Page 1

Series 525 impact storefront

Installation Instructions

Part NO. Y020

February 2013

Page 2

TABLE OF CONTENTS

SECTION PAGE

I GENERAL NOTES

II PARTS IDENTIFICATION

III FABRICATION

A. DRILLING TEMPLATE

(SCREW SPLINE VERTICALS)

B. DRILLING TEMPLATE

(SHEAR BLOCK VERTICALS)

C. DRILLING TEMPLATE

(SHEAR BLOCK AT HORIZONTALS.)

D. SILL WEEP NOTCHES

IV INTERIOR GASKET INSTALLATION

V UNIT ASSEMBLY

A. SCREW SPLINE

B. SHEAR BLOCK

1

2 - 6

7

8

9 -10

11

12

13

14

VI DOOR FRAME INSTALLATION

VII SUBSILL FABRICATION AND INSTALLATION

VIII FRAME INSTALLATION

A. SCREW SPLINE

B. SHEAR BLOCK

C. PERIMETER SEALANT

IX GLAZING

Mini mizing Condensation

NOTE: Please reference EFCO's "Understanding Condensation" brochure which can be obtained through your EFCO representative.

Condensation will form on any surface when unfavorable conditions (interior temperature and relative humidity and exterior

temperature) are present. When the formation of excessive condensation is a concern, it is highly recommended that a design

professional is utilized to perform an analysis of the shop drawings to recommend the best installation methods. Please contact

EFCO representative for information on EFCO's Thermal Analysis Services.

Many current installation practices lead to an increase in the possibility of the formation of condensation. Though not all

inclusive, the list of examples below illustrates conditions under which condensation is likely to occur:

1. Bridging system thermal break with non-thermally broken metal flashing or lintels that are exposed to the

exterior.

2. System exposure to cold air cavities.

3. Interior relative humidity levels not maintained at recommended levels, see EFCO's "Understanding

Condensation" brochure.

4. Inadequate separation between system and surrounding condition at perimeter.

5. Product combinations during the shop drawing stage that result in bridging thermal breaks of one or all products

involved.

15 - 19

20 - 24

25 - 31

32 - 33

34

35 - 42

Page 3

PAGE 1

SECTION I - GENERAL NOTES

The "Series 525" is a framing system that is designed for impact

resistance of windborne debris. It can be used as a single-span

storefront window wall, a punched opening system, or as a ribbon

window system. The system can be fabricated for both screw

spline and shear block construction.

The Series 525 system contains primarily stock length material

with in-the-field fabrication, or it may be fabricated in the shop for

delivery to the job site. Entrance doors are also an integrated

part of this system, utilizing frame members and hardware

support systems that accommodate doors and door hardware

that will withstand impact from windborne debris.

1.) Check the shop drawings, installation instructions, and glazing instructions to

become thoroughly familiar with the project. The shop drawings take precedence and

include specific details for the project. The installation instructions are of a general

nature and cover the most common conditions encountered.

2.) Check all materials on arrival and be sure you have everything required to begin

installation. See Section II "PARTS IDENTIFICATION" for parts cross reference.

3.) All work should start from bench marks and/or column center lines as established

by the architectural drawings and the general contractor. Installers should check

building construction for compliance with architectural documents to ensure the proper

window system foundation is available before installation.

4.) The term "sealant" as used in these instructions is defined as: A weather resistant,

gunable liquid filler, when dry, provides a resilient, flexible air and water seal between

similar and dissimilar materials. In these instructions Dow Corning 795 or equivalent is

used when silicone sealant is required and PTI 707 or equivalent is used when butyl

type sealant is required. Dow Corning 995 or equivalent structural silicone is used

where glazing sealant is required.

All sealant must be compatible with all surfaces on which adhesion is required,

including other sealant surfaces. All frame surfaces should be clean and dry. All

perimeter substrate shall be cleaned and properly treated to receive sealant.

5.) All materials are to be installed plumb, level, and true.

6.) Protect materials after erection. Cement, plaster, alkaline solutions, and acid based

materials can be harmful to the finish. Clean exposed finished surfaces with a mild

detergent and water. No abrasive cleaning agent should be used.

525 IMPACT

DPS 1/2004

Page 4

SECTION II - PARTS IDENTIFICA TION CHART

PAGE 2

VERTICALS

DESCRIPTION

PERIMETER JAMB

-SHEAR BLOCK OR

SCREW SPLIN E-

VERTICAL MULLION

-SHEAR BLOCK ONLY-

VERTICAL MULLION

(Deep Pocket )

-SCREW SPLINE ONLYUse with 4481

VERTICAL MULLION FILLER

(Shallow Pocket)

-SCREW SPLINE ONLY-

Use with 4480

MALE EXPANSION

MULLION

PART NO.

4476

4477

4480

4481

16D2

DOOR FRAMES

DESCRIPTION

DOOR JAMB

-SHEAR BLOCK ONLYUses 4437/9155 door stop and

4487/4488 transom glass stop.

STD. DOOR HEADER

-SHEAR BLOCK ONLY-

Uses 4486 glazing bead.

C.O.C. DOOR HEADER

-SHEAR BLOCK ONLY-

Use with 4486 glazing bead.

DOOR HEADER

GLAZING BEAD

Use with 4483 and

4484 door headers.

FIXED TRANSOM

GLASS STOP

Use with 4488 glass stop at

4478 door jamb.

PART NO.

4478

4484

4483

4486

4487

FEMALE EXPANSION

MULLION

HORIZONTALS

HEAD

INTERMEDIATE

HORIZONTAL

SILL

Interlocks with 4482

subsill only.

Use with 4485 stop

GLAZING BEAD

Use with 4475 and 4491.

16D1

4479

4491

4475

4485

REMOVABLE TRANSOM

GLASS STOP

Use with 4487 glass stop at 4478

door jamb.

DOOR STOP

Use with 9155 door stop cover at

4478 door jamb.

DOOR STOP

Use with 9155 door stop cover at

2" doors and 4478 door jamb.

DOOR STOP COVER

Use with 4437 door stop at 4478

door jamb.

SLIDE ARM COVER/DOOR

STOP

Use with 4483 C.O.C. door header

4488

4437

4399

9155

9914

SUBSILL

Interlocks with 4475 sill only.

4482

SHAPES ON THIS PAGE ARE NOT TO SC ALE

MDM 04/06

Page 5

PAGE 3

5

SECTION II - PARTS IDENTIFICATION CHART

SHEAR BLOCKS

DESCRIPTION PART NO.

HORIZ. & SILL SHEAR

BLOCK PACKAGE

Use wit h 4 475 & 4491

(1) FU22, (1) FU21, (5) STB5, (2) STS0

FRAME HEAD SHEAR

(2) FU21, (2) S101, (2) S103, (4) STB5

DOOR HEADER SHEAR

Use wit h 4 484 & 4483

LH or RH

BLOCK PACKAGE

LH or RH

Use with 4479

BLOCK PKG.

LH or RH

(1) FV67, (2) STV2, (2) STD8

K998

K997

K876

GLAZING GASKETS

DESCRIPTION

EXTERIOR GLAZING

GASKET

Used with 9/16" and

5/8" glazing.

EXTERIOR GLAZING

GASKET

Used with 7/16" and 1/2"

glazing.

EXTERIOR GLAZING

GASKET

Used with 11/16"

glazing.

INTERIOR GLAZING

GASKET

Used w ith all glazing.

PART NO.

W164

W165

W166

WEQ1

(CONT.)

SETTING BLOCK S

GLASS SETTING BLOCK

Used wi th 4491

horizontal

and 4475 sill.

GLASS SETTING BLOCK

Used with 4483 and 4484

door headers.

WEATHER SEALS

HN43

HN91

DRILL FIXTURES

SCREW SPLINE

DRILL JIG

USED AT VERTICALS

SHEAR BLOCK

DRILL JIG

USED @ V ERTICALS AND

HORIZONTALS

DJ20

DJ19

525 IMPACT

SHAPES ON THIS PAGE ARE NOT TO SCALE

BAH 9/200

Page 6

PAGE 4

SECTION II - PARTS IDENTIFICA TION CHART

FASTENERS

DESCRIPTION

PART NO. DESCRIPTION

STC8

STB5

STV2

STS0

PART NO.

MRB8

S118

M130

M131

(CONT.

S101

S103

STT6

M148

STC7

M160

M161

SHAPES ON THIS PAGE ARE NOT TO SC ALE

Page 7

SECTION II - PARTS IDENTIFICATION CHART

PAGE 5

(CONT.)

MISC. PARTS

DESCRIPTION

WATER DEFLECTOR

@ INT. HORIZONTAL

BOND BREAKER TAPE

4" X .062"

USED @ SUBSILL SPLICES

DORMA RTS-88 C.O.C.

SUPPORT PKG. FOR BUTT

& CONTINUOUS HINGES

RHRB

DORMA RTS-88 C.O.C.

SUPPORT PKG. FOR BUTT

& CONTINUOUS HINGES

LHRB

DORMA RTS-88 C.O.C.

F-CLIP SPACER PKG. FOR

BUTT & CONT. HINGES

ATTACHMENT CLIP FOR

DORMA RTS 88 C.O.C. FOR

OFFSET PIVOTS

F-CLIP FOR DORMA RTS 88

C.O.C. AT OFFSET PIVOTS

USE FASTENERS SUPPLIED

WITH CLOSER.

RH COVER PLATE FOR

DORMA RTS 88 C.O.C. AT

OFFSET PIVOTS

(CUSTOMER SPECIFY FINISH)

PART NO.

HWD1

WM01

K874

K873

K875

K435

FT16

FT20

MISC. PARTS

DESCRIPTION

MILL COVER PLATE FOR

DORMA RTS 88 C.O.C. AT

BUTTS AND CONT. HINGE

(CUSTOMER SPECIFY FINISH)

COVER PLATE FOR

DORMA RTS 88 C.O.C. AT

BUTTS AND CONT. HINGE

(CLEAR ANODIZE)

COVER PLATE FOR

DORMA RTS 88 C.O.C. AT

BUTTS AND CONT. HINGE

(DRK. BRNZ. ANODIZE)

REINFORCING PKG. FOR

FLUSH BOLT & 3-POINT

@ HEAD

LOCK

FOR PAIR DOORS

REINFORCING PKG.

FOR 1490 PANIC & 3-POINT

LOCK @ THRESHOLD AND

@ HEAD FOR SINGLE DOOR

3-POINT LOCK

REINFORCING PKG.

FOR 1490 PANIC

@ THRESHOLD

FOR PAIR DOORS

PART NO.

K492

K495

K496

K936

K990

K987

525 IMPACT

LH COVER PLATE FOR

DORMA RTS 88 C.O.C. AT

OFFSET PIVOTS

(CUSTOMER SPECIFY FINISH)

FT26

SUBSILL END DAM

PACKAGE

USED WITH 4482 SUBSILL

SHAPES ON THIS PAGE ARE NOT TO SCALE

KN66

DPS 3/2004

Page 8

PAGE 6

SECTION II - PARTS IDENTIFICATION CHART

MISC. PARTS

DESCRIPTION

BACKER PLATE & SHIM

PACKAGE FOR 180/MP1

TOP PIVOTS

LEFT HAND MP2/195

BOTTOM PIVOT BACKER

PACKAGE

RIGHT HAND MP2/195

BOTTOM PIVOT BACKER

PACKAGE

PART NO.

K999

KN04

KN05

MISC. PARTS

PART NO.DESCRIPTION

(CONT.)

DOOR JAMB MOUNTING

PLATE & SPACER PKG.

FOR M19/MP3 INT. PIVOT

BUTT HINGE BACKER PKG.

FOR 4 1/2 X 4 BUTT HINGES

(CLEAR)

BUTT HINGE BACKER PKG.

FOR 4 1/2 X 4 BUTT HINGES

(BRONZE)

BUTT HINGE BACKER PKG.

FOR 5 X 4 1/2 BUTT HINGES

(CLEAR)

BUTT HINGE BACKER PKG.

FOR 5 X 4 1/2 BUTT HINGES

(BRONZE)

K968

K900

K901

K904

K905

525 IMPACT

SHAPES ON THIS PAGE ARE NOT TO SCALE

DPS 1/2004

Page 9

PAGE 7

SECTION III-FABRICATION A - DRILLING TEMPLATE

SCREW SPLINE VERTICALS

USE THE INTERIOR EDGE OF THE VERTICAL TO

ALIGN DRILL JIG DJ20. USE .221 DIA. (#2) DRILL

AT DARKENED AREAS ONLY.

PERIMETER JAMB SHOWN, VERTICAL MULLION AND FILLER SIMILAR.

EXTERIOR

.188"

1.687"

1.000"1.000"

1.000"1.000"

2.312"

REF.

.188"

2.312"

INTERIOR

.188"

2.500"

2.500"

(HEAD)

(HORIZONTAL)

525 IMPACT

1.687"

1.000"1.000"

[FIG. 1]

1.000"

1.000"

.188"

2.500"

(SILL)

DPS 1/2004

Page 10

PAGE 8

SECTION III-FABRICATION B - DRILLING TEMPLATE

SHEAR BLOCK VERTICALS

USE THE INTERIOR EDGE OF THE VERTICAL TO

ALIGN DRILL JIG DJ19. USE .182 DIA. (#28) DRILL

AT DARKENED AREAS ONLY.

PERIMETER JAMB SHOWN, VERTICAL MULLION SIMILAR.

EXTERIOR

2.062"

.563"

.329"

.329"

1.812"

.313"

1.000"

1.000"

1.000"

1.375"

.329"

.625"

.375"

1.437"

INTERIOR

2.500"

.563"

.313"

2.125"

(HEAD)

(HORIZONTAL)

2.500"

525 IMPACT

2.062"

.329"

1.812"

1.000"

[FIG. 2]

1.375"

.625"

.375"

1.437"

2.125"

2.500"

(SILL)

DPS 1/2004

Page 11

PAGE 9

SECTION III-FABRICATION C - DRILLING TEMPLATE

SHEAR BLOCK HORIZONTALS

USE THE INTERIOR & EXTERIOR EDGE AND EACH END OF THE

HEAD TO ALIGN DRILL JIG DJ19. USE .228 DIA. (#I) DRILL AT

DARKENED AREAS ONLY FOR STEP 1.

AFTER STEP 1 IS COMPLETE, PROCEED TO STEP 2.

COUNTERSINK HOLES 82˚ TO .438 DIAMETER.

.625"

.625"

(STEP 1)

1.000"

1.000"

1.000"

1.000"

PREP FOR FRAME HEAD.

.625"

.625"

INTERIOR

EXTERIOR

4479 HEAD

[FIG. 3]

.625"

525 IMPACT

.625"

1.000"

1.000"

82˚ CTSK

@ .438 DIA.

(2) EACH END

1.000"

1.000"

.625"

.625"

INTERIOR

4479 HEAD

[FIG. 4]

EXTERIOR

DPS 1/2004

Page 12

PAGE 10

SECTION III-FABRICATION C - DRILLING TEMPLATE

(CONT.)

SHEAR BLOCK HORIZONTALS

USE THE EXTERIOR EDGE AND EACH END OF THE HORIZONTAL OR

SILL TO ALIGN DRILL JIG DJ19. USE .228 DIA. (#I) DRILL AT DARKENED

AREAS ONLY FOR STEP 1.

AFTER STEP 1 IS COMPLETE, PROCEED TO STEP 2. ROTATE THE

MATERIAL, AND USE THE EDGE OF THE GLAZING POCKET AND THE

END OF EACH HORIZ. OR SILL TO ALIGN DRILL JIG DJ19. USE A .228

DIA. (#I) DRILL AT DARKENED AREAS ONLY FOR STEP 2.

PREP FOR FRAME

HORIZ. AND SILL

(STEP 1)

.625"

1.054"

1.000"

[FIG. 5]

(STEP 2)

1.000"

1.000"

1.000"

1.054"

.625"

4491

HORIZ.

EXTERIOR

1.054"

4475

SILL

EXTERIOR

[FIG. 6]

525 IMPACT

4491 HORIZ. SHOWN

4475 SILL SIM.

DPS 1/2004

Page 13

PAGE 11

SECTION III-FABRICATION D - SILL WEEP NOTCHES

To evacuate water from the system, weep notches must be placed at

the ends of each sill. This notch will manifest itself as a 1/8" X 1" notch

at each end of the sill, joining the vertical at the exterior face of the sill.

The notch also must remove the two extended legs in the middle

portion of the sill. These legs must be removed at the same height as

the face notch and requires that more material be removed. This

material removal will not be seen because it is under the sill and is

covered by the subsill. Refer to figures 7 and 8 below for notching

layout.

END OF

SILL

EXTERIOR

1" REF.

TOP OF

SILL

1/8"

5/16"

4475

SILL

INTERIOR

[FIG. 7]

NOTCH LEGS

AT EACH END

END OF

SILL

1" REF.

ENSURE THAT THE EXTERIOR NOTCH IS CLEAN

AND UNIFORM FOR GOOD WATER FLOW, AND TO

MAKE THE NOTCH AS UNOBTRUSIVE AS

POSSIBLE WHEN VIEWED FROM THE EXTERIOR.

525 IMPACT

1/8"

1"

BOTTOM

OF SILL

1" REF.

1"

[FIG. 8]

1/8"

DPS 1/2004

Page 14

PAGE 12

SECTION IV - INTERIOR GASKET INSTALLATION

STEP 1) INTERIOR GASKET INSTALLATION

After all material is cut to the appropriate length, the WEQ1 interior

gasket/sealant backer should be installed. Begin the installation of the WEQ1

by first ensuring that the gasket race is clean and free of debris. The WEQ1

should be cut to the same length as the frame member it is being installed into.

Begin the installation on one end of the frame member and slide the WEQ1

into the raceway. It may be advantageous to use a light mixture of soapy

water to help the gasket slide into the race. After installation, ensure that the

WEQ1 is not stretched an excessive amount.

It is "possible" to install the WEQ1 after the frame members are assembled,

but it has to be pressed into the gasket race instead of sliding in. This is "far

more difficult and time consuming" and should be avoided unless absolutely

necessary. If the WEQ1 must be installed after the frame material is

assembled, a tool with a hooked tip of some type will ease the installation of

the gasket, as will a light mixture of soapy water. Refer to figure 9 below for

WEQ1 installation.

4477 SHOWN

OTHERS SIMILAR

EXTERIOR FACE

WEQ1

INTERIOR

GASKET

WEQ1

(INSTALLED)

SLIDE WEQ1 INTO

GASKET RACE

[FIG. 9]

525 IMPACT

DPS 1/2004

Page 15

PAGE 13

SECTION V-UNIT ASSEMBLY A - SCREW SPLINE

[FIG. 10]

DEEP

POCKET

4480

4479

BUTTER THE ENDS OF

ALL HORIZONTALS WITH

PTI 707 OR EQUIVALENT

BUTYL TYPE SEALANT

AS SHOWN BY THE

SHADED AREAS PRIOR

TO ASSEMBLY OF THE

UNITS.

STC8

STC8

DEEP

POCKET

4481

4491

STC8

4475

STC8

EXTERIOR FACE

ENSURE THAT EACH MODULE HAS A DEEP GLAZING

POCKET ON ONE SIDE AND A SHALLOW GLAZING

POCKET ON THE OTHER TO FACILITATE GLAZING

INSTALLATION.

525 IMPACT

STC8

STC8

DPS 1/2004

Page 16

PAGE 14

SECTION V-UNIT ASSEMBLY B - SHEAR BLOCK

[FIG. 11]

4477

4479

BUTTER THE ENDS OF

ALL HORIZONTALS WITH

PTI 707 OR EQUIVALENT

BUTYL TYPE SEALANT

AS SHOWN BY THE

SHADED AREAS PRIOR

TO ASSEMBLY OF THE

UNITS.

4477

K997 HEAD SHEAR

BLOCK PKG. (INCLUDES

SHEAR BLOCKS AND

FASTENERS)

4491

EXTERIOR FACE

K998 HORIZ. SHEAR

BLOCK PKG. (INCLUDES

SHEAR BLOCKS AND

FASTENERS)

4475

K998 HORIZ. SHEAR

BLOCK PKG. (INCLUDES

SHEAR BLOCKS AND

FASTENERS)

ENSURE THAT EACH MODULE HAS A DEEP GLAZING

POCKET ON ONE SIDE AND A SHALLOW GLAZING

POCKET ON THE OTHER TO FACILITATE GLAZING

INSTALLATION.

525 IMPACT

DPS 1/2004

Page 17

PAGE 15

SECTION VI - DOOR FRAME INSTALLATION

STEP 1) GENERAL NOTES

Door frames should be installed first, before all other framing material, when

required. The system subsill must be installed from the door framing, ensuring that

the appropriate clearance is available for the door frame. All subsequent modules

must be installed from the door jambs outward. Because of shear block

construction methods used with the door framing, the immediate side lites must be

shear blocked to the door jambs. From this point, either shear block or screw

spline construction methods may be used on the remainder of the framing.

SHEAR BLOCK CONSTRUCTION

INSTALL 1ST

SHEAR BLOCK OR

SCREW SPLINE

[FIG. 12]

SUBSILL SUBSILL

2 1/2"

2 1/2"

SUBSILL CLEARANCE HOLE =

[DOOR OPENING WIDTH + 5"]

CONSTRUCTION

NOTE: Door jambs do not set on the subsill. Door

jambs must run through to the floor condition.

STEP 2) SUBSILL INSTALLATION AT DOOR OPENING

Where a door opening is required, use the equation in figure 12 above. Install the

door frame true and plumb in the opening as specified on the shop drawings or

architectural drawings. Install the subsill in the same manner as illustrated in

figures 21-30 on pages 20 through 24. End dams are not required at the door

frame end of the subsill. The subsill should butt up tight to the door frame. See

figure 13 on page 16 for subsill sealant requirements at the door framing.

525 IMPACT

DPS 1/2004

Page 18

PAGE 16

SECTION VI - DOOR FRAME INSTALLATION

STEP 3) SUBSILL SEALANT AT DOOR FRAME

Before installing the subsill to the door frame, seal the end of the

subsill with Dow Corning 795 or equivalent silicone type sealant.

Install the subsill and tool all excess sealant into the joint where the

subsill and door jamb meet.

If required, add more sealant to create a smooth watertight seal. Do

not build up excess sealant as it will keep the sill member of the frame

pushed away from the jamb if allowed to cure before the sidelite

frame is installed. At the glazing pockets, a build up of 795 sealant

must be used to fill the depth of the pocket up to the level of the

subsill at the glazing area. See figure 13 below for sealant application

at the subsill to door jamb joint.

(CONT.)

SIDELITE SIDE

OF 4478 DOOR JAMB

[FIG. 13]

TOOL 795

SEALANT

EXTERIOR FACE

OF 4478 DOOR JAMB

FILL VOID FLUSH

AND TOOL SO WATER

WILL FLOW TO THE SUBSILL

NOTE: Fill the glazing pocket of the door jamb flush with

the 795 sealant to the tallest portion of the subsill that

4482

SUBSILL

525 IMPACT

bridges the glazing pocket. Tool the silicone so a

watertight seal is made, and so that water will be directed

out of the glazing pocket and into the subsill.

DPS 1/2004

Page 19

PAGE 17

SECTION VI - DOOR FRAME INSTALLATION

(CONT.)

STEP 4) DOOR HEADER IDENTIFICATION

Depending on what type closer is used, two different door headers are

available. The header for surface closers has an extruded door stop and

will not have a stop applied at the door header. Concealed Overhead

Closers (COC) do not have an extruded stop and must have a slide arm

cover/door stop applied. The 9914 stop is applied with #8 FH fasteners in

prelocated holes. Match drill the holes in the stop to the door header.

See figure 14 below for door header identification and stop application.

4486

4484

4486

4483

[FIG. 14]

STEP 5) DOOR JAMB STOP APPLICATION

The door jambs are designed to accept a

screw applied door stop into a recessed

area of the door jamb. The applied door

stops should run from the top of the

threshold to the bottom of the door

header stop. They should be attached

with STT6 TEK screws @ 2" from each

end and 9" on center Maximum. After the

applied stop is attached, snap on the

applied stop cover to hide the attachment

fasteners. See figure 15 on this page for

door stop and cover application.

9155

4437

9914

4478

525 IMPACT

[FIG. 15]

DPS 1/2004

Page 20

PAGE 18

SECTION VI - DOOR FRAME INSTALLATION

(CONT.)

STEP 6) SCREW APPLIED TRANSOM STOP APPLICATION

The screw applied vertical transom glass stops should be cut to fit

between the top of the door header and the bottom of the transom head.

The stop should be attached with STT6 TEK screws 2" from each end and

9" on center Maximum. To facilitate the installation of the door header

glass stop, a 3/8" X 3/8" notch must be made on the bottom of the screw

applied transom stop. See figures 16 and 17 below for notching and

application of the screw applied transom stop.

TRANSOM STOP CUT LENGTH

BOTTOM OF TRANSOM STOP

44874487

4478

3/8"

3/8"

[FIG. 16]

[FIG. 17]

STEP 7) TRANSOM GLASS INSTALLATION

After the screw applied transom stop is applied, the glass can be

installed into the DLO. However, it may be advantageous to wait until

all frame installation is complete before the glazing is installed. Glazing

the transom at a later time may keep the glass from being broken while

other trades use the entrance area. Side loading is not required to

install the glass. It only has to be centered into the DLO and lifted into

the transom head so the setting blocks can be placed. See the dead

load charts listed in figure 58 on page 36 for setting block locations.

525 IMPACT

DPS 1/2004

Page 21

PAGE 19

SECTION VI - DOOR FRAME INSTALLATION

(CONT.)

STEP 8) TRANSOM GLASS STOP INSTALLATION

When the glass is installed, the door header glass stop should be installed

first. Once this is accomplished, the removable transom glazing stops can

be installed. The transom glass stops should run from the bottom of the

transom head to the top of the door header. The transom glazing stops

do not snap onto the applied transom stops, but rather hook on and are

held in place by the exterior glazing gasket pressure. The exterior glazing

gasket and the interior glazing seal are installed in the same manner as

shown in figures 71-73 on pages 41 and 42. See figures 18-20 below for

header glass stop and transom glass stop installation.

4486

4487

4484

SHOWN

4483

SIMILAR

[FIG. 18]

[FIG. 19]

4478

4487

4488

525 IMPACT

4488

[FIG. 20]

DPS 1/2004

Page 22

PAGE 20

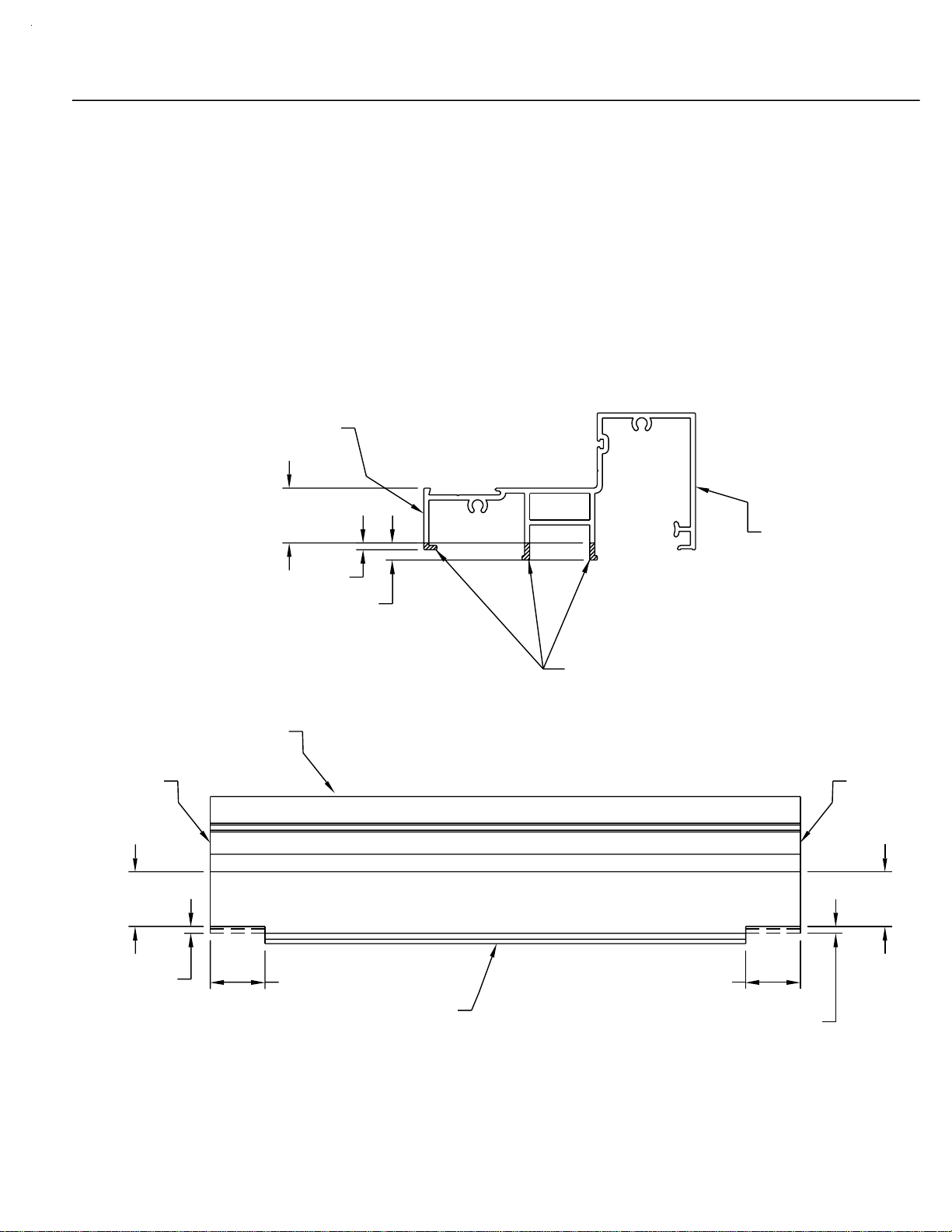

SECTION VII - SUBSILL FABRICATION

& INSTALLATION

STEP 1) SUBSILL END DAM REQUIREMENTS

Before installing the subsill into the rough opening, you must

determine whether an end dam is required or not. If the surrounding

condition does not have an open area or can be used as a water dam,

move to Step 3 on page 21.

The first step to installation of the end dams is to measure the rough

opening width. The subsill length should be, ROUGH OPENING

WIDTH - 3/8". This formula will give enough room for the end dam

and attachment screws to fit on both ends of the subsill without

interference with the rough opening. (See figure 21 below.)

KN66 END DAM

[FIG. 21]

STC7 FASTENER

3/16"

SUBSILL LENGTH = R.O. - 3/8"

ROUGH OPENING

KN66 END DAM

SUBSILL

STC7 FASTENER

3/16"

STEP 2) SUBSILL END DAM INSTALLATION

Prior to installing the end dam, apply a generous amount of silicone

type sealant to the end of the subsill. Insert the

the end dam and attach it to the end of the subsill. After the end dam

is attached, the excess sealant should be tooled at the interior of the

subsill/end dam joint to provide a watertight seal. Apply more sealant

if required for a watertight seal. (See figures 22 and 23 below below.)

TOOL SEALANT

STC7 fasteners into

[FIG. 23]

525 IMPACT

[FIG. 22]

BUTTER THE ENDS

OF THE SUBSILL

WITH SILICONE

TYPE SEALANT

PRIOR TO

INSTALLATION OF

THE END DAM

STC7

DPS 3/2004

Page 23

PAGE 21

SECTION VII - SUBSILL FABRICATION

(CONT.)

& INSTALLATION

STEP 3) SUBSILL INSTALLATION WHEN END DAMS

ARE NOT REQUIRED

An end dam may not be required in all cases. Before installing a

subsill without an end dam, you must determine if the surrounding

condition can be used to create a water dam, and if the material will

not degrade over time if it comes into contact with water. Once it has

been determined that the condition is appropriate to create a water

dam, continue the installation of the subsill as described in Steps 4-8

of this section.

STEP 4) BENCH MARKS FOR SUBSILL LOCATION

Before installing the subsill, the exterior face location of the frame

should be found using bench mark information from the shop

drawings or architectural drawings. The subsill protrudes 1/4" to the

exterior of the exterior face of the frame. Locate this line based on

the bench mark information, and snap a chalk line to follow when

installing the subsill. The subsill exterior angled leg should follow the

chalk line for correct installation.

STEP 5) PREPARING AND SEALING THE SUBSILL

FOR INSTALLATION

Regardless of whether an end dam is used or not, the subsill must be

sealed to the condition to create a watertight condition when it is

installed. Begin the process by cleaning the bottom of the subsill with

a degreasing solution and wipe it dry after all foreign material has

been removed. When the subsill is clean and dry, apply a generous

amount of 795 silicone or equivalent silicone type sealant to the areas

shown in figures 24 and 25 on page 22. This should be done just

prior to the installation of the subsill to prevent the sealant from

setting up before the subsill is installed.

525 IMPACT

DPS 1/2004

Page 24

PAGE 22

SECTION VII - SUBSILL FABRICATION

& INSTALLATION

CLEAN &

DEGREASE

THOROUGHLY

[FIG. 24] [FIG. 25]

STEP 6) ANCHORAGE OF THE SUBSILL

After the subsill has been cleaned and the 795 sealant has been

SILICONE

SEALANT

(CONT.)

applied, rotate the subsill into position and follow the chalk line

location marks. Firmly press the subsill into position so that the

sealant is pressed uniformly onto the condition. Locate anchors on

the "V" groove of the subsill and tighten firmly and uniformly to

anchor the subsill. Anchors should be placed 6" from each end and

16" on center. Seal and tool the anchor heads with 795 or

equivalent silicone type sealant. These are general anchor location

guidelines. Size, space, and embedment of anchors as required to

meet structural loads.

SEALANT

END OF

SUBSILL

[FIG. 26]

INTERIOR OF

SUBSILL

6" MAX.

EXTERIOR OF

SUBSILL

2 3/4" ±1/16"

@ "V" GROOVE

16" ± NOT TO INTERFERE

WITH VERTICAL MULLIONS

INTERIOR OF

SUBSILL

SEALANT

6" MAX.

END OF

SUBSILL

525 IMPACT

[FIG. 27]

EXTERIOR OF

SUBSILL

2 3/4"

DPS 1/2004

Page 25

PAGE 23

SECTION VII - SUBSILL FABRICATION

(CONT.)

& INSTALLATION

STEP 7) SEALING THE ENDS OF THE SUBSILL

After the subsill has been installed and anchored, it must be sealed

to the condition at each end with 795 or equivalent silicone type

sealant. If the subsill has an end dam, there should be a continuous

bead of 795 placed up both the interior and exterior and across the

top edges of the end dam where it meets the condition. The sealant

should be tooled to make a watertight seal between the end dam

and the condition.

If the subsill does not have an end dam, a continuous bead of

silicone type sealant must be applied to the end of the subsill where

it meets the condition. The sealant should be tooled to make a

watertight seal between the subsill and the condition.

See figures 28 and 29 below for sealant application.

TOOL SEALANT

AROUND END DAM

END DAM

SUBSILL

TOOL SEALANT

SUBSILL

[FIG. 28] [FIG. 29]

525 IMPACT

DPS 1/2004

Page 26

PAGE 24

SECTION VII - SUBSILL FABRICATION

(CONT.)

& INSTALLATION

STEP 8) SPLICING THE SUBSILL

Verify that the subsills have been installed according to instructions

on pages 20-23. Splice areas should be centered at the vertical

mullion only. Maximum subsill length between splices is 20 feet ±. If

a splice is required, leave a 1/4" gap between the subsill ends

centered on a vertical mullion location. Use 795 or equivalent

silicone type sealant and a strip of, WM01, bond breaker tape 2"

wide and approximately 7 1/2" long to create the splice material.

Apply the 795 to both sides of the subsill ends, and fill the void

between the subsills from the exterior to the interior at the condition

and fill the sill leg receptor cavities on both subsills to a width of 2".

Ensure that the bond breaker tape is centered over the 1/4" gap, and

set the bond breaker tape into the sealant. Tool the 795 over the

bond breaker tape to create a watertight seal. If more sealant is

required to cover the edges of the bond breaker tape, apply the

required amount. Ensure that the splice joint does not interfere with

anchor legs of the sill or the leg receptors of the subsill. This is done

by making sure the splice joint is located at the center of a vertical

mullion. Refer to the shop drawings or architectural drawings for

mullion center lines.

1/4"

1/4"

2"

1"

[FIG. 30]

WM01 SPLICE

TOOL SEALANT

OVER SPLICE

SEALANT

FILL ANCHOR

LEG RECEPTORS 2" WIDE

AT THE SPLICE JOINT

FILL VOID BETWEEN

SUBSILLS BEFORE WM01

SPLICE IS ATTACHED

2"

1"

MAKE COSMETIC SEAL

BETWEEN SUBSILLS

AFTER WM01 SPLICE AND

FRAMING ARE INSTALLED

525 IMPACT

DPS 1/2004

Page 27

SECTION VIII-FRAME INSTALLATION

A. SCREW SPLINE

STEP 1) APPLYING SEALANT TO SUBSILL FOR

FRAME INSTALLATION

Apply 795 or equivalent silicone type sealant to the areas shown in

figure 31 below.

Do not apply sealant to the sill anchor leg receptor area. Excessive

sealant at this area may cause the system to lift up above the subsill

and not seat correctly.

795

SEALANT

PAGE 25

NO SEALANT HERE

[FIG. 31]

Ensure that enough 795 has been applied to seal the areas shown in

figure 32 below. After the frame has been installed, wipe off all

excess sealant that squeezes out.

795 sealant should only be applied to the subsill immediately prior to

the installation of the frame modules.

CLEAN OFF

EXCESS SEALANT

525 IMPACT

[FIG. 32]

795

SEALANT

DPS 1/2004

Page 28

PAGE 26

SECTION VIII-FRAME INSTALLATION

(CONT.)

A. SCREW SPLINE

STEP 2) INSTALLING JAMB MODULE FOR SCREW

SPLINE FRAMES

Place the module on the subsill at an approximate 30˚ angle. While

applying pressure upward, rotate the module into the condition. See

figure 32 on page 25 for sill placement into the subsill. When rotated

correctly, the interior face of the sill should be flush against the interior

leg of the subsill and the sill should set flat into the subsill as shown in

figure 32 on page 25.

SUBSILL

[FIG. 33]

JAMB

MODULE

STEP 3) ANCHORING THE JAMB

Ensure that the frame jamb is true and

plumb. Anchor through the jamb and into

the condition as shown in figures 34 and 35

below.

These are general anchor location

guidelines. Size, space, and embedment of

anchors as required to meet structural loads.

1/2"± SHIM

AS REQUIRED

CONDITION

SCREW SPLINE

MULLION

16" MAX.

16" MAX.

16" MAX.

16" MAX.

2"

FD

FD

FD

FD

FD

[FIG. 34]

525 IMPACT

[FIG. 35]

16" MAX.

FD

2"

DPS 1/2004

Page 29

PAGE 27

SECTION VIII-FRAME INSTALLATION

(CONT.)

A. SCREW SPLINE

STEP 4) ANCHORING THE HEAD

For D.L.O.'s 22" and narrower, the anchors must be spaced 2" from the

jamb and vertical members. Also another anchor 4" from the intermediate

vertical is required. For D.L.O.'s wider than 22", the outside anchors must

be spaced in a similar manner and all center anchors must be located at

16" on center Maximum. See figures 36 and 37 below for anchor

placement. These are general anchor location guidelines. Size, space,

and embedment of anchors as required to meet structural load.

2"

16" MAX.

2"

2"

FDFD

FD

[FIG. 36]

LESS THAN OR EQUAL 22"

PERIMETER

JAMB

1/2"± SHIM

AS REQUIRED

2"

INTERMEDIATE

VERTICAL

16" MAX.

GREATER THAN 24"

FD

2"

16" MAX.

2"

FDFDFD

525 IMPACT

[FIG. 37]

DPS 1/2004

Page 30

PAGE 28

SECTION VIII-FRAME INSTALLATION

(CONT.)

A. SCREW SPLINE

STEP 5) SEALING SCREW SPLINE VERTICAL MULLIONS

Prior to inst a lling an intermediate vertic al mullion or perimeter jamb, apply

795 or equivalent silicone type sealant to the vertical mullion in the locatio n

shown in figure 38 below. Bot h sides of the entire mullion should be

sealed. Apply enough sealant so when the filler or opposite mullion half is

snapped, it will create a good seal. Wipe off excess sealant from the

exterior i f required. Thi s sealant practice should be used for screw spline

vertical mu llions only.

CLEAN OFF

ANY EXCESS

SEALANT

[FIG. 38]

[FIG. 39]

795

SEALANT

SEAL

SNAP

CLEAN IF

REQUIRED

525 IMPACT

RDM 4/2011

Page 31

PAGE 29

SECTION VIII-FRAME INSTALLATION

(CONT.)

A. SCREW SPLINE

STEP 6) INSTALLING SUBSEQUENT SCREW SPLINE

MODULES

Make sure that the anchors are installed into the head and jamb of the

first module as specified in figures 34-37 on page 26 and 27. The 795

sealant should be applied to the mullion and to the subsill as specified in

figure 31 on page 25 and in figures 38 and 39 on page 28. Place the

second module on the subsill at an approximate 30 degree angle. Rotate

the module into the condition approximately 1/4" away from the

previously installed module. Once the second module is in place 1/4"

from the first module, slide it into position and begin snapping the mullion

halves together. When the two mullion halves are fully snapped, press

the second mullion down onto the subsill to make the sill flush with the

top of the subsill as shown in figure 32 on page 25. See figures 42 and

43 on page 30 for mullion snap fit instructions.

[FIG. 40]

1/4"

30˚

525 IMPACT

[FIG. 41]

DPS 1/2004

Page 32

PAGE 30

SECTION VIII-FRAME INSTALLATION

(CONT.)

A. SCREW SPLINE

STEP 7) SNAPPING SCREW SPLINE VERTICAL

MULLIONS TOGETHER

In some cases it may be necessary to use a clamping device to get the

mullions together properly, if they cannot be snapped by hand. To do

this, place one clamp at the bottom of the mullions using wood blocks to

protect the extrusions. Tighten the clamp until the mullion halves begin

to snap together. Place another set of wood blocks and a clamp at the

middle of the mullions and tighten it. Then repeat the same process at

the top. Tighten the clamps until the mullion halves are pressed

together. The sight line should be 2 1/2". It may be necessary to work

from one clamp to the next several times, or move the clamps to ensure

the mullions are snapped together evenly. DO NOT try to hammer the

mullion halves together! This will dent, bend, scratch, or deform the

mullions and may cause them to leak. Ensure that the previous module

is fully anchored before installing the 2nd module.

C-CLAMP

OR SIMILAR

[FIG. 43]

2 1/2"

[FIG. 42]

525 IMPACT

WOOD BLOCK

OR SIMILAR

DPS 1/2004

Page 33

PAGE 31

SECTION VIII-FRAME INSTALLATION

(CONT.)

A. SCREW SPLINE

STEP 8) ANCHORING SUBSEQUENT SCREW SPLINE

MODULES

After the mullion halves are snapped correctly, ensure that the mullions

are plumb and true, and anchor the head as shown on page 27. If this is

the last module in a run, ensure that the mullion halves are snapped

correctly and install the required shims between the jamb and condition.

Install the head and jamb anchors as shown on pages 26 and 27. Ensure

that the jamb anchors do not separate the last module from the previous.

It may be necessary to shim tightly against the condition to prevent this.

Seal and tool all anchor heads with 795 or equivalent silicone type sealant.

89"

118"

38"

TYPICAL ELEVATION WITH ANCHOR LOCATIONS

525 IMPACT

[FIG. 44]

DPS 1/2004

Page 34

PAGE 32

SECTION VIII-FRAME INSTALLATION

(CONT.)

B. SHEAR BLOCK

STEP 1) INSTALLING SHEAR BLOCK FRAMES

Because of the design of the shear blocks for the 525 system, EFCO

recommends that the shear block framing be used in punched

openings only. It would be possible to stack modules side by side in

a longer run. However, the last module could not be installed without

an extremely large caulk joint at the jamb of the last module installed.

For this reason, the shear block framing system should be used for

openings where the frame can be fully assembled and positioned into

the opening as a single unit.

STEP 2) SHEAR BLOCK FRAME ASSEMBLY

Begin the installation process by assembling the shear block framing

as shown in figure 11 on page 14. Once the unit has been

assembled, position the unit to the exterior of the subsill. Ensure that

the subsill has been installed and sealed correctly according to the

instructions on pages 20-25.

SUBSILL

CONDITION

525 IMPACT

ASSEMBLED

FRAME

[FIG. 45]

DPS 1/2004

Page 35

PAGE 33

SECTION VIII-FRAME INSTALLATION

(CONT.)

B. SHEAR BLOCK

STEP 3) INSTALLING SHEAR BLOCK FRAMES

The frame should be supported at each vertical member to ensure

the shear block joints are not over stressed. Begin the installation by

evenly lifting and supporting the frame so that the bottom of the sill is

slightly higher than the top of the subsill. With even pressure, push

the frame into the rough opening. Once the frame is in the correct

position, allow the weight of the system to settle onto the subsill.

Additional weight may be required to press the sill down even with the

top of the subsill. Ensure that the frame is centered evenly in the

rough opening.

SUBSILL

CONDITION

[FIG. 46]

ASSEMBLED

FRAME

STEP 4) ANCHORING SHEAR BLOCK FRAMES

Once the frame is installed into the rough opening, ensure that it is

true and plumb. Anchor locations for the shear block frame will be

the same as for the screw spline frame. Follow the instructions as

shown in figures 34-37 on pages 26 and 27 for proper spacing of the

anchors. It may be advantageous to anchor perimeter jambs first and

heads second to ensure the correct line of the frame is maintained.

Seal and tool all anchor heads with 795 or equivalent silicone type

sealant. These are general anchor location guidelines. Size, space,

and embedment of anchors as required to meet structural load.

525 IMPACT

DPS 1/2004

Page 36

PAGE 34

SECTION VIII-FRAME INSTALLATION

(CONT.)

C. PERIMETER SEALANT

STEP 1) PERIMETER FRAME SEALANT

All portions of the frame and surrounding conditions where sealant will be

applied should be cleaned and prepped per the sealant manufacturer's

recommendations. Use 795 or equivalent silicone type sealant to create

the perimeter seal of the system at both exterior and interior perimeters.

Exterior and interior seals are required for air and water performance.

Begin by pushing caulk backer rod into position around the full perimeter of

the frame at the head and jambs. Push the backer rod into the gap

between the frame and condition so it sets below the frame edge. See

figures 47 and 48 below for backer rod placement. The 795 sealant should

be applied by a skilled tradesman to ensure proper seal and appearance.

See figures 49 and 50 below for sealant application.

CAULK BACKER

[FIG. 47]

4476

JAMB

CAULK BACKER

SEALANT

[FIG. 49]

4476

JAMB

SEALANT

CAULK

BACKER

525 IMPACT

CAULK

BACKER

SEALANT

4479

HEAD

[FIG. 48] [FIG. 50]

SEALANT

4479

HEAD

DPS 1/2004

Page 37

SECTION IX - GLAZING

STEP 1) IDENTIFICATION OF SETTING BLOCKS FOR

HORIZONTALS

The setting block for standard frame horizontals is HN43. Two

setting blocks per D.L.O. are required and should be placed at 1/4

points or 1/8 points depending on dead load requirements. Door

headers require the use of a HN91 setting block. Two per D.L.O. are

also required for the HN91. Depending on dead load requirements,

the setting blocks should be placed at 1/4 or 1/8 points. See figures

56-58 on page 36 for calculating 1/4 and 1/8 point locations.

4479 HEAD (NO BLOCKING REQUIRED)

PAGE 35

4485

HORIZ.

STOP

4485

HORIZ.

STOP

[FIG. 51]

HN43

[FIG. 52]

HN43

4491

HORIZ.

4486

DOOR

HEADER

STOP

4486

DOOR

HEADER

STOP

HN91

[FIG. 54]

HN91

4484

STD.

DOOR

HEADER

4483

C.O.C.

DOOR

HEADER

525 IMPACT

[FIG. 53]

4475

SILL

[FIG. 55]

DPS 1/2004

Page 38

PAGE 36

SECTION IX - GLAZING

(CONT.)

STEP 2) SETTING BLOCK LOCATIONS

Depending on the size and configuration of each DLO, the glass setting

blocks must be placed to give the best support of the glass without adding

dead load weight to deflect the horizontal. Figure 56 below shows typical

1/4 point and 1/8 point setting block locations. Contact EFCO Structural

Engineering for blocking requirements other than 1/4 and 1/8 points.

DLO

8

[FIG. 56]

DLO

8

DLO

4

DLO

4

DLO

4

DLO

4

Setting block locations should be determined by following the Dead Load

Charts shown in figures 57 and 58 below. These charts are for general

reference only and refer to laminated glass constructed from (2) 1/4" glass

panes and laminate material. If the glass size you require falls outside the

parameters of these charts or if your glass is not constructed from (2) 1/4"

panes of glass and laminate material, please contact EFCO Structural

Engineering.

[FIG. 57]

525 IMPACT

4491 HORIZ. DEAD LOAD

120

110

100

90

80

70

60

50

40

30

Glass Height (in inches)

20

10

60 70 90 80

.125 Deflection

Glass Width (in inches)

[FIG. 58]

1/8 Point

1/4 Point

120

110 100

4483/4484 DOOR HEADER DEAD LOAD

.0625 Deflection

120

110

100

90

80

70

60

50

40

30

Glass Height (in inches)

20

10

90 7055 60 80 110 100

Glass Width (in inches)

120

1/8 Point

1/4 Point

DPS 1/2004

Page 39

PAGE 37

SECTION IX - GLAZING

(CONT.)

STEP 3) GLAZING POCKET IDENTIFICATION IN

VERTICALS

As instructed in figures 10 and 11 on pages 13 and 14, ensure that each

vertical DLO has at least one DEEP glass pocket on either side. It is

necessary for the glazing installation that a deep pocket be used to load

the glazing units. One exception is the applied transom glazing stops.

The applied stops do not require the glass to be loaded into a deep

pocket. These details are shown with the deep glazing pockets shown

right justified for viewing clarity.

4476

DEEP

SHALLOW

4481

4480

4477

DEEP

SHALLOW

[FIG. 59] [FIG. 60] [FIG. 61]

TRANSOM

GLAZING

STOPS

4478

DEEP

DEEP

525 IMPACT

[FIG. 62]

DPS 1/2004

Page 40

SECTION IX - GLAZING

(CONT.)

STEP 4) GLASS SIZE FORMULAS AND GLASS BITE

Glass size formulas are DLO + 1 1/8" for both horizontal and vertical

DLO's. Glass bite for all glazing is 9/16". See figures 63-65 below for

PAGE 38

glass size and bite.

JAMB

4476

4481

9/16"

BITE

9/16"

BITE

DLO

DLO + 1 1/8

SS VERT. SB VERT.

4480

9/16"

BITE

9/16"

BITE

DLO

DLO + 1 1/8

4477

JAMB

9/16"

BITE

9/16"

BITE

DLO

DLO + 1 1/8

4476

[FIG. 63]

4478

9/16"

BITE

DOOR

JAMB

TRANSOM

STOP

4487

4488

DLO

DLO + 1 1/8

DOOR OPENING

WIDTH

4478

4487

9/16"

BITE

DLO + 1 1/8

DLO + 1 1/8

[FIG. 64] [FIG. 65]

525 IMPACT

9/16"

BITE

9/16"

BITE

9/16"

BITE

DLO

DLO

9/16"

BITE

4485

4485

4479

4491

4475

DLO + 1 1/8

9/16"

BITE

9/16"

BITE

9/16"

BITE

DLO

4486

4486

4479

4484

4483

DPS 1/2004

Page 41

SECTION IX - GLAZING

(CONT.)

STEP 5) INSTALLING THE HWD1 WATER DEFLECTOR

PAGE 39

The HWD1 water deflector is

designed to be used with several

EFCO storefront systems. For

this reason, the deflector needs to

be modified to fit the 525 system

glazing pockets. See figure 66 to

the right for HWD1 modification.

THE MODIFIED END OF THE HWD1

FITS INTO THE VERTICAL GLASS

POCKET OF THE 525 FRAMING.

HWD1

USE CUTTERS

TO REMOVE @

"V" GROOVES

ONE SIDE ONLY

[FIG. 66]

Install the HWD1 at the ends of the intermediate horizontals only. It is

not required at heads or sills. Use 795 or equivalent silicone type

sealant to adhere the HWD1 onto the intermediate horizontal. Ensure

that the HWD1 fits flush with the top of the intermediate horizontal

glazing pocket, and smooth any excess 795 sealant so water will flow

easily over the water deflector. See typical installation of the HWD1 in

figures 67 and 68 below.

THIS END EXTENDS INTO THE

VERTICAL GLAZING POCKET

AND OVER THE LOWER

GLASS UNIT'S CORNER

525 IMPACT

HWD1

TYP. VERTICAL

[FIG. 67]

MODIFIED

NOTCH

HWD1

GLASS

BELOW

UNIT

TYP. VERTICAL

HWD1

TYP. HORIZ.

GLASS

UNIT

BELOW

[FIG. 68]

DPS 1/2004

Page 42

PAGE 40

SECTION IX - GLAZING

(CONT.)

STEP 6) GLASS INSTALLATION

A) Make sure that the HWD1 is installed per the instructions in figures

66-68 on page 39.

B) Position the glass on the exterior of the frame without the

removable glass stop installed. Shift the glass into the deep pocket to

begin the installation.

C) Swing the opposite edge of the glass around to align the glass with

the glazing pocket.

D) Slide the glass into the shallow glazing pocket so that an equal

amount of glass bite is on each side of the DLO.

E) Lift the glass straight up into the head or horizontal, and insert the

setting blocks at the predetermined 1/4 or 1/8 point locations. Lower

the glass back down onto the setting blocks and ensure that the glass

is still centered in the DLO. Ensure that the interior glazing gasket is

not rolled out of the gasket track.

F) Snap on the removable glass stop and install the exterior glazing

gasket. See figure 71 on page 41 for exterior gasket installation.

See figures 69 and 70 below for glass installation.

[FIG. 69]

D

B

C

C

B

525 IMPACT

E

E

[FIG. 70]

DPS 1/2004

Page 43

PAGE 41

SECTION IX - GLAZING

(CONT.)

STEP 7) EXTERIOR GLAZING GASKET INSTALLATION

Ensure that the glass, setting blocks, and snap in glazing bead have

been installed according to the instructions in figures 69 and 70 on

page 40. Begin by measuring the DLO width and height. Cut the

exterior glazing gasket to length by using the following formula.

EXTERIOR GASKET LENGTH = DLO DIM. X 1.02 or (DLO DIM. + 2%)

To install the exterior gasket, start by pushing the precut gasket in

place at the ends. Move to the middle, then to 1/4 points and work the

"waves" toward the ends. Try to maintain 8" to 12" placement of the

gasket to ease the installation.

[FIG. 71]

VERT. GASKET

RUNS THRU,

INSTALL FIRST

8" - 12"

VARIES

SEAL 1" VERTICALLY AND HORIZONTALLY IN THE GASKET RACE WITH

BUTYL TYPE SEALANT AT ALL CORNERS. SEAL THE ENDS OF THE

HORIZONTAL GASKETS TO THE VERTICAL GASKETS. CLEAN OFF ANY

EXCESS SEALANT.

525 IMPACT

SEALANT

EXTERIOR

GASKET

DPS 1/2004

Page 44

PAGE 42

SECTION IX - GLAZING

(CONT.)

STEP 8) INTERIOR GLASS SEALANT APPLICATION

Begin the interior glass sealant application by ensuring that the glass and

metal are cleaned and dry per the sealant manufacturer's instructions.

Apply sufficient Dow Corning 995 or equivalent structural silicone sealant

to the gap between the glass and metal to fill the void back to the interior

gasket on all sides of each DLO. Ensure that air pockets in the sealant

are not present as this would create a weak area in the glass and metal

adhesion. Tool the sealant flat against the metal for a clean cosmetic

appearance. It may be beneficial to use a form of masking tape on the

metal and/or glass to aid in the clean appearance of the seal and to

lessen the clean-up effort. See figures 72 and 73 below for 995 sealant

application.

INTERIOR

[FIG. 72]

GASKET

INTERIOR

SEALANT

EXTERIOR

GASKET

INTERIOR

SEALANT

INTERIOR

GASKET

525 IMPACT

[FIG. 73]

DPS 1/2004

Page 45

PAGE 41

SECTION IX - GLAZING

(CONT.)

STEP 7) EXTERIOR GLAZING GASKET INSTALLATION

Ensure that the glass, setting blocks, and snap in glazing bead have

been installed according to the instructions in figures 69 and 70 on

page 40. Begin by measuring the DLO width and height. Cut the

exterior glazing gasket to length by using the following formula.

EXTERIOR GASKET LENGTH = DLO DIM. X 1.02 or (DLO DIM. + 2%)

To install the exterior gasket, start by pushing the precut gasket in

place at the ends. Move to the middle, then to 1/4 points and work the

"waves" toward the ends. Try to maintain 8" to 12" placement of the

gasket to ease the installation.

[FIG. 71]

VERT. GASKET

RUNS THRU,

INSTALL FIRST

8" - 12"

VARIES

SEAL 1" VERTICALLY AND HORIZONTALLY IN THE GASKET RACE WITH

BUTYL TYPE SEALANT AT ALL CORNERS. SEAL THE ENDS OF THE

HORIZONTAL GASKETS TO THE VERTICAL GASKETS. CLEAN OFF ANY

EXCESS SEALANT.

525 IMPACT

SEALANT

EXTERIOR

GASKET

DPS 1/2004

Loading...

Loading...