Page 1

ELECRAFT AF1 Active Audio Filter

Assembly and Operating Manual

E740102: Revision B, February 8, 2012

Copyright © 2012 Elecraft; All Rights Reserved

Introduction

The Elecraft AF1 is a versatile audio filter that can be used with any receiver or transceiver. It can improve intelligibility of

CW, phone, or data signals, and is especially well suited to radios that have inadequate I.F. or audio filtering. The AF1 uses

straightforward analog circuitry and no surface-mount components, so it’s an ideal project for first-time kit builders.

A rotary switch on the unit allows you to select a low-pass characteristic with adjustable upper frequency roll-off, or a narrow

bandpass characteristic. The bandpass filter offers two levels of selectivity, and its center frequency may be tuned from about

350 Hz to about 950 Hz. The low-pass filter is active during bandpass operation, allowing you to further control the upper

frequency response. The output amplifier drives low impedance phones or a small loudspeaker. Power can be supplied via

either an on-board 9-V battery or an external supply. An LED indicates power on/off status.

Specifications

Size: 5-1/2” L x 2-7/8” W x 7/8” H (14 cm x 7.3 cm x 2.2 cm). Height not including feet or knobs.

Internal Power: 9V battery.

External Power: 7-14 V (8 V min. recommended).

Current Drain: 10 mA minimum volume to 100 mA full volume, typical.

Functions: Low pass plus two levels of bandpass with tunable center frequency in bandpass mode.

See Typical Response Plots on page 9.

Tools Required

You will need the following tools to build this kit:

Fine-tip temperature-controlled ESD-safe soldering station with 700 to 800F tip (370-430C). Recommend a spade

tip no greater than 0.05” (1.3 mm) wide.

IC-grade solder (Kester #44 or equivalent). Small diameter solder (e.g. .031”) is easiest to work with on small

printed circuit boards. DO NOT use acid-core solder, water-soluble flux solder, additional flux or solvents.

Small, #2 Phillips screwdriver.

Needle-nose pliers.

Diagonal cutters.

Small wrench or driver for 4-40 nut.

Digital Multimeter (DMM) with voltage, resistance and diode-checking functions is useful for confirming the value

of components. A DMM with capacitance measurement capability is desirable, but not required.

Desoldering tools and supplies are invaluable. Narrow solder wick or a good vacuum desoldering tool such as the

Soldapullt® model DS017LS are recommended.

Refer to www.elecraft.com for tool sources and solder recommendations.

Parts List

We strongly recommend that you do a complete inventory before beginning assembly. The inventory helps you correctly

identify all the parts to avoid mistakes during assembly.

Identifying Parts

In some cases the component marking is self-evident. A 1N4007 diode, for example, will have “1N4007” stamped on its

body. When the markings are not so obvious, the marks you should find to identify individual components are shown in

parenthesis in the parts list and text. These may be numbers such as “(103)” on capacitors or colors on resistors such as

Elecraft • www.elecraft.com • 831-662-8345

Page 2

“(brn-blk-red)”. Look for the color band sequence starting near one end of the component. Some resistors have dark blue

bodies that make identifying the colors difficult. Use your DMM to verify the value if you aren’t sure. Remember that your

DMM usually will indicate a value close to, but not exactly what is shown, due to normal tolerances in the components and

the DMM.

There may be more numbers, letters or color bands on a component than those shown in parenthesis. The additional markings

may change from unit to unit and are not important for identifying the part supplied with the kit.

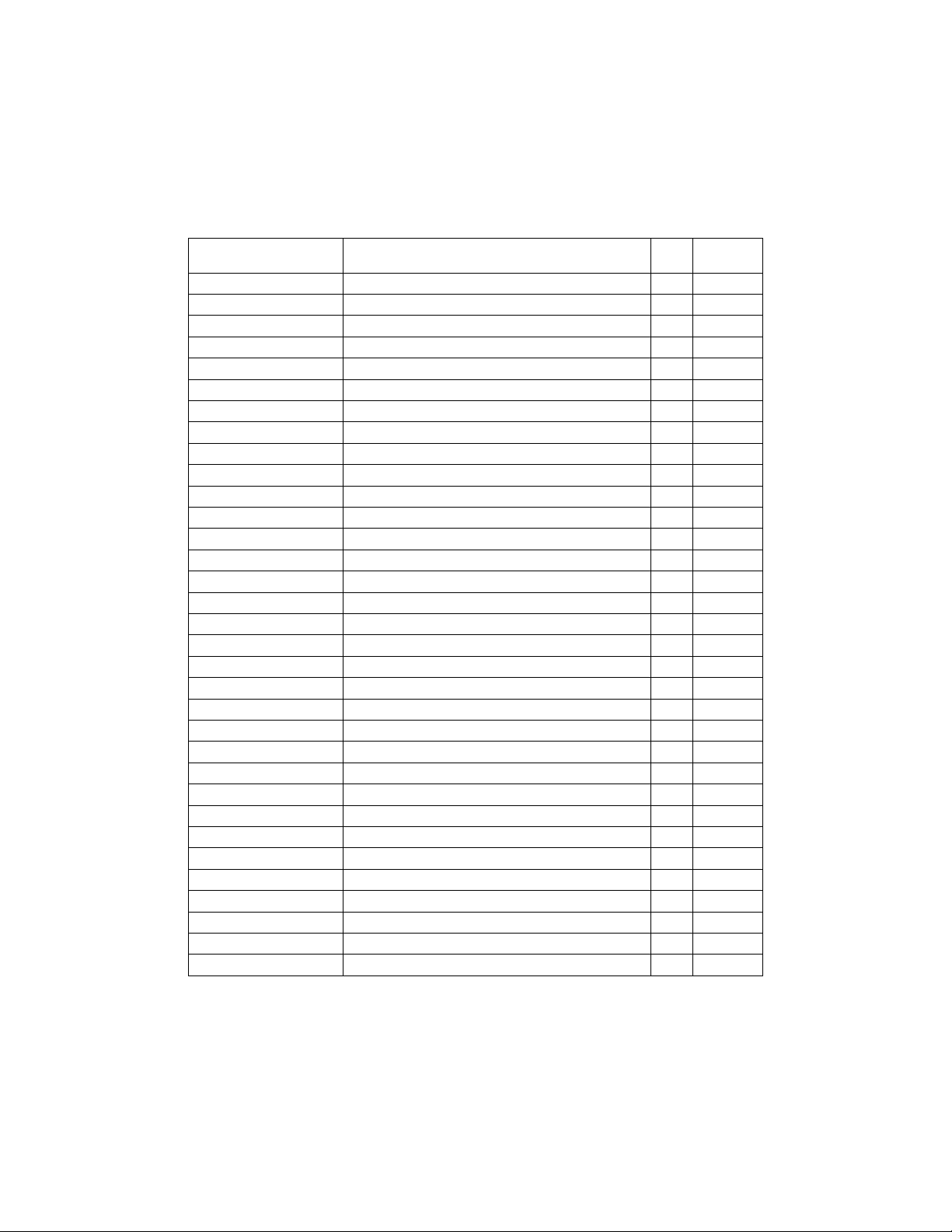

Reference. Designator Description Qty

Misc. AF1 Audio Filter Printed Circuit Board 1 E100310

B1 Battery Holder 1 E980074

C1, C10 1µF 50V Electrolytic Capacitor 2 E530022

C2, C3, C11 470µF 25V Electrolytic Capacitor 3 E530084

C4, C7, C8 , C9, C13 .01µF (103) Capacitor 5 E530009

C5 .0022µF (222) Capacitor 1 E530054

C6 .1µF (104) Capacitor 1 E530011

C12 .047µF (473) Capacitor 1 E530025

R1 1.5k (brn-grn-blk-brn-brn) 1/4W Resistor 1 E500034

R2, R4, R7, R14 1.0k (brn-blk-red) 1/4W Resistor 4 E500013

R3 15k (brn-grn-org) 1/4W Resistor 1 E500060

R6 10k (brn-blk-org) 1/4W Resistor 1 E500015

R8, R11 180k (brn-gry-yel) 1/4W Resistor 2 E500068

R9, R12 680Ω ((blu-gry-brn) 1/4W Resistor 2 E500040

R17, R13 360k (org-blu-yel) 1/4W Resistor 2 E500264

R16 10Ω (brn-blk-blk) 1/4W Resistor 1 E500054

R18 22k (red-red-org) 1/4W Resistor 1 E500090

R10 5k dual potentiometer, linear taper, 6 pin 1 E520019

R15 10K (10KD) potentiometer 1 E520018

R5 50K (50KB) potentiometer 1 E520017

D1, D2 1N4007 Diode 2 E560001

D3 LED, Red, Ultra bright 1 E570025

J1, J3 Jack, Stereo, 3.5 mm 2 E620027

J2 Jack, 2.1 mm, 12VDC power 1 E620026

SW1 Switch, Rotary, 3 Pole, 4 Position, Non-Shorting, PC 1 E640033

U1 LM348 Integrated Circuit 1 E850231

U2 LM386 Integrated Circuit 1 E600022

Hardware Screw, Pan Head, Black Machine, 4-40 4 E700008

Hardware Lock Washer, Internal Tooth, #4 4 E700010

Hardware Nut, #4-40 4 E700011

Misc Knob w/set screw for 1/4 inch shaft 4 E700118

Misc Rubber Foot 4 E700024

Misc #24 Wire, Solid, Green, Insulated 6” E760008

Part

Number

Assembly Options

The AF1 is designed to operate as a stand-alone unit without an enclosure. In the event you want to build it into existing

equipment or its own enclosure:

1. Four holes are provided in the board that you may use with your own #4 hardware and spacers as needed to mount

the unit instead of using the rubber feet.

2. The battery may be mounted on the top (component side) or bottom of the board or you may choose not to install the

battery holder if you are going to power your AF1 only from an external source.

2

Page 3

Assembly Procedure

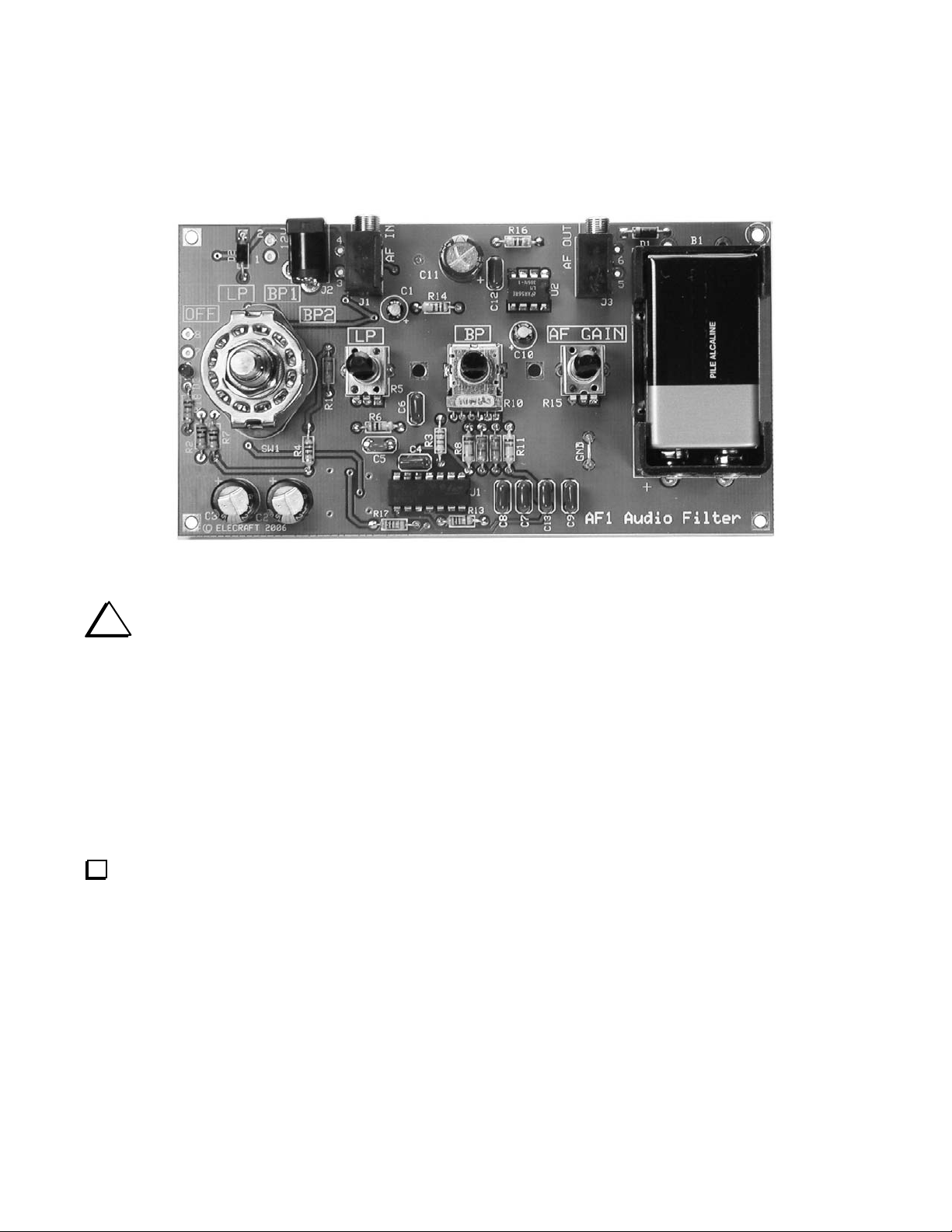

The finished audio filter is shown in Figure 1. The knobs were left off to better show the components on the board. We

recommend you follow the assembly procedure below, and refer to this figure as needed.

Figure 1. Assembled Audio Filter.

i

Use adequate ventilation when soldering; avoid inhaling smoke or fumes. Always wash your hands after

handling solder, as lead residue is highly toxic.

When applying solder, use the minimum amount required to surround the component lead and make good contact with its

printed-circuit pad. You don't need a "fillet" (build-up) of solder. This will avoid unwanted solder bridges and any need to

clean the PC boards.

The solder must flow onto both the component lead and its PC board pad. To ensure that both will be heated at the same time,

the tip of the iron should contact both the component lead and the PC board pad before solder is applied.

Solder joints should be clean and shiny. If a joint appears dull or has fine cracks, it is probably cold. Cold solder joints should

be cleaned and re-soldered. First, use solder wick (desoldering braid) to remove the old solder. Then apply fresh solder. If

you have many cold solder joints, it probably indicates that your soldering iron temperature is too low, or that the tip or

solder itself is defective.

flush on the bottom. If you position the board so the legends are right side up, you can work from left to right across the

board following the order given below. Save one of the clipped leads. You will use it to make a ground test point later.

Install the fixed resistors listed below. Position each resistor within the outline on the PC board, solder and trim the leads

__ R18, 22k (red-red-org)

__ R7, 1K (brn-blk-red)

__ R1, 1.5k (brn-grn-blk-brn)

__ R17, 360k (org-blu-yel)

__ R3, 15k (brn-grn-org)

__ R8, 180k (brn-gry-yel)

__ R12, 680Ω ((blu-gry-brn)

__ R16, 10Ω (brn-blk-blk)

__ R2, 1K (brn-blk-red)

__ R4, 1K (brn-blk-red)

__ R6, 10k (brn-blk-org)

__ R14, 1.0k (brn-blk-red)

__ R13, 360k (org-blu-yel)

__ R9, 680Ω ((blu-gry-brn)

__ R11, 180k (brn-gry-yel)

3

Page 4

Install the capacitors listed below just as you did with the resistors in the previous step:

FLARED

__ C5, .0022µF (222)

__ C6, .1µF (104)

__ C8, .01µF (103)

__ C13, .01µF (103)

__ C4, .01µF (103)

__ C12, .047µF (473) See note.

__ C7, .01µF (103)

__ C9, .01µF (103)

Note: The + symbol next to outline for C12 refers to electrolytic capacitor C11

that you’ll install later. C12 may be installed oriented either way, just like the

other capacitors in this group.

Locate LED D3. Note that one lead is slightly longer than the other. Insert the long lead in the lower, round solder pad

in the space for D3 on the left edge of the board. Position the LED as close to the board as it will fit. Solder and trim the leads

flush with the bottom of the board.

Locate diodes D1 and D2 (1N4007). Note the silver band at one end of the diode body. Install the diodes with the silver

stripe aligned with the stripe on the silk screened outline on the board.

__ D2, 1N4007 (near upper left corner)

__ D1, 1N4007 (near upper right corner)

Inspect the leads of one of the electrolytic capacitors. Note that there is a stripe with a – on the body to identify the

negative lead. The negative lead must be inserted in the round solder pad on the board. The positive lead must be inserted

in the square solder pad. There is a + symbol near that pad. The positive lead is slightly longer on most capacitors. Install the

electrolytic capacitors as follows:

__ C2, 470µF

__ C11, 470µF

__ C3, 470µF

__ C10, 1µF

__ C1, 1µF

Bend the clipped resistor lead you saved earlier into a “U” that fits into the solder pads at each end of the GND test point

near C9. Solder the lead into the pads with the loop high enough above the board to easily clip a test probe lead onto it.

Install U1 (LM348) as follows:

Place U1 on the board where shown by the outline near the bottom center. If the pins are spread too wide to fit, place

U1 on its side on a solid, flat surface and rock it gently to bend all the pins inward slightly as shown in Figure 2. Do

the same on both sides until it fits into the solder pads on the board.

Align the end of U1 that has a notch or dimple molded in the case

with the notch on the silk screened outline.

Hold U1 in place, wet the tip of your soldering iron with solder and

touch one of the corner pins on the bottom of the board to tack-solder

it in place.

PRESS AND

ROCK TO

STRAIGHTEN

STRAIGHT

Make sure U1 is correctly positioned and flat against the board, then

solder the remaining pins.

Figure 2. Straightening I.C. Pins.

Reheat the tack-soldered pin as needed to ensure it is properly

soldered.

Install U2 (LM386) using the same procedure you used for U1.

Install the 12VDC power connector, J2, as follows:

Position the connector over the J2 outline on the board.

Tack-solder one pin to hold it in place.

Check the position of the connector. If necessary reheat the soldered pin to adjust it.

Solder the remaining two terminals, then finish soldering the terminal you tacked in place.

4

Page 5

Install the stereo jacks using the same procedure you used for the 12VDC connector above:

J

R

__ J1

If the circuit board in your kit is Revision A (shown in the lower left corner on the top of the board), make the following

changes so it will work properly with a monaural plug at the input and a stereo plug at the output. Skip this step if your circuit

board is a later revision.

At the pins of J1 (AF IN) on the bottom of the board, use a sharp knife to cut and remove the segment of the trace

shown below. Use the green insulated wire to make a jumper to reach between the pin on J1 shown and the small

hole at the circuit via where the trace passes through to the top of the board. This change isolates the ring connection

so a monaural plug at J1 it won’t short the audio to ground.

At the pins of J3 (AF OUT) on the bottom of the board, install a jumper between the pins shown below. Use a short

section of the green insulated wire or a discarded component lead. Take care to ensure the middle connection of J3 is

not shorted to ground. This ties tip and ring together so audio is present on both at the output.

CIRCUIT

__ J3

CUT TRACE HERE

VIA

JUMPE

JUMPER

BE CAREFUL

NOT TO CREATE

A SHORT TO

GROUND HERE

J1 - AF IN

Figure 3. Rev. A Board Modifications.

Install 6-pin dual potentiometer R10 as follows:

Position R10 on the board. Be sure all six pins pass through their respective solder pads, then press down on the

body of the potentiometer, if necessary, to snap it in place. Do not push on the shaft.

Solder only one pin, then inspect the potentiometer to be sure it is sitting flat against the board. Look at it from two

directions to be sure the shaft is perpendicular to the board. If necessary, reheat the soldered pin and reposition the

R10.

Solder all six signal pins and the two side clips to the board.

Install potentiometers R5 and R15 using the same procedure you used for R10:

__ R5 (50KB)

Install rotary switch SW1 as follows:

Position SW1 inside its outline on the board. Note that the pins will fit through the solder pads when the switch is

oriented one way.

Solder one pin and inspect the switch to be sure it is perpendicular to the board, just as you did for the

potentiometers.

Solder all the pins.

__ R15 (10KD)

2 - AF OUT

5

Page 6

i

The battery holder many be installed on the top or the bottom of the board. No rmally you will want to install

it on the top so the finished unit will sit flat on its feet. However, if you plan to install the filter in an enclosure, you can

mount the battery holder on the bottom of the board. Solder pads are provided to mount the holder on either side as

indicated on the circuit board. Also, if plan to supply only external power to the filter, you can leave the battery

holder off entirely.

Install the battery holder as follows:

Position the battery holder on the board within the outline. Be sure you have it on the correct side of the board.

Unless you have a special need, you will want to put it on the top side along with the other components. Do not

solder yet.

Attach the holder to the board with the 4-40 screws in four places, using lock washers and nuts. The screw heads

should be on the holder side so the battery will fit correctly. You may need to bend the battery holder terminals

slightly to align the screw holes with those in the board.

Solder the two terminals to the pads and trim them flush.

Attach the four feet to the corners of the board on the bottom. If you plan to build the filter into a rig or separate

enclosure, you may leave the feet off and use the four corner holes for mounting the filter.

Attach the four knobs to the rotary switch and potentiometer shafts. Line up the index mark on the knob for the rotary

switch so it is pointing to OFF when the switch is rotated to the fully left position. The potentiometer shafts may wobble a

little because long shafts are required to approximate the height of the rotary switch shaft.

Checkout and Operation

If you have difficulty with the following steps, refer to the circuit description and troubleshooting notes in the following

sections.

Install a 9-volt battery in the holder or connect a d-c supply between 9 and 14VDC to J2 (positive to center pin).

Connect an audio source to the AF IN jack (J1). This can be a headphone output from your receiver or other audio

source.

Connect your headphones or a small loudspeaker to the AF OUT jack (J3).

Position the LPF, BP and AF GAIN pots to minimum (counter-clockwise).

Turn SW1 to LP (low-pass) position. The red LED D3 should light.

Rotate the AF GAIN clockwise for a convenient audio level in the phones or loudspeaker.

Rotate the LP pot clockwise. You’ll hear high frequency sound increase in volume as you turn the pot. This is raising

the cutoff frequency from minimum (fully counter-clockwise) to maximum. Leave LP fully clockwise.

Rotate SW1 to BP1 (bandpass filter 1) position. If possible supply a single frequency tone to the input (such as tuning in

a CW signal on your rig).

Rotate the BP pot. The volume of the signal will rise abruptly as you pass its frequency.

Rotate SW1 to BP2 (bandpass filter 2) position and repeat tuning the BP pot. You should notice that the adjustment is

now noticeably sharper. BP 2 adds a second bandpass filter to further improve the selectivity.

i

Be sure the LPF is always set so it will pass the frequency you’ve chosen for the bandpass filter. You can set

the LPF cutoff frequency close to the BPF frequency so it aids in rejecting high-frequencies above the bandpass

frequency.

6

Page 7

Circuit Description

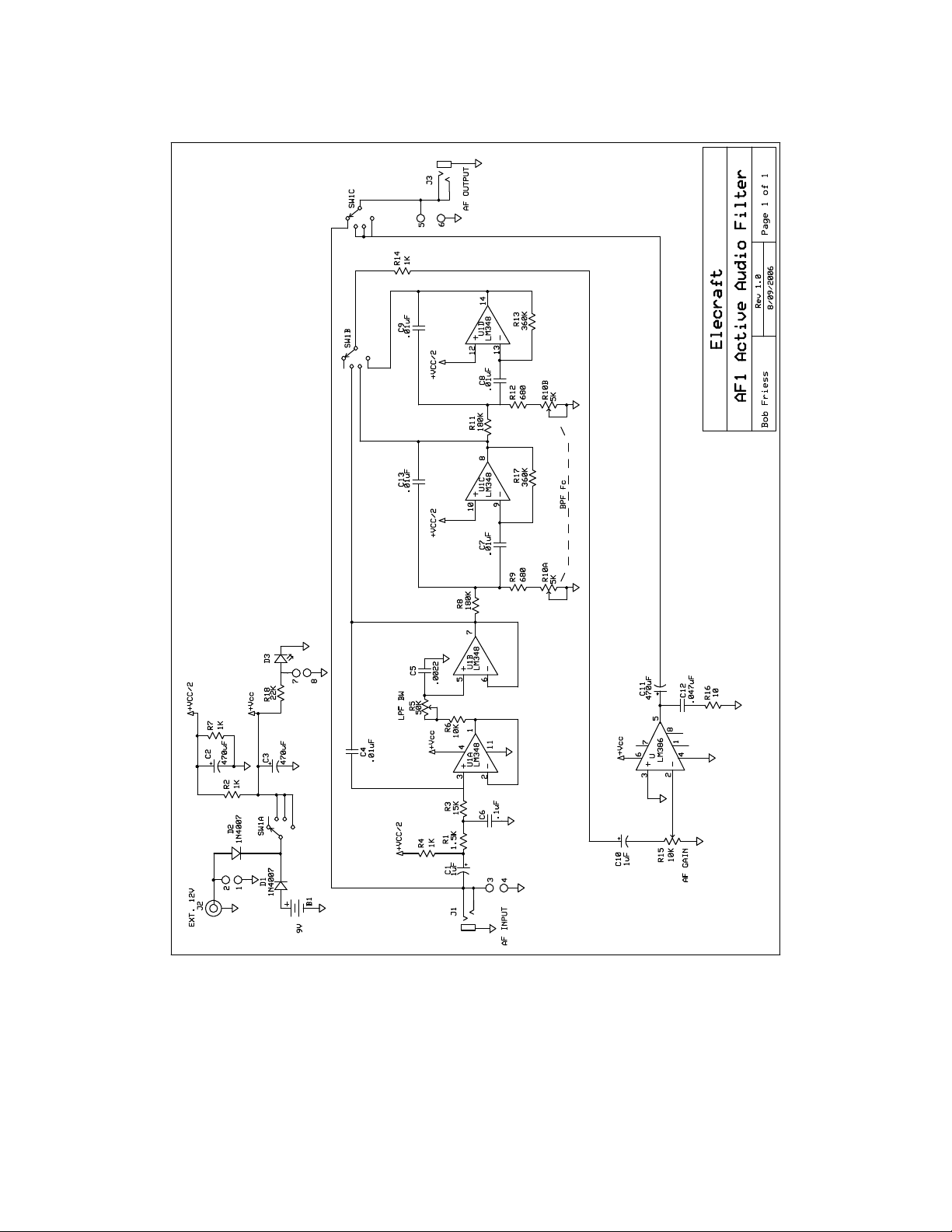

Refer to the schematic diagram on page 8. The filter circuit uses a quad operational amplifier integrated circuit that features

excellent isolation between the stages. Audio applied at J1 passes through a low-pass filter formed U1A and B. Potentiometer

R5 varies the high-frequency cutoff. U1C and D form two independent bandpass filters whose center frequencies are

controlled by ganged potentiometers R10A and R10B. These stages tune together so they are both centered on the same

frequency at all times. U2 is an audio amplifier that drives the AF output.

Rotary Switch SW1 has three sections. Section B selects the output of the low-pass filter, the output of the low-pass filter

plus one bandpass filter, or the output of the low-pass filter plus both bandpass filters. In the OFF position, SW1C routes the

audio from the input directly to the output so you don’t have to remove the filter when it is not in use. SW1A controls power

to the filter.

The power circuit allows you to use either a 9V battery or an external power supply. Diodes D1 and D2 isolate the battery

from an external supply to avoid the possibility of an external supply driving current into the battery and causing it to rupture.

Troubleshooting

If LED D3 does not light when SW1 is positioned to LP, check the orientation of diode D1 (if using internal battery) or D2 if

using an external supply. Test points 2 (+) and 1 (-) also allow you to check to be sure voltage is present at J2. Next check the

voltage across test points 7(+) and 8(-). If the voltage is above about 2VDC, D3 is either installed backwards or it is

defective.

If there is power but no audio output except when SW1 is in OFF position, turn the AF GAIN pot fully clockwise and touch a

metal test probe to the center pin of pot R15. You should hear a slight click, indicating that amplifier U2 is working. If so, the

problem is most likely in the circuits of U1A or U1B. Similarly, loss of output or function in BP1 indicates a problem in the

U1C circuit and problems in BP2 indicates a problem with the U1D circuit (see the schematic diagram on the next page). The

usual cause of problems in these stages is an incorrectly installed part, an electrolytic capacitor installed backwards or a

solder bridge across two adjacent pads. Use a magnifier and carefully inspect the board for correct component values and

solder bridges around the affected circuit.

7

Page 8

Schematic Diagram

8

Page 9

Typical Response Plots

/

/

O

The following plots AF1 plots were made with a network analyzer. The results should be typical of your filter.

L

W PASS FILTER AT MAXIMUM BANDWIDTH

LOW PASS FILTER AT MINIMUM BANDWIDTH

5 dB/Division

0.3 5.04.063.122.18

BANDPASS FILTER POSITION 1 BANDPASS FILTER POSITION 2

LOW PASS FILTER SET TO MAXIMUM BANDWIDTH LOW PASS FILTER SET TO MAXIMUM BANDWIDTH

0.1 0.3 0.5 0.7 0.9 1.0

1.24

kHz

Center

Frequency

600 Hz

kHz

BANDPASS FILTER POSITION 2

LOW PASS FILTER SET TO MINIMUM BANDWIDTH

5.04.063.122.18

5dB

Division

0.3

0.1

1.24

kHz

Center

Frequency

600 Hz

0.3 0.5 0.7 0.9 1.0

kHz

5dB

Division

Center

Frequency

600 Hz

0.1 0.3 0.5 0.7 0.9 1.0

kHz

9

Loading...

Loading...