Page 1

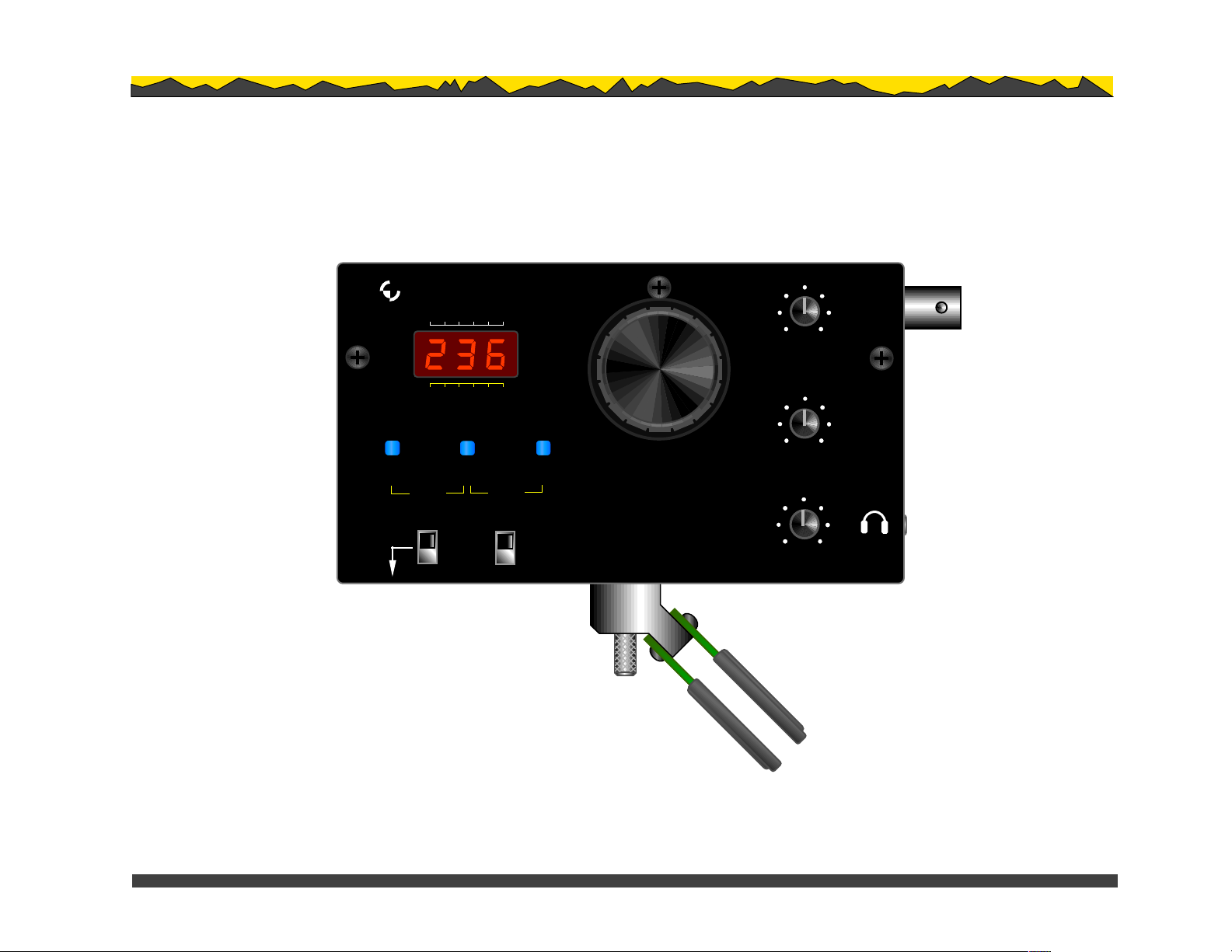

E L E C R A F T K X 1 T R A N S C E I V E R

12V

E L E C R A F T K X 1

37+S1 5 9

123RF

MENU

EDIT

BAND

SPEED

TUNE

LAMP

ON

OFF

1

DISP

POWER

RX

TX

RIT

CLR

2

TAP: 10 HZ / 100 HZ

\

KEY /

PADDLE

HOLD: 1 kHz

RF GAIN

0.5

FILTER

AF GAIN

ANT.

1.0

2.0

O W N E R’S M A N U A L

Page 2

E LECRAFT KX1

Ultra-Portable

CW Transceiver

Owner’s Manual

Revision E, May 21, 2010

Copyright

2010 Elecraft, Inc.

All Rights Reserved

Elecraft www.elecraft.com P.O. Box 69 Aptos, CA 95001-0069 (831) 662-8345 Fax: (831) 662-0830

Page 3

2 ELECRAFT

Table of Contents

INTRODUCTION .......................................................................................................................................................................................... 3

SPECIFICATIONS ........................................................................................................................................................................................ 5

PREPARATION FOR ASSEMBLY .............................................................................................................................................................. 6

ASSEMBLY - PART I ................................................................................................................................................................................. 14

ALIGNMENT AND TEST - PART I ............................................................................................................................................................ 27

ASSEMBLY – PART II ............................................................................................................................................................................... 30

ALIGNMENT AND TEST - PART II ........................................................................................................................................................... 43

ASSEMBLY - PART III ............................................................................................................................................................................... 48

ALIGNMENT AND TEST - PART III .......................................................................................................................................................... 58

FINAL ASSEMBLY .................................................................................................................................................................................... 60

OPERATION .............................................................................................................................................................................................. 62

KX1 OPTIONS ............................................................................................................................................................................................ 71

CIRCUIT DETAILS ..................................................................................................................................................................................... 72

PARTS LIST ............................................................................................................................................................................. APPENDIX A

SCHEMATIC ............................................................................................................................................................................ APPENDIX B

BLOCK DIAGRAM ................................................................................................................................................................... APPENDIX C

PHOTOGRAPHS ...................................................................................................................................................................... APPENDIX D

TROUBLESHOOTING ............................................................................................................................................................. APPENDIX E

PARTS PLACEMENT DRAWINGS ......................................................................................................................................... APPENDIX F

QUICK REFERENCE ............................................................................................................................................................... APPENDIX G

Page 4

ELECRAFT 3

Introduction

The Elecraft KX1 is a compact, multi-band CW transceiver

optimized for backpacking and travel use. With internal battery,

internal automatic antenna tuner, log-book lamp, and plug-in keyer

paddle, it offers a high level of integration.

Unlike most transceivers, the KX1’s controls are located on the top

of the cabinet, and the keyer paddle attaches at the front. This “trailfriendly” format is ideal for hand-held or lap-top operation, e.g.

when sitting on the ground, using a camp chair, reclining, or even

standing. The KX1 is also at home on a table or desk, providing an

optimal display viewing angle without the need for a tilt stand. The

unique plug-in keyer paddle is both physically reversible for right- or

left-handed use.

The transceiver covers the full 40 and 20 meter bands, and optionally

80 and 30 meters. The VFO is based on a DDS (direct digital

synthesis) IC, so it can also tune well outside each band, covering

many popular SWL band segments. A variable bandwidth crystal

filter permits reception of SSB and AM as well as CW, facilitating

cross-mode contacts and broadcast reception.

The KX1’s internal six-cell battery pack can be changed in seconds

with the removal of two thumb screws. The battery provides 1 to 2

watts power output, which represents a good tradeoff between

battery life and communications efficiency. An external 12 V supply

increases output to about 4 watts. Low receive-mode current drain

(35 mA typ.) results in battery life of 20 hours or more. The lowbattery warning threshold can be adjusted to match the battery type

used.

The KX1 uses a 3-digit LED display that is physically rugged and

extremely efficient. It requires just 1 to 2 milliamps total current in

moderate lighting conditions, and about 10 mA at its brightest setting.

The operator can optionally configure the display to turn off 5 to 60

seconds after any front-panel control has been used. Operation without

the display is possible if the CW feedback feature is turned on (audio

Morse code). This provides audible announcement for the VFO dial,

menu text, and all controls.

Additional operating features include instant band selection, nine

frequency memories, three VFO tuning rates, receive incremental tuning

(RIT), USB/LSB receive on all bands, and an S-meter display mode.

The built-in keyer offers Iambic modes A and B and two message

buffers. In an emergency, two of the front panel switches can be

configured for use as a manual key or keyer paddle.

Despite its compact size and many built-in accessories, the KX1 is easy

to build. The basic unit consists of a single printed circuit board, with no

surface mount components to install (the three surface mount parts used

are pre-installed). Assembly and test are completed in phases to simplify

any needed troubleshooting, and only a few alignment steps are

required.

We’d like to thank you for choosing the KX1 transceiver, and hope it

meets your expectations for ultra-lightweight portable operation.

Wayne Burdick, N6KR

Eric Swartz, WA6HHQ

Page 5

4 ELECRAFT

Customer Service Information

Elecraft's 1-Year Limited Warranty

Technical Assistance

If you have difficulty with kit construction, operation, or

troubleshooting, we’re here to help. You may be able to save time by

first consulting our web site, www.elecraft.com

question on the Elecraft e-mail forum, elecraft@mailman.qth.net

, or by posting your

.

Telephone assistance is available from 9 A.M. to 5 P.M. Pacific time

(weekdays only) at 831-662-8345. You can also send e-mail to

support@elecraft.com

. Please use e-mail, rather than call, when

possible since this gives us a written record of the details of your

problem.

Repair Service

If necessary, you may return your completed kit to us for repair.

Contact Elecraft before mailing your kit to obtain the repair

shipping address, as well as information on repair fees. (Kits that

have been soldered using acid core solder, water-soluble flux solder,

or other corrosive or conductive fluxes or solvents cannot be

accepted for repair–see Warranty.)

The following information should be provided to expedite repair:

your name, address, and phone number; your e-mail address (if

applicable); and a complete description of the problem.

Shipping: First, seal the unit in a plastic bag to protect the finish

from dust and abrasion. Use a sturdy packing carton with 3" or more

of foam or shredded paper on all sides. Seal the package with

reinforced tape. (Neither Elecraft nor the carrier will accept liability

for damage due to improper packaging.) Cover the "to" address label

with clear tape.

This warranty is effective as of the date of first consumer purchase (or if shipped from

factory, date product is shipped to customer). It covers both our kits and fully

assembled products. For kits, before requesting warranty service, you should fully

complete the assembly, carefully following all instructions in the manual.

Who is covered: This warranty covers the original owner of the Elecraft product as

disclosed to Elecraft at the time of order. Elecraft products transferred by the

purchaser to a third party, either by sale, gift or other method, who is not disclosed to

Elecraft at the time of original order, are not covered by this warranty. If the Elecraft

product is being bought indirectly for a third party, the third party's name and address

must be provided to Elecraft at time of order to insure warranty coverage

What is covered:

defective or missing parts free of charge (post-paid). We will also correct any

malfunction to kits or assembled units caused by defective parts and materials.

Purchaser pays inbound shipping to Elecraft for warranty repair, Elecraft will pay

shipping to return the repaired equipment to you by UPS ground service or equivalent

to the continental USA and Canada. Alaska, Hawaii and outside U.S. and Canada

actual return shipping cost paid by owner

What is not covered:

errors. It also does not cover misalignment; repair of damage caused by misuse,

negligence, or builder modifications; or any performance malfunctions involving nonElecraft accessory equipment. The use of acid-core solder, water-soluble flux solder,

or any corrosive or conductive flux or solvent will void this warranty in its entirety.

Also not covered is reimbursement for loss of use, inconvenience, customer assembly

or alignment time, or cost of unauthorized service

Limitation of incidental or consequential damages:

extend to non-Elecraft equipment or components used in conjunction with our

products. Any such repair or replacement is the responsibility of the customer.

Elecraft will not be liable for any special, indirect, incidental or consequential

damages, including but not limited to any loss of business or

During the first year after date of purchase, Elecraft will replace

.

This warranty does not cover correction of kit assembly

.

This warranty does not

profits.

.

Page 6

ELECRAFT 5

Specifications

General

Size (H x W x D)

Cabinet 1.2 x 5.3 x 3.0" (3 x 13.5 x 8 cm)

Overall 1.4 x 5.8 x 3.0" (3.5 x 15 x 8 cm)

Weight 9 oz. (0.25 kg), excluding options

Supply voltage 7-14 V (8 V min. recommended)

Current drain

Receive 35 mA typ., 40 mA max (headphones,

LED display timed out, 30-m or

30/80-m option installed)

Transmit 300-700 mA (varies with supply

voltage and power output setting)

1

Bands covered (MHz)

Receive 5.0-9.5 and 12.0-16.5 MHz

Transmit 7.000 to 7.300, and 14.000 to 4.350

Frequency control DDS with 50 MHz crystal reference

VFO drift < 50 Hz per hour after 5-minute

Display 3-digit LED w/bargraph mode;

MHz; spurious content at 3 to 4 w, 2

harmonic -40 dB typ. with LPF

adjustment (see page 59)

warm-up at 25° C

audio CW feedback on keypress

Transmitter

Max. power output (approx.)

9 V supply 1.5-2 W

12 V supply 3-4 W

Spurious content -40 dB @ 3 to 4 W

Load tolerance 2:1 or better SWR recommended

Sidetone pitch 500-650 Hz in 10 Hz steps

Keyer 8-50 WPM; Iambic modes A and B;

2 message buffers; auto-repeat

Receiver

Sensitivity Approx. 0.2 µV for 10 dB (S+N)/N

nd

I.F. 4.915 MHz, single conversion

Selectivity 3-pole variable-bandwidth crystal

filter, approx. 300-2000 Hz

Audio output 0.1 watt into 8-ohm load;

stereo plug required

1

KXB30 option adds 8.0-12.5 MHz receive and 10.1-10.15 MHz transmit.

The KXB3080 option covers the same range as the KXB30 and adds 1.5-5.5

MHz receive and 3.5-4.0 MHz transmit. Adding either module also greatly

improves sensitivity in the 49-meter band (5.9-6.4 MHz).

Page 7

6 ELECRAFT

Preparation for Assembly

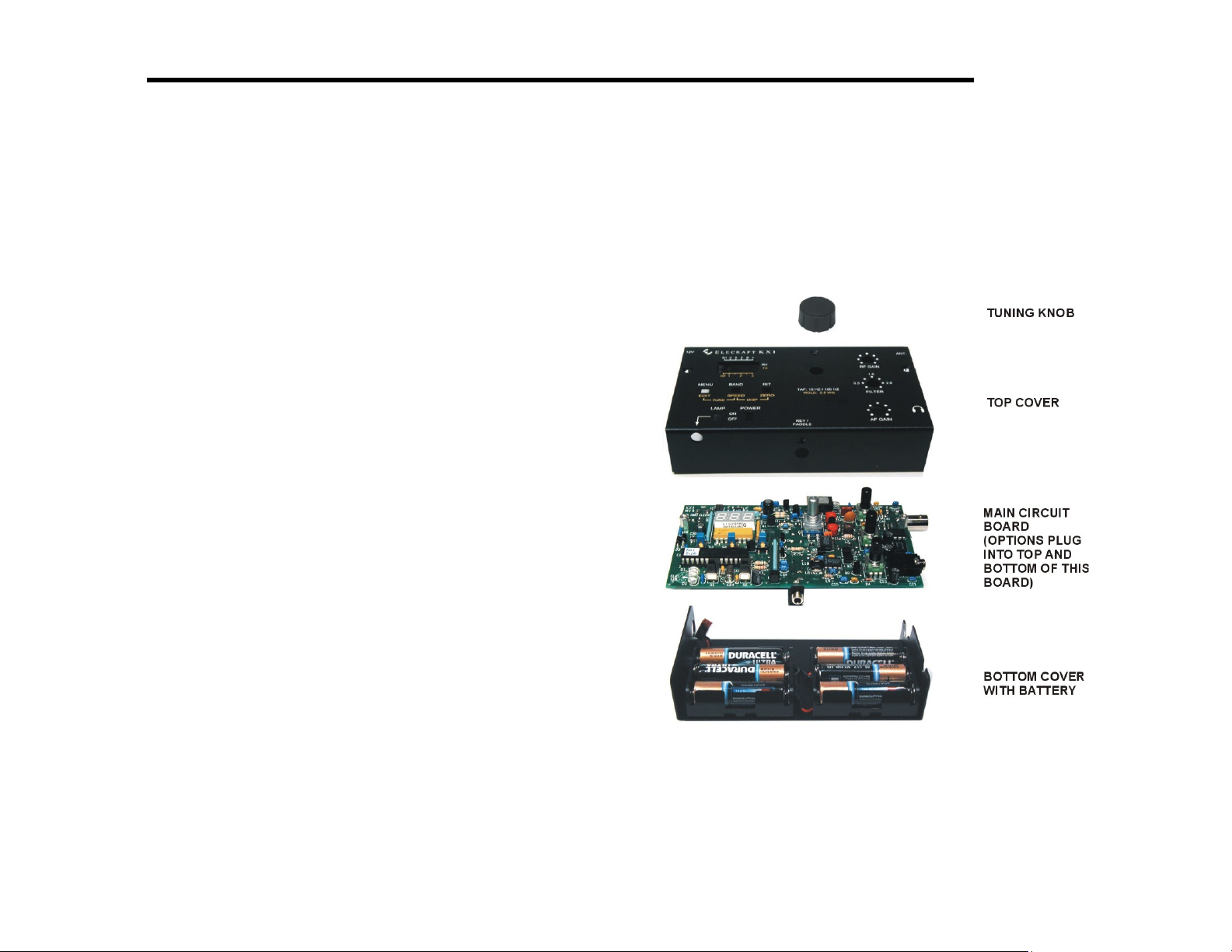

Overview of the KX1

The KX1 chassis consists of a top and bottom cover (Figure 1). All

components, including controls and connectors, are mounted on a

single printed circuit board (PCB). Only three surface-mount

components are required, and these are pre-mounted to the board.

The top cover is also the front panel. The controls face upward for

convenient operation. The printed circuit board mounts directly behind

the front panel.

The automatic antenna tuner option (KXAT1) plugs into the bottom of

the main PC board at J6, J7 and J8. The optional keyer paddle

(KXPD1) plugs into the Keyer/Paddle jack, J3, at the front edge of the

top cover.

The bottom cover is held in place by two thumbscrews. Two three-cell

AA battery sockets are attached to the bottom cover and are wired in

series to form a six-cell pack. The battery voltage is 7.2 or 9 V

depending on the battery type.

Appendix D provides close-up views of the top and bottom of the

assembled PC board.

Figure 1. KX1 Overview.

Page 8

ELECRAFT 7

Unpacking and Inventory

Preventing Electro-Static Discharge Damage

Problems caused by Electro-Static Discharge (ESD) may be very

difficult to troubleshoot because damaged components may still

operate somewhat rather than fail completely. We strongly recommend

you take the following anti-static precautions (listed in order of

importance) to avoid trouble:

Leave ESD-sensitive parts in their anti-static packaging until

you install them. The packaging may be a special plastic bag

or the component’s leads may be inserted in conductive foam.

Parts which are especially ESD-sensitive are identified in the

parts list and in the assembly procedures.

Wear a conductive wrist strap with a series 1 megohm

resistor. If you do not have a wrist strap, touch a ground

briefly before touching any sensitive parts to discharge your

body. Do this frequently while you are working. You can

collect a destructive static charge on your body just sitting at

the work bench. DO NOT attach a ground directly to

yourself as this poses a serious shock hazard.

Make sure your soldering iron is ESD-safe and has a

grounded tip

Use a grounded anti-static mat on your work bench.

Inventory

We recommend that you do a complete inventory, using the parts lists

in Appendix A.

i

DO NOT HANDLE PARTS OR CIRCUIT BOARDS

WITHOUT ANTI-STATIC PROTECTION (see Preventing

Electro-Static Discharge Damage above). Do not remove the black

foam from the leads of any parts. This foam is further protection

against static damage.

Many components are inside small envelopes and bags. Open them

one at a time, and return all of the parts to the envelope before opening

another. Be careful to avoid mixing parts and putting them in the

wrong bags or envelopes.

Page 9

8 ELECRAFT

Y

V

X

X

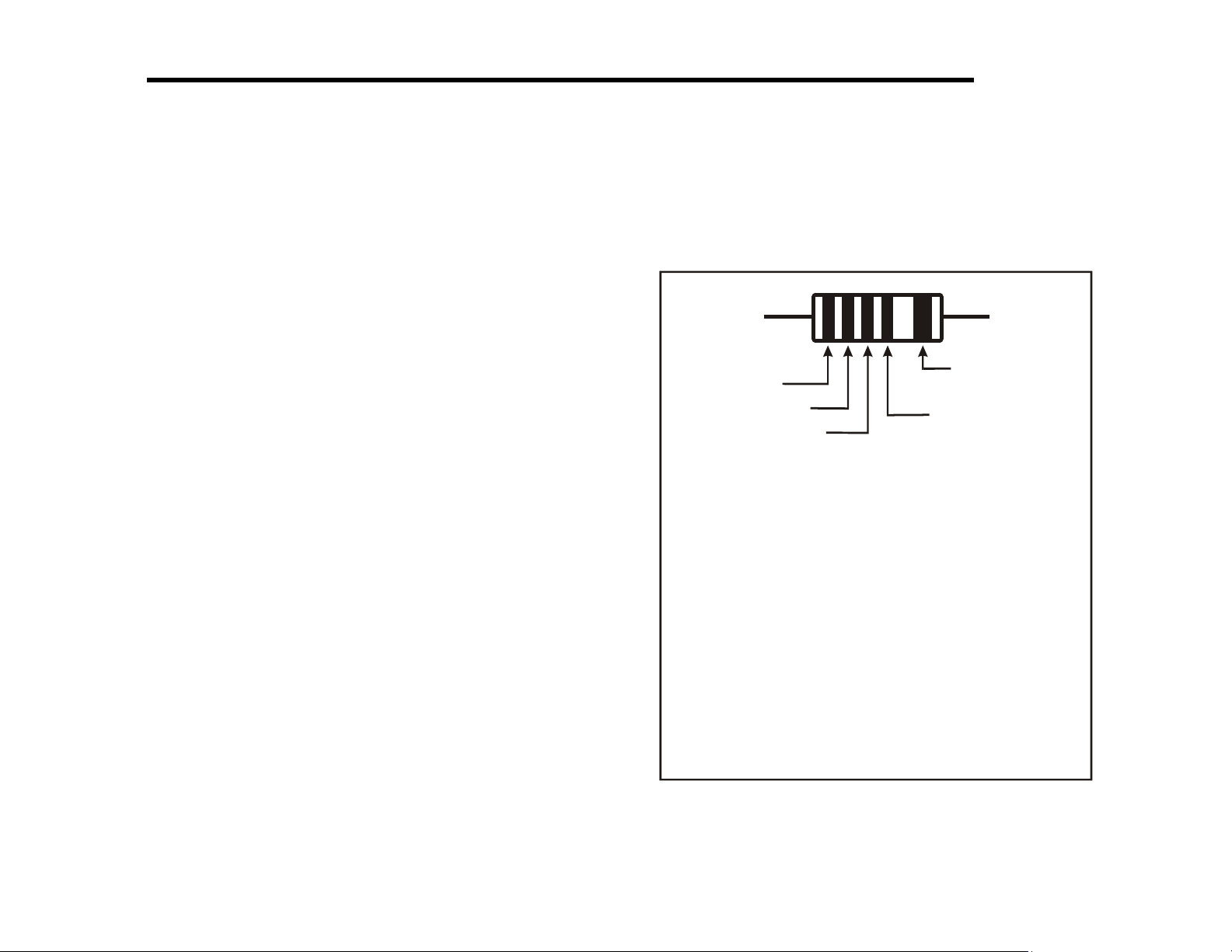

Identifying Common Resistors and RF Chokes

The color bands that indicate the value of each resistor are shown in

the text to help you identify each part. However, it's helpful to

familiarize yourself with the color code. The color-code chart (see

Figure 2) shows how to read the four color bands on 5% resistors. For

example, a 1,500 ohm (1.5 k) 5% resistor has color bands BROWN,

GREEN, RED and GOLD.

1% resistors are similar, but use five bands: three significant digits, a

multiplier instead of a gold or silver tolerance band, and a fifth and to

indicate the tolerance. Since the bands usually fill the length of the

resistor body, the fifth band is wider to indicate that the value should

be read starting at the other end.

For example, the first four bands on a 1.50 k, 1% resistor are

BROWN, GREEN, BLACK, BROWN. The multiplier value is 1

rather than 2 in this case because of the third significant digit.

If in doubt about a resistor’s value, use a DMM. It may be difficult to

see the colors on some resistors. Do not be concerned with minor

deviations of your DMM reading from the expected value. Typical

errors on most DMMs and the tolerances of the resistors normally

produce readings that are slightly different from the value indicated by

the color bands.

RF chokes and other small molded inductors look very much like short

resistors. They have color bands that represent the same numeric

values as resistors but because the inductors are short, it may not be

obvious how to read them. In general the multiplier or tolerance bands

are closer to the end than the first digit, just the opposite of the way a

resistor. On small inductors the color bands may be centered on the

body.

If you sort out the inductors before starting assembly, you will be able

to positively identify each inductor from the color bands listed in the

Parts List.

USED ON 1%

RESISTORS

FIRST DIGIT

SECOND DIGIT

MULTIPLIER

COLOR

Black

Brown

Red

Orange

ellow

Green

Blue

iolet

Gray

White

Silver

Gold

DIGIT

0

1

2

3

4

5

6

7

8

9

-

-

(SEE TEXT)

TOLERANCE:

GOLD = 5%

SILVER = 10%

MULTIPLIER

X 1

X 10

X 100

X 10K

X 10K

100K

X 1M

-

-

-

0.01

X 0.1

Figure 2. Resistor Color Codes.

Page 10

ELECRAFT 9

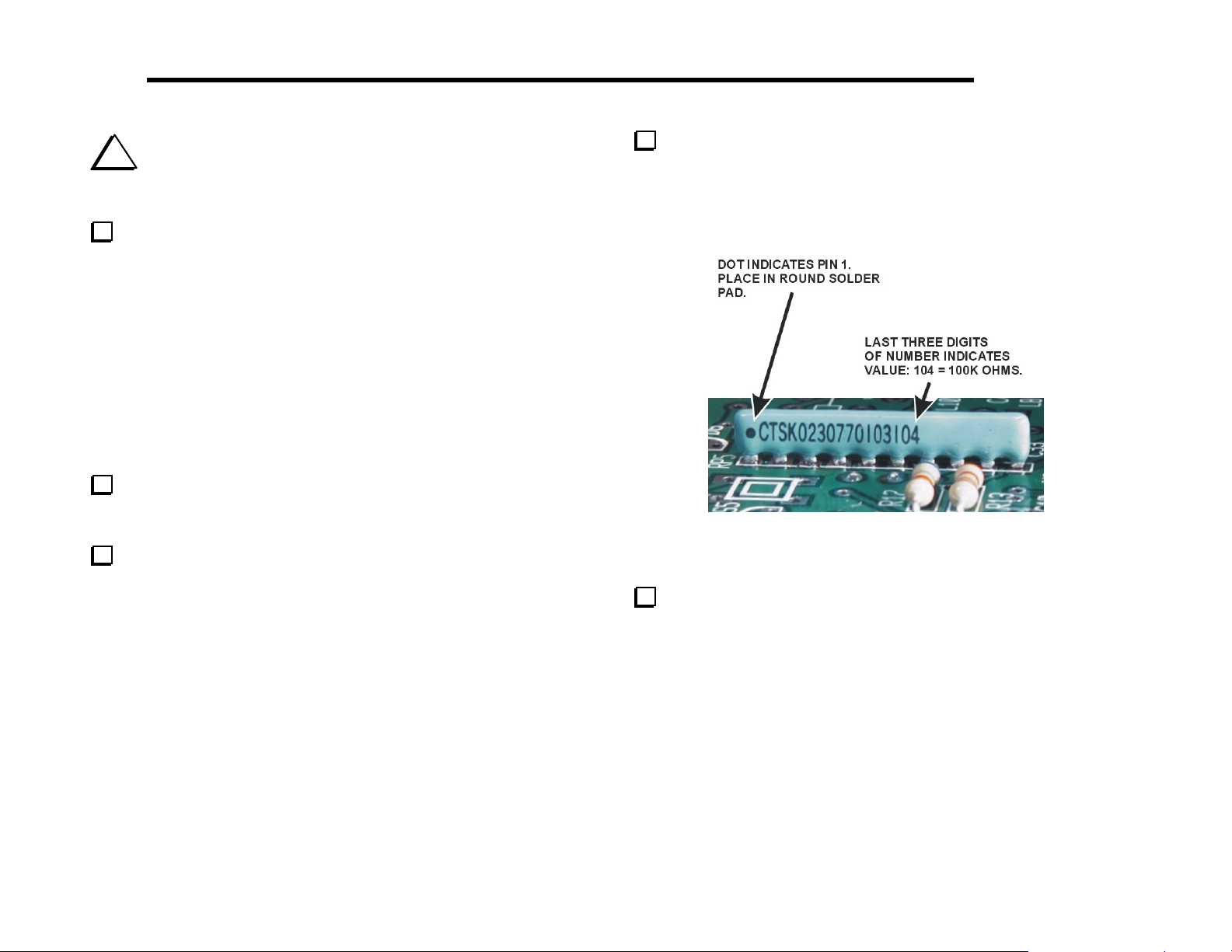

Identifying Resistor Packs

Resistor packs combine a number of resistors in one component with

multiple leads. They may be in-line packages with 6 or 10 leads in a

row or they may be in 16-pin dual in-line pin (DIP) packages similar

to many integrated circuits.

Like integrated circuits, pin 1 of each component is identified by a dot

near it. Some resistor packs are symmetrical. That is, they can be

installed either way. However, some are not. ALWAYS follow the

instructions and orient the resistor pack exactly described in the

procedure.

The value of the resistor pack is indicated in the last three digits shown

on the package. The numbering scheme is similar to capacitors. The

first two digits indicate the first and second most significant digits and

the third digit is a multiplier. For example, “...391” indicates 390 ohms

and “...104” indicates 100,000 ohms (100K).

Identifying Capacitors

Capacitors are identified by their value and the spacing of their leads.

Small-value fixed capacitors are usually marked with one, two, or

three digits and no decimal point. If one or two digits are used, that is

the value in picofarads (pF). If there are three digits, the third digit is a

multiplier. For example, a capacitor marked "151" would be 150 pF

(15 with a multiplier of 10

"102" would be 1000 pF (or .001 µF). Exceptions are described

specifically in the text and parts list.

1

). Similarly, "330" would be 33 pF, and

Fixed capacitors with values of 1000 pF or higher often use a decimal

point in the value, such as .001, .047, or 2.2. This is the value in

microfarads (µF). (1 µF is equal to 1,000,000 pF.)

The lead spacing is noted in the Parts Lists for most capacitors. If two

different types of capacitors have the same lead spacing will indicate

which one to use. When lead spacing is important, both the value and

the lead spacing is shown in the assembly procedure. For example,

“LS 0.1” means that the lead spacing is 0.1 inch (2.5 mm).

Identifying Toroid Cores

Several toroidal inductors are used in the KX1. It is important to use

the correct type of core. This can be determined from the color and

size. Two types of cores are used in the KX1: Iron powder cores and

ferrite cores. If you mix them up, your KX1 will not operate properly.

The iron powder cores used are type T37-6. The T identifies an iron-

powder core. The number following the T specifies the outside

diameter in hundredths of an inch, in this case 0.37 inches (9.4 mm).

The suffix (-6) refers to a specific mix of iron powder. You cannot tell

what mix of iron power is used by looking at the core, so they are

painted with specific colors. The -6 cores are painted yellow.

Ferrite cores are indicated in the parts list by the letters FT in the part

number. The KX1 uses FT37-6 cores. Like the iron powder cores, the

37 refers to the outside diameter. The -46 identifies the type of ferrite

used. These cores are not painted. They are dark grey.

Page 11

10 ELECRAFT

Tools

You will need the following tools to build this kit:

Fine-tip temperature-controlled ESD-safe soldering station

with 700 to 800F tip (370-430C). Recommend a spade tip

approx. 0.05” (1.3 mm) wide. Do not use a high-wattage iron

or soldering gun since this can damage pads, traces, or the

parts themselves.

IC-grade, small-diameter (.031”) solder (Kester #44 or

equivalent).

i

DO NOT use acid-core solder, water-soluble flux solder,

additional flux or solvents of any kind. Use of any of these will

void your warranty.

Desoldering tools and supplies are invaluable if you make any

modifications or need to do any repairs. Narrow solder wick or

a good vacuum desoldering tool such as the Soldapullt®

model DS017LS are recommended. See Soldering and

Desoldering, on page 11 for more information.

Screwdrivers: A small #2 Phillips, a small flat-blade for

slotted screws and a very small flat-blade (about 0.1 in or 2.5

mm wide) with an insulated handle to adjust the trimmer caps.

We strongly recommend that you use a conductive wrist strap and

anti-static mat during assembly. These items are available at very low

cost from Jameco, Mouser, and other electronics suppliers.

Refer to www.elecraft.com for tool sources and solder

recommendations.

Needle-nose pliers.

Small-point diagonal cutters. Flush-cutting type is required

(Xcelite MS54-5J or equivalent).

Digital Multimeter (DMM) for voltage checks and confirming

resistor values. A DMM with capacitance measurement

capability is desirable, but not required.

50-ohm dummy load capable of handling 5 watts, minimum.

Magnifying glass or visor.

Page 12

ELECRAFT 11

Soldering and Desoldering

Solder joints should be clean and shiny. If a joint appears dull or has

i

Use adequate ventilation when soldering; avoid

inhaling smoke or fumes. Always wash your hands after

handling solder, as lead residue is highly toxic.

Solder Recommendations

We recommend small-diameter (.02 to .03") rosin-core solder, similar

to Kester type 44. Solder with 2% silver is used by some builders and

will work equally well.

If you use a minimum of solder, there will be no need to clean PC

boards. The use of acid-core solder, water-soluble flux solder, or any

corrosive or conductive flux or solvent is likely to damage components

and/or PC boards.

fine cracks, it is probably cold. Cold solder joints should be cleaned

and re-soldered. First, use solder wick (desoldering braid) to remove

the old solder. Then apply fresh solder. If you have many cold solder

joints, it probably indicates that your soldering iron temperature is too

low, or that the tip or solder itself is defective.

New soldering iron tips must be tinned before they’re used. Allow the

iron to warm up completely, then apply solder and allow it to coat the

entire tip. After a few minutes, wipe off the excess solder. Use a

sponge for wiping the iron tip, and clean the sponge often.

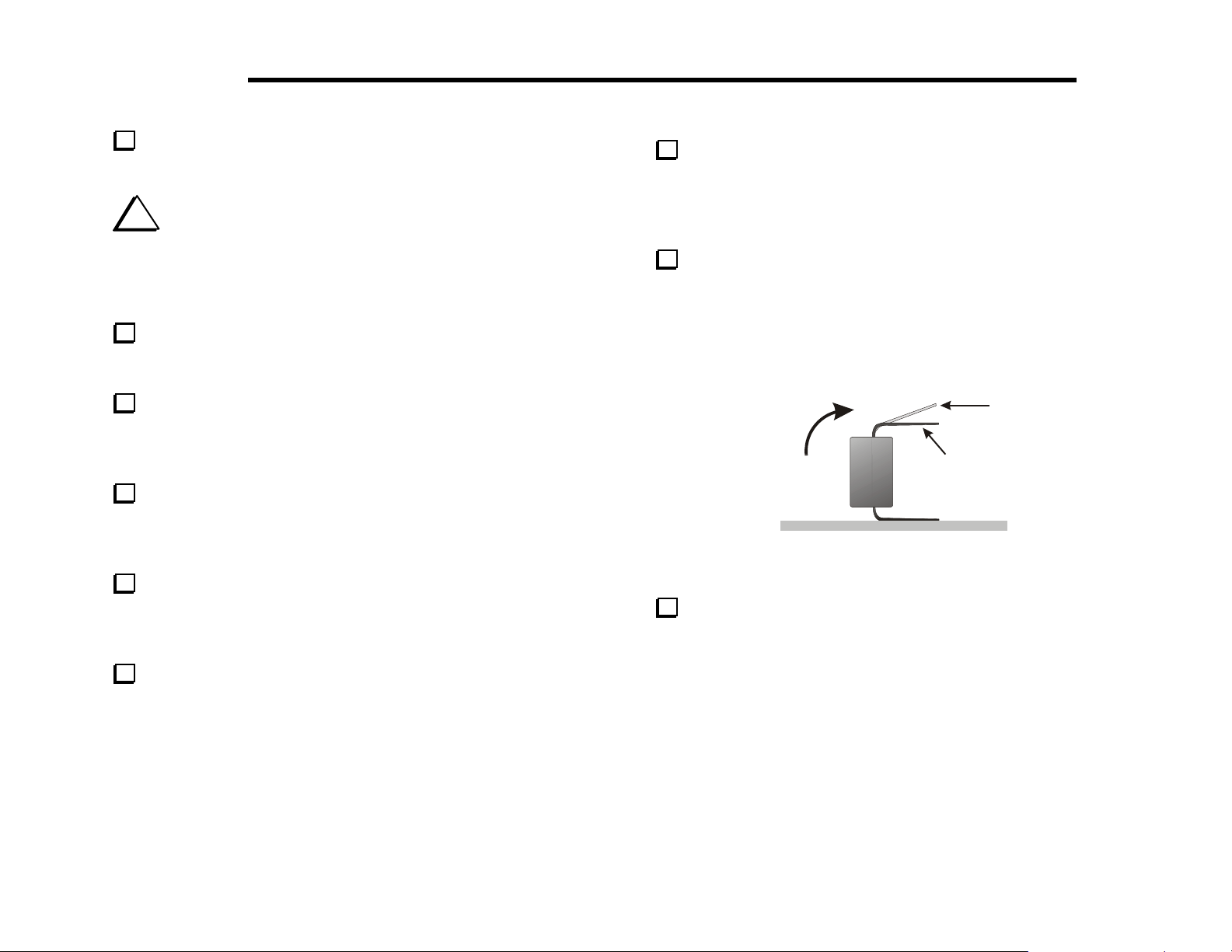

Soldering

When applying solder, use the minimum amount required to surround

the component lead and make good contact with its printed-circuit pad.

You don't need a "fillet" (build-up) of solder.

To provide a good connection, the solder must flow onto both the

component lead and its PC board pad. To ensure that both will be

heated at the same time, the tip of the iron should contact both the

component lead and the PC board pad before solder is applied.

Page 13

12 ELECRAFT

Desoldering

The printed circuit boards used in the kit are double-sided, meaning

that they have circuitry on both sides. The component mounting holes

are plated-through to complete electrical connections between the two

sides.

Removing components from double-sided boards can be difficult,

since you must get all of the solder back out of the hole before a lead

can be removed. To do this, you'll need solder wick (desoldering

braid) and/or a vacuum desoldering tool. It also takes some practice. A

number of suggestions are provided below.

The best strategy for avoiding de-soldering is to place all

components properly the first time. Double-check values and

orientations, and avoid damaging parts via ESD.

When removing components:

Don't pull a lead or pin out of a hole unless the solder has been

removed, or you are applying heat. Otherwise, you can literally

pull out the plating on the plated-through hole.

Limit soldering iron contact to a few seconds at a time.

Use small-size solder-wick, about 0.1" or 2.5 mm wide. Use the

wick on both the top and bottom pads when possible. This helps

get all of the solder out of the hole.

If you use a vacuum desoldering tool (solder sucker), use a large

unit. Small solder suckers are not very effective.

The safest way to remove ICs and other components with more

than 3 leads is to clip all of the pins at the body of the device first,

then remove all of the pins individually. You may damage pads

and traces by trying to remove such components intact.

Invest in a PC board vice with a heavy base if possible. This

makes parts removal easier because it frees up both hands.

If in doubt about a particular repair, ask for advice from Elecraft or

from someone else with PCB repair experience.

Page 14

ELECRAFT 13

Assembly Notes

Each step in the assembly process is accompanied by a check-box:

As you may have noticed already, the symbol below is used to alert

you to important information:

i

Do not skip any steps. You may adversely affect both the

performance and appearance of the kit by using the wrong

assembly order.

Installing Parts

Follow the instructions carefully about the position of parts. Many

parts must be positioned exactly as instructed or they may strike the

case or other components when the KX1 is assembled.

The value and corresponding color codes are shown for all resistors

and inductors that may have them. In some cases the value may be

stamped on the component instead of the color code.

IC Sockets

Only one integrated circuit is mounted in a socket. Do not use a

different type of socket. The one supplied is a low-profile socket that

provides just enough room for the case to fit together.

Do not use sockets on any ICs other than the one provided. Mount the

other ICs directly on the board as instructed. Sockets will not allow the

cover to close. Also sockets in RF may cause improper circuit

operation due to increased lead inductance and capacitance.

Before beginning assembly, you should review the photographs in

Appendix D to see what the completed PC boards look like. You'll

also find front and back views of each PC board in the Parts Placement

Drawings, Appendix F.

Page 15

14 ELECRAFT

Assembly - Part I

In Part I, the control, display, and audio stages will be assembled and

tested. Later sections cover receiver (Part II) and transmitter (Part III)

assembly and test.

i

BEFORE YOU START:

1. WEAR A GROUNDED WRIST STRAP or ground

yourself briefly before touching components. You can

discharge static by frequently touching an unpainted,

grounded metal surface.

2. WEAR EYE PROTECTION before trimming any leads.

3. WASH YOUR HANDS after handling solder. Solder is a

toxic substance.

4. PROVIDE VENTILATION and avoid inhaling the fumes

produced by soldering.

If you haven’t done so already, open the bag of components

labeled KX1 MAIN BAG and sort the parts into groups. Many of the

components will be in small paper envelopes. Do not mingle the

contents of one envelope with another. As you are instructed to locate

particular components, use the photographs in the KX1 PCB parts list

in Appendix A to help identify them.

i

The components pre-installed on the circuit board are

extremely static-sensitive. Wear a wrist strap or ground yourself

before handling the board.

Position the circuit board on your bench so that KX1 is visible in

the upper left corner. This is the side of the board that will be directly

under the front panel when the transceiver is completed. This side will

be referred to the as the top face of the board throughout the assembly

procedure. Components will be installed on both sides of the board.

Turn the circuit board over so the bottom is facing up and orient

it so the outline for J1 is in the upper right corner. Find the outline for

resistor R8 next to the outline for J1.

Page 16

ELECRAFT 15

A

Bend the leads of resistor R8, 6.8k (blu-gry-red), 1/4 watt, at

right angles close to the body. Insert the leads in the solder pad holes,

and bend them out on a 45-degree angle on the opposite side of the

board to hold the resistor in place.

i

Components MUST be tight against the board or the case

may not close properly during final assembly. This is especially

true of components on the bottom of the board where there is very

little clearance between the board and the battery packs.

Check the position of the resistor to ensure it is centered in the

printed outline and flush against the board as shown in Figure 3.

Solder and trim the leads.

ENSURE MARKINGS AGREE WITH

INSTRUCTIONS IN TEXT

BODY OF PART

GAINST THE BOARD

SOLDER & TRIM LEADS FLUSH

Figure 3. Installing Fixed Resistors.

Bend the leads of resistor R28, 1.8k (brn-gry-red), 1/4 watt, to fit

in the holes indicated on the board. Note that the leads should NOT be

bent close to the body of the resistor like you did for R8. Fit the leads

so the body of the resistor sits against the board within the outline,

then bend them outward at about a 45 degree angle to hold the resistor

in place.

Solder the leads to R28 and trim them flush with the board.

i

From this point forward, instructions to “install” a

component mean to position it within its outline against the board,

solder, and trim the leads flush on the opposite side.

Locate the two 200 ohm (red-blk-brn)1/8 watt fixed resistors, R6

and R7. They are about half the size of the 1/4 watt resistors you just

installed.

Install the 1/8 watt resistors in the spaces shown just to the left of

R8 near the top of the board:

_ R6, 200 ohms (red-blk-brn), 1/8 watt.

_ R7, 200 ohms (red-blk-brn), 1/8 watt.

Locate the printed outline for R28 on the back of the board. It is

about 3/4” (2 cm) down from the top edge near the center.

i

Components may be soldered one at a time or in groups.

Leads can be trimmed either before or after soldering.

Page 17

16 ELECRAFT

i

Save the longer clipped component leads. Several of them

will be needed for grounding wires and a jumper.

Install the following 1/4 watt resistors on the bottom side of the

board. Their locations are in the lower right quadrant of the board

when it is oriented the so outline for J1 is in the upper right corner.

_ R16, 1k (brn-blk-red).

_ R17 ,1k (brn-blk-red).

_ R22, 300 ohms (org-blk-brn).

_ R23, 470 ohms (yel-vio-brn).

Turn the board over (top face up) and orient it so that the KX1

lettering is in the upper left corner and the notch is on the lower edge.

Install the following 1/4 watt resistors about 3/4” (2 cm) to the left

of the notch and about 3/4” (2 cm) up from the lower edge of the

board:

_ R12, 6.8k (blu-gry-red).

_ R13, 22k (red-red-org).

Locate resistor pack RP5, 100 k ohm (104). RP5 is a ten-pin inline package whose number on the side ends in “104” (see Figure 4).

If you are in doubt about the value, use your DMM to verify that the

resistance between adjacent pins is 100k ohms. Note the dot at one end

indicating pin 1.

Figure 4. Installing Resistor Packs.

Find the outline for RP5 on the top of the circuit board. With the

board face up so that KX1 is in the upper left corner, the outline for

RP5 is just to the left and above the notch at the center of the lower

edge of the board.

Page 18

ELECRAFT 17

FLARED

Insert RP5 with Pin 1 of the pack in the round solder pad. The

round pad is farthest from the edge of the board.

i

Be careful to orient the resistor packs so the dot next to

Pin 1 on the pack is at the round solder pad on the board. Once

soldered in place, it is almost impossible to remove the pack

without destroying it.

Wet your soldering iron with a small amount of solder, and touch

it to one of the pins to tack-solder it in place.

Check the position of RP5 to verify that the pins at both ends are

inserted as far as they will go into the board as shown in Figure 4, then

solder and trim all ten leads.

Follow the same procedure to install six-pin resistor pack RP2, 1K

(102) above and to the left of RP5. Pin 1 goes at the top pointing

toward the printed outline for C51.

Install ten-pin resistor pack RP4, 10k (103) below U2 in the top

left quadrant of the board. Pin 1 goes to the left, pointing toward the

outline for RP3.

Install ten-pin resistor pack RP3, 10k (103) to the left of RP4. Pin

1 of RP3 is at the top, nearest the end of RP4.

Locate resistor pack RP1, 390 ohms (391). RP1 is in a 16-pin DIP

package that looks much like an integrated circuit. The resistance

elements run across the package (e.g. pin 1 connects to 9 through 390

ohms).

Test fit RP1 between RP2 and RP3 and just below the outline for

DS1 on the circuit board. It is normal for the pins of a DIP package to

be slightly flared so they do not easily fit into the solder pad holes. If

necessary, place RP1 so that an entire row of pins is against a smooth

surface and straighten the pins as shown in

Figure 5.

PRESS AND

ROCK TO

STRAIGHTEN

Figure 5. Straightening IC Pins.

Place RP1 on the circuit board with pin 1, indicated by a dot on

top of RP1, in the round solder pad. Be sure it is seated all the way so

the shoulders on the pins are against the board. Solder and trim all 16

pins.

STRAIGHT

Page 19

18 ELECRAFT

Turn the board face up so KX1 is in the upper left corner. Locate

the printed outlines for diodes D2 and D3 near the center of the left

edge of the board.

Locate diodes D2 and D3 (1N5817). Note that there is a band on

one end of the diode body.

i

All diodes MUST be installed with the banded end of the

diode over the band on the circuit board.

Install the following diodes:

_ D2 (1N5817)

_ D3 (1N5817)

With the board face up (KX1 in the upper left corner) position the

28-pin socket in the space provided for U1 in the lower left quadrant

of the board. The outline has (SOCKET) inside of it.

i

DO NOT TRIM the 28-pin socket pins before or after

soldering. These pins are hollow and form the lower part of the

socket for the IC pins.

i

Do not substitute a different socket for the one provided.

The very low profile of the supplied socket is required for the case

to fit together during final assembly.

Orient the socket so the notch at one end is toward the left edge of

the board, aligned with the notch in the printed outline.

Hold the socket against the circuit board and tack-solder pins at

opposite corners of the socket.

i

Do not overheat the socket pins. Too much heat will melt

the plastic socket. Use only enough solder to make a good joint.

Check to ensure that the socket is pressed against the circuit board

at both ends. If necessary, reheat the pins at each end and press down

on the socket so it rests directly against the board.

Solder all 28 pins. Double-check your work and inspect each pin.

Use a magnifier if necessary. If a pin is missed or poorly soldered, it

may make contact during initial testing, but become intermittent later.

Such intermittents can be very difficult to troubleshoot. Remember;

do not trim the socket pins!

Page 20

ELECRAFT 19

Turn the board face down so the printed outline for power

connector jack J1 is in the upper right corner.

Locate the printed outline for C39 to the left of the outline for J1

on the board.

Test fit a .1 µF (104) capacitor in the solder pad holes for C39.

Position the capacitor so that about 1/16” (1 mm) of lead shows above

the surface of the board. If necessary, gently straighten the leads using

long nosed pliers. Do not tug on the leads. Squeeze and bend them

with your pliers as needed.

Solder and trim the C39’s leads.

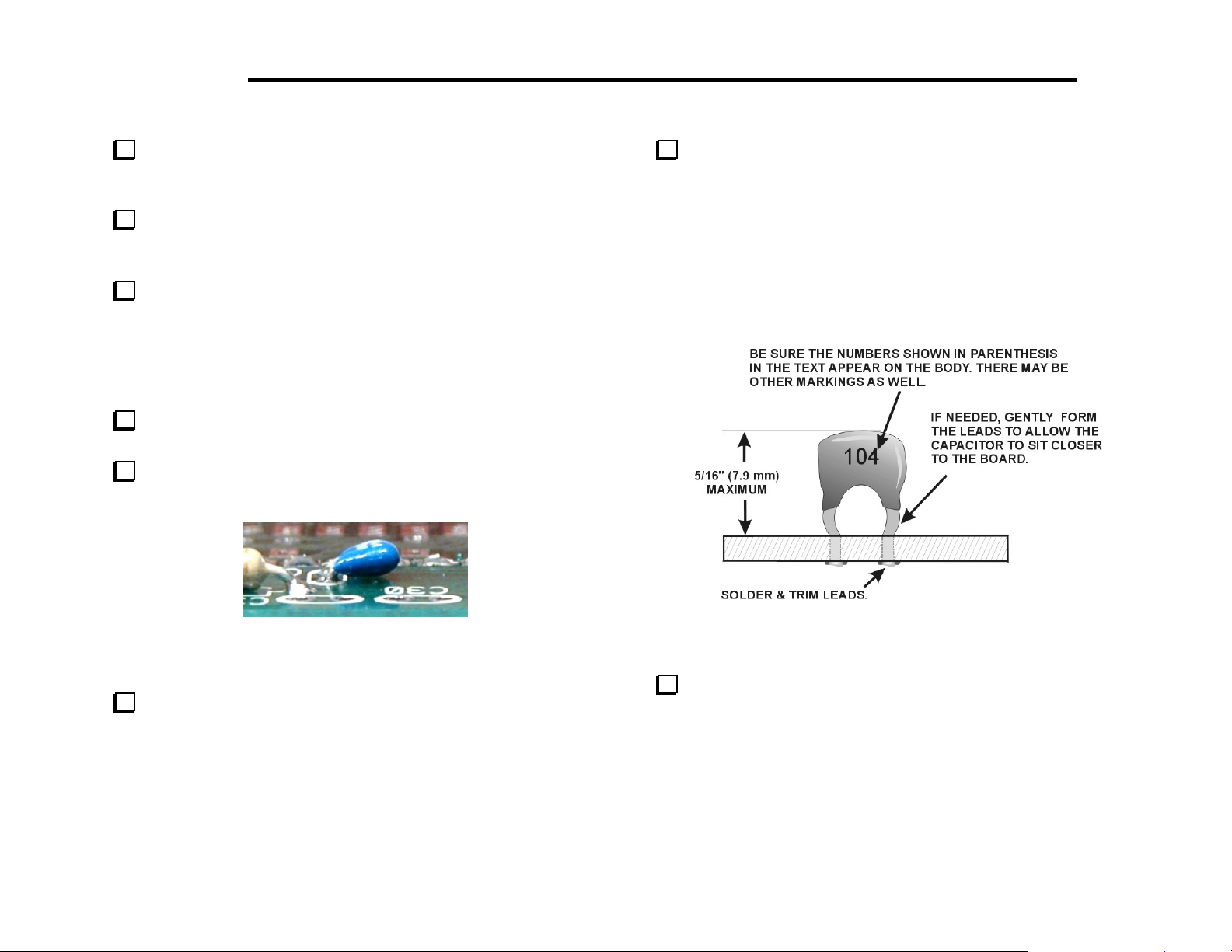

Bend C39 down against the board as shown in Figure 6.

Figure 6. Positioning C39 Against the PCB.

Test fit a .1 µF (104) capacitor in the solder pad holes for C31.

Use a ruler to verify that the top of the capacitor is no more than 5/16”

(7.9 mm) above the board. Normally these capacitors will be well

below that height limit but, if necessary, gently straighten the leads

using long nosed pliers so it will sit closer to the board and meet the

height requirement. While forming the leads, do not tug on them.

Squeeze and bend the leads with your pliers to straighten them.

Slight chipping of the epoxy around the leads will not harm the

capacitor.

Figure 7. Installing Fixed Capacitors.

Solder and trim the leads on capacitor C31.

Locate the outline for capacitor C31 along the top edge of the

board just to the left of the outline for J1.

Page 21

20 ELECRAFT

Following the same procedure, install capacitor C30, .01 µF (103)

next to C31.

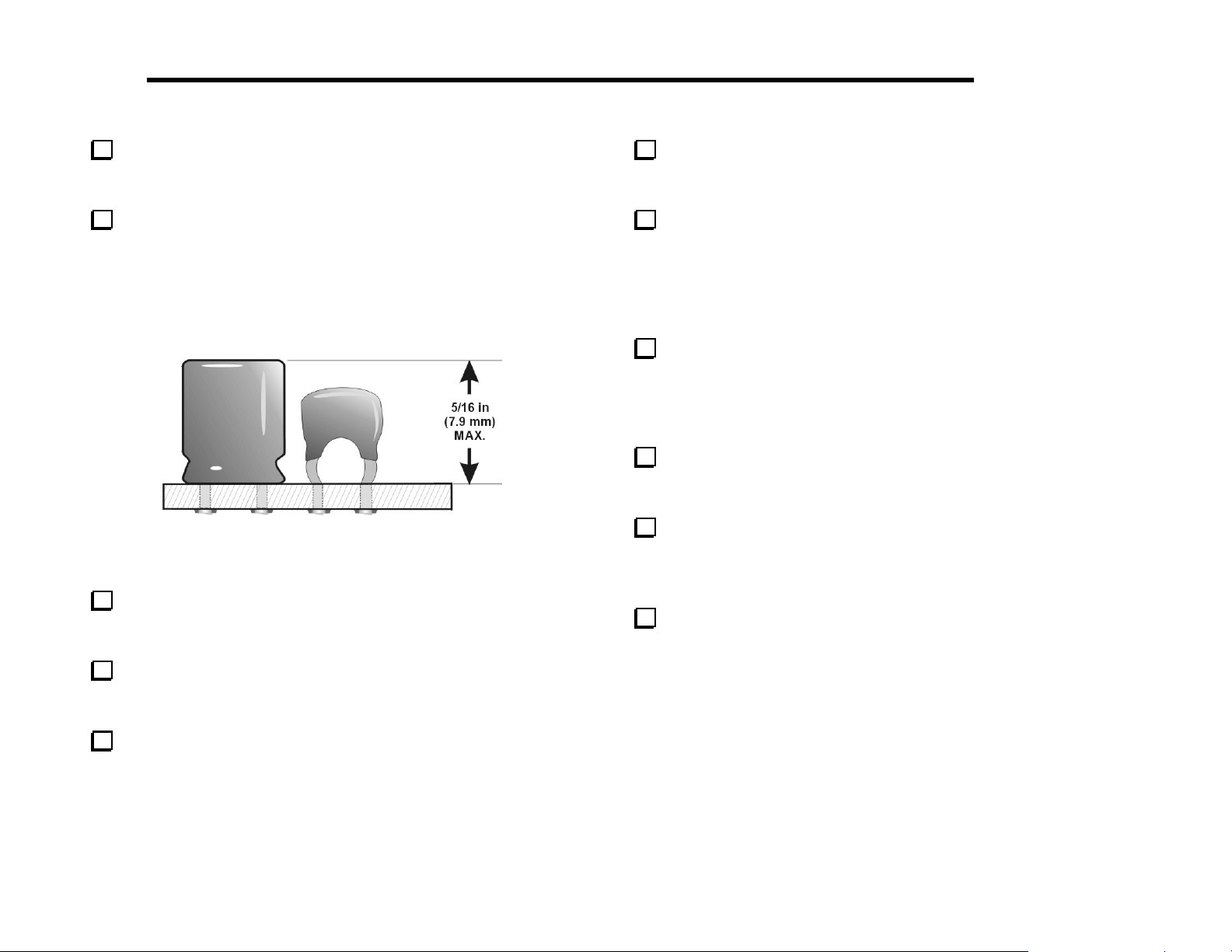

Turn the board top face up so that KX1 is in the upper left corner.

In the following steps you will install several capacitors on the top of

side of the board. Be sure that the top of no capacitor is more than

5/16” (7.9 mm) above the board. Be especially careful of the larger

electrolytic capacitors (see Figure 8). Use a ruler as needed to check

the height.

Figure 8. Maximum Height of Capacitors on Top of Board.

Install capacitor C6, .01 µF (103) directly above diode D3 on the

left edge of the board.

Install capacitor C37, .01 µF (103) between D2 and resistor pack

RP3.

Install capacitor C5, .1 µF (104) below the socket for U1 near the

bottom edge of the board.

Install the following capacitors between the socket for U1 and the

bottom edge of the board:

_ C25, 27 pF (270)

_ C24, 27 pF (270)

Install the following capacitors to the right of resistor pack RP5:

_ C32, .01 µF (103)

_ C33, .01 µF (103)

Install capacitor C55, .01 µF (103) on the bottom edge of the

board about 1-1/4” (2 cm) to the right of resistor pack RP5.

Locate electrolytic capacitor C38 (10 µF, 35 v) and inspect the

leads. One lead should be shorter than the other. The capacitor body

will have a stripe and a minus sign (—) above the shorter lead.

Locate the printed outline for C38 to the left of RP3 on the top

face of the circuit board. Note that there are two solder pads for the

capacitor leads: one is round and one is square. A plus (+) symbol is

printed next to the square pad.

Install capacitor C12, .1 µF (104) between D2 and the socket

for U1.

Page 22

ELECRAFT 21

Insert electrolytic capacitor C38 (10 µF, 35 v) with the longer lead

passing through the square solder pad with the (+) symbol next to it

and the shorter lead through the round pad. Bend the leads to hold the

capacitor in place against the board.

Be sure that the capacitor is tight against the board and solder the

leads. Use a ruler to verify that the top of the capacitor is no more than

5/16” (7.9 mm) above the board (see Figure 8). After soldering, trim

the leads flush with the bottom of the board.

i

All electrolytic capacitors MUST be installed with their

leads oriented to observe the polarity markings as described

above.

Install electrolytic capacitor C10 (10 µF, 35 v) below resistor R13

at the bottom edge of the board. Observe the proper polarity as you

did for C38 above, and be sure the capacitor is no higher than

5/16” (7.9 mm) above the board.

Turn the board over so the bottom face is up and the outline for J1

is in the upper right corner.

Turn the board over so the top face is up and test-fit the lowprofile crystal in the space provided for X1 near the bottom edge

below the socket for U1. The crystal may be installed either way.

Note: The holes in the solder pads for X1 may be larger than necessary

to fit the leads. This is normal. It is to accommodate different styles of

leads on the crystals supplied with some kits.

i

Do NOT use more solder than necessary on the leads for

X1. Too much solder will wick through the holes and may cause a

short to the case of X1 underneath the crystal. The short is

impossible to see or correct without removing the crystal.

Spread X1’s leads as necessary to hold the crystal against the

board and solder one lead. Do not hold your iron on the lead more

than 2 or 3 seconds, maximum. Too much heat will ruin the

crystal.

Check to ensure that X1 is sitting directly against the board. If

necessary, reheat the soldered lead while pressing down on the crystal.

Solder the second lead to X1 and trim the leads flush.

Install electrolytic capacitor C7 (220 µF, 25 v) at the center of the

board near resistor R28. Be sure to observe the proper polarity as

you did above. Save one of the clipped leads to use in the following

steps.

Page 23

22 ELECRAFT

Use a discarded component lead to ground the case of the crystal

as follows:

_ Solder one end of the lead in the ground hole near the edge of

the board to on the left side of the crystal.

_ Tin the top of the crystal nearest the lead with a small amount

of solder. Keep the soldering time to 3 seconds or less to

avoid overheating the crystal. Allow the crystal to cool if you

need to apply heat more than once. It often helps to tin the

case more quickly if you lightly scrape the metal with a knife

or a screwdriver blade first.

_ Bend the ground lead so it lies flat against the top of the

crystal where it is tinned and solder it to the top of the metal

case.

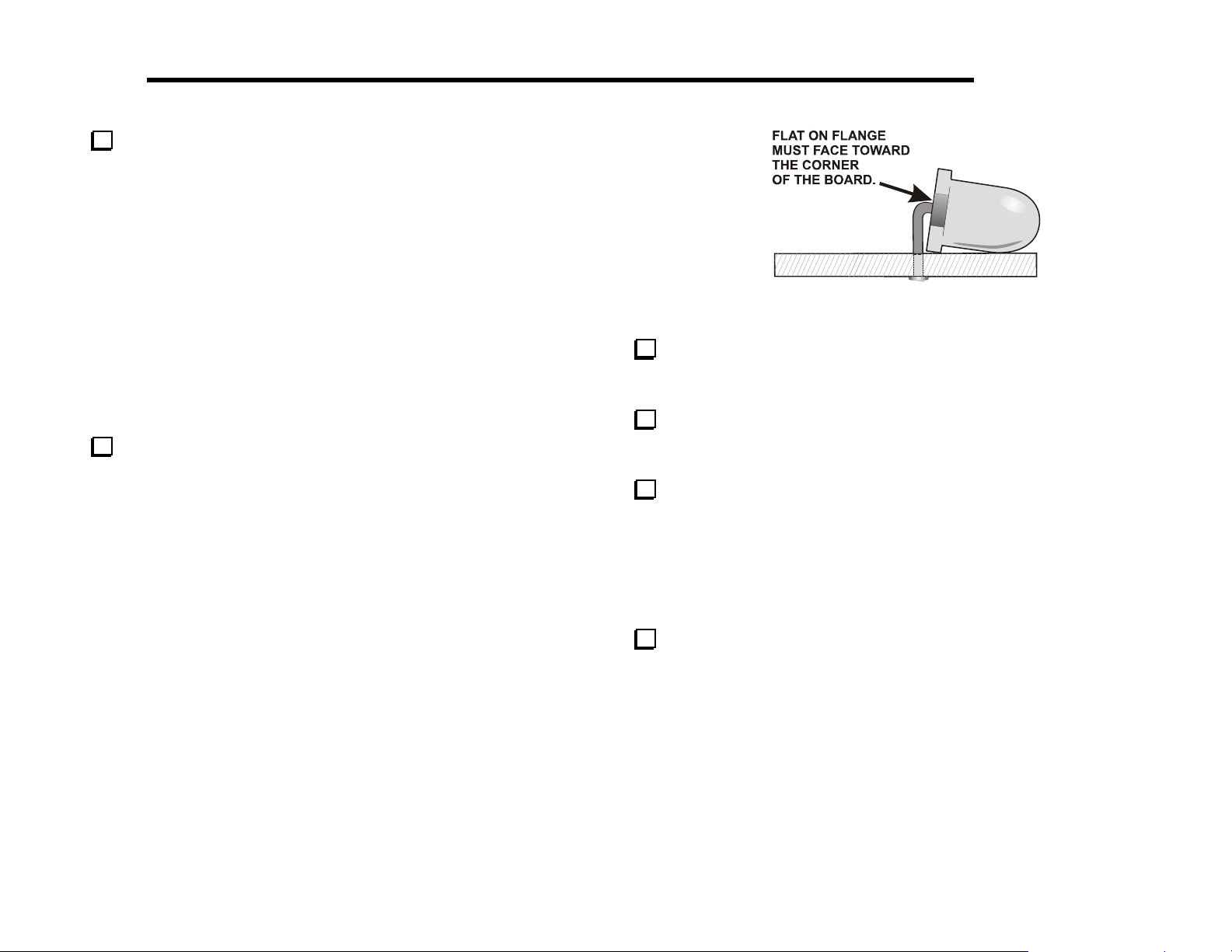

Install white LED D1 as follows:

_

Figure 9. Installing LED D1.

Turn the bottom face up with the outline for J1 in the upper right

corner.

Position J1 (DC power connector) on the board so the three tabs

on the bottom of the jack fit through the slotted solder pads.

_ Locate the flat side on D1’s flange.

_ Position D1 over the outline in the lower left corner of the

board with the flat side of the flange toward the corner of the

board.

_ Bend the leads so that when they are inserted through the

solder pads, D1 rests against the board as shown in Figure 9.

Note: This LED is provided to illuminate your note pad or log

while operating in the dark. The slight downward angle will

help direct the light down onto the table top.

_ Check to ensure that the flat side of the flange is toward the

corner of the board. D1 will not work if it is installed

backwards.

_ Solder and trim both leads.

Solder one of the tabs and then check the position of the jack. It

must be centered within the printed outline on the board with the

connector opening parallel with the edge of the board. Be sure the jack

is resting directly against the board. There must be no gap between

jack and the board. If necessary, reheat the soldered tab and adjust the

position of the jack.

When you are satisfied with the position of the jack, solder the

remaining two tabs, then recheck the first tab be sure it is properly

soldered.

Page 24

ELECRAFT 23

Test-fit two-pin plug P1 directly below J1. Orient P1 so the

locking ramp that sticks up alongside the pins is on the side farthest

from J1 as shown on the printed outline on the board.

Place the shell for the mating jack over the pins of P1 to protect

your fingers and, while holding P1 directly against the board, solder

one of P1’s pins. Check the following. If necessary, reheat the

soldered pin and adjust P1.

_ P1 is oriented so the locking ramp is on the side

farthest from J1.

_ P1 is sitting vertically and resting flat against the board.

Solder the second pin of P1 to the board, then touch up the tacksoldered connection as needed to form a good joint.

i

If J3 is not aligned correctly as described in the next step,

the front cover will not fit during final assembly.

Install J3 at the center of the bottom edge of the board using the

same procedure to ensure it is square, inside the silk-screened outline

and flat against the board. Be certain you mount the jack on the

BOTTOM face of the board within the printed outline.

Turn the board over so the top face is up with KX1 in the upper

left corner.

i

Do not install caps on pushbutton switches S3, S4, and S5

until instructed to do so later in the assembly process. It is very

easy to damage the caps while soldering adjacent parts.

Position switch S5 on the board between RP2 and RP5. it may be

oriented either way that places the four pins in the solder pad holes.

With all four pins in the solder pad holes, press down on S5 until the

plastic bumps on the bottom of the switch body are touching the

board. Use a magnifier if necessary to be certain that the bumps on the

bottom of the switch are against the board. Each of the four pins

should stick out through the solder pads on the bottom of the board

about 3/32” (2.4 mm).

When you are satisfied that the switch is firmly against the board,

solder and trim all four terminals.

Install pushbutton switches S4 and S3 next to S5 using the same

procedure.

Page 25

24 ELECRAFT

Test fit slide switch S2 along the edge of the board next to

electrolytic capacitor C10. The switch can be oriented either way

around. Note that it rests on shoulders on the three terminals that

determine its height above the board.

Hold S2 vertical and against the shoulders on the tabs with your

finger on the slide, and tack-solder the center pin to hold it in place.

Inspect the switch to be sure it is perfectly vertical and not tipped

to either side. If necessary, reheat the pin and adjust the switch’s

position.

When you are satisfied that the switch is perfectly straight, solder

the two end pins. Resolder the center pin last as needed to create a

good joint.

Use the same procedure to install slide switch S1 to the left of

crystal X1. S1 also may be mounted oriented either way.

i

Voltage regulators U8 and U9 are installed in the following

steps. These devices look very similar. Double check the markings

on each device to be sure you have the correct one before soldering

it in place.

Install U8 (78L05) next to pushbutton switch S5 as follows:

_ Align the flat side of the device as shown by the printed

outline (see Figure 10).

_ Insert the device into the solder pad holes until the top of the

device is less than 5/16” (7.9 mm) above the board. Use a

ruler to confirm the height. If necessary, remove the device

and form the center lead to allow it to sit close enough to the

board.

_ Solder and trim all three leads.

R

ROUNDED

BACK

FLATTENED

BACK

O

PCB OUTLINE

Figure 10. Transistor Orientation Guide.

Page 26

ELECRAFT 25

OTC

Install U9 (77L06) below RP5 on the lower edge of the board

using the same procedure that you used for U8 above. Be sure the top

of the device is no more than 5/16” (7.9 mm) above the board.

Install transistor Q7 (2N4124). The position for Q7 is in the upper

right quadrant of the board, about 1” (2.5 cm) down from the top edge

and 1-3/4” (4.4 cm) from the right hand edge. Be certain the top of the

transistor is no more than 5/16” (7.9 mm) above the board.

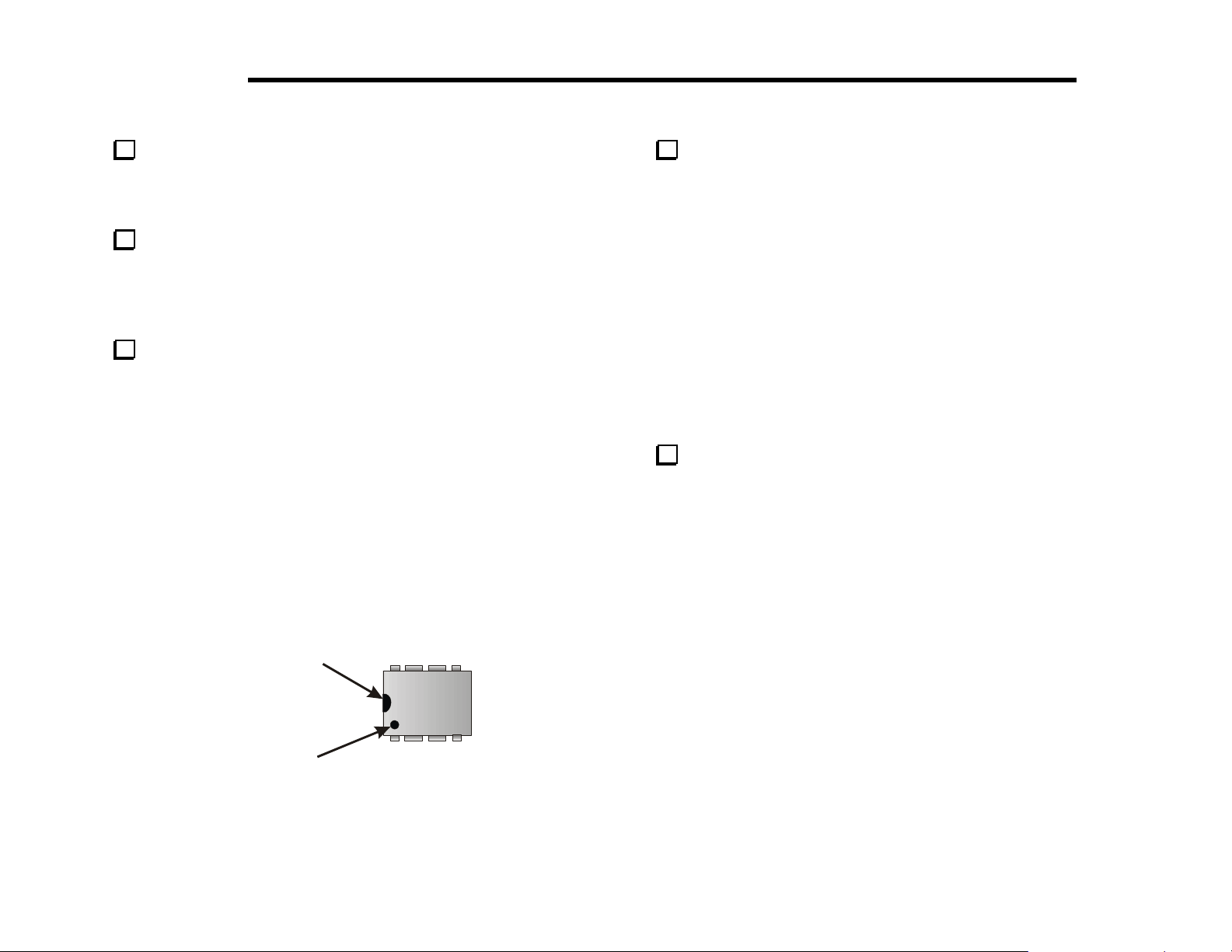

Install 8-pin integrated circuit U3 (4427) in the space provided

near the right hand edge of the board, about 1-1/4” (3.3 cm) down

from the top edge as follows:

_ Test-fit U3 to see if the pins line up with the holes in the

solder pads on the board. If needed, straighten the pins like

you did for resistor pack RP5 (see Figure 5).

_ Identify the end of U3 where pin 1 is located. It will have a

notch, a dimple, or both at this end (see Figure 11).

_ Insert U3 into the solder pad holes with the notched, pin 1

end lined up with the notch on the printed outline.

_ Spread out the pins on the opposite corners to hold U3 in

place, then solder and trim all 8 pins.

N

H

Install 3-digit LED display DS1 as follows:

_ Insert the 3-digit LED display in the space bounded by

resistor packs RP1, RP2, RP3 and RP4. The pins on DS1

allow it to be inserted only one way.

_ Hold the display against the board and tack-solder pins at the

opposite corners.

_ Inspect the display carefully to ensure that it is firmly against

the board at both ends. If necessary, reheat one of the pins

and adjust the display. It is very important that the display be

fully seated and resting directly against the board at both

ends.

_ Solder and trim all 13 pins on the display.

Install encoder Z1 as follows. Z1 mounts to the left of

transistor Q7.

_ Test fit Z1 on the board. It will only go one way. The side

with three terminals is nearest the top of the board.

_ Press down on Z1 until the small nubs at each corner rest

directly against the board. It is very important that Z1 be fully

seated against the board.

_ Solder two pins on opposite corners of the encoder, then

recheck to ensure it is sitting against the board. If necessary,

reheat the solder and press down on the encoder to position it.

_ Solder the two large tabs to the plated ring around the edge of

the mounting holes. Apply only enough solder to make a

DIMPLE A T

PIN 1

Figure 11. IC Alignment.

good mechanical and electrical connection between the tab

and circuit board. Do NOT try to fill the holes with solder.

_ Solder and trim all five pins.

Page 27

26 ELECRAFT

Visual Inspection

Verify correct orientation (banded end) of diodes D2 and D3,

using the parts placement drawing (Appendix F).

Verify the correct orientation of each electrolytic capacitor. The

side of the capacitor with the strip and minus ( - ) sign must face away

from the + sign printed on the board.

Examine both sides of the PC board closely for solder bridges,

cold solder joints, or unsoldered components.

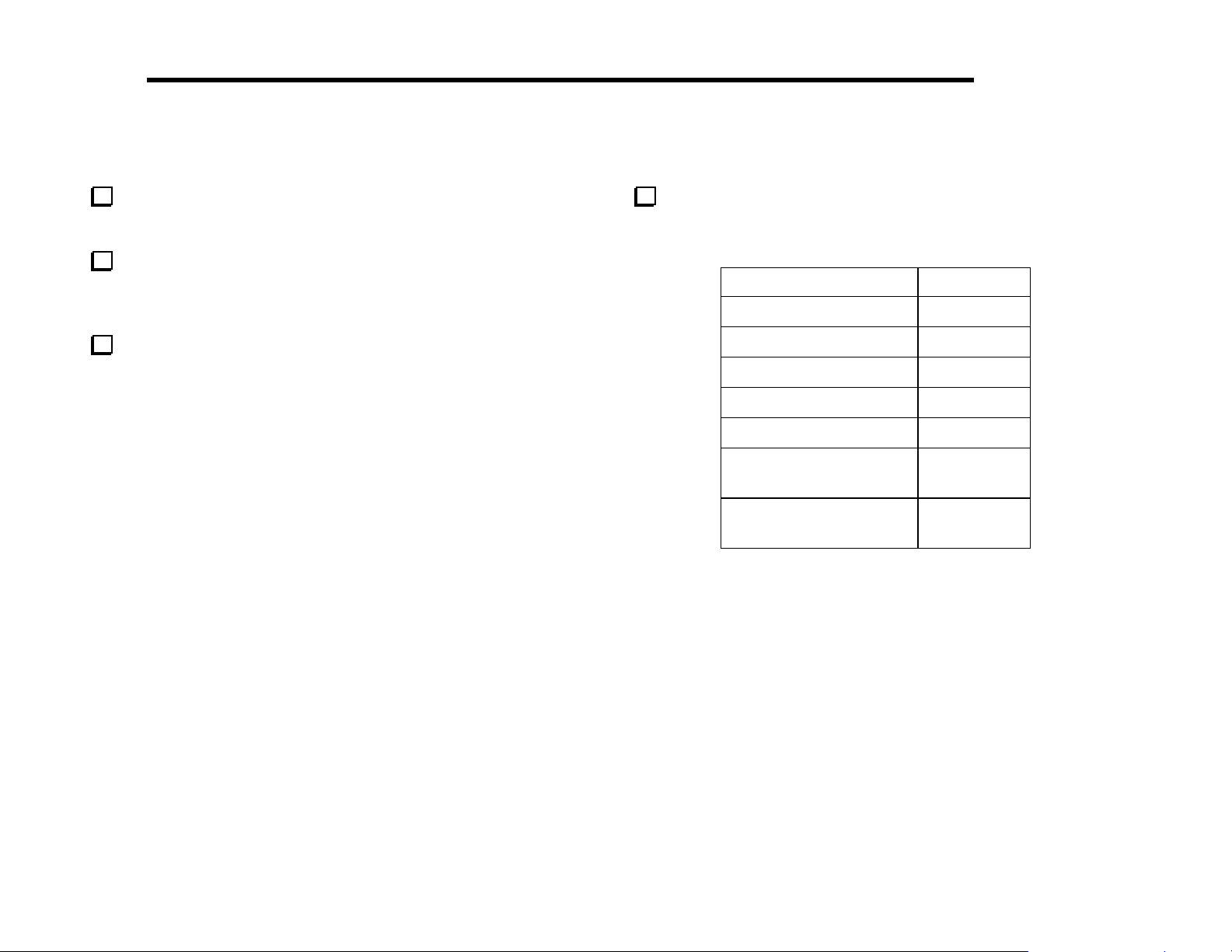

Resistance Checks

Make the resistance checks listed below with your DMM’s

negative (-) lead connected to the circuit board ground at the screw

hole just above capacitor C6.

Test Point (+) Resistance

U1 Pins 1, 3, 4, and 20 > 1 k

U1 pins 8 and 19 < 5 ohms

U1 all other pins > 10 k

U3 pin 3 < 5 ohms

U3 all other pins > 10 k

D2 or D3 cathode

(banded end), S1 On

D2 or D3 cathode,

S1 Off

> 1 k

> 10 k

Page 28

ELECRAFT 27

Alignment and Test - Part I

In this section you’ll become familiar with basic KX1 operation, while

testing the control and display functions.

i

Microcontroller U1 is extremely static-sensitive. Wear a

wrist strap or ground yourself before handling U1.

Remove microcontroller U1 from its conductive foam packing

and inspect the pins. The two rows of pins must be straight and

parallel to each other to establish the proper pin spacing for insertion

into the socket. If necessary, straighten the pins as shown in Figure 5.

Identify the end of the IC where Pin 1 is located. It will have a

notch, a dimple or both at this end (see Figure 11).

i

When U1 is pressed into its socket, you must be careful to

avoid jamming its pins. Make sure all the pins are lined up with

the associated holes before pressing down on the IC. Watch the

pins on both rows as you press down to be sure each pin goes

straight down into its socket hole and does not bend in under the

IC or outward alongside the socket. Realign each pin individually

with its socket hole, if necessary.

Press down very firmly on U1. If it is not seated as far as

possible into its socket, the pins may not make good contact.

Temporarily mount the VFO knob on the shaft of encoder Z1.

Align the set screw with the flat side of the encoder shaft and tighten it

using the Allen wrench supplied.

i

You may notice some side play in the encoder shaft. This is

normal in miniature shaft encoders with an integral pushbutton

switch.

Set slide switches S1 and S2 to the OFF position.

Connect an 8 to 14 VDC power supply to J1 with the positive (+)

lead to the center pin. A mating connector for J1 is supplied with the

kit. If you use a power supply voltage of less than about 10.5 volts,

you may see a BAT LO message flashed on the LED during initial

tests. This is because the BAT menu parameter is set to 10.0 volts by

default. You can set the BAT parameter to a lower value to eliminate

the warning message.

Unwrap the cover and set it near the circuit board so you can see

the legends identifying the switches and their functions.

Insert microcontroller U1 in its socket with pin 1 or the notched

end lined up with the notched end of the socket (the end closest to the

edge of the board).

i

If any test or alignment step fails, refer to the

Troubleshooting section (Appendix E).

Page 29

28 ELECRAFT

LED Tests

i

When testing the lamp in the following step, do NOT look

directly at the white LED. It is very bright.

Switch S1 (LAMP) On and verify that D1 lights, then turn it Off.

Switch S2 (POWER) On. If you see or smell smoke, or a

component feels hot to the touch, switch S2 Off and disconnect the

power source immediately. Locate the source of trouble before

proceeding.

You should now see either E10 or 00.0 on the 3-digit LED

display. E10 is an informational code that indicates that the EEPROM

(configuration memory) on the microcontroller has been initialized to

default values. This message will appear only once, and can be cleared

by tapping any of the three pushbutton switches. 00.0 is a portion of

the VFO frequency, which is set to 7100.00 kHz the first time you turn

power on. The display format will be described in a later step.

i

After a few seconds, the display turns off automatically if

you haven’t touched the VFO knob or pressed any switches. This

is intended to extend battery life. Moving the VFO knob or operating

one of the pushbutton switches will turn it on again. (The display time-

out is programmable. This will be discussed in the next section.)

Voltage Checks

Connect your DMM’s (-) probe to circuit board ground at the

screw hole next to capacitor C6. Use the (+) probe to check the

following DC voltages:

_ U1, pin 1: 5±0.25 Vdc

_ U3 pin 6: 6±0.25 Vdc

_ D2 anode: Supply voltage.

_ D2 cathode (banded end): supply voltage – 0.3 Vdc (approx).

Leave your DMM’s (-) probe connected to the circuit board

ground, and set your DMM for a 200 to 300 millivolt AC range.

Check the AC voltage at the following pins. A higher voltage than

shown may indicate a problem with one of the voltage regulators as

explained in the note below.

_ D2 anode: < 20 mV AC rms.

_ D2 cathode (banded end): <20 mV AC rms.

_ U1 pin 1: <20 mV AC rms.

_ U3 pin 6: <20 mV AC rms.

i

The 2.7 V and 6 V regulators used in the KX1 (U7 and U9,

respectively) are low-dropout types, which may oscillate if their

bypass capacitors are defective or are of the wrong value. If you

see high AC voltage at any of the points indicated above, verify

that electrolytic capacitors C7, C10, and C38 are installed in the

correct orientation and that their leads are properly soldered. If

they are, you may be seeing a false AC voltage indication due to

noise or probe leakage; re-test using a different DMM.

Page 30

ELECRAFT 29

The Tap/Hold Rule

Each of the push-button switches on the front panel has two functions,

one activated by a TAP (short press) and the other activated by a

HOLD (long press, about 1/2 second). The upper label on each switch

shows the TAP function (white lettering), and the lower label shows

the HOLD function (yellow lettering). To highlight this in the text, we

use two different typographical styles to identify switches:

HOLD.

Accessing the Configuration Menu

Tap MENU to enter the KX1’s configuration menu. You should

see LED on the display, which is the first menu entry (display

brightness setting and timeout period). Try rotating the VFO knob,

which scrolls through all 16 menu entries.

Use the knob to return to the LED menu entry. Then hold

EDIT to change the LED parameter. The display will change to L

followed by a number from 0 to 6.

Tap BAND and RIT to change the display brightness. Settings of

2 or 3 are about right for indoor daytime use, 0 and 1 are suitable in

low lighting, and 5 or 6 in bright lighting.

2

TAP and

Frequency Display and Band Change

The display shows three digits of the operating frequency. Which three

digits are shown depends on which tuning rate you’ve selected: 1 kHz,

100 Hz (default), or 10 Hz. At 7100.00 kHz, the three tuning rates

produce the following displays:

7100.00 7100.00 7100.00

To select 1 kHz steps, press and hold the VFO knob (from now

on, we’ll indicate this as: hold 1 kHz). Then try rotating the knob. No

decimal point is displayed at this step size.

To select 10 Hz or 100 Hz steps, tap the VFO knob (i.e., tap

10/100 Hz). The tuning rate alternates between 10 and 100 Hz steps

as you tap, and the decimal point moves accordingly.

You can check the MHz and kHz digits at any time by tapping

BAND . For example, if the VFO frequency is 7100.00 kHz, tapping

BAND will first show 7 , then 100, then return to the appropriate

display for your selected tuning rate.

To change bands, tap BAND twice, quickly. This will trigger the

MHz-kHz display, in this case showing 14 then 100 (14100.00 kHz).

(Tapping or double-tapping

for the next power-up or band change.)

BAND also stores the present frequency

Rotate the VFO knob to select the desired LED timeout (5 to 60

seconds or INF for infinite, i.e. never times out. As you rotate the

knob, the timeout period is flashed, e.g. t10 for 10 seconds. (Note:

When the LED times out, it will go blank. However, in very low

lighting or darkness, you may see a slight residual illumination.)

Tap MENU once to return to menu scroll mode, then tap it again

to return to the frequency display.

2

CW feedback on switch-press can be used in lieu of the display. This is

described in the Operation section.

Set the POWER switch to OFF.

Disconnect the power source from J1.

Remove the VFO knob and set it aside for reinstallation later.

Wrap the cover and put it in a safe place until it is needed.

i

Leave microcontroller U1 in its socket during the

remainder of the assembly process. Be sure to observe ESD

handling precautions at all times.

Page 31

30 ELECRAFT

Assembly – Part II

In this section you will assemble and test the receiver circuits. The

transmitter circuits will be assembled in Part III.

Position the board face up with KX1 in the upper left corner.

Install R19, 1.8k (brn-gry-red), 1/4 watt to the right of RP5 near

the center of the board.

Turn the board over so that J1 is in the upper right corner. Install

the following 1/4 watt resistors in the lower left quadrant of the board.

Form the leads as required so the resistors lie directly against the board

within the printed outlines.

_ R21, 2.7k (red-vio-red)

_ R14, 47 ohms (yel-vio-blk)

_ R18, 3.3 megohm (org-org-grn)

_ R29, 22k (red-red-org)

_ R5, 4.7k (yel-vio-red)

_ R20, 1k (brn-blk-red)

Open the envelope containing the seven molded inductors and

sort them to be certain you know which is which before you install the

first one. Compare the color codes you find on each inductor with the

list below. The color bands are very small. Use a magnifier as needed

to be sure of the colors.

L4: Micro (smaller) size, 2.2 µH (red-red-gold)

L5: Mini (larger) size, 5.6 µH (grn-blu-gold)

L6: Mini size, 6.8 µH (blu-gry-gold)

L7: Mini size, 4.7 µH (yel-vio-gold)

L10: Micro size, 33 µH (org-org-blk)

L8: Micro size, 18 µH (brn-gry-blk)

L9: Micro size, 100 µH (brn-blk-brn)

i

Do not pull on the inductor leads while handling them.

They are more easily damaged than the resistors or capacitors.

right corner.

Turn the board so the bottom face is up with jack J1 in the upper

_ R15, 1 megohm (brn-blk-grn)

_ R25, 10 ohm (brn-blk-blk)

Page 32

ELECRAFT 31

Install the following inductors below R6 and R7 in the upper right

quadrant.

the board.

board.

_ L4, micro (smaller) size, 2.2 µH (red-red-gold)

_ L5, mini size, 5.6 µH (grn-blu-gold). L5 may be larger than

the outline. Bend the leads to fit into the pads with the body

of L5 pressed to one side against the board. Do not space L5

above the board or it may strike other components when the

K3 is assembled.

Turn the board face up with KX1 in the upper left corner.

Install the following inductors to the left of U3 on the right side of

_ L7, mini (larger) size, 4.7 µH (yel-vio-gold)

_ L6, mini (larger) size, 6.8 µH (blu-gry-gold). If you have the

KXB3080 module to install, mount L6 on the bottom of the

PC board as shown in the KXB3080 module instructions. If

the lead spacing on L6 is larger than the hole spacing in the

board, bend the leads back under L6 to fit in the holes.

Install the following inductors below R19 near the center of the

_ L10, micro size, 33 µH (org-org-blk). L10 may be larger than

the outline. Bend the leads to fit into the pads with the body

of L10 pressed to one side against the board. Do not space

L10 above the board or it may strike other components when

the KX1 is assembled.

i

In the next step you will install a diode which must be

oriented in the proper direction. Be certain to align the banded

end of the diode over the band on the circuit board.

Install diode D4 (1N4148) on the lower edge of the board to the

right of L9.

Install varactor D5 (1SV149) as follows. When you are finished

the top of the varactor must no be more than 5/16” (7.9 mm) above the

board.

Follow the same procedure to install varactor D6 (1SV149). D6

is located above D5.

_ Locate the outline for D5 on the board. It is near the center of

the board immediately to the right of resistor pack RP5.

_ Orient the varactor according to the printed outline on the

board. The varactor may have a beveled back instead of a

rounded back as shown on the board (See Figure 10).

_ Insert the varactor leads in the solder pad holes. The varactor

has a third lead that has been clipped close to the body. Space

the varactor up off of the board slightly to ensure this lead

does not short to the board.

_ Solder one lead, then check to ensure that the top of the

varactor is no more than 5/16” (7.9 mm) above the board. If

necessary, reheat the joint while adjusting the height of the

varactor.

_ Solder the second lead and trim both leads.

_ L8, micro size, 18 µH (brn-gry-blk)

_ L9, micro size, 100 µH (brn-blk-brn)

Page 33

32 ELECRAFT

i

In the following steps you may be installing some

capacitors with leads closer together than the hole spacing in the

circuit board. Form the leads of these capacitors as shown in

Figure 12. Be sure the top of the capacitor is no higher than 5/16”

(7.9 mm) above the board (see Figure 7).

Figure 12. Forming Capacitor Leads.

Install the following capacitors above and to the right of the

3-digit LED display.

_ C50, 39 pF (39 or 390), lead spacing (LS) 0.2”

_ C51, 100 pF (101), LS 0.2”

Install capacitor C2, 27 pF (270) between capacitor C55 and

diode D4 on the lower edge of the board.

Install capacitor C21, .1 µF (104) at the lower right-hand corner

of the board.

Install the following capacitors between the printed outlines for

potentiometers R2 and R3 in the lower right quadrant of the board.

_ C17, .1 µF (104)

_ C18, .1 µF (104)

_ C19, .022 µF (223), LS 0.2”

Install capacitor C22, .01 µF (103) on the right hand edge of the

board above the printed outline for J4.

Install capacitor C27, 150 pf (151) directly above L6 in the upper

right hand quadrant of the board.

Install the following capacitors in the upper right quadrant of the

board.

_ C52, 22 pF (220)

Install capacitor C16, .1 µF (104) between varactors D5 and D6.

Install capacitor C4, 27 pF (270) between molded inductors L8

and L10.

Install capacitor C8, .1 µF (104) directly above molded

inductor L9.

_ C47, 220 pF (221) in the upper right corner of the board.

_ C54, 56 pF (56), to the left of C47.

_ C49, 1000 pF (102) below C54.

_ C48, 1000 pF (102) next to C49

_ C46, 470 pF (471) next to C54

Page 34

ELECRAFT 33

Locate C45, 68 pF (68 or 680), LS 0.2. Be sure that you do not

confuse this capacitor with C56, also 68 pF but with 0.1” lead spacing,

that has not been installed yet. Note: C45 may be a much larger disc

type, which would not fit in the location for C56. But if both are small,

you’ll need to go by the lead spacing.

Install capacitor C45 to the left of C46 in the upper right quadrant

of the board.

Install capacitor C26, 120 pF (121) pillow-style disc ceramic,

about 1/2” (1.3 cm) below C45. Be careful not to put this capacitor

in the space for C44. When C26 is installed, the space for C44

between C26 and C45 should be empty.

Test fit capacitor C1, 4.7 pF (4.7) pillow-style disc ceramic, next

to the lower right corner of the encoder. The bottom of the round

capacitor body should touch the board. If the ceramic coating on the

leads runs down too far to allow it to sit against the board, remove the

excess by squeezing the coating with long-nose pliers. It will crumble

and can be scraped away from the lead.

Install capacitor C1, 4.7 pF (4.7) making sure the bottom of the

round body is touching the board.

i

The following capacitors must be mounted closer to the

board than the others. They are installed in the area that lies

beneath the optional KXB30 30 meter or KXB3080 30 and 80

meter module. The KXB30 or KXB3080 module will not fit if these

capacitors sit too high above the board.

The capacitors installed in this step must be closer to the board

than any of the previous parts you have installed. After installation,

these capacitors must not exceed 5/32” (3.9 mm) in height.

_ C11, .1 µF (104) to the right of molded inductor L10.

_ C13, 56 pF (56) to the right of C11.

_ Use a ruler to verify that the above capacitors are no higher

than 5/32” (3.9 mm) above the board.

On the bottom of the board, ensure L5 (installed earlier) is

against the board, or it may strike other components when the KX1 is

assembled.

Page 35

34 ELECRAFT

Turn the board over so jack J1 is in the upper right corner and

locate the printed outline for C15 just to the left of electrolytic

capacitor C7 at the center of the board.

Directly above the location for C15 is one of the soldered encoder

pins. If it hasn’t been trimmed already, trim it flush.

Install the following capacitors so that about 1/16” (1 mm) of lead

shows between the capacitor and the board, so they can be folded

down against the board like you did with C39 earlier. DO NOT fold

these capacitors down against the board until you are instructed to

do so in later steps. If you fold them now, you will cover solder

pads you must reach to install other parts.

_ C15, .01 µF (103)

_ C3, .01 µF (103)

_ C14, 330 pF (331)

_ C9, 01 µF (103)

Install relay K1 (AGN2104H) to the left of R28 in the upper left

quadrant of the board as follows:

_ Position the relay on the board. It will only fit one way.

_ Hold the relay in place and solder just one of its middle pins

to hold it in place.

_ Re-heat the soldered pin while pressing down on the relay.

This will ensure that it is flush against the PC board.

_ Solder the remaining pins.

_ Trim all of the pins as short as possible.

Turn the board face up so that KX1 is in the upper left corner.

Locate the pins for K1 in the upper right quadrant. Install C56

(68) between pins 2 and 3 of K1 as shown in Figure 13. There are no

solder pads for C56. Cut the two relay pins and solder the capacitor

leads directly to the pads for the relay pins. Be sure the capacitor does

not exceed 5/16” (7.9 mm) in height above the board.

Note: There are a number of components

shown in this picture that you have not

installed yet.

Figure 13. Installing Capacitor C56.

Install relay K2 (AGN2104H) to the left of K1 following the same

procedure.

Page 36

ELECRAFT 35

Install electrolytic capacitor C53 (10 µF, 35 V) between diode D4

and capacitor C21 in the lower right corner of the board as follows:

_ Insert the capacitor with the longer lead through the square

pad with the + symbol printed next to it. Check to ensure the

strip and minus ( - ) sign on the capacitor is on the side

opposite the + sign on the board.

_ Solder one lead and be sure the capacitor is firmly against the

board. Measure the height above the board and confirm that it

is less than 5/16” (7.9 mm) If necessary, reheat the lead while

pressing down on the capacitor.

_ Solder the remaining lead and trim both leads.

Install the following electrolytic capacitors using the same

procedure:

_ C23 (100 µF, 10 V) about 3/4” (1.9 cm) above C53.

_ C20 (10 µF, 35 V) above C23.

_ C35 (100 µF, 10 V) next to C50 above the upper right corner

of the 3-digit display.

i

If you’re not wearing an anti-static wrist strap, be

especially careful to touch a ground frequently while installing

integrated circuits U4, U5 and U6 in the following steps.

With the board face up so that KX1 is in the upper left corner,

locate the printed outline for U4 on the right hand edge of the board

below U3. Install integrated circuit U4 (LM386) as follows:

_ Straighten the pins as necessary (see Figure 5).

_ Orient U4 so that the notch at the end is over the notch in the

printed outline on the board and pin 1 is in the round solder

pad (see Figure 11).

_ Bend the pins at opposite corners of U4 outward slightly to

hold it in place.

_ Check to be sure that U4 is resting against the shoulders of all

8 pins on the top of the board.

_ Solder and trim all 8 pins.

i

Type NE612, NE602, SA612, and SA602 integrated

circuits are all functionally identical. Any of these may be supplied

for use at U5 and U6.

Install U5 (NE/SA612 or NE/SA602) near L10 and L8 at the

lower center of the board. Use the same technique you used above.

i

In the following step, U6 must be fully seated before

soldering or it will interfere with the optional KXB30 30 m or

KXB3080 30 and 80m module. To ensure it is properly seated, a

different installation method will be used.

Install U6 (NE/SA612 or NE/SA602) near encoder Z1 at the

center of the board. Solder just one pin of U6.

Re-heat the soldered pin of U6 while pressing down on the it from

the other side. You may hear or feel it settle into a lower position on

the board. Once you’re certain that it is mounted as close to the board

as possible, solder the remaining pins.

Page 37

36 ELECRAFT

Install transistor Q9 (2N4124) to the right of U5. Be sure to

orient the transistor according to the outline on the board (see Figure

10) and insert the transistor so that the top is no higher than 5/16” (7.9

mm) above the board.

Install transistor Q8 (2N4124) as shown in Figure 14. Bend the

leads so that the transistor body fits within the printed outline with the

flat side facing up. The round back of the transistor must lie against

the circuit board so that the transistor does not exceed 5/32” (3.9 mm)

in height above the board.

Install JFET transistors Q2 and Q3 using the same procedure

as Q8:

_ Q2 (J309) to the right of Q8.

_ Q3 (J309) below Q2