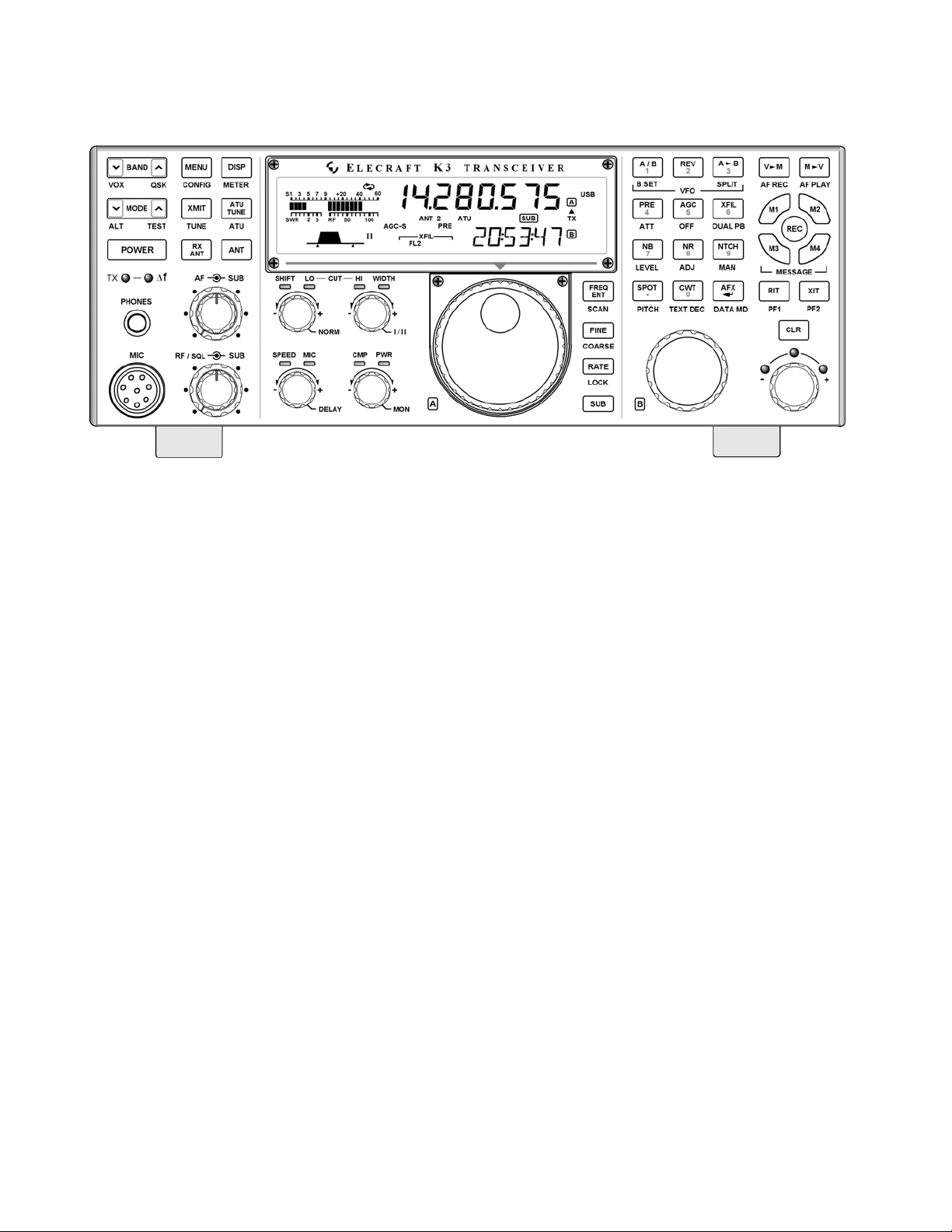

ELECRAFT

HIGH-PERFORMANCE 160 – 6 METER

T

RANSCEIVER

K3

KIT ASSEMBLY MANUAL

Rev M, September 3, 2014

Copyright © 2014, Elecraft, Inc.

K3

All Rights Reserved

Contents

Introduction ............................................................ 2

Customer Service and Support .................................. 3

Technical Assistance ............................................. 3

Preventing Electrostatic Discharge Damage ......... 5

How ESD Damage Occurs ........................................ 5

Preventing ESD Damage ........................................... 5

Preparing for Assembly ......................................... 6

Overview of the Kit ................................................... 6

Tools and Test Equipment Required ......................... 8

Unpacking and Inventory .......................................... 9

Screws ................................................................... 9

Standoffs ............................................................. 10

Lock Washers ...................................................... 10

Assembly ............................................................. 11

RF Board and Chassis ............................................. 12

RF Board Description ......................................... 12

RF Board and Chassis Assembly Procedure ....... 12

KANT3 or KAT3, Right Side and Rear Panels ...... 20

KANT3 or KAT3 Description............................. 20

Installing KANT3 or KAT3 Antenna Connectors

............................................................................. 20

Installing KRX3 AUX RF (ANT) Connector ..... 20

Preparing Right Side Panel for Installation ......... 23

Mounting the KANT3 or KAT3, Side and Rear

Panels .................................................................. 24

KIO3 Interface ........................................................ 27

KIO3 Description ................................................ 27

KIO3 Interface Installation Procedure ................ 27

Front Panel and DSP ............................................... 31

Front Panel and DSP Description........................ 31

Front Panel Assembly Procedure ........................ 31

Mounting the Subreceiver Auxiliary DSP Board 39

Installing the KDVR3 Digital Voice Recorder

Option .................................................................. 41

Mounting the DSP Board Assembly on the Front

Panel .................................................................... 42

Mounting the Front Panel Assembly ................... 44

Resistance Checks ............................................... 48

Initial Power On Check ....................................... 49

KREF3 Reference Oscillator ................................... 49

KREF3 Description ............................................. 49

KREF3 Installation Procedure ............................ 49

KSYN3 Synthesizer ................................................ 52

KSYN3 Description ............................................ 52

KSYN3 Installation Procedure ............................ 52

Loudspeaker ............................................................. 55

Loudspeaker Description ..................................... 55

Loudspeaker Installation Procedure .................... 55

KPA3 Shield ............................................................ 57

KPA3 Shield Description .................................... 57

KPA3 Shield Installation Procedure .................... 57

Bottom Cover .......................................................... 59

Bottom Cover Description ................................... 59

Bottom Cover Hardware Installation Procedure .. 59

KNB3 Noise Blanker ............................................... 61

KNB3 Noise Blanker Description ....................... 61

KNB3 Installation Procedure ............................... 61

Battery BT1 ............................................................. 62

Battery BT1 Description ...................................... 62

Battery BT1 Installation Procedure ..................... 62

KBPF3 General Coverage Receive Option ............. 63

KBPF3 Description .............................................. 63

KBPF3 Installation Procedure ............................. 63

Power Amplifier Jumper Block ............................... 64

Finishing the Enclosure ........................................... 64

Fan Opening Cover .............................................. 64

AUX RF Cable .................................................... 64

Bottom Covers ..................................................... 65

Top Cover

............................................................ 67

Test and Calibration ............................................. 69

Initial Power Checks ................................................ 69

Synthesizer Calibration ............................................ 70

Filter Setup .............................................................. 71

Reference Oscillator Calibration ............................. 71

TX Gain Calibration ................................................ 71

Option Modules ....................................................... 72

Enable Modules ....................................................... 72

KPA3 100-Watt Amplifier Installation ................... 72

KRX3 Subreceiver Installation ................................ 72

Other Calibration Procedures .................................. 72

Wattmeter Calibration (Optional) ............................ 72

S-Meter Calibration (Optional) ................................ 72

Appendix A, Illustrated Parts List.............................. A1

Elecraft manuals with color images may be downloaded from

www.elecraft.com

1

.

Key to Symbols and Text Styles

Identifies important information.

-100

DISP

AVERAGE

MENU:Font

Characters displayed on the LCD screen

Tap switch function (labeled above a switch)

Hold switch function (labeled below a switch; hold for 1/2 sec. to activate)

Typical menu entry

2

Introduction

This manual will guide you through assembly of your Elecraft K3 transceiver. We’re confident that you’ll find

the K3 easy to build, even if you’ve had no prior kit-building experience.

Every modern transceiver is complex, and the K3 is no exception. The kit includes nearly 300 individual

components, including over a dozen PC boards and a multi-element modular chassis. But the K3's unique design

eliminates some of the tedious aspects of construction, enabling you to complete assembly in far less time than

previous high-performance transceiver kits. Also, virtually all of the alignment is handled in firmware using the

K3's built-in test capabilities.

If you should you have difficulty, you'll have our full support via phone and e-mail. In addition, we hope you'll

join our growing and enthusiastic community of owner/builders via the Elecraft reflector.

Further information about the Elecraft K3, including specifications, installation, and operation instructions, can

be found in the Owner’s Manual.

Elecraft manuals with color images may be downloaded from www.elecraft.com.

Customer Service and Support

Technical Assistance

You can send e-mail to K3support@elecraft.com and we will respond quickly - typically the same day Monday

through Friday. Telephone assistance is available from 9 A.M. to 5 P.M. Pacific time (weekdays only) at

831-763-4211. Please use e-mail rather than calling when possible since this gives us a written record of the

details of your problem and allows us to handle a larger number of requests each day

Repair / Alignment Service (We want to make sure everyone succeeds!)

If necessary, you may return your Elecraft product to us for repair or alignment. (Note: We offer unlimited email

and phone support to get your kit running, so please try that route first as we can usually help you find the

problem quickly.)

.

IMPORTANT: You must contact Elecraft before mailing your product to obtain authorization for the

return, what address to ship it to and current information on repair fees and turn-around times. (Frequently we

can determine the cause of your problem and save you the trouble of shipping it back to us.) Our repair location

is different from our factory location in Aptos. We will give you the address to ship your kit to at the time of

repair authorization. Packages shipped to Aptos without authorization will incur an additional shipping charge

for reshipment from Aptos to our repair depot

.

3

Elecraft's 1-Year Limited Warranty

This warranty is effective as of the date of first consumer purchase (or if shipped from factory, date product

is shipped to customer). It covers both our kits and fully assembled products. For kits, before requesting

warranty service, you should fully complete the assembly, carefully following all instructions in the manual.

Who is covered: This warranty covers the original owner of the Elecraft product as disclosed to Elecraft at

the time of order. Elecraft products transferred by the purchaser to a third party, either by sale, gift or other

method, who is not disclosed to Elecraft at the time of original order, are not covered by this warranty. If the

Elecraft product is being bought indirectly for a third party, the third party's name and address must be

provided to Elecraft at time of order to insure warranty coverage.

What is covered: During the first year after date of purchase, Elecraft will replace defective or missing parts

free of charge (post-paid). We will also correct any malfunction to kits or assembled units caused by

defective parts and materials. Purchaser pays inbound shipping to Elecraft for warranty repair, Elecraft will

pay shipping to return the repaired equipment to you by UPS ground service or equivalent to the continental

USA and Canada. Alaska, Hawaii and outside U.S. and Canada actual return shipping cost paid by owner.

What is not covered: This warranty does not cover correction of kit assembly errors. It also does not cover

misalignment; repair of damage caused by misuse, negligence, or builder modifications; or any performance

malfunctions involving non-Elecraft accessory equipment. The use of acid-core solder, water-soluble flux

solder, or any corrosive or conductive flux or solvent will void this warranty in its entirety. Also not covered

is reimbursement for loss of use, inconvenience, customer assembly or alignment time, or cost of

unauthorized service.

Limitation of incidental or consequential damages: This warranty does not extend to non-Elecraft

equipment or components used in conjunction with our products. Any such repair or replacement is the

responsibility of the customer. Elecraft will not be liable for any special, indirect, incidental or consequential

damages, including but not limited to any loss of business or profits.

4

Preventing Electrostatic Discharge Damage

There is no climate or work location where the components of your K3 are safe from Electrostatic Discharge

(ESD) unless you take specific steps to prevent such damage. Many of the components in your K3 can be

damaged by static discharges of only a few volts: far too little for you to notice. It is those low-voltage but

destructive discharges that easily happen anywhere and under virtually any environmental conditions.

ESD damage may not be apparent at first. The damaged components may not fail completely. Instead, the

damage may result in below-normal performance for an extended period of time before you experience a total

failure.

How ESD Damage Occurs

Whenever an object containing a static charge touches a circuit in your K3, current will rush into the circuit until

the components reach the same voltage as the source of the static charge. If the voltage or current that passes

through a component in your K3 during that brief period exceeds its normal operating specifications, it may be

damaged or destroyed.

Preventing ESD Damage

ESD damage cannot occur if there is no voltage difference between the components in your K3 and any object

that touches them. That is how anti-static packaging works. Anti-static bags allow the static charge to flow over

their surface, so that any part of the bag that touches the components inside are all at the same potential at all

times. Anti-static foam keeps the leads of sensitive components at the same potential.

At your work bench, avoiding a dangerous voltage is achieved most easily by tying everything together and

connecting them to a common mains safety ground. This includes your K3, individual boards or other sensitive

components as well as everything they may touch at the work table.

Inexpensive static dissipating work mats are readily-available that will steadily and safely drain off any charges

built up on parts or circuit boards placed on them. They are supplied with a lead that connects the mat to the

common workbench ground. Also, metal cabinets on test equipment used on the bench should be tied together

and connected to the common ground.

Most importantly, you must have a way of continuously draining off any static charges that occur on your body.

Such charges are easy to create, even while sitting quietly at the work bench. Moving your feet on the floor,

shifting position in your chair or even moving your arms so that clothing rubs against itself can all produce

destructive static charges. You can discharge yourself by touching an unpainted metal ground, but that will last

only until you move in a way that produces a new static charge. The safest technique is to wear a grounded wrist

strap with a series 1-megohm resistor that continuously drains off any charges. Such wrist straps are readilyavailable and inexpensive.

WARNING

DO NOT attach a ground directly to yourself without a current-limiting resistor as this poses

a serious shock hazard. A wrist strap must include a 1-megohm resistor to limit the current

flow. If you choose to touch an unpainted, metal ground to discharge yourself, do it only

when you are not touching any live circuits with your other hand or any part of your body.

5

We strongly recommend you take the following anti-static precautions (listed in order of importance) to avoid

trouble:

Leave ESD-sensitive parts in their anti-static packaging until you install them. The packaging may be a

special plastic bag or the component’s leads may be inserted in conductive foam. Parts which are

especially ESD-sensitive are identified in the parts list and in the assembly procedures.

Wear a conductive wrist strap with a series 1-megohm resistor. If you do not have a wrist strap, touch a

ground briefly before touching any sensitive parts to discharge your body. Do this frequently while you

are working. You can collect a destructive static charge on your body just sitting at the work bench. DO

NOT attach a ground directly to yourself as this poses a serious shock hazard.

Use a grounded anti-static mat on your work bench.

If you choose to use a soldering iron to work on your K3 for any reason, be sure the iron is ESD-safe

with a grounded tip tied to the same common ground used by your mat or wrist strap.

Preparing for Assembly

Overview of the Kit

The kit comprises two major assemblies: the main chassis and the front panel. Figure 1 shows an assembled

K3/10 with its top cover removed.

The main chassis is literally built up around the RF circuit board, which fills the entire bottom of the unit of the

chassis assembly. Panels are mounted around the RF board using Elecraft’s 2D fasteners. These fasteners allow

individual removal of any one panel, if needed, to gain access to the inside of the radio for servicing. Very few

cables or wires are used in the kit. Most of the other boards and optional accessories plug directly into the RF

board or one of the boards mounted on the RF board.

The front panel assembly, including the display and main operator controls, includes the front panel board and

the digital signal processing (DSP) board.

There are many options that you can add to the basic K3/10, such as the 100 watt amplifier module, internal

antenna tuner, second receiver, additional crystal I.F. filters, etc. If you purchased these options with your K3

kit, you will find instructions to install them at proper places in the assembly procedure to make getting your

complete K3 together and operational in the most efficient manner.

6

Figure 1. Typical Assembled K3/10 (Less Top Cover and Chassis Stiffener Bar).

7

Tools and Test Equipment Required

1. #0 and #1 size Phillips screwdrivers. To avoid damaging screws and nuts, do not use a power

screwdriver. Use the screwdriver that best fits the screw in each step.

2. Soft cloth or other surface to lay cabinet panels on to avoid scratching. A clean static-dissipating mat is

ideal (see below). If using cloth, do not lay circuit boards on it. See Preventing Electrostatic

Discharge Damage on page 5.

3. Pliers or suitable wrenches for tightening 1/4”, 3/16” and 1/2” nuts. The 1/2” size is used to tighten nuts

on the front panel controls. If available, a deep socket or nut driver is recommended. Pliers or an

ordinary wrench can be used, but requires care to avoid damaging the front panel paint.

4. Long nose pliers.

5. Diagonal cutters.

6. Small rule capable of measuring lengths up to 1” (2.5 cm) with an accuracy of at least 1/16” inch

(1.6 mm).

7. Digital Multimeter (DMM) for resistance checks.

8. RF 50-ohm, 5 W (minimum) dummy load with low VSWR from 160 meters through 6 meters.

®

9. Power supply 13.8 VDC nominal (11-15 V) with a cable and Anderson PowerPole

cable kit is provided with your K3 if you do not have a suitable cable with the required Anderson

PowerPole connector. The power supply must be capable of providing at least 3 Amperes for a K3/10

and 20 Amperes for a K3/100. (See Specifications in your Owner’s manual for more information on

power supply recommendations).

connector. A power

The following tools are strongly recommended:

1. ESD wrist strap.

2. Static dissipating work mat.

Optional Equipment:

1. RF Power Meter with accurate readout from 1 mW to 5 watts, minimum.

2. Signal generator with calibrated 50 uV output at 20 or 40 meters.

In addition, two Allen wrenches, 5/64” (2mm) and .050”, are supplied with your kit.

8

Unpacking and Inventory

CAUTION

Do not handle the circuit boards without anti-static protection! Doing so may damage

sensitive components. See Preventing Electrostatic Discharge Damage on page 5 for important

information before proceeding.

Before starting construction, do a complete inventory, comparing the parts in your kit with the parts list in

Appendix A, to familiarize yourself with all of the parts and to ensure the kit is complete. When inventorying,

look in the sealed envelopes to identify their contents, but not mix them up. Some screws are very similar in

length, but must be used in the correct locations described in the procedure to avoid damaging your K3. A paper

clip or piece of tape will hold the envelopes closed after you check their contents. Note that a few extras of some

screws, nuts and washers may have been included on purpose.

All dimensions given in the assembly procedure are provided in both US customary (often called English) and

metric measurements. The native dimensions of the parts are in US Customary units. Approximate metric

equivalents are given to assist those more familiar with that system to identify the correct parts.

Screws

A number of different types and sizes of screws and washers are used in the assembly. It is very important that

you use the screw specified in each location or your finished K3 may not fit together properly. In some places,

using the wrong size screw may damage components. The following various screw types and sizes specified in

the text are shown in Figure 2. Images are shown for comparing relative sizes. They are not to scale. The lengths

of the screws called for in the text are measured as shown.

Figure 2. Screw Sizes Used in Assembly.

9

Standoffs

A number of threaded standoffs are used. As with the screws and washers, be sure you use the correct size as

specified in the text. Standoff lengths are measured from end to end as shown in Figure 3. Standoffs threaded for

2-56 and 4-40 screws are used.

Figure 3. Typical Standoff.

Lock Washers

Two types of lock washers are used in the K3 (see Figure 4). It is important that you use only the type specified

and put the washers exactly where indicated. Failing to use the correct type may result in short circuits to nearby

circuit traces. Adding washers or placing the washers in the wrong position may cause parts to fail to fit together

properly.

Figure 4. Lock Washers.

10

Assembly

IMPORTANT ASSEMBLY INFORMATION

1. Screws and other Fasteners: A variety of screws and fasteners are used to assemble your K3:

Stainless Steel Hardware Kit: If you purchased the optional hardware kit that provides

stainless steel hardware for the external fasteners, the letters (SS) are included in the procedure

wherever you should use the stainless steel parts instead of the parts supplied with this kit.

Use your rule to check the length of screws and standoffs before installing them. Some

components are only 1/16” different from others but using the wrong size may result in parts not

fitting correctly, possibly damage electrical and mechanical components. See Screws on page 9

and Standoffs on page 10 for more measurement instructions.

Loosen screws as needed for a proper fit. When mounting parts with multiple screws or

adjacent parts that fit together, such as the exterior cabinet panels, loosen adjacent mounting

screws as needed to adjust the parts for the best fit. Be certain you re-tighten the screws before

proceeding.

Ensure all screws are tight. A loose screw can cause both mechanical and electrical problems

such as intermittent operation, unexpected noise or false signals (birdies) in the receiver.

Threads can be easily stripped if too much force is applied when tightening screws. Use the

correct size hand tool and apply only moderate torque. Do not use a power screwdriver!

2. Brief circuit descriptions are provided through the manual for those interested in the functions of the

circuits. For more detailed circuit information, consult the Theory of Operation in your Owner’s

manual.

CAUTION – TO AVOID DEGRADING THE PERFORMANCE OF YOUR K3:

DO NOT DISTURB ANY ADJUSTMENTS ON THE BOARDS!

Each board was tested and aligned for optimum performance at the factory. Any change to

these adjustments will degrade the performance of your K3 or prevent its operation

altogether. All user calibrations and adjustments are done in firmware using the front panel

menus. These are described at the appropriate points in the assembly procedures.

DO NOT ADJUST THE TURNS ON ANY TOROIDS!

The position of the turns on the cores of many toroids has been adjusted at the factory to

produce exactly the inductance needed for the circuit to work properly. Any attempt to

adjust their position or to make a coil look “nicer” may seriously degrade circuit

performance.

Also, do not attempt to fix the turns or coils in place with adhesives or other materials.

Those toroids needing support have been fixed at the factory. Adding material to the other

toroids will alter their inductance, again degrading circuit performance.

ESD SENSITIVE!

Observe ESD precautions when handling the circuit boards and whenever you are working

on your K3 with the covers off. Failure to observe ESD precautions may result in your K3

not operating at all, or operating but not meeting normal factory performance

specifications due to damaged components. See page 4 for more information.

11

RF Board and Chassis

RF Board Description

The RF PCB (Printed Circuit Board) is the heart of the K3 transceiver, both physically and electrically. During

assembly, it serves as an attachment point for other PCBs as well as chassis panels, acting as the glue that holds

things together. During operation, the RF board provides signal routing to and from all modules. For more

information, see Theory of Operation, RF Board, in the K3 Owner’s Manual.

RF Board and Chassis Assembly Procedure

CAUTION

There are components on both sides of the circuit boards. When handling them, be careful not

to damage components on either side by placing the board on top of tools or other objects, or

bumping or crushing the components while mounting parts or installing the boards

Remove the RF board from its anti-static packaging. The top side of the board is the side with the toroid

inductors and relays along with other components, including several connectors along one edge. The edge with

the connectors is the back edge of the board, while the front edge has notches cut in it that will fit around front

panel controls. Locate the six rectangular bare copper pads for the 2D fasteners (see Figure 5). There is one in

each corner of the board and one in the center of each side (see Figure 11 on page 16).

Figure 5. 2D Fastener Location on RF Board.

Install 2D fasteners at the six spaces provided (one at each corner and at the center of each side of the RF

board). Mount the fasteners on the bottom side of the board as shown in Figure 6. Be sure the 2D fasteners are

oriented so the side of each fastener lines up with the edge of the RF board as shown.

Figure 6. Installing 2D Fasteners on RF Board.

12

Install a 4-40 3/8” (9.5 mm) standoff on the RF board near connector Z1 as shown in below and Figure 11

on page 16. This standoff will support the mixer to be installed later. Install the standoff using three lock

washers as shown below with two of the lock washers between the standoff and the RF board.

CAUTION: To avoid damaging the circuit trace between R74 and the metal ring around the mixer

standoff screw hole, position the lock washer under the screw head with the split facing away from the

trace, then tighten the assembly by turning the standoff while holding the screw and lock washer

stationary.

Figure 7. Installing Mixer Standoff.

Install the two KBPF3 standoffs shown in Figure 8. Even if you didn’t purchase the KBPF3 general

coverage option, the standoffs and hardware are included in the K3 kit to make installing the option easier at

some future date. Note that these standoffs have only one lock washer between each standoff and the RF board

Note that one standoff is very close to the toroid coils. The standoff may touch the coil. That will not

affect circuit performance. If you wish, you may adjust the position of the coil slightly to avoid contact. .

Figure 8. Installing KBPF3 Standoffs.

13

Install hardware to attach Q3 to the RF board near the rear left corner as shown in Figure 9 and Figure 11

on page 16.

Figure 9. Installing Q3 Hardware.

Locate the crystal I.F. filters. Two types of filters are available: standard 5-pole filters and optional 8-pole

filters (see Figure 10). One standard 5-pole 2.7 kHz filter is supplied. If you have elected to equip your K3 with

the optional 8-pole 2.8 kHz filter, it has been supplied instead of the 2.7 kHz filter. If you have purchased

additional filters, they may be installed now as well. If you plan to add filters later, spaces may be left for them.

For example, if you plan to add the FM or a 6 kHz AM filter later, you can leave spaces FL1 and FL2 open for

them and install the 2.8 kHz filter in position FL3. The filters are not hard to move about later, so if you aren’t

sure, install the widest at FL1, the next widest at FL2 and so on.

Enter the following data on Table 1.You will need this information to set up your filters after assembling

your K3. Be sure you’re following the rule described in the step above about the proper order for the filters.

Note that Table 1 is set up with FL1 to the right and FL5 to the left, just as they must be installed on the RF

board.

Enter the bandwidth of each filter in the row below the filter position in which it will be installed.

Enter the FREQ OFFSET shown on each filter. The optional 8-pole filters have no offset marked on

them. Enter a zero in the FREQ OFFSET column for those filters. For the 5-pole filters, note that the

frequency offset may be negative, indicated by a minus sign (single dash) ahead of the number.

Table 1. Filters Installed.

Note: FL1 is to the right and FL5 is to the left. In the next step you will install the filters

right-to-left on the RF board as well.

POSITION FL5 FL4 FL3 FL2 FL1

BANDWIDTH2

FREQ OFFSET3

1. If you’re installing the K-FL3B FM filter, place it in FL1 position since it is the widest bandwidth

filter available.

2. The bandwidth is shown in the label attached to the filters except the K-FL3B FM filter. Record a

bandwidth of 13 kHz for the K-FL3B FM filter.

3. All of the optional 8-pole filters have an offset of zero. Note that the 5-pole filters may have a

negative offset, indicated by a minus sign ahead of the number.

1

14

Install the filters as shown in Figure 10. Refer to the list of filters you created in Table 1 to determine which

filter to install at each location.

CAUTION

1) Do not use screws longer than 1/4” (6.4 mm) to mount the filters. Use your ruler to

measure the screws before installing them. Longer screws may extend into the optional 8pole filter and destroy it. We strongly recommend you use a 1/4” screw even when installing

the 5-pole filters to reduce the possibility of damaging an 8-pole filter should you change

them later.

2) Do not over-tighten the screws. Too much torque may pull the threaded bushing out of

the bottom of the filter module.

Figure 10. Installing Crystal I.F. Filters.

Locate the K3 top cover. On the inside is a label with places to record the bandwidth (BW), and frequency

offset (FRQ) of each filter. Copy the information from Table 1 and place a check mark by Main (for main

receiver) on the label. Use pencil in case you change your filters later. This will keep the filter information with

your K3. The label also has a row for Gain. This is a value you can determine later after your K3 is assembled

and aligned. It is a value set in the K3’s MENU to adjust the overall gain for each roofing filter so the audio

remains constant when switching from one filter to another. Making this adjustment is described under Filter

Loss Compensation in your owner’s manual.

15

Figure 11. RF Board Partially Assembled.

16

Install the Low Power Amplifier (LPA) board in the cutout on the RF board as shown in Figure 12. The

LPA board is held in place by its connectors until the bottom cover is installed..

Figure 12. Installing the Low Power Amplifier (LPA).

Check all three LPA connectors shown in Figure 12 to ensure they are fully mated as shown. If they are not

fully mated, the transistors will not rest against the K3 bottom cover as required when it is fitted later.

17

Mount a 2D fastener on each ear of the front panel shield, and then mount the shield on the RF board as

shown in Figure 13. Be sure the 2D fasteners are oriented with the widest part between the two holes and the

edge toward the outside as shown.

Figure 13. Installing Front Panel Shield.

Mount the K3 mixer board on the RF board as shown in Figure 14. The mixer plugs into Z1 on the RF

board.

Figure 14. Installing Mixer Board.

18

Locate the two side panels. They are approximately 4” (10 cm) by 9-7/8” (25 cm) in size. Both panels have

six counter-sunk screw holes near the edges. Note that the countersunk holes are farther from one end than the

other. This is important. You will need to orient the panels correctly as you install them. The side panels are

different as well. In addition to the six counter-sunk screw holes, the left side panel has two holes near the

centerline for attaching the handle and three larger counter-sunk holes near the top edge. The left side panel with

the handle attached is shown in Figure 16. The right side panel has six additional holes; four for mounting the

side feet and two for attaching other parts inside the K3 (see Figure 21). Set the right side panel aside for now.

Check the inside (partially painted) of both panels to ensure no masking tape is covering any screw holes. If

found, peel it off.

Attach the handle to the left side cover using the hardware shown in Figure 15 at each end. The ribbed side

of the handle faces away from the panel. Tighten the screws enough to compress the lock washers, but do not

tighten the screws so much that you deform the handle end cover. The handle should move easily to allow room

for your fingers between the handle and cover for carrying, then lie flat against the cover when it is not in use.

Figure 15. Installing Side Handle Mounting Hardware.

Install three 6-32, 1/4” (6.4 mm) screws in the larger holes in the side panel shown in Figure 16. Use a #6

nut and split ring lock washer on the inside to secure each screw. These holes are for mounting the optional

K144XV 2-meter module. The screws are provided to fill them when the option is not installed.

Attach the left side panel to the RF board assembly as shown in Figure 16 using five 4-40 3/16” (4.8 mm)

black flat head screws (SS). Do not use washers. When oriented correctly, the edge of the panel will extend

about 1/2” (13 mm) past the 2D fasteners at the front panel shield. If needed, loosen the screws attaching the 2D

fasteners to the RF board or front panel shield for best alignment. Tighten them again after the side panel is

installed.

Figure 16. Mounting Left Side Panel.

19

Mount a 2D fastener at the top back corner of the left side panel (the one you just installed) with a 4-40

3/16” (4.8 mm) black flat head screw (SS) as shown in Figure 17. Do not use washers. Be sure the 2D fastener

is oriented correctly as shown in the figure.

Figure 17. Installing Left Side Panel 2D Fastener.

KANT3 or KAT3, Right Side and Rear Panels

If you purchased a KAT3 with your kit, you did not get a KANT3 board with your kit.

For more information, see the KANT3 AND KAT3 Circuit Description below.

KANT3 or KAT3 Description

The basic K3/10 includes a KANT3 antenna input module. If you’ve ordered a KAT3 antenna tuner, the

KANT3 is not required and will not be supplied with the kit. In either case, the module plugs into the RF board

at the back-right corner. Both the KANT3 and KAT3 provide antenna surge protection, as well as resistors for

bleeding off static DC charge. The KAT3 provides a wide-range, switchable C-in/C-out L-network. See Theory

of Operation, KANT3 and KAT3, in the K3 Owner’s Manual for more details.

Installing KANT3 or KAT3 Antenna Connectors

Locate the rear panel and check the inside for any masking tape still covering screw holes. If found, peel it

off.

Mount the SO239 connector in the ANT1 position on the rear panel using two 4-40 1/4” (6.4 mm) black

pan head screws (SS), two 4-40 inside tooth lock washers and two 4-40 nuts as shown in Figure 18. The flange

of the SO239 connector is on the inside (unpainted side) of the rear panel.

Figure 18. Mounting the ANT1 Connector.

If you are installing the KAT3, install the second SO239 connector in the ANT2 position on the rear panel

using two 4-40 1/4” (6.4 mm) black pan head screws (SS), two 4-40 inside tooth lock washers and two 4-40 nuts

just as you did for the ANT1 connector. Set the rear panel aside for now.

Installing KRX3 AUX RF (ANT) Connector

If you do not have the KRX3 Subreceiver option kit on hand, skip this section and go directly to Preparing

Right Side Panel for Installation below to continue assembly.

20

If you have the KRX3 Subreceiver option kit on hand, you may wish to install the AUX RF antenna connector

at this time. The AUX RF connector is one optional way to connect an antenna to the subreceiver. Before you

decide, turn to your KRX3 Installation and Operation Manual and review the Auxiliary KRX3 Antenna Input

(Optional) section. It is not necessary to install the connector now, even if you decide to use it. Complete

instructions for installing it later are included in your KRX3 manual.

If you wish to install the AUX RF connector now, do so as follows.

Retrieve the following components from your KRX3 Subreceiver kit:

Coaxial cable with a pre-mounted BNC female panel connector on one end and a TMP connector on the

other end (TMP connectors are shown in Figure 75 on page 54).

Nut and inside tooth lock washer that fits the BNC connector. (They may be supplied threaded onto the

connector. If so, remove them.)

One 4-40 3/8” (9.5 mm) black pan head screw.

One #4 inside tooth lock washer.

One 4-40 nut.

The highly scratch-resistant powder coating on the rear panel may interfere with the fit of the BNC

connector through the hole. Remove the coating around the edge of the hole using a hobby knife or other sharp

tool (see Figure 19). Note that the hole is flat at the top. That is intentional.

Figure 19. Removing the Powder Coating from the AUX RF Connector Hole.

21

Thread the BNC/TMP cable through the AUX RF connector hole from the outside, lining up the flat on the

threaded section of the connector with the flat at the top of the hole. Slide the lock washer and nut onto the

cable. Fold the solder lug on the braid down against the coax to fit through the back panel hole, the lock washer

and the nut. Thread the nut onto the connector and tighten it (see Figure 20).

Mount the solder lug attached to the braid as shown in Figure 20, using a 4-40 3/8” (9.5mm) black pan head

screw (SS), #4 inside tooth lock washer and 4-40 nut. If you have the KAT3 option, there will be a shorter screw

holding the connector flange. Replace it with the 3/8” (9.5 mm) screw. If you do not have a KAT3, there will be

no connector in the ANT2 hole. In that case, the solder lug is directly against the unpainted inside surface of the

rear panel.

Figure 20. Installing the AUX RF Connector.

Carefully insulate the metal TMP connector, covering all of the metal parts with electrical tape or other

suitable material that you can remove easily later.

CAUTION

Later you will apply power to do preliminary testing and calibration before the KRX3 Subreceiver is

installed. Failure to insulate the TMP connector as described above may result in short circuits and

extensive damage to your K3 if it touches a component, solder pad or other exposed circuit points.

22

Preparing Right Side Panel for Installation

Install the four rubber side feet in the holes in the right side panel as shown in Figure 21. Two suggested

procedures for doing this are as follows:

Press Method:

Wet the tip of the foot with a tiny amount of

soap. (Do not use petroleum jelly or oils. They

can deteriorate the rubber over time).

Place the foot, tip up, on a solid work surface.

Position the panel with the outside (fully painted

side) toward the foot with the hole in the panel

against the tip and press down. The tip should

slip through the hole without further help. If

necessary, grip the tip and pull with your longnose pliers, working it from side to side until the

shoulder opens against the inside of the panel.

Do not use excessive force. You can tear the

foot apart.

Wipe any excess soap off of the panel or foot.

Twist Method:

Press the foot against the outside (fully

painted side) of the panel so the tip is in

the hole at an angle.

While pressing the tip into the hole, twist

the foot so the edge of the tip grabs the

inside edge of the hole.

Continue pressing and twisting until the

tip is fully inside the panel all the way

around its circumference. Do not twist

with excessive force. You can tear the

foot apart.

Figure 21. Installing Side Panel Feet.

Position the right side panel against the K3 to verify how it will fit against the RF board. When it is oriented

correctly, the three holes along the bottom edge will line up with the holes in the 2D fasteners on the RF board

and two holes in the side panel will be aligned with the tabs on voltage regulators U12 and U13. The end of the

panel toward the rear will very nearly line up flush with the edge of the RF board. Do not mount the side panel

yet, but note which corner of the panel is in the upper rear corner. You’ll work with this corner in the next step.

23

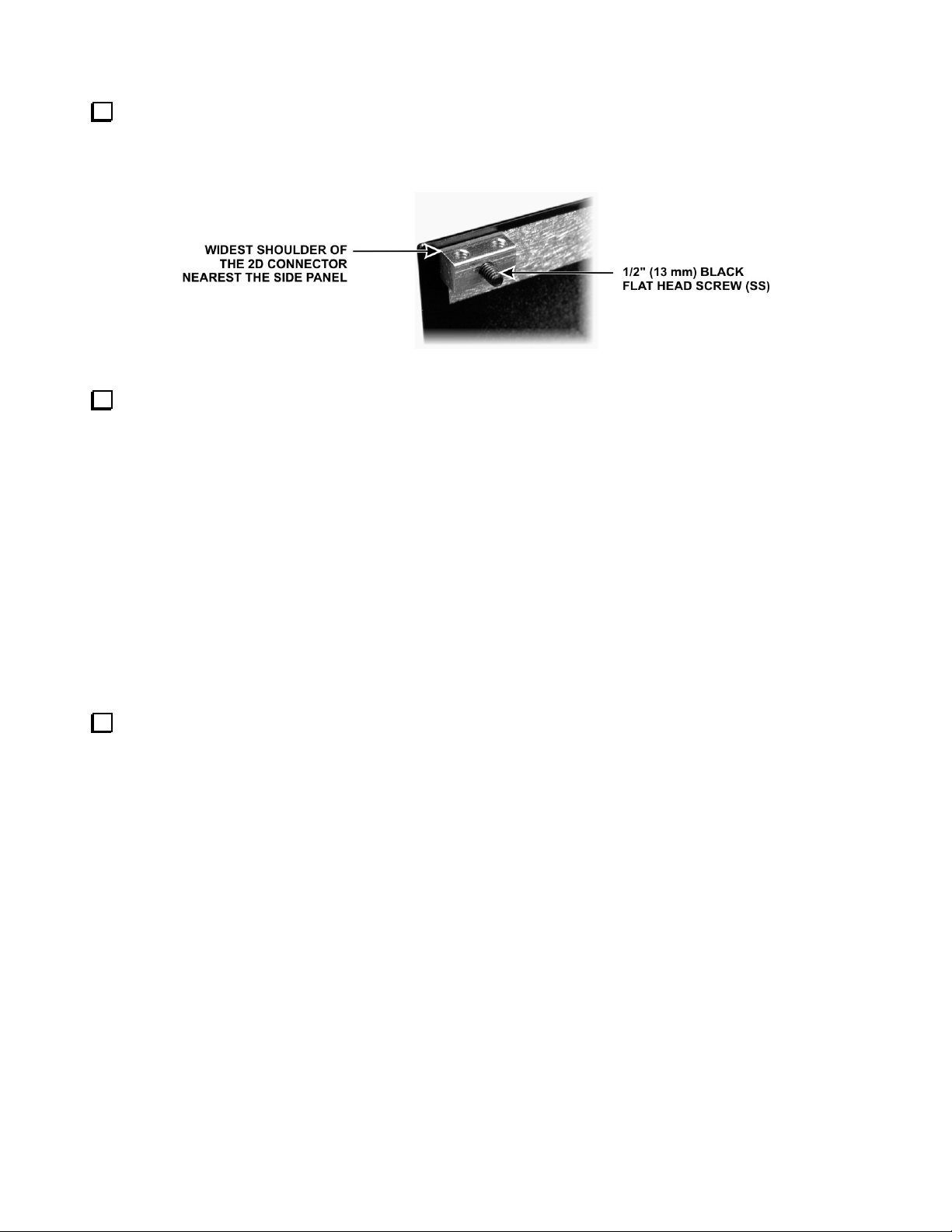

At the upper rear corner of the side panel you just identified in the previous step, mount a 2D fastener as

shown in Figure 22, using a black 4-40 1/2” (13 mm) flat head screw (SS). Remember that flat head screws are

measured from the flat top to the end of the threads. Note that the screw extends some distance through the 2D

fastener.

Figure 22. Mounting 2D fastener for KANT3 or KAT3 Standoff.

Screw a 4-40 1/2” (13 mm) standoff onto the exposed end of the screw as shown in Figure 23. Do not use a

lock washer between the standoff and the 2D fastener. Tighten the standoff securely against the 2D fastener.

Set the side panel aside temporarily.

Figure 23. KANT3/KAT3 Mounting Standoff.

Mounting the KANT3 or KAT3, Side and Rear Panels

Insert J70 on the KANT3 or the KAT3 board into P70 near the red and black APP power connectors at the

right rear corner of the RF board. The KANT3 board is shown in Figure 24. The KAT3 board fits exactly the

same way with the toroidal inductors toward the center of the RF board. I

Figure 24. Installing the KANT3 or KAT3 Board.

24

Peel the backing from the self-adhesive serial number label and attach it to the back panel as shown in

Figure 25. You may wait until the assembly is finished before attaching the serial number, but at this point you

can lay the panel flat on the work surface to easily position the label square within the outline.

Figure 25. Attaching Serial Number.

Position the rear panel on the K3 chassis assembly so that the SO239 connector(s) are at the end nearest the

KANT3 or KAT3 board. If installed, the coax cable attached to the AUX RF connector should pass between the

rear panel and the KAT3 or KANT3 board (see Figure 26). Thread the 6-32 thumbscrew into the ground

terminal position near the center of the rear panel as shown in Figure 27. Use two #6 flat washers between the

thumbscrew and the back panel as shown. If the hole in the rear panel does not line up with the threaded hole in

the ground bracket mounted on the RF board, loosen the side panel screws at the end nearest the rear panel so

you can adjust the position of the rear panel as needed.

Figure 26. Routing AUX RF Connector Coax.

If you loosened the side panel screws in the previous step, tighten them again now.

Attach the bottom lip of the rear panel to the 2D fasteners at the rear corners of the RF board with 4-40,

3/16” (4.8 mm) black pan head screws (SS). (Note that all the screws used on the bottom of the K3 are black

pan head screws.)

Figure 27. Installing Rear Panel Ground Screw

25

Connect the wires from the SO239 connector(s) to the KANT3 or KAT3 board as shown in Figure 28. Use

needle-nose pliers to grip the terminals on the wire ends and carefully insert the connectors straight into the

holes in the board. They may be very difficult to insert unless they are perfectly aligned. While inserting the

plugs, support the board with your fingers to avoid putting stress on the connector at the bottom.

Figure 28. ANT Connections to KANT3 or KAT3 Boards.

Attach the right side panel to the RF board assembly four 4-40 3/16” (4.8mm) black flat head screws: three

along the bottom and one at the top front into the 2D fastener on the front panel shield. Do not use washers.

Note that there are two open holes for screws to secure voltage regulators U12 and U13. They will be installed

later.

Mount the KANT3 or KAT3 board to the standoff on the side panel with a 4-40 1/4” (6.4mm) zinc pan

head screw and a #4 split lock washer under the screw head as shown in Figure 29. Do not place a washer

between the board and the standoff.

Figure 29. Installing KANT3/KAT3 Mounting Screw.

Install a 4-40 3/16” (4.8 mm) black flat head screw (SS) to secure the top of the rear panel to the 2D

fastener as shown in Figure 29

Install another 4-40 3/16” (4.8 mm) black flat head screw (SS) at the opposite end of the rear panel to

secure it to the top 2D fastener on the left side panel. When properly positioned, the rear panel should fit snugly

against the inside edge of the side panel as shown in Figure 29. Verify the fit is correct at both ends. If necessary

loosen the 2D fastener screws enough to adjust the position of the panels. .

26

Loading...

Loading...