Page 1

U P G R A D I N G T H E E L E C R A F T K 2 T O R E V I S I O N B

Rev. E, April 29, 2003

In October, 2002, the K2 transceiver was updated to incorporate many modifications that had been recommended by

Elecraft or our customers. Any Revision A K2 (or Revision XC, 1999 Field Test) can be brought up to Revision B by

making the changes listed in Table 1. K2s with serial numbers 3000 and higher already include all of the changes

(except the recent PLL Upgrade, which is also discussed in this document). To determine which revision of the K2 you

have, look at the RF board, near "ELECRAFT" label at the center.

Most of the items needed are supplied with the K2ATOBKT mod kit. Other mod kits and parts must be purchased

separately as indicated in the table; these kits come with their own modification instructions. Step 9 (AF GAIN control

modification) does not require a mod kit, but you'll still need to obtain the associated application note (see page 8).

If your present K2 firmware is older than revision 2.00A, you'll need a firmware upgrade (part # FWK2MCIO)

in addition to any hardware mod kits. New firmware installation and realignment will be done in steps 11 and

12, after all desired hardware changes have been made. This ensures that calibration and test steps will only

have to be performed once.

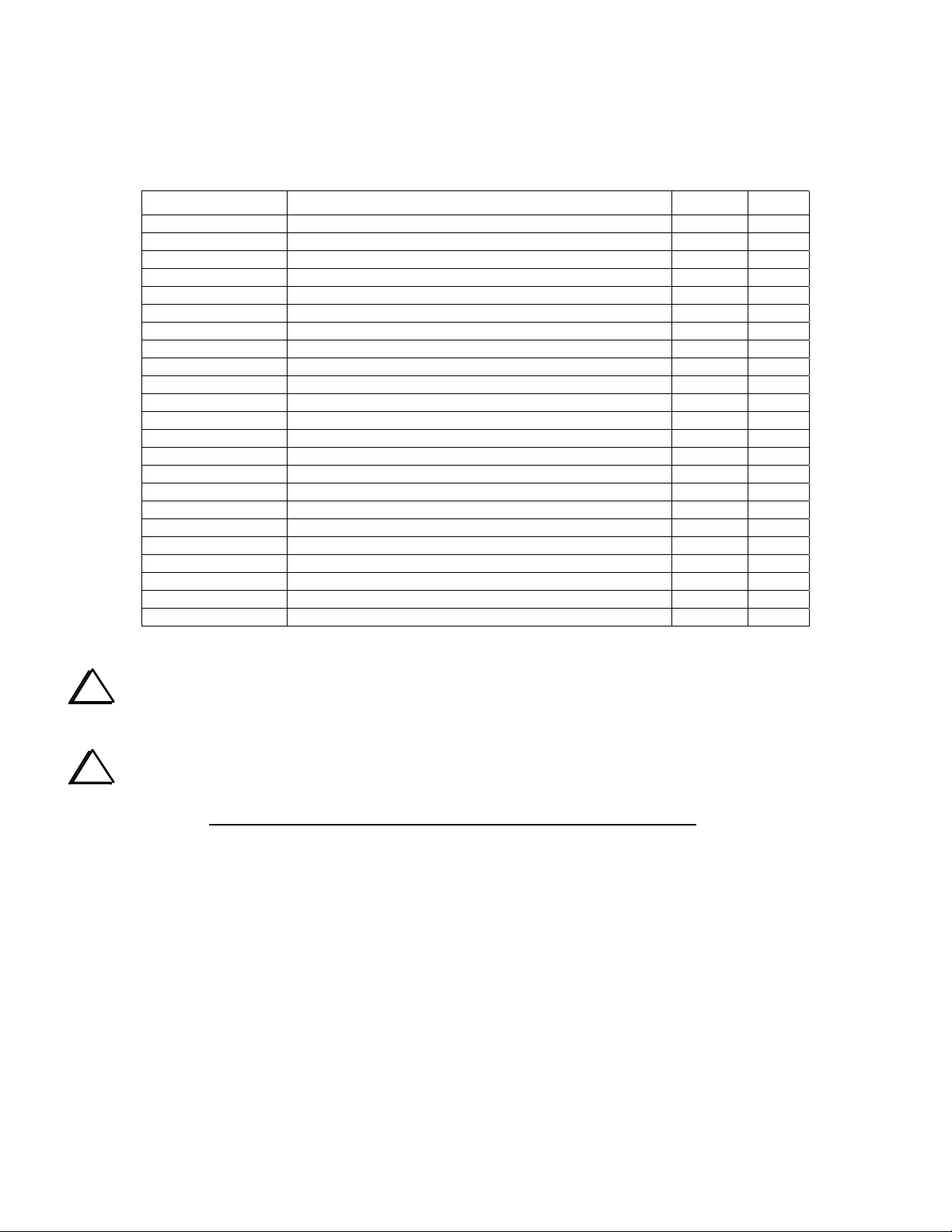

Table 1. Modification Steps

Modification Steps (do in order)

1. Firmware Revision Check and Parameter Save RF n/a 3

2. PLL Frequency Stability at 7182 kHz RF K2ATOBKT 5

3. Misc. RF Board Changes RF K2ATOBKT 6

4. 15/17 meter and 20/30 meter Band-pass Filters RF K2ATOBKT 7

5. BFO Temperature Stability RF BFOMDKT 7

5A. PLL Upgrade (Temperature compensated reference osc.) RF E850138 7

6. VFO ALC and 10/12 meter Band-pass Filter RF E850093 8

7. Second Crystal Filter Flatness RF XFILMDKT 8

8. First Crystal Filter Grounding RF n/a 8

9. AF GAIN Control Smoothness All three n/a 8

10. Misc. Control Board Changes Control K2ATOBKT 9

11. Firmware Installation Control, RF FWK2MCIO 10

12. Alignment and Test Control, RF n/a 10

Board(s) Part # Pg.

13. Speaker Grille Cloth n/a E850089 15

NOTE: Not included are Rev. B board changes that accommodate the K60XV 60 meter adapter (RF board: VCO and

40-m low-pass filter). The K60XV manual describes these changes, which should not be made until the option is

installed. Also not included are minor changes that have no impact on operation or performance (for example, RF

board: R60 bias pot changed to a fixed 100-ohm resistor; Control board: switch S1 changed to a jumper block, P7).

1

Page 2

K2ATOBKT Mod Kit Inventory

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

The parts supplied with K2ATOBKT mod kit are listed below. Other mod kits referenced in Table 1 include their own

parts lists.

Ref. Description Part Qty

RF-C33 Capacitor, 2 pF ("2") or 2.2 pF ("2r2"

RF-C68 Capacitor, 10 pF E530006 1

RF-C28,C29 Capacitor, 12 pF E530058 2

RF-CPLL Capacitor, 68 pF E530007 1

RF-C174 Capacitor, 82 pF E530038 1

RF-C30,C36 Capacitor, 470 pF ("471"

RF-C91 Capacitor, .001 µF ("102"

CTRL-C12 Capacitor, .0027 µF ("272"

RF-CRF, CTRL-C31 Capacitor, .047 µF ("473"

CTRL-C42 Capacitor, 0.1 µF ("104"

RF-D10 Diode, ultra low-drop Shottky, 95SQ015 E560009 1

RF-R50 Resistor, 1.5 ohms, 1/2 watt (brown-green-gold

RF-R64,CTRL-R6 Resistor, 100 ohms, 1/4 watt (brown-black-brown

RF-R1, R2 Resistor, 220 ohms, 1/4 watt (red-red-brown

CTRL-R12 Resistor, 820 ohms, 1/4 watt (gray-red-brown

CTRL-R7 Resistor, 1.78 k, 1/4 watt, 1% (brown-violet-gray-brown

RF-RREFA, RREFB Resistor, 10 k, 1/4 watt (brown-black-orange

RF-R11 Resistor, 47 k, 1/4 watt (yellow-violet-orange

RF-R18 Resistor, 1 M, 1/4 watt (brown-black-green

RF-RFC11 Toroid, 20 turns #26 enamel on FT37-43 core E680003 1

RF-RFC15 RF choke, miniature, 100 µH (brown-black-brown

CTRL-L1 Inductor, shielded, 82 mH ("823", dark gray, cylindrical

Misc. Enamel wire, #26, red (for RFC11) E760002 3 ft.

E530047 1

E530004 2

E530001 1

E530055 1

E530025 2

E530011 1

E500025 1

E500010 2

E500002 2

E500001 1

E500026 1

E500015 2

E500067 1

E500024 1

E690013 1

E690015 1

i

Caution: Some parts in the K2 can be damaged by static discharge. While making modifications, use an

anti-static wrist strap. Alternatively, you can touch a grounded, unpainted metal surface (do this often).

i

Updating the K2 to revision B involves a considerable amount of component removal. You will need a

full-size, hand-operated vacuum desoldering tool. The Edsyn model AS196 Anti-Static Solder Sucker ($25), is

an excellent choice. Before removing a component, straighten its leads on the solder side (use a small tool while

heating the solder joint). Next, clean out the holes using the desoldering tool. Finally, pull the component out,

being very careful not to damage pads, plated-through holes, or traces on the top or bottom sides of the board.

2

Page 3

1. Firmware Check and Parameter Save

Determine what revision of firmware you have by

turning the K2 on while pressing and holding any

switch. You'll see a display such as: 2 . 0 3 d 1 . 0 7 .

The number on the left is the firmware revision of the

main microcontroller, U6 on the Control board. The

other number is the firmware revision for the I/O

controller (IOC), U1 on the RF board. Record both of

the numbers here: K2 _______ IOC _______.

i

If your K2 firmware revision is older than

2 . 0 0 A , you'll need to install new firmware after

making all desired hardware changes. You may need to

install a new IOC in addition to the main microcontroller. This will be explained later.

Supplemental Menu Parameters: The D I S P L A Y

switch is used to access additional parameters when

editing certain menu entries. These include sidetone

source (S T L entry), 8R Hold mode (T - R entry),

Auto-Detect mode (I N P entry), and Fan mode (P A

entry, secondary menu). These will be set up

appropriately during new firmware installation (page

10) and do not need to be recorded here.

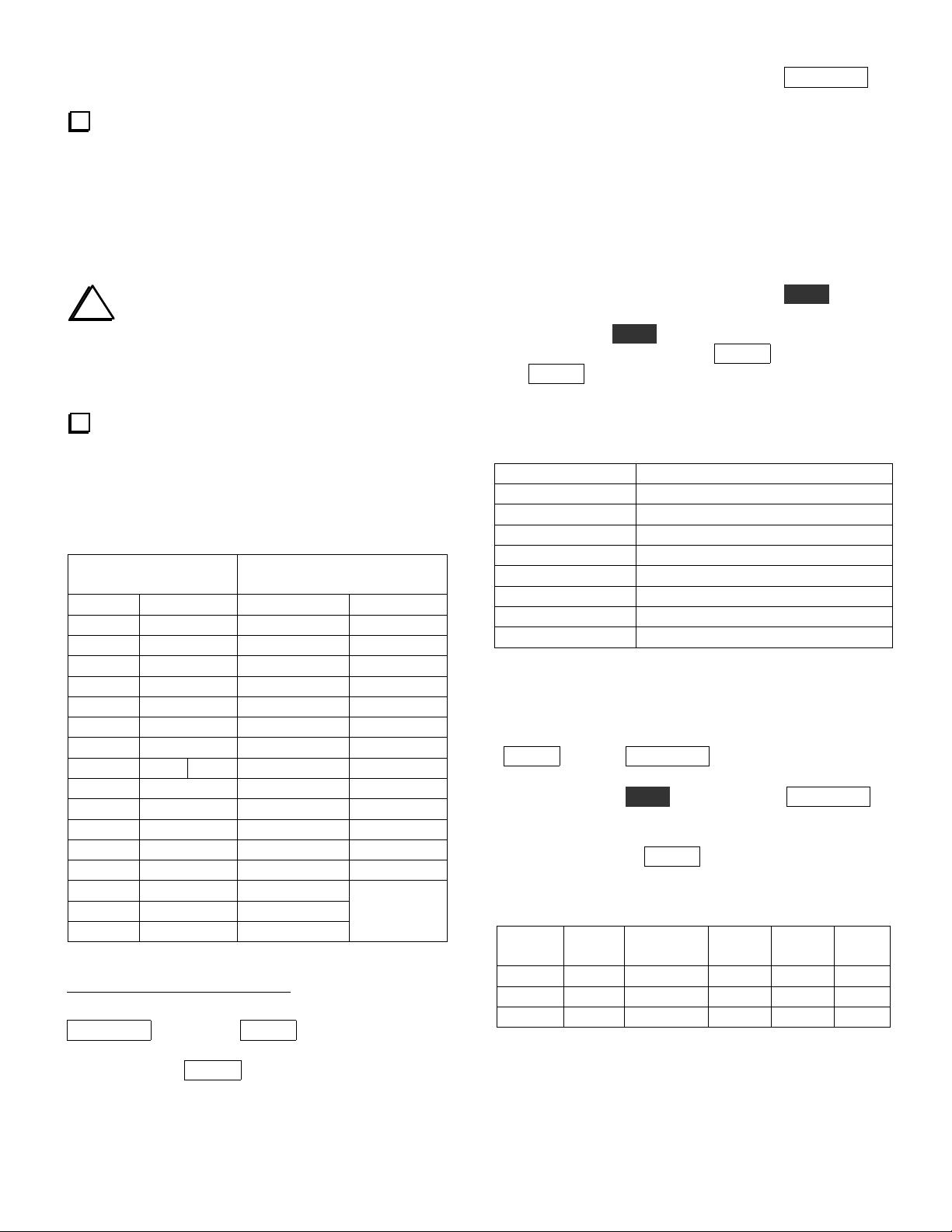

CAL Settings (Table 3): To access CAL settings, use

the primary menu to scroll to C A L , hold

E D I T to edit

the parameter, select a CAL function with the VFO

knob, then hold

E D I T again to activate the function.

After recording the setting, tap M E N U to exit, then

tap M E N U

again and access the next CAL function in

the same manner.

Whether or not you plan to install new firmware,

you should record your present configuration settings

in Tables 2 - 5. The BFO frequencies (Table 5) will be

needed if you make the Temperature Stability changes.

Table 2. Menu Parameters

Primary Menu Secondary Menu

(Rev. 2.00 up1)

Entry Param. Entry Param.

ST L SLCH

ST P RATES

T-R DOT

RPT FPLY

INP PORT

IAB SPLT

SSBA Po28

2

SSBC

SSBC SSBCr

RTTY

LCD RTC

GRPH RIT

OPT ACC

ATU AT2/D19

3

RANT PA

CAL Table 3 TRN1

PF1 TRN2

Table 4

PF2 TRN3

1

To switch between the P R I and S E C menus, tap

D I S P L A Y after tapping M E N U .

2

If RTTY is set to O N (Rev 2.00 up), and r mode has

been selected with

changes to

3

If you have revision 2.03 or later firmware, the name of

this menu entry is

never used).

S S B C r . Record both settings if applicable.

M O D E , the S S B C menu entry

D 1 9 . Otherwise it is A T 2 (which was

3

Table 3. C A L Settings

CAL Function Parameter

OFF n/a

FCTR n/a

CUR

TPA n/a (stored by KPA100)

S LO

S HI

PLL n/a (CAL PLL will be done later)

FIL Table 5

Transverter Band Displays (Table 4): You'll only

need to record these settings if you use the transverter

bands. To access transverter band display settings, tap

M E N U

, then tap D I S P L A Y to switch to the

secondary menu, then scroll to the desired T R N x

menu entry. Hold E D I T to access it. Tap D I S P L A Y

to cycle through the five parameters for each

transverter band display. To select the next transverter

band setup, first tap M E N U

to return to scroll mode.

Table 4. T R N x Band Displays (Rev 2.00 up)

Xvtr # On

RF IF OFS OUT

/Off

TRN1

TRN2

TRN3

(see next page for Table 5)

Page 4

4

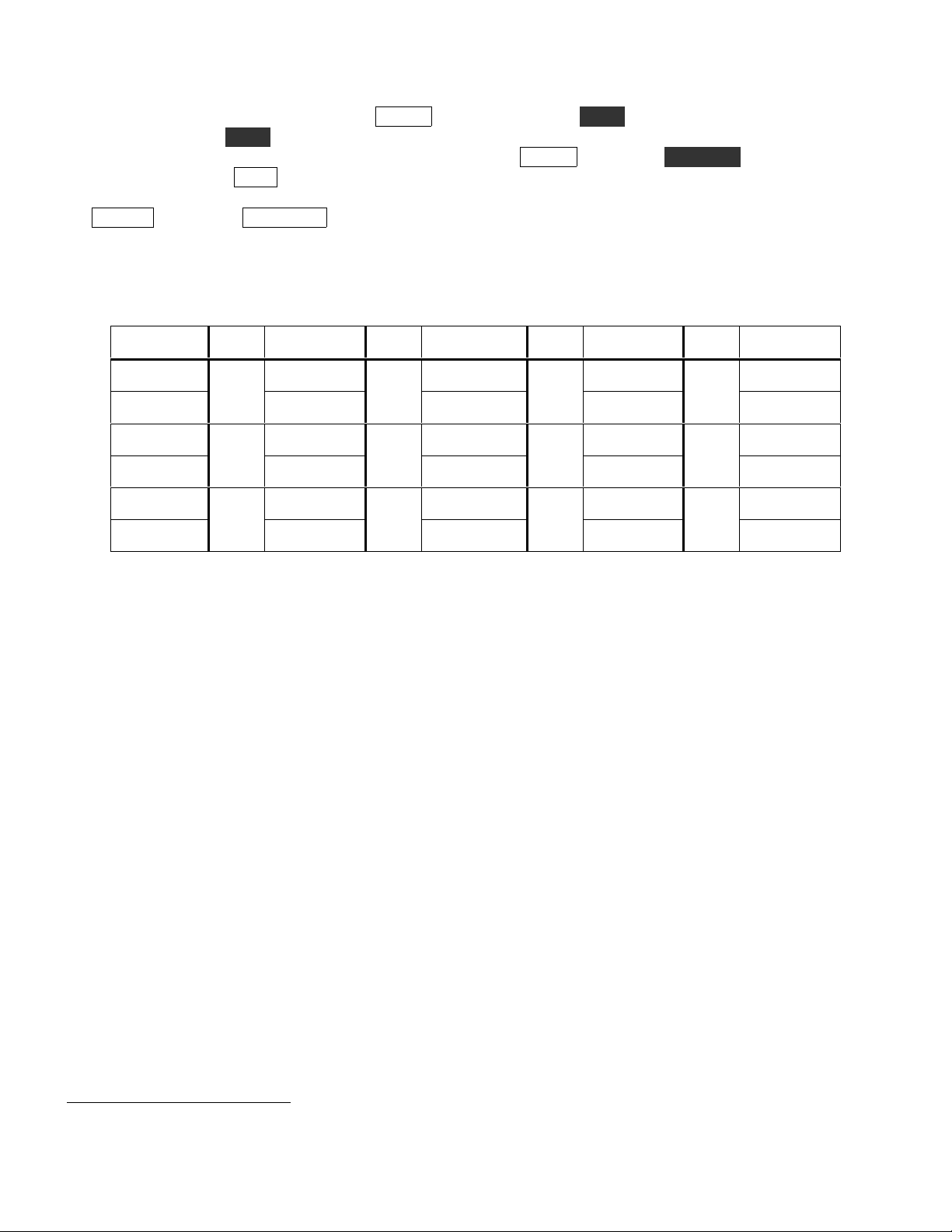

Filter and BFO Settings (C A L F I L , Table 5)

: Before recording filter/BFO data, switch to any of the lower bands

(160-17 m) so LSB/USB settings won't be swapped in CAL FIL. Connect the internal frequency counter cable to TP2

(BFO). To access filter and BFO settings, tap M E N U

, scroll to C A L , hold E D I T to access the parameter, and

change it to F I L . Hold E D I T again to activate the C A L F I L function. Record filter bandwidth settings (e.g. 0 . 7 0 )

for each mode and each filter. Cycle through the modes by tapping M O D E

filters are selected using X F I L

. (RTTY mode, r , and RTTY reverse are only available with revision 2.00 and up

and holding C W R E V when appropriate;

firmware. The associated secondary menu entry, R T T Y , must be set to O N .) After all filter bandwidths are recorded,

tap B A N D -

followed by D I S P L A Y to show the BFO frequency. Record the BFO frequencies (e.g., 4 9 1 3 . 1 0 ) for

each mode and filter, as you did for the filter bandwidths.

Table 5. Present Filter and BFO Settings (C A L F I L )

Mode

CW

CW Rev.

LSB

USB

RTTY

RTTY Rev.

F L 1 B F 1 t F L 2 B F 2 F L 3 B F 3 F L 4 B F 4

4

If you're not familiar with filter and BFO configuration, review the instructions for CAL FIL in the K2 Owner's manual, starting

on page 85.

4

Page 5

2. PLL Frequency Stability at 7182 kHz

Whenever the VFO is tuned to the 5 kHz band segment

centered at about 7182 kHz, the PLL reference

oscillator and VCO will be at exactly the same

frequency. At this point, on a small percentage of K2s,

coupling between the two oscillators can result in a

"wavering" quality on both transmit and receive. If

your K2 exhibits this symptom, it must be corrected. It

compromises signal quality, and may prevent VFO

linearization (CAL PLL) from working correctly.

Frequency Stability Test

Pin 13

You'll first need to identify the segment of 40

meters over which the two oscillators are at the same

frequency. Switch to 40 meters, LSB or CW mode, and

tune to about 7182 kHz. Then activate C A L F C T R

using the menu. Alternately insert the internal counter

probe into TP1 (VCO) and TP3 (PLL reference

oscillator), and make sure they indicate the same

frequency (in the 12 MHz range). They'll be equal over

some 5 kHz segment, typically 7179-7184, but

possibly lower or higher

5

. (Note that you can tune the

VFO while in C A L F C T R .) Don't change modes or

filters, as this will move the target range.

Range: 7____- 7____ kHz (mode: ___, filter: ___ )

Listen to a few signals in this range to see if they

exhibit the "wavering" sound. Compare them to signals

outside the range. You can use another ham transmitter

as a signal generator. (Don't change modes or filters.)

Modifications to Cure Instability

The following modifications can be used to cure

the instability, if required. Try them in order, and stop

when the symptom disappears. All necessary parts are

included in mod kit K2ATOBKT.

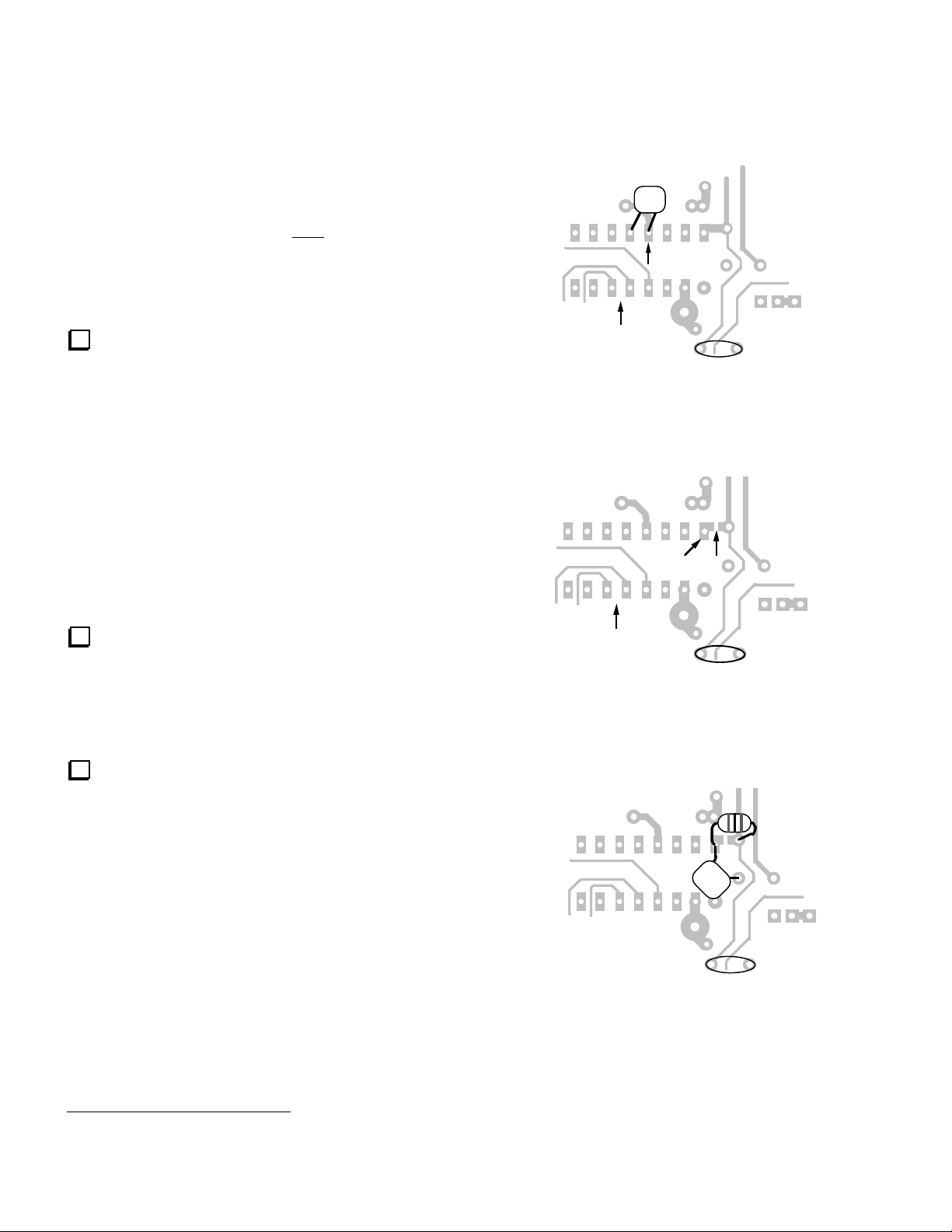

MC145170

(bottom view)

Pin 16

MC145170

(bottom view)

C90

Figure 1

X

C90

Figure 2

RFC15

Make sure C70 and C71 (VCO area) have the shortest

possible leads.

Solder a 68-pF capacitor (RF-C

RF board, between pins 13 and 12 of the MC145170,

U4 (see Figure 1). Keep the lead length short.

Add an RF choke in series with U4 pin 16. First locate

point "X" in Figure 2. Cut the indicated small trace

segment between pin 16 of U4 and capacitor C89 (on

the top side). Next, solder a miniature 100-µH RF choke

(RFC15) across the cut as shown in Figure 3. Finally,

solder a.001-µF capacitor (C91) from pin 16 to ground.

Remove C70 (4.7 pF).

5

Due to differences in the way old and new firmware did

CAL PLL.

PLL) on the bottom of the

5

C91

C90

Figure 3

Page 6

3. Misc. RF Board Changes

This step describes all RF board changes not covered

elsewhere. Parts can be found in K2ATOBKT.

Turn the K2 off. Touch an unpainted, grounded

metal surface. Remove the top cover.

Remove all options plugged into the RF board.

Remove the two screws holding the Control board

to the Front Panel board. Unplug the KAF2 if present.

Remove the Front Panel assembly (there is no

need to separate the panel from the PC board).

Remove the bottom cover.

Remove the rear panel/heatsink. Save all of the

PA hardware, including the thermal pads.

Add CRF (.047, "473") on the bottom of the RF

board as shown in Figure 4. One trace cut is required.

(This capacitor is important if you have a KBT2

internal battery or KPA100 module. It prevents

damage to the K2's low-pass filter relays in the event

that the AUX RF and AUX DC cables are reversed. On

the Rev. B RF board, the capacitor is C224.)

J3

J4

Revision XC and older Rev. C K2s Only

The following steps apply to Rev. XC and some Rev.

A K2s (prior to s/n 2000). Check the components to

see if you already have the correct values installed.

Change C68 (VCO area) from 4.7 or 5 pF to 10

pF. (Eliminates possible VCO problem on 160 meters.)

Change R1 and R2 (near the key jack) from 470

ohms (or 1k) to 220 ohms. (Lowers the voltage seen by

the K2 when a paddle is closed. With 1 k, noise

immunity may be inadequate. The microcontroller's

internal pull-up resistors can pull these lines up too

close to the "0" logic threshold.)

Change R50 from 1/4 watt to 1/2 watt (1.5 ohms,

brown-green-gold). (1/4 watt in the driver emitter was

too low to ensure adequate heat dissipation.)

Note: Other minor (preventative) design changes were made

from revision XC to revision A. Except in rare cases, they

will not significantly affect performance, and we

recommend that they not be changed. These include: L31

from 12 to 10 µH (PLL reference), C153 from 39 to 68 pF

(TX mixer coupling), C162 from .01 to .047 (post-mixer

amp), D9 from 1N34A to 1N5711 and R68 from 237 to 226

(RF detector).

Crf

K9

P6

Cut

K10

Figure 4

Change D10, at the right edge of the RF board,

from an SB530 to a 95SQ015. (The latter is an ultralow-drop diode, having a drop of only about 0.1 to 0.2

volts. This reduces wasted power in the diode on

transmit, nearly eliminates the discrepancy between

external voltmeters and the K2's internal voltage

display, and allows the use of a slightly lower voltage

supply for recharging the KBT2 internal battery.)

Re-installing the Heat Sink

Note: Skip these two steps for now if you plan to make

the bandpass filter changes on the next page.

Revision A and XC K2

Change R64 (center of the board, near U1) from

470 to 100 ohms. (Improves auxBus noise immunity.)

Change RFC11 from an RF choke to an FT37-43

toroid with 20 turns #26 enamel. Mount RFC11 on the

bottom of the board with short leads. (Reduces

unwanted S-meter activation, esp. on 17 meters.)

6

Inspect the thermal pads for Q7 and Q8. Brush

away any aluminum fragments which might have

become stuck to the pads.

Re-install the rear panel/heat sink and PA

hardware as described in the K2 owner's manual

(Assembly, Part III).

Page 7

4. 15/17 m & 20/30 m Bandpass Filters

See descriptions below. Band-pass filter realignment

will be done following all hardware and firmware

updates.

15/17 m Bandpass Filter

These optional changes narrow the 15/17 m bandpass

filter to improve image rejection. In Europe in

particular, strong shortwave broadcast stations in the

16 MHz range may produce low-level image responses

in the 15-m band with the original filter values.

Change C30 and C36 from 330 to 470 pF ("471").

Change C33 from 3 (or 3.3) pF to 2 (or 2.2) pF.

20/30 m Bandpass Filter

This optional change adds 12-pF capacitors in parallel

with each of the 20/30-m bandpass filter trim caps,

which should eliminate any difficulty in aligning the

bandpass filter on 20 meters. Some builders found that

the 20-meter trimmers "topped out" before the peak

was located.

Solder 12 pF capacitors across C21 and C23, on

the bottom of the board in the bandpass filter area.

(These capacitors are designated C28 and C29 on the

Rev. B RF board.)

Re-installing the Heat Sink

Inspect the PA thermal pads and re-install the heat sink

as described in the last two steps on page 6.

If you have an older K2 (Rev. A or XC), you may

have installed a large capacitor (150 pF or larger) at

C174 due to inadequate BFO range. Increasing only

the size of C174, without a proportional increase in

C173, may cause excessive BFO injection and is no

longer recommended. Restore C174 to its original

value if applicable (82 pF; supplied with

K2ATOBKT.)

Note: The crystals supplied with BFOMDKT should

have adequate range with the standard capacitor value

at C174 (82 pF). If the range is found to be slightly

low, two supplemental capacitors (47 pF and 120 pF),

which are supplied with BFOMDKT, can safely be

added in parallel with C174 and C173. This is

explained on page 12 as part of the BFO range test.

If you have an older K2 (Rev. A or XC), you

may have a 100 k RPACK at RP2. In this case, solder

10 k resistors (

pins 3-4, on the bottom of the board in the VCO area.

(There's no need to remove RP2, which can be

difficult. The two paralleled resistors will suffice.)

Locate the instructions supplied with BFOMDKT.

Put an "X" by the instructions covering installation of

firmware, as well as BFO and PLL test and alignment.

These steps will be skipped for now.

Follow all instructions supplied with part #

BFOMDKT, except those you marked with an "X"

above.

RREFA, RREFB) across RP2 pins 1-2 and

5A. PLL Upgrade

5. BFO Temperature Stability

This optional set of modifications reduces BFO

frequency drift an average of 70-80%. The parts and

documentation for the change are supplied with part #

BFOMDKT.

If you previously installed this mod kit, make sure

that R19 (soldered to the bottom of the board in the

PLL reference oscillator area) is 2.7 k. Some early

BFOMDKT kits were sent out with 220 ohms for use

at R19, which can cause PLL reference oscillator

instability. (1.8 to 3.3 k can be used.)

Note: Skip to step 5A, at right (PLL Upgrade) if

you've already installed BFOMDKT.

7

The PLL Upgrade is a very important design change

that was recently added to the K2 (s/n 3446 and later).

It uses a thermistor to temperature-compensate the PLL

reference oscillator, reducing drift by a factor of 5 to

10. This upgrade kit should only be installed if you

have also made the BFO mod described above. The

parts, small PC board, and documentation for this

upgrade are supplied with part # E850138.

Follow all instructions supplied with the PLL

Upgrade kit, E850138, except those dealing with

alignment and test. This will be done later.

Page 8

6. VFO ALC & 10/12 m Bandpass Filter

This set of modifications enhances the VFO ALC

circuit and narrows the 10/12 m filter. Without the

mods, a small increase in VFO spurious output will

sometimes occur when switching bands to or from 10

meters. This is usually significant only if the K2 is

driving a KPA100 or other amplifier, but we

recommend making the changes in all cases. The parts

and documentation for this mod are supplied with part

# E850093.

Follow all instructions supplied with the VFO

ALC mod kit, E850093, except 10/12 meter bandpass

filter alignment. Alignment will be done later.

If you have a rev. XC K2, you must also add R18

(1 M) to the VFO ALC circuit. Solder R18 on the

bottom of the board, directly across the pads of C59.

7. Second Crystal Filter Flatness

This change flattens the K2's second crystal filter

response, and allows the I.F. adjustment, L34, to be set

optimally for both CW and SSB. As a result, a much

better pitch match can be obtained on LSB and USB.

The parts and documentation for this mod are supplied

with part # XFILMDKT.

i

In the following step, be careful not to

overheat the crystals. Use a temperature-controlled

iron, and limit soldering time to about 3 seconds per

soldering attempt.

There are two ground pads each for X7-X11, one

on either side. Use bare wires (10 total) for grounding

the crystals, but do not solder the wires to the tops of

the crystals. The wires must be soldered to the sides,

instead, about 1/4" (6 mm) up from the surface of the

PC board.

9. AF GAIN Control Smoothness

The original "2-wire" AF gain potentiometer circuit is

susceptible to mechanical potentiometer noise at the

counter-clockwise end of its rotation. The "3-wire"

modification used in the Rev. B K2 completely

eliminates this problem, making AF GAIN adjustment

smooth. The modification also allows the AF GAIN

pot to completely turn off the audio when rotated fully

counter-clockwise. In some cases, the old circuit would

permit some residual signal to circumvent the

potentiometer in this position.

This change is optional but recommended.

Follow all instructions supplied with

XFILMDKT, except those instructions dealing with

I.F. alignment, which will be done later.

8. First Crystal Filter Grounding

The instructions for grounding the crystals in the 5pole first CW crystal filter (X7-X11) originally called

for the wires to be soldered to the tops of the cans. A

few builders subsequently determined that soldering

the ground wires closer to the base of the cans resulted

in better ultimate attenuation. Some builders also

experimented with additional bypassing of filter

control lines using surface-mount capacitors, but this

appears to offer very little additional benefit, if any.

This change is optional. Most K2 builders who used

top-grounding of the crystals in the first crystal filter

found the ultimate attenuation to be completely

satisfactory.

Follow all instructions in the application note,

except those dealing with testing the new circuit, which

will be done later. The application note can be found

at:

http://www.elecraft.com/Apps/K2_AF_pot/K2_AF_gai

n_app_note.htm (HTML)

or:

http://www.elecraft.com/Apps/K2_AF_pot/K2_AF_gai

n_app_note.pdf (PDF)

8

Page 9

10. Misc. Control Board Changes

These changes improve various operating

characteristics of the K2, as explained in each of the

steps below. The parts for these changes are included

in K2ATOBKT.

Change R6 from 470 to 100 ohms (brown-black-

brown). (Improves auxBus noise immunity.)

Change R7 from 1.96 to 1.78k (brown-violetgray-brown). (Improves current measurement

accuracy.)

Sidetone Modification

These optional changes provide a more pleasantsounding sidetone.

Locate capacitor C24 (.0027 µF), which is on the

right side of the Control board between RP7 and RP3.

As shown in Figure 6, cut the trace on the top side of

the board between C24 and pin 6 of RP7. On the

bottom side of the board, solder a 47 k resistor (yellowviolet-orange) between these two pads. (Reduces

digital switching noise in the sidetone; designated R11

on the Rev. B Control board.)

Change C12 from .001 to .0027 µF ("272").

(Improves auxBus noise immunity.)

Change C42 from .01 to 0.1 µF ("104").

(Stabilizes voltage display.)

Locate the trace on the top side of the board that

runs directly between resistors R8 and R9 (Figure 5).

Cut the trace. On the bottom side of the board, solder

an 820-ohm resistor (gray-red-brown) between the two

vias. You'll need to pre-trim the resistor's leads since it

isn't possible to cut the lead that falls between R8 and

R9. (Protects the microcontroller in the event that an

RS232 signal is accidentally connected to the

VRFDET line via the KIO2's or KPA100's AUX I/O

connector. Designated R12 on the Rev. B Control

board.)

R8 R9

R12 (on back)

Cut

R11 (on back)

RP7

C24

RP7

C24

Cut

Figure 6

Locate RP5, the 10-pin, 470-ohm RPACK at the

right side of the board. Solder an 82-mH shielded

inductor ("823") on the bottom of the Control board

between pins 7 and 10 of RP5. The leads of the

inductor should be formed such that the body can be

folded down flat against the PC board. (Designated L1

on the Rev. B board. Creates a low-frequency resonant

tank in conjunction with C33, greatly attenuating

harmonics of the sidetone. The resonant frequency is

approximately 400 Hz, but the Q is quite low, so

sidetone frequencies from 400-800 can still be used

effectively.)

RS-232 and Sidetone Source (KIO2/KPA100)

Figure 5

If you have an older K2 (Rev XC or A), C31 may

be 0.1 µF ("104"). Change C31 to .047 µF ("473").

(Improves CW keying envelope shape.)

9

If either a KIO2 or KPA100 option is installed in the

Rev. A or XC K2, the builder must make a few

additional changes to the Control board. These changes

are fully documented in the KIO2 and KPA100

manuals. (The sidetone generation is re-routed from

pin 25 of the microcontroller, U6, to pin 4 of the quad

D-to-A converter, U8. This allows pin 25 of U6 to be

used for full-duplex RS232 communications.)

There is no need to make these changes until you add a

KIO2 or KPA100. In a later step, you'll set up your

K2's configuration based on whether or not you have at

some point installed either of these options.

Page 10

AGC Threshold Control

R1 on the Control board sets the AGC threshold, which

also establishes the K2's I.F. gain. On Rev. A and Rev.

XC Control boards, R1 is fixed. A small number of K2

owners found that reducing the size of R1 slightly

could optimize the AGC threshold setting and/or bring

up the I.F. gain, so we used a trimmer at R1 on the

Rev. B board.

12. Alignment and Test

Re-Installation of Boards and Panels

Reinstall the front panel assembly.

Reinstall the Control board (and KAF2 option if

applicable). Secure the Control board to the Front

Panel board using the provided hardware.

We don't recommend replacing R1 with a trimmer on

older K2s, for two reasons: the number of K2s that

would benefit from it is quite small; and adding a

potentiometer here is difficult because R1 is very close

to the side panel.

After you've completed all hardware changes and have

the K2 reassembled, you can test your AGC threshold

to determine if a change in the value of R1 is

warranted. This is covered in on page 14.

11. Firmware Installation

If you determined earlier (page 3) that your

firmware must be replaced, complete the following

steps. Otherwise skip to Alignment and Test (right

column).

Touch an unpainted, grounded metal surface.

Remove the old K2 firmware, U6 (Control board),

using a small screwdriver to pry it gently out of its

socket at both ends. Store it in a safe place.

Straighten the leads of the new microcontroller

(PIC18C452).

Install the new microcontroller. Orient the

notched or dimpled end of the IC with the notched end

of its component outline.

If your I/O controller (IOC) firmware is revision

is 1.05 or earlier, or if you were sent a new I/O

controller by Elecraft (PIC16F872), remove U1 on the

RF board. Store it in a safe place. Install the

replacement IOC at U1.

Reinstall the bottom cover.

Reinstall all options that plug into the RF board.

Reinstall the rear panel/heatsink if you have not

done so already (last two steps on page 7).

Firmware Configuration

Turn on the K2. You may see I N F O 2 0 1 (for

about 11 seconds) if you have installed new firmware.

The sidetone may not be working at this point, and the

filters and S-meter may not be calibrated.

If you saw I N F O 2 0 1 , you must re-enter all of

your menu and CAL parameters as explained in the

following steps. If you didn't see INFO 201, skip to

Supplemental Menu Parameters (next page).

Set up all primary menu entries using data

recorded in Table 2 (page 3). S T L and S T P must

be set up, even though you may not have any sidetone

at this point. This will be corrected later.

If your old firmware was older than revision 2.00,

please read the "K2 Revision 2 Firmware" manual,

which you should have received with the new firmware

(you can also download it from our web site). This will

explain what the secondary menu entries are used for,

and how to access this menu.

Set up all secondary menu entries from Table 2.

If you have the K60XV option installed (60 meter

adapter), set the D 1 9 secondary menu entry to Y (see

K60XV manual). Otherwise leave D 1 9 set to N .

Set up the C A L C U R , C A L S L O , and C A L

S H I entries from Table 3. C A L T P A is stored by

the microcontroller in the KPA100, if applicable, and

does not need to be set up here. C A L P L L will be

done later.

10

If applicable, set up transverter bands (Table 4).

Set up the filter bandwidths (but not the BFOs)

for each mode using data from Table 5. The BFOs will

be set up after the BFO range check.

Page 11

Supplemental Menu Parameters

The D I S P L A Y

parameters when editing certain menu entries. Set up

these parameters as follows:

Test your sidetone using the S T L menu entry. If

the sidetone is missing,

then tap D I S P L A Y

The default is U 8 - 4 , compatible with the Control

board modifications required for the KPA100 and

KIO2. If you have never installed a KIO2 or KPA100,

the source should be set to U 6 - 2 5 .

"8R Hold" mode keeps the 8R (8 volts receive)

line low between CW elements. This is now the default

mode for 8R; it eliminates excessive T-R relay

switching when the K2 is used with transverters or

amplifiers. At present we don't know of any reason to

set the 8R mode to "normal," where 8R is allowed to

go back to 8 volts between CW elements. However, if

you wish to select this mode, locate the T - R menu

E D I T its parameter, and tap D I S P L A Y .

entry,

You'll see 8 R n o r on the LCD.

switch is used to access additional

E D I T the S T L parameter,

to change the sidetone source.

PLL Reference Oscillator Range Test

This test is necessary if you made the Temperature

Stability modifications or changed any other

components in the PLL reference oscillator.

Make sure the bottom cover is securely attached,

and that the K2 has been turned on for at least 5

minutes (operating at room temperature).

Plug the frequency counter probe into P6 (Control

board).

Connect the probe tip to the PLL reference

oscillator test point, TP3 (left-front corner of the RF

board, near U4). Note: If an audio filter module is

installed, you'll need to remove it to get to TP3.

Using the menu, select C A L F C T R , then hold

E D I T a second time to enable the frequency counter.

The counter should show a frequency of 1 2 0 9 0 kHz

+/- 30 kHz. If it is 0000.00, changing rapidly, or out of

range, you could have a problem with the counter

probe or the PLL Reference Oscillator.

"Auto-detect" allows you to connect a keyer,

computer, or hand key to the K2 along with a keyer

paddle. Auto-detect is normally on. To turn it off,

locate the I N P menu entry,

tap D I S P L A Y . You'll see A D E T O F F .

The default fan mode for the KPA100 option is

F A N n o r . If you prefer F A N L o H i or F A N H i ,

locate the P A entry in the secondary menu,

parameter, and tap D I S P L A Y to select the desired

mode.

E D I T its parameter, and

E D I T the

When you’re in frequency counter mode, the

B A N D +

the range of the PLL reference oscillator. First, tap

B A N D +

space below (typically about 12097-12100 kHz). Then

tap B A N D - and write down this frequency reading

(typically 12085-12092 kHz).

Ref. High Freq. Ref. Low Freq. Range (kHz)

____________ ____________ __________

higher reading. The range must be between 9.0 and 15

kHz (if not, you may have a problem in the PLL

reference oscillator, most likely with one of the

components recently installed). Tap M E N U

C A L F C T R .

and B A N D - switches can be used to check

and write down the frequency reading in the

Subtract the lower frequency reading from the

to exit

If you removed an audio filter option temporarily

to get to test point TP3, reinstall it now.

11

Page 12

BFO Test

The BFO will be tested in the following steps. You

should do this test even if you did not make the

Temperature Stability modifications.

Make sure the bottom cover is securely attached.

Switch to the 40-m band.

Connect the frequency counter to the BFO test

point (TP2), which is on the right side of the RF board

near the crystal filter.

Using the menu, activate C A L F C T R . The

counter should show a frequency between 4908 and

4918 kHz.

If your BFO range is slightly less than 3.6 kHz,

and/or the low frequency is higher than 4912.7, your

BFO crystals probably have higher than average Q.

You can safely compensate for this by increasing the

size of C174 and C173 in the BFO circuit. The

Temperature Stability mod kit (BFOMDKT) includes

two capacitors for this purpose, 47 pF to parallel with

C174, and 120 pF to parallel with C173. If you didn't

order this mod kit, you can use any temperature-stable

capacitors (NPO, C0G, or N750 types) in the following

ranges: 39-68 pF (in parallel with C174), and 100-180

pF (in parallel with C173).

If the BFO doesn't appear to be working, or its

frequency range is shifted too high or too low, it may

be due to one of the following:

i

If you see a reading of 0 0 0 0 . 0 0 kHz or one

that is changing rapidly, you may not have the

frequency counter probe connected properly. Also

inspect the leads of L33 carefully. They could be

broken or poorly soldered.

When you’re in frequency counter mode, the

B A N D +

the range of the BFO. First, tap B A N D +

and B A N D - switches can be used to check

and write

down the frequency reading below (typically about

4916-4917 kHz). Then tap B A N D -

and write down

this frequency reading (usually about 4911-4913 kHz).

Finally, calculate the BFO range (high - low) in kHz.

Typical range is 4 to 5 kHz.

BFO High Freq. ___________

(must be 4916.3 kHz or higher)

BFO Low Freq. ___________

(must be 4912.7 kHz or lower)

Range (High - Low) ___________

(must be 3.6 kHz or more)

If you didn't calibrate the K2's internal frequency

counter using an external counter, it may not be reading

accurately. If possible, borrow an accurate counter and

re-do the 4 MHz Oscillator Calibration as described in

the K2 owner's manual.

If you installed the new BFO toroid at L33 (T44-7),

look closely at its leads using a magnifying glass. The

wire used is very small, and easily broken during

installation.

One or more of the capacitors in the BFO circuit could

be of the wrong value.

BFO Alignment

The following two steps will be necessary if you saw

I N F O 2 0 1 on the display following firmware

installation, or if you made the Temperature Stability

modifications to the BFO.

Make sure the bottom cover is securely attached.

Set up the BFOs for all modes and filters using

the frequencies from Table 5 (page 4). You'll have a

chance later on to fine-tune the BFO settings.

12

Page 13

VFO Linearization

I.F. Amplifier Alignment

This procedure will be necessary if you installed new

firmware or if you installed the PLL Upgrade (or made

other changes in the PLL area of the RF board). The

procedure will be done only on 40 meters. It should

not be repeated on each band.

Allow the K2 to warm up at normal operating

room temperature for at least five minutes. The

bottom cover must be installed.

Plug the K2 frequency counter cable into P6 on

the Control board. Connect the probe end to test point

TP1 on the RF board (VCO, center-left side of the RF

board).

Switch to 40 meters and set the VFO to about

7100 kHz.

Tap M E N U and locate the C A L entry. Hold

E D I T , then change the parameter to P L L . Hold

E D I T again to begin the calibration procedure. You'll

see a frequency in the 12 MHz range displayed, and the

letter "d " will flash as the firmware records calibration

data. After approximately 5-10 minutes, you'll hear a

short tone, and E N D will be displayed. Tap any switch

to clear this message.

If you made the recommended modification to the

second crystal filter, L34 will need readjustment. L34,

located near the right front corner of the RF board, is

used to peak the output of the I.F. amplifier.

Using the wide end of the plastic tuning tool,

adjust the slug in L34 until it is near the top of the can.

Stop turning the slug when it appears to be at the

top or when you feel resistance.

Turn L34’s slug one full turn clockwise (down

into the can).

Set the band to 40 meters using B A N D + or

B A N D -

nominal bandwidth).

clockwise (max. gain). Disconnect the antenna from

J4, if one was connected.

turns on.

the front panel jack, and turn the AF GAIN control to

about midway.

. Select CW Normal and FL2 (700 Hz

Make sure the RF GAIN control is fully

Tap P R E / A T T N until the PRE annunciator

Connect a pair of headphones (stereo or mono) to

i

If you see I N F O 2 3 2 at any time during

VFO calibration, verify that you were on 40 m, with

the counter cable at TP1.

You can check the VFO's accuracy using a signal

at a known frequency (see page 98 of the revision C

K2 manual). Note: In the Revision C manual, steps 8

and 11 on page 98 are incorrect for the new firmware.

C A L P L L is now run only once, and only on 40 m.

Move the K2 counter cable to the BFO test point,

TP2.

Slowly tune the VFO to locate the weak

internally-generated signal near 7000 kHz.

While listening to the signal at 7000 kHz, adjust

L34 for best signal strength and lowest noise. This

setting occurs at about 1 to 1.5 turns below the top of

the can. (You can use your DMM on AC volts, at the

speaker jack, to obtain a more sensitive indication.)

13

Page 14

Receiver Pre-Alignment, 10-30 meters

Transmitter Alignment, 10-30 Meters

This step is necessary if you made any changes to the

10-30 m band-pass filters (steps 4, and 6, page 8). If

you didn't make these changes, continue with FineTuning Filter Settings, page 15.

Switch to 20 meters and set the VFO for about

14100 kHz.

Turn on the RF preamp by tapping P R E / A T T N

until you see the PRE annunciator turn on.

Use a signal generator or an antenna to inject a

signal or noise at this frequency.

i

Since some inductors are shared between two

bands, you must always align the bands in the order

indicated. Always use this procedure if you re-align the

filters later.

Set C21 and C23 to their mid-points. Adjust L8

and L9 for maximum signal strength. (This step presets C21, C23, L8, and L9 before final adjustment in

the next two steps.)

Note: When switching to each of the remaining bands

to be aligned, you'll need to inject a signal or use an

antenna.

Switch to 30 meters (10100 kHz) and turn on the

preamp. Adjust L8 and L9 for maximum signal

strength.

Switch back to 20 meters (14100 kHz). Adjust

C21 and C23 for maximum signal strength.

Switch to 15 meters (21100 kHz) and turn on the

preamp. Adjust L10 and L11 for maximum signal

strength.

Switch to 17 meters (18100 kHz) and turn on the

preamp. Adjust C32 and C34 for maximum signal

strength.

Switch to 10 meters (28200 kHz) and turn on the

preamp. Adjust L12 and L13 for maximum signal

strength.

Switch to 12 meters (24900 kHz) and turn on the

preamp. Adjust C44 and C46 for maximum signal

strength.

Set the POWER control for 2.0 watts. Connect a

dummy load at the antenna jack.

Switch to 30 meters. Adjust L8 and L9 for

maximum power output in TUNE mode. Avoiding

using TUNE mode for more than 5 seconds at a time.

Switch to 20 meters (14100 kHz) and adjust C21

and C23 for maximum power output.

Switch to 15 meters (21100 kHz) and adjust L10

and L11 for maximum power output.

Switch to 17 meters (18100 kHz) and adjust C32

and C34 for maximum power output.

Switch to 10 meters (28200 kHz) and adjust L12

and L13 for maximum power output.

Switch to 12 meters (24900 kHz) and adjust C44

and C46 for maximum power output.

AGC Threshold Test

A few K2 builders found that their overall receive gain

was too low because of a less-than-ideal AGC

threshold setting. If you think you might benefit from a

change in this threshold, follow the steps below.

Otherwise, skip to the next page.

Connect an antenna to the K2, and switch to a

quiet band (one with little atmospheric noise). Turn

AGC off by holding the P R E / A T T N

switches together.

If the level of background noise increases

significantly with AGC off, even on a quiet band, you

may benefit from an adjustment to the AGC threshold.

Remove the Control board and temporarily substitute a

potentiometer for R1, presetting it to R1's fixed value.

Once you find a value of R1 that brings I.F. gain up

slightly while not compromising AGC performance on

large signals, you can install a fixed resistor of that

value.

If you did make a change to R1's value, you'll

need to recalibrate C A L S H I and C A L S L O

(owner's manual, page 84).

and A G C

14

Page 15

Fine-Tuning Filter Settings

13. Speaker grille cloth

You can optionally fine-tune your BFO settings

for each mode by ear or by using a computer-based

tool such as Spectrogram.

If you have the KSB2 option (SSB adapter), and

you made the recommended changes to the second

crystal filter, you may wish to fine-tune the LSB and

USB BFO settings so that the filters have the same

noise pitch.

Note: Only the SSB BFO settings for FL2, 3, and 4

should be made in receive mode. The SSB BFO

settings for FL1 should be made in transmit mode,

either listening to your signal locally or having a

nearby station listen for you. This is because FL1 is

always used in transmit mode (and for receive, when

selected), whereas FL2-4 are only used in receive

mode. FL2-4 can be set up differently without affecting

your transmitted signal. Refer to the KSB2 manual for

more details.

AF GAIN Potentiometer Test

The following two steps apply if you made the AF

GAIN potentiometer smoothness modification.

Grille cloth (part #E850089) can optionally be added to

your original K2 top cover. (The KPA100 module

already has grille cloth for its speaker.)

Remove the speaker from the top cover. This may

involve removing the battery option (KBT2) or other

top-cover options. If you do have to remove a battery,

be sure to turn the battery switch OFF using the rearpanel slide switch. Also, disconnect both leads from

the battery terminals and cover the terminals with tape

to prevent accidental shorts.

Trim the supplied grille cloth to the size of the

speaker frame.

Place the #4 fibre washers (black) at each of the

top cover's four speaker mounting holes. Trim the

corners of the grille cloth so it just fits between the

fibre washers, not touching them.

Place the speaker on top of the fibre washers and

grille cloth. Secure it with four 3/8" (9.5 mm) screws,

#4 lock washers, and 4-40 nuts. Do not over-tighten the

nuts.

Re-install the top cover or KPA100 module.

Rotate the AF GAIN control slowly, near the

counter-clockwise end of its rotation, while listening to

a steady carrier (e.g., the internally-generated signal at

4.000 MHz). There should be no noticeable noise

(crackles, etc.) as you rotate the control.

Set the AF GAIN control to its fully counterclockwise position (minimum gain). You should hear

complete silence, with no audio signal leak-through.

15

Loading...

Loading...