Page 1

ELE C R A F T KR C 2

BA N D D E C O D E R a n d C O N T R O L L E R

Accessibility Upgrade and Operating Instructions

Revision A, March 4, 2004. Copyright © 2004, Elecraft; All Rights Reserved

Introduction

The KRC2 Accessibility Upgrade adds the capability of Morse code announcement of K2

functions. Along with this function, the KRC2 is configured to control K2 functions using KRC2

button combinations.

The upgrade kit adds two parts to the KRC2 circuit board, and replaces the KRC2’s

microcontroller.

If your KRC2 is not yet assembled, make the following changes to the Owner’s manual:

On page 13 of the KRC2 Assembly and operations Manual, between the first and second steps,

insert the two instructions from page 2 of these instructions for installing R5 and SP1. Use the test

procedures from these instructions for testing and initial power-up of the KRC2.

Firmware Requirements

The KRC2 Accessibility Configuration will work with any K2 or K2/100 transceiver with K2

main microcontroller firmware revision 2.01 or later and either the KIO2 or KPA100 options. In

order to use the KDSP2 support functions, the K2 is required to use firmware revision 2.04 or

later.

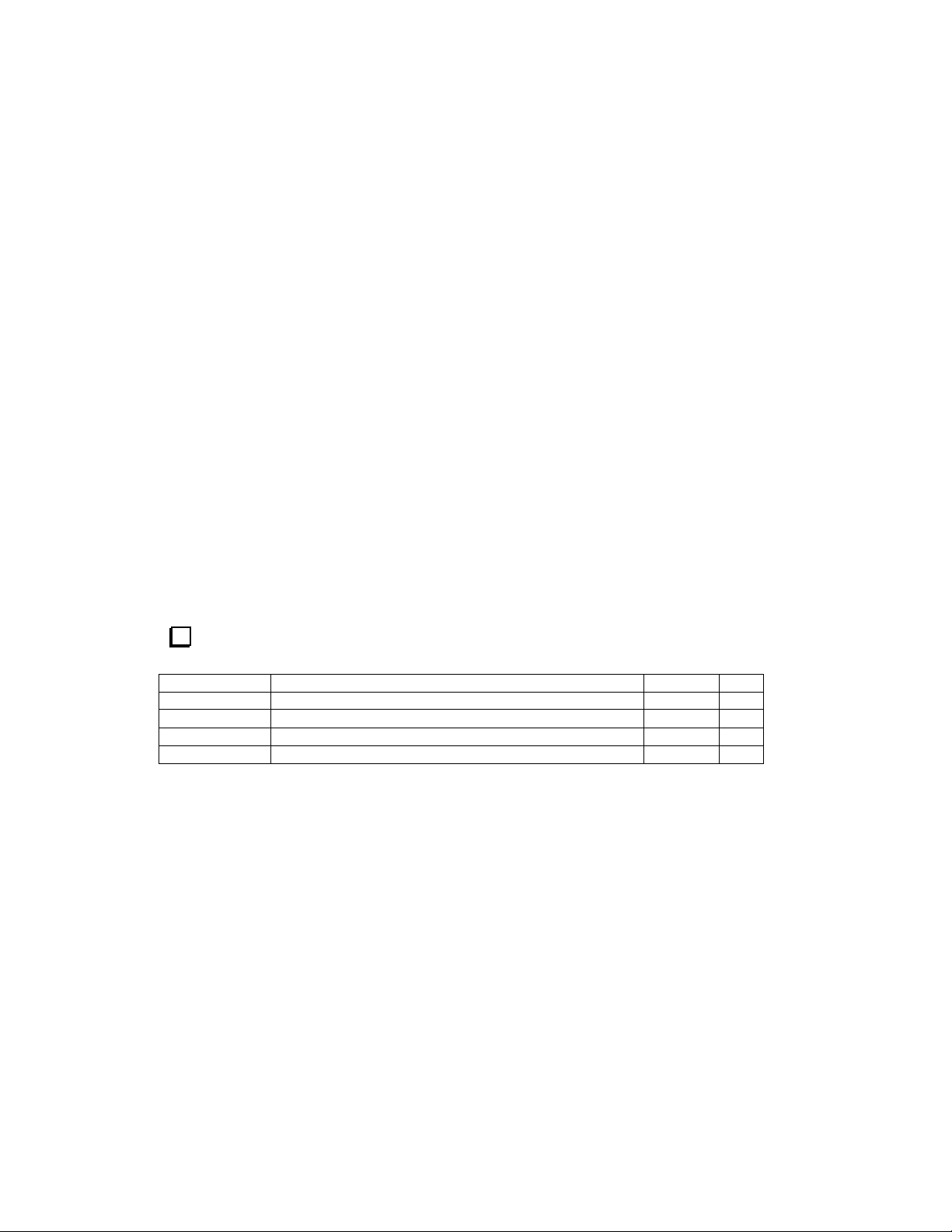

Upgrade Kit Parts List

The table below lists all parts in the kit. Typical markings on capacitors, as well as resistor

and RF choke color codes, are shown in parentheses.

Ref.

Description

Part No.

Qty

R5

Trimmer Potentiometer, 5K (“502”)

E520009

1

SP1

Miniature Piezo Speaker

E980064

1U1IC, programmed microcontroller, PIC16F877A-I/P

E610019

1

MISC

KRC2 Accessibility Upgrade Instructions

E740071

1

Page 2

2

Assembly

Disconnect all cables, including power sources, from the KRC2. Remove the two Philips

screws from the bottom cover and remove the bottom cover. CAUTION: Touch an unpainted,

grounded metal surface frequently while handling PC boards and ICs.

Remove the two flat-head Philips screws holding the “2D” fastener at the end of the case

opposite the DB9 connectors, and remove the “2D” fastener.

Remove the Philips screw and washer that holds the PCB to the case. This screw is located

near the end of the PC board opposite the DB9 connectors.

Remove the four male-female hex standoffs that hold the DB9 connectors to the case.

Remove the PCB assembly from the case.

i

The side of the board with IC U1 is the bottom; the opposite side is the top.

Install the 5K trimmer potentiometer, R5, on the bottom side of the PCB. After soldering the

three leads, adjust the pot to its full clockwise position. R5 is used for setting the volume of the

CW tones from the speaker.

Install the piezo speaker, SP1, on the top side of the PCB. The speaker mounting posts must

be mounted flush against the PCB to give proper clearance for the case bottom.

Carefully remove the old microprocessor, U1 using a small screwdriver to pry it gently out of

its socket at both ends. Store U1 in a safe place as a backup.

i

Before handling U1, touch an unpainted, grounded metal surface.

Carefully straighten the pins on the microcontroller, U1 (PIC16F877A). The two rows of pins

must be parallel to each other, with no pins bent. See Figure 4 of the KRC2 Assembly and

Operations Manual.

Orient the notched or dimpled end of the IC with the notched end of its component outline

on the PCB, then press the microcontroller into its socket

Page 3

3

Case Assembly

Re-install the PCB into the case top following the procedure on page 14 of the KRC2

Assembly and Operations Manual. Use the hardware you previously removed when

disassembling the KRC2.

KRC2 Test Procedure

The KRC2 should be powered from its DC barrel jack using a +12 volt supply for its initial

power-up. No other connections should be made to the unit.

Connect the power source to the unit. After a short delay while the KRC2 performs

diagnostics, the front-panel LED should turn on to its dim level. If this does not happen, turn

power off to the unit and refer to the troubleshooting section.

Driver Relay Test: You will need a DC voltmeter for this procedure. Connect the BLACK lead

(common) to the ground jumper located near J1 on the KRC2. The RED lead should be used to

measure the voltage on each terminal of J6, J7, J8 and J9. Be sure to check the voltage at the side

connector of each terminal. The initial readings should be 0 volts on each terminal.

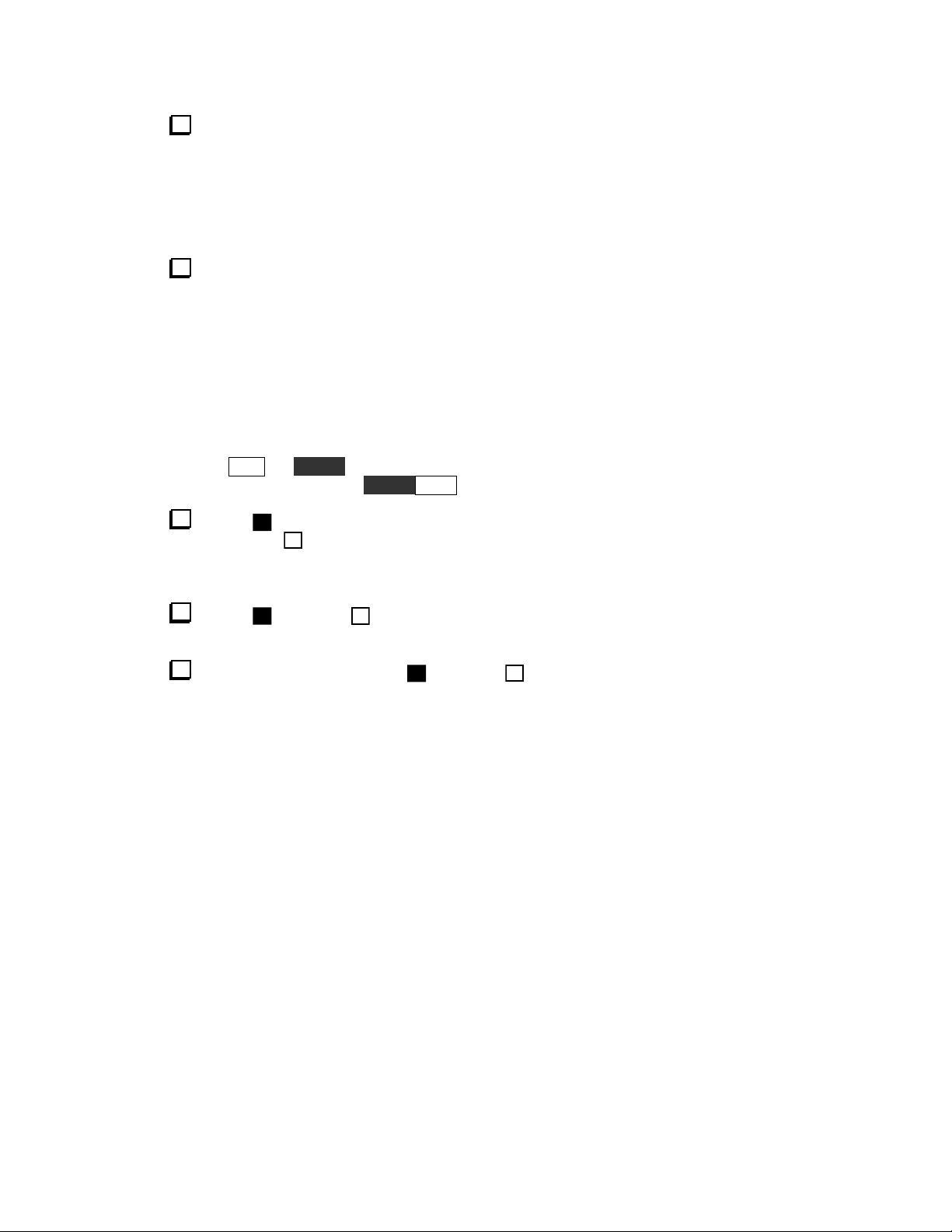

The Tap/Hold Rule: Each of the pushbutton switches on the top of the KRC2 has two functions,

one activated by a TAP (short press) and the other activated by a HOLD (long press, about 1/2

second). To highlight this in the text, we use two different typographical styles to identify

switches: T AP and H OLD . Shift functions require a key to be held, then a second key to be

pressed. These are indicated by HOL D TA P .

Holding

F3

should cause the KRC2 to announce a Morse ‘I’ from the speaker, and brighten

the LED. Now tap

F1

to change the driven band terminal. The KRC2 should emit a CW ‘D’. Only

the 60m source terminal should indicate 12 volts. The LED should be alternating between dim and

bright.

Holding F3 and tapping

F1

again should cause the 10m source terminal to indicate 12 volts,

and all others to remain off.

Continue this procedure, Holding F3 and tapping

F1

until all HF source terminals have been

checked.

This completes checkout of the KRC2. Continue to the Final Assembly section on page 16 of the

KRC2 Assembly and Operations Manual.

Page 4

4

KRC2 Accessibility Configuration Operation

The KRC2 with the Accessibility Configuration gives the K2 a Morse code voice to announce its

status and operational characteristics. The KRC2 may be set up to automatically announce changes

in the K2’s settings, including the announcement of the operating frequency whenever it changes.

The user may control the amount of chatter generated by the KRC2 by setting it to one of four

‘verbosity’ levels. The lowest level requires the user to press the KRC2’s keys in order to

announce K2 information, while the highest sends out Morse text whenever almost any parameter

changes on the K2, including the frequency. Additional button combinations allow the user to

control K2 operations and also those of the KRC2 itself.

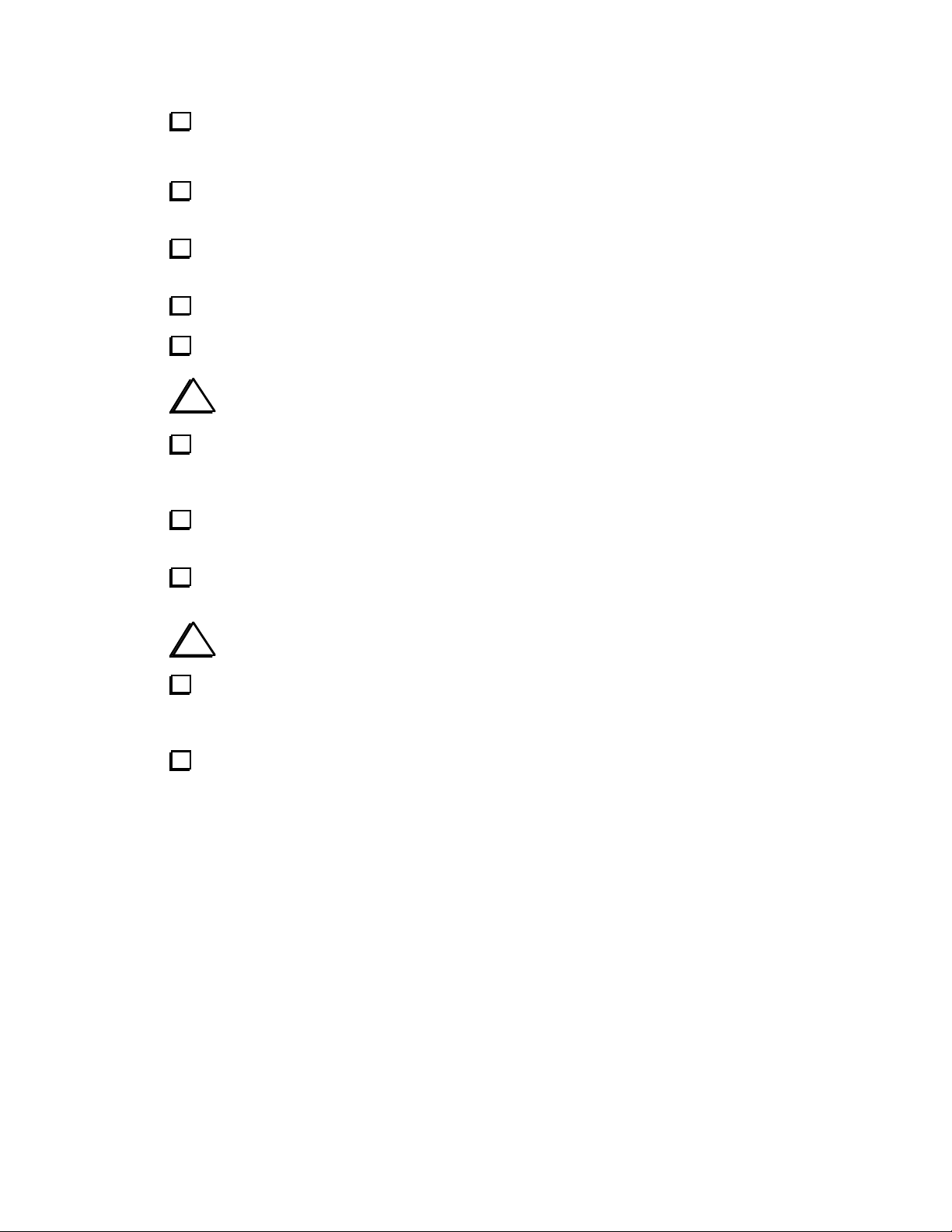

Accessibility Configuration Key Behavior

There are four buttons in a row on the top of the KRC2, labeled, from left to right, F1, F2, F3 and

F4. In the accessibility configuration, the F1-F4 buttons have the following TAP, HOL D and

HOL D TA P (shift) functions:

F 1 Announce the kilohertz portion of the current K2 frequency.

F 2 Announce the K2 LCD display text.

F 3 Announce the K2 S-Meter level.

F 4 Place K2 in direct frequency entry mode.

F 1 Holding this button will cause a Morse ‘I’ to be announced and the KRC2 to enter

shift-1 condition. Tapping a button will then cause one of the functions listed below

to be performed.

F 1 Announce the megahertz portion of the current K2 frequency.

F 2 Toggle Fine RIT mode.

F 3 Announce RIT status.

F 4 Announce XIT status.

Holding F 1 instead of tapping a key will again announce a Morse ‘I’, but will cancel

the shift-1 condition.

F 2 Holding this button will cause a Morse ‘I’ to be announced and the KRC2 to enter

shift-2 condition. Tapping a button will then cause one of the functions listed below

to be performed.

F 1 Announce AGC status.

F 2 Toggle RxAnt on/off.

F 3 Toggle KDSP2 Noise Reduction on/off.

F 4 Toggle KDSP2 noise Threshold on/off (USB/LSB modes only).

Holding F 2 instead of tapping a key will again announce a Morse ‘I’, but will cancel

the shift-2 condition.

The KDSP2 control functions require the K2 to have firmware version 2.04 or higher and the

KDSP2 to have control firmware version 3.10 or higher.

Page 5

5

F 3 Holding this button will cause a Morse ‘I’ to be announced and the KRC2 to enter

shift-3 condition. Tapping a button will then cause one of the functions listed below

to be performed.

F 1 Decrease KRC2 selected antenna terminal.

F 2 Increase KRC2 selected antenna terminal.

F 3 Announce current KRC2 antenna selection.

F 4 Announce KRC2 firmware version.

Holding F 3 instead of tapping a key will again announce a Morse ‘I’, but will cancel

the shift-3 condition.

F 4 Holding this button will cause a Morse ‘I’ to be announced and the KRC2 to enter

shift-4 condition. Tapping a button will then cause one of the functions listed below

to be performed.

F 1 Decrease KRC2 CW announcement speed by about 3 wpm.

F 2 Increase KRC2 CW announcement speed by about 3 wpm.

F 3 Increase CW tone frequency (500Hz, 600 Hz, 750 Hz, 1000 Hz).

F 4 Increase Announcement verbosity level.

Holding F 4 instead of tapping a key will again announce a Morse ‘I’, but will cancel

the shift-4 condition.

The F 3 F 1 and F 3 F 2 functions change the output terminal for the relay drivers up or down in

single band increments. When the highest band is selected, the next F 3 F 2 sequence will cause

the drivers to go to the 160m setting. Conversely, when the lowest band is selected, the next usage

of the F 3 F 2 function causes the drivers to go to the highest band. The band map follows the

values indicated in Table 5 of the KRC2 Assembly and Operations Manual, which places the 60m

band above the 10m band. Thus the sequence will be:

…12m<->10m<->60m<->160m<->80m<->40m… While the selected driver is different from the

current band indicated by the transceiver, the green LED will flash between dim and bright states.

The XVT drivers do not participate in the sequence, and when the transceiver selects a transverter

these buttons will not change the driver selection.

KRC2 Accessibility Configuration Jumper Settings

The KRC2’s W1-W8 jumpers should be set for K2 operation. Thus W1, W2 and W3 should be

removed in order to allow the K2’s AuxBus to indicate band settings to the KRC2. These jumpers

may also be set for Serial Port Mode, which disables AuxBus processing in the KRC2. This

setting may be preferred since AuxBus processing tends to disturb the timing of the KRC2’s

Morse code characters. With this setting, the KRC2 will automatically set the antenna selector

outputs based on serial port frequency information.

The W6 jumper should also be installed for normal use to enable the K2 to automatically report

changes. If the K2/KRC2 is used with a computer, you may want to remove this jumper since the

automatic status messages may interfere with the operation of software on the computer.

Page 6

6

Determination of the proper setting of this jumper when used with third-party software is left to

the user to determine.

The following chart summarizes the functions for each key.

ConditionF1F2F3F4

Tap

Announce KHz of

frequency

Announce LCD

text

Announce S-

Meter Value

Set K2 for Direct

Frequency Entry

Hold

Set shift-1

Set shift-2

Set shift-3

Set shift-4

Shift-1

Announce MHz

of Frequency

Toggle Fine RIT

Announce RIT

Status

Announce XIT

Status

Shift-2

Cycle AGC

Switch Rx Ant

KDSP2 NR

On/Off

KDSP2 NT

On/Off

Shift-3

Decrement KRC2

Antenna Selection

Increment KRC2

Antenna

Selection

Announce KRC2

Antenna

Selection

Announce KRC2

Version

Shift-4

Decrease Morse

Announce Speed

Increase Morse

Announce Speed

Increment Morse

Tone Frequency

Increase

Verbosity Level

KRC2 Accessibility Configuration Event Operations

The KRC2 operates by listening for information from the K2 over the serial port or from the keys,

then performing some operation. The incoming information creates an event, which causes an

operation to be executed. There are four levels of event detection that may be set by the user. In

the accessibility configuration, these are used to set the amount of information announced by the

KRC2. Thus at level 1, only information requested by the KRC2 is announced. At level 2, this

information is extended to include button and knob changes from the KRC2, but does not include

frequency QSY changes within a single band. The third and fourth levels add this information,

with minimal identification information added at level 3, and full identifiers used at level 4. The

listing below shows, for each level, the events that the accessibility configuration recognizes and

the action taken.

Status information for on/off parameters is announced with an ‘F’ for Off, and an ‘N’ for On.

Normal Morse numeric characters are used in values, except for the 0, which is shortened to an

extra long ‘dah’. The letter ‘R’ is replaces a decimal point or period.

Page 7

7

Level Event Operation

All Hold F1 Set Shift-1, Announce 'I'

All Hold F2 Set Shift-2, Announce 'I'

All Hold F3 Set Shift-3, Announce 'I'

All Hold F3 Set Shift-4, Announce 'I'

All Tap F1 Announce KHz portion of frequency

All Tap F2 Get and Announce LCD Text

All Tap F3 Get and Announce S-meter value

All Tap F4 Put K2 in direct Freq Entry mode, Announce 'F'

All Hold F1 & Tap F1 Announce MHz portion of frequency

All Hold F1 & Tap F2 Toggle K2 Fine RIT, Announce 'E'

All Hold F1 & Tap F3 Announce RIT status. If on, announce RIT offset

All Hold F1 & Tap F4 Announce XIT status. If on, announce XIT offset

All Hold F2 & Tap F1 Increment AGC in Off, fast, slow cycle - note fast indicated by '2',

slow indicated by '4'

All Hold F2 & Tap F2 Toggle K2 RxAnt, announce 'E'

All Hold F2 & Tap F3 Toggle KDSP2 NR, announce 'E'

All Hold F2 & Tap F4 Toggle KDSP2 NT, announce 'E'

All Hold F3 & Tap F1 Decrement KRC2 band selection, announce 'D'

All Hold F3 & Tap F2 Increment KRC2 band selection, announce 'U'

All Hold F3 & Tap F3 Announce KRC2 band selection

All Hold F3 & Tap F4 Announce KRC2 firmware version

All Hold F4 & Tap F1 Decrease KRC2 Morse speed, announce 'S'

All Hold F4 & Tap F2 Increase KRC2 Morse speed, announce 'S'

All Hold F4 & Tap F3 Increment KRC2 Morse tone frequency, announce 'T'

All Hold F4 & Tap F4 Increment KRC2 verbosity level, announce level

2 K2 Keyer Speed change Announce Keyer Speed

2 K2 Tx Power Change Announce 'P', Tx Power

2 K2 Band Change Announce Rx VFO, Band MHz, 'M'

2 K2 Mode Change Announce Mode

2 K2 AGC Change Announce 'G', AGC setting

2 KAT Antenna Change Announce 'AN', KAT antenna selection

2 K2 Attenuator Change Announce 'AT', Attenuator status

2 K2 AFIL Change Announce 'A', AFIL setting

2 K2 XFIL Filter Change Announce 'F', XFIL setting

2 K2 Noise Blanker Change Announce 'NB', Noise Blanker status

2 K2 NB Level Change Announce 'NT', NB Level setting

2 K2 Rx Preamp Change Announce 'PR', Preamp status

2 K2 RIT Change Announce 'R', RIT status

2 K2 XIT Change Announce 'X', XIT status

2 K2 Rx VFO Change Announce 'R', VFO identifier

2 K2 Tx VFO Change Announce 'T', VFO identifier

Page 8

8

Level Event Operation

3 K2 Keyer Speed change Announce Keyer Speed

3 K2 Tx Power Change Announce 'P', Tx Power

3 K2 Band Change Announce Rx VFO, Band MHz, 'M'

3 K2 Mode Change Announce Mode (one character only)

3 K2 AGC Change Announce 'G', AGC setting

3 KAT Antenna Change Announce 'AN', KAT antenna selection

3 K2 Attenuator Change Announce 'AT', Attenuator status

3 K2 AFIL Change Announce 'A', AFIL setting

3 K2 XFIL Filter Change Announce 'F', XFIL setting

3 K2 Noise Blanker Change Announce 'NB', Noise Blanker status

3 K2 NB Level Change Announce 'NT', NB Level setting

3 K2 Rx Preamp Change Announce 'PR', Preamp status

3 K2 RIT Change Announce 'R', RIT status

3 K2 XIT Change Announce 'X', XIT status

3 K2 RIT/XIT Offset Change Announce 'OF', Offset value

3 K2 Rx VFO Change Announce 'R', VFO identifier

3 K2 Tx VFO Change Announce 'T', VFO identifier

3 K2 VFO A QSY Announce 'A', VFOA KHz portion of frequency

3 K2 VFO B QSY Announce 'B', VFOA KHz portion of frequency

3 RxAnt Change Announce 'RX', RxAnt status

4 K2 Keyer Speed change Announce Keyer Speed

4 K2 Tx Power Change Announce 'P', Tx Power

4 K2 Band Change Announce Rx VFO, Band MHz, 'M'

4 K2 Mode Change Announce Mode (long format)

4 K2 AGC Change Announce 'G', AGC setting

4 KAT Antenna Change Announce 'AN', KAT antenna selection

4 K2 Attenuator Change Announce 'AT', Attenuator status

4 K2 AFIL Change Announce 'A', AFIL setting

4 K2 XFIL Filter Change Announce 'F', XFIL setting

4 K2 Noise Blanker Change Announce 'NB', Noise Blanker status

4 K2 NB Level Change Announce 'NT', NB Level setting

4 K2 Rx Preamp Change Announce 'PR', Preamp status

4 K2 RIT Change Announce 'R', RIT status

4 K2 XIT Change Announce 'X', XIT status

4 K2 RIT/XIT Offset Change Announce 'OF', Offset value

4 K2 Rx VFO Change Announce 'R', VFO identifier

4 K2 Tx VFO Change Announce 'T', VFO identifier

4 K2 VFO A QSY Announce 'A', VFOA KHz portion of frequency, 'K'

4 K2 VFO B QSY Announce 'B', VFOA KHz portion of frequency, 'K'

4 RxAnt Change Announce 'RX', RxAnt status

Loading...

Loading...