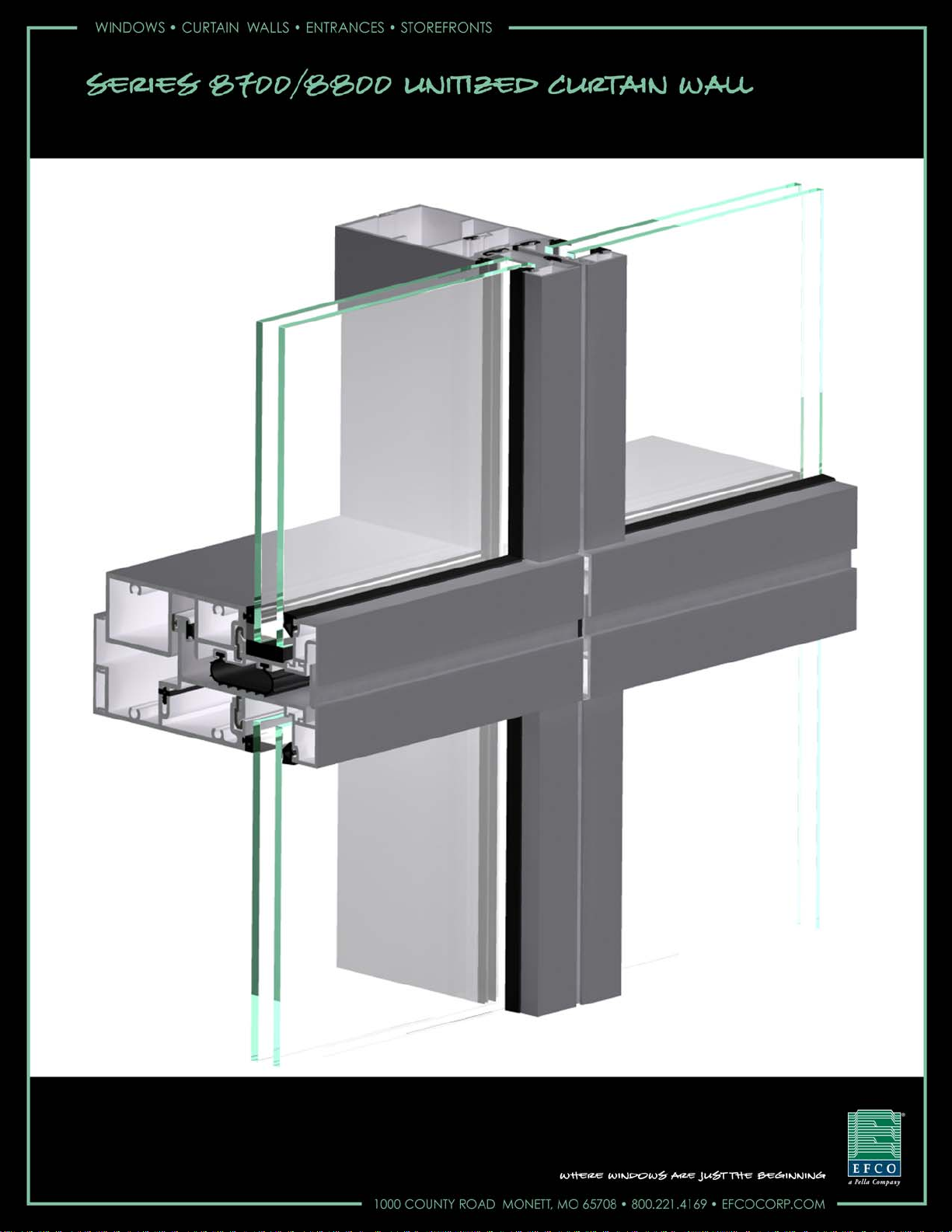

Page 1

EFCO 2012 Page

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Flat Wall Assembly Instructions Volume 2 of 6 - Sections 4 - 6

April 2012

PART NO. Y802

Page 2

EFCO 2009 Page 2

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Table of Contents

Volume 1 of 6

1. General Notes and Guidelines

2. Parts Identification

3. Frame Assembly

Volume 2 of 6

SECTION PAGE

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

4. Unit Glazing Preparation : SSG and Captured………….........................................

5. SSG Unit Glazing

A. Temporary Glazing Locators…………………………......................................

B. Setting and Caulking Glazing ……………………………………………………

C. Adapter Installation………………….……………………………………………..

D. Weather Seal Application…………………………………………………………

E. Jamb Mullion Installation………………………………...……………………….

6. Captured Unit Glazing

A. Temporary Glazing Locators……………………………………………………..

B. Setting and Caulking Glazing ……………………………………………………

C. Adapter and Cover Installation……….………………………………………….

D. Joint Plug Installation………………….…………………………………………..

E. Jamb Mullion Installation………………………………...……………………….

6 - 7

8

9 - 10

11 - 15

16 - 17

18 - 19

20

21 - 22

23 -30

31 - 32

33 - 34

Note: Assembly Instructions are provided as a supplement, and should be used in conjunction with

the approved shop drawings.

EFCO 2009 Page 2

Page 3

EFCO 2009 Page 3

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Table of Contents

Volume 3 of 6

7. Outside 90° Corner Frame Assembly

8. Inside 90° Corner Frame Assembly

9. Outside 90° Corner Unit Glazing Preparation : SSG and Captured

10. Inside 90° Corner Unit Glazing Preparation : SSG and Captured

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Volume 4 of 6

11. Outside 90° Corner SSG Unit Glazing

12. Inside 90° Corner SSG Unit Glazing

13. Outside 90° Corner Captured Unit Glazing

14. Inside 90° Corner Captured Unit Glazing

Note: Assembly Instructions are provided as a supplement, and should be used in conjunction with

the approved shop drawings.

EFCO 2009 Page 3

Page 4

EFCO 2009 Page 4

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Table of Contents

Volume 5 of 6

15. General Notes and Guidelines

16. Size Limitations

17. Standard Hardware Identification

18. Frame Assembly - Vent at Fixed Horizontal

19. Frame Assembly - Vent at Stack Sill

20. Unit Glazing Preparation - Vent at Fixed Horizontal

21. Unit Glazing Preparation - Vent at Stack Sill

22. SSG Vent Unit Glazing at Fixed Horizontal

23. SSG Vent Unit Glazing at Stack Sill

24. Captured Vent Unit Glazing at Fixed Sill

25. Captured Vent Unit Glazing at Stack Sill

26. Assembly and Glazing - SSG Vent at Fixed Horizontal

27. Assembly and Glazing - SSG Vent at Stack Sill

28. Assembly and Glazing - Captured Vent at Fixed Horizontal

29. Assembly and Glazing - Captured Vent at Stack Horizontal

30. Hardware Mounting On Unit Assembly

31. Hardware Mounting On Sash

32. Mounting Vent Assembly Into Unit Assembly

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Note: Assembly Instructions are provided as a supplement, and should be used in conjunction with

the approved shop drawings.

EFCO 2009 Page 4

Page 5

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Table of Contents

Volume 6 of 6

33. Shadow Box Assembly

34. Shadow Box Installation

35. Shadow Box Insulation Installation

36. Back Panel Installation

37. Back Panel Insulation Installation

38. Final Cleaning

Minimizing Condensation

Note: Please reference EFCO's "Understanding Condensation" brochure which can be obtained through your EFCO

representative.

Condensation will form on any surface when unfavorable conditions (interior temperature and relative humidity and

exterior temperature) are present. When the formation of excessive condensation is a concern, it is highly recommend ed that a

design professional is utilized to perform an analysis of the shop drawings to recommend the best possible installation methods.

Please contact your EFCO representative for information on EFCO's Thermal Analysis Services.

Many current installation practices lead to an increase in the possibility of the formation of condensation. Though not all

inclusive, the list of examples below illustrates conditions under which condensation is lik ely to occur:

1. Bridging system thermal break with non-thermally broken metal flashing or lintels th at are exposed to the exterior

2. System exposure to cold air cavities

3. Interior relative humidity levels not maintained at recommended levels, see EFCO’s “Understanding

Condensation” brochure

4. Inadequate separation between system and surrounding condition at perimeter

5. Product combinations during the shop drawing stage that result in bridging thermal breaks

of one or all products involved

Note: Assembly Instructions are provided as a supplement, and should be used in conjunction with

EFCO 2009 Page 5

the approved shop drawings.

EFCO 2011 Page 5

Page 6

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 4 - Unit Glazing Preparation : SSG and Captured

1. Using an approved solvent or cleaner, clean the surfaces of the mullions to receive the WC18 spacer gasket and sealant of all oils and other

contaminants. The sealant manufacturer’s preparation and application instructions should be followed exactly.

2. If sealant primer is required, apply it per the primer/sealant manufacturer’s instructions. See the note in Figure 1 below.

3. Frames must be true and square before being structurally glazed. Improperly squared units will ca use significant problems during the erection process.

Check the frame for squareness by comparing the difference between the two diagonal measurements of the frame by measuring from corner to opposing

corner for the two diagonal dimensions. The maximum out of square tolerance for a 10’-0” unit frame dimension is a dia gonal dimens ion difference of 1/16”.

If frames are found to exceed this tolerance limit, the frame must be squared using bar clamps. Additionally, individual D.L.O. squareness should be checked

using the procedure above. If bar clamps or other methods are used to square the frame, the device may need to remain on the frame until the sealant is

cured (8 hours minimum).

4. Inspect the I.G. units for the frame. Any excessive sealant or irregularities in the dual seal or glass edge should be cleaned and trimmed. Check for glass

damage, particularly along the glass edges and discard any unacceptable units. At this time, the secondary sealant joints of the insulated glass units should

be checked for proper size. The approved shop drawings will indicate the required secondary sealant joint size on the general information page. Check the

alignment of each pane making up the I.G. unit to ensure they are within acceptable limits. The I.G. unit overall dimensions should be verified for proper size.

Note: After cleaning and priming the glazing substrates

(priming when required), the glazing must be set

immediately and the structural silicone applied. The time

between cleaning, priming and applying the structural

silicone should be less than two hours. Otherwise, the

substrates may become contaminated, and the primer will

oxidize. If units have been prepared for glazing at the end

of the day, and sealant has not yet been applied, cleaning

and priming must be redone prior to glazing the next day.

Apply the WC18 spacer

gasket to the mullions.

Figure 1

EFCO 2009 Page 6

Page 7

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 4 - Unit Glazing Preparation : SSG and Captured

5. Apply the WC18 spacer gasket to the mullions as shown below and on page 6. The gasket will run through vertically, and butt together at the corners (see

Figure 4). “Crowd” in extra gasket, (approximately 10% extra) where it runs between the vertical gaskets to ensure a snug butt joint at the corners. It is

important that there are no gaps in the gaskets where they meet in the corners. Note that the gasket is not symmetrical, and must be installed so that it is

flush with the side of the mullions (see Figure 2).

6. A 3/8” backer rod should be applied into the isolator reglet to prevent sealant from getting into the reglet. Remove the backer rod immediately after the

sealant is applied, and before the sealant begins to cure and skin over (See Figure 3).

Insert a 3/8” backer rod into isolator reglets to

keep free of sealant. Remove the backer rod

immediately, before sealant begins to skin over.

Apply WC18 gaskets

flush with the side of

the mullions.

Isolator

Reglet

Figure 2

JAMB

Butt gaskets at

D.L.O. corners.

SILL

Butt gaskets at

D.L.O. corners.

JAMB

INTERMEDIATE

Figure 4

Figure 3

Butt gaskets at

D.L.O. corners.

JAMB

HEAD

EFCO 2009 Page 7

Page 8

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

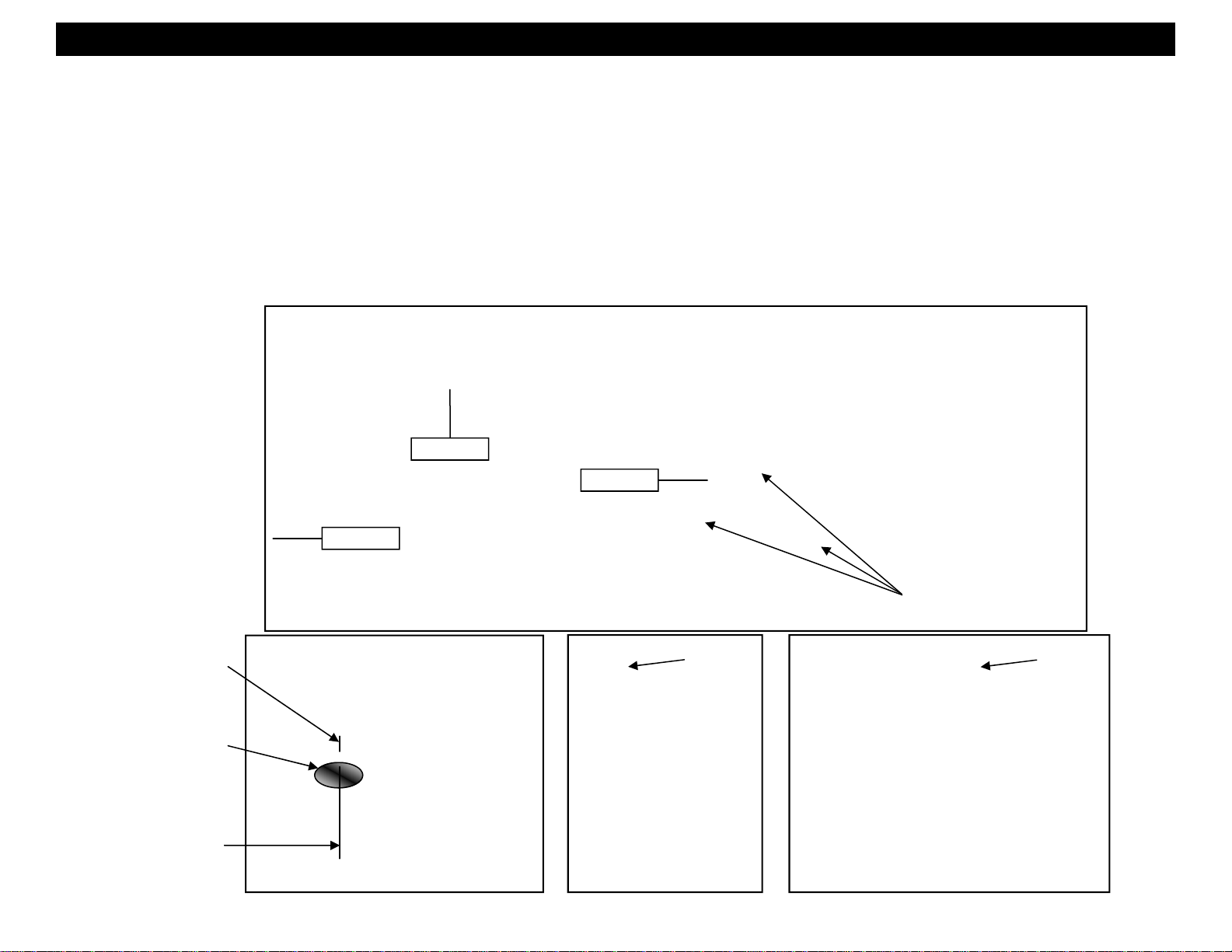

Section 5 - SSG Unit Glazing : A. Temporary Glazing Locators

1. In order to properly

locate the glazing,

temporary adapters must

be used at the bottom

edge of the glazing.

Apply two temporary

glazing locators (KV01,

KV02) at approximate

quarter points at the sill

and intermediate

horizontal locations as

shown in Figures 5, 6,

and 7.

2. Using an approved

solvent or cleaner,

thoroughly clean the

edges of the glazing

that will contact the

structural silicone and

spacer of all oils and

other contaminants.

Once the glass has been

cleaned, it should be

handled with gloves to

avoid contaminating the

edges that come into

contact with the

structural silicone

glazing joint.

Temporary Glazing

Locators

Figure 5

17H6

L142

HS32

KV02

Figure 6 - SSG Intermediate Horizontal

HS32 17B7

L142

EFCO 2009 Page 8

Figure 7 - SSG Stack Sill

KV01

Page 9

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 5 - SSG Unit Glazing: B. Setting and Caulking Glazing

3. Set the glazing on the silicone spacer gaskets positioned as shown below. The edge of the gla zing i s flush with the edge of the vertical mullion. Refer to

Figure 9 below. Ensure the glazing is pressed firmly onto the setting blocks of the temporary retainers as shown in Figures 10 and 11.

4. Align the glazing as shown and noted. Ensure the glazing is positioned with the exterior side out, and the bottom of the glazing to the setting blocks. Care

should be exercised to avoid shifting or rolling the spacer gaskets when adjusting the position of the glass.

5. After the glass is aligned and in the final position, remove the setting blocks and temporary glazing locators.

6. Apply structural silicone sealant into the void between the glass and mullion per the sealant manufacturer’s application instructions. A 3/8” backer rod should

be applied into the isolator reglet to prevent sealant from getting into the reglet (see Figure 9). See additional notes, and Figures 12, 13, and 14 on page 10

for sealant application and tooling instructions.

7. Immediately tool the sealant joint after application to insure the joint is completely filled with sealant on all four sides of each piece of glazing. Make sure no

air bubbles or voids are present in the sealant joint.

8. Remove the backer rod, before the sealant begins to cure and skin over.

Note:

Only silicone sealants

which have been

developed and tested

specifically for structural

glazing applications

should be used for

glazing purposes.

Apply structural silicone

sealant into the void and

tool the joint to fill the

void completely.

Insert a 3/8” backer rod

into isolator reglet to keep

free of sealant. Remove the

backer rod immediately

before sealant begins to

skin over.

Glass is flush with

edge of mullion.

SILL

Figure 10

Figure 9

JAMB

Figure 11

JAMB

Figure 8

KV01

HEAD

Set glazing onto the silicone

spacer gaskets and against

the setting blocks at the

temporary glazing locators.

KV02

EFCO 2009 Page 9

Figure 9

Figure 10 Figure 11

Page 10

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 5 - SSG Unit Glazing: B. Setting and Caulking Glazing

9. Follow the sealant manufacturer’s instructions for application equipment preparation and qu ality control procedures.

10. Apply sealant and tool the frames as required per the sealant manufacturer’s application instructions in the Structural Sealant Glazing Manual. Care should

be taken to insure that the sealant void at the glass edge is completely filled. The sealant gun operator should visually confirm that this void is being filled at

the time of application (See figures 12, 13 and 14). Clean up any excess sealant that may get into the gasket reglets or any other areas that sealant would

be undesirable.

11. Frames should not be moved until the sealant has cured and per the sealant manufacturer’s recommendations.

Figure 12

Note:

Only silicone sealants

which have been

developed and tested

specifically for structural

glazing applications

should be used for

glazing purposes.

Figure 13

GLASS SIZE FORMULAS

Per Side Add Dimensions

Standard Mullions - D.L.O. + 13/16”

Inside Corner Mullion - D.L.O. + 13/16”

Outside Corner Mullion - D.L.O. + 1 7/16”

Note: Job specific corner conditions may

vary glass bite. Refer to final approved

shop drawings.

Figure 14

EFCO 2012 Page 10

Page 11

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 5 - SSG Unit Glazing: C. Adapter Installation

1. After sealant has cured, cut L142 to length with vinyl cutters. Apply the thermal isolator L142 into the verticals and horizontals. L142 is supplied in 1 0’-0”

lengths. L142 may be used in several pieces to accommodate the required length. By butting multiple pieces together, waste will be avoided and the desired

length can be obtained.

2. Apply the preset thermal isolator (WC16) to the head, running the gasket continuously between the vertical mullions (See Figure 18).

3. Figure 17 shows the various isolators and gaskets used in this section.

L142 Thermal

Isolator Clip

L142

Vinyl Cutters

Figure 15

WC16

L142

WC19

WC16

LC23

WC17

Figure 17

L142 Thermal

Isolator Clip

Figure 16

Figure 18

WC16 Isolator

Gasket

EFCO 2009 Page 11

Page 12

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 5 - SSG Unit Glazing: C. Adapter Installation

4. Apply 17B7 SSG glazing adapter to the stack sill. Final adjustment of the 17B7 will be made after the vertical glazing adapters are applied.

5. Slide the WC17 horizontal stack joint rain screen gasket into position as shown in Figures 20, 21, and 22. WC17 runs the same length as 17B7 and is applied

flush with each end of 17B7.

6. Insert HS32 setting blocks between the stack sill glazing adapter and the glass at quarter points, or as directed per the final approved shop drawings. Light

prying pressure may need to be applied to the glazing adapter to insert the setting blocks into place. Use care so that the glazing is not damaged.

HS32 Setting

Blocks

17B7 SSG Stack Sill

Glazing Adapter

Figure 19

Figure 20

Slide WC17 gasket

into 17B7

L142 stops 3/4” short of

the end of the mullion at

this location.

Figure 22

WC17 Horizontal

Stack Joint Rain

Screen Gasket

Figure 21

HS32

L142

WC17

17B7

EFCO 2009 Page 12

Page 13

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 5 - SSG Unit Glazing: C. Adapter Installation

7. Clean the sealant contact surfaces of the mullion with an approved solvent or cleaner and apply a heavy bead of sealant to the tops of the vertical

mullions as shown in Figure 23.

8. Clean the sealant contact surfaces of the gutter with an approved solvent or cleaner. Apply sealant to the underside of the gutter where it will contact

the ends of the vertical with a bed of sealant. This will ensure that all voids are filled and good sealant contact is achieved once the gutter is applied t o the

frame. Install the SSG gutter to the frame at the head horizontal and secure with SPZ1. See Figure 24. It is critical that the sealants applied to the

gutter and mullion are thoroughly tooled and blended together to make watertight. See Figure 25.

9. Slide in WC19 gasket and LC23 spacer into the gutter. LC23 spacer runs continuously and is flush with the ends of the gutter. WC19 runs continuously, and

is cut 3” longer than the gutter (1 1/2” on each end). See figure 26.

Note! Critical seal!

The sealant must be

thoroughly tooled and

blended over the adjacent

surfaces all around the

sealant contact areas

shown in Figure 23. This

seal occurs at the top of

each vertical mullion.

Apply a h e avy

bead of sealant to

the tops of the

verticals.

Figure 25

Slide in WC19 Horizontal

Stack Joint Seal Gasket.

SPZ1

Slide in LC23 Horizontal

Stack Joint Spacer Gasket.

Figure 26

17B6 SSG Horizontal

Stack Gutter

Figure 23

SSG Gutter

SPZ1

SPZ1

Figure 24

EFCO 2009 Page 13

Page 14

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 5 - SSG Unit Glazing: C. Adapter Installation

10. Slide WC20 bulb gasket into 17A6 SSG vertical fin bar. Exercise care to avoid stretching the gasket during installation. Let the bulb gasket run approximately

1/4” longer than 17A6. The bulb gasket must be installed prior to applying 17A6.

11. Crimp the bulb in place to prevent slippage during unit installation. Crimp at each end of the adapter, and 24” on center.

12. Roll the 17A6 SSG vertical fin bar into the isolator in each vertical mullion of the assembled unit (See Figures 27 and 28). Crowd the bulb gasket so it is flush

with each end of the fin bar during fin bar installation. The fin bar runs between the gutter and the stack sill glazing adapter with approximately 1/8” gaps at

each end for sealant continuity.

13. Adjust the 17B7 stack sill adapter so that it is flush with the 17A6 vertical fin bar on each end as shown in Figure 29.

17A6 SSG Vertical Fin Bar

17B7 SSG Stack Sill

Glazing Adapter

WC20

Insert 17A6 into the isolator

and roll into position.

WC20

Figure 29

1/8” gap for sealant

continuity.

Figure 27

Figure 28 Figure 30

EFCO 2009 Page 14

Page 15

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 5 - SSG Unit Glazing: C. Adapter Installation

14. Using an approved solvent or cleaner, clean the surfaces of the mullions at the intersection of the intermediate horizontal and vertical.

15. Apply a heavy bead of sealant at the intersection of the intermediate horizontal and vertical (See Figure 32). The sealant should run between the structural

seals of the adjacent lites and extend from the edge of the vertical over to below where the intermediate horizo ntal adapter will be set.

16. Roll the 17H6 SSG glazing adapter into the isolator at the horizontal as shown in Figure 33. This must be done immediately after step 14 and 15 above,

before the sealant begins to cure. The adapter should be setting in sealant at the ends while leaving the notched areas free of sealant. The notch areas at

the ends are to be left open and sealant free for use as a weep system for the horizontals.

17. Insert HS32 setting blocks between the glazing adapter and the glass at quarter points, or as directed per the final approved shop drawings. Light prying

pressure may need to be applied to the glazing adapter to insert the setting blocks into place.

HS32 Setting

Figure 31

Apply a heavy bead of sealant at

the intersection of the intermediate

horizontal and vertical.

Figure 32 Figure 33

Block

17H6 SSG

Glazing Adapter

EFCO 2009 Page 15

Page 16

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 5 - SSG Unit Glazing: D. Weather Seal Application

1. Using an approved solvent or cleaner, clean the sealant contact surfaces of the gla zin g and adapters of all oils and other contaminants.

2. If sealant primer is required, apply it per the primer/sealant manufacturer’s instructions.

3. Insert 3/8” diameter backer rod between the glazing and adapters around all four corners of each lite of glazing. Refer to Figure 38 on the following page for

more information.

4. Apply sealant into the void between the adapters and glazing. If the sealant is properly and carefully applied, masking tape is not necessary on the adjacent

surfaces.

5. Before the sealant begins to cure or skin over, tool the sealant into the joints smoothly, taking care to smooth and blend the sealant in the corners and

intermediate intersections as shown below. Seen in section view, the sealant should have an hourglass shape and maintain a 2:1 width to depth ratio as

shown in Figure 38 on page 17. Remove any excess sealant from the surrounding surfaces before the sealant begins to cure.

Figure 34

Sealant

Continuity Joint

Sealant

Continuity Joint

Sealant

Continuity Joint

Figure 35 Figure 36 Figure 37

EFCO 2009 Page 16

Page 17

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 5 - SSG Unit Glazing: D. Weather Seal Application

6. Ensure the sealant continuity joints between the adapters are properly filled with sealant and tooled smoothly for best aesthetics. Refer to Figures 35, 36,

and 37 on page 16 for detailed views of the weather seals and sealant continuity joints.

7. Allow units to sit undisturbed until the sealant is cured and per the sealant manufacturer’s recommendations.

8. If units are being stored or shipped on their sides, prevent any pressure from being applied to the adapters, or the weather seals will be damaged.

Glazing Infill

Silicone Sealant

Weather Seal

3/8” Backer Rod

Stack Sill

Assembly

Figure 38

Vertical Mullion

Assembly

EFCO 2009 Page 17

Page 18

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 5 - SSG Unit Glazing: E. Jamb Mullion Installation

1. Clean the sealant contact surfaces on the underside of the gutter (Figure 40) and the top of the jamb (Figure 41) using an approved solvent or

cleaner. Apply a heavy bed of sealant to the underside of the gutter and onto the mullion stack leg of the assembled mullion as shown in Figure 40.

2. Apply a heavy bead of sealant to the jamb as shown in Figure 41.

3. Tilting the jamb at an angle as shown in Figures 41 and 42, mate the jamb and unit mullions beginning at the gutter end and rotating the jamb into place as

shown. Use clamps to snap together the jamb to the unit mullion. Light tapping with a glazing hammer will aid in snapping the mullions.

4. Secure the jamb mullion to the unit with SFQ5 fasteners into the 8806 spacers. Tool the sealant smooth as shown in Figure 43.

HEAD

8806 Spacer

(See Volume 1, Page 31).

SILL

SFQ5

8806 Spacer

(See Volume 1, Page 31).

Figure 39

Apply a heavy bead

of sealant to the end

of the jamb.

Insert the top of the

mullion first, mating it

with the unit mullion

Apply the “Z” clip to the vertical mullion

(See Volume 1, Pages 29 and 30.

Slide WC21 gasket into the jamb

mullion (See Volume 1, Page 26.

Figure 42 Figure 41 Figure 43

Apply a heavy bed of sealant

on the underside of the gutter

and onto the mullion stack leg.

8806

Figure 40

Tool sealant smooth,

blending it into the

adjacent surfaces.

EFCO 2009 Page 18

Page 19

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 5 - SSG Unit Glazing: E. Jamb Mullion Installation

5. Clean the end dam of all oils and contaminants and apply a bed of sealant to the jamb corresponding to where the end dam will be applied.

6. Before the sealant begins to cure or skin over from steps 1 and 2, apply the gutter end dam flush with the underside and notched face of the gutter with (2)

STT6 screws.

7. Apply a heavy bead of sealant where the top of the gutter and the inside of the end dam meet (See figure 46). Tool all of the sealant around the end dam

smooth.

8. Insert L142 isolator into the jamb mullion and roll on the 17A9 jamb mullion cover (See Figures 47 and 48). Center 17A9 between the gutter and the stack sill

glazing adapter with equal spacing on each end.

9. Drive in WVD1 wedge gasket between 17A9 and the jamb mullion (See Figures 47 and 48).

Apply a bed of sealant

for the end dam

End Dam

STT6

WVD1 Wedge

Gaskets

Figure 44

17A9 Jamb

Mullion Cover

Apply the end dam

flush with notch.

Figure 45

Tool sealant smooth,

blending it into the

adjacent surfaces.

Figure 46

17A9 Jamb

L142

Mullion Cover

Figure 49 Figure 48 Figure 47

EFCO 2009 Page 19

Page 20

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 6 - Captured Unit Glazing : A. Temporary Glazing Locators

1. In order to properly

locate the glazing,

temporary adapters must

be used at the bottom

edge of the glazing.

Apply two temporary

glazing locators KV03

AND KV04 at

approximate quarter

points of the sill and

intermediate horizontal

locations as shown in

Figures 50, 51, and 52.

2. Using an approved

solvent or cleaner,

thoroughly clean the

edges of the glazing

that will contact the

structural silicone and

spacer of all oils and

other contaminants.

Once the glass has been

cleaned, it should be

handled with gloves to

avoid contaminating the

edges that come into

contact with the

structural silicone

glazing joint.

Temporary Glazing

Locators

Figure 50

17B9

L142

Figure 51 - Captured Intermediate Horizontal

(2) HS31

KV03

17B5

(2) HS31

L142

Figure 52 - Captured Stack Sill

KV04

EFCO 2009 Page 20

Page 21

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 6 - Captured Unit Glazing : B. Setting and Caulking Glazing

3. Set the glazing on the silicone spacer gaskets positioned as shown below. The edge of the gla zing i s flush with the edge of the vertical mullion. Refer to

Figure 54 below. Ensure the glazing is pressed firmly onto the setting blocks of the temporary retainers as shown in Figures 55 and 56.

4. Align the glazing as shown and noted. Ensure the glazing is positioned with the exterior side out, and the bottom of the glazing to the setting blocks. Care

should be exercised to avoid shifting or rolling the spacer gaskets when adjusting the position of the glass.

5. After the glass is aligned and in the final position, remove the setting blocks and temporary glazing locators.

6. Apply structural silicone sealant into the void between the glass and mullion per the sealant manufacturer’s application instructions. A 3/8” backer rod should

be applied into the isolator reglet to prevent sealant from getting into the reglet (see Figure 54). See additional notes, and Figures 57, 58, and 59 on page 22

for sealant application and tooling instructions.

7. Immediately tool the sealant joint after application to insure the joint is completely filled with sealant on all four sides of each piece of glazing. Make sure no

air bubbles or voids are present in the sealant joint.

8. Remove the backer rod, before the sealant begins to cure and skin over.

JAMB

Note:

Only silicone sealants

which have been

developed and tested

specifically for structural

glazing applications

should be used for

glazing purposes.

SILL

Figure 55

Figure 54

Figure 56

JAMB

Figure 53

HEAD

Set glazing onto the silicone

spacer gaskets and against

the setting blocks at the

temporary glazing locators.

Apply structural silicone

sealant into the void and

tool the joint to fill the

void completely.

Insert a 3/8” backer rod

into isolator reglet to keep

free of sealant. Remove the

backer rod immediately

before sealant begins to

skin over.

Glass is flush with

edge of mullion.

KV04

L142

Figure 54 Figure 55 Figure 56

KV03

L142

EFCO 2009 Page 21

Page 22

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 6 - Captured Unit Glazing : B. Setting and Caulking Glazing

9. Follow the sealant manufacturer’s instructions for application equipment preparation and qu ality control procedures.

10. Apply sealant and tool the frames as required per the sealant manufacturer’s application instructions in the Structural Sealant Glazing Manual. Care should

be taken to insure that the sealant void at the glass edge is completely filled. The sealant gun operator should visually confirm that this void is being filled at

the time of application (See figures 57, 58 and 59). Clean up any excess sealant that may get into the gasket reglets or any other areas that sealant would

be undesirable.

11. Frames should not be moved until the sealant has cured and per the sealant manufacturer’s recommendations.

Figure 57

Note:

Only silicone sealants

which have been

developed and tested

specifically for structural

glazing applications

should be used for

glazing purposes.

Figure 59

Figure 58

GLASS SIZE FORMULAS

Per Side Add Dimensions

Standard Mullions - D.L.O. + 13/16”

Inside Corner Mullion - D.L.O. + 13/16”

Outside Corner Mullion - D.L.O. + 7/8”

EFCO 2009 Page 22

Page 23

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

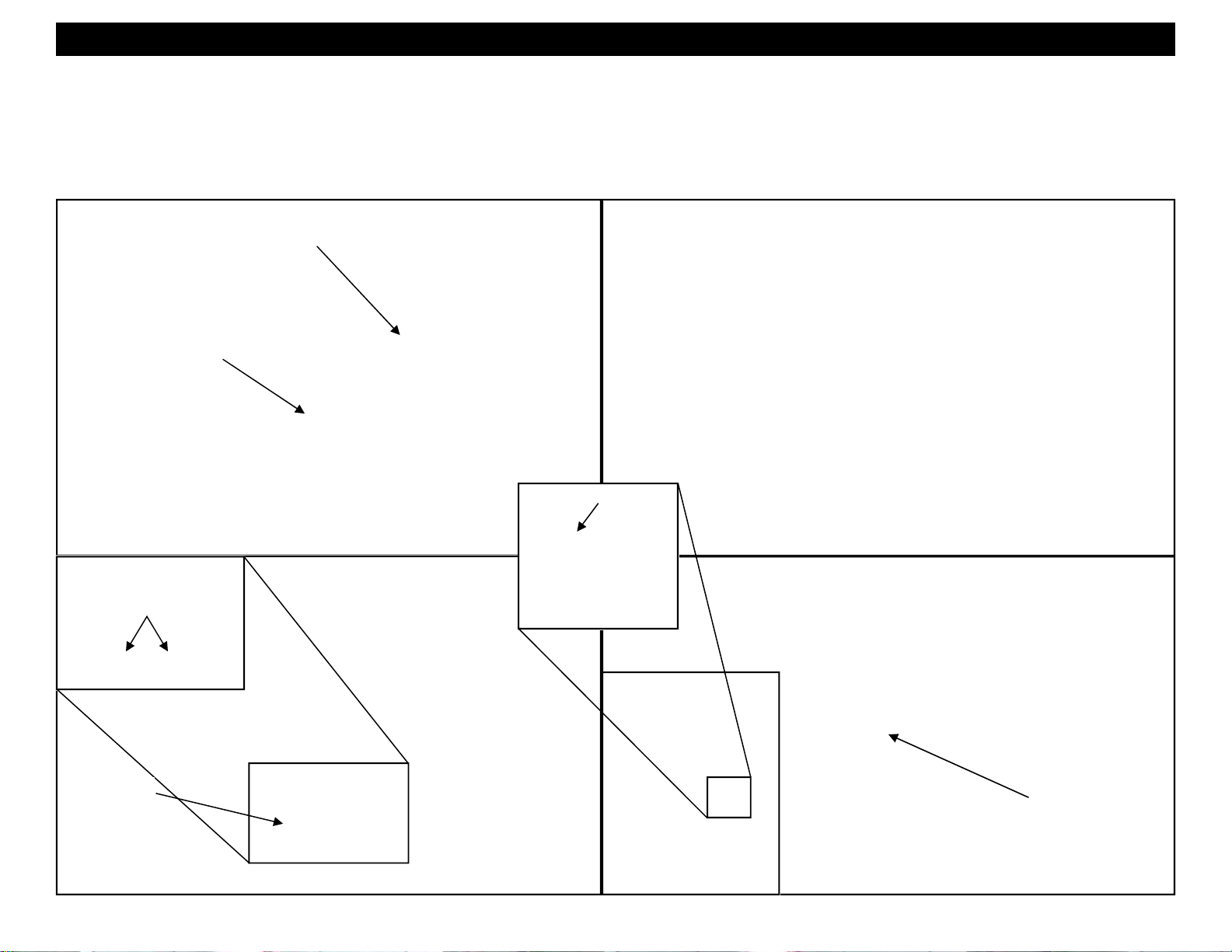

Section 6 - Captured Unit Glazing: C. Adapter and Cover Installation

1. Cut L142 to length with vinyl cutters. Apply the thermal isolator L142 into the verticals and horizontals. L142 is supplied in 10’-0” lengths. L142 may be used

in several pieces to accommodate the required length. By butting multiple pieces together, waste will be avoided and the desired length can be obtained.

2. Apply the preset thermal isolator (WC16) to the head running the gasket continuously between the vertical mullions (See Figure 63).

3. Figure 62 shows the various isolators and gaskets used in this section.

L142 Thermal

Isolator Clip

L142

Vinyl Cutters

Figure 60

WC16

L142

WC19

WC16

LC23

WC17

Figure 62

L142 Thermal

Isolator Clip

Figure 61

Figure 63

WC16

Isolator

Gasket

EFCO 2009 Page 23

Page 24

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 6 - Captured Unit Glazing: C. Adapter and Cover Installation

4. Apply 17B5 Captured glazing adapter to the stack sill. Final adjustment of the 17B5 will be made after the vertical glazing adapters are applied.

5. Slide the WC17 horizontal stack joint rain screen gasket into position as shown in Figures 65, 66, and 67. WC17 runs the same length as 17B5 and is applied

flush with each end of 17B5.

6. Insert HS31 setting blocks (2 at each location) between the stack sill glazing adapter and the glass at quarter points, or as directed per the final approved

shop drawings. Light prying pressure may need to be applied to the glazing adapter to insert the setting blocks into place.

(4) HS31 Setting

Blocks

WC17 Horizontal

Stack Joint Rain

Screen Gasket

17B5 Captured Stack

Sill Glazing Adapter

L142 stops 3/4” short of

the end of the mullion at

this location.

Figure 64

Figure 65

Slide WC17 gasket

into 17B5

Figure 67

Figure 66

WC17

HS31

L142

17B5

EFCO 2009 Page 24

Page 25

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 6 - Captured Unit Glazing: C. Adapter and Cover Installation

7. Clean the sealant contact surfaces of the mullion with an approved solvent or cleaner and apply a heavy bead of sealant to the tops of the vertical

mullions as shown in Figure 68.

8. Clean the sealant contact surfaces of the gutter with an approved solvent or cleaner. Apply sealant to the underside of the gutter where it will contact

the ends of the vertical with a bed of sealant. This will ensure that all voids are filled and good sealant contact is achieved once the gutter is applied t o the

frame. Install the SSG gutter to the frame at the head horizontal and secure with SPZ1. See Figure 69. It is critical that the sealants applied to the

gutter and mullion are thoroughly tooled and blended together to make watertight. See Figure 70.

9. Slide in WC19 gasket and LC23 spacer into the gutter. LC23 spacer runs continuously and is flush with the ends of the gutter. WC19 runs continuously, and

is cut 3” longer than the gutter (1 1/2” on each end). See figure 71.

Note! Critical seal!

The sealant must be

thoroughly tooled and

blended over the adjacent

surfaces all around the

sealant contact areas

shown in Figure 68. This

seal occurs at the top of

each vertical mullion.

Apply a h e avy

bead of sealant to

the tops of the

verticals.

Figure 70

WC19 Horizontal Stack

Joint Seal Gasket

SPZ1

LC23 Horizontal Stack Joint

Spacer Gasket

Figure 71

Horizontal Stack Gutter

17B1 Captured

Figure 68

Captured Gutter

SPZ1

SPZ1

Figure 69

EFCO 2009 Page 25

Page 26

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 6 - Captured Unit Glazing: C. Adapter and Cover Installation

10. Insert 17K1 glazing retainer into 17B5 and roll into position (See Figure 73). Insert 17K0 glazing retainer into 17B1 and roll into position (See Figure 74). The

glazing retainers will be flush with the ends of the adapters.

11. Drive in WC22 wedge gasket between 17K0, 17K1 and the glazing infill as shown in Figures 75 and 76. Start in the center, then move to the ends crowding

in as much gasket as possible (approximately 4% to 5% extra). Do not stretch the gasket during application. The WC22 should be trimmed to the same

length as 17K0 and 17K1.

WC22

17K0

17B1

WC22

17K1

17B5

Figure 72

17K1 17K0

17B5

17B1

Figure 73 Figure 75 Figure 76 Figure 74

WC22 WC22

EFCO 2009 Page 26

Page 27

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 6 - Captured Unit Glazing: C. Adapter and Cover Installation

12. Slide WC20 bulb gasket into 17A2 captured vertical fin bar. Exercise care to avoid stretching the gasket during installation. Let the bulb gasket extend

approximately 1 1/2” longer than 17A2 on each end. The bulb gasket should be installed prior to applying 17A2.

13. Crimp the bulb in place to prevent slippage during unit installation. Crimp at each end of the adapter, and then about 24” on center.

14. Roll the 17A2 captured vertical fin bar into the isolator in each vertical mullion of the assembled unit (See Figures below).

15. Adjust the 17B5 stack sill adapter so that it is flush with the 17A2 vertical fin bar on each end as shown in Figure 78.

17K1 Glazing Retainer

17B5 Captured Stack

Sill Glazing Adapter

17A2 Fin Bar Extend WC20 on

each end as shown.

WC20

Figure 78

WC20

Insert 17A2 into the isolator

and roll into position.

Figure 77

Figure 79 Figure 80

EFCO 2009 Page 27

Page 28

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 6 - Captured Unit Glazing: C. Adapter and Cover Installation

16. Using an approved solvent or cleaner, clean the surfaces of the mullions at the intersection of the intermediate horizontal and vertical.

17. Apply a heavy bead of sealant at the intersection of the intermediate horizontal and vertical (See Figure 83). The sealant should run between the structural

seals of the adjacent lites and the areas that will contact the 17B9 glazing adapter.

18. Clean the ends of 17B9 captured glazing adapter .

19. Apply beads of sealant to each end of 17B9 as shown in Figure 82.

20. Roll the 17B9 captured glazing adapter into the isolator at the horizontal as shown in Figures 84 and 85. This must be done immediately after the steps

above, before the sealant begins to cure.

21. Using a putty knife, thoroughly tool the sealant, blending it into the adjacent surfaces.

22. Insert HS31 setting blocks, (2) per location, between the glazing adapter and the glass at quarter points, or as directed per the final approved shop drawings.

Light prying pressure may need to be applied to the glazing adapter to insert the setting blocks into place (See figures 84 and 85).

17B9 Captured

Glazing Adapter

Figure 82

HS31 Setting

Blocks (2) per

location.

17B9

Figure 83

Figure 81

Apply a heavy bead of

sealant at the intersection

of the intermediate

horizontal and vertical.

Figure 84

17B9

Figure 85

EFCO 2009 Page 28

Page 29

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 6 - Captured Unit Glazing: C. Adapter and Cover Installation

23. Insert 17B8 cover onto 17B9 captured glazing adapter and rotate into place as shown in Figures 86 and 87.

24. Cut the WC22 gaskets approximately 2” longer than the D.L.O. dimension.

25. Drive in WC22 wedge gaskets starting with the gasket on the setting block side of the glazing pocket. The gaskets should be applied starting in the center of

the D.L.O., and then working from the ends, work the gasket in place to the center of the lite.

17B8 Cover

WC22

Wedge

Gasket

17B8 Cover

WC22

Wedge

Gasket

17B9 17B9

Figure 86 Figure 87

EFCO 2009 Page 29

Page 30

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 6 - Captured Unit Glazing: C. Adapter and Cover Installation

26. Insert 17A3 cover into 17A2 captured glazing adapter at each unit jamb and rotate into place as shown in Figures 89 and 90.

27. Cut the WC22 gaskets approximately 2” longer than the D.L.O. dimension.

28. Drive in WC22 wedge gaskets as shown in Figure 90. The gaskets should be applied starting in the center of the D.L.O., and then working from the ends,

work the gaskets in place to the center of the lite.

17A3 Cover

17A3 Cover

17A2 Captured Glazing Adapter

17A2 Fin Bar

Figure 88

WC22

Wedge

Gasket

17A2 Captured

Glazing Adapter

17A3 Cover

Figure 89

Figure 90

EFCO 2009 Page 30

Page 31

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 6 - Captured Unit Glazing: D. Joint Plug Installation

1. HNC4 joint plugs will be required at the head and sill of the assembled unit frame. Using an approved solvent or cleaner, clean the surfaces of the

mullions where the joint plug will be applied.

HNC4

HNC4

HNC4

HNC4

Figure 91 Figure 92

Figure 90

HNC4

HNC4 Joint Plug

EFCO 2009 Page 31

Page 32

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 6 - Captured Unit Glazing: D. Joint Plug Installation

2. Examine the joint plugs, and if contamination has occurred, clean them if necessary.

3. Apply a heavy bead of sealant around the joint plug on the sealant contact surfaces (See Figure 94).

4. Insert the joint plug into the opening between the adapter and covers at the head and sill of the unit.

5. Apply beads of sealant over the joint plug as shown in Figure 95.

6. Tool the sealant smooth, filling the voids around the joint plug.

Apply sealant around

the joint plug.

Clean with approved

cleaner.

Apply a bead of sealant

around the joint plug.

Figure 93

Tool the sealant

over the joint plug.

HNC4

Figure 94 Figure 96

Figure 95

EFCO 2009 Page 32

Page 33

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 6 - Captured Unit Glazing: E. Jamb Mullion Installation

1. Clean the sealant contact surfaces on the underside of the gutter (Figure 98) and the top of the jamb (Figure 99) using an approved solvent or

cleaner. Apply a heavy bed of sealant to the underside of the gutter and onto the mullion stack leg of the assembled mullion as shown in Figure 98.

2. Apply a heavy bead of sealant to the jamb as shown in Figure 99.

3. Tilting the jamb at an angle as shown in Figures 98 and 99, mate the jamb and unit mullions beginning at the gutter end and rotating the jamb into place as

shown. Use clamps to snap together the jamb to the unit mullion. Light tapping with a glazing hammer will aid in snapping the mullions.

4. Secure the jamb mullion to the unit with SFQ5 fasteners into the 8806 spacers. Tool the sealant smooth as shown in Figure 101.

HEAD

SFQ5

8806 Spacer

(See Volume 1, Page 31).

Figure 97

Apply a heavy bead

of sealant to the end

of the jamb.

8806 Spacer

(See Volume 1, Page 31).

Apply the “Z” clip to the vertical mullion

(See Volume 1, Pages 29 and 30.

Insert the top of the

mullion first, mating it

with the unit mullion

Figure 100 Figure 99 Figure 101

SILL

Slide WC21 gasket into the jamb

mullion (See Volume 1, Page 26.

Apply a heavy bed of sealant

on the underside of the gutter

and onto the mullion stack leg.

Figure 98

Tool sealant smooth,

blending it into the

adjacent surfaces.

8806

EFCO 2009 Page 33

Page 34

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 6 - Captured Unit Glazing: E. Jamb Mullion Installation

5. Clean the end dam of all oils and contaminants and apply a bed of sealant to the jamb corresponding to where the end dam will be applied.

6. Before the sealant begins to cure or skin over from steps 1 and 2, apply the gutter end dam flush with the underside and notched face of the gutter with (2)

STT6 screws.

7. Apply a heavy bead of sealant where the top of the gutter and the inside of the end dam meet (See figure 104). Tool all of the sealant around the end dam

smooth.

8. Insert L142 isolator into the jamb mullion and roll on the 17H5 jamb mullion cover (See Figures 105 and 106). Center 17A9 between the gutter and the stack

sill glazing adapter with equal spacing on each end.

9. Drive in WVD1 wedge gasket between 17H5 and the jamb mullion (See Figures 105 and 106).

Apply a bed of sealant

for the end dam

End Dam

STT6

WVD1 Wedge

Gasket

Figure 102

17H5 Jamb

Mullion Cover

Apply the end dam

flush with notch.

Figure 103

Tool sealant smooth,

blending it into the

adjacent surfaces.

Figure 104

17H5 Jamb

Mullion Cover

Figure 107 Figure 106 Figure 105

EFCO 2009 Page 34

Loading...

Loading...