Page 1

8

Y

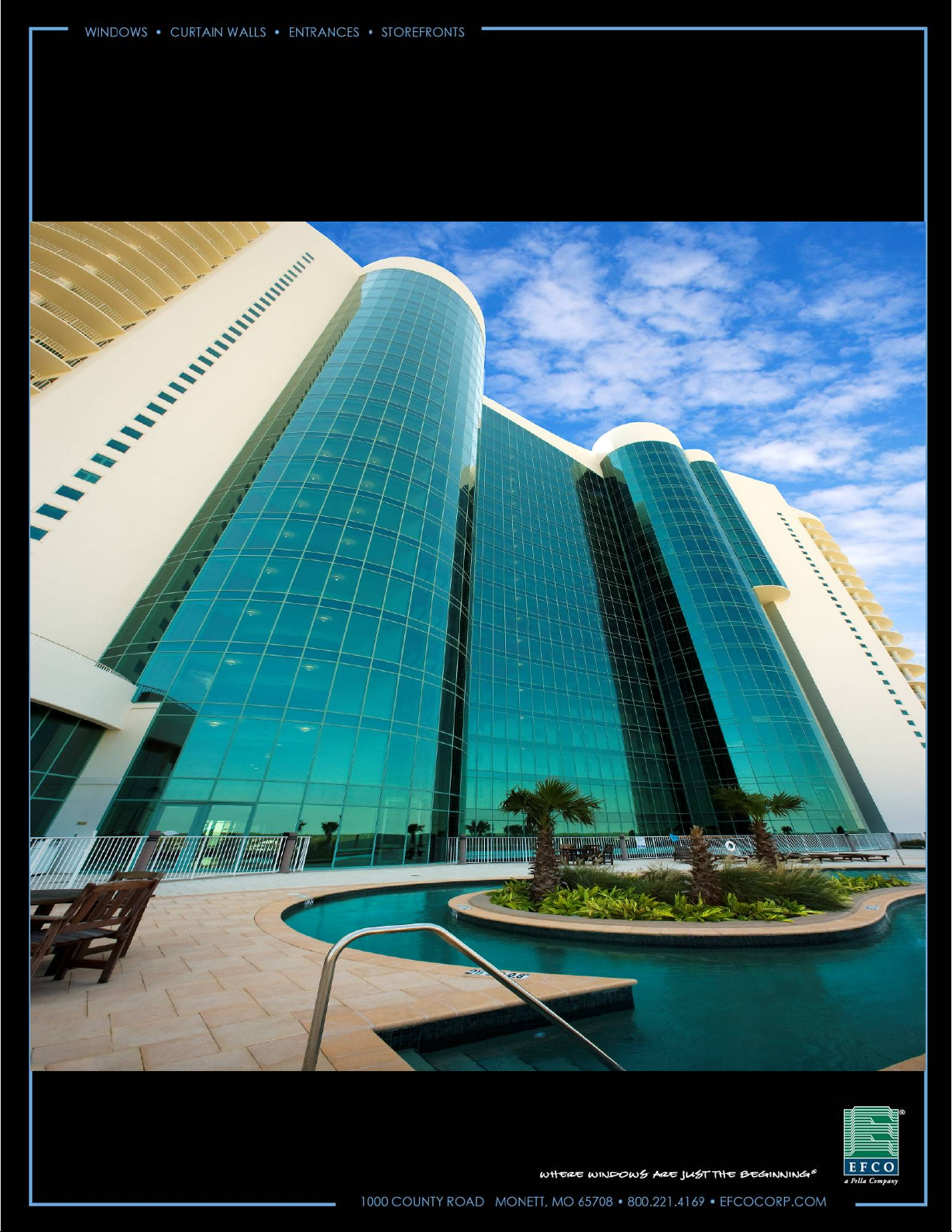

Series 5

00

E-wall silicone gasket curtain wall system

Installation instructions

Part NO.

February 2013

330

Page 2

Minimizing Condensation

Note: Please reference EFCO's "Understanding Condensation" brochure which can be obtained

through your EFCO representative.

Condensation will form on any surface when unfavorable conditions (interiro temperature and

relative humidity and exterior temperature) are present. When the formation of extensive condensation

is a concern, it is highly recommended that a design professional is utilized to perform an analysis of

the shop drawings to recommend the best possible installation methods. Please contact your EFCO

representative for information on EFCO's Thermal Analysis Serv ices.

Many current installation practices lead to an increase in the possibility of the formation of

condensation. Though not all inclusive, the list of examples below illustrates conditions under which

condensation is lik ely to occur:

1. Bridging system thermal break with non-thermally broken metal flashing or lintels that

are exposed to the exterior

2. System exposure to the cold air cavities

3. Interior relative humidity levels not maintained at recommended levels, see EFCO's

"Understanding Condensation" brochure

4. Inadequate separation between system and surrounding condition at perimeter

5. Product conbinations during the shop drawing stage that result in bridging thermal

breaks of one or all products involved

7/2011

Page 3

SECTION I: GENERAL NOTES AND GUIDELINES

PAGE 1

NOTE:

THESE INSTALLATION INSTRUCTIONS ARE A SUPPLEMENT TO

THE APPROVED SHOP DRAWINGS AND MUST BE USED IN

CONJUNCTION WITH THOSE DRAWINGS.

1.

HANDLING/STORING/PROTECTING ALUMINUM - The following precautions

are recommended to assure early acceptance of your products and

workmanship.

A. HANDLE CAREFULLY - Store with adequate separation between com-

ponents so material will not become scratched or rubbed at points

of contact. Store off the ground. Protect against weather elements

and other construction trades in adjacent areas of the job site.

B. KEEP MATERIAL AWAY FROM WATER, MUD, AND SPRAY - Prevent cement,

plaster, and other materials from coming in contact with and

damaging the finish. Do not allow moisture to be trapped between the

finished surface and the wrapping material.

C. PROTECT MATERIALS AFTER ERECTION - Wrap or erect screens of plastic

sheeting. Cement, plaster, terrazzo, and other alkaline materials are

very harmful to the finish and must be removed with water and mild

soap before hardening. Under no circumstances should these

materials be allowed to dry or permanent staining will occur.

GENERAL GUIDELINES - The following practices are recommended for all

2.

installations.

A. REVIEW THE APPROVED SHOP DRAWINGS to become thoroughly familiar

with the project.

B. INSTALL ALL FRAMING MATERIALS PLUMB, LEVEL, AND TRUE - Proper

alignment and relationships to benchmarks and column center lines,

as established by the architectural drawings and the general

contractor, must be maintained.

C. The sequence of erection should be coordinated with the project

superintendent to prevent delays and minimize the risk of material

damage. IF PRESET ANCHORS ARE REQUIRED, COORDINATE

WITH THE GENERAL CONTRACTOR AND SUPERVISE THE LOCATION.

9/2000

Page 4

PAGE 2

SECTION I: GENERAL NOTES AND GUIDELINES CONT.

D. Verify that all job site conditions and accompanying substrates

receiving the installation are in accordance with the contract

documents. If deviations occur, notification must be given IN WRITING

to the general contractor and differences resolved before proceeding

further with the installation in the questionable area.

E. Coat all aluminum, to be placed directly in contact with masonry or

dissimilar materials, with a heavy coating of bituminous primer such

as zinc chromate.

F. Follow EFCO’s framing installation and glazing instructions.

G. Verify the contents of all material shipments upon arrival. Verify

quantities and correct finishes. NOTIFY EFCO IMMEDIATELY OF ANY

DISCREPANCIES OR DAMAGE WHICH MAY HAVE OCCURRED.

H. Throughout these instructions the term SEALANT will appear. For the

purpose of these instructions, sealant is to be defined as follows:

SEALANT - A weather resistant, gunnable, liquid filler which when dry

provides a resilient, flexible air and water seal between similar and

dissimilar materials. All sealant must meet FEDERAL SPECIFICATIONS

TT-S-001543A, TT-S-00230C, and ASTM C 290.

NOTE:

Do not assume compatibility of materials in a glazing system already

exists. Chemical reactions from physical contact of incompatible materials

can adversely affect one or all of the glass or glazing materials. It is

strongly advised that sealant manufacturers conduct compatibility and

adhesion tests in their laboratories using each exact component of the

glazing system (i.e., glass product, structural silicone, aluminum with

painted or anodized finish, setting blocks, glazing tapes, etc.) and

document compatibility or other findings in written test reports. All

frame surfaces should be clean, dry, dust free, and frost free. If a primer

is required, it must be applied to clean surfaces. All perimeter substrate

should be cleaned and properly treated to receive sealant. It is the

responsibility of the installer to follow these guidelines.

TOOLS NEEDED:

1. Dead blow hammer, part #HM46

2. Deglazing tool, part #HM47

3. Brush

4. Cutting tool, do not use box or craft knives.

5. Needle nose pliers

6. Metal spatula

7/2003

Page 5

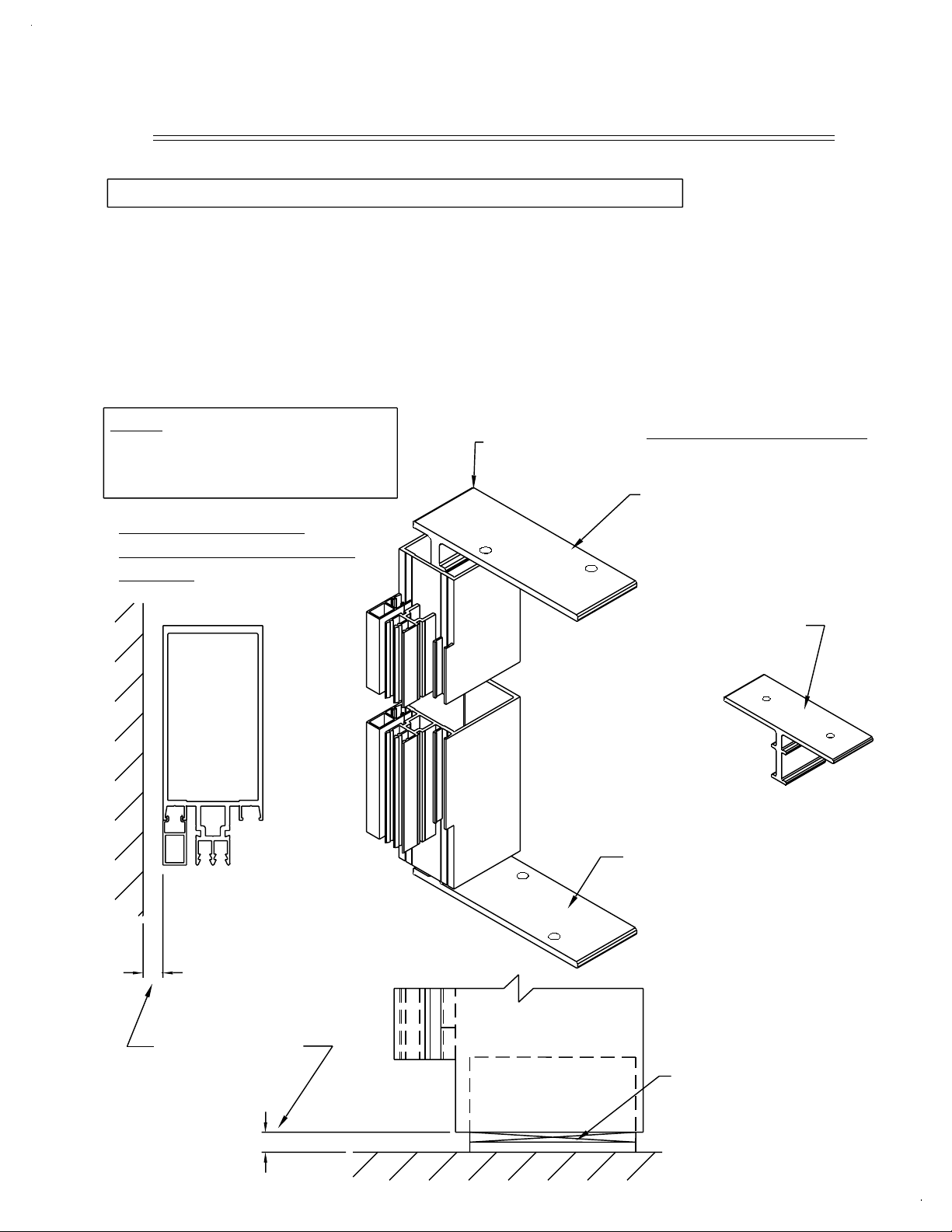

SECTION II: VERTICAL FRAME INSTALLATION

STEP #1 INSTALL VERTICAL MULLIONS AND ANCHORS

Prestage necessary tools and materials in the work area. Prepare all head,

sill, and jamb substrates by cleaning and setting all flashings and/or

membrane seals as specified by the project shop drawings.

Insert the mullion and/or head anchor, as specified by the project

shop drawings, into the end of tubular mullions. For splice joints and floor

anchors at multispan conditions, refer to steps #2 and #3 on pages 4

and 5.

PAGE 3

Note: When attaching pocket

fillers, start at one end and

work into place along the

remaining length.

PERIMETER WITH

CONTINUOUS POCKET

FILLER

"F" ANCHOR

MULLION ANCHORS

TOP ANCHOR IS REQUIRED

AT HEAD CONNECTION

FOR THERMAL MOVEMENT.

MULL ANCHOR AT INTERMEDIATE

VERTICAL MULLIONS.

SIZE AND LOCATE ALL

BOLTS BASED ON JOB

CONDITIONS AND STRUCTURAL

REQUIREMENTS.

SEE APPROVED

SHOP DRAWINGS

FOR DIMENSION.

SHIM UNDER VERTICAL

MULLION.

7/2003

Page 6

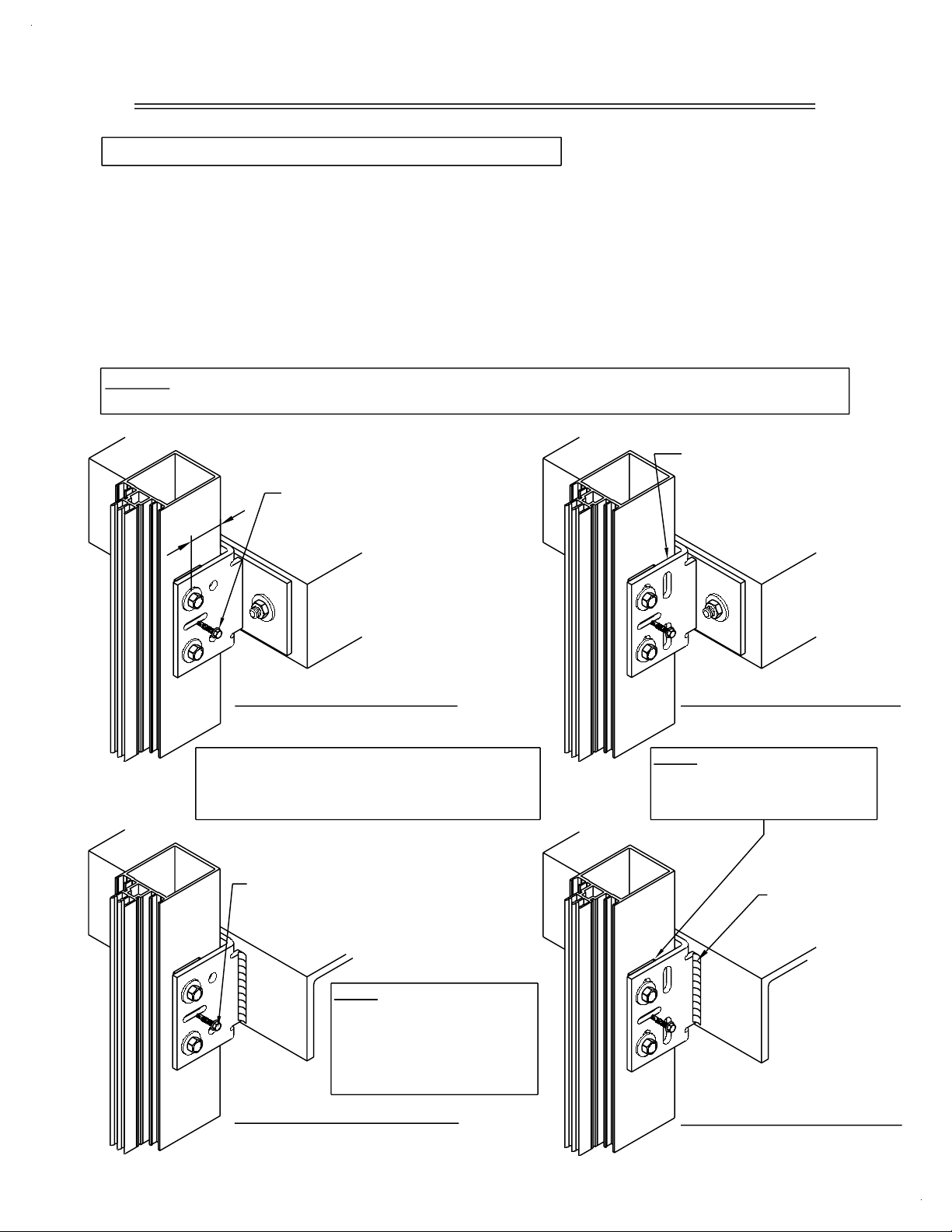

SECTION II: VERTICAL FRAME INSTALLATION

STEP #2 APPLY MIDSPAN FLOOR ANCHORS

Attach the midspan floor anchors to the mullions with temporary alignment

screws. Set the vertical mullion in place, plumb and true. Make permanent

attachment of base anchors, head anchors, and midspan floor anchors to

the building structure as specified in the approved project shop drawings.

After completing permanent anchorage, remove all temporary alignment

screws and fasteners. Multiple runs of vertical mullions can be set in

advance of erecting the horizontal members if desired, or the horizontals can

be filled in as additional mullions are erected.

NOTE: On long runs, check overall frame dimensions at every fifth opening

to avoid dimensional build-up.

POSITION THE MULLION

PLUMB AND TRUE.

PERMANENTLY ATTACH

THE ANCHOR TO THE

STRUCTURE PER PROJECT

SHOP DRAWINGS.

1"

MIN.

TEMPORARY ALIGNMENT

SCREW (REMOVE

AFTER ANCHORING).

PAGE 4

DEAD LOAD ANCHOR

BOLTED TO STRUCTURE

THE FLOOR SLABS MUST BE WITHIN THE

ADJUSTMENT CAPABILITY OF THE ANCHORING

SYSTEM. REFER TO THE PROJECT SHOP

DRAWINGS FOR THE ALLOWABLE ADJUSTMENT.

DRILL THROUGH THE MULLION AT

THE HOLE LOCATION IN THE CLIP

A MINIMUM OF 1" FROM THE

BACK OF THE MULLION.

COMPLETE THE BOLT CONNECTION

PER PROJECT SHOP DRAWINGS.

NOTE: REFER TO PROJECT

SHOP DRAWINGS FOR

WELDING INSTRUCTIONS.

PROTECT THE INSTALLED

GLASS AND METAL FROM

WELD SPLATTER.

DEAD LOAD ANCHOR

WELDED TO STRUCTURE

WIND LOAD ANCHOR

BOLTED TO STRUCTURE

NOTE: USE 1/16" HORSESHOE SHIMS BETWEEN

THE STEEL ANCHORS AND

MULLIONS.

FILLET WELD AT

BOTH SIDES OF

THE ANCHOR.

WIND LOAD ANCHOR

WELDED TO STRUCTURE

9/2000

Page 7

PAGE 5

SECTION II: VERTICAL FRAME INSTALLATION CONT.

STEP #3 INSTALL VERTICAL SPLICE JOINTS

Splice joints should occur at spandrel areas (if possible).

Refer to approved shop drawings for actual locations.

Splice sleeves will be shop assembled in the top of the lower mullion.

GENERAL NOTE: The following details depicts a splice joint of 1/2".

The required joint width must be determined at the design stage and

shown on the approved shop drawings, on a job by job basis.

The actual width of this joint depends on the expected amount of

thermal movement plus the expected movement of the building structure.

Once a final check of expansion joint placement and mullion

position is made, the final match drilling of mullion through anchor

holes and sealing of the splice joint may be completed.

1

2

UPPER MULLION

SPLICE

SLEEVE

SLEEVE

FASTENERS

SHIM UNTIL ALL

ANCHORS ARE

SET IN PLACE,

THEN FACE

SEAL WITH AN

APPROVED SEALANT.

1/2"

SHIM

3

LOWER MULLION

7/2003

Page 8

SECTION III: HORIZONTAL FRAME INSTALLATION

STEP #1 PLUG ENDS OF PERIMETER HORIZONTALS

Prior to horizontal attachment, insert a 2 1/2" piece of backer rod folded to

90 degree into the jamb end of the head and sill horizontals. Seal the ends with

silicone to create an end plug. The end plug will act as a back-up for the

perimeter seal later.

STEP #2 PERIMETER HORIZONTALS

Clean all mating surfaces and apply a thin film of specified sealant

to the factory notched vertical mullion, at the horizontal locations. Attach the

appropriate horizontal member to the vertical mullion at the notch with (2)

Stalgard , #10-16 x 3/4", PL-PH-SMS, Tek/2, self drilling fasteners through

the predrilled holes in the ends of each horizontal. Confirm the mullion

center line dimension at each horizontal installation before and after fastening

the horizontal into place. Verify the mullion locations at every fifth mullion

spacing to avoid dimensional build-up across the opening.

R

PAGE 6

CUT AND FOLD

THE BACKER

ROD 90 DEG.

Note: Prior to sealing

any area, clean the

surface with denatured

alcohol.

INSERT THE BACKER

ROD 1/4" INSIDE

THE EXTRUSION.

ONCE THE HORIZONTALS

ARE INSTALLED, INSERT

BACKER ROD INTO THE

HOLE AND SEAL THE

HOLE FLUSH WITH

SILICONE.

APPLY A THIN LAYER OF

SPECIFIED SEALANT TO THE

ENTIRE FACE OF THE COPED

MULLION. APPLY SEALANT TO

THE ENDS OF THE MULLION AT

THE PERIMETER HEAD AND

SILL HORIZONTAL MEMBERS ONLY.

SEAL OVER THE END

AND TOOL FLUSH WITH

THE EDGE OF THE

EXTRUSION.

7/2003

Page 9

PAGE 7

SECTION III: HORIZONTAL FRAME INSTALLATION CONT.

STEP #3 INTERMEDIATE HORIZONTALS

Attach the appropriate horizontal member to the vertical mullion at the notch

with (2) Stalgard, #10-16 x 3/4", PL-PH-SMS, Tek/2, self drilling fasteners

through predrilled holes in the ends of each horizontal member. Confirm the

mullion center line to center line dimension at each horizontal installation

before and after fastening the horizontal in place. Verify the mullion

locations at every fifth mullion spacing to avoid dimensional build-up across

the opening.

SEALANT IS NOT REQUIRED

AT INTERMEDIATE HORIZONTAL

TO VERTICAL CONNECTIONS.

9/2000

Page 10

SECTION IV: CONDENSATION WICK INSTALLATION

STEP #1 INSTALL CONDENSATION WICK

To install the condensation wick into the horizontal, first cut the wick

approximately 3" longer than the center line dimension of the vertical mullions.

Locate the approximate center of the condensation wick and the center of

the horizontal. Using the deglazing tool, press about 6" of the condensation

wick into the wick pocket, leaving each end free. Using a needle nose pliers,

insert about 1 1/2" of each end of the condensation wick into the hole

provided in each vertical mullion. Starting at the middle of the horizontal

and working toward the verticals, press the remaining condensation wick into

the horizontal pocket. Continue this process until all the slack has been

removed and the ends extend freely into the vertical mullion cavity.

PAGE 8

INSERT APPROXIMATELY

1 1/2" OF EACH END

OF THE CONDENSATION

WICK INTO THE HOLE IN

THE VERTICAL MULLIONS.

CONDENSATION

WICK

Note: To facilitate insertion of the

condensation wick into the vertical,

burn each end of the wick and

insert with needle nose pliers.

HOLE IN MULLION

9/2000

Page 11

SECTION V: GLAZING ADAPTOR INSTALLATION

STEP #1 INSTALL GLAZING ADAPTORS

Locate and insert the glazing adaptors for openings that have a glazing

thickness of less than 1". Horizontal adaptors run through and must be

inserted first at the top and bottom of each light. Horizontal adaptors are

cut shorter than the opening dimension. Locate and insert the adaptor in the

center of the space provided, allowing equal distance between each end. The

vertical adaptors may now be installed between the horizontal adaptors.

PAGE 9

VERTICAL GLAZING

ADAPTOR

HORIZONTAL

GLAZING ADAPTOR

HORIZONTAL ADAPTORS RUN THROUGH.

7/2003

Page 12

SECTION VI: INTERIOR GASKET INSTALLATION

STEP #1 INSTALL HORIZONTAL GASKET

Cut the specified interior horizontal gasket 1 3/4" longer than the daylight

opening width. Center the gasket on the horizontal member and press

straight into the gasket pocket.

STEP #2 INSTALL VERTICAL GASKET

Cut the interior vertical gasket 1/8" longer than the daylight opening. Center

the gasket on the vertical opening and press straight into the gasket pocket.

Allow the horizontal gasket to run through. Butt the vertical gasket to the

horizontal gasket at the open corners. Crowd in any excess gasket.

PAGE 10

VERTICAL GASKET

THE HORIZONTAL GASKET

RUNS THROUGH. THE

VERTICAL GASKET BUTTS

TIGHT TO THE HORIZONTAL.

INTERIOR GASKET

9/2000

Page 13

SECTION VII: GLAZING INSTALLATION

STEP #1 INSTALL GLAZING MATERIALS

Verify that all gasket retainer pockets are free from dirt and foreign

matter. Place the specified setting blocks and antiwalk blocks as shown in

the approved project shop drawings. Set the specified glazing infill into

the corresponding opening, ensuring positive bearing on the setting blocks

and an equal glass bite at all sides of the infill panel. The typical glass

bite should be 9/16" in a 2 1/2" wide system. Push the infill completely

back against the interior gaskets.

POSITION THE ANTIWALK

BLOCK AT THE CENTER

OF THE VERTICAL GLASS

OPENING. SILICONE THE

BLOCK INTO POSITION

AFTER THE GLASS IS

INSTALLED.

PAGE 11

POSITION THE SETTING

BLOCK EVEN WITH THE

FRONT OF THE MULLION

TONGUE.

THE HORIZONTAL SETTING BLOCKS

MUST BE POSITIONED AT 1/4

POINTS OR AS SPECIFIED IN THE

PROJECT SHOP DRAWINGS.

9/2000

Page 14

SECTION VIII: EXTERIOR GASKET INSTALLATION

STEP #1 TEMPORARY GASKET INSTALLATION

Depending on your sequence of installation, you may or may not want to

use temporary glazing retainers to hold the glass in place until the final

gasket installation can be achieved. To allow for temporary installation,

12" long gasket retainers can be provided for your use. Temporary retainers

should be positioned in the center of any glass edge that is less than

30" long and at quarter points for edges over 30".

STEP #2 PERMANENT GASKET INSTALLATION

If, and when, permanent glazing is possible, remove the temporary glazing

retainers and insert permanent gaskets as specified in the following instructions. Depending on weather conditions and considering public safety, it is

recommended that the temporary glazing retainers only be used for short

periods of time.

PAGE 12

12" LONG TEMPORARY GASKETS

SHOULD BE USED FOR SHORT

PERIODS OF TIME ONLY.

TYPICAL GASKET INSTALLATION

AT THE TIME OF FINAL GLAZING

ASSEMBLY.

NOTE: Temporary retainers are intended

for short term temporary applications

only, and are not intended to be left

unattended or overnight. (TEMPORARY

RETAINERS DO NOT MEET STRUCTURAL

REQUIREMENTS AND CAN FAIL UNDER

STRUCTURAL LOADS.)

NOTE: Temporary retainers are available from EFCO by request only and are not

included in the cost of the materials for the job.

9/2000

Page 15

PAGE 13

SECTION VIII: EXTERIOR GASKET INSTALLATION CONT.

STEP #3 GASKET INSTALLATION AND INSPECTION

Select a formed corner gasket corresponding to the opening in process and

lubricate with the recommended gasket lubricant. Position the gasket to the

opening and install the gasket corner darts into the retainer pockets at the

top corners of the opening, using a #HM46 dead blow mallet (see illustration

"A" on page #14). Care must be taken to strike the gasket flatly, with only

as much force as required to set the gasket dart into the retainer pocket,

(see below). Repeat the procedure at the bottom corners of the opening (see

illustration "B" on page #14). Caution must be used to ensure that the

gaskets are not overdriven into the gasket receiving pocket (see the

illustrations below for proper installation of the exterior gasket).

NOTE: To facilitate the gasket

installation, it is best to wet the

gasket and the glass or panel.

YES

NO

GASKET

CORRECTLY

INSTALLED

NO

GASKET

OVER

INSTALLED

GASKET

UNDER

INSTALLED

NOTE: Inspect each gasket after

installation. Do not allow the

gasket lip to fold under itself.

If this occurs, correct the lip

placement by using a thin metal

spatula or the back edge of a

knife to reposition the gasket.

NOTE: The recommended gasket lubricant is:

Summer Installation (40 deg. F plus):

Winter Installation (40 deg. F or less):

5% liquid soap and 95% water

5% liquid soap, 10% methylated

spirits, and 85% water

7/2003

Page 16

PAGE 14

SECTION VIII: EXTERIOR GASKET INSTALLATION CONT.

STEP #4 STEP BY STEP GASKET INSTALLATION

Align the center of the linear sides of the gasket with the center line of the

opening. Use the #HM46 mallet to engage the gasket dart into the gasket

retainer pocket at this half point. See illustration "B" below. Continue to install the gasket by dividing the remaining loose gasket material in half and

work it into the gasket retainer pocket. See illustration "C" below. Continue

until the entire length of gasket is engaged in the retainer pocket at all

sides. See illustration "D".

CENTER

CORNER

INSTALLATION

INSTALLATION

C

L

A

C

STEP #5 FINAL GASKET INSPECTION

B

C

L

D

The gasket surface should be smooth when fully installed. Both a visual and

"by feel" inspection of the gasket should be made to ensure that the dart is

fully engaged in the retainer pocket continuously along the gasket length,

including the corners. All corners should be pushed into alignment with other

corners at the intersections of the vertical and horizontal members.

9/2000

Page 17

PAGE 15

SECTION VIII: EXTERIOR GASKET INSTALLATION CONT.

BEFORE ADJUSTMENT

INCORRECT

GASKETS DO NOT

ALIGN PROPERLY.

AFTER ADJUSTMENT

CORRECT

ALL GASKET

CORNERS LINE UP.

NOTE: Feel the gasket surface

to ensure it is smooth and flat.

7/2003

Page 18

PAGE 16

SECTION VIII: EXTERIOR GASKET INSTALLATION CONT.

STEP #6 PERIMETER GASKET INSTALLATION

At very large openings, a butt joint may be required to facilitate handling

and installation. A butt joint in the perimeter gasket will generally occur at

center of daylight opening. Install the gasket at the opening corners

per the typical gasket installation. Clean each gasket end. A factory cut end

will be provided. Apply a small amount of specified silicone sealant to the

full cross section of each end of the gasket to be jointed. Insert 2" to 3"

of each gasket dart into the retainer pocket. Push the gasket ends together

to engage the wet silicone sealant. The gasket should lay flat across the

joint and all residue sealant should be removed from the gasket surface.

Install the remainder of the gasket per the typical installation, taking care

not to separate the gasket joints. Do not stretch the gaskets to make them fit.

FINISHED

SPLICE JOINT

9/2000

Page 19

SECTION IX: PERIMETER SEAL INSTRUCTIONS

STEP #1 PERIMETER SEAL INSTRUCTIONS

Insert the specified backer material into the perimeter joint and apply

perimeter sealant continuously to the prepared substrate and previously cleaned

surface of the system framing. Professionally tool the sealant joint to verify

that a continuous sealant contact is between the frame and substrate.

Perimeter seals can be fully applied before or after the system is glazed.

BACKER ROD

SILICONE SEALANT

PAGE 17

JAMB DETAIL

POCKET

FILLER

BACKER ROD

SILICONE SEALANT MUST

MARRY WITH THE SILICONE

GASKET EDGE.

VERTICAL

MULLION

HEAD DETAIL

PERIMETER

HORIZONTAL

PERIMETER POCKET

FILLER

SEAL

BETWEEN

THE SYSTEM

AND CONDITION.

SEAL

BETWEEN THE

ADAPTOR AND

THE HORIZONTAL.

SEAL THE GASKET

POCKET 1/2" FROM

THE ENDS TO MATE

WITH THE PERIMETER

SEAL.

FRONT VIEW JOINERY DETAIL AT SILL

*Joint detail similar at head.

7/2003

Page 20

SECTION X: DEGLAZING PROCEDURE

STEP #1 GASKET REMOVAL

If the glazing must be removed, use the following procedure. Insert the

deglazing tool provided directly between the gasket intersection point, at the

corner. Insert the point of the tool directly down until the point hits the

back of the vertical gasket retainer pocket. Using a prying motion, rotate the

point of the deglazing tool until the curved back portion seats against the

gasket retainer pocket. This action will allow the point of the tool to press

out against the back of the molded corner dart. Pry the tool toward the face

of the glass until the corner dart pops out of the gasket retainer pocket.

Using your free hand, hold the gasket back and away from the wall and

reposition the tool under the continuous dart. Using the same prying motion,

push the tool inward and pull gently outward on the gasket to facilitate

removal.

NOTE: Always pull the gasket gently, directly out, and perpendicular to the

plane of the wall. Never twist the gasket when pulling it out as this may

cause the material to tear or cut the gasket dart legs.

PAGE 18

A

A

POSITION THE DEGLAZING TOOL

UNDER THE DART IN THE CORNER

OF THE GASKET. DISENGAGE THE

DART PRIOR TO REMOVING THE

GASKET.

DEGLAZING TOOL

PART #HM47

VIEW A-A

Stalgard is a registered trademark of Textron, Inc.

MOLDED CORNER DART

7/2003

Loading...

Loading...