Page 1

Troubleshooting Guide

MT3700 Chainsaw

WARNING: Always stop unit and disconnect spark plug before performing all of the

recommended solutions below except solutions which require operation of the unit.

If you are still experiencing problems after checking all possible

causes and solutions, please contact your servicing dealer.

!

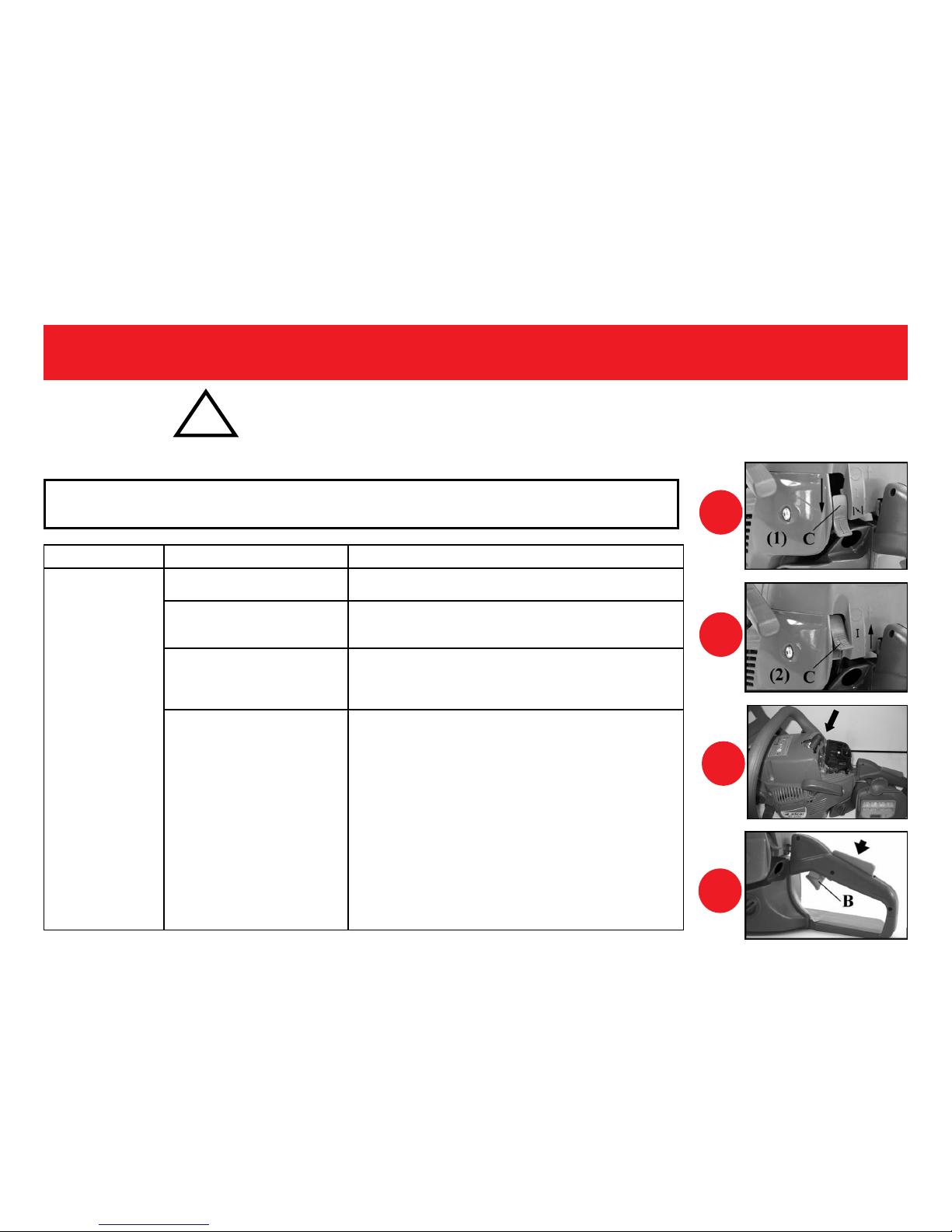

Problem Possible Cause Solution

Engine will not start Bad or old fuel mix Make sure the unit has fresh fuel (less than 30 days old) and

correct 2-cycle oil mix.

Ignition switch is turned off Make sure the ignition switch/choke lever (C) is in the choke

position (1) if the engine is cold, see Fig. 1; or in the start “I”

position (2) if the engine is warm, see Fig. 2.

Spark plug wire disconnected Make sure the spark plug wire is properly connected. With

the ignition switch off, remove the air lter cover and verify

that the spark plug boot is pushed completely down on the

spark plug, see Fig. 3.

Improper starting procedure Follow correct starting procedure:

Starting Cold Engine

1) Push ignition switch/choke lever (C) fully down to choke

position (1), see Fig. 1.

2) Pull the starter rope rapidly until the engine attempts to

start or starts momentarily.

3) Move ignition switch/choke lever (C) to intermediate position (2), see Fig. 2.

4) Pull starter rope rapidly until engine starts.

5) Once the engine is running, accelerate with the throttle

(B), to release the half-throttle lock device, see Fig. 4.

Starting Warm Engine

1) Push ignition switch/choke lever (C) to intermediate position (2), see Fig. 2.

2) Pull starter rope rapidly until engine starts.

2

3

4

1

Page 2

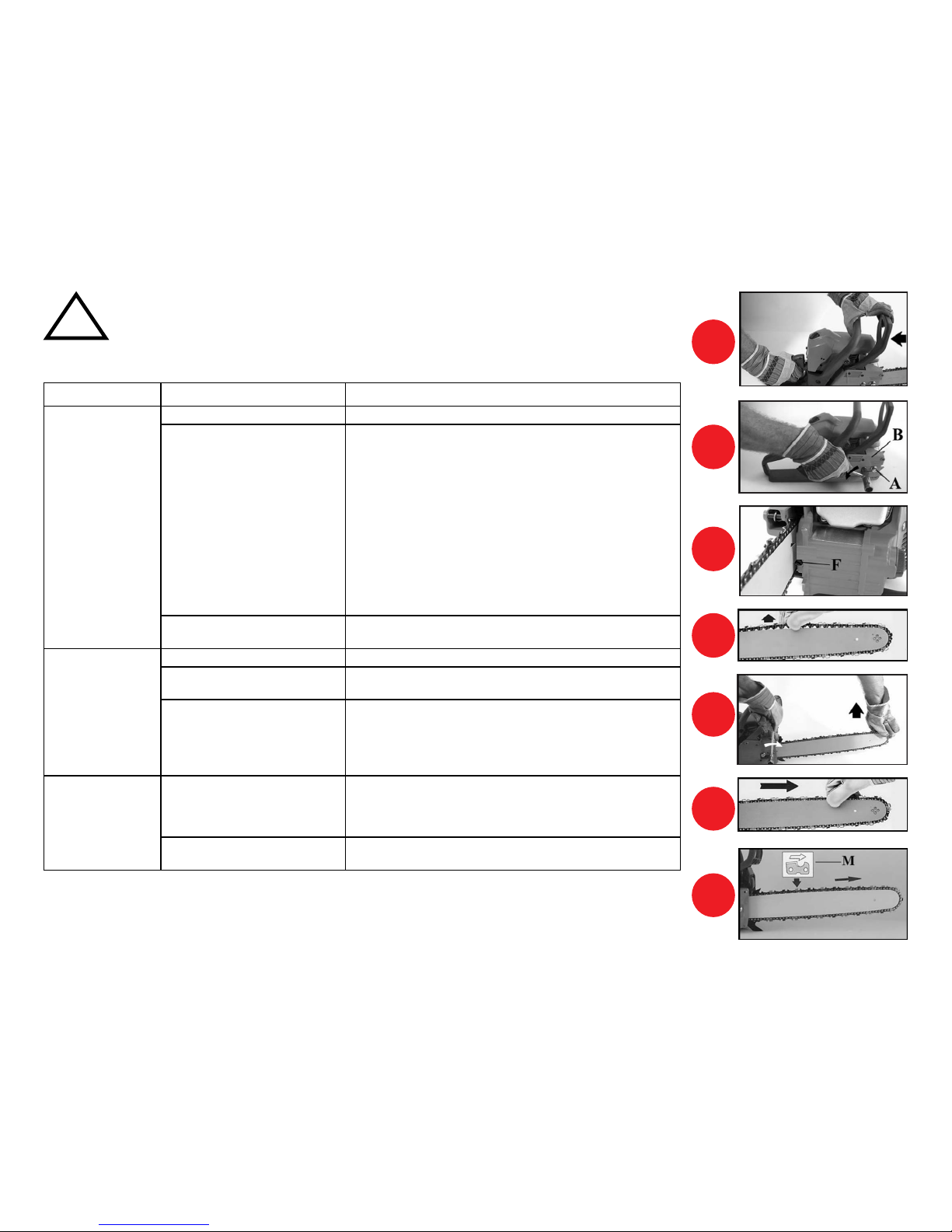

Problem Possible Cause Solution

Engine starts and

runs, but the chain

is not rotating

Chain brake engaged Release chain break, see Fig. 5.

Chain tension too tight Properly adjust chain tension:

1) Loosen the guide bar nuts (A) slightly, see Fig. 6.

2) Turn the chain tensioning screw (F) counter-clockwise to

loosen chain tension, see Fig 7.

3) Lift the tip of the guide bar up to check for chain sag, see

Fig. 8. Release the tip of the guide bar and turn the chain

tensioning screw (F) 1/2 turn clockwise, see Fig. 7. Repeat

this process until sag does not exist.

4) Hold the tip of the guide bar up and tighten the bar nuts

securely, see Fig. 9.

5) The chain is correctly tensioned when there is no slack on

the underside of the guide bar, the chain is snug, but it can

be turned by hand without binding, see Fig. 10.

Guide bar and chain incorrectly

assembled

Refer to Owner’s Manual for proper instalation.

Bar and chain

running hot and

smoking

Bar and chain oil tank empty Fill oil tank with bar and chain oil.

Chain tension too tight Properly adjust chain tension following the instructions

above.

Oiler not functioning Run at full throttle for 30 seconds. Stop saw and check for

oil dripping from guide bar. If oil is present, the chain may be

dull or the guide bar may be damaged. Have chain sharpened or replace chain and guide bar as needed. If there is no

oil then contact servicing dealer.

Poor cutting performance

Chain installed backwards Properly install chain on guide bar. The cutters on the top of

the guide bar should face toward the bar tip, in the direction

of the chain rotation, see Fig. 11. Refer to Owner’s Manual

for proper installation.

Dull or damaged chain Inspect chain for dull or damaged cutters. Have chain sharp-

ened or replaced as needed.

WARNING: Never touch or adjust the chain while the engine is running. The saw chain is

very sharp! Always wear protective gloves when performing maintenance to the chain.

5

6

7

8

9

10

11

!

Loading...

Loading...