Page 1

Rev. 7/24/07

Design Spot 575E

Elation Prof es s ional

4295 Charter Stre et

Los Angeles , Ca 90058

www.elationlighting.com

Page 2

Contents

1. General Information……………………………………………………………………… 3

a. Introduction………………………………………………………………………. 3

b. Unpacking………………………………………………………..…………..… 3

c. Customer Support…………………………………………….………………… 3

d. Warranty Registration……………………………………………………..…… 4

e. Discharge Lamp Warning……………………………………………………… 4

2. Safety Instructions………………………………………………………........…………. 6

3. Features…………………………………………………………………………………… 8

4. General Guidelines………………………………………………………………………. 9

5. Lamp Installation…………………………………………………………………………. 10

a. Lamp installation…………………………………………………….………….. 10

b. Lamp optimization……………………………………………………..………… 11

Design Spot 575E™

6. Mounting and Installation………………………………………………………….……. 13

a. Mounting Positions……………………………………………………………… 13

b. Mounting Points…………………………………………………………………. 14

c. Securing………………………………………………………………………….. 15

7. Understanding DMX……………………………………………………………………... 16

a. DMX Connections………………………………………………………………. 16

b. DMX Terminator…………………………………………………………………. 17

c. 3-P in to 5-Pin Co nversion…………………………………… …………………. 18

d. DMX Addressing………………………………………………………………… 18

8. Display Indicators……………………………………………………………………….. 20

9. Fixture Menu……………………………………………………………………………… 21

a. Menu functions………………………………………………………………….. 23

10. DMX Channel Traits…………………………………………………………………….. 39

a. DMX Channel Values…………………………………………………………… 40

11. Error Codes………………………………………………………………………………. 45

12. Cleaning and Maintenance……………………………………………………………… 48

13. Warranty…………………………………………………………………………………... 49

14. Photometric Data………………………………………………………………………… 51

15. Gobo Patterns……………………………………………………………. .……………... 52

16. Dimensional Drawings………………………………………………….………… …….. 5 3

17. Circuit Schematic………...………………………………………………………………. 54

18. Technical Specifications…………………………………………...………….………… 55

©Elation Professional® 2

Design Spot 575E™

Page 3

Design Spot 575E™

1. GENERAL INFORMATION

INTRODUCTION: Congratulations, you have just purchased one of the most innovative and

reliable lighting fixtures on the market today! The Design Spot 575E,™ has been designed

to perform reliably for years when the guidelines in this booklet are followed. Please read

and understand the instructions in this manual carefully and thoroughly before attempting to

operate this unit. These instructions contain important information regarding safety during

use and maintenance.

UNPACKING: Thank you for purchasing the Design Spot 575E™ by Elation Professional®.

Every Design Spot 575E™ has been thoroughly tested and has been shipped in perfect

operating condition. Carefully check the shipping carton for damage that may have occurred

during shipping. If the carton appears to be damaged, carefully inspect your unit for damage

and be sure all accessories necessary to operate the unit have arrived intact. In the event

damage has been found or parts are missing, please contact our customer support team for

further instructions. Please do not return this unit to your dealer without first contacting

customer support at the number listed below.

CUSTOMER SUPPOR T: Elation Professional® provides a customer support line, to provide

set up help and to answer any question should you encounter problems during your set up

or initial operation. You may also visit us on the web at www.elationlighting.com for any

comments or suggestions. For service related issue please contact Elation Professional®.

Service Hours are Monday through Friday 9:00 a.m. to 5:00 p.m. Pacific Standard Time.

Voice: (323) 582-3322

Fax: (323) 582-3108

E-mail: support@elationlighting.com

Forum: www.ElationLighting.com/forum

Warning! To prevent or reduce the risk of electrical shock or fire, do not expose this unit to

rain or moisture.

Caution! There are no user serviceable parts inside this unit. Do not attempt any repairs

yourself, doing so will void your manufactures warranty.

©Elation Professional® 3

Design Spot 575E™

Page 4

Design Spot 575E™

Please do not discard the shipping carton in the trash. Please recycle whenever possible.

WARRANTY REGISTRATION: The Design Spot 575E™ carries a two year (730 days)

limited warranty. Please fill out the enclosed warranty card to validate your purchase. All

returned service items whether under warranty or not, must be freight pre-paid and

accompany a return authorization (R.A.) number. The R.A. number must be clearly written

on the outside of the return package. A brief description of the problem as well as the R.A.

number must also be written down on a piece of paper and included in the shipping

container. If the unit is under warranty, you must provide a copy of your proof of purchase

invoice. Items returned without a R.A. number clearly marked on the outside of the package

will be refused and returned at customer’s expense. You may obtain a R.A. number by

contacting customer support at (323) 582-3322.

DISCHARGE LAMP WARNING: This fixture is fitted with a discharge

lamp, which is highl y suscepti ble to damage if i mprope rly han dled. N eve r

touch the lamp with your bare hands, as the oil from your hands will

shorten lamp life. Also, never move the fixture until the lamps have had

ample time to cool. Remember, lamps are not covered under warranty

conditions.

This fixture emits intense UV radiation, which is harmful to the eyes and skin. The intense

luminance of the lamp can cause severe damage to the retina. Never operate this fixture

with the protective covers removed, these covers have been specially designed to shield

against UV radiation.

Epileptic Warning: Those suffering from epilepsy should avoid looking directly into the

lamp at all times.

Avoid switching the fixture on and off repeatedly in short intervals, as this will reduce lamp

life and intensity.

To achieve the intensity associated with discharge lamps, these la mps use a g as sealed in a

high-pressure environment to emit a brilliant output. Du e to the high pressure involved with

the construction of the lamp, the lamp may explode during prolonged extensive use. This

risk is increased with age; added care is encouraged when dealing with older lamps. Thus,

©Elation Professional® 4

Design Spot 575E™

Page 5

Design Spot 575E™

lamp should always be replaced at the end of their recommended duty cycle. Extreme

caution should be used when operated this or any fixture fitted with a gas discharge lamp.

Never open this fixture while in use!

During the initial operation of this fixture, a light smoke or smell may emit from the interior of

the fixture. This is a normal process and is caused by excess paint in the interior of the

casing burning off from the heat associated with the lamp and will decrease gradually over

time.

This device falls under protection-class 1. Therefore it is essential that the device be

grounded properly.

All electrical connections must performed by qualified personal.

Be sure the available voltage matches the voltage requirements of the unit.

Be sure the power cord is neve r crimp ed or d a maged. If t he pow er c ord is dam aged, repl ace

it immediately with a new one of similar power rating.

Always disconnect from main power before performing any type of service or any cleaning

procedure.

Only handle the pow e r co rd by the plug. Never pull ou t the plug by tugging the w ire portio n of

the cord.

Please be aware that damages caused by manual modifications to the device are not

subject to warranty.

©Elation Professional® 5

Design Spot 575E™

Page 6

2. SAFETY INSTRUCTIONS

Design Spot 575E™

The Design Spot 575E™ is an extremely sophisticated piece of

electronic equipment. To guarantee a smooth operation, it is

important to follow the guidelines in this manual. The

manufacturer of this device will not accept responsibility for

damages resulting from the misuse of this fixture due to the

disregard of the information printed in this manual.

1. Always be sure that the fan and the air inlets remain clean and are never blocked.

Allow about 6” (15cm) between this fixture and other devices or a wall to allow for

proper cooling.

2. Never touch the fixture during normal operation. This can cause severe personal

injuries and/or damage to the fixture.

3. Be sure to unplug the DESIGN SPOT 575E™ from the power outlet before

performing any service related issues.

4. Lamp Replacement; Allow at least 30 minutes after disconnecting main power

before you open the DESIGN SPOT 575E™. To prevent personal injury, never

touch the lamp if you are not absolutely sure it has cooled.

5. Never look directly into the lamp beam. You risk injury to your retina, which may

induce blindness.

6. Be sure to track and record the lamp running time. The lamp should be changed at

the end of the specified lamp life, regardless of lamp output. You may also have to

change the lamp if it shows any deformations or damage. The same is with all

glass components, color filters, lenses and mirrors.

7. For safe operation, follow the Installation guide described in chapter two of this

manual. Operating the DESIGN SPOT 575E™ without suited safety aids such as

safety cables or clamps can increase the risk of damage and/or personal injury.

8. Installation should only be performed by qualified and certified personal.

9. When mounting this fixture, use only the original rigging parts included with this

fixture. Any structural modification will void the original manufactures warranty and

©Elation Professional® 6

Design Spot 575E™

Page 7

Design Spot 575E™

may increase the risk of damage and/or personal injury.

10. To reduce the risk of fire or shock, do not expose this fixture to rain or moisture.

11. Do not attempt to operate this fixture if the power cord has become damaged or

frayed.

Important Notice: Damages resulting from the disregard of safety and general user

instructions found in this user manual are not subject to any warranty claims.

Never touch the device during operation!

The housing may heat up

Never look directly into the light source,

as sensitive persons may suffer an epileptic shock.

©Elation Professional® 7

Design Spot 575E™

Page 8

3. FEATURES

• Pan 630° or 540˚ (User selectable) / Tilt 265°

• Built-In Macros (Color, Gobo, Prism)

• 3 operation mode: DMX Controlled, Stand-Alone or Sound Activated

• Color Wheel: 8 colors plus white (including UV filter), with rainbow effect

• CMY Variable Color Mixing

• Easy to Navigate On-Board LCD Menu (may be turned 180°)

• Animation Effect Wheel

• Two Gobos Wheels:

o Rotating gobo wheel with 7 rotating gobos plus open, all gobos can be easily

replaceable and gobo indexing

Design Spot 575E™

o Static gobo wheel with 7 static gobos plus open with different speed gobo

shaking and gobo indexing

• Strobe Effect: 0~10 flashes per second or random strobe

• Motorized Focus (Near to Far)

• Prism and Prism Rotation, with 16 prism macros (Indexable)

• Bright Phillips Gold MSR 575/2 SA DE Lamp (575w / 7200K / 750Hrs / 43,000Lm)

• Linear Dimmer from 0%~100%

• Electronic, Switching Power Supply (90v~240v)

• Variable, Linear Frost Filter (0% ~ 100%)

• RDMX (Remote DMX addressing from any DMX console)

• Auto test for all functions

• Automatic Pan/Tilt Correction

• Built-in Iris (5% ~ 100% - Seamless), with Iris Pulse Effect

• Motorized Linear Zoom (15˚ ~ 30˚)

• Glass Dichroic Reflector for Even Lamp Output

• USITT DMX-512 Complaint

o 24 DMX Channels (16bit Operation)

o 22 DMX Channels (8bit Operation)

• 8 User Assignable Program Presets - Internal Program: Edit and save programs to

the incor porated EEPROM. Maximum of 48 scenes.

©Elation Professional® 8

Design Spot 575E™

Page 9

Design Spot 575E™

4. GENERAL GUIDELINES

This fixture is a professional lighting effect designed for use on stage, in nightclubs, in

theatres, etc. Do not attempt operation or installation without a proper knowledge on how to

so.

This fixture was designed for indoor use only.

Consistent operational breaks may ensure that the fixture will function properly for may

years to come.

Do not shake the fixture around. Avoid brute force when installing or operating the device.

While choosing an installation location, please be sure that the fixture will not be exposed to

extreme heat, moisture or dust. The minimum distance between the fixture and a wall or flat

surface should be at least .5 meter (about 1.5ft).

Always install the fixture with an appropriate safety cable. When installing the fixture in a

suspended environment always be to use mounting hardware no less than M10 x 25 mm,

also be sure the hardware i s insert in the pre-arranged screw hol e s in the base of t he fi xture .

When using the quick release “Omega” cam-lock system, be sure the four quick lock

fasteners are locked in the quick lock holes correctly.

Do not attempt to operate this fixture until you have familiarized yourself with its functions.

Do not permit operation by persons not qualified for operating this type of theatrical fixture,

most damages are the result of operations by nonprofessionals.

Please use the original packaging to transport the fixture in for service.

©Elation Professional® 9

Design Spot 575E™

Page 10

Design Spot 575E™

5. LAMP INSTALL ATION INSTRUCTIO NS

For a proper and safe lamp change, please read this chapter carefully and follow all

instructions.

Safety Regulations

• Disconnect the unit’s main power supply.

• Allow the unit to cool for at least 20 minutes before attempting any type of service.

• Before you put the Design Spot 575E™ into operation be su re al l covers have be en

replaced, otherwise you risk damage to the retina and expose to UV radiation!

• Replace the lamp with an approved r eplacem ent type. B e sure t o follow all the l am p

handleing procedures included with your new lamp. Never handle the new lamp

with your bare hands, th e oi ls fro m you r skin may dam age th e lamp. A lw ays replace

with the lamp with a lamp that meets the orginal lamp specification, failure to do so

may damage the unit and will void your manufactures warranty.

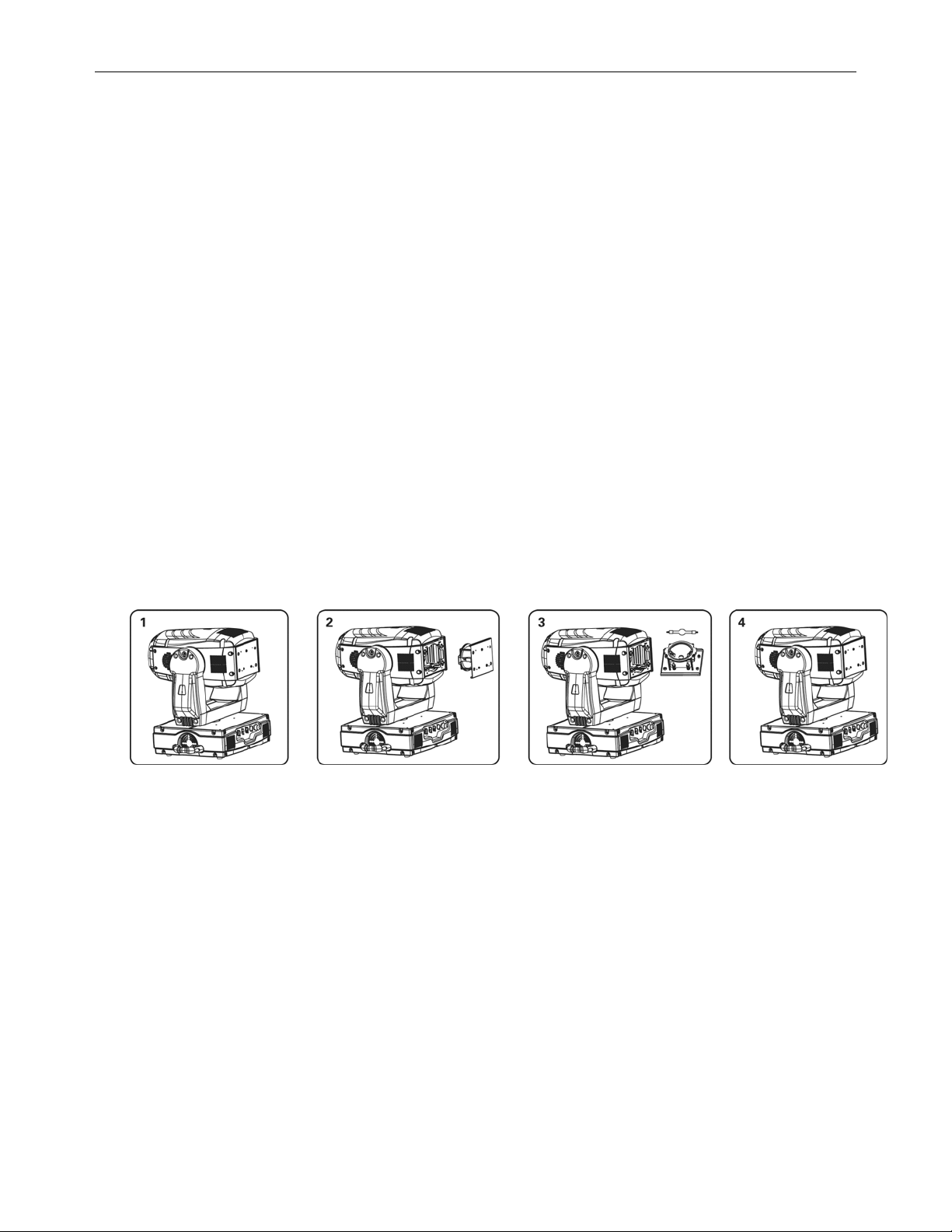

Installation Procedure:

1. Set the fixture on a flat surface and remove the four screws labeled “A” “B,” “C,” and

“D” found on the back plate of the head assembly.

2. Gently pull out the lamp/socket assembly to access the lamp.

3. Gently remove the old lamp by grasping it by metal ends.

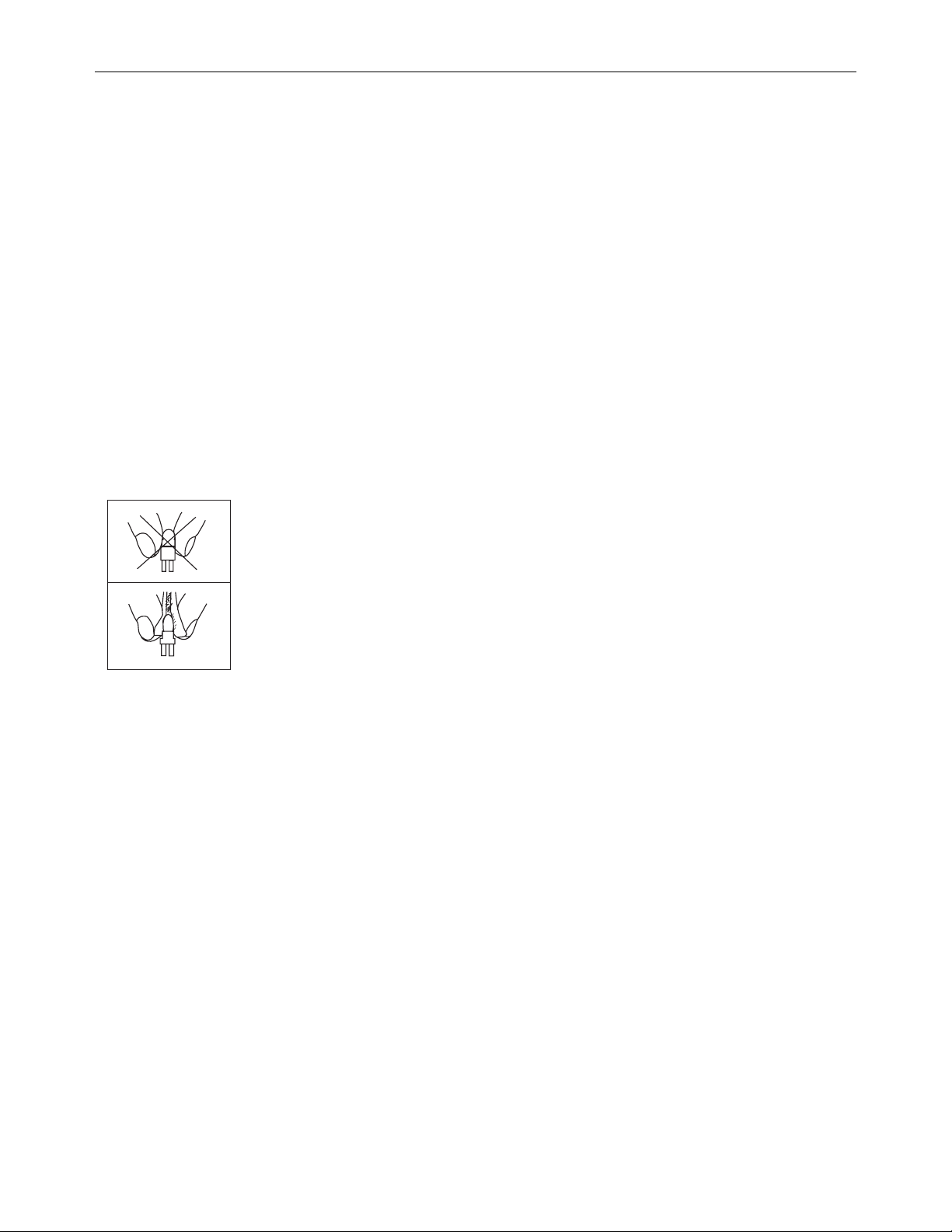

4. Insert the new lamp securel y, locking the lamp in place a s illustrate d in the d iagram

on the next page. Orientate the lamp filler tube towards the backside of the reflector.

Before reassembling the unit, be sure the new lamp is securely seated in the lamp

socket. Always be sure to o nly use specified la mp types! (MS R 5 75 S A/2 D E lam p or

equivalent).

©Elation Professional® 10

Design Spot 575E™

Page 11

Design Spot 575E™

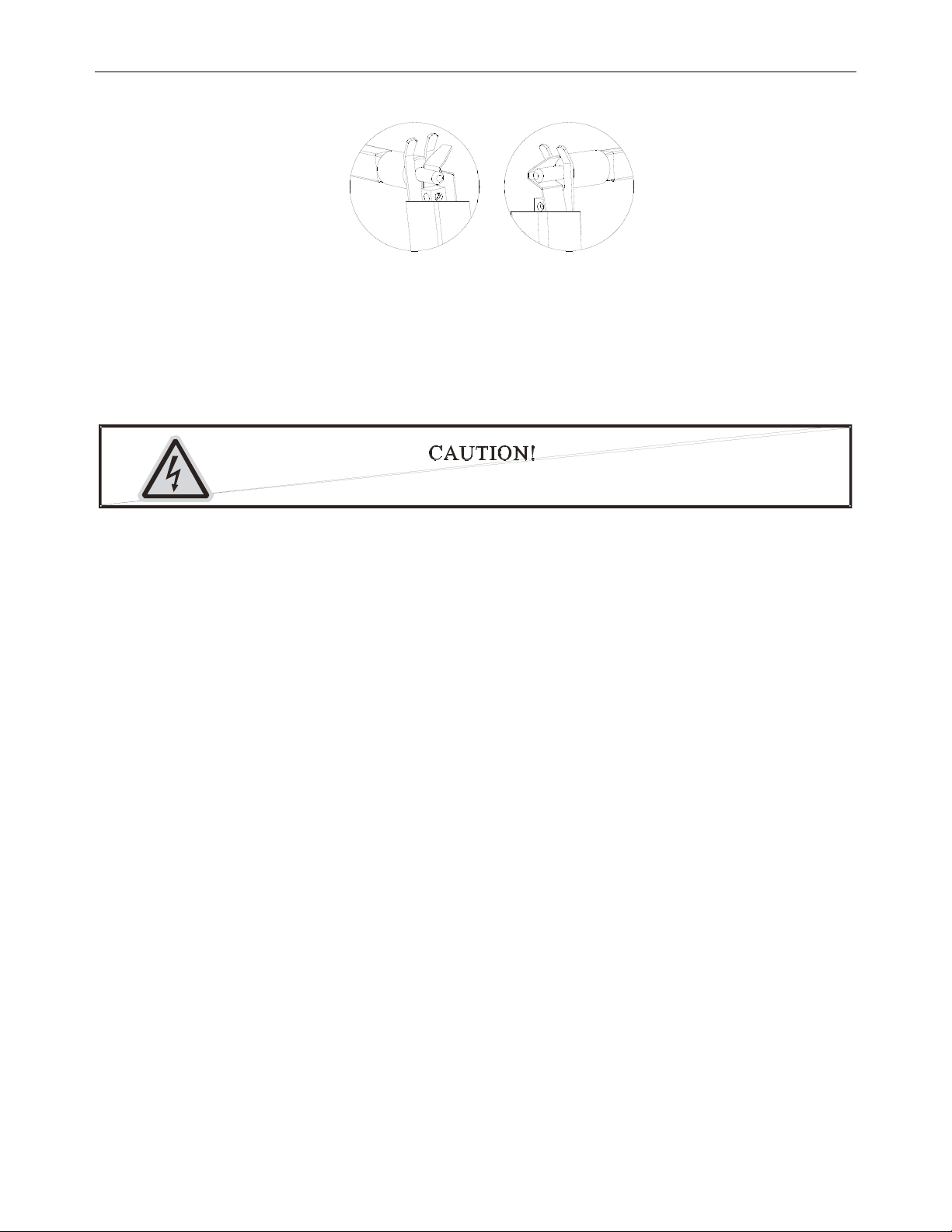

OK NO

5. Once the lamp has been inserted into the socket, gently slide the socket assembly

back into place and secure with the four retaining screws.

6. Reset the lamp run time in the system menu.

7. Always be sure to optimize the lamp after lamp replacement.

Do not operate this device with open cover

Lamp Optimization

The lamp orientation and optimization must be adjusted after every lamp change. This

procedure centers the lamp in the reflector. Proper optimization will increase lamp life and

ensure a bright, crisp, and even output. Improper optimization may add a yellow tint to the

lamp output and reduce intensity. The minimum deviation amount is 1.0mm. Running the

fixture within a lower deviation can cause damage to the lamp and/or lens.

The Design Spot 575E™ lamp holder is aligned at the factory. However, due to slight

imperfections in all lamps, fine adjustments will improve light performance. Please follow the

procedure below for proper lamp optimization:

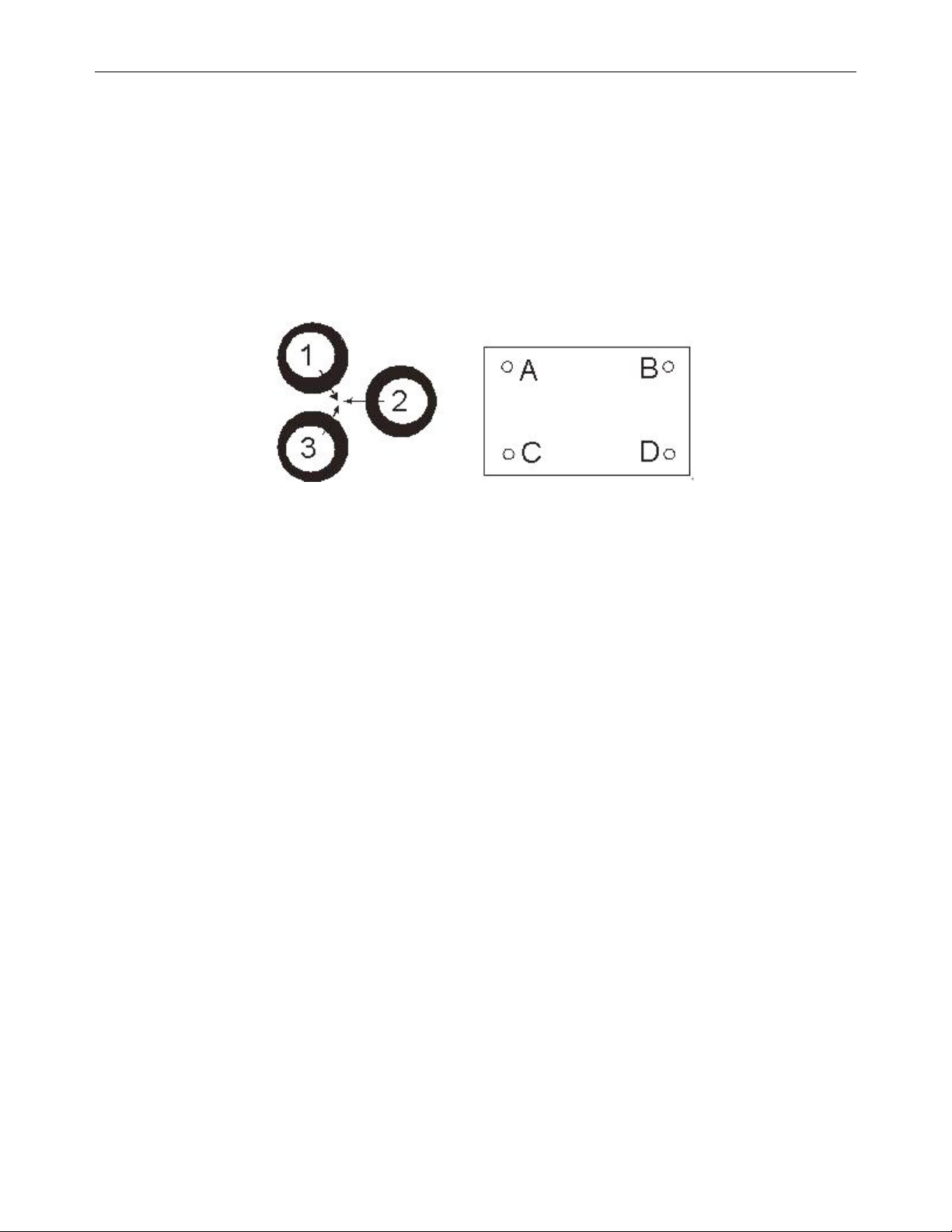

1. Using either a DMX controller or the control panel on the unit (see “SPOT” in the

fixture menu on page 33), strike the lamp and focus the light on a flat surface (beam

open, white, no gobo, no effect).

2. Center the hot-spot (the brightest part of the beam) using the 3 adjustment screws

labeled 1, 2, and 3 as illustrated on the next page. Turn one screw at a time to drag

the hot-spot diagonally across the projected image. If you cannot detect a hot-spot,

adjust the lamp until the light is even.

©Elation Professional® 11

Design Spot 575E™

Page 12

Design Spot 575E™

3. To reduce a hot-spot, pull the lamp in by turning all three screws clockwise a 1/4-turn

at a time until the light is evenly distributed.

4. If the light is brighter around the edge than it is in the center, or if light output is low,

the lamp is too far back in the reflector. "Push” the lamp out by turning each of the

adjustment screws ("1, 2, 3”) counterclockwise turn until the light is bright and evenly

distributed.

Please remember that a MSR 575 SA/2 DE lamp is not a hot-restrike lamp therefore, you

must wait approximately 15 minutes before you can attempt to strike the lamp once it has

been turned off.

©Elation Professional® 12

Design Spot 575E™

Page 13

Design Spot 575E™

6. MOUNTING AND INSTALLATION

Cautions:

For added protection mount the fixtures in areas outside walking paths, seating areas, or in

areas were the fixture might be reached by unauthorized personal.

Before mounting the fixture to any surface, make sure that the installation area can hold a

minimum point load of 10 times the device’s weight.

Fixture installation must always be secured with a secondary safety attachment, such as an

appropriate safety cable.

Never stand directly below the device when mounting, removing, or servicing the fixture.

Before taking into operation for the first time,

the installation has to be approved by an expert.

When installing the device, make sure there is no highly

inflammable material within a distance of min. 0,5m

Mounting

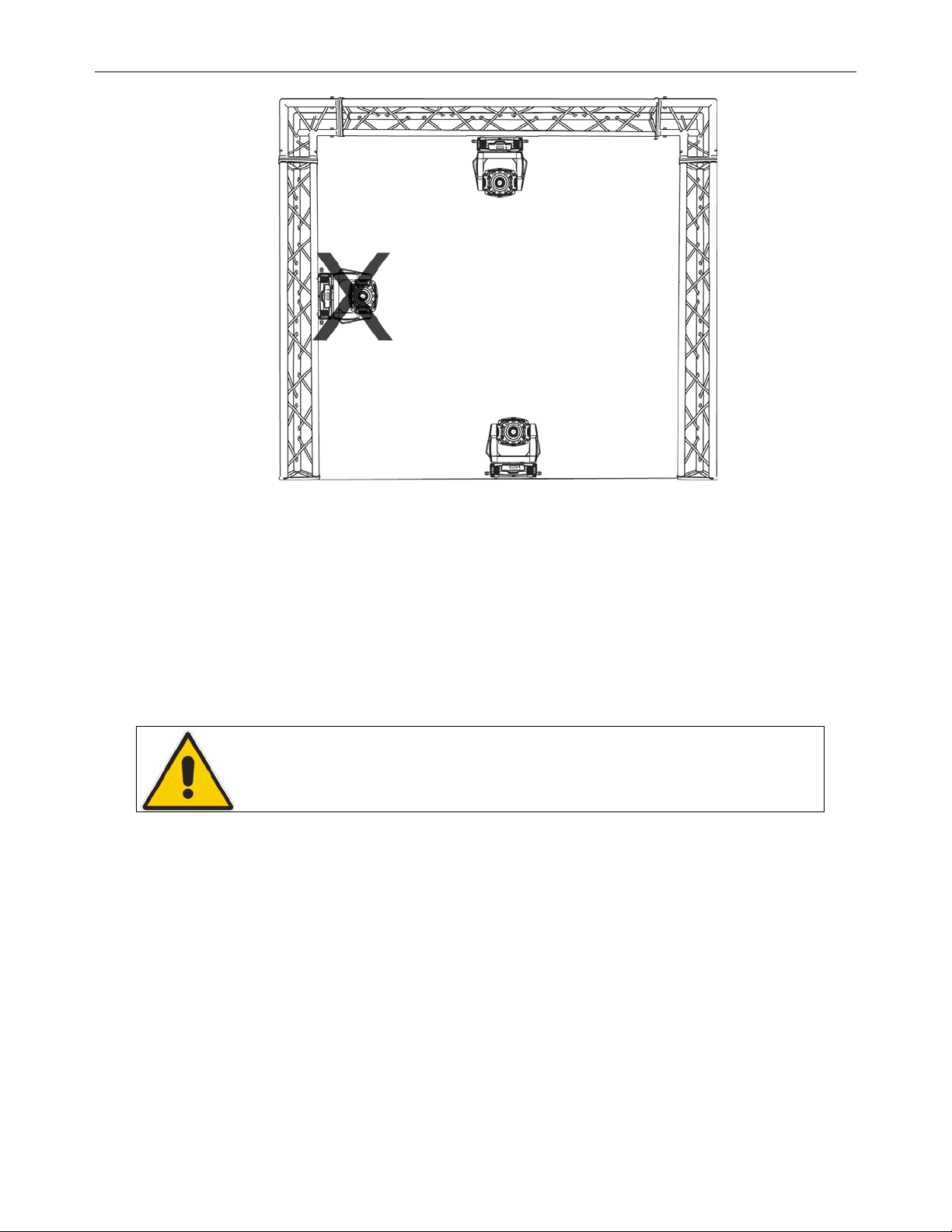

The DESIGN SPOT 575E™ is fully operational in two different mounting positions, hanging

upside-down from a ceiling, or set on a flat level surface (see illustration on next page). Be

sure this fixture is kept at least 0.5m away from any flammable materials (decoration etc.).

Always use and install the supplied safety cable as a safety measure to prevent accidental

damage and/or injury in the event the clamp fails.

Refer to regulati o ns BGV C1 (f ormer ly V BG 70) and DIN VDE0 71 1-217

for proper installation in Europe To ensure proper installation, only

qualified sta ff shoul d attem pt instal lati on.

©Elation Professional® 13

Design Spot 575E™

Page 14

Design Spot 575E™

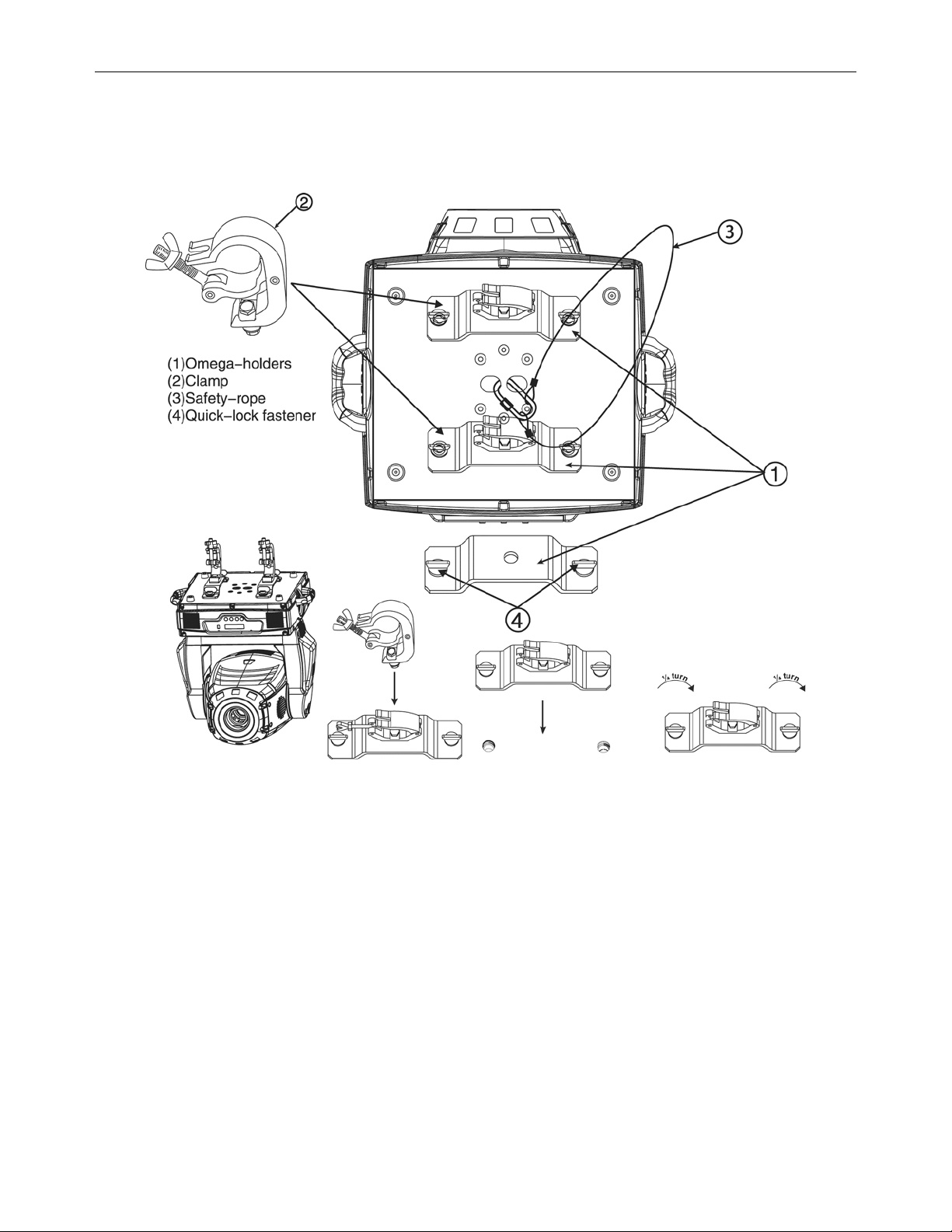

Mounting poi nts

Overhead mounting requires extensive experience, including amongst others calculating

working load limits, a fine knowledge of the installation material being used, and periodic

safety inspection of all installati on mate rial and the fixture. If you lack these qualificati o ns, d o

not attempt the installation yourself. Improper installation can result in bodily injury.

CAUTION!

Be sure all electrical connections are performed by a qualified

electrician.

Be sure to complete all rigging and installation procedures before connecting the main

power cord to the appropriate wall outlet.

Clamp Mounting

The Design Spot 575E™ provides a unique mounting bracket assembly that integrates the

hanging yoke as well as the safety cable rigging point in one unit (see the illustration below).

When mounting this fixture to truss be sure to secure an appropriately rated clamp to the

hanging yoke using a M10 screw fitted through the center hole of the hanging yoke. As an

©Elation Professional® 14

Design Spot 575E™

Page 15

Design Spot 575E™

added safety measure be sure to attached at least one properly rated safety cable to the

fixture using on of the safety cable rigging point integrated in the bracket assembly

Securing the DESIGN SPOT 575E™

Regardless of the rigging option you choose for your Design Spot 575E™ always be sure to

secure your fixture with a safety cable. The fixture provides a built-in rigging point for a

safety cable on the hanging bracket as illustrated above. Be sure to only use the designated

rigging point for the safety cable and never secure a safety cable to a carrying handle.

©Elation Professional® 15

Design Spot 575E™

Page 16

Design Spot 575E™

7. UNDERSTANDING DMX

DMX-512: DMX is short for Digital Multiplex. This is a universal protocol used by most

lighting and controller manufactures as a form of communication between intelligent fixtures

and controllers. A DMX controller sends DMX data instructions from the controller to the

fixture. DMX data is sent out as serial data that travels from fixture to fixture via the DATA

“IN” and DATA “OUT” XLR terminals located on all DMX fixtures (most controllers only have

a DATA “OUT” terminals). DMX Linking: DMX is a language allowing all makes and models

of different manufactures to be linked together and operate from a single controller, as long

as all fixtures and the controller are DMX compliant. To ensure proper DMX data

transmission, when using several DMX fixtures try to use the shortest cable path possible.

The order in which fixtures are connected in a DMX line does not influence the DMX

addressing. For ex ample; a fi xtu re assi gned a D MX address of 1 may be placed anyw her e in

a DMX line, at the beginning, at the end, or anywhere in the middle. Therefore, the first

fixture controlled by the controller could be the last fixture in the chain. When a fixture is

assigned a DMX address of 1, the DMX contr oller know s to send DA TA assigned to address

1 to that fixture, no matter where it is located in the DMX chain.

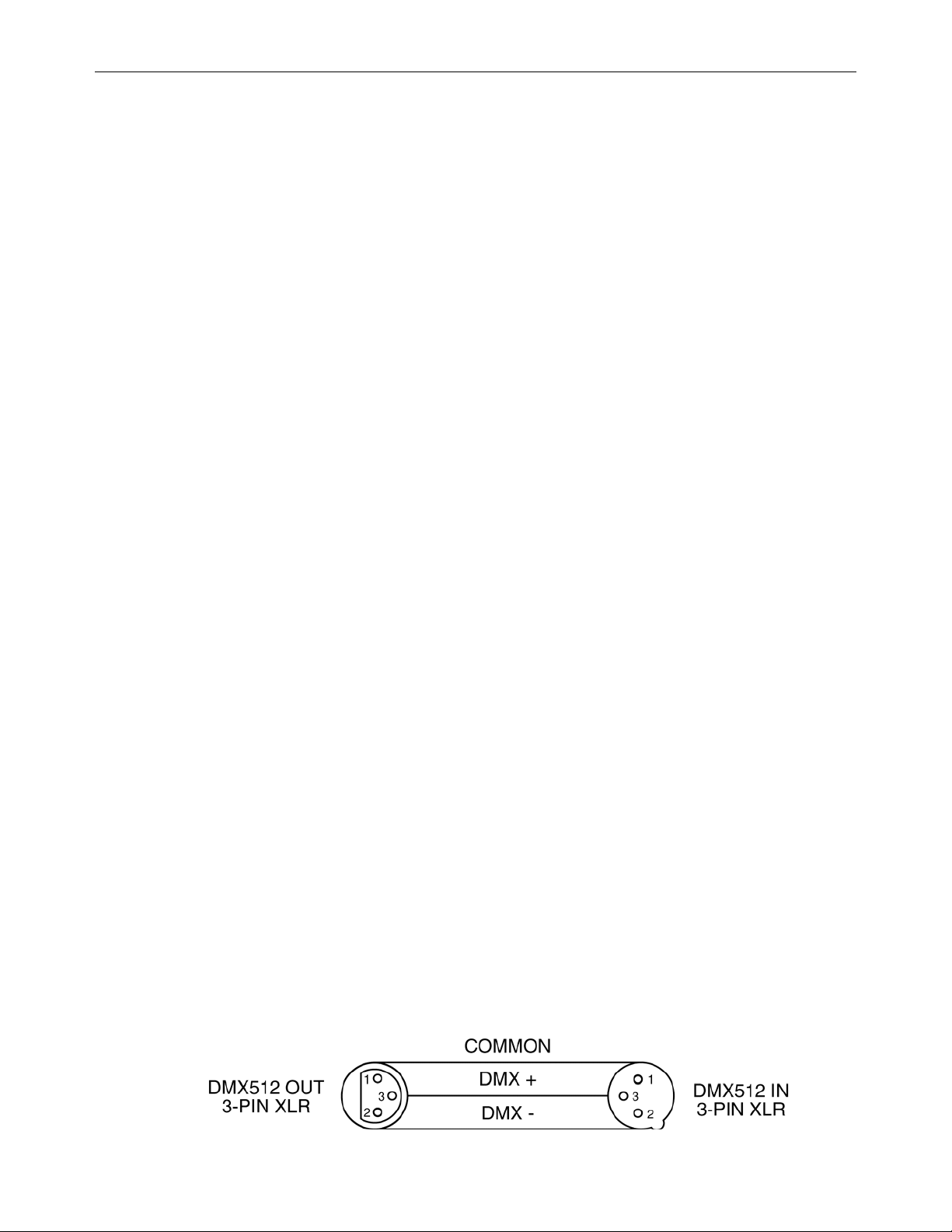

Data Cable (DMX Cable) Requirements (For DMX and Master/Slave Operation): The

Design Spot 575E™ can be controlled via DMX-512 protocol. The Design Spot 575E™ is a

24 channel DMX fixture. The DMX address is set electronically using the controls on the

LCD menu. Your fixture and your DMX controller require a standard 3-pin or 5-pin XLR

connector for data input and data output (Figure below is of a 3-Pin XLR connector). If you

are making your own cables, be sure to use standard two conductor shielded cable (This

cable may be purchased from your Elation dealer or at most professional lighting retailers).

Your cables should be made with a male and female XLR connector on either end of the

cable. A lso, remember that DMX c a bl e must b e da i s y ch ained a nd cannot be split. unl ess yo u

are using an approved DMX splitter such as the Elation Opto Branch 4™ or DMX

Branch/4™.

©Elation Professional® 16

Design Spot 575E™

Page 17

Design Spot 575E™

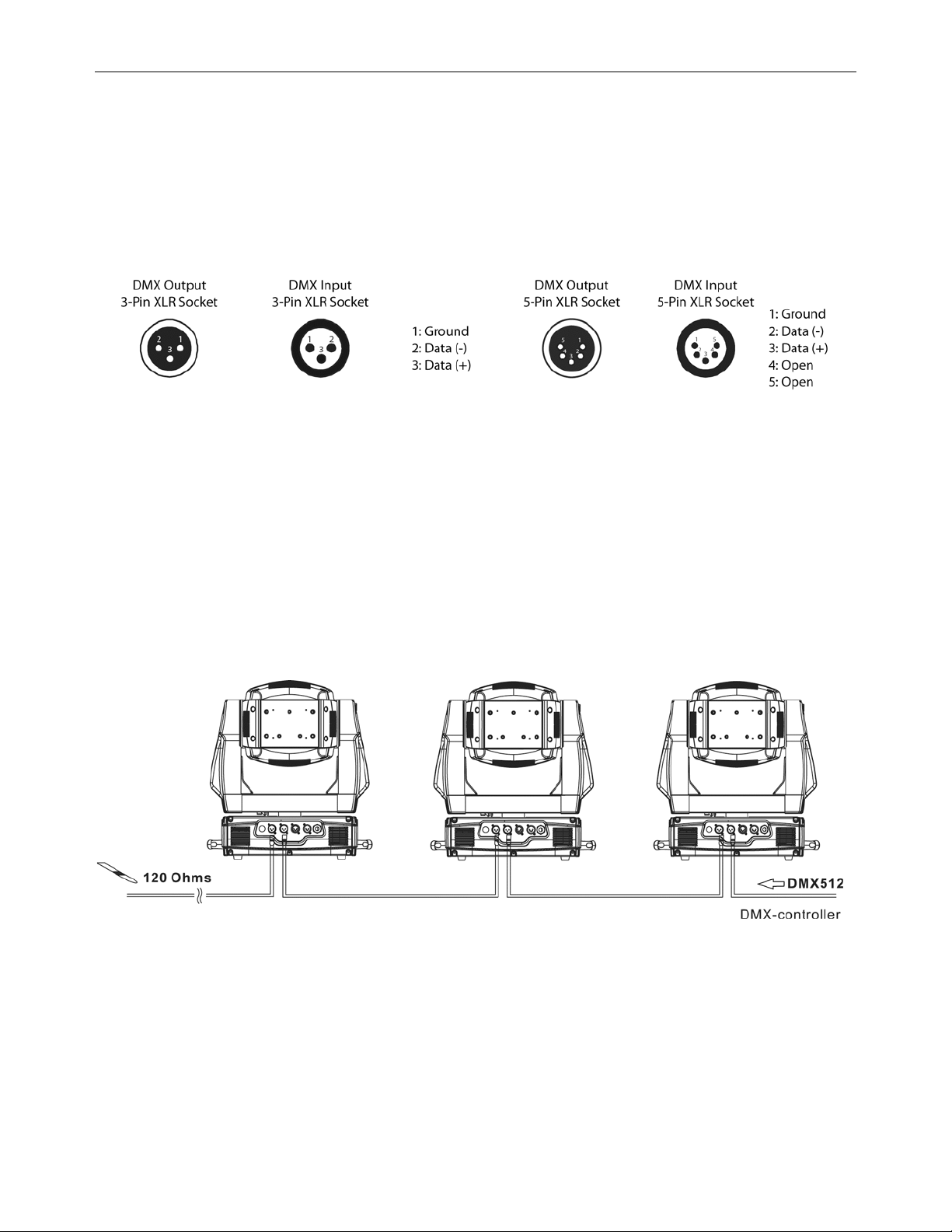

Be sure to follow the pin configuration chart below when making your own cables. Do not

use the ground lug on t he XLR connec tor. Do not connect the cable’s shield con ducto r to the

ground lug or allow the shield conductor to come in contact with the XLR’s outer casing.

Grounding the shield could cause a short circuit and erratic behavior.

DMX-512 control connection

Connect the provided XLR cable to the female 3-pin XLR output of your controller and the

other side to the male 3-pin XLR input of the moving head (Please refer to the diagram

below.). You can chain multiple moving heads together through serial linking. Always be

sure daisy chain your in and out data connections, never split or “Y” your DMX connections

unless you are using an approved DMX splitter such as the Elation Opt o B ranch 4™ o r DMX

Branch/4™.

DMX-512 connection with DMX terminator

When longer runs of cable are used, you may need to use a terminator on the last fixture to

avoid erratic behavior. A terminator is a 90-120 ohm 1/4 watt resistor that is connected

between pins 2 and 3 of a male XLR con necto r (DA TA + and DAT A -). This fixture is i nsert ed

in the female XLR conn ector of th e last fixtu re i n your d aisy chain t o ter minate the l ine. Usi ng

©Elation Professional® 17

Design Spot 575E™

Page 18

Design Spot 575E™

a cable terminator (Elation pa rt number Z-DMX/T) will decr ease the possibilities of erratic

behavior.

Fixture DMX addressing;

All fixtures should be given a DMX starting address when using a DMX controller, so the

correct fixture responds to the correct control signal. This digital starting address is the

channel number from which the fixture starts to “listen” to the digital control information sent

out from the DMX controller. The allocation of this starting DMX address is achieved by

setting the correct DMX address on the digital display located on the head of the fixture.

You can set the same starting address for all fixtures or a group of fixtures, or set different

address for each individual fixture. Be advised that setting all you fixtures to the same DMX

address will subsequently control all fixtures in the same fashion, in other words, changing

the settings of one channel will affect all the fixtures simultaneously.

If you set each fixture to a different DMX address, each unit will start to “listen” to the

channel number you have set, based on the quantity of control channels (DMX channels) of

each fixture. That means changing the settings of one channel will only affect the selected

fixture.

In the case of the Design Spot 575E™, which is a 24 channel fixture, you should set the

starting DMX address of the first unit to 1, the second unit to 25 (24 + 1), the third unit to 49

(24 + 25), and so on.

Note: During start-up the Design Spot 575E™ will automatically detect whether a DMX data

signal is being received or not. If DMX data signal is being received, the display will show

"A.XXX" (XX X representing the actual DMX address). If the fixture is not receiving a DMX

©Elation Professional® 18

Design Spot 575E™

Page 19

Design Spot 575E™

signal the display will flash "A.XXX" (XXX representing the actual DMX address).

If your fixture is connected to a DMX controller and the display is flashing (not receiving a

DMX signal), please check the following:

- The 3 PIN XLR plug (cable w ith DMX sign al fr om cont roller ) is no t conn ected or is not

inserted completely into the DMX input jack.

- The DMX controller is switched off or defective.

- The DMX cable or connector is defective.

- A DMX terminator has been inserted into the last fixture in your DMX chain.

©Elation Professional® 19

Design Spot 575E™

Page 20

Design Spot 575E™

8. Display LED Indicators.

The Design Spot 575E™ has two LED indicators on the display. These indicators are

designed to give a quick visual indication of the fixtures’ status. The illustration below details

the functionality of the LED indicators.

.. .

.

DMX OK

Lamp on

NO DMX

Lamp on

NO DMX

Lamp off

DMX OK

Lamp off

The first LED indicators represents DMX signal:

• If the indicators is on a clean DMX signal is present

• If the indicator is off there is no DMX signal present

The second LED indicator represents lamp condition:

• If the indicator is on the lamp is struck and in working condition

• If the LED indicator is off the lamp has not struck, has been turned off, or is bad.

©Elation Professional® 20

Design Spot 575E™

Page 21

Design Spot 575E™

9. FIXTURE MENU

On-Board System Menu: The DESIGN SPOT 575E™ comes with an easy to navigate

system menu. This next section will detail the functions of each command in the system

menu.

LCD Control Panel: The control panel located on the side of the fixture allows you to

access the main menu and make necessary adjustments to the Design Spot 575E™.

During normal operation, tapping the “MODE/ESC” key once will access the fixture’s main

menu. Once in the main menu you can navigate through the different functions and access

the sub-menus with the Up and Down buttons. Once you reach a field that requires

adjusting, tap the ENTER button to activate that field and use the UP and Down button to

adjust the field. Tapping the Enter b utton on ce more will conf irm your setting. You may exit

the main menu at any time without making any adjustments by tapping the MODE/ESC

button.

Set DMX Address

Value Display

Set To Slave

Auto Progra m

Func ti o n Mo de

Music Control

Time

Information

Temperature

Current Time

Total Run Time

Total Lamp Time

Lamp Off Time

Clear Lam p Time

Base Temperat ure

A001~AXXX

PAN M o v ing …

Slave1, Sl av e2, Slave3

Master / Alone

Master / Alone

XXXX (Hours)

XXXX (Hours)

XXXX (Hours)

XXXX (Minute)

ON/OFF

XX /

DMX addr es s s et t ing

DMX value display

Slave sett ing

Auto program

Music control

Total po wer r un t ime

Fixture running time

Lamp running time

Lamp off time

Reset lamp time

Base temperature

Info

Information

Head Temperat ure

XXX/

display

Head te mp erature

display

Software

Version

©Elation Professional® 21

Ver1.0 Display will read out

current firmware version

Design Spot 575E™

Page 22

Design Spot 575E™

Lamp On or Off

Automatic La-On

Lamp On Via DMX

Lamp Off Via DMX

Lamp Control

Lamp Off No DMX

Lamp On at Temp.

Lamp Off at Temp.

ON/OFF

ON/OFF

ON/OFF

ON/OFF

OFF, 0 F F~1 9 M

45C, 20~79/

130C, 80~139 /

Status Set t ings Address via DMX

No DMX St at us

Pan Reve rs e

Til t Re ver se

Fine Resolut ion

ON/OFF

Auto/Music/Close/Hold

ON/OFF

ON/OFF

ON/OFF

Manual Lam p on/off

Automatic lamp strike

when power is applied

Enables Lamp on via

DMX

Enables lamp off via

DMX

Lamp off if no DMX is

present

Lamp restart at temp.

Lamp off at temp.

Add via D MX

Auto run if n o D M X

Pan Reve rs e movement

Tilt Reverse move ment

Fine resol ut ion switch

Pan Degree

Feedback

Movement Speed

Mic Sensitivit y

Fans Control Auto Fans Speed

630/540

ON/OFF

Speed 1~ 4

70%, 0~99 %

Pan Degree Select

Scan Feedback switch

Scan Mode Select

Micropho ne Sens itivit y

Automatic fan speed

Personality

Temperature

C/F

High Fans Speed

Celsius

Fahrenheit

control

Fans set to high speed

Change t emperature

readout f rom C˚ to F˚

Initial Effect PAN PAN =XXX User selec table PAN

Reset Default ON/OFF Restore factory defaults

home (Start-up) position

©Elation Professional® 22

Design Spot 575E™

Page 23

Design Spot 575E™

Reset All

Reset Pan&Tilt

Reset Colors

Reset Gobos

Reset Funct ion

Reset Shutter

Reset Oth ers

Reset all motors

Reset Pan and tile

motors

Reset color wheel

Reset gobo wheel

motors

Reset shutt er and/or

dimmer

Reset oth er motors

Test Channe l PAN …… Test the various

functions of the fixture

Manual Contr ol PAN

PAN =XXX

Allows the us er manual

control all functions of

the fixture

Effect Adjust

Calibrate

Values

--Password--

Password=XXX

Allows manual

calibratio n of int ernal

Color whe el

User Mo de XXXXX X (Band)

User Mo de A

User Mode B

User Mo de C

Color whe el=XXX

effect motors.

Password “050”

0 ~ 255

This mode chan ges the

channel functions to

match similar fixtures

from differ ent

manufact ures for easier

Users Mode Set

control.

Edit User Mode PAN PAN = CH01 Preset User modes

Select

Programs

Auto Progra m

Part 1

Auto Progra m

Progra m 1 ~ 10 Program 1

Progra m 1 ~ 10 Program 2

Progra m 1 ~ 10 Program 3

Allows the us er to select

from 1 of 10 int ernal

programs

Part 2

Auto Progra m

Edit Program

Edit Program Progra m 1

©Elation Professional® 23

Part 3

:

Progra m Test

Step

Design Spot 575E™

(“STEP XX”) Test ing program

Page 24

Design Spot 575E™

Program 10 01=SCxxx

Step

64=SCxxx

Edit Scen es Edit Scen e 001

Rec. Controller XX~XX Automatic s c ene record

~ Edit Scene

250

Pan, Tilt…

--Scenes

Time-Input By

Outside

Pan=xxx…

TIME=xx.xs

Progra m in l oop

Save and exit

Save and auto matic ally

return

Scene edit m ode

1. DMX address setting

After applying power and the rest process the Design Spot 575™ LCD will display the

fixture’s current DMX. If the fixture is not receiving a DMX signal the display will flash

continuously. To set or adjust a DMX address, please follow the procedure below:

1. Toggle through the menu by pressing the Up and Down buttons until the display

shows “Set DMX Address.” Tap the enter button to make changes to the address,.

2. While the current three-digit address is flashing, use the Up and Down buttons to

select adjust the address. Lock your new address into the unit’s memory by

pressing the Enter button.

The DMX address is non-destructible and will remain in the fixture’s memory even

when power to the fixture has been switch ed off. Memory is backed-up and r etai ned by

an internal power source with a five year shelf life.

2. Display the DMX 512 value of each channel

With this function you can display the DMX 512 value of each channel. The display will

automatically readout the changing DMX values as they are received.

3. Slave setting

With this function, you can define the device as slave for operation in Master/Slave

mode.

©Elation Professional® 24

Design Spot 575E™

Page 25

Design Spot 575E™

4. Auto Program

This function allows the internal programs to run. The desired program is selected in the

“Select program” section of the control menu. You can set the number of steps under

“Edit program”. You can edit the individual scenes under “Edit scenes”. With this

function, you can run the individual scenes either automatically, i.e. with the adjusted

Step-Time.

5. Music control

With this function, you can run the internal program via sound.

Information:

1. Time information

Curren t time

This function displays the running time of the fixture from the last power on. The

display shows “XXXX”, where “XXXX” represents the num ber of hours the f i xture

has been running. This counter is automatically reset after every power-on.

Machine on time

This function tracks the total running time of the fixture from the very first start-up.

Where “XXXX ”represent s the total number o f running hours. This time is none

destructive and will remain in the fixtures memory indefinitely.

Lamp on time

This function tracks the total number of lamp running hours. Where “XXXX”

represents the number of hours the lamp has been running. This counter should be

reset after every lamp change.

Lamp off time

This function displays the running time of the lamp from the last power on. The

display sh ows “XXXX”, where “XXXX” repre sents the number of hours the lamp has

©Elation Professional® 25

Design Spot 575E™

Page 26

Design Spot 575E™

been running since it was last struck. This counter is automatically reset after every

power-on.

Clear lamp time

This function resets the lamp “ON” time to zero. Please reset the lamp “ON” time at

every lamp replacement. This procedure tracks the lamp running time so the lamp

can be replaced at the end of it’s recommended duty cycle.

• Select “Clear lamp time” in the system menu.

• The LCD will display “ON” or “OFF.” Were “ON” will reset the lamp time.

• Press enter to confirm.

• Press the Mode/Esc-button to return to the main menu.

2. Temp. Info.

Base Temp – This function will display the base temperature of the fixture.

Inside head Temp – This function will display the head temperature of the fixture.

3. Software version

This function will display the current operating software version of the fixture.

• Select “Software Version” in the system menu.

• Press enter to confirm.

• The LCD will read “V-X.X”, “X.X” represents the version number, e.g. “V-1.0”,

“V-2.6”.

• Use the UP and DOWN buttons to toggle through the software version of

different IC’s.

• Press the Mode/Esc-button to return to the main menu.

LAMP CONTROL:

1. Lamp on/off

With this function you can switch the lamp on or off via the Control Board.

• Select "Lamp on/off" by turning the LCD controls.

©Elation Professional® 26

Design Spot 575E™

Page 27

Design Spot 575E™

• Press the LCD controls, the display shows “ON” or “OFF”.

• Turn the LCD controls to select “ON” if you wish to strike the lamp or “OFF” in order

to switch it off.

• Press the LCD controls to confirm.

• Press the Mode/Esc-button in order to return to the main menu.

2. Automatic La-On

With this function you can select if the lamp will be switched on when switching the

power on. Select “ON” by turning the LCD controls if you wish to enable this function or

“OFF” if you don’t.

3. Lamp on via external controller

With this function you can select if you can switch the lamp on via an external controller.

Select “ON” by turning the LCD controls if you wish to enable this function or “OFF” if

you don’t.

4. Lamp off via external controller

With this function you can select if you can switch the lamp off via an external controller.

Select “ON” by turning the LCD controls if you wish to enable this function or “OFF” if

you don’t.

5. Lamp Off if no DMX

With this function you can select to switch off the lamp off automatically if there is no

DMX signal). Select “ON” by turning the LCD controls if you wish to enable this function

or “OFF” if you don’t.

6. Lamp on at temp.

With this function you can set the inside temperature from which the projector will

restrike the lamp after automatic lamp shut off.

7. Lamp off at temp.

With this function you can set the inside temperature at which the projector will

©Elation Professional® 27

Design Spot 575E™

Page 28

Design Spot 575E™

automatically switch the lamp off. Turn the LCD controls to select the maximum inside

temperature between 80° C and 139° C . Insid e tempe ratur es below 90° C are n ot criti cal .

90° C and more should lead to the lamp being switched off. Please note that the outside

temperature should not exceed 45° C.

PERSONALITY:

1. Status setting

A. Address via DMX - This function allows the DMX address to remotely be

adjusted from a DMX console. This setting requires special settings for both the

controller and the fixture. RDMX is on by default. Follow the procedure listed

below to access the RDMX functions:

Fixture Settings:

1. Access the main menu.

2. Tap the UP button until “Address via DMX” is displayed, press ENTER.

3. Tap the UP button until “RDMX” is displayed, press ENTER.

4. The display will show “ON/OFF.”

5. Press the UP button to display “ON” to activate this function, or “OFF” to

deactivate this function.

6. Press ENTER to confirm.

7. Press MODE/ESC to return to the main menu.

Controller Settings:

1. Set the DMX value of channel 1 to a value of 7.

2. Set the DMX value of channel 2 to a value of 7 or 8. When channel 2 is

set to "7" you can adjust the starting address between 1 and 255. When

set to "8" you can adjust the starting address between 256 and 511.

3. Use channel 3 to set your desired DMX starting address. For example: If

you want to set the starting address to 57, set channel 1 to a value of “7,”

set channel 2 to a value of “7” and use channel 3 to set your address to

57 by selecting a channel value of 57. Example 2: If you want to set the

starting address to 420, set channel 1 to a value of “7,” channel 2 to "8"

©Elation Professional® 28

Design Spot 575E™

Page 29

Design Spot 575E™

and channel 3 to "164" (256+164=420).

4. Wait for approximately 20 seconds for the unit to complete the

address reset function.

B. Run if no DMX – This function dictates how the fixture will function if it

looses DMX signal during normal operation. The default function is set to

hold, in which the fixture will lock into the last DMX signal it received and

remain in that position until it is turned off or begins receiving a new DMX

signal. If the fixture is turned on without any DMX signal, the fixture will

automatically go in to sound-active mode. Available settings are: “Close” –

Shutter flags will close. “Hold” – Fixture will remain at it’s last settings. “Auto”

– Fixture will go into stand-alone mode, runnin g the built-in program. “Music”

– The fixture will go into sound-active mode.

C. Pan Reverse - This function allows you to invert all pan movements. Use

the Up and Down buttons to turn this function On and Off. Press the Enter

button to accept the change or the Mode button to cancel and return to the

main menu.

D. Tilt Reverse - This function allows you to invert all tilt movements. Use the

Up and Down buttons to turn this function On and Off. Press the Enter

button to accept the change or the Mode button to cancel and return to the

main menu.

E. Fine resolution – This function changes the DMX channel operation from

8bit to 16bit.

F. Pan Degree – This function changes the maximum Pan resolution from

either 540˚ or 630˚. The default function is 540˚.

G. Feedback – This function turns the feedback correction on or off. This

function is set to on as default.

©Elation Professional® 29

Design Spot 575E™

Page 30

Design Spot 575E™

H. Movement Speed – This function changes the order of the DMX channels

to more closely match similar fixtures from different vendors, thus allowing

the user easier functionality when programming. There are four different

mode variations.

I. Mic Sensitivity – This function make the internal microphone more or less

sensitive to sound. This function only works in conjunction with the sound

active modes. The default setting is 70% and setting range from 0 % to 99

%.

2. Fans Control - This function is used to change the functionality of the internal cooling

fans. The available selections are: 1) “AUTO” – The fans will automatically switch

between low and high speeds depending on the internal operating temperature. 2)

“HIGH” – The fans will run in high-speed mode regardless of operating temperature. 3)

“LOW” – The fans will remain in low speeds regardless of internal operating

temperature.

10. Temperature C/F – This function changes the temperature unit readout from either the

temperature Celsius or Fahrenheit.

11. Initial effect - With this function, you can adjust with which value the respective

channels will start.

12. Restore factory settings - With this function you can restore the factory settings of the

device. All settings will be set back to the d efault values (s haded ). Any e dited sce nes will

be lost.

RESET-FUNCTIONS:

This function allows the user to reset all motors or individual motors. The reset functions

can be executed via the on-board menu functions or via a DMX using a DMX console.

©Elation Professional® 30

Design Spot 575E™

Page 31

Design Spot 575E™

1. Effect Adjust

Test function of each channel

With this function you can test each channel on its (correct) function.

Lamp adjustment (manual control)

With this function, you can adjust the lamp more easily. All effects will be canceled, the

shutter opens and the dimmer intensity will be set to 100 %. With the individual functions,

you can focus the light on a flat surface (wall) and optimize the lamp.

Calibrate values

With this function, you can calib rate and a djus t the effect wheel s to th eir corr ect positi ons.

The password of calibrate values is 050.

Users mode set

User mode

With this function, you can create user defined channel orders.

Edit User mode

With this function, you can adjust the preset user defined channel order.

Edit program

Select program

With this function, you can select the program for the Program Run.

Edit program

With this function, you can edit the internal programs.

Edit scenes

With this function, you can edit the scenes of the internal programs.

Auto scenes rec

The moving head features an integrated DMX-recorder by which you can transmit the

©Elation Professional® 31

Design Spot 575E™

Page 32

Design Spot 575E™

programmed scenes from your D MX -cont roller to the moving head. A djust the desi red scene

numbers via the LCD controls (from – to). When you call up the scenes at your controller,

they will automatically be transmitted to the moving head.

©Elation Professional® 32

Design Spot 575E™

Page 33

Design Spot 575E™

10. OPERATION

Operating Modes: The Power Spot 700CMY™ can operate in three different modes.

This next section will detail the differences in the operating modes.

• Stand alone mode - T he fixtur e will react to s ound, chasing t hroug h the built-i n prog rams.

• Master/Slave mode - You can daisy chain up to 16 fixtures together to get a

synchronized light show without the need of an external controller. The fixtures will react to

sound chasing to synchronized light show.

• DM X contro l mode - This function will allow you to control each individual fixtures traits

with a standard DMX-512 controller such as the Elation® Show Designer 2.

10.1 Universal DMX Control: This function allows you to use a universal DMX-512

controller such as the Elation® DMX Operator II™ or Elation® Show Designer 2™ to

control head movement, the color wheel, the shutter (strobe), and all other DMX traits.

A DMX controller allows you to create unique programs tailored to your individual

needs. The Power Spot 700CMY™ uses 16 DMX channels. See page 27 for detailed

description of the DMX traits.To control your fixture in DMX mode, follow the set-up

procedures on pages 13-15 as well as the set-up specifications that are included with

your DMX controller. Use the controller’s faders to control the various DMX fixture

traits.This will allow you to create your own programs.

9.1.1 Follow the instruction on page 18 to set the DMX address.

9.2.2 For longer cable runs (more than a 100 feet) be sure to use a terminator on the last

fixture.

9.2.3 For help operating in DMX mode consult the manual included with your DMX

controller.

9.2 Stand-Alone Operation (Sound Active): This mode allows a single fixture to run to

the beat of the music. Only use this mode when running a single fixture, or when

running several fixtures as individuals.

9.2.1 Mount your fixture in a secure and stable manner.

©Elation Professional® 33

Design Spot 575E™

Page 34

Design Spot 575E™

9.2.2 Access the main menu and select the AUDI function, this will give you access to

the audio submenu. See page 16 for the menu breakdown.

9.2.3 In the audio submenu choose the audio chase speed, fast or slow. Slow (ASLW)

will trigger the chase seq uence to every two b eats, while fast (AFST ) will trigger th e

chase impulse every beat. See page 16 for more details.

9.2.4 Be sure the Master (MSTR) function is switched “ON,“ and the SVPT function is

switched “OFF.“

9.2.5 Choose your room size. The size function allows you to choose a the approximate

size of the room (NORM, BIG, MIDL, SMAL). The built-in programs will

automatically adjust to your slection to optimize light output for your room.

9.2.6 Use the sound sensitivity knob on the side control panel to make the unit more or

less sensative to sound. Turning the knob in clockwise direction will make the unit

more sensetive to sound, while turning the knob counter-clockwise will make the

unit less sensetive to sound. Note: This unit will react to the low frequiencies of a

sound source, tapping on the fixture or high pitched sound may not trigger the

fixture.

9.3 Master-Slave Operation (Sound Active): This function will allow you to link up to 16

fixtures together and operate without a controller. The fixtures will be sound activated.

In Master-Slave operation one fixt ure will act a s the co ntrolling fixture and the others will

react to the controlling fixtures programs. Any fixture can act as a Master or as a Slave.

9.3.1 Using standard XLR microphone cables, daisy chain your fixtures together via the

XLR connector on the rear of the fixtures. Remember the Male XLR connector is

the input and the Female XLR connector is the output. The first fixture in the chain

(master) will use the female XLR connector only - The last fixture in the chain will

use the male XLR connector only. For longer cable runs we suggest a terminator

at the last fixture.

9.3.2 Follow the same procedures listed in the previous Stand-Alone section. With two

exceptions; Be sure the first unit in the chain is selected as the “master“ (MSTR) is

turned on in the audio submenu. All other fixtures must be in “slave“ mode (SVPT)

turned on in the audio submenu.

11. DMX CHANNEL TRAITS:

©Elation Professional® 34

Design Spot 575E™

Page 35

Design Spot 575E™

The chart below details the channel layout for 24 DMX channels (default).

In 8bit mode the “Pan Fine” and “Tilt Fine” channels are not used, thus converting the fixture

into a 22-channel DMX fixture.

CHANNEL 1: Pan Movement (max. 630° or 540˚ User Selectable)

CHANNEL 2: 16bit Pan Movement (pan fine)

CHANNEL 3: Tilt Movement (max. 265°)

CHANNEL 4: 16bit Tilt Movement (tilt fine)

CHANNEL 5: Color Wheel

CHANNEL 6: Cyan Filter

CHANNEL 7: Magenta Filter

CHANNEL 8: Yellow Filter

CHANNEL 9: Gobo Wheel 1 (Rotating)

CHANNEL 10: Gobo Index, Gobo Rotation Speed/Direction (Gobo Wheel 1)

CHANNEL 11: Gobo Wheel 2 (Rotating)

CHANNEL 12: Gobo Index, Gobo Rotation Speed/Direction (Gobo Wheel 2)

CHANNEL 13: 3-Facet Prism Control

CHANNEL 14: Focus Control Motor (Near ~ Far)

CHANNEL 15: Variable Zoom

CHANNEL 16: Strobe (0-13Hz), and Shutter close/open function + random strobe

CHANNEL 17: Dimmer (Intens ity) Cont rol

CHANNEL 18: Iris (Closed to Open)

CHANNEL 19: Frost Filter (Minimum to Maximum)

CHANNEL 20: Animation (Rotation/Insert)

CHANNEL 21: CMY Speed

CHANNEL 22: Color Macros (CMY and Color Wheels)

CHANNEL 23: Speed Control (Pan/Tilt movement, blackout selection)

CHANNEL 24: Special (Auto program control + lamp on, motor reset, lamp switch off)

DMX channel function and values:

©Elation Professional® 35

Design Spot 575E™

Page 36

Channel 1 - Pan movement 8bit:

Channel 2 - Pan fine 16bit

Channel 3 - Tilt movement 8bit:

Channel 4 - Tilt fine 16bit

Channel 5 - Color Wheel:

0-13 Open / white

14-27

28-41

42-55

56-69

70-83

84-97

98-111

112-127

Red

Blue

Green

Yellow

Magenta

Orange

UV Filter

Pink

128-187 Forwards rainbow effect from fast to slow

188-193 No rotation

194-255 Backwards rainbow effect from slow to fast

Channel 6 - Cyan Color Wheel:

0-255 Cyan (0-white, 255-100% Cyan)

Channel 7 - Magenta Color Wheel:

0-255 Magenta (0-white, 255-100% magenta)

Channel 8 - Yellow Color Wheel:

0-255 Yellow (0-white, 255-100% Yellow)

Channel 9 – Gobo Wheel 1 - rotating gobos:

0-9 Open

10-19 Gobo 1

20-29 Gobo 2

30-39 Gobo 3

40-49 Gobo 4

50-59 Gobo 5

60-69 Gobo 6

70-89 Gobo 1 shake slow to fast

90-109 Gobo 2 shake slow to fast

Design Spot 575E™

©Elation Professional® 36

Design Spot 575E™

Page 37

110-129 Gobo 3 shake slow to fast

130-149 Gobo 4 shake slow to fast

150-169 Gobo 5 shake slow to fast

170-189 Gobo 6 shake slow to fast

190-255 Gobo Wheel Scroll – Continuous rotation slow to fast

Channel 10 – Gobo Wheel 1- Indexing, rotation:

0-127 Gobo indexing

128-187 Forwards gobo rotation from fast to slow

188-193 No rotation

194-255 Backwards gobo rotation from slow to fast

Channel 11 – Gobo Wheel 2 – Rotating gobos:

0-9 Open

10-19 Gobo 1

20-29 Gobo 2

30-39 Gobo 3

40-49 Gobo 4

50-59 Gobo 5

60-69 Gobo 6

70-89 Gobo 1 shake slow to fast

90-109 Gobo 2 shake slow to fast

110-129 Gobo 3 shake slow to fast

130-149 Gobo 4 shake slow to fast

150-169 Gobo 5 shake slow to fast

170-189 Gobo 6 shake slow to fast

190-255 Gobo Wheel Scroll – Continuous rotation slow to fast

Channel 12 - Rotating gobo index, rotating gobo rotation:

0-127 Gobo indexing

128-187 Forwards gobo rotation from fast to slow

188-193 No rotation

194-255 Backwards gobo rotation from slow to fast

Channel 13 - 3 facet rotating prism, Prism / Gobo macros:

0-3 Open

4-63 Clockwise rotation from fast to slow

64-67 No rotation

68-127 Counter-Clockwise rotation from slow to fast

128-135 Macro 1

136-143 Macro 2

Design Spot 575E™

©Elation Professional® 37

Design Spot 575E™

Page 38

144-151 Macro 3

152-159 Macro 4

160-167 Macro 5

168-175 Macro 6

176-183 Macro 7

184-191 Macro 8

192-199 Macro 9

200-207 Macro 10

208-215 Macro 11

216-223 Macro 12

224-231 Macro 13

232-239 Macro 14

240-247 Macro 15

248-255 Macro 16

Channel 14 - Focus:

0-255 Continuous adjustment from near to far

Channel 15 – Variable Zoom - Seamless

0-255 Zoom adjustment from small to big

Channel 16 - Shutter, strobe:

0-31 Shutter closed

32-63 No function (shutter open)

64-95 Strobe effect slow to fast

96-127 No function (shutter open)

128-159 Pulse-effect in sequences

160-191 No function (shutter open)

192-223 Random strobe effect slow to fast

224-255 No function (shutter open)

Channel 17- Dimmer (intensity):

0-255 Intensity 0 to 100%

Channel 18 - Iris:

0-191 Max. diameter to Min. diameter

192-223 Pulse closing fast to slow

224-255 Pulse opening slow to fast

Channel 19 - Frost:

0-191 Frost 0~100%

Design Spot 575E™

©Elation Professional® 38

Design Spot 575E™

Page 39

192-223 Pulse opening fast to slow

224-254 Pulse closing slow to fast

255 Max. Frost

Channel 20 - Animation Wheel, rotating fire wheel:

0-7 Open

8-255 Forwards rotation from fast to slow

Channel 21 - Speed Of CMY And Dimmer:

0-255 Speed Maximum to Minimum

Channel 22 - Color macros - CMY and color wheel:

0-7 OFF

128-135 Macro 16

8-15 Macro1

136-143 Macro 17

16-23 Macro2

144-151 Macro 18

24-31 Macro3

152-159 Macro 19

32-39 Macro4

160-167 Macro 20

40-47 Macro5

168-175 Macro 21

48-55 Macro6

176-183 Macro 22

56-63 Macro7

184-191 Macro 23

64-71 Macro8

192-199 Macro 24

72-79 Macro9

200-207 Macro 25

80-87 Macro10

208-215 Macro 26

88-95 Macro11

216-223 Macro 27

96-103 Macro12

224-231 Macro 28

104-111 Macro13

232-239 Macro 29

112-119 Macro14

240-247 Macro 30

120-127 Macro15

248-255 Random CMY

Design Spot 575E™

©Elation Professional® 39

Design Spot 575E™

Page 40

Channel 23 - Speed pan/tilt movement:

0-225 Max to min speed

226-235 Blackout by movement

236-245 Blackout by all wheel changing

246-255 No function

Channel 24 - Lamp on/off, reset, internal programs:

0-19 Color change normal

20-39 Color change to any position

40-59 Lamp on

60-79 Lamp switch off

80-84 All motor reset

85-87 Scan motor reset

88-90 Colors motor reset

91-93 Gobo motor reset

94-96 Shutter & Dimmer motor reset

97-99 Other motor reset

100-119 Internal program 1 (secne1~8 of EPROM)

120-139 Internal program 2 (secne9~16 of EPROM)

140-159 Internal program 3 (secne17~24 of EPROM)

160-179 Internal program 4 (secne25~32 of EPROM)

180-199 Internal program 5 (secne33~40 of EPROM)

200-219 Internal program 6 (secne41~48 of EPROM)

220-239 Internal program 7 (secne49~56 of EPROM)

240-255 Music Control (scene of Program 1)

Design Spot 575E™

©Elation Professional® 40

Design Spot 575E™

Page 41

Design Spot 575E™

12. FUSE REPLACEMENT

Caution: Always replace with the exact same type fuse, unless otherwise specified by an authorized

Elation® servi ce tec hnician. Replaci ng with anythi ng othe r than th e sp ecified p art can damag e your unit

and will void your manuf ac tu res warra nty.

Warning: If you continue to blow fuses, STOP using the fixture. Contact c ustomer support for furthe r

instructions, y ou may have to retur n the u nit for se rvic ing. Continui ng to use the unit may caus e seriou s

damage.

Fuse Replacement: Locat e and remove the uni t’s power cord fro m the main power suppl y. Once the

cord has been removed located the fuse holders located on the side panel near the power input

connection. Using a flat-head screwdriver unlock the fuse holder from its’ housing by turning the holder in

a counter-clockwise direction. Once the fuse holder has been unlocked, pull back on the fuse holder

holder to exp ose the fuse. Gentl y pull out the bad f use and di scard of it p roperly and replace it with an

exact match. Reassemble in reverse order.

©Elation Professional® 41

Design Spot 575E™

Page 42

Design Spot 575E™

11. ERROR CODES:

When power is applied, the unit will automatically enter a “reset/test” mode. This mode

brings all the internal motors to a home position. If there is an internal problem with one or

more of the motors an err or c ode will flash in t he display in th e fo rm of “XXer” were as XX will

represent a function number. For example, when the display shows “02Er,” it means there is

some type of error with the channel 2 motor. If there are multiple errors during the start-up

process they will all flash in the display. For example: if the fixtures has errors on channel 1,

channel 2, and channel 5 all at the same time, you will see the er ror message “01Er ”, “02Er,”

and ”05Er” flash repeated 5 times.

If an error does occur during the initial start-up procedure the fixture will self-generate a

second reset signal and try to realign all the m otors and cor rect the errors, i f the er ror pe rsist

after a second attempt a third attempt will be made.

If after a third attempt all the errors have not been corrected the fixture will make the

following determinations: 1 ) 3 or mo re er rors - The fi xture ca nnot func tion pro perl y wi th thr ee

or more errors therefore the fixture will place itself in a stand-by mode until subsequent

repairs can be made. 2) Less than 3 errors - The fixture has less than 3 errors, therefore

most other functions will work properly. The fixture will attempt to operate normally until the

errors can be correct by a technician. The errors in question will remain flashing in the

display as a reminder of internal errors.

Pan Er

(PAN-yoke movement error) This message will appear after the reset of the fixture if the

yoke’s magnetic-indexing circuit malfunction (sensor failed or magnet missing) or the

stepping-motor is defective ( or its driving IC on the main PCB). The PAN- movement is not

located in the default position after the reset.

Tilt Er

(TILT-head movement error) This message will appear after the reset of the fixture if the

head’s magnetic-indexing circuit malfunctions (sensor failed or magnet missing) or the

stepping-motor is defective (or its driving IC on the main PCB). The TILT- movement is not

©Elation Professional® 42

Design Spot 575E™

Page 43

Design Spot 575E™

located in the default position after the reset.

Cyan Color Er

(Cyan Color-wheel error) This message will appear after the reset of the fixture if the

magnetic-indexing circuit malfunctions (sensor failed or magnet missing) or the

stepping-motor is defective (or its drive circuit on the main PCB). The Cyan Color wheel is

not located in the default position after the reset.

Magenta Color Er

(Magenta Color-wheel error ) This message will appear after the reset of the fixture if the

magnetic-indexing circuit malfunctions (sensor failed or magnet missing) or the

stepping-motor is defective (or its drive circuit on the main PCB). The Magenta Color-wheel

is not located in the default position after the reset.

Yellow Color Er

(Yellow Color-wheel error) This message will appear after the reset of the fixture and if the

magnetic-indexing circuit malfunctions (sensor failed or magnet missing) or the

stepping-motor is defective (or its dri ve r circui t on the main P CB ). The Yellow Color -wheel i s

not located in the default position after the reset.

Color Er

(Color wheel- error) This message will appear after the reset of the fixture if the yoke’s

magnetic-indexing circuit malfunction (sensor failed or magnet missing) or the

stepping-motor is defective ( or its driving IC on the main PCB). The color wheel is not

located in the default position after the reset.

Rotation go bo Er

(Rotating gobo wheel 1- error) This message will appear after the reset of the fixture if the

yoke’s magnetic-indexing circuit malfunction (sensor failed or magnet missing) or the

stepping-motor is defective ( or its driving IC on the main PCB). The Rotating gobo wheel 1

is not located in the default position after the reset.

©Elation Professional® 43

Design Spot 575E™

Page 44

Design Spot 575E™

Gobo Rotation Er

(Gobo Rotation wheel 1- error) This message will appear after the reset of the fixture if the

yoke’s magnetic-indexing circuit malfunction (sensor failed or magnet missing) or the

stepping-motor is defective ( or its driving IC on the main PCB). The Gobo Rotation wheel 1

is not located in the default position after the reset.

Rotation go bo Er

(Rotating gobo wheel 2- error) This message will appear after the reset of the fixture if the

yoke’s magnetic-indexing circuit malfunction (sensor failed or magnet missing) or the

stepping-motor is defective ( or its driving IC on the main PCB). The Rotating gobo wheel 2

is not located in the default position after the reset.

Gobo Rotation Er

(Gobo Rotation wheel 2- error) This message will appear after the reset of the fixture if the

yoke’s magnetic-indexing circuit malfunction (sensor failed or magnet missing) or the

stepping-motor is defective ( or its driving IC on the main PCB). The Gobo Rotation wheel 2

is not located in the default position after the reset.

Prism Rotation Er

(Prism Rotation-wheel error) This message will appear after the reset of the fixture if the

yoke’s magnetic-indexing circuit malfunction (sensor failed or magnet missing) or the

stepping-motor is d efecti ve ( o r it s drivi ng IC o n the main PCB). The Pris m R otation -w heel i s

not located in the default position after the reset.

Shutter, Strobe Er

(Shutter, Strobe-wheel error) This message will appear after the reset of the fixture if the

yoke’s magnetic-indexing circuit malfunction (sensor failed or magnet missing) or the

stepping-motor is defecti v e (o r it s driving IC on the mai n PC B). The S hutter, Strobe -wheel i s

not located in the default position after the reset.

Focus Er

(Focus error) This message will appear after the reset of the fixture if the yoke’s

©Elation Professional® 44

Design Spot 575E™

Page 45

Design Spot 575E™

magnetic-indexing circuit malfunction (sensor failed or magnet missing) or the

stepping-motor is defective (or its driving IC on the main PCB). The Focus is not located in

the default position after the reset.

Zoom Er

(Zoom motor error) This message will appear after the reset of the fixture if the yoke’s

magnetic-indexing circuit malfunction (sensor failed or magnet missing) or the

stepping-motor is defective (or its driving IC on the main PCB). The Stepless Zoom is not

located in the default position after the reset.

Iris Er

(Iris error) This message will appear after the reset of the fixture if the yoke’s

magnetic-indexing circuit malfunction (sensor failed or magnet missing) or the

stepping-motor is defective ( or its driving IC on the main PCB). The Iris is not located in the

default position after the reset.

Fire Wheel Er

(Fire wheel error) This message will appear after the reset of the fixture if the yoke’s

magnetic-indexing circuit malfunction (sensor failed or magnet missing) or the

stepping-motor is defective (or its driving IC on the main PCB). The Fire wheel is not located

in the default position after the reset.

©Elation Professional® 45

Design Spot 575E™

Page 46

Design Spot 575E™

12. CLEANING AND MAINTENANCE

The following points have to be considered during the inspection:

1. Be sure all screws and fasten ers a re secu rely tightened at al l tim es. Los e screw s may

fall out during normal op eration resul ting i n da mage or injury as larger parts could f all.

2. There must not be any deformations on the housing, color lenses, rigging hardware

and rigging points (ceiling, suspension, trussing). Deformations in the housing could

allow for UV radiation leakage. Damaged rigging points or unsecured rigging could

cause the unit to fall and serious injure a person.

3. All mechanical parts and motors should not show any traces of serious wear and

should rotate freely.

4. Electric power supply cables must not show any damage, material fatigue or

sediments. Never remove the ground prong from the power cable.

Further instructions depending on installation and usage have to be adhered by a skilled

installer and any safety problems should be addressed before attempting operation.

Disconnect from mains before starting maintenance operation.

We recommend frequent cleaning of the device, this will ensure operational longevity and

crisp light output. When cleaning, please use a moist, lint-free cloth. Never use alcohol or

solvents.

There are no user serviceable parts inside this fixture with the exception of the lamp. Please

refer all other service related issues to an authorized Elation service technician.

Should you decide to service the fixture yourself please order genuine Elation parts directly

from Elation.

©Elation Professional® 46

Design Spot 575E™

Page 47

13. 2-YEAR LIMITED WARRANTY

Design Spot 575E™

A. Elation Professional

® hereby warrants, to the original purchaser, Elation Professional®

products to be free of ma nufactu ring defects in material a nd w ork manship for a period of tw o

years, (730 days) from the date of purchase. This warranty shall be valid only if the product

is purchased within the United States of America, including possessions and territories. It is

the owner’s responsibility to establish the date and place of purchase by acceptable

evidence, at the time service is sought.

B. For warranty service, send the product only to the Elation Professional® factory. All

shipping charges must be pre-paid. If the requested repairs or service (including parts

replacement) are within the terms of this warranty, Elation Professional® will pay return

shipping charges only to a designated point within the United States. If the entire instrument

is sent, it must be shi ppe d in its ori ginal packa ge. N o access ories s houl d b e shipp ed wit h t he

product. If any accessories are shipped with the product, Elation Professional

® shall have no

liability what so ever for loss of or damage to any such accessories, nor for the safe return

thereof.

C. This warranty is void if the serial number has been altered o r remov ed; i f the pro duct is

modified in any manner which Elation Professional® concludes, after inspection, affects the

reliability of the product; if the product has been repaired or serviced by anyone other than

the Elation Professional® factory unless prior written authorization was issued to purchaser

by Elation Professional

®; if the product is damaged because not properly maintained as set

forth in the instruction manual.

D. This is not a service contract, and this warranty does not include maintenance, cleaning

or periodic check-up. During the period specified above, Elation Professional

® will re place

defective parts at its expense, and will absorb all expenses for warranty service and repair

labor by reason of defects in material or workmanship. The sole responsibility of Elation

Professional® under this warra nty shall be limi t ed to the re pair of th e prod uct, or r epl acem ent

thereof, including parts, at the sole discretion of Elation Professional®. All products covered

by this warranty were m anufact ured afte r January 1, 1990, and b are identifying marks to tha t

©Elation Professional® 47

Design Spot 575E™

Page 48

effect.

Design Spot 575E™

E. Elation Professional

® reserves the right to make changes in design and/or

improvements upon its products without any obligation to include these changes in any

products theretofore manufactured.

F. No warranty, whether expressed or implied, is given or made with respect to any

accessory supplied with products described above. Except to the extent prohibited by

applicable law, all implied warranties made by Elation Professional® in connection with this

product, including warranties of merchantability or fitness, are limited in duration to the

warranty period set forth above. And no warranties, whether expressed or implied, including

warranties of merchantability or fitness, shall apply to this product after said period has

expired. The consu mer’s and or Dealer’s sol e remedy shall b e such re pai r or replace ment as

is expressly provided above; and under no circumstances shall Elation Professional® be

liable for any loss or damage, direct or consequential, arising out of the use of, or inability to

use, this product.

G. This warranty is the only written warranty applicable to Elation Professional

® Products

and supersedes all prior warranties and written descriptions of warranty terms and

conditions heretofore published.

©Elation Professional® 48

Design Spot 575E™

Page 49

14. Photometric Data:

Design Spot 575E™

©Elation Professional® 49

Design Spot 575E™

Page 50

15. Gobos:

Design Spot 575E™

©Elation Professional® 50

Design Spot 575E™

Page 51

16. Dimensional Drawings:

Design Spot 575E™

©Elation Professional® 51

Design Spot 575E™

Page 52

17. Circuit Schematic

Design Spot 575E™

©Elation Professional® 52

Design Spot 575E™

Page 53

Design Spot 575E™

18. TECHNICAL SPECIFIC ATIONS

Power supply

Pow e r consumpt ion 90 ~ 260V, 5 0 ~ 60 Hz

800 Watt, 4. 5 A, electronic ballast, (blind current co mp ensated)

Fuse pr ote c ti o n 120V = 10A/ 250V, GMA ( 5x 20mm fine-wire fuse)

220V = 5A/ 250V, GMA (5x20mm fine -wire fuse)

Lamp

Type Philips Gold MSR57 5/ 2 SA DE

Life time 750 Hrs

Color temperature 7200˚ K

Luminous flux 43.000 lm

Optical system

Parabolic dichroic gl ass ref lec t or

Variable b eam angle 14˚ ~ 28 ˚

Lenses ha rdened and te mpered, anti-reflex coat ed

Colors

8 dichroic filt er plus white, half-color co mpatible

Gobos

Gobo-wheel 1: 7 interchangeable rotating go bos plus "open", 4 glass Gobos

Gobo-wheel 2: 7 interchangeable rotating gobos plus "open"

Gobo outs ide diameter 26.9 mm, i ma ge s iz e 23 mm

Gobo thickness: glass = 1 mm, steel = 0.15 mm

CMY Color mixing unit

Cyan color f ilt er 0 - 100%

Magenta color filter 0 - 100%

Yellow col or f ilt er 0 - 100%

Prism

Rotating 3-f ace prism, r ot at ing and variable in speed

Shutter / Strobe / Dimmer

Strobe effec t with variable s peed 1 - 10 flashes per second

Continuo usly mec ha nica l dimmer 0 - 100%

Iris

Motor driven iris from open to close, v ariable spee d, pulse effect

Focus

Motor driven focus from near to far away

Zoom

Zoom range 14° - 32°

Effect wheel

Rotating and indexed Effect whee l, dif f erent patterns , ex c hangeable

DMX Channels

©Elation Professional® 53

Design Spot 575E™

Page 54

Design Spot 575E™

24 (16bit – def ault) or 22 (8bit – user s elec t able)

Drive

Standard DMX-512, 3 pole XLR; [+] = Pin 3 [-] = Pin 2 [Ground] = Pin 1 or 5 pole XLR; n/a = Pin

5, n/a = Pin 4, [+] = Pin 3, [-] = Pin 2, [Ground] = Pin 1

Starting DM X [001].

Pan / Tilt

Pan - move ment 630° in max. 2.0 seconds, 16 bit resolution

Tilt - move ment 265° in max. 1.5 seconds, 16 bit resolution

Weights a n d measures

Widt h of t he bas e 61cm (W) x 46cm (L) x 51 cm (H) ~ Hea d v er ti cal

Length of the base 32.5Kgs / 72Lbs

Height ( he ad vertical)

Weight (net) 32.5Kgs / 72Lbs

Please Note: Specifications and improvements in the design of this unit and this manual are subject to change without any prior written notice.

Elation Professional

4295 Charter Street

Los Angeles, CA. 90058

323-582-3322 / 323-582-3108 fax

www.ElationLighting.com /

Info@ElationLighitng.com

©Elation Professional® 54

Design Spot 575E™

Loading...

Loading...