Page 1

Y

Series 5500

Advanced and alternate

Installation Instructions

Part NO.

February 2013

557

Page 2

Series 5500 Advanced & Alternate Installation Instructions

TABLE OF CONTENTS

S-5500 ADVANCED INSTALLATION INSTUCTIONS

SECTION PAGE

I. General Notes and Guidelines………………………………………...……... 3-4

II. Frame Unit Assembly & Frame Sealing

Shear Block……………………………………...…………………………………. 5-6

III. Alternate Anchorage Methods

Sleeve Anchors………………………………………………………………….. 7-10

Mull Anchors …………………………………………………………………… 11-17

IV. Punched Opening & Ribbon Windows

Frame Unit Assemble & Frame Sealing..………….……………………18-20

Alternate Anchorage Method……………………………………………… 21-23

V. Vertical Splice Joints……………………………………………………………. 24-33

VI. Expansion Mullions…………………………………...………………………... 34-37

VII. Glazing At Spandrel Areas of Inside Glazed Frames ……………….. 37-40

VIII. Glazing Adaptors

Captured Glazing………………………………………………………………….. 41

Silicone Structural Glazed …………………………………………………. 43-46

Note: Please reference EFCO's "Understanding Condensation" brochure which can be obtained through your EFCO

representative.

Condensation will form on any surface when unfavorable conditions (interior temperature and relati ve humidity and

exterior temperature) are present. When the formation of excessive condensation is a concern, it is highly recommended that a

design professional is utilized to perform an analysis of the shop drawings to recommend the best possible installation methods.

Please contact your EFCO representative for inf ormation on EFCO's Thermal Analysis Services.

Many current installation practices lead to an increase in the possibility of the formation of condensation. Though not all

inclusive, the list of examples below illustrates conditions under which condensation is likely to occur:

Note: This document is to be used in conjunction with the standard installation

instructions.

Note: These installation instructions are a supplement to the approved final shop drawings

and are to be used in conjunction with those drawings.

Minimizing Condensation

1. Bridging system thermal break with non-thermally broken metal flashing or lintels that are exposed to the

exterior

2. System exposure to cold air cavities

3. Interior relative humidity levels not maintained at recommended levels, see EFCO’s “Understanding

Condensation” brochure

4. Inadequate separation between system and surrounding condition at perimet er

5. Product combinations during the shop dr aw ing stage that result in bridging thermal breaks of one or all

products involved

EFCO CORPORATION 6/2012 PART NO. Y557

2

Page 3

Series 5500 Advanced & Alternate Installation Instructions

Section I: General Notes and Guidelines

I. HANDLING / STORING / PROTECTING ALUMINUM - The following precautions are

recommended to assure early acceptance of your products and workmanship.

A. HANDLE CAREFULLY - Store with adequate separation between components so

the material will not rub together. Store the material off the ground. Protect materials against weather elements and other construction trades.

B. KEEP MATERIAL AWAY FROM WATER, MUD, AND SPRAY - Prevent cement,

plaster, and other materials from contacting with and damaging the finish. Do not

allow moisture to be trapped between the finished surface and the wrapping material.

C. PROTECT MATERIALS AFTER ERECTION - Wrap or erect screens of plastic

sheeting over material. Cement, plaster, terrazzo, and other alkaline materials are

very harmful to the finish and are to be removed with soap and water before hardening. Under no circumstances should these materials be allowed to dry or permanent staining will occur.

II. GENERAL GUIDELINES - The following practices are recommended for all installations:

A. REVIEW APPROVED SHOP DRAWINGS – Become thoroughly familiar with the

project. Shop drawings govern when conflicting information exists in these installation instructions.

B. INSTALL ALL FRAMING MATERIAL PLUMB, LEVEL, AND TRUE – Proper

alignment and relationships to benchmarks and column centerlines, as established

by the architectural drawings and the general contractor, must be maintained.

C. The sequence of erection should be coordinated with the project superintendent to

prevent delays and minimize the risk of material damage. Note: If preset an-

chors are required, coordinate and supervise anchor placement with the

general contractor.

D. Verify that all job site conditions and accompanying substrates receiving the instal-

lation are in accordance with the contract documents. If deviations occur, notification must be given IN WRITING to the general contractor and differences resolved before proceeding further with the installation in the questionable area.

E. Prevent all aluminum from coming in direct contact with masonry or dissimilar ma-

terials by means of an appropriate primer.

EFCO CORPORATION 6/2012 PART NO. Y557

3

Page 4

Series 5500 Advanced & Alternate Installation Instructions

SECTION I: GENERAL NOTES and GUIDELINES

F.

G. Verify contents of all material shipments received upon their arrival. Verify quantity

H. Throughout these instructions the term “SEALANT” will appear. For the purposes of

Regardless of the sealant used, the customer should contact the sealant

Follow EFCO framing installation and glazing instructions.

and correct finishes. NOTIFY EFCO IMMEDIATELY OF ANY DISCREPANCIES

OR DAMAGE THAT MAY HAVE OCCURRED.

these instructions, sealant is to be defined as the following:

SEALANT - A weather resistant, gunnable liquid filler which when cured provides a

resilient, flexible (± 50% movement capability) air and water seal between similar

and dissimilar materials.

All sealant must meet ASTM C 920, CLASS 50.

BUTYL SEALANT- A non-skinning, non-hardening material (NAAMM Reference Standard 5C-1).

NOTE: All sealant must be compatible with all surfaces on which adhesion is re-

quired, including other sealant surfaces. All frame surfaces should be clean,

dry, dust, and frost free. If a primer is required, it must be applied to clean

surfaces. All perimeter substrates shall be clean and properly treated to receive sealant.

This system is designed and has been tested to utilize butyl or silicone sealants at all internal joineries, i.e., joint plugs, gasket intersections, etc.

manufacturer to determine compatibility and adhesion. Follow sealant manufacturer's proper application procedures and quality assurance programs for

weather sealing.

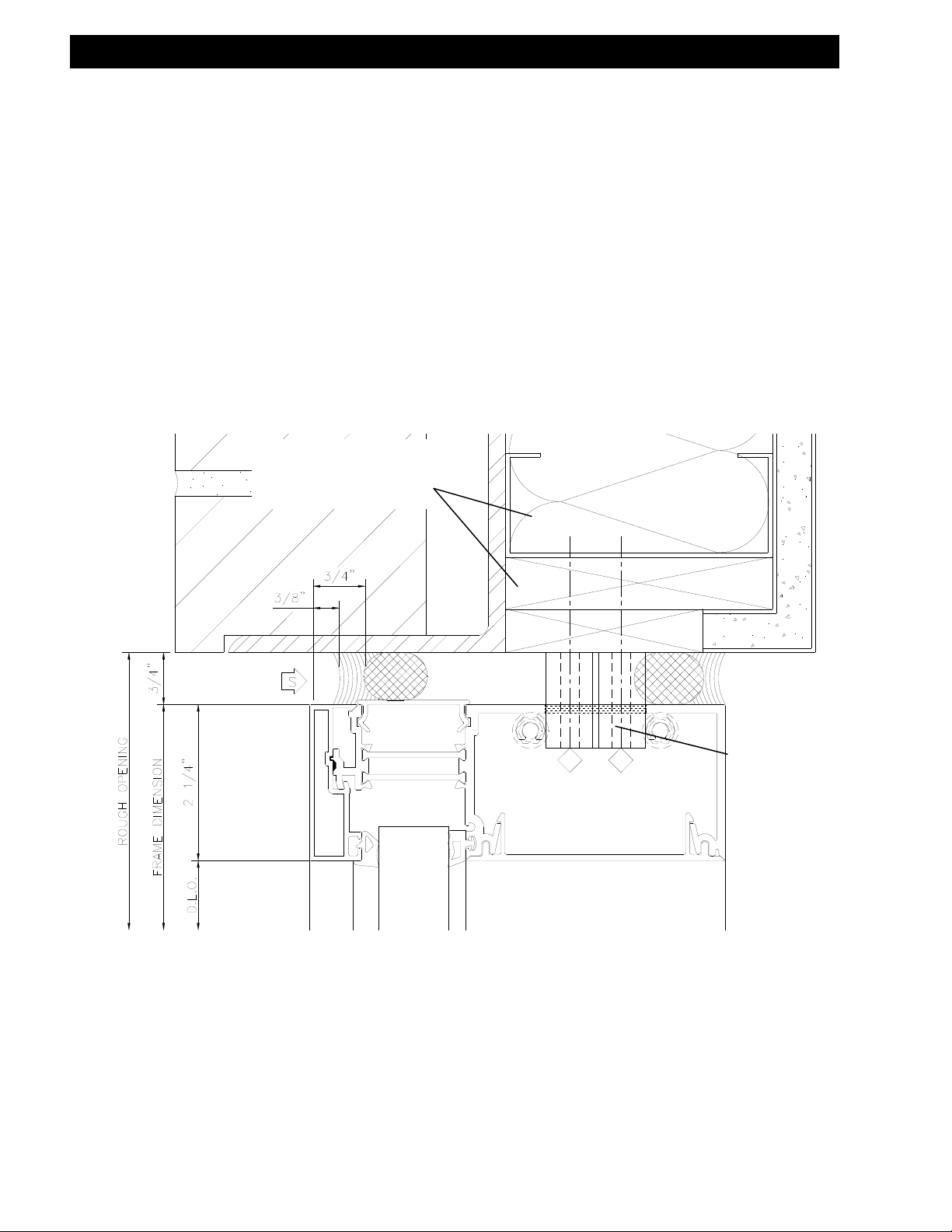

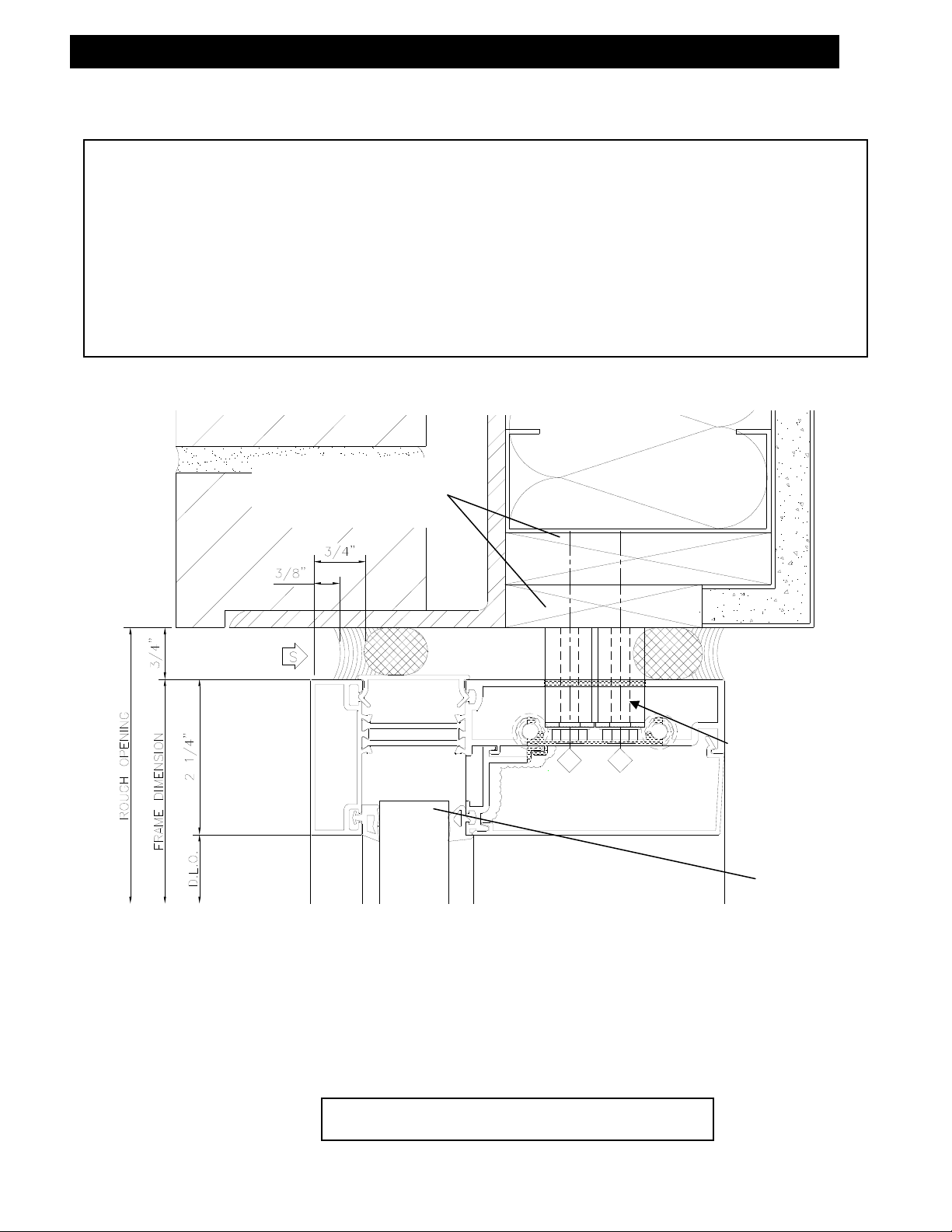

Maintain caulk joints as shown in the approved shop drawings. Unless

specified otherwise, most sealant manufacturers recommend a 3/8” minimum perimeter caulk joint. A 3/4” minimum joint is recommended at the

head condition to accommodate thermal expansion and contraction.

Anchoring surfaces of perimeter construction must be level and plumb within

the adjustable limits of the head, jamb, and sill framing.

EFCO CORPORATION 6/2012 PART NO. Y557

4

Page 5

Series 5500 Advanced & Alternate Installation Instructions

Section II: Frame Unit Assembly & Frame Sealing

(Shear Block)

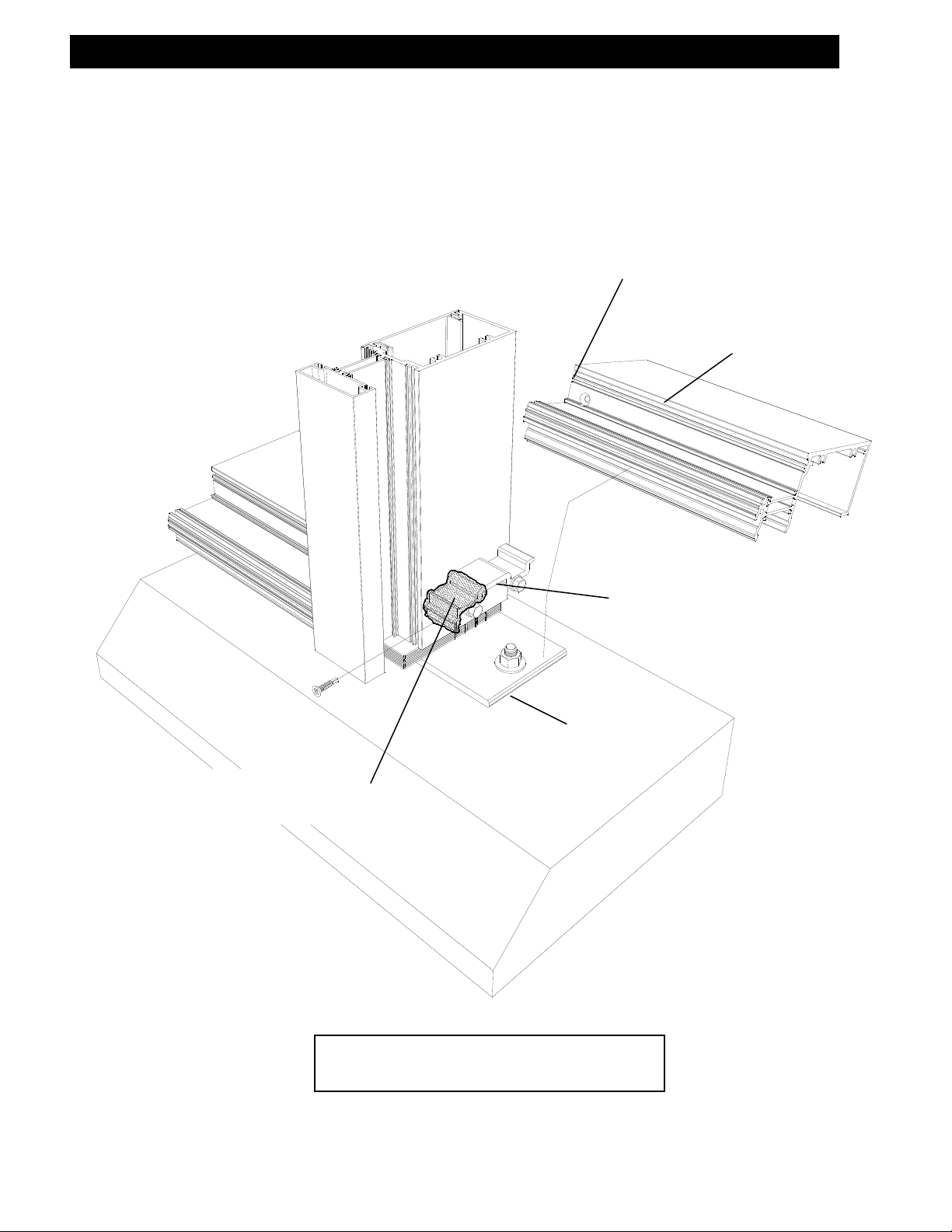

Under certain circumstances, it may be necessary to use drop-on

heads and sills with mullion ‘M’ and ‘F’ anchors. Refer to alternate

anchorage methods section for more information.

Apply sealant to the ends of the

sill as shown in the Standard

Installation Instructions

DROP-ON SILL

Apply sealant to the face of

the shear blocks as shown.

SHEAR BLOCK

‘M’ ANCHOR

SILL CONDITION WITH ‘M’ ANCHOR AND

DROP-ON HORIZONTALS

EFCO CORPORATION 6/2012 PART NO. Y557

5

Page 6

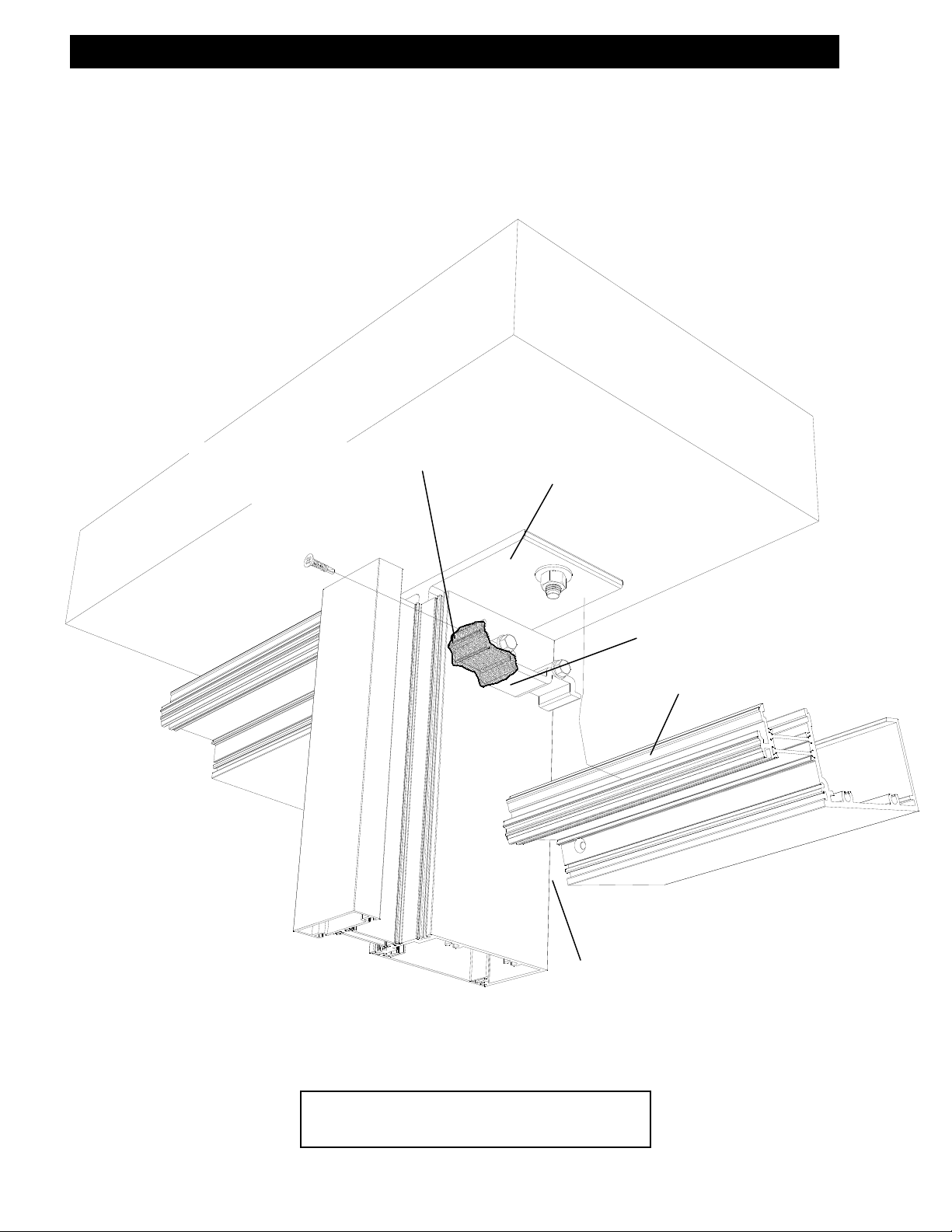

Series 5500 Advanced & Alternate Installation Instructions

Section II: Frame Unit Assembly & Frame Sealing

(Shear Block)

Apply sealant to the face of

the shear blocks as shown.

‘M’ ANCHOR

SHEAR BLOCK

DROP-ON HEAD

Apply sealant to the ends of the

sill as shown in the Standard

Installation Instructions

HEAD CONDITION WITH ‘M’ ANCHOR

AND DROP-ON HORIZONTALS

EFCO CORPORATION 6/2012 PART NO. Y557

6

Page 7

Series 5500 Advanced & Alternate Installation Instructions

Section III: Alternate Head Anchorage Method

(Sleeve Anchors)

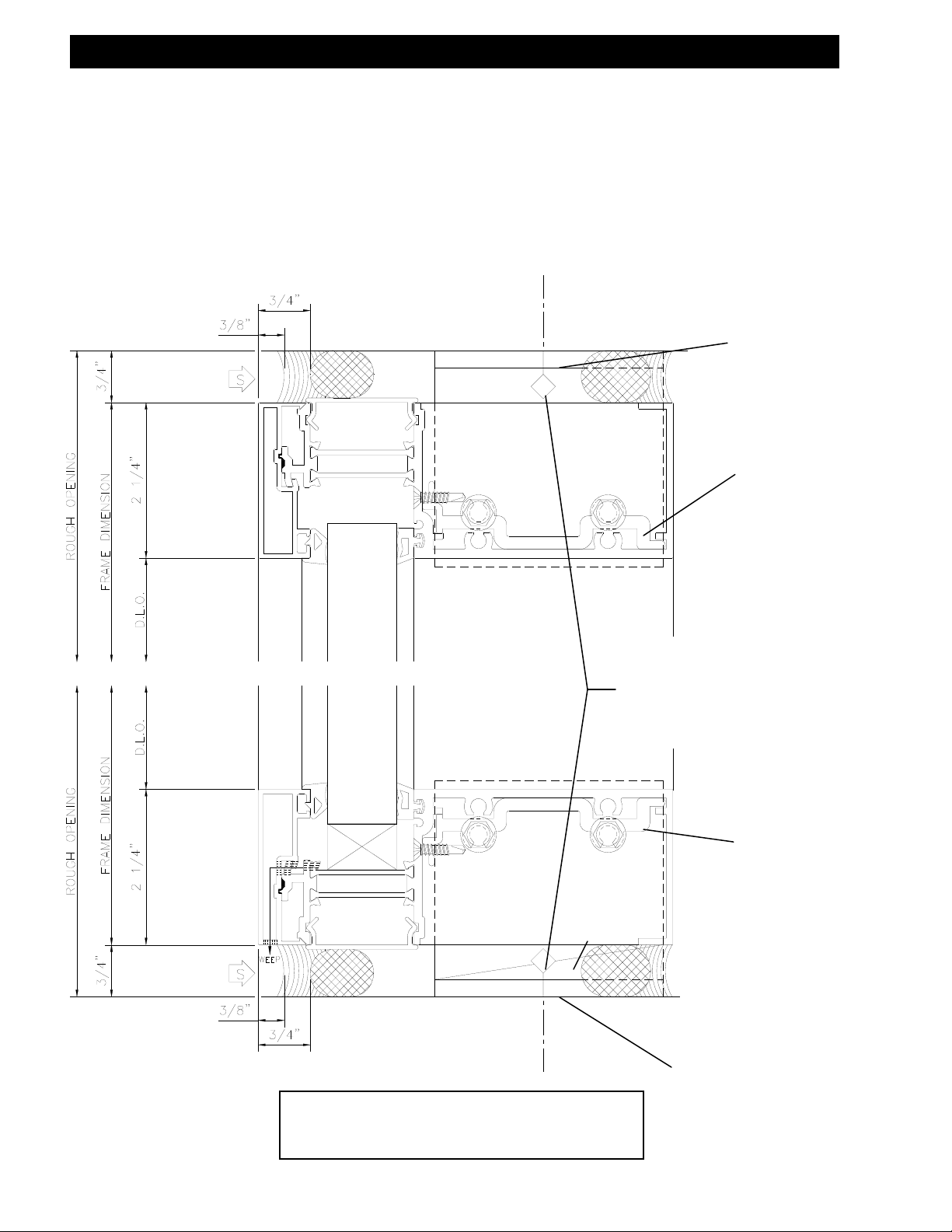

STEP #1 (Outside Glazed) INSTALL FRAME COMPONENTS

A. Refer to the approved shop drawings for job specific conditions, anchor type, anchor

bolt sizes, and locations. Install assemblies according to the approved shop drawings.

The anchor type used must be selected based on the structural requirements and the

substrate.

B. Follow steps 2 through 5 in Section III of the

complete the installation.

C. Refer to Sections IV and V of the

Preparation and Glazing Installation.

Standard Installation Instructions for Glazing

ANCHORAGE DETAIL FOR HEAD CONDITIONS

ATTACHING TO WOOD OR LIGHT GAUGE METAL STUDS

LIGHT GAUGE

METAL STUDS OR

WOOD SUBSTRATE

Standard Installation Instructions to

Note: It is up to the responsible engineer to determine

the structural adequacy and type of anchorage method

to be used for a given substrate, applied loads, and

building movements. The S-5500 has different

anchorage options available to meet these conditions.

EFCO CORPORATION 6/2012 PART NO. Y557

ANCHOR BOLTS AND

SLEEVE (Type and

quantity as required by

conditions and loads.

See Shop Drawings.)

7

Page 8

Series 5500 Advanced & Alternate Installation Instructions

Section III: Alternate Head Anchorage Method

(Sleeve Anchors)

STEP #1 (Inside Glazed) INSTALL FRAME COMPONENTS

A. Refer to the approved shop drawings for job specific conditions, anchor type, anchor

bolt sizes, and locations. Install assemblies according to the approved shop drawings.

The anchor type used must be selected based on the structural requirements and the

substrate.

B. Follow steps 2 through 5 in Section III of the

complete the installation.

C. Refer to Sections IV and V of the

Preparation and Glazing Installation.

ANCHORAGE DETAIL FOR HEAD CONDITIONS

ATTACHING TO WOOD OR LIGHT GAUGE METAL STUDS.

LIGHT GAUGE METAL

STUDS OR WOOD

SUBSTRATE

Standard Installation Instructions for Glazing

Standard Installation Instructions to

Note: The glass size formula

for Inside Glazed S-5500 is

vertical D.L.O. plus 7/8” and

horizontal D.L.O. plus 1”.

Note: It is up to the responsible engineer to determine

the structural adequacy and type of anchorage method

to be used for a given substrate, applied loads, and

building movements. The S-5500 has different

anchorage options available to meet these conditions.

ALTERNATE HEAD ANCHORAGE

ANCHOR BOLTS AND

SLEEVE (Type and

quantity as required by

conditions and loads.

See Shop Drawings.)

Note: Glass bite at

this location for

Inside Glazed S-5500

is D.L.O. plus 3/8”.

(All Inside Glazed S5500 head

horizontals.)

EFCO CORPORATION 6/2012 PART NO. Y557

8

Page 9

Series 5500 Advanced & Alternate Installation Instructions

Section III: Alternate Head Anchorage Method

(Sleeve Anchors)

ANCHOR BOLTS AND

SLEEVES (Type and

quantity as required

by condition. See

Shop Drawings)

ALTERNATE HEAD ANCHORAGE

EFCO CORPORATION 6/2012 PART NO. Y557

HEAD FILLERS

9

Page 10

Series 5500 Advanced & Alternate Installation Instructions

Section III: Alternate Head Anchorage Method

(Sleeve Anchors)

ANCHOR BOLTS AND

SLEEVES (Type and

quantity as required by

conditions and loads.

See Shop Drawings.)

Head members with

notches as required,

allowing for lateral

building movements.

ALTERNATE HEAD ANCHORAGE

EFCO CORPORATION 6/2012 PART NO. Y557

10

Page 11

Series 5500 Advanced & Alternate Installation Instructions

Section III: Alternate Anchorage Method

(Heavy-Duty Anchor Connections)

Note: It is up to the responsible engineer to determine the structural

adequacy and type of anchorage method to be used for a given

substrate, applied loads, and building movements. The S-5500 has

different anchorage options available to meet these conditions.

‘M’ AND ‘F’

ANCHORS

SHEAR BLOCK

ANCHOR BOLTS (Type

and quantity as

required by conditions

and loads. See Shop

Drawings.)

SHEAR BLOCK

Shim as required at

anchors

each vertical mullion.

(Shim under setting

blocks at heavy lites.)

‘M’ AND ‘F’

ANCHORS

and

under

DROP-ON HEAD AND SILL

WITH ‘M’ AND ‘F’ ANCHORS

EFCO CORPORATION 6/2012 PART NO. Y557

11

Page 12

Series 5500 Advanced & Alternate Installation Instructions

Section III: Alternate Anchorage Method

(Heavy-Duty Anchor Connections)

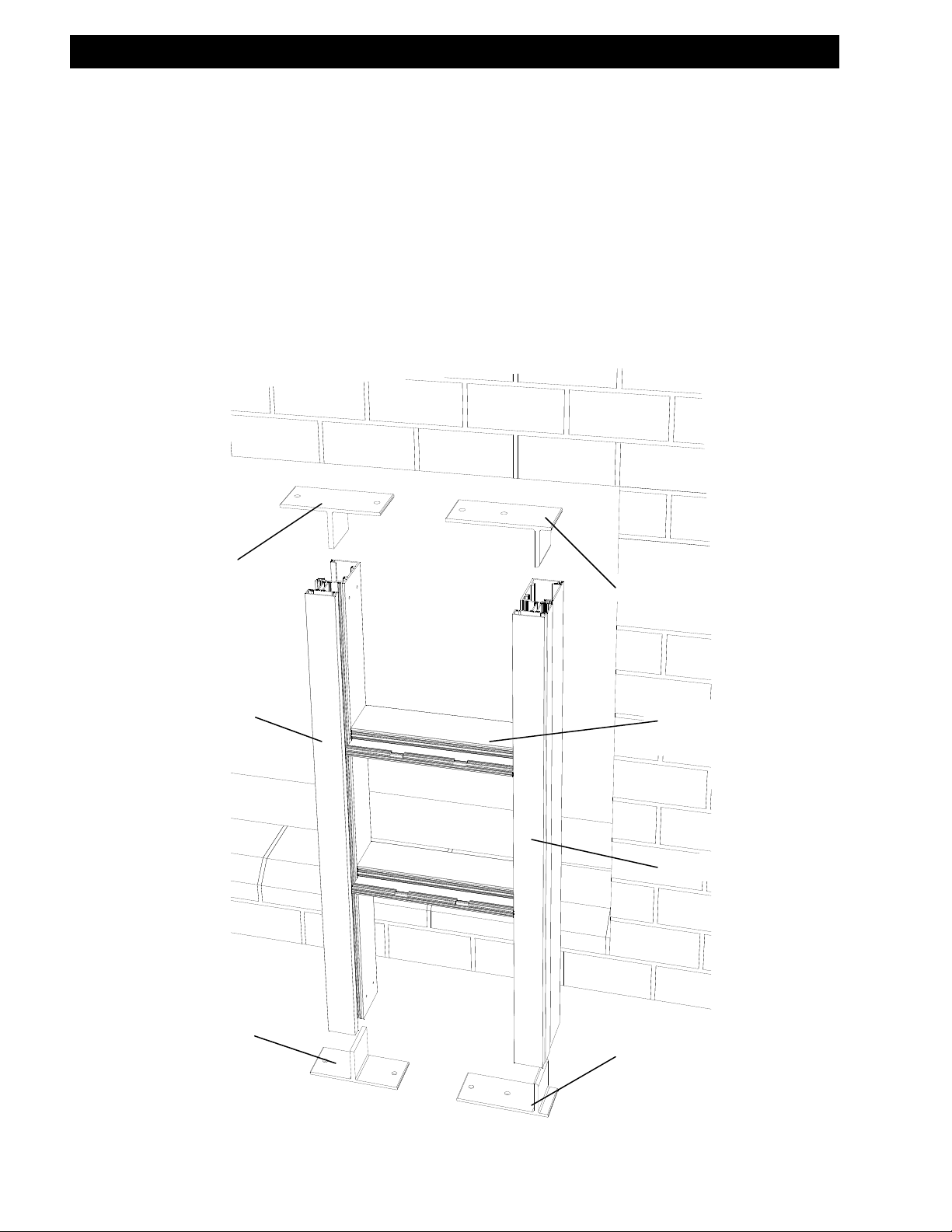

STEP #1 ASSEMBLE OUTSIDE GLAZED FRAME MEMBERS

This method of anchorage is available for conditions where the standard head and sill anchors or

alternate head anchors are not adequate for the given design criteria. Please consult with the structural

engineer responsible for the shop drawings for your project.

A. Assemble verticals and intermediate horizontals following the frame assembly and sealing

instructions in Section II. Shear blocks should be installed after the frames are set and

anchored to avoid interference with the anchor bolts.

B. Insert ‘F’ anchors into each end of the jamb mullion and ‘M’ anchors into each end of the

intermediate vertical.

‘M’ ANCHOR

INTERMEDIATE

VERTICAL

‘F’ ANCHOR

PRE-ASSEMBLED

FRAME UNIT

JAMB MULLION

‘M’ ANCHOR

EFCO CORPORATION 6/2012 PART NO. Y557

‘F’ ANCHOR

12

Page 13

Series 5500 Advanced & Alternate Installation Instructions

Section III: Alternate Anchorage Method

(Heavy-Duty Anchor Connections)

STEP #2 INSTALL FRAME COMPONENTS

A. Set the frame with ‘F’ and ‘M’ anchors into the opening. Adjust the frame’s position to place it

in the proper position with regard to established benchmarks.

B. Using dead load shims under each vertical mullion, level the frame and set it to the appropriate

elevation as indicated in the approved shop drawings.

C. After the frame is plumb and all adjustments have been made, match drill through the holes in

the ‘F’ and ‘M’ anchors into the surrounding substrate, and apply the appropriate anchor bolts.

Anchor bolt size, type, quantity, and location vary. Refer to the approved shop drawings for

more information. Anchor bolts should be installed per the recommendations of the bolt

manufacturer.

D. Apply the shear blocks to the top and bottom of the mullions as shown in the approved shop

drawings.

‘M’ ANCHOR

‘F’ ANCHOR

SHEAR BLOCKS FOR

DROP-ON HEAD

ANCHOR BOLTS

AS REQ’D.

SHEAR BLOCKS FOR

DROP ON SILL

‘M’ ANCHOR

PRE-ASSEMBLED

FRAME UNIT

ANCHOR BOLTS

AS REQ’D.

‘F’ ANCHOR

EFCO CORPORATION 6/2012 PART NO. Y557

DEAD LOAD

SHIMS

13

Page 14

Series 5500 Advanced & Alternate Installation Instructions

Section III: Alternate Anchorage Method

(Heavy-Duty Anchor Connections)

HEAD ANCHOR

ANCHOR BOLTS

AS REQ’D.

SHEAR BLOCKS FOR

DROP-ON HEAD

SHEAR BLOCKS FOR

DROP-ON SILL

SILL ANCHOR

ANCHOR BOLTS

AS REQ’D.

DEAD LOAD

SHIMS

EFCO CORPORATION 6/2012 PART NO. Y557

14

Page 15

Series 5500 Advanced & Alternate Installation Instructions

Section III: Alternate Anchorage Method

(Heavy-Duty Anchor Connections)

STEP #3 INSTALL FRAME COMPONENTS

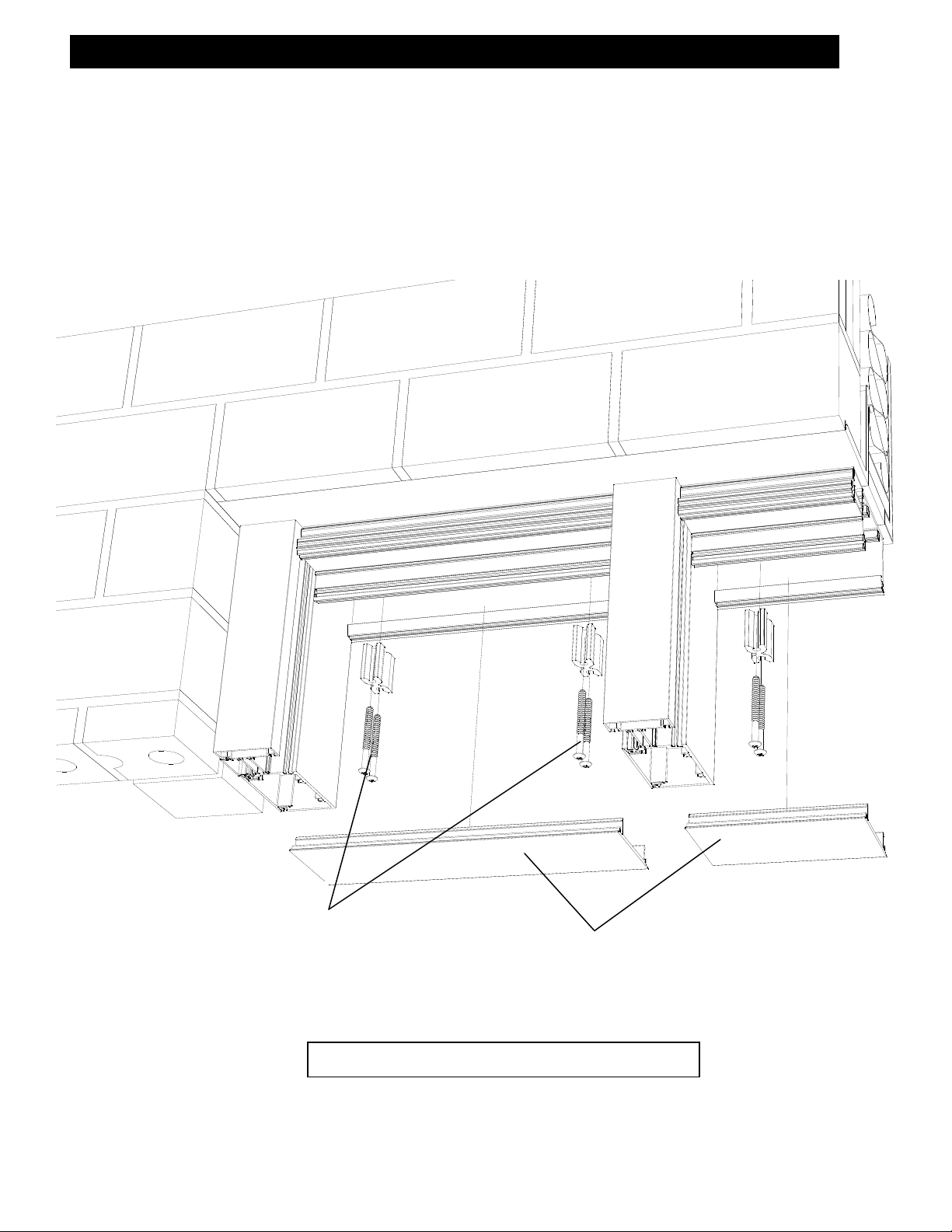

A. From pages 12, 13, and 14, repeat steps 1 and 2. Set each successive frame into the

opening, snapping the verticals and fillers at each frame-until all frames are installed up

to the last frame at the opposite jamb.

B. Check frequently to ensure the installed framing is in the proper position with regard to

established benchmarks.

‘M’ ANCHOR

‘M’ ANCHOR

NOTE: On long runs, check overall frame dimensions at every fifth opening to avoid

dimensional build-up. The commercial cut length tolerance is +/- 1/16”. It is critical

to check every fifth unit for location relative to established benchmarks.

See Section III of the

Standard Installation

Instructions for special

sealant note at horizontals.

EFCO CORPORATION 6/2012 PART NO. Y557

15

Page 16

Series 5500 Advanced & Alternate Installation Instructions

Section III: Alternate Anchorage Method

(Heavy-Duty Anchor Connections)

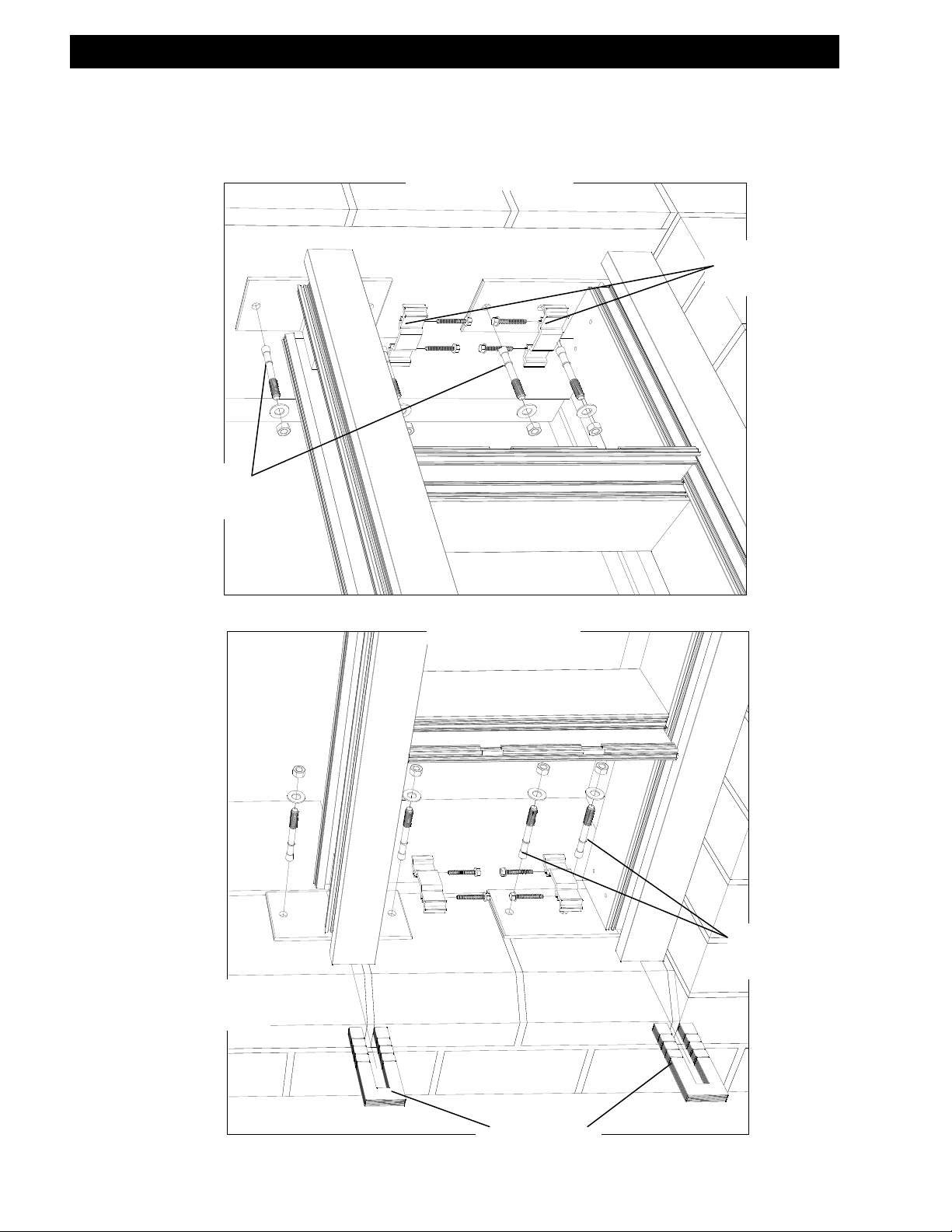

STEP #4 INSTALL FRAME HEAD & SILL COMPONENTS

A. Set the last frame in the run into the opening, mating the filler with the intermediate

vertical until the filler and vertical snap together.

B. When the frame is set level and plumb, apply dead load shims below the verticals, and

apply anchor bolts as shown per the approved shop drawings.

ANCHOR BOLTS

AS REQ’D.

‘F’ ANCHOR

ANCHOR BOLTS

AS REQ’D.

See Section III of the Standard

Installation Instructions , step 4 for

special sealant note at horizontals.

IMPORTANT NOTE:

It is critical to allow at least a ¾” space between the perimeter of the jamb mullion and

the condition for setting space for the last frame unit to be installed.

PRE-ASSEMBLED

FRAME UNIT

‘F’ ANCHOR

DEAD LOAD

SHIMS

EFCO CORPORATION 6/2012 PART NO. Y557

16

Page 17

Series 5500 Advanced & Alternate Installation Instructions

Section III: Alternate Anchorage Method

(Heavy-Duty Anchor Connections)

STEP #5 INSTALL FRAME HEAD & SILL COMPONENTS

A. Drop-on and attach head and sill horizontals as indicated in the approved shop

drawings. Be certain to properly hook the horizontal onto the shear block.

B. Section II of the

notes.

C. Refer to Sections IV and V for Glazing Preparation and Glazing Installation.

Standard Installation Instructions for special sealant and assembly

HEAD

SILL

EFCO CORPORATION 6/2012 PART NO. Y557

17

Page 18

Series 5500 Advanced & Alternate Installation Instructions

Section V: PUNCHED OPENING & RIBBON WINDOWS

(Frame Opening & Frame Sealing)

STEP #1 ASSEMBLE OUTSIDE GLAZED FRAME MEMBERS

A. Seal the ends of the vertical mullions at the exterior and snap-in the PVC fillers. (Section II of

the

Standard Installation Instructions).

B. The base section of the two-part anchor must be slid into the heads and sills prior to

assembling the frames. The remaining part of the anchor can be applied in the field.

C. Sealant must be applied to the ends of each horizontal member before assembly. (See

enlargement Section II of the

D. Assemble the frames per the approved shop drawings.

Standard Installation Instructions.)

PVC FILLER

VERTICAL FILLER

FRAME ASSEMBLY SCREWS ¼” –

14 X 1 ½” HWSMS 18-8 Typical

CUSTOM TWO-PART

EXTRUDED

ALUMINUM ANCHORS

HEAD

VERTICAL FILLER

INTERMEDIATE VERTICAL

INTERM.

HORIZ’S.

PERIMETER

MULLION

CUSTOM TWO-PART

EXTRUDED

ALUMINUM ANCHORS

PVC FILLER

PUNCHED OPENING AND RIBBON WINDOWS

EFCO CORPORATION 6/2012 PART NO. Y557

SILL

18

Page 19

Series 5500 Advanced & Alternate Installation Instructions

Section V: PUNCHED OPENING & RIBBON WINDOWS

(Frame Opening & Frame Sealing)

Punched opening and ribbon window elevations are typically used for small openings or openings of

limited height where the frames can be partially assembled off-site, moved to the jobsite, and then

groups of frames are snapped together. This allows groups of frames to be set into the opening all at

one time. Custom extruded aluminum anchors are slid into the heads and sills during frame assembly.

This method of anchorage is limited due to certain structural limitations. Please consult with the

structural engineer responsible for the shop drawings for your project. This type of installation also

requires that there be no obstructions (such as floor slabs or columns) that prevent the frames from

being installed from the interior.

SHIMS AT

ANCHOR

ANCHOR BOLTS

AS REQ’D.

CUSTOM TWO-PART

EXTRUDED

ALUMINUM ANCHORS

Note: It is up to the responsible

engineer to determine the

structural adequacy and type of

anchorage method to be used

for a given substrate, applied

loads, and building movements.

The S-5500 has different

anchorage options available to

meet these conditions.

SHIMS AT

ANCHOR

PUNCHED OPENING AND RIBBON WINDOWS

EFCO CORPORATION 6/2012 PART NO. Y557

DEAD LOAD

SHIM AT

VERTICAL

ANCHOR BOLTS

AS REQ’D.

19

Page 20

Series 5500 Advanced & Alternate Installation Instructions

Section V: PUNCHED OPENING & RIBBON WINDOWS

(Frame Opening & Frame Sealing)

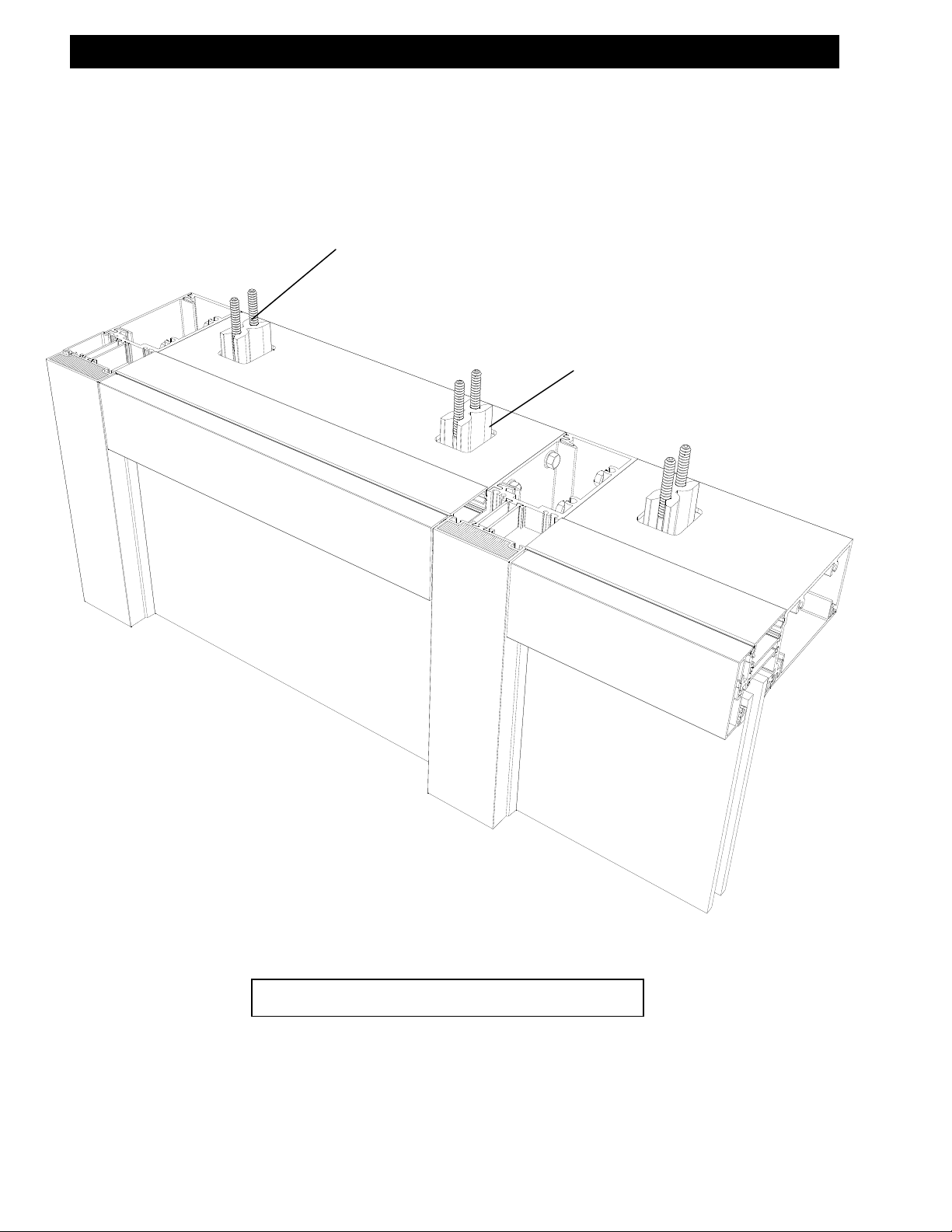

STEP #1 SIDE STACK PRE-ASSEMBLED FRAMES

Frames can be partially assembled off-site and moved to the jobsite. Then, groups of frames may be

snapped together, allowing them to be set into the opening at one time. The size of the group of

frames to be installed is limited by the field’s handling capacity due to the weight and size of the

assemblies.

PRE-ASSEMBLED

FRAMES

See Section III of the Standard

Installation Instructions , step 4 for

special sealant note at horizontals.

EFCO CORPORATION 6/2012 PART NO. Y557

20

Page 21

Series 5500 Advanced & Alternate Installation Instructions

Section V: PUNCHED OPENING & RIBBON WINDOWS

(Alternate Anchorage Method)

STEP #2 PREPARE TO SET FRAMES

A. Slide the anchor plates into the base anchors that were installed during frame assembly.

B. Refer to the approved shop drawings to review anchor placement, type, and conditions.

CUSTOM TWO-PART

EXTRUDED

ALUMINUM ANCHORS

ASSEMBLED GROUP

OF FRAMES

EFCO CORPORATION 6/2012 PART NO. Y557

21

Page 22

Series 5500 Advanced & Alternate Installation Instructions

Section V: PUNCHED OPENING & RIBBON WINDOWS

(Alternate Anchorage Method)

STEP #3 SET GROUPS OF FRAMES

A. Set the assembled groups of frames into the opening.

B. Using dead load shims under each vertical mullion, level the frame and set it to the

appropriate elevation as indicated in the approved shop drawings.

C. Use shims between the anchor plate and the condition to set the frame the proper

distance to the face of the building. After the frames are plumb and the frames have

been properly installed relative to established benchmarks, match drill through the

holes in the anchor plates into the surrounding substrate, and apply the appropriate

anchor bolts. Anchor bolt size, type, quantity, and location vary. Refer to the approved

shop drawings for more information. Anchor bolts should be installed per the

recommendations of the bolt manufacturer.

ADJUSTMENT

OPENING IN BUILDING

STRUCTURE

SHIMS

DEAD LOAD

SHIMS

EFCO CORPORATION 6/2012 PART NO. Y557

ASSEMBLED

GROUP OF

FRAMES

DEAD LOAD

SHIMS

ANCHOR BOLTS

AS REQ’D.

22

Page 23

Series 5500 Advanced & Alternate Installation Instructions

Section V: PUNCHED OPENING & RIBBON WINDOWS

(Alternate Anchorage Method)

Refer to Sections IV and V for Glazing Preparation and Glazing Installation.

EFCO CORPORATION 6/2012 PART NO. Y557

23

Page 24

Series 5500 Advanced & Alternate Installation Instructions

Section V: Vertical Splice Joints

STEP #1 LOCATE SPLICE JOINTS

A. Splice joints should occur at spandrel areas (if possible). Refer to the approved shop

drawings for actual locations.

B. Depending on job requirements, the mullion splice may be shop or field assembled in

the top of the lower mullion. The cover splice is attached to the bottom of the upper

mullion. Where head clearance is insufficient to allow the top mullion to be lifted over

the splice sleeves, retractable splices should be used. The splices are to be taped into

the bottom of the top mullion and dropped down to the stop screw in the mullion

below.

C. GENERAL NOTE: The following pages depict a splice joint of 1/2”. This will allow plus

or minus 1/4” of movement for each splice location. Thermal expansion and live

deflection requirements should be considered when determining the location and

quantities of splice joints. If the total amount of movement cannot be accommodated

locating splices at every other floor or alternatively at each floor, expansion

horizontals or some alternative method should be used. Contact EFCO for further

evaluation.

D. Refer to this section for pressure cover splice locations, mullion splice locations, and

sealing instructions.

E. Once a final check of expansion joint placement and mullion position is made, the final

match drilling of mullion through anchor holes may be completed.

BACKER

ROD

JAMB INTERMEDIATE EXPANSION MULLION

Mullion splice sleeves

with bond breaker tape.

SPLICE SLEEVE

STOP SCREWS

PLAN VIEW – MULLION SPLICE

EFCO CORPORATION 6/2012 PART NO. Y557

¼” X 1” X 5” FOAM

CAULK JOINT BACKER

Cover splice sleeves

with bond breaker

tape.

24

Page 25

Series 5500 Advanced & Alternate Installation Instructions

MULLION LENGTH

Section V: Vertical Splice Joints

MULLION

SPLICE

5/8"(MIN.)

COVER LENGTHCOVER LENGTH

1/2"

MULLION SECTION LENGTH

GLAZING ADAPTER AND REAR

1/2"

5 1/2"

3 " NOTCH

1/2"

MULLION LENGTH

COVER

SPLICE

2"

3 " NOTCH

SPLICE SLEEVE

STOP SCREW

MULLION SECTION LENGTH

GLAZING ADAPTER AND REAR

NOTE: All anchors must be fixed before glazing begins.

SIDE VIEW – MULLION SPLICE

EFCO CORPORATION 6/2012 PART NO. Y557

25

Page 26

Series 5500 Advanced & Alternate Installation Instructions

Section V: Vertical Splice Joints

STEP #2 ATTACH MULLION SPLICE SLEEVES

A. Clean all surfaces that will contact sealant per the sealant manufacturer’s instructions,

making sure to remove all oils and debris from contact surfaces.

B. Apply bond breaker tape to the mullion splice sleeve.

C. For standard installation, attach the mullion splice sleeve to the top of the lower mullion

with splice sleeve attachment screws. Cap seal the fastener heads.

MULLION SPLICE SLEEVE

BOND BREAKER TAPE

1/4” X 1” X 5”

FOAM CAULK

JOINT BACKER

SPLICE ATTACHMENT

SCREWS (cap seal)

LOWER MULLION

EFCO CORPORATION 6/2012 PART NO. Y557

SPLICE STOP SCREW

(When required) See

STEP 1, item B, , page 24.

26

Page 27

Series 5500 Advanced & Alternate Installation Instructions

Section V: Vertical Splice Joints

STEP #3 CRITICAL MULLION SEAL AT SPLICE

A. Insert the 1/4” x 1” x 5” long foam caulk joint backer as shown below leaving 1” of

the backer extending above the top of the mullion.

B. Apply sealant between the thermal struts, starting where the notch in the mullion

begins at the exterior cover, sealing the space to the top of the mullion as shown.

C. Tool the sealant flush with the face of the notch of the thermal struts.

MULLION SPLICE SLEEVE

1/4” X 1” X 5”

FOAM CAULK

JOINT BACKER

Seal the gap between the

thermal struts including

the void at the bottom of

the notch.

SPLICE ATTACHMENT

SCREWS (cap seal)

LOWER MULLION

EFCO CORPORATION 6/2012 PART NO. Y557

27

Page 28

Series 5500 Advanced & Alternate Installation Instructions

Section V: Vertical Splice Joints

STEP #4 ATTACH MULLION COVER SPLICE SLEEVES

A. Apply bond breaker tape to the mullion cover splice sleeve.

B. For standard installation, attach the mullion cover splice sleeve to the bottom of the

upper mullion with splice sleeve attachment screws. Cap seal the fastener heads.

UPPER MULLION

BOND BREAKER

TAPE

EFCO CORPORATION 6/2012 PART NO. Y557

SPLICE ATTACHMENT

SCREWS (cap seal)

MULLION COVER

SPLICE SLEEVE

28

Page 29

Series 5500 Advanced & Alternate Installation Instructions

Section V: Vertical Splice Joints

STEP #5 ALIGN AND STACK ASSEMBLED FRAMES

A. Align the pre-assembled frames and stack together at the splice joints.

B. Ensure the 1/4” x 1” x 5” long foam caulk joint backer is inserted into the gap

between the thermal struts in the upper mullion as noted below.

C. Position the mullions to the appropriate elevation with regard to established

benchmarks, and shim or fix the mullions at their respective dead load anchor

points.

D. Snap-in both of the adjacent frames before sealing the mullion splice joints.

E. Clean the splice sealant-contact areas per sealant manufacturer’s

recommendations.

F. Apply backer rod between the mullions, adapters, and splice to back-up the joint,

seal the joint and tool as shown on page 30.

ADJACENT FRAME

ASSEMBLIES

joint backer between

UPPER FRAME

ASSEMBLY

MULLION

SPLICE SLEEVES

Insert foam caulk

thermal struts.

LOWER FRAME

ASSEMBLY

EFCO CORPORATION 6/2012 PART NO. Y557

29

Page 30

Series 5500 Advanced & Alternate Installation Instructions

Section V: Vertical Splice Joints

STEP #6 SEAL MULLION SPLICE

A. Install backer rod to back-up the sealant at the mullion joints as shown on page 24.

B. Apply sealant into the mullion splice joint and tool the joint. Do not obstruct the

glazing reglets.

C. Apply sealant into the pressure cover splice joint and tool the joint. Do not obstruct

the glazing reglets.

D. Apply sealant around the 1/4” x 1” x 5” long foam caulk joint backer. Tool the joint

and blend the sealant into the mullion splice joint and over the thermal struts. A

minimum of 1/4” sealant surface contact with bonding surfaces is required.

E. Apply sealant into the joint between the notched thermal struts and the back of the

notched pressure cover and tool the joint smooth (see page 31.)

B. Apply sealant into

the mullion joint and

tool smooth.

D. Apply sealant

around the 1/4” x 1”

x 5” foam caulk joint

backer, tool smooth.

A. Install backer rod at the

mullion joint to back-up

the sealant.

E. Apply sealant into the

joint between the notched

thermal struts and the

back of the notched

pressure cover, and tool

the joint smooth.

(See page 31.)

C. Apply sealant into

the pressure cover joint

and tool smooth.

Note: Gasket and adapter

reglets on both sides of the

glazing pocket must be free of

sealant obstructions before

placing gaskets and adapters.

EFCO CORPORATION 6/2012 PART NO. Y557

30

Page 31

Series 5500 Advanced & Alternate Installation Instructions

Section V: Vertical Splice Joints

Apply sealant into the joint between

the notched thermal struts and the

back of the notched pressure cover,

and tool the joint smooth. The joint

should have an hourglass shape and a

maximum width of 5/16” at the

thinnest part of the joint.

SPLICE JOINT DETAIL

EFCO CORPORATION 6/2012 PART NO. Y557

31

Page 32

Series 5500 Advanced & Alternate Installation Instructions

Section V: Vertical Splice Joints

STEP #7 INSTALL AND SEAL ADAPTERS

A. Seal gasket races continuously and snap-in adapters, if required.

B. Snap-in adapters, carefully using a small pry bar, if required.

C. Install backer rod to back-up sealant at the glazing adapters.

D. Apply sealant and tool into joints. Do not obstruct the glazing

reglets.

Seal gasket races prior

to snapping-in adapters.

Install backer rod at the

adapter joint to back-up

the sealant.

Apply sealant into the

adapter joint and tool

smooth.

EFCO CORPORATION 6/2012 PART NO. Y557

32

Page 33

Series 5500 Advanced & Alternate Installation Instructions

Section V: Vertical Splice Joints

STEP #8 INSTALL INTERIOR GASKETS, GLAZING, AND EXTERIOR GASKETS

A. Install the interior gaskets allowing them to span the mullion splice joint.

B. Set the glazing into the opening as previously instructed.

C. Apply the exterior vertical drive-in wedge gaskets into the vertical mullions as

shown in Section VI of the Standard Installation Instructions.

D. Apply the horizontal pressure covers and horizontal exterior drive-in wedge

gaskets at the top and bottom of the lite as shown in the Standard Installation

Instructions.

GLAZING ADAPTERS

(When required)

INTERIOR GASKETS

(Runs continuously

through splice joint)

GLAZING INFILL

EFCO CORPORATION 6/2012 PART NO. Y557

EXTERIOR GASKETS

(Runs continuously

through splice joint)

33

Page 34

Series 5500 Advanced & Alternate Installation Instructions

Section VI: Expansion Mullions

STEP #1 PREPARE EXPANSION MULLIONS

Expansion mullions are required for elevations wider than 20’-0”. The maximum spacing

between expansion mullions is 20’-0”. Refer to the approved shop drawings for specific

locations and more information.

A. Thread the finger gaskets into the reglets of the male half of the expansion

mullion for the full length of the mullion. Refer to the approved shop drawings for

part numbers.

B. Crimp the reglet at the finger gaskets about ½” from each end with a chisel or

similar tool to lock the gasket in place.

FINGER GASKET

GASKET REGLET

MALE EXPANSION

MULLION

FINGER GASKET

EFCO CORPORATION 6/2012 PART NO. Y557

34

Page 35

Series 5500 Advanced & Alternate Installation Instructions

Section VI: Expansion Mullions

STEP #1 (Continued) PREPARE EXPANSION MULLIONS

When vertical D.L.O.s exceed 48”, mullion clips may be required at the center of the lite.

Contact EFCO or refer to the approved shop drawings for more information.

A. Slide the mullion clips into the grooves of the mullion as shown below.

B. Crimp the legs at each end of the mullion clip with a punch or similar tool to lock it in

place. Refer to the approved shop drawings for more information.

Crimp legs at

top and bottom

of mullion clip.

FEMALE EXPANSION

MULLION

MULLION CLIP X

4” LONG

EFCO CORPORATION 6/2012 PART NO. Y557

35

Page 36

Series 5500 Advanced & Alternate Installation Instructions

Section VI: Expansion Mullions

STEP #2 STACK EXPANSION MULLIONS

A. Apply a continuous bead of sealant to the male mullion half as noted below.

B. After the frames are assembled as instructed in Section II, install the frames using the

anchor methods required. Stack the expansion mullions together using ‘C’ clamps to

press each half of the mullion together. Use shims as shown below to prevent from

closing the expansion mullion. Remove the shims after the anchors are set.

C. Tool the sealant joint in the space between the expansion mullions as shown below.

This seal will marry with the joint plug seals when the joint plugs are applied.

SHIM

MALE MULLION

CONTINUOUS

SEALANT JOINT

1/8” notch on

male mullion side

of glazing pocket.

SHIM

EFCO CORPORATION 6/2012 PART NO. Y557

36

Page 37

Series 5500 Advanced & Alternate Installation Instructions

Section VI: Expansion Mullions

STEP #3 GLAZE EXPANSION MULLIONS

A. Glaze the curtain wall as instructed in Sections IV, V, and VI of the Standard

Installation Instructions.

IMPORTANT NOTE: The horizontal and horizontal pressure cover must be notched,

or cut 1/8” short on the male mullion side of the glazing pocket, as shown below to

allow for horizontal expansion and contraction of the curtain wall.

MALE MULLION

EFCO CORPORATION 6/2012 PART NO. Y557

Horizontal pressure

cover cut 1/8” short

on male mullion side.

37

Page 38

Series 5500 Advanced & Alternate Installation Instructions

Section VII: Glazing at Spandrel Areas of I.G. Frames

Note: S-5500 curtain wall must be outside glazed at the floor lines, some column locations, shear

walls and parapet areas, or any other area that would not allow the glazing infill to be inside set.

Refer to the approved shop drawings for locations and exact configuration of the spandrel areas. The

following is a guide for a typical floor line spandrel installation.

GLAZING SPANDREL AREAS AT FLOOR LINES

A. Vision lites will consist of inside glazed horizontals at the head of the lite as shown in

“FIGURE A” below.

B. The top of the spandrel lite and any intermediate horizontals within the spandrel areas will

consist of an outside glazed horizontal with a roll-on pressure cover as shown in “FIGURE B”

below.

C. The bottom of the spandrel lite above the vision area will consist of an inside/outside-glazed

horizontal with a roll-on pressure cover and removable interior bead as shown in “FIGURE

C” below. This will allow the spandrel lite to be outside set and the vision lite to be inside

set.

VISION AREAS

SPANDREL AREAS

SPLICE JOINT

FLOOR SLAB

FIGURE A

FIGURE B

VISION AREAS

SPANDREL AT FLOOR LINE

EFCO CORPORATION 6/2012 PART NO. Y557

FIGURE C

38

Page 39

Series 5500 Advanced & Alternate Installation Instructions

Section VII: Glazing at Spandrel Areas of I.G. Frames

STEP #1 GLAZE ADJACENT VISION AREAS

A. Apply the setting blocks at the bottom of the vision lites above and below the

spandrel areas per the approved shop drawings.

B. Install the preset glazing gaskets on the exterior side of the glazing pocket at the

vision areas per “Glazing Preparation” in Section IV of the Standard Installation

Instructions.

C. Set the glazing infill and anti-walk blocks into the vision areas as instructed per

“Glazing Installation” in Section V of the Standard Installation Instructions.

D. Apply the interior glazing beads and drive-in wedge glazing gaskets per “Interior

Drive-In Gasket & Glazing Bead Installation” in Section VI of the Standard Installation

Instructions.

SPANDREL AREAS

SPLICE JOINT

VISION AREAS

FLOOR SLAB

INTERIOR VIEW

EFCO CORPORATION 6/2012 PART NO. Y557

VISION AREAS

39

Page 40

Series 5500 Advanced & Alternate Installation Instructions

Section VII: Glazing at Spandrel Areas of I.G. Frames

STEP #2 INSTALL SETTING BLOCKS AND PRESET GASKETS INTO MULLIONS

A. Apply the setting blocks at the bottom of the spandrel lites per the approved shop

drawings.

B. Install the preset glazing gaskets per “Glazing Preparation” in Section IV of the

Standard Installation Instructions, except the gaskets will be set on the

of the glazing pocket as shown below.

VISION AREAS

interior

side

SPANDREL AREAS

SPLICE JOINT

FLOOR SLAB

EXTERIOR VIEW

VISION AREAS

EFCO CORPORATION 6/2012 PART NO. Y557

40

Page 41

Series 5500 Advanced & Alternate Installation Instructions

Section VIII: Captured Glazing Adaptor Installation

STEP #1 INSTALL GLAZING ADAPTERS

A. Prior to installing the glazing adapters, seal the full length of the gasket raceway

with sealant.

B. Snap the glazing adapters in place into the sealant starting with the verticals.

Allow at least 1/8” clearance from the bottom of the glazing adapters to the top of

the joint plugs to allow for weepage.

C. Apply sealant to the ends of the horizontal adapters prior to setting them into

position. Snap the horizontal adapters in place between the vertical adapters. Seal

the face of the adaptor intersections with sealant. Tool all sealant joints and

remove all excess sealant.

Continuously seal the

gasket raceway with

sealant prior to

installing the adapters.

NOTE: The vertical adapters

will need clearance above

the joint plugs, free from

sealant for weepage.

EFCO CORPORATION 6/2012 PART NO. Y557

GLAZING ADAPTERS

Glazing adapter cut formula:

Vertical = D.L.O. + 1”

Horizontal = D.L.O. – 1/16”

41

Page 42

Series 5500 Advanced & Alternate Installation Instructions

Section VIII: SSG Glazing Adaptor Installation

STEP #1 INSTALL GLAZING ADAPTERS IF REQUIRED

A. Prior to installing the glazing adapters, seal the full length of the gasket raceway

with sealant.

B. Snap or screw apply the glazing adapters in place into the sealant, starting with

the verticals. Allow at least 1/8” clearance from the bottom of the glazing

adapters to the top surface of the glazing pocket at captured horizontals to allow

for weepage.

C. Apply sealant to the ends of the horizontal adapters prior to setting them into

position. Snap or screw apply the horizontal adapters in place between the vertical

adapters. Seal the face of the adapter intersections with sealant. Seal all screw

heads with sealant. Tool all sealant joints, and remove all excess sealant.

SCREW APPLIED

GLAZING

ADAPTERS

Continuously seal the

gasket raceway with

sealant prior to

installing the adapters.

GLAZING ADAPTERS

STANDARD SSG JAMB WITH REVEAL AND

CAPTURED INTERMEDIATE HORIZONTAL

Seal and tool the sealant at the

ends of the adapters at the

intersection of the verticals.

NOTE: The vertical adapters

will need clearance above

the joint plugs, free from

sealant, for weepage.

NOTE: Refer to the approved

shop drawings for screw

types, adapter part numbers,

and glazing combinations.

STANDARD

SSG JAMB

CAPTURED

HORIZONTAL

EFCO CORPORATION 6/2012 PART NO. Y557

GLAZING ADAPTERS

42

Page 43

Series 5500 Advanced & Alternate Installation Instructions

Section VIII: SSG Glazing Adaptor Installation

STEP #1 INSTALL GLAZING ADAPTERS (CONTINUED)

Continuously seal the

gasket raceway with

sealant prior to

installing the adapters.

SCREW APPLIED

GLAZING

ADAPTERS

NOTE: Refer to the approved

shop drawings for screw

types, adapter part numbers,

and glazing combinations.

Seal and tool the sealant at the

ends of the adapters at the

intersection of the verticals.

STANDARD

SSG JAMB

GLAZING ADAPTERS

EFCO CORPORATION 6/2012 PART NO. Y557

43

Page 44

Series 5500 Advanced & Alternate Installation Instructions

Section VIII: SSG Glazing Adaptor Installation

STEP #1 INSTALL GLAZING ADAPTERS (CONTINUED)

Continuously seal the

gasket raceway with

sealant prior to

installing the adapters.

SCREW APPLIED

GLAZING

ADAPTERS

GLAZING ADAPTERS

NOTE: Refer to the approved

shop drawings for screw

types, adapter part numbers,

and glazing combinations.

CAPTURED

HORIZONTALS

Seal and tool the sealant at the

ends of the adapters at the

intersection of the verticals.

SSG VERTICAL

MULLION

STANDARD SSG VERTICAL AND CAPTURED

INTERMEDIATE HORIZONTAL

EFCO CORPORATION 6/2012 PART NO. Y557

44

Page 45

Series 5500 Advanced & Alternate Installation Instructions

Section VIII: SSG Glazing Adaptor Installation

STEP #1 INSTALL GLAZING ADAPTERS (CONTINUED)

Continuously seal the

gasket raceway with

sealant prior to

SCREW APPLIED

GLAZING

ADAPTERS

installing the adapters.

NOTE: Refer to the approved

shop drawings for screw

types, adapter part numbers,

and glazing combinations.

Seal and tool the sealant at

the ends of the adapters at the

intersection of the verticals.

SSG EXPANSION

MULLION

SSG HORIZONTAL

MULLIONS

SSG INTERMEDIATE EXPANSION VERTICAL AND

SSG INTERMEDIATE HORIZONTAL

EFCO CORPORATION 6/2012 PART NO. Y557

45

Page 46

Series 5500 Advanced & Alternate Installation Instructions

Section VIII: SSG Glazing Adaptor Installation

STEP #1 INSTALL GLAZING ADAPTERS (CONTINUED)

SCREW APPLIED

GLAZING

ADAPTERS

Continuously seal the

gasket raceway with

sealant prior to

installing the adapters.

NOTE: Refer to the approved

shop drawings for screw

types, adapter part numbers,

and glazing combinations.

Seal and tool the sealant at

the ends of the adapters at the

intersection of the verticals.

SSG VERTICAL

MULLION

SSG HORIZONTAL

MULLIONS

SSG INTERMEDIATE VERTICAL AND

SSG INTERMEDIATE HORIZONTAL

EFCO CORPORATION 6/2012 PART NO. Y557

46

Loading...

Loading...