4

1-2-3-4-5 Sec.

1

2

3

EN

UMX™ J-3 Cub

3

Instruction Manual

12

Bind your Transmitter to the Aircaft

For a list of compatible DSM2/DSMX transmitters, please visit www.bindnfl y.com

Binding Procedure

9

CAUTION: When using a Futaba transmitter with a Spektrum DSM®

module, you must reverse the throttle channel and rebind. Refer to

your Spektrum module manual for binding and failsafe instructions. Refer to

your Futaba transmitter manual for instructions on reversing the throttle

channel.

1. Refer to your transmitter’s unique instructions for binding to a

receiver (location of transmitter’s Bind control).

2. Make sure the fl ight battery is disconnected from the aircraft.

3. Ensure the transmitter is powered OFF.

4. Connect a fully charged fl ight battery to the aircraft and turn the

aircraft upright. The receiver LED will begin to fl ash (typically after 5

seconds).

5. Ensure that control surface trims are centered and the throttle sticks

and trim are in the lowest position to correctly set the failsafe.

6. Put your transmitter into bind mode. Refer to your transmitter’s

manual for binding button or switch instructions.

7. After 5 to 10 seconds, the receiver status LED will turn solid,

indicating that the receiver is bound to the transmitter. If the LED does

not turn solid, refer to the Troubleshooting Guide at the back of the

manual.

For subsequent fl ights, power ON the transmitter for 5 seconds before

connecting the fl ight battery.

Centering the Control Surfaces

4

Before your fi rst fl ight make sure the aircraft’s control surfaces are centered.

1. Power on the transmitter and then the aircraft.

2. Set all transmitter trims and sub-trims to zero.

3 Check the control surfaces to make sure they are centered.

4. If centering is required, use a pair of pliers to carefully bend the metal linkage

(see illustration).

In fl ight trimming may be required

During your fi rst fl ight, the aircraft should fl y straight and level. Use your transmitter

trims to fi ne tune the aircraft’s fl ight path until its fl ight path has been corrected. Any

transmitter trim that requires 4 or more clicks of trim (per channel), should be mechanically centered. Note the control surface’s postion and return the transmitter trim to zero.

Adjust the linkages mechanically so that the control surfaces are in the fl ight trimmed position.

Transmitter set up

2

A DSM2/DSMX

transmitter is required for

this aircraft.

Set wing type and servo

reversing to normal.

NOTICE: Do not set your

transmitter travel adjust

over 100%, doing so may

overdrive the servo and

cause damage.

For the fi rst fl ight, fl y the model in low rate.

For landing, we recommend using high rate elevator.

Make the U-shape narrower to make the

connector shorter. Make the U-shape wider to

make the linkage longer.

Aileron 100% 70%

Elevator 100% 70%

Rudder 100% 70%

Dual Rates

High Low

motor will turn the propeller in response to any throttle movement.

Arming the ESC/receiver also occurs after binding as previously described, but

subsequent connection of a fl ight battery requires the following steps.

AS3X

The AS3X® system will not activate until the throttle stick or trim is

increased for the first time. Once active, the control surfaces may move

rapidly and noisily on the aircraft. This is normal. AS3X technology will

remain active until the battery is disconnected.

1. Open the battery hatch from the fuselage.

2. Install the flight battery in the center of battery tray. Ensure the battery is

secured by the hook and loop strip.

Center of Gravity (CG)

At the wing root, measure back 36mm from the leading edge where the wing

meets the fuselage. The easiest way to achieve CG is to balance the aircraft

inverted.

3. Lower the throttle and throttle trim to the lowest settings on your

transmitter. Power on your transmitter, then wait 5 seconds.

4. Connect the battery to the ESC, noting proper polarity. Keep the plane

immobile and away from wind for 5 seconds to allow the AS3X system to

initialize. A series of tones and a continuous LED indicates a successful

connection.

fl ying to eliminate power supplied to the motor. The ESC does not have an

arming switch and will respond to any transmitter input when a signal

is present.

fl ying to avoid over-discharging the battery. Batteries discharged to a voltage

lower than the lowest approved voltage may become damaged, resulting in loss

of performance and potential fi re when batteries are charged.

ESC/Receiver Arming

CAUTION: Always keep hands away from the propeller. When armed, the

36mm

CAUTION: Always disconnect the Li-Po battery from the ESC when not

CAUTION: Always disconnect the Li-Po battery from the ESC when not

5

Low Voltage Cutoff (LVC)

LVC is a feature built into your ESC to protect the battery from over-discharge. When the

battery charge becomes too low, LVC limits power supplied to the motor. When you hear

the motor power pulse, land the aircraft immediately and recharge the fl ight battery.

NOTICE: Do not rely on LVC to determine when to land your aircraft. Set a flight timer to

the recommended flight time. Repeated flying to LVC will damage the battery.

6

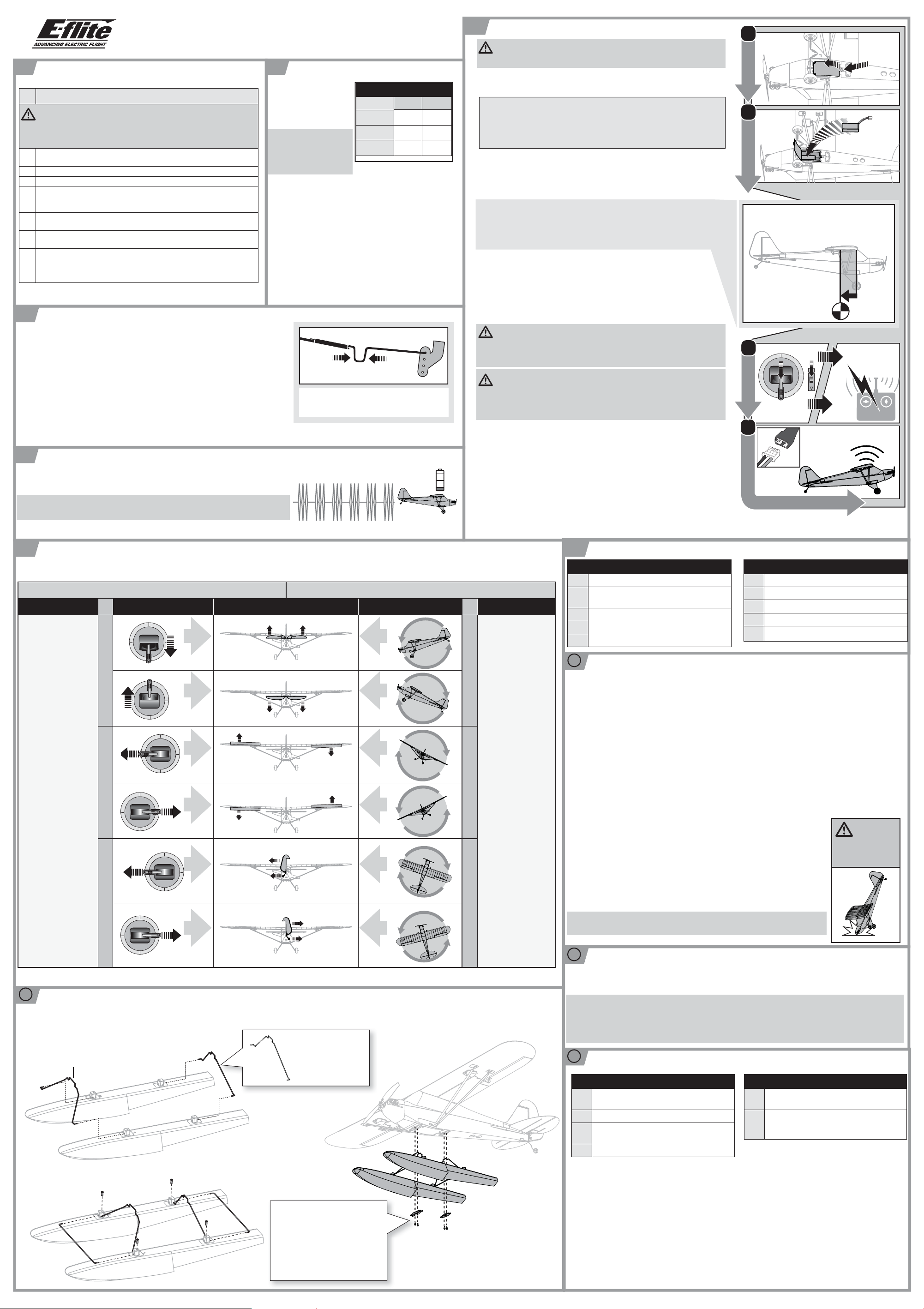

Control Direction Tests

There are 2 types of control direction tests to perform on your aircraft. One is to confi rm that your transmitter inputs are correctly performed by your aircraft. The second test

is to confi rm that AS3X

®

technology is operating correctly in your aircraft. Use the chart below to assist you with performing these test.

Test 1 Control Direction Test Test 2 AS3X Direction Test

Transmitter Input Aircraft Reaction Move Aircraft

Move the control sticks

on the transmitter to

make sure the aircraft

control surfaces move

correctly and in the

proper direction. Make

sure the tail linkages

move freely and that

paint or decals are not

adhered to them.

Elevator

Aileron

1. Advance the throttle

to 25% to activate

the AS3X system.

2. Fully lower the

throttle.

3. Move the entire

Elevator

aircraft as shown

and ensure the

control surfaces

move in the

direction indicated

in the graphic. If

the control surfaces

do not respond as

shown, do not fly

the aircraft. Refer

to the receiver

manual for more

information.

Aileron

Once the AS3X

system is active,

control surfaces may

move rapidly. This is

normal. AS3X is active

until the battery is

disconnected.

7

Prefl ight Checklist

9

1. Charge fl ight battery.

2. Install fl ight battery in aircraft (once it has

been fully charged).

3. Bind aircraft to transmitter.

4. Make sure linkages move freely.

5. Perform Control Direction Tests

Flying Tips

i

We recommend fl ying your aircraft outside in calm conditions. Always avoid fl ying near houses, trees, wires

and buildings. You should also be careful to avoid fl ying in areas where there are many people, such as busy

parks, schoolyards or soccer fi elds. Consult local laws and ordinances before choosing a location to fl y your

aircraft.

Takeoff

Place the aircraft in position for takeoff (facing into the wind if fl ying outdoors). Set dual rates to low position

and gradually increase the throttle to ¾ to full and steer with the rudder. Pull back gently on the elevator and

climb to check trim. Once the trim is adjusted, begin exploring the fl ight envelope of the aircraft.

Landing

Land into the wind. Fly the aircraft to approximately 6 inches (15cm) or less above the runway, using a small

amount of throttle for the entire descent. Keep the throttle on until the aircraft is ready to fl are.

During fl are, keep the wings level and the airplane pointed into the wind. Gently lower the throttle while

pulling back on the elevator to bring the aircraft down on all three wheels.

Failure to lower the throttle stick and trim to the lowest possible positions during

a crash could result in damage to the ESC in the receiver unit, which may require

replacement.

Over Current Protection (OCP)

This aircraft is equipped with Over Current Protection (OCP). This feature protects

the ESC from damage. OCP stops the motor when the transmitter throttle is set

too high and the propeller cannot turn. The OCP will only activate when the throttle

stick is positioned just above 1/2 throttle. After the ESC stops the motor, fully lower

the throttle to re-arm the ESC.

9

6. Set dual rates and expos.

7. Adjust center of gravity.

8. Perform a radio system Range Check.

9. Find a safe and open area.

10. Plan fl ight for fl ying fi eld conditions.

CAUTION:

Always decrease

throttle at propeller

strike.

Rudder

i

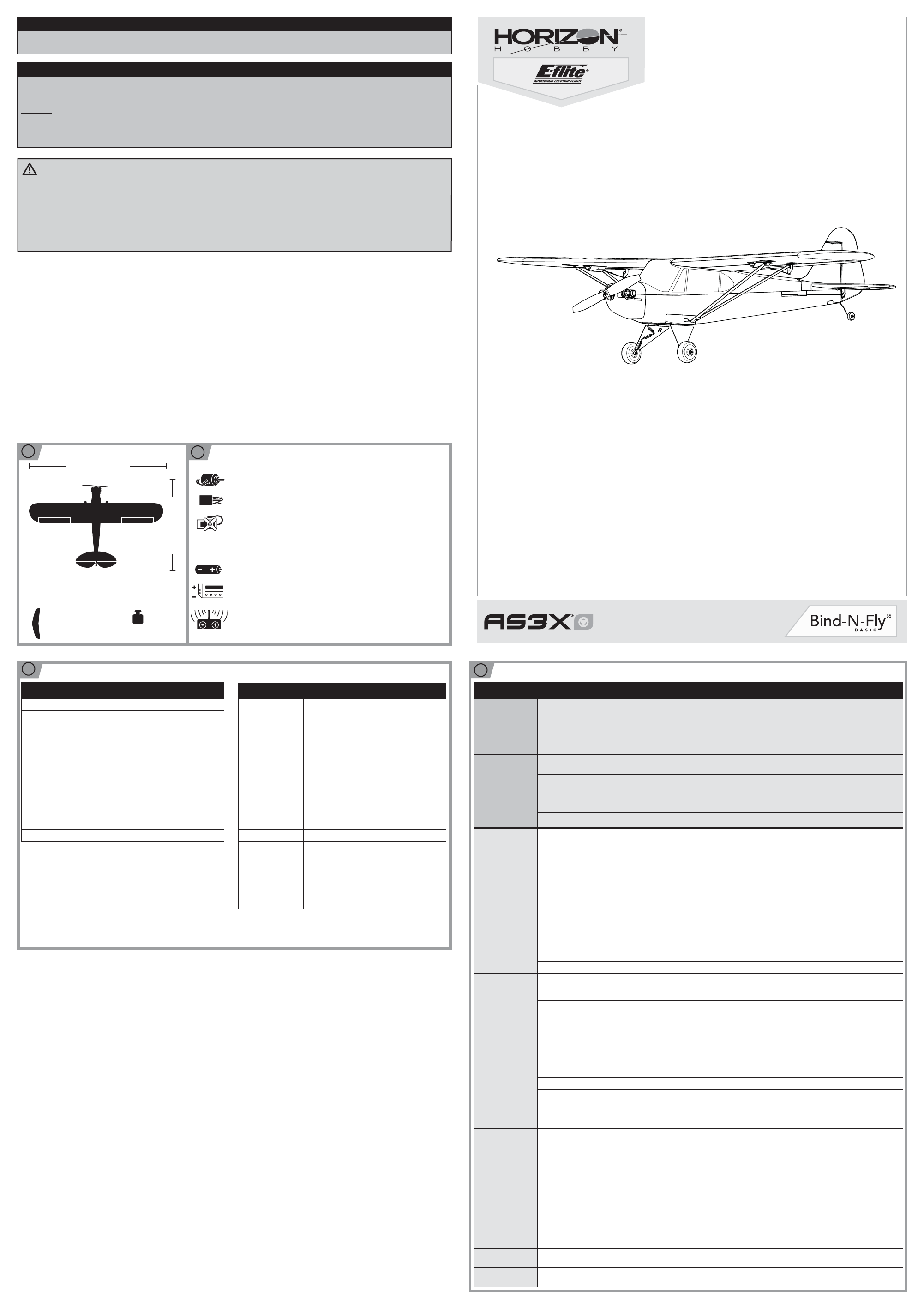

Optional Float installation (EFLUA1190)

Follow the instructions included with your optional fl oat set for assembly. Replace the rear strut on the fl oat assembly with the rear strut included with the J-3 Cub. Once the

rear strut has been switched, install the fully assembled fl oat set as shown.

Replace the rear strut

included in the fl oat

WIDER

set kit with the rear

strut included with the

aircraft.

Rudder

NOTICE: Crash damage is not covered under the warranty.

i

Repairs

Repair the aircraft only with foam-compatible CA (cyanoacrylate adhesive) or clear tape. Use of other types

of glue can damage the foam. For a listing of all replacement and optional parts, refer to the product page

online at Horizonhobby.com.

NOTICE: Use of foam-compatible CA accelerant on your aircraft can damage paint. DO NOT handle the

aircraft until the accelerant fully dries.

NOTICE: When you are fi nished fl ying, never leave the aircraft in direct sunlight or in a hot, enclosed area

such as a car. Doing so can damage the foam.

i

Post Flight Checklist

9

1. Disconnect the flight battery from the

ESC (required for safety and battery life).

2. Power OFF the transmitter.

3. Remove the flight battery from the

aircraft.

4. Recharge the flight battery.

9

5. Store the flight battery apart from the

aircraft and monitor the battery charge.

6. Make note of the flight conditions and

flight plan results, planning for future

flights.

Remove the main gear by removing

2 screws and front bracket.

Install the fl oat assembly to the

fuselage.

Secure the fl oat assembly with the

front and rear bracket and screws.

(the rear bracket and 2 screws are

included in the box).

NOTICE

All instructions, warranties and other collateral documents are subject to change at the sole discretion of Horizon Hobby, LLC. For up-todate product literature, visit www.horizonhobby.com and click on the support tab for this product.

Meaning of Special Language:

The following terms are used throughout the product literature to indicate various levels of potential harm when operating this product:

NOTICE: Procedures, which if not properly followed, create a possibility of physical property damage AND little or no possibility of injury.

CAUTION: Procedures, which if not properly followed, create the probability of physical property damage AND a possibility of

serious injury.

WARNING: Procedures, which if not properly followed, create the probability of property damage, collateral damage, and serious injury OR

create a high probability of superfi cial injury.

WARNING: Read the ENTIRE instruction manual to become familiar with the features of the product before operating. Failure to

operate the product correctly can result in damage to the product, personal property and cause serious injury.

This is a sophisticated hobby product. It must be operated with caution and common sense and requires some basic mechanical ability.

Failure to operate this product in a safe and responsible manner could result in injury or damage to the product or other property. This

product is not intended for use by children without direct adult supervision. Do not use with incompatible components or alter this

product in any way outside of the instructions provided by Horizon Hobby, LLC. This manual contains instructions for safety, operation and

maintenance. It is essential to read and follow all the instructions and warnings in the manual, prior to assembly, setup or use, in order to

operate correctly and avoid damage or serious injury.

Age Recommendation: Not for children under

14 years. This is not a toy.

designed and protected for this purpose. Moisture causes damage

to electronics.

• Never place any portion of the model in your mouth as it could

Safety Precautions and Warnings

• Always keep a safe distance in all directions around your model to

avoid collisions or injury. This model is controlled by a radio signal

subject to interference from many sources outside your control.

Interference can cause momentary loss of control.

• Always operate your model in open spaces away from full-size

vehicles, traffi c and people.

• Always carefully follow the directions and warnings for this and

any optional support equip-ment (chargers, rechargeable battery

packs, etc.).

• Always keep all chemicals, small parts and anything electrical out

of the reach of children.

• Always avoid water exposure to all equipment not specifi cally

cause serious injury or even death.

• Never operate your model with low transmitter batteries.

• Always keep aircraft in sight and under control.

• Always use fully charged batteries.

• Always keep the transmitter powered on while aircraft is powered.

• Always remove batteries before disassembly.

• Always keep moving parts clean.

• Always keep parts dry.

• Always let parts cool after use before touching.

• Always remove batteries after use.

• Always ensure failsafe is properly set before fl ying.

• Never operate aircraft with damaged wiring.

• Never touch moving parts.

UMX™ J-3 Cub

Specifi cations Component List

i

26.4 in (670mm)

16.9 in (430mm)

Wing Area: 100.1 sq. in.

(646 sq. cm.)

i

Replacement Parts

Part #

EFLU3401 Painted Fuselage: UMX J-3 BL

EFLU3402 Wing with struts: UMX J-3 B

EFLU3403 Complete Tail: UMX J-3 B

EFLU3404 Landing Gear Set: UMX J-3 B

EFLU3405 Plastic Parts Set: UMX J-3 B

EFLU3406 Pushrod Set: UMX J-3 B

EFLU3407 Decal Sheet: UMX J-3 B

SPMSA2030L 2.3-Gram Performance Linear Long Throw Servo

EFLUP575225 5.75x2.25 Electric Propeller: UMX Yak 54

EFLU4067 Prop Adapter: UMX Beast

EFLUM180BL2 180 Brushless Outrunner Motor 2500KV

EFLU4864 DSM2 6 Ch Ultra Micro AS3X Receiver BL ESC

Created 12/15 48975.1 (EN)

Description

E-fl ite, AS3X, UMX, DSM, DSM2, DSMX, ModelMatch, Bind-N-Fly, Celectra and the Horizon Hobby logo are trademarks or registered trademarks of Horizon Hobby, LLC.

3.6oz,

(102g)

The Spektrum trademark is used with permission of Bachmann Industries, Inc.

Futaba is a registered trademark of Futaba Denshi Kogyo Kabushiki Kaisha Corporation of Japan.

All other trademarks, service marks and logos are property of their respective owners.

i

Installed

Motor: BL180 Brushless Outrunner Motor, 2500Kv

Receiver : DSM2 6 Ch Ultra Micro AS3X

(2) 2.3-Gram Performance Linear Long Throw Servo

Required to Complete

Recommended Battery: 200mAh 2S 7.4V 30C Li-Po, 26AWG

Recommended Battery Charger:

Celectra™ 2S 7.4V DC Li-Po Charger

Recommended Transmitter:

Spektrum™ DSM2®/DSMX® full range with dual-rates

(DX4e and up)

©2015 Horizon Hobby, LLC.

Patents pending.

®

Receiver BL-ESC

Optional Parts and Accessories

Part #

PKZ1039 Hook and Loop Set (5): Ultra Micros

EFLUA1190 Float Set w/Accessories

SPMA3060 USB-Interface: UM AS3X Programmer

EFLUC1007 Celectra 2S 7.4V DC Li-Po Charger

EFLC1105 1S-2S AC/DC Li-Po Balancing Charger

EFLUC1008 Power Cord for EFLUC1007

EFLB2002S30 200mAh 2s 7.4V DC Li–Po, 26AWG

EFLB2802S30 280mAh 2s 7.4V DC Li–Po, 26AWG

EFLA700UM Charger Plug Adapter: EFL

EFLA7001UM Charger Plug Adapter: Thunder Power

EFLU4068 Harness Adapter: UMX Beast

SPM6825 Ultra Micro Linear Servo Reverser

EFLC4000/UK/

AU/EU

Description

AC to 12V DC,1.5 Amp Power Supply (Based upon

your sales Region)

DX6 DSMX 6-Channel Transmitter

DX7 DSMX 7-Channel Transmitter

DX9 DSMX 9-Channel Transmitter

DX18 DSMX Transmitter

Instruction Manual

Register your product online at www.e-fl iterc.com

Trouble Shooting

i

Problem Possible Cause Solution

AS3X

Control surfaces not

at neutral position

when transmitter controls are at

neutral

Model fl ies inconsistently from fl ight

to fl ight

Controls oscillate in

fl ight, (model rapidly

jumps or moves)

Aircraft will not

respond to throttle

but responds to

other controls

Extra propeller noise

or extra vibration

Reduced fl ight time

or aircraft underpowered

LED on receiver

fl ashes and aircraft

will not bind to

transmitter (during

binding)

LED on receiver

fl ashes rapidly and

aircraft will not respond to transmitter

(after binding)

Control surface does

not move

Controls reversed Transmitter settings reversed Adjust controls on transmitter appropriately

Motor loses power Damage to motor or power components Do a check of motor and power components for damage (replace

Motor power quickly

decreases and increases then motor

loses power

Motor/ESC is not

armed after landing

Servo locks or

freezes at full travel

Control surfaces may not have been mechanically centered

from factory

Aircraft was moved after the fl ight battery was connected and

before sensors initialized

Aircraft was not kept immobile for 5 seconds after battery was

plugged in

Trims are moved too far from neutral position Neutralize trims and mechanically adjust linkages to center

Propeller is unbalanced, causing excessive vibration Remove propeller and rebalance or replace it if damaged

Prop screw is too loose, causing vibration Tighten the prop screw

Throttle stick and/or throttle trim too high Reset controls with throttle stick and throttle trim at lowest

Throttle channel is reversed Reverse throttle channel on transmitter

Motor disconnected from receiver Open fuselage and make sure motor is connected to the receiver

Damaged propeller, spinner or motor Replace damaged parts

Prop screw is too loose Tighten the prop screw

Prop is out of balance Remove and balance propeller, or replace with a balanced propel-

Flight battery charge is low Completely recharge fl ight battery

Propeller installed backwards Install propeller with numbers facing forward

Flight battery damaged Replace fl ight battery and follow fl ight battery instructions

Flight conditions may be too cold Make sure battery is warm before use

Battery capacity too low for fl ight conditions Replace battery or use a larger capacity battery

Transmitter too near aircraft during binding process Power off transmitter, move transmitter a larger distance from

Bind switch or button not held long enough during bind

process

Aircraft or transmitter is too close to large metal object, wireless source or another transmitter

Less than a 5-second wait between fi rst powering on transmitter and connecting fl ight battery to aircraft

Aircraft bound to different model memory (ModelMatch

radios only)

Flight battery/transmitter battery charge is too low Replace/recharge batteries

Transmitter may have been bound to a different model (or with

a different DSM Protocol)

Aircraft or transmitter is too close to large metal object, wireless source or another transmitter

Control surface, control horn, linkage or servo damage Replace or repair damaged parts and adjust controls

Wire damaged or connections loose Do a check of wires and connections, connect or replace as

Flight battery charge is low Fully recharge fl ight battery

Control linkage does not move freely Make sure control linkage moves freely

Battery power is down to the point of receiver/ESC Low Voltage

Cutoff (LVC)

Over Current Protection (OCP) stops the motor when the transmitter throttle is set high and the propeller cannot turn

Travel adjust value is set above 100%, overdriving servo Set Travel adjust to 100% or less and/or set sub-trims to zero

™

Center control surfaces mechanically by adjusting the U-bends

on control linkages

Disconnect and reconnect the fl ight battery while keeping the

aircraft still for 5 seconds

Keep the aircraft immobile for 5 seconds after plugging in the

battery

control surfaces

setting

ler

aircraft, disconnect and reconnect fl ight battery to aircraft and

follow binding instructions

Power off transmitter and repeat bind process. Hold transmitter

bind button or switch until receiver is bound

Move aircraft and transmitter to another location and attempt

binding again

Leaving transmitter on, disconnect and reconnect fl ight battery

to aircraft

Select correct model memory on transmitter and disconnect and

reconnect fl ight battery to aircraft

Select the right transmitter or bind to the new one

Move aircraft and transmitter to another location and attempt

linking again

needed

as needed)

Recharge fl ight battery or replace battery that is no longer

performing

Fully lower throttle and throttle trim to arm ESC

and adjust linkages mechanically

Loading...

Loading...