Page 1

ELECRAFT KAT2 AUTOMATIC ANTENNA TUNER

Assembly and Operating Instructions

Revision F, August 3, 2012. Copyright © 2012, Elecraft; All Rights Reserved

Introduction

The KAT2 internal automatic antenna tuner (ATU) allows nearly any antenna to be connected directly to

the K2 and used on most if not all bands. The L-network configuration provides a wide impedancematching range, and can be used directly with coax-fed or end-fed wire antennas, or with balanced

feedlines via a balun. Unlike some internal auto-tuners, the KAT2 functions on receive as well as transmit.

This provides an increase in receive sensitivity and improves rejection of out-of-band signals.

The KAT2 uses latching relays to reduce current drain to nearly zero except when actually tuning. These

relays select appropriate combinations of inductance and capacitance, as well as either a capacitor-in or

capacitor-out L-network configuration. Tune-up is controlled by the KAT2's microprocessor, which also

supplies SWR or power information to be displayed on the K2's LCD. Once a match has been found, the L,

C, and other matching network data are stored in EEPROM so that the settings can be recalled immediately

on any band change. ATU parameters (L, C, SWR, etc.) can also be viewed using the menu.

Two antenna jacks are provided on the ATU, with the matching network data for both antennas stored on a

per-band basis. Once an initial match has been obtained for both antennas on a particular band, the operator

can tap the

fraction of a second to switch, it becomes practical to quickly try both antennas anytime the distant station

is weak, an advantage during contest operation.

Specifications

L - C Ranges L: approx. 0-20 µH in 256 steps; C: approx. 0-2400 pF in 256 steps

Network Type L-network (series L, shunt C); C switchable to transceiver or antenna side

SWR Range Matched Up to 10:1 typ. (varies with band; smaller range on lowest/highest bands)

Tuning time 1 to 5 seconds typical for initial tune-up; < 1/2 sec. to recall stored settings

SWR Display 1.0:1 to 9.9:1

Power Display 0-20 watts (approx.); forward and reflected power shown in 0.1-w increments

Current Drain Approx. 10-30 mA during TUNE; < 5 mA at all other times

Size 4.2" (L) x 1.6" (D) x 1.5" (H) (10.7 x 4.0 x 3.8 cm)

ANT 1/ 2 button on the front panel to switch between them. Since the relays take only a small

Elecraft • www.elecraft.com • 831-763-4211

Page 2

Parts Inventory

The table below lists all parts in the kit. If you have trouble identifying any of these items, consult the

K2 Owner's manual, which has photographs of similar parts.

Components on KAT2 Module

Ref. Description Qty.

C1 Capacitor, 10 pF, 500 V NPO disc 1

C2 Capacitor, 22 pF, 500 V NPO disc 1

C3 Capacitor, 39 pF, 500 V NPO disc 1

C4 Capacitor, 82 pF, 500 V NPO disc 1

C5 Capacitor, 150 pF, 500 V NPO disc 1

C6 Capacitor, 300 pF, 500 V silver mica, CDE FD301J03 1

C7 Capacitor, 620 pF, 500 V silver mica, CDE FD621J03 1

C8 Capacitor, 1200 pF, 500 V silver mica, CDE FD122J03 1

C20-27, C31-38,

C42, C45-47,

C50-C53, C57, C60

C58, C59 Capacitor, 0.1 µF, 25 V ("104") 2

C54 Capacitor, 100 pF, 200 V, NPO disc ("101") 1

C55 Ceramic trimmer, 5-30 pF 1

D1, D2 Diode, 1N5711 2

E1 Screw terminal, PC-mount, Keystone #8190 1

J1, J2 BNC jack, PC-mount 2

J4, J5 Conn., 16-pin female, .1" spcg., gold, Samtec ESW-116-23-G-S 2

J3 Not used (connections are soldered; see text) 0

K1-K18 DPDT latching relay 18

L1-L7 Toroidal inductor, T50-2 core (RED); see text 7

L8 Toroidal inductor, T50-1 core (BLUE); see text 1

P4, P5 Conn., 16-pin male, .1", gold, Samtec MTSW-116-22-G-S-420 2

R1, R2 Trimmer potentiometer, 100K 2

R6 Resistor, 47 Ω, 5%, 1/4-watt (yellow-violet-black) 1

R3 Resistor, 200 Ω, 5%, 1/4-watt (red-black-brown) 1

R5 Resistor, 470 Ω, 5%, 1/4-watt (yellow-violet-brown) 1

R4 Resistor, 3.3 K, 5%, 1/4-watt (orange-orange-red) 1

T1 Toroidal transformer, FT37-43 core (gray); see text 1

U1 IC, Microcontroller, 16C77 1

U2 IC, EEPROM, 25LC320 1

U3 IC, 6-volt regulator, 78L06 1

U4 IC, Op-amp, LM358 1

Z1 Ceramic resonator w/internal capacitors, 4.0 MHz 1

Capacitor, .001 µF, 25 V("102") Note: Two of these capacitors

may be physically smaller than the other capacitors even t

though they have value. If so, reserve those capacitors for use at

C45 and C60.

26

2

Page 3

Hardware and Miscellaneous

Ref. Description Qty.

HDWR Rubber insulator, 0.5” dia. (round, black), p/n 6135-017-BLK 6

HDWR Socket for U1, 40 pins, open frame 1

J7 Conn., 2-pin housing, 0.156", Digikey WM2111 1

HDWR Female crimp pin for J7, gold, Digikey WM2305 2

J8 Conn., 10-pin dual-row 0.1" housing, Digikey WM2522 1

HDWR Female crimp pin for J8, tin, Digikey WM2556 12

RF-P6 Conn., 2p male, 0.156”, gold, Digikey WM5224 1

HDWR #4 split lock washer 6

HDWR 4-40 x 1/4” ZN ST Phillips machine screw 4

HDWR Standoff, 3/16” dia. x 13/16”, 4-40 thd, RAF #1642-440-A 2

HDWR Binding post, black, 6-32 threaded, Keystone #7007 1

HDWR BNC connector cap, black plastic, 3/8" dia. x 1/2” long 1

MISC Enamel wire, #26 Thermaleze, GREEN 2 ft.

MISC Enamel wire, #26 Thermaleze, RED 10 ft.

MISC Insulated hookup wire, #24, solid 1 ft.

MISC Cable, 4-conductor + shield, Digikey W404-X-ND 2 ft.

MISC Coaxial cable, RG-174 1 ft.

MISC KAT2 Control board 1

MISC KAT2 L-C board 1

MISC Cable ties, 3” 4

i

Caution: Some components in this kit can be damaged by static discharge. Before

handling any transistors or integrated circuits, always put on an anti-static wrist strap or touch any

grounded, unpainted metal surface.

K2 Firmware Requirements

To use the KAT2 antenna tuner, you'll need K2 main processor firmware revision 1.04 or later. (The main

processor is U6 on the K2's control board.) Revision 1.05 or later is recommended, since it provides

additional ATU operating features (see Using the ATU). The latest K2 firmware revision can be ordered as

an upgrade (refer to our web page for details).

To check your main processor firmware revision, hold any button when powering up the K2. The number

shown at the left end of the display is the revision number. If you have an older version, contact Elecraft.

3

Page 4

ATU Control Board Assembly

i

A fine-point, temperature-controlled soldering iron (700-800 degrees F) is required

to assemble this kit, due to the high density of the PC board layout. A high-wattage iron

or one with a wide tip may damage components, pads, or traces. Use a minimum amount

of solder to avoid ground shorts.

i

To avoid difficulties in soldering adjacent components, install components only in

the order described below. Double-check all values before soldering, since removing

parts from double-sided PC boards can be difficult.

There are two identically-sized PC boards in the ATU kit. Locate the ATU Control board, which is

labeled "ATU CTRL" on the bottom. Set the L-C board aside for now.

Referring to the parts list (page 2), install R3, R4, and R5. Note: R6 (47 Ω) and R5 (470 Ω) have very

similar color codes. Be sure to install the 470-Ω resistor at R5 (yellow-violet-brown).

Install D1 and D2 (1N5711), observing proper orientation of the banded end of each diode.

Install the capacitors listed below. The capacitor markings are shown (e.g., "102" = .001 µF).

IMPORTANT: If two of the capacitors are physically smaller than the others even though they

have the same value, use them at C60 and C45.

__ C57 (102) __ C58 (104) __ C60 (102) __ C59 (104) __ C53 (102)

__ C52 (102) __ C45 (102) __ C46 (102) __ C47 (102) __ C54 (101)

__ C50 (102) __ C51 (102)

Ceramic resonator Z1 looks like a capacitor with three leads. It is not polarized, so it can be installed

in either orientation. Install Z1 near U1.

i

The IC socket to be installed in the next step is an open-frame type. A smaller IC (U4) will be

installed within an opening in this socket. Do not substitute any other socket type.

Install the 40-pin IC socket for U1, with the notched end of the socket oriented towards pin 1.

Install voltage regulator U3, which has a 3-lead package like a transistor.

(Note: Touch a grounded metal surface before handling the following components.) Install the two 8-

pin ICs, U2 (25LC320) and U4 (LM358), with the notched end of each IC oriented as indicated by its

component outline. Note that U4 fits within the opening in U1's 40-pin IC socket.

The two latching relays, K17 and K18, must be installed with their white-striped ends oriented as

indicated on the PC board. Do not bend the relay leads. Solder two diagonal corner pins on each relay

first, then re-heat the connections and press the relays flat on the board before soldering the remaining pins.

4

Page 5

Install BNC jacks J1 and J2. These connectors must be seated flat on the PC board and aligned

with the board's edge to allow for proper installation in the top cover. Solder one of the alignment pins

first, then re-heat the connection while pressing down on the jack. Once you're sure the connector is seated

correctly, solder the other pins.

Install screw terminal E1. (If E1 was supplied with a screw, remove it. The screw will not be used.)

Like J1 and J2, this component's alignment is critical. Use the same mounting technique.

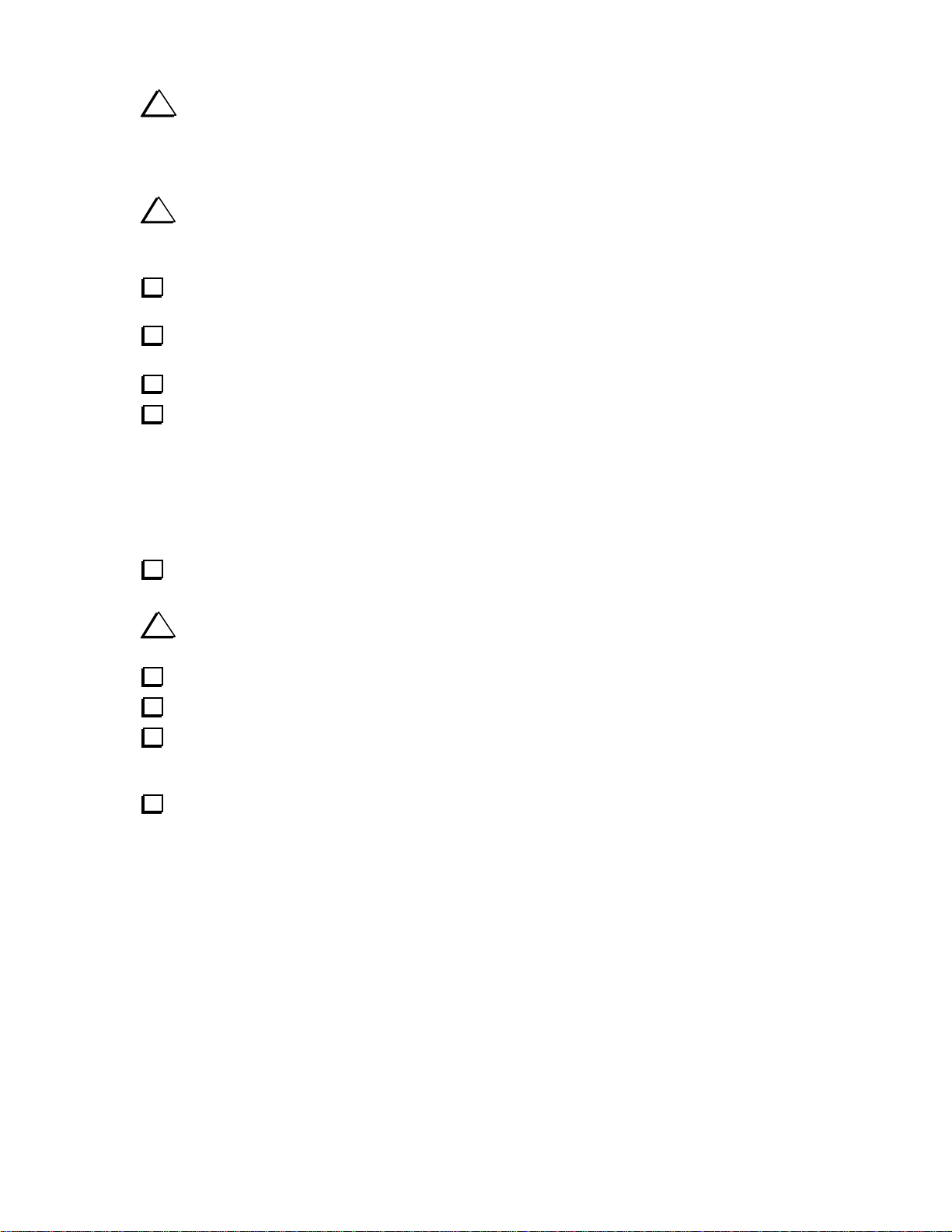

Transformer T1 is wound on a dark gray toroidal core (ferrite, 3/8" [9 mm] diameter). Cut two 10"

(25 cm) lengths of #26 enamel wire, one red and one green. Twist the two wires together loosely, crossing

over each other about 2 to 3 times per inch (once per cm). Then wind the twisted wires onto the core as

shown below, using 10 turns. Each pass through the core counts as one turn.

i

T1 must be wound exactly as shown, with leads 1 and 3 emerging from the back side of

the core and leads 2 and 4 from the front side.

4 (GRN)

2 (RED)

3 (GRN)

1 (RED)

Trim the leads of T1 to about 1/2" (12 mm) long. Completely remove the insulation from T1's leads

up to the edge of the core, using a solder pot or hot soldering iron tip. Do not attempt to burn off the

insulation using a match or lighter, as the flame may fuse the pairs of wire together, causing them to

become shorted. Another way to remove the insulation is to use fine sand paper.

Tin T1's leads with solder. If the leads do not tin easily, the insulation may not be fully removed.

Using an ohmmeter, measure between the red and green wires to make sure that they're not shorted.

Install T1 as indicated by its PC board outline near the right end of the board. Insert the leads into the

numbered holes as shown by the drawing of T1, above. Pull the leads taut on the bottom of the board.

Before soldering, use a magnifying glass to make sure that the entire portion of exposed lead is properly

tinned.

5

Page 6

Cut a 1-1/8" (2.9 cm) length of insulated, solid-conductor hookup wire. Remove exactly 1/4" (6 mm)

of insulation from each end. This jumper will form the 1-turn link winding of T1.

Insert one end of this wire through the center of T1 and into the pad labeled 5. Bend the wire down to

the right and insert the other end into the pad labeled 6. Pull the leads of the wire taut on the bottom of the

board, then solder.

Trimmer potentiometers R1 and R2 mount on the bottom of the ATU Control board. Press them down

as far as possible before soldering.

Set both trimmers fully clockwise as viewed from the bottom of the board.

Install trimmer capacitor C55 on the bottom of the board.

Note: The microprocessor and connectors J4 and J5 will be installed later.

ATU L-C Board Assembly

i

All L-C Board components should be mounted in the order given here. Any other assembly order

may make soldering or mechanical alignment difficult. Also, the components must be mounted as close as

possible to the board using short leads. Follow all instructions carefully.

Install .001 µF ("102") capacitors C20-C27 on the top of the L-C Board (the side with L1-L8 and C1-

C8). There should be no excess lead length above the board.

Install .001 µF capacitors C31-C35, C37-C38, and C42. Do not install C36 at this time.

Trim all capacitor leads on the bottom of the board to the shortest length possible.

Install relays K1-K16 on the bottom of the L-C Board as follows. First, position all 16 relays on the

board, without soldering. Align the white stripe on each relay with the striped end of its component outline.

(Note that the relays are in two rows that face in opposite directions.) Next, hold the relays in place using a

flat object such as a hard-cover book. Flip the PC board and flat object over together, then examine the

relays to make sure they are all still flat against the board.

Solder two diagonally-opposite corner pins on each relay. Look at all relays once more to verify

that they are not spaced any distance away from the board. Then solder all the remaining pins.

i

The following step is very important. Normally, relay pins need not be trimmed. But in this case

components will be mounted above the pins, so trimming them is necessary to prevent shorts. Trimming

must be done after soldering to prevent mechanical damage to the relay pins.

Trim all relays leads to the shortest possible length. Use flush-cut type diagonal cutters if available.

Note: Wear eye protection and aim the leads away from you when cutting. Trimming the leads over a waste

basket will eliminate cleanup.

6

Page 7

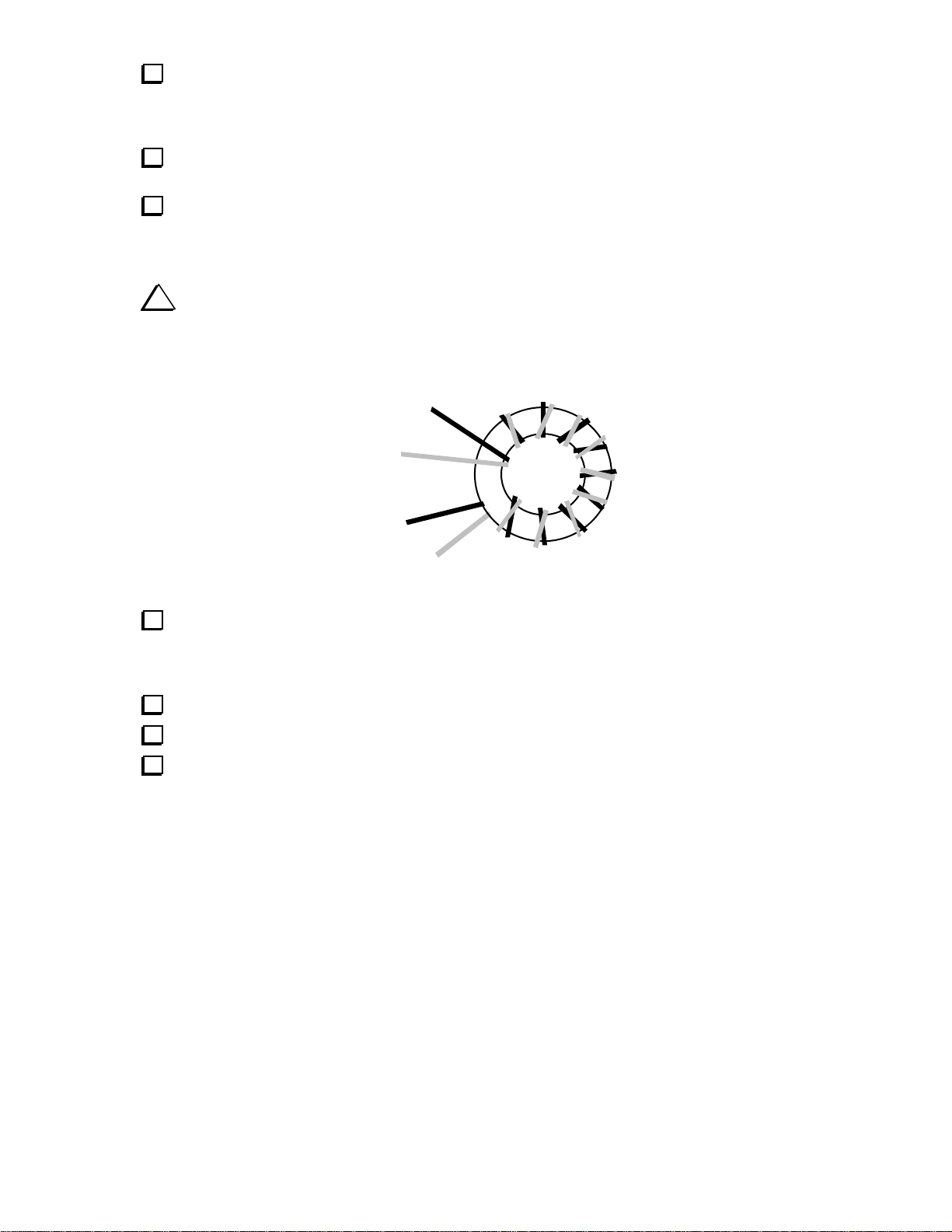

Refer to the drawing below during the following steps. This left end view shows how the L-C and

Control boards will appear when connected together. Relays K1 and K2 can be seen on the bottom of the

L-C board, along with 16-pin male connector P4. On the control board, J2 (BNC), R5, and R6 are visible,

as well as 16-pin female connector J4. The 13/16" standoffs are omitted for clarity.

L-C

P4

J4

Control

Locate the two 16-pin male connectors, P4 and P5. These connectors must be installed on the bottom

of the L-C board, between the two rows of relays (see above). Do not solder all pins of P4 and P5 at this

time. Instead, position the connectors, then solder only pins 1 and 16 on each connector. Make sure the

connectors are perpendicular to the board.

Install the two 16-pin female connectors, J4 and J5, on the top of the Control board as shown above.

Solder only pins 1 and 16 of each connector. Make sure the connectors are perpendicular to the board.

Plug the L-C board into the Control board as shown, mating P4 with J4 and P5 with J5. Be very

careful to avoid bending any pins on P4 and P5. Once the boards are properly mated, secure the L–C board

to the Control board standoffs temporarily using two 4-40 screws.

Press the two boards tightly together at both ends and in the middle. Once the 16-pin connectors

appear to be perpendicular to the boards and seated completely flat, solder all pins of P4, P5, J4, and J5.

Remove the screws holding the L-C board to the two standoffs. Then unplug the L-C board from the

Control board using the following method: Using a small screwdriver or Allen wrench, pry P4 upwards a

small amount, then pry P5 upwards a small amount, repeating this until the L-C board can be easily

unplugged. Do not pull the boards apart directly, as this may bend pins on P4 and P5.

Some pins on the bottom of the Control board must be trimmed to prevent shorting to the

K160RX option module. Trim the pins of the following components: E1, J5, C45, C46, C47, and J1

(signal pins only, not the large ground posts).

Carefully examine the entire ATU Control board for solder splashes or unsoldered pins (both sides).

Install C36 on the L-C board (.001 µF, "102").

7

Page 8

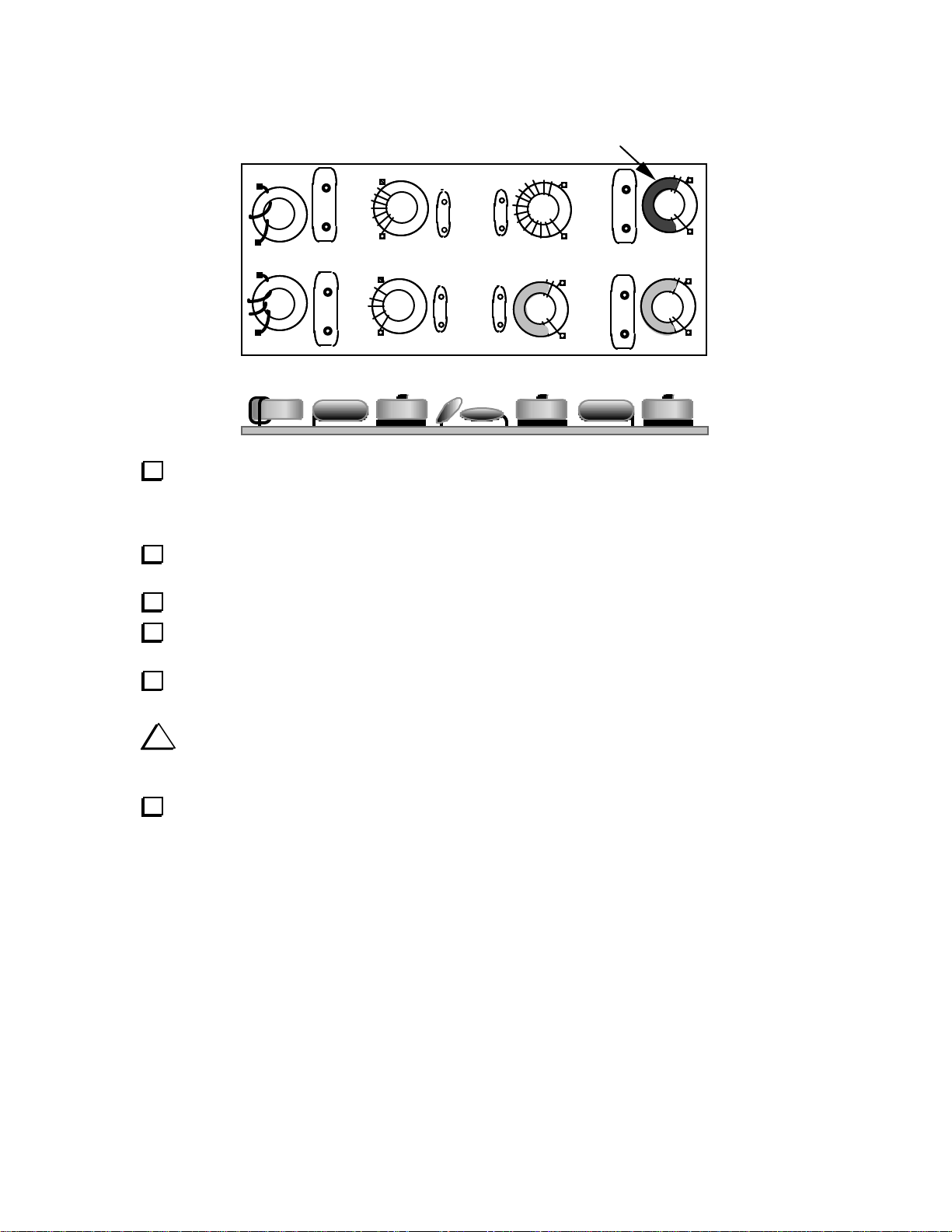

Refer to the drawing below during the following steps. The top view shows the approximate location of

the windings and pads for each inductor. The side view shows how capacitors C1-C8 and inductors L1-L8

must be mounted, including round rubber insulators for L3-L8.

BLUE CORE

L1

C5

C6 C8

L2 L7

Install C4 (82 pF) as shown above. Trim the leads to about 1/8" (3 mm) long, and bend them down at

right angles to the capacitor body. (Adjust the lead spacing to match the pads.) Insert the leads into the C4

pads just far enough to hold the capacitor in place. Do not insert the leads all the way through the board.

They could puncture the relay on the opposite side during soldering, causing a short.

Solder C4. Adjust the body of the capacitor so that it is parallel to the board and not overlapping the

location for C2 or L6. Also make sure it doesn’t touch any relay pins or pads.

Install C3 (39 pF) in the same manner as C4.

L4

C3C1

C2L3

C4

L5

C7

L8

L6

Install C1 (10 pF) and C2 (22 pF) as shown in the drawing, with the bodies of the capacitors tilted

over C3 and C4, respectively, at about a 45-degree angle.

Install C5 (150 pF), C6 (300), C7 (620) and C8 (1200). The bodies of these capacitors should be

parallel to the board and not interfering with adjacent components.

i

In the following steps, L1 through L8 will be wound and installed. There is no need to adjust the

windings to precisely match the inductances shown on the schematic. The inductances need only be

approximate, since for any given antenna match only a subset of the inductors will be used.

Cut a 2-1/8" (5.5 cm) length of insulated hookup wire. Remove 1/8" (3 mm) of insulation from each

end. Wind this wire onto a red toroid core as shown in the top view of the L-C board (2 turns).

8

Page 9

Position L1 and its winding so that you can insert the leads into the indicated square pads. Before

soldering, make sure that the insulated wire is positioned away from relay leads. Note: The toroid core may

remain somewhat loose within the winding after installation. This will not affect performance.

Cut a 2-7/8" (7.5 cm) length of hookup wire. Remove 1/8" (3 mm) of insulation from each end. Wind

this wire onto L2 (3 turns). Install L2 in the same manner as L1.

Wind L3 through L8 using red enamel wire and the number of turns listed below. Position the turns

as shown in the top view of the L-C Board. Note that L8 uses a blue core, while all others use red cores.

__ L3 (5 turns, 5" [12 cm]) __ L4 (7 turns, 6" [15 cm])

__ L5 (15 turns, 12" [30 cm]) __ L6 (22 turns, 17" [42 cm])

__ L7 (30 turns, 23" [58 cm]) __ L8 (31 turns, 24" [61 cm], BLUE core)

Trim the leads of all toroids to about 1/2" (12 mm). Completely remove the insulation to within about

1/8" (3 mm) of the core, using the same method used for T1. Tin the leads. If solder does not adhere well to

the leads, you may not have removed all of the insulation.

Install L3 as shown in the drawing. (Note: To avoid damage to the rubber insulators, they will be not

be installed until the next step.) Trim the leads so that when they are inserted into their holes, L3 sits

approximately 1/16" (2 mm) above the relay pads beneath.

Fold L3 up and place a rubber insulator underneath it. The insulator has a stem in the center that goes

through the core to hold it in place. Fold the toroid and insulator back down flat on the board. Inspect the

windings to make sure they don't touch any adjacent relay pads.

Install L4-L8 in the same manner as L3.

Examine the L-C board for solder splashes or unsoldered pins (both sides).

Locate the two 13/16" long (20.5 mm) standoffs. Install one standoff at each end of L-C board using

a 4-40 x 1/4" screw and one split lock washer between the standoff and the pc board. Refer to the end view

below.

COM PON ENT SIDE

9

Page 10

Cable Assemblies

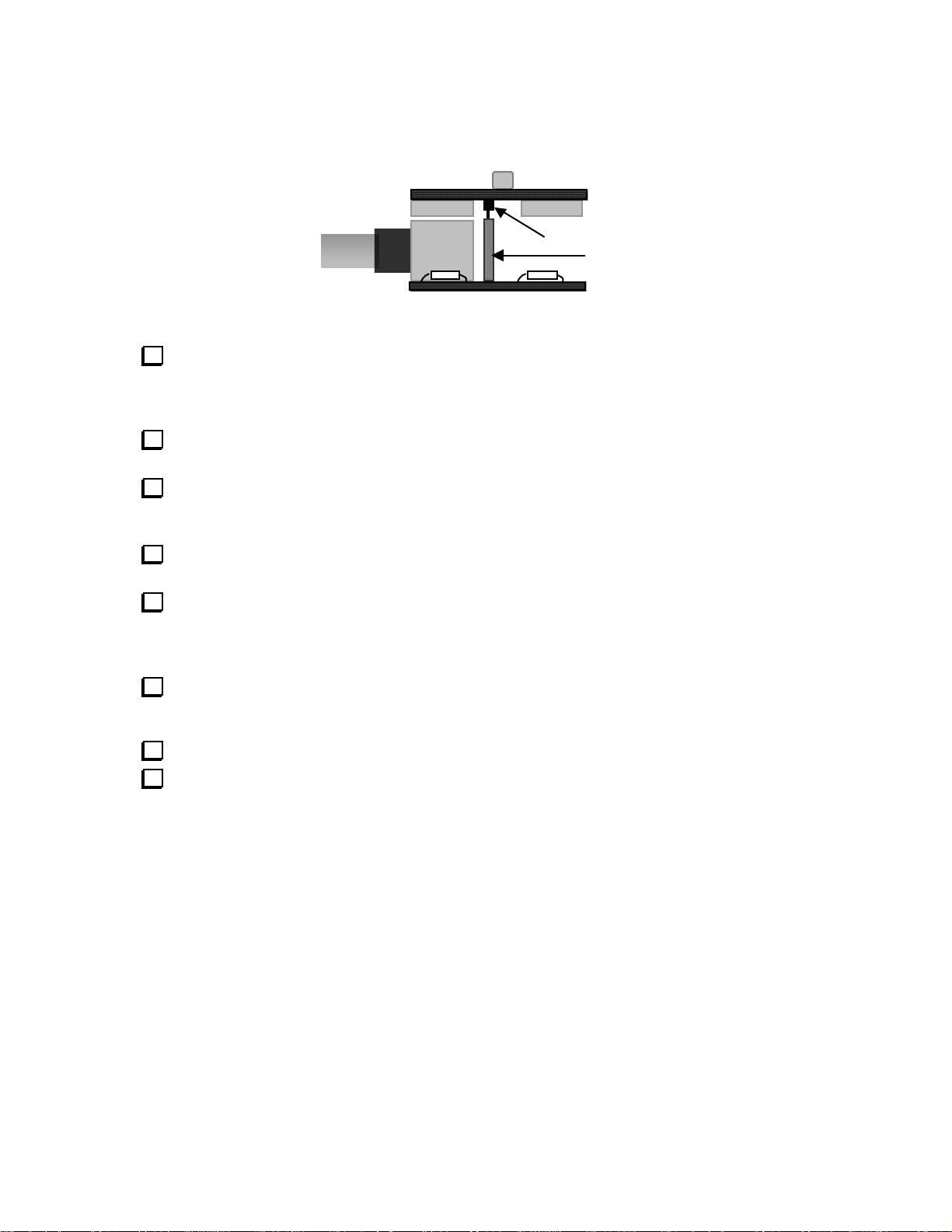

The drawing below shows the two cable assemblies that connect the ATU to the K2. A four-conductor

shielded cable is used for control signals (J3 to J8), and an RG-174 coax cable is used for RF (J7). J8 will

be connected to the K2's Control board. J7 will be connected to the RF board, near the low-pass filters.

J3

GREEN

BLACK

RED

WHITE

BARE

GND

BARE (nc)

WHITE

RED

BLACK

GREEN

J8

J7

ARROW

A C

B

10

J8

J7

RETAINER

Page 11

Cut one 15" (38 cm) length of the 4-conductor cable. Remove 3/4" (2 cm) of the gray jacket from

each end of the cable using a razor blade. Be very careful not to nick the conductors.

Carefully cut away the exposed portion of the foil shield. Once the wires are visible, examine them

for nicks. If any of the wires are nicked, cut all of the wires off and repeat the previous step.

Grip one of the insulated wires near the end using long-nose pliers, then strip off about 1/8" (3 mm)

of the insulation using a wire-stripping tool. (If you don’t have a wire-stripping tool, gently roll the wire

across a razor blade to cut the insulation to the indicated length.) Similarly, strip the remaining insulated

wires at both ends of the cable. Tin the ends of each wire.

Solder the five wires at one end of the cable to the ATU Control board pads indicated in the

illustration on the previous page. Make sure the bare wire's strands are tightly twisted together before

soldering. Note: The wires are not shown at their actual lengths in the drawing.

At the other end of the cable, cut the bare wire off.

Two sizes of crimp pins are supplied with the kit. The smaller pins are used at J8. (12 are supplied,

two of which are spares.) Attach crimp pins to each of the four insulated wires as shown in Detail A. The

insulated part of the wire can be held in place by squeezing together the tabs at the end. A second pair of

tabs is provided to hold the wire itself in place. Solder the wire to these tabs, using only the amount of

solder needed to make a clean connection. Excess solder may prevent insertion of the pin into the housing.

Locate the 10-pin housing for J8, and study the J8 detail drawings before attempting to assemble the

connector. Detail B shows the proper orientation of the crimp pins as they are inserted into the housing.

Detail C shows the retainer tabs on the crimp pins. When a crimp pin is correctly inserted, its retainer will

be visible through a hole in the side of the housing. The two rows of crimp pins face opposite directions.

You'll find an arrow on the housing near one of the small holes. Insert the green wire's crimp pin into

the associated large hole at the other end of the housing. Refer again to Details B and C.

Insert the remaining wires (with crimp pins) into the locations indicated. To provide good retention of

the connector when plugged in, you should also install crimp pins into each unused location of J8 as shown.

Check continuity of all connections between J8 (10-pin housing) and J3 (KAT2 control board end).

Cut the RG-174 coaxial cable in half to obtain two approx. 6" (15 cm) lengths. (Save one as a spare.)

Remove 3/4" (2 cm) of insulation from each end of the coax, taking care not to nick the braid. Separate the

strands of the braid, then twist about 2/3 of the strands together tightly. Trim off the remaining strands.

Remove about 1/8" (3 mm) of insulation from the center conductor at each end. Tin the wires.

Solder the braid and center conductor at one end of the coax cable to the pads labeled RF and GND.

These pads can be found at the right end of the ATU Control board as shown in the illustration.

Referring to the detail drawing of J7, attach and solder large crimp pins to the braid and center

conductor at the other end of the coax. (Use the same technique used for J8.)

Insert the two crimp pins into the 2-pin housing (J7) as shown in the drawing. Once each crimp pin is

snapped into place, its retainer tab must be visible in a small hole in the connector.

11

Page 12

The K2’s AUX RF connector (RF-P6) is the same type used for the internal battery connector (RFP3). To avoid damage to the ATU or to the K2, add some type of unique marking to RF-P6 and to its

mating ATU connector (J7). Use model paint, nail polish, or some other permanent medium.

i

Before handling the microprocessor in the following step, touch an unpainted, grounded surface or

put on a grounded wrist-strap.

Install U1, the PIC16C77 microprocessor, into its socket on the ATU Control board. The notched or

dimpled end of U1 goes to the left (towards R6). Make sure all pins are fully mated and that none are bent.

Plug the L-C board into the Control board as you did earlier, mating P4 with J4 and P5 with J5. Be

very careful to avoid bending any pins on P4 and P5. Press the two boards together along their full length.

Secure the Control board to the L-C board standoffs using two 4-40 screws and two #4 split lock

washers. These lock washers go between the screw heads and the PC board, not

board and standoffs as on the L-Cboard.

between the PC

Turn the K2 ON and use the

"i0.20", which shows the K2 drawing 200 mA or 0.2 amps). Write this number down. Then turn the K2 off

and disconnect the power supply and/or battery.

Remove the six screws identified below from the K2 top cover. Note: screws #3 and 4 must be

removed from the side panels, leaving two 2-D fasteners attached to the top cover. This is very

important since leaving these 2-D fasteners on the side panels would interfere with routing of the ATU

cables in later steps. If you remove the top cover in the future, always remove only the screws shown.

DISPLAY button to check the receive-mode current drain (for example,

12

34

56

Remove the top cover by lifting it from the back end. Disconnect the speaker and battery cables.

12

Page 13

i

Check the orientation of J8 carefully as described below before turning on power. Some

components could be damaged if power is applied with J8 plugged in incorrectly. If you have the

KIO2 serial interface option installed, J8 must be connected to P1 on the KIO2's "AUX2" junction

board rather than directly into the K2 Control board (see KIO2 manual).

Connect J8 (from the ATU Control board) to P4 (on the K2 Control board). The green wire (indicated

by the arrow on J8) corresponds to pin 2 of P4, and that end of J8 should be closest to the top edge of the

K2 Control board. Make sure that J8 is mated with all 10 pins of P4.

Mark the arrow end of J8 using model paint, nail polish, or an adhesive label with "UP" written on it.

Preliminary Tests

i

Do not transmit during these tests. Keep the ATU RF connector (J7) disconnected.

If you have the KIO2 serial interface option installed, you should disconnect it from the K2 control

board until KAT2 testing is complete. The KAT2 and KIO2 can then both be connected to the

control board using the small junction board supplied with the KIO2.

Connect a power supply or battery to the K2 and turn on power. If you see or smell smoke, turn

power OFF immediately. Check all connections and refer to the Troubleshooting section if necessary.

Tap DISPLAY to check the receive-mode current drain. The reading should be the same as you saw

earlier without the ATU module connected, or at most 20 mA higher. (Since current drain resolution is only

20 mA, it could appear to be 20 mA higher even though the actual increase is just a few milliamps.) An

increase of more than this could indicate a short on the ATU Control board.

Tap MENU and scroll through the entries until you find ATU. If the ATU Control board is

functioning, you'll see a parameter on the right end of the LCD. Hold EDIT to modify the parameter. If you

see two dashes (--) instead of the ATU parameter, refer to Troubleshooting.

Using the VFO knob, scroll through the ATU menu parameters. You may hear relays turning on and

off as you select various entries. You should see CALn, CALP, CALS, AUTO, ALT, POUT, etc.

Each menu entry will be explained in the Using the ATU section.

Set the ATU parameter to L0. You should hear a relay switch when you move from L0 to L1, then

to L2, etc., up through L8. The same should be true for C0 through C8, as well as N1 and N2. If you

don't hear any relays switching, see Troubleshooting.

Set the ATU parameter to AUTO and exit the menu.

Turn power off and back on. Use the menu to verify that the ATU parameter is still set to AUTO. If

not, U2 on the ATU (the EEPROM) may be installed backwards or have an unsoldered or shorted pin.

Tap the ANT 1/2 button, which is below the DISPLAY button. You should hear a relay switching,

and when antenna 2 is selected the ANT 2 annunciator will turn on. Leave the antenna set to ANT 1.

Turn off the K2 and disconnect the power supply.

13

Page 14

Disconnect the ATU control cable (J8) from the K2 Control board.

ATU Module Installation

The ATU is installed in the top cover as shown below. Refer to this drawing during the following steps.

C55

R2 (REFL)

R1 (FWD)

J7

J8

14

Page 15

If you have the 160-meter module installed (K160RX), remove its retaining screw and unplug the

module. Do not remove the RX Antenna connector or detach the 160-meter module from the heat sink.

Remove the K2's heat sink (6 screws, two 4-40 nuts, and the nuts on the antenna and key jacks), being

careful to save all of the hardware, including the PA transistor thermal insulators. The insulators may

remain attached to the heat sink, or they may fall off when the heat sink is removed.

Install and solder the 2-pin male connector at P6 on the K2 RF board, as shown by its outline on the

right-hand edge. (P6 is labeled AUX RF. Do not confuse P6 with P3, which is labeled AUX 12V.) P6 must

be oriented so that its plastic polarizing tab is towards the front panel of the K2.

Carefully examine all hardware associated with the PA transistors, Q7 and Q8, on the bottom of the

RF board. If any of the plastic hardware or the thermal insulators appears to be melted or damaged, you

should order the K2 PA Hardware Kit from Elecraft. Note: Do not bend the PA transistors upwards

any farther than necessary, as this may weaken their leads.

Re-install the heat sink using the method described in the K2 Owner's Manual. Do not over-tighten

any of the hardware.

Using a DMM on its lowest resistance scale, measure resistance from the collector of each PA

transistor (Q7, Q8) to ground. If you see a reading of less than 100 Ω, the heat sink may be shorted to one

of the transistor tabs. Remove the heat sink and correct the short before proceeding.

Re-install and secure the 160-meter module if applicable.

Cover the K2's main antenna jack (J4) with the black plastic BNC connector cap. This cap serves as a

reminder that the main antenna jack should not be used once the ATU is installed. Only the ATU's two

antenna jacks should be used.

If you have the K2 internal battery installed, you must remove the battery bracket temporarily in order

to install the ATU. (There is no need to remove the battery switch.) Before removing the battery bracket,

disconnect the (+) terminal lug and cover the terminal with tape.

Locate the ATU's ground binding post. The 6-32 threaded part of the binding post must fit easily

through the hole labeled GND on the K2 top cover. Some K2s may have the wrong size hole at this

location. If the shaft of the binding post does not fit, carefully enlarge the hole using a small flat-blade

screwdriver, file, or other small tool. (The binding post will be installed in a later step.)

Install the ATU module in the top cover in the location shown (previous page). The bottom of the

ATU Control board should be visible. Push the ATU module down into the top cover as far as it will go.

This will prevent any possibility of the module touching components on the 160-meter module.

Secure the ATU module to the top cover using the large lock washers and nuts supplied with the BNC

connectors. The threads on the connectors are plastic and can be easily stripped. Tighten them hand-

tight first, then turn them a small additional amount only (about 1/8 turn).

If applicable, re-install the internal battery, along with its cushioning material, bracket, and hardware.

(Lost hardware may be found sticking to the speaker magnet.)

15

Page 16

Route the ATU control cable approximately as shown in the drawing. If you will not be installing the

battery option at this time, leave a loop of the cable in the indicated position. Secure the ATU control cable

to the speaker and/or battery wiring using at least three of the supplied nylon cable ties.

Thread the binding post into the ground connector, E1 on the ATU control board, through the top

cover's GND hole. Tighten E1 using the large hex wrench supplied with the K2 as a lever. Insert either end

of the hex wrench into the wire-hole in the binding post, and tighten it until the serrated edge of the binding

post digs into the paint. Use an ohmmeter to verify that the binding post shows a very low resistance (< 1 Ω

to the top cover. If the resistance is high, carefully scrape some of the paint away by hand.

i

Check the orientation of J7 and J8 carefully as described below before turning on power.

Connect the ATU RF cable (J7) to the K2 RF board at P6 (AUX RF). The notch in J7's connector

housing must grip the locking tab of P6. Both the locking tab and notch should face the K2 front panel.

Make sure you have not plugged J7 into the internal battery connector on the RF board (P3), and

that the shield wire in J7 is closest to the side of the K2 when J7 is plugged into P6 on the K2 RF

Board.”

(indicated by the arrow on J8) corresponds to pin 2 of P4, and that end of J8 should be closest to the top

edge of the K2 Control board. Make sure that J8 is mated with all 10 pins of P4.

Connect the ATU's control cable (J8) to P4 on the K2 Control board (AUX I/O). The green wire

Examine both ends of the ATU's control and RF cables for shorted or loose wires.

Bridge Null Adjustment (C55)

Connect a 50-Ω dummy load rated at 5 watts or higher to the ATU's Ant. 1 jack.

Connect a power supply to the K2 and turn on power. (Do not install the top cover at this time.)

Select the 40 meter band (7000-7300 kHz). Set the K2's POWER control for about 5 watts.

If the ANT 2 annunciator is ON, tap the ANT 1/ 2 button to turn it OFF. This will select antenna 1.

Using the menu, change the ATU mode to CALn (Null). Exit the menu before proceeding.

Turn the FWD and REFL potentiometers on the ATU module fully clockwise (R1 and R2). Set C55

so that its adjustment slot is parallel to the K2's rear panel.

Note: When TUNE is activated in the following step, the display will show reflected voltage in millivolts

(e.g., 075 ATU). If C55 is not yet close to the proper position, you'll see HI instead of a number. You

should be able to get a reading of 010 or lower when C55 is properly adjusted.

Locate a small insulated-handle screwdriver, and prepare to adjust C55 on the ATU module. Hold in

the TUNE button and release it when you see the display change. Adjust C55 for an indication as close as

possible to 000. Tap or hold TUNE again to cancel the CALn display and return to receive mode.

You should find a 000 indication (approx.) over a small range of C55's rotation. Position C55 at

approximately the middle of this range, repeating the previous step as needed. (Note: Due to stray

capacitance on the L-C board, you may not see a 000 indication if you try to use CALn on higher bands.)

16

Page 17

Set up your DMM to read DC volts (20 or 30 volt scale).

On the bottom of the KAT2 control board, locate a pad labeled "B". Just to the left of this pad you'll

see the round pad for pin 1 of U4 (LM358). (You'll know you have the right round pad if it's part of a group

of 8 pads, 7 of which are square.) Touch your DMM's (+) probe to this pad. Connect your DMM's (-) probe

to any ground point on the K2.

In receive mode, the voltage at this test point must be 0 volts. If not, trace backwards through the

circuit to find where the voltage is coming from.

Go into TUNE mode briefly. At 5 watts, the voltage should be between 3 and 4 volts. If it is much

lower or higher than this, you probably have a wiring error in the SWR bridge. Remove the KAT2 control

board from the L-C board and check the wiring of T1. Make sure T1's leads are properly stripped.

Once you have the correct voltage indicated at U4 pin 1 in TUNE mode, install the 47-ohm resistor at

R6 (yellow-violet black). The two pads for R6 can be found looking at the bottom of the KAT2 control

board. First, locate a pad at one end of the board labeled "6V". The pads for R6 are above and below the

"6V" label. R6 can be installed on either side of the board (the component outline is located on the top, the

side with the microprocessor, etc.).

Power Calibration (R1 and R2)

Connect a known accurate wattmeter between the ATU's Ant. 1 jack and a 50-Ω dummy load. Use

short, low-loss coax cables. (An alternative to using an external wattmeter is to use an RF probe and DMM

connected to the dummy load. The reading shown on the DMM's DC volts display can be converted to

power using the formula P = V* V/ R, where R = 50. Example: 15.8 V on the DMM = about 5 watts.)

Select the 40 meter band (7000-7300 kHz). Set the K2's POWER control for 5.0 watts.

Tap the ANT 1/2 button if necessary to make sure that the ANT 2 annunciator is OFF.

Using the menu, change the ATU mode to CALP (calibrate power). Exit the menu.

Note: The ATU's power display shows both forward (F) and reflected (r) power, e.g. 5.0F 0.0r

(5.0 watts forward, 0.0 watts reflected). After calibration, accuracy will typically be +/- 0.5 watts.

Locate a small flat-blade screwdriver and prepare to adjust R1 on the ATU module. Hold in the

TUNE button and release it when you see power displayed. Adjust R1 for a power indication that matches

the reading of the external wattmeter. Hold TUNE again to return to receive mode.

Repeat the previous step as needed until the ATU reads the same as the external wattmeter.

Set R2 to exactly the same position as R1 (visually). This will provide adequate reflected-power

reading accuracy. You can position R2 more accurately by measuring the resistance from the wiper (center

terminal) to ground. Rotate R2 until its wiper-to-ground resistance closely matches that of R1.

Using the menu, change the ATU mode to CALS (calibrate SWR). Exit the menu. Verify that the

SWR is about 1:1 on each band using TUNE. Make sure that ANT 1 is selected on each band. Due to stray

capacitance, the SWR may not be exactly 1.0:1 on the highest bands; this will not affect performance.

17

Page 18

Final Assembly

Turn off the K2. If you have the 160-meter option installed: make sure it is pressed into its socket and

is secured to its standoff. If the capacitors on the module stick up above the toroids, fold them down at an

angle. Also, the ground lug on the receive antenna jack must be rotated down towards the K2's RF board.

Re-install the top cover, being careful to route the ATU, battery, and speaker cables so that they do

not come too close to the transmitter or synthesizer areas of the K2 RF board (back right and front left,

respectively). Also, make sure the ATU RF cable is not pinched between panels at the back of the K2.

Secure the top cover with six screws.

Using The ATU

Caution: Never touch an exposed antenna wire when transmitting. If you ever feel an RF burn or

shock when touching the K2 chassis, key, or microphone, see Antenna Considerations.

Basic ATU Operation (AUTO Mode)

To get started with the KAT2:

• Use the K2 menu to select ATU AUTO mode, then exit the menu.

• Connect one or two antennas to the ATU's antenna jacks.

• Tap the

• Reduce power to 2-3 watts using the POWER control to maximize the life of the ATU relays

(this may also be done automatically, as explained later)

• Hold TUNE. SWR will be displayed while the ATU matches the transmitter to the load (1-5 sec typ.).

• Watch the display for the final SWR reading. The ATU itself will terminate TUNE mode.

• Set power output back to the desired level.

• If you move significantly off frequency you may need to tune-up the antenna again.

• ATU settings are stored in EEPROM, then recalled instantly when you change bands or antennas.

ANT 1/ 2 button to select Antenna 1 or Antenna 2. The antenna switch works in all modes.

Displaying Forward and Reflected Power (POUT Mode)

The wattmeter in the ATU, once calibrated, is much more useful than the K2's standard RF detector. It will

provide accurate readings even when the load is not 50 ohms. Since the ATU's wattmeter output is fed back

to the K2, your POWER control settings will now be more accurate, too.

To use the wattmeter:

• Change the ATU mode from AUTO to POUT. The antenna tuner’s L and C settings will not change.

(If you have revision 1.05 or later of the K2 main microcontroller firmware, you can hold DISPL AY

and TUNE together to force the ATU into POUT mode.)

• Hold TUNE; forward and reflected power will be displayed until you hold TUNE again to cancel.

• If the actual power output is lower than you set with the POWER control, you may have the POWER

control set higher than the K2 is capable of on the present band. Always set POWER to a level at or

below the maximum that the K2 can achieve. Use lower power when running from a battery.

18

Page 19

Displaying

To display SWR following any auto-tune:

• Use the menu to change the ATU mode from AUTO to X.X-1 (the most recent SWR reading).

Example: 1.5-1 is the same as 1.5:1. The antenna tuner’s L and C settings will not change.

• Hold TUNE; the present SWR will be displayed until you hold TUNE again to cancel.

Bypassing the Matching Network (CALS and CALP Modes)

You can use the ATU as an SWR bridge or wattmeter only, with the matching network disabled. You

might want to do this if you're using an external antenna tuner or a resonant antenna.

To bypass the matching network, use CALS (for SWR display) or CALP (for power display). In both

cases, the L and C in the matching network will be set to approximately zero. There is some stray L and C

present that will slightly affect SWR readings on the higher bands.

As an alternative to CALS or CALP, you can tune up the ATU into a 50-ohm dummy load on each band

using AUTO mode. This will cancel out most or all of the stray inductance and capacitance so that you

can connect your external tuner or resonant antenna. After tuning up on all bands, put the ATU into

POUT or SWR (x.x-1) mode (described earlier). The matching network settings will not change.

Important ATU Operating Tips

• To maximize life of the ATU’s relays and avoid HI CUR warnings, we recommend reducing

power to 3 watts before using TUNE in AUTO mode (antenna tune-up). This is done for you

automatically if you have K2 firmware revision 1.05 or later; see below.

• Two antennas can be compared very quickly using the

• If the tuner doesn't get the SWR quite to 1:1, you can try holding TUNE a second time.

However, a 1:1 SWR is not necessary for good performance. See Antenna Considerations.

• If you switch between the various ATU modes frequently, you may wish to assign the

ATU menu entry to PF1 or PF2 (see the K2 Owner's Manual for details).

• If you tap DISPLAY to show the voltage/current display, then hold TUNE, you'll see the transmit-mode

battery voltage and current drain, not SWR or power output. The ATU settings will not change.

• You can still use the RX antenna switch on the 160-m option module, which is independent of the ATU.

• The ATU menu entry can be used to display the current values of L, C, network type, and other data.

See ATU Modes for a full listing of all status displays.

SWR (x.x-1 Mode)

ANT 1/ 2 button once they're both tuned.

If you have K2 Main Microcontroller firmware revision 1.05 (or later):

• TUNE mode automatically reduces power to 3 watts if you had the POWER control set higher

than this. After auto-tune, the power level is restored to your POWER control setting. During tune-up,

the bargraph will show 3 bars as a reminder that power has been reduced.

• Holding DISPLAY and TUNE together forces the ATU to display forward/reflected power

even if the tuner is in AUTO (or ALT) mode. This is useful when you want to simply check power

output without doing an auto-tune.

19

Page 20

Antenna Considerations

An antenna tuner will not improve your antenna–it can only tune out the antenna's reactance. In general,

use the longest, highest antenna you can put up, and keep the antenna away from power lines and buildings.

The KAT2 will work with a wide variety of antennas, some of which are covered below.

A good ground system will provide efficient radiation, better antenna loading characteristics, less RF on the

chassis, and safer operation. Use a minimum of two radials cut for each band, or at least one or two very

long radials. House plumbing and electrical wiring will provide an adequate ground in some cases, but

tuned radials are always preferred

Do I Need a 1:1 SWR?

No. This is a common misconception. For example, if the SWR is 2:1, the loss in transmitted signal

strength will be around 0.5 dB. Of course the KAT2 always tries to hit 1:1, and with most antennas it will

find an SWR below 1.5:1 on most bands. But even if the SWR ends up at 3:1, the difference in on-air

signals will often be undetectable. If the SWR is higher than 3:1 you may want to try ALT mode (see

Hard-to-match Antennas).

Resonant and Multi-Band Antennas

The KAT2 will tune up nearly any antenna cut for 40 or 80 meters on all bands. With multi-band antennas

such as beams or verticals, the KAT2 will typically improve the match on each band used. It will also allow

operation on additional bands. However, when you tune-up a beam on one of these "no extra charge"

bands, it is likely to become a no-gain or low-gain antenna with an unpredictable radiation pattern.

One useful trick with coax-fed antennas is to short the center conductor and braid together and treat the

coax as if it were a random wire. This will often allow beams and quads to be used down to 160 meters.

Random-Length Antennas

Nearly any piece of wire over about 30 feet long and end-fed can be tuned up on 80-10 meters, and

probably 160 meters as well. Results will vary depending on the actual length of the antenna and whether

you have a useful ground system. Watch for RF problems, which are more likely with end-fed antennas,

especially if they’re exactly a half-wavelength long or any multiple thereof on a given band.

The KAT2 also works well with loops. An untuned loop of wire 30 feet long (or longer), formed into any

shape, can be matched on most of the higher bands. Loops can be very narrow-banded if they're small in

relation to frequency, so you may need to re-tune after relatively small frequency excursions. Use ALT

mode if necessary (see Hard-to-match Antennas, below).

If possible, put up two wire antennas (especially for Field Day, etc.). You can then do quick comparison

tests as often as necessary using

units may be observed on some signals.

ANT 1/ 2. With two orthogonal long-wires, differences of one to three S-

20

Page 21

Hard-to-match Antennas (ALT Mode)

You may find that a particular antenna just can't be matched using AUTO mode. This is especially likely

with electrically short antennas, such as mobile whips. In this case, try the ALT tuning mode. ALT can

take longer because it tries more L/C combinations, but it may be the only choice in difficult cases. If you

experience an RF burn or feedback problems, ALT tuning mode won't help. Instead, you may need a balun

or RF isolation choke (see below). Also try increasing the length of the ground radials and/or antenna.

Note: Avoid connecting a heavy whip antenna fitted with a BNC plug directly to the ATU. The whip

will stress the BNC connector, and could even damage the ATU's Control board. Instead, mount the whip

on a metal plate, tripod, etc. Connect it to the ATU's antenna jack with hookup wire rather than coax if it's

only a few feet away. A good ground will dramatically improve the performance of a short whip.

Using Baluns and RF Isolation Chokes

A balun is a device that converts a balanced antenna or feedline to unbalanced (one side grounded) to work

with your ATU. A balun can also perform an impedance transformation and/or help isolate the antenna

from the tuner to reduce RF pickup. You may need a balun if: (1) you're using balanced feedline; (2)

you're having trouble matching an antenna on one or more bands; (3) you notice RF feedback or get an RF

burn. A low-loss, broad-band, 4:1 balun is a good choice, and may solve all three problems. A 9:1 balun is

often used with 450 or 600-Ω open-wire line, but since the tuner can handle a wide range of impedances,

4:1 may work just as well. A 1:1 balun will also work in most cases. All baluns exhibit some loss, but the

loss may be negligible if the balun is used properly.

ATU Modes

The table below lists all ATU modes, and what is displayed when TUNE is pressed in each mode. AUTO

mode is used most of the time, and occasionally ALT or POUT. (With K2 firmware rev. 1.05 or later,

you can hold DISPLAY and TUNE together to force POUT mode.) The other modes are primarily used

for calibration and troubleshooting. If you see LO P in any mode that displays SWR, power is too low to

obtain a stable SWR reading. You should increase the POWER setting if this occurs.

When you switch between CALS mode and AUTO mode, you may hear a few relays switching, since in

CALS mode (as well as CALP and CALN) the L and C relays are all reset (L and C are zero). You'll

also hear relays switching if you select the L0-L8, C0-C8, N1, or N2 modes (see Troubleshooting).

In AUTO and ALT modes the ATU terminates TUNE automatically.

Mode Description

CALn Used for C55 calibration; L/C = 0 mVDC NETx 1=Cin, 2=Cout (present band/ant.) SWR

CALP Used for calibration of R1; L/C = 0 Power Txxx L-C-net combinations tried SWR

CALS SWR bridge only; L/C = 0 SWR Exxx 0-199 = error (see Troubleshooting) SWR

AUTO Normal auto-tune mode SWR INIT Turning power off/on resets all data SWR

ALT Alternate auto-tune mode SWR Fx.xx KAT2 firmware revision, e.g. F1.00 SWR

POUT Forward/Reverse power display Power L0-L8 Individual inductor selection SWR

x.x-1 SWR from most recent tune-up SWR C0-C8 Individual capacitor selection SWR

Lxx.x Inductance, µH (present band/ant.) SWR N1 Selects Cin network (L/C = 0) SWR

Cx.xx Capacitance, nF (present band/ant.) SWR N2 Selects Cout network (L/C = 0) SWR

TUNE

Mode Description

TUNE

21

Page 22

Troubleshooting

If current drain is too high or the ATU menu parameter shows "--", verify orientation of all connections between

the ATU module and the K2. You may have a connector shifted by one position, an unsoldered crimp pin, etc. Check

both boards for shorts to ground, solder bridges, and unsoldered connections. Verify that the microcontroller is fully

seated in its socket and is not plugged in backwards. Finally, do the voltage checks listed at the end of this section.

If you can't get a reading of 010 or lower using CALn, or if readings seem way off, examine all components and

connections in the SWR bridge, especially T1's windings (which may be reversed or not making contact). Make sure

you don't have the center conductor and shield exchanged at J7. Check continuity of wires in the control cable (J8).

If the SWR doesn't read 1.0:1 with a 50-Ω load (or other calibrated load), it's probably due to stray reactances (see

Bypassing the Matching Network). C55's setting may also affect SWR accuracy.

If you see an error message in the ATU menu (Exxx, where xxx is between 001 and 199), chances are the EEPROM

(U2) is defective or is installed backwards, or you may have a defective microcontroller.

If tuning is erratic or you see frequent HI-CUR warnings, you may have high RF voltages on the K2 chassis. First,

try reducing power to 1 to 2 watts. If this cures the problem, you may need to improve your ground system, move the

antenna farther away, or use a balun. If reducing power doesn't help, or if tuning is erratic even with a 50-Ω dummy

load, you may have a communication problem between the ATU and K2. Check the value of R5 (470 Ω) and C57 (.001

µF). If these are correct, try removing the SSB adapter's microcontroller (if applicable), then re-test. If this cures the

problem, contact Elecraft. If not, check each of the following components, any of which could cause problems with the

AuxBus line if they were the wrong value: K2CTRL-R6 (470 Ω), K2CTRL-C12 (.001 µF), K2RF-R64 (470 Ω), K2RFC140 (.001 µF), SSB-R12 (470 Ω), SSB-C30 (820 pF), NB-R6 (470 Ω), NB-C9 (.001 µF).

If you receive a "distorted audio" signal report when using SSB, you could have any of the RF problems listed

above, or your microphone may be sensitive to RF. Some mics have a DTMF generator IC that can be activated by

stray RF. Try disabling this IC. You may be able to simply disconnect the DC supply voltage to the mic at the Front

Panel mic configuration connector. Also try grounding the mic jack.

If a particular tune-up that you believe should work fails repeatedly, write down the ATU parameters after the

TUNE attempt, including SWR, L, C, NET, Exxx, Txxx, and the ATU firmware revision. Send this data to Elecraft for

analysis. Also try ATU INI T.

If the tuner is unable to achieve a low SWR on some bands, even with several different antennas, you could have a

single defective relay or component on the L-C board. Start by slowly scrolling through ATU parameters L0 through

L8, C0 through C8, N1, and N2. At each setting you should hear relays switching. If you find one that doesn't, this

may pinpoint a bad relay. You can also check each L and C relay using resistance measurements. For example, when

you select L1, pins 4 and 7 of K1 should be shorted, and with all other Lx settings these pins should be open. When you

select C1, pins 2 and 9 of K9 should be open, and with all other Cx settings, these pins should be shorted. L0 and C0

turn off all L and C relays. If the relays are all working but you suspect an inductor or capacitor, you can test each L

and C by noting their effect on SWR, one at a time. Start on 10 meters. Connect a 50-ohm dummy load to one of the

antenna jacks, select L0, hold TUNE, and note the SWR reading. Then select L1 and hold TUNE again; the SWR

should change by a small amount. L2 should have a larger effect, etc. When the inductance selections cause the SWR

to go off the scale (9.9), switch to a lower band (say 30 meters), go back to L0, then test the remaining inductors.

Similarly, you can test all 8 capacitors, starting on 10 meters with C0, C1, etc. You'll know you have found the bad

component if it has too large or small an effect (or no effect) on SWR, in relation to the others tested.

DC Voltages

All pins of U1 through U4 should measure close to 0 volts (in receive mode), with the following exceptions: U1 pins 1,

11, 20, 32, and 39: 6 V; U1 pin 40, 5.7 V; U2 pins 1, 3, 7, 8: 6 V; U3 IN, supply voltage; U3 OUT, 6 V; U4 pin 8, 6 V.

Tolerance on all measurements is +/- 0.3 V.

22

Page 23

Circuit Details, KAT2 L-C Board

The L-C board provides eight series inductors and eight parallel capacitors, configured as an L-network. The

capacitance can be placed at the transmitter or antenna end of the network via a relay on the Control board (see next

page). Each inductor and capacitor has its own DPDT relay, with the individual sections of each relay placed in parallel

for reliability. The relays are selected under control of the ATU's microcontroller. Latching relays are used so that they

will not consume any power except when the operator is actually tuning. The relays are switched one at a time to keep

switching current low and to provide acoustically and electrically quiet operation. This results in somewhat longer tune

times.

For additional reliability, the connectors used between the L-C and control boards have gold-plated contacts, and

redundant pins are used for RF signals. Bypass capacitors are used on relay control lines to prevent RF signals from

reaching the microcontroller.

L-C Board Schematic

L8 is wound on T50-1 core (blue). All others are wound on T50-2 core (red).

*

L-NET OUT

L1 L2

.08µH .16µH

K1

3

24

9

7

8

K2

3

24

9

7

8

L3 L4

X

.32µH

K3 K5

3

24

9

7

8

K4

3

24

9

7

8

L5 L6

Y

3

24

9

7

8

L7 L8

K6

3

24

9

7

8

K7

3

24

9

8

*

10.4 µH.64 µH 1.3 µH 2.6 µH 5.2 µH

L-NET IN

K8

3

24

7

9

7

8

C1_2

C1

10

K9

3

7

8

K10

24

9

7

C3_4

C2

22

3

24

9

8

C3 C4

39 82

K11

3

7

8

K12

24

9

7

C5_6 C7_8

3

24

9

8

P4

123456789 123456789

.001

C20

C23

C22

C21

10 10K210

10

1111

K1

K13

NOTE: K1-K18 are single-coil latching relays, shown in the RESET position.

Pins 5 and 6 of each relay are used as tie points but are not internally connected.

= On bottom of PC board. All relays on the L-C board are on the bottom.

10 11 12 13 14 15 16 10 11 12 13 14 15 16

C5_6

10 10

1111

K4

K14

X

K9

C1_2

.001 .001 .001

C24

C25

C26

C27

10

10

K3

RELAY COMMON

K10

C31

C42

C32

.001

C33

C34

23

K13

C5

150

3

7

8

C3_4

K14

24

9

10 10

11

K5 K6 K7

K11

C6

300

3

7

8

K15

24

9

P5

Y

10 10

11

K12 K15 K16

C7_8

10 10

11

C7

620

3

24

9

7

8

10

1

K8

Elecraft

By

W. Burdick

E. Swartz

C8

1200

K16

3

24

9

7

8

C35

C36

C37

C38

10

1

KAT2 ATU L-C Board

Rev. Sht.

Date

F 11/27/00

1 of 2

Page 24

Circuit Details, KAT2 Control Board

T1, D1, D2 (etc.) form a directional coupler for SWR and power measurements. This type of bridge is much more

accurate than the K2's standard RF detector (D9) in the presence of non-50-ohm loads. The bridge output is buffered by

op-amp U4 and routed to the K2 control board, overriding the signal from D9. The bridge outputs are also connected to

A-to-D inputs on the microcontroller, U1. U1 measures these voltages and converts them to SWR or power readings,

using averaging and linearization techniques to improve accuracy. The EEPROM (U2) stores network and SWR data

for each band and antenna. K17 selects either a capacitor-in or capacitor-out network configuration, while K18 controls

the antenna switch. U1 "sleeps" at all times except during actually antenna tune-up, so it generates no receiver noise.

Control Board Schematic

Antenna Switch

C47

.001

1

2

3

4

Elecraft

By

W. Burdick

E. Swartz

J1

K18

2439

Antenna 1

8

7

J2

Antenna 2

L-NET IN

J5

10 11 12 13 14 15 16

8

/CS

VCC

7

/HOLD

SDO

6

/WP

SCK

5

VSS

SDI

U2

25LC320

KAT2 ATU Control Board

Rev. Sht.

Date

11/27/00

2 of 2

F

6V

J3

Aux I/O

RF

GND

GND POST

FWD

54321

U4A

LM358

R6

47

FWD

SWR Bridge

65

T1

E1

D1

1N5711

C50

.001

C52

.001

U4B

5

+

6

-

NOT USED

AUXBUS

12V

6V

8

1

4

231

4

C54

100

R3

D2

200

1N5711

R1

R2

100K

7

+

-

L-NET OUT

C57

.001

3

2

R5

470

G

C58

0.1

C55

5-30pF

R4

3.3K

C51

.001

REFL

C53

.001

123456789 123456789

6V

6V

C60

U3

IN

LM78L06

OUT

.001

C59

REFL

0.1

L-NET IN

(Sheet 1)

24

9

K17

C TX/ANT Select

CAP COMMON

J4

10 11 12 13 14 15 16

nc nc

A

40

RB7

MCLR

1

35

RB3

RB4

RB5

RB6

RA0

RA1

RA2

5

B

VDD

RB0

RB1

RB2

RE1

RA4

RA3

RA5

RE0

10

U1

16C77

MCU

L-NET OUT

3

7

8

C45

K18

.001

K17

11

10 10

RELAY

COMMON

C46

.001

30

RD4

RD5

RD6

RD7

VSS

RE2

RC7

RC0

VDD

VSS

OSC1

OSC2

15

25

RC6

RC1

4.0MHz

21

RD3

RC4

RC5

RC2

RC3

RD0

RD1 RD2

20

Z1

= On bottom of PC board.

24

Loading...

Loading...