Page 1

Elecraft • www.elecraft.com • 831-662-8345

EL E C R A F T K S B 2 S S B A D A PT E R

Assembly and Operating Instructions

Revision G, July 2, 2011. Copyright © 2011, Elecraft; All Rights Reserved

Introduction

The KSB2 option provides the Elecraft K2 with single-sideband transceive capability. With the KSB2

installed, the operator can use digital communications modes such as RTTY, packet, SSTV and PSK31 in

addition to SSB voice.

The KSB2 includes a 7-pole crystal filter optimized for SSB transmit and receive. This filter is always used

for SSB transmit. During receive, either the fixed SSB filter or the variable-bandwidth CW crystal filter can

be specified for each of the remaining SSB filter settings (FL2-FL4). The SSB filter can also be used for

receive in CW mode if desired. The BFO is individually programmable for each filter, allowing

considerable flexibly in optimizing settings for SSB, CW, or digital modes. Transmit and receive BFO

settings can be adjusted independently in SSB modes if desired.

Other features of the KSB2 include a programmable speech compressor and basic VOX (voice-operated

transmit) capability. In addition, the K2 provides a Carrier Balance mode in which the SSB transmit signal

is routed directly to the receiver. This mode facilitates carrier balance adjustment, and can also be used with

headphones to listen to mic audio whenever the mic gain or compression level is changed.

A wide variety of 8-pin microphones can be used with the KSB2. A mic configuration jumper block is

provided on the Front Panel PC board (see Microphone Configuration for details).

This manual supercedes relevant sections of the K2 Owner's Manual.

Specifications

Crystal Filter Bandwidth approx. 2.3 kHz @ -6 dB; 6/60 dB shape factor approx. 2:1

Carrier Rejection -40 dB or better (typ)

Speech Compressor Compression ratios: 1:1, 2:1, 3:1, 4:1

Current Drain 10-15 mA

Size 4.1 x 2.2 inches (10.4 x 5.6 cm)

i

Caution: Some components in this kit can be damaged by static discharge. Before

handling any transistors or integrated circuits, always put on an anti-static wrist strap or touch any

grounded, unpainted metal surface.

Page 2

2

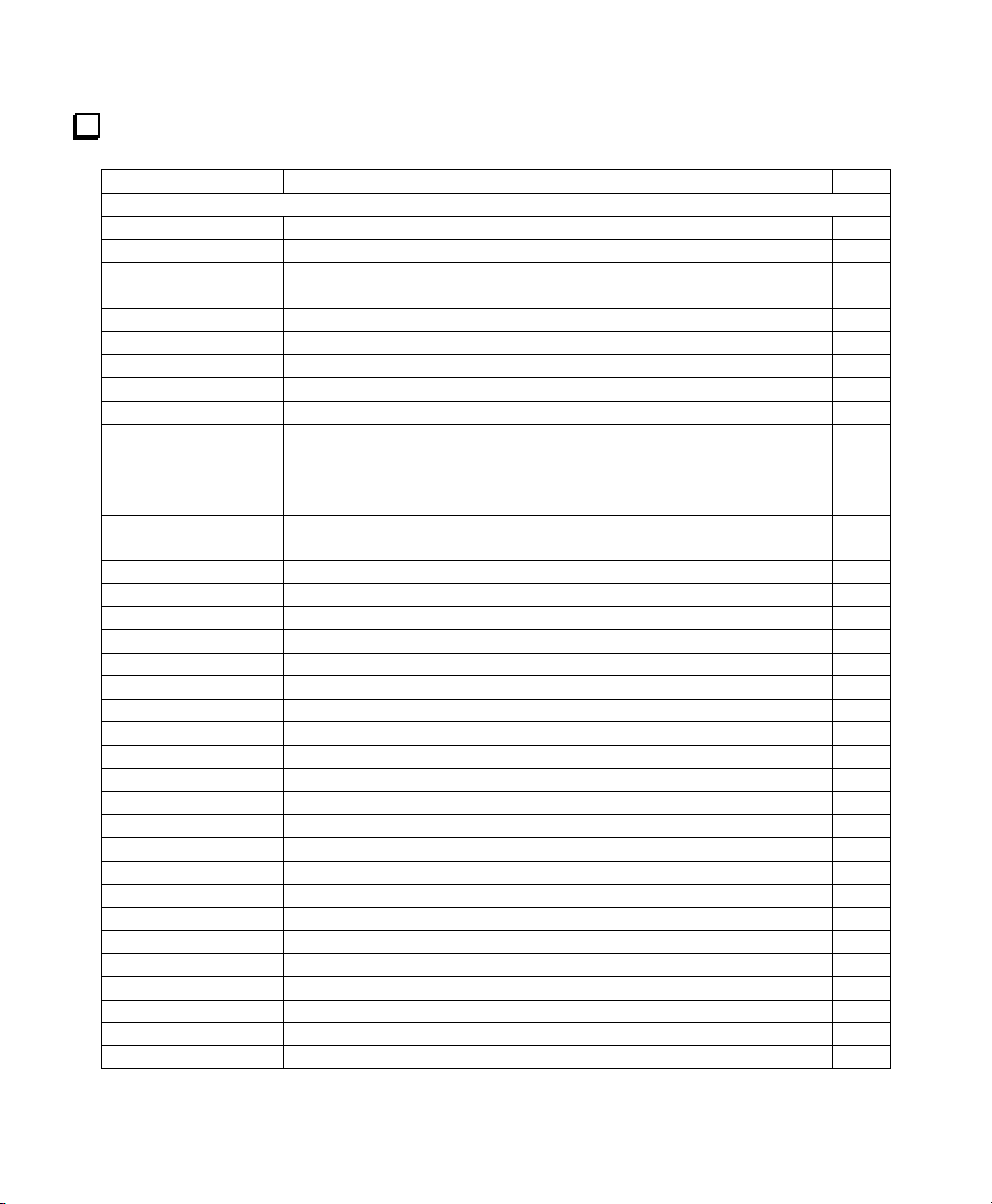

Parts Inventory

The table below lists all parts in the kit. The K2 Owner's manual has photographs of similar parts.

Ref.

Description

Qty.

Components on KSB2 Module

CB,CN

Capacitor, not used (leave open)

0

CC,CM

Capacitor, 27 pF ("27" or "270")

2

CG,CH,CE,CK,

CA,CP

Capacitor, 39 pF ("39" or "390")

6

CF,CJ

Capacitor, 100 pF ("101")

2

CD,CL

Use short wire jumpers in place of these capacitors (see text)

0

C25

Capacitor, 22 pF ("22" or "220")

1

C30, C36

Capacitor, 820 pF ("821")

2

C37

Capacitor, .001 µF ("102")

1

C1-3,C5-12,C16,

C17,C19,C21,C22,

C24,C26,C33,C35,

C39-44

Capacitor, .01 µF ("103"), with 0.1" (2.5 mm) lead spacing.

Note 1: Quantity shown includes one spare.

Note 2: There are also five (5) .01 µF capacitors with 0.2" (5 mm)

lead spacing, listed with Front Panel board components (page 3).

27

C15,C18,C27,

C32,C46

Capacitor, 0.1 µF ("104"), with 0.2" (5 mm) lead spacing

5

C4, C13

Capacitor, 0.1 µF ("104"), with 0.1" (2.5 mm) lead spacing

2

C20,C23

Capacitor, 0.33 µF electrolytic ("0.33" or "334")

2

C31,C34,C50,C51

Capacitor, 2.2 µF electrolytic ("2.2" or "225")

4

C14

Capacitor, 22 µF electrolytic ("22" or "226")

1

C38

Capacitor, 47 µF electrolytic ("47" or "476")

1

D1,D2,D6-14

Diode, 1N4007 (black body)

11

D3,D4,D5

Diode, 1N4148 (glass body)

3

L1

RF choke, 22 µH (red-red-black)

1

P1

Conn., 12-pin male, 0.1" pin spcg

1

P2,P3

Conn., 3-pin male, 0.1" pin spcg

2

Q1,Q2,Q3

Transistor, NPN plastic, PN2222A

3

R8,R10

Resistor, 100 ohms, 5%, 1/4-watt (brown-black-brown)

2

R11

Resistor, 150 ohms, 5%, 1/4-watt (brown-green-brown)

1

R15

Resistor, 180 ohms, 5%, 1/4-watt (brown-gray-brown)

1

R5,R12

Resistor, 470 ohms, 5%, 1/4-watt (yellow-violet-brown)

2

R14

Resistor, 1K, 5%, 1/4-watt (brown-black-red)

1

R6

Resistor, 2.7K, 5%, 1/4-watt (red-violet-red)

1

R2

Resistor, 5.6K, 5%, 1/4-watt (green-blue-red)

1

R9,R16,R23,R24

Resistor, 10K, 5%, 1/4-watt (brown-black-orange)

4

R20

Resistor, 18K, 5%, 1/4-watt (brown-gray-orange)

1

R7

Resistor, 33K, 5%, 1/4-watt (orange-orange-orange)

1

R4

Resistor, 56K, 5%, 1/4-watt (green-blue-orange)

1

Page 3

3

Components on KSB2 Module, continued

R21

Resistor, 68K, 5%, 1/4-watt (blue-gray-orange)

1

R22

Resistor, 560K, 5%, 1/4-watt (green-blue-yellow)

1

R1

Potentiometer, 1 M trimmer ("105")

1

RP3

Resistor network, 2.0 K, 3 R, 6 pins (77063202 or 980663202)

1

RP1,RP2

Resistor network, 2.7 K, 4 R, 8 pins (77083272)

2

RP5

Resistor network, 47K, 5 R, 6 pins (61473)

1

RFC1,RFC2

Toroidal inductor, 19 turns on FT23-43 core (0.23")

2

T1

Toroidal transformer on FT37-43 core (0.375"), 7:22 turns

1

T2

Toroidal transformer on FT37-43 core (0.375"), 4:22 turns

1

U1

IC, Microcontroller, 16F872 or 16F872A

1

U2

IC, Digital-to-analog converter, 8 bits, MAX522

1

U3

IC, Audio amp/speech compressor, SSM2166 (SMD, pre-installed)

1

U4

IC, Dual comparator, LM393

1

U5

IC, Balanced Mixer/Modulator, NE602 (alt: SA602, NE612, etc.)

1

U6

IC, voltage regulator (6 volts), 78L06

1

X1-X7

Crystal, 4.9136 MHz (matched for crystal filter).

Note: Save the envelope, which is labeled with a calibration value.

7

Z1

4.0 MHz ceramic resonator w/internal capacitors

1

Components on Front Panel Board

P1

Conn., dual-row 16p male, 0.1" spcg

1

C4-C8

Capacitor, .01 µF, 0.2" (5 mm) lead spacing

5

Q3

Transistor, PNP, 2N3906

1

RP3

Resistor network, 10 K, 4 R, 8 pins (77083103)

1

Rbias

Resistor, 10 K, 5%, 1/4 W (optional mic bias; see text)

1

R13

Resistor, 68.1K, 1%, 1/4 W

1

Components on RF Board

J11

Conn., 12-pin female, 0.1" pin spcg

1

J9, J10

Conn., 3-pin female, 0.1" pin spcg

2

Hardware and Miscellaneous

HDWR

Socket for U1 on KSB2 module, 28 pins

1

HDWR

#4 split lock washer (quantity shown includes 2 spares)

6

HDWR

4-40 x 1/4" ZN ST phillips machine screw

2

HDWR

Standoff, 3/16" dia. x 3/8" long, round, 4-40 threaded

1

MISC

Wire, #26 enamel, GREEN

2 ft.

MISC

Wire, #28 enamel, RED

5 ft.

MISC

Wire, #24 insulated, solid conductor

2 ft.

MISC

KSB2 PC Board

1

Page 4

4

Firmware Upgrades

If you received new main-processor firmware (U6 on the K2 control board) along with your SSB adapter,

you should install and test it before proceeding with assembly. The SSB adapter requires main processor

firmware revision 1.04A or later. (Hold any button on power-up to check your revision number.) See

separate instructions that were supplied with the firmware upgrade.

BFO Crystals

If you have a field-test K2 (s/n 1-100), you should have received two replacement BFO crystals. These are

required to allow proper SSB operation. Install the new BFO crystals and any associated components

before proceeding with KSB2 assembly. See separate instruction sheet.

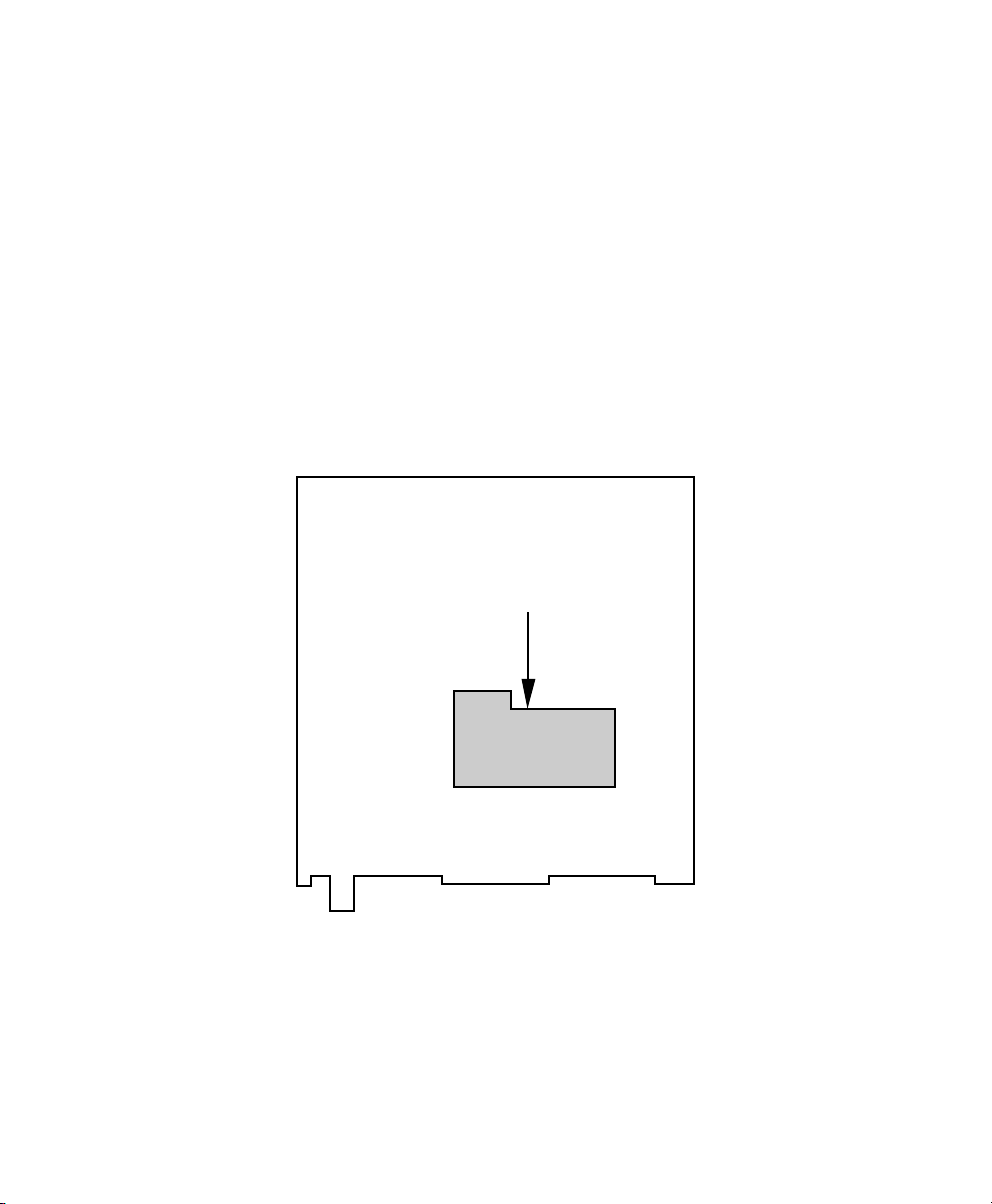

Assembly Overview

The KSB2 module plugs into the K2 RF board at approximately the location shown below.

RF Board

SSB Adapter

As indicated in the parts list, most of the parts in the kit will be installed on the KSB2 PC board. A small

group of parts will be installed on the K2's RF board, and a few on the Front Panel board. The last step in

the assembly process is to wire the microphone connector for your particular mic (P1, Front Panel).

Page 5

5

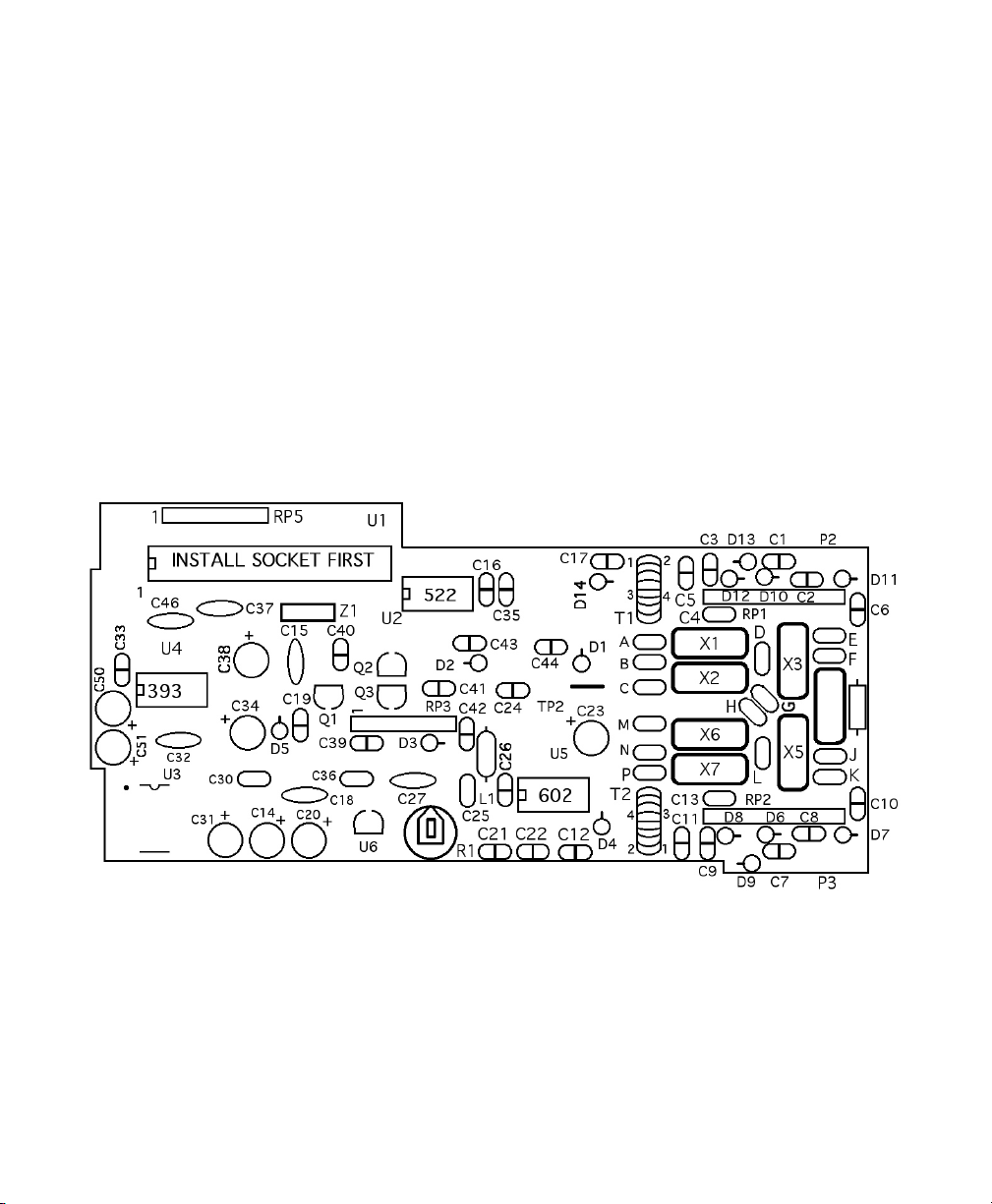

The KSB2 PC board uses close-spaced components in the crystal filter area to minimize stray signal

pickup. Some capacitors are assigned letters rather than numbers, and some components are not labeled.

Place the KSB2 PC board in front of you as shown below. At the far right end of the board, you'll find an

area with a very symmetrical layout. This area contains the SSB crystal filter and filter switching

components. In the middle of this area are a number of capacitors that are labeled only with letters (A, B,

C, D, E, F, G, H, J, K, L, M, N, P). For example, "A" corresponds to capacitor "CA" in the parts list.

Above and below the crystal filter are the filter switching components. Some of the diodes and capacitors

are not labeled on the board itself, but can be identified in the parts placement drawing below.

The only other unlabeled components are P2 and P3, which will be installed on the bottom of the board.

These are indicated in the upper-right and lower-right corners, below.

All .01 µF capacitors with 0.1" lead spacing use a special symbol with a line between the two pads to

distinguish them from small-value capacitors of the same physical size.

U3 (bottom left-hand corner) is a surface-mount device (SMD) and has been pre-installed.

Parts Placement Drawing

Page 6

6

KSB2 PC Board Assembly

i

A fine-point, temperature-controlled soldering iron (700-800 deg. F, 340-370 deg.

C) is required to assemble this kit, due to the high density of the PC board layout. A highwattage iron or one with a wide tip may damage components, pads, or traces. Use a

minimum amount of solder to avoid ground shorts.

i

To avoid difficulties in soldering adjacent components, install components only in

the order described below. Double-check all values before soldering, since removing

small parts from double-sided PC boards can be difficult.

Using the parts list (page 3), identify all of the components that are to be installed on the K2's Front

Panel and RF boards and separate them from the remaining items. Note: The .01 µF capacitors with small

lead spacing (0.1", 2.5 mm) are only used on the KSB2 module, while the .01 µF capacitors with the wider

lead spacing (0.2", 5 mm) will be installed on the Front Panel board.

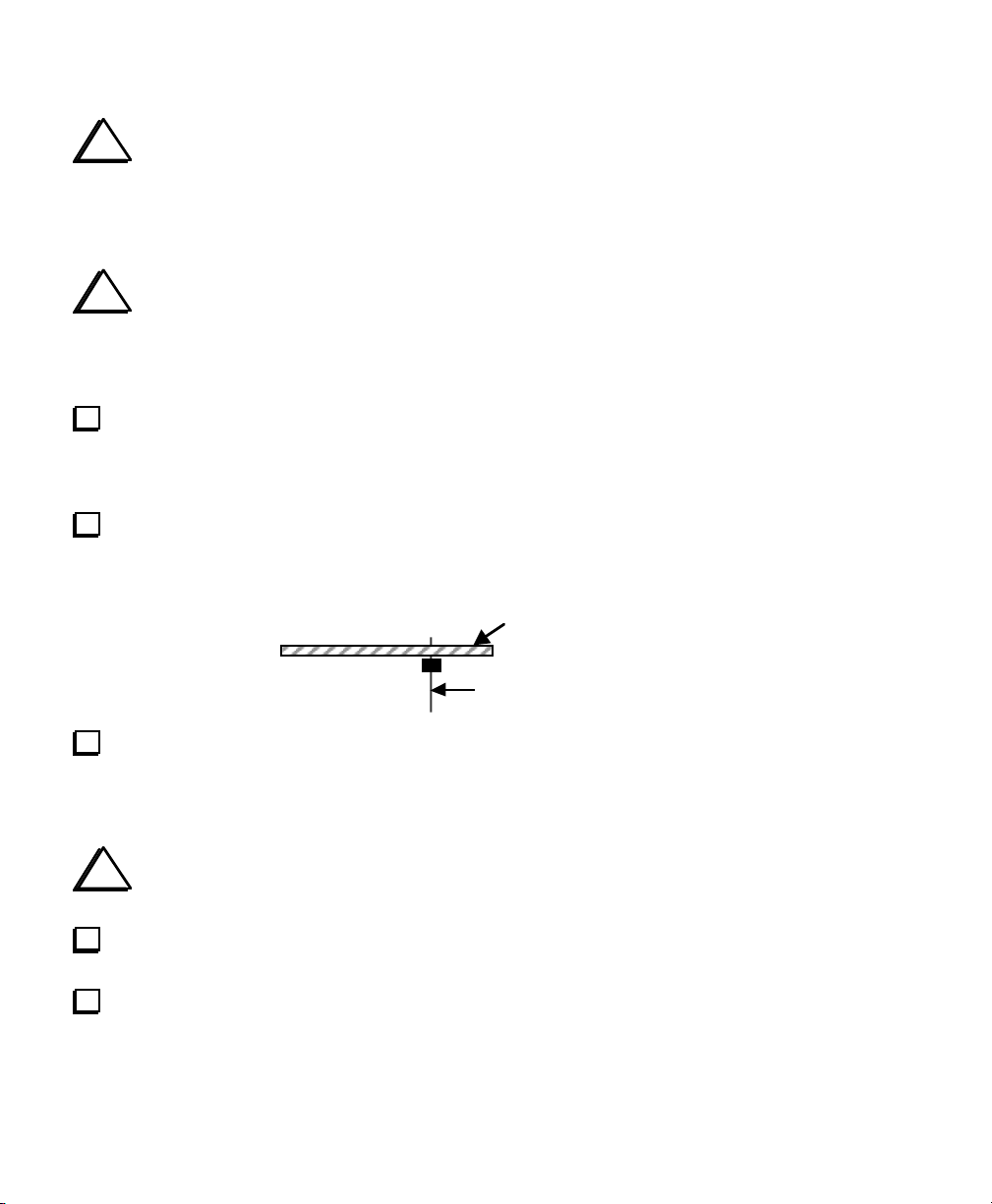

Install 12-pin male connector P1 on the bottom of the PC board in the position indicated by its

component outline. Do not solder yet. The drawing below shows how P1 should appear viewed from the

left end of the board, with the component side up.

P1 (on bottom)

Solder just one pin of P1 on the top of the board, near the middle of the connector (pin 6 or 7). Verify

that P1 is now perpendicular to the PC board and is seated completely flat. If not, re-heat the soldered pin

and press down on all of P1's pins until the connector drops into place. Once the connector is seated

correctly, solder the remaining pins. This connector must not be tilted or installed at the wrong height.

i

All component leads should be kept short to avoid stray signal coupling. The leads on small

capacitors do not need to be straightened, but keep their mounted height at about 1/8" (3 mm) or less.

Install C30 and C36 (820 pF, "821"), near P1 on the top side of the board. Be careful not to confuse

C30 or C36 with C18, which is farther from P1 and has wider lead spacing.

Install C25 (22 pF, "22" or "220"), which is near the right end of P1 (viewed from the top side).

Page 7

7

Install all of the lettered capacitors shown below (CC, CM, etc.). After inserting each capacitor, bend

its leads slightly to hold it in place. Limit soldering time to 2 or 3 seconds per lead, using a minimum

amount of solder to avoid ground shorts.

__CC and __CM (27 pF, "27" or "270")

__CG and __CH (39 pF, "39" or "390")

__CE and __ CK (39 pF, "39" or "390")

__CA and __ CP (39 pF, "39" or "390")

__CF and __ CJ (100 pF, "101")

Install short wire jumpers at CD and CL. Use discarded component leads to form the jumpers. Do not

leave any excess lead length above the board.

Capacitors CB and CN are not used and should be left open.

Install the 0.1 µF capacitors ("104") with 0.1" (2.5 mm) lead spacing.

__C4 (near X1) __C13 (near X7)

Install the 0.1 µF capacitors ("104") with 0.2" (5 mm) lead spacing.

__C15 __C18 __C27 __C32 __C46

Install the .01 µF capacitors ("103") with 0.1" (2.5 mm) lead spacing (C1-C3, etc.). Use the Parts

Placement Drawing to verify the reference designators on capacitors in the crystal filter area that are not

labeled.

__C1 __C2 __C3 __C5 __C6

__C7 __C8 __C9 __C10 __C11

__C12 __C16 __C17 __C19 __C21

__C22 __C24 __C26 __C33 __C35

__C39 __C40 __C41 __C42 __C43

__C44

Note: You'll have one .01 µF capacitor of this type left, which has been included as a spare.

Install C37 (.001 µF, "102"), which is near the microcontroller, U1.

Page 8

8

i

All diodes will be installed vertically as shown below. The anode lead will be inserted into the pad

enclosed by a circle. The cathode lead (banded end) must be folded down and inserted into the adjacent

pad, which is connected to the first pad by a white line. When installing diodes, check the Parts Placement

Drawing as needed to make sure that you're inserting the leads into the correct pads.

Install D3 and D4 (1N4148), both of which are near U5.

Install D5 (1N4148), on the left side of the board near C34.

Install D1 (1N4007), which is located near the middle of the board. As indicated by the short white

line, the cathode lead (banded end) goes into the pad to the left of the D1 label. (There are two other pads

nearby D1, so be careful to use the correct one.) Push the diode down so no excess lead length is exposed.

Install D2 (1N4007), to the left of D1. The cathode lead goes into the pad closest to the D2 label.

Install D6 through D14 (1N4007). Be sure to insert the leads into the correct holes as indicated on the

PC board and the Parts Placement Diagram.

__D6 __D7 __D8 __D9 __D10

__D11 __D12 _D13 __D14

Install resistor networks RP1, RP2, RP3 and RP5. Pin 1 of each network is identified by a dot. This

pin must be inserted into the round pad (the other pads are square). Clip the leads of all resistor networks

after soldering to reduce stray signal coupling. Note: RP3 and RP5 both have six pins, but

different values. Check the labels carefully.

__RP1 (2.7K 8 pins) __RP2 (2.7K, 8 pins)

__RP3 (2.0K, 6 pins) __RP5 (47K, 6 pins)

Transistors Q1-Q3 are all type PN2222A (plastic, TO-92 package). Install these transistors with their

flat sides oriented as indicated by their component outlines. Note that Q2 and Q3 will end up with their flat

sides facing each other when correctly installed.

__Q1 __Q2 __Q3

Page 9

9

U3 is a surface-mount IC that should already be installed on the top side of the board (SSM-2166).

Examine U3 with a magnifying glass to verify that all leads are soldered.

Install U6, the 78L06 voltage regulator IC. This device has a plastic package like a transistor. The flat

side must face the U6 label as indicated by the component outline.

Install the 28-pin socket for U1. The notched end goes towards the left edge of the board.

Install the 8-pin DIP ICs, U2 through U5. A portion of the part number of each IC is printed on the

board. Compare this number with the number printed on each IC before installation. In all cases, pin 1 of

the IC (the notched or dimpled end) goes into the round pad (the remaining pads are square).

__U2 (MAX522) __U4 (LM393) __U5 (NE602)

Clip the leads of U5 after soldering to reduce stray coupling. Other IC leads need not be clipped.

Install all of the electrolytic capacitors as indicated by their board outlines. The negative lead is

identified on the case. The positive lead must be inserted into the pad marked "+". The electrolytic

capacitors may all be identical in appearance, so check the values carefully before installation.

__C20 (0.33 µF) __C23 (0.33 µF) __C14 (22 µF) __C31 (2.2 µF)

__C34 (2.2 µF) __C38 (47 µF) __C50 (2.2 µF) __C51 (2.2 µF)

Install L1, a solenoidal RF choke, to the right of P1.

The carrier-balance control, R1, is located near the front edge of the board. Press R1 down as far as at

will go, and make sure it is parallel to the board before soldering. Set R1 to its mid-point after soldering.

Install ceramic resonator Z1 near the microcontroller (U1).

Install R5 (470 ohms, yellow-violet-brown), which is located on the far right edge of the board.

Install the remaining resistors on the bottom side of the board. To avoid lead trimming problems, preform and trim each resistor's leads before installation. The leads should be just long enough to be visible on

the component side (top). Solder the resistors on the bottom side only. Note: R16's leads will be obscured

by the socket for U1. Trim the leads of R16 so that it sits flat on the bottom of the board.

__R8, __R10 (100 ohms, brown-black-brown)

__R11 (150 ohms, brown-green-brown)

__R15 (180 ohms, brown-gray-brown)

__R12 (470 ohms, yellow-violet-brown)

__R14 (1K, brown-black-red)

__R6 (2.7K, red-violet-red)

__R2 (5.6K, green-blue-red)

__R16, __R9 (10K, brown-black-orange; see note on lead trimming above)

__R7 (33K, orange-orange-orange)

Page 10

10

__R4 (56K, green-blue-orange)

__R20 (18K, brown-gray-orange)

__R21 (68K, blue-gray-orange)

__R22 (560K, green-blue-yellow)

__R23, __R24 (10K, brown-black-orange)

Re-check the values of capacitors CG and CH (39 pF). Once the crystals are installed (following steps)

it is difficult to gain access to these two capacitors.

Locate the envelope containing the matched SSB filter crystals (X1-X7). On the outside of the

envelope you'll find a calibration number that ranges between 3.2 and 3.9. Record the number: ______.

Note: If the envelope is unmarked, use 3.6.

Using the number recorded in the previous step, look up the corresponding LSB and USB transmit

BFO frequencies in the table below. Record these frequencies in Table 3 (page 20) in the two spaces

provided in the BF1t column.

Xtal Cal #

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

LSB

4913.1

4913.2

4913.3

4913.4

4913.5

4913.6

4913.7

4913.8

USB

4915.9

4916.0

4916.1

4916.2

4916.3

4916.4

4916.5

4916.6

Install all 7 crystals, making sure that they are flush with the top of the PC board and are not tilted.

There should be no excess lead length.

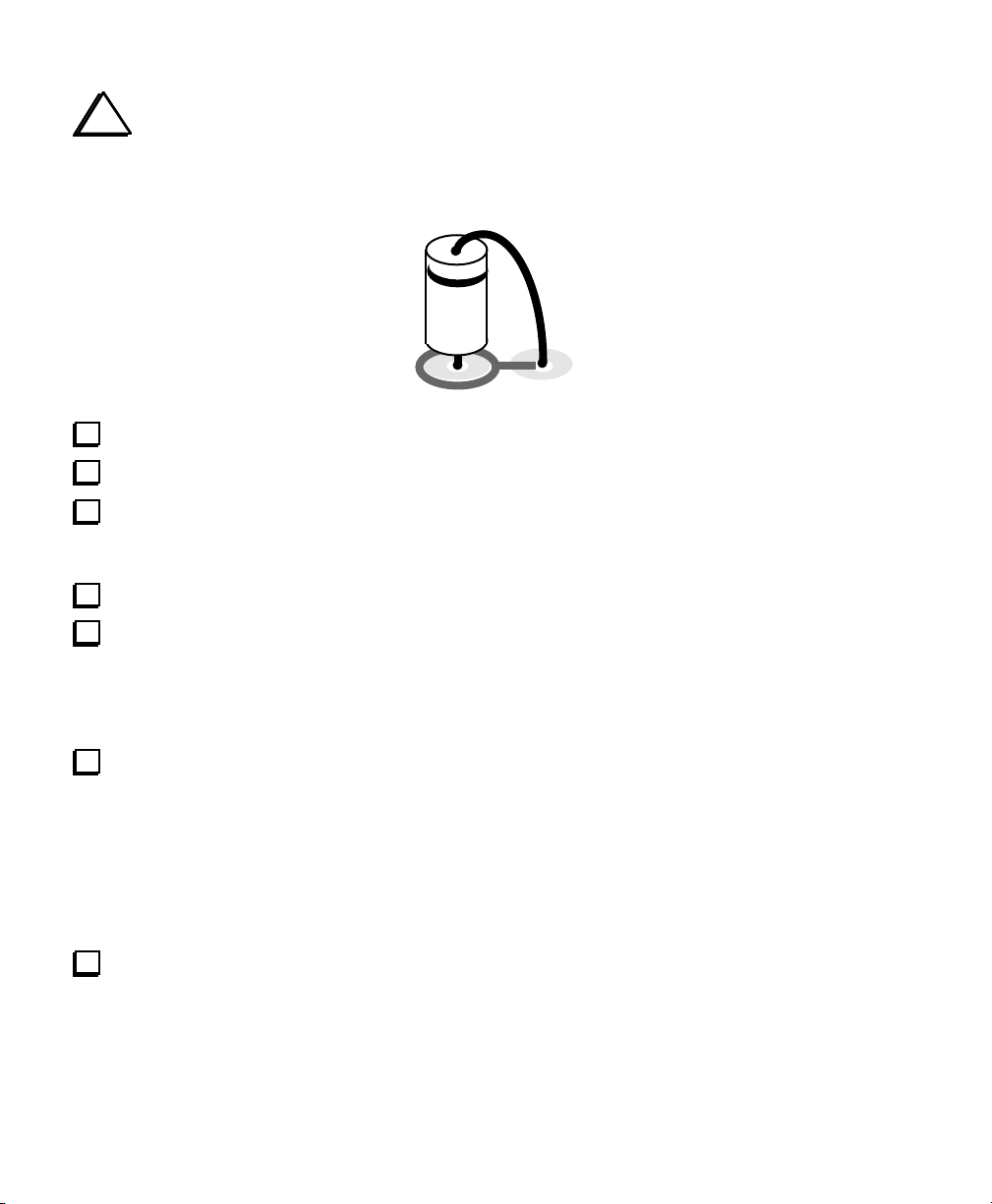

The cases of the crystals should be grounded to the adjacent ground pads using jumpers formed from

discarded component leads. The drawing below shows the ground pads and jumpers as viewed from above

the board. Solder the jumpers to the board first, then fold them over the crystal cans. Be careful not to

overheat the crystal cans when soldering the jumpers in place.

Install 3-pin male connectors P2 and P3 on the bottom of the board. Use the same technique you used

when installing P1. These connectors must not be tilted, and must be seated flush with the board.

Page 11

11

i

T1 and T2 are toroidal transformers, with two numbered windings: 1–2 and 3–4. These numbers

are printed next to the pads on the PC board, and they also appear on the schematic drawing.

T1 will be wound on a ferrite core (FT37-43, 3/8” [9.5 mm] diameter). For the larger winding, 3-4,

use 22 turns of red enamel wire (13”, 33 cm). This winding will occupy about 80 to 90% of the core, as

shown in the drawing below. (The drawing shows only 14 turns on the 3-4 winding.) Each pass through the

core counts as one turn. Some turns of the 1-2 winding may cross over those of the 3-4 winding.

Green

4

3

1

2

Carefully strip and tin the leads of T1’s 3-4 winding as follows: First, cut the leads to about 1/2" (12

mm) long. Next, completely remove the enamel insulation from the leads to within 1/8” (3 mm) of the core.

You can use a small amount of solder on your iron's tip to heat-strip the insulation (preferred method), or

use a butane lighter or sand-paper. If you scrape the insulation off, be careful not to nick the wire.

T1’s other winding, 1–2, uses 7 turns of green enamel wire (5”, 13 cm). (The drawing shows only 4

turns.) Wind the 1–2 winding on top of the 3–4 winding, using about 20% of the core. Strip and tin the

leads of the 1–2 winding.

Install T1 vertically as shown by its component outline, with the 1–2 winding facing the edge of the

board. Pull the leads taut on the bottom so that the transformer is held firmly in place. Make sure that the

exposed part of each lead is shiny and has no remaining insulation.

Trim and solder all four leads of T1. When soldering, make sure that the solder binds well to the

leads. If the lead appears to be an “island” in a small pool of solder, chances are it is not making good

contact. Measure from leads 1 to 2 and 3 to 4 using an ohmmeter to be sure the leads are making contact.

Wind T2 in the same manner as T1, with 22 turns on the 3-4 winding (red) but only 4 turns on the

1–2 winding (green).

Install T2. It will be rotated 180 degrees with respect to T1, with its 1–2 winding (green) facing the

closest edge of the board.

Page 12

12

i

Very small ferrite cores are used for RFC1 and RFC2 to minimize stray signal coupling. These

cores are a little harder to work with than larger cores, and are also more fragile. If you find it necessary to

hold them with a vice, use only plastic or rubber jaws and a minimum of pressure.

Inductor RFC1 is wound with 19 turns of red enamel wire (9" [23 cm]) on an FT23-43 core. Since

this winding completely fills the core, you may end up with one or two turns overlapping each other on the

ends, which is acceptable. The edges of the core are sharp, so while winding, try to avoid scraping the wire

against the core. Prepare the leads as you did with T1 and T2, but leave them long (about 1").

Install RFC1 on the top of the board, even though the component outline appears on the bottom (in

the crystal filter area). The component outline identifies the proper holes to use. Insert the leads into these

holes from the top, then pull the toroid down until it is seated on the board between RP1 and X3. Before

soldering, look at the leads with a magnifying glass (if necessary) to make sure that all insulation is

removed where the leads intersect the pads. Solder RFC1 on the bottom and clip the excess lead length.

Wind and install RFC2 in the same manner as RFC1.

Use an ohmmeter to verify continuity (< 1 ohm) between the pads for RFC1. Do the same for RFC2.

In the middle of the board, directly above the "C23" label, you'll find two pads connected by a white

line. Install a 1/4" (6 mm) tall U-shaped ground jumper between these two pads, on the top side of the

board. The jumper can be formed from a discarded component lead. (One of the thick leads from a 1N4007

diode is ideal.) This jumper can be used as a ground point for test instruments.

Re-check the orientation of the following using the Parts Placement drawing:

__ ICs __ Resistor Networks __ Diodes

__ Transistors __ Electrolytic capacitors

Carefully examine both sides of the board for solder bridges and cold solder joints.

i

Before handling microcontroller U1, touch an unpainted, grounded surface. U1 is a CMOS IC that

can be damaged by static discharge.

Install U1 in its socket. The notched or dimpled end of U1 should be nearest the left edge of the

board. (Pin 1 is indicated by a round pad on the board.)

Page 13

13

KSB2 Module Installation

Remove the top and bottom covers. (Do not remove the heat sink.)

Disconnect and remove the frequency counter probe.

Locate the 5-crystal CW filter on the K2 RF board (X7 through X11). If any ground wires are soldered

to the tops of these crystals, re-locate them to the sides of the crystals, about 1/4" (6 mm) up from the

surface of the PC board. Note: There are two ground pads for each of these crystals (one on either side).

For best performance, solder two wires to each crystal. (Early revisions of the K2 manual called for the use

of just one wire each, soldered to the tops of the cans, resulting in worse rejection of out-of-band signals.)

Locate the 2nd crystal filter on the RF board (X5 and X6). The ground wires on these two crystals

should be positioned approximately as shown below to maintain clearance from the SSB adapter.

(Grounding of these crystals is non-critical, so either top or side grounding will work.)

Remove jumpers W2 and W3 on the RF board (near the 5-crystal filter). It is best to de-solder these

jumpers and remove them completely rather than just cut them at both ends. If the SSB adapter must be

removed later, W2 and W3 can be re-installed, or you can insert jumpers between pins 1 and 3 of J9/J10.

Desolder and remove C167 from the RF board. C167 is located near the SSB option connector, J11.

Save C167 in case you need to remove the SSB adapter at a later date.

Install the 12-pin female connector on the RF board at J11(labeled "SSB") as shown by its outline. Do

not solder yet. The side view of J11, below, shows how it should appear once properly seated.

Solder just one pin near the middle of J11. If the connector is not sitting completely flat against the RF

board, reheat this pin and press the connector down. Then solder the remaining pins of J11.

Install 3-pin female connectors on the RF board at J9 and J10, using the same technique used with J11.

Page 14

14

Install the 3/8" (9.5 mm) standoff on the top of the RF board as shown below, using three split lock

washers and a 1/4" (6 mm) machine screw. The hole for the standoff is near the BFO test point (TP2).

i

If you have difficulty getting the screw threads started into the standoff, hold the standoff with

pliers on one side while pushing and turning the screw from the other with a phillips screwdriver. Once the

lock washers start to compress, the screw will mate adequately with the standoff.

If your K2 serial number is 2999 or lower, you should make the 2nd XFIL modification to the K2 RF

board at this time. This equalizes the pitch of LSB and USB signals on receive, and provides optimal

sensitivity in all operating modes. (It has no effect on transmit.) The parts for the modification can be

purchased from Elecraft (part #XFILMDKT ). Instructions can be found in this PDF document:

http://www.elecraft.com/Apps/new_fil_docs/k2_2nd_xfil_ssb_mod.pdf

If you don’t have web access, call or write for a printed copy of the instructions.

Note: The modification has already been incorporated into K2's with serial number 3000 and higher. You

may also have made this modification already if you upgraded your K2 to revision B.

Plug the SSB module into the RF board. P1 on the SSB module mates with J11 on the RF board, and

P2-P3 on the SSB module mate with J9-J10. Note that J11 will be obscured by the SSB adapter as you plug

it in, so you won't be able to see whether the pins of P1 are mating correctly. However, if you line up the

pins on P2-P3 with J9-J10, the alignment of P1 and J11 should also be correct. Also look at the hole labeled

"TP2" on the SSB module: you should see the BFO test point centered below this hole.

Secure the SSB adapter to the RF board standoff using a 4-40 screw and one split lock washer.

Re-install the bottom cover (6 screws).

Page 15

15

Initial Test

Turn on the K2 and verify that you see the usual E LECR A F T display. If you see INFO 0 8 0 or no

display, you may have the SSB adapter plugged in incorrectly. If it appears to be installed correctly, unplug

the adapter and look for a short to ground on one of the pins of P1.

Tap the M E N U button, then use the B A N D + / B A N D - buttons to get to the S SB A and SSB C

menu entries. If you see "- - " displayed for SS B A and S S B C , the SSB adapter's microcontroller is not

communicating with the main processor on the Control board. Make sure U1 on the SSB adapter is not

plugged in backwards. Also verify that R12 is installed (470 ohms).

Tap M O D E to select CW mode. Set the RF GAIN to max; AF GAIN, mid-way; preamp ON.

Switch to 40 meters using B A N D + / B A N D - . Connect an antenna and headphones or speaker.

Verify that the K2 performs the same on CW receive as it did prior to installing the SSB adapter. The

filters you had set up should sound the same, and there should be no loss of signal strength. If signals

appear to be weaker, see Troubleshooting.

BFO Test

Connect the K2's internal frequency counter cable to TP2 (BFO) through the hole labeled "TP2" near

the center of the SSB module. Tap the M E N U button and scroll to the C A L menu entry. Then hold E DIT

and scroll the C A L parameter until you see CAL F C T R . Hold E D I T a second time to activate the

frequency counter display. You should now see a BFO frequency reading between 4910 and 4918 kHz on

the LCD. The last digit may flicker. If the reading is 0000.00 or out of range, the SSB adapter may be

loading down the BFO signal. Check C42, RP3, L1, C25, and C26 on the adapter. Look for shorts or opens

in this part of the circuit. Also see Troubleshooting.

Receive-Mode SSB Filter Test

Selecting the Fixed-Bandwidth SSB Filter

If you're still in C A L FC T R mode, tap M E N U . Select 40 meters using B A N D + / BAN D - .

Switch to LSB mode using the M O D E button, and use X F I L to select FL1.

Use the menu to select C A L FI L and activate the filter setup display. You'll see filter FL1's setting

displayed. If a bandwidth number appears after FL1, e.g. F L1 2 . 2 0 L , it indicates that the variablebandwidth CW filter is presently being used for SSB receive. The small "L" indicates LSB mode.

Use the VFO knob to change the setting for FL1 to FL1 OP1 L . (O P1 is the next available setting

after 2 .4 9 . "OP1" refers to the first option filter, in this case the fixed filter on the SSB adapter.) You

should hear a pronounced difference in the receiver's audio when you go from 2.4 9 to OP1 , since this

causes the SSB adapter to switch between the CW filter and the SSB filter. Leave the filter set for

F L1 O P 1 L . Note: OP2 - OP5 also select O P1 since only one fixed filter is available on the KSB2.

Page 16

16

BFO Setup for LSB/USB

Tap the B A N D - button to see the BFO setting for the first SSB filter (BF1). You should see a display

similar to B F1t12 0 L . The BFO frequency control parameter (in this case 1 2 0 ) has a range of 000-255.

(A lower-case letter t appears in the BFO display for BF1, e.g. B F1t12 0 L . This is a reminder that on

transmit, BFO setting B F1 is always used, regardless of how you set the BFO for FL2 through FL4.)

Tap D I S P L AY to show the present LSB BFO frequency in kHz. Adjust the VFO knob until the BFO

is as close as possible to the LSB/BF1t freq. from Table 3. Then tap B A N D - to return to the BFO

parameter display.

Tap M O D E to select USB mode. You should now see a display similar to B F 1 t 200U .

Tap D I S P L AY to show the present USB BFO frequency in kHz. Adjust the VFO knob until the BFO

is as close as possible to the USB/BF1t freq. from Table 3. Tap B A N D - .

Exit the menu by tapping M E N U .

Using only FL1, listen to a few SSB stations. (Use LSB on 40 meters and below, and USB on 20

meters and above.) In later sections we'll describe various ways to set up FL2, 3, and 4 on receive (see

Table 3). You'll also be able to fine-tune the transmit BFO settings, if necessary, to match your voice.

Note: Use CAL FIL only on 17 meters and below. The BFO settings for LSB and USB are swapped on 15,

12 and 10 meters due to the K2's frequency mixing scheme.

Front Panel Board Components

Remove the two screws that hold the Control board to the Front Panel board. Remove the four chassis

screws that hold the Front Panel assembly to the chassis, then carefully unplug the Front Panel assembly.

Remove the knobs, optical encoder hardware, and the flat-head screw to the left of the encoder shaft.

(Do not remove the screw holding the associated standoff to the Front Panel PC board.) Separate the Front

Panel from its PC board.

i

The front-panel SSB components will be installed in a small area located between the four

potentiometers on the left-hand side of the board.

Install the following components on the Front Panel board:

__ C4-C8 (all .01 µF) __ Q3 (2N3906)

__ RP3 (10 K, 8 pins) __ R13 (68.1K, 1%)

Turn the Front Panel board upside down and install the microphone configuration connector, P1. The

short ends of the pins go into the board, and the connector must be soldered on the front side. Be very

careful when soldering the pins of P1, which are very close to pushbutton switch S6.

Re-assemble the Front Panel board (including knobs and hardware), but leave it unplugged.

Page 17

17

Microphone Configuration

Follow the steps below to configure the K2 for your microphone.

1. If the Front Panel assembly is plugged in, remove the appropriate screws and unplug it. There are two

screws holding the Front Panel board to the Control board, and four chassis screws that hold the Front

Panel assembly to the chassis.

2. Place the Front Panel board upside-down on a soft cloth, with P1 to your right. P1's left-hand pins are

the K2 signal lines, while those on the right correspond to the 8 pins of the microphone jack.

3. Determine the proper P1 wiring for your mic. First look in Table 2 (following page) to see if your mic

is listed. (Also check our web site, www.elecraft.com, which lists additional microphones). If you have

a mic that is not listed, use Table 1 in conjunction with your microphone's schematic to determine

which wires to use. If your mic has the wrong connector type, you can use a Radio Shack #274-025.

4. Connect each of the required signal lines using hookup wire, wire-wrap wire, or discarded component

leads. (You can optionally use 2-pin computer "jumper blocks" for connections that tie adjacent P1

pins together.) Some mics also require a bias resistor between the AF and 5V lines, as described in

Table 1 or Table 2.

5.

Plug the Front Panel assembly into the RF board. Secure it to the chassis (4 screws) and control board

(2 screws).

Table 1. P1 Signal Descriptions. (Also see Table 2.)

Signal

Description

Notes

AF

Mic audio, Low-Z

(approx. 600 ohms).

Approx. 100 mVp-p

audio level.

With some mics it is necessary to connect 5V to AF

through a resistor. The kit includes a 10 K resistor (Rbias)

for use with many condenser mics. Some mics may require

a much smaller resistor to supply operating current for a

buffer stage. Consult the transceiver and microphone

schematics.

PTT

Push-to-talk

Contact closure to ground when PTT button pressed.

The PTT signal is the same as the DOT key line, making it

easy to use a foot switch or other method of enabling xmit.

DN

"Down" button

(optional)

UP

"Up" button

(optional)

FUNC

Function button

(optional)

Contact closure to ground when button pressed, otherwise

open (infinite resistance).

You can activate the VFO A/B switching function using

any contact closure to ground (UP, DN, FUNC). The

present version of the KSB2 firmware does not support

other mic button functions.

5V

5 volts DC (10 mA

max.)

Some microphones will work well with 5 volts even though

the schematic calls for a higher voltage.

GND

GND

Ground

Signal, logic, or shield ground.

Page 18

18

Table 2. P1 Wiring for Selected Microphones (NC = no connection).

Elecraft MH2, MD2,

Proset-K2

Kenwood (MC-43,47,48,60),

Alinco EMS-11

Icom (HM-7,12,22,23,36)

Mic kit includes 8 jumper blocks

for use at P1, plus a 5.6-k resistor.

Install the jumpers first, then solder

the resistor from pin 1 to 6.

Note: Do not attempt do

disassemble the microphone.

Do not connect pin 5 unless mic

has internal preamp. Touch-tone

ICs may be sensitive to stray RF.

CAUTION: 5V goes to pin 5, not

pin 6 (not straight across). Leave

pin 6 of the mic unconnected.

Do not connect pin 2 unless mic

has internal preamp. Touch-tone

ICs may be sensitive to stray RF.

Resistor, AF to 5V: HM-7, 820

ohms; HM-12/22/23/36, 10 K

Signal

Mic pin

Signal

Mic pin

Signal

Mic pin

AF

1

(resistor to pin 6)

AF1AF

1

(see resistor, above)

PTT2PTT2PTT

5

DN3DN3DN

3

UP4UP4UP

NC

FUNC

5

FUNC

NC

FUNC

NC

5V65V

5 (see note above)

5V

2 (see note above)

GND

7

GND

7

GND

6

GND

8

GND

8

GND

7

Yaesu (MD-1, MH-1, 27, 31,

YM-35, MD-100)

Radio Shack (mic supplied

with HTX-100)

The MD-100 is slightly different

from the other mics in the list:

connect 5V to pin 2

Signal

Mic pin

Signal

Mic pin

Signal

Mic pin

AF8AF1AF

PTT6PTT2PTT

DN3DN3DN

UP1UP4UP

FUNC

NC

FUNC

NC

FUNC

5V

NC (MD-100: pin 2)

5VNC5V

GND

2 (all but MD-100)

GND

7

GND

GND

5, 7

GND

8

GND

Page 19

19

Alignment

If your K2 serial number is 2999 or lower: Locate the PA Bias control, R60, on the K2's RF board

near the PA transformer. Set R60 fully counter-clockwise. (Newer K2s have a fixed resistor at R60.)

Locate the carrier balance control, R1 on the KSB2 module. Set it close to the center of its range.

Turn on power to the K2. Select 40 meters, LSB mode, and filter FL1. Set RF GAIN = max.

Coarse Carrier Balance Adjustment

Disconnect the microphone.

Select S SBC in the menu, and set the parameter to 2- 1 (2:1 compression).

Select S SBA in the menu, and set the parameter to BA L (carrier balance). Then exit the menu. You

may see an S-meter indication, since the low-level SSB signal is now being fed back into the receiver.

Adjust R1 on the KSB2 slowly for a minimum indication on the S-meter. This should occur close to

the center of R1's range. If R1 has no effect, see Troubleshooting.

Select S SBA in the menu and set the parameter to 3. This will disable carrier balance mode.

Fine Carrier Balance Adjustment

A ham-band receiver is required to do fine carrier balance adjustment.

Use the menu to set SSB A to 3 and SS B C to 2 - 1 .

Connect a microphone to the K2. Select LSB mode and FL1. Set power to 5 watts.

Connect a dummy load to the K2.

Verify that pushing the PTT (push-to-talk) switch on the mic puts the K2 into transmit mode.

Press PTT, but do not talk into the mic. Locate the K2's transmitted signal on the external receiver.

The VFO setting you use on the external receiver to listen to your K2's carrier will be different from that

used to tune in the SSB voice signal. If you're tuned to a setting that allows you to hear the voice signal,

you'll be at the zero-beat frequency of the carrier and will not be able to hear a tone.

With the PTT switch pressed, adjust R1 on the SSB adapter for minimum carrier signal amplitude

using the receiver's S-meter. This should occur near the middle of R1's range (typically slightly to the

right). Repeat the adjustment using USB. Find the best compromise setting between LSB and USB.

Page 20

20

Filter Setup

Connect the K2's internal frequency counter probe to TP2 (BFO).

Select 40 meters, LSB mode, and filter FL1. (It's important to always do filter setup on 17 m or

below to avoid confusion due to the K2's sideband inversion above 17 m. The settings apply to all bands.)

Set up your filters exactly as shown in Table 3 (below), using CAL FIL. Both the filters (FL1-4) and

BFOs (BF1-4) must be set up for each operating mode. The BFO settings are given as actual frequencies

(4912-4917 kHz) rather than as BFO control values (0-255). As described earlier, the D I SP LAY button is

used in CAL FIL to setup the BFO frequencies. You may not be able to set the frequencies to exactly those

shown, but try to get as close as possible. The 10 Hz digit may flicker, which is normal.

Read all of pages 21 and 22 carefully to become familiar with SSB operation.

Set POWER for 5 watts and select LSB mode. Monitor your transmitted voice signal in another

receiver, or contact a nearby station and have them listen critically. Then, as explained on page 22 (SSB

Transmit BFO Optimization), adjust the LSB BF1 value for best transmitted signal quality.

Switch to USB mode and adjust the USB BF1 value for best transmitted signal quality.

Optional: For receive-mode BFO fine-tuning (BF2-BF4) you can use an audio spectrum analysis

program such as Spectrogram, which runs on PC-compatible computers. This is described on our web site.

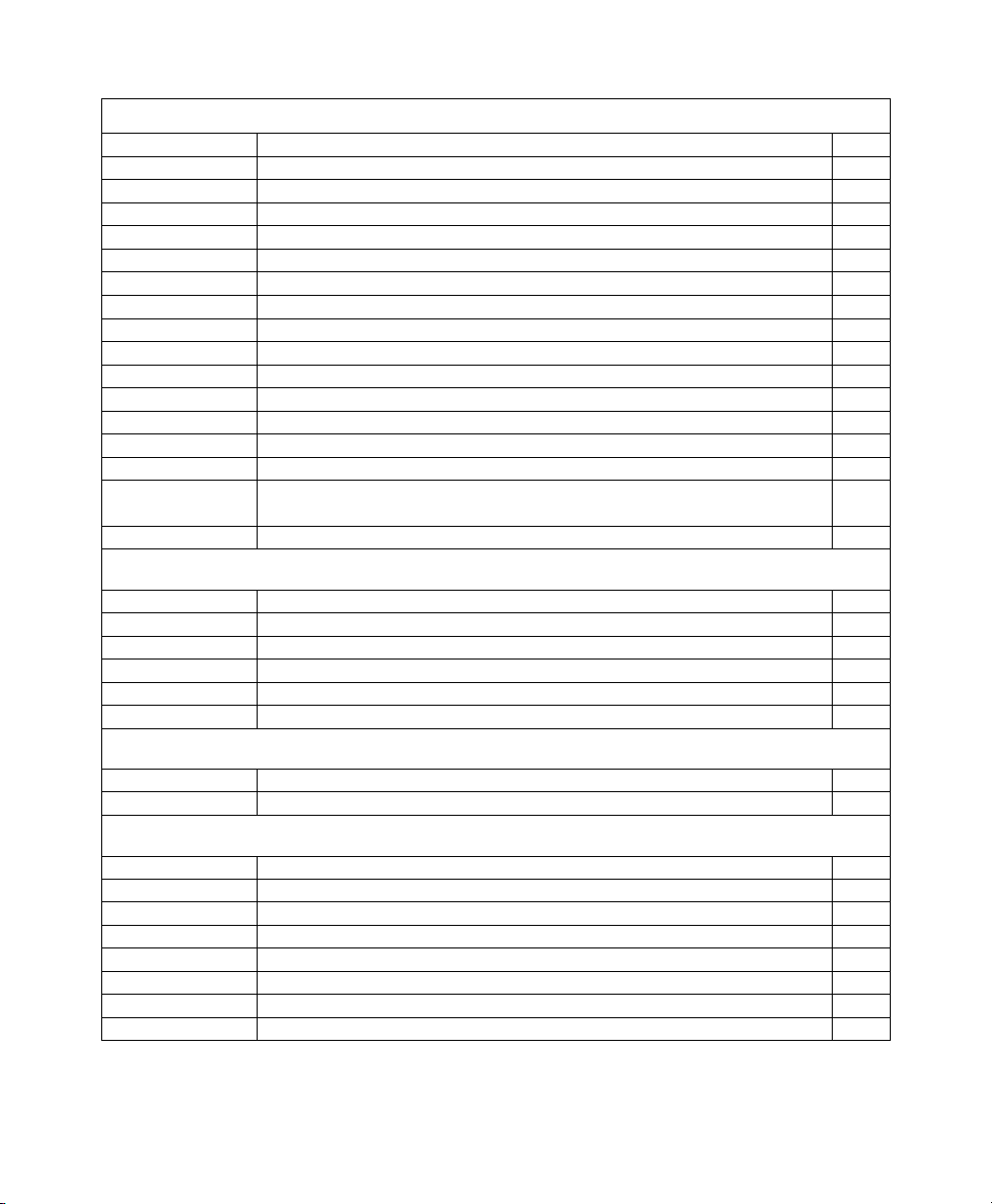

Table 3. Suggested Filter and BFO Settings. (Also see notes below.)

Mode

F L1

B F1 t (note 1)

F L2

B F2

F L3

B F3

F L4

B F4

CW

4913.6

4913.1

4913.1

4913.0

CW Rev.

OP1

(note 2)

4916.0

0.70

4914.3

0.40

4914.3

0.20

4914.2

LSB

( _________ )

From Page 10

4913.5

4913.0

4912.7

USB

OP1

( _________ )

From Page 10

OP1

4916.1

1.80

4915.5

OFF or

0.70

(note 3)

4914.7

Table 3 Notes

1. The LSB and USB BFO settings are derived from the filter crystal frequency (see page 10) to ensure

good SSB transmit performance. The lower-case t after B F1 is a reminder that these BFO settings

are always used on transmit, regardless of which filter you select for receive.

2. F L 1 on CW is set for OP1 since the SSB filter is ideal for casual CW tuning. The remaining CW

filters provide narrower bandwidths, and are centered at approximately 600 Hz.

3. F L 4 on LSB/USB is shown set to OFF, which means it will not be accessible with the X F I L button.

(Any filter can be turned off except for FL1.) To use this filter for PSK-31 or other data modes, set

FL4 to 0.70 or narrower. The BF4 settings shown provide a center frequency of about 1000 Hz.

Page 21

21

Using The SSB Adapter

Basic SSB Setup

Mode Selection: To use SSB, select LSB or USB using the M O D E button. Tap A G C to select S L O

AGC (recommended for all data modes).

Filter Selection and Setup: Use the X F I L button to select the desired receive-mode crystal filter. In SSB

modes you'll usually select FL2 , since the BFO settings for this filter have been optimized for receive (see

Table 3). In transmit, the BFO settings for FL1 are always used, regardless of what receive filter is

selected. This allows you to fine-tune the way your voice sounds on transmit (see SSB Transmit BFO

Optimization). For receive purposes, you can set up FL2, 3, and 4 according to Table 3 or modify these

settings for particular applications. For example, FL4 is shown set to OFF in the table (for SSB modes), but

it could be set to any desired bandwidth for voice or data.

Mic Gain: SSB A controls the mic's audio gain. Level 1 attenuates the mic audio by about 10 dB and is

useful when operating outdoors or mobile. (You can change R15 on the SSB adapter if you want a different

attenuation level.) Level 2 turns the mic attenuator off and is the recommended setting for normal indoor

operation. Level 3 is similar to level 2, but provides slightly better VOX sensitivity. BAL is used for

carrier balance adjustment, routing the SSB adapter's output directly to the receiver's I.F. input.

Speech Compressor Level: SSB C controls the speech compressor. 1-1 turns speech compression off.

This minimizes audio distortion for digital data modes. 2 -1 is the recommended setting for normal voice

operation. 3 -1 and 4-1 may be useful for contest or DX work.

Power/ALC Metering: On power-up, the K2 bargraph LED defaults to RF output metering. To select

ALC metering (automatic level control), hold R F / ALC . You'll see A L C flashed on the LCD. In ALC

metering mode, the LEDs illuminate from the right end of the display to distinguish ALC readings from RF

power readings. ALC readings are always shown in BAR mode. (See Power Control and ALC, below.)

Using PTT (SSB and CW modes): On power-up, the K2 defaults to PTT mode. You can also use a foot

switch connected to the DOT input (key jack). In CW mode, the mic button can be used as a hand key by

setting I NP to HA N D in the menu.

Using VOX: Using voice operated transmit (VOX), you can simply talk into the microphone to transmit.

To select VOX mode, hold the V O X button. You'll see SPC H 0. 2 flashed on the LCD. ("SPCH" means

"speech," and "0.2" means an 0.2-second hold time.) Holding the V O X button again selects SPC H 0 . 4

(0.4 second hold time), and holding again selects SPC H 1. 0 (1 second). The mode letter flashes slowly

as a reminder that the mic is "live." You'll need to keep the mic away from the K2's speaker, since the K2

does not provide "anti-vox" circuitry. This is usually not a problem since the K2's speaker faces upwards.

For mobile use or in other high-noise situations, you can set SSB A to 1 to reduce mic gain.

MIC Buttons: Either an UP or DOWN button on your mic can be used to switch between VFOs A and B,

assuming you have these lines connected. You'll hear one beep when VFO A is selected, two for VFO B.

Page 22

22

Power Control and ALC

Tracking ALC: SSB transceivers use Automatic Level Control (ALC) to reduce transmit drive if output

exceeds a desired level. Many transceivers require that you adjust the mic gain manually until the ALC

indication is in a certain range. The K2's ALC is different: the drive level is automatically adjusted, over

time, to keep ALC close to the optimal level. This tracking ALC (TALC) eliminates the need to adjust mic

gain in most cases. You can set the POWER control, mic gain, or speech compression to any level, and the

ALC level will average between 1 and 3 bars (in ALC meter mode) as you talk.

POWER control: This control is used to set the desired SSB peak power output. The maximum is about

10 to 15 watts PEP, depending on the band, antenna impedance, and power supply voltage.1 The minimum

power output in SSB modes is about 1 watt, even if you set the POWER control below this level. (If you set

the POWER level near maximum, the ALC indication will typically be between 0 and 2 bars. Low power

settings (3 watts or less) will result in about 3 bars on average.) Other POWER considerations:

1. Don't set the POWER control any higher than the transmitter is capable of. For example, if you

hold TUNE and find that you can only get to 9 watts on 10 meters even with the POWER control all

the way up, you should use POWER settings of 9 watts or less on 10 meters, in all modes.

2. Use lower power when using a battery. Don't use > 10 watts unless you're running from 13-15V.

3. Set CAL CUR to no more than 3.5 amps. This will allow the K2 to remind you when the PA

transistors are drawing too much current, so you can reduce power before they get too warm. If you

see a HI CUR warning message, reduce power until the warning goes away.

4. If you get a mic burn or a report that your signal is distorted: This is usually an indication that you

have high RF voltage on the K2 chassis due to the use of an end-fed or poorly-matched antenna. The

problem can be solved by using an RF Isolator, available from Elecraft and other manufactures.

5. Use 5 watts or less for digital data modes, since the duty cycle for digital modes can approach 100%.

Use 1:1 or 2:1 speech compression for minimum data distortion (SSB C 1 -1 or 2-1).

SSB Transmit BFO Optimization (Important)

When you transmit using SSB mode, the fixed filter on the SSB adapter is always used (OP1). The way

your voice sounds to other stations depends on the BFO settings for this filter (i.e., BF1 in CAL FIL).

Table 3 provides BF1 values for LSB and USB based on the measured crystal filter frequency (from page

10). However, you may have to experiment with these settings, adjusting them slightly to obtain best voice

quality. You can use another ham-band receiver, or ask a nearby station listen to your signal as you vary

BF1. Use CAL FIL, moving the BFO as much as +/- 200 Hz from the frequencies shown in Table 3. Start

with lower sideband, then upper. Moving the BFO too close to the filter will worsen carrier rejection, so be

sure to re-check carrier amplitude whenever you change the BFO setting.

Note: The BFO settings for LSB and USB are swapped on 15, 12 and 10 meters due to the K2's frequency

mixing scheme. If you use 17 m or below for making BFO changes, the following rules apply:

LSB: moving the LSB BFO lower in frequency will raise the voice pitch and improve carrier rejection.

USB: moving the USB BFO higher in frequency will raise the voice pitch and improve carrier rejection.

1

Operation above 10 watts PEP output may result in a small increase in transmit IMD.

Page 23

23

Troubleshooting

If you have difficulty during test or alignment, do the following:

1. Check the orientation of all ICs, diodes, transistors, electrolytic capacitors and resistor networks.

2. Look for unsoldered pins, solder splashes, or shorts to ground, especially in the area of the crystal filter.

3. Measure resistances to ground in the crystal filter area, checking each crystal, both resistor networks, all diodes,

numbered capacitors, and R5. Leads of these components should show not low resistance to ground.

4. Do the IC and filter switching diode voltage checks listed below. Be sure to set up the K2 exactly as described.

DC Voltage Charts

ICs: Voltages were measured under the following conditions: LSB mode, filter FL1 selected (OP1), VOX = PTT,

POWER set to 0.1W. Menu: SSBA = 3; SSBC = 2-1. Some IC ground pins are not listed.

IC/PIN

RX(V)

TX(V)

IC/PIN

RX(V)

TX(V)

IC/PIN

RX(V)

TX(V)

IC/PIN

RX(V)

TX(V)

U1-1

6.0

6.0

U1-17

6.0

5.6

U2-6

5.6

5.6

U3-14

6.0

6.0

U1-2

5.9

5.3-5.9

U1-18

6.0

6.0

U2-7

6.0

6.0

U4-1

0.0

0.0

U1-3

2.3

2.3

U1-19

0.0

0.0

U2-8

6.0

5.4

U4-2

2.2

2.2

U1-4

0.0

0.0

U1-20

6.0

6.0

U3-1

0.0

0.0

U4-3

0.6

0.6

U1-5

0.0

0.0

U1-21

5.8

0.1

U3-2

0.2

0.2

U4-5

2.2

2.2

U1-6

5.1

0.0

U1-22

0.2

0.0

U3-3

2.5

2.5

U4-6

5.1

0.0

U1-7

0.0

0.0

U1-23

0.0

0.0

U3-4

2.5

2.5

U4-7

0.0

0.0

U1-8

0.0

0.0

U1-24

0.0

0.0

U3-5

2.2

2.2

U4-8

6.0

6.0

U1-9

0.0

2.3

U1-25

0.0

0.8-1.2

U3-6

2.2

2.2

U5-1

0.0

1.4

U1-10

0.0

3.1

U1-26

0.0

0.0

U3-7

1.5

1.5

U5-2

0.0

1.4

U1-11

0.0

0.0

U1-27

0.0

0.0

U3-8

0.36

0.44

U5-4

0.0

3.4

U1-12

0.0

0.0

U1-28

5.6

2.4

U3-9

5.2

5.6

U5-5

0.0

4.8

U1-13

0.0

5.9

U2-1

6.0

5.6

U3-10

0.0

0.0-2.0

U5-6

0.0

5.9

U1-14

6.0

5.9

U2-2

6.0

5.9

U3-11

5.4

5.4

U5-7

0.0

5.1

U1-15

0.0

6.0

U2-3

6.0

6.0

U3-12

0.0

0.0

U5-8

0.0

5.9

U1-16

6.0

5.4

U2-5

0.6

0.6

U3-13

2.3

2.3

Filter Switching Diodes: Voltages were measured at the cathode (banded end) of each diode, in receive mode only.

For CW, use FL = 0.00-2.49 (selects variable bandwidth filter). For SSB, use FL = OP1 (selects fixed SSB filter).

Diode

CW(V)

SSB(V)

Diode

CW(V)

SSB(V)

Diode

CW(V)

SSB(V)

Diode

CW(V)

SSB(V)

D10

5.46D1260D646D8

4.6

1.4

D1160

D13

5.46D7

4.6

1.4D94

6

Circuit Details

RF Circuits: X1-X7 form an optimized, fixed-bandwidth SSB filter. T1 and T2 match the SSB filter's 1500-ohm

input/output impedance to the 150-ohm I.F. path. D6-D13 select either the fixed SSB filter or the CW filter, and also

provide T-R signal routing. D1 sets the overall TX gain via firmware (see Tracking ALC, above), while D2 provides

fast-attack ALC. Q2 and Q3 are emitter followers, buffering the transmit signal on either SSB or CW, respectively.

Audio and Control: Mic audio is amplified and compressed by U3. D-to-A converter U2 controls the ALC threshold

(via Q1), power scaling (D1), and VOX detection threshold (U4). U1 configures the SSB adapter under control of the

K2's main processor, via the 1-wire AuxBus network.

Page 24

24

Loading...

Loading...