Page 1

Quick Set can system

Installation Instructions

Part NO. Y003

February 2013

Page 2

SECTION

TABLE OF CONTENTS

PAGE

I GENERAL NOTES

II PARTS IDENTIFICATION

A) 901 PARTS IDENTIFICATION

B) 902 PARTS IDENTIFICATION

C) 903 PARTS IDENTIFICATION

D) 904 PARTS IDENTIFICATION

III FABRICATION

A) DRILLING TEMPLATE

(901/902 INTERMEDIATE HORIZONTAL)

B) DRILLING TEMPLATE

(903/904 INTERMEDIATE HORIZONTAL)

C) HEAD AND SILL CAN

D) HEAD AND SILL CAN FILLER

1) CAPTURED MULL ION SYSTEM

2) BUTT GLAZED SYSTEM

E) VERTICAL INTERMEDIAT E AN D 2 PIECE JAMB

F) THERMAL STRUT INTERM ED IA TE VERTICAL

G) INTERMEDIATE HORIZONTAL

IV INSTALLATION

A) HEAD AND SILL CAN ANCHORING

HEAD AND SILL CAN SPLICE

B) 2 PC. JAMBS AND I NTERMEDIATE VER TICALS

C) BUTT GLAZED VERTICALS

D) INTERMEDIATE HORIZONTAL

1

2-3

4-6

7-8

9-10

11

12

13-15

16

16

17-19

20-21

22-24

25

26-27

28-31

32-34

35-36

V GLAZING PROCEDURES

A) WITH BUTT GLAZED VERTICAL

B) WITH BUTT GLAZED VERTICAL AND

INTERMEDIATE HORIZONTAL

C) WITH CAPTURED VERTICAL MULLION AND

INTERMEDIATE HORIZONTAL

VI DOOR FRAME INSTALLATION

A) DOOR FRAME ANCHORING

Minimizing Condensation

NOTE: Please reference EFCO's "Understanding Condensation" brochure which can be obtained through your EFCO representative.

Condensation will form on any surface when unfavorable condition s (interior temperature and relative humidity and exterior

temperature) are present. When the formation of excessive condensation is a concern, it is highly recommended that a design

professional is utilized to perform an analysis of the shop drawings to recommend the best installation methods. Please contact

EFCO representative for information on EFCO's Thermal Analysis Servi c es .

Many current installation practices lead to an increase in the possibility of the formation of condensation. Though not all

inclusive, the list of examples below illustrates conditions under which condensation is likely to occur:

1. Bridging system thermal br eak with non-thermall y broken metal flashi ng or l intels that are exposed to the

exterior.

2. System exposure to cold air cavities.

3. Interior relative humidity levels not maintained at recommended levels, see EFCO's "Understanding

Condensation" brochure.

4. Inadequate separation between system and surrounding condition at perimet er.

5. Product combinations during the shop dra wing stage that result in br i dging thermal br eaks of one or al l products

involved.

37-44

45

46

47-50

JWH 8/2011

Page 3

SECTION I - GENERAL NOTES

EFCO Series 901 (4 1/2" Nonthermal System)

EFCO Series 902 (5 1/4" Thermal System)

EFCO Series 903 (3 1/4" Nonthermal System)

EFCO Series 904 (4" Thermal System)

Series 901 & 903 accommodates 1/4" glazing.

Series 902 & 904 accommodates 1" glazing.

PAGE 1

The storefront family is a ribbon window system,

having many advantages over other systems due to the minimum

fabrication and installation steps.

The Quick Set family contains primarily stock length systems

with in-the-field fabrication. Entrance doors are also a designed

part of the 901 & 902 systems, utilizing frames that can accommodate

many types of doors and hardware combinations.

Check the shop drawings, installation instructions, and glazing

1)

instructions to become thoroughly familiar with the project.

The shop drawings take precedence and include specific details

for the project. The installation instructions are of a general

nature and cover the most common conditions encountered.

Check all materials on arrival and be sure you have everything

2)

required to begin installation.

See Section II "PARTS IDENTIFICATION".

"QUICK SET"

All work should start from bench marks and/or column center

3)

lines as established by the architectural drawings and the

general contractor. Check construction for compliance with

the contract documents.

Sealants must be compatible with all surfaces. Consult with

4)

the sealant manufacturer for recommendatons regarding

compatibility and adhesion.

All materials are to be installed plumb, level, and true.

5)

Protect materials after erection. Cement, plaster, alkaline

6)

solutions, and acid based materials can be harmful to the finish.

Clean exposed finished surfaces with a mild detergent and water.

No abrasive agent shall be used.

DPS 7/2001

Page 4

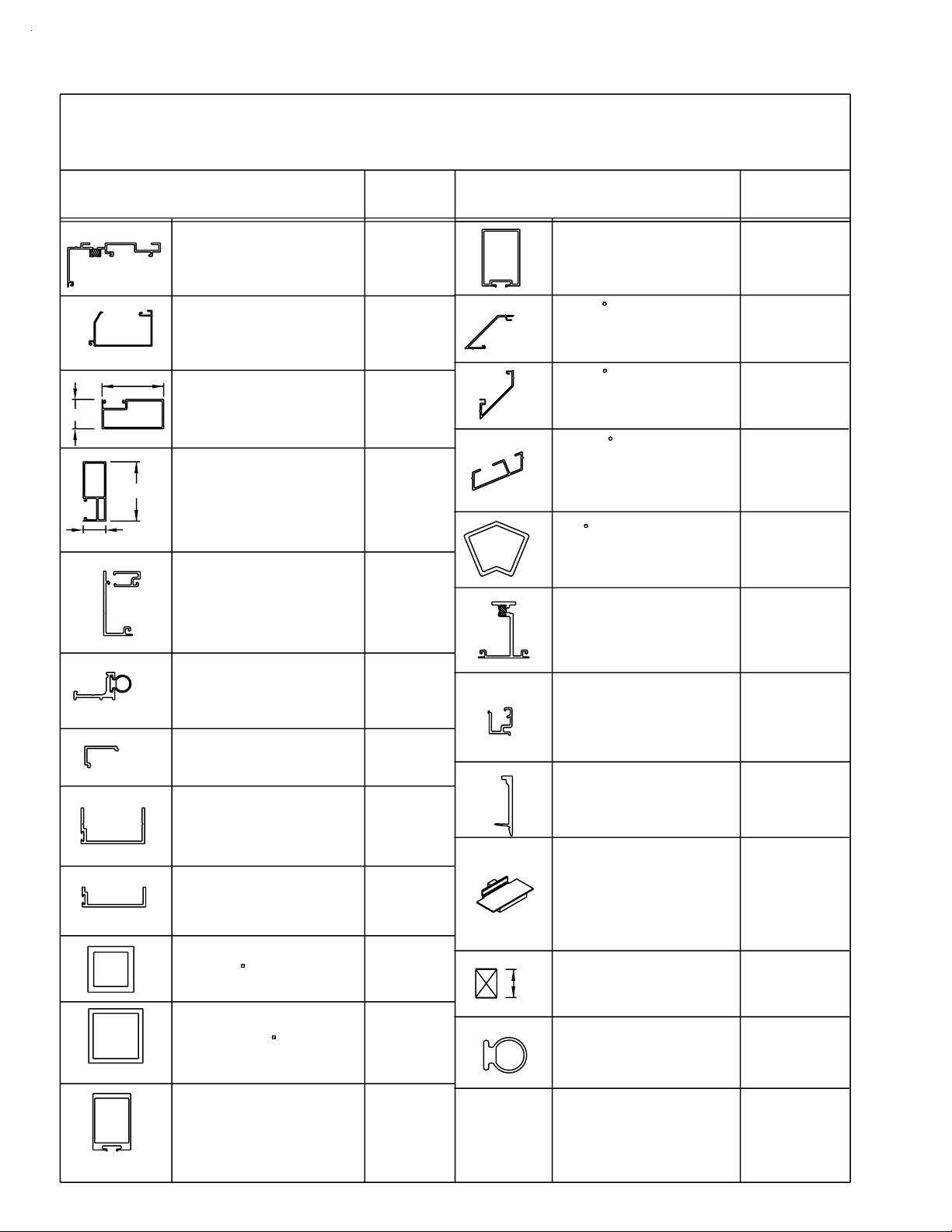

PAGE 2

SECTION II A -

4 1/2" NONTHERMAL FRAMING

DESCRIPTION

HEAD AND SILL

4 1/2" CAN

USE 9485 CAN FILLER

CAN FILLER

USE w/ 9479

INTERMEDIATE

HORIZONTAL

USE 9587 & 9565

INTERMEDIATE

HORIZONTAL FACE

USE w/ 9469

PARTS IDENTIFICATION CHART

SERIES 901 QUICK SET

1/4" GLAZING

PART NO.

9479

9485

9469

9565

DESCRIPTION

BUTT GLAZED

VERTICAL MULLION

90 CORNER

MULLION HALF

MATES w/ 7256

90 CORNER

MULLION HALF

MATES w/ 7255

135 CORNER

MULLION HALF

2 REQUIRED

PART NO.

7253

7255

7256

7260

INTERMEDIATE

HORIZONTAL STOP

USE w/ 9469

CAPTURED MULLION/

JAMB BACK

8593 2 pc. JAMB

9579 VERT. FACE

CAPTURED

VERT. MULLION

FACE

USE w/ 9578

CAPTURED VERT.

MULLION STOP

2 REQUIRED w/ 9578 - 9579

CAPTURED

2 PC JAMB

SLIDE on FACE

USE w/ 9578

2 PC. JAMB

GLAZING STOP

USE w/ 8593

2 COLOR COVER

USE w/ 9479

HEAD/SILL CAN

9587

9578

9579

9580

8593

8589

9571

4 1/2"

2 1/2"

2"

4 1/2"

TRANSOM HEAD

1/4" GLAZING

USE 7861 STOP

TRANSOM HEAD

GLAZING STOP

1/4" GLAZING

2" DOOR JAMB or

DOOR HEADER W/

SURFACE CLOSER

USE w/ 9154/9155 STOP

2 1/2" DOOR HEADER

for C.O.C.

USE 9914 STOP/COVER

OR 9933 STOP/COVER

APPLIED DOOR STOP

USE w/ 9155. USE W138

WEATHER STRIP

ATTACH w/ STT6 SCREW

APPLIED DOOR STOP

COVER

USE w/ 9154

DOOR STOP FOR C.O.C.

DOOR HEADER

USE w/ DORMA RTS 88 C.O.C.

OR INTERNATIONAL C.O.C.

DOOR STOP FOR C.O.C.

DOOR HEADER

USE w/ LCN 2030 C.O.C.

9472

7861

9597

9598

9154

9155

9914

9933

HEAVY-DUTY

BUTT GLAZED

VERTICAL MULLION

7028

DPS 7/2001

Page 5

PAGE 3

SECTION II A - PARTS IDENTIFICATION CHART

SERIES 901 QUICK SET 4 1/2" NONTH ERMAL FRAMING

1/4" GLAZING

DESCRIPTION PART NO. DESCRIPTION PART NO.

EX32

9470

F076

F077

FS67

FT14

INTERMEDIATE

HORIZONTAL SH EAR

BLOCK USE

w/ 9469 (1) F365, (3) MRF8, (1) S110

2 1/2" C.O.C. DOOR

HEADER SHEAR BLOCK

901 - 9598

(2) STV2, (1) F076/(1) F077

(2) S117/(2) STD8

2" DOOR JAMB as DOOR

HEADER SHEAR BLOCK

901 - 9597

(1) FS67, (2) STV2, (2) MRF1/(2)

MRF6

TRANSOM HEADER SHE AR

BLOCK PACKAGE USE w/

9472

(1)F259,(1)F260,(6)STT6,(4)MRF6

HEAD/SILL CAN ANCHOR

CLIP (USE w/ 9578 at

JAMBS)

(1) FT14, (4) SFP8

HORIZONTAL BRIDGE

ASSEMBLY 1/4" GLAZING

at BUTT GLAZE

MULLIONS ONLY w/ INT.

HORIZ.

(1) F023, (1) H189, (1) WM76

K176

K309/K311

(CLR. - R / L )

K310/K312

(BRZ. - R / L)

K278

(CLR.)

K279

(BRZ.)

K277

K433

K143

SHEAR BLOCK PKG. F OR

#8583 HORIZ. at 135°

S.S.G. OUTSIDE CORNER

(1) FT92, (1) FT93, (2) MTZ4, (4) SPC9,

(1) S110

SHEAR BLOCK PKG. F OR

#8583 HORIZ. at 135°

S.S.G. INSIDE CORNER

(1) FT94, (1) FT95, (4) MTZ4, (2) SPC9,

(1) S110

1/4" SETTING BLOCK A T

SILL CAN

WEEP BAFFLES

25 PER PKG.

INTERMEDIATE

HORIZONTAL SETTING

BLOCK US E w/ 9469

BUTT GLAZED SPACER

3/8" x 1/2" TAPE USE w/

7028 & 7253

TEMPORARY GLAZING

CLIP USE w/ 7028 & 7253

K490

K491

HNA1

HCW6

HEP2

WM10

HV11

7885

FT98

FT99

Q-SET

INTERMEDIATE

HORIZONTAL FACE SPLICE

USE w/ 9565 FACE

(1) F024, (1) F025

HEAD/SILL SPLICE for 901

(USE w/ 9479)

25 PER PACKAGE (1) F014, (1) WM96,

(1) WM01

SHEAR BLOCK PKG. F OR

#8583 HORIZ. @ 90° S.S.G.

INSIDE/OUTSIDE CORNER

(1) FT98, (1) FT99, (4) STV2, (4) ST K4

K146

K376

K493

HORIZONTAL END DAM

at 2 PC JAMB INSTALLS

IN GLAZING POCKET IN

HEAD & SILL CAN

GLAZING GASKET

500' PER ROLL

STANDARD WEATHER

SEAL @ DOOR STOPS

HN30

W164

W138

CDB 9/2009

Page 6

PAGE 4

SECTION II B -

DESCRIPTION

HEAD and SILL

5 1/4" CAN

USE 9485 CAN FILLER

CAN FILLER

USE w/ 9484, 9845 OR 1G66

THERMAL STRUT

HEAD and SILL

5 1/4" CAN

USE 9485 CAN FILLER

OUTSIDE GLAZED

HEAD/SILL CAN

USE 9485 CAN FILLER

9846 or 9847 FACE

OUTSIDE GLAZED

SILL CA N FA CE

USE w/ 9845

OUTSIDE GLAZED

HEAD C A N FACE

USE w/ 9845

INTERMEDIATE

HORIZONTAL

USE w/ 8499, 8584, 9541

INTERMEDIATE

HORIZONTAL FACE

USE w/ 8583 or 8500

INTERMEDIATE

HORIZONTAL

GLAZING STOP

USE w/ 8583

OPT. H.D. HORIZONTAL

INTERMEDIATE

USE K176 S.B.

8499 FACE & 9587 STO P

H.D. INTERMEDIATE

HORIZONTAL

GLAZING STOP

USE w/ 8500

OPT. INTERMEDIATE

HORIZONTAL

GLAZING STOP

1/4" GLASS W/ 8583/8500

PARTS IDENTIFICATION CHART

SERIES 902 QUICK SET

5 1/4" THERMAL FRAMING

1" GLAZING

PART NO.

9484

9485

1G66

9845

9846

9847

8583

8499

8584

8500

9587

9541

DESCRIPTION

CAPTURED

MULLION BACK

USE w/ 9576 & 8594

CAPTURED MULLION

SLIDE ON FACE

USE w/ 9578

CAPTURED

MULLION STOP

2 REQUIRED w/

9578 & 1G41

2 PC JAMB

SLIDE on FACE

USE w/ 9578

& 8589

2 PC JAMB

GLASS STOP

USE w/

9578 & 8594

CAPTURED VERTICAL

'I' BAR (2) COLOR

USE WITH

(2) 9580 STOPS

OPTIONAL

CAPTURED VERTICAL

MULLION & JAMB STOP

for 1/4" GLASS

USE w/

9578 & 1G41

1/2" GLAZING ADPT.

at 1" GLAZING PO CK ETS

1/4" GLAZING ADPT.

at 1" GLAZING PO CK ETS

2 COLOR COVER

(9484 HEAD/SILL CAN)

PART NO.

9578

9576

9580

8594

8589

1G41

9542

9260

9261

9570

BAH 4/2005

Page 7

PAGE 5

SECTION II B -

DESCRIPTION

TRANSOM HEAD

USE w/ 7861

& K267 CLIP

TRANSOM HEAD

GLAZING STOP

1" GLAZING

5 1/4"

2 1/2"

5 1/4"

2"

APPLIED DOOR STOP

USE W138 WEATHERING

ATTACH w/ STT6 SCREW

APPLIED DOOR STOP

C.O.C. DOOR HEADER

C.O.C. DOOR HEADER

USE w/ (1) 7255 &(1) 7256

For C.O.C.

DOOR HEADER

2 1/2"

SURFACE CLOSER

DOOR HEADER w/

2" DOOR JAMB

TRANSOM JAMB

APPLIED GLAZING

1" SIGHT LINE

(USE w/ 9592)

USE w/ 9155

COVER

USE w/ 9154

DOOR STOP FOR

USE w/ DORMA RTS 88

OR INTERNATIONAL

DOOR STOP FOR

USE w/ LCN 2030 C.O.C.

1" x 1" x 1/8" TUBE

@ 90 CORNER

PARTS IDENTIFICATION CHART

SERIES 902 QUICK SET

5 1/4" THERMAL FRAMING

1" GLAZING

PART NO.

9539

7861

9593

9592

9133

9295

9154

9155

9914

9933

EY54

DESCRIPTION

BUTT GLAZED

VERTICAL MULLION

90 CORNER

MULLION HALF

(MATES w/ 7256)

90 CORNER

MULLION HALF

(MATES w/ 7255)

135 CORNER

MULLION HALF

(2 REQUIRED

SELF-MATING)

45 BUTT GLAZED

CORNER ADAPTOR

USE w/ (2) 7260

BUTT GLAZED ADAPT.

USE w/ 7028 or 7253

for BUTT GLAZE ABOVE

CAPTURED BELOW

1/4" GLAZING ADPT.

USE at BUTT

GLAZED MULLS

USE w/ 7253 or 7028

TEMPORARY

GLAZING CLIP

for 7028 or 7253

25 PER PKG.

HORIZONTAL

BRIDGE ASSEMBLY

1" GLAZING at BUTT

GLAZE MULLIONS ONLY

w/ INT. HORIZ.

USE w/ 9558 & 9559

BUTT GLAZED SPACER

1/2"

3/8 x 1/2 TAPE USED

w/ 7028 & 7253

CONT.

PART NO.

7253

7255

7256

7260

9258

9471

9574

HV10

K142

WM10

Q-SET

1 1/2" x 1 1/2" x 1/8"

TUBE @ 90 CORNER

USE w/ (2) 7253 OR 7028

HEAVY-DUTY

BUTT GLAZED

VERTICAL MULLION

EX85

7028

STANDARD

WEATHER SEAL

@ DOOR STOPS

W138

DPS 12/2002

Page 8

PAGE 6

SECTION II B - PARTS IDENTIFICATION CHART

SERIES 902 QUICK SET 5 1/4" THERMAL FRAMING

1" GLAZING

EX32

FT14

DESCRIPTION

INTERMEDIATE HORIZONTAL

SHEAR BLOCK USE w/ 8583

or 8500

(1) F365, (3) MRF8, (1) S110

HEAD/SILL CAN ANCHOR

CLIP USE w/ 9578 at JAMBS

(1) FT14, (4) SFP8

TRANSOM HEADER SHEAR

BLOCK PACKAGE USE w/ 9539

(1) F344, (1) F345, (8) STT6, (4) MRF6

2" DOOR JAMB as DOOR

HEADER SHEAR BLOCK 902

- 9592

FS67

FT98

FT99

(1) FS67, (2) STV2, (2) MRF1/(2) MRF6

F078

2 1/2" - C.O.C. DOOR HEADER

F079

SHEAR BLOCK 902 - 9593

(1) F078, (1) F079, (4) STV2, (4) S117/(4)

STD8

SHEAR BLOCK PKG. FOR

#8583 HORIZ. at 135°

S.S.G. OUTSIDE CORNER

(1) FT92, (1) FT93, (2) MTZ4, (4) SPC9,

(1) S110

SHEAR BLOCK PKG. FOR

#8583 HORIZ. at 135°

S.S.G. INSIDE CORNER

(1) FT94, (1) FT95, (4) MTZ4, (2) SPC9,

(1) S110

SHEAR BLOCK PKG. FOR

#8583 HORIZ. @ 90° S.S.G.

INSIDE/OUTSIDE CORNER

(1) FT98, (1) FT99, (4) STV2, (4) STK4

1" SETTING BLOCK for

INTERMEDIATE HORIZONTAL

PART NO.

K176

K433

K267

K278

(CLR.)

K279

(BRZ.)

K273

(CLR.)

K274

(BRZ.)

K490

K491

K493

HN90

DESCRIPTION

HEAD/SILL CAN SPLICE

(USE WITH 9484)

25 PER PACKAGE (1) F015, (1) WM96,

(1) WM01

HEAD/SILL CAN SPLICE

(USE WITH 1G66)

(1) FU12, (1) WM96

OUTSIDE GLAZED

HEAD/SILL SPLICE (USE

WITH 9845)

(1) F001, (1) WM96

WEEP BAFFLES

INTERMEDIATE

HORIZONTAL FACE

SPLICE USE w/ 8499

(2) FT49

WATER DEFLECTOR @ INT.

HORIZONTAL

GLAZING GASKET

500' PER ROLL

1" SETTING BLOCK at

1G66 SILL CAN

25 PER PACKAGE

SETTING BLOCK for 9592

JAMB when used as

TRANSOM

PART NO.

K377

K917

K375

HCW6

K460

HWD1

W164

FU08

HN32

HORIZONTAL END DAM for

1" GLZ. @ 2 PC. JAMB

1" SETTING BLOCK at SILL

CAN

25 PER PACKAGE

HN31

HN33

CDB 9/2009

Page 9

PAGE 7

SECTION II C -

SERIES 903 QUICK SET

3 1/4" NONTHERMAL FRAMING

DESCRIPTION

HEAD and SILL

3 1/4" CAN

USE 9478 FILLER

CAN FILLER

USE w/ 9476

INTERMEDIATE

HORIZONTAL

USE W/ 9565 & 9566

INTERMEDIATE

HORIZONTAL STOP

USE W/ 9586

INTERMEDIATE

HORIZONTAL FACE

USE w/ 9586

PARTS IDENTIFICATION CHART

1/4" GLAZING

PART NO.

9476

9478

9586

9566

9565

DESCRIPTION

BUTT GLAZED

VERTICAL MULLION

HEAVY-DUTY

BUTT GLAZED

VERTICAL MULLION

90 CORNER

MULLION HALF

(2 REQUIRED)

135 CORNER

MULLION HALF

(2 REQUIRED)

PART NO.

9558

9559

9563

9562

CAPTURED VERTICAL

MULLION / JAMB

BACK

9579 VERT. FACE

8593 2 pc. JAMB FACE

CAPTURED

MULLION FACE

USE W/ 9575

CAPTURED

MULLION STOP

USE (2) w/ 9575 & 9579

2 PC JAMB

SLIDE on FACE

USE W/ 9575

2 PC JAMB

GLASS STOP

USE w/ 9575 & 8593

2 COLOR COVER

at HEAD and SILL CAN

USE w/ 9476

9575

9579

9577

8593

8590

9572

DPS 7/2001

Page 10

PAGE 8

SECTION II C - PARTS IDENTIFI CATION CHART

SERIES 903 QUICK SET 3 1/4" NONTHERMAL FRAMING

1/4" GLAZING

CONT.

FT15

7885

DESCRIPTION PART NO. PART NO.

INTERMEDIATE HORIZONTAL

SHEAR BLOCK USE w/ 958

(1) F021, (3) MRF7

HEAD/SILL CAN ANCHOR

CLIP USE w/ 9575 at JAMB

(1) FT15, (4) SFP8

HEAD/SILL CAN SPLICE

USE w/ 9476

25 PER PACKAGE

INTERMEDIATE

HORIZONTAL FA CE

SPLICE USE w/ 9565 FACE

(1) F024, (1) F025

HORIZONTAL BRIDGE

ASSEMBLY 1/4" GLAZING at

BUTT GLAZE MULLIONS ONLY

w/ INT. HORIZ. USE w/ 9558

and 9559

(1) F023, (1) H189, (1) WM76

ANCHOR CLIP @ PERIMETER

JAMBS

(1) FT15, (4) SFP8

K141

K434

K378

K146

K143

K434

DESCRIPTION

1/4" SETTING BLOCK

USE w/ 9476

HORIZONTAL END DAM

for 1/4" GLZ. at 2 PC.

JAMB INSTALLS in

GLAZING POCKET in HEAD

and SILL CAN

WEEP BAFFLES

25 PER PKG.

GLAZING GASKET

500' PER ROLL

INTERMEDIATE

HORIZONTAL SETTING

BLOCK USE w/ 9586

BUTT GLAZED SPACER 3/8"

x 1/2" TAPE USE w/ 9558

and 9559

TEMPORARY GLAZING

CLIP USE w/ 9558 and

9559

HNA2

HN30

HCW6

W164

H191

WM10

HV11

CDB 9/2009

Page 11

PAGE 9

SECTION II D -

SERIES 904 QUICK SET

4" THERMAL FRAMING

DESCRIPTION

HEAD and SILL CAN

FLAT BOTTOM

USE 9478 CAN FILLER

HEAD and SILL CAN

CONCEALED WEEP

USE 9478 CAN FILLER

CAN FILLER

USE w/ 9477 & 9468

OUTSIDE GLAZED

HEAD / SILL CAN

USE 9478 CAN FILLER

PARTS IDENTIFICATION CHART

1" GLAZING

PART NO.

9477

9468

9478

8716

DESCRIPTION

2 PC JAMB

SLIDE on FACE

(USE w/ 9575)

2 PC JAMB

GLASS STOP

USE w/ 9575

HEAVY-DUTY

BUTT GLAZED

VERTICAL MULLION

BUTT GLAZED

VERTICAL MULLION

PART NO.

8594

8590

9559

9558

OUTSIDE GLAZED

SILL CAN

USE w/ 8716 CAN

OUTSIDE GLAZED

HEAD CAN

USE w/ 8716 CAN

INTERMEDIATE

HORIZONTAL

USE w/ 9565 & 9566

INTERMEDIATE

HORIZONTAL STOP

USE w/ 9564

INTERMEDIATE

HORIZONTAL FACE

USE w/ 9564

CAPTURED VERT.

MULLION / JAMB

BACK

9576 VERT. FACE

8594 2 pc. JAMB FACE

CAPTURED VERT.

MULLION FACE

USE w/ 9575

CAPTURED VERT.

MULLION STOP

USE (2) w/ 9575

9846

9847

9564

9566

9565

9575

9576

9577

90 CORNER

MULLION HALF

(2 REQUIRED)

135 CORNER

MULLION HALF

(2 REQUIRED)

1" x 1" x 1/8" TUBE

@ 90 CORNER

USE w/ (2) 9563

at 90 CORNER

45 BUTT GLAZED

CORNER ADAPTOR

USE w/ (2) 9562

1 1/2"x1 1/2"x1/8"

TUBE @ 90 CORNER

USE w/ (2) 9558 or 9559

BUTT GLAZED

ADAPTOR

USE w/ 9558 or 9559

for BUTT GLAZED ABOVE

CAPTURED BELOW

1/2" GLAZING ADPT.

at 1" GLAZING POCKETS

1/4" GLAZING ADPT.

at 1" GLAZING POCKETS

9563

9562

EY54

9258

EX85

9471

9260

9261

DPS 7/2001

Page 12

PAGE 10

9

SECTION II D - PARTS IDENTIFICATION CHART

SERIES 904 QUICK SET 4" THERMAL

FRAMING 1" GLAZING

CONT.

PART NO.DESCRIPTIONPAR T NO.DESCRIPTION

INTERMEDIATE HORIZONTAL

SHEAR BLOCK USE w/ 9564

(1) F021, (3) MRF7

1/4" GLAZING ADPT. at

BUTT GLAZED MUL L USE w/

9558 or 9559

OUTSIDE GLAZED HEAD/SILL

SPLICE USE w/ 8716 O.G.

CAN

(1) F001, (1) WM96

HEAD/SILL CAN SPLICE USE

w/ 9477 & 9468 25 PER

PACKAGE

(1) F017, (1) WM96, (1) WM01

HORIZONTAL BRIDGE

ASSEMBLY 1" GLAZING at

BUTT GLAZE MULLIONS

ONLY w/ INT. HORIZ. USE w/

(1) F022, (1) H189, (1) WM76

9564

K141

9574

K375

K379

K142

WATER DEFLECTOR @

INT. HORIZONTAL

1" SETTING BLOCK at

SILL CAN

GLAZING GASKET

500' PER ROLL

BUTT GLAZED SPACER

3/8" x 1/2" TAPE USE w/

1/2"

TEMPORARY GLAZING

CLIP for 7028 or 7253

25 PER PKG.

7028 & 7253

HWD1

HN34

W164

WM10

HV10

INTERMEDIATE HORIZONTAL

FACE SPLICE USE w/ 9565

(1) F024, (1) F025

FACE

ANCHOR CLIP @ PERIMETER

JAMBS

(1) FT15, (4) SFP8

HORIZONTAL END DAM for 1"

GLZ. at 2 PC. JAMB INSTALLS

in GLAZING POCKET in HEAD

and SILL CAN

WEEP BAFFLES

25 PER PKG.

1" SETTING BLOCK for

INTERMEDIATE

HORIZONTAL

K146

K434

HN31

HCW6

HN90

CDB 9/200

Page 13

PAGE 11

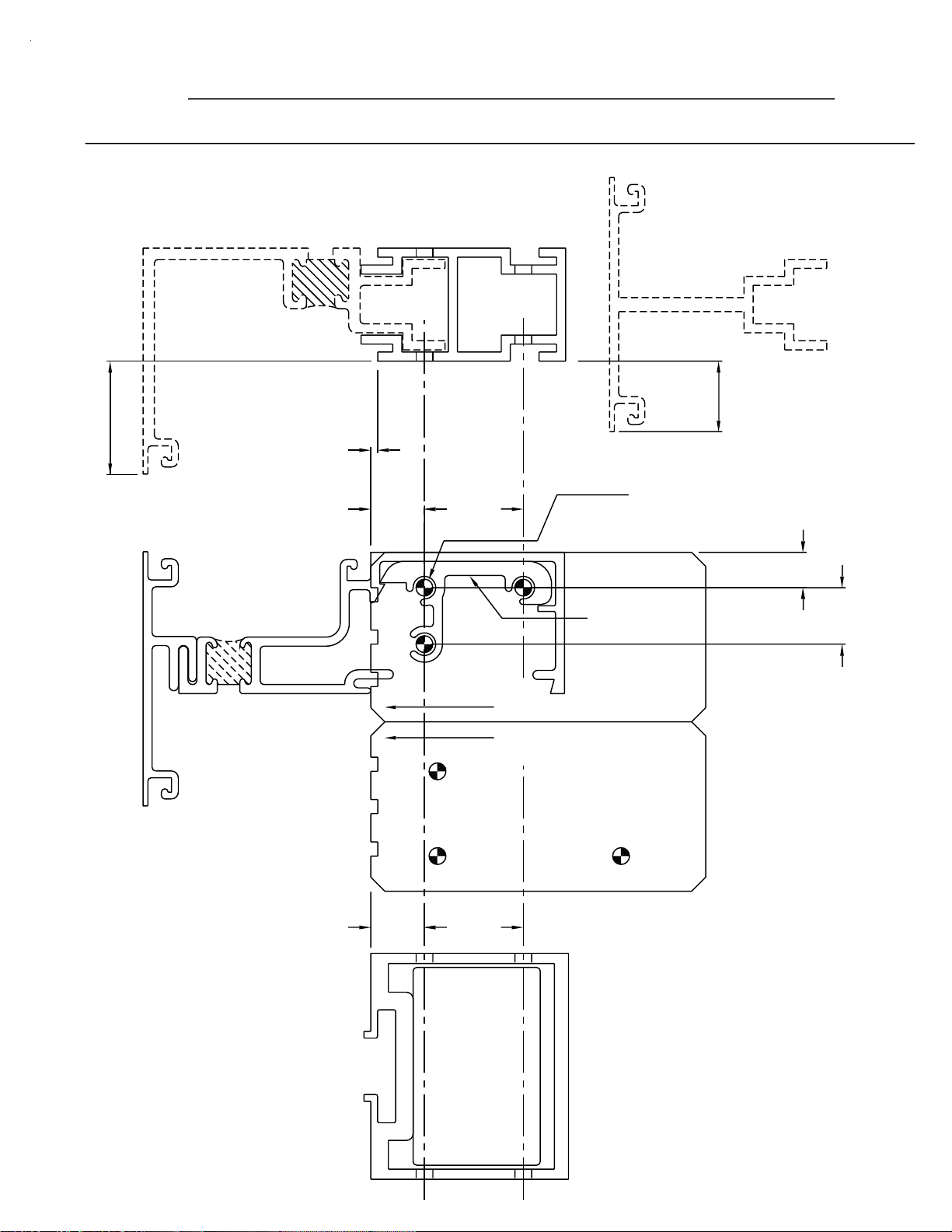

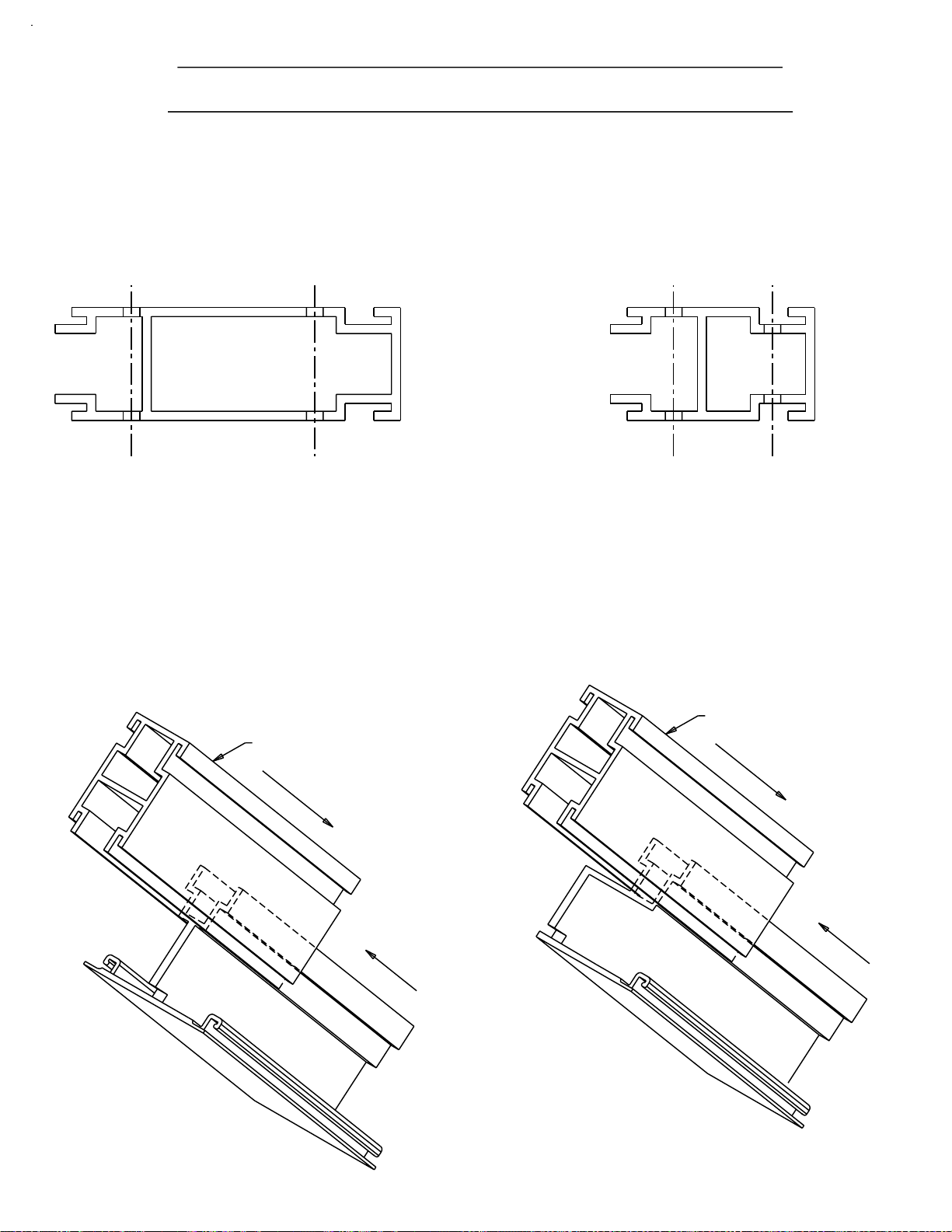

SECTION III A - FABRICATION

DRILLING TEMPLATE - 901/902 INTERMEDIATE HORIZONTAL

2 PC. CAPTURED

JAMBS

VERTICALS

1.000

5/8" NOTCH

AT VERTICALS

AT JAMB

1" NOTCH

8594

OR 8593

NOTE: OFFSET

.062

#10-24x

1/2" F.H.

(S110)

8583

.590

9578

TOP OF

HORIZONTAL

1.625

901/902 SYSTEMS

FRONT OF MULLION

9576

OR 9579

.625

.149 DIA. (#25 DRILL)

FOR #10-24 x 1 3/4" P.H.S.M.S.

(3) MRF8

.312

.750

K176

FRONT OF MULLION

903/904 SYSTEMS

(9470)

8499

.590

HORIZONTAL

TOP OF

1.625

BUTT GLAZED

VERTICALS

7028

7253

JDA 10/2001

Page 14

PAGE 12

SECTION III B - FABRICATION

DRILLING TEMPLATE - 903/904 INTERMEDIATE HORIZONTAL

1.000

8594

OR 8593

NOTE: OFFSET

9586/9564

2 PC. JAMB

.062

.475

9575

.875

TOP OF

HORIZONTAL

K141

(9567)

CAPTURED

9579

OR 9576

.149 DIA. (#25 DRILL)

FOR #10-24 x 1 3/4" P.H.S.M.S.

(3) MRF8

VERTICALS

.625

.313

.500

9565

.475

903/904 SYSTEMS

FRONT OF MULLION

.875

9559

FRONT OF MULLION

901/902 SYSTEMS

HORIZONTAL

TOP OF

BUTT GLAZED

VERTICALS

9558

JDA 10/2001

Page 15

SECTION III C - FABRICATION

HEAD AND SILL CAN

INCLUDES CAPTURED AND BUTT

GLAZED MULLION SYSTEMS

STEP 1)

Measure the opening to determine the cut length of the head

and sill frame components. Allow for shims if applicable.

STEP 2)

Cut head and sill cans to frame width. This includes any

"2" color covers that are being used.

NOTE: Expansion/splice joints are required in elevations that exceed

20’-0" in width. Plan for expansion/splice joints to fall at

the center of the nearest lite and adjust cut lengths accordingly.

PAGE 13

1/4"

OPT.

SHIM

JAMB

HEAD & SILL LENGTH

20 FT. MAXIMUM

20 FT. TYPICAL

[FIG. 1]

1/2"

1/4"

OPT.

SHIM

JAMB

EXPANSION/SPLICE

JOINT

STEP 3)

Drill 1/4" weep holes in sill can 6" from jambs and 48" on

center or if the length is less than 48", drill (1) per lite. This

includes 2 color covers, installed prior to weeping and anchoring.

See Fig. 3 on Page 14.

NOTE: Sill cans with riser legs are bottom weeped and sill cans with flat

bottoms are face weeped.

HCW6

HOLE IN BOTTOM

901/902

[FIG. 2]

HCW6

903/904

HOLE IN FACE

DPS 7/2001

Page 16

SECTION III C - FABRICATION

PAGE 14

HEAD AND SILL CAN

INCLUDES CAPTURED AND BUTT

GLAZED MULLION SYSTEMS

TAP LIGHTLY

TO SNAP IN PLACE

HOOK COVER OVER LEG

CRIMP THIS LEG SLIGHTLY TO

DRILL 1/4" DIA. WEEP HOLES

THRU COVER AND SILL

OPTIONAL SEAL

(LEAVE 1/4" SPACE

AT WEEP HOLES)

LOCATE PRIMARY SEAL

BEHIND COVER LEG.

[FIG. 3]

STEP 4) 90 AND 135 CORNER FABRICATION

PREVENT COVER FROM WALKING

OUT OF POSITION WITH THERMAL

EXPANSION.

(CONT.)

Head and sill cans are mitered for inside or outside corners.

This includes 2 color covers installed prior to anchoring.

See Fig. 4 below.

NOTE: An expansion/splice joint located 12" from the miter joint is

recommended to reduce expansion at the miter joint.

1/2"12"

90

FRAME DIM.

12"

1/2" 12"

1/2"

FRAME DIM.

12"

1/2"

FRAME DIM.

TOP VIEW OF THE SILL CAN AT

90˚ OUTSIDE AND 135˚ INSIDE CORNERS.

135

[FIG. 4]

DPS 7/2001

Page 17

SECTION III C - FABRICATION

PAGE 15

HEAD AND SILL CAN

STEP 5) Weep Baffle Installation

1/2 HCW6

SEALANT

BAFFLE

[FIG. 5]

(CONT.)

APPLY A SMALL AMOUNT OF SILICONE TYPE

SEALANT TO THE BAFFLES THAT WILL

STRADDLE THE DRILLED WEEP HOLE, AND

LOCATE THEM OVER THE WEEP HOLES AS

SHOWN. DO NOT PLUG THE WEEP HOLES

WITH SEALANT. CUT HCW6 IN HALF TO

CREATE CORRECT SIZE BAFFLES.

SEE FIG. 17 ON PAGE 23.

BAFFLE

WEEP HOLE

STEP 6) End Dam Installation

Install the dams in the ends of the head and sill flush with the end.

Tool sealant over the inside edges of the dam to insure a water seal.

The end dam must seal to the web of the jamb member (not shown).

See Fig. 6.

WEEP HOLE

SEALANT

[FIG. 6]

HN30 - 1/4" GLAZING POCKET [901 & 903]

HN31 - 1" GLAZING POCKET [902 & 904]

DPS 7/2001

Page 18

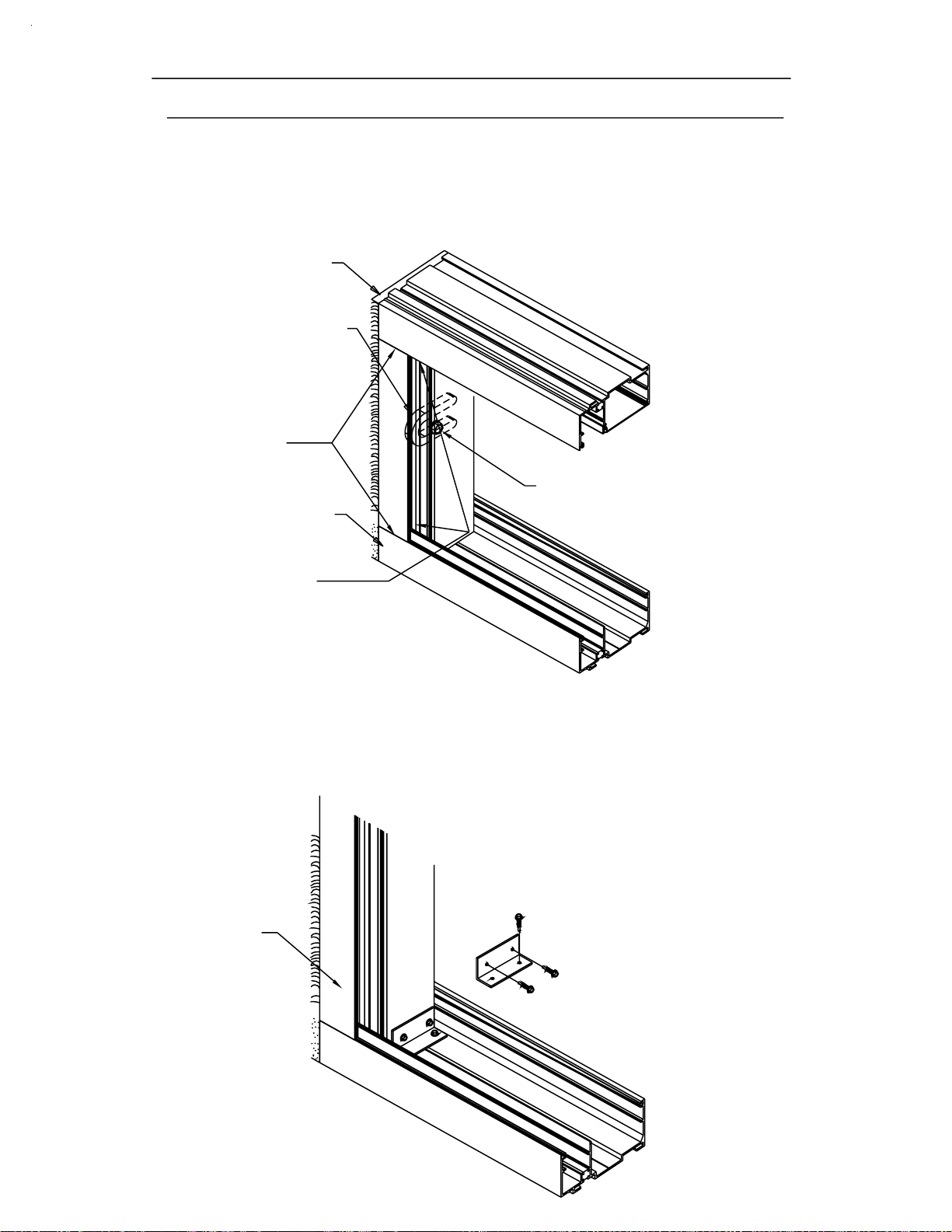

SECTION III D - FABRICATION

HEAD AND SILL CAN FILLER

PAGE 16

1) CAN FILLER CUT LENGTHS

Step 1) Determine center lines of each vertical mullion.

Step 2) Jamb to first mullion cut length = End of head/sill can

to center line of first mullion minus 1 1/2".

Step 3) Mullion to mullion cut length = Center line to center line

minus 1".

(Head and sill cans run through. Can fillers run mullion to mullion,

and mullion to jamb.)

CAN FILLER LENGTH

1"

1"

CAN FILLER

CUT LENGTH

MULLION

CENTER LINE

2"

1"

C

CENTER LINE

L

[FIG. 7]

C

L

(CAPTURED MULLION SYSTEMS)

1"

C

CAN FILLER LENGTH

MULLION MULLION

CENTER LINE

L

1"

C

L

2) CAN FILLER CUT LENGTHS

Step 1) Determine center lines of each vertical mullion.

Step 2) Jamb to first mullion cut length = End of head/sill can

to center line of first mullion minus 2".

Step 3) Mullion to mullion cut length = Center line to center line

minus 2".

(Head and sill cans run through. Can fillers run mullion to mullion,

and mullion to jamb.)

1"

1"

CAN FILLER

CUT LENGTH

MULLION

CENTER LINE

2"

CAN FILLER LENGTH

2"

MULLION

CENTER LINE

C

L

[FIG. 8]

C

L

(BUTT GLAZED SYSTEMS)

CAN FILLER LENGTH

2"

MULLION

CENTER LINE

C

L

2"

C

L

DPS 7/2001

Page 19

SECTION III E - FABRICATION

*

VERTICAL INTERMEDIATE AND 2 PIECE JAMB

(BUTT GLAZED and CAPTURED MULLION SYSTEMS)

PAGE 17

STEP 1)

SERIES

901

902

Cut the captured mullion/jamb backs to the lengths shown in chart A

below. This will allow 1/8" clearance inside the head can.

Cut the butt glazed mullions to the lengths shown in chart A below.

This will allow 1/4" minimum clearance inside the head can.

Cut the captured mullion face and the 2 pc. jamb face to the D.L.O. height.

SYSTEM

DEPTH

HEAD/SILL

CAN #

9479

MULL #

9578

DESCRIPTION

CAPTURED VERTICAL

MULLION BACK

CUT LENGTHS

D.L.O. + 3 3/4"

4 1/2"

D.L.O. + 3 5/8"

D.L.O. + 4 1/4"

D.L.O. + 4 1/8"

D.L.O. + 3 11/16"

D.L.O. + 3 1/2"

D.L.O. + 3 1/4"

5 1/4"

9479

9484 or 9845

9484 or 9845

9484 or 9845

1G66

1G66

7253/7028

9578

7253/7028

1G41

NOTCHING REQ.

1G41

NOTCHING REQ.

7253/7028

BUTT GLAZED MULLIONS

CAPTURED VERTICAL

MULLION BACK

BUTT GLAZED MULLIONS

CAPTURED VERTICAL

I-BAR MULLION

CAPTURED VERTICAL

I-BAR MULLION

BUTT GLAZED MULLIONS

903

904

901/903

902/904

901/902

903/904

NOTE:

9476

9575

CAPTURED VERTICAL

MULLION BACK

D.L.O. + 3 1/4"

3 1/4"

D.L.O. + 3 1/8"

D.L.O. + 3 1/4"

D.L.O. + 3 1/8"

D.L.O. + 3 1/2"

D.L.O. + 3 3/8"

*

D.L.O.

D.L.O.

4"

4 1/2"-3 1/4"

5 1/4" - 4"

4 1/2"-5 1/4"

3 1/4" - 4"

9476

9477

9477

9468 or 8716

9468 or 8716

9558/9559

9575

9558/9559

9575

9558/9559

9579 & 8593

9576 & 8594

9580 & 8589

9577 & 8590

BUTT GLAZED MULLIONS

CAPTURED VERTICAL

MULLION BACK

BUTT GLAZED MULLIONS

CAPTURED VERTICAL

MULLION BACK

BUTT GLAZED MULLIONS

VERTICAL MULLION &

2 PC JAMB

FACE MEMBERS

GLASS STOPS

[CHART "A"]

HEAD AND SILL CANS, 9476, 9477, AND 1G66, DO NOT HAVE A RELIEF FOR

THE PERIMETER FASTENER HEAD. THEREFORE, AN ADDITIONAL

1/4" CLEARANCE +/- IS REQUIRED WHEN USING THESE CANS.

THIS CLEARANCE IS INCLUDED IN THE CUT LENGTH FORMULAS

IN CHART A.

Quick Set

If 2 color covers are used at the head and sill, the cut length of the vertical

*

mullion face member is D.L.O. minus 1/8".

JDA 4/2002

Page 20

SECTION III E - FABRICATION

PAGE 18

STEP 2)

VERTICAL INTERMEDIATE AND 2 PIECE JAMB

(BUTT GLAZED and CAPTURED MULLION SYSTEMS)

Notch the top of the mullion and jamb face 1/8" x 1/4" as shown in

Fig. 9 below. This prep is for ease of installation of the jamb and

vertical mullion.

8594

8593

(CONT.)

TOP OF MULLION FACE

9579 or 9576

1/4"

[FIG. 9]

1/8"

DPS 7/2001

Page 21

SECTION III E - FABRICATION

PAGE 19

STEP 3)

STEP 4)

VERTICAL INTERMEDIATE AND 2 PIECE JAMB

(BUTT GLAZED and CAPTURED MULLION SYSTEMS)

If horizontal intermediates are incorporated, drill for shear block

attachment screws using the drilling templates on pages 11 & 12.

Typical drilled members are shown in Fig. 10 below.

Jamb members will have preps on one side only.

9575

9578

[FIG. 10]

Cut length for the vertical mullion and jamb face is similar.

Please refer to chart ’A’ on page 17 and notching required

shown on page 18.

(CONT.)

STEP 5)

Slide the mullion face onto the mullion back as shown in Fig. 11.

See Section IV B for installation procedures.

JAMB BACK

MULLION BACK

MULLION

FACE

JAMB FACE

[FIG. 11]

DPS 7/2001

Page 22

SECTION III F - FABRICATION

t

INSULBAR INTERMEDIATE VERTICAL

PAGE 20

STEP 1)

STEP 2)

STEP 3)

Cut the thermal strut vertical mullion to the length shown in [CHART "A"]

on page 17 (SECTION III E - FABRICATION).

Notch the top of the mullion face 1/8" x 1/4" as shown in Fig. 12.

This prep is for ease of installation of the vertical mullion.

Notch the TOP of the mullion to leave the appropriate portion

as shown in Fig. 12 below.

The 2" dimension take n from the exterior face will be applicable

to all solid vertical intermediate mullions with 1" glazing.

COMPOSIT E #1G41 SHO WN

OTHER MULLIONS ARE SIMILAR

9546

9547

TOP OF MULLION FACE

1/8"

3/32"

2"

1/4"

3" (VARIES)

[FIG. 12]

1 17/32" @ #9484 & #9485 CAN

NOTCHING AT TOP OF MULLION

S902

{

1 5/8" @ 1G66 I-BAR CAN

S904

1 5/32" @ #9468 & #9477 CAN

{

1 1/2" @ #8716 CAN

Quick Se

BAH 4/2005

Page 23

SECTION III F - FABRICATION

Q

t

PAGE 21

STEP 4)

THERMAL STRUT INTERMEDIATE VERTICAL

Notch the BOT TOM of the mullion to leave the appropriate portion

as shown in Fig. 13 below.

The 2" dimension take n from the exterior face will be applicable

to all solid vertical intermediate mullion with 1" glazing.

COMPOSIT E #1G41 SHO WN

OTHER MULLIONS ARE SIMILAR

9546

9547

(CONT.)

BOTTOM OF MULLION FA CE

2 3/16" @ #9484 & #9485 CAN

2"

3" (VARIES)

[FIG. 13]

NOTCHING AT THE BOTTOM OF THE MULLION

uick Se

S902

{

1 29/32" @ 1G66 I-BAR CAN

BAH 4/2005

S904

{

2 3/16" @ #8716 CAN

1 25/32" @ #9468 & #9477 CAN

Page 24

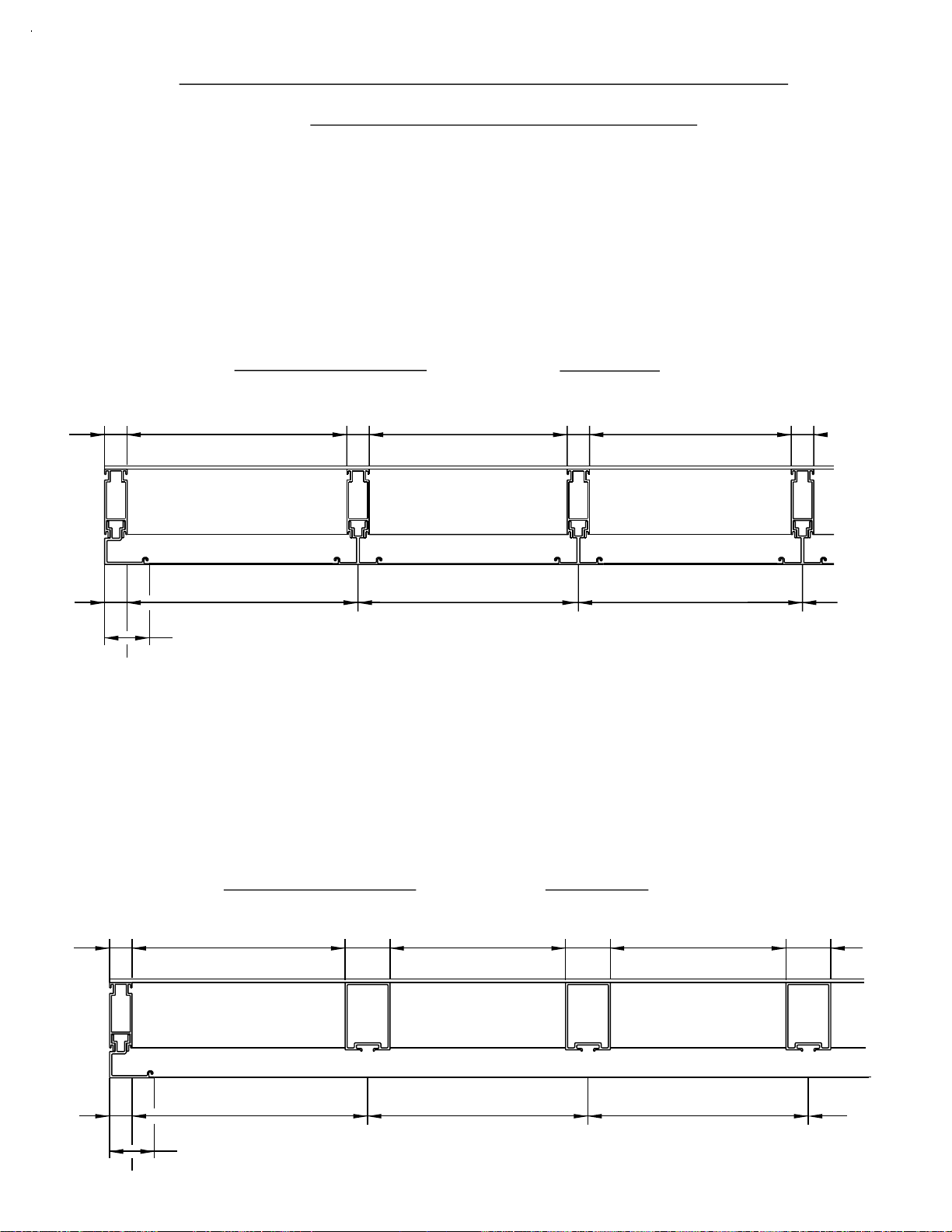

PAGE 22

SECTION III G - FABRICATION

INTERMEDIATE HORIZONTAL

HORIZONTAL CUT LENGTH FORMULAS

CUT LENGTH = EXTERIOR D.L.O. + 1" {at 2 pc. JAMB to BUTT GLAZED MULLION

CUT LENGTH = EXTERIOR D.L.O. + 1 5/8" {at 2 pc. JAMB to

CAPTURED VERTICAL MULLION

CUT LENGTH = EXTERIOR D.L.O. + 1 1/4" {at CAPTURED VERTICAL MULLION to

CAPTURED VERTICAL MULLION

CUT LENGTH = EXTERIOR D.L.O. {at BUTT GLAZED MULLION to

BUTT GLAZED MULLION

THE FOLLOWING PREPS APPLY TO 902 AND 901 ONLY.

SYSTEMS 903 AND 904 HAVE A ’SNAP FIT’ TO THE SHEAR

BLOCK AND DO NOT REQUIRE DRILL/SCREW ATTACHMENT

OR NOTCHING.

NOTCH

5/8" LONG

AT VERTICALS

NOTCH

1" LONG

AT JAMB

1" x 7/32" NOTCH IS REQUIRED AT 2 PC. JAMBS ONLY.

5/8" x 7/32" NOTCH IS REQUIRED AT CAPTURED VERTICALS ONLY.

#10-24x

1/2" F.H.

(S110)

8583 SHOWN

9469 SIMILAR

PLEASE REFERENCE PAGE 35 FIG. 36.

[Fig. 14]

*

7/32"

[Fig. 15]

*

.344 (11/32") DRILL

BOTH ENDS

1"

5/8" NOTCH AT

CAPTURED VERTICALS

.542

8583

1" NOTCH AT

2 PC. JAMBS ONLY

DPS 7/2001

Page 25

SECTION III G - FABRICATION

PAGE 23

STEP 1)

NOTE:

INTERMEDIATE HORIZONTAL

(CONT.)

Cut horizontal face member to span 3 lites (or a maximum

of 15’-0"). Allow 1/4" at splice joints for expansion.

Splice ONLY at center lines of vertical mullions.

See Fig. 16 below.

D.L.O. 2"

INTERIOR

D.L.O.

D.L.O.2"

[FIG. 16]

HORIZONTAL FACE LENGTH (15 ft. max.)

Due to the expansion characteristics of the aluminum face member

and also to maintain the 1/4" splice joint, 15 feet is the

{

recommended cut length for the face member.

2"

D.L.O.

1/4"

STEP 2)

HCW6

5/8"

WEEP

HOLES

Weep baffles are cut from (1) HCW6, halved, to provide (2)

2" x 3/8" x 1/2" weep baffles. See Fig. 17 below.

1/2"

2"

2"

3/4"

[FIG. 17]

48" O.C.

3/8"

1/2"

9565 SHOWN

8499 SIMILAR

STEP 3)

APPLY BAFFLES WITH a SMALL

[FIG. 18]

AMOUNT of SILICONE TYPE SEALANT.

Drill 1/4" diameter weep holes in the horizontal face member at 48"

on center or 2 per lite at quarter points. Install weep baffles

over holes with silicone. Do not plug weep holes with silicone.

See Fig. 18 above.

DPS 7/2001

Page 26

SECTION III G - FABRICATION

PAGE 24

INTERMEDIATE HORIZONTAL

(Cont.)

CUT LENGTH FOR GLASS STOP = D.L.O. MINUS 1/32".

VERTICAL to VERTICAL - INTERIOR D.L.O.

CUT LENGTH FOR FACE MEMBER = 3 Lites - Not to exceed 15’

at BUTT GLAZE VERTICAL APPLICATIONS.

SYSTEM

& DEPTH

901 - 4 1/2"

902 - 5 1/4"

903 - 3 1/4"

904 - 4"

INTERM. HORIZ.

EXTRUSION NOS.

9469/9587/9565

8583/8584/8499

9586/9566/9565

9564/9566/9565

SHEAR BLOCK

REQUIRED

K-176

K-176

K-141

K-141

[CHART B]

STEP 4)

Figure the splice joint location to fall at the center line of a

vertical mullion, with respect to the 3 lite/15’ guideline.

SET SPLICE PLATES IN

SILICONE ONE END ONLY.

FILL VOID WITH SILICONE

CLEAN EXCESS FOR A

NEAT APPEARANCE

CENTER LINE OF VERTICAL MULLION

[FIG. 19]

EXPANSION JOINT

1/4"

DPS 7/2001

Page 27

SECTION IV A - INSTALLATION

HEAD AND SILL CAN ANCHORING

PAGE 25

STEP 1)

END DAMS

Fasten head and sill cans to surround through back portion

of the can shape. Seal over all fastener heads in sill can.

See Fig. 20 below.

901/903 - HN30

END DAMS AT

JAMBS ONLY

SEALANT

902/904 - HN31

END DAMS

1/4" DIAMETER

MINIMUM FASTENERS

AT 3" EACH SIDE OF

VERTICAL MULLIONS

AND 24" MAXIMUM

ON CENTER.

(TYPICAL ALL SYSTEMS)

SHIMS ARE OPTIONAL WITH

THESE HEAD/SILL CANS

#9479 - S901

#9484 - S902

#9476 - S903

[FIG. 20]

#9468 - S904

DPS 7/2001

Page 28

SECTION IV A - INSTALLATION

HEAD AND SILL CAN SPLICE

PAGE 26

STEP 1)

[FIG. 21]

The main purpose of this operation is to ensure a water tight

seal between the two lengths of the sill can and prevent water from

entering the interior of the building. See Fig. 21 below.

SILL CAN

SPLICE SLEEVE

1" WIDE

BOND BREAKER

TAPE WRAPPED AROUND

THE SPLICE SLEEVE

AT THE CENTER.

SPLICE

JOINT

1/2"

STEP 2)

To ensure proper adhesion of sealant to all parts, clean the sill cans

at the splice area and the splice sleeve with "MEK" to remove all oils.

Slide the splice sleeve into the glazing pocket and center the sleeve

over the splice joint. See Fig. 22 below.

WM01 - 1" WIDE BOND

BREAKER TAPE WRAPPED

AROUND THE SPLICE SLEEVE

AT THE CENTER AND USED AS

A CAULK BACKER.

CAN # / SPLICE #

901 - 9479 / K376

902 - 9484 / K377

902 - 1G66 / K917

902 - 9845 / K375

903 - 9476 / K378

904 - 9477 / K379

904 - 9468 / K379

904 - 8716 / K375

SPLICE SLEEVE WITH

BOND BREAKER TAPE

CENTERED ON THE

SPLICE JOINT

[FIG. 22]

CLV 7/2001

Page 29

SECTION IV A - INSTALLATION

PAGE 27

STEP 3)

"A"

HEAD AND SILL CAN SPLICE

Apply a 1/4" bead of sealant over the ends of the splice sleeve.

Then tool the sealant across the edges of the sleeve and

onto the glazing pocket cavity surface. Be sure to work out any

air gaps that might occur. See Fig. 23 below.

APPLY SEALANT

ACROSS THE GAP TO

ADHERE TO THE SILL CAN

AND THE SPLICE SLEEVE.

WM01 - 1" WIDE BOND

BREAKER TAPE WRAPPED

AROUND THE SPLICE SLEEVE

AT THE CENTER AND USED AS

A CAULK BACKER.

(cont.)

TOOL SEALANT

TO ADHERE TO

BOTH SURFACES.

STEP 4)

STEP 5)

TOOL SEALANT

OVER ENDS

[FIG. 23]

"A"

CENTER VERTICAL

LEG OF SILL CAN

Apply sealant to the center vertical leg of the can, marrying

the seal to the splice sleeve and the two can members.

Proceed to the exterior face. Apply sealant to the exterior

splice joint gap, and tool sealant smooth.

BOND BREAKER TAPE

1.000

Quick Set

SECTION "A-A"

1/2"

SILL CAN

JDA 2/14/02

Page 30

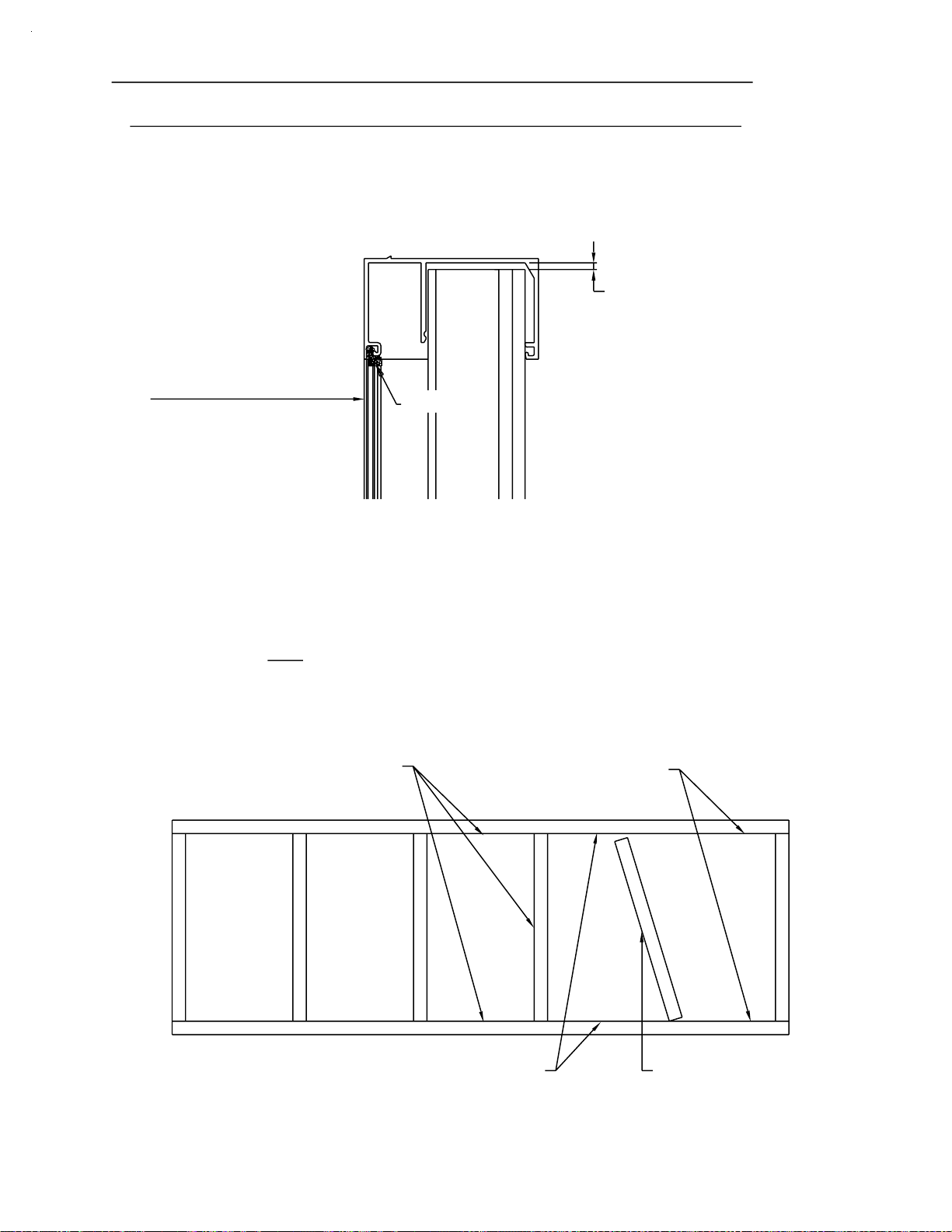

SECTION IV B - INSTALLATION

2 pc. JAMBS AND INTERMEDIATE VERTICALS

PAGE 28

STEP 1)

Position the jamb assembly angled above the sill can at

the jamb location. Let the back portion of the jamb set

into the back portion of the sill can.

See Fig. 24 below.

Apply a butyl type sealant to

the glazing gasket receiver track

at the top and bottom

of the jamb location.

NOTE THAT THE

FACE PORTION IS

SHORTER THAN THE

BACK PORTION.

SWING UP

PERIMETER

STEP 2)

TAKE CARE NOT TO SCRATCH

THE FINISH ON THE HEAD CAN.

JAMB MEMBER

[FIG. 24]

While holding the assembly toward the exterior, swing the jamb

assembly up, letting the mullion back enter the back portion of

the head can. Using this procedure, the 1/8" notch in the face

portion of the vertical will allow clearance around the glazing

leg at the head.

HOLD JAMB OUT

UNTIL IT IS VERTICAL.

SEALANT IN GASKET

RECEIVER TRACK

See Fig. 25 below.

[FIG. 25]

THEN PUSH BACK

UNTIL THE FACE IS FLUSH

NOTCH IN THE VERTICAL

MULLION FACE

DPS 7/2001

Page 31

SECTION IV B - INSTALLATION

PAGE 29

2 pc. JAMBS AND INTERMEDIATE VERTICALS

NOTE:

AFTER THE JAMB IS IN PLACE,

APPLY A HEAVY COAT OF BUTYL

TYPE SEALANT AT THE HEAD AND

SILL GLAZING LEG AND ACROSS

THE TOP OF THE END DAMS.

The back member of the (2) pc. jamb and the intermediate vertical

will align the head and sill cans as it is installed.

END DAM

INSIDE

STANDARD HORSESHOE

SHIM, TYPICAL.

END DAM

INSIDE

(CONT.)

ATTACH THE 2 pc. JAMB

TO THE SURROUND

3" FROM TOP AND BOTTOM

AND 24" O.C. MAXIMUM.

AFTER THE JAMB IS IN PLACE,

SEAL ACROSS THE JOINT OF

THE JAMB-HEAD/SILL IN THE

GLAZING POCKET.

THIS STEP IS AT THE JAMBS ONLY.

2 pc. JAMB, TYP.

[FIG. 26]

2 pc. JAMB ANCHOR CLIP INSTALLATION

K433 for S901/S902

K434 for S903/S904

ANCHOR CLIPS ARE

REQUIRED AT THE

HEAD AND SILL CAN.

[FIG. 27]

ONLY AT PERIMETER

JAMBS.

DPS 7/2001

Page 32

SECTION IV B - INSTALLATION

PAGE 30

2 pc. JAMB AND INTERMEDIATE VERTICALS

STEP 3)

Apply a butyl type sealant to

the glazing gasket receiver track

at the top and bottom

of the vertical mullion location.

Position the vertical mullion assembly angled above the sill can at

approximately the vertical location. Let the back portion of the

vertical set into the back portion of the sill can.

See Fig. 28 below.

(CONT.)

NOTE THAT THE

FACE PORTION IS

SHORTER THAN THE

BACK PORTION.

STEP 4)

TAKE CARE NOT TO SCRATCH

THE FINISH ON THE HEAD CAN.

SWING UP

VERTICAL

INTERMEDIATE

[FIG. 28]

Swing the captured mullion assembly up, letting the mullion back enter

the back portion of the head can. The notch in the face portion

of the vertical will allow clearance around the glazing leg at the head.

See Fig. 29 below.

HOLD MULLION OUT

UNTIL IT IS VERTICAL.

SEALANT IN GASKET

RECEIVER TRACK

[FIG. 29]

NOTCH IN THE VERTICAL

MULLION FACE

DPS 7/2001

Page 33

SECTION IV B - INSTALLATION

PAGE 31

2pc. JAMBS AND INTERMEDIATE VERTICALS

STEP 5)

STEP 6)

After the vertical mullion is in position, let it move back

flush with the exterior face of the head and sill cans.

See Fig. 30 below.

CLEARANCE VARIES

SEE CHART ’A’ ON PAGE 17 FOR

MULLION CUT LENGTHS THAT

ESTABLISH THIS CLEARANCE.

MOVE BACK to FLUSH

FACES of MEMBERS

SEALANT

[FIG. 30]

Tap vertical mullion tight against the can fillers already in place.

Then repeat the installation of the next can fillers and vertical

mullions. Check every third mullion for correct spacing.

(CONT.)

NOTE:

MULLIONS INSTALLED TO HERE

[FIG. 31]

Install the last can filler of a run before the second to last.

This will allow tilting the last vertical mullion into place.

See Fig. 31 below.

CAN FILLERS AND VERT.

THESE CAN FILLERS ARE HELD OFF

UNTIL THE LAST VERTICAL IS INSTALLED

CAN FILLERS INSTALLED

TILT THE LAST VERTICAL INTO

POSITION AGAINST THE

CAN FILLERS

DPS 7/2001

Page 34

STEP 1)

The vertical butt glazed mullion is set into the rear portion of the HEAD/SILL

cans similar to the captured mullion. Then it is tapped against the can

fillers as before. Proceed to the next vertical.

See Fig. 32 below.

PAGE 32

SECTION IV C - INSTALLATION

BUTT GLAZED VERTICALS

CAN FILLER

INSTALLED

SILL CAN

VERTICAL BUTT

GLAZED MULLION

[FIG. 32]

DPS 7/2001

Page 35

SECTION IV C - INSTALLATION

PAGE 33

STEP 2)

#7256 MULL HALF MUST BE

INSTALLED BEFORE #7255

MULL HALF.

#7256

BUTT GLAZED VERTICALS

(cont.)

The butt glazed corners are (2) piece and require the first

half of the corner to be installed and then the other half.

Refer to the figures below to determine the related parts.

#7255

SILL CAN

for 90#7255

CORNER

(901 & 902)

NOTE:

Below are butt glazed corner mullion halves for each system

pertaining to available degree of corner combinations.

(2) 7260 FOR

135 CORNER

(901 & 902)

THIS HALF OF

MULLION IS SET

IN HEAD/SILL CAN

FIRST.

[FIG. 33]

APPLY DOUBLE

FACE TAPE

THIS HALF OF

MULLION IS SET

IN HEAD/SILL CAN

FIRST.

(2) 9563 FOR

90 CORNER

(903 & 904)

APPLY DOUBLE

(2) 9562 F0R

135 CORNER

(903 & 904)

FACE TAPE

THIS HALF OF

MULLION IS SET

IN HEAD/SILL CAN

FIRST.

[FIG. 34]

DPS 7/2001

Page 36

SECTION IV C - INSTALLATION

PAGE 34

STEP 3)

BUTT GLAZED VERTICALS

(cont.)

TYPICAL SHEAR BLOCK ATTACHMENT FOR S.S.G. CORNERS.

90 CORNER SHOWN BELOW IN FIG. 35, OTHERS SIMILAR.

ATTACH THE HORIZONTAL TO THE SHEAR BLOCKS WITH THE

FLAT HEAD SCREW SUPPLIED IN THE SHEAR BLOCK PACKAGE.

EDGE OF

MULLION

8583 HORIZ. SHOWN

OTHER HORIZ. TYP.

STK4

1.132"

2.117

K493

SHEAR BLOCK

PACKAGE

[FIG. 35]

STV2

7255/7256

S.S.G. CORNER

MULLION SHOWN

OTHERS SIMILAR

901/902 - 7255/7256 90 DEG. INSIDE OR OUTSIDE - K493

901/902 - 7260/7260 135 DEG. OUTSIDE - K490

3/4" TO TOP

OF HORIZONTAL

901/902 - 7260/7260 135 DEG. INSIDE - K491

DPS 7/2001

Page 37

SECTION IV D - INSTALLATION

INTERMEDIATE HORIZONTAL

PAGE 35

STEP 1)

Shear block locations may be drilled before verticals are installed

or after installation.

Refer to pages 11 and 12 for drilling templates.

STEP 2)

STEP 3)

TYPICAL VERTICAL MEMBER

Install shear block to vertical using (3) #10-24 x 1 3/4" PL-PH-SMS.

"Butter" ends of horizontals with a butyl type sealant (nonhardening).

2 pc. JAMB SHOWN

K-141 for 903/904

K-176 for 901/902

(Includes (3) MRF8 SCREWS

& (1) S110 SCREW)

BUTYL TYPE SEALANT

ACROSS THE ENDS

STEP 4)

Rotate the horizontal over the shear block until it snaps in place.

901/902 shear block and horizontal do not snap fit. The

horizontal is screw attached to the shear block with

(2) #12-24 x 1/2" PH-FH-TYPE "F" SCREWS. (#S110)

See Fig. 37 below.

ROTATE THE HORIZONTAL OVER

THE SHEAR BLOCK UNTIL IT

SNAPS INTO PLACE.

ROTATE

9586 - 903

9564 - 904

K141

[FIG. 36]

HORIZONTAL

904 SHOWN

903 SIMILAR

Refer to Page 22 for

901-902 Horizontal Notching.

9469 - 901

8583 - 902

S110

K176

903/904

[FIG. 37]

901/902

JDA 10/2001

Page 38

SECTION IV D - INSTALLATION

.

6

PAGE 3

STEP 5)

904 SYSTEM SHOWN

BUTYL TYPE SEALANT

INTERMEDIATE HORIZONTAL

(CONT.)

Water deflectors are used at both ends of horizontal intermediates and

are intended to divert any water in the glazing pocket from reaching and

eventually sitting on top of the insulated glass unit below. Water

deflectors are not used with V.B.G. mullions or with 901 and 903.

See Fig. 38 below.

HWD1

WATER DEFLECTOR

NOTCH LEG AT

902 SIMILAR

CAPTURED JAMB SHOWN,

CAPTURED VERTICAL

INTERMEDIATE IS SIMILAR.

"V" NOTCH

NOTE:

POSITION WITH NOTCH

TOWARD THE EXTERIOR

HORIZONTAL

STEP 6)

[FIG. 38]

The horizontal bridge is intended to prevent any water in the glazing

pocket from running down the butt glazed vertical intermediate at the

vertical. Correct sealing is important in this step.

Systems 901 and 903 use K-143.

Systems 902 and 904 use K-142.

BUTT GLAZED

MULLION

HORIZONTAL

RUN SEALANT INTO

GASKET RACE

Quick Set

HORIZONTAL BRIDGE

[FIG. 39]

SEAL AROUND BRIDGE

WITH NONHARDENING

BUTYL TYPE SEALANT.

JDA 2/14/02

Page 39

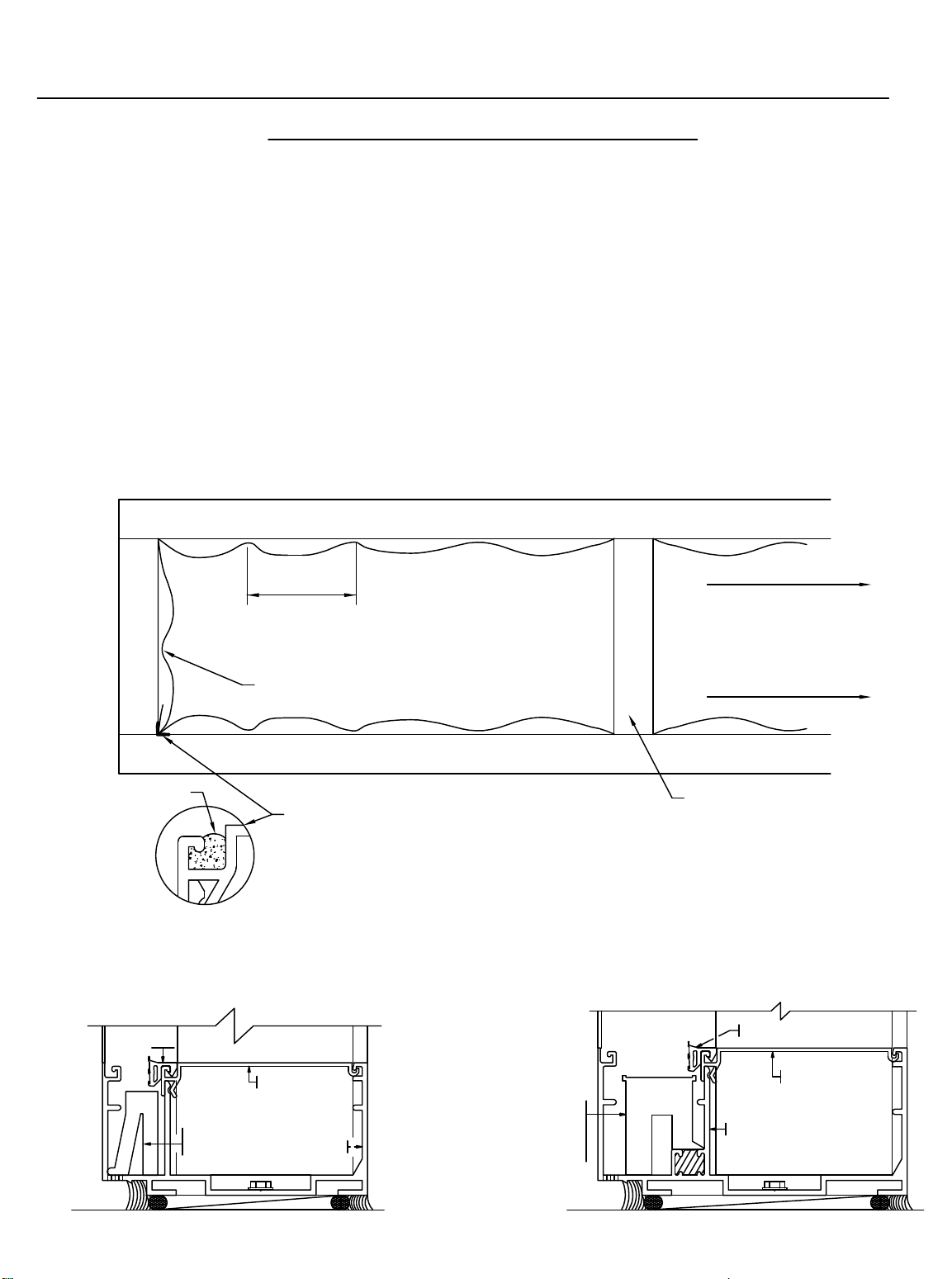

PAGE 37

SECTION V A - GLAZING PROCEDURES

FOR BUTT GLAZED VERTICAL

STEP 1)

JAMB

Glazing gasket (W164) will be continuous in the head / sill cans.

The jamb gasket will run between. The gasket will run across

the front of the butt glazed vertical. The glass will be installed

from the exterior; install the interior gasket as follows.

Start by pushing the gasket in place at the ends. Move to

the middle, then to quarter points and work the "WAVES" toward

the ends.

DO NOT STRETCH THE GASKET OR IT WILL RETURN

TO ITS ORIGINAL FORM, CREATING GAPS AT THE GASKET

INTERSECTIONS.

See Fig. 40 below.

HEAD

GASKET LENGTH = D.L.O. + 2%

8" - 12"

VARIES

GASKET RUNS TO JAMB

SEALANT

STEP 2)

JAMB GA S KET TO

RUN THRU.

SILL

BEFORE THE GASKETS ARE INSTALLED, SEAL 1"

VERTICALLY AND HORIZONTALLY IN THE GASKET

RACES WITH SILICONE T YPE SEALANT AT ALL

CORNER S . AFTER INSTAL LATION SEAL THE ENDS

OF ALL GASKETS. SEALING RACES & GASKET END IS

REQUIR ED AT TH E INTERI OR OF THE SYSTEM.

EXTERIOR SEALANT AT RACE AND GASKETS ARE

OPTIONAL.

GASKET RUNS TO JAMB

BUTT GLAZED

VERTICAL

[FIG. 40]

Install setting block assemblies at 1/4 points in the sill can glazing

pockets. See Fig. 41 below.

W164

HNA1 - 901

HNA2 - 903

9485

9479

HN33 - 902

HN34 - 904

FU08 @ 1G66

902 I-BAR CAN

W164

9485

9484

[FIG. 41]

CDB 9/2009

Page 40

PAGE 38

SECTION V A - GLAZING PROCEDURES

STEP 3)

BUTT GLAZED

MULLION

FOR BUTT GLAZED VERTICAL

(CONT.)

Refer to page 17 for the cut lengths for the butt glazed mullions.

Cut the can fillers to the correct length to position the vertical mullions

on the required center lines. Refer to page 31 to set the mullions.

Install the glazing gasket to the interior gasket track as shown below.

GASKET RUNS THRU

AT VERTICALS

CAN

FILLER

JAMB

CAN

FILLER

JAMB

GLASS STOP

STEP 4)

CENTER LINE

OF MULLION

CENTER LINE

OF MULLION

[FIG. 42]

Fill the cavity in the vertical mullion behind the glazing gasket with

silicone sealant, 3/8" above and below the gasket. This should be

done at the head and sill can before the glass units are installed.

See Fig. 43 below.

FILL THIS CAVITY BEHIND

THE GLAZING GASKET

AT HEAD & SILL CANS

BEFORE INSTALLING

THE GLASS UNITS

[FIG. 43]

DPS 7/2001

Page 41

PAGE 39

SECTION V A - GLAZING PROCEDURES

STEP 5)

FOR BUTT GLAZED VERTICAL

(CONT.)

Apply WM10 (2 sided tape) to the butt glazed mullion vertically, from

head can gasket track to sill can gasket track, located on the butt

glazed mullion as shown below.

DO NOT remove the exterior protective film until the glass unit has been

set and positioned correctly.

1/2"

STEP 6)

BUTT GLAZED

MULLION

WM10

3/8" x 1/2" TAPE

[FIG. 44]

Follow the glass setting procedure as detailed in

Fig. 45 below and Fig. 46 on page 40.

GASKET RUNS THRU

AT VERTICALS

JAMB

JAMB

GLASS STOP

INSTALL THIS UNIT

- LAST -

INSTALL THIS UNIT

- 2nd TO LAST -

[FIG. 45]

DPS 7/2001

Page 42

PAGE 40

SECTION V A - GLAZING PROCEDURES FOR

BUTT GLAZED VERTICAL

(CONT.)

STEP 7) Lift the gl ass into the head ca n gl azin g pocket. Then set it

down on the setting blocks in the sill can glazing pocket, and

slide the glass horizontally into proper position.

NOTE: If there are no vertical intermediates being used, proceed to

nstall the exterior glazing gasket as described at Step 1 on page 37.

9484

HEAD

1/2"

G.B.

N

U

S

S

LA

G

I

9485

W102

T

QUICK SET

HN33

SILL

1/2"

G.B.

[FIG. 46]

W102

9485

9484

DPS 6/2003

Page 43

PAGE 41

SECTION V A - GLAZING PROCEDURES

STEP 8)

A)

FOR BUTT GLAZED VERTICAL

(CONT.)

WHEN THE GLASS UNITS ARE POSITIONED CORRECTLY-

At the jamb, install the glazing stop and the vertical glazing gasket.

2 PC. JAMB

JAMB

GLASS STOP

[FIG. 47]

1/2"

Remove the exterior protective film on the glazing tape and press the

B)

glass units into contact with the now exposed adhesive.

Vertical glass size formula is DLO + 1". Horizontal glass size

formula is DLO + 1 1/2" between butt glazed mullions, and

DLO + 1 1/4" between butt glazed mullions and captured jambs.

GLASS UNIT

3/4"

GLASS

BITE

1/2"

GAP

Quick Set

GASKET RUNS THRU

AT VERTICALS

BUTT GLAZED

MULLIONS

GLASS UNIT

3/4"

GLASS

BITE

3/4"

GLASS

BITE

1/2"

GAP

GLASS UNIT

3/4"

GLASS

BITE

[FIG. 48]

JAMB

1/2"

GLASS

BITE

DPS 12/2002

Page 44

PAGE 42

SECTION V A - GLAZING PROCEDURES

FOR BUTT GLAZED VERTICAL

(CONT.)

FOR SAFETY, THE USE OF GLAZING CLIPS IS RECOMMENDED.

STEP 9)

Locate the glazing clips with a spacing of 24" on center maximum.

See Fig. 49 and Fig. 50 below.

WM10

HV11

901/903

[FIG. 49]

HV10

902/904

24" MAXIMUM

GLASS UNIT

STEP 10)

BUTT GLAZED

MULLION

HOOK THE TEMPORARY GLAZING CLIPS

INTO THE MULLION CAVITY AND SLIDE

THEM TOGETHER UNTIL THE CLIPS

ARE BACK TO BACK.

GLASS UNIT

[FIG. 50]

Install the exterior glazing gasket in the same manner as

described in Step 1, page 37.

DPS 7/2001

Page 45

PAGE 43

SECTION V A - GLAZING PROCEDURES

STEP 11)

STRUCTURAL

SILICONE

FOR BUTT GLAZED VERTICAL

(CONT.)

Apply the structural silicone to the interior side tying the

mullion, spacer tape, and glass unit together.

WM10

STRUCTURAL

SILICONE

HV11

901/903

STRUCTURAL

SILICONE

[FIG. 51]

WM10

STRUCTURAL

SILICONE

[FIG. 52]

HV10

902/904

DPS 7/2001

Page 46

PAGE 44

SECTION V A - GLAZING PROCEDURES

STEP 12)

FOR BUTT GLAZED VERTICAL

After the interior sealant has cured, typically an overnight setup is

required. Then remove the temporary glazing clips and proceed with

filling the void between the glass units at the exterior with backer

rod and structural silicone sealant for a weather tight seal.

Remove excess silicone from the glass surface for a neat and

professional appearance.

See Fig. 53 below.

(CONT.)

SEE THE SILICONE MANUFACTURER’S

INSTRUCTIONS FOR APPLICATION

[FIG. 53]

OF WEATHER SEAL.

NOTE:

THE SUCCESS OF STRUCTURAL SILICONE GLAZED PROJECTS HAS

BEEN THE RESULT OF COMPATIBILITY TESTS PERFORMED ON

ACTUAL MATERIALS SUPPLIED TO THE PROJECT. THE INSTALLER

MUST MAKE SURE THAT SUCCESSFUL COMPATIBILITY TESTS ARE

PERFORMED IN ACCORDANCE WITH THE SILICONE MANUFACTURER’S

RECOMMENDATIONS AND PROCEDURES.

DPS 7/2001

Page 47

PAGE 45

SECTION V B - GLAZING PROCEDURES

FOR BUTT GLAZED VERTICAL AND INTERMEDIATE HORIZONTAL

STEP 1)

WHEN A HORIZONTAL INTERMEDIATE IS BEING USED,

GLASS SETTING OPTIONS INCLUDE INSIDE/OUTSIDE

GLAZING OPPORTUNITIES. THE GLASS ABOVE THE

HORIZONTAL WILL BE SET FROM THE OUTSIDE, AND

THE GLASS BELOW MAY BE SET FROM THE OUTSIDE

OR THE INSIDE. SEE FIG. 54 BELOW.

HEAD

1/2"

GLASS BITE

NOTE:

GLASS ABOVE HORIZONTAL

MUST BE OUTSIDE GLAZED.

SNAP ON HORIZONTAL

FACE AFTER ALL LITES

ARE SET.

(1) Tip the glass into the head

glazing pocket.

(2) Raise the glass to clear the

setting blocks.

(3) Set the glass on the setting blocks.

1

3

HORIZONTAL

2

-OPTIONAL AT LOWER LITE-

The glass unit may also be set

as described for the top lite,

except from the inside.

2

(1) Tip the glass back to

set on the setting block.

(2) Tip the glass to vertical.

(3) Install the face cover.

Quick Set

3

1

1/2"

GLASS BITE

SILL

3a

1a

2a

(1a) Hold the glass vertical.

(2a) Rotate the glass to the

glass plane.

(3a) Set the glass on the

setting blocks.

[FIG. 54]

DPS 12/2002

Page 48

PAGE 46

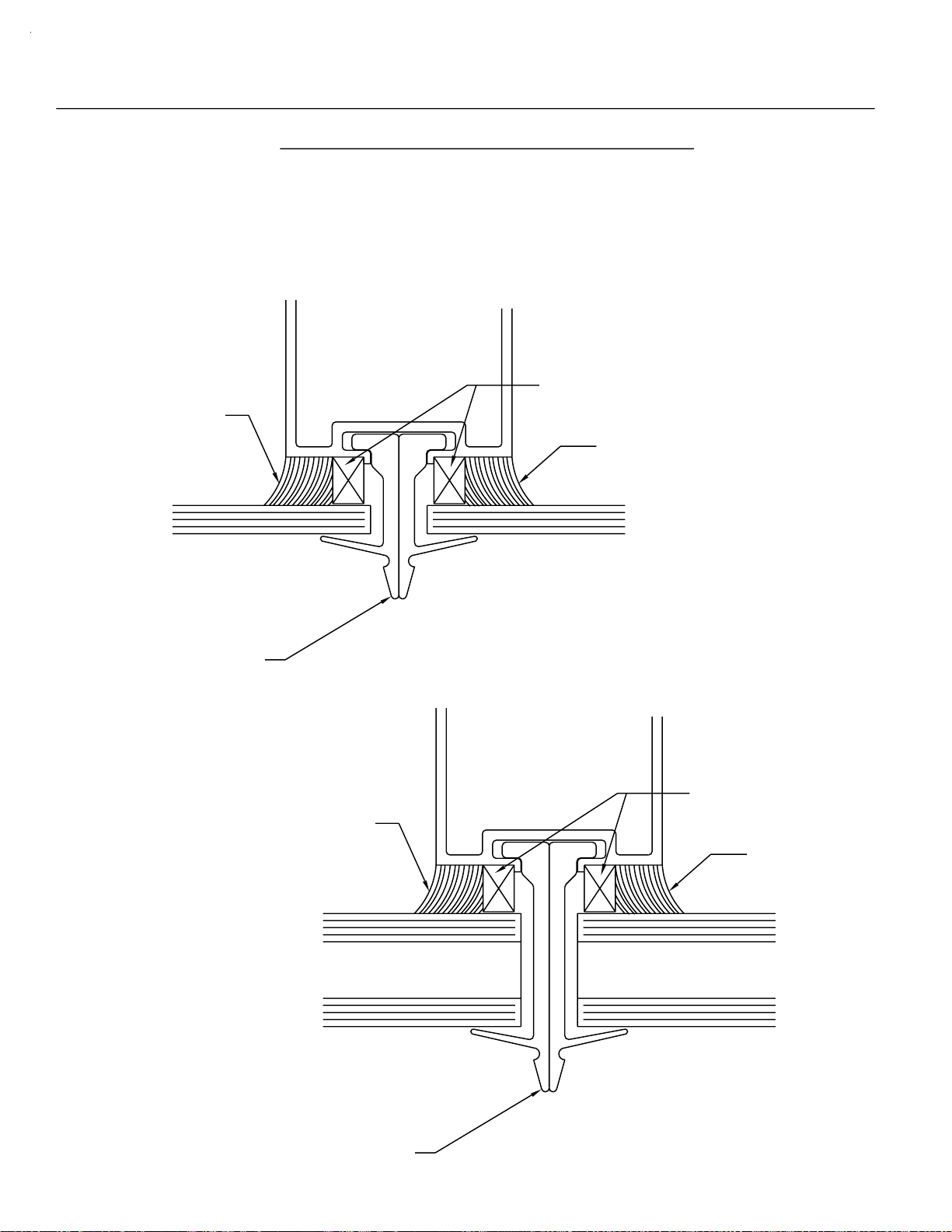

SECTION V C - GLAZING PROCEDURES

FOR CAPTURED VERTICAL MULLION

AND INTERMEDIATE HORIZONTAL

WHEN USING A CAPTURED VETICAL MULLION, THE GLASS SIZE

FORMULA IS DLO + 7/8" HORIZONTALLY AND VERTICALLY.

NOTE:

When using a captured vertical mullion, glass setting tends to

become easier because the number of removable stops per

opening increases. The same glass setting options included in

Section V B will be available with this mullion, and the inside glass

setting of the top lite becomes available also.

See Fig. 55 below.

2 pc. JAMB

REMOVABLE VERTICAL

STOPS

REMOVABLE

VERTICAL

STOPS

HORIZONTAL STOP

RUNS THRU

[FIG. 55]

REMOVABLE

VERTICAL

STOPS

DPS 7/2001

Page 49

PAGE 47

SECTION VI A - DOOR FRAME INSTALLATION

NOTE: If an entrance frame is required, it must be installed first.

See the parts description pages in SECTION II for the appropriate

door jamb and transom bar for the system being used.

STEP 1)

STEP 2)

STEP 3)

STEP 4)

NOTE:

Correctly locate the entrance frame in the opening.

Apply a bead of sealant around the interior portion of the jamb

to set the member into. Tie the side lite sealant or condition

sealant into the bead of sealant to be applied under the threshold.

The concept is to have a continuous bead of sealant at the interior

connected from the side lite sill can/condition through the door

jamb, continuing under the threshold to the opposite jamb and

onto the opposite side lite sill can.

Set the assembled door frame in the opening, plumb and level.

Anchor the door frame and threshold as indicated below in Fig. 56 below

and also in Fig. 57 through Fig. 60 on page 48.

THRESHOLD FASTENER

SIDE LITE SILL CAN

12" FROM JAMB & 12" O.C.

(3) PER SINGLE DOOR

The door jamb runs to the

floor and is cut longer

than any other vertical

member.

K-124/K-125 Threshold Clip & Screws

@ Offset Pivots & Butt Hinges

K-153/K-154 Threshold Clip & Screws

@ Concealed Rod Panic

THRESHOLD

[FIG. 56]

12" MAX.

(9950)

CONTINUOUS BEAD

OF SEALANT

DPS 7/2001

Page 50

PAGE 48

SECTION VI A - DOOR FRAME INSTALLATION

K273 RH

K274 LH

9593

1/4" Dia. Weep

at 1/4 Points

(CONT.)

5/8"

9593

K273 RH

K274 LH

9914

W138

At condition, attach through

the header with flat head

screws, located 6" from

[FIG. 57]

the ends and 24" on center,

maximum spacing.

Attach through the threshold with flat head screws.

12" from jambs and 12" on center max.

EXTERIOR INTERIOR

[FIG. 59]

9914

W138

[FIG. 58]

Continuous bead of sealant at

the back of the threshold and sides of the

jambs, and tied into mullion sealant

at the condition.

Quick Set

DOOR JAMB SET IN SEALANT

SIDE LITE

9154/9155

W138

ANCHOR THROUGH THE JAMB

AT THE DOOR LOCATION.

FRAMING

THRESHOLD

CLIP

[FIG. 60]

SEE THE DOOR AND HARDWARE INSTALLATION INSTRUCTIONS

FOR MORE DETAILED STEPS, PART # Y015.

9154/9155

W138

JDA 3/2002

Page 51

PAGE 49

SECTION VI A - DOOR FRAME INSTALLATION

CONT.

TRANSOM/JAMB GLAZING ADAPTOR ANCHORING

Use the Transom/Jamb Glazing Adaptor (ext. #9295) with Jamb #9597, Glazing Stop

#9133 and 1/4" Glazing Adaptor #9261 at 901. At 902, use the Transom/Jamb Glazing

Adaptor #9295 with Jam #9592 and Glazing Stop #9133.

Anchor the Transom/Jamb Glazing Adaptor as shown in Fig. 61.

9295

STT6

16" MAX. O.C. 16" MAX. O.C. 16" MAX. O.C.

[FIG. 61]

REMOVEABLE GLASS STOP CUT LENGTH AND FABRICATION

Removeable Glass Stop (ext. #7861)

Cut length = Head Length - 1/16".

NOTCH THESE SURFACES

1/4" (AS SHOWN)

TYPICAL AT EACH END

1/4"

4"4"

11/16"

[FIG. 62]

BAB 11/2001

Page 52

PAGE 50

SECTION VI A - DOOR FRAME INSTALLATION

CONT.

TRANSOM HEADER AND APPLIED TRANSOM GLAZING

9539 @ 902

(901 SIMILIAR)

K267 CLIP @ 902

K277 CLIP @ 901

SEALANT

9592 DOOR JAMB @ 902

(901 SIMILIAR)

9484 HEAD CAN

AT THE SIDE LITE

TYP. @ 902

(901 SIMILIAR)

SEALANT

#STT6

SCREWS

[FIG. 63]

9295

SET IN A BEAD OF SEALANT VERTICALLY

Slide the header clip onto the end of the header. Drill and fasten the clip to the header

with the screws provided in the clip package.

Temporarily locate the header / clip combination at the correct mounting position to

locate and drill the mounting holes for the clip into the jamb.

Apply sealant to the ends of the header and install with the screws provided.

Attach the header to the condition with 1/4" diameter fasteners minimum, 6" from

the jambs and 16" on center maximum.

Apply a thin bead of sealant vertically to set the screw applied glazing stop into. Then

fasten into place with #STT6 screws, 4" from the ends and 12" on center maximum.

Apply sealant to the ends of the header and vertical glazing adaptor as shown in

Fig. 63 above.

BAB 11/2001

Loading...

Loading...