Page 1

Wv410 window

Installation Instructions

Part NO. Y007

February 2014

Page 2

WV410 WINDOW - INSTALLATION INSTRUCTIONS

TABLE OF CONTENTS

SECTION PAGE

I. Product Description and Limitations…...………….………………....…...3

II. General Statements and Definitions..……………….………..…………....3

III. Standard Parts Identification……………….…………….…….….……….…4

IV. Size Formulas

A. Window and Glass Size Formulas……..………………………………....5

B. Egress Formulas…………………………..……………………..…...…..…..6

V. Captured WV410 Vent Glazing….……………………………………..…….7-8

VI. SSG WV410 Vent Glazing………..………………………………………….9-10

VII. Vent Gasket Preparation…………………………………………………...11

VIII.

Window Installation

A. Single Window Installation……………………………………….…………12

B. Dual Window Installation…………………………………………………..13-15

C. Ribbon Window Installation……………………………………………….16-19

IX. Casement Lift Block Installation…………………………………….………20

X.

Note: Please reference EFCO's "Understanding Condensation" brochure which can be obtained through your EFCO representative.

Condensation will form on any surface when unfavorabl e cond itions (interior temperature and relative humidity and exterior

temperature) are present. When the formation of excessive condensation is a concern, it is highly recomm ended that a design

professional is utilized to perform an analysis of the shop drawings to recommend the best possible installation methods. Please

contact your EFCO representative for information on EFCO's Thermal Analysis Services.

Many current installation practices lead to an increase in the possibility of the formation of condensati on. Though not all

inclusive, the list of examples below illustrates conditions under which condensation is likely to occur:

Vent Removal and Adjustment..……………..……..…….…………..…..….21

Minimizing Condensation

1. Bridging system thermal break with non-thermally broken metal flashing or lintels that are exposed to the exterior

2. System exposure to cold air cavities

3. Interior relative humidity levels not maintained at recommended levels, see EFCO’s “Understanding

Condensation” brochure

4. Inadequate separation between system and surrounding condition at perimeter

5. Product combinations during the shop drawing stage that result in bridging thermal brea ks

of one or all products involved

EFCO CORPORATION 2/2014 PART NO. Y007 Page 2 of 21

Page 3

WV410 WINDOW - INSTALLATION INSTRUCTIONS

Section I – Product Description and Limitations

The WV410 storefront window system is designed and engineered to be field glazed and installed

with a limited amount of labor and tools. Although the WV410 window is designed to

complement the S401, S402, S403, and S433 center set systems, it may be glazed into any

system with a smooth surface opening that has a minimum depth of 3 7/16”.

The WV410 allows the plane of glass to be equal to that of the S401, S402, S403, and S433

center set systems. The correct location or inset of the WV410 is easily found by measuring out

from the interior surface to the storefront 1/32”. This will allow a 1/32” offset from the storefront

face to the window frame. If the WV410 intermediate mullion is used, the interior face of the

mullion will align flush with the storefront horizontal.

Section II – General Statements and Definitions

The user is encouraged to read and understand all of the instructions prior to proceeding with

installation. These instructions define several configurations and methods of installation that may

or may not apply to your project.

The instructions covered in this manual are pertinent to the S401, S402, S403, and S433 systems.

Consult approved shop drawings for special applications not covered herein.

The following terminology will be utilized throughout these instructions and has been included to

better orient the reader to the areas discussed.

Storefront Opening: Storefront or other mounting surface for the window are typically called

D.L.O. (Day Light Opening).

WV410 Frame: The interior mounting and fixed portion of the operable window.

Vent: The operable and glazed portion of the window.

Intermediate mullion: The adaptor system designed to allow the windows to be stacked side by

side in a dual or ribbon application.

The steps and details on the following pages have been developed to aid in the assembly and

installation of the WV410 storefront window system.

EFCO CORPORATION 2/2014 PART NO. Y007 Page 3 of 21

Page 4

WV410 WINDOW - INSTALLATION INSTRUCTIONS

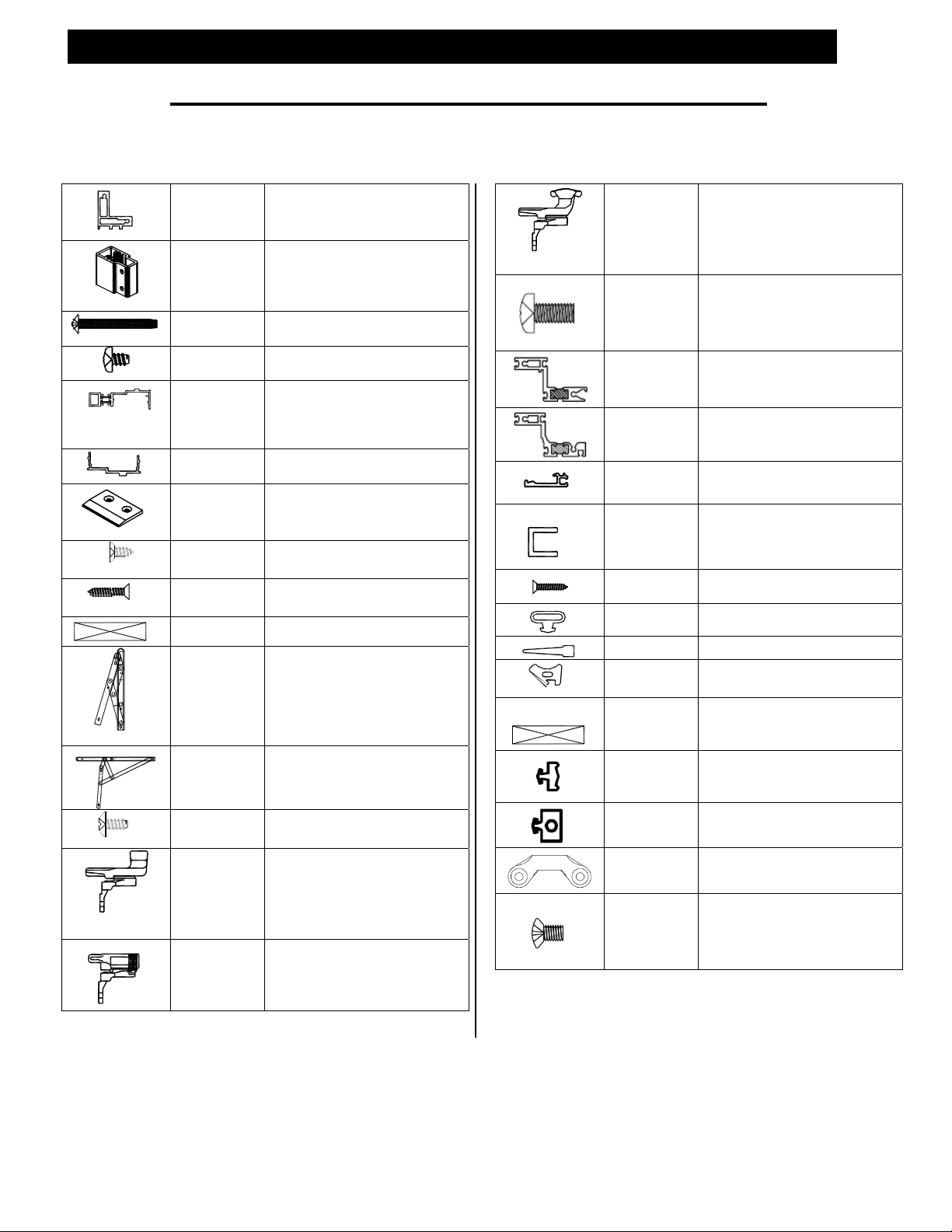

Section III – Standard Parts Identification

Detail Part No. Description Detail Part No. Description

WV410 Frame

9833

K320

MRF7

SPC7

1F10

9837

HB64

Use with 23X3 or 23X4 vent

WV410 Mullion Shear

Block Package

2) packages required per mullion

complete with fasteners

Shear block to storefront

screw- included in K320

Mullion to shear block screwincluded in K320

Female Vertical Mullion

Half

Thermal Strut Connected

Used with K320 and 9867

Male Vertical Mullion Half

Used with K320 and 1F10

Casement Vent Lift Block

Use SFZ5 attachment screws

Lift Block Attachment

Screw

WV410 Frame to

Storefront

Perimeter Shim Block

4-Bar Hinge

used for casement and projected

hinges

90° 4-Bar Hinge

Casement vents only- Minimum

casement width = 19 5/8”

SFZ5

SFP1

HN91

LA09

LA15

LA21

LA23

LA01

H989

H990

H991

H992

MFM3

MFM4

23X4

23X3

9834

EY45

SFP1

W142

W113

WEB5

HN91

W174

STT5

H927

H928

H935

4-Bar Hinge Attachment

Screw

Cam Handle (RH) (CLR)

Cam Handle (LH) (CLR)

Cam Handle (LH) (BRZ)

Cam Handle (RH) (BRZ)

(6) per hinge

H936

A.C. Lock (CLR)

H987

H988

A.C. Lock (BRZ)

WEQ4

HK15

HP15

MON9

MOO0

* Drawings on this page are not to scale.

Pole Ring Cam Handle (RH) (CLR)

Pole Ring Cam Handle (LH) (CLR)

Pole Ring Cam Handle (RH) (BRZ)

Pole Ring Cam Handle (LH) (BRZ)

Cam Handle Attachment

Screw (CLR)

Cam Handle Attachment

Screw (BRZ)

Standard Bead Glazed

Vent

Structural Glazed Vent

Removable Glass Stop

Used with 23X4 Vent

¼” Glazing Adaptor

Channel

use SFP1 attachment screws

Attachment screw

Use at ¼” glazing adaptor

Vent Bulb Gasket

Perimeter Wiper Gasket

Removable Glass Stop

Glazing Wedge

Glass Setting Block

(4) required per casement vent

(8) required per projected vent

1/8” Pre-shim Gasket

For bead glazed vents

¼” SSG Pre-shim Gasket

For SSG glazed vents

Strike (CLR)

Strike (BRZ)

Strike Attachment Screw

(CLR)

Strike Attachment Screw

(BRZ)

EFCO CORPORATION 2/2014 PART NO. Y007 Page 4 of 21

Page 5

WV410 WINDOW - INSTALLATION INSTRUCTIONS

Section IV – Size Formulas

A. Window and Glass Size Formulas

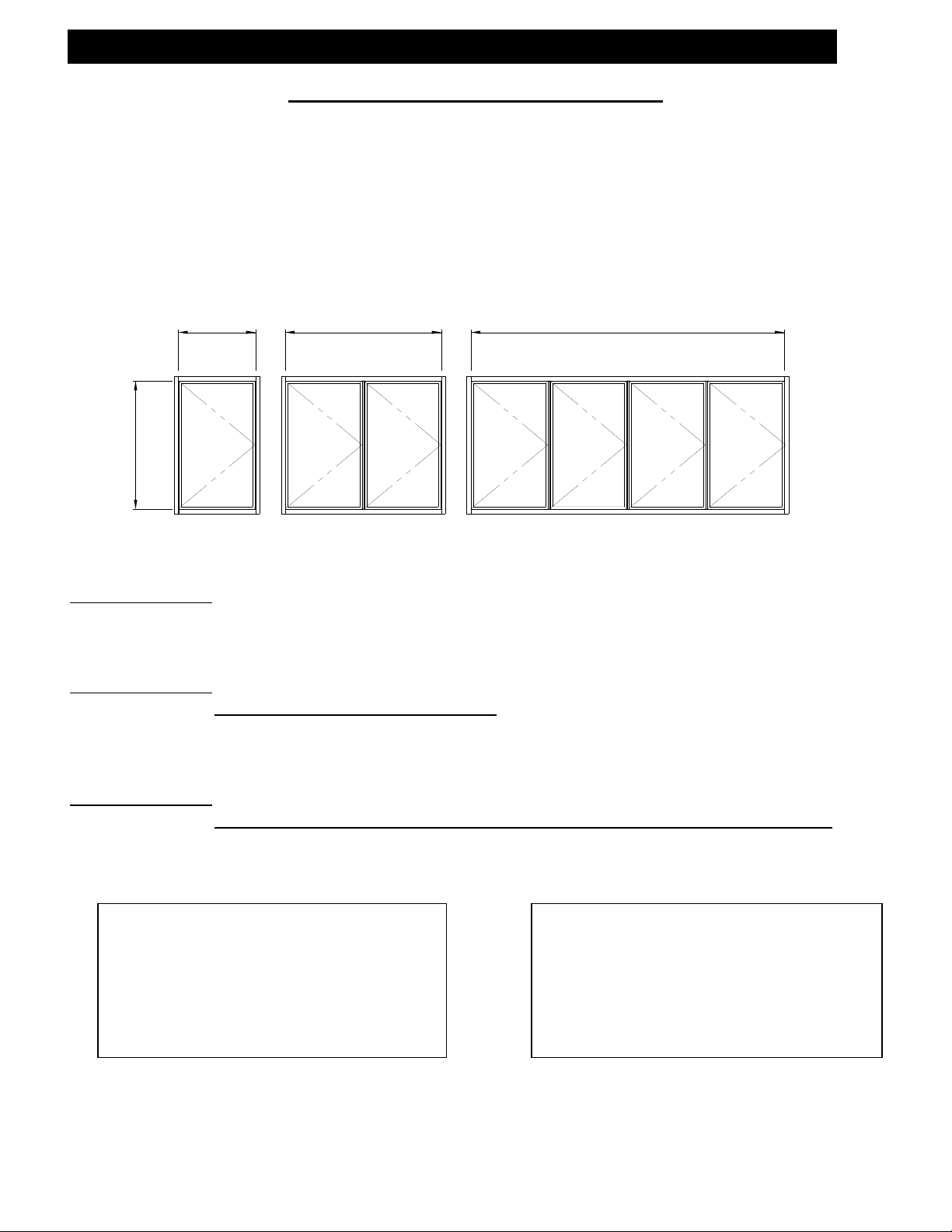

There are three (3) different configurations of the WV410 window system. Each of the

configurations will determine the horizontal dimensions of the glass and individual units.

Note: The storefront D.L.O. horizontal and vertical dimensions must be known to calculate the

sizes. Glass and window size formulas for the WV410 units are provided below for each

configuration. Refer to the information given that corresponds with the appropriate configuration.

STOREFRONT

D.L.O. WIDTH

STOREFRONT

D.L.O. WIDTH

A B

STOREFRONT

D.L.O. HEIGHT

STOREFRONT

D.L.O. WIDTH

C

DUAL VENTSSINGLE VENT

RIBBON RUN VENTS

Configuration “A”

Window Width = Storefront D.L.O. Width – 3/8”

Window Height = Storefront D.L.O. Height – 3/8”

Configuration “B”

Window Width = (Storefront D.L.O. Width – 1 3/8”)

2

Window Height = Storefront D.L.O. Height – 3/8”

Configuration “C”

Window Width = ( Storefront D.L.O. Width – 3/8”) – (Number of Intermediate Mullions x 1”)

Number of Windows

Window Height = Storefront D.L.O. – 3/8”

Standard Glazing

Glass Size Formula

Configurations “A”, “B”, & “C”

Glass width = Window width – 1 1/2”

Glass height = Window height – 1 1/2”

Structural Glazed

Glass Size Formula

Configuration “A”, “B”, & “C”

Glass width = Window Width – 1 1/2”

Glass Height = Window Height – 1 1/2”

* Drawings on this page are not to scale.

EFCO CORPORATION 2/2014 PART NO. Y007 Page 5 of 21

Page 6

WV410 WINDOW - INSTALLATION INSTRUCTIONS

Section IV- Size Formulas

B. Egress Formulas

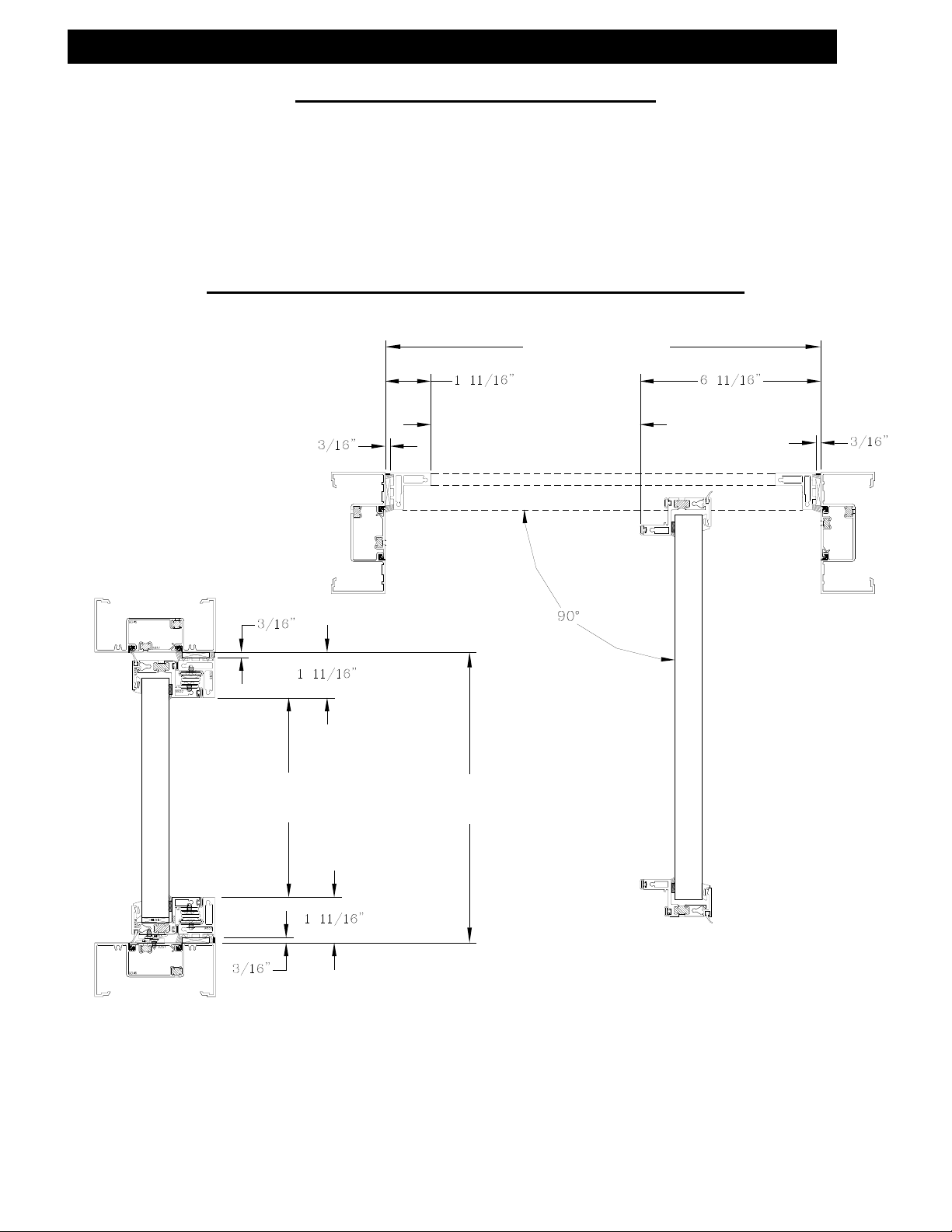

Egress openings must be figured based on the clear opening after the vent is opened to the 90

degree position. See the figures and equations below for window sizes at the egress opening.

Use standard window sizing requirements as shown on Page 5 once the egress has been used to

determine the storefront D.L.O. size.

Egress Windows must use LA01 Arms Only!

STOREFRONT D.L.O.

EGRESS OPENING =

STOREFRONT D.L.O. - 8 3/8"

EGRESS OPENING =

STOREFRONT D.L.O. - 3 3/8"

STOREFONT

D.L.O.

* Drawings on this page are not to scale.

Storefront D.L.O. width – 8 3/8” = 90 degree clear opening width

Storefront D.L.O. height – 3 3/8” = Egress clear opening height

EFCO CORPORATION 2/2014 PART NO. Y007 Page 6 of 21

Page 7

WV410 WINDOW - INSTALLATION INSTRUCTIONS

Section V – Captured WV410 Vent Glazing

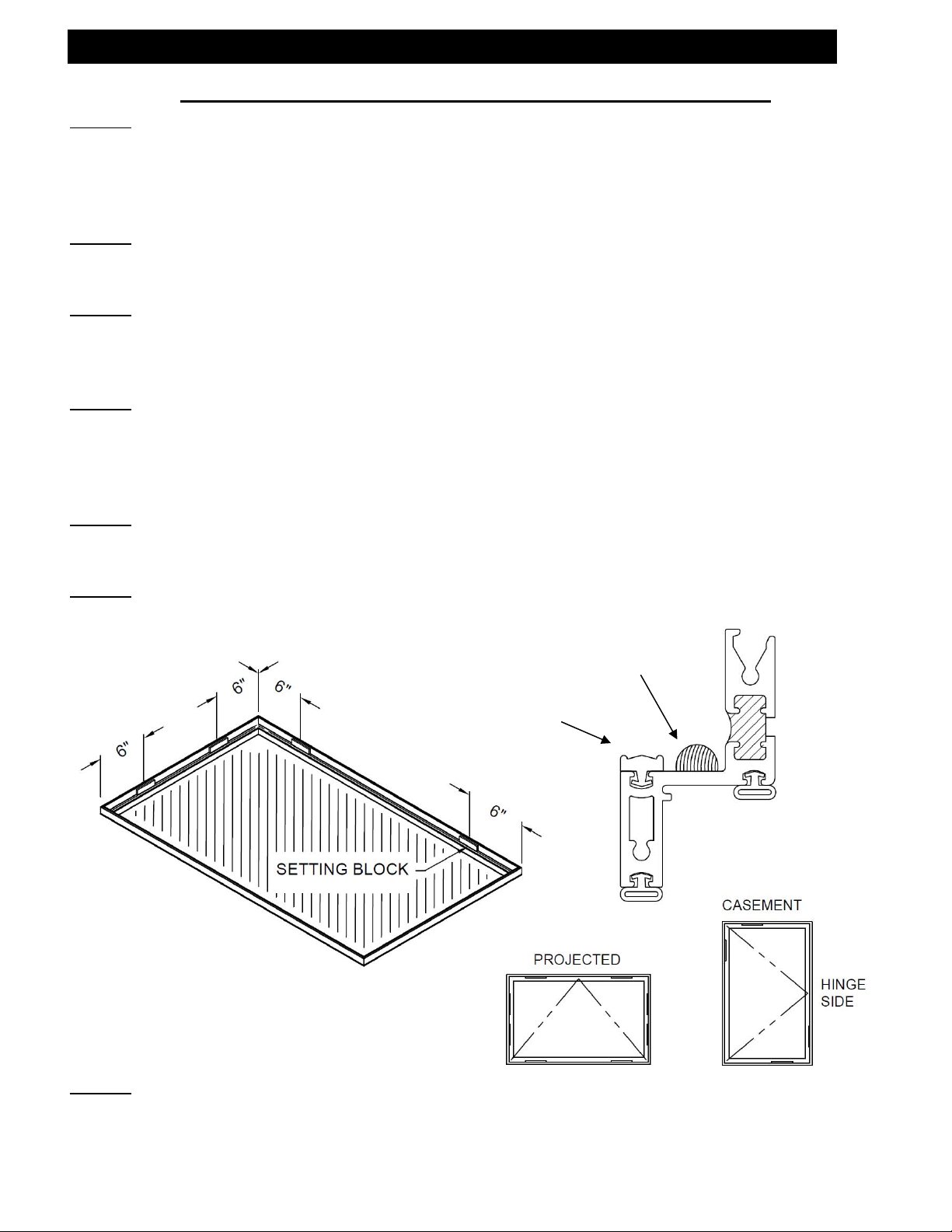

Step 1

Unlock the cam locks and open the vent to expose the hardware. Remove the vent from the

WV410 frame by removing the screws from the hinges. Be sure to mark the vent to correspond

with the appropriate frame. This will insure that the vent is reinstalled correctly.

Step 2

Lay the vent face up on a flat, smooth working surface. Remove the glass stops from the vent.

Step 3

Make sure that the glazing surfaces of the vent are free from oil and metal shavings. Clean the

glazing surfaces as needed with alcohol. (Do not use glass cleaners).

Step 4

Insert a continuous row of pre-shimmed gasket W174 around the vent perimeter glazing leg.

Insert the gasket beginning at each end of the frame and work toward the middle then work out

any waves toward the ends forming tight joints. Do not stretch the gasket.

Step 5

Run a continuous bead of structural silicone sealant behind the tape as shown in Figure 1.

Step 6

Keeping the glass level and centered within the vent material, lower the glass down into place.

Structural

Silicone

Pre-Shimmed

Gasket

Figure 2

Figure 1

Step 7

Insert two (2) HN91 - 3/16” x 1” x 4” setting blocks on each side of the glass 6” from the corners,

as required, based on the configurations shown in Figure 2 above. Adjust the blocks as required

to keep the vent square.

EFCO CORPORATION 2/2014 PART NO. Y007 Page 7 of 21

Page 8

WV410 WINDOW - INSTALLATION INSTRUCTIONS

Section V – Captured WV410 Vent Glazing

Step 8

Reinstall the glass stops. The glass stops are designed to be inserted into the vent material and

rotated up and out toward the edges to lock into place. Insert a 3” long temporary piece of the

glazing wedge WEB5 at the midpoint of each stop until all four (4) are in place. See Figure 3.

WEB5

Drive-In

Gasket

Note: Horizontal

Gaskets Run Through

Figure 3

Pivot Point

Step 9

Cut the horizontal and ve rt ical lengths of the WEB5 drive-in gasket to the exterior daylight

opening of the vent plus 2% to allow for shrinkage. Insert the glazing wedge, beginning at each

end of the stops and the middle of the gasket. Continue to divide each loop in half, working out

the “waves” toward the ends of the glass stops. Do not stretch the gasket. See Figure 4.

Figure 4

Figure 5

WEB5 GLAZING

GASKET

Pre-Shimmed

Gasket

Step 10

After all of the gaskets are in place, flip the vent over and check for squeeze out that may have

appeared. Clean off any excess with a razor blade and paper towels.

* Drawings on this page are not to scale.

EFCO CORPORATION 2/2014 PART NO. Y007 Page 8 of 21

Page 9

WV410 WINDOW - INSTALLATION INSTRUCTIONS

Section VI – SSG WV410 Vent Glazing

Step 1

Unlock the cam locks and open the vent to expose the hardware. Remove the vent from the

WV410 frame by removing the screws from the hinges. Be sure to mark the vent to correspond

with the appropriate frame. This is to insure that the vent is reinstalled correctly.

Step 2

Lay the vent face up on a flat, smooth working surface.

Step 3

Make sure that the glazing surfaces of the vent are free from oil and metal shavings. Clean the

glazing surfaces as needed with alcohol. (Do not use glass cleaners).

Step 4

Insert a continuous row of pre-shimmed gasket WEQ4 around the vent perimeter glazing leg.

Insert the gasket beginning at each end of the frame and work toward the middle then work out

any waves toward the ends forming tight joints. Do not stretch the gasket.

Step 5

Run a continuous bead of structural silicone sealant behind the tape as shown in Figure 6.

Step 6

Keeping the glass level and centered within the vent material lower, the glass down into place.

Figure 7

* Drawings on this page are not to scale.

Pre-Shimmed

Gasket

Structural

Silicone

Figure 6

EFCO CORPORATION 2/2014 PART NO. Y007 Page 9 of 21

Page 10

WV410 WINDOW - INSTALLATION INSTRUCTIONS

Section VI – SSG WV410 Vent Glazing

Step 7

Insert two (2) HN91 - 3/16” x 1” x 4” setting blocks on each side of the glass 6” from the corners,

as required, based on the configurations shown in Figure 7. Adjust the blocks as required to keep

the vent square.

Step 8

Insert backer rod material between the glass and the vent material around the entire perimeter

except at setting block locations. The backer rod needs to be recessed far enough to leave the

end of the outer glass lite exposed. See figure 8.

Step 9

Mask off the outside edges of the glass and vent to minimize cleanup and provide a professional

appearance. Fill the void between the glass and the vent with structural sealant. Tool in sealant

and remove the masking tape before a skin begins to form. See Figure 8.

An overnight setup is required to allow the silicone to partially cure before movement of the unit.

Figure 8

* Drawings on this page are not to scale.

EFCO CORPORATION 2/2014 PART NO. Y007 Page 10 of 21

Page 11

WV410 WINDOW - INSTALLATION INSTRUCTIONS

Section VII – Vent Gasket Preparation

The exterior weatherstrip flap is to be trimmed at the sill to jamb corners. Trim the weatherstrip

3” from the sash corner both horizontally and vertically. This gasket preparation applies to both

Captured & SSG versions of the WV410 vents. See Figure 9.

Figure 9

EFCO CORPORATION 2/2014 PART NO. Y007 Page 11 of 21

Page 12

WV410 WINDOW - INSTALLATION INSTRUCTIONS

Section VIII – Window Installation

A. Single Window Installation

Step 1

Locate the 1/32” inset for the WV410 frame at the horizontal mullions of the storefront D.L.O.

Step 2

The WV410 frame is mounted into the storefront opening by first drilling and countersinking

attachment holes. Drill .201” diameter (No. 7 drill) mounting holes at the WV410 frame and

countersinking for No. 10 FH-SMS SFP1 screws, 4” from the ends and 16” on center maximum.

NOTE: Be sure not to re-drill or countersink through the hinge mounting holes. See Figure 12

below.

Fig u re #12

4"

E

4"16"16"16"

4"

16"

16"

16"

4"

Detail E

F

F

Note: Do not re-drill or

countersink through the hinge

.625"

mounting holes.

Section F-F

* Drawings on this page are not to scale.

Step 3

Place the WV410 frame into position keeping the 1/32” offset from the interior face of the

storefront to the interior face of the WV410 frame. Place HN91 shims at the mounting screw

location and clamp the WV410 frame into place. Using the WV410 frame as a guide, drill .159”

diameter (No. 21 drill) holes into the storefront frame. Secure the vent with SFP1 screws.

Step 4

Prior to installing the window, refer to Step 8 on page 14 for the required sealing locations. If

casement vents are used, see Section VIII for lift block installation. If projected windows are

used, continue to Step 5 for vent installation.

Step 5

Reinstall the vent into the WV410 frame. Be sure to mount the hinge to the same location as

preinstalled by EFCO. See Section IX on page 20.

EFCO CORPORATION 2/2014 PART NO. Y007 Page 12 of 21

Page 13

WV410 WINDOW - INSTALLATION INSTRUCTIONS

Section VIII – Window Installation

B. Dual Window Installation

The procedure for installing the vertical mullion in a dual window application differs fr om the

ribbon run application. In a dual window application, the WV410 frame side clearances are ample

enough to install the windows after the vertical mullion. In a dual window application the mullion

is always installed first.

Step 1

Establish the mullion center lines in the opening per the approved shop drawings. Refer to the

elevation in Figure 13 to locate the mullion center.

Step 2

Cut the vertical mullion halves 1F10/9837 to the daylight opening height and prep the ends as

detailed in Figure 14 below.

* Drawings on this page are not to scale.

EFCO CORPORATION 2/2014 PART NO. Y007 Page 13 of 21

Page 14

WV410 WINDOW - INSTALLATION INSTRUCTIONS

Section VIII – Window Installation

B. Dual Window Installation

Step 3

At the predetermined mullion locations, drill and tap the storefront horizontals for two (2) MRF7

10-24 PH-SMS fasteners. See Figure 15 below.

#SPC6

#9837

#

K320

Figure #15

#MRF7

#1F10

Detail G

Interior of

Storefront

Shear block and all screws are

included in the K320 package.

(2) required per mullion.

C/L of

Mullion

DETAIL G

DETAIL G

7/8 in [.874]

7/32 in [.224]

15/32 in [.467]

* Drawings on this page are not to scale.

Interior of

Storefront

Step 4

First apply sealant to the attachment hole in the storefront horizontals to insure against water

penetration, then install the K320 shear blocks using (2) MRF7 screws.

Step 5

Apply sealant to both ends of the female 1F10 and the male 9837 halves of the vertical mullion.

Step 6

Attach female portion 1F10 of the mullion to the shear block with (1) SFP6 screws at each end of

the mullion half. See Figure 15 above.

EFCO CORPORATION 2/2014 PART NO. Y007 Page 14 of 21

Page 15

WV410 WINDOW - INSTALLATION INSTRUCTIONS

Section VIII – Window Installation

B. Dual Window Installation

Step 7

Install the male portion 9837 of the mullion over the shear blocks and snap into the female

portion of the mullion. Attach the male mullion half to the shear blocks with (1) SPC6 fastener at

each end. See Figure 15 on page 13.

Step 8

NOTE: Do not complete this step unless you are prepared to install the window into the prepared

openings. Seal around the top and bottom edge of the mullion. Additionally, apply a continuous

bead of sealant along the mullion at the interlock location at both sides of the mullion as shown in

Figures 16 and 17.

Mullion interlock

TYPICAL SEAL AT THE

HEAD, JAMB, & SILL

INTERIOR

Sealant

JAMB

MULLION

Figure 17

Figure 16

* Drawings on this page are not to scale.

Step 9

The WV410 frame installation may now be completed. Both WV410 frames are installed by

inserting the windows into the openings at the jamb sides and sliding them toward the mullion.

Position the WV410 frames tight against the interlock of the mullion and shim into place with one

(1) HN91 shim at the top, bottom, and extreme jambs at each fastener location. Refer to Steps 1

through 3 on pages 11 and 12 for the recommended fastener locations. No shims are required at

the mullion anchor locations.

Step 10

After the WV410 frames have been installed, seal the exterior perimeter joint between the WV410

frame and the storefront frame and the mullion. At the interior of the storefront jamb, seal the

joint between the WV410 frame and the storefront frame. No additional sealant is required at the

interior surface of the mullions. See Figure 17.

EFCO CORPORATION 2/2014 PART NO. Y007 Page 15 of 21

Page 16

WV410 WINDOW - INSTALLATION INSTRUCTIONS

Section VIII – Window Installation

C. Ribbon Window Installation

The legs of the window engage the tracks of the vertical mullions, allowing a positive location

situation for the windows. The ribbon run installation is the same as the dual window installation

where the first mullion is installed prior to the WV410 frames. After the first mullion is installed,

the remaining window and mullions will be sequentially stacked. See Figure 18.

The mullion center lines must be laid out before the first window can be installed. Take into

account the 3/16” shim at the extreme jambs and the leg engagement at the vertical mullion.

The vertical mullion is designed to be set flush with the interior side of the storefront frame. This

is necessary to position the vent glass in the same plane as the storefront glass.

* Drawings on this page are not to scale.

EFCO CORPORATION 2/2014 PART NO. Y007 Page 16 of 21

Page 17

WV410 WINDOW - INSTALLATION INSTRUCTIONS

Section VIII – Window Installation

C. Ribbon Window Installation

Step 1

Follow the procedures detailed in Steps 1 through 10 of pages 12 through 14 for the first mullion

and WV410 frame.

Step 2

After the first and second WV410 frames have been installed, the method of installation will differ

from the previous steps. Beginning at the exposed jamb of the second WV410 frame, seal around

the top and bottom of the WV410 frame where it meets the storefront horizontals. Run a bead of

sealant along the interlock of the vertical frame. See Figure 20.

#1F10 Female

Mullion Ha lf

DETA IL I

DETA IL I

1st Vent

Frame

Figure #2 1

I

Exterior

Surface

2n d Vent

Frame

Figure #20

K320

#9837 Male

H

Apply sealant to

the Vent Frame

Interlock

Seal joints at the top

and bottom of the

vent frame

Mullion Half

DETAIL H

DETAIL H

* Drawings on this page are not to scale.

EFCO CORPORATION 2/2014 PART NO. Y007 Page 17 of 21

Page 18

WV410 WINDOW - INSTALLATION INSTRUCTIONS

Section VIII – Window Installation

C. Ribbon Window Installation

Step 3

Apply sealant to both ends of the female half of the mullion and apply to the interlock of the

WV410 frame. See Figure 20 on page 15.

Step 4

Install one (1) K320 shear block and two (2) MRF7 screws at the top and bottom horizontal.

NOTE: The screw holes must be predrilled and tapped for screw insertion. Due to the available

space within the mullion, a long handled screwdriver is recommended. See Figure 22.

J

Figure 22

DETAIL J

* Drawings on this page are not to scale.

DETAIL J

Step 5

Insert one (1) SPC6 into the shear block at the top and bottom of the mullion half to secure. See

Figure 15 on Page 13.

Step 6

Apply sealant to both ends of the male half 9837 of the mullion, snap into the female portion, and

fasten with (1) SPC6 at each end of the shear block. See Figure 15 on Page 13.

Step 7

Seal around the top and bottom of the mullion and the window interlock to receive the next

window. See Figure 16 on Page 14.

EFCO CORPORATION 2/2014 PART NO. Y007 Page 18 of 21

Page 19

WV410 WINDOW - INSTALLATION INSTRUCTIONS

Section VIII – Window Installation

C. Ribbon Window Installation

Step 8

Install the next WV410 frame by aligning the interlock of the window with the mullion interlock.

Step 9

Shim the WV410 frame into the correct location and anchor to the opening at the top, bottom,

and mullion side at the recommended locations covered in Steps 2 through 3 on Pages 16 and 17.

Step 11

After the WV410 frames and intermediate mullions have been installed, the interior and exterior

perimeter seals are to be applied. Seal the interior joint between the vertical frame and the

storefront opening at the top, bottom, and end jambs of the ribbon run. The vertical mullion

required no additional sealant at the interior surface. The exterior joint between the WV410

frame, storefront opening, and the intermediate vertical requires a continuous seal at all four (4)

sides of the WV410 frames. See Figure 21 on Page 16 and Figure 23 below.

Typical Seal at the Head, Jamb,

Mullion, and Sill

Interior

Figure 23

Jamb

Mullion

* Drawings on this page are not to scale.

Step12

If your application includes projected vents only, the operable vent may now be installed. See

section IX on page 20. Casement vents must first have the lift blocks installed. See Section VIII

on Page 19 for installation. Reinstall the operable vent to the WV410 frame. Be sure to mount

the vent and hinges in the same locations preinstalled by EFCO.

EFCO CORPORATION 2/2014 PART NO. Y007 Page 19 of 21

Page 20

WV410 WINDOW - INSTALLATION INSTRUCTIONS

Section IX – Casement Lift Block Installation

Due to the weight of the vent, lift blocks are used to elevate the vent upon closing. Elevating the

vent aligns the gaskets and cam locks to the proper location. All WV410 casement vents receive

one (1) or two (2) pairs of lift blocks, depending on the vent size. Casement vents over 30” wide

will receive two (2) pairs and vents under 30” will receive one (1) pair. The blocks are designed

to be located directly over each other. The vent portion of the lift block pair will be preinstalled

by EFCO.

* Drawings on this pageare not to scale.

Step 1

Locate the center line of the lift block HB64 as required per the vent size. See Figure 24. Check

the lift block location mounted on the vent for correct center line.

Step 2

Drill (2) .136” diameter (No. 29 drill) holes per block through the storefront framing shown in

Figure 24, and install with (2) SFZ5 fasteners per lift block.

Step 3

The operable vent may now be installed. Reinstall the operable vent to the WV410 frame. Be

sure to mount the vent and hinges in the same locations preinstalled by EFCO. See section IX on

Page 20.

EFCO CORPORATION 2/2014 PART NO. Y007 Page 20 of 21

Page 21

WV410 WINDOW - INSTALLATION INSTRUCTIONS

Section X– Vent Removal and Adjustment

Unlock the vent and open the operable vent far enough to expose the hinge attachment screws

STT5 at the WV410 frame. See Figure 25. Support the vent and remove the six (6) hinge

attachment screws from the WV410 frame. Note: If the vent is equipped with an optional limit

stop, this will need to be removed before the vent will open far enough to expose the mounting

screws. The vent can now be removed from the exterior. Reinstall the vent in the reverse order.

The hold open force for the vent can be adjusted by a set screw located in the hinge friction shoe.

See Figure 25. Open the vent far enough to access the set screw. Turn the screw clockwise to

increase the friction, counterclockwise will decrease the friction. Adjust both hinges equally, make

small adjustments, and check operation.

Figure 25

Operating Force

Adjustment Screw

Location of

Optional Limit

Stop

STT4

Hinge Mounting

Screw

* Drawings on this page are not to scale.

EFCO CORPORATION 2/2014 PART NO. Y007 Page 21 of 21

Loading...

Loading...