Page 1

Elecraft • www.elecraft.com • 831-662-8345

ELE C R A F T KR C 2

BA N D D E C O D E R a n d C O N T R O L L E R

Assembly and Operating Instructions

For firmware Version 1.5 and later

Revision C, May 1, 2008. Copyright © 2004-2008, Elecraft; All Rights Reserved

Introduction

The KRC2 is a universal, programmable station control unit that can switch any combination of

antennas, filters, amplifiers, or other equipment. It supports analog, digital, and RS232 control

inputs, so it's compatible with transceivers from Elecraft as well as other manufacturers. Decoded

outputs are provided for all HF bands (including WARC bands and 60m), three transverter bands,

and general accessories. High-side (source) and low-side (sink) relay drivers are included. All

signal lines are RF bypassed to minimize RFI and noise pickup.

Individual driver outputs can be wire-ORed. However, the KRC2 also provides a PC-based

command interface, allowing the user to configure the unit. New firmware can even be

downloaded via the Internet.

Additional features are available when the KRC2 is used with our K2, K2/100, K3 and K3/100

transceivers. The ACC menu entry can be used to directly control the KRC2's accessory outputs.

Four buttons on the top of the KRC2 can be used as "hot keys" for instant access to CW message

buffers, fast switching of the RXANT jack, or other functions.

Specifications

Outputs 32 (16 sink, 16 source)

Output Driver Ratings 500 mA max, 50 V max (sink and source)

Analog Inputs 0-5 V (1 input), 0-10 V (2 inputs)

Band Decode Formats Elecraft, Icom, Yaesu, Kenwood

1

Internal Current Drain Approx. 20 mA (excludes output driver current)

Size 5.5" (L) x 3.5" (D) x 1.5" (H) (14 x 11.4 x 4 cm)

i

Caution: Some parts in this kit can be damaged by static discharge. Before handling any

transistors or ICs, put on an anti-static wrist strap, or touch a grounded, unpainted metal surface.

1

Refer to our web site for a complete listing of compatible formats and transceivers.

Page 2

2

Table of Contents

Specifications

....................................................

1

Parts Inventory

..................................................

2

Firmware Requirements

....................................

5

Assembly

...........................................................

5

Case Assembly

................................................

14

KRC2 Test Procedure

.....................................

15

KRC2 Final Assembly

....................................

16

K2 to KRC2 Control Cable Assembly

...........

16

Using the KRC2

..............................................

18

KRC2 Jumper Configuration

..........................

20

KRC2 Power Connections

...............................

25

Connecting the KRC2’s Drivers

.....................

25

Connecting other Elecraft Peripherals

............

25

KRC2 PC Connections

....................................

25

Using the KRC2 with non-Elecraft Radios

....

26

Troubleshooting

...............................................

27

DC Voltage Chart

............................................

28

Circuit Details

..................................................

29

PCB Layout

......................................................

31

Customer Service Information

........................

34

Page 3

3

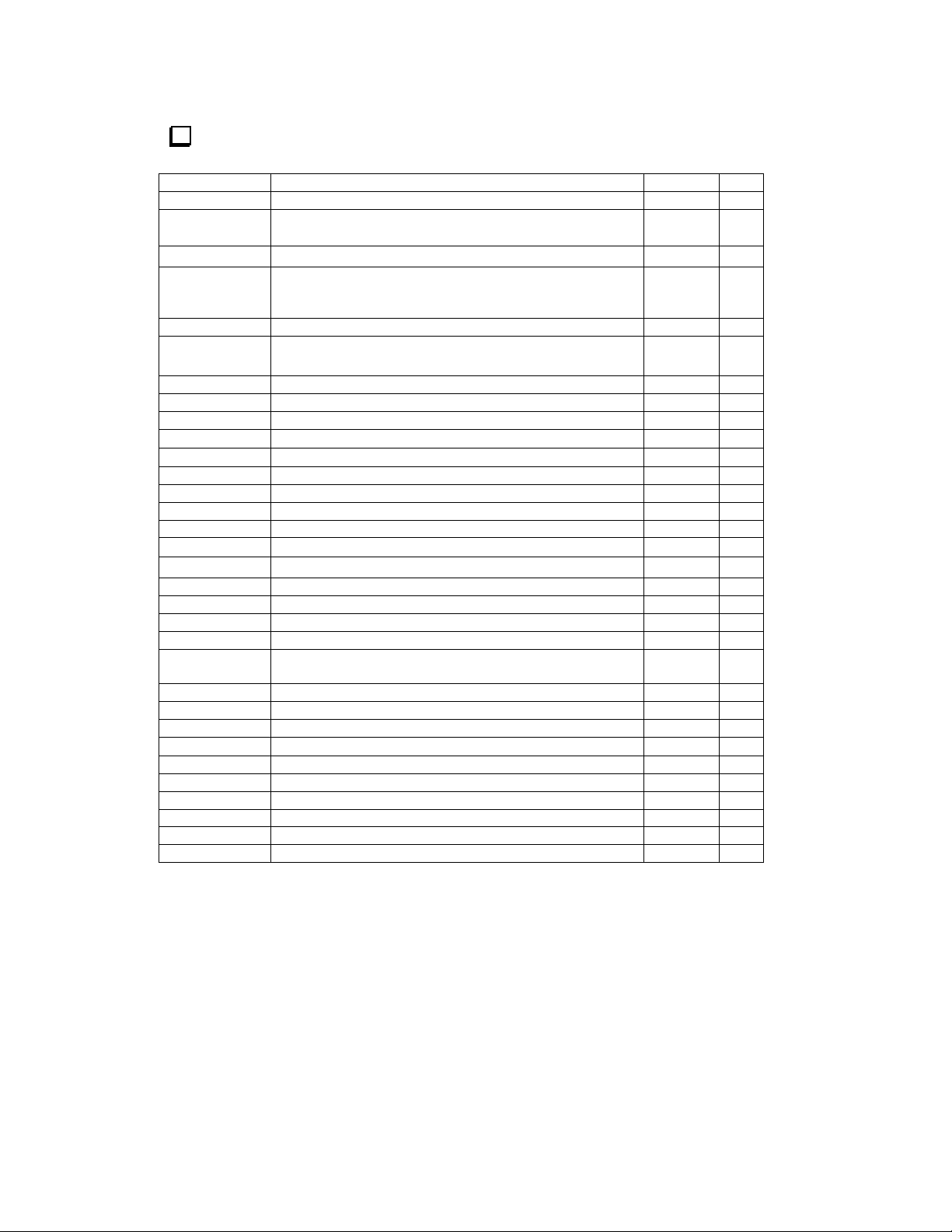

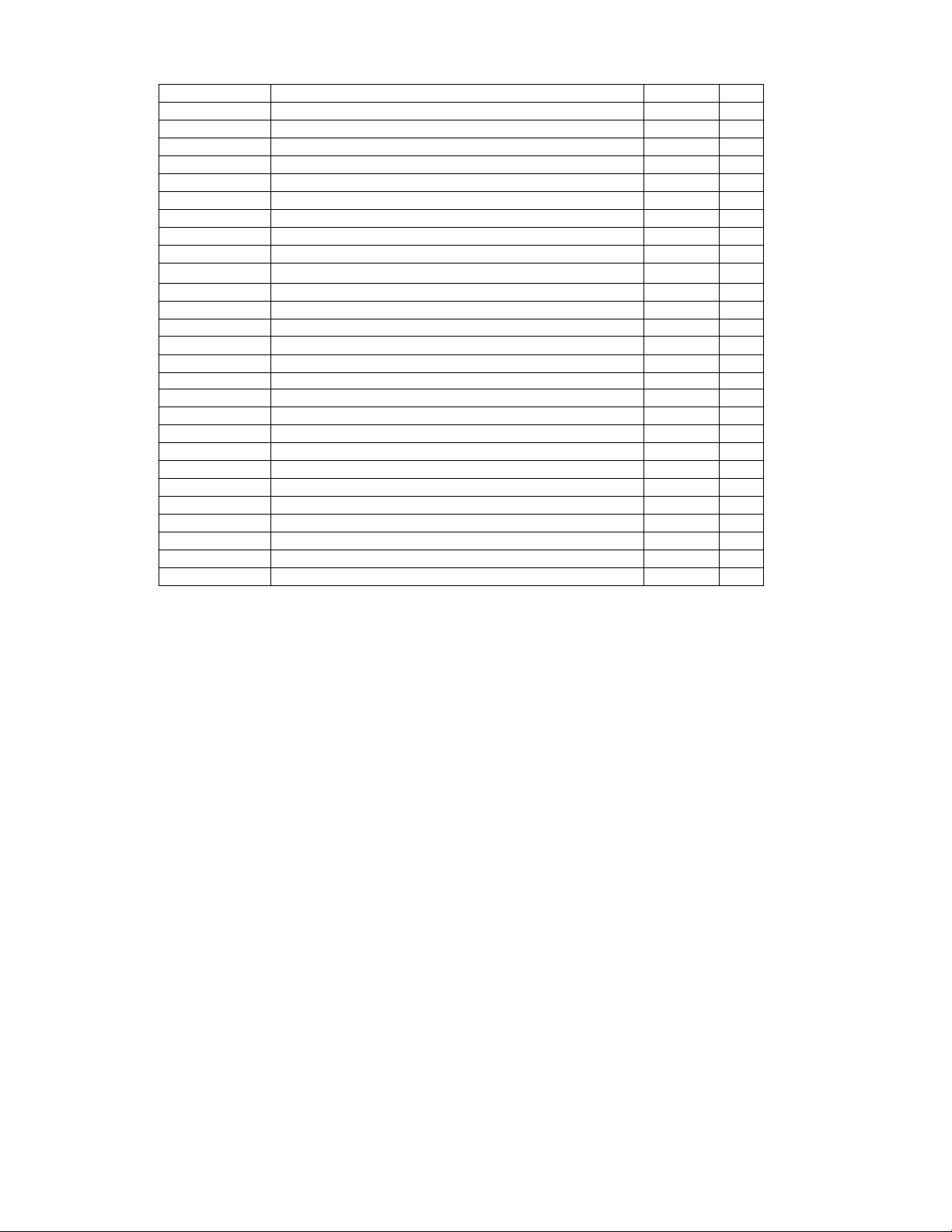

Parts Inventory

The table below lists all parts in the kit. Typical markings on capacitors, as well as resistor

and RF choke color codes, are shown in parentheses.

Ref.

Description

Part No.

Qty

C1, C2

Capacitor, 33 pF ("33" or "330")

E530064

2

C3 - C6,

C8-C11

Capacitor, .001 µF (“102”), 0.2" lead spacing

E530001

8

C7

Capacitor, .001 µF (“102”), 0.1" lead spacing

E530129

1

C16, C17,

C21-C24,

C28-C59

Capacitor, .01 µF ("103"), 0.1" lead spacing

E530019

39

C12

Capacitor, electrolytic, 220 µF

E530062

1

C13, C14,

C20, C26, C27

Capacitor, .1 µF ("104"), 0.2" lead spacing

E530011

5

C15

Capacitor, electrolytic, 10 µF

E530045

1

C18

Capacitor, 120 pF ("121")

E530077

1

C19

Capacitor, 56 pF ("56" or "560")

E530015

1

C25, C60

Capacitor, .1µF (“104”), 0.1" lead spacing

E530020

2

D6-D10

Diode, 1N4148

E560002

5

D2-D5

Diode, 1N4007

E560001

4

DS1

LED, green, rectangular

E570008

1J1PC-Mount Connector, DB9 Female

E620058

1J2PC-Mount Connector, DB9 Male

E620068

1

J3

Connector, DC barrel power 2.1mm

E620026

1

J4-J13

Connector, screw terminal

E700079

10

L1-L3

Inductor, 100 µH mini (brn-blk-brn)

E690013

3

L4

Inductor, 15 µH mini (brn-grn-blk)

E690012

1

Q1

Transistor, J310 JFET

E580012

1R1Resistor, 47 k, 1/4 watt, 5% (yel-vio-org)

E500067

1

R2, R6-R8,

R10, R11

Resistor, 10 k, 1/4 watt, 5% (brn-blk-org)

E500015

6

R3

Resistor, 1 k, 1/4 watt, 5% (brn-blk-red)

E500013

1R4Resistor, 470 ohms, 1/4 watt, 5% (yel-vio-brn)

E500003

1R9Resistor, 100 ohms, 1/4 watt, 5% (brn-blk-brn)

E500010

1

R12

Resistor, 4.7 k, 1/4 watt, 5% (yel-vio-red)

E500047

1

R13

Resistor, 47 ohms, 1/4 watt, 5% (yel-vio-blk)

E500019

1

R14

Resistor, 4.7 k, 1/8 watt (yel-vio-red)

1

RP1

Resistor network, 390 ohms, 4 resistors, 8 pins (391)

E510021

1

RP2

Resistor network, 47 k, 7 resistors, 8 pins (473)

E510022

1

S1- S4

Momentary push button switch

E640005

4

S5

Miniature slide switch, DPDT

E640009

1

Page 4

4

U1

IC, programmed microcontroller, PIC16F877A-I/P

E610013

1

U2

IC, MAX1406 or LT1039

E600036

1U3IC, voltage regulator, 5V, 78L05

E600029

1

U4, U5

IC, UCN5891A

E600049

2

U6, U7

IC, TPIC6595

E600048

2X1Crystal, 4.0 MHz

E660006

1

X2

Crystal, 16.2 MHz (S162ECSL)

E660014

1

HDWR

2-D Fasteners

E100078

2

HDWR

1/4 x 3/16” round threaded standoff

E700026

1

HDWR

4-40x3/16” flat head Philips machine screw, black oxide

E700025

5

HDWR

4-40x3/16” pan head Philips machine screw, black oxide

E700015

3

HDWR

#4 internal-tooth lock washer

E700010

3

HDWR

#4 Standoff, hex male-female (for DB9 connectors)

E700078

4

MISC

Jumper, 2-pin shorting (for W1-23)

E620055

23

MISC

KRC2 Printed Circuit board

E100163

1

MISC

IC socket (for U1), 40 pins

E620017

1

MISC

Keycap, rectangular, black for pushbuttons

E980000

4

MISC

Rubber foot, self-adhesive

E700024

4

MISC

Connector, dual-row 16-pin male header

E620010

3

MISC

Cable Tie, 3-inch

E980002

2

MISC

8-conductor shielded cable

E760014

2 ft

MISC

9-pin female “D” connector (DB9F)

E620048

1

MISC

9-pin male “D” connector (DB9M)

E620049

1

MISC

DB9 backshell assembly

E620050

2

MISC

Case Top Shell

E100166

1

MISC

Case Bottom Shell

E100167

1

MISC

2.1mm DC Barrel plug

E620032

1

MISC

KRC2 Manual

E740047

1

The following ICs are packed on a piece of black foam for their protection:

E580012 J310

E610013 programmed PIC16F877A microcontroller chip

E600036 MAX1406

E600049 UCN5891A

E600048 TPIC6595

E620017 40 pin socket

Page 5

5

Firmware Requirements

To use the KRC2 with a K2 or K2/100 transceiver, you will need K2 main microcontroller

firmware revision 2.01 or later and either the KIO2 or KPA100 options.

Note: The main K2 microcontroller is U6 on the K2 Control board. To check your firmware

revision, hold any K2 pushbutton when powering up the K2. When you release the pushbutton, the

revision will be shown on the LCD (left side).

Assembly

i

A fine-point, temperature-controlled soldering iron (700-800 degrees F maximum) is

required to assemble the printed circuit board. A higher-wattage iron or one with a wide tip

may damage components, pads, or traces. We also recommend the use of a Panavise (or

equivalent bench vise) and an illuminated magnifying glass to facilitate PCB and connector

assembly. Additionally, flush-cut wire cutters are recommended for steps where component

leads must be cut close to the circuit board.

i

To avoid soldering conflicts, install components only in the order described below.

Double-check all values before soldering, since removing parts from double-sided printed circuit

boards can be difficult.

i

The leads on small capacitors can be fragile. When handling capacitors in the

following steps, do not pull on the leads or bend them excessively.

Locate the KRC2 PCB and identify the top and bottom sides. The side of the board with

outlines of ICs U4-U7 and most other components is the top; the side with the "KRC2" label is

the bottom. If an assembly step does not specify top or bottom, the component should be installed

on the top side.

Install the two 0.1-µF (104) capacitors with 0.1" (2.5 mm) lead spacing on the top side of the

board:

__C25, __C60

Solder C25 and C60. Trim the leads of C25 as short as possible, using flush-cutters if

available. If the leads are not kept very short, they will interfere with installation of J5 on the

bottom side of the board.

Page 6

6

On the top side of the board, install the 0.01 µF (103) capacitors with 0.1" (2.5 mm) lead

spacing listed below, beginning with C28 in the upper center of the board and proceeding in a line

to the end of the board. After installing each capacitor, bend the leads outward to hold it in place.

The capacitors line up so that you can solder them in one step after inserting them into the circuit

board. You may solder the components in smaller groups if desired.

Note: When multiple items appear on one line in a component list such as the one below,

complete all items on one line before moving on to the next, as indicated by the small arrow. (In

other words, install C28 first, then C29, C30 and C31, then go to the second line.)

__C28, __C29, __C30, __C31,

__C32, __C33, __C34, __C35,

__C24, __C23, __C22, __C21,

__C44, __C45, __C46, __C47,

__C48, __C49, __C50, __C51

Solder the fixed capacitors. After soldering the leads of the capacitors, be sure to flush trim

the leads so that terminals J6, J8, J10 and J12 will seat properly on the bottom side of the PCB

when they are installed later in these instructions.

On the top side of the board, install the small 0.01 µF (103) capacitors with 0.1" (2.5 mm)

lead spacing listed below, beginning with C36 in the upper right of the board and proceeding to

the end of the board. After installing each capacitor, bend the leads outward to hold it in place.

__C36, __C37, __C38, __C39,

__C40, __C41, __C42, __C43,

__C52, __C53, __C54, __C55,

__C56, __C57, __C58, __C59

Solder the small fixed capacitors. After soldering the leads of the capacitors, be sure to flush

trim the leads so that terminals J7, J9, J11 and J13 will seat properly on the bottom side of the

PCB when they are installed later in these instructions.

Install the three remaining small 0.01 µF (103) capacitors with 0.1” (2.5mm) lead spacing

listed below on the top side of the PCB:

__C7, __C16, __C17

Solder the small fixed capacitors.

Note: For all remaining assembly steps, you should solder then trim component leads after

installing each group of components unless otherwise instructed. Leads can be trimmed before or

after soldering, but trim them as short as possible.

Page 7

7

Install the two 33pF ceramic disk capacitors on the top side of the PCB. Note that the lead

spacing for C1 and C2 may be too wide for the holes in the PC board. If so, use a pair of needlenose pliers to crush the ceramic ‘flash’ which covers the leads up close to the body of the capacitor

and then re-bend the leads so they fit the available holes and scrape away the crushed flash debris.

__C1, __C2

Install the following 0.1µF (104) capacitors with 0.2” (5.0mm) lead spacing on the top side

of the PCB:

__C13, __C14, __C20, __C26, __C27

Install the following 0.001µF (102) capacitors with 0.2” (5.0mm) lead spacing on the top

side of the PCB:

__C3, __C4, __C5, __C6

Install the following miniature inductors on the bottom side of the circuit board. The

components should be mounted vertically, with one end resting on the pc board and the lead of the

other end bent down into the corresponding solder pad. You should also alternate the orientation

of the RF chokes, with L1 and L3 mounted towards the left and L2 mounted to the right. Then

solder and trim the leads.

__L1 100µH Inductor, (brn-blk-brn)

__L2 100µH Inductor, (brn-blk-brn)

__L3 100µH Inductor, (brn-blk-brn)

Install L4, a 15µH miniature inductor (brn-grn-blk) on the top side of the PCB.

Install C18, a 120pF (121) capacitor, with 0.1” (2.5mm) lead-spacing on the top side of the

PCB.

Install C19, a 56pF (560) capacitor, with 0.1” (2.5mm) lead-spacing on the top side of the

PCB.

Install the following 0.001µF (102) capacitors with 0.2” (5.0mm) lead spacing on the top

side of the PCB:

__C8, __C9, __C10, __C11

Page 8

8

Install the following resistors on the top side of the circuit board. Be sure to use the 4.7k 1/4

watt resistor at R12. The smaller 1/8 watt resistor will be used later.

__R1 47k, (yel-vio-org)

__R3 1k, (brn-blk-red)

__R4 470 ohms, (yel-vio-brn)

__R6 10K (brn-blk-org)

__R7 10K, (brn-blk-org)

__R8 10K, (brn-blk-org)

__R9 100 ohms, (brn-blk-brn)

__R10 10K, (brn-blk-org)

__R12 4.7K, 1/4 watt (yel-vio-red)

__R13 47 ohms, (yel-vio-blk)

Install two 1N4007 diodes D4 and D5 on the top side of the board. Make sure the cathode

(banded end) of the diodes follow the same orientation as that silk-screened on the PCB then

solder and trim the leads. D5 must be flush-trimmed on the bottom side in order not to interfere

with J5. Be sure to save these cut leads for later use as ground jumpers.

__D4, __D5

Install the following 1N4148 diodes on the top side of the board. Make sure the cathode

(banded end) of each diode follows the same orientation as that silk-screened on the PCB, then

solder and trim the leads.

__D6, __D7, __D8, __D9, __D10

i

Before handling ICs and transistors, touch an unpainted, grounded metal surface.

Install voltage regulator U3 (78L05C) on the top side of the board as indicated by its outline.

The voltage regulator has a 3-pin TO-92 package, like a transistor. The installed height of the

regulator must be no more than 3/8" (9 mm). Use a minimum of soldering time (1-2 seconds per

lead).

Locate the four pushbutton switches. One of these will now be installed on the top side of the

board. Insert the switch into its mounting holes at S1, spreading the legs slightly so they will

properly engage the holes. Press the switch down until it is fully seated on the bends in its leads.

When the switch is fully seated, there will be a slight gap between the switch body and PCB. This

is normal. Solder the switch onto the circuit board from the bottom side.

Page 9

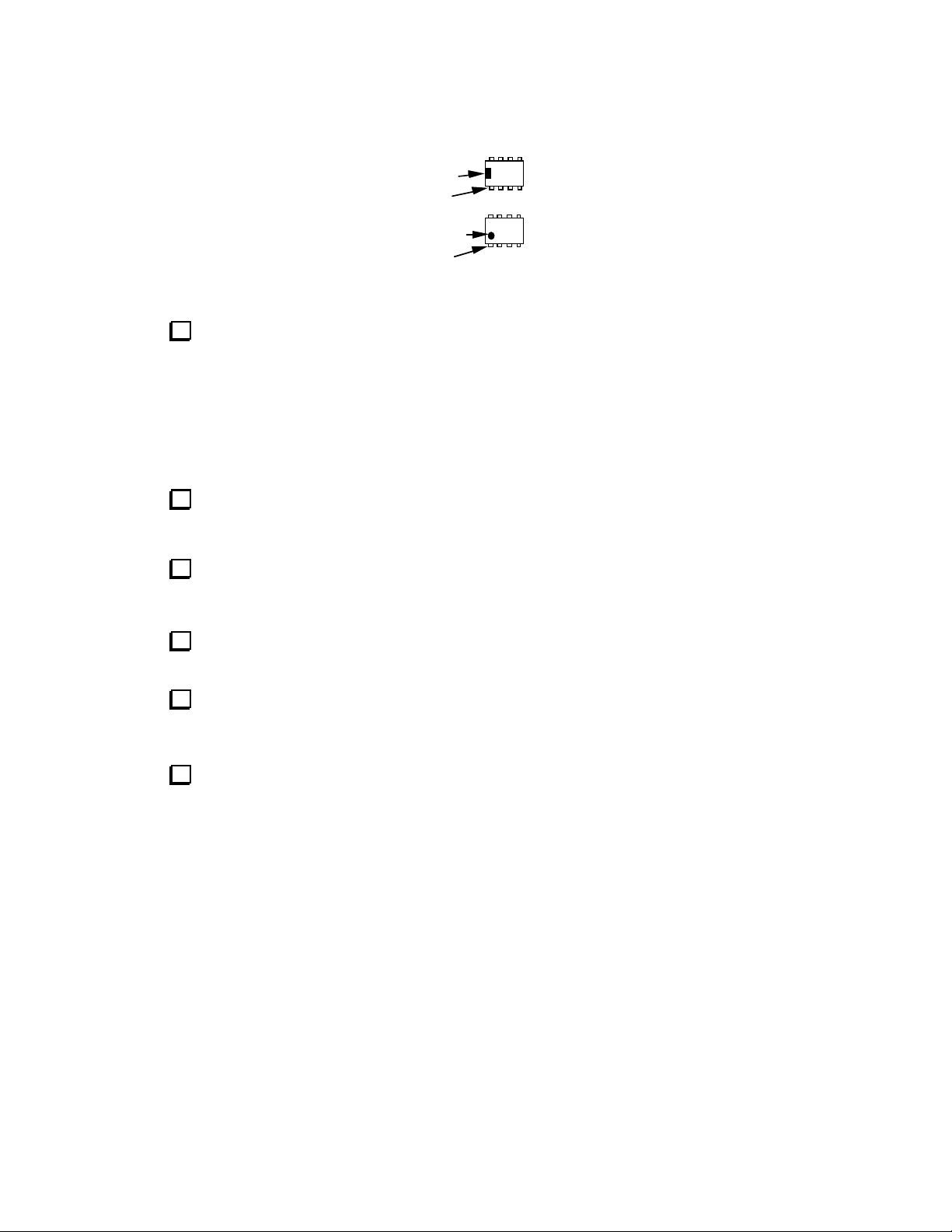

9

Note: The pin 1 end of ICs can be identified by a notch or dimple as shown in Figure 1. This end

must be oriented toward the notched end of the component outline.

Pin 1

Notch

Pin 1

Dimple

Figure 1

Install the following ICs on the top side of the board. Orient the notched or dimpled end

toward the notched end of their PCB outline (pin 1 end, to the left). Double-check the orientation

before soldering. Be sure to flush-trim the leads of each IC after soldering so as not to interfere

with cables on the bottom side of the board.

__U4 UCN5891A

__U5 UCN5891A

__U6 TPIC6595

__U7 TPIC6595

Install the rectangular Green LED at DS1 on the top side of the board. Spacing the LED

about 1/8” (3 mm) above the board will nicely align the top of the LED with the case top. The dot

marked on the PCB next to DS1 indicates the placement for the longest lead of the LED.

Visual Inspection: Using a magnifying glass, examine the entire board for unsoldered pins,

solder bridges, broken leads, or backward diodes or ICs. Reheat any suspect joints This simple

check could save you hours of troubleshooting later.

The following components will be installed on the bottom side of the circuit board. Turn over

the circuit board to install the components.

Install 1N4007 diodes at D2 and D3 on the bottom side of the PCB. Make sure the cathode

(banded end) of the diode matches the silk-screened outline on the PCB.

__D2, __D3

Install a 4.7k, 1/8 watt (yel-vio-red) resistor at D1 on the bottom side of the PCB. The

resistor replaces a small diode that was previously used in this position.

Page 10

10

Install 10k, 1/4 watt resistors (brn-blk-org) at R2 and R11 on the bottom side of the PCB.

__R2, __R11

Install the 40-pin IC socket at U1 on the bottom side of the board. The notched end should

be oriented toward the notched end of the PCB outline (pin 1 end, to the left). Solder just two

corner pins. If the socket is not sitting completely flat against the PC board, reheat these two pins

one at a time, pushing the socket down until it snaps into position. Then solder the remaining pins

of the socket.

Install U2, (MAX1406CPE or LT1039CN16) on the bottom side of the PCB. Orient the

notched or dimpled end toward the notched end of their PCB outline (pin 1 end, to the left).

Double-check the orientation before soldering. There is no need to trim the leads of U2.

Install resistor network RP1, 390 ohms (391), 8 pins, on the bottom side of the PCB. This

resistor network is symmetrical and can be installed in either orientation, but for consistency you

should orient it with the pin 1 end (black dot) toward pin 1 of the PCB outline (round pad, also

labeled "1").

Install resistor network RP2, 47k (473), 8 pins, on the bottom side of the PCB. This resistor

network should be oriented with the pin 1 end (black dot) toward pin 1 of the PCB outline (round

pad, also labeled "1").

Install low-profile crystal X2 on the bottom side of the PCB. This is a

short

16.289 MHz

device. Make sure it is flat against the board before soldering. Use a minimum of solder so that it

does not wick through and cause a short on the opposite side of the PCB..

Locate the ground pad near X2. Insert a discarded component lead through this pad, then fold

it over the top of X2. Solder this lead at the ground pad, then solder it to the crystal can. Avoid

overheating the crystal.

Install electrolytic capacitor C15 (10 µF) on the bottom side of the PCB. The (+) lead of C15

must be installed in the hole marked "+". The (+) lead is usually longer than the (-) lead. The (-)

lead is identified by a stripe on the body of the capacitor.

Install transistor Q1 (J310) as indicated by its outline on the bottom side of the PCB. The

installed height of the transistors must be no more than 3/8" (9 mm). The top of Q1 must be no

higher than the top of C15. Use a minimum of soldering time (1-2 seconds per lead).

Page 11

11

Install the subminiature DPDT slide switch S5 on the bottom side of the PCB. Make sure the

switch is firmly seated against the board when soldering. After installing the switch, move its

handle to the position closest to J2.

Install a 16-pin dual-row header at W1-W8 on the bottom side of the PCB. The short pins

are inserted into the PCB. The header must be firmly seated against the board when soldering.

Install a 16-pin dual-row header at W12-W19 on the bottom side of the PCB. The short pins

are inserted into the PCB. The header must be firmly seated against the board when soldering.

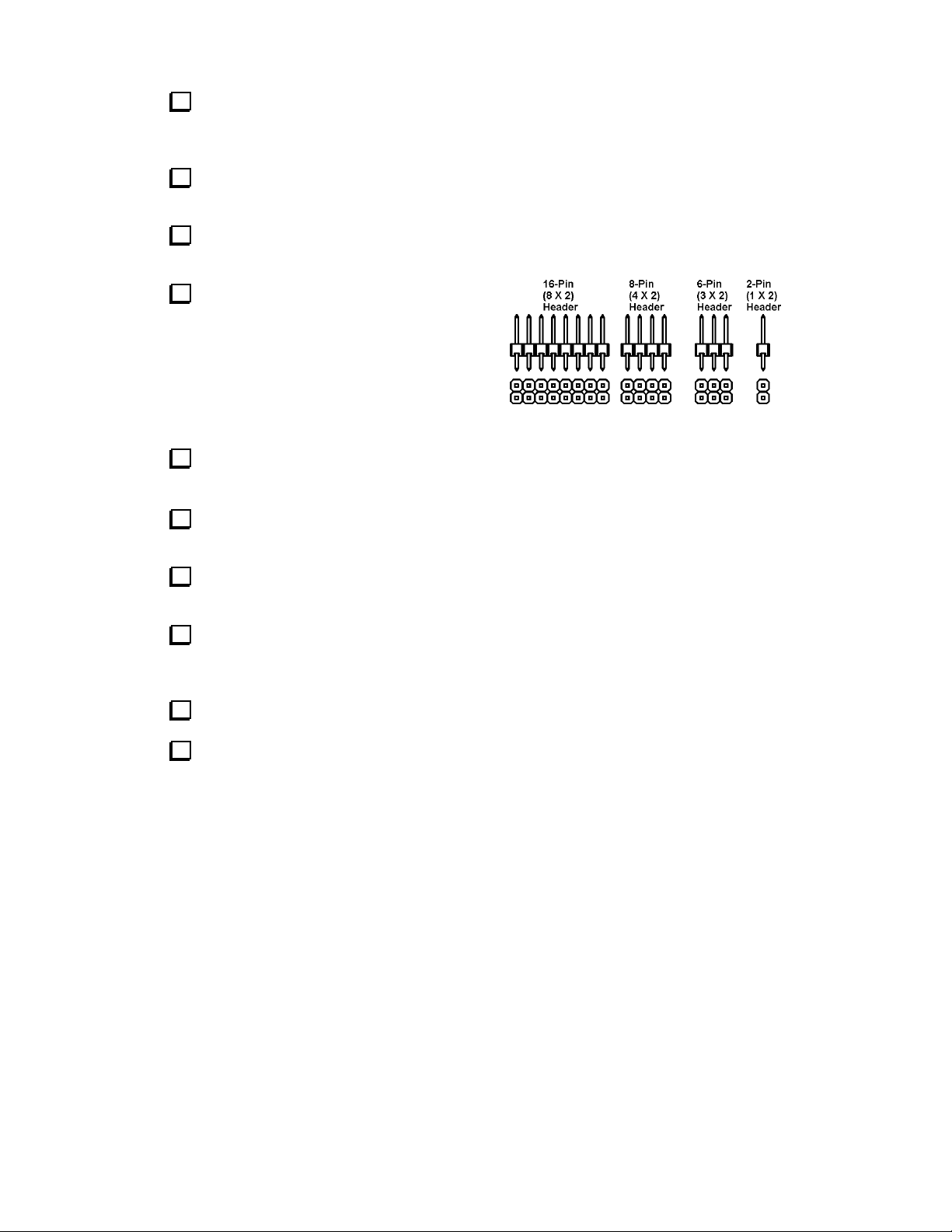

Locate the remaining 16-pin dual-row header.

Cut the header into three pieces so that you have one

8-pin dual row header, a six-pin header and a 2-pin

header. This is best done using diagonal cutters. Cut

the header on the side, then bend the portion to be

cut off away from the rest of the header. The two

pieces should snap apart somewhat cleanly. Discard

the 2-pin header.

Install the 8-pin dual-row header at W20-W23 on the bottom side of the PCB. The short pins

are inserted into the PCB. The header must be firmly seated against the board when soldering.

Install the 6-pin dual-row header at W9-W11 on the bottom side of the PCB. The short pins

are inserted into the PCB. The header must be firmly seated against the board when soldering.

Locate the shorting headers. Install 14 shorting headers on the dual-row headers W9-W19

and W21-W23 by plugging them onto the header pins. Do not install a jumper at W20 at this time.

Install electrolytic capacitor C12 (220 µF) on the bottom side of the PCB. The (+) lead of

C10 must be installed in the hole marked "+". The (+) lead is usually longer than the (-) lead. The

(-) lead is identified by a stripe on the body of the capacitor.

Install the DC barrel jack (J3) on the bottom side of the PCB.

Install J2, a male PC-mount DB9 connector on the bottom side of the PCB. This position is

next to the side of the PCB. The connector will “snap” into the board as its mounting tabs “grab”

the board. Be sure you have installed the MALE connector (with pins) before soldering the

connector pins onto the board.

Figure 2

Page 12

12

Install J1, a female PC-mount DB9 connector on the bottom side of the PCB. This position is

approximately in the center at the end of the PCB. The connector will “snap” into the board as its

mounting tabs “grab” the board. Be sure you have installed the FEMALE connector (with sockets)

before soldering the connector pins onto the board.

Refer to Figure 3, and install screw

terminal connectors at J4 and J5 on the

bottom side of the PCB. The opening

between the connectors forms a “trough” for

control cables to external devices. The

terminals must be mounted so their side

openings face this trough. Make sure the feet

of the terminals are firmly seated against the

board, leaving a very slight gap between the

body of the terminal and the PCB.

__J4, __J5

Connect two terminals together end-to

end by sliding the tab of one connector into

the slot of another. This forms a single 8-pin

connector. Form three other eight-pin

terminals following the same procedure, then

install the screw terminals at the locations

indicated in Figure 3 on the bottom side of

the PCB. Make sure the terminals are

mounted so their side openings face the

trough. Also make sure the feet of the

terminals are firmly seated against the board,

leaving a very slight gap between the body of

the terminal and the PCB.

__J6/J8 __J7/J9,

__J10/J12, __J11/J13

Install crystal X1, a

tall

, 4.000 MHz

device, on the bottom side of the PCB. Make sure it is flat against the board before soldering. Use

a minimum of solder to avoid the solder wicking through to the other side, causing a short.

Locate the ground pad near X1. Insert a discarded component lead through this pad, then fold

it over the top of X1. Solder this lead at the ground pad, then solder it to the crystal can. Avoid

overheating the crystal.

Figure 3

Page 13

13

Adjacent to J1, on the bottom side of the board, you will find two pads connected by a white

line. Using one of the 1N4007 diode leads previously saved, install a 1/4" (6 mm) tall U-shaped

ground jumper between these two pads, on the bottom side of the board. This jumper can be used

as a ground point for test instruments.

Locate the remaining three pushbutton switches. These will now be installed on the top side

of the board. Insert the switches into their mounting holes at S2, S3 and S4, spreading the legs

slightly so they will properly engage the holes. Press the switch down until it is fully seated on the

bends in its leads. There will be a slight gap between the switch body and PCB. Solder the

switches onto the circuit board from the top side.

__S2, __S3 __S4

Locate the four pushbutton key caps. Making sure the key caps are oriented from end-to-end

across the board, press the key caps onto the pushbutton switch stems until they lock into place.

i

Before handling U1, touch an unpainted, grounded metal surface.

i

When you install the IC in the following step, always straighten the leads of the IC first as

shown in Figure 4. The two rows of pins must be straight and parallel to each other to establish the

proper pin spacing for insertion into the PC board or socket. To straighten the pins, rest one entire

row of pins against a hard, flat surface. Press down gently on the other row of pins and rock the IC

forward to bend the pins into position as shown below.

Straight

Flared

Figure 4

Carefully straighten the pins on the microcontroller, U1 (PIC16F877A). The two rows of pins

must be parallel to each other, with no pins bent.

Press the microcontroller into its socket, orienting the notched or dimpled end of the IC with

the notched end of its component outline. The labeling on the microcontroller should read from

left to right.

This completes assembly of the KRC2 circuit board. There are two remaining parts locations, R5

and SP1, which are used with the accessibility speaker option. All other component locations

should now be filled.

Page 14

14

Visual Inspection: Using a magnifying glass, examine the entire board for unsoldered pins,

solder bridges, broken leads, or backward diodes or ICs. Reheat any suspect joints This simple

check could save you hours of troubleshooting later.

Case Assembly

Locate the case top cover. This piece has three rectangular holes punched into the face.

Locate a 4-40 x 3/16” flat head screw. Push it through the hole on the top of the case, holding

it in place with a finger as you turn the case over. Locate two #4 internal-tooth lock washers. Slide

both lock washers onto the screw shaft inside the case. Locate the 1/4 x 3/16” round threaded

standoff. While holding the screw with a Philips screwdriver, screw the standoff onto the screw.

Tighten the assembly.

Insert the circuit board assembly into the case with the pushbutton switches and LED passing

through the rectangular holes in the case. Secure the circuit board to the case with a single 4-40 x

3/16” pan head Philips screw and #4 lock washer.

Locate the four #4 male-female hex standoffs. These are used to secure the DB9 connectors

to the case. Screw each standoff through one of the mounting holes next to the DB9 connectors in

the end of the case into the threaded DB9 assemblies.

Locate the two “2-D” fasteners. These are used to secure the

case top and bottom. Note that on the side of the fastener with

two screw holes, there is more space to one side of the holes than

the other. The side with the most space will face away from the

circuit board.

Using two 4-40 x 3/16” flat-head screws, attach one “2-D”

fastener to the case top just above the J1 DB9 connector. Make

sure the wide side of the fastener side faces away from the circuit

board.

Attach the second “2-D” fastener, using two 4-40 x 3/16” flat head screws, to the end of the

top case away from the DB9 connectors. Follow the same procedure as in the previous step.

Again, the wide side of the fastener should face away from the circuit board.

Figure 5

Page 15

15

KRC2 Test Procedure

The KRC2 should be powered from its DC barrel jack using a +12 volt supply for its initial

power-up. No other connections should be made to the unit.

Connect the power source to the unit. After a short delay while the KRC2 performs

diagnostics, the front-panel LED should turn on to its dim level. If this does not happen, turn

power off to the unit and refer to the troubleshooting section.

Driver Relay Test: You will need a DC voltmeter for this procedure. Connect the black lead

(common) to the ground jumper located near J1 on the KRC2. The red lead should be used to

measure the voltage on each terminal of J6, J7, J8 and J9. Be sure to check the voltage at the side

connector of each terminal. The initial readings should be 0 volts on each terminal.

The Tap/Hold Rule: Each of the pushbutton switches on the front panel has two functions, one

activated by a TAP (short press) and the other activated by a HOLD (long press, about 1/2

second). To highlight this in the text, we use two different typographical styles to identify

switches: T AP and H OLD .

Holding

should cause the KRC2 to change the driven band terminal. Only the 60m source

terminal should indicate 12 volts. The LED should be alternating between dim and bright.

Holding

again should cause the 10m source terminal to indicate 12 volts, and all others to

remain off.

Continue this procedure, actuating the

command until all HF source terminals have been

checked.

The

function is used to switch the AC1-AC3 outputs. First, hold

,

then tap

F1.

The

AC1 source terminal should now indicate +12V and AC2 and AC3 source terminals indicate 0V.

Hold

,

then tap

F2.

The AC2 source terminal should now indicate 12V with AC1 and AC3

at 0 V.

Hold

,

then tap

F3.

The AC3 source terminal should now indicate 12V with AC1 and AC2

at 0 V.

Hold

,

then tap

F4.

All three AC source terminals should now indicate 0 volts.

This completes checkout of the KRC2. Continue to the Final Assembly section.

Page 16

16

KRC2 Final Assembly

Place the case bottom onto the case top, aligning the screw holes at each end of the case. The

case may be a tight fit, but the two halves should slide into place without difficulty.

Using two 4 x 3/16” pan-head screws, secure the case bottom to the top.

Locate the four rubber stick-on feet. Remove the adhesive backing from each foot, and place

the foot securely into place in a corner of the case bottom about 1/8” in from each side.

K2 to KRC2 Control Cable Assembly

Locate the 8-conductor cable. Note: A shorter cable may be used as long as it accommodates

the physical orientation of the K2 and the KRC2. A longer cable can also be used, but it will have

to be tested to ensure that it is not subject to RF interference. A more heavily-shielded control

cable may be required. A standard shielded male-female DB9 straight-through cable has been

tested and should work well with the KRC2/K2 combination.

Remove 1/2" (12 mm) of the jacket from the cable at each end. Be very careful not to nick

the individual wires.

Peel back and cut away the foil shield.

Strip 3/16" (5 mm) of insulation from each insulated wire.

Twist the strands of each wire together. Tin lightly with solder.

Locate the male and female DB9 connectors.

Insert the female DB9 connector (KRC2 end) into the vise, with the solder cups facing up.

Solder the wires to the indicated connector pins at the KRC2 end of the cable as shown in

Figure 6. It may be helpful to melt some solder into each solder cup on the connector first.

Pin 1 Bare wire Pin 2 Orange Pin 3 Blue

Pin 4 Red w/ Black stripe Pin 5 White w/ Black stripe Pin 6 Green

Pin 7 White Pin 8 Red Pin 9 Black

Page 17

17

Figure 6

Remove the female connector from the vise (K2 or K2/100 end), and insert the male

connector (KRC2 end). Solder the wires to this connector using the same colors and pins as in the

previous step.

Locate the connector housing (backshell) and associated hardware.

Note: A single hinged backshell may be provided rather than a two-piece backshell.

Attach a backshell to the male connector at the

K2 or K2/100 end of the cable. Figure 7 shows how

the backshell appears when assembled. Use the

provided cable clamp to hold the cable in position,

then secure the clamp with two screws. The

jackscrews must be retained by the shells. Secure

the backshell halves with the provided hardware (or,

if the shell is hinged, snap the backshell closed). Do

not over-tighten the two screws which secure the

cable clamp!

Attach the remaining backshell to the female

connector at the KRC2 end using the procedure

described above.

Figure 7

Page 18

18

Using the KRC2

The features described in this section are available with KRC2 firmware version 1.5 and later.

Please see earlier revisions of this manual for operation with previous firmware versions.

KRC2 operation with an Elecraft K2 or K2/100 Transceiver

The KRC2 should be connected to the K2 using the Male/Female DB9 cable assembly described

in the previous section. The KRC2 derives its operating power from the K2 in this configuration.

In the KRC2's factory configuration, the per-band outputs (both sink and source) will be turned on

or off based on the K2's selected band. This default behavior will suffice for many amateur station

applications. However, the correspondence between selected band and output driver states is fully

programmable. Band mapping and other configuration changes are accomplished using the KRC2

configuration utility, available from the Elecraft web site (www.elecraft.com). For example, if the

station includes a 20/15/10 meter tri-band beam, the 20 m sink output could be programmed to be

turned on whenever the K2 is set for 20, 15, or 10 meters. Another alternative for mapping

multiple bands to a single antenna or other device is to "wire-OR" the outputs. This is explained in

more detail later in the manual.

Switch S5, accessible through a small hole in the side of the KRC2 sets the operational mode of

the unit. For normal operation, the OP (operate) position of S5 is used. This allows the KRC2 to

communicate with the K2 via its AuxBus and RS-232 interfaces. Set S5 to the DL (Download)

position for downloading firmware upgrades or device configurations to the unit. Firmware

upgrades can be downloaded using the KRC2 download utility, available from the Elecraft web

site.

Page 19

19

Default Key Behavior

There are four buttons on the top of the KRC2, labeled F1, F2, F3 and F4. In the KRC2's factory

configuration, the F1-F4 buttons have the following TA P and H OL D functions:

F 1 Sends the contents of K2 CW message buffer #1.

F 2 Sends the contents of K2 CW message buffer #2.

F 3 Sends the contents of K2 CW message buffer #3.

F 4 Sends the contents of K2 CW message buffer #4.

Note: Playing messages using F 1 - F 4 is more convenient than using the K2’s

FAST PLAY (1-touch) technique.

F 1 Selects the next lower HF band’s relay driver output in the KRC2.

F 2 Selects the next higher HF band’s relay driver output in the KRC2.

Note: This is useful in cases where you switch to a K2 band for which no antenna

relay has been connected in the KRC2. See next page for details.

F 3 Switches the K2 receiver to (or from) the RCV ANT jack. This is a toggle operation.

F 4 Holding this button, then tapping any button, will then cause one of the ACC drivers

to be turned on or off as shown in the list below. The KRC2 will illuminate the green

LED at full brightness while it is awaiting the key tap.

F 1 Turn on AC1 driver.

F 2 Turn on AC2 driver.

F 3 Turn on AC3 driver.

F 4 Turn OFF all ACC drivers.

Note that holding F 4 instead of tapping a key will cancel the function.

The F 1 and F 2 functions change the output terminal for the relay drivers up or down in single

band increments. When the highest band is selected, the next hold of F 2 will cause the drivers to

go to the 160m setting. Conversely, when the lowest band is selected, the next usage of the F 1

function causes the drivers to go to the highest band. The band map follows the values indicated in

Table 5, which places the 60m band above the 10m band. Thus the sequence will be:

…12m<->10m<->60m<->160m<->80m<->40m… While the selected driver is different from the

current band indicated by the transceiver, the green LED will flash between dim and bright states.

The XVT drivers do not participate in the sequence, and when the transceiver selects a transverter

these buttons will not change the driver selection.

Page 20

20

KRC2 Jumper Configuration

There are 21 jumpers in the KRC2 allowing for a wide range of device options. The W1-8 block,

located near the front of the case, controls device configuration for different radio setups and

driver output logic. Table 1, Table 2 and Table 3 show the different settings.

Jmpr

Jumper Out (default)

Jumper In

W1

Use digital band decoding

Use analog band decoding

W2

Band decode option bit 1 - see Table 2

Band decode option bit 1 - see Table 2

W3

Band decode option bit 2 - see Table 2

Band decode option bit 2 - see Table 2

W4

ACn drivers use 1 of 3 decoding

ACn drivers use binary coding

W5

Xvtr drivers use 1 of 3 decoding

Xvtr drivers use binary decoding

W6

No auto-report mode

Place XCVR in auto-report mode

W7

Data Rate bit 0 – see Table 3

Data Rate bit 0 – see Table 3

W8

Data Rate bit 1 – see Table 3

Data Rate bit 1 – see Table 3

Table 1

W1W2W3

Band decode source

Out

Out

Out

AuxBus Mode – K2 operation

Out

OutInSerial Port Mode – K2 or Kenwood operation

OutInOut

Digital Input through J4

OutInIn

Not used

In

Out

Out

Analog input using ALC input (DB9 pin 4)

In

OutInAnalog input using 8R input (DB9 pin 9)

InInOut

Analog input using VRDET input (DB9 Pin 7)

InInIn

Analog input using 8R input (DB9 pin 9) with

reference voltage on ALC input (DB9 pin 4)

Table 2

W8W7Data Rate

Out

Out

4800

OutIn9600

In

Out

19200

InIn4800

Table 3

Page 21

21

Jumpers W4 and W5 determine the bandmap used for outputting band data. For normal use they

should be removed. The KRC2 Configuration tool allows the bandmaps to be edited by the user.

Jumpers W4 and W5 may be used in conjunction with the Configuration tool remapping in order

to allow alternate or extended output configurations. See the KRC2 Configuration Tool

documentation for more information.

Jumpers W9-W23 are used to connect or disconnect the DB-9 connectors from the KRC2.

Normally these jumpers should be left installed. When used with a K2, the minimum jumpers that

must be installed in this block are W16, 18, 19, 21 and 23. DO NOT install jumper W20 when

using the KRC2 with the K2. Doing so will cause problems in the K2, including disabling SSB

output. If the PC connector (J1) is used to pass K2 information through to a peripheral such as a

KAT100, it is important that all jumpers in the W9-W23 block with the exception of W20, be

installed.

Jmpr

Connector

Discussion

W9

J1 Pin 2 - PC

Enables Serial Data to PC from KRC2 or XCVR.

W10

J1 Pin 3 - PC

Enables Serial Data from PC to KRC2 or through to XCVR.

W11

J1 Pin 4 - PC

Enables J1 Pin 4

W12

J1 Pin 9 - PC

Enables J1 Pin 9

W13

J1 Pin 8 - PC

Enables J1 Pin 8

W14

J1 Pin 7 - PC

Enables J1 Pin 7

W15

J1 Pin 6 - PC

Enables J1 Pin 6

W16

J2 Pin 6 - XCVR

Enables K2 AuxBus signal into KRC2. Must be installed for

KRC2 AuxBus band decode mode operation.

W17

J2 Pin 7 - XCVR

Enables K2 VRDET signal into KRC2.

W18

J2 Pin 8 - XCVR

Enables K2 12CTRL signal into KRC2. This signal normally

powers the KRC2.

W19

J2 Pin 9 - XCVR

Enables K2 8R signal into KRC2. Used to determine

transmit/receive activity in K2 operating mode.

W20

J2 Pin 4 - XCVR

Enables K2 ALC signal into KRC2.

DO NOT insert this jumper when using the KRC2 with the K2!

W21

J2 Pin 3 - XCVR

Enables K2 TxD signal from KRC2 serial port driver.

W22

J2 Pin 3 - XCVR

Enables K2 TxD signal from J1 pin 3 (PC serial port driver).

W23

J2 Pin 2 - XCVR

Enables K2 RxD serial port signal into KRC2.

Table 4

Page 22

22

When the KRC2 is set to receive band data in an analog mode, the jumpers associated with the

selected input should be removed from the J2 connection. The analog input should then be fed into

the KRC2 using the PC connector. Use J1 pin 1 for the ground return connection. These settings

and connections are listed in Table 5.

Analog Input

Remove Jumper(s)

J1 Pin for input

Comments

8R / AN1

W19

9

0 - 10 volt input range

VRDET / AN2

W17

7

0 - 5 volt input range

ALC / AN3

W20

4

0 - 10 volt input range

Table 5

i

Important! Do NOT use the jumper connections to bridge external RS-232

serial port signals. This may cause serious damage to your radio when moving the

KRC2 from one radio to another. The preferred method is to provide the bridging

in the cable used with the radio needing it. This specifically applies to Kenwood

transceivers.

Rig-Specific Setup

The following settings are suggested for each radio. Note that these are suggested that have been

successful for users. Other setups are possible and may be preferred. Note that W4 and W5 should

be set as required for the desired bandmap configuration.

Elecraft K2.

• K2 AuxBus used for band, serial port for control and data. PC logging program in use:

Installed

Removed

W1, W2, W3, W6, W7, W8

W9, W10, W16-W19, W21-W23

W11-W15, W20

• K2 AuxBus used for band, serial port for control and data. Stand-alone (no PC):

Installed

Removed

W6

W1, W2, W3, W7, W8

W9 -W19, W21-W23

W20

• K2 serial port used for band, data and control communications. PC logging program in use:

The KRC2ACC may use this setup for communications with the K2.

Installed

Removed

W3

W1, W2, W6, W7, W8

W9, W10, W16-W19, W21-W23

W11 – W15, W20

Page 23

23

• K2 serial port used for band, data and control communications. Stand-alone (no PC):

The KRC2ACC may use this setup for communications with the K2.

Installed

Removed

W3, W6

W1, W2, W7, W8

W9 -W19, W21-W23

W20

Elecraft K3. The preferred setup for the K3 uses the AuxBus for band communications. This

mode uses the K3’s AuxBus for band communications.. Connect J1/J2 pin 6 to pin 2 of the K3’s

AuxIO connector. J1/J2 pin 1 (Ch Gnd) should be connected to K3 Aux IO pin 5. The KRC2 may

also be connected to the K3’s serial port to determine bands. In this configuration control and data

communications will be functional, however not all K3 commands or data may be recognized by

the KRC2.

• AuxBus. Control and data transfers are not available.

Installed

Removed

W1, W2, W3, W6, W7, W8

W9 -W23

• Serial port, PC Logging in use, data rate set to 19200 bps:

Installed

Removed

W3, W8

W1, W2, W6, W7

W9, W10, W21-W23

W11-W20

• Serial port, (no PC), data rate set to 19200 bps:

Installed

Removed

W3, W6, W8

W1, W2, W7

W9, W10, W21-W23

W11-W20

Kenwood. This mode uses Kenwood’s serial port for control and data communications. The data

rate may be set using the W7 and W8 jumpers as required. See Table 3 for this information. Some

Kenwood radios require the use of RTS/CTS handshaking in order to enable communications. If

this is required with your radio, connect a jumper wire from W14 to W17. The wire should be

connected to the jumper pins nearest the DB-9 connectors.

• PC Log program in use, data rate of 19200 bps

Installed

Removed

W3, W6, W8

W1,W2, W7

W9, W10, W21-W23

W11-W20

• Stand-alone (no PC) operation, data rate of 19200 bps

Installed

Removed

W3, W6, W8

W1, W2, W7

W9, W10, W21-W23

W11-W20

Page 24

24

Icom using analog band data. Here we use the radio’s analog band output for band information.

Control and data transfers are not available. Some Icom radios have shown a tendency for the

band output to drift with increased transmit output power. For this reason it is recommended that

the reference input setup be used. In this configuration, the band data is connected to pin 9 and the

8 volt reference is connected to pin 4. This mode is set with jumpers W1, W2 and W3 installed.

• Analog band input on J1/2 pin 4:

Installed

Removed

W1

W2, W3, W6, W7, W8

W11, W20

W9, W10, W12-19, W21-W23

• Analog band input on J1/2 pin 9:

Installed

Removed

W1,W2

W3, W6, W7, W8

W12, W19

W9 -W11, W13-18, W20-W23

• Analog band input on J1/2 pin 9 with reference voltage on J1/2 pin 4:

Installed

Removed

W1, W2, W3

W6, W7, W8

W11, W12, W19, W20

W9, W10, W13-18, W21-W23

Yaesu FT817 using analog band data. Band is determined from the radio’s analog voltage

output. Control and data transfers are not available

• Analog input on J1/2 pin 7:

Installed

Removed

W1, W3

W2, W6, W7, W8

W14, W17

W9–W13, W15, W16, W18-W23

Computer parallel printer port. BCDband information is communicated using the parallel data

available from some computer’s parallel port or parallel BCD data from some radios. Control and

data transfers are not available

• Parallel PCB information

Installed

Removed

W2

W1, W3, W6, W7, W8

W9–W23

For all analog inputs, use J1 or J2 (same connector as the analog input), pin 1 for ground

connection.

Page 25

25

KRC2 Power Connections

The KRC2 may be powered from one of several sources. The

microcontroller and logic are powered either from the K2 through the

DB-9 connector, or from the +12V DC barrel jack. The voltage

applied at the DC barrel jack must not exceed 15 volts.

Power for the Source drivers can come either from the DC barrel jack

or the J5 terminal connector. Voltage applied to the J5 ‘V’ terminal

must not exceed +50 volts. Maximum current drain for either source is

1 amp.

Connecting the KRC2’s Drivers

There are 36 driver output terminals. The terminals are accessible by

removing two access screws on the bottom case. Sixteen of the drivers

will source current, and another sixteen will sink current. The

remaining four drivers, labeled A, B, C and D, are TTL-compatible

inputs or outputs depending on the operating mode. In normal KRC2

or analog modes, the terminals are outputs. In digital parallel input

mode, they become inputs, and receive the BCD-encoded band data.

An additional four terminals are provided for connecting the KRC2 to

ground returns, and to provide a supply voltage for the source drivers

as described in the KRC2 Power Connections section. Figure 8

illustrates the connections. A bar over the terminal label indicates the

output is a sink driver. Sink driver terminals are located near the front

of the box. Source drivers are located toward the rear of the box.

Like-drivers may be wire-ORed (connected together) in order to allow a relay to be selected on

more than one band. For example, the control line from a tri-band beam would connect to

terminals 20, 15 and 10 for source drivers, or /20, /15 and /10 for sink drivers.

IN NO CASE SHOULD THE SOURCE AND SINK TERMINALS BE CONNECTED

TOGETHER IN ANY WAY!

Connecting other Elecraft Peripherals

Additional Elecraft peripherals, such as a KAT-100 or XV-Series transverter, may be connected to

the KRC2’s PC port in a “daisy-chain” fashion in order to operate with the K2. Simply plug the

DB-9 connector from the peripheral into the KRC2’s PC port, and use the peripheral as if it were

directly connected to the K2. Be sure to follow the rules outlined in the jumper discussion and

insert all jumpers in the W9-W23 block with the exception of W20 when using this configuration.

KRC2 PC Connections

A personal computer’s RS-232 serial port may be connected to the KRC2’s PC port using the PC

connector. Normally the K2 does not automatically report its settings to the KRC2. If you have an

alternate KRC2 configuration that needs for the K2 to report its settings, install jumper W6 to

enable the K2’s auto-report mode.

Figure 8

Page 26

26

Using the KRC2 with non-Elecraft Radios

The KRC2 is designed to accept band information from radios other than the K2. As discussed in

KRC2 Jumper Configuration, setting jumpers W1-3 for Kenwood mode operations allows the

KRC2 to interface with those radios in a manner similar to the K2. Other radios that do not use

this command set may not be interfaced using this mode.

To use the KRC2 with an ICOM transceiver that has analog (stepped voltage) band output, you

should set the W1-3 jumpers for Analog Mode using the desired input (8R/AN1 or ALC/AN3),

and connect the transceiver’s analog output to the appropriate input pin on J1 or J2. Be sure to

remove W19 or W20 as appropriate. Power the KRC2 using an external 12-volt supply connected

to the KRC2’s DC barrel jack. The KRC2 should now set its band outputs according to the voltage

presented by the radio.

The three analog inputs have slightly different characteristics you should consider when choosing

which to use. The 8R/AN1 and ALC/AN3 inputs have voltage divider networks on their inputs

that divide the input by 2. Thus their input range is from 0 to 10 volts. The VRDET/AN2 input has

no divider network, giving it a voltage range of 0 to 5 volts. Each input voltage is filtered through

a band selection table that determines the selected band. There are three tables, one for each input.

The factory-configured tables are set up for Icom radios with voltage range of 0 to 8 volts for the

wide-range inputs, with the third table set for the Yaesu FT-817 transceiver’s analog output. These

tables are user-configurable using the KRC2 Configuration tool

To use the KRC2 with a Yaesu radio or computer parallel port outputs, set jumpers W1-3 as

follows: W1 OUT, W2 IN, W3 OUT as described in Table 2. You may then connect the radio or

computer outputs to the KRC2’s ABCD terminals, with the return ground connected to one of the

terminals labeled ‘G’. Power the KRC2 from an external 12-volt supply connected to the DC

barrel jack. The unit should now switch the driver outputs in accordance to the digital inputs it

sees. Note that in addition to the standard BCD outputs, the KRC2 recognizes additional band

codes according to Table 5.

Binary coding

Hex

Band

Binary coding

Hex

BAND

0001

01

160m

10000812m

00100280m

10010910m

00110340m

10100A60m

01000430m

1011

0B

unused

01010520m

1100

0C

XVT1

01100617m

1101

0D

XVT2

01110715m

1110

0E

XVT3

Table 6

Page 27

27

Troubleshooting

If you have any difficulty with your KRC2:

Most problems in building the KRC2 are caused by poor or non-existent solder joints. Closely

examine the PC board for poor solder joints and incorrect, broken or missing components.

Problem: The KRC2’s LED does not turn on.

Make sure the KRC2 is powered, either from the K2 or from the DC barrel jack. The KRC2 must

be powered from one of these two sources. The internal controller circuits may not be powered

from J5’s ‘V’ terminal.

Problem: Source drivers inoperative.

The source drivers require that a DC supply of up to 15 volts be attached to the KRC2’s DC barrel

jack, or a DC supply of up to 50 volts be connected to terminal ‘V’ of J5. The source drivers are

not capable of supplying voltage from the K2’s power supply.

Problem: KRC2 does not communicate with K2.

Check jumpers W9-W23. All but W20 must be installed for the KRC2 to communicate properly

with the K2. If these are properly installed, check the cable connecting the KRC2 and K2. This

must be a straight-through Male DB9-Female DB9 cable as constructed in this manual.

Problem: K2 has no transmitter output in voice modes.

Remove jumper W20 from the KRC2. The KRC2 adversely affects the K2’s ALC system, causing

low voice power output of the transceiver. The K2 works quite well without the external ALC line

installed, so simply leave jumper W20 out of the KRC2.

Problem: LED Flashing on and off.

On/off LED flashing indicates that the KRC2’s microcontroller has not passed its startup tests, and

is waiting for a firmware download. This is not to be confused with the slower bright/dim LED

flashing which indicates the driver band selection does not match the K2’s band setting. Try

turning power off then on to the unit. If the condition persists, contact Elecraft technical support

for an upgrade.

Included below are complete DC Voltage Tables for all ICs.

Page 28

28

DC Voltage Chart

Voltages are approximate and will vary up to +/- 10% due to normal component variation without

affecting the operation of the KRC2. Measurements were made under the following conditions:

KRC2 powered by K2, K2 powered by a 14.0 V (measured) power supply, K2 powered on, set to

14290.9 MHz. Switch to this band from another after powering on K2/KRC2 combination.

Nothing attached to the KRC2’s DC barrel jack or PC DB9 connectors. No wires attached to the

J4-J13 terminal connectors. Measurements taken with Metex ME-22 Digital Volt Meter.

PinVPinVPinVPinVPin

V

U1 P1

4.75

U1 P27

4.56

U2 P13

4.95

U5 P7

0.00

U6 P17

0.00

U1 P2

2.77

U1 P28

0.00

U2 P14

0.00

U5 P8

0.00

U6 P18

0.00

U1 P3

3.45

U1 P29

4.56

U2 P15

4.95

U5 P9

0.00

U6 P19

0.00

U1 P4

0.00

U1 P30

0.00

U2 P16

4.95

U5 P10

0.00

U6 P20

0.00

U1 P5

0.00

U1 P31

0.00

U4 P1

0.00

U5 P11

0.00

U7 P1

0.00

U1 P6

0.79

U1 P32

4.95

U4 P2

4.95

U5 P12

0.00

U7 P2

4.95

U1 P7

4.93

U1 P33

4.95

U4 P3

4.95

U5 P13

13.35

U7 P3

0.00

U1 P8

5.55

U1 P34

4.95

U4 P4

0.00

U5 P14

0.00

U7 P4

0.00

U1 P9

1.97

U1 P35

4.95

U4 P5

0.00

U5 P15

4.95

U7 P5

0.00

U1 P10

4.63

U1 P36

4.95

U4 P6

0.00

U5 P16

0.00

U7 P6

0.00

U1 P11

4.95

U1 P37

4.95

U4 P7

0.00

U6 P1

0.00

U7 P7

0.00

U1 P12

0.00

U1 P38

4.95

U4 P8

0.00

U6 P2

4.95

U7 P8

4.95

U1 P13

1.77

U1 P39

4.95

U4 P9

0.00

U6 P3

4.95

U7 P9

0.00

U1 P14

2.21

U1 P40

4.95

U4 P10

0.00

U6 P4

0.00

U7 P10

0.00

U1 P15

4.93

U2 P1

12.86

U4 P11

0.00

U6 P5

0.00

U7 P11

0.00

U1 P16

0.00

U2 P2

0.00

U4 P12

0.00

U6 P6

0.00

U7 P12

0.00

U1 P17

4.90

U2 P3

12.42

U4 P13

13.35

U6 P7

0.00

U7 P13

4.95

U1 P18

4.95

U2 P4

-2.52

U4 P14

0.00

U6 P8

4.95

U7 P14

0.00

U1 P19

4.93

U2 P5

-7.56

U4 P15

4.95

U6 P9

0.00

U7 P15

0.00

U1 P20

4.93

U2 P6

-6.80

U4 P16

0.00

U6 P10

0.00

U7 P16

0.00

U1 P21

4.93

U2 P7

12.42

U5 P1

0.00

U6 P11

0.00

U7 P17

0.00

U1 P22

4.93

U2 P8

-7.55

U5 P2

4.95

U6 P12

0.00

U7 P18

0.00

U1 P23

4.93

U2 P9

0.00

U5 P3

0.00

U6 P13

4.95

U7 P19

0.00

U1 P24

4.95

U2 P10

0.00

U5 P4

0.00

U6 P14

0.00

U7 P20

0.00

U1 P25

4.95

U2 P11

4.95

U5 P5

0.00

U6 P15

0.00

U1 P26

4.95

U2 P12

4.95

U5 P6

11.97

U6 P16

0.00

Note: U6 Pins 4, 5, 6, 7, 14, 15, 16, 17 and U7 Pins 4, 6, 7, 14, 15, 16, 17 are floating (not driven)

with no pullup. U6 pin 5 is driven to zero for 14 MHz as shown in the voltage chart.

Page 29

29

Circuit Details

Refer to the schematic diagram, Figure 7 on page 29.

U1 is a PCI 16F877A microcontroller. This device controls the operation of the KRC2. U1

operates at a clock frequency of 4 MHz, as determined by X1. It communicates with relay drivers

U4-U7 using its built-in Serial Peripheral Interconnect (SPI) interface, commanding them to turn

their outputs on or off. Which outputs should be on or off is determined during execution of the

microcontroller’s internal program. It uses band input from the attached radio or computer to

determine which driver output(s) should be enabled.

The MCU receives band information from the attached radio through one of six input channels.

Three channels are analog, using the MCU’s built-in analog to digital converters to measure band

voltages, while the other three are digital in nature. These consist of a BCD parallel input and two

serial inputs. One serial input enables the MCU to participate on the K2’s AuxBus channel, while

the other uses the MCU’s built-in UART serial port to communicate using the Elecraft serial

protocol (similar to the Kenwood serial protocol). Selection of the active input method is made by

setting the W1-W3 jumpers.

The UART serial port uses industry-standard RS-232 voltages. These are switched in the KRC2

using U2, a MAX1406 (or similar) RS-232 interface. U2 requires a negative power supply for its

operation. This is developed using the oscillator and rectifier circuitry of Q1. Q1 and X2 and their

associated components form an oscillator running at 18.289 MHz. Output from this oscillator is

fed to a voltage-doubling rectifier made up of D6, D7, and C15, then fed to U2’s –12V input pin.

The circuit typically provides –7.5 volts, well within the range required by the RS-232

specification.

For analog band operation, the input voltage is connected to the microcontroller’s AN1, AN2 or

AN3 inputs through divider or isolation networks. The AN1 input comes from pin 9 of J1 or J2,

depending on jumper selection. It is reduced by the divider network made up of R6 and R10. The

values for these resistors provide a division by 2, giving the input a maximum range of 0 to +10

volts. The AN3 input is identical to that of AN1, with RR8 and R11 making up the divide-by-2

network. This input comes from J1 or J2 pin 4. AN2 comes from J1/J2 pin 7, and is fed directly to

the MCU input without a voltage divider. Its input range is 0 to +5V.

The KRC2 can communicate with two devices using the RS-232 port, depending on the setting of

S5. In S5’s normal operation position, the KRC2 listens directly to the transceiver’s serial output,

and also can send directly to the radio attached to the XVCR port. Additionally, the RS-232

signals from a computer attached to the PC port (J1) are ORed with the KRC2’s serial port,

allowing it to send, and listen, to the transceiver as well. No protection is provided to keep

transmissions from the KRC2 and PC from colliding on this channel, so care must be taken to

prevent this in the PC and KRC2 operation. The S5’s Download (DL) position enables the

microcontroller to communicate directly with a PC. This is used in downloading configuration and

firmware upgrades to the KRC2.

Page 30

30

C1

C2

VoutVin

Gnd

1 3

2

U3 78L05

C13

C14

+

C12

.1.1220 µF

R3

1K

C20

.1

33

33

Rx

Tx

C16

.01

D7

1N4148

D6

1N4148

+

C15

10 µF

S4

S3

S2

S1

F1

F2

F3

F4

D3 1N4007

C9

C11

C8

C6

C10

L2

L3

L1

8R

R9 100

.001

ALC

0.001

0.001

0.001

0.001

100uH

100uH

100uH

ISD-D

ISD -C

SP1

Piezo Spkr

W5

W4

T2OUT

R2OUT

R1OUT

T1OUT

T3OUT

R3OUT

R2IN

T2IN

T1IN

R1IN

R3IN

T3IN

GND

VCC

VDD

VSS

16121415131110

2

391

8

547

6

U2

12

3

4

5

6

7

8

9

J2

W16

W17

W18

W19

W23

D2

1N4007

J3

DS1

RP 1 12

390

RP 1 56

390

RP 1 78

390

RP 1

34

390

X1

4.0 MHz

X2

G

DS

Q1

D8

C18

L4

J31 0

120

16.289 MHz

1N4148

C19

56

R13 47

C17

.01

15uH

TTL Level

+12V DC Power

MAX140 6

R4 470

R5

5K

(BACK VIEW)

12345

6789

DB-9 Male

Status

8R

VRDET

C3

.001

R6 10K

R7 10K

C4 .001

8R

VRDET

VPP

1

2 3 4

5

6

7 8

9

J1

C7

0.001

(BACK VIEW)

1 2 3 4 5

6 7 8 9

+5V

+5V

+12V

+5V

+5V

+5V

+12V

+5V

DB-9 F emale

PC

C25

.1

R1

R2

10K

47K

2V nominal

-12V

-12V

RxD

TxD

W10

W9

RP 2

14

47K

D5

1N4007

D4

1N4007

W6

W7

W2 W8

W13

W14

W15

W11

W12

8R

12CTRL

12CTRL

AuxBus

AuxBus

ALC

TxD

RxD

SIG GND

SIG GND

CH GND

CH GND

BRL12

BRL12

+12V

GND

VBB

GND

GND

4 3

2

1

J4

4

3 2

1

J5

AUXBU S

AUXBU S

G

S

D

Q1

GND

OUT

IN

U3

D

C

B

A

.01uF each

C21-C2 4

C26

.1

RP 2

13

47K

RP 2

12

47K

RP 2

15

47K

RP 2

16

47K

RP 2

18

47K

RP 2

17

47K

W3

RA5

RA5

OSC1

OSC2

MCLR

AN0

AN1

AN2

RA3

RA4

RA5

RE0

RE1

RE2

VDD

VSS

RC0

RC1

RC2

SCK

RD0

RD1 RD2

RD3

SDI

SDO

RD4

RD5

RD6

RD7

VSS

VDD

RB0

RB1

RB2

RB3

RB4

RB5

RB6

RB7

TX

RX

10

15

20

21

25

30

35

40

PIC16F8 77AU1

5

1

R10 10K

R11 10K

S5A

S5B

Optional

W1

D9

1N4148

D10

1N4148

R12

4.7K

W21

W22

R8 10K

C5

.001

AN3

AN3

Band I/O

MON

MON

OP

DL OP DL

XCVR

VRDET

VRDET

VBB

SDO

SCK

SRWRT

W20

D1 4.7K 1/8 Watt

Figure 9 – KRC2 Schematic

Page 31

31

/SRCLR

SRCK

SOUT

VCC

RCK

SIN

GND

GND

GND

/Q0

/Q1

/Q2

/Q3

/Q4

/Q5

/Q6

/Q7

/G

12

13

19

11

10

14

15

16

17

18

2

9

8

3

4

5

6

7

U6

/SRCLR

SRCK

SOUT

VCC

RCK

SIN

GND

GND

GND

/Q0

/Q1

/Q2

/Q3

/Q4

/Q5

/Q6

/Q7

/G

12

13

19

11

10

14

15

16

17

18

2

9

8

3

4

5

6

7

U7

TPIC65 95

TPIC65 95

C27

.1

Elecraft

Rev. Sht. DateBy

1 of 1

J. Brindle

W. Burdick

KRC2 Remote Control/AuxBox

+5V

Driver Outputs: High-side

GND

CLK

SDI

VBBVDD

SDO

STQ1Q2

Q3

Q4

Q5

10

Q6

11

Q7

12

Q8

1315

16

OE

14

1

2

3

4

5

6

7

8

9

U4

GND

CLK

SDI

VBBVDD

SDO

STQ1Q2

Q3

Q4

Q5

10

Q6

11

Q7

12

Q8

1315

16

OE

14

1

2

3

4

5

6

7

8

9

U5

UCN5891A

UCN5891A

160

80

40

20

15

10

60

30

12

17

XV1

XV3

.01uF each

Driver Outputs: Low-side

/160

/80

/60

/40

/30

/20

/17

/15

/12

/10

/XV1

/XV2

/XV3

.01uF each

C28-C 43

C44-C 59

C60

.1

XV2

AC1

AC2

AC3

/AC1

/AC2

/AC3

4

3

2

1

J6

4

3

2

1

J7

4

3

2

1

J8

4

3

2

1

J9

4

3

2

1

J1 0

4

3

2

1

J1 1

4

3

2

1

J1 2

4

3

2

1

J1 3

SDO

SRWRT

SCK

VBB

C 02/12 /06

Page 32

32

PCB Layout

The corrected PCB layout is shown in Figure 10 for the top side and Figure 9 on page 31 for the

bottom side.

Figure 10 - KRC2 PCB corrected top view / silk screen parts placement

Page 33

33

Figure 11 - KRC2 PCB corrected bottom view / silk screen parts placement.

Page 34

34

Customer Service Information

Technical Assistance

If you have difficulty with kit construction, operation, or troubleshooting, we’re here to help. You

may be able to save time by first consulting our web site, www.elecraft.com, or by posting your

question on our e-mail forum,

elecraft@mailman.qth.net

. Telephone assistance is available

from 9 A.M. to 5 P.M. Pacific time (weekdays) at 831-662-8345. Via e-mail, use

support@elecraft.com for support and parts@elecraft.com to request replacement parts. Please use

e-mail when possible; this gives us a written record of the details of your problem.

Repair Service

If necessary, you may return your completed kit to us for repair. Contact Elecraft before mailing

your kit to obtain current information on repair fees. (Kits that have been soldered using acid core

solder, water-soluble flux solder, or other corrosive or conductive fluxes or solvents cannot be

accepted for repair.) The following information should be provided to expedite repair:

your name, address, and

phone number; your e-mail

address (if applicable); and

a complete description of

the problem.

Shipping: First, seal the

unit in a plastic bag to

protect the finish from dust

and abrasion. Use a sturdy

packing carton with 3" or

more of foam or shredded

paper on all sides. Seal the

package with reinforced

tape. (Neither Elecraft nor

the carrier will accept

liability for damage due to

improper packaging.)

Cover the "to" address label

with clear tape so it will be

weatherproof. Finally, call

or send e-mail to obtain the

proper shipping address.

Loading...

Loading...