Page 1

T

T

Series

200 / t300

ie rod door

Installation Instructions

Part NO. Y009

February 2013

Page 2

SECTION

PAGE 1

TABLE OF CONT E N TS

I

II

III

IV

V

VI

VII

VIII

IX

X

XI

XII

XIII

XIV

GENERAL NOTES AND GUIDELINES

DOOR PACKAG E IDEN TIFICATION

PARTS IDENTIFICATION

OFFSET JACK SC REW ASSEMBLY

TIE ROD CUT LENGTH

TIE ROD ASSEMBLY

GLAZING AND REGLAZING DO ORS

PUSH/PULL ASSEMBLY

OFFSET PIVOT APPLICATION

BUTT HINGE APPLIC ATION

HEADER PREPARATION FOR C.O.C.

CLOSER ADJUSTMENTS

CLEARANCE ADJUSTMENTS

TIE ROD DOOR CUT LENGTH ALTERATIONS

PAGE 2

PAGE 3-4

PAGE 5-7

PAGE 8

PAGE 8

PAGE 9

PAGE 10

PAGE 11

PAGE 12-14

PAGE 14

PAGE 15

PAGE 15

PAGE 16

PAGE 17

Mini mizin g Condensation

NOTE: Please reference EFCO's "Understanding Condensation" brochure which can be obtained through your EFCO representative.

Condensation will form on any surface when unfavorable conditions (interior temperature and relative humidity and exterior

temperature) are present. When the formation of excessive condensation is a concern, it is highly recommended that a design

professional is utilized to perform an analysis of the shop drawings to recommend the best installation methods. Please contact

EFCO representative for information on EFCO's Thermal Analysis Services.

Many current installation practices lead to an increase in the possibility of the formation of condensation. Though not all

inclusive, the list of examples below illustrates conditions under which condensation is likely to occur:

1. Bridging system thermal break with non-thermally broken metal flashing or lintels that are exposed to the

exterior.

2. System exposure to cold air cavities.

3. Interior relative humidity levels not maintained at recommended levels, see EFCO's "Understanding

Condensation" brochure.

4. Inadequate separation between system and surrounding condition at perimeter.

5. Product combinations during the shop drawing stage that result in bridging thermal breaks of one or all products

involved.

Page 3

T200/T300 TIE ROD DOOR

NOTE: THESE INSTALLATION INSTRUCTIONS ARE A SUPPLEMENT TO THE

APPROVED SHOP DRAWINGS AND MUST BE USED IN CONJUNCTION WITH

THOSE DRAWINGS.

SECTION I: GENERAL NOTES AND GUIDELINES

I.

HANDLING-STORING-PROTECTING ALUMINUM -

Tie rod doors and components are finished products that must be protected while in the

packing boxes and after assembly. The following procedures and precautions are

recommended.

A. PROTECTION AND STORAGE OF PACKAGED, UNASSEMBLED DOORS

1. Handle the boxes carefully, do not shake or drop.

2. Store the boxes off the ground.

3. If the boxes become wet, remove the contents, repack and move to a dry location.

4. Do not over stack boxes. Recommended capacity is four (4) boxes high.

PAGE 2

B. PROTECTION AND STORAGE OF ASSEMBLED DOORS

1. If stored outside, protect the doors against the elements and other

construction trades by using a well ventilated covering, as required.

2. Do not drop or drag the doors. This may cause racking or damage to the corner

joinery.

3. If the doors are stacked together, be sure to allow adequate separation to

protect the finish.

C. CHECK MATERIAL

Check all of the door material upon arrival for quantity and damage. Any visibly

damaged material must be noted on the freight bill at the time of receipt. If a claim is

required, the receiving party must process a claim with the freight carrier. If the delivery

is by an EFCO truck, any damage or variance in the quantity of door units or boxes must

be reported to the EFCO driver during the unloading process.

D. CLEANING THE DOOR UNITS

Cement, plaster, terrazzo, alkaline, and acid based materials used to clean masonry are

very harmful to finishes and must be removed with water and mild soap immediately.

Otherwise, permanent staining will occur. A spot test is recommended before any

cleaning agent is used.

TOOLS NEEDED:

1.) 9/16" COMBINATION WRENCH for tie rod lock nuts

2.) 7/16" SOCKET WITH RATCHET for adjustable jack screw

3.) #3 TIPPED PHILLIPS SCREWDRIVER for butt hinge installation

4.) FLAT TIPPED SCREWDRIVER for offset pivot adjustment

5.) SOFT FACED MALLET for door glazing

6.) PUTTY KNIFE for glass adjustment

7.) LEVEL

DPS/BB JULY 2000

Page 4

PAGE 3

SECTION II: DOOR PACKAGE IDENTIFICATION

AVAILABLE DOOR SIZES, COLORS, AND HARDWARE PACKAGES

BLANK T200 DOORS:

SINGLE DOORS:

3’0" X 7’0" CLEAR, BRONZE, OR BLACK

3’6" X 7’0" CLEAR, BRONZE, OR BLACK

4’0" X 7’0" CLEAR, BRONZE, OR BLACK

3’0" X 8’0" CLEAR, BRONZE, OR BLACK

3’6" X 8’0" CLEAR, BRONZE, OR BLACK

4’0" X 8’0" CLEAR, BRONZE, OR BLACK

INCLUDES 1/4" GLASS STOPS (NO HARDWARE OR HARDWARE PREPARATION)

PAIR DOORS:

6’0" X 7’0" CLEAR, BRONZE, OR BLACK

7’0" X 7’0" CLEAR, BRONZE, OR BLACK

8’0" X 7’0" CLEAR, BRONZE, OR BLACK

6’0" X 8’0" CLEAR, BRONZE, OR BLACK

7’0" X 8’0" CLEAR, BRONZE, OR BLACK

8’0" X 8’0" CLEAR, BRONZE, OR BLACK

T200 DOORS WITH BUTT HINGES FOR SURFACE CLOSER:

INCLUDES MAXIMUM SECURITY DEAD LOCK, INTERIOR THUMB TURN CYLINDER, EXTERIOR CYLINDER,

BUTT HINGES, EFCO EXTRUDED PUSH/PULLS, AND 1/4" GLASS STOPS. (INACTIVE LEAF OF PAIR

DOORS INCLUDE FLUSH BOLTS)

SINGLE DOORS:

3’0" X 7’0" CLEAR, BRONZE, OR BLACK

3’6" X 7’0" CLEAR, BRONZE, OR BLACK

4’0" X 7’0" CLEAR, BRONZE, OR BLACK

PAIR DOORS:

6’0" X 7’0" CLEAR, BRONZE, OR BLACK

7’0" X 7’0" CLEAR, BRONZE, OR BLACK

8’0" X 7’0" CLEAR, BRONZE, OR BLACK

3’0" X 8’0" CLEAR, BRONZE, OR BLACK

3’6" X 8’0" CLEAR, BRONZE, OR BLACK

4’0" X 8’0" CLEAR, BRONZE, OR BLACK

6’0" X 8’0" CLEAR, BRONZE, OR BLACK

7’0" X 8’0" CLEAR, BRONZE, OR BLACK

8’0" X 8’0" CLEAR, BRONZE, OR BLACK

T200 DOORS WITH OFFSET PIVOTS FOR SURFACE CLOSER:

INCLUDES MAXIMUM SECURITY DEAD LOCK, INTERIOR THUMB TURN CYLINDER, EXTERIOR

CYLINDER, OFFSET PIVOTS, EFCO EXTRUDED PUSH/PULLS, AND 1/4" GLASS STOPS. (INACTIVE LEAF

OF PAIR DOORS INCLUDE FLUSH BOLTS)

SINGLE DOORS:

3’0" X 7’0" CLEAR, BRONZE, OR BLACK

3’6" X 7’0" CLEAR, BRONZE, OR BLACK

4’0" X 7’0" CLEAR, BRONZE, OR BLACK

3’0" X 8’0" CLEAR, BRONZE, OR BLACK

3’6" X 8’0" CLEAR, BRONZE, OR BLACK

4’0" X 8’0" CLEAR, BRONZE, OR BLACK

PAIR DOORS:

6’0" X 7’0" CLEAR, BRONZE, OR BLACK

7’0" X 7’0" CLEAR, BRONZE, OR BLACK

8’0" X 7’0" CLEAR, BRONZE, OR BLACK

6’0" X 8’0" CLEAR, BRONZE, OR BLACK

7’0" X 8’0" CLEAR, BRONZE, OR BLACK

8’0" X 8’0" CLEAR, BRONZE, OR BLACK

DPS/BB JULY 2000

Page 5

PAGE 4

SECTION II: DOOR PACKAGE IDENTIFICATION

(CONTINUED)

T200 DOORS WITH BUTT HINGES FOR CONCEALED OVERHEAD CLOSER:

INCLUDES MAXIMUM SECURITY DEAD LOCK, INTERIOR THUMB TURN CYLINDER, EXTERIOR

CYLINDER, BUTT HINGES, EFCO EXTRUDED PUSH/PULLS, AND 1/4" GLASS STOPS. (INACTIVE LEAF

OF PAIR DOORS INCLUDE FLUSH BOLTS)

SINGLE DOORS:

3’0" X 7’0" CLEAR, BRONZE, OR BLACK

3’6" X 7’0" CLEAR, BRONZE, OR BLACK

4’0" X 7’0" CLEAR, BRONZE, OR BLACK

3’0" X 8’0" CLEAR, BRONZE, OR BLACK

3’6" X 8’0" CLEAR, BRONZE, OR BLACK

4’0" X 8’0" CLEAR, BRONZE, OR BLACK

PAIR DOORS:

6’0" X 7’0" CLEAR, BRONZE, OR BLACK

7’0" X 7’0" CLEAR, BRONZE, OR BLACK

8’0" X 7’0" CLEAR, BRONZE, OR BLACK

6’0" X 8’0" CLEAR, BRONZE, OR BLACK

7’0" X 8’0" CLEAR, BRONZE, OR BLACK

8’0" X 8’0" CLEAR, BRONZE, OR BLACK

T200 DOORS WITH OFFSET PIVOTS FOR CONCEALED OVERHEAD CLOSER:

INCLUDES MAXIMUM SECURITY DEAD LOCK, INTERIOR THUMB TURN CYLINDER, EXTERIOR

CYLINDER, OFFSET PIVOTS, EFCO EXTRUDED PUSH/PULLS, AND 1/4" GLASS STOPS. (INACTIVE

LEAF OF PAIR DOORS INCLUDE FLUSH BOLTS)

SINGLE DOORS:

3’0" X 7’0" CLEAR, BRONZE, OR BLACK

3’6" X 7’0" CLEAR, BRONZE, OR BLACK

4’0" X 7’0" CLEAR, BRONZE, OR BLACK

3’0" X 8’0" CLEAR, BRONZE, OR BLACK

PAIR DOORS:

6’0" X 7’0" CLEAR, BRONZE, OR BLACK

7’0" X 7’0" CLEAR, BRONZE, OR BLACK

8’0" X 7’0" CLEAR, BRONZE, OR BLACK

6’0" X 8’0" CLEAR, BRONZE, OR BLACK

3’6" X 8’0" CLEAR, BRONZE, OR BLACK

4’0" X 8’0" CLEAR, BRONZE, OR BLACK

7’0" X 8’0" CLEAR, BRONZE, OR BLACK

8’0" X 8’0" CLEAR, BRONZE, OR BLACK

NOTE: SINGLE DOORS ARE AVAILABLE AS HINGED RIGHT SWING OUT, HINGED LEFT SWING

OUT, HINGED RIGHT SWING IN, AND HINGED LEFT SWING IN WHEN HARDWARE

PREPARATIONS ARE SPECIFIED.

SEE SECTION B25 IN THE EFCO PRICE CATALOG FOR AVAILABLE PACKAGE

OPTIONS. INCLUDED OPTIONS ARE:

T300 MEDIUM STILE TIE ROD DOOR

1" GLASS STOPS

7 1/2" BOTTOM RAIL

10" BOTTOM RAIL

DPS/BB JULY 2000

Page 6

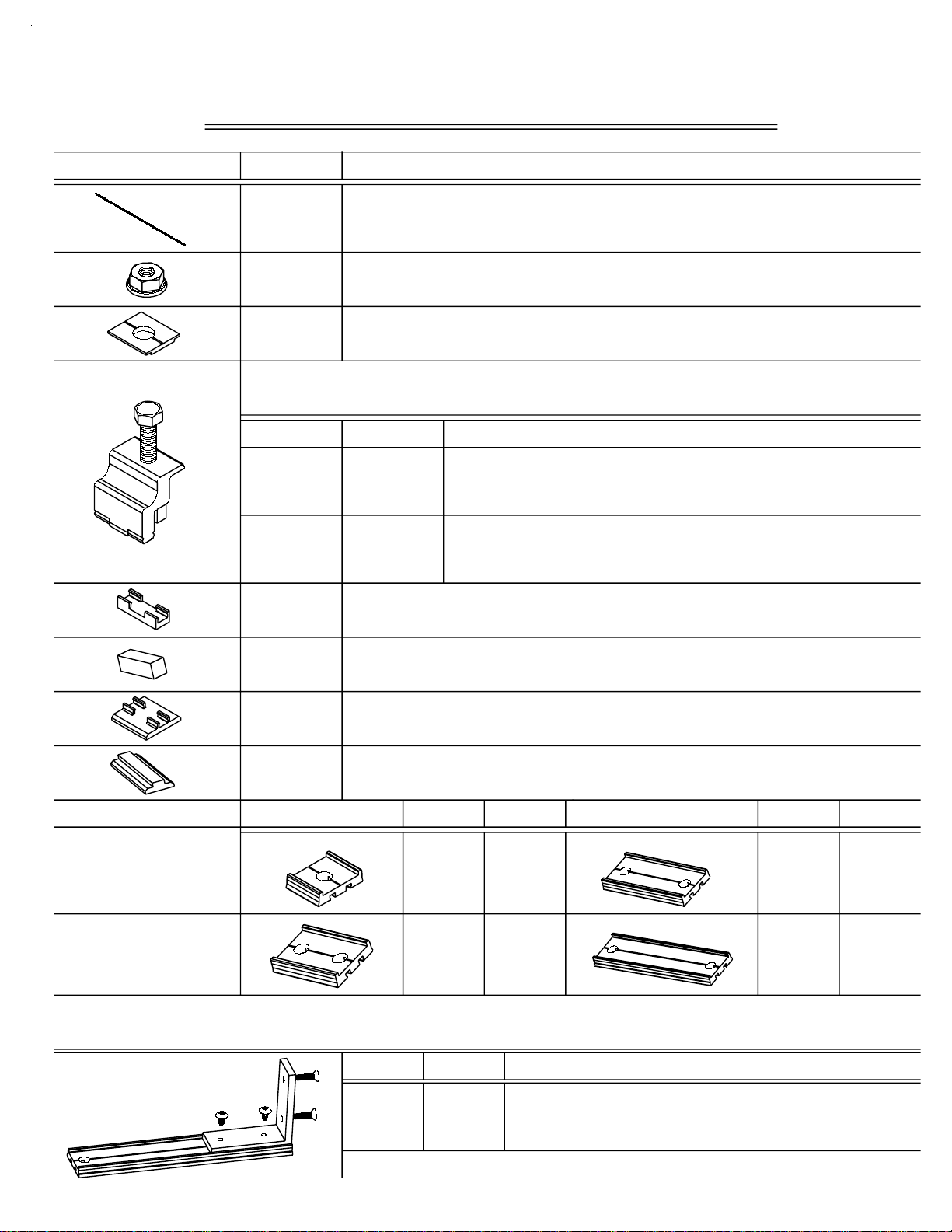

SECTION III: PARTS IDENTIFICATION

DETAIL PART # DESCRIPTION/ PARTS IN PACKAGE

M120 36" TIE ROD

M151 48" TIE ROD

IQT1 3/8"-16 SERRATED LOCK NUT

PAGE 5

FS75 TIE ROD WASHER

OFFSET JACK SCREW ASSEMBLY

PART #

STILE

K421 T200

K432 T300

HB17 - OFFSET JACK SCREW BLOCK

WM62 - FOAM SPRING BLOCK

IHP2 - OFFSET JACK SCREW 1/4"-20 X 3/4" HX-MS

HB17 - OFFSET JACK SCREW BLOCK

WM62 - FOAM SPRING BLOCK

M103 - OFFSET JACK SCREW 1/4"-20 X 2" HX-MS

# / DESCRIPTION

HB18 1/4" OFFSET JACK SCREW CAP

H159 1/4" SETTING BLOCK

HB19 1" OFFSET JACK SCREW CAP

H348 1" SETTING BLOCK

(TR200 ONLY)

TOP RAIL

ADAPTORS

BOTTOM

RAIL

ADAPTORS

PART #

STILE

T200

FS76

(2 3/8"

TOP RAIL)

T200

FS77

(4"

BOTTOM

RAIL)

10" BOTTOM RAIL ADAPTOR PACKAGE

PART #

K459

STILE

T200

T300

NOTE: SEE PAGE 9 FOR APPROPRIATE APPLICATION.

FT29 - 10" BOTTOM RAIL ADAPTOR

FT30 - 10" BOTTOM RAIL ADAPTOR CLIP

MS01 - #12-24 X 1/2" PL-PH-MS 18-8

S123 - #12-24 X 3/4" PH-FH-SMS 18-8 F

# / DESCRIPTION

PART #

STILE

T300

FT13

FT03

DPS/BB NOVEMBER 2000

(3 1/2"

TOP RAIL)

T200/T300

(7 1/2"

BOTTOM

RAIL)

Page 7

PAGE 6

SECTION III: PARTS IDENTIFICATION

BUTT HINGE PACKAGES

PART #

FINISH

HY90 CLR.

HY92 BRZ.

FINISH PART #

K900 CLR.

K901 BRZ.

4" X 4 1/2" BUTT HINGES

BUTT HINGE BACKER PACKAGES

# / QUANTITY / DESCRIPTION

F528 - 1 - 4" X 4 1/2" BUTT HINGE BACKER PLATE

M100 - 4 - #12-24 X 3/4" PH-FH-MS 18-8

F528 - 1 - 4" X 4 1/2" BUTT HINGE BACKER PLATE

M108 - 4 - #12-24 X 3/4" PL-FH-MS 18-8 OX

PUSH/PULL PACKAGES

DESCRIPTION

(CONT.)

FINISH

CLR.

BRZ.

BLK.

CLR.

BRZ.

BLK.

IHP2 - 1/4" - 20 X 3/4"HX-MS 18-8 PULL HANDLE ATTACHMENT

M104 - 1/4" - 20 X 2 1/4" PL-TH-MS 18-8 BOLT FOR PUSH BAR

M105 - 1/4" - 20 X 2 1/2" HX-MS 18-8 THRU BOLT FOR PUSH BAR

ATTACH.

IHP2 -1/4"-20 X 3/4"HX-MS 18-8 PULL HANDLE ATTACHMENT

M104 -1/4"-20 X 2 1/4" PL-TH-MS 18-8 BOLT FOR PUSH BAR

M105 -1/4"-20 X 2 1/2" HX-MS 18-8 THRU BOLT FOR PUSH BAR

ATTACH.

DESCRIPTION

36" & BELOW

LEAF SIZES

36" TO 48"

LEAF SIZES

PART #

K415

K416

K417

K418

K419

K420

TOP, BOTTOM, AND INTERMEDIATE OFFSET PIVOT FRAME PORTIONS

DESCRIPTION

H25C

HZ1N

HZ1L

HZ1M

HZ1Q

HZ1R

FINISH/HANDEDPART #

CLR.

BRZ.

CLR.-LH

CLR.-RH

BRZ.-LH

BRZ.-RH

REGENT TOP PIVOT

(TOP PIVOTS ARE NOT HANDED)

REGENT BOTTOM PIVOT

HZ1J

HZ1K

HZ1O

HZ1P

CLR.-LH

CLR.-RH

BRZ.-LH

BRZ.-RH

REGENT INTERMEDIATE OFFSET

PIVOT

DPS NOV. 2003TIE ROD DOORS

Page 8

PAGE 7

SECTION III: PARTS IDENTIFICATION (CONTINUED)

DESCRIPTION

LOCK SUPPORT CHANNEL FOR REGENT 2333

K110 MILL

PART # FINISH DESCRIPTION

1 1/8" BACKSET DEAD LOCK

(T300 BEVELED STILE ONLY)

LOCK FACE PLATES

HZ80 CLR.

HZ82 CLR.

HZ81 BRZ.

HZ83 BRZ.

HZ78 CLR.

HZ79 BRZ.

PART # DESCRIPTION

HZ77 REGENT 2333 1 1/8" BACKSET DEAD LOCK

PART #

HZ0N CLR.

H20P BRZ.

PART # FINISH DESCRIPTION

FINISH DESCRIPTION

RH

LH

RH

LH

RADIUS

RADIUS

THUMB TURN CYLINDER

HZ0L CLR.

HZ0M BRZ.

HZ1F CLR.

HZ1G BRZ.

TIE ROD DOORS DPS JAN. 2004

KEYED DIFFERENT OR KEYED ALIKE

(AS SPECIFIED ON FACTORY ORDER)

DESCRIPTIONFINISHPART #

EFCO STANDARD TOP & BOTTOM FLUSH BOLTS

(USE AT INACTIVE DOOR LEAF @ PAIR DOORS)

Page 9

PAGE 8

SECTION IV: OFFSET JACK SCREW ASSEMBLY

STEP #1 OFFSET JACK SCREW BLOCK INSERTION

Insert the offset jack screw block assembly (#K421/K432) through the end of the top rail

and down into the slot cut in the glazing side of the rail. Position the edge of the jack

screw assembly toward the side of the top rail with the hole prep for the jack screw.

See Figure #1.

STEP #2 JACK SCREW INSERTION

Insert one (1) jack screw (#IHP2/M103) per top rail. Tighten the screw enough to allow

the jack screw cap (#HB18 or #HB19) to be snapped to the jack screw block

(#K421/K432). See Figure #2.

STEP #3 JACK SCREW CAPS

Determine which door glazing is used. For 1/4" glass, use the 1/4" jack screw cap

(#HB18). For 1" glass, use the 1" jack screw cap (#HB19). Snap the correct jack screw

cap to the jack screw block. Use one cap per top rail. See Figure #2 below.

ALIGN THIS EDGE

WITH HOLE PREP

FIGURE #1

STEP #4 TIE ROD CUT LENGTH

Measure the tie rod (#M120 or #M151) as shown in Figure #3 and cut, if required, to the

formulas below.

FIGURE #2

OFFSET HOLE PREP

#K421

#K432

#HB19 AT 1" GLASS

#HB18 AT 1/4" GLASS

#IHP2

#M103

SLOT IN TOP RAIL

SECTION V: TIE ROD CUT LENGTH

CUT LENGTH = D.O.W. minus 2 3/4" T200

CUT LENGTH = D.O.W. minus 5 1/2" T300

#M120 OR #M151

FIGURE #3

DPS/BB JULY 2000

Page 10

PAGE 9

SECTION VI: TIE ROD ASSEMBLY

STEP #5 TOP AND BOTTOM RAIL ADAPTOR INSERTION

Slide the top rail adaptors (#FS76) into the vertical stiles and center the hole in the

adaptors over the top hole in the door stiles, as shown in Figure #4.

Note: Position the bottom rail adaptors by aligning the bottom hole of the adaptor with the

hole in the bottom of the stile, as shown in figure #5.

STEP #6 TIE ROD AND RAIL ASSEMBLY

Insert the tie rod (#M120 or #M150) through the adaptor and door stile. Apply two (2)

washers (#FS75) and two (2) (#IQT1) lock nuts per rail to the tie rod. Note: The washer is

required at the beveled stile T200 ONLY. Align the top and bottom rails over the tie rods

and rail adaptors and install the lock nuts and washers to the opposing stile, as shown in

Figure #6. Use a 9/16" combination wrench and tighten the lock nuts at each corner.

CAUTION: Over tightening the lock nuts may cause the door rails to bow.

Note: Follow the instructions above for 10" bottom rail assembly, and fasten the 10" bottom

rail to the K459 10" bottom rail adaptor clip with the supplied S123 #12-24 x 3/4" fasteners

(Figure 7). Attachment of the 10" bottom rail is through the top of the rail in prefabricated

countersink holes that provide the correct location for the S123 fasteners.

#IQT1 (2)

3/8"-16 HEX

LOCK NUT-ZC

FS77

-

4" BOTTOM RAIL (8601)

FT03

7 1/2" BOTTOM RAIL (8608)

FOR T200

-

FOR T200/T300

#FS75

(T200 BEVELED STILE ONLY)

FIGURE #4

FS76 -

FOR T200 2 3/8" TOP RAIL (8600)

FT13 -

FOR T300 3 1/2" BOTTOM RAIL (8596)

FIGURE #5

FIGURE #6

#S123

12-24 X 3/4"

#M120/#M151

3/8"-16 ALL THREAD-ZC

K459 -

10" BOTTOM RAIL (8561)

FOR T200/T300

#FS75

#IQT1

3/8"-16 HEX

LOCK NUT-ZC

#M120/#M151

3/8"-16 ALL THREAD-ZC

FIGURE #7

DPS/BB NOVEMBER 2000

Page 11

PAGE 10

SECTION VII: GLAZING AND REGLAZING DOORS

STEP #7 SETTING BLOCKS APPLICATION

Insert three (3) setting blocks (#H348 or #H159) at approximately 6" from the inside

corners. Setting blocks are used at the door stiles and the bottom rail only. An adjustable

jack screw will be used at the top rail. Refer to Figure #1 on page 8. If required, apply

silicone to the back of the setting blocks to keep them in the correct position until the

glass is installed. See Figure #8.

STEP #8 CLEANING THE GLAZING TRACK

Check to ensure that the glazing surface of the door and glazing bead are free from metal

shavings. Metal shavings may be blown out with air or brushed out. See Figure #9.

STEP #9 INSTALLING GLASS STOPS

The glass stops are designed to be inserted into the glazing tabs in the door rails and then

rotated down to lock into place. See Figure #9. Use a soft faced mallet, if needed. Hit on

the corner of the glass stop, making sure not to distort the metal. Start at one end and

work toward the other end of the glass stop.

6"

FIGURE #9

ADJUSTABLE

JACK SCREW

1.

GLAZING

TRACK

FIGURE #8

2.

PIVOT EDGE

SETTING

BLOCK

LOCK STILE

3.

6"

DPS/BB JULY 2000

Page 12

PAGE 11

SECTION VIII: PUSH/PULL ASSEMBLY

STEP #10 PUSH BAR END CAPS

If required, cut the push bar to length. The push bar must be cut from the hinge end.

Consult the chart below for the correct cut length formula. Insert the push bar end caps

into the ends of the push bar as shown in Figure #10. Note: To ensure a tight fit, EFCO

recommends applying a thin coat of two part epoxy to the legs of the end caps prior to

being inserted into the push bar. See Figure #10.

STEP #11 PULL HANDLE BOLTS

Start one (1) 1/4"-20 x 3/4" (#IHP2) hex head bolt into the factory installed riv nut located

in the lock stile. Insert one (1) 1/4"-20 x 2 1/2" (#M105) hex head bolt into the predrilled

hole in the lock stile.

STEP #12 PUSH BAR APPLICATION

Hold the push bar to the door and start the hex head bolt (#M105) at the lock stile as

shown in Figure #10. After installing the hex head bolts (#IHP2 and #M105), leave hex

head bolts loose, with a minimum 5/16" gap. This will allow the pull handle to slide under

the hex head bolt.

STEP #13 LOCK STILE BOLT

Continue holding the push bar to the door and align the hole on the hinge stile with the

hole in the mounting cap. Attach the hinge stile of the push bar with the 1/4"-20 x 2 1/4"

PL-TH-MS (M104) dress bolt shown in Figure #10.

STEP #14 PULL HANDLE APPLICATION

Slide the pull handle under the hex head bolts at the lock stile and tighten.

#M105

1/4"-20 X 2 1/2

HX-MS 18-8

1/4"-20 X 2 1/4

#M104

PL-TH-MS 18-8

#IHP2

Hinge/Pivot Stile

FIGURE #10

TWO PART EPOXY

APPLIED TO LEGS

OF END CAPS

HB20/HB21 PUSH

BAR END CAPS

#I107 1/4"-20

RIV NUT

LOCK STILE

SINGLES

PUSH BAR CUT LENGTH FORMULA

(DOOR OPENING WIDTH) - 3.500"

(DOOR OPENING WIDTH) (1/2) - 3.438" PAIRS

DPS/BB JULY 2000

Page 13

PAGE 12

SECTION IX: OFFSET PIVOT APPLICATION

STEP #15 SETTING THE DOOR INTO THE FRAME

The top pivot will be attached to the door stile and requires no adjustment after the door

has been set into the frame. All adjustments to the door are by the intermediate offset

pivot if used, and the bottom offset pivot. To set the door, depress the top pivot pin and

hold down with your index finger. Place the door portion of the bottom pivot onto the

frame portion of the bottom pivot. Align the pin in the door portion of the top pivot with the

hole in the frame portion of the top pivot and release the pin as shown in Figure #11.

NOTE: If an intermediate offset pivot is used, retract the pin in the frame portion of the

intermediate pivot before releasing the pin in the top pivot. Use a flat screwdriver to

remove the cap on the bottom of the intermediate pivot and turn the pin counterclockwise

to lower. See page 13, Step #16 for details.

DOOR REMOVAL

To remove the door, remove the cap and lower the pin in the intermediate pivot, if used.

If the pin will not lower, remove the screws from the frame portion. Open the door to 90˚

and depress and rotate the pin toward the pivot edge of the door to lock in the retaining

pin as shown in Figure #12. After the top pivot pin is clear from the frame portion, the

intermediate pivot will slide free from the frame. See Figure #12.

FRAME PORTION

OF PIVOT

DOOR PORTION

OF PIVOT

PIN ROTATION

TO LOCK

RETAINING PIN

HINGE PIN

PIN SHOWN

RETRACTED

TOP PIVOT

PIVOT EDGE

FIGURE #11

FIGURE #12

DPS/BB JULY 2000

Page 14

PAGE 13

SECTION IX: OFFSET PIVOT APPLICATION (CONT.)

STEP #16 SETTING THE DOOR INTO THE FRAME

Use a flat tipped screwdriver to remove the cap from the bottom of the intermediate offset

pivot. Turn the pivot pin counterclockwise to lower the pin. After the pin has been retracted,

rotate the door open to 90˚ and set the door on the bottom pivot. Then, raise the pivot pin

on the intermediate pivot by turning the pivot pin clockwise. See Figure #13.

DOOR REMOVAL

Remove the pivot caps and retract the pivot pins. Open and tilt the door away from the pivot

jamb to clear the frame pivots.

PIVOT PIN

FRAME PORTION

OF PIVOT

PIVOT CAP

FIGURE #13

DOOR PORTION

OF PIVOT

DPS/BB JULY 2000

Page 15

PAGE 14

SECTION IX: OFFSET PIVOT APPLICATION (CONT.)

STEP #17 BOTTOM OFFSET PIVOT

Attach the bottom offset pivot frame portion to the bottom of the jamb using three (3)

#12-24-1/4" F.H.M.S., and attach the threshold to the bottom pivot with two (2) #12-24 x

1/4" PL-FH-MS. Adjust the door clearance by turning the pin clockwise to lower the door,

and counterclockwise to raise the door. After the proper door clearances are reached,

tighten the set screw on the pivot with a 3/32" Allen wrench. See Figure #14.

#12-24 X 3/4"

F.H.M.S.

FIGURE #14

PIVOT PIN

SET SCREW

#12-24 X 1/4"

F.H.M.S.

SECTION X: BUTT HINGE APPLICATION

STEP #18 BUTT HINGE INSTALLATION

Be sure the butt hinge reinforcing plate in the frame is in the correct position. Align the

hinged side of the door to the hinge reinforcing plate in the frame. Using a #3 tipped

screwdriver, attach the hinges to the frame with four (4) #12-24 x 3/4" F.H.M.S. as shown

in Figure #15.

#12-24 X 1/2"

F.H.M.S.

FIGURE #15

DPS/BB JULY 2000

Page 16

PAGE 15

SECTION XI: HEADER PREPARATION FOR C.O.C.

STEP #19 HEADER PREPARATION

For C.O.C. header preps, see chart below for dimensions based on application.

1. DIMENSION ’A’, face of jamb to center line of spindle must be maintained.

2. DIMENSION ’B’, pivot or hinge side of header to center line of spindle regardless of header

width. See Figure #16.

STEP #20 C.O.C. INSTALLATION

1. Install the closer in the prepared header.

2. Install the slide in the slide channel with the end marked 90˚ toward the hinge edge of

the door, if the 90˚ backstop closer is used, or with the end marked 105˚ backstop closer.

3. Place the arm on the closer spindle and tighten the 1/4"-20 socket head screw

securely. Rotate the arm from center as if the door was open. Place the hole in the arm

over the pin in the slide and secure with the ’C’ clip.

NOTE: For other information on C.O.C.’s, contact EFCO’s Manufacturing Department.

A

FIGURE #16

105

90

CHART FOR C.O.C. HEADER PREPARATIONS

HINGING

OFFSET PIVOTED DOOR

3/32" RECESSED DOOR

MINIMUM 4" HEADER

BUTT HINGED DOOR

4"x 4 1/2" W/ 3/32" RECESS

MINIMUM 4" HEADER

SECTION XII: CLOSER ADJUSTMENTS

STEP #21 LATCHING AND CLOSING SPEEDS

BACKSTOP

105

90

105

90

DIM"A"

2"

2"

2"

2"

"C""L"

DIM"B"

3 3/4"

3"

2 3/4"

2 3/4"

A. The latch and closing speeds have been preset, but

may require further adjustment. See Figure #17.

B. The closing valve is preset to the minimum speed.

C. To increase latching and/or closing speed, turn the

valves counterclockwise.

D. To decrease latching and/or closing speed, turn the

valves clockwise.

LATCHING SPEED

"L" valve

CLOSING SPEED

"C" valve

FIGURE #17

DPS/BB JULY 2000

Page 17

PAGE 16

SECTION XIII: CLEARANCE ADJUSTMENTS

STEP #22 MINOR CLEARANCE ADJUSTMENT

Open and support the door with a wedge. Use the wedge to raise the door to the

desired position. With a 7/16" socket and ratchet, turn the jack screw clockwise until

pressure is applied to the glass. To lower the corner, turn the jack screw

counterclockwise. Readjust the wedge and tighten the jack screw until pressure is

applied to the glass. The door can be adjusted again, if required. See Figure #18.

Note: Do not attempt to raise the door by the jack screw. Damage may occur to the

jack screw or door glass. The jack screw is used to hold the glass and door in position.

Use the wedge to raise the door.

FIGURE #18

DOOR WEDGE

DPS/BB JULY 2000

Page 18

PAGE 17

SECTION XIV: TIE ROD DOOR CUT

LENGTH ALTERATIONS

STEP #23 LOCK STILE LENGTH ALTERATIONS

The minimum cutoff for the lock stile is 9/16" as shown in Figure #19. The minimum cutoff

needs to be taken from the top of the lock stile only. This will prevent having to relocate

the M.S. lock.

STEP #24 HINGED STILE LENGTH ALTERATIONS

The minimum cutoff for the hinged stile is 9/16" as shown in Figure #20. When using a

C.O.C., the cutoff must be taken from the bottom of the hinged stile only. This will prevent

interference with the preps for the concealed overhead closer at the top of the stile.

STEP #25 TOP RAIL LENGTH ALTERATIONS

The maximum cutoff for the top rail is 11/16" as shown in Figure #21. The cutoff must be

taken from the offset jack screw end so as not to interfere with the concealed overhead

closer prep at the hinged end of the rail.

Note: Fabrication done in the field must bypass the factory drilled holes by 1/2 the

diameter of the hole. There is no minimum cutoff length for the bottom rail.

LOCK STILE CUTOFF

FACTORY PREPPED HOLE

1 9/16"

9/16"

REF.

.391"(25/64")

DRILL THRU

FIGURE #19

.391" (25/64")

DRILL THRU

9/16" MIN.

CUTOFF

1 1/8"

TOP RAIL CUTOFF

FIGURE #21

CUTOFF

11/16" MAX.

MIN.

FACTORY PREPPED HOLE

9/16" MIN.

CUTOFF

9/16"

REF.

HINGED STILE CUTOFF

FIGURE #20

2 1/8"

DPS/BB JULY 2000

Loading...

Loading...