Page 1

SERIES 8750XD UNITIZED CURTAIN WALL

Installation Instructions Sections 1-15

Nov 2012

PART NO. Y80B

1000 COUNTY ROAD MONETT, MO 65708 • 800.221.4169 • EFCOCORP.COM

Page 2

Series 8750XD Unitized Curtain Wall Installation Instructions

Series 8750XD Unitized Curtain Wall Installation Instructions

Table Of Contents

SECTION PAGES

1. General Notes and Guidelines………………………………………………………………………………………………………………………………

2. Parts Identification…………………………………………………………………………………………………………………………………………….

3. Static Starter Sill Preparation and Installation……………………………..…………………………………………………………………………….

4. Dynamic Starter Sill Preparation and Installation…………………..………………..………………………………………………………………….

5. Intermediate Floor Slab Anchor Installation……………………………………….....………………………………………………………………….

6. Unit Inspection and Preparation for Installation……………………………..….......………………………………………………………………….

7. Setting Units at Static Starter Sills………………………………………………..…....………………………………………………………………….

8. Setting Units at Dynamic Starter Sills………………………………………………….……………………… ………………………………………….

9. Applying Critical Seals and Stack Gaskets……………………………………...……………………………………………………………………….

10. Setting Typical intermediate Units….......................................................................………………………………………………………………….

11. Setting Typical Head Condition Units………………………………………………….………………………………………………………………….

12. Setting Typical 90 Degree Corner Units……………………………………………….………………………………………………………………….

13. Appling Typical Perimeter Seals………………………………………………………..…………………… …………………………………………….

14. Deglaze / Re-glaze Procedures - Captured System................................................………………………………………………………………….

15. Deglaze / Re-glaze Procedures - SSG System…….................................................………………………………………………………………….

3 - 4

5 - 11

12 - 18

19 - 22

23 - 24

25 - 27

28 - 30

31 - 32

33

34 - 35

36

37

38

39 - 40

41 - 43

Minimizing Condensation

Note: Please reference EFCO's "Understanding Condensation" brochure which can be obtained through your EFCO representative.

Condensation will form on any surface when unfavorable conditions (interior temperature and relative humidity and exterior temperature) are present. When the formation of excessive condensation is a concern, it is highly recommended that a design professional is utilized to perform an analysis of the shop drawings to recommend the best possible installation methods. Please contact your EFCO representative for information on EFCO's Thermal Analysis Services.

Many current installation practices lead to an increase in the possibility of the formation of condensation. Though not all inclusive, the list of examples below illustrates conditions

under which condensation is likely to occur:

Note: Assembly Instructions ( Y807 ) are provided as a supplement, and should be used in conjunction with the approved shop drawings.

EFCO 2012 Page 2

EFCO 2012 Page 2

1. Bridging system thermal break with non-thermally broken metal flashing or lintels that are exposed to the exterior

2. System exposure to cold air cavities

3. Interior relative humidity levels not maintained at recommended levels, see EFCO’s “Understanding Condensation” brochure

4. Inadequate separation between system and surrounding condition at perimeter

5. Product combinations during the shop drawing stage that result in bridging thermal breaks

of one or all products involved.

Page 3

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 1: General Notes And Guidelines

HANDLING / STORING / PROTECTING ALUMINUM

The following guidelines are recommended to ensure early acceptance of your

products and workmanship.

A. HANDLE CAREFULLY - Store with adequate separation between

components so the material will not rub together. Store the material off the

ground. Protect materials against weather elements and other

construction trades.

B. KEEP MATERIAL AWAY FROM WATER, MUD, AND SPRAY - Prevent

cement, plaster, and other materials from contacting with and damaging

the finish. Do not allow moisture to be trapped between the finished

surface and the wrapping material.

C. PROTECT MATERIALS AFTER ERECTION - Wrap or erect screens of

plastic sheeting over material. Cement, plaster, terrazzo, and other

alkaline materials are very harmful to the finish and are to be immediately

removed with soap and water. Under no circumstances should these

materials be allowed to dry or permanent staining may occur.

GENERAL GUIDELINES

The following practices are recommended for all installations:

A. REVIEW CONTRACT DOCUMENTS – Become thoroughly familiar with

the project. Check shop drawings, installation instructions, architectural

drawings and shipping lists. The shop drawings take precedence and

include specific details for the project. Shop drawings govern when

conflicting information exists in the assembly and installation instructions.

Note any field verified notes on the shop drawings prior to installing.

EFCO assembly and installation instructions are general in nature and

cover many conditions.

B. INSTALL ALL FRAMING MATERIAL PLUMB, LEVEL, AND TRUE –

Proper alignment and relationships to benchmarks and column

centerlines, as established by the architectural drawings and the general

contractor, must be maintained.

C. ERECTION SEQUENCE - The sequence of erection should be

coordinated with the project general contractor to prevent delays and

minimize the risk of material damage. Note: When preset anchors are

required, coordinate and supervise anchor and insert placement with the

general contractor including insert layout drawings, where required.

Manufacturing, assembly, glazing, and shipment of the preglazed units

must be carefully coordinated with the general contractor to ensure a

continuous and sustained flow of materials to the appropriate areas of the

project to meet the project schedule.

D. PERIMETER CONDITIONS - Verify that all job site co nditions and

accompanying substrates receiving the installation are in accordance with

the contract documents. If deviations occur, notification must be given in

writing to the general contractor and differences resolved before

proceeding further with the installation in the area in question.

E. ISOLATION OF ALUMINUM - Prevent all aluminum from coming in direct

contact with masonry or dissimilar materials by means of an appropriate

primer. Typical slab anchors may be set directly onto concrete surfaces in

a block-out pocket at the edge of the slab. The block-out pocket is later

filled in with grout thereby covering the slab anchor. In such cases, a

heavy coat of zinc chromate or bituminous paint must be pre-applie d to

the slab anchor.

F. SHIPMENT VERIFICATION - Verify contents of all material shipments

received upon their arrival. Verify quantity and correct finishes. Notify

EFCO immediately of any discrepancies or damage that may have

occurred.

G. SEALANT - All sealant must meet [ASTM C 920, CLASS 50]. For the

purposes of these instructions, sealant is to be defined as the following:

SEALANT - A weather resistant, gunnable liquid filler which when cured

provides a resilient, flexible (± 50% movement capability min.) air and

water seal between similar and dissimilar materials.

All sealant must be compatible with all surfaces on which adhesion is

required, including other sealant surfaces. All frame surfaces should be

clean, dry, dust, and frost free. If a primer is required, it must be applied to

clean surfaces. All perimeter substrates shall be clean and properly

treated to receive sealant. All sealants and primers must be applied

according to the sealant manufacturers instructions and

recommendations.

This system is designed and has been tested to utilize silicone sealants at

all internal joineries, i.e., joint plugs, gasket intersections, etc.

EFCO 2012 Page 3

Page 4

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 1: General Notes And Guidelines

It is the responsibility of the glazing contractor to submit a statement from

the sealant manufacturer indicating that glass and glazing materials have

been tested for compatibility and adhesion with glazing sealants, and

interpreting test results relative to material performance, including

recommendations for primers and substrate preparation required to obtain

adhesion. The chemical compatibility of all glazing materials and framing

sealants with each other and with like materials used in glass fabrication

must be established.

Maintain caulk joints as shown in the approved shop drawings. A 1”

minimum joint is required at the head and jamb condition to accommodate

installation, building movements, and thermal expansion and contraction.

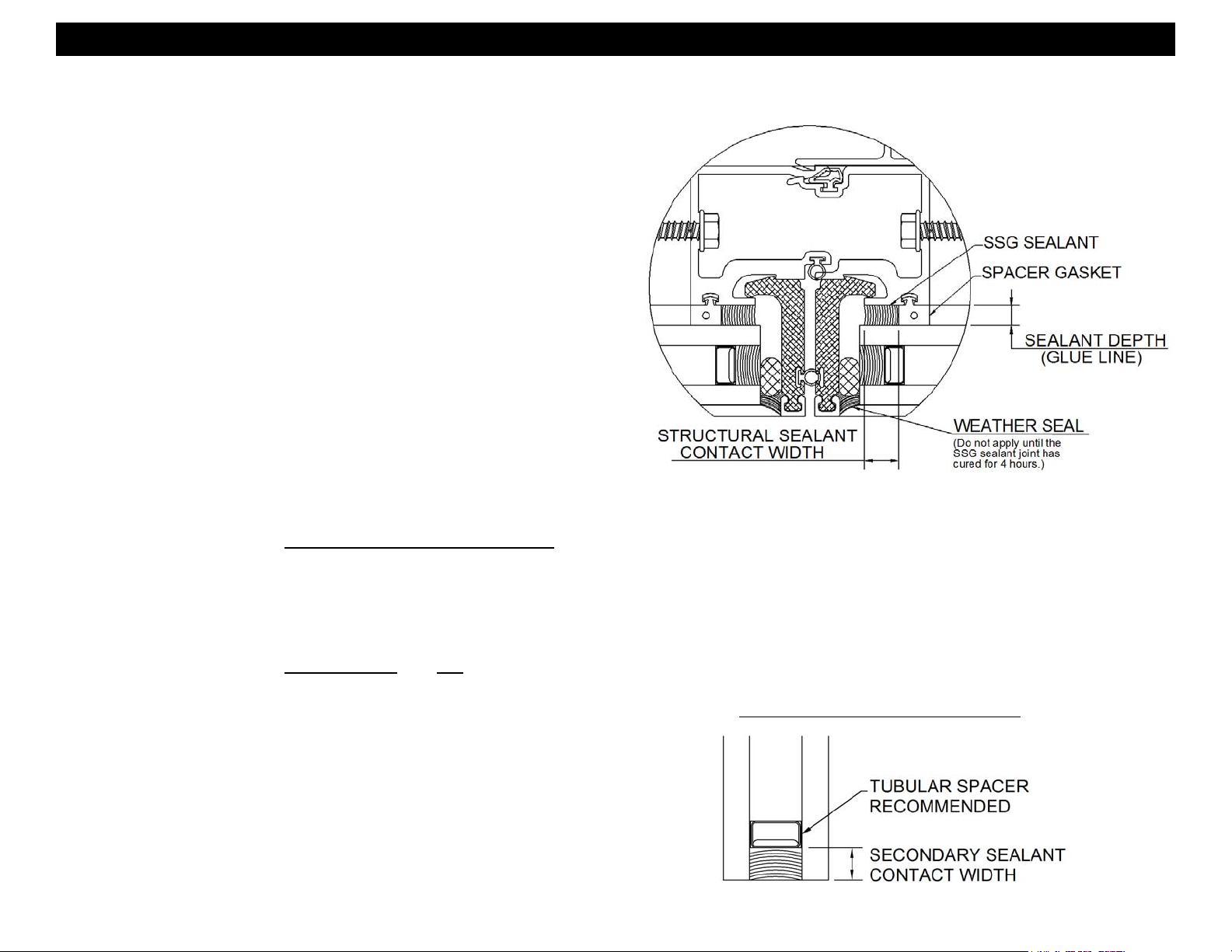

H. STRUCTURAL SEALANT JOINTS - The maximum allowable size of the

glass lite is controlled by the width and depth of the structural silicone joint

combined with the specified design wind load (PSF or Pa). The stress on

the structural silicone must not exceed 20 PSI (137 KPa) for a 6:1 safety

factor.

In order to determine the structural silicone sealant contact width or bite

which adheres the glass to the frame, a calculation must be performed on a

job by job basis. The formula which determines the sealant width is based

on using a trapezoidal load distribution rule. This formula is expressed as

follows:

Structural Sealant = 0.5 x Short Span (ft) x Wind load (lb/ft²)

Bite or Contact Width (in) Sealant Design Strength (=20 lb/in²) x 12 in/ft

Example: Lite size is 4’0” x 5’0” and wind load for the project is 60 psf.

Structural Sealant = 0.5 x 4’ x 60 psf

Bite or Contact Width (in) 20 x 12 240

Sealant manufacturers, as a general rule, specify the structural sealant

depth (glue line) to be one half of the contact width for a 2:1 width to height

ratio. The glue line should not exceed 3/8” thickness nor be less than 1/4”

thick. The standard joint size for Series 8750XD is 1/2” x 1/4”. Note:

Weather seals must be applied a minimum of four hours after the

application of the SSG sealant joint to allow for proper cure time.

or 120 or .500”

SECONDARY SEALANT JOINT DETAIL

I. SECONDARY SEALANT JOINT DESIGN - The design of the secondary

sealant joint is based on the 50:50 load sharing principal where the I.G. unit

is comprised of two symmetrical lites of glass. The secondary sealant joint

that adheres the two lites of glass together only carries half the wind load

applied to the I.G. unit. Since the load is halved, the secondary sealant

contact width is half that of the SSG joint. Using the example earlier for the

1/2” x 1/4” SSG joint, the secondary sealant contact width for the I.G. unit in

the example is 1/4”.

Edge deletion is required on the coated surface (#2 or #3) for hard or soft

coated glazing products.

SECONDARY SEALANT JOINT DETAIL

EFCO 2012 Page 4

Page 5

Series 8750XD Unitized Curtain Wall Installation Instructions

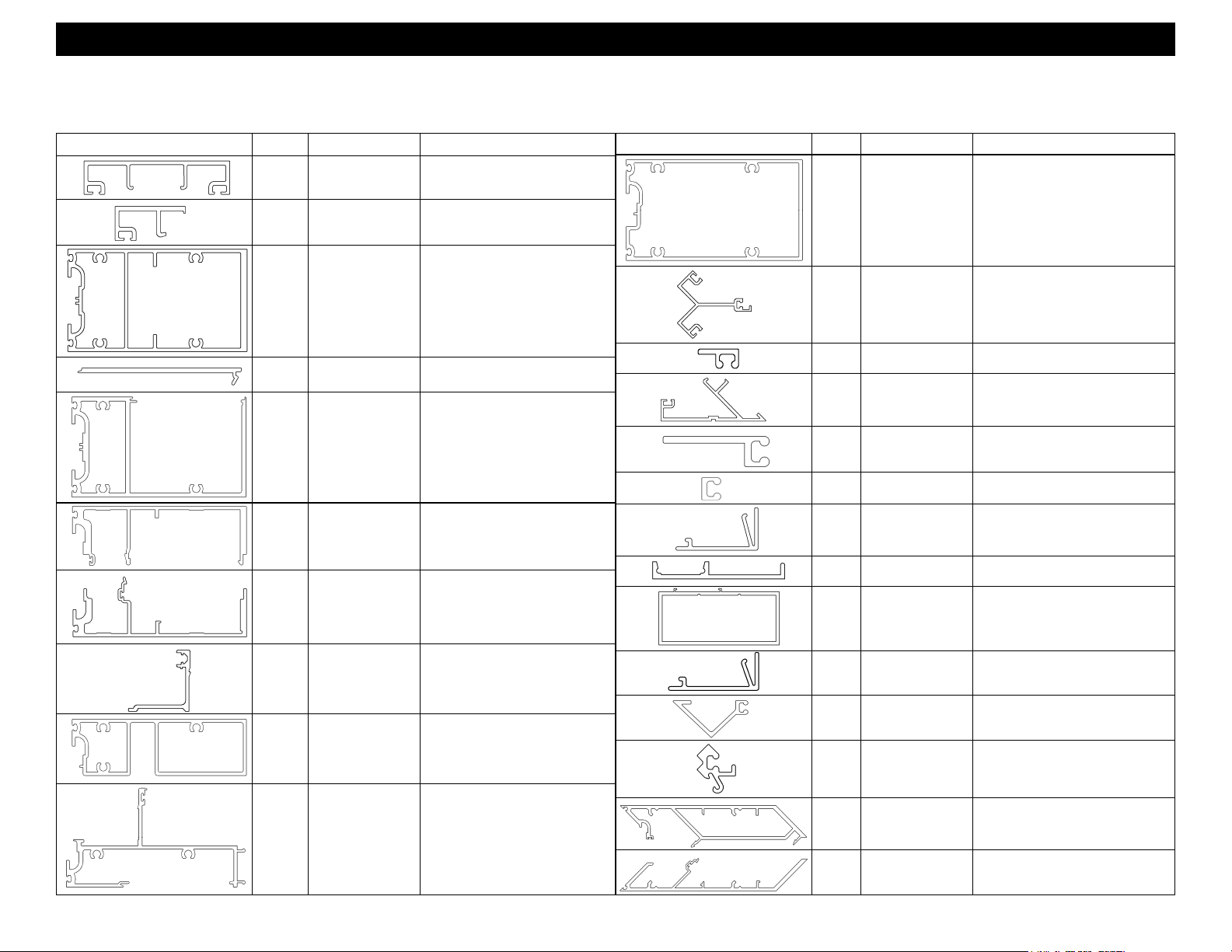

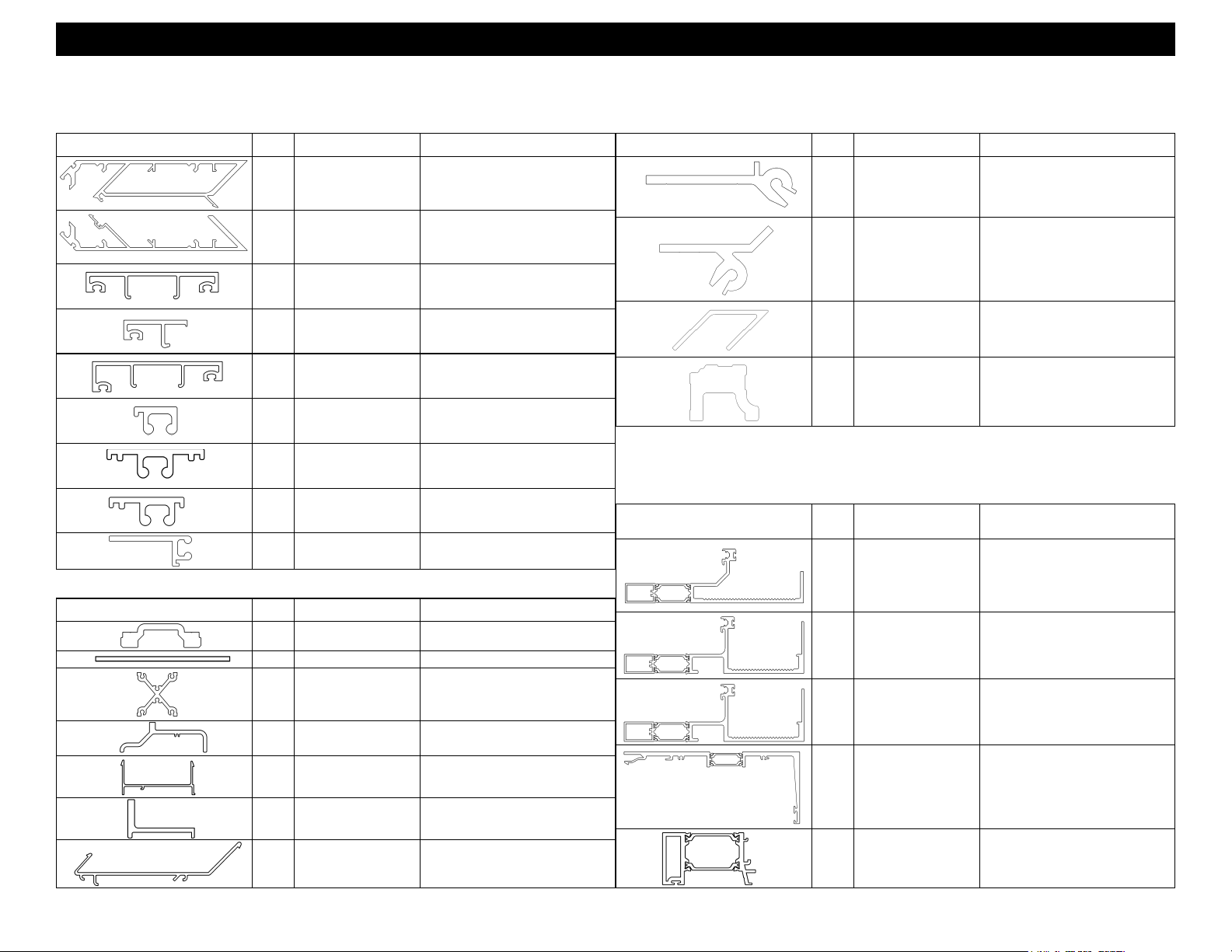

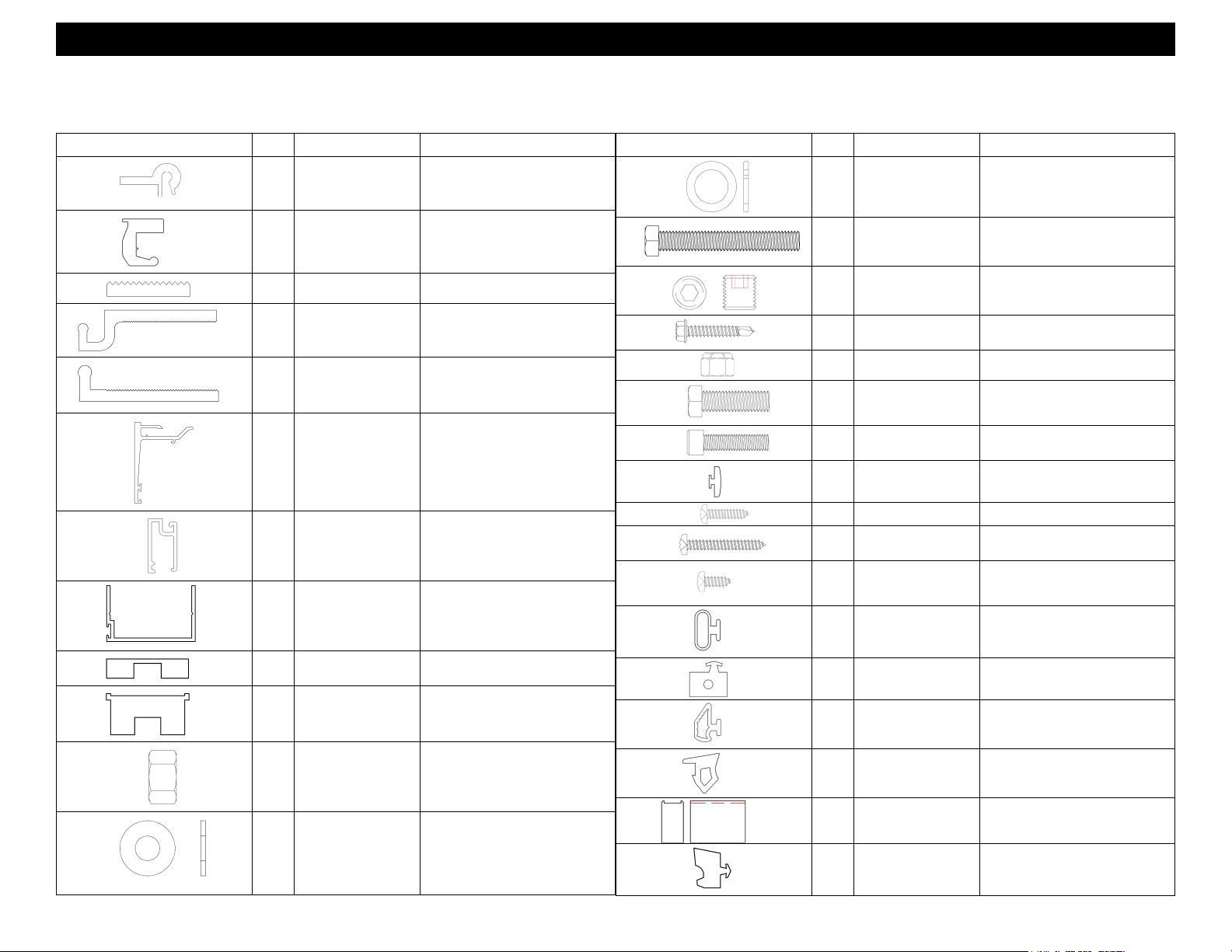

EXTRUSION IDENTIFICATION

Profile Part # Description Tooling/Cut Length Formula

17T1

17T2

17T3

17T5

17T6

17T7

17T8

3" STANDARD

COVER

STANDARD

HALF COVER

STANDARD

INTERMEDIATE

HORIZONTAL

HEAD OR JAMB

FILLER

HEAD

OR CUSTOM

JAMB

SPLIT MULLION

#1

SPLIT MULLION

#2

Section 2 - Parts Identification

EXTRUSION IDENTIFICATION

Profile Part # Description Tooling/Cut Length Formula

17T1-001

17T2-001

17T3-001, 17T3-002, 17T3-003,

17T3-004, 17T3-005, 17T3-006,

17T3-007, 17T3-008, 17T3-009,

17T3-010, 17T3-01

17T5-001, 17T5-002, 17T5-003,

17T5-004, 17T5-005, 17T5-006

17T6-001, 17T6-002, 17T6-003,

17T6-004, 17T6-005, 17T6-006

17T7-001, 17T7-002, 17T7-003,

17T7-004, 17T7-005, 17T7-006

17T8-001, 17T8-002, 17T8-003,

17T8-004, 17T8-005, 17T8-006

17U3

17U4

17V1

17V2

17V3

17V4

17V5

17V6

17V9

SSG

HORIZONTAL

90 DEG INSIDE

CORNER COVER

SSG DROP LEG

COVER

90 DEG OUTSIDE

CORNER COVER

EXTENDED LEG

SSG COVER

STANDARD SSG

COVER

5/8" THERMAL

DOOR STOP

COVER

INTERIOR HORIZ.

SNAP TRIM

TRANSOM DOOR

HEADER

17U3-001, 17U3-002, 17U3-003

17U4-001

17V1-001

17V2-001

17V3-001, 17V3-002, 17V3-003,

17V3-004, 17V3-005, 17V3-006,

17V3-007

17V4-001

DOOR FRAME CLEAR OPENING

(NEED PREP)

STOCK LENGTH

(NEED PREP)

DOOR FRAME CLEAR OPENING

(NEED PREP)

17T9

17U0 STACK SILL

17U1 STACK HEAD

SNAP IN

NECK

17T9-001, 17T9-002, 17T9-003,

17T9-004, 17T9-005,

17T9-006

17U0-001, 17U0-002, 17U0-003,

17U0-004, 17U0-005, 17U0-006

17U1-001, 17U1-002, 17U1-003,

17U1-004, 17U1-005, 17U1-006

17W2

17W3

17W4

17W6

17W7

1/2" THERMAL

DOOR STOP

COVER

SSG 90 DEG

OUTSIDE COR-

NER COVER

SSG 90 DEG

INSIDE CORNER

COVER

MALE 90 DEG

INSIDE CORNER

HALF

FEMALE 90 DEG

INSIDE CORNER

HALF

DOOR FRAME CLEAR OPENING

(NEED PREP)

17W3-001

17W4-001

17W6-001, 17W6-002, 17W6-003,

17W6-004, 17W6-005, 17W6-006

17W6-007

17W7-001, 17W7002, 17W7-003,

17W7-004, 17W7-005, 17W7-006

17W7-007

EFCO 2012 Page 5

Page 6

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 2 - Parts Identification

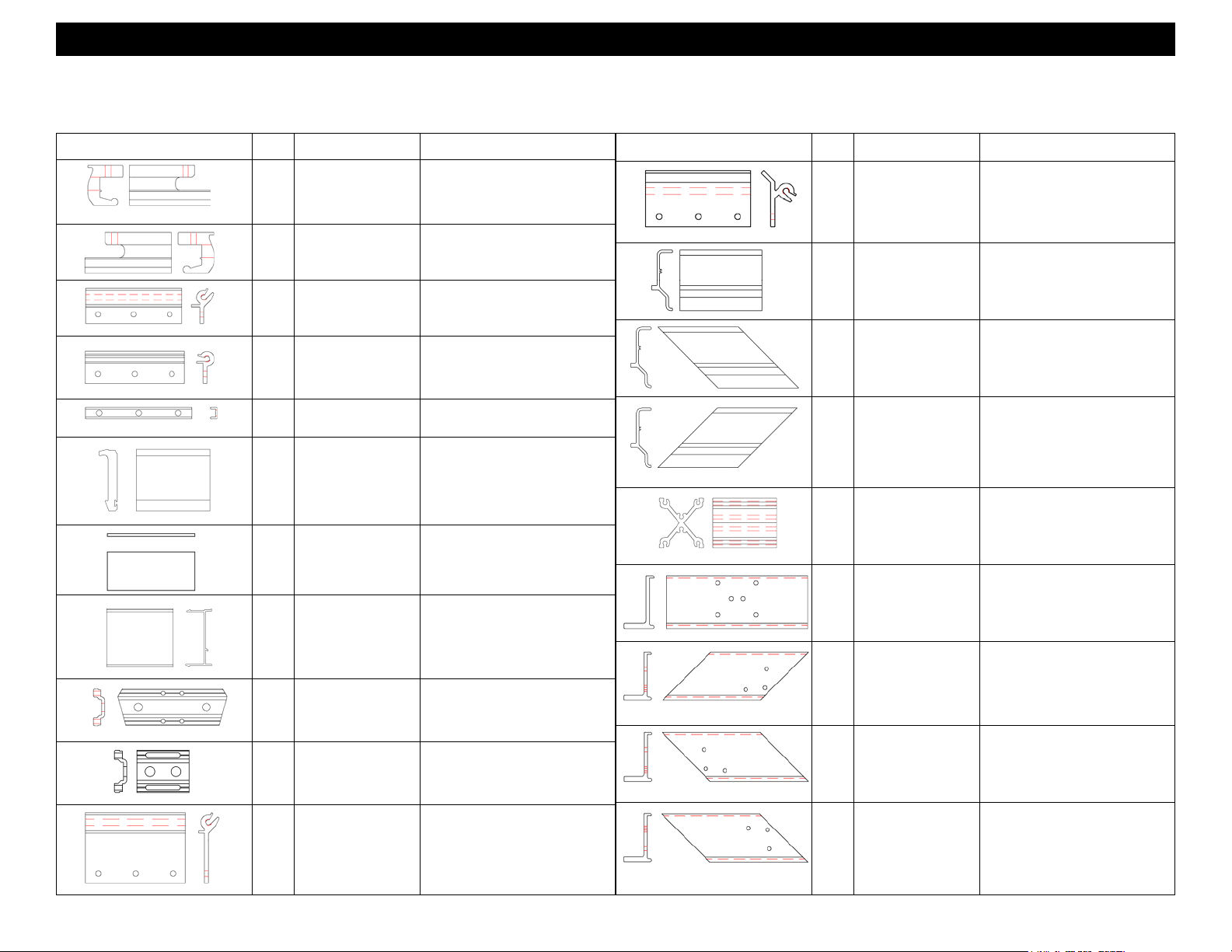

EXTRUSION IDENTIFICATION

Profile Part # Description Tooling/Cut Length Formula

17W8

17W9

17X5

17X6

17X7

17X8

17X9

17Y0

17Y1

MALE OUTSIDE

CORNER HALF

FEMALE OUTSIDE

CORNER HALF

3" COVER FOR

1 1/4" GLAZING

AND VENTS

HALF COVER FOR

1 1/4" GLAZING

AND VENTS

3" COVER FOR 1"

GLAZING OVER

VENTS

STANDARD SSG

COVER FOR VENT

LOCATIONS

SSG COVER INTER.

HORIZONTAL VENT

OVER VENT

SSG COVER FOR

VENTS AT SILL OR

HORIZONTAL

SSG COVER FOR

VENTS AT JAMBS

17W8-001, 17W8-002, 17W8-003,

17W8-004, 17W8-005, 17W8-006,

17W9-001, 17W9-002, 17W9-003,

17W9-004, 17W9-005, 17W9-006,

FABRICATED PART EXTRUSION IDENTIFICATION

Profile Part # Description Tooling/Cut Length Formula

17T4 HANGER FM41

17U2 .090 X 3.000 BAR FM39

17W8-007

17W9-007

17X5-001

17X6-001

17X7-001

17X8-001

17X9-001

17Y0-001

17Y1-001

FABRICATED PART EXTRUSION IDENTIFICATION

Profile Part # Description Tooling/Cut Length Formula

17X0

17X1

17Z7

17Z8

90° OUTSIDE COR-

NER MULLION AN-

CHOR

90° INTSIDE COR-

NER MULLION AN-

CHOR

INSIDE OUTSIDE

CORNER GUIDE

CLIP

SUN SHADE

BRACKET

COMPOSITE IDENTIFICATION

Profile Part # Description Tooling/Cut Length Formula

1H91 STATIC SILL CAN

1H92 DYNAMIC SILL CAN

FM43

FM44

FM78

FM82

STOCK LENGTH

1H91-001

STOCK LENGTH

1H92-001

17U8

17U9 STATIC LOAD CLIPS FM45, FM46 & FM47

17V0 SPLIT MULL CLIP FM40

17V8

17W5 CORNER SNAP CLIP FM70

DYNAMIC LOAD

CLIPS

DYNAMIC LOAD

CLIPS

FM48

FM49, FM50, FM51,

FM52 & FM53

1H93 DOOR ADAPTOR

1H94

1H97

SUB HEAD FOR 7

1/2" SYSTEM DEPTH

SCREW APPLIED

THERMAL JAMB

ADAPTOR

FABRICATED ONLY

(NEED PREP)

FABRICATED ONLY

(NEED PREP)

STOCK LENGTH

EFCO 2012 Page 6

Page 7

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 2 - Parts Identification

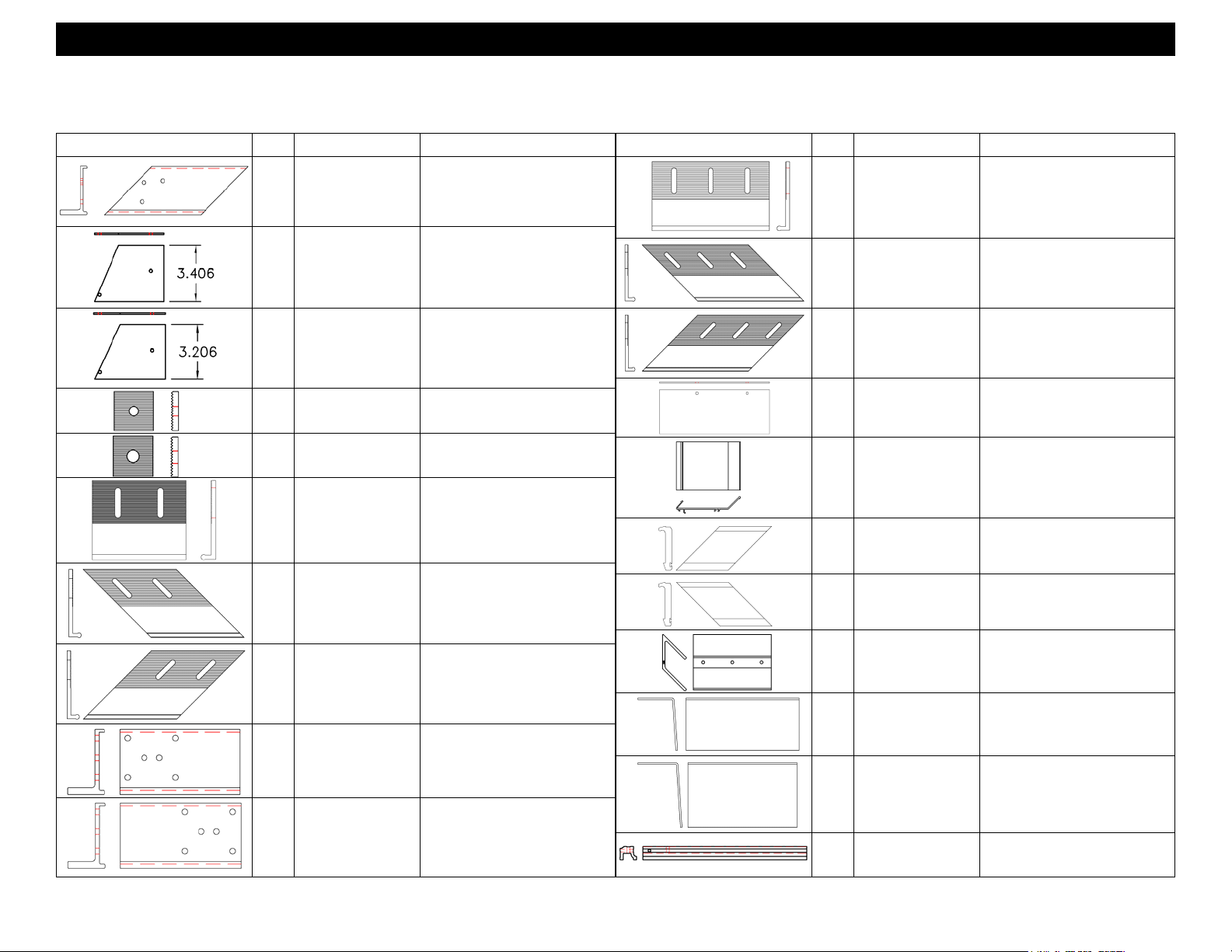

“ F ” PART IDENTIFICATION

Profile Part # Description Materials

FM05

FM06

FM07

FM11 MULLION ANCHOR 17D1 (MILL)

FM17

FM38

FM39

FM40

FM41

FM42

HOOK ANCHOR

(LEFT)

HOOK ANCHOR

(RIGHT)

90 DEG OUTSIDE

CORNER MULLION

ANCHOR

ANCHOR BOLT

RETAINER

LARGE DURACAST

CLIP

SILL CAN END CAP

BEHIND DOOR

JAMB

SPLIT MULLION

ATTACHMENT CLIP

RIGHT HAND

HANGER/LOAD CLIP

OPTIONAL RE-

TRACTABLE

HANGER

17D2 (MILL)

17D2 (MILL)

17F3 (MILL)

12D8 (MILL)

LC46

PAINTED DARK BROWN

17U2

FINISH PER JOB

17V0

CLEAR ANODIZED

17T4 (MILL)

17T4 (MILL)

“ F ” PART IDENTIFICATION

Profile Part # Description Materials

FM44

FM45

FM46

FM47

FM48

FM49

FM50

FM51

90 DEG INSIDE

CORNER MULLION

ANCHOR

STATIC SILL

LOADING CLIP

LEFT HAND STATIC

SILL LOADING CLIP

FOR 90 DEG OUT-

SIDE CORNERS

RIGHT HAND

STATIC SILL LOAD-

ING CLIP FOR 90

DEG OUTSIDE COR-

NERS

DYNAMIC LOAD

CLIP (TOP HALF)

DYNAMIC LOAD

CLIP (BASE)

LEFT HAND 90 DEG

INSIDE CORNER

DYNAMIC LOAD

CLIP (BASE)

RIGHT HAND 90

DEG INSIDE COR-

NER DYNAMIC

LOAD CLIP (BASE)

17X1 (MILL)

17U9 (MILL)

17U9 (MILL)

17U9 (MILL)

17U8 (MILL)

17V8 (MILL)

17V8 (MILL)

17V8 (MILL)

LEFT HAND 90 DEG

OUTSIDE CORNER

DYNAMIC LOAD

CLIP (BASE)

17V8 (MILL)

FM43

90 DEG OUTSIDE

CORNER MULLION

ANCHOR

17X0 (MILL)

FM52

EFCO 2012 Page 7

Page 8

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 2 - Parts Identification

“ F ” PART IDENTIFICATION

Profile Part # Description Materials

FM53

FM55

FM56

FM59

FM60

FM61 11" SLAB ANCHOR 17D4 (MILL)

RIGHT HAND 90

DEG OUTSIDE COR-

NER DYNAMIC

LOAD CLIP (BASE)

DYNAMIC SILL END

DAM

STATIC SILL END

DAM

SERRATED

WASHER FOR 3/8"

FASTENER

SERRATED

WASHER FOR 1/2"

FASTENER

17V8 (MILL)

.090 THICK ALUMINUM SHEET

(MILL)

.090 THICK ALUMINUM SHEET

(MILL)

17D3 (MILL)

17D3 (MILL)

“ F ” PART IDENTIFICATION

Profile Part # Description Materials

FM66

FM67

FM68

FM69

FM70

FM71

16" HIGH LOAD

SLAB ANCHOR

LEFT HAND HIGH

LOAD SLAB AN-

CHOR FOR COR-

NERS

RIGHT HAND HIGH

LOAD SLAB AN-

CHOR FOR COR-

NERS

SUB HEAD END

DAM

INSIDE/OUTSIDE

CORNER MULLION

ATTACHMENT CLIP

DURACAST COR-

NER CLIP #1

17D4 (MILL)

17D4 (MILL)

17D4 (MILL)

.090 THICK ALUMINUM (MILL)

17W5

CLEAR ANODIZED

LC46

PAINTED DARK BROWN

FM62

FM63

FM64

FM65

LEFT HAND SLAB

ANCHOR FOR 90

DEG CORNERS

RIGHT HAND SLAB

ANCHOR FOR 90

DEG CORNERS

LEFT HAND JAMB

DYNAMIC LOAD

CLIP (BASE)

RIGHT HAND JAMB

DYNAMIC LOAD

CLIP (BASE)

17D4 (MILL)

17D4 (MILL)

17V8 (MILL)

17V8 (MILL)

FM72

FM78

FM79

FM80

FM82

DURACAST COR-

NER CLIP #2

CORNER ALIGN-

MENT CLIP

SPLICE SLEEVE

FOR 17N1 SUB

HEAD

SPLICE SLEEVE

FOR 1H94 SUB

HEAD

SUNSHADE

BRACKET FOR 11" &

13" ARMS

PAINTED DARK BROWN

17X7 (MILL)

ABB2 (MILL)

SHEET ALUM

ABB2 (MILL)

SHEET ALUM

17Z8 (MILL)

EFCO 2012 Page 8

LC46

Page 9

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 2 - Parts Identification

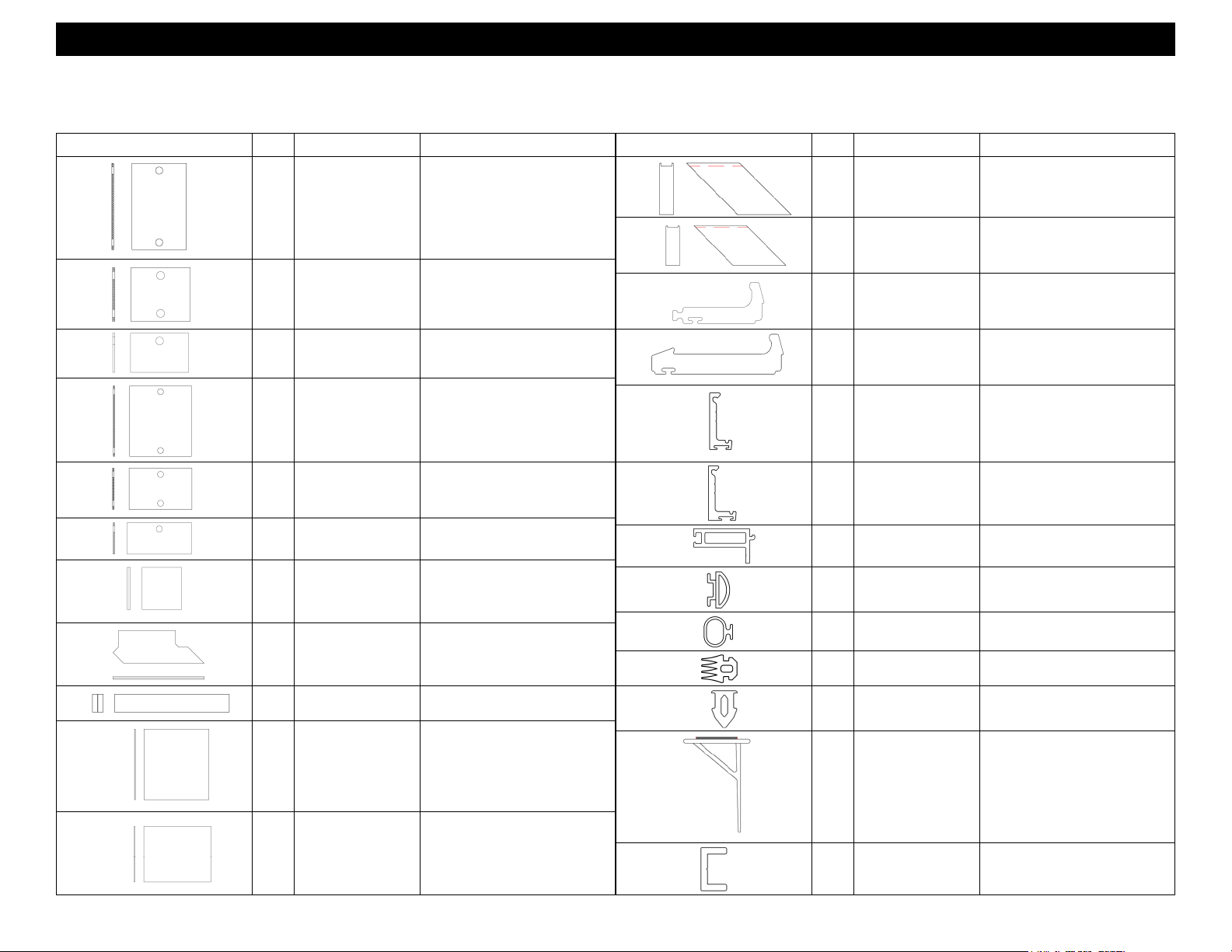

PART IDENTIFICATION

Profile Part # Description Materials

H12A

H12B

H12C

H12D

H12E

H12F

FIXED FRAME

GASKET #1

FIXED FRAME

GASKET #2

FIXED FRAME

GASKET #3

90 DEG CORNER

FRAME GASKET #1

90 DEG CORNER

FRAME GASKET #2

90 DEG CORNER

FRAME GASKET #3

PVC FOAM (BLACK)

PVC FOAM (BLACK)

PVC FOAM (BLACK)

PVC FOAM (BLACK)

PVC FOAM (BLACK)

PVC FOAM (BLACK)

EXISTIING EXTRUSIONS, PARTS, FASTENERS & WEATHERING ID

Profile Part # Description Materials

HD25

HD26

LC45

LC46

LC47

LC48

LC50

CAPTURED OUT-

SIDE CORNER

JOINT PLUG

CAPTURED INSIDE

CORNER JOINT

PLUG

SSG THERMAL

SPACER

STANDARD THER-

MAL SPACER

1/2" THERMAL

DOOR STOP BASE

5/8" THERMAL

DOOR STOP BASE

THERMAL POCKET

FILLER

EPDM GP SPONGE (BLACK)

EPDM GP SPONGE (BLACK)

DURACAST

(PAINTED DARK BROWN)

DURACAST

(PAINTED DARK BROWN)

HIGH IMPACT

PVC (BLACK)

HIGH IMPACT

PVC (BLACK)

HIGH IMPACT

PVC (BLACK)

H12G

H12H

HC05

HC13

HC14

MULLION CAP

GASKET

90 DEG CORNER

MULLION CAP

GASKET

FOAM SEALANT

BACKER

FIXED FRAME

SILICONE SPLICE

SHEET

SSG FRAME

SILICONE SPLICE

SHEET

PVC FOAM (BLACK)

PVC FOAM (BLACK)

PVC FOAM (GREY)

SILICONE SHEET (BLACK)

SILICONE SHEET (BLACK)

WA12

WC20

WEA2 STACK GASKET EPDM (BLACK)

WEA4

LC54 STACK SWEEP PVC WITH VHB TAPE

12D8

SUBHEAD WEATH-

ERING

INSIDE CORNER

EXTERIOR BULB

GLAZING DART

FOR VENTS

BOLT RETAINER

EXTRUSION

ALCRYN AND

PVC (BLACK)

EPDM (BLACK)

SANTOPRENE (BLACK

12D8 (MILL)

EFCO 2012 Page 9

Page 10

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 2 - Parts Identification

EXISTIING EXTRUSIONS, PARTS, FASTENERS & WEATHERING ID EXISTIING EXTRUSIONS, PARTS, FASTENERS & WEATHERING ID

Profile Part # Description Tooling/Cut Length Formula

Profile Part # Description Materials

17D1

17D2

17D3

17M6

17M7

17N1

9123

9914

HN09

HN32

MULLION ANCHOR

EXTRUSION

STANDARD HOOK

ANCHOR EXTRU-

SION

SILL WASHER EX-

TRUSION

UNDER SLAB AN-

CHOR EXTRUSION

SLAB ANCHOR

EXTRUSION

SUB HEAD COVER

EXTRUSION

HEADER GLASS

STOP

HEADER DOOR

STOP

STANDARD SET-

TING BLOCK

HEADER SETTING

BLOCK

17D1 (MILL)

17D2 (MILL)

17D3 (MILL)

17M6 (MILL)

17M7 (MILL)

17N1

FINISH PER JOB

9123

FINISH PER JOB

9914

FINISH PER JOB

HNO9

SILICONE

HN32 SILICONE

M141

M169

M170

M171

M173

M174

MTZ0 UNIT HANGER BOLT

LC23 NECK SPACER PVC (BLACK)

SPZ1 END DAM SCREW #8-15 X 3/4 PL-PH-SMS 18-8 AB

SPZ3

STC7

WA02

WC18

WC21

HANGER LOCK

WASHER

SLAB HANGER

JACKING BOLT

SLAB HANGER

JACKING SCREW

SLAB HANGER

LOCKING SCREW

UNIT HANGER BOLT

LOCK NUT

MULLION MOUNT-

ING BOLT

DOOR STOP

MOUNTING SCREW

JAMB/HEAD END

DAM MOUNTING

SCREW

BULB WEATHERING

FOR DURACAST

OFFSET SSG

SPACER

VERTICAL STACK

AIR SEAL

M141 SPRGLW BLK STL

MS 18-8 #1/2-13 X 3 1/2

1/2"-13 X 1/2" SOCKET SET

SCREW

W/ CUP POINT STEEL

#1/4-14 X 1 1/2 HW- -SMS SG

TEK/3

1/4-20 NYLON INSERT HEX NUT

-18-8

MTZ0 - 1/4"-20 X 1" SHCS-MS 18-

8

#8-15 x 1 1/4 PL-PH-SMS 18-8 A

#6-18 X 3/8 PL-PH-SMS 18-8 A

EPDM (BLACK)

SILICONE (BLACK)

SILICONE (BLACK)

5/16" WEDGE DRY

GLAZE EXTERIOR

GASKET

STANDARD JOINT

PLUG

STANDARD DRY

GLAZE INTERIOR

GASKET

EPDM (BLACK)

EPDM SPONGE (BLACK)

EPDM SPONGE (BLACK)

HIQ2

ILK6

UNIT HANGER

MOUNTING NUT

UNIT HANGER BOLT

WASHER/SPACER

IHQ2 #3/8-16 HEX NUT-ZC

ILK6 #12 (1/4-ID., 9/16-OD.)

FWSHR 18-8

WC22

WNC1

WSD2

EFCO 2012 Page 10

Page 11

Series 8750XD Unitized Curtain Wall Installation Instructions

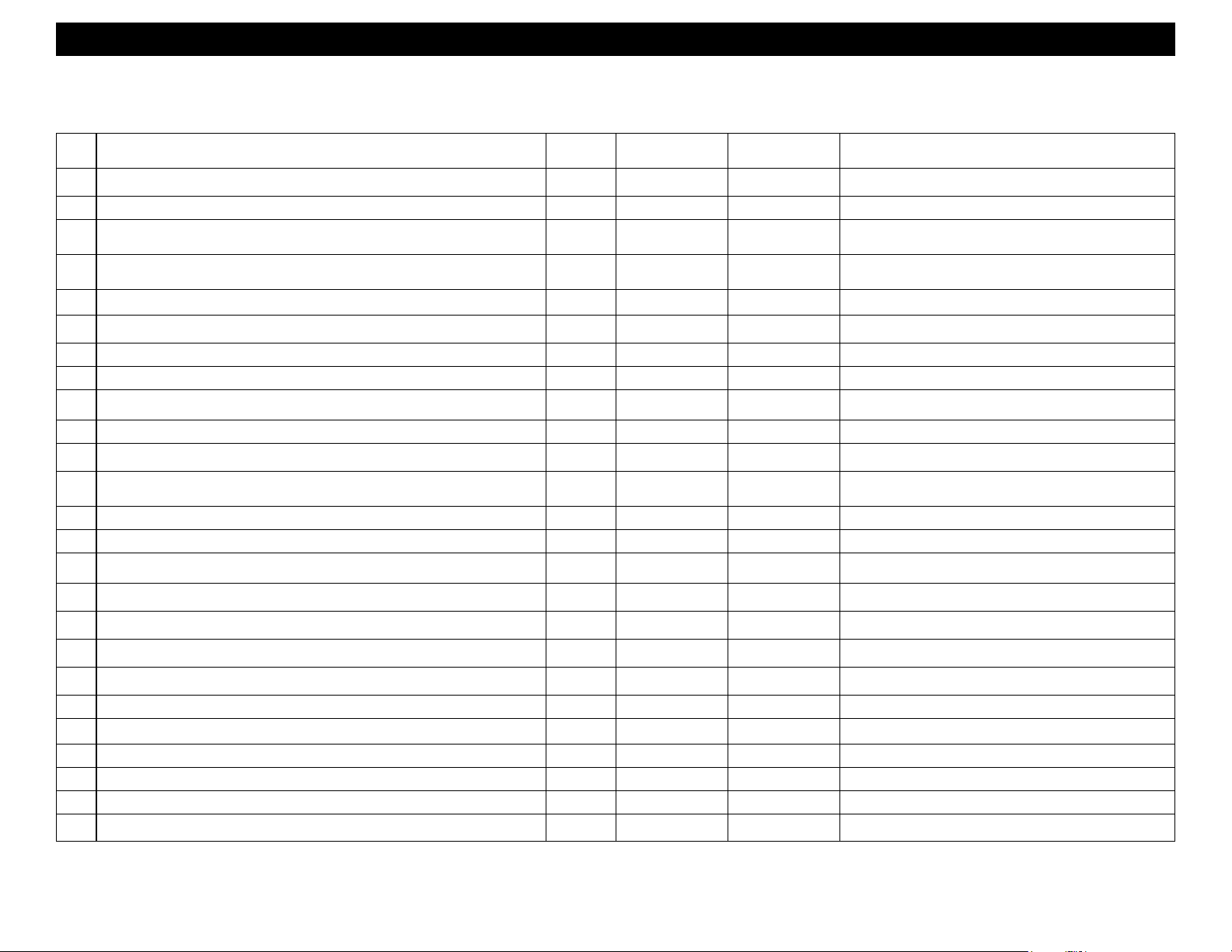

Section 2 - Package Identification

“ K ” PACKAGE IDENTIFICATION

Part Description Finish Cut Length Tooling Reference Parts used For Assembly

KV19 HANGER/LOAD CLIP MILL FM41 - 6.223 PUNCH FM41 (2) MTZO (4) M173 (4)

KV20 OPTIONAL RETRACTABLE HANGER MILL FM42 - 3.000 CUT & MILL FM42 (2) MTZO (4) M173 (4)

KV21 90 DEG OUTSIDE CORNER MULLION ANCHOR MILL FM43/17 - 8.000 CUT & DRILL FM43 (1) FM17 (1) M170 (1) M172 (3) M174 (3) M169 (1)

KV22 90 DEG INSIDE CORNER MULLION ANCHOR MILL FM44/17 - 8.000 CUT & DRILL FM44 (1) FM17 (1) M170 (1) M172 (3) M174 (3) M169 (1)

KV23 RIGHT HAND 90 DEG OUTSIDE CORNER SLAB ANCHOR MILL FM62 - 16.000 CUT & MILL FM62 (1) FM60 (2)

KV24 JAMB OR 90 DEG INSIDE CORNER SLAB ANCHOR MILL FM61 - 11.000 CUT & MILL FM61 (1) FM60 (2)

KV25 MULLION DYNAMIC LOADING CLIP MILL FM49 - 8.000 CUT FM49 (1) FM48 (1) STB1 (6)

KV26 LEFT HAND JAMB DYNAMIC LOADING CLIP MILL FM64 - 8.000 CUT FM64 (1) FM48 (1) STB1 (6)

KV27 STANDARD MULLION ANCHOR MILL FM11/17 - 8.000 CUT & DRILL FM11 (1) FM17 (1) M170 (1) M172 (3) M174 (3) M169 (1)

KV28 RIGHT HAND JAMB DYNAMIC LOADING ANCHOR MILL FM65 - 5.500 CUT FM65 (1) FM48 (1) STB1(6)

KV29 INSIDE CORNER DYNAMIC LOADING CLIP MILL FM50/51 - 8.000 CUT FM50 (1) FM51 (1) FM48 (1) STB1 (6)

KV30 OUTSIDE CORNER DYNAMIC LOADING CLIP MILL FM52/53 - 8.000 CUT

KV31 DYNAMIC SILL END DAM MILL FM55 - 5.188 SHEAR & PUNCH FM55 (1) STC7 (2)

KV32 STATIC SILL END DAM MILL FM56 - 4.188 SHEAR & PUNCH FM56 (1) STC7 (2)

FM52 (1) FM53 (1)

FM48 (1) STB1 (6)

KV34 LEFT HAND 90 DEG OUTSIDE CORNER SLAB ANCHOR MILL FM63 - 16.000 CUT & MILL FM63 (1) FM60 (2)

KV35 HIGH LOAD RIGHT HAND 90 DEG OUTSIDE CORNER SLAB ANCHOR MILL FM67 - 21.000 CUT & MILL FM67 (1) FM60 (3)

KV36 HIGH LOAD LEFT HAND 90 DEG OUTSIDE CORNER SLAB ANCHOR MILL FM68 - 21.000 CUT & MILL FM68 (1) FM60 (3)

KV37 HIGH LOAD MULLION, JAMB OR 90 DEG INSIDE CORNER SLAB ANCHOR MILL FM66 - 21.000 CUT & MILL FM66 (1) FM60 (3)

KV39 STACK SILICONE END DAM SILICONE HC13 - 5.250 HC13 (1) WO7V (4")

KV41 SUB HEAD END DAM MILL FM69 - 8.156 SHEAR & PUNCH FM69 (1) SPZ1 (2)

KV43 DOOR JAMB END CAP PER JOB FM39 - 3.000 SHEAR FM39 (1) WO7V (3")

KV46 RIGHT HAND SLAB HOOK ANCHOR MILL FM06 - 3.000 CUT & MILL FM06 (1) M171 (1)

KV47 LEFT HAND SLAB HOOK ANCHOR MILL FM05 - 3.000 CUT & MILL FM05 (1) M171 (1)

KV48 11" & 13" SUN SHADE ARM MOUNTING BRACKET MILL FM82 - 13.000 CUT & DRILL FM82 (1) S124 (5) S134 (6)

KV49 INSIDE OR OUTSIDE CORNER ALIGNMENT CLIP MILL FM78 - 4.000 CUT & MILL FM78 (1) STC7 (3)

EFCO 2012 Page 11

Page 12

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 3 - Static Starter Sill Preparation and Installation

Projects will be produced by EFCO in on e of two ways: 1) As a stock length product where all fabrication, assembly, and glazing will be performed by

the customer, or: 2) Prefabricated “kno ck down” where EFCO fabricates the materials, and the customer performs the assembly, and glazing. The

materials shown here in the installatio n instructions may be received in the field with varying degrees of shop assembly, with some items shop installed,

and other items to be field installed. Certain assembly and installation procedures shown and described in this document may be performed in the shop

or the field at the discretion of the assembler.

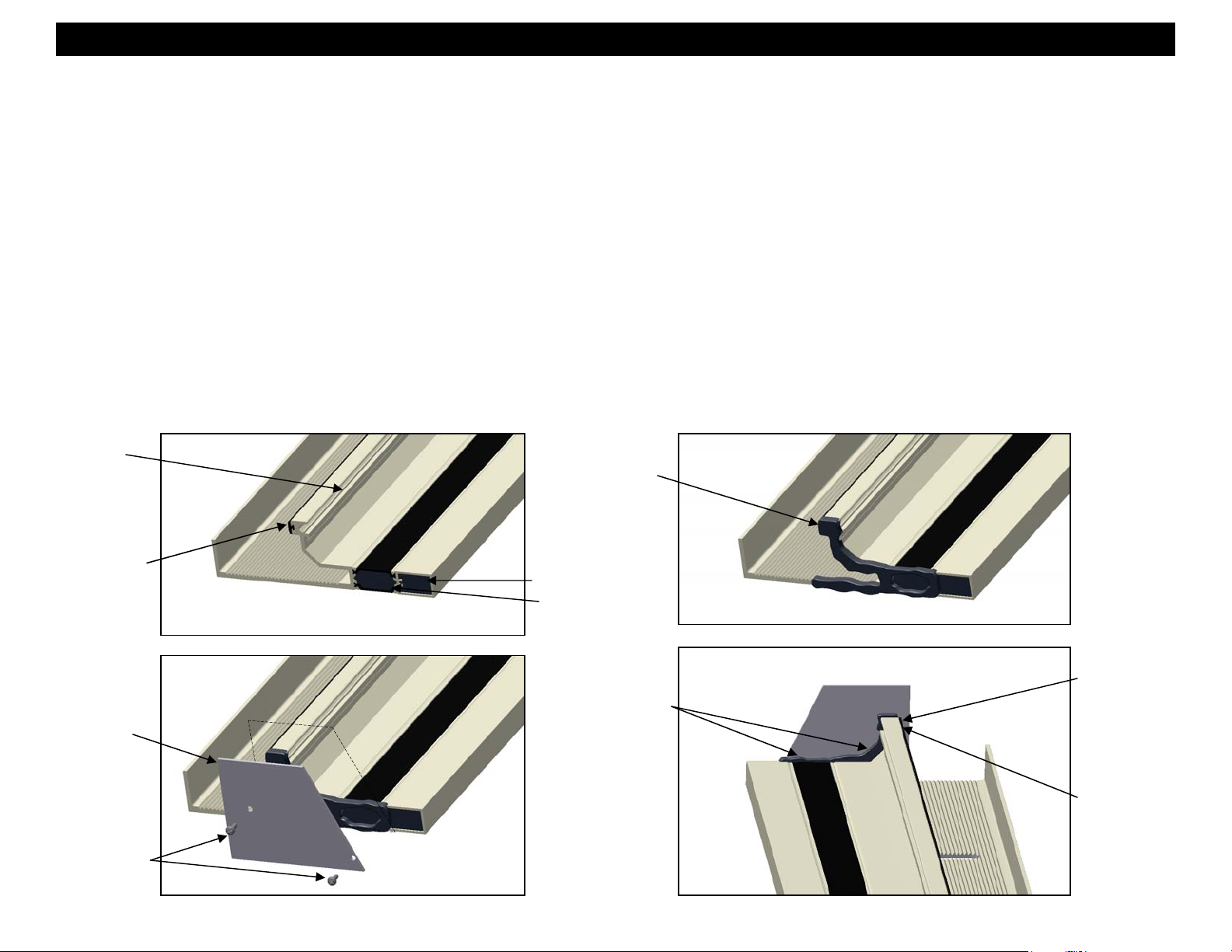

1. Preparation of the Static Starter Sill:

a. The static starter sill may have an end dam pre-attached and sealed at the jamb condition. Ensure that the end dam is properly applied and sealed

to the starter sill as described below. This is a critical seal and the joint must be carefully tooled to create a watertight seal. See Figures 1, 2, 3 & 4.

b. The starter sill may have LC23 spacer pre-applied. The LC23 is cut to the length of the starter sill. The WEA2 gasket will not be applied at this point,

it will be applied once all sections of the sill are set to avoid having seams or splices. This will be covered later in these instructions.

c. Plug the both ends of the tubular section of the starter sill by recessing backer rod at least 1” into the end of the tube. Fill the voids in the tube and

between the thermal struts with sealant and tool smooth.

Clean all sealant contact surfaces using an approved solvent or cleaner of all oils and other contaminants. The sealant manufacturer’s

preparation and application instructions should be followed exactly. If sealant primer is required, apply it per the primer/sealant

manufacturer’s instructions.

Pocket for

WEA2

LC23

Spacer

FM56 End Dam

Attach with

(2) STC7

STC7

Figure 1

Silicone Sealant

along profile to be

covered by end

dam

Plug with backer

rod and fill the

voids in the tube

and between the

thermal struts

with sealant and

tool sealant

Tool sealant smooth

into joints.

Figure 3 Figure 4

Figure 2

Ensure LC23

Butts into the

end dam

fully.

Back Seal

End Dam to

Starter Sill

EFCO 2012 Page 12

Page 13

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 3 - Static Starter Sill Preparation and Installation

d. A static loading clip (FM45) is required at each jamb and intermediate vertical. Two are required at corner mullion conditions (FM46 and FM47). The

anchors are used to transfer end load reactions from the verticals into the anchoring syste m . Before installation of the static starter sill, slide the

appropriate number of static loading clips into each section of starter sill. See Figures 5 and 6.

e. Slide the static loading clips into final position before the starter sill anchor bolts have been applied.

Slide static loading clips into

the static starter sill at corners.

(Left hand-FM46, Right handFM47)

Figure 5

Slide FM45 static

loading clips into

the static starter sill.

Plug with backer rod and

fill the voids in the tube

and between the thermal

struts with sealant and

tool sealant smooth.

46° Cut at Corner

Figure 6

EFCO 2012 Page 13

Page 14

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 3 - Static Starter Sill Preparation and Installation

2. Verify that all job site conditions and accompanying substrates receiving the installation are in tolerance and are in accordance with the contract documents.

3. Pre-cleaning the substrates where the caulk joints will be applied later may be advisable prior to setting the starter sill. Final cleaning and sealant primer

application where required should be performed only immediately before caulk joint sealant applicatio n.

4. Use established bench marks to ensure the accuracy of the starter sill location. Precise measurements and coordination with regard to established bench

marks are critical to ensure that the starter sills are installed in the correct location. Improperly installed, or miss-located starter sill s will cause significant

problems for the remainder of the erection process. Align with slab anchors on all floors a bove before unit installation starts. See page 24

5. Refer to the approved shop drawings for type, size, and specific anchor details. Shim the starter sill to the proper elevation height making sure the starter sill

is level. The shims used must be full bearing shims. The shims must fully support the entire load bearing surface of the starter sill at each anchor location.

Refer to the project structural calculation package and final approved shop drawings for detailed information.

6. EFCO recommends minimum of a 1/2” caulk joint between the starter sill and the substrate.

7.

When applying anchor bolts to the starter sill, pre-fabricated serrated washers (FM59 or FM60) must be used. The serrated washers will lock the starter sill

into position when the anchor bolt is tightened. See Figures 7 thru 9. After verifying the final position of the starter sill, secure the anchor bolts as required.

and shop drawings.

Figure 7

Anchor bolts as required.

Static Starter Sill

Serrated Washer

Slide static loading clips in

place before anchoring sill

Apply shims between

starter sill and substrate.

Shim starter

sill to proper

elevation

height.

Pre-fabricated oversized

anchoring slot.

Figure 8

Figure 9

Shim as necessary to

support entire load.

EFCO 2012 Page 14

Page 15

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 3 - Static Starter Sill Preparation and Installation (90° Inside Corner)

8. Using an approved solvent or cleaner, clean the sealant contact surfaces of the corner splice joint of all oils and oth er contaminants.

9. The starter sill will be spliced at corner conditions. Refer to the approved shop dra wing s for p roject specific joint size.

10. Anchor the new starter sill section ensuring the starter sill is level and while maintaining the appropriate joint size at the splice joint.

11. Slide the base anchors into the corner, butting them together.

12. Apply sealant into the joint between the sections of starter sill and tool smooth to create a water tight seal. Use backer rods in the joint where appropriate.

The splice joint width will vary per project requirements. See Figure 11.

13. Apply a bed of sealant over joint then and use pieces cut from HC13 silicone splice sheet to cover joint. Apply sealant around the edges and seams of the

pieces cut from the splices sheet. See Figures 12 and 13.

Figure 11

Static Starter Sill

Serrated Washer

Slide base anchors into

final position before

securing anchors.

90° Inside Corner

Back seal down leg

Butt Joint Typical

Shim starter sill to

proper elevation

height.

Figure 10

Pieces of Silicone

Splice Sheet (2)

Bed of sealant

Figure 12 Figure 13

Anchor bolts as required.

Seal over all

edges of

splice sheets.

Sealant

Seal over all

seams between

splice sheets.

EFCO 2012 Page 15

Page 16

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 3 - Static Starter Sill Preparation and Installation (Splices)

14. Using an approved solvent or cleaner, clean the sealant contact surfaces shown below of all oils and other contaminants.

15. The starter sill should be spliced per the shop drawings. Refer to the approved shop drawings for specific locations and conditions.

16. Anchor the starter sill sections ensuring they are level and while maintaining the appropri ate joint size and splice joint.

17. Apply sealant into the joint between the sections of starter sill and tool to create a water tight seal. The splice joint width will vary per project requirements.

See Figure 14.

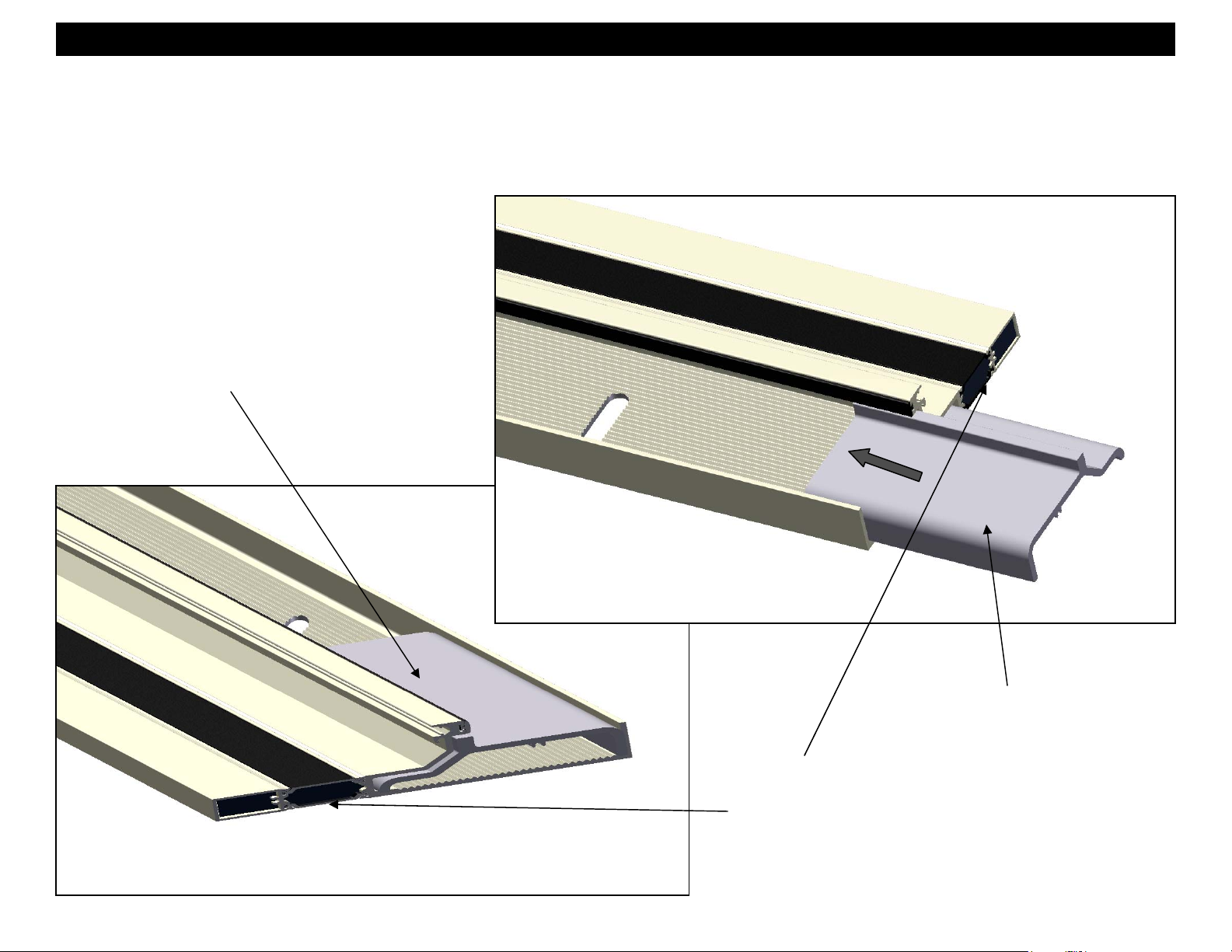

18. Set HC13 or HC14 silicone splice sheet in a bed of sealant centered on the starter sill splice joint as shown in Figures 15 and 16. Force the splice down onto

the gutter, forcing out all air bubbles.

19. Apply sealant around the edges of the splice an tool smooth and water tight. See Figure 16.

Anchor bolts as required.

Static Starter Sill

Figure 14

Figure 15

Back seal down leg

Place splice

sheet HC13 into

a bed of sealant.

Slide splice sheet up

under gasket track and

tool sealant to ensure a

watertight seal.

Apply sealant around

entire perimeter of

splice sheet and tool to

create a watertight seal.

Apply sealant between

the two starter sills

and tool to create a

watertight seal.

Marry the splice

sheet sealant with

the reveal splice

Figure 16

sealant to create a

watertight seal.

EFCO 2012 Page 16

Page 17

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 3 - Static Starter Sill Preparation and Installation (90° Outside Corner)

20. Using an approved solvent or cleaner, clean the sealant contact surfaces of the corner splice joint of all oils and other contaminants.

21. The starter sill will be spliced at corner conditions. Refer to the approved shop drawings for project specific joint size.

22. Anchor the new starter sill section ensuring the starter sill is level and while maintaining the appropriate joint size at the splice joint.

23. Slide the static loading clips into the corner, butting them together.

24. Apply sealant into the joint between the sections of starter sill and tool smooth to create a water tight seal. Use backer rods in the joint where appropriate.

The splice joint width may vary per project requirements. See Figure 17.

25. Apply a bed of sealant over joint and use pieces cut from HC13 silicone splice sheet cover joint. Apply sealant around the edges and seams of the

pieces cut from the splices sheet. See Figures 18, 19 and 20.

Shim starter sill

to proper

elevation height.

Apply sealant between

the two starter sills

and tool to create a

watertight seal.

Figure 17

Static Starter Sill

Anchor bolts

as required

90° Outside Corner

Place pieces of

splice sheet

HC13 into a bed

of sealant.

Figure 18

Slide splice sheet up

under gasket track and

tool sealant to ensure a

watertight seal.

Butt Joint Typical

Back seal down leg

Marry the splice

sheet sealant with

the reveal splice

sealant to create a

watertight seal.

Pieces of HC13

Splice sheet (2)

Figure 19 Figure 20

Apply sealant around

entire perimeter and

all seams of splice

sheet pieces and tool

to create a watertight

seal.

EFCO 2012 Page 17

Page 18

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 3 - Static Starter Sill Preparation and Installation

26. Finish installing starter sill sections as previously described until the installation is completed.

27. Push Stack Gasket WEA2 into gasket reglet beginning at one jamb condition and continuing to next jamb condition. Gasket should run continuously through

all corners and splices. Ensure that the gasket is not stretched while performing this task. See Figures 21 and 22.

28. Installation of the Static Starter Sill is now complete.

Figure 21

FM45 Static Loading Clips

FM46 and FM47

FM45 Static Loading Clip

FM46 and FM47

Static Starter Sill

Stack Gasket WEA2

Figure 22

EFCO 2012 Page 18

Page 19

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 4 - Dynamic Starter Sill Preparation and Installation

1. Preparation of the Dynamic Starter Sill:

a. The dynamic starter sill may have an end dam pre-attached and sealed at the jamb condition. Ensure that the end dam is properly applied and

sealed to the starter sill as described below. This is a critical seal and the joint must be carefully tooled to create a watertight seal. See Figures 23

thru 27.

b. The starter sill may have LC23 spacer pre-applied. The LC23 is cut to the length of the starter sill. The WEA2 gasket will not be applied at this point

it will be applied once all sections of the sill are set to avoid having unnecessary seams or splices. This will be covered later in these instructions.

c. Plug the both ends of the tubular sections of the starter sill by recessing backer rod at least 1/4” into the end of the tube. Fill the voids in the tube and

between the thermal struts with sealant and tool smooth.

Clean all sealant contact surfaces using an approved solvent or cleaner of all oils and other contaminants. The sealant manufacturer’s

preparation and application instructions should be followed exactly. If sealant primer is required, apply it per the primer/sealant

manufacturer’s instructions.

Figure 23

LC23

Spacer

Pocket for

WEA2

Plug with backer rod

and fill the voids in

the tube and between

the thermal struts

with sealant and tool

sealant smooth.

Figure 26

Figure 24

Silicone Sealant

along profile to be

covered by end

dam

Tool sealant smooth

into joints.

Ensure LC23

Butts into the

end dam

fully.

FM55 End Dam

Attach with

(2) STC7

STC7

Figure 25

Figure 27

EFCO 2012 Page 19

Back Seal

End Dam to

Starter Sill

Page 20

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 4 - Dynamic Starter Sill Preparation and Installation

2. Dynamic loading Clip Assembly:

a. Assemble the dynamic loading clips by attaching the anchor bar to the loading clip base with (6) STB1 fasteners. Anchors may come to the field

preassembled, depending on project requirements. Refer to the final shop drawings for project specifi c information.

b. Offset dynamic loading clips be required at the jamb conditions. Outside and inside corner conditions will require different dynamic loading clips.

Dynamic

loading clip

base

STB1(6)

Mullion

(KV25)

Figure 28

Anchor bar

Right Jamb

(KV28)

Left Jamb

(KV26)

Figure 30

Figure 31

Figure 32

Figure 33

Figure 34

90° Outside

Figure 29

EFCO 2012 Page 20

Corner (KV30)

90° Inside

Corner (KV29)

Page 21

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 4 - Dynamic Starter Sill Preparation and Installation

3. Slide in dynamic loading clips. The dynamic loading clips with the exception of the corner s must be installed before the dynamic starter sill sections are set

and anchored. See Figure 35.

4. Reference pages 14 –18 “Static Starter Sill Installation” for Setting, shimming and anchoring the dynamic starter sill sections. The only difference will be at

the corner conditions as a result of the dynamic loading clips (see step 5).

5. At corner conditions slide corner dynamic loading clip into starter sill section that is already anchored then slide the second starter sill section to it. See

figures 36 and 37.

6. Anchor the second starter sill section ensuring the starter sill is level and while maintaining the appropriate joint size at the splice joint.

7. Reference pages 15 –17 for sealing corners joints and splice joints.

Starter Sill Base

Corner Dynamic

Loading Clip

Dynamic Loading Clip

Starter Sill Base

Anchor bolts as required.

Figure 35

Figure 37

Figure 36

Butt joint typical

Starter Sill Base

Back seal down leg

Figure 38

90° Inside Corner

EFCO 2012 Page 21

Page 22

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 4 - Dynamic Starter Sill Preparation and Installation

8. Finish installing starter sill sections as previously described until the installation is completed.

9. Push Stack Gasket WEA2 into gasket reglet beginning at one jamb condition and continuing to next jamb condition. Gasket should run continuously through

all corners and splices. Ensure that the gasket is not stretched while performing this task. See Figures 39 and 40.

10. Installation of the Dynamic Starter Sill is now complete.

Figure 39

KV25 Mullion

Dynamic

Loading Clip

KV29 Inside

Corner Dynamic

Loading Clip

KV28 Right Hand

Jamb Dynamic

Loading Clip

KV30 Outside

Corner Dynamic

Loading Clip

KV25 Mullion

Dynamic

Loading Clip

Static Starter Sill

Stack Gasket WEA2

Figure 40

EFCO 2012 Page 22

Page 23

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 5 - Intermediate Floor Slab Anchor Installation

1. Set the slab anchors into the opening inserting anchor bolts into the slots in the approximate locations required. Do not use shims between the slab anchor

and the slab. Use bituminous coating or other appropriate primer to separate slab anchor from substrate. Anchors are typically located at the mullion center

line at intermediate locations. Jamb anchor locations vary. Refer to the approved final shop drawings for l ocatio n.

2. Apply flat and lock washers and the serrated washers onto the anchor bolts. Turn the serrated washer so that the teeth don't interlock to simplify anchor

adjustments. Leave the nuts loose enough to allow free movement of the anchor assembly. Once the units are set, and final adjustments are made, turn the

serrated washers so that the teeth interlock and secure the anchor assembly.

3. Refer to the final approved shop drawings or supplemental installation instructions for more inf ormation.

FM61 Slab

Anchor

Figure 41

Anchor bolts as

required.

FM56 or FM60

Serrated Washers

FM61 Slab

Anchor

Figure 42

Turn the serrated washer so that

the teeth don't interlock to

simplify anchor adjustments.

FM63 Slab

Anchor

FM62 Slab

Anchor

Once the units are set, and final

adjustments are made, turn the

washer so that the teeth interlock

and secure anchor bolts.

FM61 Slab

Note:

Bolt size and type specified in the

approved shop drawing must be used.

Figure 44

Anchor

Figure 43

EFCO 2012 Page 23

Page 24

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 5 - Intermediate Floor Slab Anchor Installation

4. Slab anchors on all floors must be aligned with each other and with the started sill.

a. Use established bench marks to ensure the accuracy of the starter sill location and the alignment of the slab anchors. Precise measurement and

coordination with regard to established bench marks are critical to ensure that both the starter sills and slab anchors are installed in the correct

location. Improperly installed or mis-located starter sills or slab anchors will cause significant problems for the remainder of the install.

b. In order to accommodate variation in slab size and location. It is important to place and align all slab anchors before final anchorage of the starter sill.

c. The typical spacing between the front face of the slab anchors and the interior face of the static sill is 1-1/16”. See figure 45 below.

d. The typical spacing between the front face of the slab anchors and the interior face of the dynamic sill is 1”. See figure 46 below.

e. Refer to the final approved shop drawings or supplemental installation instructions for more inf ormation.

Slab Anchor

Slab Anchor

1” Typical

Dynamic Starter Sill

Static Starter Sill

1-1/16”

Typical

Figure 46

Figure 45

EFCO 2012 Page 24

Page 25

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 6 - Unit Inspection and Preparation for Installation

1. Before installing the units, follow this checklist to ensure they are ready for installation:

a. Inspect the units to ensure that each unit has all external gaskets and screws

Verify these gaskets have been crimped securely to the frame. Always check for proper crimping and for missing ga skets.

b. Using an approved solvent or cleaner, clean the vertical and horizontal stack gaskets of all oils and other contaminants ( LC23, LC54,

WC21 and WA02).

c. Mullion plugs are required at the head. Also plugs are required at the head end of the captured system at the end of the Duracast verticals. The

mullion plugs are shop applied and sealed in place. Check to ensure the mullion plugs have been properly applied.

d. All front screw spline screws head should be sealed. See figure 49.

. The WA02 and WC21 gaskets will be shop crimped in place.

LC23

spacer

FM41

Hanger

FM40 Split Mullion

Attachment Clip

WNC1 With Sealant

to cover cavity

WA02

LC54 sweep

cut 1/8”

short per

side to allow

weeping

Figure 48

FM41

Hanger

H12C Mull

Plug

Figure 49

FM11

Mullion

Anchor

WC21

Figure 47

Front screw spline

screw heads sealed.

EFCO 2012 Page 25

Page 26

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 6 - Unit Inspection and Preparation for Installation

e. Using an approved solvent or cleaner, clean the sealant contact surfaces of the expansion cavity of the stack sill and jamb of all oils and

other contaminants. See Figure 50.

f. Apply a generous amount of sealant in both ends of the stack cavity approximately 4” to 6” long. See Figure 50.

g. Place the HC05 foam sealant backer into one end of the stack cavity with approximately 4” extending out of the cavity at split mullion and about 1/2”

extending from the face at jamb. The HC05 foam sealant backer should be applied to the jamb or split mullion half where the backer will be exposed

after the frame has been set. See Figure 50. The HC05 will be applied at both side of the jamb condition unit on each row. All sequential units will

get sealant on both side but will only get one HC05. These units will get the HC05 in the side opposing the previous unit.

h. Generously apply sealant to surface of he HC05 that will contact the stack leg of the sill or unit below. This should be done just before the units is set.

i. Apply a continuous bead of sealant up the entire split mull on the along the WC21 gasket and the adjacent snap leg (top to bottom). See figure 51.

Clean the cavity at

SILL

Split

Mullion

Half

4”

the sill approximately

6” to 8“ from each

end. Apply a

generous amount of

sealant about 4” to 6”

into the cavity.

Split

Mullion

Half

Apply a continuous

bead of sealant up

the split mull along

the WC21 gasket.

Apply a generous

bead of sealant to

the length of the

HC05 foam backer.

Weep area.

Push the HC05 foam backer into

the cavity so that it forces the

sealant into all corners of the

cavity to ensure a watertight

seal at unit installation.

Figure 51 Figure 50

SILL

EFCO 2012 Page 26

Weep area.

Page 27

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 6 - Unit Inspection and Preparation for Installation

2. Preparations are different at the jamb condition units.

a. Apply backer rod and sealant into the hollows of the jamb adapter.

b. Apply a splice sheet following steps 2-6 on page 33. See figure 52. Note: steps a & b can be done before or after the unit is set. Steps c thru e must

be done immediately before the unit above is set.

c. Apply HC05 sealant backer per instructions on page 26. See figure 53. Note that the HC05 only needs to extend slightly past the face of the mull.

d. A splice sheet will be applied the condition side of the unit to act as an end dam. There is a special splice sheet for this application with double stick

tape on one end. (KV39) Use this tape to attach the splice sheet to the unit. See figure 54.

e. Apply sealant to the side of the splice sheet that is hanging this will be used to seal it to the unit below. See figure 54.

f. Once the unit is completely set press the hanging end of the splice sheet to the unit below and smooth to remove any bubbles. See figure 55.

g. Finally liberally apply sealant around the perimeter of the splice sheet. See Figure 55.

Figure 52

WEA2 Stack Gasket

Splice sheet set

and bed of sealant

and edge sealed.

Figure 54

HC05

Extending

Slightly

Figure 55

Apply sealant

to the HC05.

Figure 53

LC54 to be cut 1/4”

short to allow

weeping.

Sealant around

perimeter of sheet

Use double stick

Apply sealant to

the free end of

the splice sheet,

to be stuck to the

unit below.

tape to apply

HC13 or HC14 Silicone

Splice Sleeve, leave

edge hanging

Press free end of

sheet to the unit

below once it is

completely set.

EFCO 2012 Page 27

Condition

removed to

allow process

to be seen

better.

Note Jamb

Page 28

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 7 - Setting Units at Static Starter Sills

1. Static starter sills are used with installations that don’t require provisions for vertical movements at the beginning floor of the curtain wall.

2. Ensure that end dam is properly sealed and apply a bead sealant to top of stack leg about 8” long where HC05 foam sealant backer will contact it.

3. Units are typically installed from left to right from as seen from the exterior of the building. Install each frame unit in sequence, starting at the left jamb unit.

4. Units are lifted by the splice bars attached at the head of each unit. These bars are also used to align the units when stacked vertically.

5. Lower the jamb unit down into position onto the starter sill. The hook anchors should also be hooked onto the slab anchors. The unit should now be setting

hard on the starter sill. See Figures 56 and 58.

6. If the starter sill was properly installed and the unit is square and is setting hard on the starter sill, the unit will be at the proper elevation and will be level and

plumb from side to side.

7. Compare the jamb unit to established bench marks and move the unit side to side to position it laterally to the final required location.

8. Adjust the unit for plumb, parallel to the plane of the wall, by sliding the slab anchor forward or backward until the unit is plumb. See Figure 57.

9. Rotate the serrated washers where the serrations align with the serrations in the anchor and secure the slab anchor’s anchor bolts. See Page 23 Figure 43.

Match drill the slab anchors through the hook anchors on both sides of the unit, and install the pinning screw to lock the frame unit into the final position. See

Figure 58.

Splice Bar

Jamb Unit

lift point

Once final adjustments

have been made, match

drill the hook anchor and

install the M171 pin screw

to lock the lateral position

of the frame unit.

Mullion Anchor

Sealant

Once the units are set

and final adjustments

are made, turn the

washer so that the

Static Starter Sill

Figure 56

Figure 57

serrations align and

secure anchor bolts.

EFCO 2012 Page 28

Figure 58

Page 29

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 7 - Setting Units at Static Starter Sills

10. Before setting the next unit apply a generous amount of sealant to the foam sealant backer. Run a bead down the entire length . See Figure 59.

11. Set the next unit after the jamb unit by nesting the vertical stacking mullions together without snapping them. See Figure 61.

12. Lower the unit to the static starter sill, but still be approximately 1/2” above the engagement leg of the starter sill. The unit hook anchors should have enough

vertical adjustment to hook onto the slab anchors.

Figure 59

Apply sealant

to foam backer

Figure 60

Once unit is approximately 1/2”

above engagement leg of stack

sill, snap mullions together.

Mate mullions without snapping them

together before setting on the starter

sill, then lower unit to with 1/2” of the

starter sill engagement leg.

Figure 61

1/2”

EFCO 2012 Page 29

Figure 62

Page 30

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 7 - Setting Units at Static Starter Sills

13. Once the unit is approximately 1/2” above the engagement leg of the starter sill, use clamps to snap the mullions together. Place one clamp at the center of

the mullion at the bottom of the units. Use wood blocks to protect the finished surfaces of the mullions. Tighten the clamp until the mullion halves begin to

snap together. Place another set of wood blocks and a clamp a couple of feet up the unit mullions and tighten it until the mullions snap together. Repeat this

process up the length of the mullion until the mullion halves are snapped together continuously. It may be necessary to work from one clamp to the next

several times, or move the clamps to ensure the mullions are snapped together evenly. See Figure 63.

14. Lower the unit the rest of the way down until it sets hard on the static starter sill.

15. Slide the unit laterally to adjust the mullion width to 3”. This will allow 1/8” for expansion at each mullion.

16. Adjust the free end of the unit for plumb, parallel to the plane of the wall, by sliding the slab anchor forward or backward until the unit is plumb.

17. Rotate the serrated washers where the serrations align with the serrations in the anchor and secure the slab anchor’s anchor bolts.

18. Match drill the slab anchors through the hook anchors on both sides of the unit, and install the pinning screws to lock the frame unit into the final position.

See Figures 64 and 65.

19. Repeat steps 10 through 18 until all units on the static starter sill level have been installed.

20. When erecting a long run of units, check overall frame location dimensions at every fifth unit to avoid dimensional buildup and to ensure that units are

properly positioned with regard to established bench marks.

21. Proceed to “Section 9 - Applying Critical Seals and Stack Gasket”.

Once final adjustments have

been made, match drill the

hook anchor and install the

pin screw to lock the lateral

position of the frame unit.

Clamp

mullions

and snap

together.

Wood block

on both sides

of mullion.

Figure 63

Once the units are set and

final adjustments are made,

turn the washer so that the

serrations align and secure

anchor bolts.

Figure 64 Figure 65

EFCO 2012 Page 30

Page 31

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 8 - Setting Units at Dynamic Starter Sills

1. Dynamic starter sills are used with installations that require provisions for vertical movements at the beginning floor of the curtain wall.

2. Setting unit units at the dynamic starter sill is very similar to setting units at the static starter sill. There are however a few differences. These differences are

explained verbally and graphically below. Also reference pages 26 through 28 “Setting Units at Static Starter Sills”.

3. Place temporary 3/4” shims between the unit sill and the front of the dynamic starter sill. The shims are used to maintain the correct spacing at the stack joint

area of the starter sill. See Figures 66 and 67.

4. Lower the jamb unit down into position while inserting the dynamic load clip (FM48) and stacking the unit onto the starter sill. The hook anchors should also

be hooked onto the slab anchors. The unit should now be setting hard on the shims.

5. Reference page 28 steps 6-8 for plumbing unit and fastening slab anchors.

6. Tighten the jack bolts of the mullion anchors just tight enough so that the shims can be removed and the unit stays in the nominal positi on. Remove the

shims between the sill and the starter sill that were applied in step 3.

7. Set the unit to the required elevation height and level it by turning the jack bolt at each mullion anchor clockwise to raise, or counterclockwise to lower the unit

in to the final position.

8. Match drill the slab anchors through the hook anchors on both sides of the unit, and install the pinning screws to lock the frame unit into the final position.

See Figure 58 on page 28.

Jamb Unit

Adjust the jack bolt as required

for the unit to set hard on the

shim pack at the stack joint

below. Rotate the bolt clockwise

to raise or counterclockwise to

lower the unit.

Dynamic

load clip

Sealant

3/4” shim pack

3/4” shim pack

Dynamic Starter Sill

Figure 66 Figure 68 Figure 67

placed between

the starter sill

and the unit sill.

placed between the

starter sill and the

unit sill.

Once the units are set and final

adjustments are made, turn the

washer so that the serrations

align and secure anchor bolts.

Splice Bar

lift point

EFCO 2012 Page 31

Page 32

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 8 - Setting Units at Dynamic Starter Sills

9. Before setting the next unit adjust the dynamic loading clip so that it aligns with the vertical. The anchor can be slid from side to side on the insert.

10. Next apply a generous amount of sealant to the foam sealant backer. Run a bead down the entire length. See Figure 69.

11. Set the next unit after the jamb unit by nesting the vertical stacking mullions together without snapping them. See Figure 61 on page 29.

12. Lower the units enough to engage the slab anchor bar (FM48) at the sill, but still be approximately 1/2” above the engagement leg of the starter sill. The unit

hook anchors should have enough vertical adjustment to hook onto the slab anchors. Reference page 29.

13. Place temporary 3/4” shims between the unit sill and the front of the dynamic starter sill.

14. Once the unit is approximately 1/2” above the engagement leg of the starter sill, use clamps to snap the mullions together. Reference Figure 63 and step 13

on page 30. See also Figure 72 below.

15. Lower the unit down into position to completely engage the anchor bars (FM48) and the unit sets hard on the shims between the unit sill and the dynamic

starter sill. The hook anchors should also be hooked onto the slab anchors.

16. Adjust the jack bolt as required for the unit to set hard on the shim pack at the starter sill below.

17. Reference steps 15-17 on page 30 for adjusting and plumbing, then fastening sl ab anchors

18. Tighten the jack bolts of the mullion anchors just tight enough so that the shims at the starter sill below can be removed and the unit stays in the nominal

position. Remove the shims between the sill and the starter sill that were applied in step 13.

18. Set the unit to the required elevation height and level it by turning the jack bolt at each mullion anchor clockwise to raise, or counterclockwise to lower the unit

in to the final position.

19. Match drill the slab anchors through the hook anchors on both sides of the unit, and install the pinning screws to lock the frame unit into the final position.

20. Repeat steps 9 through 20 until all units on the dynamic starter sill level have been installed.

21. When erecting a long run of units, check overall frame location dimensions at every fifth unit to avoid dimensional buildup and to ensure that units are

properly positioned with regard to established bench marks.

22. Proceed to “Section 9 - Applying Critical Seals and Stack Gasket”.

Sealant

Adjust dynamic

loading clip by

sliding side to

side.

Figure 69 Figure 70 Figure 71 Figure 72

Shim

EFCO 2012 Page 32

Page 33

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 9 - Applying Critical Seals and Stack Gasket

1. Once a complete row of units has been installed the WEA2 stack gasket must be applied from the roll to avoid unnece ssary splicing. See Figures 73 and 74.

2. A splice is also required at the gutter at the top of the units, before units are stacked on top of them. Clean the gutter sill sealant contact surfaces using

an approved solvent or cleaner of all oils and other contaminants where the gutter splice will be applied. The sealant manufacturer’s preparation

and application instructions should be followed exactly. If sealant primer is required, apply it per the primer/sealant manufacturer’s instructions.

3. Apply a bed of sealant on the gutter that will cover the area where the splice sheet (HC13 or HC14) will be applied. When creating the bed of sealant, apply

a generous amount of sealant directly on top of the primary seal location as shown in Figure 74.

4. The sealant must go from the front of the gutter up the engagement leg to the WEA2 gasket track. The sealant bed must be wide enough to cover the entire

area of the gutter splice. See Figure 74.

5. Lay the gutter splice into the bed of sealant. Press the gutter splice up under the WEA2 gasket track. See Figure 75. Smooth the splice down onto the

gutter, forcing out all air bubbles.

6. Apply sealant around the perimeter of the gutter splice. Tool the sealant to ensure a watertight seal at the splice. See Figure 76.

7. Apply sealant in the gap between the two snap in legs for the WEA2 gasket, across the top of the engagement leg and down the back leg. Tool the sealant

into all voids to ensure a watertight seal. See Figure 76.

Figure 73 Figure 74

Figure 75

WEA2 Stack Gasket

HC13 or HC14 Silicone

Splice Sleeve

Create a bed of

sealant to lay the

gutter splice into.

Apply sealant around

the entire perimeter of

the gutter splice and

tool to create a

watertight seal.

Figure 76

WEA2 Stack Gasket

Back seal

down leg.

Apply sealant between

the engagement legs

of the two units. Tool

sealant to create a

watertight seal.

EFCO 2012 Page 33

Page 34

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 10 - Setting Typical Intermediate Units

1. Install each frame unit in sequence, starting at the left jamb unit.

2. Lift the jamb unit with the splice bars at the head of the unit.

3. Ensure the HC05 caulk backer has been inserted into the sill as shown in Figure 50 on page 26. Note that jamb units will receive HC05 on both ends of the

sill. Subsequent units will require HC05 on the right end only of the unit sill as viewed from the exterior.

4. When stacking units vertically, place a temporary 1” shim between the units as shown in Figure 77. The shims are used to hold the unit in the nominal

installed position.

5. Lower the jamb unit down into position to engage the unit hanger load clips (FM41) at the stack joint. The hook anchors should also be hooke d onto the slab

anchor. (See Figure 58 on page 28) The unit should now be setting hard on the shims.

6. The final adjustment and setting of a typical intermediate jamb condition unit is the same as the final adjustment and setting at sill units. See steps 5-8 on

page 31 for adjustment and final setting of the unit.

Adjust the jack bolt as

required for the unit to set

hard on the shim pack at the

Jamb Unit

stack joint below. Rotate the

bolt clockwise to raise or

counterclockwise to lower

the unit.

Splice sheet

applied before

setting unit.

See page 26

Splice Bar

Sealant

Jamb Unit

1” shim pack placed

around the splice bar on

top of the mullion at the

head of the unit below.

HC05 caulk backer

Once the units are set and final

adjustments are made, remove the

shim by tightening the jack bolts

EFCO 2012 Page 34

Figure 78 Figure 77

Page 35

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 10 - Setting Typical Intermediate Units

7. Before setting the next unit apply a generous amount of sealant to the foam sealant backer. Run a bead down the entire length. See Figure 79.

8. Set the next unit after the jamb by nesting the vertical stacking mullions together without snapping them. See Figure 61 On page 29.

9. Lower the units enough to engage the unit splice bar (FM41) at the sill but still be approximately 1/2” above the engagement leg of the starter sill. The unit

hook anchors should have enough vertical adjustment to hook onto the slab anchors.

10. Place a 1” shim pack around the hanger load clip on top of the mullion at the head of the unit below. See Figure 89.

11. Once the unit is approximately 1/2” above the engagement leg of the gutter at the stack joint, use clamps to snap the mullions together. Reference Figure 63

and step 13 on page 30.

12. Lower the unit down into position to completely engage the unit splice bars at the stack joint. The hook anchors should also be hoo ked onto the slab anchor.

The unit should now be setting hard on the shims.

13. Adjust the jack bolt as required for the unit to set hard on the shim pack at the starter sill below.

14. The final adjustment and setting of a typical intermediate unit is the same as the final adjustment and setting at sill units. See steps 5-8 on page 31 for

adjustment and final setting of the unit.

15. Repeat steps 2 through 14 until all units on the intermediate floor levels have been installed.

16. When erecting a long run of units, check overall frame dimensions at every fifth unit to avoid dimensional buildup and to ensure that units are properly

positioned with regard to established bench marks.

Figure 79 Figure 80

Apply sealant

to foam backer

Figure 82

1/2”

Once unit is approximately 1/2”

above engagement leg of stack

sill, snap mullions together.

Place 1” shim around the splice

Figure 81

bars on top of the mullion at the

head of the unit below

EFCO 2012 Page 35

Page 36

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 11 - Setting Typical Head Condition Units

1. Setting typical head condition units is very similar to setting typical intermediate units. Reference paged 34 and 35. There are however a few differences

these will be explained verbally and graphically below.

2. Apply splice sheet to the top corners per steps a & b on page 27, leaving a portion of the slice sheet hanging over the edge. Apply sealant to the underside

of the portion hanging over the edge, and wrap it down over the edge. Smooth it to remove any bubbles in the sealant. Apply sealant to the edge and tool to

create a water tight seal. See figures 83 thru 86.

3. The typical head condition units have an optional retractable hanger (KV20), which can be drive down with a mallet to get it out of the way for setting the unit.

See figures 86 and 87.

Figure 83

Screw hole to

be plugged

and sealed

Apply sealant to

the edges of the

splice sheet and

tool to create a

water tight seal.

Apply backer rod

and sealant in

the hollow of the

jamb adapter

Figure 84

Set splice sheet in

a bead of sealant

Apply sealant to

the underneath

side of the splice

sheet that hangs

over the edge

Figure 85

Retractable hanger

can be driven down

with a mallet.

Wrap splice

sheet down over

the edge of the

unit and smooth

top remove any

Figure 86 Figure 87

air bubbles

EFCO 2012 Page 36

Page 37

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 12 - Setting Corner Units

1. Follow the check list in “Section 6 - Unit Inspection and Preparation for Installation” on pages 2 5, 26 and 27 before installing the corner units.

2. Verify the adjacent unit has been installed properly before installing corner units. If not make necessary adjustments to align the units.

3. Corner units are designed to be installed from left to the right as viewed from the exterior of the building.

4. Setting Inside and Outside corner units is very similar to setting typical units at both static and dynamic sills and typical intermediate units. Reference the

corresponding section that applies for detailed instructions. Section 7 “Setting Units at Static Starter Sills” pages 28-30, Section 8 “Setting Units at Dynamic

Starter Sills” pages 31-32, Section 10 “Setting Typical intermediate Units” pages 34-35, and Section 11 “Setting Typical Head Condition Units” page 36.

5. The exception being inside corners. The unit on the left (viewed from the exterior) will have the right edge of the unit coming in without a cover or duracast

spacer. This is designed to come together with the left edge of the unit on the right. Before setting the left unit the HD26 Joint plugs will need to be sealed.

See shop drawings for more detail.

90 degree inside corner

at dynamic starter sill

viewed from interior

Clamp

mullions

and snap

together.

Place 1” shim around the splice

bars on top of the mullion at the

head of the unit below

Wood block

on both sides

of mullion.

Figure 89

90 degree outside corner

at typical intermediate

viewed from interior

Figure 88 Figure 90

EFCO 2012 Page 37

90 degree

inside corner

at dynamic

starter sill

viewed from

interior

Page 38

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 13 - Applying Typical Perimeter Seals

1. The typical head, jamb and starter sill are as shown below. The caulk joint size is job specific, below a 1” caulk joint is shown at head and jambs and a 1/2”

caulk joint at the sill. All seals should join each other head and sill seals should join verticals.

2. The condition at the head is job specific. See Figure 91 for a typical generic head sealant detail. See shop drawings of job specific details.

3. The line of sealant at the jamb will follow the front edge of the back member. See Figure 92. Special care is needed to ensure that the end dam is properly

sealed and marries into the perimeter sealant correctly at the jamb to sill condition. See Figures 94.

4. At jamb conditions of the unit stack joint, a splice sheet has been applied. Special care is needed to ensure the splice sheet is properly sealed and marries

into the perimeter sealant correctly. See Figure 95.

5. The caulk joint at the starter sill is located at the exterior part of the starter sill and must return at the jambs to marry with the perimeter caulking of the jambs.

Backer Rod and

Perimeter Seal

Backer Rod and

Perimeter Seal

Backer Rod and

Perimeter Seal

Figure 91 Figure 92

Note:

Jamb condition not

shown for clarity.

Note:

Jamb condition not

shown for clarity.

Marry jamb

sealant line to

sill sealant line.

Figure 94 Figure 95

Marry jamb sealant

line with splice

sheet sealant

EFCO 2012 Page 38

Figure 93

Page 39

Series 8750XD Unitized Curtain Wall Installation Instructions

Section 14 - Deglaze / Re-glaze Procedures - Captured System

1. The captured system units can be structural silicone glazed to the frame or may be dry glazed. The deglaze and re-glaze of the dry glazed system should be

very straight forward and will be similar to the captured structural silicone glazing instructions below; minus the structural and sealant and using WSD2

interior gasket in place if WC18 spacer. The deglaze and re-glaze procedure must be performed from a swing stage or man lift from the exterior of the

building. Follow the sealant manufacture’s sealant application instruction for deglazing and re-glazing. When deglazing an opening or ope nings at a