Page 1

Page 1

Elecraft K 2 V CO S h ielding I n struct i o n s

Rev. E, Oct. 6, 2005

The K2’s VCO (voltage-controlled oscillator) may be susceptible to low-frequency modulation by nearby large power transformers,

such as those found in high-current linear power supplies and antenna rotator controllers. Since the magnetic field from a

transformer falls off rapidly with distance, such modulation can usually be eliminated by simply moving the equipment away from

the transceiver (or moving it to the right side of the transceiver, farther from the VCO circuitry). In difficult cases, magnetic

shielding can be used, alone or in combination with repositioning of equipment.

These instructions describe how magnetic shielding can be added to the K2. Toroidal transformer T5 must be replaced with a

smaller iron-powder core that can be shielded by a high-permeability ferrite sleeve. In addition, slug-tuned inductor L30 must be

electrically disabled since it, too, is affected by magnetic fields. With L30 out of the circuit, the VCO inductance can still be

adjusted, if necessary, by squeezing or spreading the turns of T5. A DMM (digital multimeter) is used during this adjustment.

Parts Inventory (Order #K2VCOSHLDKT)

(1) E680013 T37-6 toroid core (yellow)

(1) E680024 Ferrite toroidal sleeve (dark gray), 16 mm OD, 12 mm ID, 8 mm tall (0.63 x 0.50 x 0.32”)

(1) E500003 470 ohm, 1/4-watt resistor

(2) E700021 4-40 nylon hex nut

(1) E700107 4-40 x 5/8” (16 mm) nylon machine screw

(1) E700108 Nylon flat washer, 5/8" (16 mm) diameter

(1) E700109 Paper flat washer, 5/8" (16 mm) diameter

(2 ft.) E760002 #26 red enamel wire

(1 ft.) E760004 #26 green enamel wire

Modification Instructions

Turn off the K2 (or K2/100) and disconnect all external equipment.

Remove the top cover, disconnecting all cables.

Remove the bottom cover (flat part only — not the heatsink/rear panel).

Locate slug-tuned inductor L30, which is near the left side panel and adjacent to toroidal transformer T5. In the next step, L30

will be isolated from the VCO, so it can no longer be used to adjust the VCO frequency. The new method is explained later.

Find L30’s pads on the bottom side of the RF board. Cut the trace identified in Figure 1 that connects L30 to pin 2 of T5. Use

the tip of an Xacto knife or other sharp tool. Inspect the trace using a magnifying glass to ensure that it is cut.

Figure 1

Locate R10 (top side of the RF board, near L30). Remove R10, being careful not to damage the pads. Re-install R10 on the

bottom side of the RF board, using the same pads. (If R10 is damaged, use the 470-ohm resistor supplied with this kit.)

Locate T5 (near L30). Remove the nylon hardware holding T5 to the RF board.

Unsolder all four leads of T5 and remove it, being very careful not to damage the pads or traces. One method is to hold a lead

with long-nose pliers, heat the joint completely, then pull the lead out slowly.

Clean T5’s four holes out completely using solder wick or a vacuum desoldering tool.

Page 2

Page 2

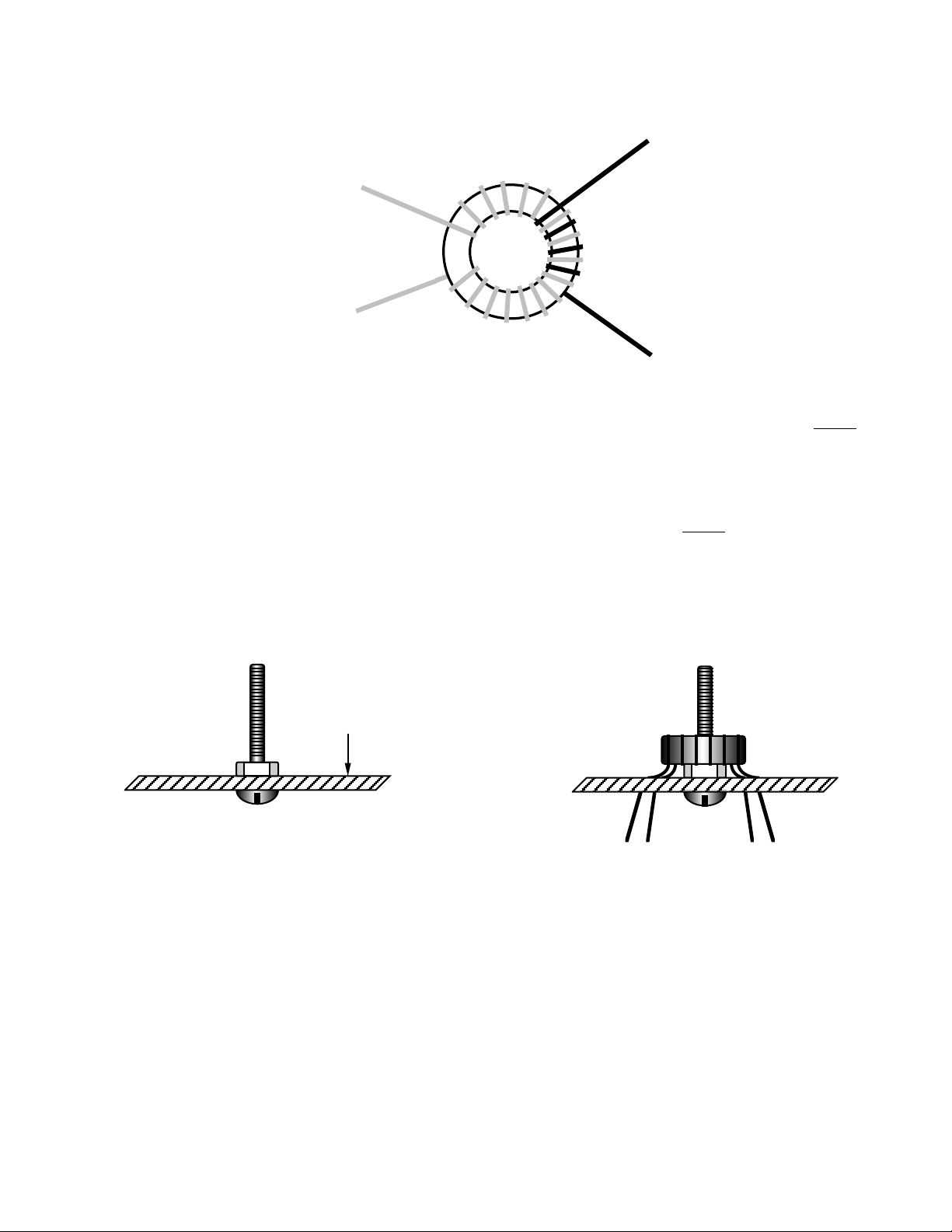

Locate the T37-6 core (yellow), which is smaller than the original T50-6 core. It will be used to wind a new T5. As shown in

Figure 2, T5 will have two windings, identified as leads 1-2 (red wire) and 3-4 (green wire).

Figure 2

Green,

4 turns

1

2

3

4

Red,

17 turns

Cut a 14-inch (35 cm) length of red enamel wire, and an 8-inch (20 cm) length of green.

For the 1-2 winding, use 17 turns of red enamel wire. (Each pass through the core counts as one turn.) Wind the wire tightly

against the core. Leave the leads at least 1” (2.5 cm) long, and do not strip the enamel insulation off yet.

Examine the 1-2 winding closely. As shown in Figure 2, lead #2 must exit from below the core, and lead #1 from above the

core. If this is not the case, remove the wire and correct the winding sense.

Distribute the 17 turns of the 1-2 winding evenly over about 90% of the core as shown.

For the 3-4 winding, use 4 turns of green enamel wire, positioned as in Figure 2. Wind the wire tightly against the core. Leave

the leads about 1” (2.5 cm) long and do not strip them yet.

Examine the 3-4 winding for correct sense as you did for the 1-2 winding. Lead #4 must exit from below the core.

Trim all four leads of T5 to about 1 inch (2.5 cm) long.

Referring to Figure 3, insert the 5/8” (16 mm) nylon screw through the hole at the center of T5 from the bottom side of the RF

board. Secure the screw to the RF board using a nylon hex nut on the top side.

Top side of RF board

Figure 3 Figure 4

Install T5 temporarily (Figure 4), inserting the leads into their numbered pads on the RF board. The nylon screw should pass

through T5. Press down until T5 rests on the nylon nut.

Pull the leads through on the bottom, leaving a small amount of slack on the top as shown in Figure 4. The reason for the slack

is to accommodate the paper insulating washer, which will be added in a later step (see Figure 5, next page).

Using a black felt pen, mark the point on each lead where it enters its pad on the top side of the board. Then remove T5.

Remove the insulation from T5’s leads up to approximately the marked locations, then tin the leads. The enamel wire is heat-

strippable, so this can be done using a soldering iron. Additional information on stripping toroid leads can be found in the

“Assembly, Part II” section of your K2 owner’s manual; see Stripping Toroid Leads (page 54 in the latest revision).

Re-install T5 (see Figure 4).

Page 3

Page 3

Look closely at T5’s leads where they exit the holes on the bottom side. The leads must have no enamel residue, and should be

tinned so that they appear clean and shiny. If not, remove T5 and prepare the leads as described earlier.

Place the paper washer over T5 as shown in Figure 5. Push downward gently on T5’s leads until the washer lays flat.

Figure 5

Paper washer

Solder and trim T5’s leads.

Connect a power supply to the K2 and turn it on.

Use B A ND + or B A ND- to select the 80-meter band, and set the VFO for a frequency of about 4000.10 kHz.

Connect the frequency counter probe to the VCO test point, TP1. Activate the counter using C AL FC T R in the menu.

You should now see a frequency counter reading in the 8 to 10 MHz range. It may or may not be stable at this time (i.e., the

frequency may be changing). If the reading is 0000 kHz or is changing rapidly, you probably don’t have the counter cable

connected to the VCO test point, or T5 may not be properly wound or soldered.

Tap M E N U to exit C A L F C T R .

Disconnect the internal frequency counter probe and remove it completely from the K2.

Connect a DMM (digital multimeter) to the left end of resistor R30 (near the center of the synthesizer area of the RF board) and

ground. Use a small alligator clip to ensure a good connection. Select the DMM’s 20 or 30-volt DC voltage scale.

On each band, set the VFO to the low/high frequencies listed the in table below, and record (in pencil) the DC voltages at R30.

Band Low Freq. Voltage High Freq. Voltage

160 m 1800 ______ 2000 ______ (If K160RX option is installed)

80 m 3500 ______ 4000 ______

60 m 5300 ______ 5450 ______ (If K60XV option is installed)

40 m 7000 ______ 7300 ______

30 m 10000 ______ 10150 ______

20 m 14000 ______ 15000 ______

17 m 18000 ______ 18200 ______

15 m 21000 ______ 21450 ______

12 m 24800 ______ 25000 ______

10 m 28000 ______ 28800 ______

If some VCO control voltage readings above are less than 1.0 V, or some of them are greater than 7.5 V, you’ll need to shift the

entire set of readings so that they are all within this range. First, switch to the band (and frequency) that had the highest or

lowest voltage. Next, squeeze or spread the turns on T5’s 1-2 winding slightly to bring that reading into range. (Squeezing the

turns closer together increases the inductance; spreading them out decreases the inductance.) Finally, re-measure all of the

voltages to make sure they're in range. Note: In rare cases, you may have to re-wind T5, adding or removing one turn. If you

cannot spread the turns far enough apart, remove one turn. If you cannot squeeze the turns together tightly enough, add one turn.

Disconnect the DMM from R30.

Turn the K2 off and disconnect the power supply.

Page 4

Page 4

Place the ferrite sleeve over T5, aligning both the ferrite sleeve and paper washer with T5’s component outline.

Place the 5/8” (16 mm) diameter nylon washer on top of the ferrite sleeve (Figure 6). Secure using a nylon 4-40 nut.

Figure 6

Re-install the K2’s bottom cover.

Re-install the K2’s top cover. Reconnect all cables carefully to avoid misalignment of connector pins.

Make the following notation in your K2 manual near Table 6-1: “L30 Removed. Set VCO by changing T5 turn spacing.”

Loading...

Loading...