Page 1

Y

Series 5900

Silicone structural glazed curtain wall

Installation instructions

Part NO.

February 2013

354

Page 2

Series 5900 Silicone Structural Glazed Curtain Wall Installation

TABLE OF CONTENTS

SECTION PAGE

I. General Notes & Guidelines …………………………………………….……. 3-4

II. Perimeter Application ………...…….…………………………………….…… 5-6

III. Anchor Installation ………………..………………………………………..….. 7

IV. Frame Assembly .………………….…………………………………………..… 8-9

V. Vertical Splice Applications ……….……………………………….……….. 10-12

VI. Glazing Preparation …………………………………………………………….. 13-14

VII. Glazing Adaptors ………………………………………………………..….…… 15

VIII. Sealant at Splice Joint ….……………………………………………..……… 16

IX. Preset Gaskets …………………………………………………………………… 17

X. Miscellaneous Applications …………………………………………………… 18

XI. Pressure Plate Attachment ………………………………………………….. 19-20

XII. Temporary Retainers and Sealant ………………………………………… 21

XIII. Exterior Cover Installation …………………………………………………… 22

XIV. Steel Reinforcement …………………………………………………………… 23

Note: Please reference EFCO's "Understanding Condensation" brochure which can be obtained

through your EFCO representative.

Condensation will form on any surface when unfavorable conditions (interior temperature

and relative humidity and exterior temperature) are present. When the formation of excessive

condensation is a concern, it is highly recommended that a design professional is utilized to

perform an analysis of the shop drawings to recommend the best possible installation methods.

Please contact your EFCO representative for information on EFCO's Thermal Analysis Services.

Many current installation practices lead to an increase in the possibility of the formation of

condensation. Though not all inclusive, the list of examples below illustrates conditions under

which condensation is likely to occur:

1. Bridging system thermal break with non-thermally broken metal flashing or lint els

that are exposed to the exterior

2. System exposure to cold air cavities

3. Interior relative humidity levels not maintained at recommended levels, see

EFCO’s “Understanding Condensation” brochure

4. Inadequate separation between system and surrounding condition at perimeter

5. Product combinations during the shop drawing stage that result in bridging thermal

breaks of one or all products involved

Minimizing Condensation

EFCO CORPORATION 6/2012 PART NO. Y354 Page 2 of 23

Page 3

Series 5900 Silicone Structural Glazed Curtain Wall Installation

Section I: General Notes & Guidelines

I. HANDLING / STORING / PROTECTING ALUMINUM - The following

precautions are recommended to assure early acceptance of your products and

workmanship.

A. HANDLE CAREFULLY - Store with adequate separation between

components so the material will not rub together. Store material off the

ground. Protect materials against weather elements and other construction

trades.

B. KEEP MATERIAL AWAY FROM WATER, MUD, AND SPRAY - Prevent

cement, plaster, and other materials from contacting with and damaging the

finish. Do not allow moisture to be trapped between the finished surface and

the wrapping material.

C. PROTECT MATERIALS AFTER ERECTION - Wrap or erect screens with

plastic sheeting over material. Cement, plaster, terrazzo, and other alkaline

materials are very harmful to the finish and are to be removed with soap and

water before hardening. Under no circumstances should these materials be

allowed to dry or permanent staining will occur.

II. GENERAL GUIDELINES - The following practices are recommended for all

installations:

A. REVIEW APPROVED SHOP DRAWINGS – Become thoroughly familiar

with the project. Shop drawings govern when conflicting information exists in

these installation instructions.

B. INSTALL ALL FRAMING MATERIAL PLUMB, LEVEL, AND TRUE –

Proper alignment and relationships to benchmarks and column centerlines, as

established by the architectural drawings and the general contractor, must be

maintained.

C. The sequence of erection should be coordinated with the project

superintendent to prevent delays and minimize the risk of material damage.

Note: If preset anchors are required, coordinate and supervise

anchor placement with the general contractor.

D. Verify that all job site conditions and accompanying substrates receiving the

installation are in accordance with the contract documents. If deviations

occur, notification must be given IN WRITING to the general contractor and

differences resolved before proceeding further with the installation in the

questionable area.

E. Prevent all aluminum from coming in direct contact with masonry or dissimilar

materials by means of an appropriate primer.

EFCO CORPORATION 6/2012 PART NO. Y354 Page 3 of 23

Page 4

Series 5900 Silicone Structural Glazed Curtain Wall Installation

Section I: General Notes & Guidelines

F. Follow EFCO framing installation and glazing instructions.

G. Verify contents of all material shipments received upon arrival. Verify quantity

and correct finishes. NOTIFY EFCO IMMEDIATELY OF ANY

DISCREPANCIES OR DAMAGE, THAT MAY HAVE OCCURRED.

H. Throughout these instructions the term “SEALANT” will appear. For the

purposes of these instructions, sealant is to be defined as the following:

SEALANT - A weather resistant, gunnable liquid filler which when cured

provides a resilient, flexible (± 50% movement capability) air and water seal

between similar and dissimilar materials.

All sealant must meet ASTM C 920, CLASS 50.

BUTYL SEALANT- A non-skinning, non-hardening material (NAAMM

Reference Standard 5C-1)

NOTE: All sealant must be compatible with all surfaces where adhesion is

required, including other sealant surfaces. All frame surfaces should

be clean, dry, dust, and frost free. If a primer is required, it must be

applied to clean surfaces. All perimeter substrates shall be clean and

properly treated to receive sealant.

This system is designed and has been tested to utilize butyl or

silicone sealants at all internal joineries, i.e., joint plugs, gasket

intersections, etc.

Regardless of the sealant used, the customer should contact the

sealant manufacturer to determine compatibility and adhesion.

Follow sealant manufacturer's proper application procedures and

quality assurance programs for weather sealing.

Maintain caulk joints as shown in the approved shop drawings.

Unless specified otherwise, most sealant manufacturers recommend

a 3/8” minimum perimeter caulk joint. A 3/4” minimum joint is

recommended at the head condition to accommodate thermal

expansion and contraction.

Anchoring surfaces of perimeter construction must be level and

plumb within the adjustable limits of the head, jamb, and sill

framing.

EFCO CORPORATION 6/2012 PART NO. Y354 Page 4 of 23

Page 5

T

“

“

“

Series 5900 Silicone Structural Glazed Curtain Wall Installation

Section II: Perimeter Application

Perimeter Application

A.) For anchoring to perimeter and providing a spacer for glazing pockets at head,

jamb, and sill.

Note: Anchoring surfaces of perimeter constructions must be level and plumb

Fill gasket race with sealant in top

bottom of each vertical mullion to

marry with perimeter sealant.

within the adjustments of the head, jamb, or sill. See “APPROVED” shop

drawings for adjustment limits.

op anchor is recommended

at head connection to

accommodate thermal

movement.

M” Anchor

CRITICAL

SEAL LINE

Primary seal

Optional

cosmetic seal

½” Nominal.

(3/8” Minimum)

M” Anchor

Pressure plate

with return

Erector to supply and apply

bond breaker tape across face

of anchor to prevent 3-sided

sealant adhesion.

F” Anchor

Line of critical

perimeter

sealant shown

Size and locate

anchor bolts in the

field, based on job

conditions and

structural load

requirements.

Filler is cut short to

clear shear block.

Mullion Anchors

Refer to page #8 for further information on

horizontal installation and sealant methods.

Note: The perimeter caulking must be done prior to glazing. Reference the

“APPROVED” shop drawings for caulk joint size unless otherwise specified.

Most sealant manufacturers recommend a 3/8” minimum joint width.

EFCO CORPORATION 6/2012 PART NO. Y354 Page 5 of 23

Page 6

Series 5900 Silicone Structural Glazed Curtain Wall Installation

Section II: Perimeter Application

Optional Perimeter Mullions

Cap seal fastener

heads with sealant.

CRITICAL

SEAL LINE.

Primary seal

Optional

cosmetic seal

½” Nominal

3/8” Minimum)

(

Miter adaptor

and filler at

vertical to

horizontal

intersections

and seal

watertight.

Optional Perimeter Jamb Mullion

Perimeter With Channel Adaptor Reveal

Note: The caulking must

overlap the metal to

metal joint at the

critical seal line.

Set adaptors

in sealant

typical.

Note:

Setting

chair

must be

rolled into

position

before

glazing

adaptors.

Optional Perimeter Sill Mullion

Optional Perimeter Head Mullion

EFCO CORPORATION 6/2012 PART NO. Y354 Page 6 of 23

Page 7

g

“

A

g

A

g

Series 5900 Silicone Structural Glazed Curtain Wall Installation

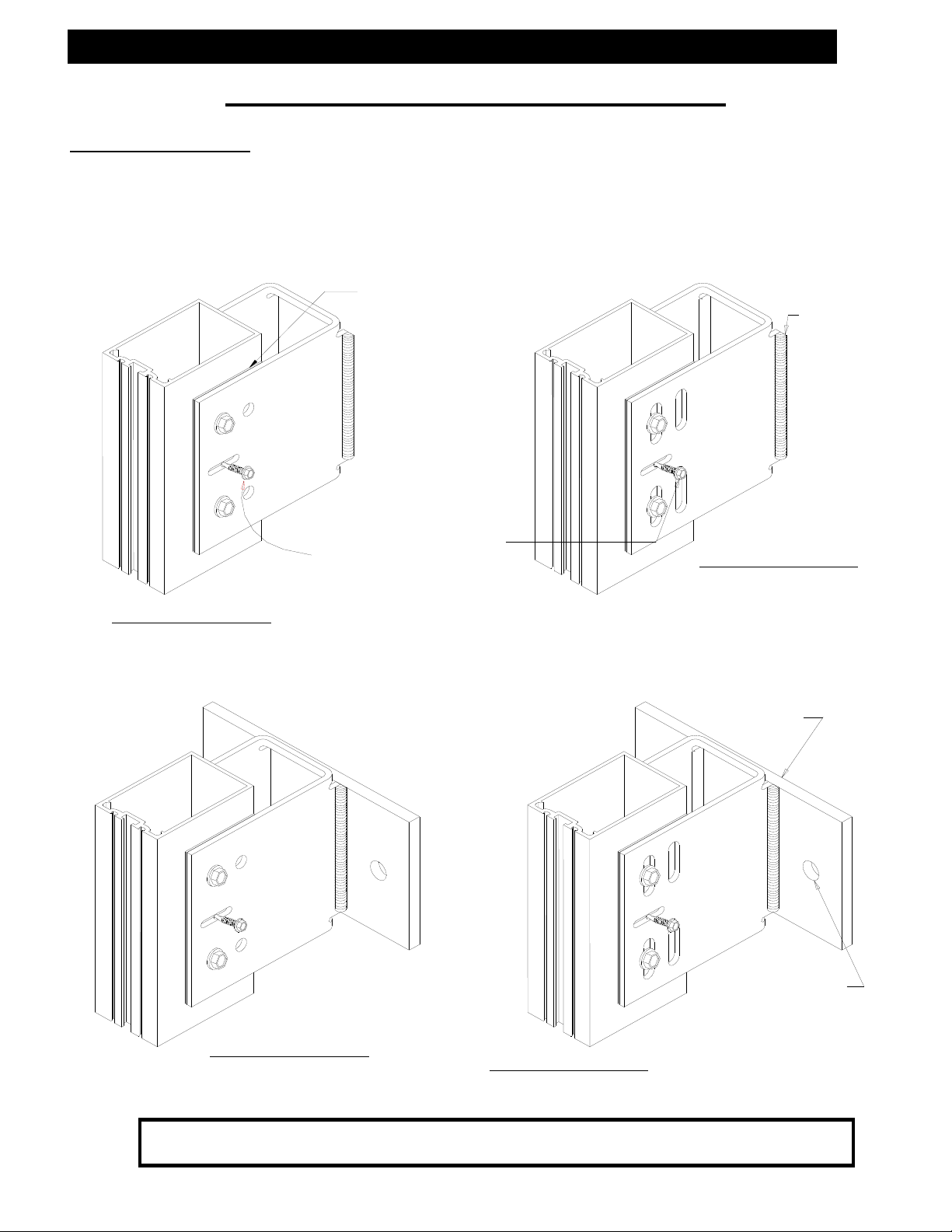

Section III: Anchor Installation

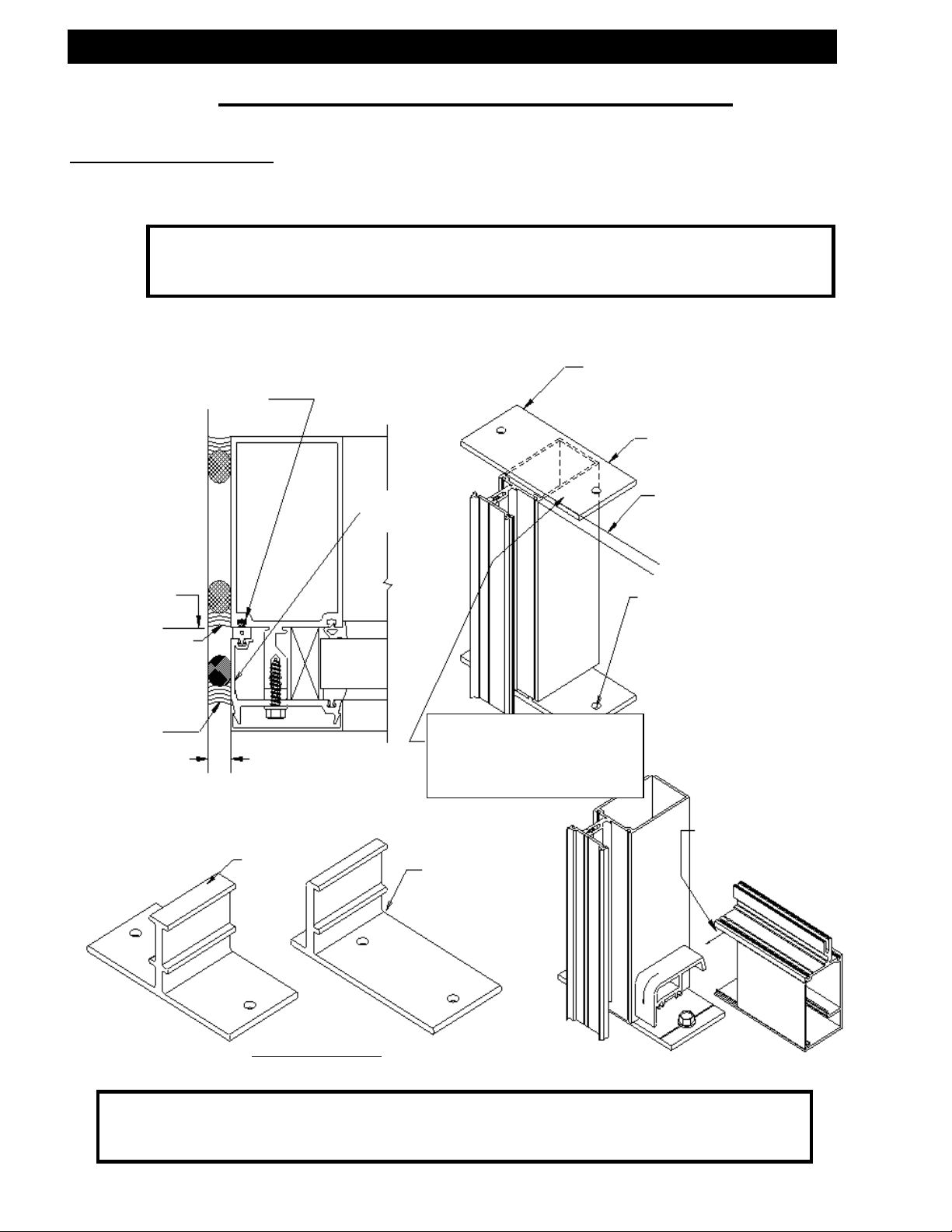

Anchor Installation

A.) Attach anchors to mullions with temporary alignment screws as shown below.

B.) Install the vertical mullions in position and attach anchors to the building structure

per the “APPROVED” shop drawings.

High impact polystyrene

Dead Load Anchors

Welded to building structure

horseshoe shim

fter final alignment

of mullion, align drill

mullion in best hole

location. Note that

the hole must be a

minimum of 1” from

the back of the

mullion to clear any

steel reinforcement

required for the job.

Use #12 X 1” Tek screw

for alignment only. The

screw must be removed

after installation of the

thru bolt at the wind

load anchor to allow for

thermal expansion and

contraction.

Dead Load Anchors

Bolted to building structure

Note: Elevation of slabs must be within adjustment limits of the anchorage

system. See “APPROVED” shop drawings for allowable adjustment.

EFCO CORPORATION 6/2012 PART NO. Y354 Page 7 of 23

Wind Load Anchors

Bolted to buildin

structure

Weld to buildin

structure per

APPROVED”

shop drawings.

Wind Load Anchors

Welded to building structure

steel plate is factory

welded to the channel

anchor and is sized per

the job requirements.

Refer to the “APPROVED”

shop drawings.

Size and locate anchor

bolts based on the job

conditions and structural

requirements. Refer to

the “APPROVED” shop

drawin

s.

Page 8

A

Series 5900 Silicone Structural Glazed Curtain Wall Installation

Section IV: Frame Assembly

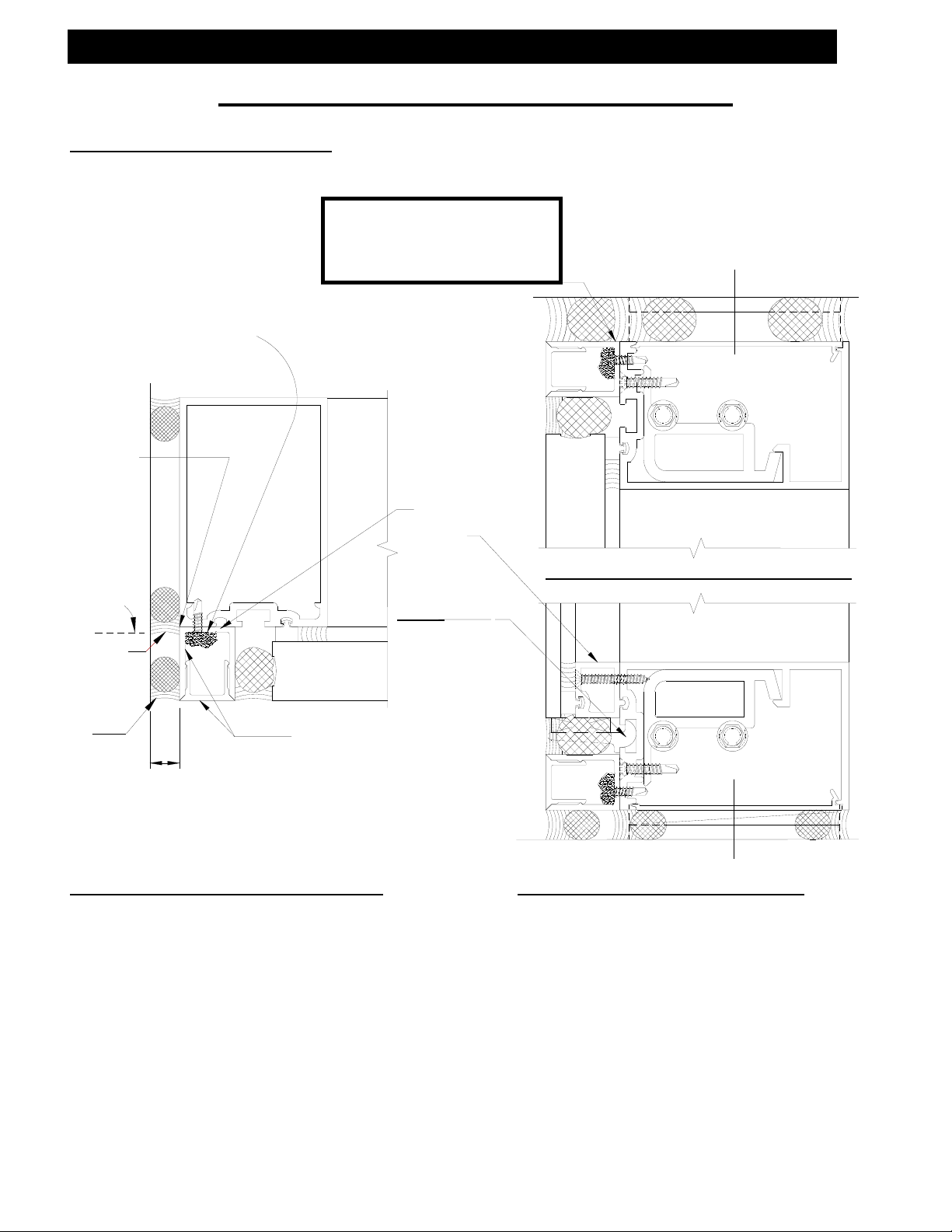

Frame Assembly – Captured Horizontals

A.) Assemble shear blocks, splices, anchors, etc., to mullions as required.

B.) Install and anchor vertical mullions to form the vertical sections per “APPROVED”

shop drawings

Note: Check overall frame

dimensions on every 5

openings on long runs to

avoid dimensional build-up.

*

DIMENSION CHECK

EVERY 5 UNITS

Interior horizontals are

cut D.L.O. – 1/32”. The

erector is to split the

difference on both sides.

1” Minimum

Rotate the horizontal over the shear

block from the interior of the

system. With the horizontal in

position, fasten with (1) #10-16 X

1” PLFH Tek3 screw on each end of

horizontal, and tighten as required.

¼” X 1 ½” HWHSMS

pply sealant to the

face and top of the

shear block as shown.

Note: The commercial cut to length tolerance is +- 1/16”.

It is critical to check every 5

Insert front edge of filler into front

race in horizontal. Rotate trailing

edge up and engage into snap.

th

“UNIT” for location.

EFCO CORPORATION 6/2012 PART NO. Y354 Page 8 of 23

OVERALL

DIMENSION CHECK

#10-16 X 1”

PLFH Tek3

Filler

Page 9

A

Series 5900 Silicone Structural Glazed Curtain Wall Installation

Section IV: Frame Assembly

Frame Assembly – Silicone Structural Glazed Horizontals

A.) Assemble shear blocks, splices, anchors, etc., to mullions as required.

B.) Install and anchor vertical mullions to form the vertical sections per “APPROVED”

shop drawings.

Rotate the horizontal over the shear

1” Minimum

block from the interior of the

system. With the horizontal in

position, fasten with (1) #10-16 X

1” PLFH Tek3 screw on each end of

horizontal, and tighten as required.

pply sealant to the

face and top of the

shear block as shown.

¼” X 1 ½” HWHSMS

Note: The commercial cut to length tolerance is +- 1/16”.

It is critical to check every 5

EFCO CORPORATION 6/2012 PART NO. Y354 Page 9 of 23

#10-16 X 1”

PLFH Tek3

th

“UNIT” for location.

Filler

Page 10

p

r

p

A

Series 5900 Silicone Structural Glazed Curtain Wall Installation

V: Vertical Splice Applications

Vertical Splice Joints

A.) Space vertical mullion expansion joints per “APPROVED” shop drawings and in

conjunction with SSG splice locations.

B.) Keep in mind that spacing may vary with job site temperature. On multiple stacked

applications, key horizontals must be installed to establish grades regardless of

expansion joint dimension.

C.) Splice joints should occur at spandrel areas.

D.) Mullion splice joints for this system are not

designed to compensate for varying floor

levels. (Reference “APPROVED”

shop drawings for allowable

adjustment, i.e., anchors.)

Backer rod at

pressure plate

ansion joint

ex

E.) The splice joint width should be

based on sealant movement

capabilities and the following

formula.

Linear expansion for aluminum in

inches = Length X F

(temperature degrees difference

in Fahrenheit) X .0000129.

MULL DIM.MULL DIM.

1/2" EXP. JT.

F.) Where head clearance is

insufficient to allow top mullions

to be lifted over the splice sleeve, a

retractable sleeve will be used. The

sleeve is taped in the top mullion

4" REF.

and dropped to the stop screw in

the mullion below.

G.) Do not match drill anchors until a

check of expansion joints and wall

installation is performed.

EFCO CORPORATION 6/2012 PART NO. Y354 Page 10 of 23

Note: All anchors must be fixed

before glazing begins.

Note: When the mullion splice is

shop installed in the lower

mullion, screws will be used

in the standard location as

shown.

Erector Note: Apply no screws below splice

in the upper pressure plate.

Note: SSG Vertical Splice Locations EFCO

recommends that Vertical Splice Line

be below the Intermediate Horizontal

Member. This will Minimize Shear Stress at

the Structural Seal Line.

2 1/2"

PRESSURE

PLATE SCREWS

SEALANT AT

MULL JOINT

1" MIN.

1"

PRESSURE BAR DIM.PRESSURE BAR DIM.

COVER DIMENSIONCOVER DIMENSION

1/2"

1/2" JT.

1"

3 1/2" MAX.

2"

ttach splice sleeve to

upper mullion with (2)

#10-12 X ¾” PLFHSMS.

Backer rod & sealant at

of lower cove

to

2"

2"

should

4 1/2" SPLICE

Page 11

A

“

Series 5900 Silicone Structural Glazed Curtain Wall Installation

V: Vertical Splice Applications

Vertical Splice Joints at SSG Verticals and Captured Horizontals

A.) Splice should occur at the spandrel areas.

B.) Fabrication Note: Match drill the splice for shear block attachment.

C.) Splice Note: The vertical

mullions that are structurally

glazed must be spliced at the

horizontal locations. (All mullion

splice locations must be

reviewed by a factory

engineer.)

Note: SSG Vertical Splice Locations EFCO

recommends that Vertical Splice Line

be below the Intermediate Horizontal

Member. This will Minimize Shear Stress at

the Structural Seal Line.

D.) Where the head clearance is

insufficient to allow the top

mullions to be lifted over the

splice, a retractable splice will

be used. The splice is taped

into the top mullion and

dropped to a stop screw in the

mullion below. Don’t match

drill the anchors until a check of

the expansion joints and wall

installation is made.

Note: All anchors must be fixed

before glazing begins.

Note: When the mullion splice is

shop installed into the lower

mullion, (2) fasteners will be

used in the standard locations

as shown.

should

MULL DIM.

2 1/2"

1/2" EXP. JT.

MULL DIM.

2 1/2"

A-A” Section Above Splice

5/8"

IF REQUIRED

1" MIN.

A

ttach splice sleeve to upper

mullion with shear block screws

2"

A

4 1/2" SPLICE

2"

EFCO CORPORATION 6/2012 PART NO. Y354 Page 11 of 23

Page 12

“

A

Series 5900 Silicone Structural Glazed Curtain Wall Installation

V: Vertical Splice Applications

Vertical Splice Joints at SSG Verticals and Horizontals

A.) Splice should occur at the spandrel areas.

B.) Fabrication Note: Match drill the splice for shear block attachment.

C.) Splice Note: The vertical mullions that

are structurally glazed must be

spliced at the horizontal locations.

(All mullion splice locations must

be reviewed by a factory

engineer.)

Note: SSG Vertical Splice Locations EFCO

recommends that Vertical Splice Line

be below the Intermediate Horizontal

Member, this will Minimize Shear Stress at

the Structural Seal Line.

should

D.) Where the head clearance is

insufficient to allow the top

mullions to be lifted over the

splice, a retractable splice will be

used. The splice is taped into the

top mullion and dropped to a stop

screw in the mullion below. Don’t

match drill the anchors until a

check of the expansion joints and

wall installation is made.

Note: All anchors must be fixed

before glazing begins.

Note: When the mullion splice is

shop installed into the lower

mullion, (2) fasteners will be

used in the standard locations

as shown.

EFCO CORPORATION 6/2012 PART NO. Y354 Page 12 of 23

2 1/2"

A-A” Section Through Splice

ttach splice sleeve to upper

mullion with shear block

5/8"

2 1/2"

IF REQUIRED

1" MIN.

A

1/2" EXP. JT.

MULL DIM. MULL DIM.

2"

A

2"

4 1/2" SPLICE

Page 13

plug

g

A

j

g

Series 5900 Silicone Structural Glazed Curtain Wall Installation

VI: Glazing Preparation

Glazing Preparation at Structural Glazed Mullions

Note: All thermal isolators should be

Install thermal isolator

prior to installing the

mullion

removed from the reels and allowed

to shrink prior to installation.

s.

Prior to installin

seal all three sides of the plug,

making sure all cavities are filled.

With sealant in place, the mullion

plugs can be installed.

Provide a downward slope with the

sealant, without interfering with

the edge of the glass, to allow for

drainage of condensation.

Closed cell sponge joint plug

Seal the

direction at all corners with

sealant, making sure that all

fastener heads are sealed.

asket race 2” in each

Elevation of Joinery at the S.S.G.

Mullion Prior to Setting the Glass

the mullion plugs,

Edge of glass

Prior to installing the mullion plugs,

seal all three sides of the pocket,

making sure all cavities are filled.

2"

pply sealant to the face of the

oint plug prior to installation of the

pressure plate. See page #19.

EFCO CORPORATION 6/2012 PART NO. Y354 Page 13 of 23

Page 14

g

y

)

g

A

Series 5900 Silicone Structural Glazed Curtain Wall Installation

VI: Glazing Preparation

Glazing Preparation At Captured Mullions

A.) Install the thermal isolator in the vertical

mullion, run continuously, and butt joint

as required.

B.) Seal vertical mullion raceway 1” long

prior to the installation of the joint

plugs.

C.) Place and seal the joint plug.

D.) Tool off all excess sealant.

E.) Apply sealant to the face

of the joint plug prior to

installation of the pressure

plate. See page #19.

Provide a downward slope with

sealant, without interferin

the edge of the glass, to allow

for drainage of condensation.

Closed cell sponge joint plugs

Seal gasket race 2” in each

direction at all corners with

sealant, making sure that all

fastener heads are sealed.

(Captured system shown,

SSG s

Note: Each daylite opening should

be sealed individually with

gaskets and glazing installed

immediately following with

pressure at the corners.

stem similar.

Elevation of Joinery Prior to Setting the Glass

Seal vertical mullion

asket raceway 1” prior to

installation of joint plugs.

with

2"

Place and seal the mullion plug. Prior to

installation, apply sealant on all contact

surfaces, and tool off excess sealant to

prevent obstructing the water path.

Edge of glass

2"

pply sealant to the face of

the joint plug prior to the

installation of the pressure

plate. See page #19.

EFCO CORPORATION 6/2012 PART NO. Y354 Page 14 of 23

Page 15

V

r

g

Series 5900 Silicone Structural Glazed Curtain Wall Installation

VII: Glazing Adaptors

Installation of Glazing Adaptors at Silicone Structural Glazed Mullions

A.) Vertical adaptor length without a

mullion expansion joint equal

D.L.O. plus 1”.

B.) Vertical adaptor length with a

mullion expansion joint, see the

“APPROVED” shop drawings.

C.) Horizontal adaptor length equal

D.L.O. minus 1/16”.

D.) Install the vertical

adaptors first, and attach

with #8 X 1 ¼” PLPH SMS

at a minimum of 18” on

center. (Seal fastener

heads with sealant.)

ertical Adaptor

E.) Install the horizontal adaptors

between the vertical adaptors.

Horizontal Adapto

Installation of Glazing Adaptors at Captured Mullions

Set all adaptors in a continuous

bead of sealant, and seal all

vertical to horizontal adaptor

intersections.

A.) Position the vertical adaptors as

shown.

B.) Place horizontal adaptors

between the verticals.

C.) Seat adaptors by applying sealant

to all four corners.

D.) Cut formula for vertical adaptors

equal D.L.O. plus 1”. Horizontal

adaptors equal D.L.O. minus

1/16”.

Note: Vertical adaptors need a minimum

of 1/8” clearance above the

mullion plug, free from sealant.

Continuously seal the

gasket raceway with

sealant prior to

installin

the adaptors.

EFCO CORPORATION 6/2012 PART NO. Y354 Page 15 of 23

Page 16

Series 5900 Silicone Structural Glazed Curtain Wall Installation

VIII: Sealant At Splice Joint

Installation of Backer Rods at Structurally Glazed Mullion Splices

Expansion joint

Splice sleeve

Note: At corner mullions, use

more than one backer rod

as required, and miter it to

fit the corner joint.

Note: Each daylite opening should

Closed cell sponge joint plug

be sealed individually with

gaskets and glazing installed,

immediately followed with

pressure at the corners.

Install backer rod foam

at expansion joint.

½” Between adaptors

Expansion joint

Install backer rod foam

Splice sleeve

at expansion joint.

Reference pages 11 through 13 for mullion splice detail.

EFCO CORPORATION 6/2012 PART NO. Y354 Page 16 of 23

Page 17

r

Series 5900 Silicone Structural Glazed Curtain Wall Installation

IX: Preset Gaskets

Apply Preset Glazing Gaskets to Mullions

A.) Apply sealant into gasket race a minimum of 2” each direction at each corner.

B.) Remove glazing gaskets

from the reel and allow to

shrink.

C.) Cut vertical gaskets D.L.O.

plus 1 ¾”.

D.) Cut horizontal gaskets

D.L.O. plus ½”.

E.) Seal all gasket corners: Pull

horizontal gaskets back, seal end,

and compress into the vertical

gasket to insure a snug fit.

Note: If the gaskets are difficult to

insert into the gasket race, a

light coat of mineral spirits

can be applied to the gasket

for lubrication.

F.) Cut horizontal gaskets at

structural glazed mullions

D.L.O. plus ½”. Cut

vertical spacers to D.L.O.

plus 1 ¼”.

Preset space

EFCO CORPORATION 6/2012 PART NO. Y354 Page 17 of 23

Preset gaskets

Preset gaskets

Page 18

V

Series 5900 Silicone Structural Glazed Curtain Wall Installation

X: Miscellaneous Applications

Clean

A.) Clean all metal and infill surfaces that will come in contact with the structural

silicone sealant with the proper cleaner.

B.) Apply silicone primer as recommended by the silicone manufacturer.

Setting Blocks

A.) Position and install the setting blocks per the “APPROVED” shop drawings.

Position Glazing Infill

A.) Set the glazing infill into the framing opening tight against the interior gasket,

and position squarely onto the setting blocks.

Gaskets to Pressure Plates

A.) Apply the glazing gasket to the pressure plates.

B.) The gaskets applied to the vertical pressure plates are to be cut flush at both

ends, except in multi-story applications where gaskets are to extend 1” beyond

the end at expansion joints.

C.) The gaskets applied to horizontal pressure plates are cut ¼” long, both ends

maximum.

ertical Gasket

Preset gasket

Note: The vertical gasket runs through the joint

plug notch at the horizontal location. Seal

Mull plug

all corners of the gaskets with sealant.

D.) Apply sealant to the face of the mullion plug prior to installing the vertical or

horizontal pressure plate.

EFCO CORPORATION 6/2012 PART NO. Y354 Page 18 of 23

Page 19

k

p

g

”

Series 5900 Silicone Structural Glazed Curtain Wall Installation

XI: Pressure Plate Attachment

Pressure Plate Attachment

A.) Attach pressure plates with ¼” X 1” stainless steel hex washer head pressure

plate screws. Typical spacing is 6” on center.

B.) Torque all pressure plate screws to 80 inch pounds. In cold weather, first torque

all screws to 40 inch pounds. When possible, work from the center outward on

horizontal and from sill upward on verticals. Then torque all screws to 80 inch

pounds after all four sides of the opening have been clamped.

½” Glass Bite

(typical)

1/8

3/16” X 1” weep slot

centered 4” off each

end of the pressure

plate.

½” Glass Bite

(typical)

1/8”

OPTIONAL WEEP HOLES

5/16” dia. weep holes

Drill 3 side by side centered

Line of Mullion

Edge of Glass

4” off each end of pressure

plate. Locate C/L of holes

5/32” above to

of tongue.

Line of Mullion

Ed

e of Glass

Erector Note: Special structural dual seals are required

for structural glazing infill. The insulated glass

may require a structural sealant bead at the

spacer. This will be determined by job specific

information, such as design pressure, infill lite

size, and other pertinent information. Consult the

glass supplier and or manufacturer for specific

application recommendations.

Customer / Installer Note:

EFCO setting blocks are

typically 4” in length with

Setting bloc

Glass line

different depths. If the

glazing infill is “NOT BY

EFCO” and glazing sizes are

larger than 40 square feet,

then the glazing details

must be reviewed by the

glazing manufacturer for

proper setting block size.

EFCO CORPORATION 6/2012 PART NO. Y354 Page 19 of 23

Page 20

p

g

Series 5900 Silicone Structural Glazed Curtain Wall Installation

XI: Pressure Plate Attachment

C

MULL

Pressure Plate Attachment

4" TYPICAL

Seal joints

with sealant

Note: Reference pages 11 through 13 for recommended pressure plates at splice

locations. Install the first screw approximately 3” from the end. Typical screw

spacing is 6” on center. The glazier should always insert a screw in the vertical

pressure plate directly opposite each horizontal, to provide maximum control of

pressure on the mullion plugs, which provide a critical sealing function.

L

2 1/2"

1/4"

Weep slots

Customer / Installer Note:

EFCO setting blocks are

typically 4” in length with

different depths. If the

glazing infill is “NOT BY

EFCO” and glazing sizes are

larger than 40 square feet,

then the glazing details

must be reviewed by the

glazing manufacturer for

proper setting block size.

¼” x 1”

HWHSMS

Settin

Seal the horizontal pressure

plate to the vertical pressure

late to be air and watertight.

EFCO CORPORATION 6/2012 PART NO. Y354 Page 20 of 23

block

Glass line

Page 21

Series 5900 Silicone Structural Glazed Curtain Wall Installation

XII: Temporary Retainers and Sealant

Temporary Retainers

A.) Temporary retainers are supplied by EFCO based on the lineal footage of

structural glazed members divided by 2.

B.) The location of the temporary exterior infill retainers should not exceed a

maximum of 24”* on center. *(If high wind conditions are anticipated, additional

retainers may be required. Please consult the sealant and /or glazing infill

supplier for spacing recommendations.)

Erector Note: Special structural dual seals are required for structural glazing infill.

The insulated glass may require a structural sealant bead at the spacer. This

will be determined by job specific information, such as design pressure, infill

lite size and other pertinent information. Consult the glass supplier and or

structural sealant manufacturer for specific application recommendations.

Apply The Structural Silicone Sealant

A.) EFCO does not supply sealant.

B.) The sealant is to be a structural silicone as recommended by the sealant

manufacturer.

C.) The infill and metal is to be cleaned per the silicone manufacturer’s

recommendations.

D.) Allow the structural silicone seal to cure per the manufacturer’s

recommendations before removing the temporary glazing retainers.

Exterior Weather Seal

A.) Install backer rod between the two insulated infill units or bond breaker tape

behind the monolithic infills. (Not By EFCO)

B.) Apply the exterior weather seal as recommended by the sealant manufacturer.

NOTE: Seal up to the temporary retainers. After the structural sealant cures,

remove the temporary retainers, and seal the remaining gaps.

Reversible temporary glazing retainer

EFCO CORPORATION 6/2012 PART NO. Y354 Page 21 of 23

Weather sealBond breaker tapeWeather sealBacker rod

Page 22

A

g

V

A

Series 5900 Silicone Structural Glazed Curtain Wall Installation

Section XIII: Exterior Cover Installation

Snap-On Exterior Covers

A.) Set vertical covers as shown on “APPROVED” shop drawings.

7/16"

B.) Center the horizontal snap cover in the opening, align and

engage one side, then use a block and mallet to engage

the opposite side.

C.) Gaps at the ends should be equalized

and are provided to allow installation,

thermal movement, and weepage.

D.) Exterior horizontal covers are cut

D.L.O. – 1/16”.

E.) The erector is to split the

difference on both ends.

Drill 5/16”

diameter weep

holes in the

horizontal covers

2” from each end.

Note: Care must be taken

to avoid damage to

the covers during

installation. Use a

nominal 12” long 2

X 4 and mallet or

hammer to seat the

cover.

ertical cover

pprox. 12” long

wood block

Mallet or hammer

Horizontal

cover

Equal space at both ends

of horizontal cover

Note: Horizontal covers 1” or

more in depth must be

mechanically attached,

similar to detail below.

1/16” X 5/16” roll pin at the center of the

cut length is recommended to prevent

slippa

horizontal to eliminate exposure.

e. The roll pin can be located at the

EFCO CORPORATION 6/2012 PART NO. Y354 Page 22 of 23

Page 23

Series 5900 Silicone Structural Glazed Curtain Wall Installation

Section XIV: Steel Reinforcement

Steel Reinforcement

A.) At large spans or in high wind load areas, steel reinforcement may be necessary.

B.) Reinforcement requirements will vary on a per job basis.

C.) Reference the “APPROVED” shop drawings for steel requirements and locations.

D.) When steel reinforcement is factory installed in the mullions, use fasteners to

prevent damage or slippage of the steel during shipping.

EFCO CORPORATION 6/2012 PART NO. Y354 Page 23 of 23

Loading...

Loading...