Page 1

d

Storefront –

orma rts 88

Concealed overhead closer supplement

Installation Instructions

Part NO. Y013

February 2013

Page 2

SECTION

TABLE OF CONTENTS

I PARTS IDENTIFICATION

PAGE 1-2

II HEADER/TRANSOM BAR INSTALLATION

A) BUTT HINGE, CONTINUOUS HINGE, CENTER PIVOTS

1) 1 3/4" AND 2" HEADER/T'BAR INSTALLATION STEPS

2) 4" AND 4 1/2" HEADER/T'BAR INSTALLATION STEPS

B) OFFSET PIVOT STEPS

1) 1 3/4" AND 2" HEADER/T'BAR INSTALLATION STEPS

2) 4" AND 4 1/2" HEADER/T'BAR INSTALLATION STEPS

PAGES 3-4

PAGES 5-6

PAGE 7

PAGE 8

III CLOSER PREPARATION AND INSTALLATION

A) BUTT HINGE, CONTINUOUS HINGE, CENTER PIVOTS

1) CLOS ER PREP A ND INSTA LLATION STEPS FOR 1 3/4" AND 2" HDR/T'BAR

2) CLOS ER PREP A ND INSTA LLATION STEPS FOR 4" AND 4 1/2" HDR/T'BAR

B) OFFSET PIVOT

1) CLOSER PREP AND INSTALLATION STEPS PAGES 15-17

PAGES 9-11

PAGES 12-14

IV EXPLODED VIEWS

A) BUTT HINGE AN D CONTINUOUS HINGE

B) CENTER PIVOTS PAGE 19

C) OFFSET PIVOTS PAGE 20

PAGE 18

V DOOR INSTALLATION

VI CLOSER ADJUSTMENT

THESE INSTRUCTIONS USE FLUSH GLAZE STOREFRONT AS A BASIS

FOR DETAILING. THE TRANSOM BAR PREPS WILL BE THE SAME

FOR ALL OTHER FRAMING SYSTEMS THAT REQUIRE A C.O.C. AND

HAVE A TUBULAR TRANSOM BAR TO ACCEPT THE CLOSER.

PLEASE CONSULT THE INSTALLATION INSTRUCTIONS FOR THE

PARTICULAR SYSTEM BEING INCORPORATED FOR THE TRANSOM

BAR AND SHEAR BL OCKS REQUIRED AS A REPLACEMENT

THROUGHOUT THESE INSTRUCTIONS.

Minimizing Condensation

NOTE: Please reference EFCO 's "Understanding Condensation" br ochure which can be obtained through your EFCO representative.

Condensation will form on any surfac e when unf avorable conditions (interior temperature and relative humidity and exterior

temperature) are pres ent. When the formation of excessive condensation is a concern, it is highly recommended that a design

professional is utilized to perf or m an analysis of the shop drawings to r ecommend the best installation methods. Please contact

EFCO representative for i nf or m at i on on EFCO's Thermal Analysis Services.

Many current inst al l ati on pr actices lead to an increase in the possibility of the formation of condensation. Though not all

inclusive, the list of ex amples below illustrates conditions under which condensation is likely to occur:

1. Bridging system thermal break with non-thermally broken metal flashin g or linte l s t hat are exposed to the

exterior.

2. System exposur e to cold air cavities.

3. Interior relative hu midit y leve ls not maintained at recommended levels, see EFCO's "Understanding

Condensation" brochure.

4. Inadequate separation between s y stem and surrounding condition at perimeter.

5. Product combinations during the shop drawing stage that result in bridging thermal breaks of one or all products

involved.

PAGE 21

PAGE 21

Page 3

PAGE

1

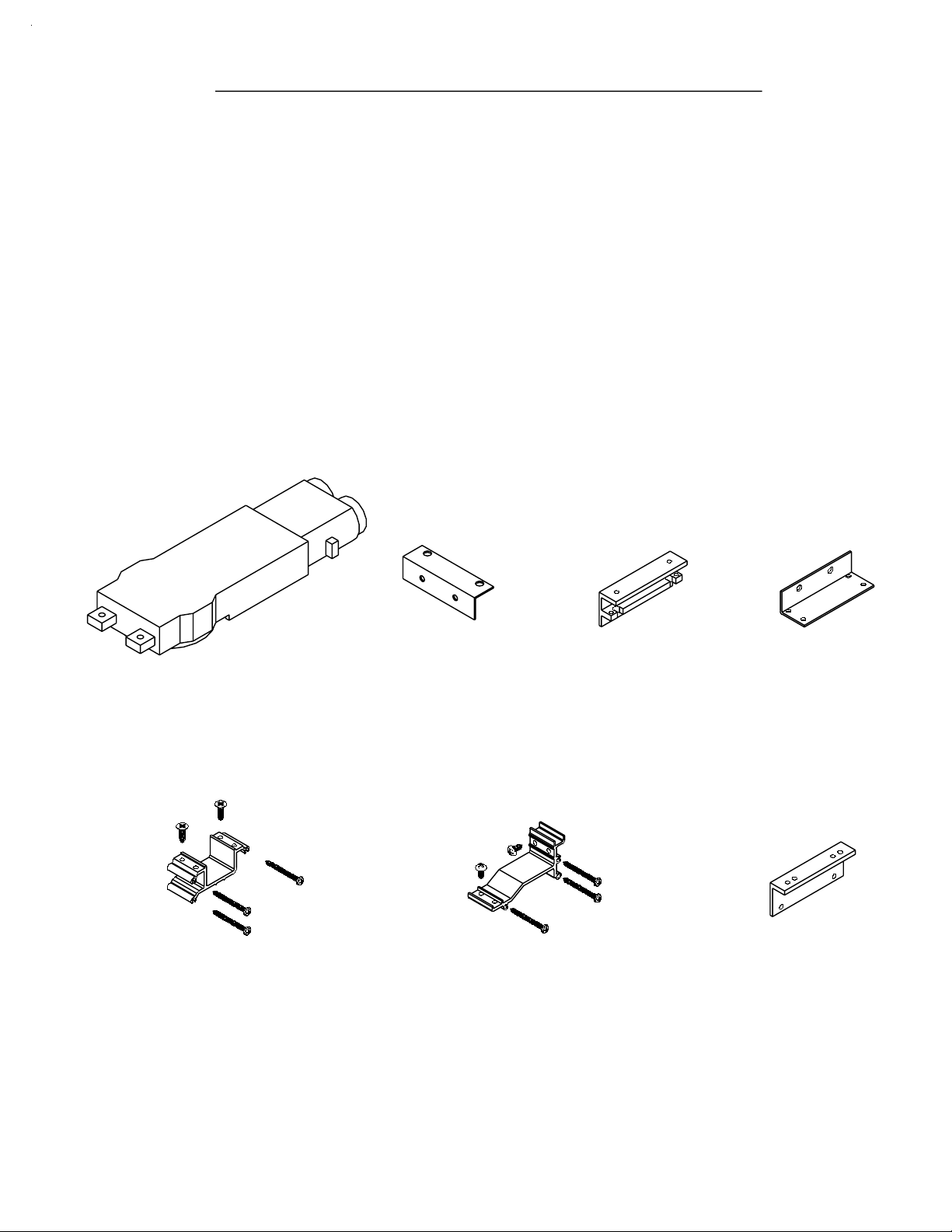

SECTION I PARTS IDENTIFICATION

CONCEALED OVERHEAD CLOSERS REQUIRE PRECISE ASSEMBLY TO FUNCTION

PROPERLY. CORRECT CLOSER APPLICATION MUST BE DETERMINED (CENTER

PIVOT, BUTT HINGE, GEARED HINGE OR OFFSET PIVOT) AND ASSEMBLY

FOLLOWED PER THESE INSTRUCTIONS. SOME OR ALL OF THE PARTS SHOWN

BELOW WILL BE REQUIRED FOR INSTALLATION OF THE C.O.C. PARTS

IDENTIFICATION:

- ALL PARTS FOLLOWED BY (C) ARE INCLUDED IN THE CONCEALED OVERHEAD CLOSER PACKAGE.

- ALL PART NUMBERS ENCLOSED BY { } ARE SUPPLIED BY EFCO.

- SCREWS ARE LABELED AT DETAILS WITH EFCO PART NUMBERS ADDED.

EFCO STANDARD C.O.C.

DORMA RTS 88 (C)

SHEAR BLOCK w/ SCREWS

(S401 & S402)

{K120} - CLR. & BRZ.

"F" CLIP for BUTT

HINGES or GEARED

HINGES (C)

SHEAR BLOCK w/ SCREWS

4" & 4 1/2" HEADER

(S402)

{K173}

ANGLE BRACKET for

BUTT HINGES or

GEARED HINGES (C)

ANGLE CLIP for

OFFSET PIVOTS

HQ42 (C)

ANGLE CLIP w/

OFFSET PIVOTS

{FT16}

BAH 8-9-04

Page 4

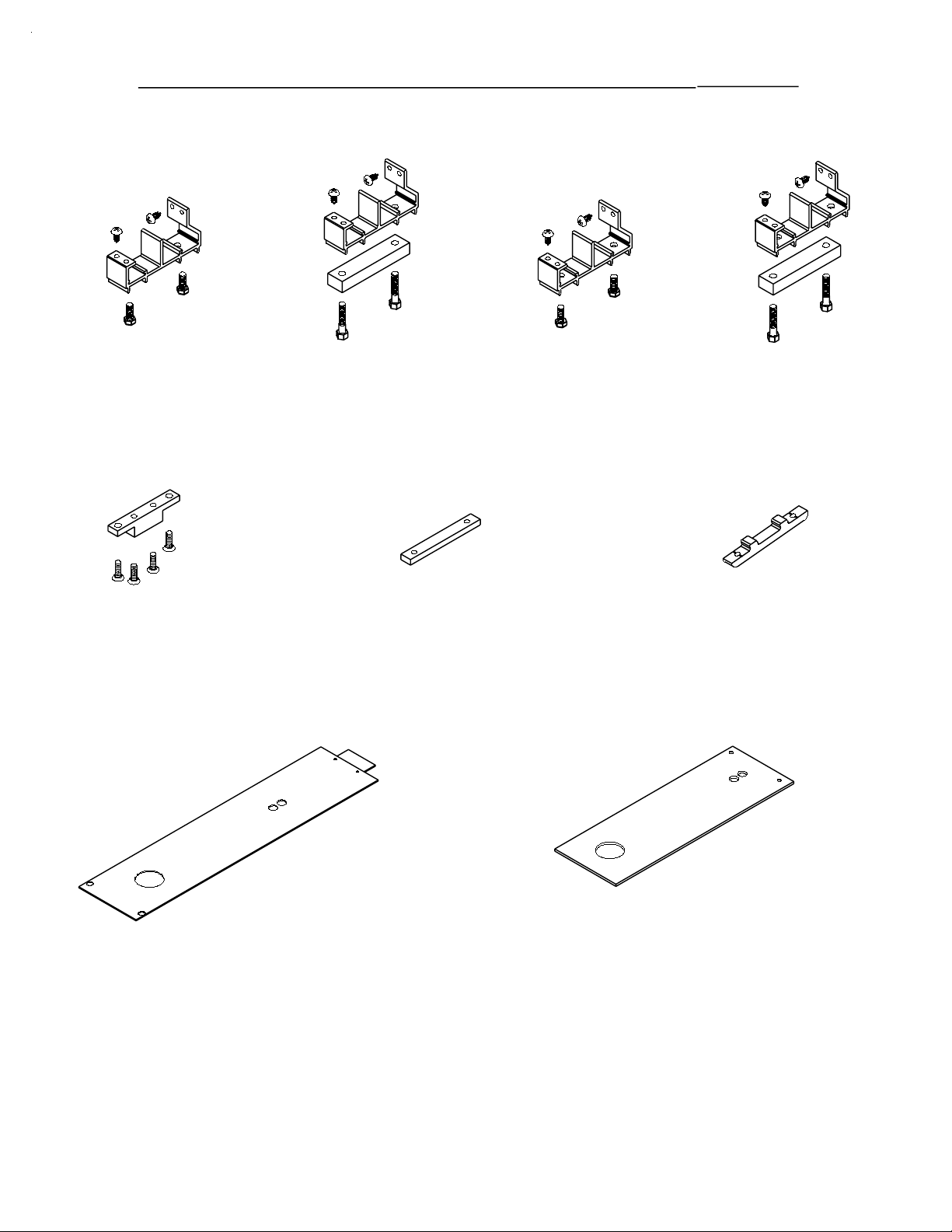

PAGE 2

SECTION I PARTS IDENTIFICATION

MOUNT w/ SCREWS

for 4" HEADER @ BUTT

or GEARED HINGES

{K497}

MOUNT w/ SPACER &

SCREWS for 4 1/2"

HEADER @ BUTT or

GEARED HINGES

{K929}

MOUNT w/ SCREWS

for 4" HEADER @

CENTER PIVOTS

{K498}

(CON’T)

MOUNT w/ SPACER &

SCREWS for 4 1/2"

HEADER @ CENTER

PIVOTS

{K928}

MOUNTING BLOCK

w/ SCREWS

for OFFSET PIVOTS

{K435}

COVER PLATE w/ BUTT HINGES, GEARED

HINGES, or CENTER PIVOTS

{K492} PKG. MILL

{K495} PKG. CLR

{K496} PKG. BRZ

1/4" SPACER BLOCK for 2"

TRANSOM BAR @ BUTT

HINGES or GEARED HINGES

2 REQUIRED

1/2" SPACER BLOCK for S945

SYSTEM

- MUST SPECIFY NOT SUPPLIED {FT71}

{F045}

COVER PLATE w/ OFFSET PIVOTS

{FT20} RIGHT HAND MILL

{FT26} LEFT HAND MILL

{FU02} RIGHT HAND CLR

{FU04} LEFT HAND CLR

{FU03} RIGHT HAND BRZ

{FU05} LEFT HAND BRZ

BAB 7/01

Page 5

PAGE 3

SECTION II HEADER/TRANSOM BAR INSTALLATION

THE BUTT HINGE AND GEARED HINGE APPLICATION HEADER PREPS ARE IDENTICAL.

THE CENTER PIVOT AND OFFSET PIVOT APPLICATION HEADER PREP ARE NOT, DUE

TO THE DIFFERING CLOSER LOCATIONS. THE BUTT HINGE, GEARED HINGE, AND

CENTER PIVOT INSTALLATION PROCESS IS IDENTICAL. PLEASE FOLLOW THE

CORRECT INSTRUCTIONS FOR YOUR C.O.C. APPLICATION.

A. BUTT HINGE, CONTINUOUS HINGE, AND CENTER PIVOTS

1. 1 3/4" OR 2" HEADER/T’BAR INSTALLATION STEPS

A.

ATTACH THE DORMA "F" CLIP TO THE HEADER/TRANSOM BAR WITH TWO

#10-32x5/8" PL-FH-MS.

B.

PLACE TWO 1/4-20x1" PL-FH-MS THROUGH THE HOLES IN THE HEADER/T-BAR

AND SECURE THEM WITH TWO 1/4"-20 HEX NUTS AND LOCK WASHERS. PLACE THE

ANGLE BRACKET ON THE THREADS THAT EXTEND PAST THE NUTS AND SECURE

WITH TWO MORE 1 /4"-20 HEX NUTS AND LOCK WASHERS.

C.

APPLICATIONS WITH A 2" HEADER/T-BAR:

ONE SPACER BLOCK {F045} MUST BE USED BETWEEN THE "F" CLIP AND THE

HEADER/T-BAR. USE TWO #10-32x5/8" PL-FH-MS TO FASTEN THE ASSEMBLY INTO

PLACE.

D.

APPLICATIONS WITH A 2" HDR/T-BAR:

USE TWO 1/4-20x1" PL-FH-MS THROUGH THE HOLES IN THE HEADER/T-BAR TO

SECURE ONE SPACER BLOCK {F045} WITH TWO 1/4"-20 HEX NUTS AND LOCK

WASHERS. PLACE THE ANGLE BRACKET ON THE THREADS THAT EXTEND PAST

THE NUTS AND SECURE WITH TWO MORE 1/4"-20 HEX NUTS AND LOCK WASHERS.

E.

COAT BOTH ENDS OF THE HDR/T-BAR WITH BUTYL TYPE SEALANT AND FASTEN

THE "F" CLIP(S) TO THE HINGE/PIVOT JAMB(S) WITH THREE #8-32x5/8" PL-PH-MS

EACH.

F.

AT SINGLE DOORS LOCATE THE HDR/T-BAR ON THE SHEAR BLOCK {K120} AT

THE LOCK JAMB AND FASTEN INTO PLACE WITH SUPPLIED SCREWS.

BAB 7/01

Page 6

SECTION II HEADER/TRANSOM BAR

PAGE 4

INSTALLATION

(CON’T)

A. BUTT HINGE, CONTINUOUS HINGE, AND CENTER PIVOTS

1. 1 3/4" OR 2" HEADER/T’BAR INSTALLATION STEPS

(CON’T)

NOTE: 2" HEADER/T’BAR PREPARATION (SHOWN)

1 3/4" HEADER/T’BAR PREPARATION SIMILAR

FOR SINGLE DOORS AT LOCK JAMB USE K120 SHEAR BLOCK

STEP A. (1 3/4" HEADER/T’BAR)

STEP C. (2" HEADER/T’BAR)

"F" CLIP (C)

(CON’T)

STEP E.

#8-32 X 5/8"

PL-PH-SMS (C)

STEP B. (1 3/4" HEADER/T’BAR)

ANGLE BRACKET (C)

STEP D. (2" HEADER/T’BAR)

ANGLE BRACKET (C) AND SPACER BLOCK {F045}

"F" CLIP (C) AND SPACER BLOCK {F045}

#10-32x5/8" PL-FH-MS 18-8 {M130}

1/4-20 X 1"

PL-FH-MS {M119}

BAB 7/01

Page 7

SECTION II HEADER/TRANSOM BAR

PAGE 5

INSTALLATION

(CON’T)

A. BUTT HINGE, CONTINUOUS HINGE, AND CENTER PIVOTS

2. 4" OR 4 1/2" HEADER/T’BAR INSTALLATION STEPS

A.

ATTACH THE SHEAR BLOCK (K173) TO THE HINGE/PIVOT JAMB(S) WITH

THREE #8-15X1 3/4" PL-PH-SMS {S100}.

B.

REPEAT STEP 1 ON THE LOCK JAMB(S).

C.

ATTACH THE DORMA "F" CLIP TO THE HINGE/PIVOT JAMB(S) WITH TWO

#10-32x5/8" PH-MS (C).

D.

COAT BOTH ENDS OF THE HEADER/TRANSOM BAR WITH BUTYL TYPE

(CON’T)

SEALANT AND INSTALL IT OVER THE SHEAR BLOCKS.

E.

FASTEN THE HEADER/TRANSOM BAR AT THE HINGE/PIVOT JAMB(S) TO THE

SHEAR BLOCK WITH TWO #12-11 X 1/2" PL-RH-SMS 18-8 A {STB9}.

F.

REPEAT STEP E. ON THE LOCK JAMB(S).

BAB 7/01

Page 8

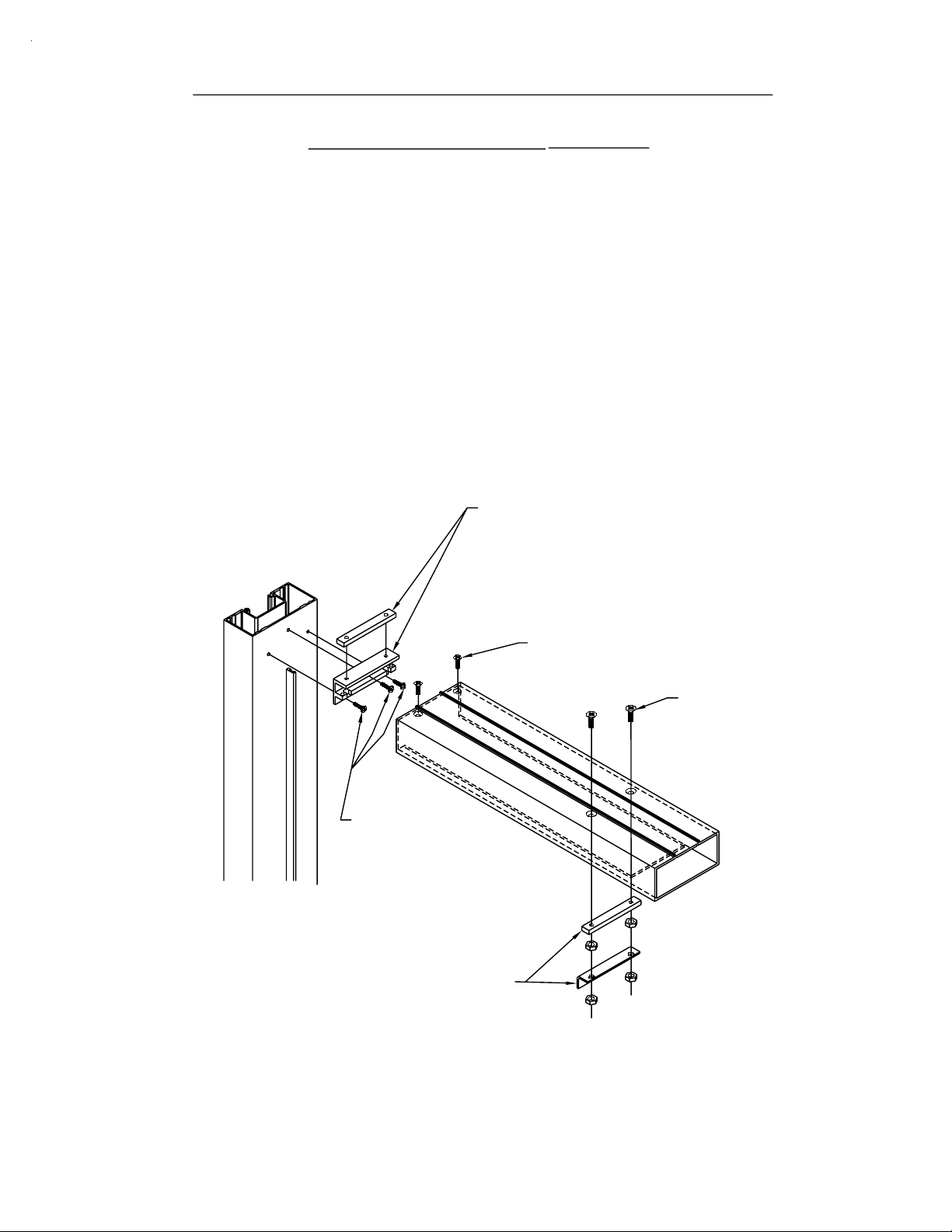

SECTION II HEADER/TRANSOM BAR

PAGE 6

INSTALLATION

(CON’T)

A. BUTT HINGE, CONTINUOUS HINGE, AND CENTER PIVOTS

1. 4" OR 4 1/2" HEADER/T’BAR INSTALLATION STEPS

(CON’T)

STEP A.

K173}

{

{S100} #8-15 X 1 3/4" PL-PH-SMS ZC A

(SUPPLIED W/ K173)

STEP E.

STB9} #12-11 X 1/2" PL-RH SMS 18-8 A

{

(SUPPLIED W/ K173)

(CON’T)

STEP C.

"F" CLIP (C)

HINGE

STILE

#10-32 X 5/8"

PL-PH-MS (C)

STEP F.

STB9} #12-11 X 1/2" PL-RH SMS 18-8 A

{

(SUPPLIED W/ K173)

{8428} (4" DOOR HEADER) SHOWN

{8429} (4 1/2" DOOR HEADER)

{S100} #8-15 X 1 3/4"

PL-PH-SMS ZC A

(SUPPLIED W/ K173)

STEP B.

{

K173}

LOCK STILE

BAB 7/01

Page 9

SECTION II HEADER/TRANSOM BAR

PAGE 7

INSTALLATION

(CON’T)

B. OFFSET PIVOTS

2. 1 3/4" OR 2" HEADER/T’BAR INSTALLATION STEPS

A.

ATTACH ANGLE CLIP {FT16} TO THE HEADER/T’BAR WITH TWO #10-32X5/8’

FH-MS.

B.

APPLICATIONS WITH A 2" HEADER/T’BAR:

ONE SPACER BLOCK {F045} MUST BE USED BETWEEN THE ANGLE CLIP {FT16} AND

THE HEADER/T’BAR. USE TWO #10-32X5/8" FH-MS TO FASTEN THE ASSEMBLY INTO

PLACE.

C.

COAT THE ENDS OF THE HEADER/T’BAR WITH BUTYL TYPE SEALANT AND

FASTEN THE ANGLE CLIP(S) {FT16} AND THE HEADER/T’BAR TO THE HINGE/PIVOT

JAMB(S) WITH THREE #8-32X5/8" PL-PH-SMS.

D.

AT SINGLE DOORS:

LOCATE THE HEADER/T’BAR ON THE SHEAR BLOCK AT THE LOCK JAMB AND

FASTEN IN PLACE WITH THE SUPPLIED SCREWS.

STEP A.

ANGLE CLIP {FT16}

STEP B.

SPACER {F045}

#10-32X5/8"

PL-FH-MS 18-8

{M130}

STEP C.

#8-32X5/8"

PL-PH-SMS

NOTE:

FOR SINGLE DOORS AT LOCK

JAMB USE K120 SHEAR BLOCK

WITH 2" HDR/T-BAR.

BAB 7/01

Page 10

PAGE 8

SECTION II HEADER/TRANSOM BAR AND CLOSER

PREPARATION AND INSTALLATION

B. OFFSET PIVOTS

(CON’T)

(CON’T)

2. 4" OR 4 1/2" HEADER/T’BAR INSTALLATION STEPS

A.

ATTACH THE SHEAR BLOCK (K173) TO THE HINGE/PIVOT JAMB(S) WITH

THREE #8-15X1 3/4" PL-PH-SMS {S100}.

B.

REPEAT STEP A ON THE LOCK JAMB(S).

C.

COAT BOTH ENDS OF THE HEADER/TRANSOM BAR WITH BUTYL TYPE

SEALANT AND INSTALL IT OVER THE SHEAR BLOCKS.

D.

FASTEN THE HEADER/TRANSOM BAR AT THE HINGE/PIVOT JAMB(S) TO THE

SHEAR BLOCK WITH TWO #12-11 X 1/2" PL-RH-SMS 18-8 A {STB9}.

E.

REPEAT STEP D. ON THE LOCK JAMB(S).

STEP A.

K173}

{

{S100} #8-15 X 1 3/4" PL-PH-SMS ZC A

(SUPPLIED W/ K173)

STEP E.

STB9} #12-11 X 1/2"

{

PL-RH SMS 18-8 A

(SUPPLIED W/ K173)

HINGE

STILE

STB9} #12-11 X 1/2"

{

PL-RH SMS 18-8 A

(SUPPLIED W/ K173)

STEP F.

STEP B.

{

K173}

{8428} (4" DOOR HEADER) SHOWN

{8429} (4 1/2" DOOR HEADER)

{S100} #8-15 X 1 3/4"

PL-PH-SMS ZC A

(SUPPLIED W/ K173)

LOCK STILE

BAB 7/01

Page 11

PAGE 9

SECTION III CLOSER PREPARATION AND

INSTALLATION

A. BUTT HINGE, CONTINUOUS HINGE, CENTER PIVOTS

1. CLOSER PREP AND INSTALLATION STEPS FOR 1 3/4" AND

2" HEADER/T’BAR

A.

THREAD TWO 1/4-20 X 5/8" FILLISTER HEAD MACHINE SCREWS (SUPPLIED

BY DORMA) APPROX. TWO TO THREE TURNS INTO THE THREADED HOLES ON

THE HINGE/PIVOT SIDE OF THE CLOSER. LEAVE LOOSE UNTIL THE CLOSER IS

INSTALLED IN THE "F" CLIP.

1/4-20 X 5/8" (C)

BAB 7/01

Page 12

SECTION III CLOSER PREPARATION AND

PAGE 10

INSTALLATION

A. BUTT HINGE, CONTINUOUS HINGE, CENTER PIVOTS

(CON’T)

(CON’T)

1. CLOSER PREP AND INSTALLATION STEPS FOR 1 3/4" AND

2" HEADER/T’BAR

INSTALLATION OF THE CLOSER IS IDENTICAL FOR THE 1 3/4" AND 2" HEADERS.

THE 2" HEADER IS SHOWN IN THE FOLLOWING DETAILS.

B.

WHILE HOLDING THE CLOSER AT A 15˚ ANGLE TO THE HDR/T-BAR, INSERT

THE CLOSER MOUNTING LUGS INTO THE "F" CLIP AND RAISE THE OPPOSITE

END OF THE CLOSER TO ALIGN THE ANGLE CLIP SCREW HOLES WITH THE

THREADED HOLES IN THE CLOSER END. SECURE THE CLOSER IN PLACE WITH

(CON’T)

TWO 1/4-20 HEX BOLTS AND WASHERS.

C.

TIGHTEN THE FILLISTER HEAD SCREWS AND RECHECK TO MAKE SURE

THAT ALL SCREWS / NUTS ARE TIGHT.

F045 (2" HEADER ONLY)

"F" CLIP (C)

2" HEADER/TRANSOM BAR (SHOWN)

HINGE/

PIVOT

JAMB

ANGLE BRACKET (C)

15˚ APPROX.

DORMA RTS 88

OVERHEAD CLOSER

LOCATING SCREWS

F045

(2" HEADER ONLY)

1/4-20 X 1/2" HXMS

& LOCK WASHERS (C)

1/4" LOCK WASHERS

& 1/4-20 HEX NUTS

BAB 7/01

Page 13

SECTION III CLOSER PREPARATION AND

PAGE 11

INSTALLATION

A. BUTT HINGE, CONTINUOUS HINGE, CENTER PIVOTS

(CON’T)

(CON’T)

1. CLOSER PREP AND INSTALLATION FOR 1 3/4" AND

2" HEADER/T’BAR

D.

LOCATE THE C.O.C. COVER PLATE INTO THE HEADER/TRANSOM BAR CUTOUT AND

FASTEN THE COVER PLATE INTO PLACE WITH THE SUPPLIED SCREWS THAT WILL

THREAD INTO THE ’F’ CLIP.

DRILLING IN THIS AREA MAY DAMAGE THE CLOSER, THE

HEADER/T’BAR AND/OR C.O.C. THE COVER PLATE SHOULD

BE FULLY PREPPED FOR ANY ADDITIONAL HARDWARE

(SLIDE ARM COVER, HOLD-OPEN ARM, ETC.) BEFORE

(CON’T)

CAUTION!

INSTALLING THE CLOSER UNIT.

2" HEADER/TRANSOM BAR (SHOWN)

HINGE/

PIVOT

JAMB

#6-32x3/4" FHMS (C)

COVER PLATE TO ’F’ CLIP

E.

ATTACH THE DOOR STOP / SLIDE ARM COVER IN THE CORRECT LOCATION TO LINE

DORMA RTS 88

OVERHEAD CLOSER

COVER PLATES

{K492 PKG. MILL}

{K495 PKG. CLR}

{K496 PKG. BRZ}

UP WITH THE DOOR STOPS AT THE JAMBS.

BAB 7/01

Page 14

SECTION III CLOSER PREPARATION AND

PAGE 12

INSTALLATION

A. BUTT HINGE, CONTINUOUS HINGE, CENTER PIVOTS

(CON’T)

(CON’T)

2. CLOSER PREP AND INSTALLATION STEPS FOR 4" AND

4 1/2" HEADER/T’BAR

A.

THREAD TWO 1/4-20 X 5/8" FILLISTER HEAD MACHINE SCREW (SUPPLIED BY DORMA)

APPROX. TWO TO THREE TURNS INTO THE THREADED HOLES ON THE HINGE/PIVOT SIDE OF

THE CLOSER. LEAVE LOOSE UNTIL THE CLOSER IS INSTALLED IN THE "F" CLIP.

B.

FASTEN THE DORMA ANGLE BRACKET TO THE CLOSER USING THE 1/4"-20 BOLTS AND

WASHERS, SUPPLIED WITH THE CLOSER.

C.

4" HEADER/TRANSOM BAR:

FASTEN THE MOUNT {K497 OR K498} TO THE ANGLE BRACKET USING THE TWO 1/4"-20 X 5/8"

HEX BOLTS {ISS1}, SUPPLIED WITH THE K497. USE THE 1/4"-20 LOCK WASHERS AND 1/4"-20

NUTS THAT ARE SUPPLIED WITH THE CLOSER.

4 1/2" HEADER/TRANSOM BAR:

FASTEN THE MOUNT {K929 OR K928} TO THE ANGLE BRACKET, PLACING THE SPACER BLOCK

(SUPPLIED WITH THE K929) BETWEEN THE ANGLE BRACKET AND THE MOUNT, USING THE TWO

1/4"-20 X 1 1/4" HEX BOLTS {IHP9}, SUPPLIED WITH THE K929. USE THE 1/4"-20 LOCK WASHERS

AND 1/4"-20 NUTS THAT ARE SUPPLIED WITH THE CLOSER.

CLOSER

1/4"-20 X 5/8" (C)

1/4-20 NUTS (C)

1/4 I.D. LOCK WASHER

MOUNT {

{4" - K498 CENTER PIVOTS}

{4 1/2" - K929 CONT./BUTT HINGES}

{4 1/2" - K928 CENTER PIVOTS}

SPACER BLOCK

-4 1/2" HEADER/T’BAR ONLY{SUPPLIED IN K501 AND K500}

ANGLE BRACKET (C)

4" - K497 CONT./BUTT HINGES}

READY TO INSTALL

1/4 I.D. LOCK WASHER

4" HEADER/T’BAR - 1/4-20 X 5/8" {K497 AND K498}

4 1/2" HEADER/T’BAR - 1/4-20 X 1 1/4" {K929 AND K928}

1/4-20 X 1/2" (C)

BAB 7/01

Page 15

SECTION III CLOSER PREPARATION AND

PAGE 13

INSTALLATION

A. BUTT HINGE, CONTINUOUS HINGE, CENTER PIVOTS

(CON’T)

(CON’T)

2. CLOSER PREP AND INSTALLATION STEPS FOR 4" AND

4 1/2" HEADER/T’BAR

INSTALLATION OF THE CLOSER IS IDENTICAL FOR THE 4" AND 4 1/2" HEADERS.

THE 4 1/2" HEADER IS SHOWN IN THE FOLLOWING DETAILS.

D.

WHILE HOLDING THE CLOSER AT A 15˚ ANGLE TO THE HDR/T-BAR, INSERT

THE CLOSER MOUNTING LUGS INTO THE "F" CLIP AND RAISE THE OPPOSITE

END OF THE CLOSER TO ALIGN THE MOUNT SCREW HOLES WITH THE PREP IN

THE HEADER/T’BAR. SECURE THE CLOSER IN PLACE WITH TWO #12-11 X 1/2"

PL-RH-SMS {STB9}.

(CON’T)

HINGE/

PIVOT

JAMB

SHEAR BLOCK {K173}

MOUNT SCREW LOCATION

4 1/2" HEADER/TRANSOM BAR (SHOWN)

"F" CLIP (C)

MOUNT

15˚ APPROX.

DORMA RTS 88

OVERHEAD CLOSER

SPACER BLOCK

4 1/2" HEADER ONLY

{FU09}

BAB 7/01

Page 16

SECTION III CLOSER PREPARATION AND

PAGE 14

INSTALLATION

(CON’T)

A. BUTT HINGE, CONTINUOUS HINGE, AND CENTER PIVOTS

2. CLOSER PREP AND INSTALLATION STEPS FOR 4" AND

4 1/2" HEADER/T’BAR

E.

TIGHTEN THE FILLISTER HEAD SCREWS AND RECHECK TO MAKE SURE THAT ALL

SCREWS / NUTS ARE TIGHT.

F.

LOCATE THE C.O.C. COVER PLATE INTO THE HEADER/TRANSOM BAR CUTOUT AND

FASTEN THE COVER PLATE INTO PLACE WITH THE SUPPLIED SCREWS THAT WILL

THREAD INTO THE ’F’ CLIP.

DRILLING IN THIS AREA MAY DAMAGE THE CLOSER, THE

HEADER/T’BAR AND/OR C.O.C. THE COVER PLATE SHOULD

BE FULLY PREPPED FOR ANY ADDITIONAL HARDWARE

(SLIDE ARM COVER, HOLD-OPEN ARM, ETC.) BEFORE

(CON’T)

CAUTION!

INSTALLING THE CLOSER UNIT.

(CON’T)

4 1/2" HEADER/TRANSOM BAR (SHOWN)

HINGE/

PIVOT

JAMB

DORMA RTS 88

OVERHEAD CLOSER

#6-32x3/4" FHMS (C)

COVER PLATE TO ’F’ CLIP

4.

ATTACH THE DOOR STOP / SLIDE ARM COVER IN THE CORRECT LOCATION TO

COVER PLATES

{K492 PKG. MILL}

{K495 PKG. CLR}

{K496 PKG. BRZ}

LINE UP WITH THE DOOR STOPS AT THE JAMBS.

BAB 7/01

Page 17

SECTION III CLOSER PREPARATION AND

PAGE 15

INSTALLATION

(CON’T)

B. OFFSET PIVOTS

1. CLOSER PREPARATION AND INSTALLATION STEPS

A.

ATTACH THE MOUNTING BLOCK TO THE CLOSER WITH TWO #12-24X3/4"

FH-MS THROUGH THE BLOCK AND INTO THE CLOSER AS SHOWN.

RETAIN THE SCREWS THAT MATCH THE COLOR OF THE FRAME FOR

ATTACHMENT OF THE ASSEMBLY TO THE HEADER/T-BAR.

B.

ATTACH THE ANGLE CLIP TO THE CLOSER WITH TWO 1/4"-20X5/8" BOLTS

WITH LOCK WASHERS THROUGH THE ANGLE CLIP AND INTO THE CLOSER AS

SHOWN.

STEP A.

MOUNTING

BLOCK

{K435}

#12-24X3/4"

PL-FH-MS 18-8 UC

{M100 - CLR}

{M108 - BRZ}

STEP B.

1/4" ID WASHER (C)

1/4"-20X1/2" HX-MS (C)

BAB 7/01

Page 18

SECTION III CLOSER PREPARATION AND

PAGE 16

(CON’T)

B. OFFSET PIVOTS

INSTALLATION

(CON’T)

1. CLOSER PREPARATION AND INSTALLATION STEPS

C.

INSERT THE CLOSER, WITH THE ANGLE CLIP AND THE SPACER BLOCK

ATTACHED (402 ONLY), INTO THE TRANSOM BAR. LOCATE THE SPACER BLOCK

OVER THE PREPPED HOLES IN THE TRANSOM BAR AND ATTACH WITH TWO

#12-24X3/4" FH-MS.

D.

SECURE THE CLOSER IN PLACE WITH TWO #10-32X5/8" FH-MS INTO THE

ANGLE CLIP AT THE OPPOSITE END.

SPACER {F045}

HINGE/

PIVOT

JAMB

ANGLE CLIP {FT16}

2" HEADER/TRANSOM BAR (SHOWN)

#12-24X3/4"PL-FH-MS 18-8 UC

- SEE NOTE BELOW {M100 - CLR}

{M108 - BRZ}

DORMA RTS 88

OVERHEAD CLOSER

ANGLE CLIP

HQ42 (C)

#10-32X5/8"

PL-FH-MS 18-8

- SEE NOTE BELOW {M130 - CLR}

{M131 - BRZ}

NOTE:

THE FINISH ON THE ATTACHMENT SCREWS SHOULD MATCH THE FRAME’S FINISH.

BAB 7/01

Page 19

SECTION III CLOSER PREPARATION AND

PAGE 17

(CON’T)

B. OFFSET PIVOTS

INSTALLATION

(CON’T)

1. CLOSER PREPARATION AND INSTALLATION STEPS

E.

TIGHTEN THE FLAT HEAD SCREWS AND RECHECK TO MAKE SURE THAT ALL

SCREWS AND NUTS ARE TIGHT.

CAUTION!

DRILLING IN THIS AREA MAY DAMAGE THE CLOSER, THE

HEADER/T’BAR AND/OR C.O.C. THE COVER PLATE SHOULD

BE FULLY PREPPED FOR ANY ADDITIONAL HARDWARE

(SLIDE ARM COVER, HOLD-OPEN ARM, ETC.) BEFORE

INSTALLING THE CLOSER UNIT.

2" HEADER/TRANSOM BAR (SHOWN)

(CON’T)

HINGE/

PIVOT

DORMA RTS 88

OVERHEAD CLOSER

JAMB

#10-32X5/8"

COVER PLATE

FT20 - RH - MILL} {FT26 - LH - MILL}

{

{FU02 - RH- CLR} {FU04 - LH-CLR}

{FU03 - RH - BRZ} {FU05 - LH - BRZ}

F.

LOCATE THE C.O.C. COVER PLATE INTO THE HEADER/T’BAR CUTOUT AND

PL-FH-MS 18-8

{M130}

FASTEN THE COVER PLATE IN PLACE WITH THE SUPPLIED FASTENERS AT THE

ANGLE CLIP END.

NOTE: THE DOOR STOP/SLIDE ARM COVER WILL RETAIN THE SPINDLE END OF

THE COVER, WHEN IT IS ATTACHED.

G.

ATTACH THE DOOR STOP/SLIDE ARM COVER IN THE CORRECT LOCATION

TO LINE UP WITH THE DOOR STOPS AT THE JAMBS.

BAB 7/01

Page 20

8

SECTION IV EXPLODED VIEWS

A. BUTT HINGE AND CONTINUOUS HINGE

F CLIP

(BY DORMA)

FO45

(402 ONLY)

PAGE 1

FO45

(402 ONLY)

ANGLE BRACKET

(BY DORMA)

CLOSER

COVER PLATE

{K492} PKG. MILL

{K495} PKG. CLR

{K496} PKG. BRZ

SHIM BY EFCO

-IF REQUIRED-

SHEAR BLOCK

at SINGLE DOOR

{K120 - CLR & BRZ}

SLIDE ARM

(BY DORMA)

SLIDE BLOCK

(BY DORMA)

BUSHING

(BY DORMA)

{9914}

DOOR STOP

SLIDE TRACK

(BY DORMA)

DOOR STILE

TOP RAIL

BAH 8-9-04

Page 21

PAGE 19

SECTION IV EXPLODED VIEWS

B. CENTER PIVOTS

SHEAR BLOCK

{

K173}

F CLIP

(BY DORMA)

(CON’T)

MOUNT

4" HEADER

{

K497} CONT. AND BUTT HINGES

{

K498} CENTER PIVOTS

4 1/2" HEADER

{

K928} CENTER PIVOTS

{

K929} CONT. AND BUTT HINGES

SHEAR BLOCK

{K173}

CLOSER

(BY DORMA)

COVER PLATE

{

K492} PKG. MILL

{

K495} PKG. CLR

{

K496} PKG. BRZ

SPACER BLOCK

ANGLE BRACKET

(BY DORMA)

SLIDE ARM

(BY DORMA)

TOP RAIL

BAB 7/01

Page 22

0

SECTION IV EXPLODED VIEWS (CON’T)

C. OFFSET PIVOTS

PAGE 2

FT16

CLOSER

(BY DORMA)

K435

COVER PLATE

FT20 - RH MILL

FT26 - LH MILL

FU02 - RH CLR

FU04 - LH CLR

FU03 - RH BRZ

FU05 - LH BRZ

FO45

(402 ONLY)

HQ42

SHEAR BLOCK

{K120 - CLR & BRZ}

SLIDE ARM

(BY DORMA)

SLIDE BLOCK

(BY DORMA)

BUSHING

(BY DORMA)

SHIM BY EFCO

-IF REQUIRED-

9914-DOOR STOP

SLIDE TRACK

(BY DORMA)

SLIDE TRACK

CUSHION

(BY DORMA)

TOP RAIL

BAH 8-9-04

Page 23

SECTION V DOOR INSTALLATION

A

.

HANG THE DOOR ON THE PREPARED FRAMES WITH THE APPROPRIATE HINGING

AND ADJUST THE DOOR HEIGHT CLEARANCE TO 1/8".

B.

AND INSTALL THE OPPOSITE END ON THE SPINDLE OF THE C.O.C.

HEADER/T’BAR WITH THE SCREWS PROVIDED.

SLIDE THE C.O.C. ARM INTO THE SLIDE TRACK IN THE TOP RAIL OF THE DOOR

C.

CLOSE THE DOOR AND TIGHTEN THE SCREW IN THE ARM AT THE SPINDLE END.

D.

CORRECTLY LOCATE AND ATTACH THE SLIDE ARM COVER/DOOR STOP TO THE

SECTION VI CLOSER ADJUSTMENT

PAGE 21

A

.

CHECK THE LATCHING SPEED OF THE DOOR AND ADJUST THIS WITH VALVE "A",

WHICH IS TOWARD THE CENTER OF THE DOOR. CLOCKWISE TURNS DECREASE

THE LATCHING SPEED, WHEREAS COUNTERCLOCKWISE TURNS INCREASE THE

LATCHING SPEED.

B.

WHICH IS TOWARD THE SPINDLE OF THE C.O.C. COUNTERCLOCKWISE TURNS

INCREASE THE CLOSING SPEED.

CHECK THE CLOSING SPEED OF THE DOOR AND ADJUST THIS WITH VALVE "B",

SPINDLE

STEP B.

VALVE "B"

STEP A.

VALVE "A"

BAB 7/01

Loading...

Loading...