Page 1

Series 955 Tech Set storefront

Installation Instructions

Part NO. Y008

February 2013

Page 2

SECTION

GENERAL NOTES AND GUIDELINES

I

TABLE OF CONTENTS

PAGE

1-2

II

III

IV

V

VI

VIII

PARTS IDENTIFICATION

DRILL JIGS

DRILL JIG GUIDES

FABRICATION

ASSEMBLY

FRAME INSTALLATION

GLASS INSTALLATIONVII

DOOR FRAME INSTALLATION

3-5

6-7

8-11

12-21

22-26

27-30

31-39

40-43

Minimizing Condensation

NOTE: Please reference EFCO's "Understanding Condensation" brochure which can be obtained through your EFCO representative.

Condensation will form on any surface when unfavorab le con dition s (interior temperature an d relative humidity and exterior

temperature) are present. When the formation of excessive condensation is a concern, it is highly recommended that a design

professional is utilized to perform an analysis of the shop drawings to recommend the best installation methods. Please contac t

EFCO representative for information on EFCO's Thermal Analysis Servi c es .

Many current installation practices lead to an increase in the possibility of the formation of condensation. Though not all

inclusive, the list of examples below illustrates conditions under which condensation is likely to occur:

1. Bridging system thermal br eak with non-thermally br o ke n meta l flashing or lintel s th a t are exposed to the

exterior.

2. System exposure to cold air cavities.

3. Interior relative humidity levels not maintained at recommended levels, see EFCO's "Understanding

Condensation" brochure.

4. Inadequate separation between system and surrounding condition at perim eter.

5. Product combinations during the shop dra wing stage that result in bri d ging thermal brea ks of one or all pr oduct s

involved.

JWH 8/2011

Page 3

SECTION I - GENERAL NOTES AND GUIDELINES

SERIES 955 5" TECH SET

NOTE:

1.

THESE INSTALLATION INSTRUCTIONS ARE A SUP P L EM E NT TO

THE APPROVED SHOP DRAWINGS AND MUST BE USED IN

CONJUNCTION WITH THOSE DRAWINGS.

THESE INSTALLATION INSTRUCTIONS ARE ALSO WRITTEN TO

ACCOMMODATE THE STOCK LENGTH PURCHASE OF ALL

MATERIALS, PARTS, AND EXTRUSIONS.

HANDLING-S TORING-PRO TE CT IN G ALUMINUM- The foll owing

precautions are recommende d to assure ea rly accept an ce of your pro du ct s

and workmanship.

A. HANDLE CAR EFULLY- Store with adequate separation between com-

ponents so material will not become scratched or rubbed at points

of contact. Store off the ground. Protect against weather elements

and other construction trades in adjacent areas of the job site.

B. KEEP MATERIAL AWAY FROM WATER, MUD, AND SPRAY- Prevent

cement, plaster, and other materials from coming in contact with and

damaging the finish. Do no t allow moisture to be trapped between the

finished surface and the wrapping material.

C. PROTECT MATERIALS AFTER ER ECTI ON- Wr ap or erect visqueen

screens. Cement, plaster, terrazzo, and other alkaline materials are

very harmful to the finish and must be removed with water and mild

soap before setting occurs. Under no circumstances should these

materials be allowed to dry or permanent staining will occur.

GENERAL GUIDE LINES- The fol lowing practices are recommended for all

2.

installations.

A. Review the approved shop drawings to become thoroughly famillar

with the project.

B. All thermal strut horizontal and sill members require sealant applied

to the upper most cavity of the thermal strut race.

Refer to typical details of this system.

C. Install all framing mat erials plumb, level, and true.

Proper alignment and relationships to benchmarks and column center

lines, as established by the architectural drawings and the general

contractor, must be maintained.

BAH 4/2005

Page 4

PAGE #2

SECTION I - GENERAL NOTES AND GUIDELINES

CONT.

D. The sequence of erection should be coordinated with the project

superintendent so delays are prevented and the risk of material

damage is minimized. If preset anchors are required, coordinate

with the general contractor and supervise the locations.

E. Verify that all job site conditions and accompanying substrates

receiving the installation are in accordance with the contract documents. If deviations occur, notification must be given IN WRITING

to the general contractor and differences resolved before proceeding

further with the installation in the questionable area.

F. Coat all aluminum, to be placed directly in contact with masonry or

dissimilar materials, with a heavy coating of bituminous primer such

as zinc chromate.

G. Follow EFCO’s framing installation and glazing instructions.

H. Verify the contents of all material shipments upon arrival. Verify

quantities and correct finishes.

NOTIFY EFCO IMMEDIATELY OF ANY DESCREPANCIES OR

DAMAGES WHICH MAY HAVE OCCURRED.

I. Throughout these instructions the term SEALANT will appear. For the

purpose of these instructions, sealant is defined as follows:

SEALANT- A weather resistant, gunnable, liquid filler which when dry

provides a resilient, flexible air and water seal between similar and

dissimilar materials. Use Dow Corning 795 or equal. All sealant must

meet FEDERAL SPECIFICATION TT-S-00227E, TT-S-001543A, AND

TT-S-00230G.

NOTE:

NOTE:

All sealant must be compatible with all surfaces on which adhesion

is required, including other sealant surfaces. All frame surfaces

should be clean and dry. All perimeter substrate shall be cleaned

and properly treated to receive sealant.

DUE TO THE SCREW TENSIONS REQUIRED FOR CORRECT

INSTALLATION, IT WILL BE NECESSARY TO ’WAX’ THE FRAME

ASSEMBLY SCREWS TO PREVENT GALLING AND BREAKAGE.

TOOLS NEEDED:

1. Wedge hammer and/or gasket roller

2. Putty knife

3. Level and square

4. Cutting tool, hand pruner, etc.

5. #2 Phillips tipped screwdriver

6. Flat pry bar

7. Soft faced mallet

8. Tube wax

JDA 11/2000

Page 5

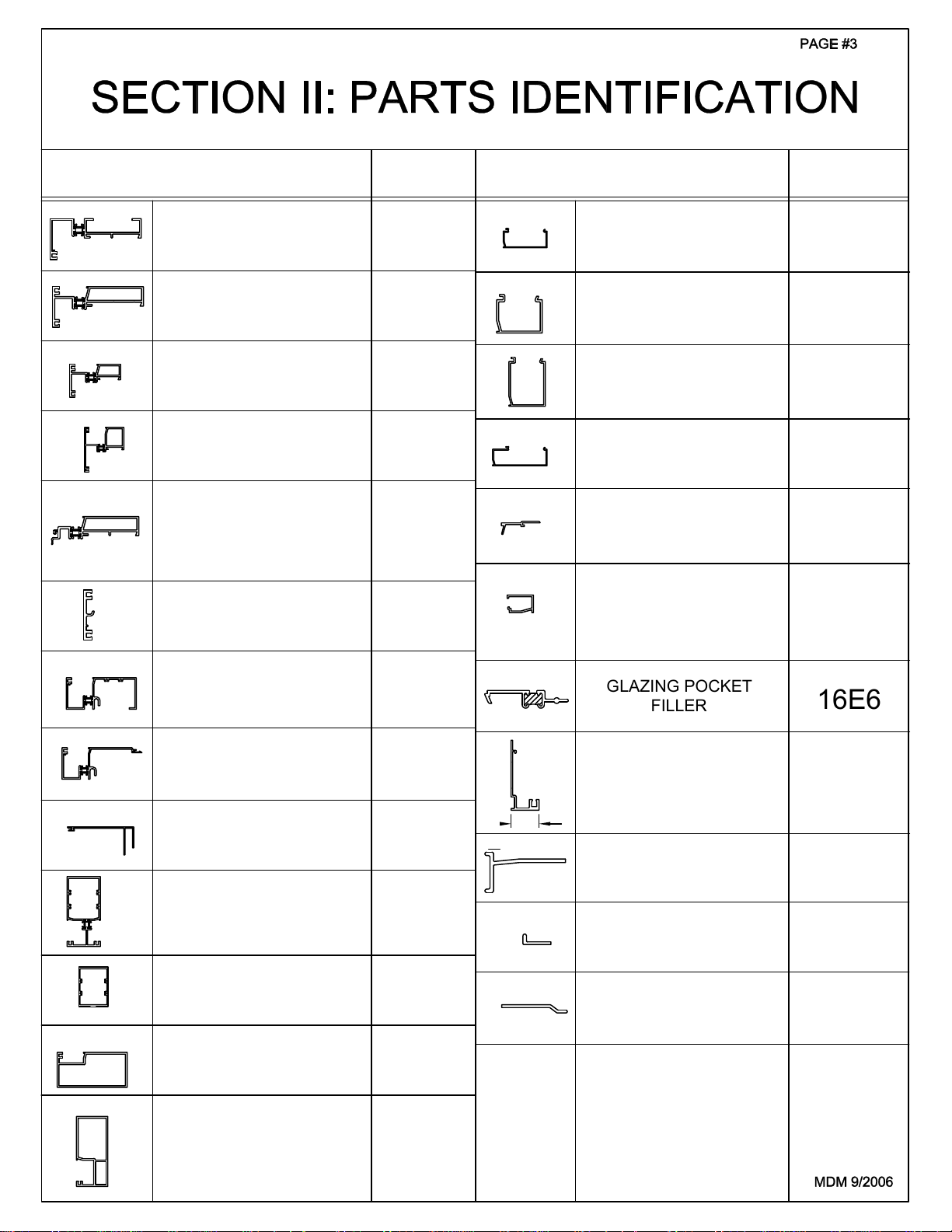

8687

8633

8554

DESCRIPTION

8686

8634

8633

8666

8687

8664

8667

8634

8688

FRAME HEAD

2 1/4" X 5" DEEP

USE 8685 STOP

INT. HORIZONTAL

2 1/4" X 5" DEEP

USE 8685 STOP

INT. HORIZONTAL

2 1/4" X 3 1/2" DEEP

USE #8665 GLASS STOP

INT. HORIZONTAL

4" X 3 1/2" DEEP

USE #8668 GLASS STOP

INT. HORIZONTAL

for BUTT GLAZE APPS.

2 1/4" X 5" DEEP

USE 8553 EXT. FACE

USE 8685 STOP

EXTERIOR FACE for

INT. HORIZONTAL 2G23

FRAME SILL/JAMB

2 1/4" X 5" DEEP

PART

NO.

IG58

IG67

IG72

IG73

2G23

8553

IG59

DESCRIPTION

REMOVABLE STOP

8685

USE w/ IG58, IG67 or 2G23

REMOVABLE STOP

8665

8685

8652

8651

1 INCH GLAZING

REMOVABLE STOP

1 INCH GLAZING

REMOVABLE STOP

1/4 INCH GLAZING

USE w/ IG58 or IG67

1/4" GLAZING

AT HORZ. AND VERT.

w/ SFZ5 SCREW

HOOK ON GLAZING

STOP for APPLIED

GLAZING at TRANSOM

GLAZING POCKET

1 INCH GLAZING

USE w/ IG72

USE w/ IG73

ADAPTOR

USE w/#8579

FILLER

PART

NO.

8685

8665

8668

8652

8651

8578

16E6

8687

8691

8690

8692

8693

8663

FRAME SILL for

STOOL TRIM

USE 8691 STOOL TRIM

SILL STOOL TRIM

4 3/4" DEEP

USE IG60 SILL

INT. VERT. MULL

2 3/8" X 5" DEEP

BUTT GLAZE

VERT. MULLION

2 3/8" X 5" DEEP

2 1/2" SIGHT LINE

TRANSOM BAR

FOR C.O.C. APLICATIONS

2 1/4" SIGHT LINE

DOOR JAMB

or TRANSOM BAR for

SURFACE CLOSER

IG60

8691

IG61

8663

8580

8581

1"

8695

8694

8635

SCREW APPLIED

STOP for TRANSOM

USE w/#8578

HEAD ANCHOR

3" LONG

SLIDE FIT w/ 1G58

HORZ. SILL ANCHOR

USE IG59 OR IG60 SILL

3" LONG

VERT. SILL ANCHOR

USE IG59 OR IG60 SILL

3" LONG

8579

FS97

FS99

FT01

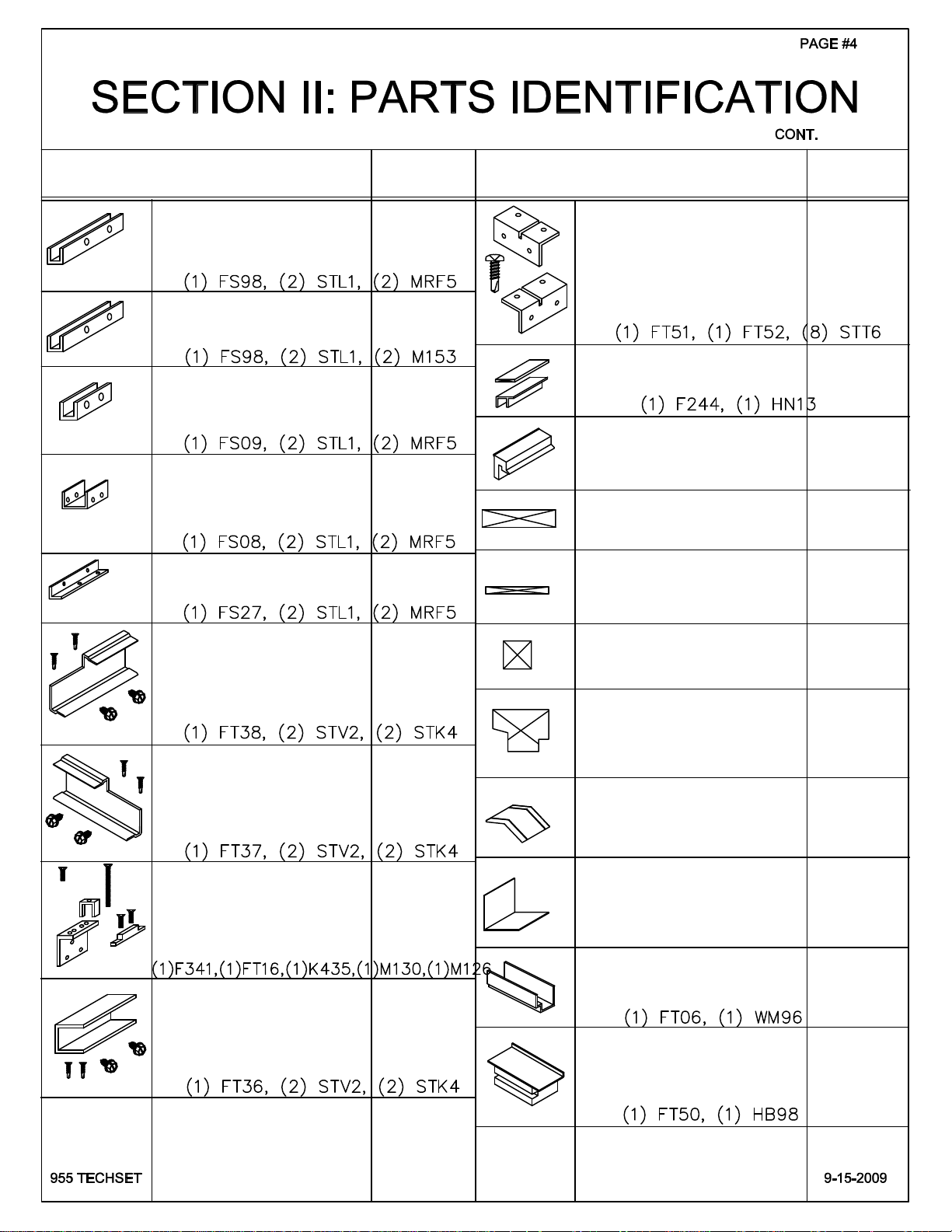

Page 6

DESCRIPTION

PART

NO.

DESCRIPTION

PART

NO.

FT38

M130

F340

FT36

FS98

FS98

FS08

FS09

FS27

FT16

FT37

M126

K435

SHEAR BLOCK PKG.

for 1G67 & 2G23 HORIZ.

to VERTICALS

(HEAD & SILL RUN THRU)

SHEAR BLOCK PKG.

for 1G59 SILL at

VERT. INTER. THRU

SHEAR BLOCK PKG.

for 1G72 HORIZ.

to VERTICALS

(HEAD & SILL RUN THRU)

SHEAR BLOCK PKG.

for 1G73 HORIZ.

to VERTICALS

(HEAD & SILL RUN THRU)

SHEAR BLOCK PKG.

for HEAD & SILL

at VERT. THRU APP.

SHEAR BLOCK PAC KAGE

for S955 TRANSOM

BAR # 8580

CLEAR & BRONZ E

LEFT JAMB

SHEAR BLOCK PAC KAGE

for S955 TRANSOM

BAR # 8580

CLEAR & BRONZ E

RIGHT JAMB

SHEAR BLOCK PAC KAGE

for S955 TRANSOM

BAR # 8580

DORMA 88 COC

OFFSET PIVOTS

SHEAR BLOCK PAC KAGE

for S955 DOOR JAMB

# 8581 when used

as TRANSOM BAR

SURFACE CLOSER

K368

K319

K198

K197

K193

K451

K450

K453

K452

HN13

HB98

1918

1783

FT50

TRANSOM HEADER

CLIP PACKAGE

for 1G58

INCLUDES-

(1)FT51 & (1) FT52

& (8) STT6 SCREWS

SETTING CHAIR P KG.

for 1G73 HORIZ.

SETTING CHAIR P KG.

FOR 1G59 & 1G 60

GLASS SETTING B LOCK

AT TRANSOM BAR #8580

1/8" x 1" GLASS

SETTING BLOC K

USE w/ 1G67, 1G72 & 2G23

1/4" X 1/4" GLASS

SETTING BLOC K

USE w/ 8651 ADAPT OR

GLASS SETTING B LOCK

AT TRANSOM BAR #8581

DOOR JAMB AS TRANSOM BAR

w/ SURFACE CLOSER

WATER DEFLE C TOR

@ INT. HORIZONTAL

END CAP AT

HEAD & SILL

AT GLAZING POCKET

ALL 4 CORNERS

SPLICE JOINT

(BRAKE METAL)

AT GLAZING POCKET

HEAD & SILL

HORIZ. BRIDGE

ASSEMBLY for

BUTT GLAZE APPLICATIONS

K462

K196

HN35

HEP0

HN92

HEP2

H190

HWD1

FS96

K424

K461

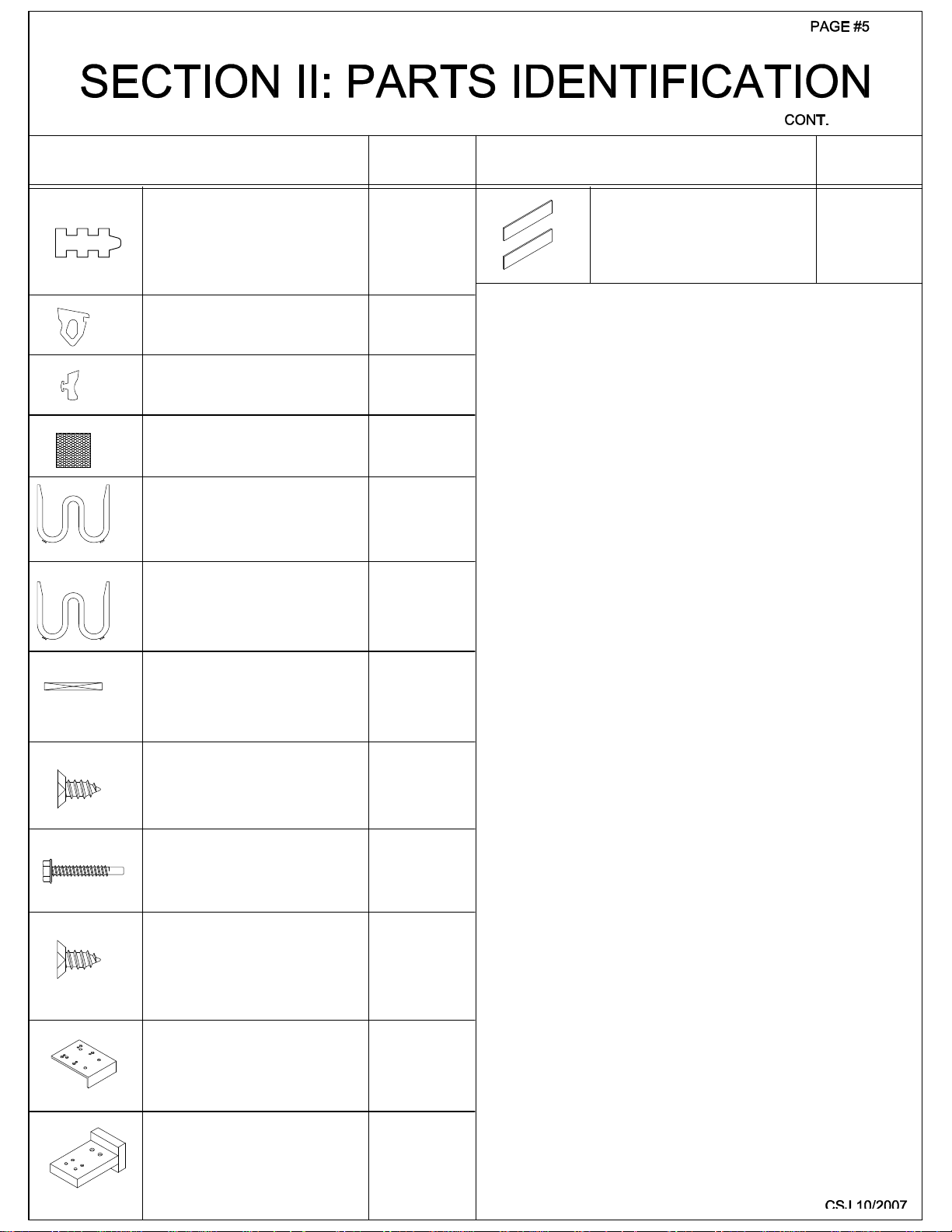

Page 7

DESCRIPTION

PART

NO.

DESCRIPTION

PART

NO.

BUTT GLAZE

SPACER

1/2" x 1/4"

INTERIOR GLAZING

GASKET

EXTERIOR GLAZING

GASKET

WEEP BAFFLE

AT IG59 OR IG60 SILL

1/2" ANTIWALK BLOCK

USED AT 1/4" G L ASS

7/8" ANTIWALK BLOCK

USED AT 1" GLASS

WSA1

W105

WNB9

HCW3

HN50

HN53

FACE SPLICE

CAULK BACKER TAPE

(2) 1" X 3" PC. REQUIRED

PER SPLICE JOINT

WM96

1/8" X 1"

ANTIWALK BLOCK

AT VERTICAL

SHALLOW POCKET

1/4" G LAZING ADAPTOR

ATTACHMENT SCREW

USE w/ 8651

#8-15 x 3/8"

SCREW SPLINE

FRAME SCREW

#10-16 x 1 1/4"

TRANSOM JAMB

GLAZING ADAPTOR

ATTACHMENT SCREW

USE w/ 8579

#8-15 x 3/8"

DRILL JIG

FOR SHEAR BLOCK

& SCREW SPLINE

HN92

SFZ5

STV3

SFZ5

H262

DRILL JIG

FOR SHEAR BLOCK &

HORIZONTAL END PREP

WHEN USING 1G72 & 1G73

DJ06

Page 8

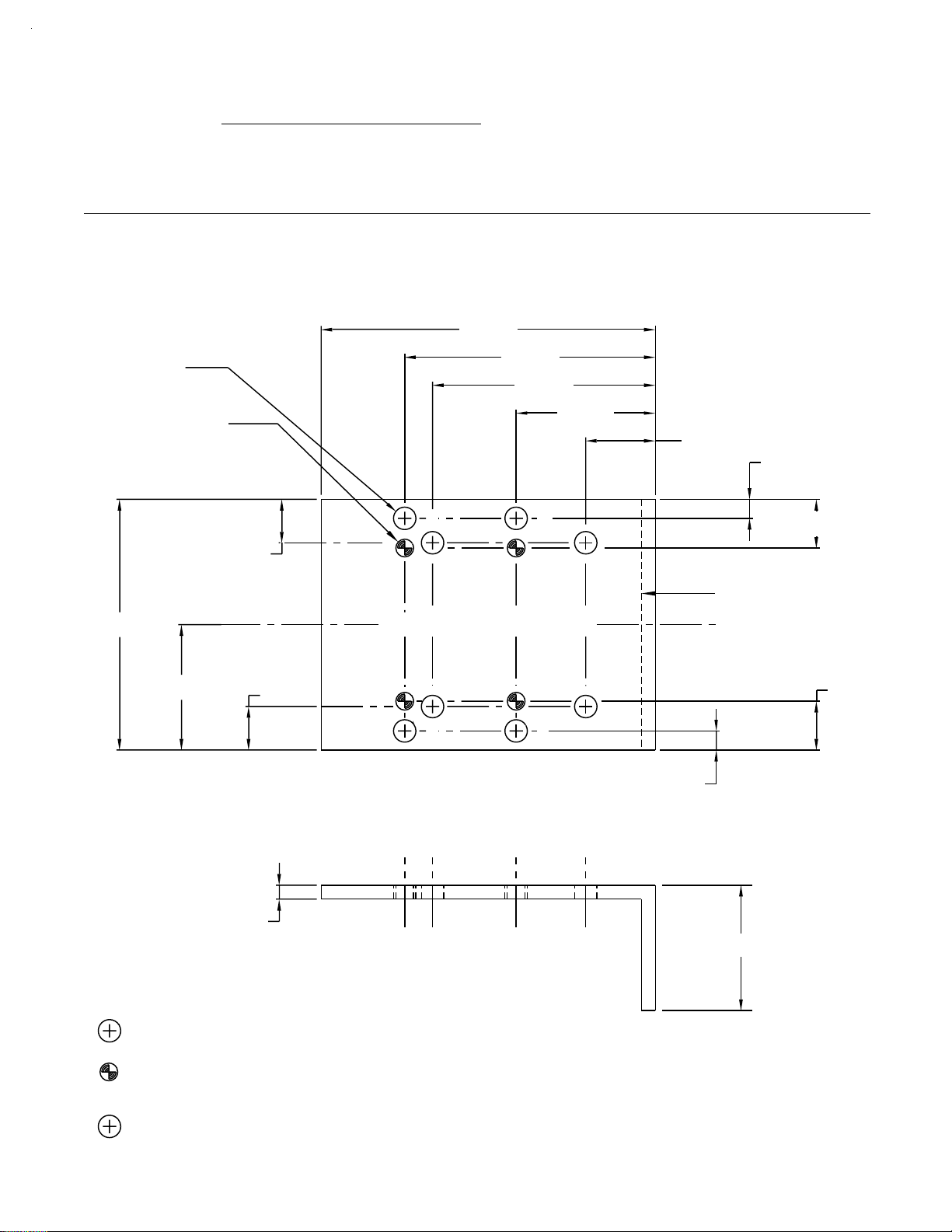

PAGE #6

SECTION III - DRILL JIGS

DRILL JIG #H262 CAN ALSO BE PURCHASED

DRILL FIXTURE FOR INTERMEDIATE HORIZONTALS, VERTICALS AND JAMBS

The drill guide shown below is designed to be field prepared from 1" x 3"

aluminum angle. The drill guide is used by aligning off the back and

ends of the member being prepared.

3.000

#7 DRILL

.201 dia. (8)

#21 DRILL

.159" dia. (4)

LOCATE JIG EDGE AT

END OF HORIZONTAL

2.250

2.000

1.250

.625

.178

.375

2.375

1.188

.375

LOCATE JIG EDGE AT

END OF HORIZONTAL

.125

A

B

CENTER LINE OF MULLION

B

C

B

C

A

B

AA

.431

C

LOCATE JIG AT

BACK OF MULLION

.431

C

.178

1.000

= A = #7 (.201 dia.) drill for all screw spline

= B = #21 (.159 dia.) drill shear block to vertical mullion

REF. TOOLING DRAWING (001052 S.B. TO VERT. PREP)

= C = #7 (.201 dia.) intermediate horizontal to shear block

REF. TOOLING DRAWING (001051 HORIZ. END PREP)

KDE 12/2002955 Tech Set

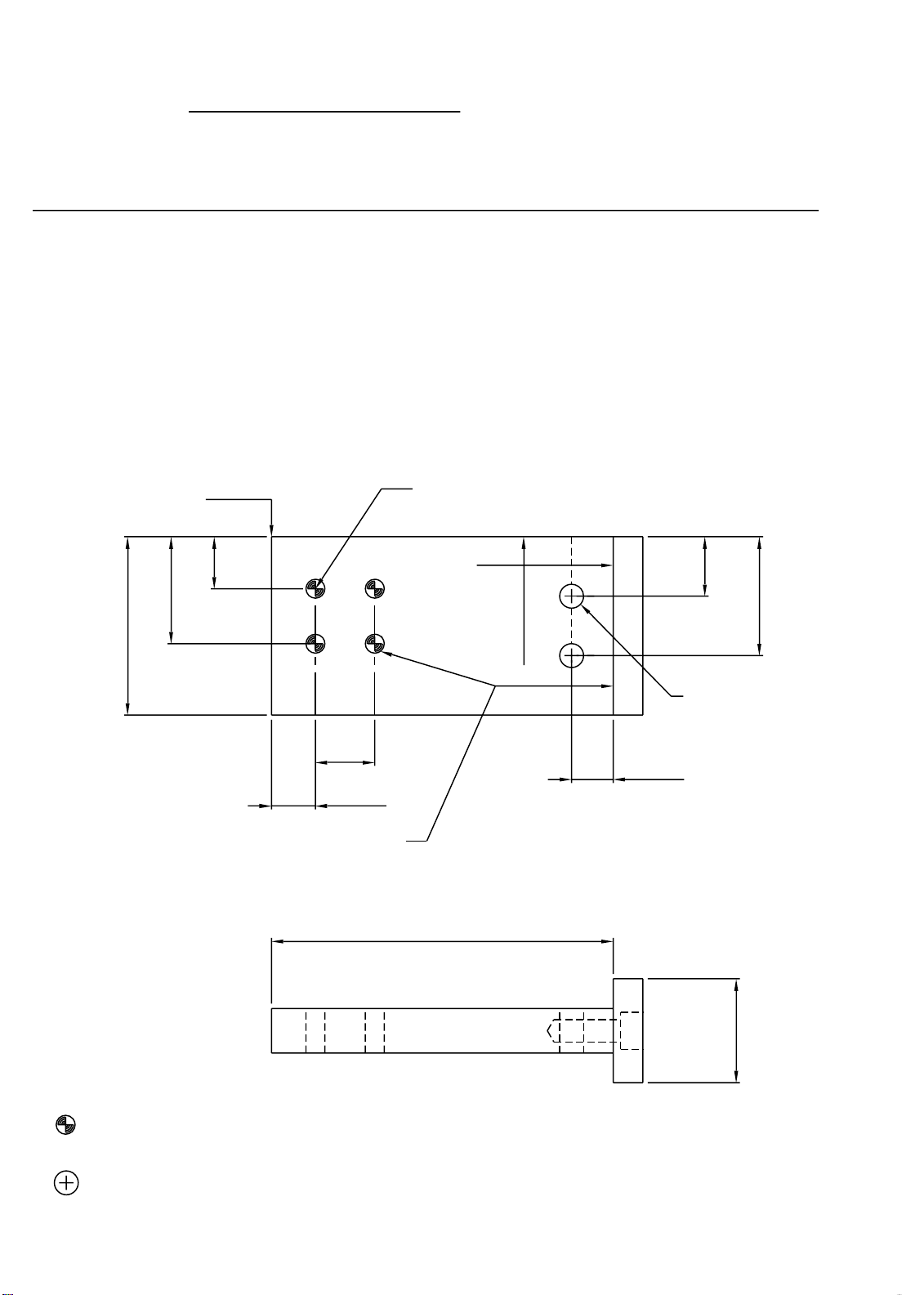

Page 9

PAGE #7

SECTION III - DRILL JIGS

DRILL JIG #DJ06 FOR INTERMEDIATE HORIZONTALS #1G72 AND #1G73

The drill guide is used by aligning off the back and ends of the members being

prepared for shear blocks.

For the left side vertical members, drill from this side as shown below.

For the right side vertical members, turn the drill jig over and drill from the

opposite side.

TOP OF 1G72 or 1G73

HORIZONTAL

INTERMEDIATE

.438

.900

1.500

VERTICAL PREP FOR

HORIZONTAL INTERMEDIATE

SHEAR BLOCK ATTACHMENT

B

B

.500

.369

.159 DIA.

(#21 DRILL)

1G72

1G73

2.875

C

C

END PREP

HORIZONTAL

.500

1.000

.201 DIA.

(#7 DRILL)

.350

= B = #21 (.159 dia.) drill shear block to vertical mullion

= C = #7 (.201 dia.) intermediate horizontal to shear block

.875

JDA 9/2000

Page 10

PAGE #8

SECTION III - DRILL JIG GUIDE

CONT.

DRILL FIXTURE FOR INTERMEDIATE HORIZONTALS,

INTERMEDIATE VERTICALS AND JAMBS

The drill guide is used by aligning off the back and

ends or center lines of the member being prepared.

JAMB LOCATION

LOCATE DRILL JIG AT

END OF SILL AND HEAD.

APPLICATION

SCREW SPLINE

CENTER LINE OF

VERTICAL MULLION

C

L

2 3/8"

2 3/8"

SILL SHOWN,

HEAD SIMILAR

Detail #1

REFER TO PAGE #6 FOR SPECIFIC HOLE LOCATIONS.

= A = #7 (.201 dia.) drill for all screw spline

= B = #21 (.159 dia.) drill shear block to vertical mullion

REF. TOOLING DRAWING (001052 S.B. TO VERT. PREP)

= C = #7 (.201 dia.) intermediate horizontal to shear block

REF. TOOLING DRAWING (001051 HORIZ. END PREP)

JDA 11/2000

Page 11

SECTION III - DRILL JIG GUIDE

LEFT JAMB SHOWN,

RIGHT JAMB AND

INTERMEDIATE VERTICALS

ARE PREPPED SIMILAR.

PAGE #9

CONT.

CENTER LINE OF

HORIZONTAL

INTERMEDIATE

REFER TO PAGE #6

FOR SPECIFIC HOLE

LOCATIONS ON THE

DRILL JIG.

1G59

H262

DRILL JIG

SHEAR BLOCK

APPLICATION

C

L

K368 SHEAR BLOCK

SHOWN

Detail #2

JDA 9/2000

Page 12

PAGE #10

SECTION III - DRILL JIG GUIDE

CONT.

DRILL JIG #DJ06 FOR INTERMEDIATE HORIZONTALS #1G72 AND #1G73

INTERMEDIATE HORIZONTAL TO SHEAR BLOCK ATTACHMENT

This drill guide is used by aligning off the ends of the

horizontal intermediate member being prepared.

See Detail #3 below.

C

C

DJ06

DRILL JIG

Detail #3

1G72

1G73

C

C

DJ06

DRILL JIG

= C = #7 (.201 dia.) intermediate horizontal to shear block

JDA 9/2000

Page 13

SECTION III - DRILL JIG GUIDE

LEFT JAMB SHOWN,

RIGHT JAMB AND

INTERMEDIATE VERTICALS

ARE PREPPED SIMILAR.

PAGE #11

CONT.

TOP OF

HORIZONTAL

INTERMEDIATE

REFER TO PAGE #7

FOR SPECIFIC HOLE

LOCATIONS ON THE

DRILL JIG.

1G59

DJ06

DRILL JIG

FOR 1G72 (B)

FOR 1G73 (B)

K198 SHEAR BLOCK

SHOWN,

K197 IS SIMILAR.

Detail #4

= B = #21 (.159 dia.) drill shear block to vertical mullion.

JDA 9/2000

Page 14

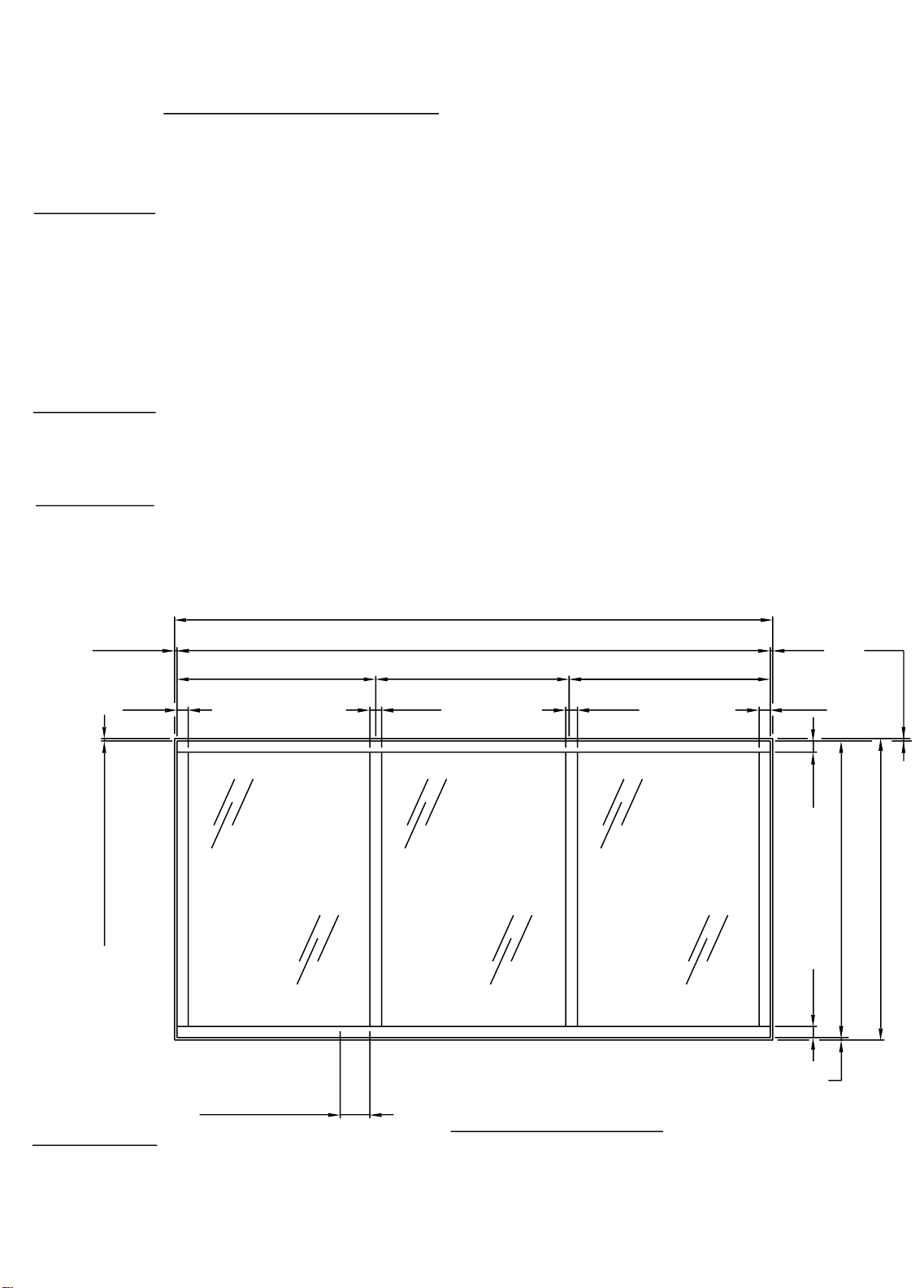

SECTION IV - FABRICATION

HEAD AND SILL FABRICATION AND PREPARATION

STEP #1

The series 955 Tech Set system is designed to be fabricated with the head

and sill running through. The jambs and vertical mullions will meet at the

top of the sill and at the snap location of the removable stop at the head.

Cut the head and sill members to the rough opening measurement minus

(-) the vertical caulk joints. This dimension could be 1/4" through 3/4"

depending upon the condition. See Elevation #1 below.

STEP #2

Establish and mark the mullion center lines and jamb locations on the head

and sill. Mullion widths are 2 3/8" as shown below.

STEP #3

PAGE #12

Position the drill guides over the mullion and jamb locations and drill as

required. See pages #6 thru #11 for the drill jigs and drill jig guides required

for assembling this system.

ROUGH OPENING WIDTH

CAULK

JOINT

2 1/4"

3/4" TOP CAULK JOINT

MULL. CENTER

FRAME WIDTH

MULL. CENTER

2 3/8"

MULL. CENTER

2 3/8"

CAULK

JOINT

2 1/4"

2 1/4"

FRAME HEIGHT

2 1/4"

ROUGH OPENING HEIGHT

WEEP 6"

FROM MULL

TYPICAL

1/2" BTM. CAULK JOINT

ELEVATION #1

STEP #4

Drill the sill member for two 1/4" weep holes per daylight opening, at 6" from each mullion.

See Elevation #1 above and Detail #5 & #6 on page #13.

JDA 9/2000

Page 15

1/4" dia.

WEEP

C

L

APPLY A CONTINU OUS

BEAD OF SEALANT A ND

TOOL INTO THE TH ERMAL

STRUT RACE.

DO NOT BLOCK

1/4"

THE WEEP HOL E

WITH SEALANT

APPLY A SMALL AMOUNT OF

SILICONE SEALANT TO BOTH SIDES

OF THE WEEP HOLE LOCA TION.

USE ONE BLOCK PER WEEP HOLE,

AS REQUIRED.

CENTER LINE

3/4"

OF WEEP HOLE

4"

2"

Detail #5

FS96

1"

#HCW3

CUT IN HALF

Detail #6

1/2"

GAP

Detail #7

SEAL ALL

INTERIOR

CORNERS WIT H

SEALANT

K424

Detail #8

FS96

BAH 4/2005

Page 16

PAGE #14

SECTION IV - FABRICATION

CONT.

INTERMEDIATE HORIZONTAL FABRICATION AND PREPARATION

STEP #7

Cut the intermediate horizontals to D.L.O. width. Cut the glass stops for the

intermediate horizontals and head member to D.L.O. minus (-) 1/32" for

ease of installation.

STEP #8

Prep the ends of the intermediate horizontals for the horizontal to shear block prep.

See detail #9 below. See page #6 for the drill guide required to correctly

identify the holes required for the shear block attachment.

2G23

1G67

K368

SHEAR BLOCK

PKG.

Detail #9

1.875

.500

CB

A

A

B C

.375

C

A

B

DRILL GUIDE

A

BC

.201" DIA. THRU (1) WALL

(2 PLACES)

955 Tech Set

KDE 01/2003

Page 17

PAGE #15

SECTION IV - FABRICATION

(CONT.)

INTERMEDIATE HORIZONTAL FACE

STEP #9

Cut horizontal face member (#8553) to span 3 lites (or a maximum of 15’-0"). Allow

1/4" at splice joints for expansion. Splice ONLY at center lines of vertical mullions.

See Detail #10 below.

1G59

NOTE:

D.L.O. 2 3/8"

INTERIOR

8663

HORIZONTAL FACE LENGTH (15 ft. max.)

D.L.O.

K461 BRIDGE

REQUIRED

2 3/8"

8663

D.L.O.

Detail #10

Due to the expansion characteristics of the aluminum face member

and also to maintain the 1/4" splice joint, 15 feet is the recommended

cut length for the face member. Use #WM96 bond breaker tape,

{

3" long and trimmed to fit, for the face splice caulk backer.

1/4"

D.L.O.2 3/8"

8663

1/4"

BOND BREAKER TAPE APPLIED

TO INSIDE OF FACE MEMBER

CENTERED ON GAP

GAP DETAIL EXAGGERATED

STEP #10

FOR CLARITY

Weep baffles are cut from (1) HCW3, halved and then quartered. This provides

8) weep baffles per HCW3 to be used at the horizontal face. See Detail #11 below.

3/8"

3/4"

4"

2"

1"

1/2"

Detail #11

HCW3

JDA 11/2000

Page 18

PAGE #16

SECTION IV - FABRICATION

(CONT.)

INTERMEDIATE HORIZONTAL FACE

STEP #11

Drill 1/4" diameter weep holes in the horizontal face member at 48" on center or

2 per D.L.O. at quarter points. Install weep baffles over the holes with silicone.

Do not plug the weep holes with silicone.

See Detail #12 below.

1/4" DIA.

WEEP

HOLES

15/16"

C

L

8553 FACE

WNB9

WNB9

APPLY BAFFLES WITH A SMALL

AMOUNT OF SILICONE TYPE SEALANT.

DAYLIGHT OPENING

48" O.C.

Detail #12

STEP #12

Install the exterior glazing gasket into the face member at this time, (WNB9).

Be sure to add 2% to the cut length to prevent gaps at gasket intersections.

See Detail #12 above.

JDA 9/2000

Page 19

PAGE #17

SECTION IV - FABRICATION

(CONT.)

INTERMEDIATE HORIZONTAL FACE

JAMB AND VERTICAL MULLION FABRICATION AND PREPARATION

STEP #13

If the project is being built as head and sill thru, the vertical members will be cut to

D.L.O. plus (+) 1 3/16".

STEP #14

The vertical members must also be coped to fit into the head.

See details #13 and #14 below.

Detail #13

Detail #14

1G59 JAMB

1G61

VERTICAL MULLION

1.187

1G58 HEAD

1.187

TO HEAD

STEP #15

If there are NO horizontal members being used, the vertical members are

now ready to be screw spline attached to the head and sill members.

Refer to page 22 for assembly procedures.

JDA 9/2000

Page 20

PAGE #18

SECTION IV - FABRICATION

CONT.

STEP #16

If horizontal intermediates are being incorporated, the verticals must be

prepped for the horizontal shear block attachment.

See detail #15 below to determine the horizontal location.

Refer to pages #6 through #11 for the drill jigs and the drill jig guides to correctly

identify the required holes to drill for the particular horizontal / shear block

being used.

THIS PREP FOR

1G67 & 2G23

HORIZONTALS

C

L

1.187

1.187

TO HEAD

.431

2.250

.159 DIA. (#21) DRILL

THRU (1) WALL

(2 PLACES)

REF.

Detail #15

955 Tech Set

2.125

1.125

H262

DRILL JIG

KDE 12/2002

Page 21

PAGE #19

SECTION IV - FABRICATION

HORIZONTAL INTERMEDIATE

SHEAR BLOCK FABRICATION

STEP #17

The intermediate horizontal shear blocks are to be prepped from #EX43.

One (1) #EX43 is required at each end of the intermediate horizontal.

See detail #16 below for preparation.

2.750

1.000

#7 DRILL (.201) THRU

CLEAR HOLE FOR

#10 SCREW

#STL1 - TYP.

{K368 FABRICATED PACKAGE}

.968

C

L

.350

CONT.

EX43

# 25 DRILL (.1495)

Detail #16

1.375

.360

.350

THRU 2 WALLS

PILOT HOLE FOR

#10 SCREW

#MRF5 - TYP.

SILL ANCHOR FABRICATION

{FS99 & FT01 ARE

STEP #18

There are two (2) types of sill anchors used for the 955 system. Cut and

fabricate #8694 or #8635 as shown in detail #17 below.

3.000"

1.500"

.313" DIA. (5/16")

DRILL THRU

FABRICATED PARTS}

(5/16" x 13/16" SLOT)

1.500"

3.000"

FS99

.875"

8694

FT01

8635

Detail #17

.500"

1.000"

JDA 9/2000

Page 22

PAGE #20

SECTION IV - FABRICATION

HEAD ANCHOR FABRICATION

STEP #19

Cut and fabricate the head anchors from #8695 as shown in detail #18

below.

FS97

.500"

{FS97 - FABRICATED PART}

CONT.

1.000"

5/16" x 13/16"

SLOT

1.500"

Detail #18

1/2 SIZE

SETTING BLOCK

FABRICATION

3.000"

K196 FOR 1G73

FABRICATED PACKAGE IS AVAILABLE.

STEP #20

Cut and fabricate the setting blocks from #1918 extrusions. Two (2) setting

blocks are required per daylight opening. See detail #19 below for fabrication.

STEP #21

Install one (1) #HN13 to the top of #1918 for use with 1G73 intermediate horizontal.

Detail #19

HN13

APPLY A SMALL

AMOUNT OF

SILICONE TO THE

SETTING CHAIR TO

SET THE BLOCK IN.

1/2 SIZE

4.000"

BAB 3/2001

Page 23

PAGE #21

SECTION IV - FABRICATION

CONT.

1/4" GLAZING ADAPTOR FABRICATION AND PREPARATION

STEP #22

Cut the #8651 glazing adaptor to daylight opening minus 1/16" for verticals and

horizontals. See detail #20 below.

STEP #23

Notch the #8651 horizontal glazing adaptors to clear the vertical adaptors as shown

in detail #21 below.

Prep the glazing adaptors for the attachment screws as shown below.

Butt the horizontal adaptor to the vertical and fasten with SFZ5 screws as shown.

DAYLIGHT OPENING

HORIZONTAL & VERTICAL

.128" DIA. (#30)

DRILL THRU

& CNTR SINK

for SFZ5

2" FROM END 12" O.C. 2" FROM END12" O.C.

VERTICAL ADAPTOR

RUNS THROUGH

NOTCH HORIZONTAL

ADAPTOR AROUND

VERTICAL ADAPTOR

Detail #20

#SFZ5

.125

.687

8651

Detail #21

SEE TOOLING DRAWING

001096 FOR END PREP

JDA 9/2000

Page 24

1G67

Apply a continuous

bead of silicone and

tool into the thermal

strut race .

1G67 SHOWN,

SEALANT APPLICATION

TYPICAL AT ALL

HORIZONTALS.

Apply silicone sealant

to the ends of the

intermediate horizontals

Detail #22

Apply a continuous

bead of silicone and

tool into the thermal

strut race .

2G23

Apply silicone sealant

to the ends of the

intermediate horizontals

Detail #23

BAH 4/2005

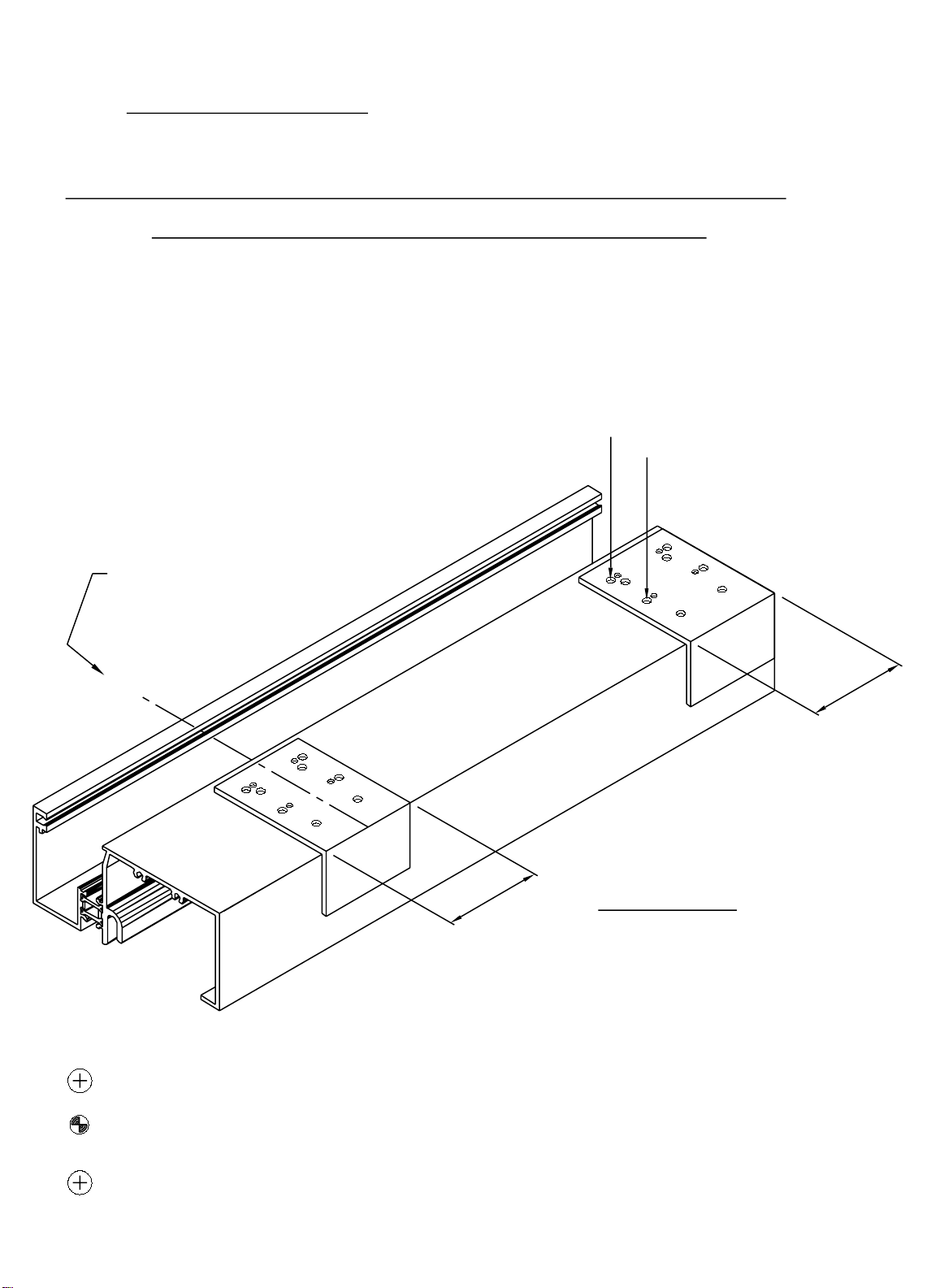

Page 25

PAGE #23

SECTION V - ASSEMBLY

CONT.

FRAME PREASSEMBLY

with standard verticals and horizontals.

STEP #26

Attach the intermediate horizontal shear blocks to the vertical mullions and

jambs. See detail #24 below.

STEP #27

Attach the intermediate horizontals to the vertical mullions and jambs.

See detail #24 below.

JAMB

1G59

#K368 SHEAR BLOCK

(1) PER END OF

HORIZONTAL INTERMEDIATE

VERTICAL

MULLION

1G61

STANDARD

HORIZONTAL

INTERMEDIATE

1G67

Detail #24

JDA 9/2000

Page 26

PAGE #24

SECTION V - ASSEMBLY

CONT.

STEP #28

Butter the top ends of the jambs and vertical mullions. Then attach the head

to the verticals with #STV3 screws. It will be necessary to coat the screws with

wax before installation to prevent stripping. See details #25 and #26 below.

STEP #29

Butter the bottom ends of the jambs and vertical mullions. Then attach the sill

to the verticals with #STV3 screws. It will be necessary to coat the screws with

wax before installation to prevent stripping. See details #27 and #26 below.

Detail #25

Detail #26

Detail #27

STEP #30

Depending on the height of the assembled frame, it may be easier to install the exterior

glazing gasket (WMB9) with the frame laying flat. This is at the discretion of the installer.

Be sure to add approximately 2% of the cut length to prevent gaps at the gasket

intersections.

JDA 8/2000

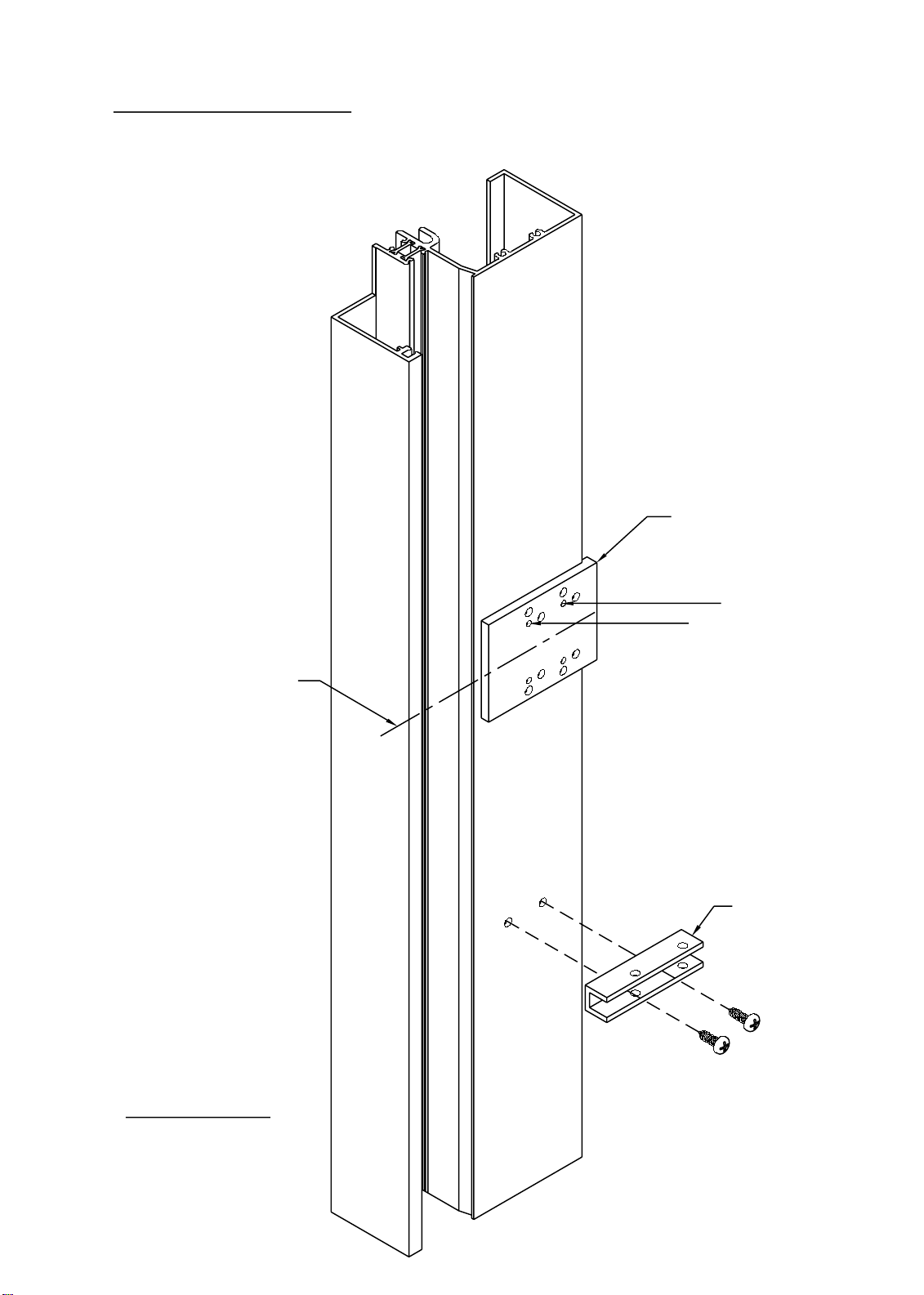

Page 27

PAGE #25

SECTION V - ASSEMBLY

CONT.

FRAME PREASSEMBLY

with butt glazed vertical intermediates and roll on

face horizontals.

STEP #31

Attach the intermediate horizontal shear blocks to the vertical mullions and

jambs. See detail #28 below.

STEP #32

Attach the intermediate horizontals to the vertical mullions and jambs. See

detail #28 below.

JAMB

1G59

Detail #28

#K368 (1)

PER SIDE

ROLL ON FACE

HORIZONTAL

2G23

ROLL ON FACE

HORIZONTAL

2G23

BUTT GLAZE

MULLION

8663

JDA 9/2000

Page 28

PAGE #26

SECTION V - ASSEMBLY

CONT.

STEP #33

Butter the top ends of the jambs and vertical butt glaze mullions. Then attach the head

to the verticals with #STV3 screws. It will be necessary to coat the screws with

wax before installation to prevent stripping. See details #29 and #30 below.

STEP #34

Butter the bottom ends of the jambs and vertical butt glaze mullions. Then attach the

sill to the verticals with #STV3 screws. It will be necessary to coat the screws with

wax before installation to prevent stripping. See details #31 and #30 below.

NOTE THE GAP BETWEEN

THE HORIZONTALS. THIS

WILL BE FILLED WITH

THE K461 BRIDGE ASSEMBLY.

REFERENCE SECTION VII

Detail #29

1G59 STD. JAMB

FRAME SILL

1G59 or 1G60

2G23

VERTICAL

8663 BUTT GLAZE

2G23

VERTICAL

8663 BUTT GLAZE

2G23

1G59 STD. JAMB

1G58 STD. HEAD

Detail #30

Detail #31

STEP #35

Depending on the height of the assembled frame, it may be easier to install the exterior

glazing gasket (WMB9) with the frame laying flat. This is at the discretion of the installer.

Be sure to add approximately 2% of the cut length to prevent gaps at the gasket

intersections.

JDA 9/2000

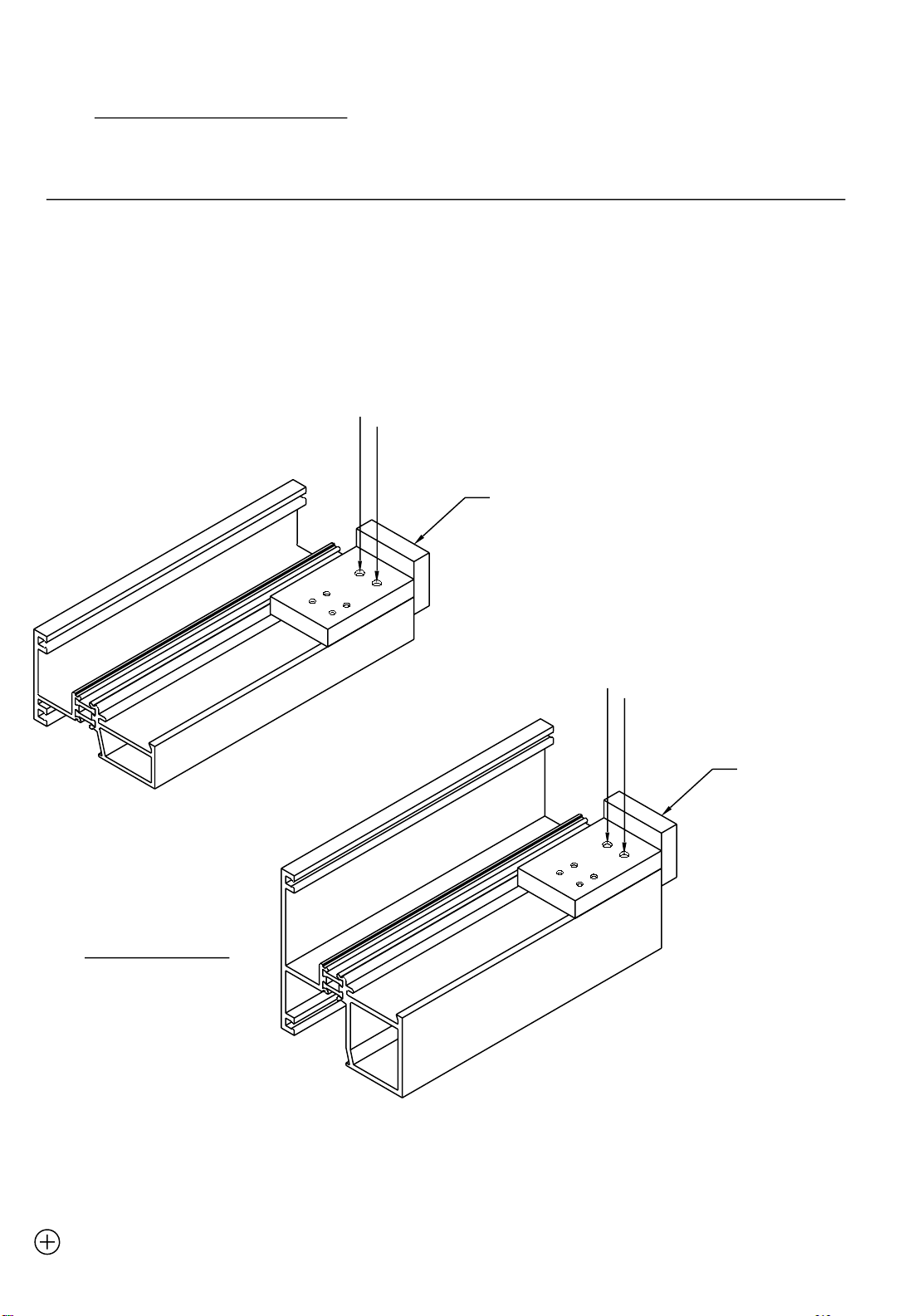

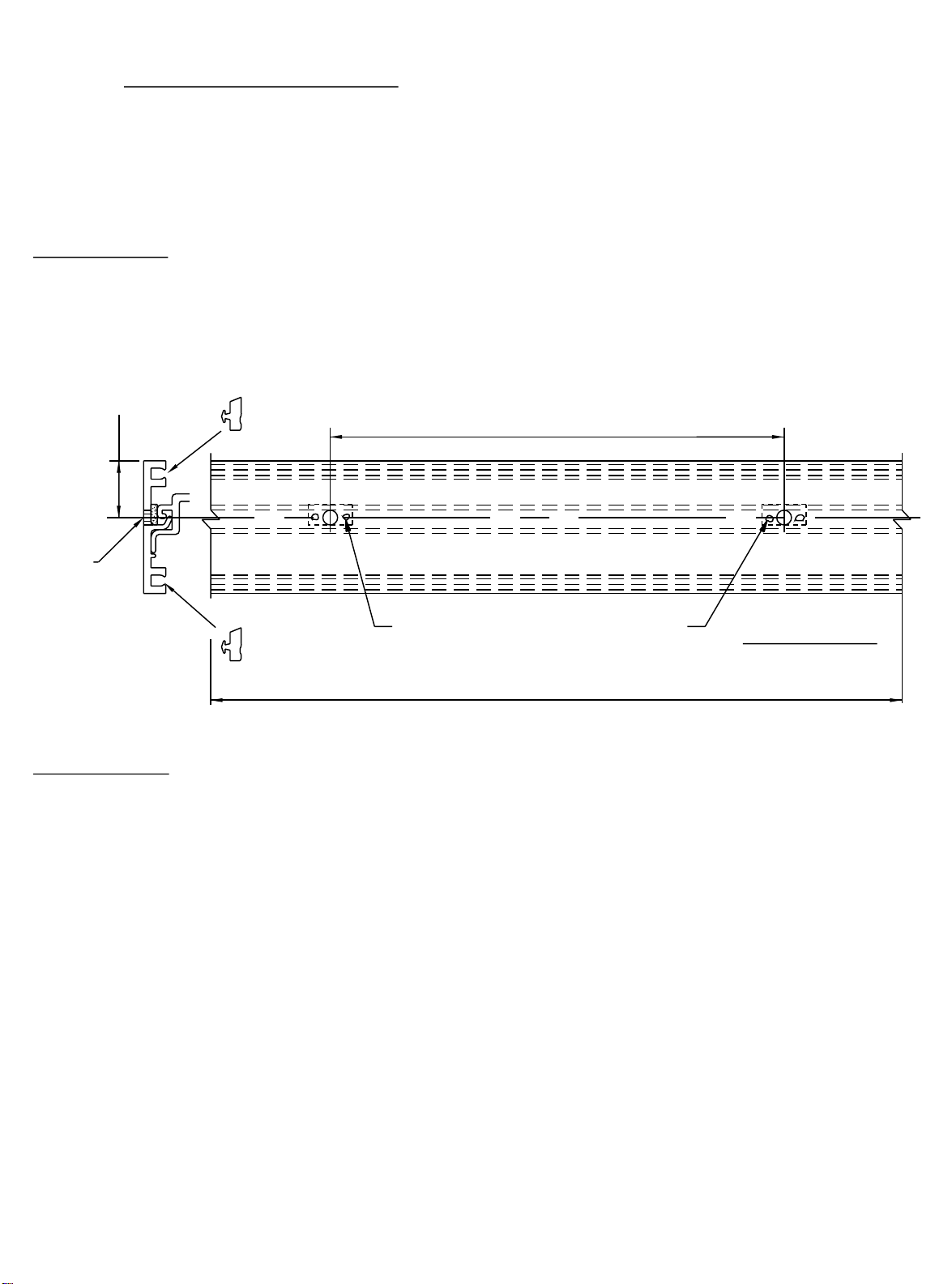

Page 29

PAGE #27

SECTION VI - FRAME INSTALLATION

CONT.

HORIZONTAL SILL ANCHOR INSTALLATION

STEP #36

At both ends of the rough opening, mark where the face of the frame is

intended to be located. Snap a chalk line from both marks. From this

dimension, snap another line 3 1/8" back toward the interior of the opening.

This will be the center line of the sill anchor prep. See detail #32 below.

STEP #37

Mark the center lines of the frame mullions on the rough opening. Measure

over from the mullion and jamb centers 6" and 16" O.C. and mark the interior line. This will be the center line of the anchor fastener. Drill the holes

for 1/4" diameter fasteners. Shim and install the anchor. See detail #33 below.

R.O. HEIGHT

6" 6"6"

ROUGH OPENING WIDTH

EXTERIOR FACE

OF OPENING

Detail #32

FACE OF

FRAME

CENTER LINE

OF ANCHOR

{FS99}

1/2" SHIM

3 1/8"

MULLION

CENTER

CENTER LINE

OF SILL ANCHOR

TYPICAL BOTH SIDES

OF VERT. MULLION

AND FROM JAMBS

6"6"

MULLION

CENTER

Detail #33

JDA 9/2000

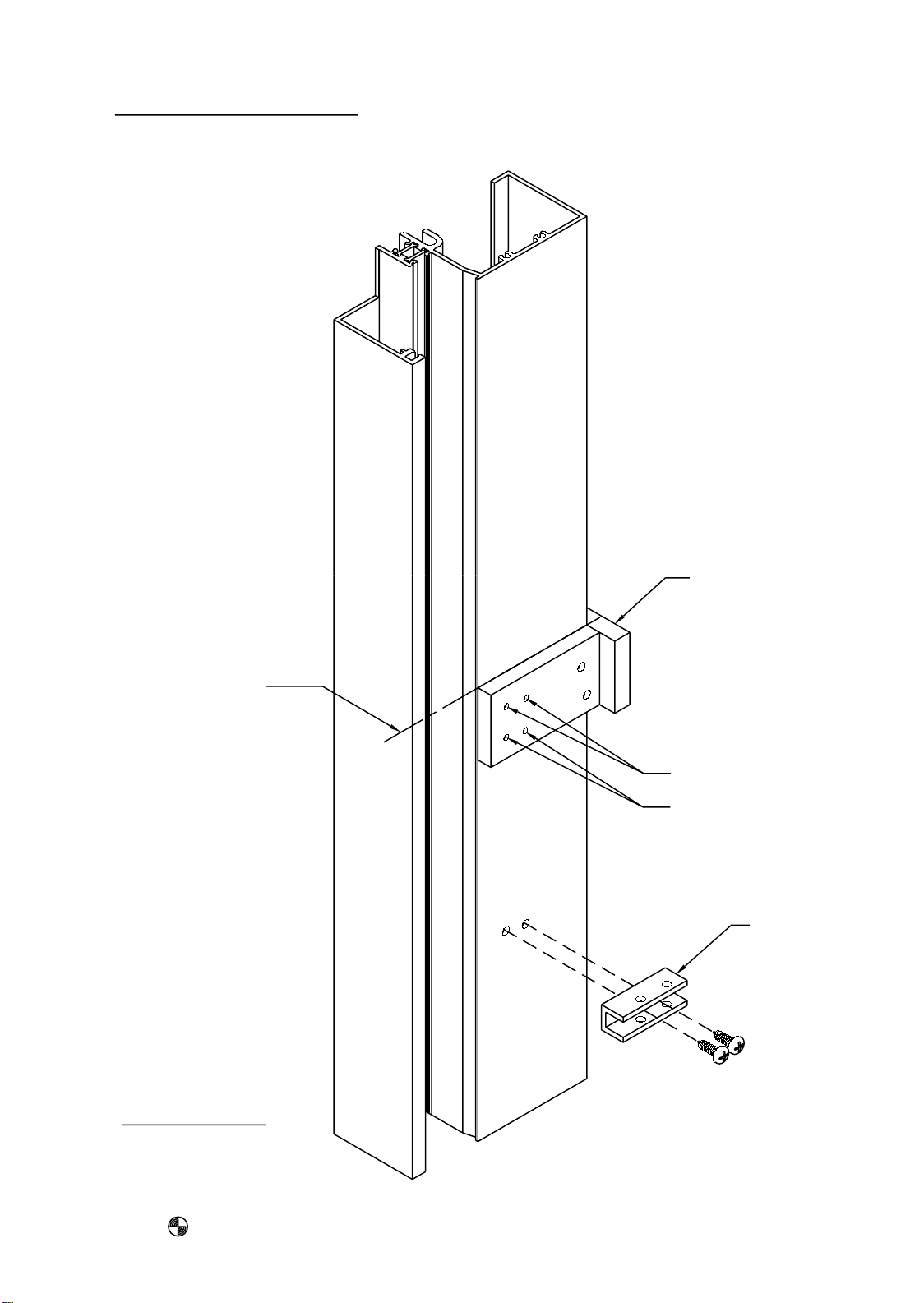

Page 30

PAGE #28

SECTION VI - FRAME INSTALLATION

CONT.

HEAD ANCHOR AND VERTICAL SILL ANCHOR INSTALLATION

{FS97 & FT01 - FABRICATED PARTS}

STEP #38

Mark the center lines of the frame mullions on the rough opening. Measure

over from the mullion and jamb centers 6" and 16" O.C.

The vertical sill anchors, FT01, will be installed prior to

setting the assembled frame, as shown in Detail #35 below.

The silde in head anchors, FS97, are installed into the assembled frame head,

2 per D.L.O. and maintain the anchor dimensions as above.

Refer to Detail #34 below and page #29.

2 1/2"

MIN.

Detail #34

IG58

FS97

3"

L

C

ANCHOR

LOCATIONS

16" O.C.

5" MIN.

3/4"

16" O.C.

6"

6"6"6"

6"

MULLION

CENTER

2 1/2"

MIN.

INTERIOR FACE

OF OPENING

1G59

1G60

3/4"

MULLION

CENTER

Detail #35

FT01

3"

4" MIN.

JDA 9/2000

Page 31

PAGE #29

SECTION VI - FRAME INSTALLATION

CONT.

FRAME INSTALLATION INTO THE OPENING

{FS97, FT01 & FS99 - FABRICATED PARTS}

STEP #39

Slide the FS97 head anchor into the head as shown in Detail #36 below.

SLIDE THE HEAD

ANCHOR INTO THE

HEAD MEMBER 6"

OFF EACH MULLION

AND 16" ON CENTER.

Detail #36

FS97

6" FROM

VERTICALS

6" FROM

VERTICALS

16" O.C.

MAX.

INTERIOR

Detail #37

Detail #38

STEP #40

The 955 system is designed to rotate into the opening from the interior of

the building. Align the sill over the sill anchors and rotate the frame

into the opening and fasten as required. See details #37 and #38 above.

FS99

FT01

JDA 9/2000

Page 32

PAGE #30

SECTION VI - FRAME INSTALLATION

CONT.

BACKER ROD / EXTERIOR SEAL AND EXTERIOR GASKET

STEP #41

Install a continuous row of backer rod at the exterior side of the frame

and seal with silicone sealant. See the various details below.

STEP #42

If the exterior glazing preset gasket (WNB9) has not been installed at this time,

do so now. Be sure to add 2% of the cut length to the gasket to prevent gaps

at the gasket ends due to gasket shrinkage.

CUT LENGTH FORMULA

FOR WNB9 = D.L.O. + 2%

JAMB

WNB9

WNB9

HEAD ANCHOR

(FS97)

HEAD

SILL

HORIZ. SILL

ANCHOR

(FS99)

WNB9

3/4"

1/2"

WNB9

SILL

3/4"

VERT. SILL

ANCHOR

(FT01)

1/2"

Detail #39

JDA 9/2000

Page 33

PO

1

IN

HN07

SETTING BLO CK

SEAL HN92

IN PLACE

/4

T

1

/4

PO

IN

T

HN3

PO

1

IN

/4

T

1

/4

PO

IN

T

Page 34

PAGE #32

SECTION VII - GLASS INSTALLATION

CONT.

STEP #46

HWD1 WATER DEFLECTOR

AT VERTICAL INTERMEDIATE,

LEFT JAMB, AND RIGHT JAMB

1G61

Remove the paper backing and

position the water deflector

as shown in this figure.

It will be necessary to set the water deflector

in a small amount of sealant, to ensure

that it stays in place when setting the lower

glass unit.

1G67 STD.

Detail # 44

This end extends into

the vertical glazing pocket

and over the lower glass

unit’s corner.

1G72, 1G73,

& 2G23 OPT.

TYP. VERTICAL

HWD1

WATER DEFLECTOR

SET IN SEALANT

TYP. HORIZONTAL

Detail # 45

GLASS UNIT BELOW

955 TECH SET

DPS 12/2001

Page 35

PAGE #33

SECTION VII - GLASS INSTALLATION

USING BUTT GLAZED MULLIONS

CONT.

STEP #47

The horizontal bridge is intended to prevent any water in the glazing

pocket from running down the butt glazed vertical intermediate at the

horizontal connection. Correct sealing is important in this step.

Apply a bead of sealant around the opening of the left and right horizontals and

across the vertical butt glaze mullion. This is to set the bridge assembly into.

See detail #47 below.

FT51

K461

Detail #46

BEAD OF

SEALANT

HORIZONTAL BRIDGE

HB98

BUTT GLAZE

MULLION

8663

HORIZONTAL

2G23

Detail #47

JDA 9/2000

Page 36

PAGE #34

SECTION VII - GLASS INSTALLATION

USING BUTT GLAZED MULLIONS

CONT.

BUTT GLAZE

MULLION

8663

HORIZONTAL

2G23

K461

STEP #48

AFTER THE BRIDGE IS SET IN PLACE,

SEAL AROUND BRIDGE PERIMETER

WITH A NONHARDENING

BUTYL TYPE SEALANT.

Detail #48

JDA 9/2000

Page 37

PAGE #35

SECTION VII - GLASS INSTALLATION

USING BUTT GLAZED MULLIONS

STEP #49

Follow the glass setting procedure as shown in

Detail #50 below and Detail #51 on page #36.

8663 1G688663

BUTT GLAZED

MULLION

INSTALL THIS UNIT

BUTT GLAZED

MULLION

- LAST -

CONT.

JAMB

INSTALL THIS UNIT

- 2nd TO LAST -

EXTERIOR GLAZING GASKET

WNB9 INSTALLED

STEP #50

Position the glass units as shown in Detail #50 below maintain the

appropriate glass bite per mullion.

Detail #49

8663 8663

1/2"

GAP

15/16"

GLASS

BITE

1/2"

GAP

15/16"

GLASS

BITE

1G68

1/2"

GLASS

BITE

Detail #50

JDA 9/2000

Page 38

PAGE #36

SECTION VII - GLASS INSTALLATION

USING BUTT GLAZED MULLIONS

CONT.

STEP #51

Install the butt glazing spacer (WSA1) between the butt glaze mullion and the

glass unit. This gap should be small enough to provide tension on the spacer

to hold it in place. The space will bottom out against the locator on the mullion.

K368

WSA1

Detail #51

WSA1

K368

8663

1/2"

GAP

NOTE:

Any type of temporary glazing retainer will have to be field fabricated and

installed by the contractor.

STEP #52

Be sure the glass units are set correctly and the butt glaze spacer is bottomed

out, before proceeding with the application of the structural silicone.

Fill the cavity created by the spacer with structural silicone, tying the glass unit,

the spacer, and the butt glaze mullion together.

A clean professional application of the structural silicone is required here.

This structural silicone joint will require an overnight cure.

8663

MULLION

WSA1

STRUCTURAL

SILICONE

Detail #52

GLASS

UNIT

JDA 9/2000

Page 39

PAGE #37

SECTION VII - GLASS INSTALLATION

USING BUTT GLAZED MULLIONS

CONT.

STEP #53

After the interior structural joint has cured overnight the exterior joint seal

can then be applied. Use backer rod to fill the cavity to 2/3 full leaving

enough void to seal the exterior glass panes together. See Detail # 53 below.

A clean professional application of the structural silicone is required here.

8663

MULLION

WSA1

STRUCTURAL

SILICONE

Detail #53

GLASS

UNIT

JDA 9/2000

Page 40

PAGE #38

SECTION VII - GLASS INSTALLATION

CONT.

HORIZONTAL GLASS SIZE FORMULA (D.L.O. + 1.000")

VERTICAL GLASS SIZE FORMULA (D.L.O. + 1" or D.L.O. + 7/8")

STEP #54

The glass size formulas for the 955 system are based on D.L.O. plus 1", horizontally

and D.L.O. plus 1" or 7/8", vertically. This applies to both 1" and 1/4" glazed systems.

If only a head and sill are used, use D.L.O. + 1". If any intermediate horizontals

are used, the formula should be D.L.O. + 7/8". See detail #54 below.

TYP.

1/2"

8685 GLZ. STOP

Detail #54

D.L.O.

GLASS SIZE = D.L.O. + 1"

TYP.

1/2"

GLASS INSTALLATION

TYP.

7/16"

D.L.O.

GLASS SIZE =

TYP.

7/16"

D.L.O.

D.L.O. + 7/8" D.L.O. + 7/8"

GLASS SIZE =

TYP.

7/16"

8685 GLZ. STOP

8685 GLZ. STOP

STEP #55

From the interior of the system, install the glass into the deep glass pocket.

Swing the opposing end of the glass around to align with the glass pocket.

Shift the glass into the shallow glass pocket until there is equal glass bite

at both sides of the glass. Rest the glass on the setting blocks.

See Detail #55 below.

1

Detail #55

2

8651

3

955 TECHSET

DPS 4/2004

Page 41

PAGE #3

9

SECTION VII - GLASS INSTALLATION

CONT.

ANTIWALK BLOCK INSTALLATION

STEP #56

Choose the appropriate antiwalk block for the required glass type. Use

block #HN50 at 1/4" glass and #HN53 at 1" glass. Compress the anti-

walk and insert into the deep pocket at midpoint. See the details below.

#HN50 OR

#HN53

#8685 OR

#8652 STOP

Detail #56

ANTIWALK

BLOCK

REQUIRED AT

DEEP POCKET

ONLY

ANTIWALK

INTERIOR GASKET INSTALLATION

LOCATE AT THE

MIDPOINT OF LITE

Detail #57

BLOCK

Detail #58

STEP #57

Install the horizontal removable glass stops to the openings at the head and

intermediate horizontals. See detail #57 above.

STEP #58

Cut the drive-in wedge gasket (W105) to the height and width D.L.O (+) 2%.

Install the vertical gasket first, then follow with the horizontal gasket.

Insert the ends of the gasket first, then set the middle and proceed to set

the middle of the loops until the gasket is installed.

JDA 9/2000

Page 42

PAGE #40

SECTION VIII - DOOR FRAME INSTALLATION

NOTE: If an entrance frame is required, it must be installed first.

See the parts description pages for the appropriate door jamb

and transom bar for the system being used.

STEP 1)

STEP 2)

STEP 3)

STEP 4)

Correctly locate the entrance frame in the opening.

Apply a bead of sealant around the interior portion of the jamb

to set the member into, and tie the side lite sealant or condition

sealant into the bead of sealant to be applied under the threshold.

The concept is to have a continuous bead of sealant at the interior

and connected from the sill flashing condition through the door

jamb and continuing under the threshold to the opposite door jamb.

Set assembled door frame in opening, plumb, and level.

Anchor the door frame as indicated below in Detail #59 and also in

Detail #60, #62, and #64 through Detail #66 on page # 41.

SIDE LITE SILL MEMBER

NOTE:

The door jamb runs to the

floor and is cut longer

than any other vertical

member.

K-124/K-125 Threshold Clip & Screws

@ Offset Pivots & Butt Hinges

K-153/K-154 Threshold Clip & Screws

@ Concealed Rod Panic

THRESHOLD

Continuous bead

of sealant

(9950)

Detail # 59

JDA 9/2000

Page 43

PAGE #41

SECTION VIII - DOOR FRAME INSTALLATION

CONT.

C.O.C. APPLICATION

5/8"

1/4" Dia. Weep

K450 RJ

K451 LJ

8580

At condition attach through

at 1/4 Points

K450 RJ

K451 LJ

8580

W138 W138

Detail # 60

the header with flat head

screws, located 6" from

the ends and 24" on center,

maximum spacing.

SURFACE CLOSER

K452

8581

APPLICATION

9154/9155

W138

Detail # 62

Attach through the threshold

with flat head screws. #9950 Shown.

EXTERIOR INTERIOR

Detail # 64

Detail # 61

1/4" Dia. Weep

at 1/4 Points

1.000"

Detail # 63

Continuous bead of sealant at

the back of the threshold and sides of the

jambs and tied into the mullion sealant

at the condition.

K452

9154/9155

W138

8581

955 Tech Set

Door jamb set in sealant.

8581

SIDELITE

9154/9155

W138

FRAMING

Anchor through the jamb

at the door location.

THRESHOLD

CLIP

Detail # 65

SEE THE DOOR INSTALLATION INSTRUCTIONS # Y015

8581

9154/9155

W138

Detail # 66

JDA 3/2002

Page 44

T

PAGE #42

SECTION VIII - DOOR FRAME INSTALLATION

CONT.

TRANSOM JAMB APPLIED GLAZING

8581

DRILL & CNTR. SINK for

SFZ5 #8-15 X 3/8

8578

PL-FH-SMS 18-8 AB UC

4" FROM ENDS

& 16" ON CENTER

W105

BEAD OF SEALANT

WNB9

8579

BEAD OF SEALANT

Detail # 67

VERTICAL CUT LENGTH FORMULA

for 8579 / 8578 APPLIED GLAZING

8578

8579

1.000

= D.L.O. minus 1/16"

955 Tech Set

BEAD OF SEALANT

Detail # 68

WEEP

APPLY SEALANT TO

INSIDE OF GLAZING POCKE

TO SEAL END CUTS

JDA 3/2002

Page 45

N

PAGE #43

SECTION VI A - DOOR FRAME INSTALLATIO

CONT.

TRANSOM HEADER AND APPLIED TRANSOM GLAZING

K462 CLIP

ATTACHED WITH

STT6 SCREWS

1G58

TRANSOM HEADER

SEALANT

8579

TRANSOM

GLAZING STOP

SET IN A BEAD OF

SEALANT VERTICALLY

1G58 HEAD

8581

DOOR JAMB

Detail # 69

Locate the header clip onto the end of the header, fasten the clip to the header

with the screws provided in the clip package.

Apply sealant to the ends of the header and install with the screws provided.

Attach the header to the condition with 1/4" dia. fasteners (min.), 6" from the jambs

and 16" on center maximum.

Apply a thin bead of sealant vertically to set the screw applied glazing stop into. Then

fasten into place with #STU8 screws, 4" from ends and 12" on center.

Apply sealant to the ends of the header and vertical glazing adaptor as shown in

Detail #69 above.

JDA 9/2000

Loading...

Loading...