editing is shown in the display directly

above the PGM key. When the PGM LED is lit, the

program number displayed is also the current active

program.

3 - Channel Key, LED and Display

The CHN key allows the desired output channel to be

selected for setpoint viewing/programming. The selected

channel number is shown in the display directly above the

CHN key. When the CHN LED is lit, the channel currently

selected is in the ON state.

The CHN key is also used to select channel numbers during

Function programming. Details are given in the programming sections.

4 - Value Display, Position/RPM Key and LEDs, ON Key

and LED, PULSE Key and LED, OFF Key and LED, and

View Keys

The POS/RPM key selects between Position and RPM

being shown in the value display immediately to the left of

the key. The corresponding POS or RPM LED will be lit

when either item is displayed. Pressing the POS/RPM

allows programming functions to be exited/aborted

and returns the control to displaying Position or RPM.

The ON and OFF keys are used to specify the ON and OFF

pulse edges during setpoint programming. The

corresponding ON and OFF LEDs will be lit during these

3

6

4

5

setpoint programming operations. (The ON and OFF keys

and LEDs are also used when programming the optional

leading and trailing edge speed compensation feature).

The VIEW keys allow the current On and Off setpoints of the

currently selected channel to be displayed in sequence, one

at a time. The corresponding ON or OFF LED will be lit to

indicate whether an ON or OFF edge is currently displayed.

The >VIEW key displays the setpoints in increasing numeric

order, the <VIEW key displays them in decreasing numeric

order.

The PULSE key allows setpoint pairs (pulses) to be

incremented and decremented simultaneously. When the

PULSE LED is lit steadily, the pulse (both edges) whose

edge is currently displayed will increment and decrement

when the INC and DEC keys are pressed. Pressing the

PULSE key a second time will cause the LED to blink. This

indicates that the multi-pulse mode is activated and all of the

pulses in the currently selected output channel will increment

and decrement when the INC and DEC keys are pressed.

5 - MOTION, POWER and CPU LEDs

The Motion LED is lit whenever the machine speed is within

the current motion setpoints (FCN 1).

The Power LED is lit whenever the PLuS control is powered

up.

The CPU LED only lights when a Fatal error condition is

detected by the controller. A list of these error conditions is

detailed on page A-5 of this manual.

6 - Numeric Keys, CLR/CLE Key, ENT Key, INC and DEC

Keys

The number keys are used to input all numeric values

needed during setpoint and function programming.

The CLR/CLE key is used to clear numeric values during

programming operations.

The ENT key is used to actually enter numeric values into

the controller after they have been keyed in. Failing to press

ENT when programming numeric values will result in the old

value remaining in the control's memory. Numeric value

changes must be “Entered” by pressing the ENT key before

they are accepted by the controller.

The INC and DEC keys cause numeric values that are

displayed in the controls POS display to be incremented

and/or decremented each time the corresponding key is

pressed. Output setpoints, speed compensation and timed

output values are examples of items that can be incremented

and decremented with the INC and DEC keys.

4-2 Programming, Standard Features

Page 31

Output Setpoint Programming

OFF

FCN

PGM

CHN

POS

Programming Error Messages

Flashing error messages indicate programming mistakes

as they occur.

Simply press to cancel flashing error message.

E1 OLAP: Output pulse just attempted overlapped an existing output

E2 -run: Attempted programming can NOT be done while machine is

E4 -Pro: Program enable Off when programming was attempted.

E5 8888: Value entered NOT valid for item being programmed.

E6 -379: Invalid setpoint entered: A setpoint ending in 3, 7, or 9 was

E7 -dEF: Attempted to program too many Enable Inputs (FCN 9).

E9-tdE: Attempted to program too many timed outputs (FCN 5).

E11-ScE: Attempted to program more than 16 speed compensated

CLR

pulse on same channel.

running (transducer is turning).

entered. (Encoder Only - Exceptions: 89, 179, 269, and 359)

outputs (48 I/O controls only).

See pgs. A-12 thru A-14 for more details on error messages.

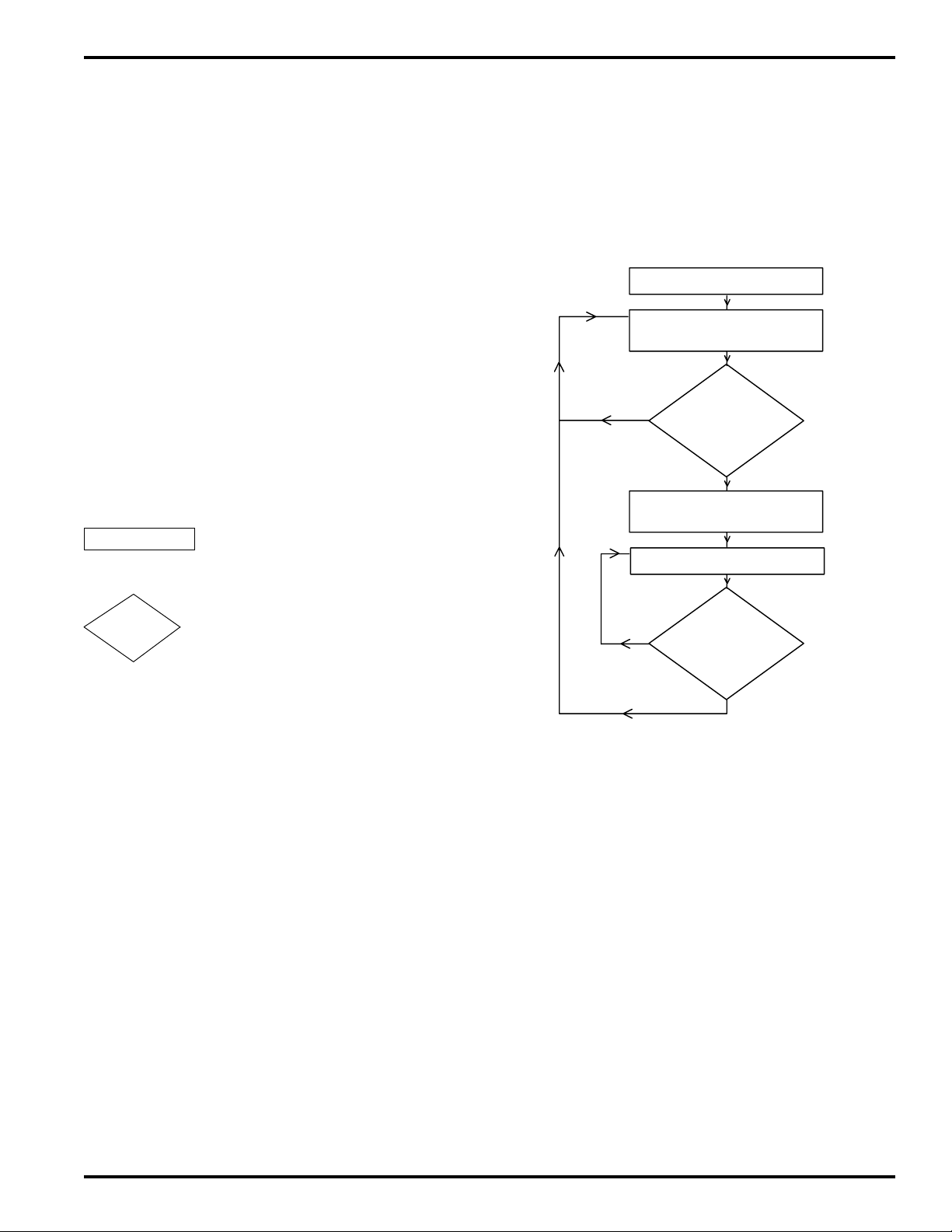

Output Setpoint Programming

Desired output channel MUST be selected before its

setpoints can be created, viewed, adjusted, or cleared.

If POS or RPM

led NOT lit press:

POS or RPM

led now lit

SELECT OUTPUT CHANNEL

POS

RPM

CHN

CHN and POS

displays blank

1st Digit shown

in CHN display

Channel 16 used as example.

1

6

2 Digit value in

CHN display

To create setpoints in output channel presently selected.

ON

On led lit, POS

blank

3

1st Digit shown in

POS display

0

2 Digits shown in

POS display

On at 30 degrees used as example.

6

OFF led lit, POS

blank

1st Digit shown in

POS display

Off at 60 degrees used as example.

Note: When entering multiple pulses, press

pulse.

2 Digits shown in

POS display

0

ENT

ENT

POS display blinks

once to confirm

setpoint entry.

after each

CHANGE SETPOINTS

CREATE SETPOINTS

To change setpoints in output channel presently selected.

INC/DEC

INC

Displayed ON/OFF setpoint increases 1

increment each time INC key is pressed.

INC

DEC

Displayed ON/OFF setpoint decreases 1

increment each time DEC key is pressed.

DEC

NUMERIC ENTRY

5

1st Digit shown in

POS display

0

2 Digits shown in

POS display

Changing setpoint to 50 degrees used as example.

ENT

POS display blinks once to

confirm setpoint change.

PULSE MODE

To change both setpoints of a pulse simultaneously.

PULSE

Pulse led lit

INC

ON and OFF setpoints of ALL pulses

increase/decrease 1 increment each

time INC/DEC key is pressed.

OR

DEC

MULTI-PULSE MODE

To change all setpoints in the output channel simultaneously.

PULSE

Pulse led lit

PULSE

Pulse led

blinking

ON and OFF setpoints of ALL pulses

increase/decrease 1 increment each

time INC/DEC key is pressed.

INC

OR

DEC

CLEAR SETPOINTS

CLEAR 1 PULSE

To clear 1 pulse (1 pair of setpoints) on selected output channel.

Use numeric entry method (shown in CHANGE SETPOINTS above) to set OFF setpoint equal to ON setpoint

value. Both setpoints will be erased.

View setpoints of output channel presently selected.

VIEW

ON/OFF setpoints shown in position

display in increasing order with ON

and OFF LEDs. 0 is shown and both

LEDs off if no setpoints exist.

VIEW

ON/OFF setpoints shown in position

display in decreasing order with ON

and OFF LEDs. 0 is shown and both

LEDs off if no setpoints exist.

4-3 Programming, Standard Features

VIEW SETPOINTS

CLEAR EXISTING SETPOINTS

To clear all setpoints on selected output channel.

VIEWVIEW

ON

ON Led lit,

POS blanks

0

0 shown in

POS display

OFF

OFF Led

lit, POS

blanks

0

0 shown in

POS

display

ENT

POS display

blinks and

shows 0, ON

and OFF LEDs

are off.

Page 32

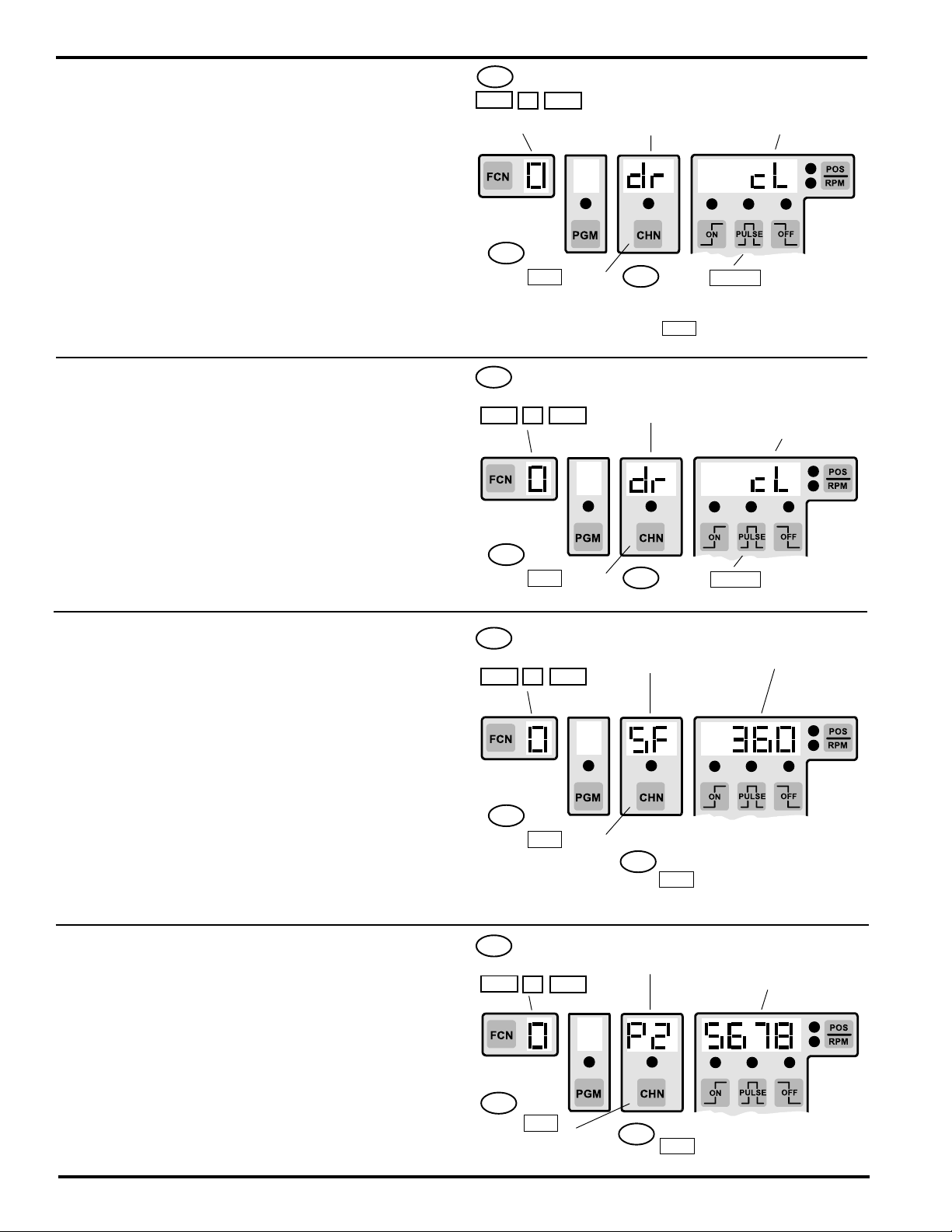

Master Level Programming, Standard Controls: FCN 0

FCN 0 Programming at the Master Level

(Master Program Enable Input MUST be energized)

Function 0 allows specific features of the PLµS control to be

programmed when the Master Program Enable input is

energized. Standard Function 0 features include: Direction

of Increasing Rotation, Scale Factor, Set-up Enable Code,

Operator Enable Code, and Output Timing Resolution.

Normally, the features controlled by Function 0 will be

programmed only once for a specific application.

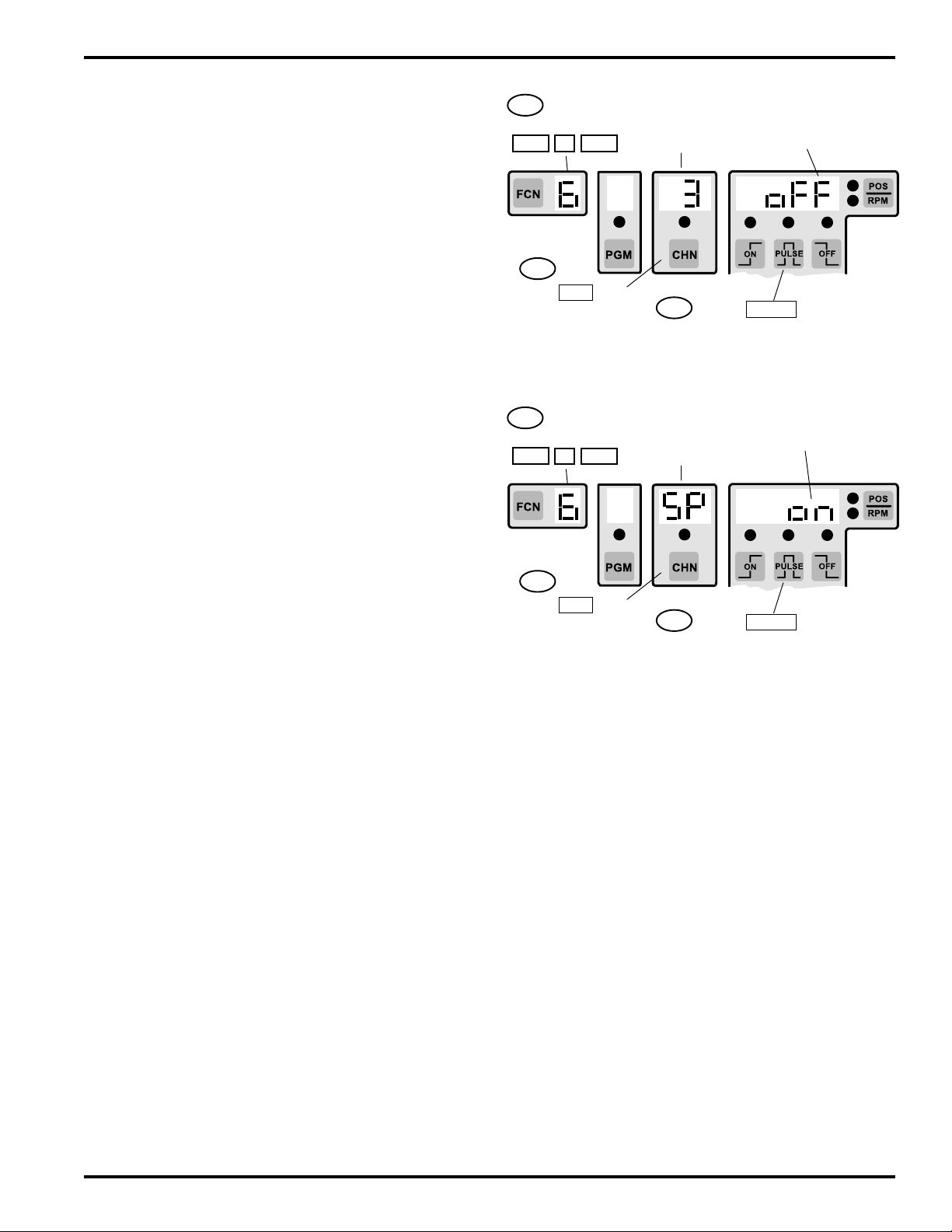

Optional Function 0 features are covered under

“Options Programming,” Section 5. They include: Sc

(leading/trailing edge speed comp), ct (communication

type), cS (communication Speed), cA (communication

Address), and rU (RPM update frequency).

dr - Direction of Increasing Rotation

This allows the direction of increasing rotation of the position

transducer (encoder / resolver) to be cL (clockwise) or ccL

(counter clockwise) as required by the machine installation.

This is normally set so the position value increases when

the machine turns in its forward direction.

Resolver: cL or ccL as viewed from shaft end.

1st Press:

FCN 0 ENT

FCN 0 Shown

2nd

Press CHN key

to step through the

FCN 0 features

1st If FCN 0

not shown press:

FCN 0 ENT

FCN 0

Feature being

Programmed

3rd

Press PULSE key to select

desired choice OR

Press numeric keys followed by

ENT key to change values

dr - direction

of increasing

rotation

Present Value / Choice

for displayed FCN 0

feature shown

Present direction

shown:

cL - clockwise

ccL - counter clockwise

Encoder: cL or ccL as viewed from shaft end with cable

entrance on the right.

SF - Scale Factor (Resolver units only)

The Scale Factor is the number of increments each revolution

of the resolver will be broken into. A Scale Factor of 360 (0-

359) allows programming to be done in degrees. A Scale

Factor of 1024 (0-1023) allows setpoint programming to be

done at fine resolution (.35 degree increments).

Scale Factors range from 2-1024 on standard 5000 controls.

Scale Factors range from 2-4096 on high resolution 5000

controls (“H” option).

Note: When Scale Factor is changed, all programmed

setpoints are recalculated to convert them to the new Scale

Factor. The keyboard will be inoperative during this time.

Scale Factor value will blink once when calculation is

completed.

P1 & P2 Keyboard Enable Codes

P1 - Setup Enable Code Number

P2 - Operator Enable Code Number

2nd

Press CHN key

until dr is shown

1st If FCN 0

not shown press:

FCN 0 ENT

2nd

Press CHN key

until SF is shown

1st If FCN 0

not shown press:

FCN 0 ENT

3rd

Press PULSE key to select

between cL and ccL

SF Scale Factor

3rd

Press number keys followed by

ENT to change Scale Factor

value (change will take time)

P1 or P2

selected

Present Scale Factor

value shown

Present Enable Code

value shown for P1 or

P2 code selected

These are the keyboard entry code numbers that will be

used to access the Setup (P1) and Operator (P2)

programming levels.

Any 1, 2, 3, or 4 digit value can be used for either P1 or P2.

4-4 Programming, Standard Features

2nd

Press CHN

key until desired P1

or P2 is shown

Press number keys followed by

3rd

ENT to change Enable Code

value

Page 33

Master Level Programming, Standard Controls: FCN 0 (continued)

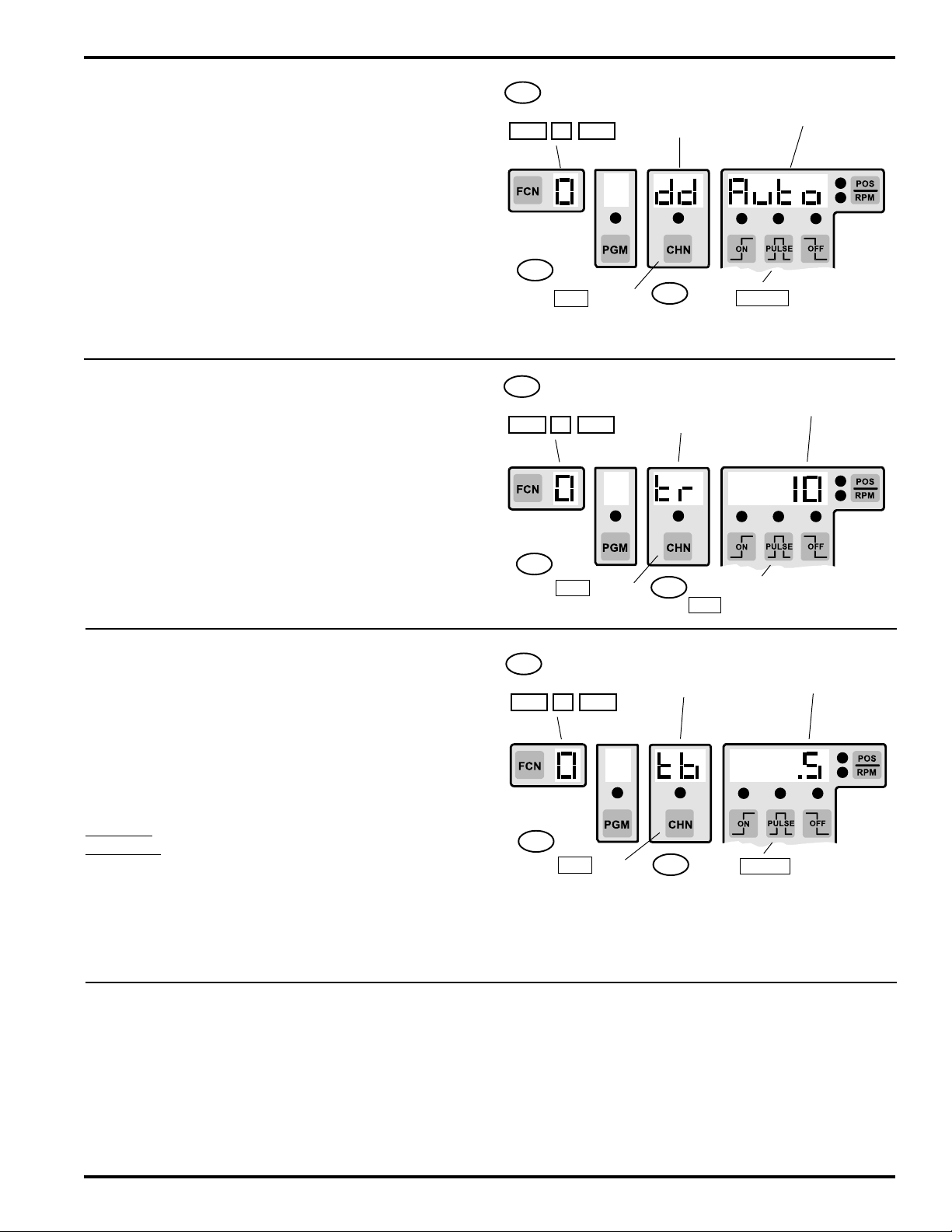

dd - Display Default (PS-51XX after 5/12/92)

Auto, Spd, or PoS can be selected for the display default by

pressing the Pulse key while “dd” is displayed in function 0.

Auto - (Automatic) Display will automatically switch between

POS and RPM when speed goes above and below the “tr”

(toggle RPM) value programmed.

Spd - (Speed) On power up, the control will default to

displaying RPM. The POS/RPM key can be used to switch

between position and RPM display.

PoS - (Position) On power up, the control will default to

displaying position. The POS/RPM key can be used to

switch between position and RPM display.

tr - Toggle RPM (All units after 5/12/92)

When the “Auto” mode is selected as the “dd” (display

default), the value programmed in “tr” determines the speed

where the display switches from position to RPM.

At speeds below “tr”, position will be displayed and the

“POS” LED will be lit.

At speed equal to or above “tr”, RPM will be displayed and

the “RPM” LED will be lit.

1st If FCN 0

not shown press:

FCN 0 ENT

2nd

Press CHN key

until dd is shown

1st If FCN 0

not shown press:

FCN 0 ENT

2nd

Press CHN key

until tr is shown

dd

display default

selected

3rd

Press PULSE key to select

Auto, Spd, or Pos

tr

toggle rPM

selected

3rd

Press number keys followed by

ENT to change toggle RPM

Present display

default (dd) shown

Present toggle RPM

value shown

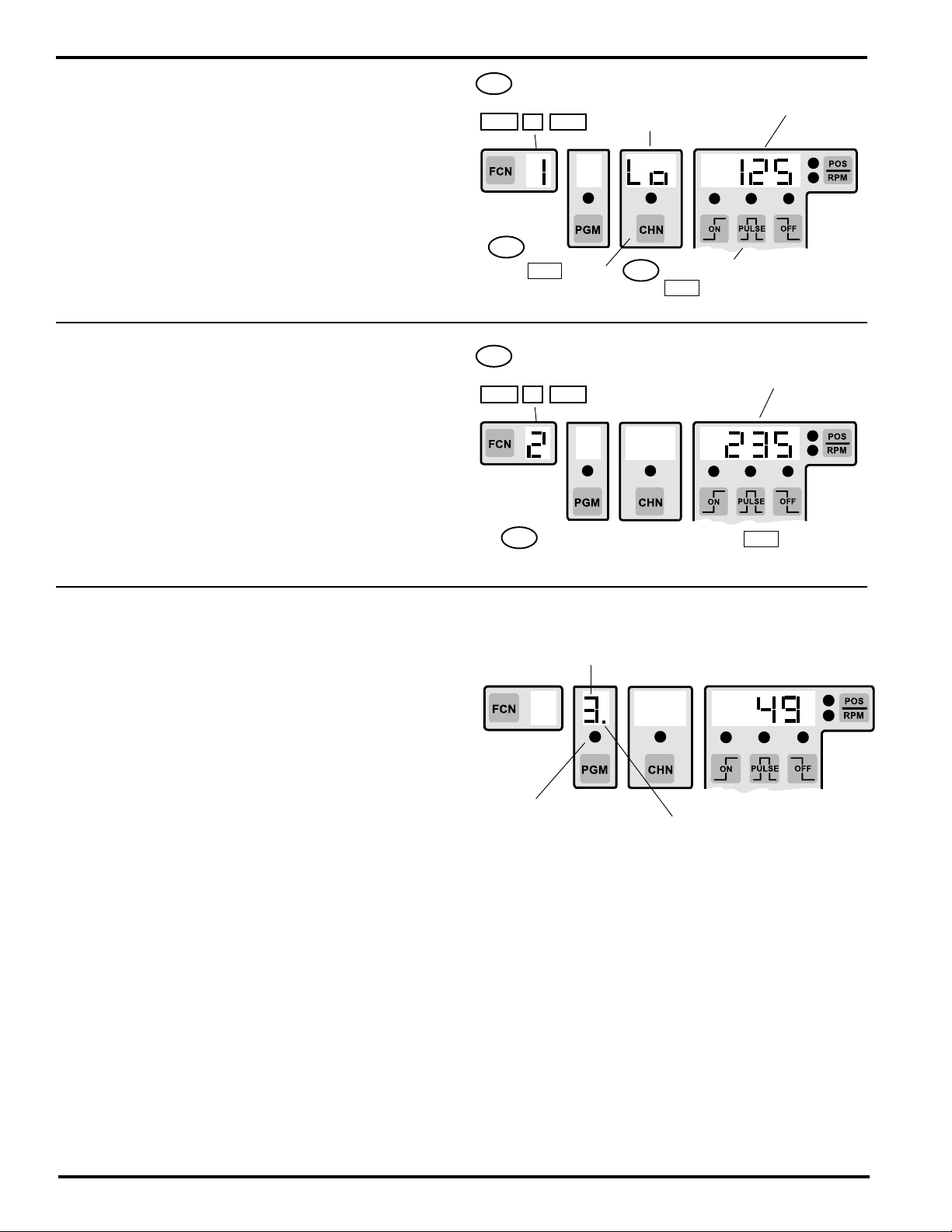

tb - Time Base Used for Output Timing

The timing resolution is selectable between 1 mSec and .5

mSec increments on 8, 9, and 16 output controls (24 and 48

output controls have a fixed 1 mSec tb and do not display

tb in FCN 0). All timed outputs use the same time base.

Timing accuracy of all timed outputs is -0, +1 tb increment.

The number of outputs that can be timed is affected by the

time base selected: (24 and 48 output systems can time up

to 4 outputs)

1mSec tb - Up to 8 outputs can be timed (.001 - 9.999 Sec)

.5 mSec tb - Up to 4 outputs can be timed (.0005 - .9995

Sec)

Note: Adding too many timed outputs will cause an E9

programming error. The “.5” tb value will flash and cannot

be selected if more than 4 timed outputs already exist in

FCN 5.

Consult factory if more timed outputs are required.

Enhanced Position/RPM Display Logic

All PS-51XX (Resolver) Series controls made after 5/12/92

include a feature that allows the user to program the display

default to RPM, position, or automatically switch between

RPM and position. Previous controls always defaulted to

displaying RPM with the POS/RPM key, allowing manual

selection of the item displayed. The POS/RPM key still

1st If FCN 0

not shown press:

FCN 0 ENT

2nd

Press CHN key

until tb is shown

tb

time base

3rd

Press PULSE key to select

1 or .5 mSec Time Base (.5 will

flash if more than 4 timed outputs

exist in FCN 5)

Present Time Base

value shown

allows manual selection of the item displayed on the PS5000 versions with the new display logic.

To control these display features, two items have been

added to FCN 0 programming : dd (display default) and tr

(toggle RPM).

4-5 Programming, Standard Features

Page 34

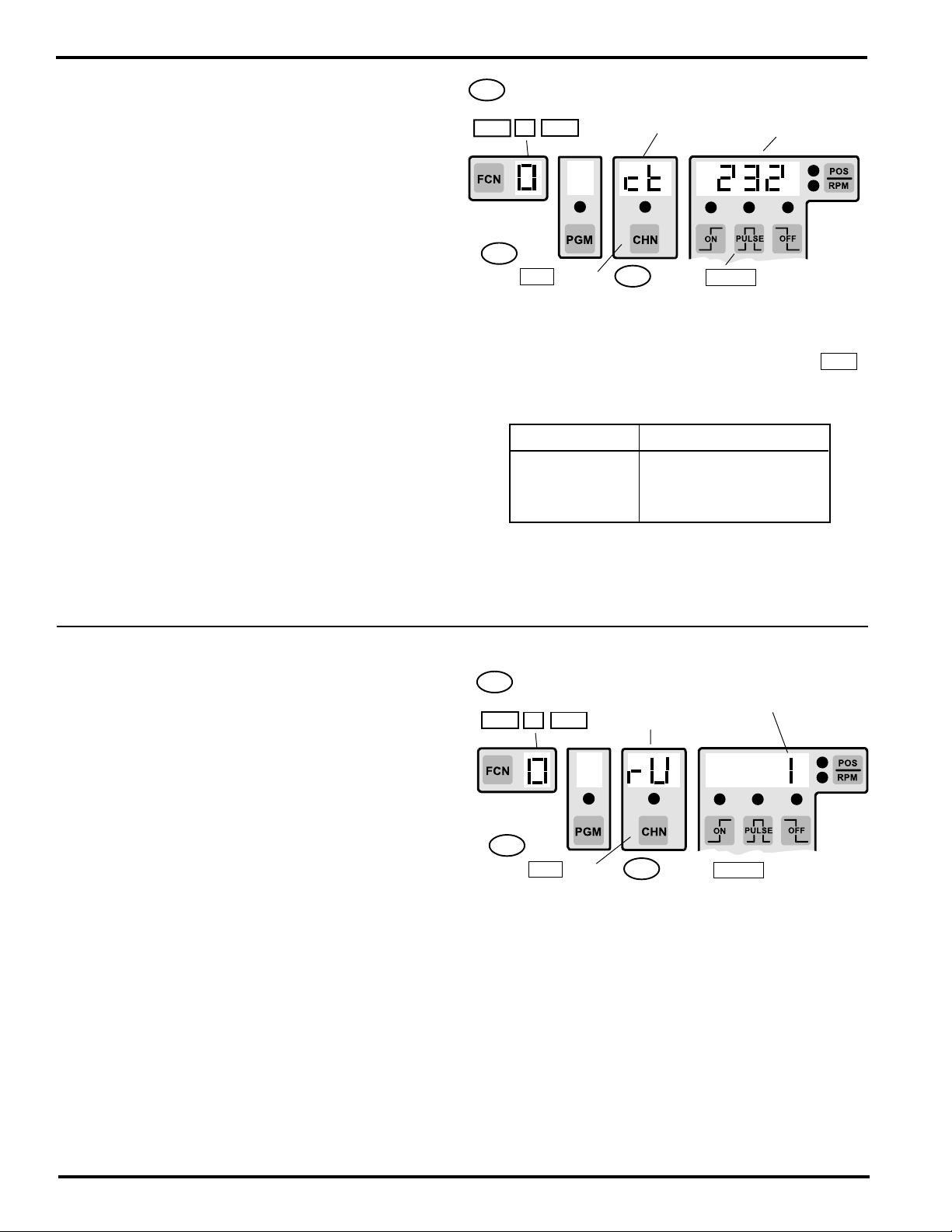

ct, cS, cA - Communication Parameters

ct - communication type: Specifies the type of

communication port being used by the PLµS control. It

contains both an RS-232 and an RS-485 port. RS-485 is

the default setting. Both of these ports share the DB-9

connector located at the top of the power supply section.

The type of port being used on the PLµS must match the

type of port being used by the device communicating with

the PLµS.

cS - communication Speed: Specifies the baud rate (bits

per second) that the PLµS communication port will operate

at. It must be set for the same baud rate as the device

communicating with the PLµS control. The choices are:

4800, 9600, 19200, and 38400 baud. 9600 is the default

setting.

cA - communication Address: Each control can have

a unique communication address (0-255) because multiple

controls can be wired to the same host device in a RS-485

network. This allows the host to send information to a

specific control while the other controls will ignore the

information. A PLµS control will ignore incoming information

if the address that information specifies does not match the

communication address of the control.

1st If FCN 0

not shown press:

FCN 0 ENT

2nd

Press CHN key

to choose ct, cS, or

cA

Comm Item Choices

ct (port type) RS-232, RS-485

cS (baud) 4800, 9600, 19200, 38400

cA (comm add) 0-255; 1 is default

Default settings are shown in bold face.

ct - comm type

cS - comm speed

cA - comm Address

3rd

Present value for

selected comm

item selected

Press PULSE key to select

desired option when ct or cS are

selected

When cA is selected press

number keys followed by ENT

to change comm address

NOTE: On units manufactured prior to date code 9740,

the Communications Parameters (-C) option was

required for communications features.

rU - rPM Display Update Frequency

This function determines the frequency with which the

display of RPM is updated.

1 Display updates RPM once per second

2 Display updates RPM twice per second

10 Display updates RPM ten times per second

NOTE: On units manufactured prior to date code 9740,

the Expanded Operator Access (-E) option was required

for rPM Display Update Frequency (rU).

Viewing / Changing Program Banks

1st If FCN 0

not shown press:

FCN 0 ENT

2nd

Press CHN key to

select rU

rU

rPM Update

selected

3rd

Present rPM Update

frequency shown

Press PULSE key to select

desired update frequency.

4-6 Programming, Standard Features

Page 35

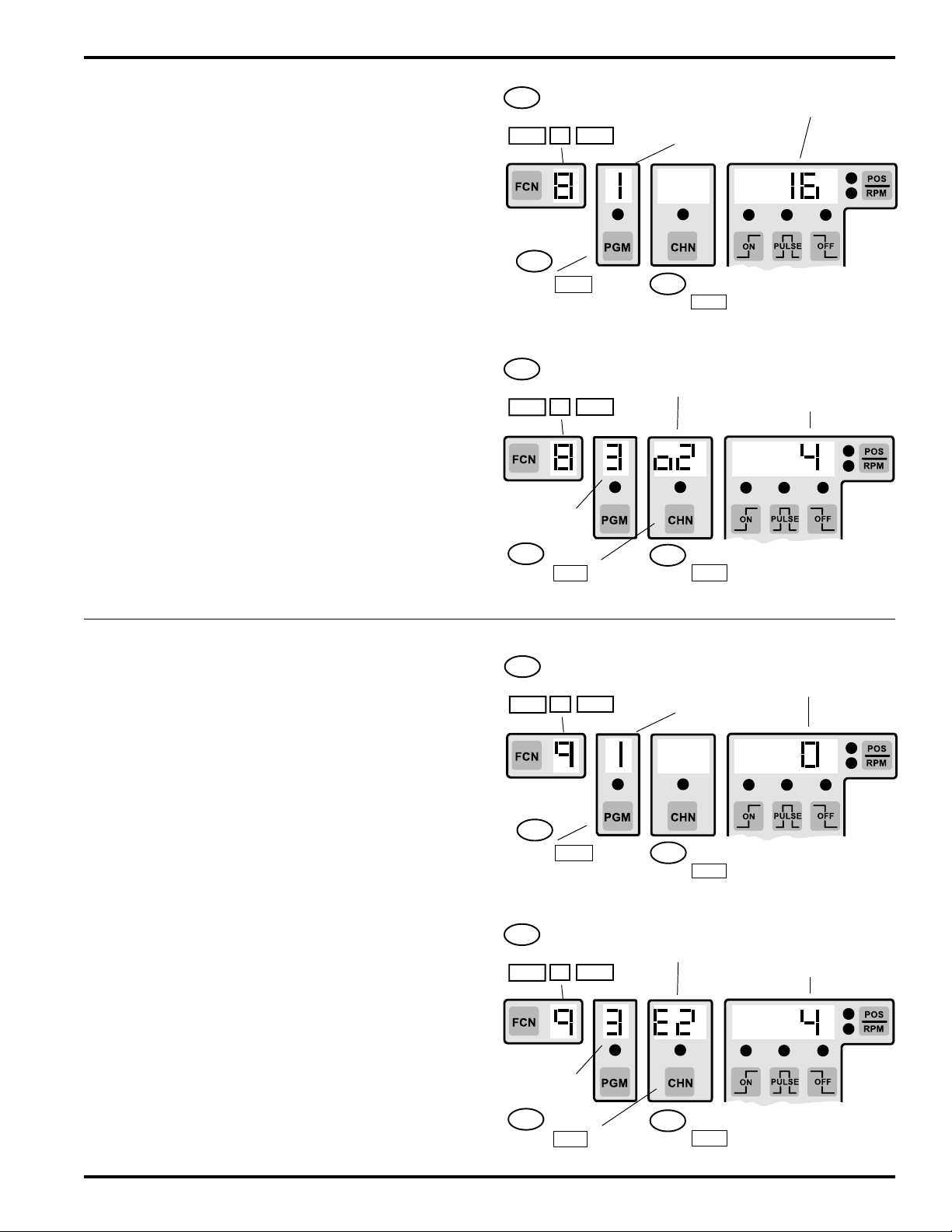

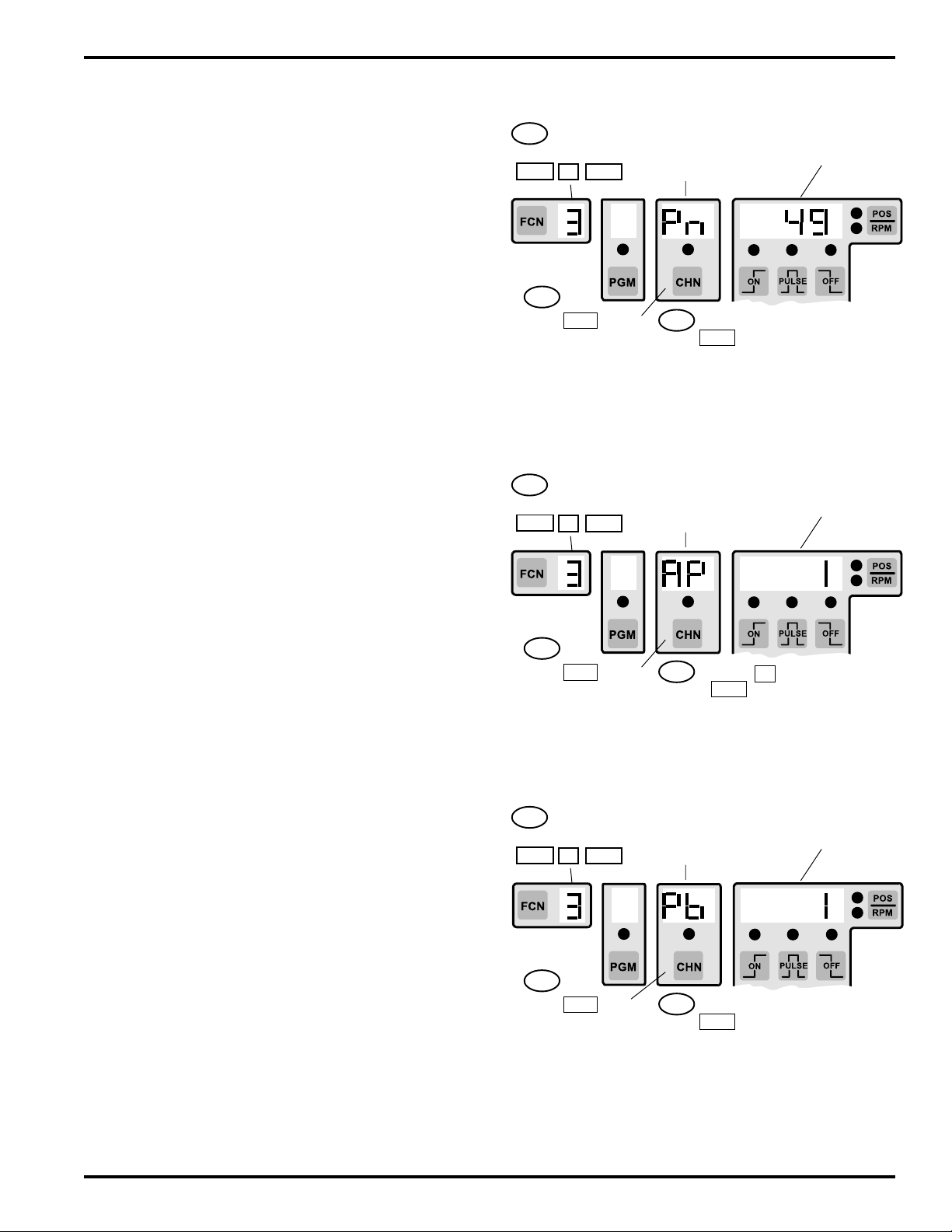

Master Level Programming, Standard Controls: FCN 6 & FCN 7

FCN 6 - Operator Access

(Master Program Enable Input MUST be energized)

This function selects which features can be adjusted at

the Operator access level. Step through them one at a

time, and select On or Off according to whether or not

the Operator should be able to adjust them.

Functions that are not Channel-Specific:

Sd—Speed Detection (FCN 1, Motion Setpoints and Analog

Parameters if control has the “-A” option)

on Operator can adjust FCN 1 values

oFF Operator cannot adjust FCN 1 values

oF—Offset (FCN 2)

on Operator can adjust offset values

oFF Operator cannot adjust offset values

AP—Active Program (FCN 3)

on Operator can change program number

oFF Operator cannot change program number