Page 1

E L E C R A F T K 1 T R A N S C E I V E R

BAND

DISPLAY

MENU

E L E C R A F T

RIT/XIT

TX

RX

K 1 T R A N S C E I V E R

EDIT

+

AF GAIN

RIT

-

+

XIT

O W N E R’S M A N U A L

ATTEN

WPM

FILTER

WPM

ATTEN

MSG

TUNE

+

1

-

2

Page 2

E

LECRAFT K1

Multiband

CW Transceiver

Owner’s Manual

Revision I, April 15, 2011

Copyright

2011 Elecraft, LLC

All Rights Reserved

Elecraft www.elecraft.com P.O. Box 69 Aptos, CA 95001-0069 (831) 763-4211 Fax: (831) 763-4218

Page 3

2 ELECRAFT

Table of Contents

1. INTRODUCTION....................................................................................................................................................................................3

2. SPECIFICATIONS................................................................................................................................................................................ 5

3. PREPARATION FOR ASSEMBLY....................................................................................................................................................6

4. FILTER BOARD..................................................................................................................................................................................11

5. FRONT PANEL BOARD....................................................................................................................................................................17

6. RF BOARD, PART I ........................................................................................................................................................................... 25

7. ALIGNMENT AND TEST, PART I...................................................................................................................................................... 36

8. RF BOARD, PART II..........................................................................................................................................................................42

9. ALIGNMENT AND TEST, PART II.....................................................................................................................................................46

10. FINAL ASSEMBLY............................................................................................................................................................................48

11. OPERATION.......................................................................................................................................................................................50

12. CIRCUIT DETAILS............................................................................................................................................................................. 58

PARTS LIST .............................................................................................................................................................................APPENDIX A

SCHEMATIC .............................................................................................................................................................................APPENDIX B

BLOCK DIAGRAM..................................................................................................................................................................APPENDIX C

PHOTOGRAPHS.....................................................................................................................................................................APPENDIX D

TROUBLESHOOTING............................................................................................................................................................APPENDIX E

PARTS PLACEMENT DRAWINGS.......................................................................................................................................APPENDIX F

QUICK REFERENCE..............................................................................................................................................................APPENDIX G

Page 4

ELECRAFT 3

1. Introduction

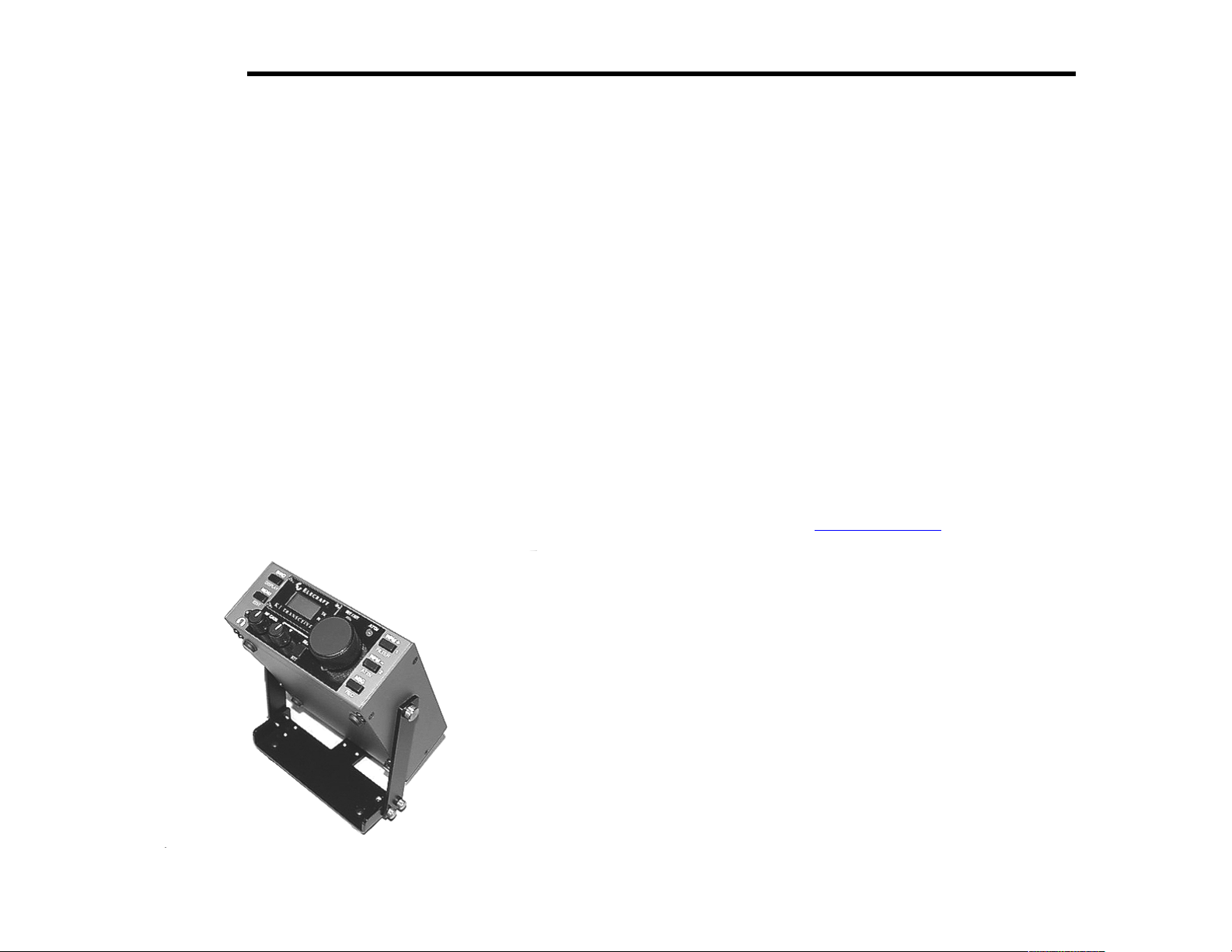

The K1 is a versatile, low-power CW transceiver that covers two

or four builder-selected HF bands. It provides 5 watts or more of

power output; excellent receiver sensitivity and selectivity; and

many useful operating features, including instant band selection,

receive and transmit incremental tuning (RIT/XIT), digital

display, configuration menu, and multiple crystal filter

bandwidths.

With receive-mode current drain of about 55 mA, built-in keyer,

and a stable, low-frequency VFO, the K1 is ideal for portable

operation. It's also one of the smallest multi-band HF transceivers

available–smaller than many single-band rigs. And, when used with

the optional wide-range tilt stand (KTS1), the K1 is truly trail-

friendly. The tilt stand comes with long arms for ground-mounting

(see below), as well as shorter arms for desk-top use.

Like our all-band K2 transceiver, the K1 uses modular construction,

allowing it to adapt to your operating needs. The Filter board covers

either two (KFL1-2) or four (KFL1-4) bands, and a different Filter

board can be swapped in at any time. There are two plug-in options,

including a noise blanker (KNB1) and automatic antenna tuner

(KAT1). There's also an internal AA-cell battery option (KBT1).

These options can be installed easily at any time.

The K1's modular assembly will also appeal to first-time builders.

The kit requires almost no point-to-point wiring, unlike earlier

designs that used wiring harnesses. The K1 even provides its own

built-in test equipment, including battery voltage monitor,

wattmeter, and frequency counter. The manual provides complete

troubleshooting and signal tracing procedures, and you’ll find further

support on our website, www.elecraft.com.

We’d like to thank you for choosing the K1 transceiver, and hope it

meets your expectations for operation both at home and in the field.

Wayne Burdick, N6KR

Eric Swartz, WA6HHQ

Page 5

4 ELECRAFT

Customer Service Information

Technical Assistance

If you have difficulty with kit construction, operation, or

troubleshooting, we’re here to help. You may be able to save time by

first consulting our web site, www.elecraft.com

question on the Elecraft e-mail forum, elecraft@qth.net

Telephone assistance is available from 9 A.M. to 5 P.M. Pacific time

(weekdays only) at 831-763-4211. You can also send e-mail to

support@elecraft.com

. Please use e-mail, rather than call, when

possible since this gives us a written record of the details of your

problem.

Repair Service

If necessary, you may return your completed kit to us for repair.

Contact Elecraft before mailing your kit to obtain the repair

shipping address, as well as information on repair fees. (Kits that

have been soldered using acid core solder, water-soluble flux solder,

or other corrosive or conductive fluxes or solvents cannot be

accepted for repair–see Warranty.)

The following information should be provided to expedite repair:

your name, address, and phone number; your e-mail address (if

applicable); and a complete description of the problem.

Shipping: First, seal the unit in a plastic bag to protect the finish

from dust and abrasion. Use a sturdy packing carton with 3" or more

of foam or shredded paper on all sides. Seal the package with

reinforced tape. (Neither Elecraft nor the carrier will accept liability

for damage due to improper packaging.) Cover the "to" address label

with clear tape.

, or by posting your

.

Elecraft’s 1-Year Limited Warranty

This warranty is effectiv e as o f th e d ate of fi rst consum er purchase (or i f

shipped from factory, date product is shipped to customer). It covers both our

kits and fully assembled products. For kits, before requesting warranty service,

you should complete the assem bly, careful ly fol lowing all instructions in the

manual.

Who is covered: This warranty covers the original owner of the Elecraft

product as disclosed to Elecraft at the time of order. Elecraft products

transferred by the purchaser to a third party, either by sale, gift or other

method, who is not disclosed to Elecraft at the time of original order, are not

covered by this warranty. If the Elecraft product is being bought indirectly for a

third party, the third party's name and address must be provided to Elecraft at

time of order to insure warranty coverage.

What is covered: During the first year after date of purchase, Elecraft will

replace defective or missing parts free of charge (post-paid). We will also

correct any malfunction to kits or assembled units caused by defective parts

and materials. Purchaser pays inbound shipping to Elecraft for warranty repair,

Elecraft will pay shipping to return the repaired equipment to you by UPS

ground service or equivalent to the continental USA and Canada. Alaska,

Hawaii and outside U.S. and Canada actual return shipping cost paid by owner.

What is not covered: This warranty does not cover correction of kit assembly

errors. It also does not cover misalignment; repair of damage caused by misuse,

negligence, or bui lder m odifications; or any performance malfunctions

involving non-Elecraft accessory equipment. The use of acid-core solder,

water-soluble flux solder, or any corrosi ve or conductive flux or solvent will

void this warranty in its entirety. Also not covered is reimbursement for loss of

use, inconvenience, customer assembly or al ignment t ime, or cost of

unauthorized service.

Limitation of incidental or consequential damages: This warranty does not

extend to non-Elecraft equipment or com ponents used i n conjunction with our

products. Any such repair or replacem ent is the responsibility of the custom er.

Elecraft will n ot be liable for any special, indirect, incidental or consequential

damages, including but not limited to any loss of business or profits.

Page 6

ELECRAFT 5

2. Specifications

Measurements were made using a 14-V supply and 50-ohm load.

General

Size (H x W x D)

Weight 1.4 lbs. (0.6 kg), excluding options

Supply voltage 8.5 to 15 VDC

Current drain

Bands covered (MHz) 3.5, 7.0, 10.1, 14.0, 18.05, 21.0

Frequency control Electronically-tuned 3 MHz VFO;

VFO drift < 200 Hz per hour after 5-minute

Cabinet 2.2 x 5.2 x 5.6" (5.6 x 13 x 14 cm)

Overall 2.4 x 5.2 x 7.1" (6 x 13 x 18 cm)

Receive 55 mA typ. (no signal)

Transmit 700-900 mA typ. (5 W, 14 VDC)

(2 or 4 selected bands per module)

approx. 80 or 150 kHz range,

selected during assembly

warm-up at 25° C

Transmitter

Power output 0-5 watts or higher; spurious and

harmonic content -40 dB @ 5 W

Load tolerance 2:1 or better SWR recommended;

will survive high-SWR operation

Sidetone pitch 400-800 Hz in 10 Hz steps

Internal keyer 8-50 WPM; Iambic modes A and B;

2 message buffers; auto-repeat

Receiver

Sensitivity Approx. 0.2 µV for 10 dB (S+N)/N

I.F. 4.915 MHz, single conversion

Selectivity 4-pole variable-bandwidth crystal

filter, approx. 200-800 Hz

Audio output 1 watt (peak) into 8-ohm load

RIT/XIT range Approx. +/- 3 kHz

Display 3-digit LCD w/bargraph modes

1

The RIT/XIT range can be easily modified; see page 55.

1

Int. speaker 8 ohms, high-efficiency

Headphones 8 ohms or higher; stereo plug

or ext. speaker (mono optional--see page 31,

second assembly step)

Page 7

6 ELECRAFT

3. Preparation for Assembly

Overview of the K1

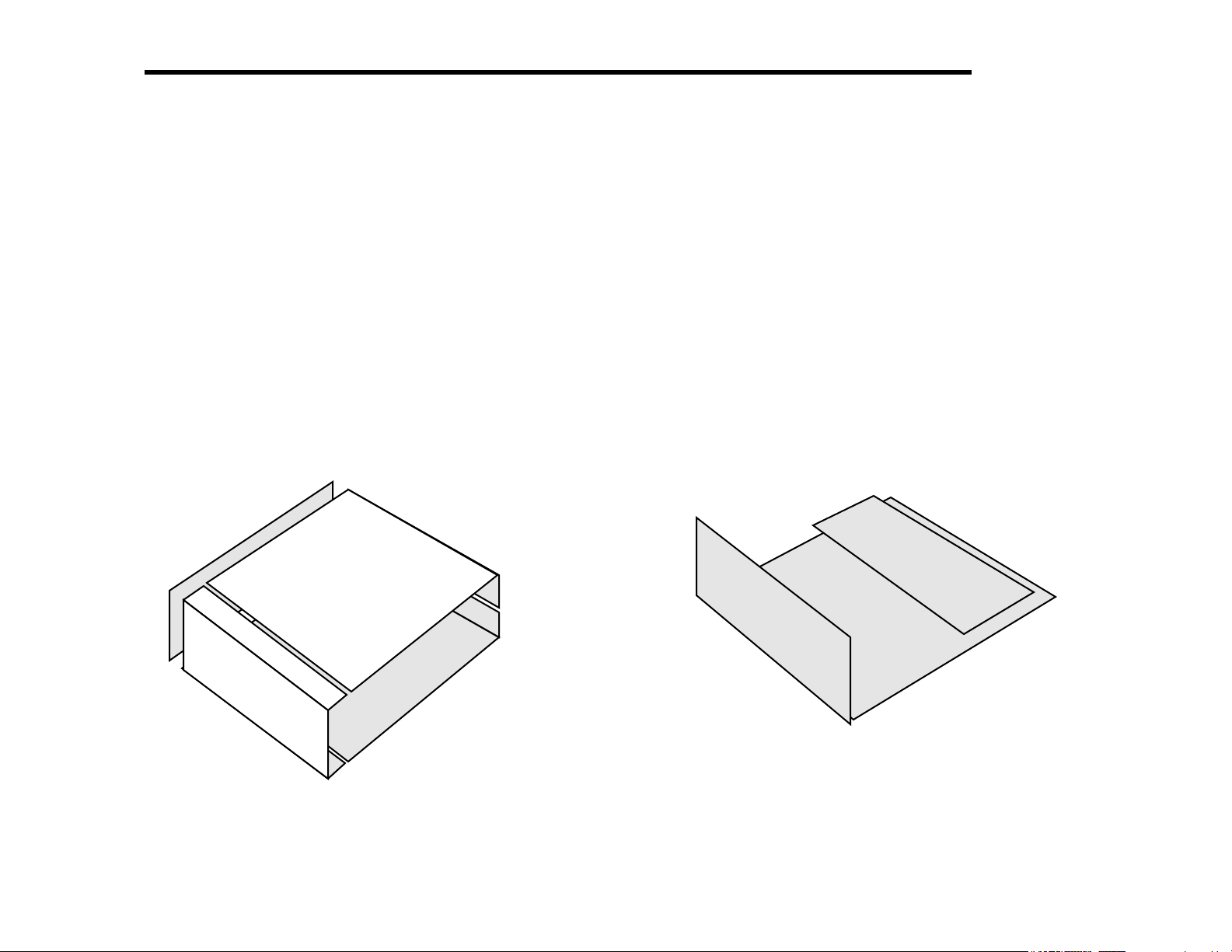

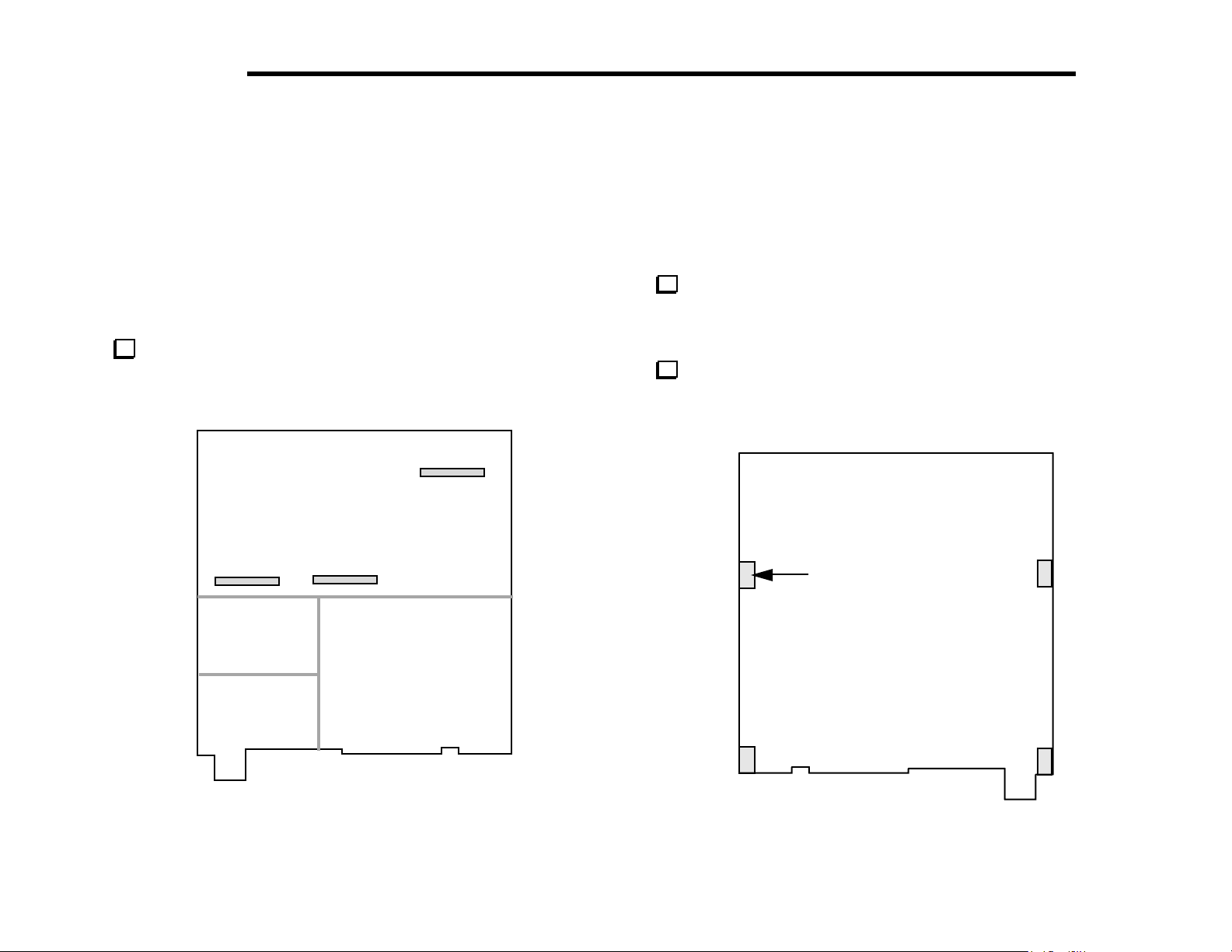

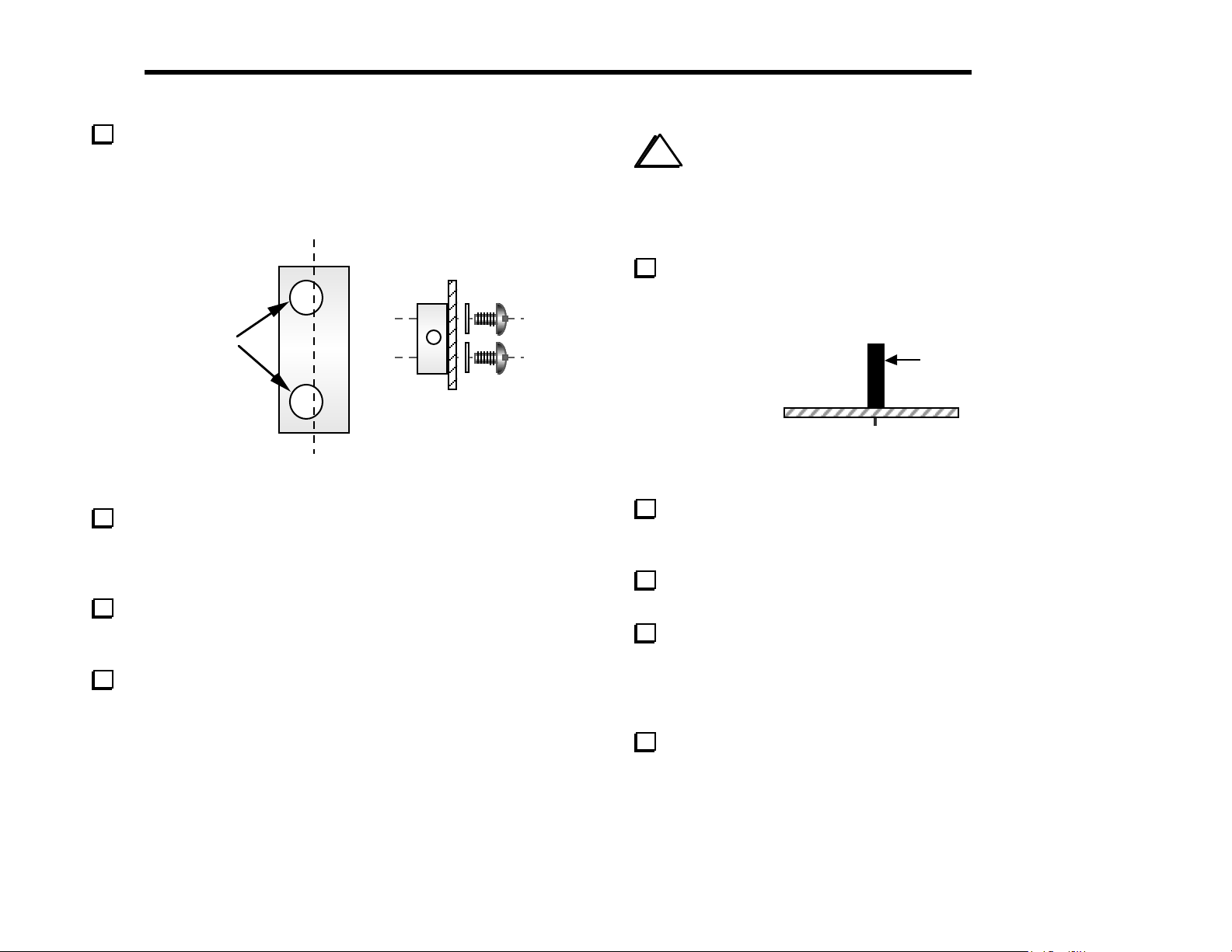

The K1 uses modular design for ease of assembly and

troubleshooting. The chassis is made up of five pieces (Figure 3-1),

any of which can be removed individually. The RF power amplifier

transistor uses the right side panel as a heat sink, so there is no

separate heat sink element. Each side panel includes a 10-32

threaded PEM nut as a mounting point for the KTS1 tilt stand.

Side

Panel

Top Cover

Front

Panel

Bottom

Cover

(Right side panel

not shown)

There are three printed circuit boards (PCBs), as shown in

Figure 3-2: Front Panel board, Filter board, and RF board. These

boards plug in together with no wiring, as explained in the next

section. K1 options, such as the KNB1 noise blanker, also plug in

directly. Appendix D shows photographs of each completed PC

board assembly.

Filter

Front

RF

Panel

Figure 3-2

Figure 3-1

Page 8

ELECRAFT 7

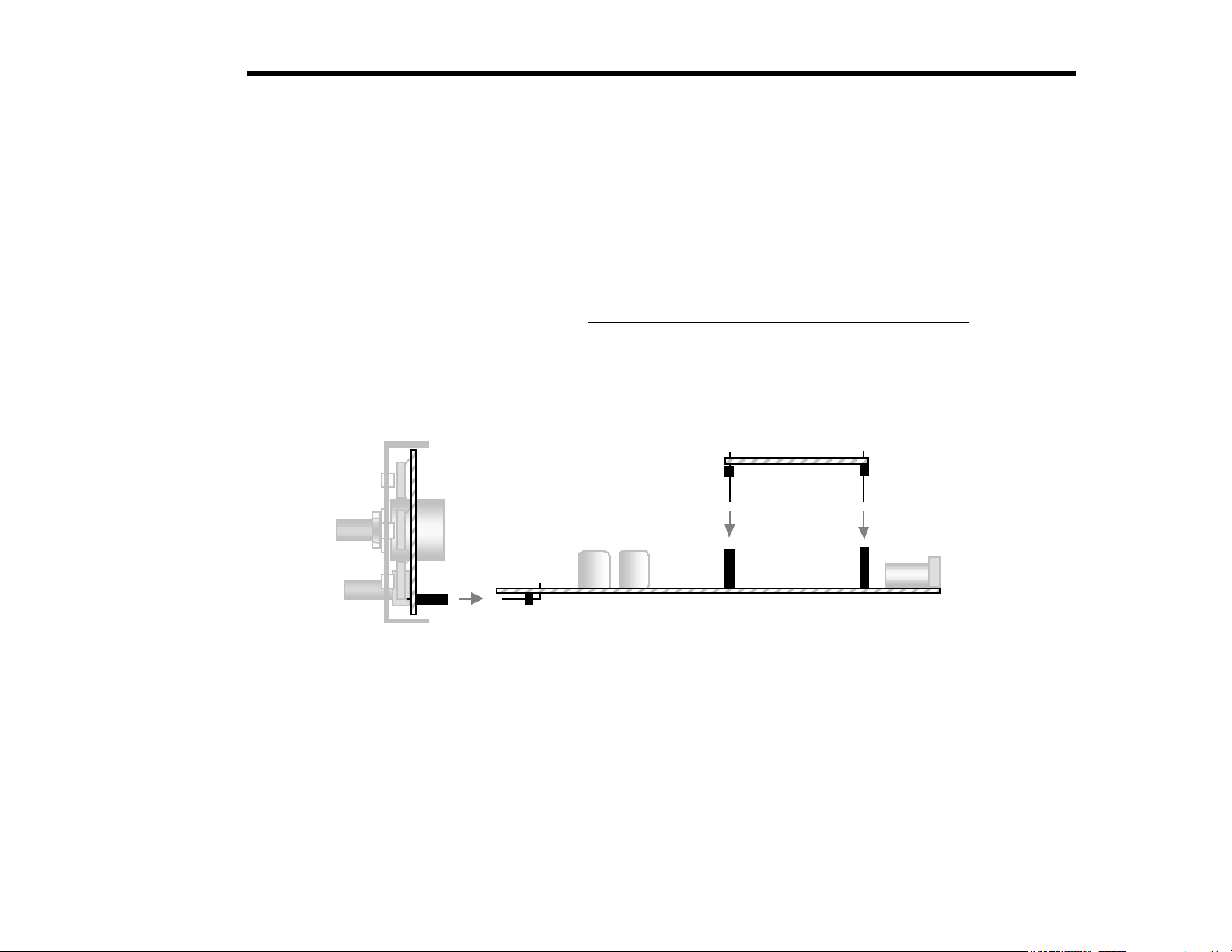

Board-to-board Connectors

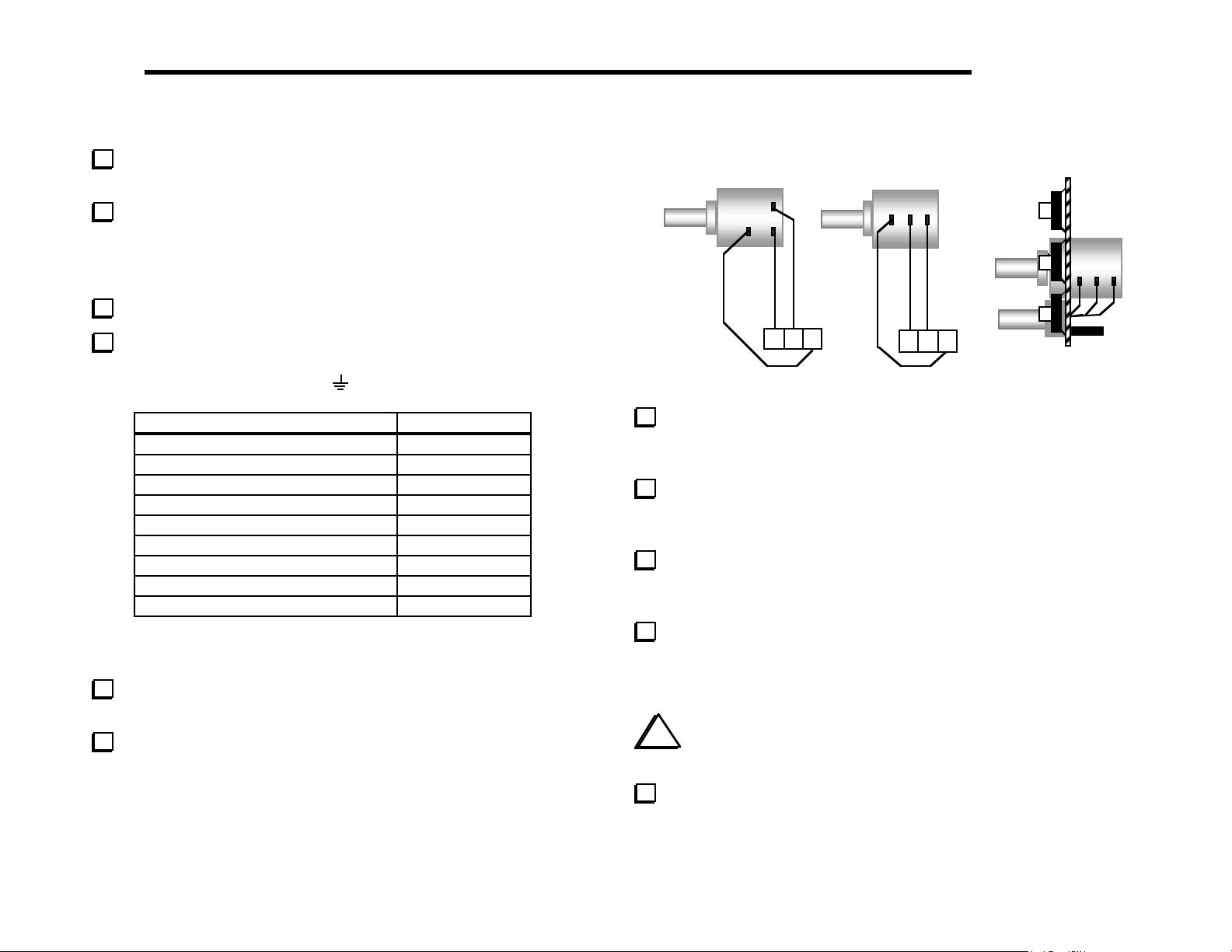

The circuit boards in the K1 plug in together using board-to-board connectors, which eliminates nearly all hand wiring. Gold-plated contacts

are used on these connectors for reliability and corrosion resistance.

Figure 3-3 shows a side view of the PC boards and board-to-board connectors. As can be seen in the drawing, the Front Panel board has a

connector J1 which mates with right-angle connector P1 on the RF board. The Filter board has three connectors, P1, P2 and P3, which mate

with J6, J7 and J8 on the RF board.

These multi-pin connectors are difficult to remove once soldered in place. Refer to Figure 3-3 during assembly to make sure

you have each connector placed correctly before soldering. If you install a multi-pin connector incorrectly, clip all of the pins at

the body of the device first, remove all of the pins individually, and call us to request a new connector. You may damage pads

and traces by trying to remove such components intact.

Front Panel

Filter Board

J1

P1,P2

J6,J7

1

Figure 3-3

RF Board

3

8

K1-2 (2-band version) and K1-4 (4-band version)

This manual covers all aspects of assembly for the two-band K1 (model K1-2). If you purchased a four-band K1 (model K1-4), you'll use the

KFL1-4 assembly manual during assembly and alignment of the Filter board. You'll find instructions specific to the 4-band module at all

appropriate places in this Owner's manual.

Page 9

8 ELECRAFT

Unpacking and Inventory

Handling Integrated Circuits and Transistors

This kit uses integrated circuits (ICs) and transistors that

can be damaged by electrostatic discharge (ESD). Problems

caused by ESD can often be difficult to troubleshoot. To

avoid this:

Leave parts in their anti-static packaging until you install them

Use an anti-static mat on your work bench

Use a soldering iron with a grounded tip

Ground yourself using a wrist strap with 1-Mohm series resistor

At minimum, touch an unpainted, grounded metal surface

before handling ESD-sensitive components

Inventory

We recommend that you do a complete inventory, using the parts

lists in Appendix A. Start with the K1 Packing Box Parts list,

which details the items you should find when you first open the

box. Additional parts lists are provided for components used in each

subassembly. Component photographs are provided in most cases.

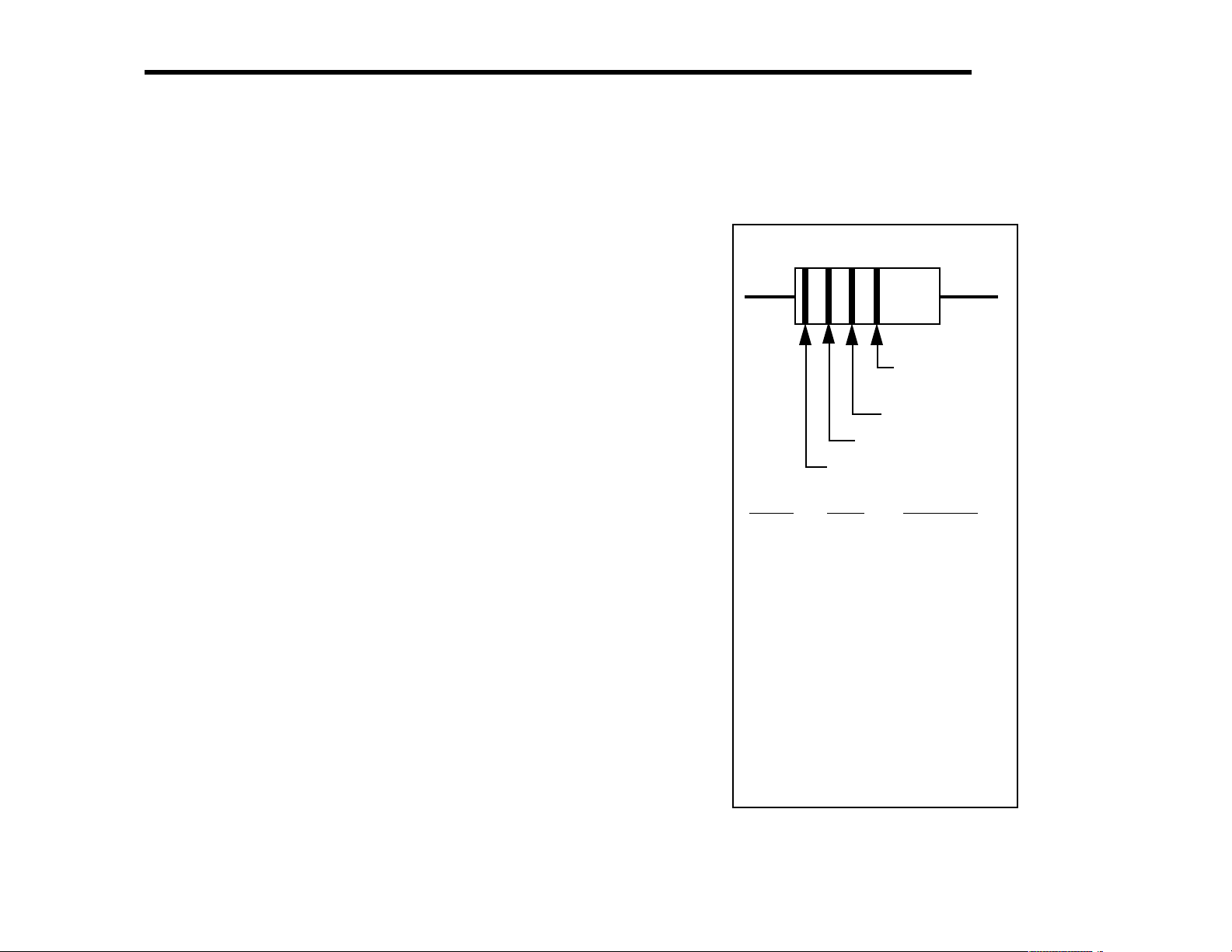

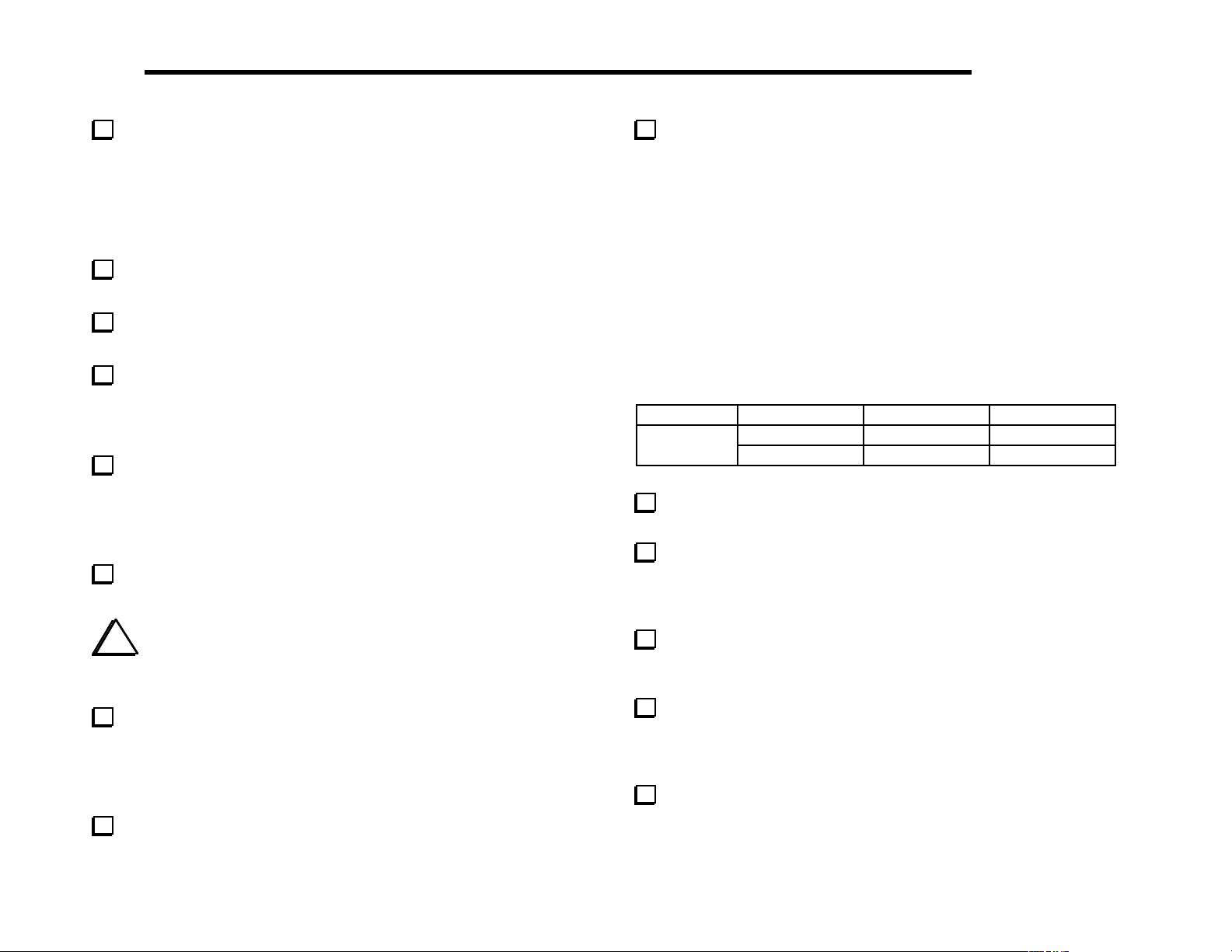

Identifying Resistors and RF Chokes

Resistor and RF choke values and color bands are provided in the

text. However, it's helpful to familiarize yourself with the color

code. The color-code chart, Figure 3-4, shows how to read the four

color bands on 5% resistors. For example, a 1,500 ohm (1.5 k) 5%

resistor has color bands BROWN, GREEN, RED and GOLD.

1% resistors are similar, but use five bands: three significant digits, a

multiplier, and tolerance. The first four bands on a 1.5 k, 1%

resistor are BROWN, GREEN, BLACK, BROWN. The multiplier

value is 1 rather than 2 in the this case because of the third

significant digit. 1% resistors have color bands that are sometimes

hard to distinguish clearly; use an ohmmeter to identify them.

The markings on RF chokes reflect their value in microhenries

(µH), using two significant digits and a multiplier. Example: a choke

with color bands RED, VIOLET, BLACK has value of 27 µH.

Color Code

Tolerance

(gold = 5%,

silver = 10%)

Multiplier

Second Digit

First Digit

Color MultiplierDigit

Black 0 x 1

Brown 1 x 10

Red 2

Orange x 1K

3

Yellow 4 x 10K

Green 5 x 100K

Blue 6 x 1M

Violet 7

Gray 8

White 9

Silver -- x .01

Gold -- x 0.1

Figure 3-4

x 100

Page 10

ELECRAFT 9

Identifying Capacitors

Small-value fixed capacitors are usually marked with one, two, or

three digits and no decimal point. If one or two digits are used, that

is the value in picofarads (pF). If there are three digits, the third

digit is a multiplier. For example, a capacitor marked "151" would

be 150 pF (15 with a multiplier of 10

33 pF, and "102" would be 1000 pF (or .001 µF). Exceptions are

described specifically in the text and parts list.

Fixed capacitors with values of 1000 pF or higher often use a

decimal point in the value, such as .001, .047, or 2.2. This is the

value in microfarads (µF). (1 µF is equal to 1,000,000 pF.)

1

). Similarly, "330" would be

Tools

The following specialized tools are supplied with the K1:

.050" (1.3 mm) and 5/64" (2 mm) Allen wrenches

Double-ended plastic alignment tool

In addition to the tools supplied, you will need these standard tools:

Temperature-controlled soldering iron, 700-800°F (370-430°C)

Fine-point soldering iron tip, approx. .05" (spade type)

Small-diameter, IC-grade solder (see Solder Recommendations)

Desoldering tools (wick, solder-sucker, etc.)

Needle-nose pliers

Small-point diagonal cutters, preferably flush-cutting

Small Phillips and flat-blade screwdrivers

DMM (digital multimeter; do not use an analog VOM)

Magnifying glass

Soldering and Desoldering

Use adequate ventilation when soldering, and avoid

inhaling smoke or fumes. Always wash your hands after

handling solder, as lead residue is highly toxic.

Solder Recommendations

We recommend small-diameter (.02 to .04") rosin-core solder,

similar to Kester type 44. Solder with 2% silver is used by some

builders and will work equally well. If you use a minimum of solder,

there will be no need to clean PC boards. The use of acid-core

solder, water-soluble flux solder, or any corrosive or conductive flux

or solvent is likely to damage components and/or PC boards.

Soldering

When applying solder, use the minimum amount required to

surround the component lead and make good contact with its

printed-circuit pad. You don't need a "fillet" (build-up) of solder.

To provide a good connection, the solder must flow onto both the

component lead and its PC board pad. To ensure that both will be

heated at the same time, the tip of the iron should contact both the

component lead and the PC board pad before solder is applied.

Solder joints should be clean and shiny. If a joint appears dull or has

fine cracks, it is probably cold. Cold solder joints should be cleaned

and re-soldered. First, use solder wick (desoldering braid) to remove

the old solder. Then apply fresh solder. If you have many cold

solder joints, it probably indicates that your soldering iron

temperature is too low, or that the tip or solder itself is defective.

We strongly recommend that you use a conductive wrist strap and

anti-static mat during assembly. These items are available at very

low cost from Jameco, Mouser, and other electronics suppliers.

New soldering iron tips must be tinned before they’re used. Allow

the iron to warm up completely, then apply solder and allow it to

coat the entire tip. After a few minutes, wipe off the excess solder.

Use a sponge for wiping the iron tip, and clean the sponge often.

Page 11

10 ELECRAFT

Desoldering

The printed circuit boards used in the kit are double-sided, meaning

that they have circuitry on both sides. The component mounting

holes are plated-through to complete electrical connections

between the two sides.

Removing components from double-sided boards can be difficult,

since you must get all of the solder back out of the hole before a

lead can be removed. To do this, you'll need solder wick

(desoldering braid) and/or a vacuum desoldering tool. It also takes

some practice. A number of suggestions are provided below.

The best strategy for avoiding de-soldering is to place all

components properly the first time. Double-check values

and orientations, and avoid damaging parts via ESD.

When removing components:

Don't pull a lead or pin out of a hole unless the solder has been

removed, or you are applying heat. Otherwise, you can literally

pull out the plating on the plated-through hole.

Limit soldering iron contact to a few seconds at a time.

Use small-size solder-wick, about 0.1" or 2.5 mm wide. Use the

wick on both the top and bottom pads when possible. This

helps get all of the solder out of the hole.

If you use a vacuum desoldering tool (solder sucker), use a large

unit. Small solder suckers are not very effective.

The safest way to remove ICs and other components with more

than 3 leads is to clip all of the pins at the body of the device

first, then remove all of the pins individually. You may damage

pads and traces by trying to remove such components intact.

Invest in a PC board vice with a heavy base if possible. This

makes parts removal easier because it frees up both hands.

Assembly Notes

Each step in the assembly process is accompanied by a check-box:

This symbol is used to alert you to important information:

i

Do not skip any steps. You may adversely affect both the

performance and appearance of the kit by using the wrong

assembly order.

Components

Sometimes we refer to components by their PC board and reference

designator. For example, "FP-Q1" refers to transistor Q1 on the

Front Panel board.

A few components in the kit are mounted on the bottom of PC

boards. Component outline symbols are provided on the

appropriate side of the board, so it will always be clear which side a

particular component goes on. Bottom-mounted parts are also

identified on the schematics by this symbol:

Photographs

If in doubt about a particular repair, ask for advice from Elecraft or

from someone else with PCB repair experience.

Before beginning assembly, you should review the photographs in

Appendix D to get an idea of what the completed PC boards look

like. You'll also find front and back views of each PC board in the

Parts Placement Drawings, Appendix F.

Page 12

ELECRAFT 11

4. Filter Board

This section applies only to the two-band K1 Filter board. If

you have a four-band K1, refer to the assembly instructions

in the KFL1-4 manual.

The Filter board determines the K1's bands of operation.

A photograph of the completed board appears in Appendix D.

Open the bag of components labeled KFL-2 and

sort the parts into groups. Identify components using the

photographs in the Filter board parts list in Appendix A.

Locate the Filter printed circuit board (PCB), labeled "K1

FIL2" on one side.

With the top side of the PC board facing you (notch at the

lower right), locate the position of resistor R1, along the front

edge. The label "R1" appears just left of the resistor’s outline.

Install a 100-ohm, 5% resistor (brown-black-brown) at R1,

with its first color band (brown) toward the left. Make sure it is

seated flat on the board, then bend the leads outward at about a 45degree angle to hold it in place.

Solder R1 on the bottom of the board. Trim the leads as close

as possible to the solder joints.

i

Components may be soldered one at a time or in groups.

Leads can be trimmed either before or after soldering.

Install an 18-pin IC socket at U1, with the notched end of the

socket oriented towards the "K1 FIL2" label. Bend two leads of the

socket outward slightly to hold it in place while soldering. (U1 itself

will be installed in a later step.)

i

In the following steps you'll install three relays (K1-K3).

Relay pins must not be bent, even after placement on the PC board,

as this may cause unreliable mechanical operation.

Place relays K1-K3 on the top side of the board. One end of

each relay has a heavy line printed across the top to indicate the

pin 1 end. This end must be matched with the same end of the

relay’s PC board outline. Do not solder the relays yet.

When all three relays have been placed on the board, lay a flat

object such as a book or piece of cardboard on top of the relays to

keep them in place, then flip the board over.

Solder only two pins (at opposite corners) on each relay, using

a minimum amount of solder. Limit soldering time to 2 or 3

seconds per pin. Do not bend or trim the leads.

Turn the board back over and verify that all of the relays are

in the correct orientation and are seated flat on the board. To

check the orientation, refer to the Filter board drawing in

Appendix F, at the bottom of the page.

Solder all of the remaining relay pins. Do not bend or trim the

leads.

Page 13

12 ELECRAFT

Install the capacitors listed below. The list shows the

capacitance value, followed by the labeling (in parentheses). After

installing each capacitor, bend the leads outward at about a 45degree angle to hold it in place until it is soldered and trimmed.

__ C29, .001 (102) __ C30, .001 (102) __ C27, .047 (473)

Place a bookmark at this page, and another at the

Per-Band Components table in Appendix A.

Locate the two bags of per-band components, which are

labeled by band, e.g. "40m" or "K1B40" (40 meters).

Under Reference Designators in the Per-Band Components

table, there are Band 1 and Band 2 columns. Fill in the blanks at

the top with your two bands (e.g., "40" and "20"). The lowerfrequency band should be designated as Band 1.

Using strips of paper, or labels with a light adhesive such as

“post-its,” temporarily cover the band 2 reference designators

column. Similarly, cover all of the components columns except the

column associated with band 1. This is a very important step

that will eliminate possible confusion during assembly.

Open the bag of components for band 1 only, setting the

band 2 components aside for now.

At this point you’ll need to choose whether to set up the VFO

for 80-kHz or 150-kHz coverage (approx.). The smaller range

covers the most-used portion of every band, provides smoother

tuning, and is strongly recommended if you plan to upgrade to the

four-band module (KFL1-4), which has narrower band-pass filters.

Record your VFO range selection here for reference:

___ 80 kHz ___ 150 kHz

Note: Two different crystals are supplied for 30 meters,

corresponding to two different lower band edges. Which one to use

depends on your selected VFO range (see below). In the following

steps you’ll select one of the two crystals when applicable.

Band VFO Range Crystal Band Edge

30 Meters

If band 1 is 30 meters, select the appropriate crystal using the

table above. Save the other crystal for possible future use.

Install the band 1 crystal at X1 on the filter board (to the right

of X2), bending the leads to hold it in place. Make sure the crystal is

seated correctly, then solder. Use a minimum amount of solder to

avoid a short under the can.

80 kHz 18.100 10.100

150 kHz 18.000 10.000

i

The leads on small capacitors may be pre-formed so that

the capacitor sits slightly above the board when inserted; this will

not affect performance. The leads are also somewhat fragile.

Install the capacitors for band 1, using the reference

designators and values from the appropriate columns in the parts

list. For example, if band 1 is 40 meters, install 390-pF capacitors

at C1 and C5, then 330 pF capacitors at C2 and C4, etc. Double-

check each capacitor value as it is installed. Do not solder yet.

Solder all of the band 1 capacitors.

Move the strips of paper or labels that you used earlier so that

they cover the band 1 reference designators column, and all of the

components columns except the column associated with band 2.

Open the components bag for band 2. Install the band 2

capacitors, using the reference designators and values from the

appropriate columns as before. (Example: if band 2 is 20 meters,

you'll install 180-pF capacitors at C6 and C10, etc.)

Locate the band 2 crystal and verify that it is the correct

frequency. If band 2 is 30 meters, select one of the two crystals

supplied (see table above). Install it at X2 and solder.

Page 14

ELECRAFT 13

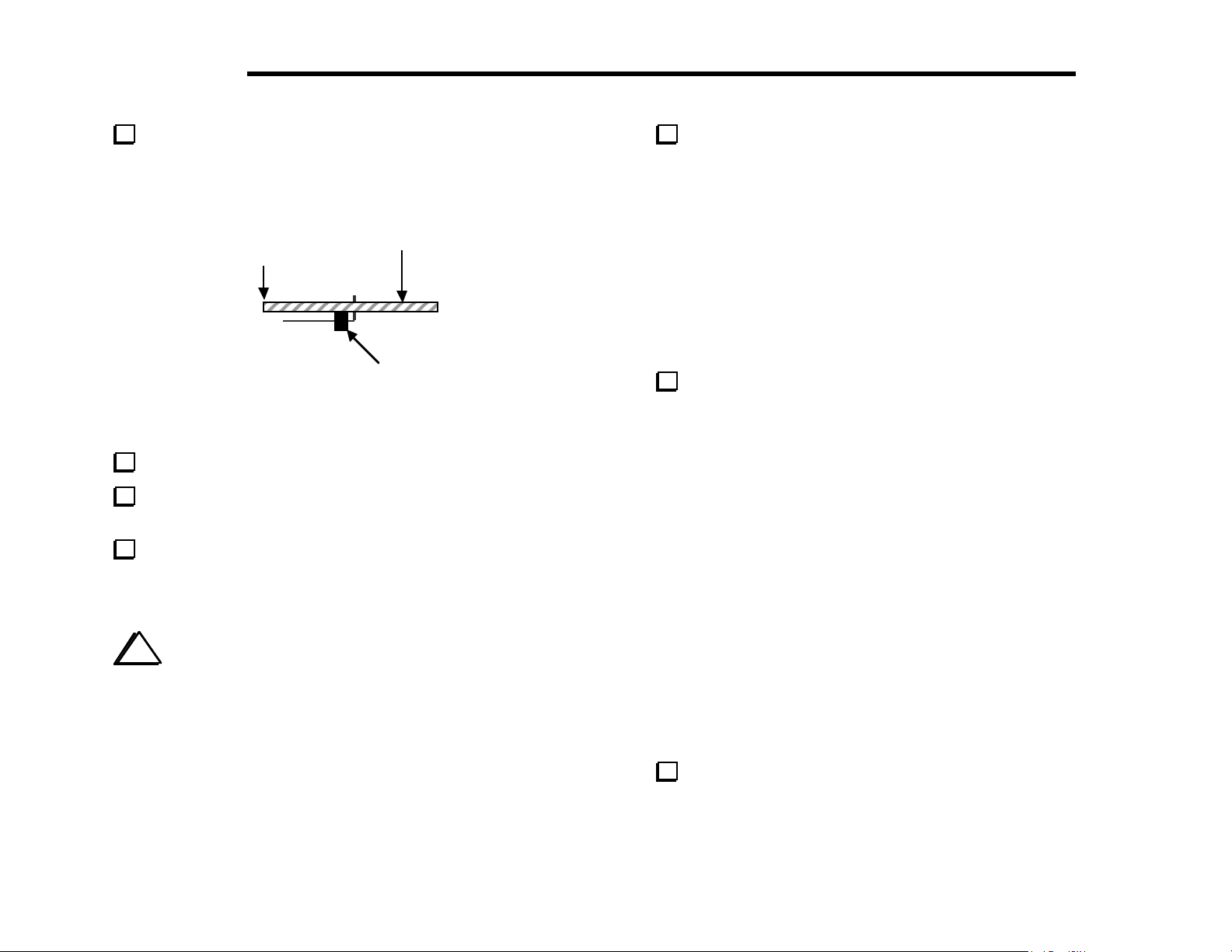

Cut two 3/4" (19 mm) bare wires (use component leads).

Referring to Figure 4-1, insert bare wires into the grounding

holes provided near X1 and X2. Fold each wire over the top of the

crystal and solder it on top. Keep soldering time below 5 seconds at

a time; if it takes longer, your iron may not be hot enough, or your

iron tip may not be making good contact with the crystal can.

Solder and trim the wires on the bottom of the board.

2

Figure 4-1

Install the ceramic resonator, Z1, to the right of U1. (The

ceramic resonator looks like a capacitor with three pins, and can be

oriented in either direction.) Limit soldering time to 2 or 3 seconds

on each pin to avoid altering the oscillation frequency.

Locate the eight 1-µH slug-tuned inductors, and make sure

they are all have a red stripe or are labeled "T1050".

Install the inductors at L1 through L8, pressing each one down

as far as it will go. They have five pins, plus ground tabs, and can

only be installed on the board one way. Solder the inductors.

1

At the left and right ends of the board you’ll find two short

jumper locations, each labeled with a ground symbol (

component leads to make 3/4" (19 mm) U-shaped wires for each

jumper (Figure 4-2). Solder the jumpers on the bottom of the board,

with the top of the U-shape approx. 1/4" (6 mm) above the board.

). Use

op side

Figure 4-2

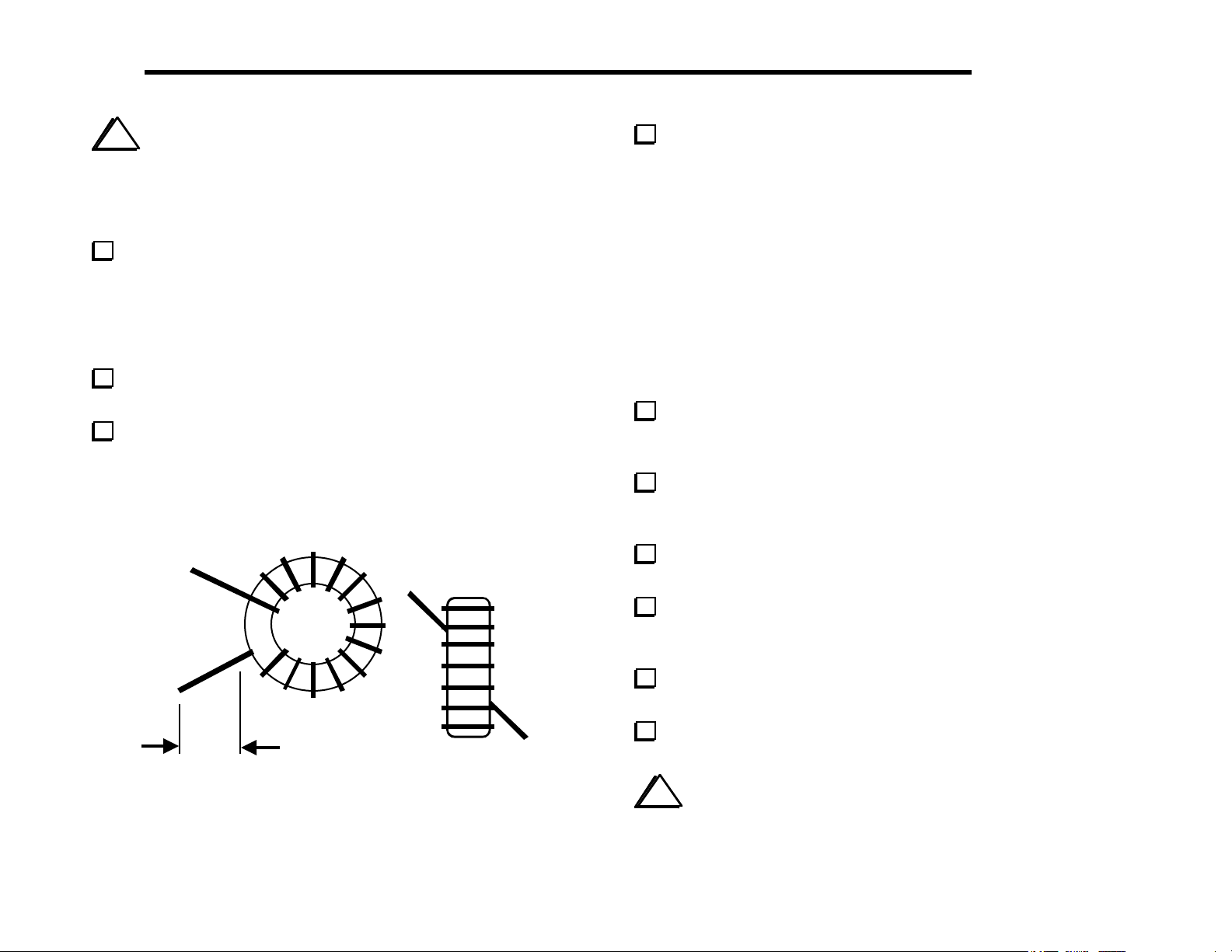

Identifying Toroid Cores

Several toroidal inductors are used in the K1, including four on the

Filter board. It is important to use the correct type of core. This

can be determined from the color and size.

The cores used on the Filter board are type T37-6. The T identifies

an iron-powder core. The number following the T specifies the

outside diameter in hundredths of an inch, in this case 0.37 inches

(9.4 mm). The suffix (-6) refers to a specific mix of iron powder,

which uses a particular color, in this case yellow.

Later in assembly you'll encounter ferrite cores, for example type

FT50-43. In this part number, FT identifies the core as ferrite, and

50 is the size (0.50", 12.5 mm). The suffix (-43) identifies the type

of ferrite used, although all ferrite cores are dark gray in color. All

ferrite cores used in the K1 are of the -43 type.

Page 15

14 ELECRAFT

i

In the following steps you’ll install toroidal inductors L9L12 (type T37-6 cores). They must be wound as indicated in the

instructions, or the transceiver will not operate correctly. Use only

the number of turns specified. It is not necessary to attempt to

precisely match the inductances specified in the parts list.

Find the component outline for L9 on the Filter board.

Compare this component outline to Figure 4-3, which shows two

views of a typical toroidal inductor. L9 will be mounted vertically

as shown at the right side of the drawing, with one wire exiting at

the core’s upper left, and the other at the lower right. There are

pads on the PC board in these two locations.

Using the Per-Band Components parts table (Band 1),

determine the number of turns and wire length for L9 and L10.

To wind L9, cut the specified length of #26 red enamel-coated

wire, then "sew" the long end of the wire through the core. Each

pass through the core counts as one turn. The finished winding

should look similar to Figure 4-3, but with the number of turns

indicated in the parts list. Figure 4-3 shows 14 turns.

Verify that the turns of L9 are not bunched together. They

should be evenly spaced, and should occupy about 80-90% of the

core.

Stripping Toroid Leads

The enamel wire supplied with the kit can be heat-stripped. One

way to do this is to place a small amount of solder (a "blob") on the

end of your soldering iron, then insert the wire into the hot solder.

If the iron is hot enough, you should see the insulation vaporize

after 3 to 6 seconds. Another possibility is to burn the insulation

off by heating it with a small butane lighter for a few seconds, then

use fine-grain sandpaper to remove the enamel residue. Avoid

scraping insulation off with a razor blade, as this may nick the wire.

Strip the leads of L9, as explained above. You should remove

the enamel from the leads up to about 1/8" (3 mm) from the core

(Figure 4-3).

Tin L9's leads. The solder should appear clean and shiny. If it

looks dull or is not adhering very well to the bare lead, there is

probably some insulation remaining. Remove it as described above.

Install L9 vertically as shown by its component outline. Pull

the leads taut on the bottom of the board.

Remove insulation

Figure 4-3

Solder the leads of L9. When soldering, make sure that the

solder binds well to the leads. If the lead appears to be an "island" in

a small pool of solder, chances are it is not making good contact.

Wind and install L10 in the same manner as L9, using the

same number of turns. Install L10 vertically, to the right of L9.

Wind and install L11 and L12. Use the Per-Band Components

table (Band 2) to look up the wire length and number of turns.

i

Do not use adhesives or fixatives of any kind to secure L9L12 to the PC board. They will be adequately held to the board by

their leads alone.

Page 16

ELECRAFT 15

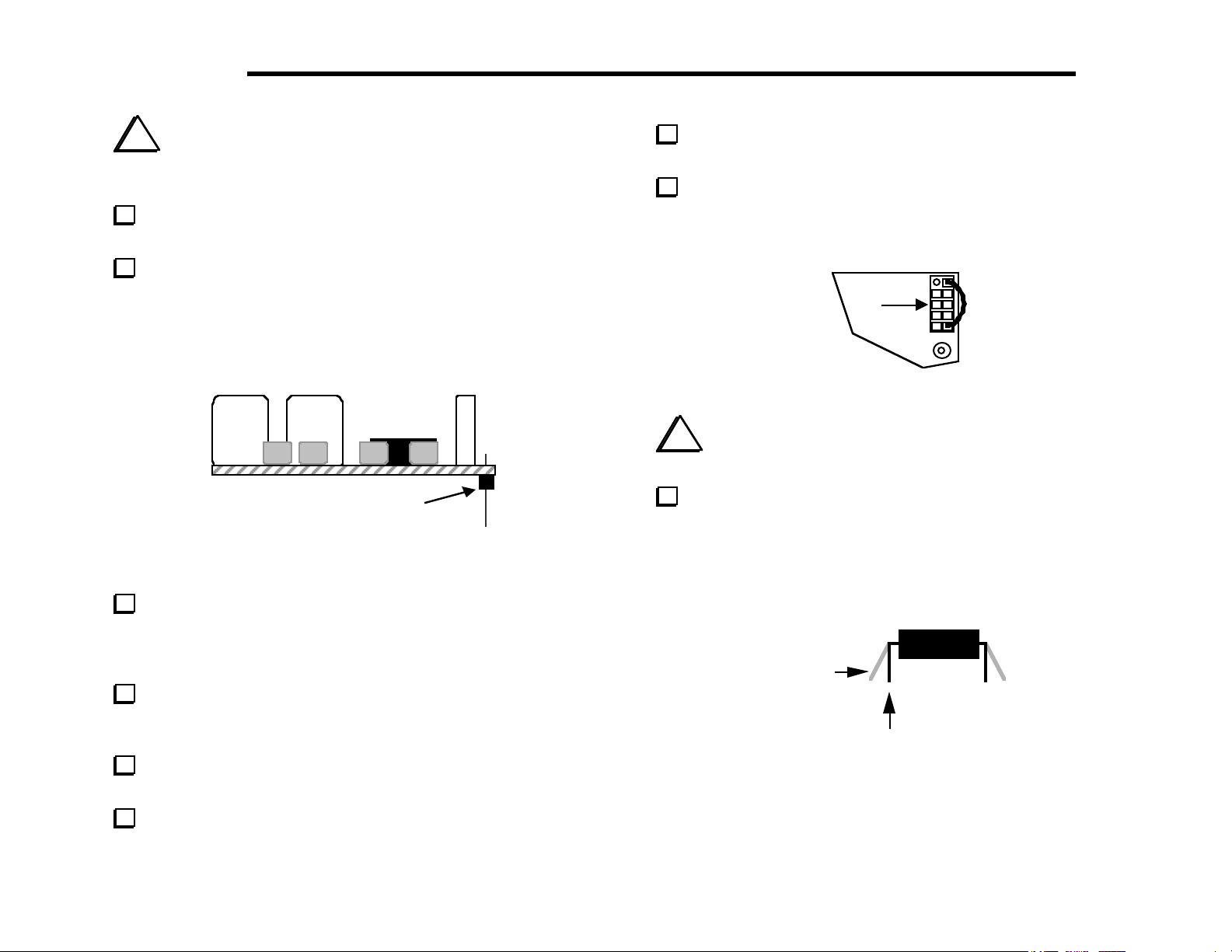

i

The connectors to be installed in the following steps

must be positioned correctly to avoid intermittent or

unreliable operation.

information on page 7.

yet. Figure 4-4 shows P1 as viewed from the left end of the Filter

board. The plastic part of the connector must be on the bottom

side of the board, with the long end of the pins pointed down. The

short pins are inserted into the board.

Before attempting to install multi-pin connectors, review the

Install an 8-pin male connector (plug) at P1, but do not solder

P1

Figure 4-4

Solder just one of the middle pins of P1, on the top side.

Note: multi-pin connectors have plastic bodies that can melt if too

much heat is applied, causing the pins to be mis-positioned. Limit

soldering time for each pin to 2 to 3 seconds.

Examine the placement of P1 closely. If it is tilted or is not

flat against the board, re-heat the solder while pressing down on the

connector.

Cut a 1" (25 mm) length of insulated hookup wire. Strip about

1/8" (3 mm) of insulation off of each end.

Install this wire between pins 2 and 10 of J2, in the upper righthand corner of the board (Figure 4-5). The pins on J2 are counted

from left to right and top to bottom as shown.

1 2

2

109

Figure 4-5

i

Before handling U1 in the next step, touch an unpainted,

grounded metal surface.

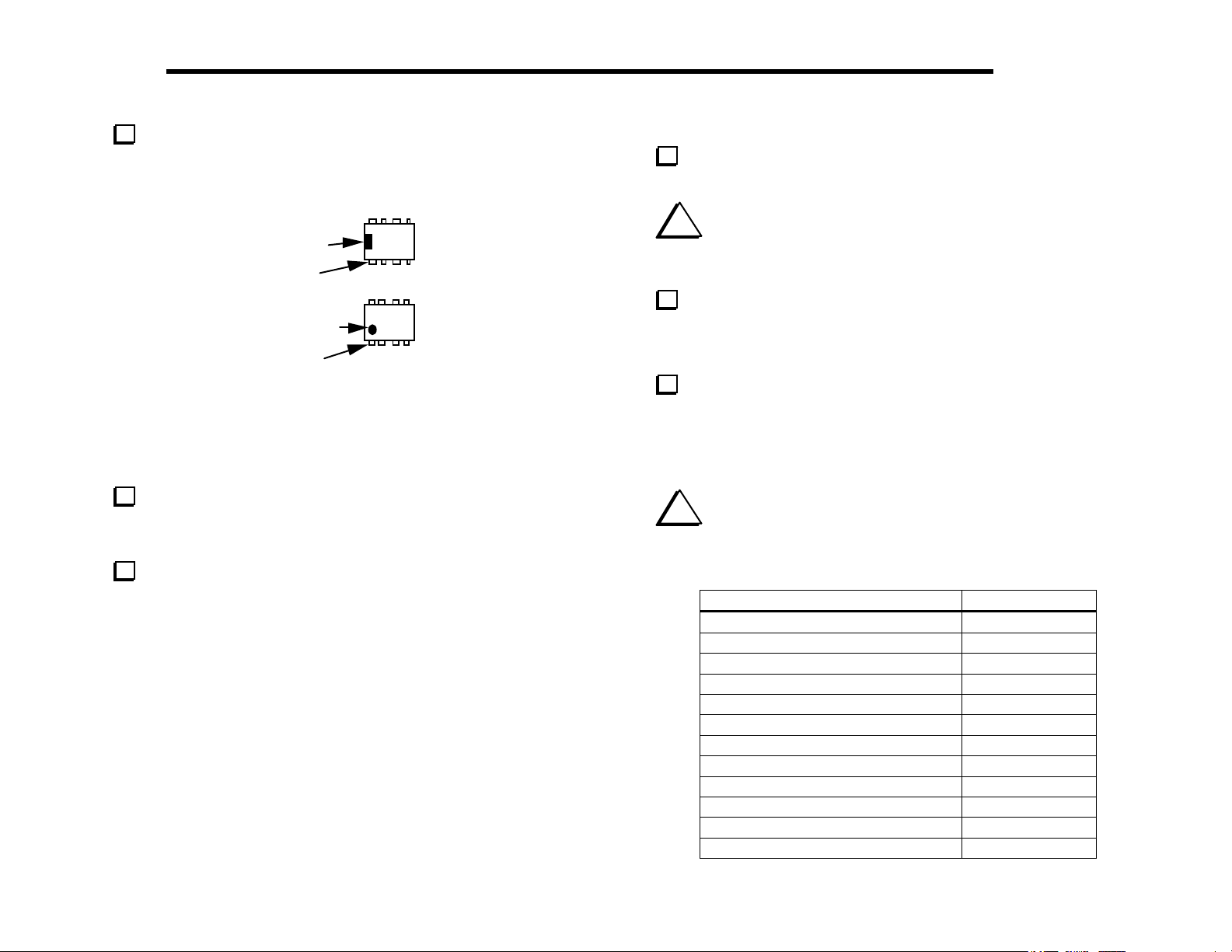

Straighten the leads of U1 (PIC16C620) as shown in Figure

4-6. The two rows of pins must be straight and parallel to each

other to establish the proper pin spacing. To straighten the pins,

rest one entire row of pins against a hard, flat surface. Press down

gently on the other row of pins and rock the IC forward to bend the

pins into position as shown below.

Flared

Straight

Once P1 is in the right position, solder the remaining pins. Do

not trim the leads.

Install P2 and P3 in the same manner as P1. Before soldering,

verify that each connector is flat against the board and not tilted.

Figure 4-6

Page 17

16 ELECRAFT

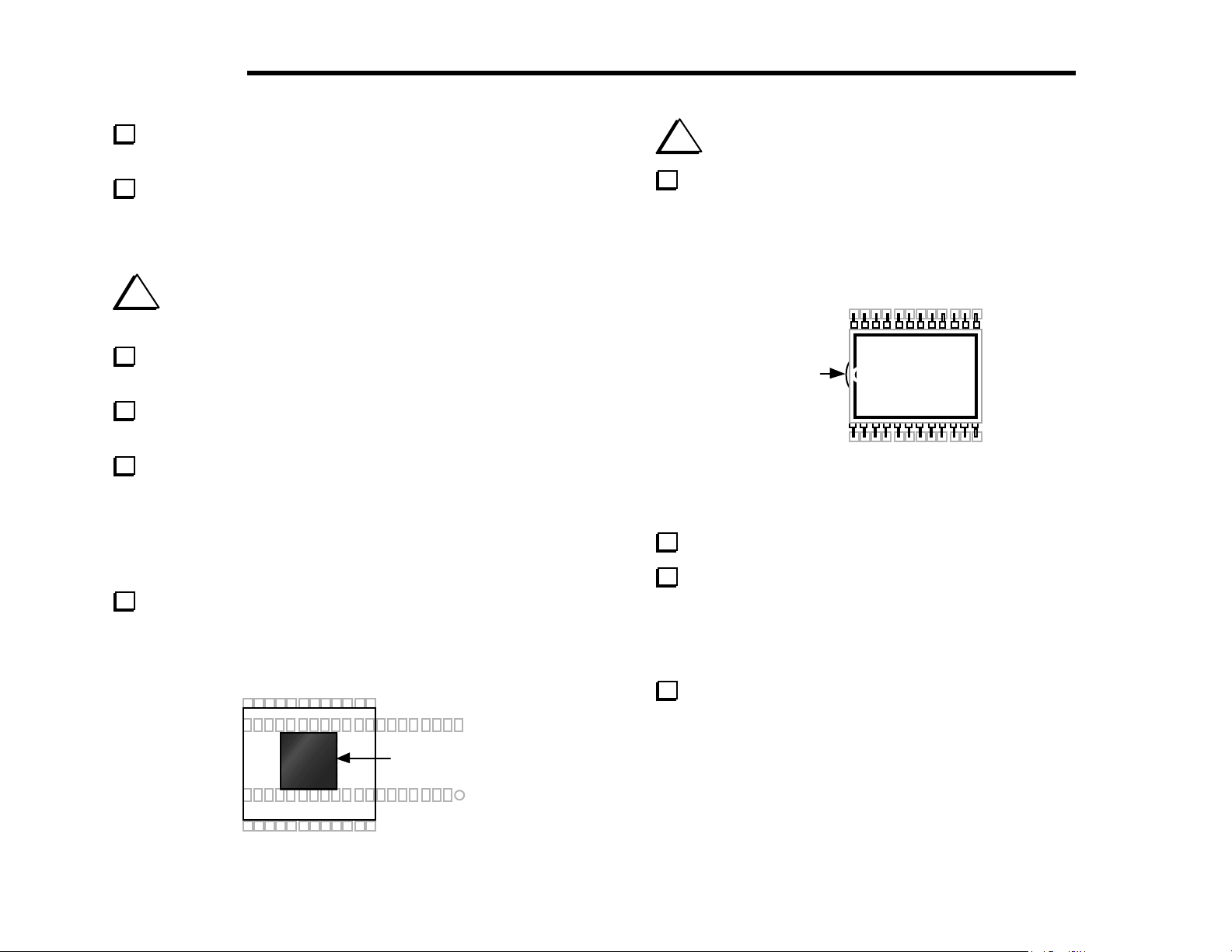

Insert U1 into its socket, with the notched or dimpled end of the

IC aligned with the notched end of the PC board outline. Figure 4-7

shows an 8-pin IC; U1 is similar but has 18 pins.) Press U1 down into

the socket as far as it will go.

Notch

Pin 1

Dimple

Pin 1

Figure 4-7

Note: IC pins are counted by going around the IC counter-clockwise

from pin 1.

Examine U1 closely. If any pins are bent, remove the IC and

straighten them. (To remove U1 from its socket, pry it up gently on

each end using a small flat-blade screwdriver.)

Locate the blank white area near U1. This area is provided for

labeling the Filter board with the two bands covered (e.g. "40, 20").

Use an indelible marker, dry transfers, or an adhesive label.

Uninstalled Components

All component locations on the Filter board should now be filled

except J1 and J2, which are provided for the automatic antenna tuner

(KAT1). The KAT1 option should be installed only after the basic K1

kit has been completed and tested. At that time, the jumper you

installed between pins 2 and 10 of J2 will be removed. If you’re

building a 2-band Filter board that includes 80 meters, you’ll have a

10 µF electrolytic capacitor left over at this point. This will be

installed on the RF board at C78 in a later step.

Visual Inspection

Using the parts placement drawings in Appendix F, re-check the

orientation of the relays (K1, K2, K3) and U1.

i

About 90% of all problems with kits are caused by poorlysoldered component leads. Such problems can be avoided by doing a

careful inspection of the board, preferably with a magnifying glass.

solder bridges, and unsoldered components.

Examine the bottom of the PC board closely for cold solder joints,

Resistance Checks

Make the measurements listed below, touching the meter's (+)

and (-) leads to the indicated points. Measurements at relay K3 must

be made on the bottom side. Relay pins are numbered like ICs, with

pin 1 identified by its round pad. The Filter board schematic (in

Appendix B) may help you troubleshoot any incorrect readings.

i

The symbol > means greater than, and < means less than.

Your DMM may indicate infinite resistance (all digits flashing) for

readings that are listed as "> 100 k." (Do not use an analog VOM.)

Test Points (+, -) Resistance

U1 pin 6, U1 pin 7 230-270 ohms

U1 pin 6, U1 pin 8 230-270 ohms

U1 pin 6, U1 pin 12 230-270 ohms

U1 pin 13, P2 pin 6 90-110 ohms

P1 pin 1, P1 pin 3 > 100 k

P1 pin 2, P1 pin 3 > 100 k

P1 pin 3, P1 pin 4 > 100 k

P1 pin 3, P1 pin 6 > 100 k

P2 pin 1, P2 pin 2 > 100 k

P2 pin 7, P2 pin 8 > 100 k

K3 pin 2, K3 pin 9 < 5 ohms

K3 pin 4, K3 pin 7 < 5 ohms

Page 18

ELECRAFT 17

5. Front Panel Board

The liquid-crystal display (LCD), switches, and other controls are

located on the Front Panel board, as well as the microcontroller.

See Appendix D for photos of the completed assembly.

Open the bag labeled FRONT PANEL and sort the parts into

groups. Observe anti-static precautions with ICs and transistors.

Locate the front panel PC board, which is labeled "K1 FP"

along one edge. In the steps that follow, we will refer to the side

with the switches and LCD (S1-S6 and DS1) as the top side.

Place the board in front of you with the bottom side up.

Locate the component outline for J1, below the large hole.

Install a 20-pin female connector (receptacle) at J1 as shown

in Figure 5-1. Do not solder yet.

Solder one pin of J1 on the top side, near the middle of the

connector. If J1 is not seated flat against the PC board or is tilted,

re-heat the solder and press down on the connector.

Once you're sure that J1 is correctly installed, solder the

remaining pins. Do not use an excessive amount of solder.

Locate the Switch Spacing Tool (made of PC board

material).

Position push-button switch S1 on the top side of the board as

shown in Figure 5-2, using the switch spacing tool to set the switch

height. Make sure all four legs of the switch are centered in their

holes, then gently push the switch until it is resting flush against the

switch-spacing tool. (Caution: switch pins are fragile.) Do not

solder yet.

Top side

(with LCD)

S1

Bottom

side

J1

Figure 5-2

Figure 5-1

Page 19

18 ELECRAFT

If the socket does not appear to be seated flat on the PC

Top of

board

board, reheat these two pins while pressing on the socket. If the

leads of C4 hit the socket, trim them closer to the board.

1/16”

Solder the remaining pins of U1. (U1 itself will be installed in

the socket in a later step.)

Install and solder the following components. When soldering

Figure 5-3

components near the push-button switches, be careful not to touch

the switches with the soldering iron.

Figure 5-3 shows a side view of a switch that is properly mounted

(spacing tool not shown). The leads of the switches will just be

visible on the bottom of the board. Proper switch height is

important for maintaining an even appearance.

Once S1 is seated correctly, solder the leads on the bottom side

of the board. Leave the spacing tool in place while soldering.

Install S3, once again using the switch spacing tool to adjust

the switch height. When soldering S3, be careful not to contact the

plastic body of J1 with the soldering iron.

Install switches S2, S4, S5, and S6 using the same technique.

Note: Switch caps will be installed later.

Install these parts on the top side of the board. Solder them on

the bottom side, using a minimum of solder.

__ R8, 22 (RED-RED-BLK) __ C4, .047 µF (473)

Trim the leads of R8 and C4 as close to the board as possible

so that they won't interfere with the 40-pin IC socket (next step).

Install the 40-pin IC socket at U1, on the bottom side of the

board. The board is labeled "SOCKET" at this location. Orient the

socket's notched end to the left (the pin 1 end). To hold the socket

in place, bend pins 1 and 21 outward slightly; these two pins are

diagonally opposite. Solder only these two pins.

Top side:

__ R4 and __ R5, 10 k (BRN-BLK-ORG)

__ R11, 100 k (BRN-BLK-YEL)

Bottom side:

__ R6, 12.7 k, 1% (BRN-RED-VIO-RED)

__ R7, 3.92 k, 1% (ORG-WHT-RED-BRN)

__ R9, __ R10, and __ R19, 100 k (BRN-BLK-YEL)

__ R13, 470 (YEL-VIO-BRN)

__ R12, 2.7 k (RED-VIO-RED)

__ R14 and __ R15, 1 k (BRN-BLK-RED)

__ R16, 2.7 k (RED-VIO-RED)

__ C5 and __ C6, .01 µF (103)

Install capacitors C1 and C2 (82 pF), near U1.

Locate resistor network RP1. ("RP" means "resistor pack,"

another name for resistor networks.) One end of RP1 has a band or dot,

indicating pin 1. RP1 should be labeled 77083102, 83C102, or

8A3102G. If the labeling differs, verify the resistance. You should

measure about 1.0 k between each pair of adjacent pins.

Install RP1 on the bottom side of the board. The end with a

dot or bar should be oriented towards pin 1 of the PCB outline.

When soldering RP1, keep the iron tip away from S4 and S5.

Install and solder the two 82-µH RF chokes, RFC1 and RFC2

(GRAY-RED-BLK).

Page 20

ELECRAFT 19

i

Before handling ICs and transistors in the following steps,

touch an unpainted, grounded metal surface.

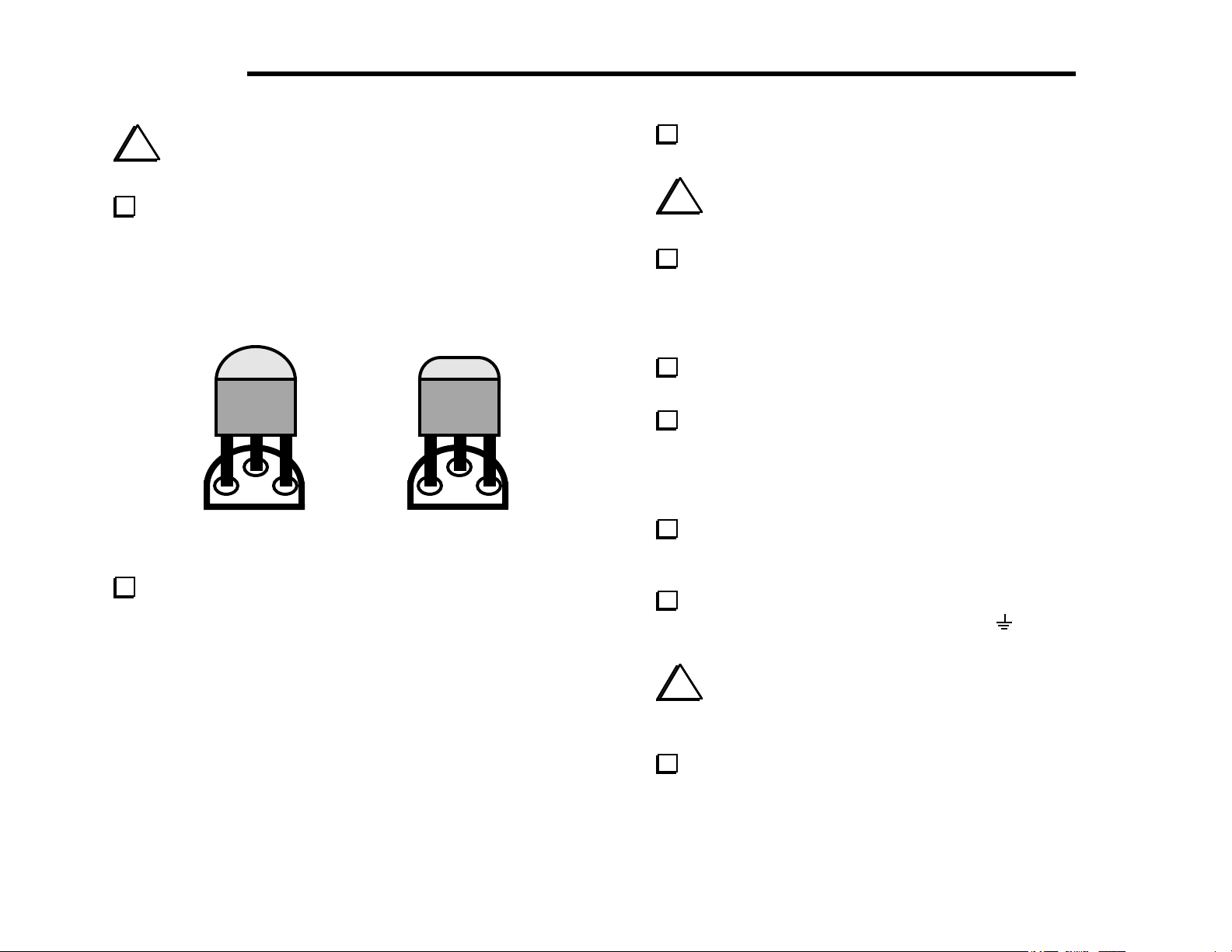

Locate transistor Q1 (type 2N4124), which has a small, 3-lead

TO-92 package. Q1 and other TO-92 devices may have either of

the two shapes shown in Figure 5-4. The right-hand illustration

shows a "modified TO-92" package, which may be labeled on either

the front or back side. The large flat side of each device will be

aligned with the flat side of its component outline.

Figure 5-4

Install Q1 on the bottom side of the board, to the right of the

large hole. Align Q1 as shown above. The transistor should be

mounted about 1/8" (3 mm) above the board; don’t force it down

too far or you may break the leads. Bend the leads outward slightly

to hold Q1 in place, then solder and trim the leads.

Locate U4, a 78L06 voltage regulator, which has a TO-92

package similar to Q1. Install U4 below the large hole.

i

Touch an unpainted, grounded metal surface before

handling the 2N7000 transistor in the next two steps.

Locate the component outline for Q2 (2N7000) on the top

side of the board near the rectangular hole. Q2's outline has the

three pins side-by-side, not in a triangular pattern. Pre-form the

leads of Q2 to match this hole pattern, so that it can be mounted

very close to the PC board with little excess lead length.

Install Q2. Make sure the top of Q2's body is no more

than 0.25" (6 mm) above the board when seated. Solder Q2.

Install the 8-pin ICs, U2 (MAX518), U3 (24LC04), and U5

(LM358) on the bottom side. Orient the notched or dimpled end of

each IC with the notched end of its component outline (see Figure

4-7). Bend two leads outward slightly on the opposite side of the

board to hold the devices in place, but do not solder yet.

Turn to Appendix F (parts placement drawings) to verify that

you have the ICs installed in the proper locations, then solder.

Limit soldering time to 2 to 3 seconds on each lead.

On the top side of the board at the left end you’ll find a short

jumper location, labeled with a ground symbol (

(19 mm) U-shaped wire here, as you did earlier on the Filter board.

i

The potentiometers to be installed in the next step can be

damaged if you push on their plastic shafts. When seating a

potentiometer, press down only on the metal frame.

). Install a 3/4"

Install the two 10-k potentiometers at R2 and R3 (on the top

side of the board). They must be pressed downward until the metal

frame is fully contacting the PC board on both sides. Do not use

excessive heat when soldering.

Page 21

20 ELECRAFT

e

Open the bag labeled MISCELLANEOUS and empty the

contents into a shallow box or pan. This will prevent loss of any of

the small hardware while allowing you to locate items as needed.

i

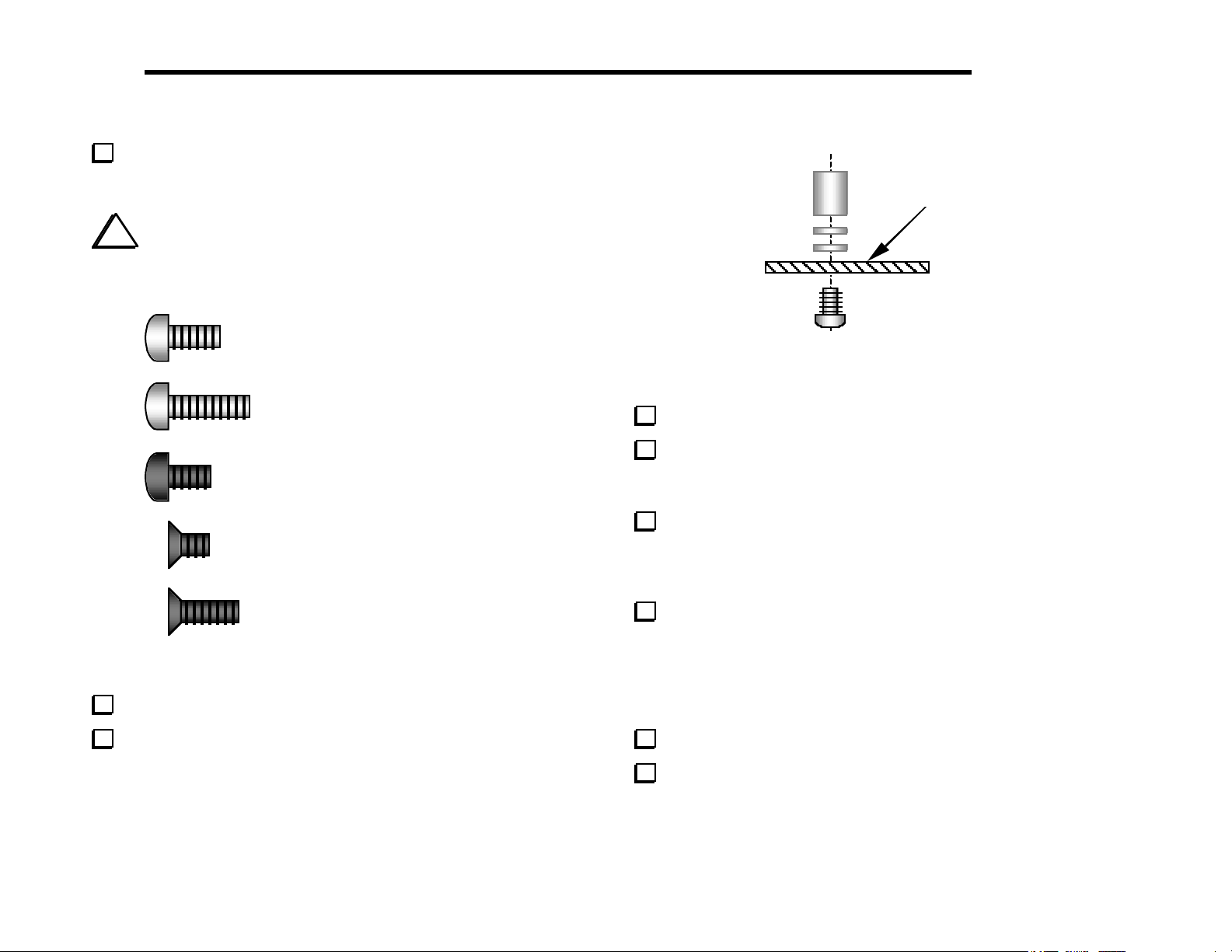

Five sizes of 4-40 screws are used. All are black anodized

except the 1/4" and 3/8" pan heads (see Figure 5-5). The length of

flat-head screw is measured from the top of the head.

Top Sid

Pan-head, 1/4” (6 mm)

Figure 5-6

Pan-head, 3/8” (9.5 mm)

Pan-head, 3/16” (4.8 mm)

Flat-head, 3/16” (4.8 mm)

Flat-head, 5/16” (8 mm)

Figure 5-5

Identify all of the 4-40 screws and sort them into groups.

Install a 3/16" (4.8 mm) diameter x 1/4" (6.4 mm) long round

standoff on the top of the board (Figure 5-6). The hole for this

standoff is just below the large hole. Use two #4 split lock washers

and a 1/4" (6 mm) pan-head screw (not black anodized) as shown.

Insert the lock washers between the standoff and PC board.

Install crystal X1, near C1 and C2 on the bottom of the board.

To the right of X1 you'll find a ground pad for the crystal can.

Use a discarded component lead to make the grounding wire, as

shown in Figure 4-1 (page 13).

Locate LEDs D1 and D2, which are identical in size but have

different-colored bodies. D1 has a clear diffuse body, while D2 has a

yellow tint. Near the point where the leads exit the body, you'll find

a flat side in the plastic, which identifies the cathode lead.

Install D1 (clear diffuse body) on the top side of the board,

with its flat side aligned with the flat side of the component

outline. (This is the side nearest the square pad.) Position D1 about

1/16" (1.5 mm) above the board. You can use the switch-spacing

tool, a toothpick, or short length of insulated hookup wire to

maintain the proper spacing while soldering.

Verify the orientation of D1's flat side, then solder.

Install and solder D2 using the same method.

Page 22

ELECRAFT 21

Inspect the solder side of U1's socket on the top side of the board.

Make sure all pins are soldered, with no cold solder joints.

Using a DMM, check every pair of adjacent pads on U1 on the

top side of the board (pins 1-20 and 21-40). The resistance between

pads should be over 1000 ohms (1 k) in all cases, and may read infinite

on your DMM (often indicated by a flashing display).

i

Before handling U1 in the next step, touch an unpainted,

grounded metal surface.

i

Caution: the LCD (DS1) and its pins are fragile.

Remove the LCD from its packing materials, being careful not to

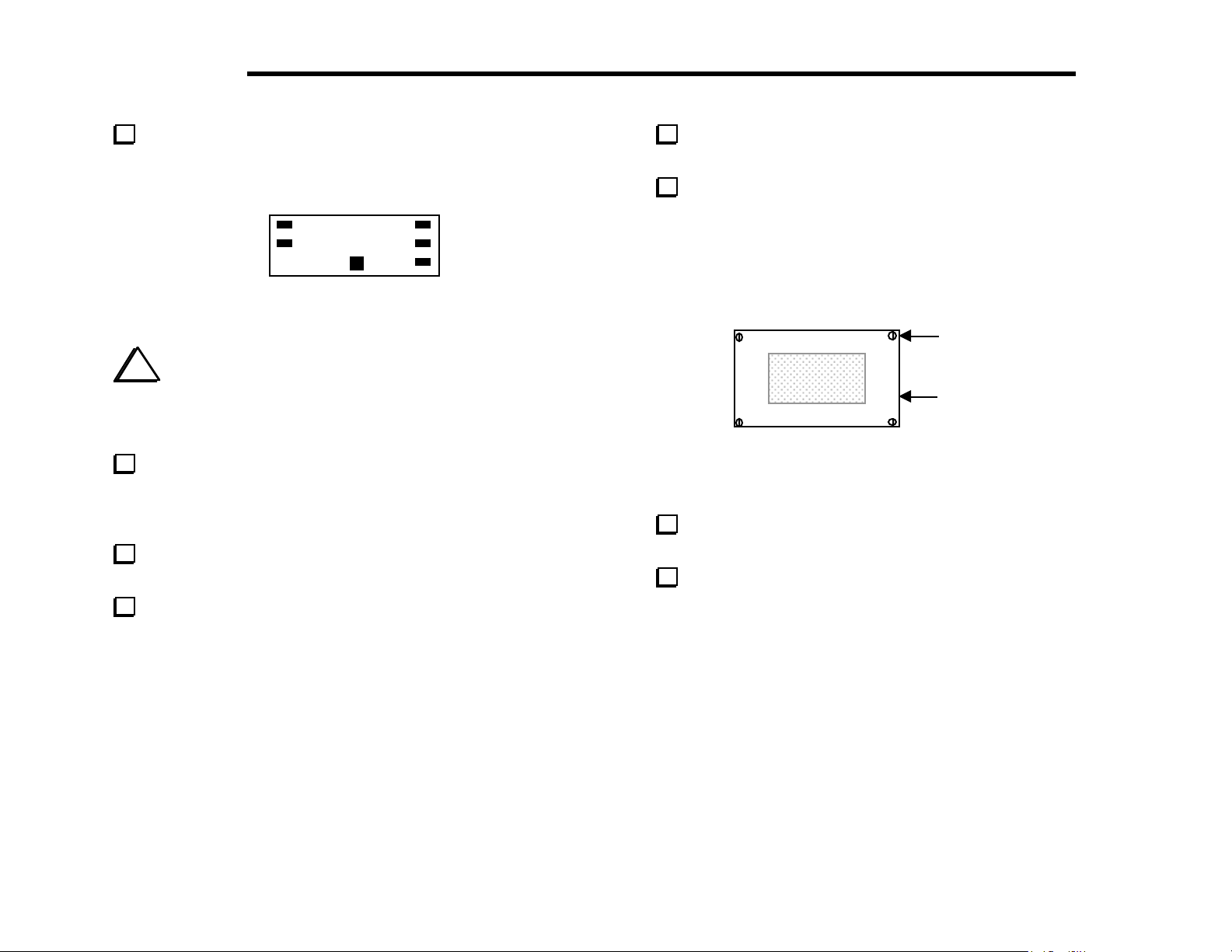

bend the pins. As shown in Figure 5-8, the pin 1 end of the LCD glass

has a very slight bump, along with a break in the black border. This

end will be oriented towards the pin 1 end of DS1's component

outline.

24

13

Straighten the pins of the microcontroller, U1. You can hold the

IC body at the ends as you re-form each row of pins.

Insert U1 into its socket, with the notched end oriented towards

the pin 1 end of the component outline.

Look at both rows of pins on U1 closely. If any pins are bent,

carefully remove the IC by prying at both ends using a small flat-blade

screwdriver. Straighten the pins using long-nose pliers.

NOTE:

install it into your K1 now, refer to the instructions for adding the

backlight, then go directly to Visual Inspection on the next page.

x 1/2 square and 3/16" thick (12 x 12 x 5 mm). Remove the adhesive

backing from one side and position the spacer as shown in Figure 5-7.

It must be mounted flat against the PC board, centered between the

two rows of pins on U1's socket.

If you purchased the K1 LCD Backlight Kit and are going to

Locate the black neoprene LCD spacer (MISC. bag), which is 1/2

Spacer

Bump

DS1

112

Figure 5-8

Remove the adhesive backing from top side of the LCD spacer.

Install the LCD at DS1, oriented as shown above. Make sure that

all 24 pins are inserted into their holes, then press down gently on the

LCD to secure it to the LCD spacer's adhesive surface. The LCD pins

may not extend all the way through the holes. The surface of the LCD

must be parallel to the PC board.

Once the LCD is positioned correctly, solder all pins.

Figure 5-7

Page 23

22 ELECRAFT

Visual Inspection

Using the parts placement drawings in Appendix F, re-check

the orientation of the LEDs (D1 and D2), LCD (DS1), and all ICs.

Examine both sides of the PC board closely for solder bridges,

cold solder joints, or unsoldered components.

Resistance Checks

Set both potentiometers to their mid-points.

The resistance measurements shown below can all be made

from the top side of the board. The (-) lead of your DMM should be

connected to the ground jumper (

Test Points (+) Resistance

DS1 (LCD) pins 1-24 > 100 k

J1 pin 6 > 100 k

J1 pin 7 > 100 k

J1 pin 8 > 100 k

J1 pin 10 90-200 k

J1 pin 12 > 100 k

J1 pin 15 < 50 k

J1 pin 16 15-18 k

J1 pin 19 > 100 k

) at the left side of the board.

ype 1 Type 2

CCW

CW

Attach the prepared wires to the three lugs Each wire should be

wrapped around its lug, leaving the other end free. (Do not solder

yet.)

R1’s plastic body can be damaged if you apply too much heat

to the lugs. Solder the three lugs, limiting soldering time to about

two seconds each.

Insert R1 through the large round hole in the Front Panel

board, rotating it into approximately the position indicated above.

Make sure that none of the lugs are touching the PC board.

S

3

1 2 3 R1

Figure 5-9

2 1

1 2 3 R1

Front Panel Final Assembly

Cut three 1.25" (32 mm) lengths of hookup wire. Remove 1/4"

(6 mm) of insulation from both ends of each wire.

Locate the 10-turn potentiometer, R1. Look closely at

Figure 5-9, which shows the positions of the three lugs. The lugs

may be labeled 1, 2, and 3, or S, CW, and CCW. 10-turn

potentiometer labeling can be confusing, so use the drawing to

identify the lugs. Your potentiometer may be either of the two

types shown.

Near the large hole in the board, you'll find three pads for R1's

leads (labeled 1, 2, and 3). Referring to Figure 5-9, insert the

potentiometer's wires into their corresponding holes. Do not

solder yet.

i

Caution: If the leads of R1 are not connected to the

correct pads, the potentiometer is very likely to be damaged.

Re-check the connections, then solder R1's leads on the top

side of the board. Avoid touching nearby parts with the iron.

Page 24

ELECRAFT 23

Install caps on switches S1 through S6. S3's cap is square, while

the others are rectangular, as shown in Figure 5-10. The caps are

installed by pressing them onto the switch plungers.

Figure 5-10

i

The LCD's glass surface is protected by a very thin,

nearly invisible piece of protective film. In the following

step, be very careful to remove only the thin film, not the

LCD's glass top. Do not use any type of metallic tool.

Hold the Front Panel PC board assembly under a strong light so

that you can see the surface of the LCD glass clearly. Using a

fingernail, rub one corner of the LCD's glass top to loosen the

protective film, then peel it off.

Locate the front panel chassis piece. Place it on a soft cloth

to protect the finish and labeling.

Some holes in the front panel are masked on the inside surface

during painting. If masking tape (usually green in color) is still

present, you'll need to remove it. To remove masking tape:

After removing any masking tape, turn the front panel face

up, with the Elecraft logo at the top.

Position the clear plastic LCD bezel over the large LCD

opening, then secure it with four 2-56 screws (stainless steel) as

shown in Figure 5-11. Tighten the 2-56 screws only the amount

needed to hold the bezel to the front panel. Over-tightening may

crack the bezel or strip the threaded holes in the panel.

2-56 Screw (4)

LCD Bezel

Figure 5-11

Remove all hardware from the shaft of the 10-turn

potentiometer (R1). It will be re-attached in a later step.

Locate the 0.75" (19 mm) diameter nylon washer. Place this

washer over R1's threaded bushing.

Use a blunt instrument such as a ball-point pen to push on the

tape through a hole until the tape begins to lift away.

Peel the tape off, using a sharp tool if necessary. Be careful not

to scratch the outer surface of the panel.

Page 25

24 ELECRAFT

Insert the Front Panel PC board assembly into the front panel

(Figure 5-12). The push-button switch caps should protrude slightly.

Figure 5-12

The 1/4" (6.4 mm) standoff on the PC board should now be

visible through the countersunk panel hole just below R1. Secure the

panel to the standoff with a 3/16" (4.8 mm) flat-head screw.

i

Caution: The 10-turn potentiometer may have a

plastic bushing. In the following step, do not over-tighten

the nut or you may strip the threads.

Use the nut and lock washer supplied with R1 to secure it to

the front panel. It should be just tight enough to keep R1 from

rotating.

i

The Allen wrenches are located in a small bag with the

MISCELLANEOUS items. These wrenches may have been oiled

during manufacturing. Remove the wrenches and wipe off the oil, if

any, then discard the bag.

Use the larger Allen wrench (5/64" [2 mm]) to tighten the two

set screws on the large knob.

Set the AF GAIN and RIT/XIT potentiometers to midway in

their rotation, and place a small knob on each. Do not push down

hard on the knobs, as this may damage the potentiometers.

Tighten each knob's two set screws using the smaller Allen

wrench (.050" [1.3 mm]). Align the pointers per panel labeling.

i

At this point in the assembly, the push-button switches

may not all protrude an equal distance. The switch height will

become equalized once the front panel assembly is mated to the RF

board in a later step.

i

When you rotate the VFO knob, you may hear a faint

sound produced by the wiper of the 10-turn potentiometer as it

moves across its resistance element. This is normal.

Uninstalled Components

All component locations should now be filled.

Place the large knob on R1's shaft. Push the knob on until it

just touches the bushing. If the knob does not spin freely, move it

out slightly. If the shaft or knob appears to be tilted, the large

nylon washer may not be positioned correctly (behind the panel).

Page 26

ELECRAFT 25

6. RF Board, Part I

In Part I, the VFO (variable-frequency oscillator) and receiver

sections will be assembled.

Open the bag labeled RF and sort the components into groups.

Observe anti-static precautions when handling transistors and ICs.

J8

T-R Switch

and Transmitter

J6

VFO

AF Amp

J7

Receiver

Locate the RF board and orient it as shown in Figure 6-1. This

illustration shows the major areas of the board. Receiver and VFO

circuits occupy the front half; transmitter and T-R switch stages use

the rear half. The Filter board plugs into J6, J7, and J8.

Turn the board over. (Figure 6-2 shows the bottom side.)

Four 2-D fasteners will be attached to the RF board at the indicated

locations to secure it to the chassis panels.

-D Fastener

Figure 6-1

Figure 6-2

Page 27

26 ELECRAFT

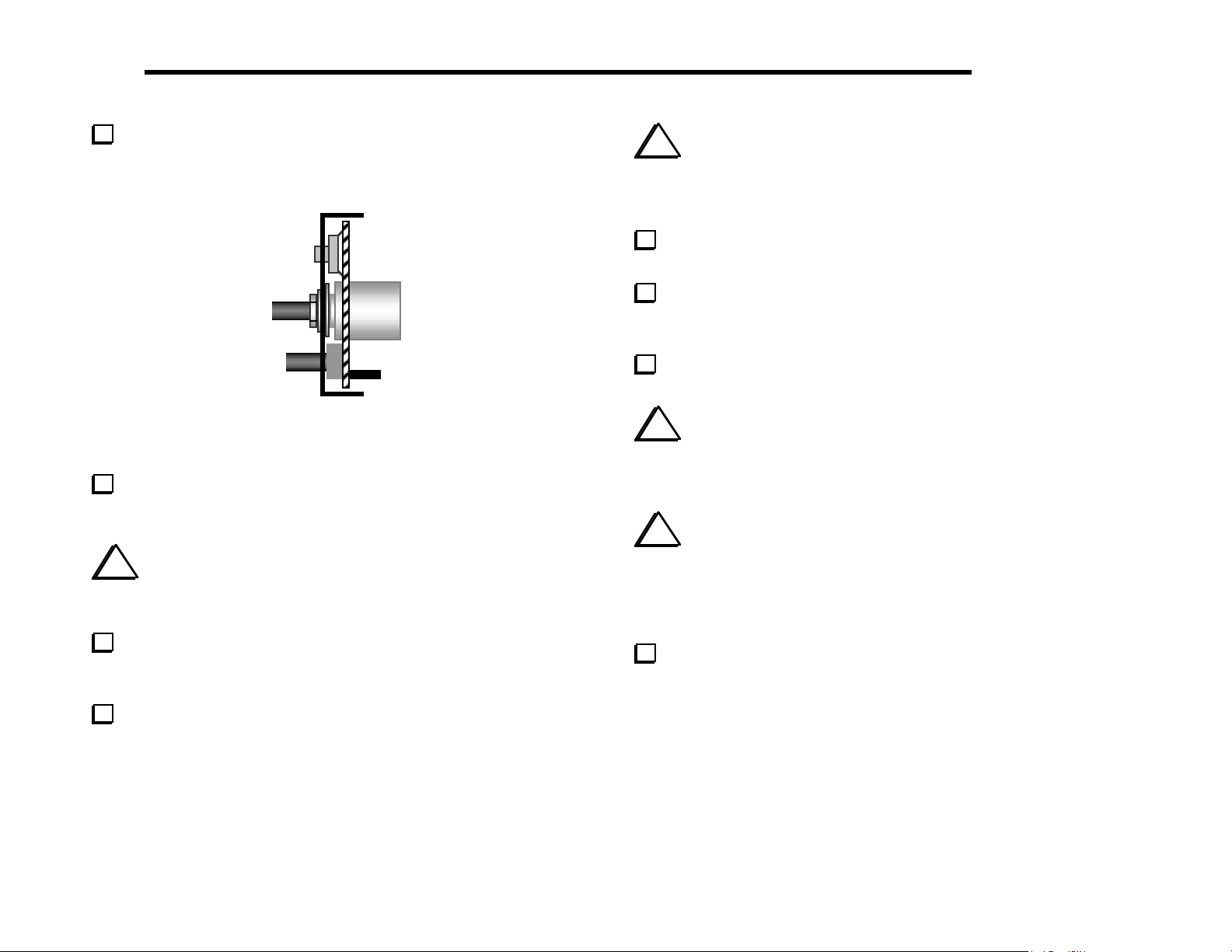

Locate a 2-D fastener and hold it vertically (Figure 6-3a).

Looking at a side with two holes, note that the holes are offset

from the center. The PC board outlines for the 2-D fasteners have

a matching offset, which will aid in installing them in the next step.

i

In the steps that follow you’ll install the connectors that

mate with the Filter and Front Panel boards. These connectors

must be installed properly to ensure reliable mechanical connection.

They are difficult to remove once installed, so follow all

instructions carefully. Review Figure 3-3 before proceeding.

Install an 8-pin female connector at J6, on the top side of the

RF board. It must be flush with the board and not tilted (Figure 6-4).

Solder just one pin near the center of J6.

Holes offset

from center

J6

(a)

Figure 6-3

Install 2-D fasteners at the four locations indicated in Figure

6-2, on the bottom of the RF board. Secure each fastener from the

top side of the board with 3/16" (4.8 mm) pan-head screws and #4

split lock washers (Figure 6-3b).

Make sure that the 2-D fasteners line up with the edges of the

PC board and do not hang over. If they hang over or do not match

their component outlines, they are installed backwards.

Install relay K1, near the center of the board. Make sure the

pin 1 end (with the heavy line) is oriented as indicated by K1’s

component outline. Do not bend or trim the relay leads.

(b)

Figure 6-4

If J6 does not appear to be completely flush with the board, or

it is tilted, re-heat the soldered pin and press down. Do not solder

the remaining pins yet.

Install J7 and J8 in the same manner as J6, soldering just one

pin in each case.

The Filter board can now be used to check for proper

installation of the three 8-pin connectors. Place the Filter board

above the connectors (do not plug it in). Verify that all pins of P1,

2, and 3 on the Filter board align with the corresponding holes of

J6, 7 and 8 on the RF board.

Remove the Filter board. Solder all remaining pins of J6, 7,

and 8 on the bottom of the RF board.

Page 28

ELECRAFT 27

Position 20-pin male right-angle connector P1 on the bottom

of the RF board (Figure 6-5), but do not solder yet. Review Figure

3-3 for correct placement. The short ends of the bent pins are

inserted into the holes, and the long ends are parallel to the board.

Top of board

Front edge

P1

Figure 6-5

Solder just the two end pins of P1.

Make sure that the front-panel assembly can be plugged into

P1 as shown in Figure 3-3. Then unplug the front panel assembly.

Look closely at P1 to make sure that its plastic support is

pressed down as far as it will go, and that the pins are parallel to the

board. If not, re-heat the soldered ends while pressing it into place.

Once it is seated properly, solder the remaining pins.

i

In the steps that follow, you'll be installing larger groups of

components. When working from a long list, install all of the items

on one line before moving on to the next. Arrows (⇒) appear in

the list to remind you of this order. In general, assembly proceeds

from left to right across the board.

Install the resistors listed below. R23 is at the left-front edge.

__ R23, 1.5 Ω (BRN-GRN-GOLD) ⇒ __ R7, 680 (BLUE_GRAY-BRN)

__ R21, 2.7 k (RED-VIO-RED) __ R13, 2.2 M (RED-RED-GRN)

__ R2, 100 k (BRN-BLK-YEL) __ R16, 75 (VIO-GRN-BLK)

__ R17, 120 (BRN-RED-BRN) __ R18, 75 (VIO-GRN-BLK)

__ R14, 2.7 k (RED-VIO-RED) __ R1, 1.8 k (BRN-GRAY-RED)

These resistors start on the left edge of the board near J6:

__ R19, 39 k (ORG-WHT-ORG) ⇒ __ R20, 20 k (RED-BLK-ORG)

__ R9, 2.7 k (RED-VIO-RED) __ R26, 1.8 k (BRN-GRAY-RED)

__ R34, 100 k (BRN-BLK_YEL) (at the back-right edge near J8)

The following capacitors are all of the disc or monolithic

type. Start with C26, which is on the left edge close to J6.

Note: C65 (22 pF) may be labeled "220J" (see top of page 9).

__ C26, 39 (39) ⇒ __ C27, 39 (39) ⇒ __ C42, 220 (221)

__ C41, .047 (473) __ C30, .047 (473) __ C40, .01 (103)

__ C25, .01 (103) __ C7, 39 (39) __ C4, .01 (103)

__ C6, .01 (103) __ C69, 220 (221) __ C72, .01 (103)

__ C18, .01 (103) __ C74, .01 (103) __ C73, 0.1 (104)

__ C64, .01 (103) __ C68, 0.1 (104) __ C17, .01 (103)

__ C32, .047 (473)

__ C70, 0.1 (104) __ C71, 0.1 (104) __ C23, .01 (103)

__ C75, .01 (103) __ C63, 330 (331) __ C65, 22 (22, 220J)

__ C61, .047 (473) __ C24, .047 (473) __ C19, .001 (102)

__ C66, .01 (103) __ C21, .01 (103) __ C22, .001 (102)

__ C39, 220 (221) __ C37, .01 (103) __ C38, 220 (221)

__ C36, .01 (103) __ C34, 0.1 (104)

__ C28 and __ C29, .001 (102) (back-left corner of the board)

__ C49 and __ C48, .01 (103) (back-right corner)

__ C45, .01 (103) (near J4, which is on the back edge)

Note: All components mounted in the T-R switch and transmitter

areas must be kept as low-profile as possible since the Filter board

will be plugged in directly above.

1200-pF polystyrene capacitor C11 (labeled “1200J”) has

axial leads, like a resistor. Note: the kit also includes a 120 pF

polystyrene ("120J"). Install C11 in the VFO area of the board,

near J6. Limit soldering time to 2-3 seconds.

Page 29

28 ELECRAFT

Install the resistor networks listed below, checking the part

numbers carefully before installation. Orient the black dot or bar on

each network towards pin 1 of its component outline.

__ RP3, 47 k, 10 pins (10A3473G, 103C104, or 770103473)

__ RP1, 100 k, 8 pins (8A3104G, 83C104, or 77083104)

__ RP2, 100 k, 8 pins (8A3104G, 83C104, or 77083104)

__ RP6, 27 k, 6 pins (6A3273G, 63C273, 4306R-102 LF273 or 77063273)

__ RP4, 3.9 k, 6 pins (6A3392G, 63C392, 94163392P or 77063392)

__ RP5, 3.9 k, 6 pins (6A3392G, 63C392, 4163392 or 77063392)

Install a 33-µH RF choke (ORG-ORG-BLK) at RFC1, near the

front edge of the board. (Orange bands may appear to be brown.)

Install a 100-µH RF choke (BRN-BLK-BRN) at RFC4, in the

transmit area of the board.

The ceramic trimmer capacitors (C13 and C20) have one side

that is flattened. This side must be oriented towards the flattened

side of the component outline. Install C20 near the front edge of

the board, and C13 in the back-left corner.

Sort the diodes into groups for identification purposes. You

should have two types of small glass-bodied diodes: 1N5711, and

1N4148. The 1N4753 zener diode may also be glass, and is larger.

If necessary, use a magnifying glass to read the labels.

i

Diodes with long axial leads (such as the types mentioned

above) must be installed with the banded end (cathode) oriented

towards the banded end of their component outlines. If a diode has

more than one band, the widest band indicates the cathode end.

Install 1N4148 diodes at D17 and D1, observing the proper

orientation as explained above. Do not solder yet. D17 and D1 are

both near RP2, in the VFO area.

Install 1N5711 diodes at D2 and D15, but do not solder yet. D2

is in the VFO area. D15 is in the back-right corner near J8.

Identify the two types of black, axial-lead diodes: 1N4007 and

SB530. The 1N4007 is the smaller of the two.

Install the SB530 diode at D16, near the back edge of the

board.

Install 1N4007 diodes at D11 and D10, to the left of D16.

Install a 1N4007 diode at D5, near J7.

The varactor diodes have a small plastic package, like a TO-92

transistor, but with only two leads. Sort the varactor diodes into

two types: MV209 (quantity 1) and 1SV149 or V149SL (quantity 4).

Install the varactor diodes listed below. The flat side of each

diode must match the flat side of its PC board outline. Bend the

leads slightly on the bottom to hold the diodes in place.

__ D4, MV209 (in the VFO area)

Note: The 1SV149 diodes may have a third lead in the center, cut off near the

body. Mount them slightly above the board to avoid letting this lead short

the two pads together.

__ D3, 1SV149 (in the VFO area)

__ D6, __ D7, __ D8, 1SV149 (right-front corner)

i

TO-92 package may have either of the package types

shown in Figure 5-4 (page 19). Orient the large flat side of the

package with the flat side of the component outline. Verify the

part numbers using a magnifying glass if necessary.

Install the TO-92 package transistors listed below, starting with

Q9 in the VFO area. Observe anti-static precautions.

__ Q9, 2N3906 ⇒ __ Q8, J309 ⇒ __ Q11, J309

__ Q10, 2N7000 __ Q2, MPSA14 __ Q1, 2N7000

__ Q3, 2N4124

Re-check the orientation of the diodes, then solder.

Page 30

ELECRAFT 29

i

Transistor Q4 (ZVN4424) is labeled on the back (the side

with smaller area), which is different from most TO-92 devices.

The labeled side of Q4 must face the power switch, S1.

Install Q4 (ZVN4424A) in the back-right corner near S1.

Install U6 (78L06) near the left edge of the VFO area.

Install the 8-pin ICs listed below. Orient the notched or

dimpled end of each IC with the notched end of its component

outline (see Figure 4-7). Make sure the part numbers on the ICs

match the numbers on the component outlines.

__ U4, LM380N-8 (do not confuse with U3--check part numbers carefully)

__ U3, LM386N-1

__ U2, __ U7, and __ U1, SA602AN (alternates: NE602, SA612, NE612)

Install the following components on the bottom of the board,

soldering them on the top side. Note: R3 is easier to solder on the

bottom. In this case, pre-trim the leads to the correct length.

__ R3, 8.25 k, 1% (GRAY-RED-GRN-BRN) (see note above)

__ R15, 10 ohms, 5% (BRN-BLK-BLK)

__ R5 and __ R6, 2.7 k (RED-VIO-RED)

__ R27, 1.8 k (BRN-GRY-RED)

__ D12, 1N4007 (black body)

__ RFC6 and __ RFC7, 100 µH (BRN-BLK-BRN)

__ C5, 3300 pF polystyrene (3300J)

__ C12, 1200 pF polystyrene (1200J)

Install C8 (82 pF) on the bottom of the board, near P1.

Before soldering, fold it down against the board, towards the back.

On the top and bottom sides of the board near J7 you’ll find

short jumpers (

Locate the DC power switch, S1. Install S1 near the back of

the board, with the plunger facing the back edge. Make sure S1 is

pressed firmly onto the board, and that it is not tilted.

). Install U-shaped wires at both locations.

Push the black keycap onto S1’s plunger until it snaps.

Install the DC input jack, J4, at the back edge. The 3 leads on

the jack must be lined up with the slot-shaped holes in the

component outline. If the holes are a tight fit, press firmly until

the connector snaps into position, flat against the board.

Visual Inspection

Verify correct orientation (banded end) of each diode installed

so far, using the parts placement drawing (Appendix F).

Examine both sides of the PC board closely for solder bridges,

cold solder joints, or unsoldered components.

Resistance Checks

Make the resistance checks listed below, with your DMM's (-)

lead connected to the ground jumper (

measurements on P1 (the 20-pin right-angle connector) should be

taken from the bottom side of the board.

Test Points (+) Resistance

P1 pin 6 > 100 k

P1 pin 7 > 100 k

P1 pin 8 > 100 k

P1 pin 12 > 10 k

P1 pin 14 > 100 k

P1 pin 15 > 100 ohms

P1 pin 16 > 1 k

P1 pin 17 > 1 k

U3 pin 3 < 200 k

U3 pin 5 > 10 k

U4 pin 3 > 50 k

U4 pin 6 > 10 k

U4 pin 7 > 1 k

) near J7. The

Page 31

30 ELECRAFT

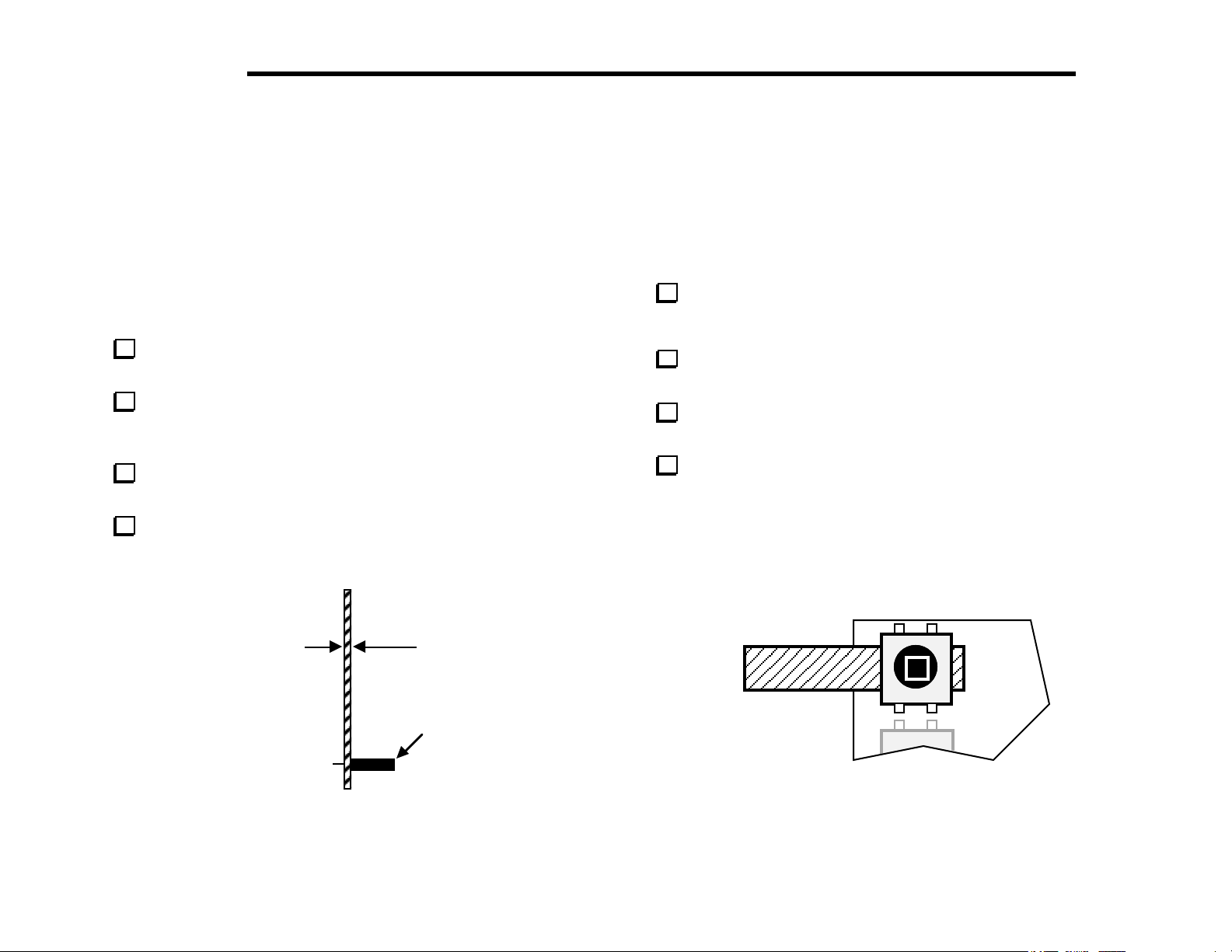

i

board outlines are circular. The (+) lead must be installed in the hole

marked with a "+" symbol. The (+) lead is usually longer than the (–)

lead, and the (–) lead is identified by a black stripe (Figure 6-6).

Electrolytic capacitors are mounted vertically, so their PC

+

-

Figure 6-6

Install the electrolytic capacitors listed below. They must be

seated as close to the PC board as possible to avoid interfering with

option modules that you may install later. Note: The 10-µF capacitors

are of the low-profile type, so they may be smaller than the 2.2-µF

capacitors.

__ C33, __ C59, and __ C35, 10 µF (see note above)

__ C54, __ C31, and __ C67, 2.2 µF

__ C9, __ C10, and __ C53, 220 µF

8-volt regulator U5 (LM2930T-8) is a TO-220 package device

with 3 leads (see photo in parts list). Mount U5 vertically at the back

edge of the PC board (Figure 6-7). Only the wide part of the leads

should be above the board. The hole in the tab of U5 will not be used

for mounting, so positioning is not critical.

Locate the component outline for RFC8, on the bottom of the RF

board in the transmitter area. Install a short wire jumper at RFC8,

formed from a component lead or solid hookup wire.

Note: an RF choke may be supplied with the 80-meter band kit (2band Filter board only) for use at RFC8. This RF choke can be

installed at any time, and will have no effect on K1 alignment or

testing on any band. Its function is to improve stability on 80 meters

when the K1 is used with poorly-matched loads or an ATU.

DC Voltage Checks

Set power switch S1 to its OFF position, with the plunger out

(extended toward the back).

Connect a 12 to 14-V DC power supply or battery to J4. If your

power source does not already have a plug that mates with J4, use the

supplied mating plug and prepare a suitable power cable. The center

lead of the plug is positive (+).

Turn on S1. If you see or smell smoke, or a component feels

hot to the touch, disconnect the power source immediately. Locate

the source of trouble before proceeding.

Using your DMM's DC voltage setting, make the DC voltage

checks listed below. The (-) lead of your DMM should be connected to

one of the ground jumpers.

Figure 6-7

i

Be careful not to short adjacent pins of ICs with the DMM

probe (use only a fine-point probe).

Test Point (+) DC Voltage

P1 pin 15 5.8-6.2

P1 pin 16 (supply - 0.3 V)

U3 pin 5 3.8-4.2

U3 pin 6 7.6-8.7

Page 32

31 ELECRAFT

Turn the K1 off and disconnect the power supply.

Install the headphone jack, J2, on the small board extension near

the front-left corner. The pins on J2 are not very long, so they will be

nearly flush with the bottom of the board. Solder the pin closest to the

front edge first (ground), then verify that the jack is seated flat on its

plastic nubs before soldering the other pins.

Mono Headphones: If you plan to use only a mono plug at J2, cut the

trace marked "cut = mono" on the bottom of the board, under J2.

(You'll lose the sound on one side of stereo headphones.)

Install the key jack, J3, at the back-left corner. Before soldering,

make sure that the jack is aligned with its PC board outline.

Install the antenna jack, J5 (BNC), in the back-right corner.

Solder one of the large ground mounting pins first. If J5 then appears

to be tilted or twisted, reheat this ground pin while pushing J5 down

onto the board. Once it is seated properly, solder the remaining pins.

The internal speaker connector, P2, is a 2-pin connector with a

locking tab. Orient P2 as shown by its PC board outline, near the

front-right corner of the board, with the locking tab facing the front.

P2 must be seated flat against the board before soldering.

Install crystal X5, near the front edge of the board. Make sure it

is flat against the board and not tilted before soldering. (The leads can

be bent to hold it in place.)

Install R39 (1.8 k, BRN-GRAY-RED) on the bottom of the board

near crystal X6.

In the back right corner of the board near the antenna jack (J5),

install P3, a 3-pin male connector. The long end of P3's pins face up.

Install the two-pin shorting jumper across pins 1 and 2 of P3 (the

two terminals closest to J5).

On the bottom of the board, install R4 (5.6 k, GRN-BLUE-RED).

Locate the miniature slide switch, S2. Install S2 on the bottom of

the board, with the switch pressed down onto the board as far as it will

go. (If it isn't pressed all the way down, the actuator might hit the

bottom panel.) Limit soldering time on each of S2's pins to 2 seconds

to avoid melting the plastic body.

Set S2's actuator to the "OPER" (operate) position.

Locate the component outline for RF choke RFC9, on the bottom

of the board between the pins of relay K1. Flush-trim the four pins of

K1 closest to RFC9.

Form the leads of RFC9 (15 µH, BRN-GRN-BLK) to fit between

the indicated pads. Install RFC9 and position its leads so that they

don't contact any adjacent pads of K1. Solder and trim RFC9's leads

from the top side of the board.

Install X6 near the back-left corner.

Install X1-X4 at the front-right corner.

Ground the cases of all six crystals, using the near-by ground

pads. Use discarded component leads as before. Limit soldering time