Page 1

E L E C R A F T K N B 2 N O I S E B L A N K E R

Assembly and Operating Instructions

Revision D, Aug. 20, 2002. Copyright © 2002, Elecraft; All Rights Reserved

Introduction

The KNB2 noise blanker can be used to suppress most wide-band noise, including that generated by

automobile ignition systems, power lines, and appliances. In many cases, signals that were completely

"buried" in noise will become easy to copy with the blanker turned on.

Various settings are provided to make the noise blanker more versatile. Two blanking pulse widths are

available, as well as two noise threshold settings. These selections are made using the K2's front panel

and L E V E L buttons, respectively. Refer to Using The Noise Blanker for details.

The KNB2 plugs directly into the K2's RF board with no additional wiring. It is controlled by the main

processor on the control board via the K2's "AuxBus" network. (Complete circuit details can be found on

the back cover.)

Specifications

Blanking Widths NB1, 10 µS; NB2, 70 µS

N B

Current Drain Approx. 13 mA when turned on, 2 mA off

Size 2.3 x 1.4 inches (58 x 36 mm)

i

Caution: Some components in this kit can be damaged by static discharge. Before

handling any transistors or integrated circuits, always put on an anti-static wrist strap or touch any

grounded, unpainted metal surface.

Page 2

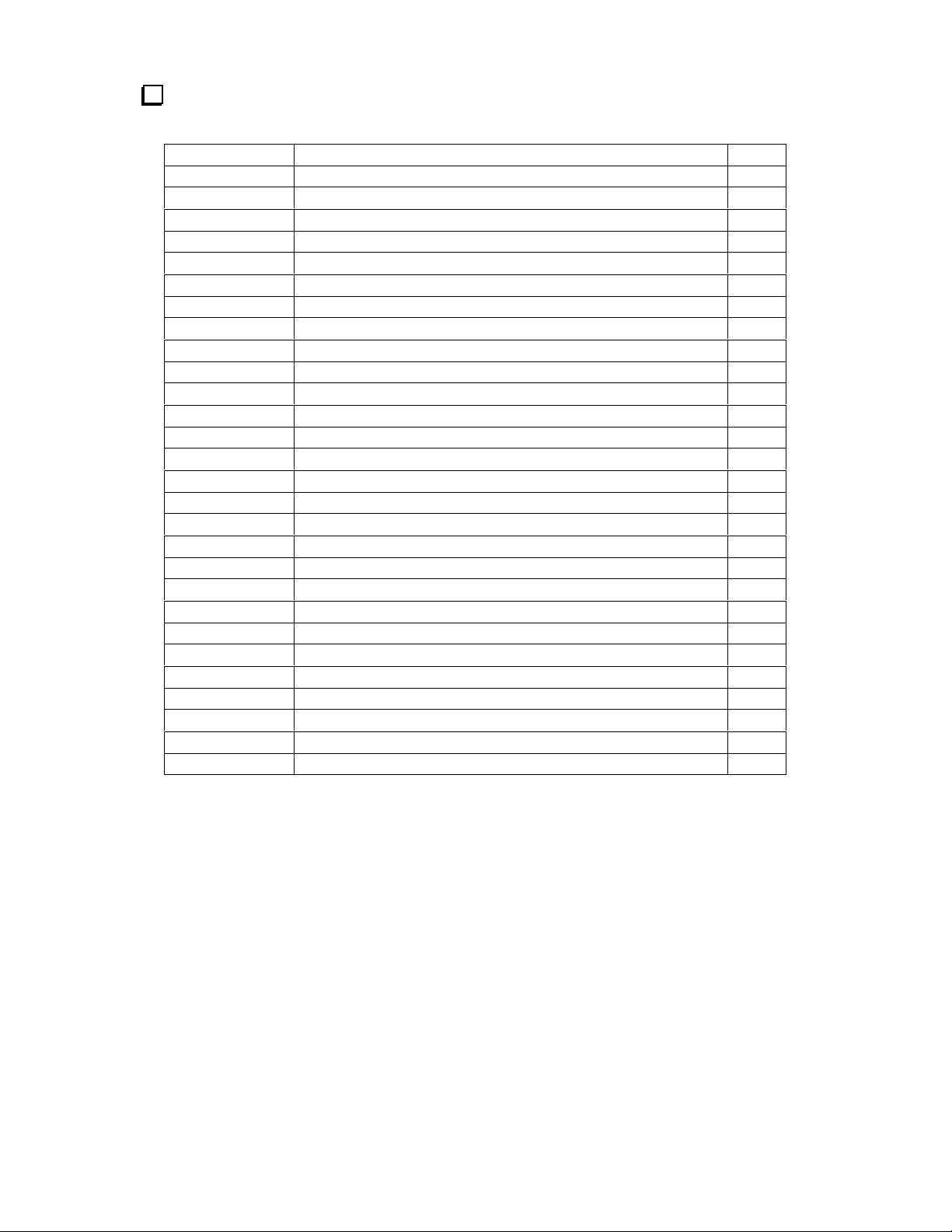

Parts Inventory

p

Qty

)

)

)

)

)

)

)

)

)

)

y)

Q1, Q2, Q4, Q

Q3, Q

Q

)

)

)

)

)

)

)

)

The table below lists all parts in the kit. If you have trouble identifying any of these items, consult the

K2 Owner's manual, which has photographs of similar parts.

Ref. Descri

C16 Capacitor, 39 pF, 5%, disc 1

C4 Capacitor, 100 pF, 5%, disc ("101"

C3 Capacitor, 820 pF, 5%, disc or monolithic ("821"

C9, C11, C13 Capacitor, .001 µF disc or monolithic ("102"

C6 Capacitor, 1500 pF, 5%, disc or monolithic ("152"

C7 Capacitor, 1800 pF, 5%, disc or monolithic ("182"

C12 Capacitor, .0068 µF disc or monolithic ("682"

C8, C14, C17 Capacitor, .01 µF disc or monolithic ("103"

C10 Capacitor, 0.1 µF disc or monolithic ("104"

C15 Capacitor, electrolytic, 22 µF1

D2, D3 Diode, 1N34A (alternates: 1N191, 1N5711

L1, L2 Toroidal inductor, 1.2 µH, 16 turns #26 on T37-2 core (red

L3 Toroidal inductor, 40 µH, 15 turns #26 on FT37-43 core (gra

P1 Conn., 8-pin male, 0.1" spcg., gold, Samtec TSW-108-07-G-S 1

7 Transistor, PNP, 2N3906 4

5 Transistor, NPN, 2N2222A 2

6 Transistor, MOSFET, 2N7000 1

R8 Resistor, 120 ohms, 1/4 W, 5% (brown-red-brown

R4, R5, R6 Resistor, 220 ohms, 1/4 W, 5% (red-red-brown

R9 Resistor, 300 ohms, 1/4 W, 5% (orange-black-brown

R3 Resistor, 1.8 K, 1/4 W, 5% (brown-gray-red

R7, RF-R88 Resistor, 2.7 K, 1/4 W, 5% (red-violet-red

R10 Resistor, 1 megohm, 1/4 W, 5% (brown-black-green

R1 Resistor, 100 K, 1/4 W, 5% (brown-black-yellow

RP1,RP2 Resistor network, 3.9 K, 4 resistors (isolated), 8 pins 2

U1 IC, RF amplifier, MC1350P 1

U2 IC, voltage regulator, 78L06 1

U3 IC, Microcontroller, 12C509A (alternate: 12C508A

tion

.

1

1

3

1

1

1

3

1

2

2

1

1

3

1

1

2

1

1

1

(parts list continues on next page)

2

Page 3

Ref. Description Qty.

J12 (RF board) Conn., 8 pin female, 0.1" spcg., gold, Samtec SSW-108-01-G-S 1

HDWR Split lock washer, #4 (Note: 2 spares provided) 6

HDWR Machine screw, 4-40 x 1/4", phillips 2

HDWR Standoff, 3/16" dia. x 3/8" long, round, 4-40 threaded 1

MISC Wire, #26 enamel 3 ft.

MISC KNB2 PC board, Elecraft P/N E100087 1

Assembly

i

The noise blanker board will be mounted directly above the K2's I.F. amplifier transistor,

Q22. To avoid shorts between the bottom of the noise blanker and Q22 (or Q22's heat sink), you must

trim all noise blanker component leads to 1/16" (1.5 mm) or less. Flush-cutters are ideal for this. If

you don't have flush-cutters, trim leads close to the board before soldering.

including C15). Bend the leads of each capacitor slightly to hold it in place. Trim the leads before soldering

or flush-cut afterward, as described above.

banded end of each diode as indicated by its PC board outline.

Install all of the capacitors in the order shown in the parts list (C16, C4, C3, etc., up to but not

Install electrolytic capacitor C15 with its positive (+) lead inserted into the hole labeled "+".

Install Diodes D2 and D3. These are glass-bodied diodes and should be handled carefully. Orient the

Install all of the transistors (Q1-Q7). (Note: Be sure not to install a transistor at the location labeled

"U2," near the standoff hole. U2 is a voltage regulator IC.) Transistors should be mounted so that their

bodies are approximately 1/8" (3 mm) above the PC board. Re-check each part number against the list

before soldering.

Install resistors R8, R9, and R10, which are located on the top side of the board near U1 (MC1350).

i

In the following step, you'll install several resistors on the bottom side of the PC board. Since

components on the top side of the board are very closely spaced, you should solder the bottom-mounted

resistors on the bottom side. This will prevent damage to top-mounted components. To avoid difficulty in

trimming resistors leads, pre-trim the leads to the correct length before mounting.

clearance is maintained for the I.F. amplifier (RF board, Q22), keep the resistors flush against the bottom of

the board. Pre-trim the leads and solder on the bottom side as explained above.

Install the remaining resistors, all of which are on the bottom side of the board. To ensure that

3

Page 4

Install resistor networks RP1 and RP2. These networks are symmetrical and can be installed in either

of two orientations. Note: Don’t confuse RP1 with connector P1, which also has 8 pins.

i

Before handling U3, touch an unpainted, grounded surface. This is a CMOS IC that can be

damaged by static discharge.

end of its PC board outline. The labels on the PC board correspond to the labels on the ICs.

Note: Sockets are not supplied and are not needed for these ICs.

inductor, “sew” the long end of the wire through the core exactly 16 times. Each pass through the core

counts as one turn. The winding should look like the illustration below, except it will have 16 turns.

Install 8-pin ICs U1 and U3. Be sure to align the notched or dotted end of each IC with the notched

Install voltage regulator U2. This device has a plastic body similar to a transistor.

Inductor L1 is wound on a T37-2 core (red) using 12 inches (30 cm) of #26 enamel wire. To wind the

Remove insulation

Spread out the turns of L1 so they occupy about 85% of the core’s circumference as shown.

Cut L1's leads to about 1/2" (12 mm) long. Completely remove the enamel insulation from the leads

to within 1/8” (3 mm) of the core. You can use a "blob" of solder, a solder pot, butane lighter, or sandpaper to remove the insulation. If you scrape the insulation off, be careful not to nick the wire.

Install L1 vertically on the PC board as shown by its component outline, then pull the leads taut on

the bottom of the board. Make sure that the exposed part of each lead is shiny and has no insulation.

4

Page 5

Trim and solder the leads of L1. When soldering, make sure that the solder binds well to the leads. If

P

the lead appears to be an “island” in a small pool of solder, chances are it is not making good contact. It’s a

good idea to measure from pad to pad using an ohmmeter to be sure the leads are making contact.

Wind and install L2 in exactly the same way as L1.

Inductor L3 is wound using 10" (25 cm) of enamel wire on an FT37-43 core (gray). Wind 15 turns

on the core, and prepare the leads as you did with L1 and L2. Install and solder L3 vertically as indicated

by its PC board outline.

Install 8-pin male connector P1 on the bottom of the PC board in the position indicated by its

component outline. Do not solder yet. The drawing below shows how P1 should appear viewed from the

left end of the board, with the component side up.

Components on top

1 (on bottom)

Solder just one pin of P1, near the middle of the connector. Verify that P1 is now perpendicular to the

PC board and is seated completely flat. If not, re-heat the soldered pin and press down on all of P1's pins

until the connector drops into place. Once the connector is seated correctly, solder the remaining pins.

Installation

Turn the K2 off and disconnect any power supply or battery connected to the DC power jack (J3).

Remove the top and bottom covers. (Do not remove the heat sink panel.)

Remove jumper W5 on the RF board (near the heat-sinked I.F. amplifier transistor, Q22). It is best to

de-solder W5 and remove it completely rather than just cut it at both ends. If the noise blanker must be

removed later, W5 can be re-installed, or you can insert a wire between pins 1 and 6 of J12.

Remove resistors R88, R89, and R90 from the RF board (near J12). Be careful not to damage any pads

or traces when you remove these components.

Install a short jumper wire at R89. You can use a discarded component lead.

Install a 2.7 k resistor at R88 (this resistor is listed as RF-R88 in the noise blanker parts list).

5

Page 6

Install the 8-pin female connector on the RF board at J12 as shown by its outline near W5. Do not

solder yet. The side view of J12, below, shows how it should appear once properly seated.

J12

Solder just one pin near the middle of J12, on the bottom of the RF board. Then, if the connector is not

sitting completely flat against the RF board (or is not vertical), reheat this pin and carefully press the

connector down. You may hear it snap into place. Then solder the remaining pins of J12.

Install the 3/8" (9.5 mm) standoff on the top of the RF board as shown below, using a total of three

split lock washers and a 1/4" (6 mm) machine screw. The mounting hole for the standoff is just to the right

of I.F. amplifier transistor Q22. Use two split lock washers between the standoff and the top of the RF

board in order to position the module at the correct height.

If Q22 on the RF board is not seated flat against the board, re-heat all three pins alternately and push it

down until it is flush. Make sure that Q22's heat sink is pushed down as far as it will go and is not loose.

Plug the noise blanker module into J12 (above Q22), being careful to line up all pins of P1 with J12.

Secure the module to the standoff provided using a 1/4" (6 mm) screw and one split lock washer.

Re-install the bottom cover (6 screws).

6

Page 7

Initial Test

Turn on the K2 and verify that you see the usual E L E C R A F T display. If you see I N F O 0 8 0 or no

display, you may have the noise blanker plugged into J12 incorrectly (offset by one or more pins). If it

appears to be installed correctly, check for a short on the 12 V or AuxBus lines (pins 3 and 7 of P1,

respectively).

i

Installing the noise blanker should have no effect on receiver sensitivity. If it seems that signals

have become weaker, L1 or L2 may have the wrong number of turns, or their leads may not be stripped and

tinned properly. Another possibility is an incorrect capacitor value at C3, C4, C6, or C7.

on the display. Leave the noise blanker in the O F F position for now. If you see N O T I N S T (not

installed), you may have U3 soldered in backwards or the noise blanker may not be plugged in correctly.

Tap the N B button on the front panel. As you tap this button, you should see N B 1 , N B 2 , and O F F

Using The Noise Blanker

The KNB2 works best on wide-band pulse noise, such as that created by power lines, auto ignition, and

some appliances. Like other pulse-type noise blankers, it will not suppress atmospheric (random) noise or

noise that occurs only at specific frequencies.

You should leave the noise blanker OFF unless noise is present. If signals become degraded with the

noise blanker turned on, try a different setting, or try turning off the preamp.

The

N B button controls the noise blanker mode, which is O F F on power-up. If you hear pulse-type noise,

first tap

does not improve the signal to noise ratio, tap

wider pulse width can result in audible modulation of strong signals, especially in CW mode.

N B to select N B 1 (narrow pulse width). The "NB" annunciator on the LCD will turn on. If this

N B again to select N B 2 (wide pulse width). Note: The

The

L E V E L button controls the blanking threshold. When you turn on the K2, the threshold will be set to

H I T H R . This means that only strong noise pulses will activate the blanker, which minimizes received-

signal degradation. However, on a quiet band or when using low-efficiency antennas, you may find the

L O T H R setting more effective. This is especially true when operating mobile, since a whip antenna may

be inefficient yet still pick up ignition noise. L O T H R is selected by holding

again switches back to H I T H R . The "NB" annunciator will blink whenever L O T H R is in use. This

serves as a reminder that any signal degradation that you hear may be due to the low blanking threshold.

Optional Modification for use with the Low Threshold Setting

If you use L O T H R frequently and find that it causes receiver modulation products to appear, it may be

helpful to solder a small capacitor between pins 7 and 8 of the MC1350 IC. A value of 33 pF is

recommended, but it isn't critical. Be sure that adding this capacitor doesn't cause problems with the

H I T H R setting. If possible, test the noise blanker before and after the modification using a controlled

noise source.

L E V E L , and holding it

7

Page 8

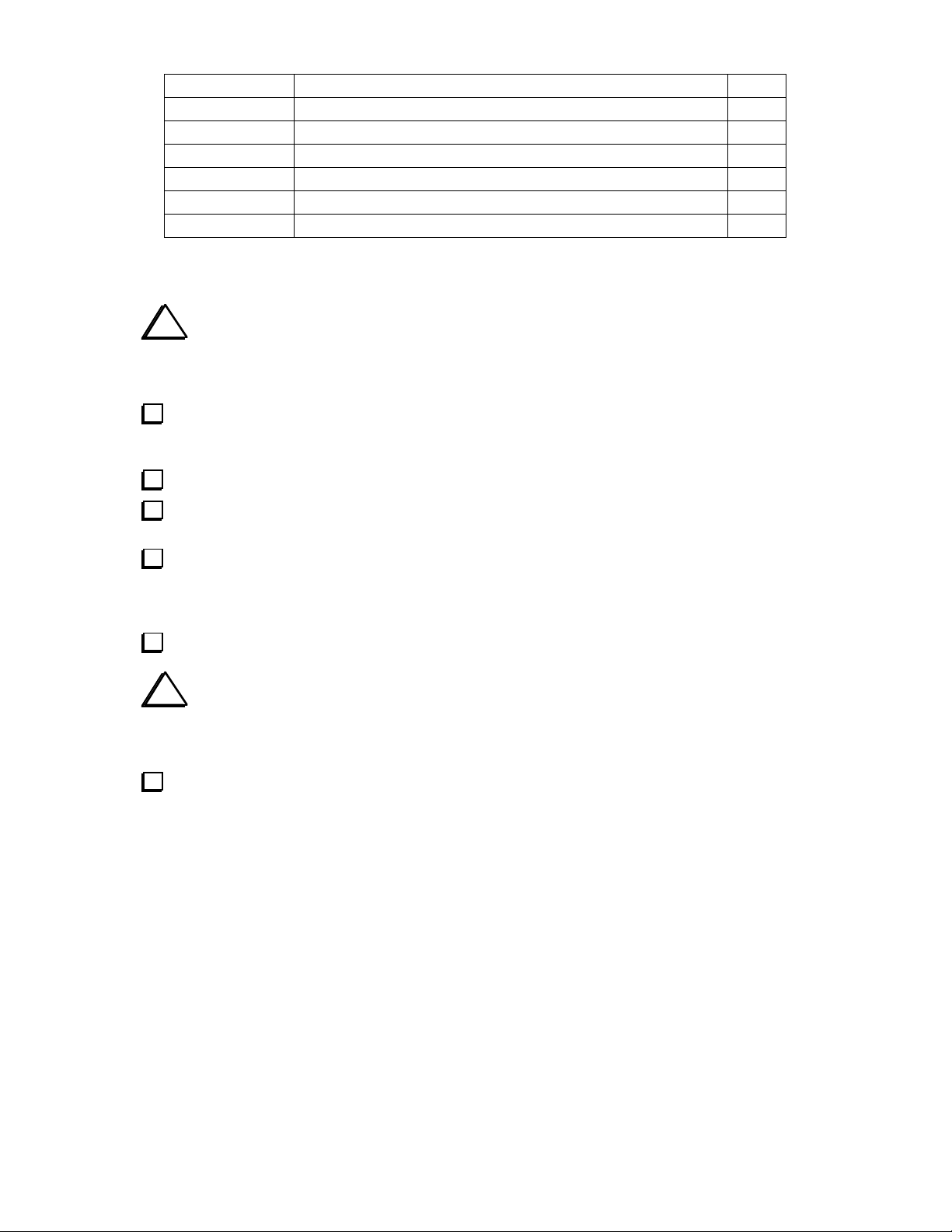

Circuit Details

U1 amplifies the I.F. signal, which is then detected by D2 (1N34A). Q1 reduces the gain of U1 in proportion to overall

signal strength, keeping the signal at D2 relatively constant. Negative-going pulses that are above the threshold

established by D3 and R3 turn Q2 on, triggering the one-shot (Q3/Q4). Q6 can be used to switch in a larger-value

capacitor, increasing the blanking time. The pulse output of the one-shot (GATE) saturates Q5, attenuating the signal at

the output of the band-pass filter. The band-pass filter creates a small delay between input and output, so that the GATE

signal arrives just ahead of the noise pulses. The controller, U3, decodes auxBus commands from the main processor. It

then controls power to the blanker (via Q7), pulse width (via Q6), and blanking threshold (via R3).

6NB

+

.01

1

2

P1

2N7000

S

ALC

Q1

2N3906

R1

100K

L3

40 µH

3.9K

RP1

C13

.001

C6

1500

C7

1800

To RF Board, J12

2N3906,

PN2222A

D

E

G

6NB

B

6

5

R10

1M

D2

1N34A

Noise Gate

C8

.01

RF OUT

AUXBUS

C

OUT

RP1

3.9K

.001

78L06

GND

2N3906

PN2222A

78L06

IN

C9

IN

1N34A

Q2

7

RP1

3.9K

8

Pulse Amp

Q5

R5

220

U2

OUT

R6

220

MC1350, 12C509A

1

2

3

45

6NB

Q3

PN2222A

Q6

2N7000

81

7

6

5

4

RP2

3.9K

3

2

RP2

3.9K

1

.001

SD

.0068

G

PULSE WIDTH

0V = NARROW

6V = WIDE

0V = ON

6V = OFF

Q4

2N3906

One-shot

C11

56

C12

6V Switch

Q7

2N3906

R7

2.7K

RP2

3.9K

RP2

3.9K

6NB

GATE

7

8

6V

D3

R3

1.8K

R4

220

THRESHOLD

0V = HIGH

6V = LOW

GATE

6V

VDD

VSS

2

GP5

C10

0.1

GP0

3

GP4

GP1

4

GP3

GP2

U3

12C509A

Controller

= On bottom of PC board.

8

7

6

KNB2 Noise Blanker

Elecraft

By

W. Burdick

E. Swartz

Rev. Sht.

Date

D 8-19-02

1 of 1

U1

MC1350

RF Amp

C16

39

Band-Pass Filter

(-6 dB)

R8

120

R9

300

C3

820

L1 L2

1.2 µH

12V

12345678

RP1

3.9K

34

C15

22µF

AGC

5867

C17

.01

100

C4

C14

1234

1.2 µH

Elecraft • www.elecraft.com • 831-662-8345

Loading...

Loading...