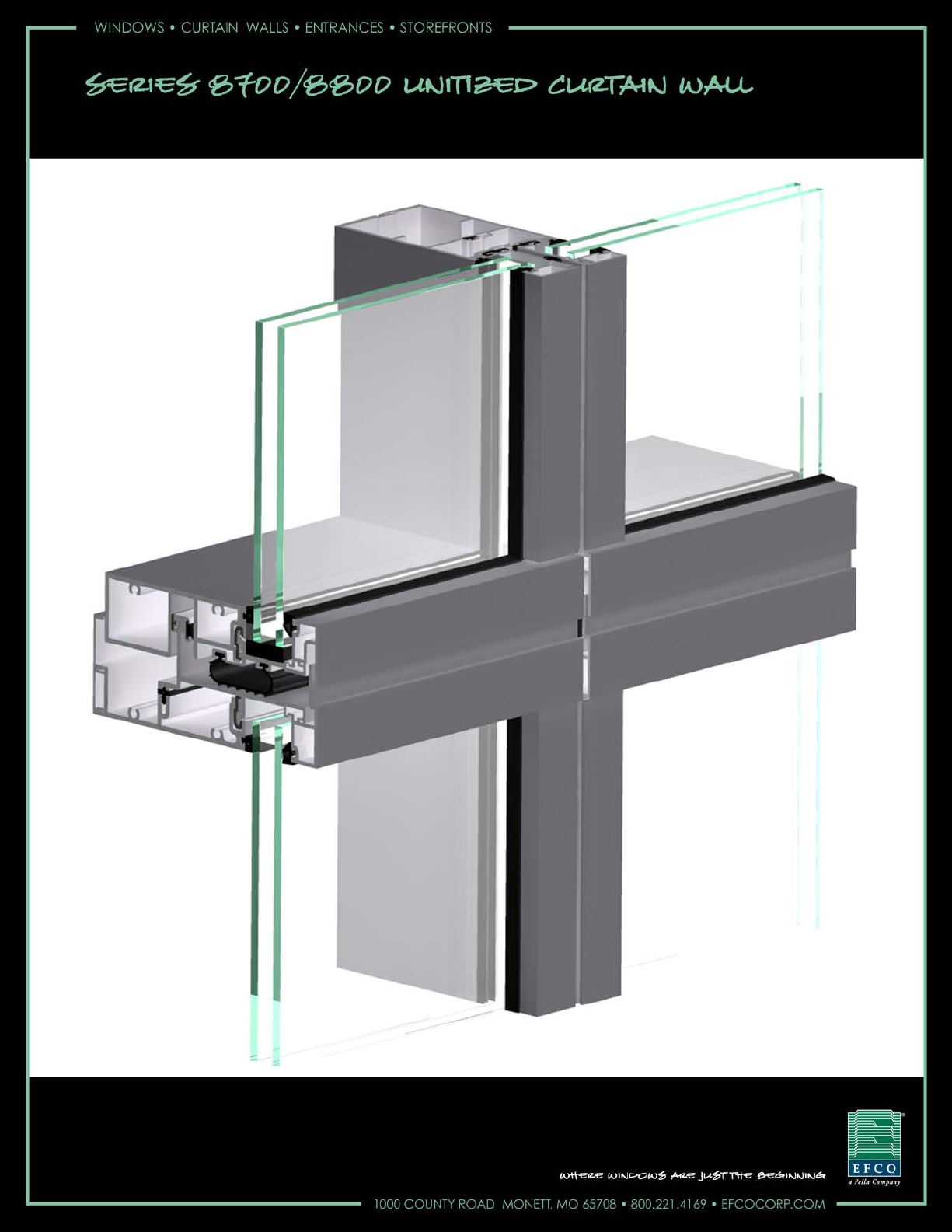

Page 1

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 6

Shadow Box and Back Panel Assembly Instructions Volume 6 of 6 - Sections 33 - 38

July 2011

PART NO. Y806

Page 2

EFCO 2009 Page 2

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 6

Table of Contents

Volume 1 of 6

1. General Notes and Guidelines

2. Parts Identification

3. Frame Assembly

Volume 2 of 6

4. Unit Glazing Preparation : SSG and Captured

5. SSG Unit Glazing

6. Captured Unit Glazing

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 6

Volume 3 of 6

7. Outside 90° Corner Frame Assembly

8. Inside 90° Corner Frame Assembly

9. Outside 90° Corner Unit Glazing Preparation : SSG and Captured

10. Inside 90° Corner Unit Glazing Preparation : SSG and Captured

Volume 4 of 6

11. Outside 90° Corner SSG Unit Glazing

12. Inside 90° Corner SSG Unit Glazing

13. Outside 90° Corner Captured Unit Glazing

14. Inside 90° Corner Captured Unit Glazing

Note: Assembly Instructions are provided as a supplement, and should be used in conjunction with

the approved shop drawings.

EFCO 2009 Page 2

Page 3

EFCO 2009 Page 3

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 6

Table of Contents

Volume 5 of 6

SECTION PAGE

15. General Notes and Guidelines

16. Size Limitations

17. Standard Hardware Identification

18. Frame Assembly - Vent at Fixed Horizontal

19. Frame Assembly - Vent at Stack Sill

20. Unit Glazing Preparation - Vent at Fixed Horizontal

21. Unit Glazing Preparation - Vent at Stack Sill

22. SSG Vent Unit Glazing at Fixed Horizontal

23. SSG Vent Unit Glazing at Stack Sill

24. Captured Vent Unit Glazing at Fixed Sill

25. Captured Vent Unit Glazing at Stack Sill

26. Assembly and Glazing - SSG Vent at Fixed Horizontal

27. Assembly and Glazing - SSG Vent at Stack Sill

28. Assembly and Glazing - Captured Vent at Fixed Horizontal

29. Assembly and Glazing - Captured Vent at Stack Horizontal

30. Hardware Mounting On Unit Assembly

31. Hardware Mounting On Sash

32. Mounting Vent Assembly Into Unit Assembly

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 6

Note: Assembly Instructions are provided as a supplement, and should be used in conjunction with

the approved shop drawings.

EFCO 2009 Page 3

Page 4

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 6

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 6

Table of Contents

Volume 6 of 6

SECTION PAGE

33. Shadow Box Assembly……………………………………………………………………

34. Shadow Box Installation………………………………………………………………….

35. Shadow Box Insulation Installation…………………………………………………….

36. Back Panel Installation……………………………………………………………………

37. Back Panel Insulation Installation………………………………………………………

38. Final Cleaning………………………………………………………………………………

5 - 7

8 - 9

10 - 11

12 - 13

14 - 15

16

Minimizing Condensation

Note: Please reference EFCO's "Understanding Condensation" brochure which can be obtained through your EFCO

representative.

Condensation will form on any surface when unfavorabl e cond itions (interior temperature and relative humidity and exterior

temperature) are present. When the formation of excessive condensation is a concern, it is highly recomm ended that a design

professional is utilized to perform an analysis of the shop drawings to recommend the best possible installation methods. Please

contact your EFCO representative for information on EFCO's Thermal Analysis Services.

Many current installation practices lead to an increase in the possibility of the formation of condensation. Though not all

inclusive, the list of examples below illustrates conditions under which condensation is lik ely to occur:

1. Bridging system thermal break with non-thermally broken metal flashing or lintels th at are exposed to the exterior

2. System exposure to cold air cavities

3. Interior relative humidity levels not maintained at recommended levels, see EFCO’s “Understanding

Condensation” brochure

4. Inadequate separation between system and surrounding condition at perimeter

5. Product combinations during the shop drawing stage that result in bridging thermal breaks

of one or all products involved

Note: Assembly Instructions are provided as a supplement, and should be used in conjunction with

the approved shop drawings.

EFCO 2011 Page 4

Page 5

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 6

Section 33 - Shadow Box Assembly

1. Assemble the unit frame as shown in Volume 1 of Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions, through “Section 3 - B. Unit Frame

Assembly”. For reduced handling for units with shadow boxes, assemble the unit frame with the interior side facing upward.

2. Clean the ends of the shadow box framing members where sealant will be applied with an approved solvent or cleaner.

3. Seal the ends of the shadow box frame members with sealant. See Figure 2.

4. Assembly the shadow box frame with (8) SLQ5 fasteners. Remove excess sealant from the outside areas of the frame corners.

5. Cap seal the fastener heads, seal inside the frame corners, and frame screw splines in the corners of the frame. Tool the sealant carefully to make water

tight. See Figures 3 and Figure 4.

Seal ends of shadow box

frames before assembly.

Shadow

Box Panel

Figure 1

Seal ends of shadow box

frames before assembly.

SLQ5

Fasteners

Figure 2 Figure 3 Figure 4

Cap seal

fastener heads.

Seal inside of

frame corners and

tool water tight.

SLQ5

Fasteners

EFCO 2009 Page 5

Page 6

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 6

Section 33 - Shadow Box Assembly

6. Clean the surfaces of the shadow box frame where the tape and sealant will be applied with an approved solvent or cleaner.

7. Apply 1/4” x 1/4” glazing tape (WM86) to the shadow box frame. Remove the liner only from the side of the tape to be applied. See Figure 6.

8. Peel the remaining liner back about 1” from each end of the glazing tape to allow easy removal once the panel has been set.

9. Measure opposing corners and compare the dimensions to make sure the frame is square, and straig hten if required. Squareness of the frame is critical.

10. Set the panel onto the tape making sure the panel overhangs equally around all four edges (1/16” overhang). See Figures 7 and 8.

11. When the panel is in position, pull the remaining liner from the glazing tape and press the panel firmly into place.

Shadow

Box Frame

WM86

Glazing Tape

Figure 5

WM86

Glazing

Tape

Butt tape

ends square

at corners

Figure 6 Figure 8

Shadow

Box Panel

WM86

Glazing

Tape

Shadow

Box Frame

Shadow

Box Frame

Figure 7

1/16”

Shadow

Box Panel

EFCO 2009 Page 6

Page 7

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 6

Section 33 - Shadow Box Assembly

12. Apply silicone sealant into the voids formed by the panel, tape, and shadow box frame being sure to fill the void completely.

13. Tool the sealant smooth and flush with the panel and the shadow box frame. The sealant joint should be continuous around all four sides of the shadow box

panel assembly. Allow proper cure time for the sealant joint before proceeding to the next step.

Apply silicone

sealant.

WM86

Glazing Tape

Apply silicone

sealant.

Shadow

Box Frame

Figure 9

Shadow

Box Frame

Figure 10

EFCO 2009 Page 7

Page 8

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 6

Section 34 - Shadow Box Installation

1. For reduced handling, assemble the unit frame with the interior side facing upward. Use wood blocking set below the panel, clamped to the mullions on four

sides of the opening to provide the proper spacing for the shadow box. The number of wood blocks will very with the size of the panel to be applied.

2. Frames must be true and square. Prior to installing the shadow box panel, ensure the unit frame is square. Improperly squared units will cause significant

problems during the erection process. Check the frame for squareness by comp aring the difference between the two diagonal measurements of the frame

by measuring from corner to opposing corner for the two diagonal dimensions. The maximum out of square tolerance for a 10’-0” unit frame dimension is a

diagonal dimension difference of 1/16”.

3. Set the shadow box panel into the opening onto the wood blocking and apply 1/8” thick shims between the shadow box frame and the mullions at each

fastener location all around the shadow box panel. Place the shims at the horizontals where they won’t interfere with the sealant in step 4.

4. Apply sealant into the attachment holes in the shadow box frame adjacent to the horizontals filling the space around where the fastener will pass. See Figure

16 on page 9.

5. Attach the shadow box panel to the unit frame with STK3.

Set the shadow box panel

assembly into the opening on

wood blocking supports.

Use wood blocking

clamped to the mullions to

support the shadow box

The unit frame must be placed

with the interior side of the

framing facing upward for

shadow box installation.

Figure 11

Apply 1/8” shims and

attach with STK3

Apply 1/8” shims and

attach with STK3

Figure 12 Figure 13

EFCO 2009 Page 8

Page 9

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 6

Section 34 - Shadow Box Installation

6. Clean the shadow box frame and mullion surfaces that will contact sealant with an approved solvent or cleaner.

7. Cap seal the tip of the fastener where it penetrates the vertical mullions with silicone sealant as shown below. Tool the sealant over the end of the fastener

and smooth it onto the mullion.

8. Apply backer rod and fill the void between the shadow box frame and the mullion with silicone sealant. The se al must be continuous and uninterrupted

around all four sides of the shadow box frame.

9. Tool the sealant into the joint, smoothing it around the four sides of the opening as shown below.

Shadow

Box Panel

Apply backer rod and fill the

void between the shadow

box frame and the mullion

with silicone sealant.

Figure 14

Vertical Mullion

Cap seal fastener

penetrations with

silicone sealant.

Apply backer rod and

sealant and tool the

sealant into the joint.

Figure 15 Figure 16

1/16”

Apply backer rod and

sealant and tool the

sealant into the joint.

Horizontal

Mullion

Apply sealant into

attachment holes in the

shadow box frame filling

the space around where

the fastener will pass

EFCO 2009 Page 9

Page 10

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 6

Section 35 - Shadow Box Insulation Installation

1. Clean the panel and impaling pin surfaces that will contact sealant (or adhesive) with an approved solvent or cleaner.

2. Apply adhesive or sealant to the surface of the panel in a pattern per the manufacture’s recommendations. See Figure 17.

3. Apply impaling pins into the adhesive or sealant forcing the material through the holes in the base of the impaling pin. See Figure 19.

4. Tool the adhesive or sealant over the impaling pin base, and smooth it onto the panel. See Figure 20.

Impaling Pins

Apply sealant or adhesive in a

pattern as recommended by the

Adhesive

Shadow

Box Panel

impaling pin manufacturer.

Figure 17

Impaling Pin

Tool sealant

or adhesive

Impaling Pin

Apply pins into the

sealant or adhesive

Figure 18 Figure 20

Figure 19

EFCO 2009 Page 10

Page 11

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 6

Section 35 - Shadow Box Insulation Installation

5. Cut the specified rigid insulation to size. The insulation should fit tightly into the framed opening. The edges of the insulation may be cut slightly angled to

assist with insertion into the opening.

6. Insert the insulation onto the impaling pins into the opening so that the insulation is flush with the back of the mullion.

7. Clean the surfaces of the mullion where the foil scrim tape will be applied with an approved solvent or cleaner.

8. Apply foil scrim tape to the four edges of the insulation and mullions to form an air tight seal. If the insulation is in more than one piece, tape the edges

together. See Figures 21 and 22.

9. Insert the self locking washers onto the impaling pins and force them down to the surface of the insulation to hold the insulation securely. Fold the exposed

end of the impaling down, flush with the insulation, and apply foil scrim tape to cover the pin and washer completely. See Figure 23.

Foil Scrim

Tape

Rigid insulation with scrim

Self Locking

Washers

reinforced foil facing on

interior surface.

Impaling Pins

Foil Scrim

Tape

Figure 22

Figure 21

Impaling Pins

Shadow

Box Panel

Foil Scrim

Tape

Self Locking

Washers

Impaling Pins

Figure 23

EFCO 2009 Page 11

Page 12

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 6

Section 36 - Back Panel Installation

1. Rotate the assembled unit frame over so that the exterior side facing upward. Use wood blocking set below the panel, clamped to the mullions around the

opening to provide the proper spacing for the back panel. The number of wood blocks will very with the size of the back panel to be applied.

2. Frame must be true and square. Prior to installing the back panel, ensure the unit frame is square.

3. Set the back panel into the opening onto the wood blocking.

4. Attach the back panel to the unit frame with STK3 on all four sides of the panel.

5. Cap seal the fastener heads to the panel with silicone sealant.

Set the shadow box panel

into the opening on wood

blocking supports.

Attach the back panel to the unit frame with

STK3 on all four sides of the panel. Cap seal the

fastener heads to the panel with silicone sealant.

Use wood blocking

clamped to the mullions to

support the shadow box

Rotate the frame so that the

exterior side of the framing is

facing upward.

Figure 24

Figure 25

EFCO 2009 Page 12

Page 13

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 6

Section 36 - Back Panel Installation

6. Using an approved solvent or cleaner, clean the surfaces to receive sealant of all oils and oth er contaminants.

7. The back panel has a raised lip that runs around the four sides of the panel. Apply sealant between this lip and the side of the mullion as shown below, filling

the void thoroughly. See Figure 28.

8. Tool the sealant into the joint smoothly, around all four sides continuously. See Figures 27 and 28.

9. Seal the corners of the back panel thoroughly with sealant. See Figure 27.

Seal continuously

with silicone sealant.

Seal the four

corners of the

Seal the four corners

of the back panel.

Cap seal all

fastener heads.

back panel.

Seal continuously on (4)

sides with silicone sealant.

Cap seal all

fastener heads.

Galvanized Steel

Back Panel

Figure 27

Seal continuously

with silicone sealant.

Cap seal all

fastener heads.

Galvanized Steel

Back Panel

Figure 26

Figure 28

EFCO 2009 Page 13

Page 14

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 6

Section 37 - Back Panel Insulation Installation

1. Clean the panel and impaling pin surfaces that will contact sealant (or adhesive) with an approved solvent or cleaner.

2. Apply adhesive or sealant to the surface of the panel in a pattern per the manufacture’s recommendations. See Figure 29.

3. Apply impaling pins into the adhesive or sealant forcing the material through the holes in the base of the impaling pin. See Figure 31.

4. Tool the adhesive or sealant over the impaling pin base, and smooth it onto the panel. See Figure 32.

Apply sealant or adhesive in a

pattern as recommended by the

impaling pin manufacturer.

Impaling Pins

Adhesive

Galvanized Steel

Back Panel

Impaling Pin

Apply pins into the

sealant or adhesive

Figure 30

Figure 29

Impaling Pin

Figure 31

Tool sealant

or adhesive

Figure 32

EFCO 2009 Page 14

Page 15

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 6

Section 37 - Back Panel Insulation Installation

5. Cut the specified rigid insulation to size. The insulation should fit tightly into the framed opening. The edges of the insulation may be cut slightly angled to

assist with insertion into the opening.

6. Insert the insulation onto the impaling pins into the opening so that the insulation is flush with the back of the mullion.

7. Clean the surfaces of the mullion where the foil scrim tape will be applied with an approved solvent or cleaner.

8. Apply foil scrim tape to the four edges of the insulation and mullions to form an air tight seal. If the insulation is in more than one piece, tape the edges

together. See Figures 33, 34 and 35.

9. Insert the self locking washers onto the impaling pins and force them down to the surface of the insulation to hold the insulation securely. Fold the exposed

end of the impaling down, flush with the insulation, and apply foil scrim tape to cover the pin and washer completely. See Figure 36.

Foil Scrim

Tape

Rigid insulation with scrim

Self Locking

Washers

Impaling Pins

reinforced foil facing on

interior surface.

Galvanized Steel

Back Panel

Figure 33

Foil Scrim

Tape

Figure 34

Impaling Pins

Self Locking

Washers

Figure 35

Foil Scrim

Tape

Impaling Pins

Foil Scrim

Tape

Self Locking

Washers

Impaling Pins

Figure 36

EFCO 2009 Page 15

Page 16

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 6

Section 38 - Final Cleaning

1. Before proceeding with the glazing process, a thorough cleaning of the exposed areas of the shad ow box must be done.

2. Blow all debris out of the joints around the edges and exposed areas of the shadow box. Any metal shavings or dirt must be removed from the opening.

After the unit is glazed, during handling, debris could dislodge and become visible through the glass unless proper cleaning is performed.

3. Use isopropyl alcohol to clean the exposed finished surfaces of all smudges, finger prints, and sealant. Once the unit is glazed, these areas will be

inaccessible, so a thorough cleaning is essential.

4. Proceed to Volume 2, Section 4 “Unit Glazing Preparation”.

Thoroughly blow all debris

out of the joints around the

edges of the shadow box.

Use isopropyl alcohol to clean the

shadow box exposed finished surfaces of

all smudges, finger prints, and sealant.

Figure 37

EFCO 2009 Page 16

Loading...

Loading...