Page 1

SERIES 433 Triple Set ®

Installation Instructions

Part NO. Y017

January 2013

Page 2

Series 433 Triple Set Installation Instructions

TABLE OF CONTENTS

SECTION PAGE

I. General Notes……………………………………..…………………………………………………………………..…...3

II. Parts Identification Charts………………………………………………………………………………………..……..4

III. Fabrication

A. Drilling Template (Offset Screw Spline Verticals)………………………………………..………..….…12

B. Drilling Template (Offset Shear Block Verticals)….………………………………………….……..……15

C. Drilling Template (Center-Set Screw Spline Verticals)………………………………………………....18

D. Drilling Template (Center-Set Shear Block Verticals)….…………………………………………….….20

E. Drilling Template (Offset @ 90 Corner Horiz/Head /Sill)………………………………………….….23

F. Drilling Template (Offset & Center-Set Shear Blocks @ Sills)……………………………………….….25

G. Drilling Template (Offset & Center-Set Shear Blocks @ Horiz)………………………………………27

H. Drilling Template (Offset Glazed Head & Sill Through)……………………………………………..….29

IV. Unit Assembly

A. Screw Spline (Offset and Center-Set)…………………………………………………………..………......32

B. Shear Block (Offset and Center-Set)…..…………………………………………………….…...…..…….40

C. Head and Sill Through (Offset)……………………..…………..……………………………….....…..……43

D. Screw Spline 90 Corner (Offset)…………………..…………..…………………………………..…..……44

E. Rolled Arch Top & Sloped Top (Center-Set)………………………………………………………..……..45

F. Adjustable Height Side Lite (Offset)…………………………………………………………………..……..46

V. Door Frame Installation…………………..………………..…………..…...…………………………………..…..49

VI. Subsill Fabrication and Installation…………………..…………..…...…..……………………………………..51

VII. Corners……………………………………………………………..…………..…...………………………………....….59

VIII. Installation………………………………………………………..…………..…………………………………...…..….62

IX. Glazing………………………………………………….…………..…………..…………………………………..…..….73

X. Door Stop Installation…

……………………………………..…………..……………………………….....…..…..90

Note: Please reference EFCO's "Understanding Condensation" brochure which can be obtained thro ugh your EFCO

representative.

Condensation will form on any surface when unfavorable conditions (interior temperature and relative humidity and

exterior temperature) are present. When the formation of excessive condensation is a concern, it is highly recommend ed that a

design professional is utilized to perform an analysis of the shop drawings to recommend the best possible installation methods.

Please contact your EFCO representative for information on EFCO's Thermal Analysis Services.

Many current installation practices lead to an increase in the possibility of the formation of condensation. Though not all

inclusive, the list of examples below illustrates conditions under which condensation is lik ely to occur:

1. Bridging system thermal break with non-thermally broken metal flashin g or lintels that are exposed to the

exterior

2. System exposure to cold air cavities

3. Interior relative humidity levels not maintained at recommended levels, see EFCO’s “Understanding

Condensation” brochure

4. Inadequate separation between system and surrounding condition at perimeter

5. Product combinations during the shop drawing stage that result in bridging thermal

breaks of one or all products involved

June 2012 PART NO. Y017 Page 2 of 90

Page 3

Series 433 Triple Set Installation Instructions

SECTION I: General Notes

The “433 TRIPLE SET” is a framing system that has many advantages over other framing

systems. It can be used as a single-span storefront window wall, a punched opening

system, or as a ribbon window system. The main advantage is the ability to set the glass

plane in three different positions within the same elevation.

The 433 Triple Set system contains primarily stock length systems with in-the-field

fabrication. Entrance doors are also a designed part of these systems, utilizing frames

that can accommodate many types of doors and hardware combinations.

1. Check the shop drawings, installation instructions, and glazing instructions to become

thoroughly familiar with the project. The shop drawings take precedence and include

specific details for the project. The installation instructions are of a general nature and

cover the most comm on conditions enco untered.

2. Check all materials on arrival and be sure you have everything required to begin

installation. See Section II “PARTS IDENTIFICATION” for parts cross-reference.

3. All work should start from benchmarks and/or column centerlines as established by the

architectural drawings and the general contractor. Installers should check building

construction for compliance with architectural documents to ensure the proper window

system foundation is available before installation.

4. Throughout these instructions the term “SEALANT” will appear. For the purposes of these

instructions, sealant is to be defined as the following:

SEALANT – A weather resistant, gunnable liquid filler which when cured provides a

resilient, flexible (+ 50% movement capability) air and water seal between similar and

dissimilar materials.

All sealants must meet ASTM C 920, CLASS 50.

When required Butyl sealant – A non-skinning, non-hardening material (NAAMM

Reference Standard 5C-1)

NOTE: All sealant must by compatible with all surfaces where adhesion is required,

including other sealant surfaces. All frame surfaces should be clean and dry. All perimeter

substrate shall be cleaned and properly treated to receive sealant.

5. All materials are to be installed plumb, level, and true.

6. Protect materials after erection. Cement, plaster, alkaline solutions, and acid based

materials can be harmful to the finish. Clean exposed finished surfaces with a mild

detergent and water. No abrasive cleaning agent should be used.

June 2012 PART NO. Y017 Page 3 of 90

Page 4

Series 433 Triple Set Installation Instructions

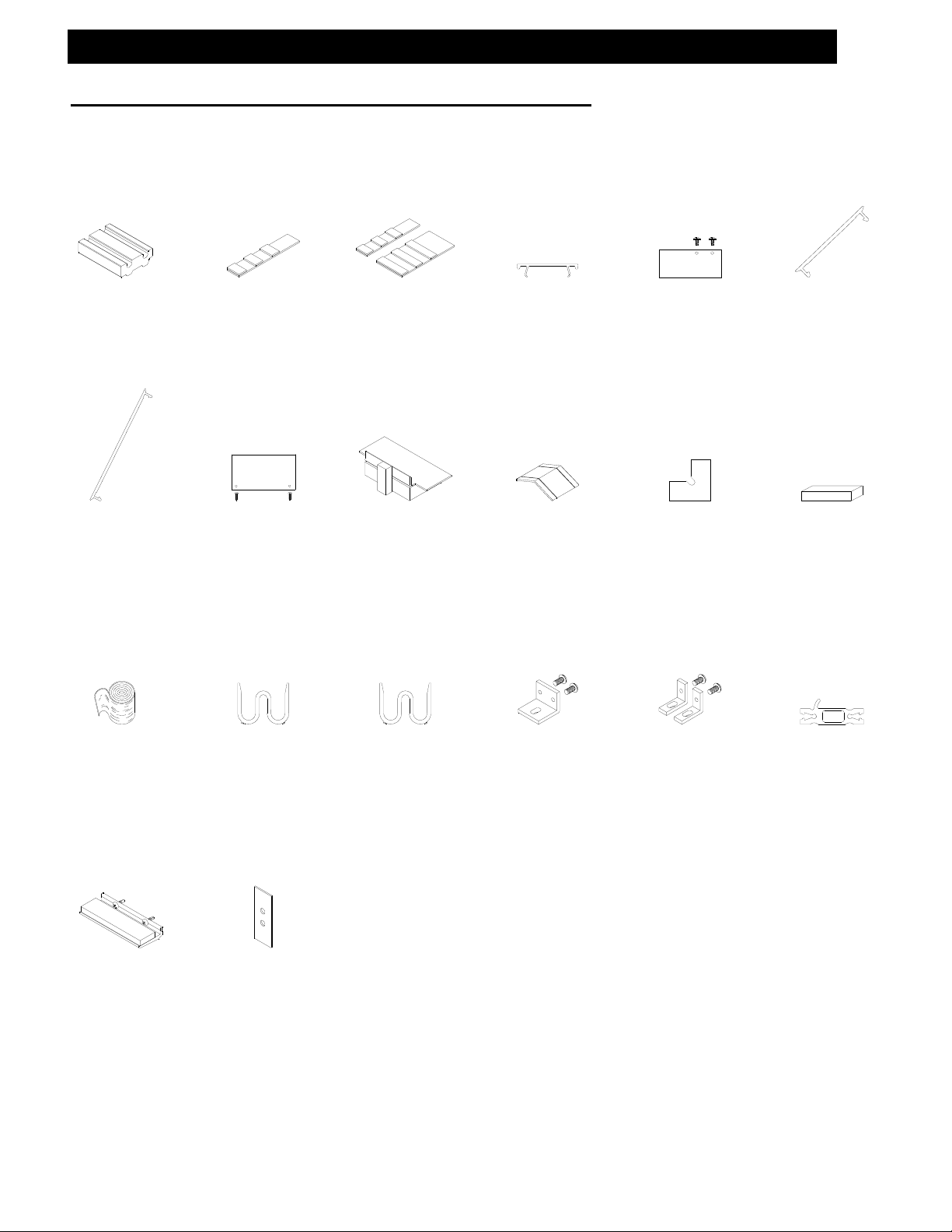

SECTION II: Parts Identification Chart

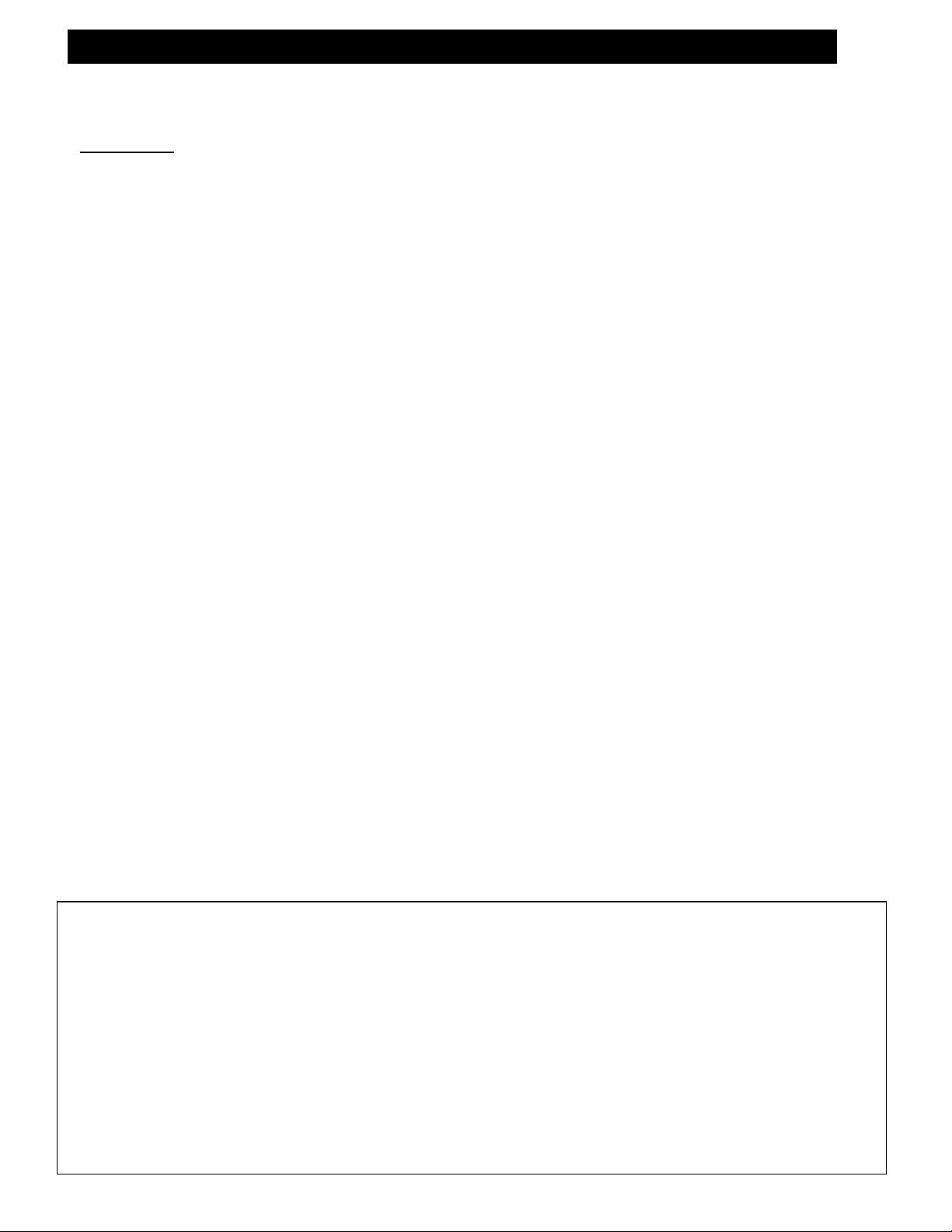

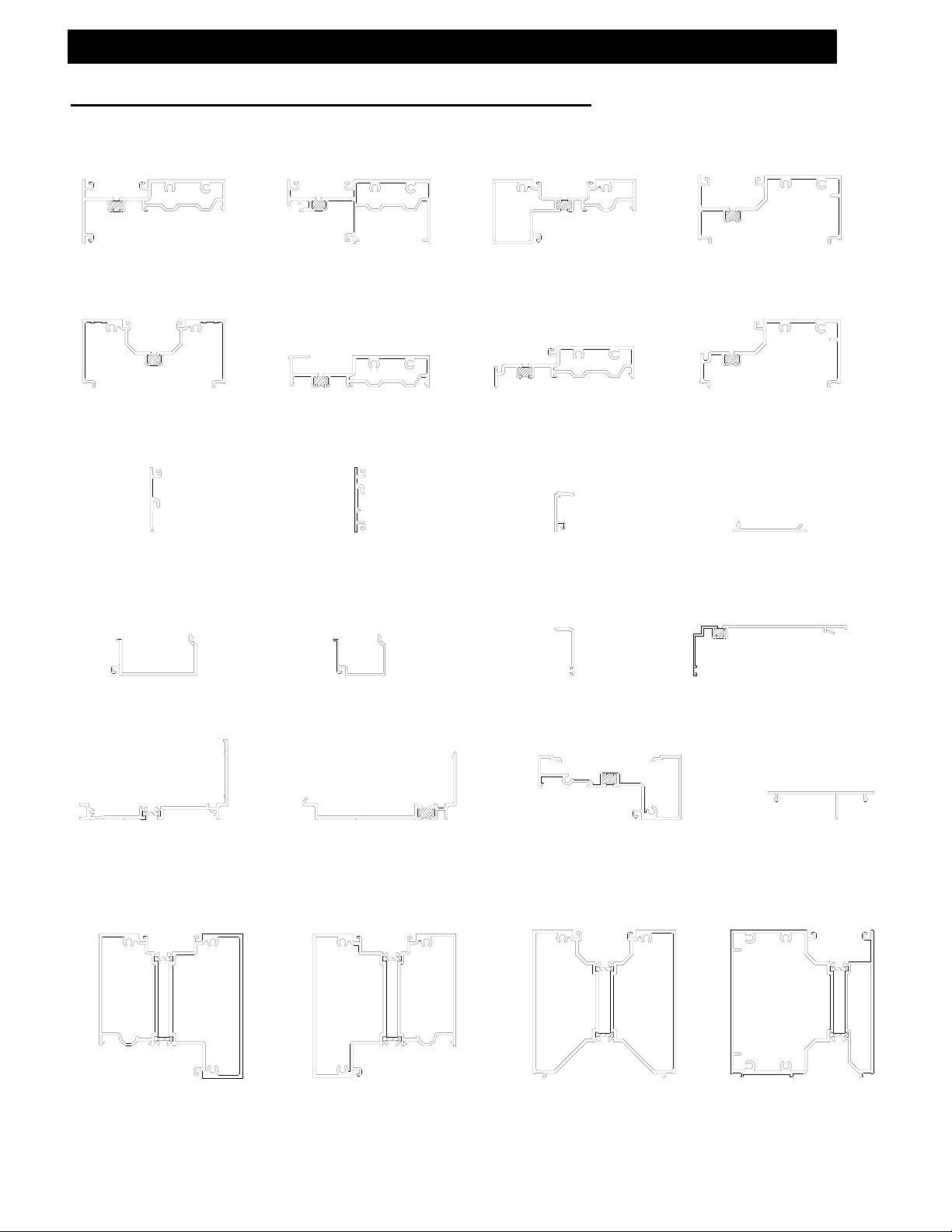

Vertical Parts:

8349

Offset Glazed Vertical

-Shear Block Only-

8353

Offset Glazed Vertical

Use w/8352

8352

Offset Glazed Vertical

Filler

Use w/8353

8354

Inside/Outside Offset

Vertical Half

Mates w/Itself

8356

Offset to Center-Set

Shallow Vertical Half

Use w/8359

8359

Center-Set to Offset

Deep Vertical Half

Use w/8356

8357

Center-Set Glazed

Vertical

-Shear Block Only-

8360

Center-Set to Center-Set

Shallow Vertical Half

Use w/8361

8396

Center Glaze Female

Expansion Mullion Half

Use w/8397

8394

Offset Glaze Female

Expansion Mullion Half

Use w/8395

8395

Offset Glaze Male

Expansion Mullion Half

Use w/8394

4470

Center Glaze Open Back

Sill/Vertical

4356

4 ½” Vertical

Mullion Half

4357

4 ½” Vertical Corner

4 ½” Single Pocket

Vertical Corner

June 2012 PART NO. Y017 Page 4 of 90

Drawings on this page are not to scale.

8355

Offset to Center-Set

Deep Vertical Half

Use w/8358

Center-Set to Offset

Shallow Vertical Half

Use w/8355

8361

Center-Set to Center-Set

Deep Vertical Half

Use w/8360

Offset Glaze Male

Expansion Mullion Half

4383

Screw Spline Sidelite

Door Jamb Deep Pocket

Filler Use w/4371 & 4372

Vertical Mullion Half

Shallow Pocket Non-

4358

8358

8397

Use w/8396

4393

Thermal

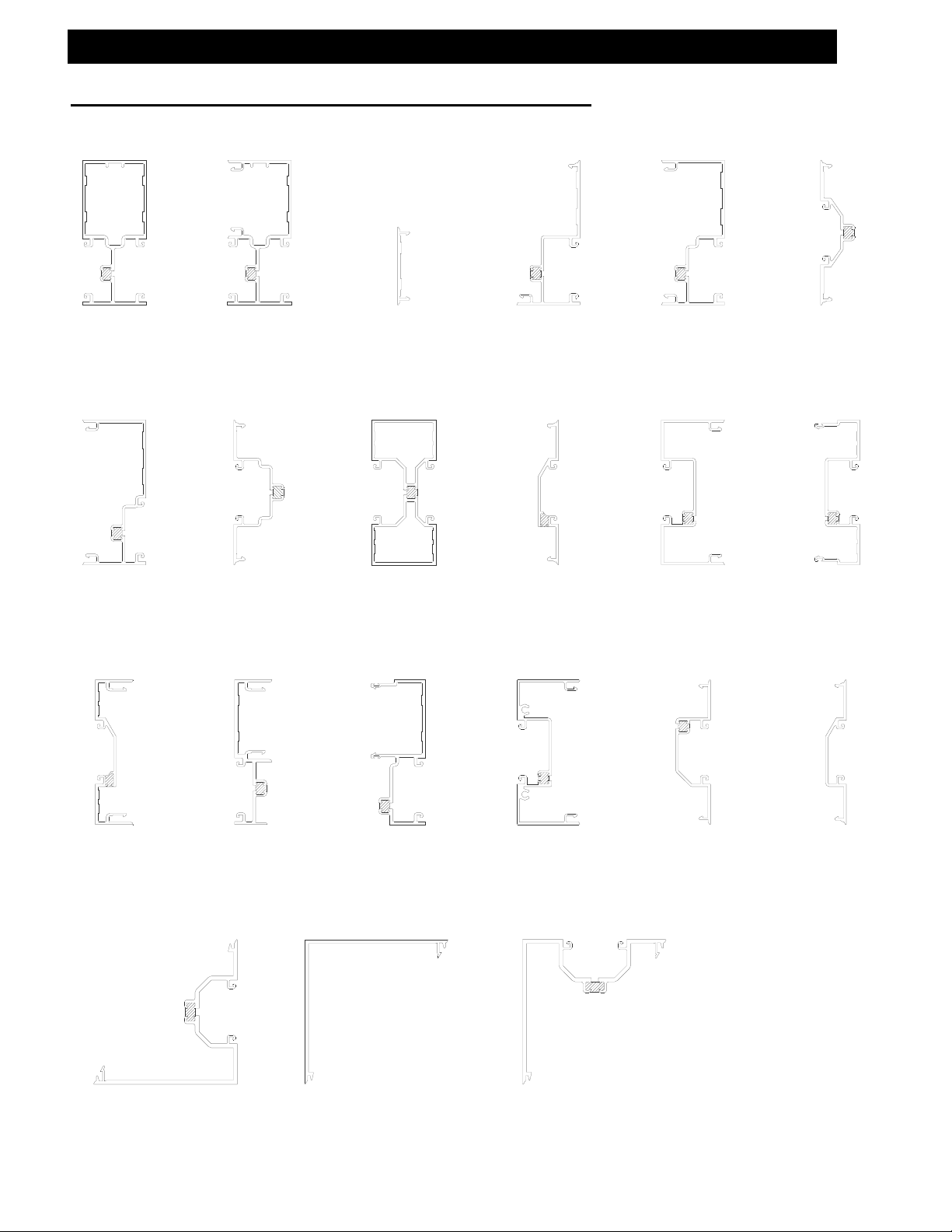

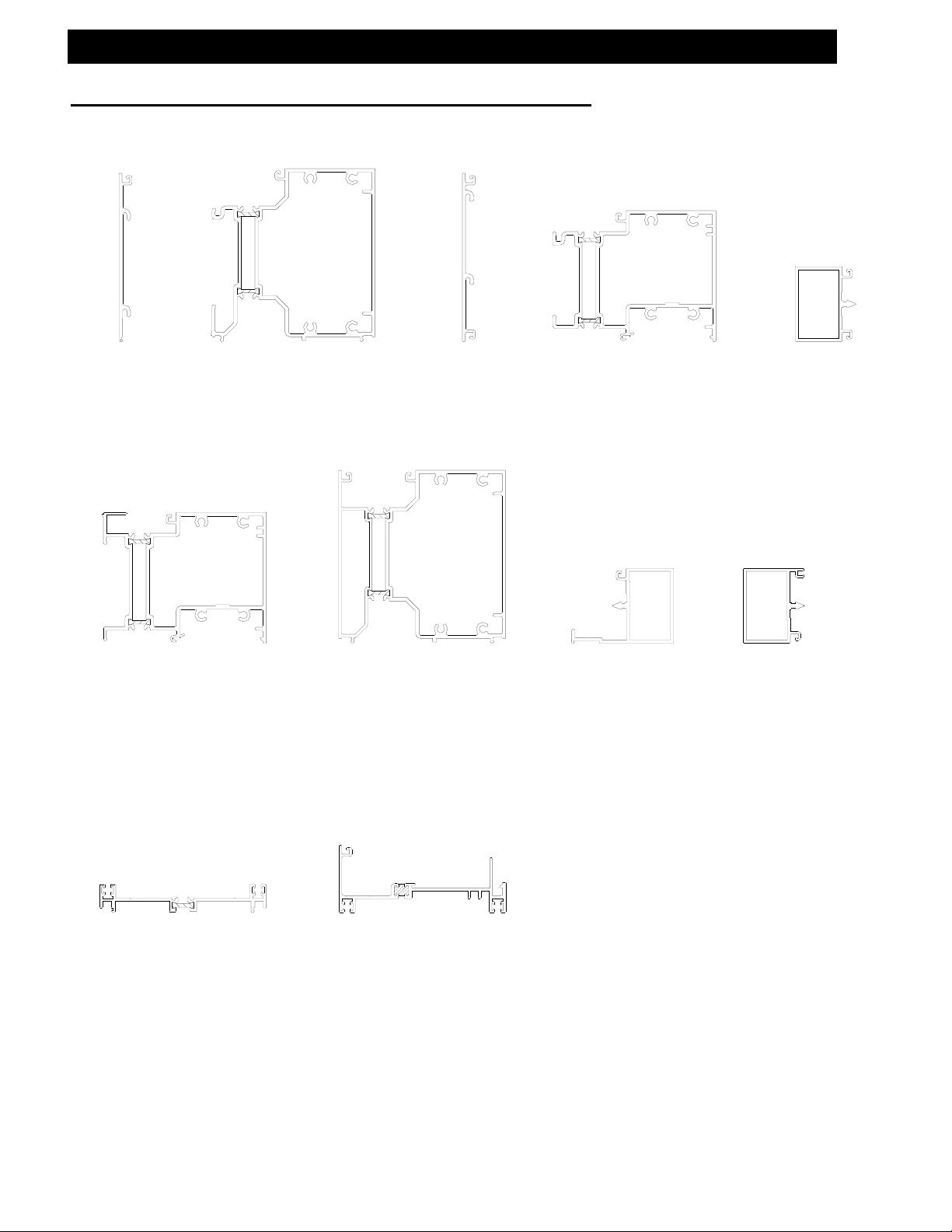

Page 5

Series 433 Triple Set Installation Instructions

SECTION II: Parts Identification Chart

Vertical Parts cont.:

Use w/8355, 8356 & 8361

8380

135 Corner Mullion

8439

Structural Glaze

Jamb w/Head & Sill

through

Structural Glaze

9838

Adjustable Sidelite

Dead Load Support Tube

8475

90 Structural Glaze Corner

Mullion

8389

Mullion

Structural Glaze Mullion

90 Corner Mullion

Use with

8355, 8356 & 8361

8387

Screw Spline

Use w/8388

Drawings on this page are not to scale.

8381

Out side to Inside Set

Expansion Mullion

Mates with Itself

8388

Screw Spline Structural

Glaze Mullion Filler

Use w/8387

Adjustable Sidelite

4380

16E1

Vertical

June 2012 PART NO. Y017 Page 5 of 90

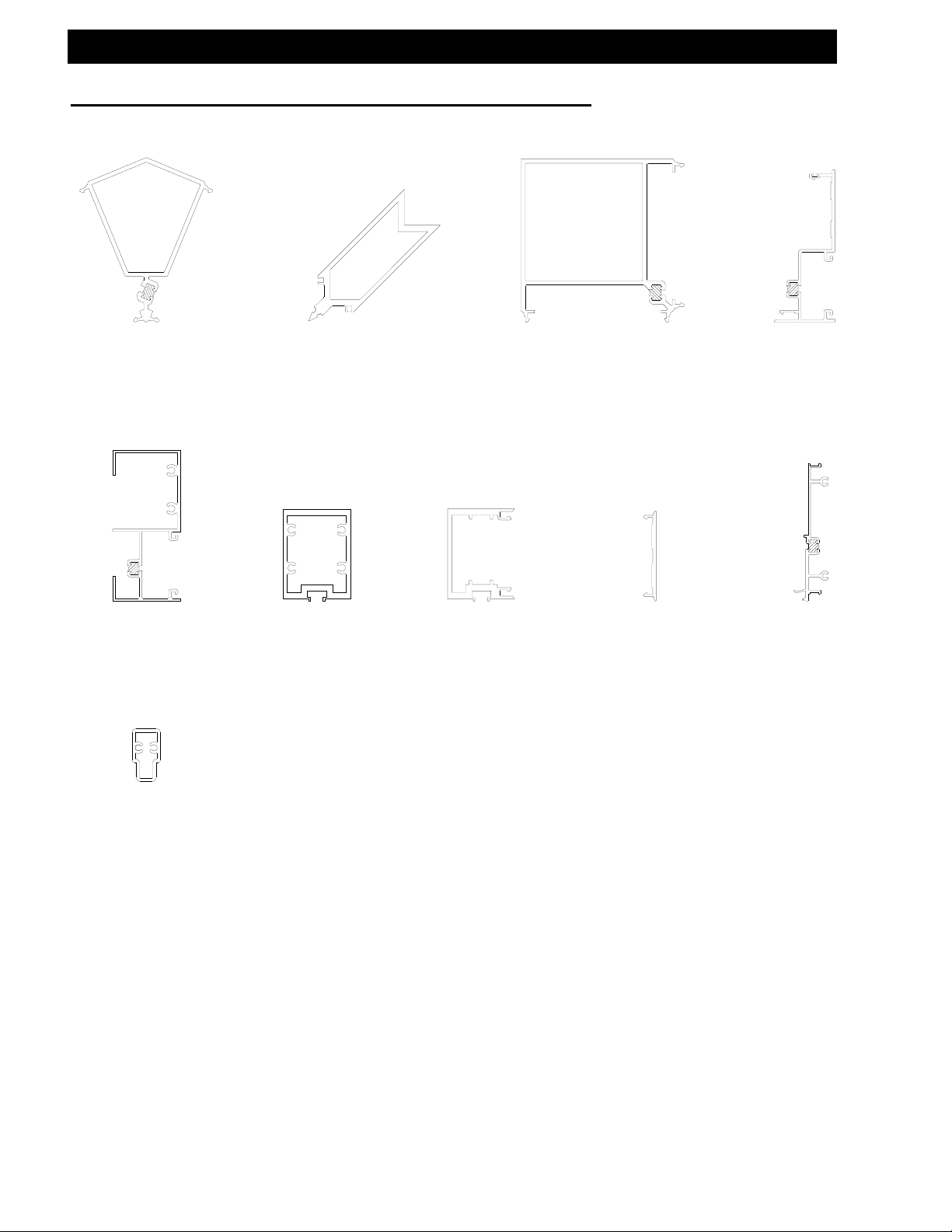

Page 6

Series 433 Triple Set Installation Instructions

SECTION II: Parts Identification Chart

Horizontal Parts:

8363

Offset Intermediate

Horizoantal/Head

Use w/8365

8375

Center-Set Sill

Used @ 2S44 Subsill

8382

Head & Sill Face Cover

Use w/8384 & 8393

8365

Offset Glazing Bead

Use w/8363, 8385 & 8393

2S44

High Performance Subsill

Use w/8362 & 8375 Sills

4 ½” Horizontal for Center-

3G45

Set Outside Glazed

Offset Outside Set/ Outside

8366

Glazed, Inside Set/Inside Glazed

Horizontal/Head

Use w/8364 & 8367

8393

Structural Glaze Head

Use w/8365 & 8382

8386

Horizontal Face Cover

Use w/8385

8368

Center-Set Glazing Bead

Use w/8372

4471

Fill & Debridged Subsill

3G46

4 ½” Horizontal for Center-

Set Inside Glazed

8372

Center-Set Horizontal

Use w/8368

8385

Structural Glaze Horizontal

Use w/8365 & 8386

8367

Horizontal Face Snap

Use w/8366

E178

Frame Receptor Closer

Use w/1510

Center-Set Open Back Head

4 ½” Sill for Center-Set

Drawings on this page are not to scale.

8362

Offset Sill

Used @ 2S44 Subsill

8384

Structural Glaze Sill

Use w/8382

8364

Offset Horizontal Filler

Use w/8366

1510

Frame Receptor

Use w/E178

4369

3G48

Glazing

8746

Perimeter Adaptor

4G33

4 ½” Inside Set

Fixed Stop

June 2012 PART NO. Y017 Page 6 of 90

Page 7

Series 433 Triple Set Installation Instructions

SECTION II: Parts Identification Chart

Horizontal Parts:

16B9

4 ½” Offset Head & Sill

Face Cover

Use w/4G31

4G29

4 ½” Offset

Glazed Head

3S67

Adjustable Sidelite Sill

4G31

4 ½” Outside Set Sill

Use w/16B9

16B3

4 ½” Offset Intermediate

Horizontal Face Cover

Use w/4G30

4G32

4 ½” Outside Set Sill

Fixed Stop

16D9

Adjustable Sidelite

Horizontal

Drawings on this page are not to scale.

4G30

4 ½” Outside Set

Intermediate Horizontal

Use w/16B3

16C8

2-Part Perimeter

Interior Half

2-Part Perimeter

2-Part Mullion Half

16C9

Exterior Half

16C7

June 2012 PART NO. Y017 Page 7 of 90

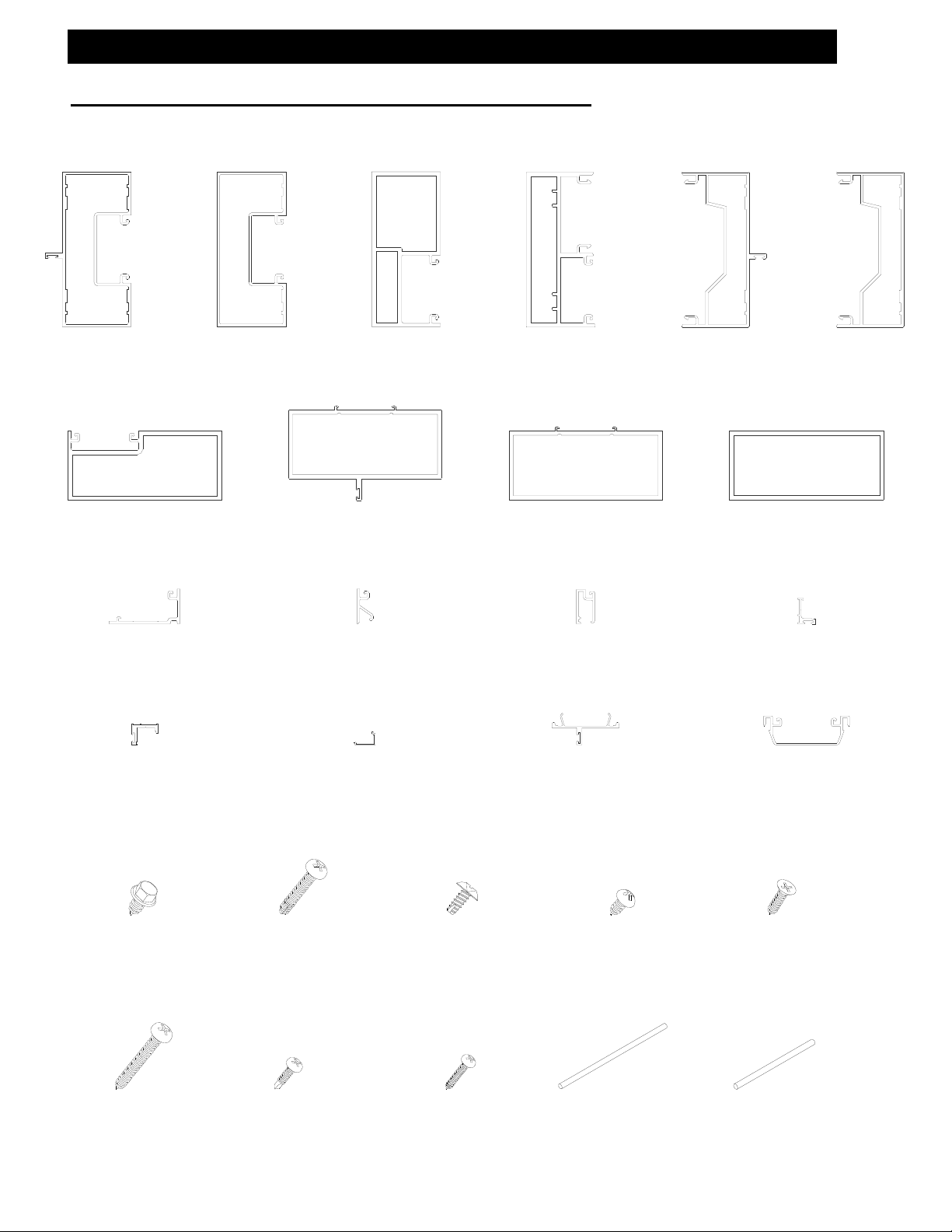

Page 8

Series 433 Triple Set Installation Instructions

SECTION II: Parts Identification Chart

Door Frame Parts:

Drawings on this page are not to scale.

9209

Single Acting Door

Jamb

9208

Double Acting Door

Jamb

Door Jamb for Offset Glazing

Use 9154/9155 Door Stops

Use 8377/8378 Transom Stops

8374

4374

Offset Glazed Door Jamb

for Screw Spline Sidelites

4371

Standard Door Jamb for

Screw Spline Sidelites

Center Pivot Door Jamb

for Screw Spline Sidelites

Door Header @ Surface Closure

Use 4437/9155 Door Stop

8373

9234

Single Acting Door Header

Use 9123 for 1” Glass

9227

Dual Acting Door Header

Use 4437/9155 Door Stop

2556

2 X 4 ½ X 1/8” Wall Tube

Use 8377 & 8378 for Offset Glazing

@ C.O.C.

Use 4437/9155 Door Stop

8377

Applied Transom Glazing Stop

Use w/8378

8378

Transom Glass Stop

Use w/8377

9123

Transom Glazing Bead

Use w/9227 & 9234

9154

Applied Jamb Door Stop

Use w/9155 Cover

4437

Applied Head Door Stop

Use w/9155 Cover

Use w/9154 & 4437 Stops

9155

Door Stop Cover

9257

Snap-In Door Stop

Use w/ 8357

Snap-In Transom Glass Adapter

4376

Use w/9208 & 9209

Fasteners:

STV2

#14-10 X 1/2

HW-SMS 18-8 AB

STC8

#12-140 X 1 1/4

PH-SMS 18-8 TYPE 25

Assembly Screw

STD1

#12-24 X 1/2

TH-SMS 18-8

TYPE 23

STB9

#12-11 X 1/2

RH-SMS 18-8 A

STD8(Clr)/S117(Brz)

#10-12 X 3/4

FH-SMS 18-8 AB

STB5

#12-11 X 1 5/8

PH-SMS 18-8 A

June 2012 PART NO. Y017 Page 8 of 90

STT6

#8-18 X 9/16

PH-SMS 18-8 TEK

Door Stop/Transom Stop

Fastener

SPZ1

#8-18 X 3/4

PH-SMS 18-8 AB

Adjustable Sidelite

Assembly Fastener

FW95

3" Rod for Horizontal

Dead Load Support

at Intermediate Vert.

FW96

2" Rod for Horizontal

Dead Load Support

at Perimeter Vert.

4372

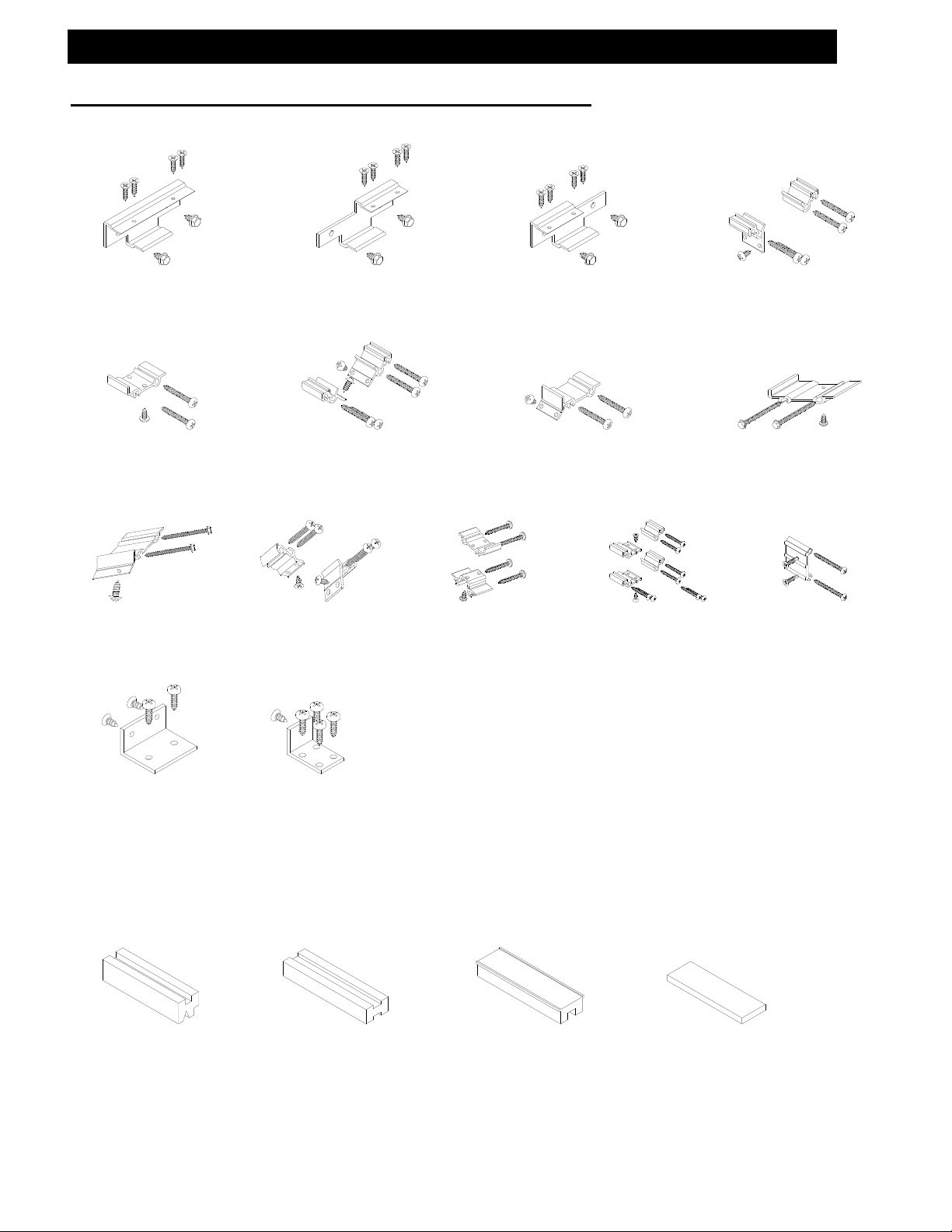

Page 9

,

,

Series 433 Triple Set Installation Instructions

SECTION II: Parts Identification Chart

Shear Blocks:

LH or RH C.O.C. Header Shear Block

Pkg. for Pivots, Butts or Cont. Hinge

Use w/ 9227

K918

9234 or 2556

Shear Block Pkg. for Offset

Use w/8363,8366

K925

Horizontal/Head

8385 or 8393

RH STD Door Header Shear Block Pkg.

K919

for Pivots, Butts or Cont. Hinge

Use w/8373

K926

Shear Block Pkg. for

Center-Set Sill

Use w/8375

Drawings on this page are not to scale.

K923

LH STD Door Header Shear Block Pkg.

for Pivots, Butts or Cont. Hinge

Use w/8373

K927

Shear Block Pkg. For

Offset Sill

Use w/8362 & 8384

Use (2) w/4G31, 4G32 & 4G33

Shear Block Pkg. for Center-

K924

Set Horizontal/Head

Use w/8372

KN52

Shear Block Pkg. for 90 Structural

Glaze Corner @ Head/ Horizontal

Use w/8475

KN53

Shear Block Pkg. for 90

Structural Glaze Corner @ Sill

Use w/8475

Shear Block Pkg. for Offset

KN73

Vertical to Horizontal thru

Attachment

Setting Blocks:

HN64

Setting Block @ Adjustable

Sidelite Horizontal (16D9)

KN67

Shear Block Pkg. for

Center Set Head

Use w/4369

KN74

Shear Block Pkg. for Center Set

Vertical to Horizontal thru

Attachment

HN38

Setting Block @ Applied

Transom Glass Stops 8377 &

8378

KN91

Shear Block Pkg. for 4 ½”

Horizontal/Head

Use w/4G30 & 4G29

HN32

Setting Block @ Sill

(or Applied Transom Glass

Stops 9123)

KN69

Shear Block Pkg. for 4 ½”

Center-Set Horizontal/Head

Use w/3G45

HN92

Setting Block @ Horizontals

(including 8373 Door Header)

KN92

Shear Block Pkg. for

2-Piece Rolld Horizontal

June 2012 PART NO. Y017 Page 9 of 90

Page 10

(

)

Series 433 Triple Set Installation Instructions

SECTION II: Parts Identification Chart

Glazing Gaskets:

W164

Standard Glazing Gasket

1” Infill @ 1” Pocket

W115

Glazing Gasket for 2Piece Rolled Framing

@ 1” Pocket

Weather Seals:

WA04

Standard Weather Seal

@ Subframes 1510 & E178

W166

Glazing Gasket for

Oversized Glass 1 1/16”

Infill @ 1” Pocket

WM10

Tape for 90・・・・・

SSG Mullion

WQ02

Optional Weather Seal

@ Subframes 1510 & E178

W165

Glazing Gasket for

Undersized Glass 3/4” Infill

@ 1” Pocket

W161

Adjustable Sidelite

Gasket at Sill

Standard Weather Seal

@ Door Stops

W138

Drawings on this page are not to scale.

W166/W164

Glazing Gasket for Undersized

Glass 7/8”-15/16” Infill @ 1”

Pocket-Use W165 Exterior

and W164 Interior

W104

Standard Weather Seal

@ Expansion Mullion and

Adjustable Sidelite

WM80

SSG Mullions

Tape for

Drill Jigs:

DJ12

Offset Glazing Head &

Horizontal Drill Fixture

Shear Block Drill Fixture for

4 ½” Center-Set Horizontals

DJ23

DJ13

Offset & Center-Set

Sill Drill Fixture

DJ24

Screw Spline Drill Fixture for

4 ½” Offset Horizontals

Shear Block Drill Fixture for

DJ14

Vertical Fabrication

DJ25

Shear Block Drill Fixture for

4 ½” Center Set & Offset

Horizontals

Screw Spline Drill Fixture for

DJ15

Vertical Fabrication

Shear Block Drill Fixture for

DJ22

Dead Load Support Pin

Drill Fixture

DJ26

4 ½” Horizontals

Center-Set & Offset

June 2012 PART NO. Y017 Page 10 of 90

Page 11

Series 433 Triple Set Installation Instructions

SECTION II: Parts Identification Chart

Misc. Parts:

HN44

Head & Sill Foam

Splice Joint

LB90

Vinyl Center-Set Pocket

Filler @ Perimeter

Condition

Use W/8355, 8356, 8361

K898

Sill Splice Plates (2)

per Splice Required

K941

Subsill End-Dam

Package

Use w/2S44 Subsill

K898/K897

Head Splice Plates

K895

Horizontal Bridge

Assembly

LB77

Vinyl Pocket Filler

Glass Pockets @

Perimeter Condition

HWD1

Water Deflector @

Intermediate Horizontal

Drawings on this page are not to scale.

KN11

Structural Glaze

Head End-Dam

Package

FW33

90 Structural

Glaze Corner

Water Diverter

LB89

Vinyl Offset Pocket

Filler @ Perimeter

Condition

Use W/8353

HCW6

Weep Baffle used

@ Subsill

WM01

Bond Breaker Tape

4” X .062”

Used @ Subsill Splices

KN93

2-Piece Rolled

Horizontal Setting

Chair

Use w/ 16C9 & 16C7

HN50

1/2” Anti Walk Block

Use w/8349, 8353,

8357 & 8361

FWB6

Adjustable Side Lite

Dead Load Support

Tube Washer

HN52

5/8” Anti Walk Block

Use w/8354, 8355,

& 8359

K473

Vertical Anchor

Package Used with

Offset Glazed

Verticals

K992

Vertical Anchor

Package Used with

Center-Set Glazed

Verticals

H260

2-Piece Rolled/Slope

Frame Clips

June 2012 PART NO. Y017 Page 11 of 90

Page 12

Series 433 Triple Set Installation Instructions

SECTION III: Fabrication

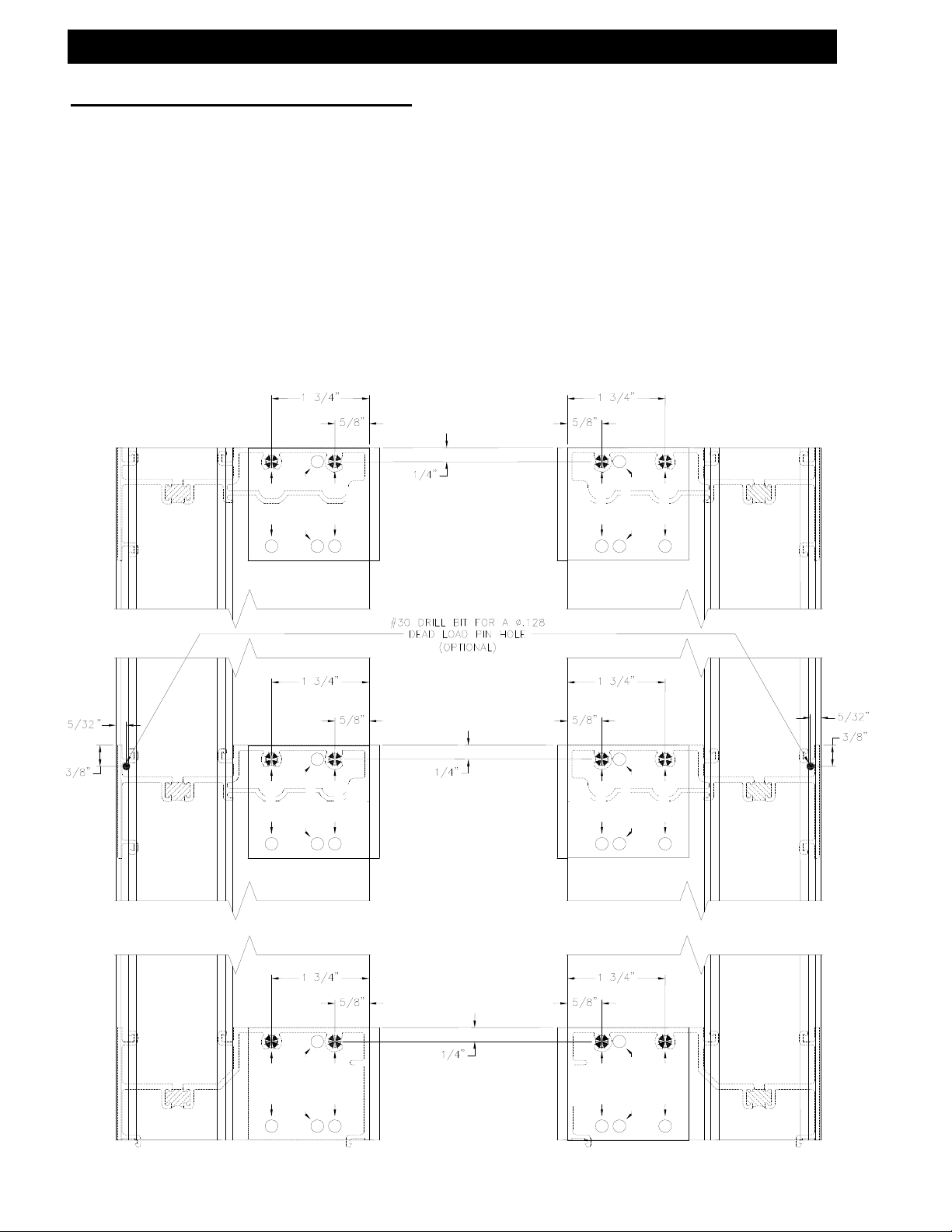

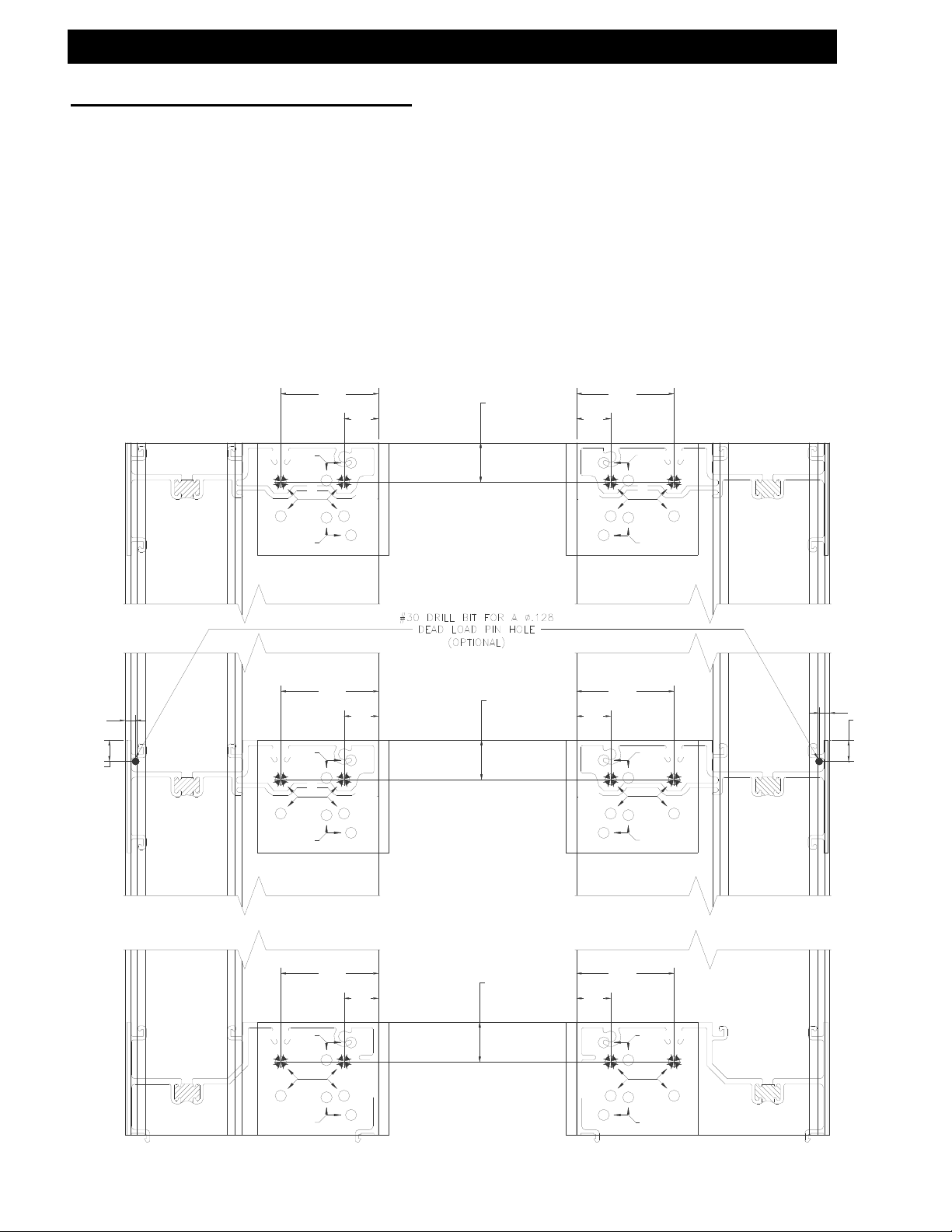

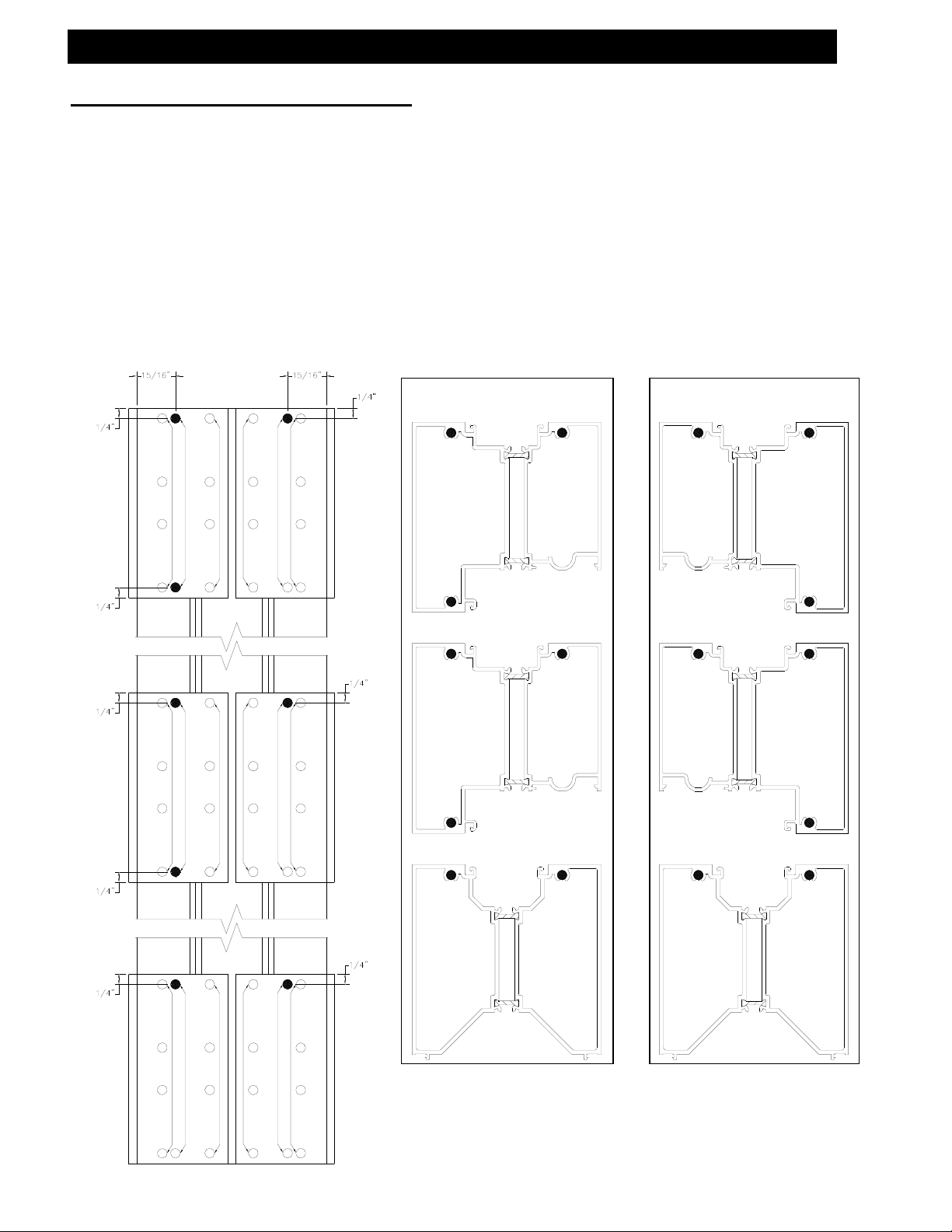

A. Drilling Template Offset Screw Spline Verticals (Offset Mullion)

Left Hand Mullion Shown, Right Hand Opposite

Use the exterior edge of the vertical to align Drill Jig DJ15. Use .221 dia. (#2) drill at

darkened areas only.

These preps work for both inside and outside glazed versions.

Outside Set Mullion Inside Set Mullion

OFF SET

433 S.S.

DJ15

OFF SET

CENTER SET

OFF SET

DJ15

433 S.S.

CENTER SET

OFF SET

OFF SET

433 S.S.

OFF SET

CENTER SET

OFF SET

DJ15

433 S.S.

DJ15

CENTER SET

OFF SET

CENTER SET

OFF SET

OFF SET

CENTER SET

OFF SET

OFF SET

DJ15

433 S.S.

433 S.S.

DJ15

June 2012 PART NO. Y017 Page 12 of 90

Page 13

Series 433 Triple Set Installation Instructions

SECTION III: Fabrication

A. Drilling Template Offset Screw Spline Verticals (Offset Mullion Filler)

Left Hand Mullion Filler Shown, Right Hand Opposite

Use the exterior edge of the vertical to align Drill Jig DJ15. Use .221 dia. (#2) drill at

darkened areas only.

These preps work for both inside and outside glazed versions.

Outside Set Mullion Inside Set Mullion

CENTER SET

OFF SET

433 S.S.

OFF SET

DJ15

DJ15

433 S.S.

OFF SET

OFF SET

CENTER SET

CENTER SET

OFF SET

433 S.S.

OFF SET

DJ15

DJ15

433 S.S.

OFF SET

OFF SET

CENTER SET

OFF SET

CENTER SET

433 S.S.

OFF SET

DJ15

DJ15

433 S.S.

OFF SET

OFF SET

CENTER SET

June 2012 PART NO. Y017 Page 13 of 90

Page 14

Series 433 Triple Set Installation Instructions

SECTION III: Fabrication

A. Drilling Template Offset Screw Spline Verticals (Offset Mullion)

with 4 ½” Horizontals

Left Hand Mullion Shown, Right Hand Opposite

Use the exterior edge of the vertical to align Drill Jig DJ25. Use .221 dia. (#2) drill at

darkened areas only.

These preps work for both inside and outside glazed versions.

CENTER SET

OFF SET

OFF SET

OFF SET

OFF SET

CENTER SET

433 S.S.

OFF SET

DJxx

CENTER SET

OFF SET

433 S.S.

DJxx

OFF SET

OFF SET

CENTER SET

CENTER SET

OFF SET

OFF SET

OFF SET

OFF SET

CENTER SET

June 2012 PART NO. Y017 Page 14 of 90

Page 15

Series 433 Triple Set Installation Instructions

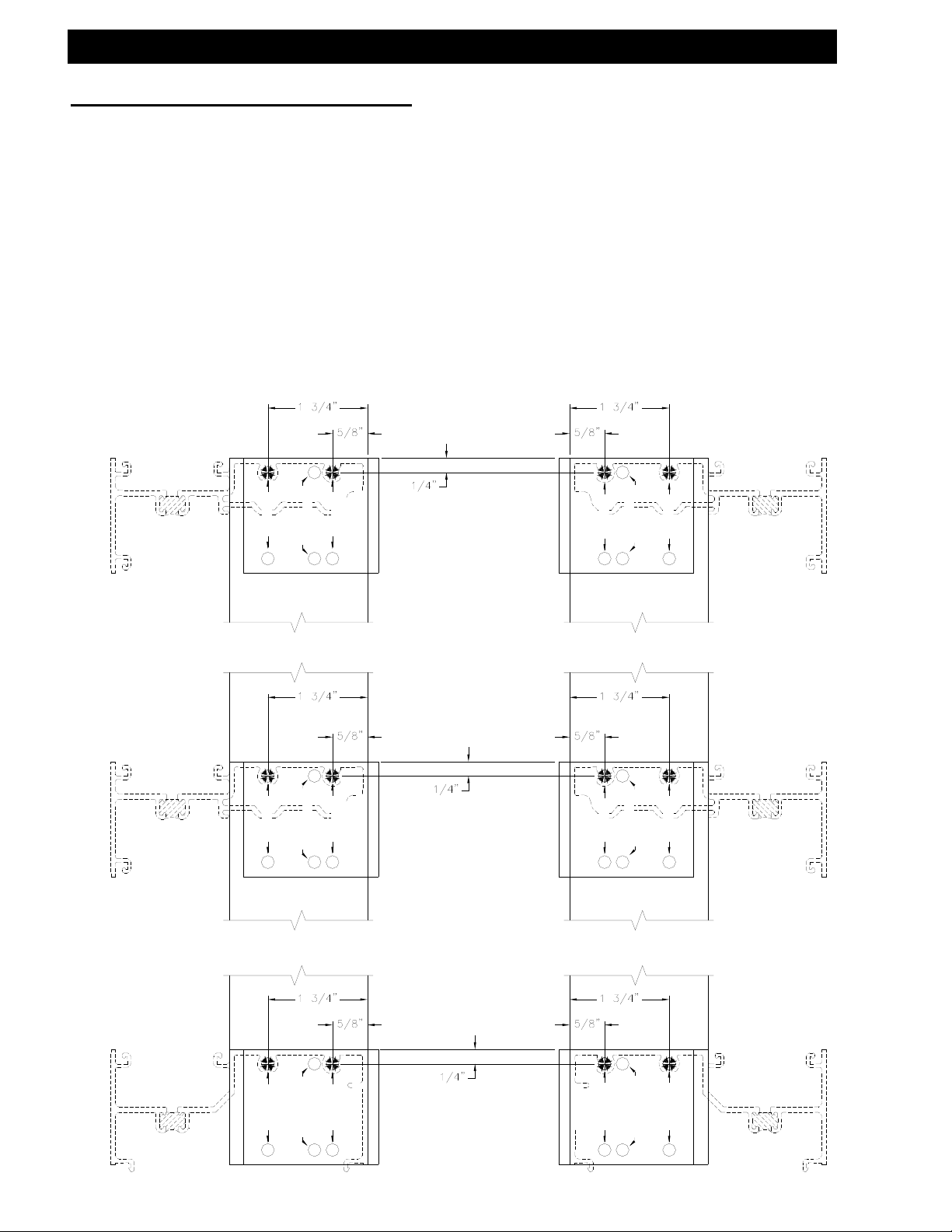

SECTION III: Fabrication

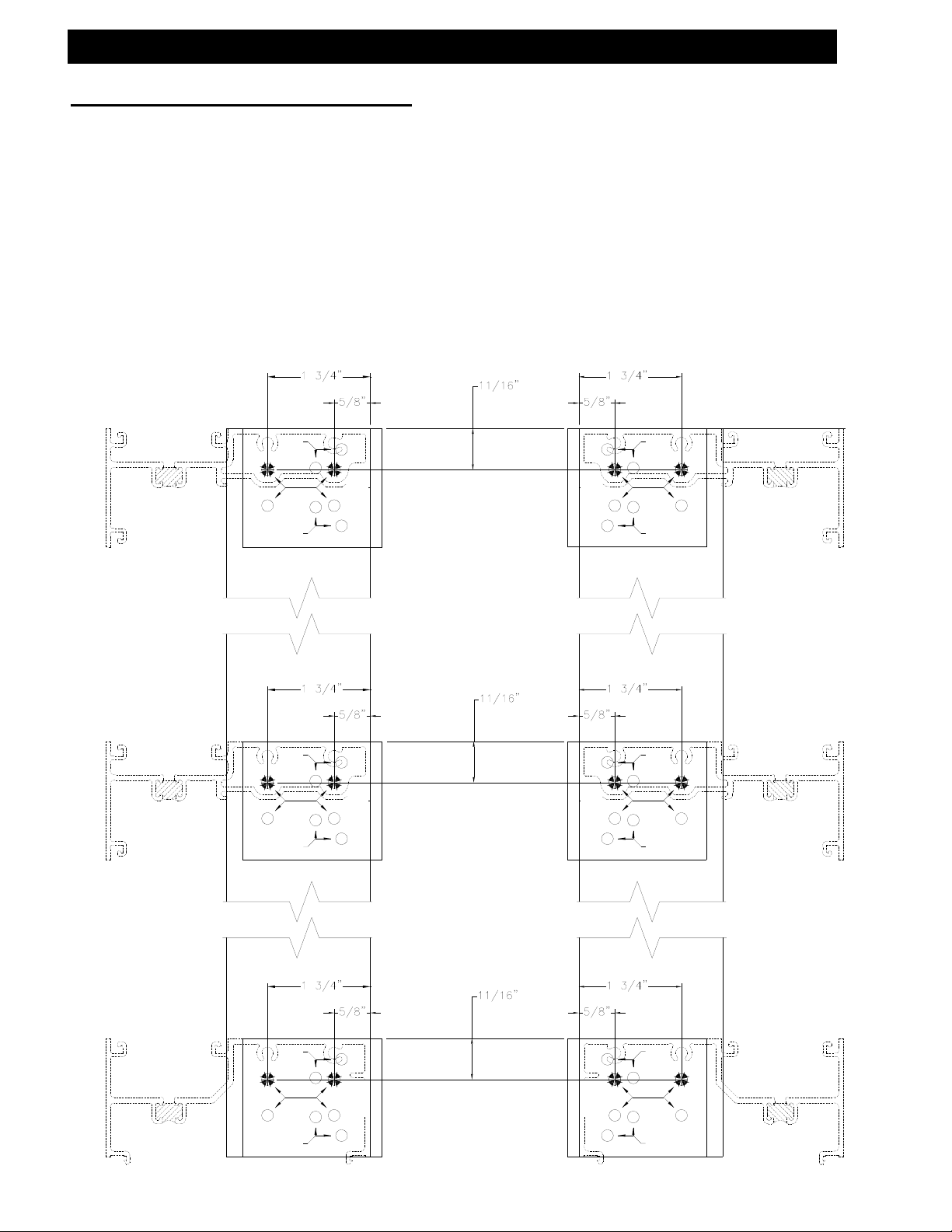

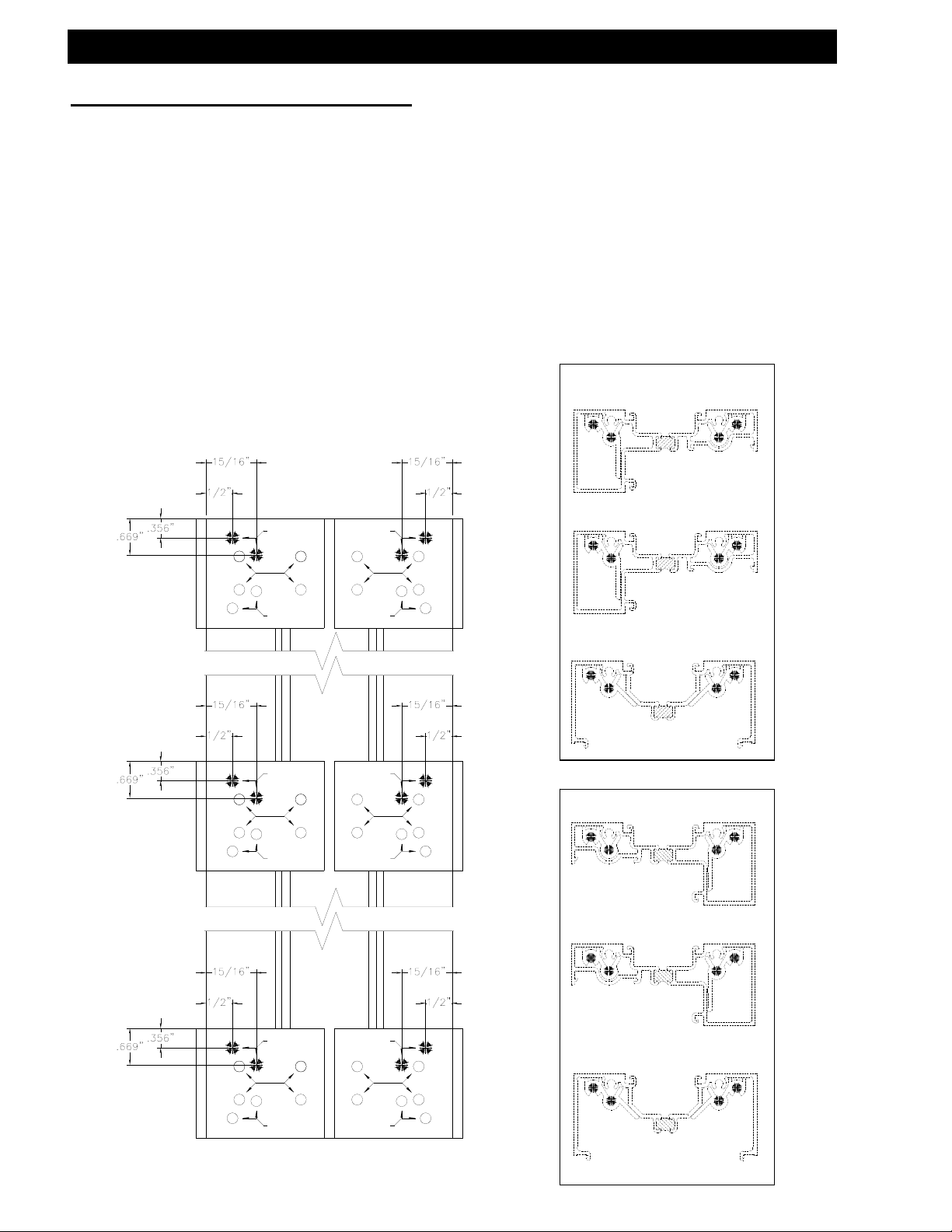

B. Drilling Template Offset Shear Block Verticals (Offset Mullion)

Left Hand Mullion Shown, Right Hand Opposite

Use the exterior edge of the vertical to align Drill Jig DJ14. Use .182 dia. (#14) drill at

darkened areas only.

These preps work for both inside and outside glazed versions.

5/32"

3/8"

June 2012 PART NO. Y017 Page 15 of 90

Outside Set Mullion Inside Set Mullion

1 3/4"

5/8"

11/16"

11/16"

1 3/4"

5/8"

CENTER SET

OFF SET

CENTER SET

433 S.B.

DJ14

433 S.B.

DJ14

CENTER SET

OFF SET

CENTER SET

1 3/4"

5/8"

11/16"

11/16"

1 3/4"

5/8"

CENTER SET

OFF SET

CENTER SET

433 S.B.

DJ14

433 S.B.

DJ14

CENTER SET

OFF SET

CENTER SET

5/8"

433 S.B.

DJ14

1 3/4"

CENTER SET

OFF SET

CENTER SET

CENTER SET

1 3/4"

OFF SET

5/8"

11/16"

11/16"

433 S.B.

DJ14

CENTER SET

5/32"

3/8"

Page 16

Series 433 Triple Set Installation Instructions

SECTION III: Fabrication

B. Drilling Template Offset Shear Block Verticals (Offset Mullion Filler)

Left Hand Mullion Shown, Right Hand Opposite

Use the exterior edge of the vertical to align Drill Jig DJ14. Use .182 dia. (#14) drill at

darkened areas only.

These preps work for both inside and outside glazed versions.

June 2012 PART NO. Y017 Page 16 of 90

Outside Set Mullion Filler Inside Set Mullion Filler

CENTER SET

OFF SET

CENTER SET

433 S.B.

DJ14

433 S.B.

DJ14

CENTER SET

OFF SET

CENTER SET

CENTER SET

OFF SET

CENTER SET

433 S.B.

433 S.B.

DJ14

CENTER SET

OFF SET

CENTER SET

CENTER SET

OFF SET

CENTER SET

433 S.B.

DJ14DJ14

433 S.B.

DJ14

CENTER SET

OFF SET

CENTER SET

Page 17

Series 433 Triple Set Installation Instructions

SECTION III: Fabrication

B. Drilling Template Offset Shear Block Verticals (Offset Mullion)

with 4 ½” Horizontals

Left Hand Mullion Shown, Right Hand Opposite

Use the exterior edge of the vertical to align Drill Jig DJ24. Use .182 dia. (#14) drill at

darkened areas only.

These preps work for both inside and outside glazed versions.

Outside Set Mullion Inside Set Mullion

June 2012 PART NO. Y017 Page 17 of 90

Page 18

Series 433 Triple Set Installation Instructions

SECTION III: Fabrication

C. Drilling Template Center-Set Screw Spline Verticals (Center-Set Mullion)

Left Hand Mullion Shown, Right Hand Opposite

Use the exterior edge of the vertical to align Drill Jig DJ15. Use .221 dia. (#2) drill at

darkened areas only.

These preps work for both inside and outside glazed versions.

Center-Set Mullion

(Reverse Drill Jig for

the opposite side)

Inside Glazed

CENTER SET

OFF SET

DJ15

433 S.S.

OFF SET

CENTER SET

OFF SET

OFF SET

433 S.S.

DJ15

DJ15

433 S.S.

OFF SET

OFF SET

CENTER SET

CENTER SET

OFF SET

OFF SET

433 S.S.

DJ15

Outside Glazed

DJ15

433 S.S.

OFF SET

OFF SET

CENTER SET

OFF SET

CENTER SET

OFF SET

DJ15

433 S.S.

June 2012 PART NO. Y017 Page 18 of 90

Page 19

Series 433 Triple Set Installation Instructions

SECTION III: Fabrication

C. Drilling Template Center-Set Screw Spline Verticals (Center-Set Mullion)

with 4 ½” Horizontals

Left Hand Mullion Shown, Right Hand Opposite

Use the exterior edge of the vertical to align Drill Jig DJ25. Use .221 dia. (#2) drill at

darkened areas only.

These preps work for both inside and outside glazed versions.

Center-Set Mullion

(Reverse Drill Jig for

the opposite side)

Inside Glazed Outside Glazed

OFF SET

OFF SET

CENTER SET

OFF SET

CENTER SET

OFF SET

CENTER SET

OFF SET

CENTER SET

OFF SET

OFF SET

OFF SET

CENTER SET

OFF SET

OFF SET

OFF SET

CENTER SET

OFF SET

June 2012 PART NO. Y017 Page 19 of 90

Page 20

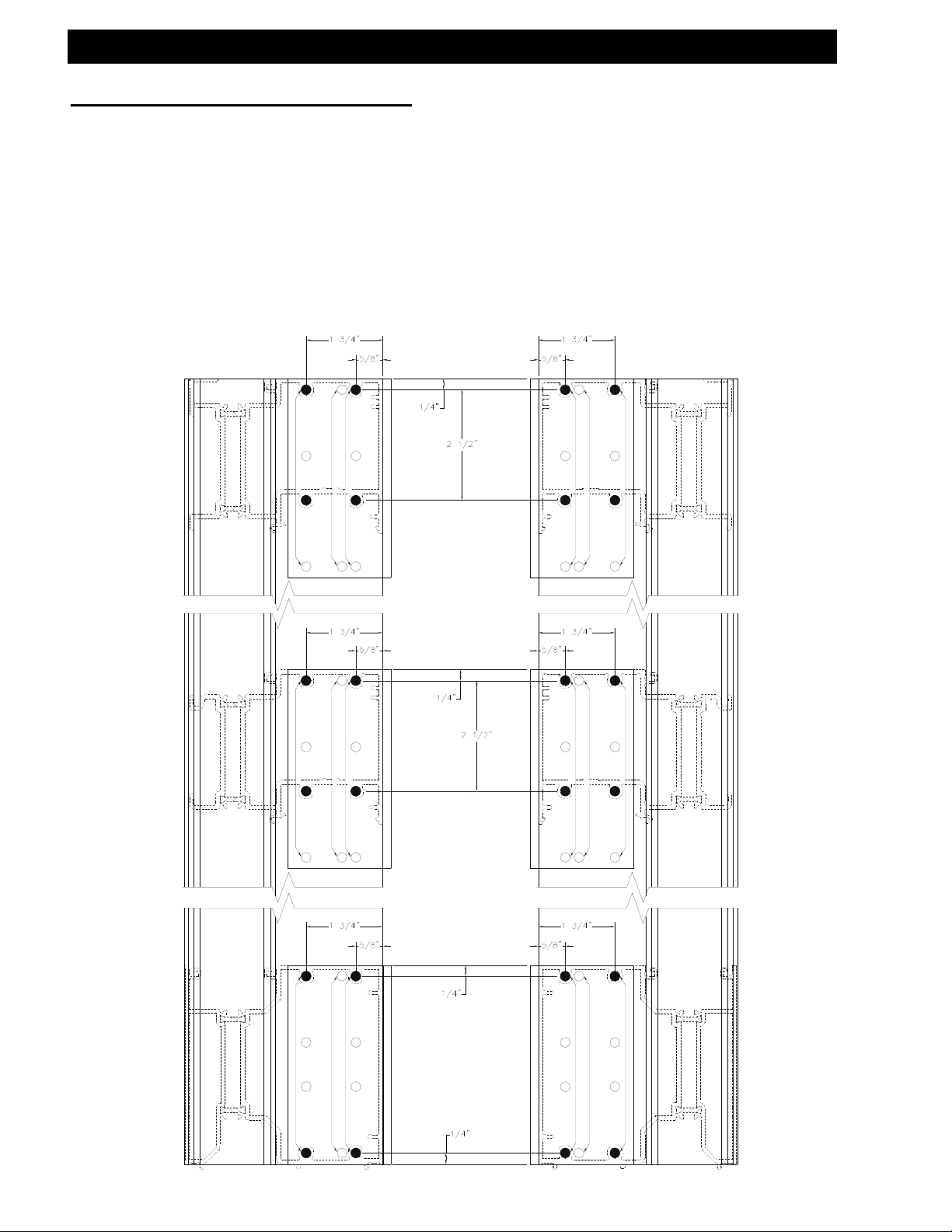

Series 433 Triple Set Installation Instructions

SECTION III: Fabrication

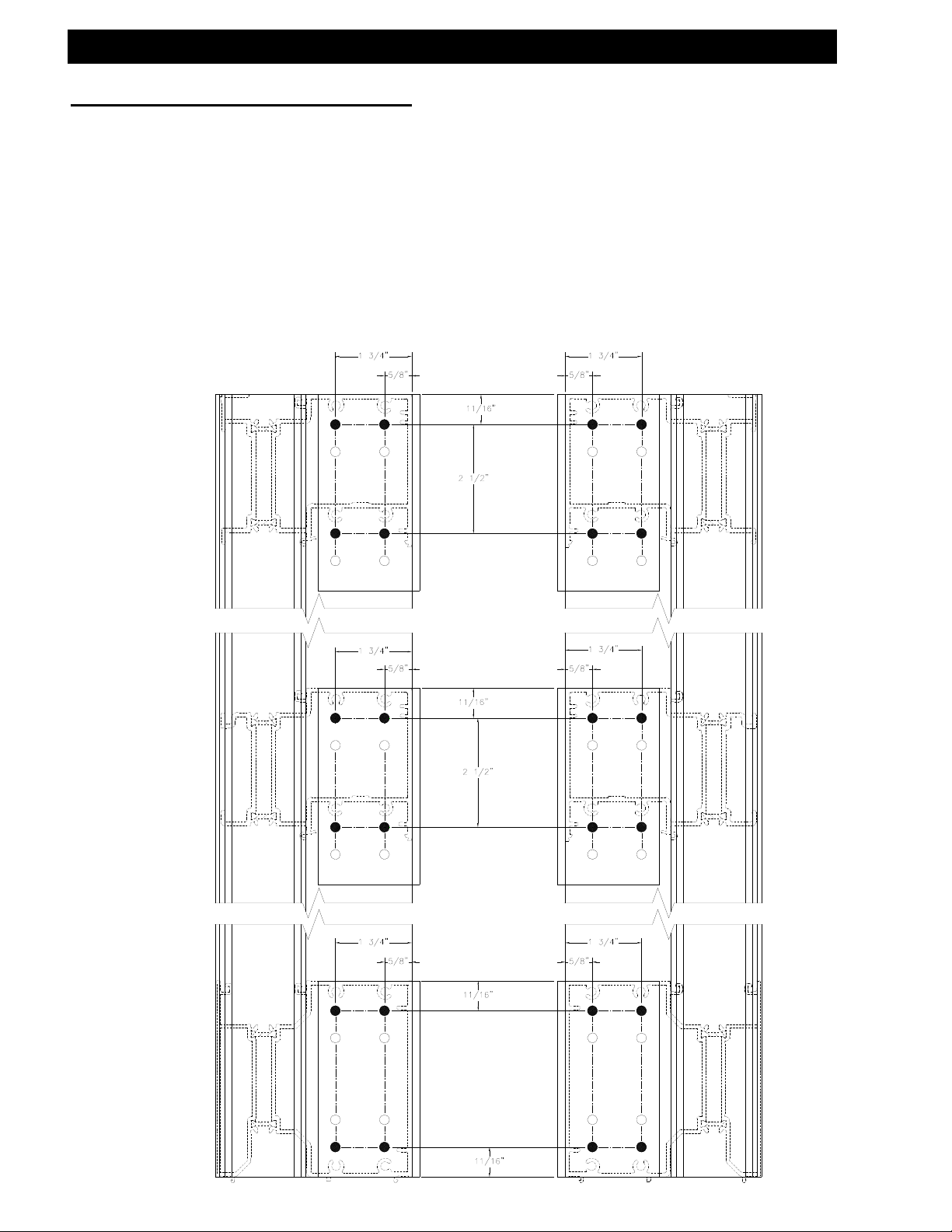

D. Drilling Template Center-Set Shear Block Verticals (Center-Set Mullion)

Left Hand Mullion Shown, Right Hand Opposite

Use the exterior edge of the vertical to align Drill Jig DJ14. Use .182 dia. (#14) drill at

darkened areas only.

These preps work for both inside and outside glazed versions.

June 2012 PART NO. Y017 Page 20 of 90

Center-Set Mullion

(Reverse Drill Jig for

the opposite side)

Inside Glazed

CENTER SET

DJ14

433 S.B.

OFF SET

CENTER SET

CENTER SET

OFF SET

CENTER SET

DJ14

433 S.B.

CENTER SET

DJ14

433 S.B.

OFF SET

CENTER SET

OFF SET

CENTER SET CENTER SET

433 S.B.

DJ14

Outside Glazed

CENTER SET

DJ14

433 S.B.

OFF SET

CENTER SET

OFF SET

CENTER SET CENTER SET

DJ14

433 S.B.

Page 21

Series 433 Triple Set Installation Instructions

SECTION III: Fabrication

D. Drilling Template Center-Set Shear Block Verticals (Center-Set Mullion)

with 4 ½” Horizontals

Left Hand Mullion Shown, Right Hand Opposite

Use the exterior edge of the vertical to align Drill Jig DJ23. Use .182 dia. (#14) drill at

darkened areas only.

These preps work for both inside and outside glazed versions.

Center-Set Mullion

(Reverse Drill Jig for

the opposite side)

Inside Glazed Outside Glazed

June 2012 PART NO. Y017 Page 21 of 90

Page 22

(2)

Series 433 Triple Set Installation Instructions

SECTION III: Fabrication

D. Drilling Template Center-Set Shear Block Verticals & Horizontals

(2-Piece Slope or Arch Top)

Left Hand Mullion Shown, Right Hand Opposite

preps work for both inside and

Vertical Fabrication:

Outside Glazed Shown

Inside Opposite

Use .147 dia. (#26) drill at

darkened areas only. These

outside glazed versions.

Horizontal Fabrication

3/16” Dia. Thru Hole

#8 Flat Head Screw

(1) Wall.

Countersink For

Thru (1) Wall

Holes Each End

June 2012 PART NO. Y017 Page 22 of 90

Page 23

Series 433 Triple Set Installation Instructions

SECTION III: Fabrication

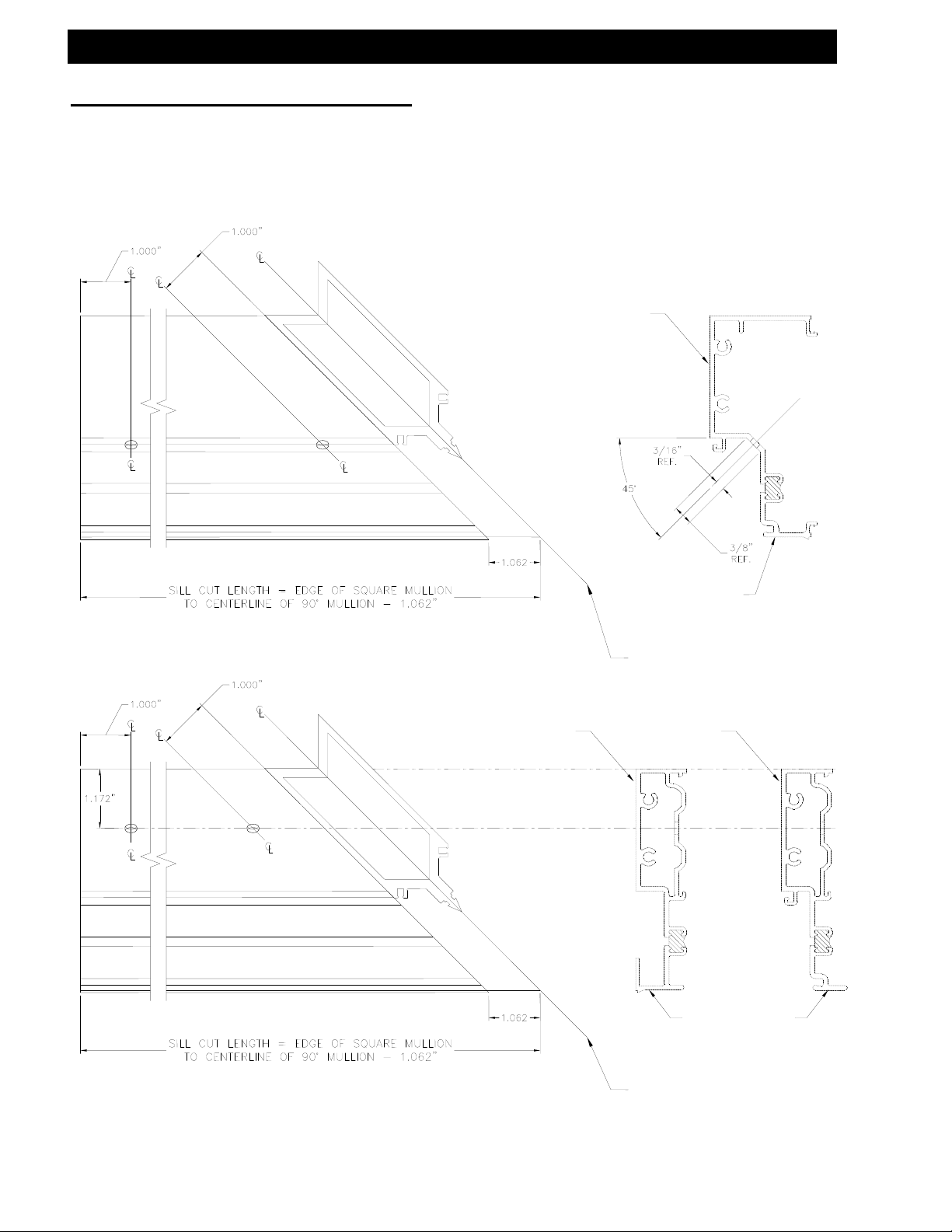

E. Drilling Template Offset @ 90° Corner Horizontal/Head/Sill

8475

Use .246 Diameter

(#D) Drill Bit

TOP OF

SILL

8384

MEASURE CUT

LENGTH FROM

THIS FLAT EDGE

CENTERLINE OF

MULLION

8475

TOP OF

HEAD

8393

TOP OF

HORIZ.

8385

CENTERLINE OF

MULLION

MEASURE CUT

LENGTH FROM

THIS FLAT EDGE

June 2012 PART NO. Y017 Page 23 of 90

Page 24

Series 433 Triple Set Installation Instructions

SECTION III: Fabrication

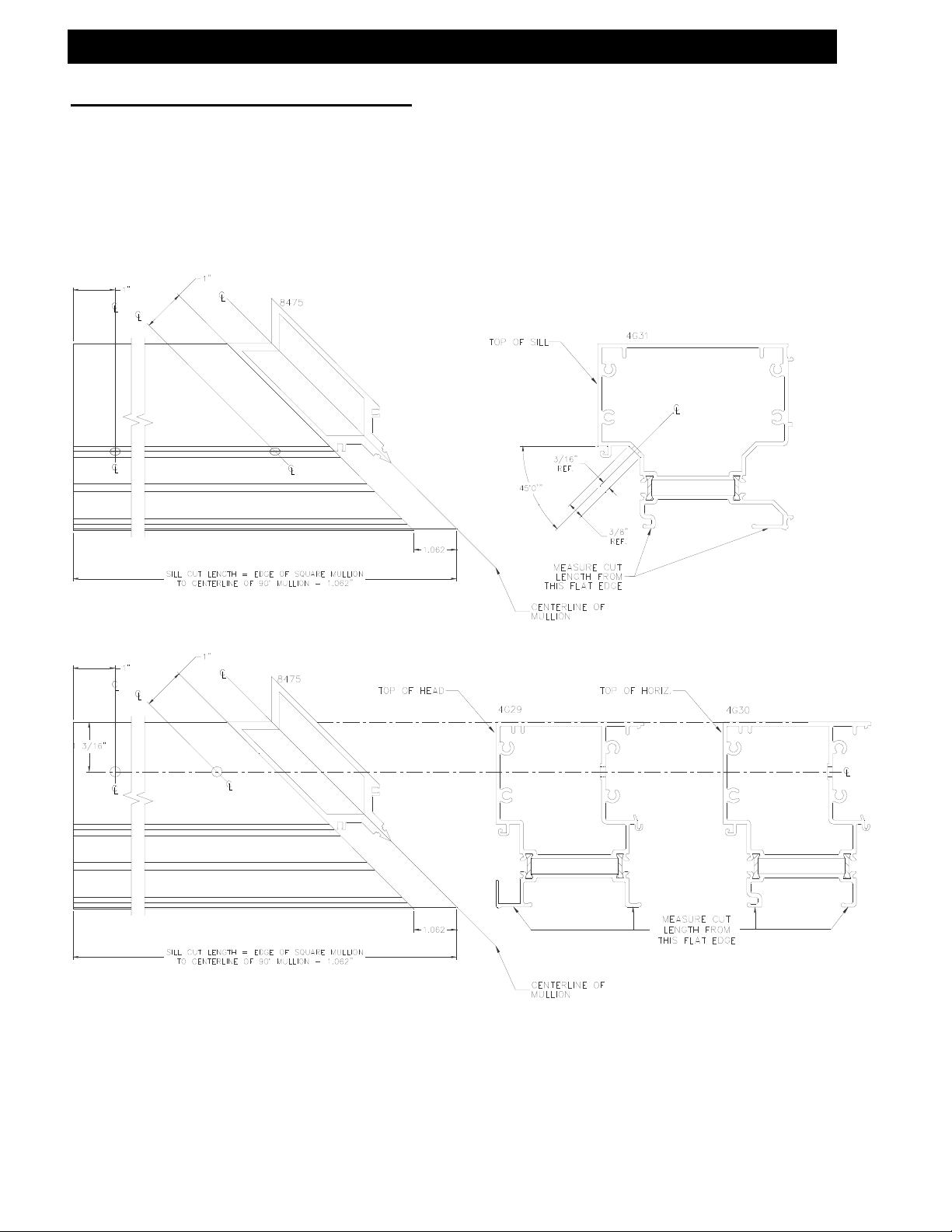

E. Drilling Template Offset @ 90° Corner Horizontal/Head/Sill

4 ½” Horizontals

Use .246 Diameter

(#D) Drill Bit

June 2012 PART NO. Y017 Page 24 of 90

Page 25

(Typ. at each end)

Series 433 Triple Set Installation Instructions

SECTION III: Fabrication

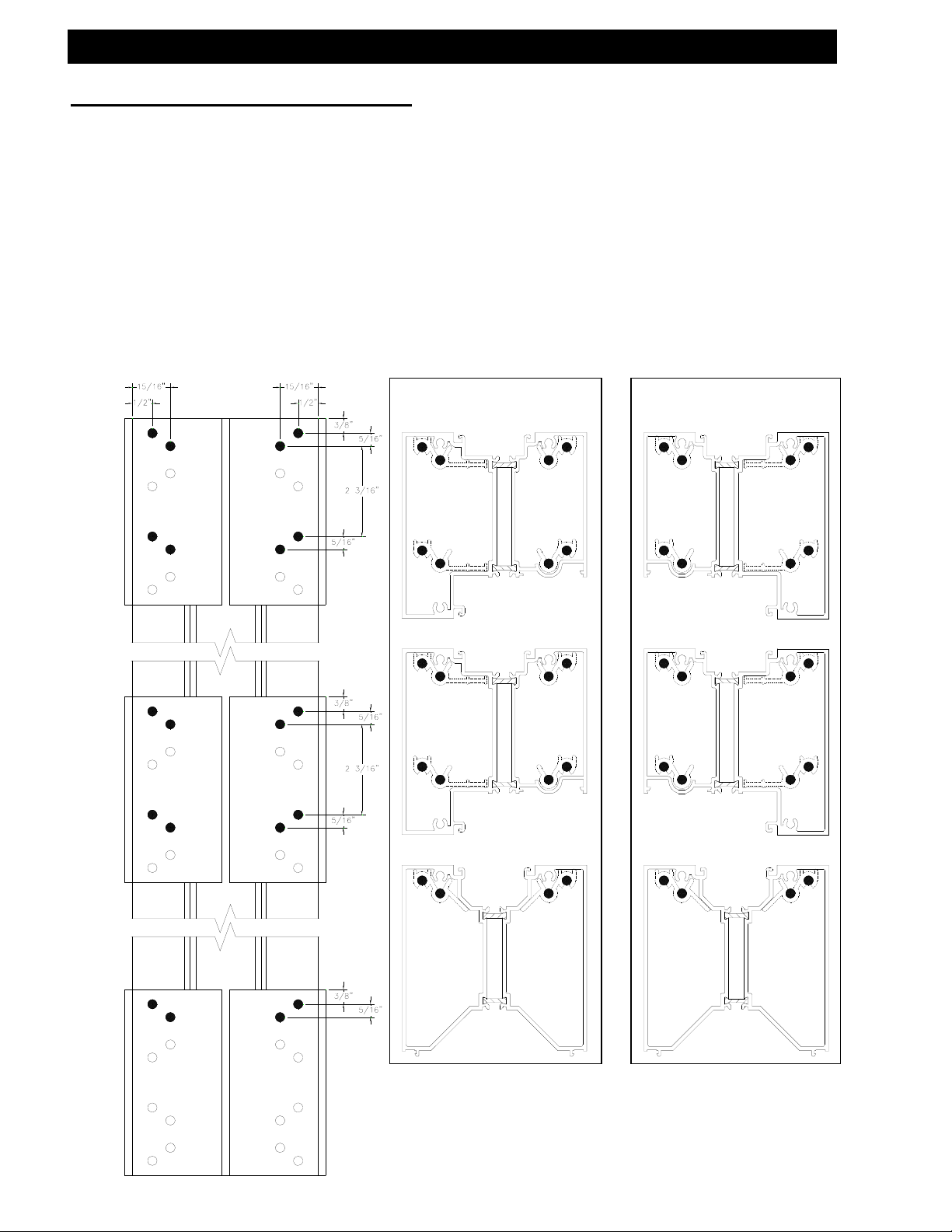

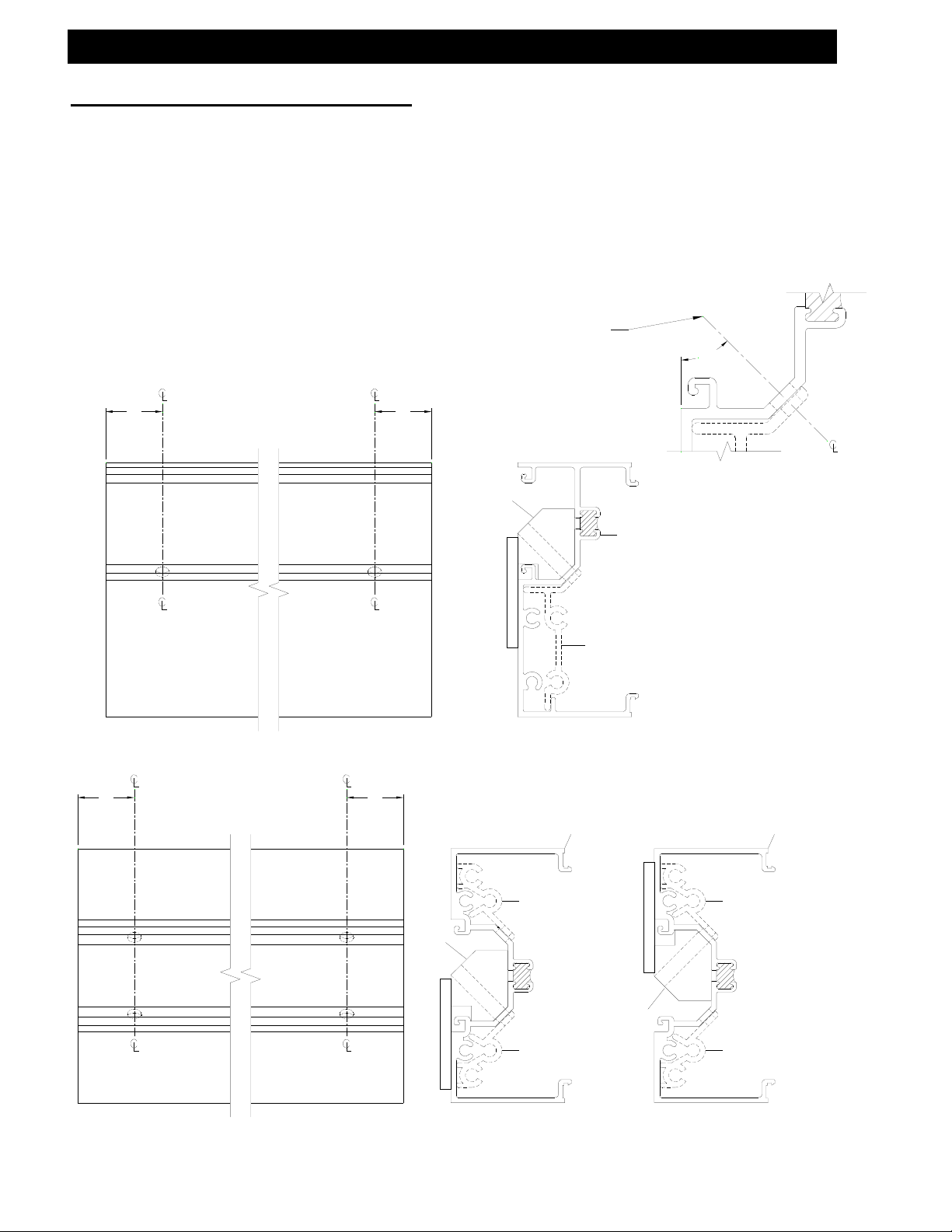

F. Drilling Template for Offset and Center-Set Shear Block at Sills

1" 1"

June 2012 PART NO. Y017 Page 25 of 90

Fixture DJ13 should be placed at the end of the sills as

shown. These preps work on all offset and center-set sills.

Use .246 Diameter (#D) Drill Bit

1" 1"

Drill one side and flip the fixture to drill the opposite side.

CENTER THE .246

DIA. HOLE AT

MIDPOINT OF FLAT

DJ13

(Typ. at each end)

FU19

DJ13

FU19

8372

45°

8362

FU20

8372

FU19

DJ13

FU19

Page 26

Series 433 Triple Set Installation Instructions

SECTION III: Fabrication

F. Drilling Template for Offset and Center-Set Shear Block at 4 ½” Sills

Fixture DJ13 should be placed at the end of the sills as

shown. These preps work on all offset and center-set sills.

1" 1"

Use .246 Diameter (#D) Drill Bit

CENTER THE .246

DIA. HOLE AT

MIDPOINT OF FLAT

4G33

DJ13

FU20

45°

FU20

1" 1"

DJ13

(Typ. at each end)

3G48

FU19

FU19

3G48

FU19

DJ13

FU19

June 2012 PART NO. Y017 Page 26 of 90

Page 27

Series 433 Triple Set Installation Instructions

SECTION III: Fabrication

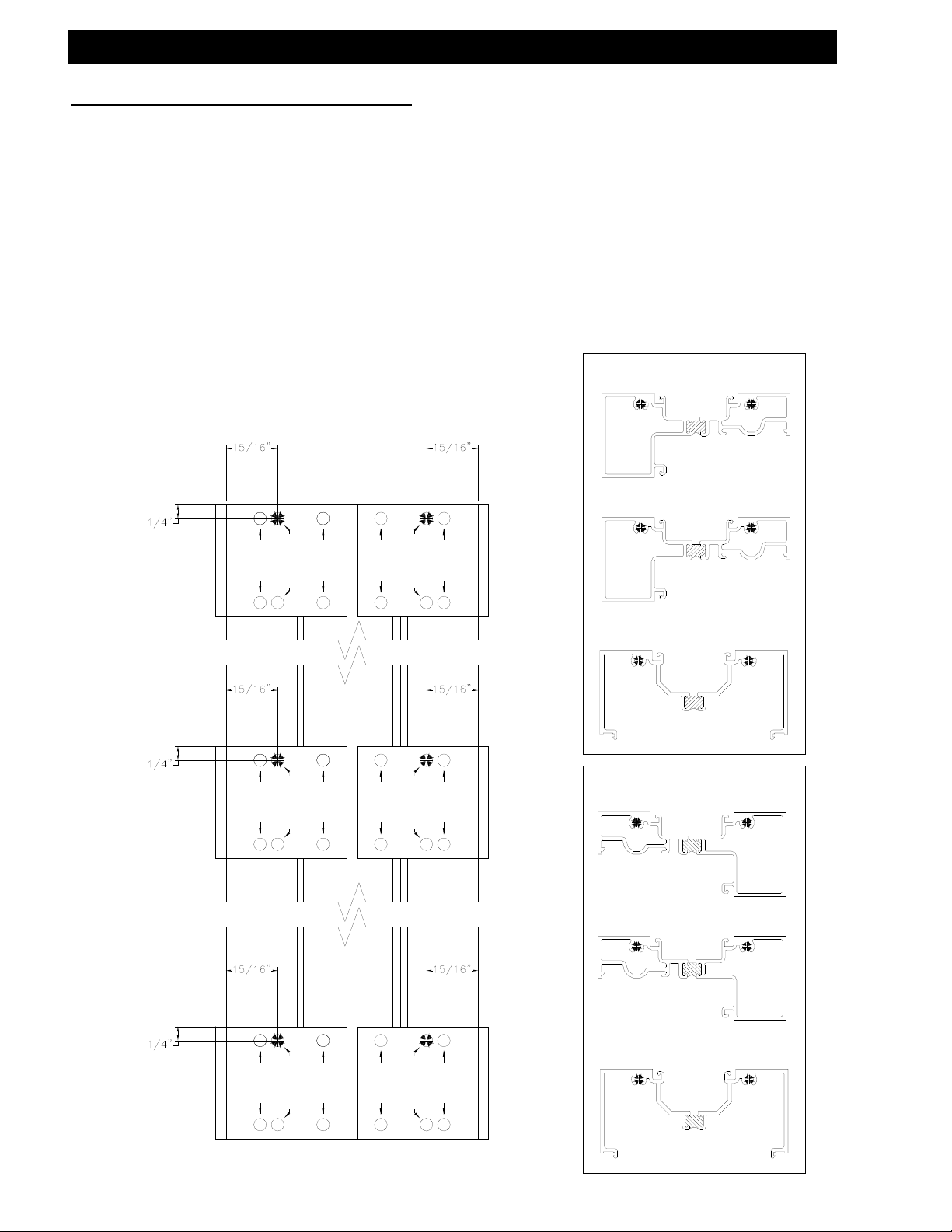

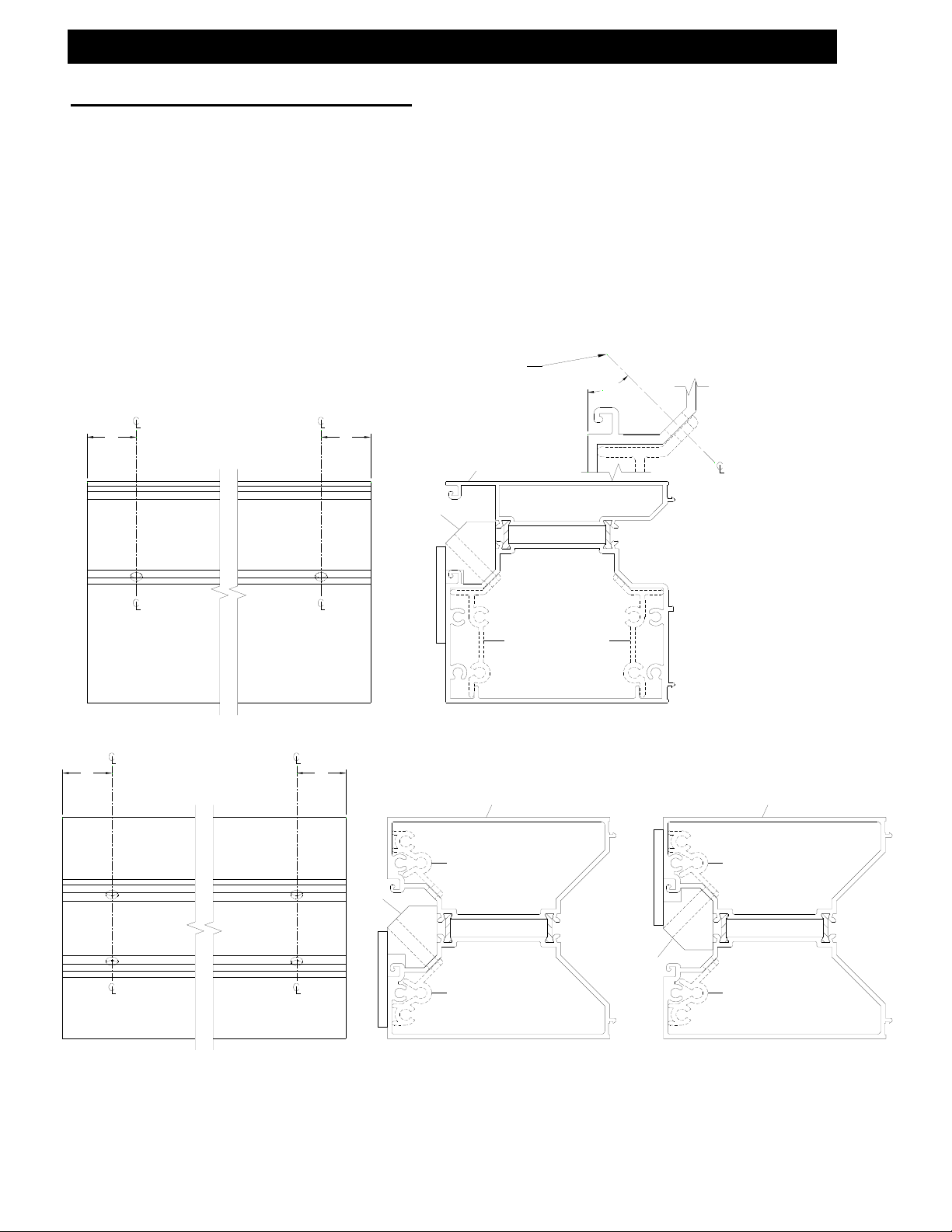

G. Drilling Template Offset and Center-Set Shear Block at Horizontals

June 2012 PART NO. Y017 Page 27 of 90

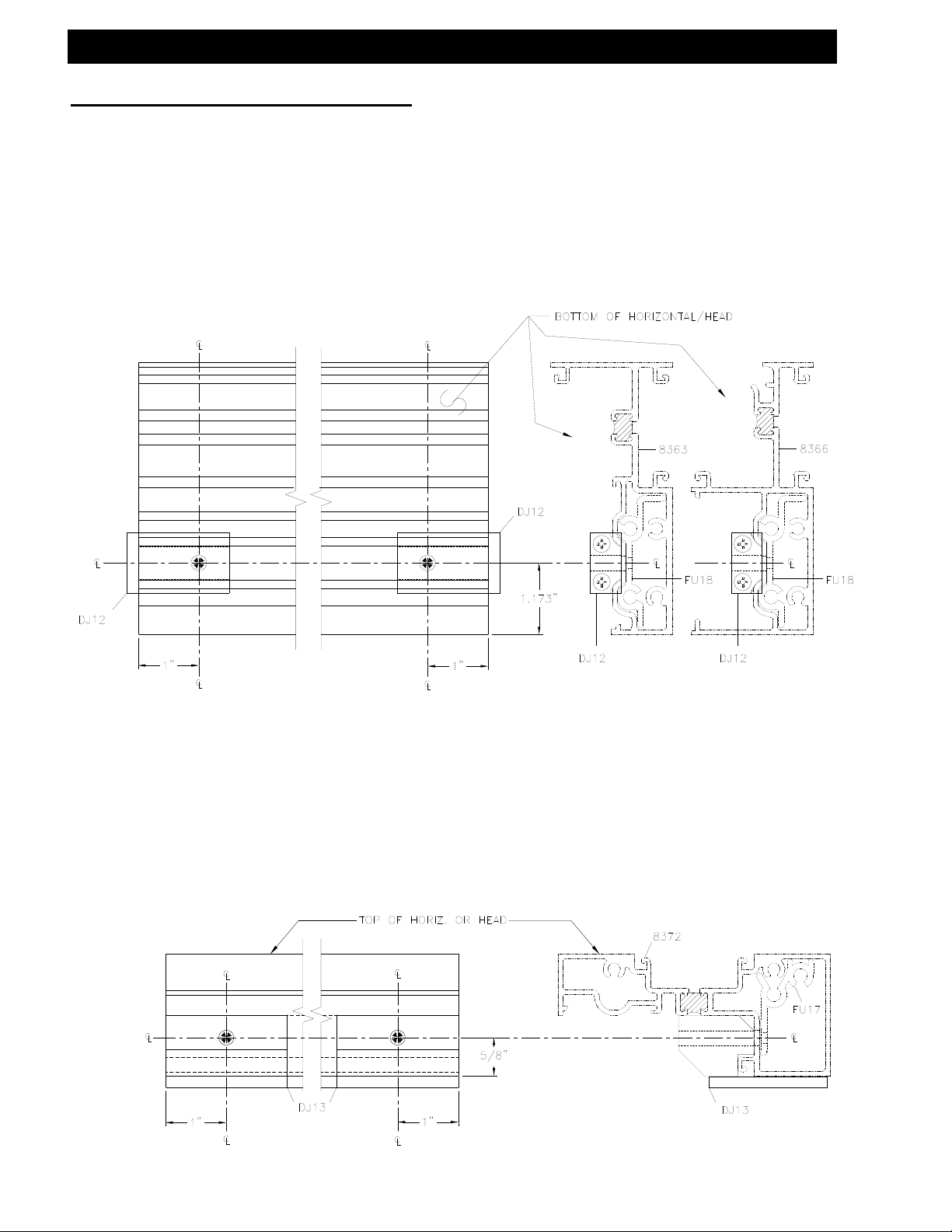

Fixture DJ12 is self-aligning and should be placed at the end

of the horizontal as shown. These preps work on all offset

head and intermediate horizontals.

Use .246 Diameter (#D) Drill Bit

Fixture DJ13 should be placed at the end of the horizontal as

shown. These preps work on all center-set head and

intermediate horizontals.

Use .246 Diameter (#D) Drill Bit

Page 28

Series 433 Triple Set Installation Instructions

SECTION III: Fabrication

G. Drilling Template Offset and Center-Set Shear Block at 4 ½” Horiz.

Fixture DJ26 is self-aligning and should be placed at the end

of the horizontal as shown. These preps work on all offset

head and intermediate horizontals.

Use .246 Diameter (#D) Drill Bit

Fixture DJ26 should be placed at the end of the horizontal as

shown. These preps work on all center-set head and

intermediate horizontals.

Use .246 Diameter (#D) Drill Bit

June 2012 PART NO. Y017 Page 28 of 90

Page 29

Series 433 Triple Set Installation Instructions

SECTION III: Fabrication

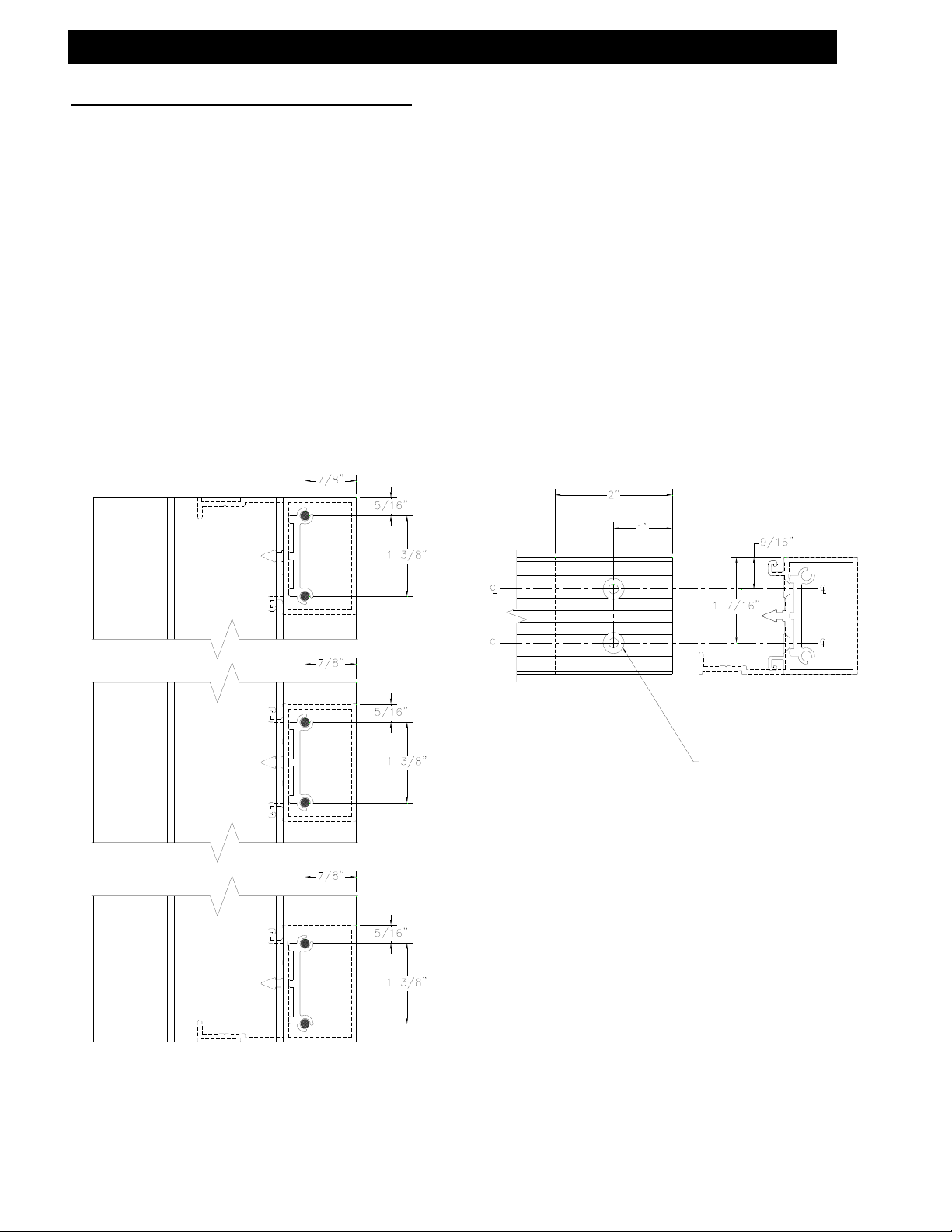

H. Drilling Template Offset Glazed Head & Sill Through

June 2012 PART NO. Y017 Page 29 of 90

Head and Sill through Butt Glazed Jamb and Vertical

Use the exterior edge of the jamb or vertical to align

drill jig DJ15.

Use .221 diameter (#2) drill bit at darkened areas only.

Page 30

Series 433 Triple Set Installation Instructions

SECTION III: Fabrication

H. Drilling Template Offset Screw Spline SSG Verticals for Intermediate

Horizontal with Head & Sill Through

Use the exterior edge of the vertical to align Drill Jig DJ15 for 2” mullions and DJ25 for

4 ½” mullions. Use .221 dia. (#2) drill at darkened areas only.

CENTER SET

OFF SET

433 S.S.

OFF SET

DJ15

CENTER SET

OFF SET

OFF SET

8387

8388

8387

8388

June 2012 PART NO. Y017 Page 30 of 90

Page 31

Series 433 Triple Set Installation Instructions

SECTION III: Fabrication

H. Drilling Template Offset Shear Block SSG Verticals for Intermediate

Horizontal with Head & Sill Through

Use the exterior edge of the vertical to align Drill Jig DJ14 for 2” mullions and DJ24 for

4 ½” mullions. Use .201 dia. (#7) drill at darkened areas only.

CENTER SET

OFF SET

DJ14

433 S.B.

CENTER SET

8389

8389

June 2012 PART NO. Y017 Page 31 of 90

Page 32

Series 433 Triple Set Installation Instructions

SECTION IV: Unit Assembly

A. Screw Spline (Offset and Center-Set)

Note: Clean off all

excess sealant after

assembly.

Offset Glazed Assembly

Outside Set, Inside glazed shown,

Outside Set, Outside Glazed Similar

Note: Wax Type Lubricate may be

required @ Assembly Fasteners

4 ½” Head,

Horizontal &

Sill Similar

June 2012 PART NO. Y017 Page 32 of 90

Page 33

a

Series 433 Triple Set Installation Instructions

SECTION IV: Unit Assembly

A. Screw Spline (Offset and Center-Set)

Offset Glazed Assembly

Inside Set, Outside glazed shown,

Inside Set, Inside Glazed Similar

Note: Wax Type Lubricate may be

required @ Assembly Fasteners

Note: Clean off all

excess sealant after

assembly.

4 ½” Head,

Horizontal &

Sill Similar

Butter the ends fo all horizontals with se

June 2012 PART NO. Y017 Page 33 of 90

Page 34

Series 433 Triple Set Installation Instructions

June 2012 PART NO. Y017 Page 34 of 90

Page 35

Series 433 Triple Set Installation Instructions

SECTION IV: Unit Assembly

A. Screw Spline (Offset and Center-Set)

8361 SHOWN

(8358, 8359 SIM.)

June 2012 PART NO. Y017 Page 35 of 90

EXTERIOR FACE

Note: Clean off all

excess sealant after

assembly.

Center Glazed Assembly

Inside Glazed

Note: Wax Type Lubricate may be

required @ Assembly Fasteners

4 ½” Head,

Horizontal &

Sill Similar

BUTTER THE ENDS OF ALL

HORIZONTALS WITH BUTYL TYPE

SEALANT AS SHOWN BY THE

SHADED AREAS PRIOR TO

ASSEMBLY OF THE UNITS.

STC8

STC8

STC8

8360

Page 36

Series 433 Triple Set Installation Instructions

SECTION IV: Unit Assembly

A. Screw Spline (Offset and Center-Set)

Note: Clean off all

excess sealant after

assembly.

Offset Structural Glazed Assembly

HORIZONTALS WITH BUTYL TYPE

STC8

8355

8384

BUTTER THE ENDS OF ALL

SEALANT AS SHOWN BY THE

SHADED AREAS PRIOR TO

ASSEMBLY OF THE UNITS.

Note: Wax Type Lubricate may be

required @ Assembly Fasteners

Details shown without removable

face for clarity.

8393

8387

8385

4 ½” Head,

Horizontal &

Sill Similar

STC8

STC8

8388

8393

8385

8384

June 2012 PART NO. Y017 Page 36 of 90

Page 37

Series 433 Triple Set Installation Instructions

SECTION IV: Unit Assembly

A. Screw Spline (Offset and Center-Set)

Note: Clean off all

excess sealant after

assembly.

Offset Glazed Assembly With Expansion Mullion

Outside Set, Inside Glazed Shown,

Outside Set, Outside Glazed Similar

4 ½” Head,

Horizontal, &

Sill Similar

Note: Wax Type Lubricate may be

required @ Assembly Fasteners.

Expansion mullions are required in elevations that are over 20’-25’ wide

and can be used with both screw spline and shear block systems.

June 2012 PART NO. Y017 Page 37 of 90

Page 38

Series 433 Triple Set Installation Instructions

SECTION IV: Unit Assembly

A. Screw Spline (Offset and Center-Set)

Center Glazed Assembly With Expansion Mullion

Inside Glazed

4 ½” Head,

Horizontal, &

Sill Similar

Note: Wax Type Lubricant may be

required @ Assembly Fasteners.

EXTERIOR FACE

Note: Clean off all

excess sealant after

assembly.

BUTTER THE ENDS OF ALL

HORIZONTALS WITH BUTYL TYPE

SEALANT AS SHOWN BY THE

SHADED AREAS PRIOR TO

ASSEMBLY OF THE UNITS.

Expansion mullions are required in elevations that are over 20’-25’ wide

and can be used with both screw spline and shear block systems.

June 2012 PART NO. Y017 Page 38 of 90

Page 39

Series 433 Triple Set Installation Instructions

SECTION IV: Unit Assembly

A. Screw Spline (Offset and Center-Set)

Use FW95 3” Dead Load Support Pin when

there is a Horizontal member on both

sides of the Transom Jamb or Vertical.

Dead Load Pin Installation

Outside Set Shown

Use FW96 2” Dead Load Support Pin when

there is a Horizontal member on one side

of the Vertical or for Door Jambs with side

lites.

4374

8353

8354 8356

8355 8374

DIES SIMILAR TO

ONE’S SHOWN.

June 2012 PART NO. Y017 Page 39 of 90

Page 40

Series 433 Triple Set Installation Instructions

SECTION IV: Unit Assembly

B. Shear Block (Offset and Center-Set)

Note: Clean off all

excess sealant after

assembly.

June 2012 PART NO. Y017 Page 40 of 90

4 ½” Head,

Horizontal &

Sill Similar

EXTERIOR FACE

Offset Glazed Assembly

Inside Set, Inside Glazed shown,

Other Glazing Variations Similar

K925

KN91 (4 ½”)

Note: Wax Type Lubricate may be

required @ Assembly Fasteners

K925

KN91 (4 ½”)

K927

K927 (4 ½”)

K925

KN91 (4 ½”)

8362

K927

K927 (4 ½”)

Shear block packages

come with all required

fasteners.

BUTTER THE ENDS OF ALL

HORIZONTALS WITH BUTYL TYPE

SEALANT AS SHOWN BY THE

SHADED AREAS PRIOR TO

ASSEMBLY OF THE UNITS.

K925

KN91 (4 ½”)

Page 41

Series 433 Triple Set Installation Instructions

SECTION IV: Unit Assembly

B. Shear Block (Offset and Center-Set)

8359 SHOWN

(8357, 8360,

8361 SIM.)

June 2012 PART NO. Y017 Page 41 of 90

4 ½” Head,

Horizontal &

Sill Similar

EXTERIOR FACE

Note: Clean off all

excess sealant after

assembly.

Center-Set Glazed Assembly

Inside Glazed shown,

Outside Glazed similar

K924

KN69 (4 ½”)

K924

KN69 (4 ½”)

K926

K926 (4 ½”)

KN69 (4 ½”)

8375

K926 (4 ½”)

Note: Wax Type Lubricate may be

required @ Assembly Fasteners

8372

K924

K926

Shear block packages

come with all required

fasteners.

8372

BUTTER THE ENDS OF ALL

HORIZONTALS WITH BUTYL

TYPE SEALANT AS SHOWN

BY THE SHADED AREAS

PRIOR TO ASSEMBLY OF

THE UNITS.

K924

KN69 (4 ½”)

8358

Page 42

r

Series 433 Triple Set Installation Instructions

SECTION IV: Unit Assembly

B. Shear Block (Offset and Center-Set)

Use FW95 3” Dead Load Support Pin when

there is a Horizontal member on both

sides of the Transom Jamb or Vertical.

Dead Load Pin Installation

Outside Set Shown

Inside Set Simila

Use FW96 2” Dead Load Support Pin when

there is a Horizontal member on one side

of the Vertical or for Door Jambs with side

lites.

8374

8349

OTHER

DIES SIMILAR TO

ONE’S SHOWN.

June 2012 PART NO. Y017 Page 42 of 90

Page 43

Series 433 Triple Set Installation Instructions

SECTION IV: Unit Assembly

C. Head & Sill Through (Offset)

Note: Clean off all

excess sealant after

assembly.

June 2012 PART NO. Y017 Page 43 of 90

8363

8439

EXTERIOR FACE

Offset Structural Glazed Assembly

STB5

K925

KN91 (4 ½”)

8389

STC8

8385

8362

Horizontal shown without

removable face for clarity

Note: Wax Type Lubricate may be

required @ Assembly Fasteners

BUTTER THE ENDS OF ALL

HORIZONTALS WITH BUTYL TYPE

SEALANT AS SHOWN BY THE

SHADED AREAS PRIOR TO

ASSEMBLY OF THE UNITS.

Shear block packages

come with all required

fasteners.

K925

KN91 (4 ½”)

Page 44

Series 433 Triple Set Installation Instructions

SECTION IV: Unit Assembly

D. Screw Spline 90 Corner (Offset)

Note: Wax Type Lubricate may be

required @ Assembly Fasteners

June 2012 PART NO. Y017 Page 44 of 90

Corner Mullion can be used at horizontal with removable face only.

Offset Glazed Assembly with 90 Mullion

See page 31 for sealant notes and locations.

4 ½” Head,

Horizontal &

Sill Similar

Page 45

K

A

Series 433 Triple Set Installation Instructions

SECTION IV: Unit Assembly

E. Rolled Arch Top & Sloped Top (Center Set)

Note: Wax Type Lubricate

may be required @

Assembly Fasteners

Center Glazed Assembly for Slope or Arch Top

16C8

ROLLED

16C8

Inside or Outside Glazed

CUSTOM

FABRICATED

SHEAR BLOCK

KN92

CUSTOM

FABRICATED

SHEAR BLOC

16C7

BUTTER THE ENDS OF ALL

HORIZONTALS WITH BUTYL TYPE

SEALANT AS SHOWN BY THE

SHADED AREAS PRIOR TO

SSEMBLY OF THE UNITS.

Shear block

packages come

with all required

fasteners.

16C8

Arch/Slope Top

material may be

attached to regular

Center-Set frame

material when

required.

KN92

KN92

16C8

Note: Clean off all

excess sealant after

assembly.

KN92

June 2012 PART NO. Y017 Page 45 of 90

Page 46

T

T

Series 433 Triple Set Installation Instructions

SECTION IV: Unit Assembly

F. Adjustable Height Side Lite (Offset)

D.L.O.

BREAKMETAL WIDTH = D.L.O.

SEALAN

STT6

16E1

SEALAN

HN64

8365

16D9

W104

SPZ1

STT6

D.L.O.

SIDE LITE HEIGHT = 4 1/2" MIN. TO 48" MAX.

BREAKMETAL HEIGHT = D.L.O. + .656

W161

.375

June 2012 PART NO. Y017 Page 46 of 90

2S44 SUBSILL

3S67

Page 47

Series 433 Triple Set Installation Instructions

SECTION IV: Unit Assembly

F. Adjustable Height Side Lite (Offset)

1.500 1.500

.156

.375 .375

Part Fabrication

CUT LENGTH = D.L.O. - .75

12" O.C.

MAX

12" O.C.

MAX

.156

.563 .563

Ø.177 THRU HOLE FOR #8-18 FASTENERS (2) AT

EACH END, ADD (1) IN THE MID SPAN IF CUT

LENGTH EXCEEDS 19" AND UP TO 35" OR 12"

O.C. FOR CUT LENGTHS OVER 35"

.500

16E1

.375 .375

.500 .500

CUT LENGTH = D.L.O.

.423

Ø.177 THRU

HOLE (4)

OF HORIZONTAL

2.786

16D9

1.000

.500

.234

CUT LENGTH = D.L.O.

.234

Ø.375 THRU

HOLE (2)

INTERIOR

.500

.401

LOCATE .313 DIA. WEEPS 3" FROM EACH

END AND NO MORE THAN 42.000 APART

Ø.177 THRU

HOLE (4)

16E0

2.786

3.000 3.000

Ø.313 TYP.

42.000

O.C. MAX.

42.000

O.C. MAX.

EXTERIOR

June 2012 PART NO. Y017 Page 47 of 90

Page 48

A

T

A

A

Series 433 Triple Set Installation Instructions

SECTION IV: Unit Assembly

F. Adjustable Height Side Lite (Offset)

Assembly

9838 DEAD LOAD

SUPPORT TUBE

TTACH THE VERTICAL MEMBERS TO

HE SILL AS SHOWN. OPTIONAL DEAD

SPZ1

LOAD SUPPORT TUBE TO BE USED AS

NEEDED.

RUN A CONTINUOUS BEAD OF

SEALANT UP THE INTERIOR GASKET

RACEWAY FOR THE FULL LENGTH OF

THE SIDE LITE VERTICAL.

BUTTER THE ENDS OF ALL

HORIZONTALS WITH BUTYL TYPE

SEALANT PRIOR TO ASSEMBLY OF THE

UNITS.

PLACE ASSEMBLY IN THE FRAME D.L.O.

ND ATTACH TO THE JAMBS WITH

STT6 FASTENERS.

RUN A CONTINUOUS BEAD OF

SEALANT UP THE VERTICAL SEALANT

TRACK (INTERIOR & EXTERIOR).

SLIDE BREAK METAL INTO PLACE AND

TTACH HORIZONTAL AS SHOWN

BELOW.

S129

S129

FWB6 WASHER

SPZ1

Note: Wax Type Lubricate may be

required @ Assembly Fasteners

SEALANT

W161 GASKET

TO RUN D.L.O.

Note: Clean off all

excess sealant after

assembly.

SEALANT

June 2012 PART NO. Y017 Page 48 of 90

Page 49

Series 433 Triple Set Installation Instructions

SECTION V: Door Frame Installation

Step 1) General Notes

If a door opening is required, the doorframe must be installed first. The subsill must be

installed into the opening from the door framing, ensuring that the appropriate

clearance is available for the doorframe. All subsequent ladders must be installed from

the doorjamb out.

Step 2) Subsill Installation at Door Opening

Where a door opening is required, use the equation in Figure 1. Install the door frame

true and plumb in the opening as specified on the shop drawings or architectural

drawings. Install the subsill in the same manner as illustrated on pages 46 through 54.

End dams are not required at the door frame end of the subsill. The subsill should butt

up tight tot the door frame. See Figures on page 46 for subsill sealant requirements at

the door framing.

June 2012 PART NO. Y017 Page 49 of 90

Fig. 1

INSTALL 1ST

2" 2"

SUBFRAME CLEARANCE HOLE =

[DOOR OPENING WIDTH + 4"]

Note: Door jambs do not set on the subsill. Door

jambs must run through to the floor condition.

Page 50

g

Series 433 Triple Set Installation Instructions

SECTION V: Door Frame Installation

Step 3) Subsill Installation at Door Opening

Before installing the subsill to the door frame, seal the end of the subsill with a silicone

type sealant. Install the subsill and tool all excess sealant into the joint where the

subsill and door jamb meet. If required , add more sealant to create a smooth

watertight seal. At the glazing pockets, a build-up of silicone sealant must be used to

fill the depth of the pocket up to the level of the subsill at the glaz ing area. See below

for sealant application at the subsill to door jamb joint.

NOTE:

tallest portion of the subsill that bridges the glazing pocket. Tool the silicone sealant

so a watertight seal is made, so that water will be directed out of the glazing pocket

and into the subsill.

Pocket of the door jamb flush with the silicone sealant to the tallest portion of the

subsill that bridges the glazing pocket. Tool the silicone sealant so a watertight seal

is made, so that water will be directed out of the

June 2012 PART NO. Y017 Page 50 of 90

[Fig. 2] [Fig. 3] [Fig. 4]

Fill the glazing pocket of the door jamb flush with the silicone sealant to the

lazing pocket and into the subsill.

Page 51

q

Series 433 Triple Set Installation Instructions

SECTION VI: Subsill Fabrication and Installation

(Includes Offset and Center-Set Glazing)

Step 1) Cut Length

Measure the opening to determine the cut length of the subsill. Subtract ¼” for the

width of the end dam and fastener head from the rough opening for each end. Cut the

subsill to the determined length.

If end dams are not re

END DAM

ROUGH

OPENING

Step 2) End Dam Installation

The end dam shall be attached to the subsill with 2 SPP2 fasteners on each end. Seal

the end of the subsill with silicone sealant before attaching the end dam to the subsill.

Tool the sealant at the interior joint of the end dam to ensure a good watertight seal.

See Figure 6 below. If end dams are not required, ensure the subsill is tight against

the condition and seal the joint between the subsill and condition similar to Figure 6.

CUT LENGTH = R.O. - 1/2" for end dams (See Figure 5)

CUT LENGTH = R.O. for no end dams (See Figure 5)

K941

3/16"

[Fig. 6]

uired, cut the subsill to the rough opening width.

+1/8"

- 0"

SUBSILL 2S44

4471 SIMILAR

CUT LENGTH =

ROUGH OPENING-1/2"

WITH END DAMS

2S44

K941

END DAM

CUT LENGTH =

ROUGH OPENING

WITHOUT END DAMS

TOOL SEALANT AT JOINT

APPLY SEALANT TO ENDS OF

THE SUBSILL BEFORE

ATTACHING END DAM

K941 END DAM

FASTENERS WILL

NOT BE USED

ROUGH

OPENING

[Fig. 5]

APPLY SEALANT TO THE TOP

OF THE THERMAL CAVITY

ACROSS ENTIRE SUBSILL AND

TOOL SMOOTH

4471

June 2012 PART NO. Y017 Page 51 of 90

Page 52

Series 433 Triple Set Installation Instructions

SECTION VI: Subsill Fabrication and Installation

(Includes Offset and Center-Set Glazing)

Step 3) Weep Fabrication

Drill 5/16” weep holes in the subsill 6” from jambs and no more than 42” apart.

Step 4) Weep Baffle Installation

Weep baffles are cut from (1) HCW6, halved. This provides (2) weep baffles per

HCW6. See Fig. 8 below.

Apply a small amount of silicone type sealant to the baffles, and locate them over the

weep holes as shown in Figure 8 below.

SEALANT

SUBSILL

2S44

42" MAXIMUM O.C.6" 6"

SEALANT

[Fig. 7]

SUBSILL

4471

HCW6

2"

1/2"

3/4"

2"

1/2"

3/8"

SUBSILL

WEEP BAFFLE

2S44 SHOWN

4471 SIMILAR

2S44

WEEP BAFFLE

[FIG. 8]

[Fig. 8]

June 2012 PART NO. Y017 Page 52 of 90

Page 53

Series 433 Triple Set Installation Instructions

SECTION VI: Subsill Fabrication and Installation

(Includes Offset and Center-Set Glazing)

Step 5) Chalk Line for Subsill

Before installing the subsill, measure the distance from the exterior of the condition to

the desired location at the EXTERIOR of the subsill. (The exterior of the subsill will be

flush with the rest of the system.) Do this at both ends of the condition. Snap a chalk

line between the two marks to align the subsill. If the condition is too wide for just two

marks, measure every 15 feet and snap a chalk line.

Step 6) Sealant Bed

Apply sealant to the subsill as shown in Figures 9 and 10. Place the subsill into the

rough opening, and rotate the exterior face down into position. Apply enough sealant

to ensure a complete seal as shown in

Figure 11.

CONDITION

[FIG. 9]

SUBSILL

2S44

SEALANT

SEALANT

SEALANT

SUBSILL

2S44

[FIG. 10]

SEALANT

SUBSILL

[FIG. 11]

SEALANT

SUBSILL

4471

2S44

SUBSILL

4471

June 2012 PART NO. Y017 Page 53 of 90

Page 54

y

T

p

Series 433 Triple Set Installation Instructions

SECTION VI: Subsill Fabrication and Installation

(Includes Offset and Center-Set Glazing)

Step 7) Subsill Anchor Installation

At a minimum, anchor at 6" from jambs and corners and 16" O.C. Staggering locations

from one side of thermal area to the other for 2S44 only

hese recommendations are for general erection procedures only. For actual job

conditions, see the details on the shop drawings. For perimeter anchor type and

s

acing, refer to the approved shop drawings or consult the project design professional.

For standard applications, utilize anchorage shown in Figure 12. If heavy-duty

anchorage is required, install standard anchors as shown, and refer to the location of

heav

.

(ANCHORING FASTENERS NOT SUPPLIE D BY EFCO )

[FIG. 12]

SUBSILL

2S44

-duty anchors as shown in Figures 14 through 18 on page 51.

SUBSILL

2S44

[FIG. 13]

SUBSILL

4471

SUBSILL

4471

June 2012 PART NO. Y017 Page 54 of 90

Page 55

T

p

Series 433 Triple Set Installation Instructions

SECTION VI: Subsill Fabrication and Installation

(Includes Offset and Center-Set Glazing)

Step 8) Heavy-Duty Anchor Installation

OUTSIDE SET GLASS

21/64"

7/8"

7/16"

K473

Install required vertical mullion

anchors as shown in Figures 14

through 18. Anchors should be

installed on the vertical mullions and

anchored thru the subsill after the

frame unit is installed in the

opening. HD anchors will not work

with 8349 or 8357 mullions.

SUBSILL

2S44

[FIG. 14]

23/64"

CENTER-SET GLASS

27/64"

27/64"

K473

3/16"

K992

K992

5/16"

[FIG. 15]

OFFSET MULLIONS CENTER-SET MULLIONS

1 1/8" ± 1/16" 1 1/8" ± 1/16"

K473

1 5/16"

29/64"

SUBSILL

2S44

3 5/16"

NOTE: K992 COMES WITH TWO ANGLE

BRACKETS AND TWO FASTENERS. K473

COMES WITH ONE ANGLE BRACKET AND

[FIG. 16] [FIG. 18]

1 1/8" ± 1/16"

hese recommendations are for general erection procedures only. For actual job

conditions, see the details on the shop drawings. For perimeter anchor type and

s

acing, refer to the approved shop drawings or consult the project design professional.

Do not use 4471 Subsill

with heavy duty anchors.

INSIDE SET GLASS

51/64"

SUBSILL

2S44

TWO FASTENERS.

K992

[FIG. 17]

7/8"

3 5/8"

June 2012 PART NO. Y017 Page 55 of 90

Page 56

Series 433 Triple Set Installation Instructions

SECTION VI: Subsill Fabrication and Installation

(Includes Offset and Center-Set Glazing)

Step 9) Subsill Anchor Seal

The subsill anchors must be sealed with a silicone type sealant. To ensure a good seal,

tool the sealant onto the fastener and surrounding metal. If HD anchors are used,

ensure that the anchor angle and fasteners are sealed also. This procedure should be

followed immediately after anchor installation so it is not forgotten.

Step 10) Subsill Perimeter Seal

The subsill interior should be sealed with a silicone type seala nt. Apply sealant and tool

the sealant to ensure a good seal. Clean off all excess sealant. At this time, use a

silicone type sealant to seal the thermal break area as shown in Figure 20. Tool the

sealants into the thermal break area, and ensure that sealant is smooth and flat with

the subsill surface. This procedure should be done prior to installation of the framing

system so it is not forgotten.

[FIG. 19]

SILICONE

TYPE

SEALANT

SILICONE TYPE SEALANT

[FIG. 20]

SUBSILL

2S44

SUBSILL

SUBSILL

2S44

SILICONE

TYPE

SEALANT

4471

SUBSILL

4471

SILICONE

TYPE

SEALANT

SILICONE

TYPE

SEALANT

June 2012 PART NO. Y017 Page 56 of 90

Page 57

Series 433 Triple Set Installation Instructions

SECTION VI: Subsill Fabrication and Installation

(Includes Offset and Center-Set Glazing)

Step 11) Subsill Splicing

Verify that the subsill has been installed according to the instructions on pages 45

through 52. Splice areas are to be centered at a vertical mullion only. Maximum subsill

length between splices is 20’ to 25’. If a splice is required, leave a 1/4" gap between

the subsill ends at the splice area. Install and anchor the next run of subsill. Use a

silicone type sealant and a strip of WM01, bond breaker tape 1 7/8", wide and

approximately 7 1/2" long to create the splice material. Apply silicone to both sides of

the subsill ends and fill the void between the subsills as shown in Figure 21. Ensure

that the bond breaker tape is centered over the 1/4" gap, and set the bond breaker

tape into the sealant. Tool the silicone over the bond breaker tape to create a

watertight seal. If more sealant is required to cover the bond breaker tape, apply the

required amount. Ensure that the splice joint does not interfere with the anchor legs of

the sill and subsill. Making sure that the splice joint is located at the center of the

vertical mullions does this. Refer to the shop drawings or architectural drawings for

mullion centerlines.

APPLY SILICONE TYPE SEALANT TO

CREATE A THIN BED TO SET THE

BOND BREAKER TAPE INTO.

[FIG. 21]

SUBSILL

2S44

FILL VOID BETWEEN

SUBSILLS WITH A SILICONE

TYPE SEALANT FROM THE

INTERIOR LEG TO THE BACK

OF THE EXTERIOR LEG.

AFTER INSTALLING THE BOND

BREAKER TAPE, TOOL THE

SEALANT OVER THE EDGE OF

THE TAPE TO PRODUCE A

WATERTIGHT SEAL.

AFTER THE SPLICE IS INSTALLED, APPLY A

COSMETIC SEAL TO THE INTERIOR GAP,

VERTICALLY UP THE SUBSILL SPLICE.

2S44 Shown

SUBSILL

4471 Similar

2S44

June 2012 PART NO. Y017 Page 57 of 90

Page 58

Series 433 Triple Set Installation Instructions

SECTION VI: Subsill Fabrication and Installation

(Includes Offset and Center-Set Glazing)

Step 12) Subsill Corner Miter and Splicing

When mitering the subsill for corner applications, cut the subsill material at the

appropriate angle required to form the correct corner. Install the subsill by follow ing

the previous subsill installation instructions. Once the subsill is installed and a tight

miter joint is achieved, use the instructions on page 53 for creating a splice joint seal.

Follow the instructions for sealing a standard splice joint except there should be no gap

between the ends of the mitered subsills. Ensure that the bond breaker tape and

sealant used to create the seal are smooth, so they do not interfere with the anchor

legs on the sill and subsill. If a 90° SSG mullion is used, the bond breaker tape should

be 1-1/2" wide because the corner mullion is 1-3/4" wide.

2S44 Shown

SUBSILL

4471 Similar

2S44

[FIG. 22]

June 2012 PART NO. Y017 Page 58 of 90

Page 59

Series 433 Triple Set Installation Instructions

SECTION VII: Corners

(Includes Offset and Center-Set Glazing)

Corner Identification and Assembly

Proper identification of the required corner members is necessary to ensure a timely

installation process. See details of each corner variation on pages 55 through 57 in

Figures 23 through 33.

23) 90° outside set corner 27) 135° outside set corner

24) 90° inside set corner 28) 135° inside set corner

25) 90° center-set corner 29) 135° center-set corner

26) 90° multiple glass plane corner 30) 135° multiple glass plane corner

31) 90° outside set SSG corner

Both inside and outside corners can be accommodated with these details.

Figures 32 and 33 on page 61 show typical inside corners.

Determine that the subsill has been installed according to the instructions lis ted on

pages 46-51. Ensure the adjacent ladders are built with the appropriat e mullion half to

be used with the corner mullion. Install the corner member into the subsill. It may be

necessary to temporarily brace the vertical corner member until the adjacent ladders

are installed and anchored. Install and snap one corner ladder completely, and then

install and snap the other onto the corner mullion.

If door openings are required on a run that incorporates a corner member, begin at the

doorframe and assemble towards the corner area with the required ladders.

Unassembled corner extrusions must be attached to the ladders, and the corner

member must be assembled after installation of both adjacent ladders.

[FIG. 23] [FIG. 24]

June 2012 PART NO. Y017 Page 59 of 90

Page 60

Series 433 Triple Set Installation Instructions

SECTION VII: Corners

(Includes Offset and Center-Set Glazing)

[FIG. 25]

[FIG. 27]

NOTE: Figure 26 shows Inside and Outside

set verticals. You can create a multi-plane

configuration by using any of the vertical

mullions shown in figures 23, 24 and 25.

NOTE: Figure 26 can be

accommodated by using vertical

mullions from Figures 23, 24, and 25

in any combination.

[FIG. 26]

[FIG. 28]

June 2012 PART NO. Y017 Page 60 of 90

Page 61

Series 433 Triple Set Installation Instructions

SECTION VII: Corners

(Includes Offset and Center-Set Glazing)

[FIG. 29] [FIG. 30]

[FIG. 32] [FIG. 33]

[FIG. 31]

NOTE: Figure 30 can be

NOTE: Figure 30 shows Inside

accommodated by using vertical

and Outside set verticals. You

mullions from Figures 27, 28, and 29

in any combination.

can create a multi-plane

configuration by using any of

the vertical mullions shown in

figures 27, 28 and 29.

NOTE: Figures 32 and 33 show the typical use

of corner mullions as inside corners. All glass

planes can be accommodated in both inside

and outside corners.

June 2012 PART NO. Y017 Page 61 of 90

Page 62

Series 433 Triple Set Installation Instructions

SECTION VIII: Installation

(Includes Offset and Center-Set Glazing)

Step 1) Sealing the Sill onto the Subsill

Apply a silicone type sealant to the subsill in the location shown in Figure 34 before

installing the first ladder. Make sure that enough se alant is applied to seal the areas

shown in Figure 35. After installing the ladder and anchoring it, clean off all excess

sealant from exposed areas. Do not allow sealant to cure before placing the system

frames. It will interfere with the sill to subsill engagement.

SEALANT

2S44 SHOWN

4471 SIMILAR

[FIG. 34]

8362 SHOWN

8375 SIMILAR

SEALANT

2S44 SHOWN

4471 SIMILAR

[FIG. 35]

June 2012 PART NO. Y017 Page 62 of 90

Page 63

Series 433 Triple Set Installation Instructions

SECTION VIII: Installation

(Includes Offset and Center-Set Glazing)

Step 2) Installing Jamb Side Ladder

Place the ladder on the subsill at an approximate 30° angle. While applying pressure

upward, rotate the ladder into the condition. See Figure 35 on page 58 for sill

placement into the subsill. When rotated correctly, the exterior face of the sill should

be flush with the exterior face of the subsill.

CONDITION

LADDER

[FIG. 36]

CONDITION

2S44

SUBSILL

LADDER

[FIG. 37]

June 2012 PART NO. Y017 Page 63 of 90

Page 64

Series 433 Triple Set Installation Instructions

SECTION VIII: Installation

(Includes Offset and Center-Set Glazing)

Step 3) Anchoring the Head

For D.L.O.s 36" and narrower, the anchors must be spaced 6" from the jamb or

vertical members. For D.L.O.s 36" and wider, the outside anchors must be spaced 6"

from the jamb with the center anchor centered on the D.L.O. See Figure 38 below.

These recommendations are for general erection procedures only. For actual

job conditions, see the details on the shop drawings. For perimeter anchor

type and spacing, refer to the approved shop drawings or consult the project

design professional.

June 2012 PART NO. Y017 Page 64 of 90

6" "VARIES"

FD

LESS THAN OR EQUAL 36"

8363 SHOWN

8393 SIMILAR

1 1/8"

REF.

1 3/16"

REF.

EQUAL

6"

FD

6"

FD

GREATER THAN 36"

FD

EQUAL

6"

FD

[FIG. 38]

8372

2 11/16" REF.

8366

3 5/16" REF.

4G29

3G46

2 11/16" REF.

Page 65

gn p

Series 433 Triple Set Installation Instructions

SECTION VIII: Installation

(Includes Offset and Center-Set Glazing)

Step 4) Anchoring the Jambs

Anchors must be spaced 6" from the sill or head, and 24" O.C. ± 4", so they do not

interfere with the horizontal members. See Figure 42. Regardless of glass pocket

configuration, the anchors should be placed so they do not fasten through the thermal

area. See Figures 43 through 46.

These recommendations are for general erection procedures only. For actual

job conditions, see the details on the shop drawings. For perimeter anchor

type and spacing, refer to the approved shop drawings or consult the project

desi

24" ± 4"

24" ± 4"

24" ± 4"

rofessional.

6"

6"

[FIG. 42]

8439 SYM.

8349

[FIG. 43]

8356

[FIG. 45]

1 7/16"

REF

8359

1 7/8"

REF

8359

[FIG. 44]

8361

LB90

[FIG. 46]

8356

1 7/16"

REF

2"

REF

June 2012 PART NO. Y017 Page 65 of 90

Page 66

Series 433 Triple Set Installation Instructions

SECTION VIII: Installation

(Includes Offset and Center-Set Glazing)

Step 5) Sealing Vertical Mullions

Prior to installing an intermediate vertical mullion or perimeter jamb, apply silicone type

sealant to the vertical mullion in the location shown in Figure 47 below at the Interior

joints only. Apply sealant where indicated 6-8 inch es up from the bottom of the vertical

joints. Apply enough sealant so when the filler or opposite mullion half is snapped, it

will create a good seal. Wipe off excess sealant from the exposed Interior of the frame.

This sealant practice should be followed for all variations of vertical mullions including

corners and perimeter jambs, except where a perimeter mullion uses vinyl filler. See

Figures 48 through 54.

SEAL

[FIG. 47]

8352

[FIG. 48] [FIG. 49] [FIG. 50]

SEAL

8353

SEAL

8360

SNAP

EXCESS

CLEAN

SEAL

8358

8361

8355

June 2012 PART NO. Y017 Page 66 of 90

Page 67

Series 433 Triple Set Installation Instructions

SECTION VIII: Installation

(Includes Offset and Center-Set Glazing)

SEAL

8356

[FIG. 53]

8354

8359

8356

[FIG. 51]

SEAL

[FIG. 52]

8356 SHOWN IN CORNER

MULLIONS, OTHERS SIMILAR.

8380

Seal Vertical 6”-8” from the bottom up.

8356

8356

8354

SEAL

8381

[FIG. 54]

SEAL

8356

June 2012 PART NO. Y017 Page 67 of 90

Page 68

R

R

R

Series 433 Triple Set Installation Instructions

SECTION VIII: Installation

(Includes Offset and Center-Set Glazing)

Step 6) Installing the Second Ladder

Make sure that the anchors are installed into the head and jamb of the first ladder.

Apply the sealant as specified in Figures 47 through 54 on pages 66 and 67. Apply

sealant to the subsill as shown on page 40. Place the second ladder on the subsill at an

approximate 30° angle. Rotate the ladder into the condition approximately 1/4" away

from the previously installed ladder.

[FIG. 55]

8359 SHOWN

OTHERS SIMILAR

[FIG. 56]

8356 SHOWN

OTHERS SIMILA

CONDITION

SECOND

LADDE

CONDITION

[FIG. 57]

SECOND

LADDE

June 2012 PART NO. Y017 Page 68 of 90

Page 69

R

R

Series 433 Triple Set Installation Instructions

SECTION VIII: Installation

(Includes Offset and Center-Set Glazing)

Step 7) Snapping Vertical Mullions Together

To snap vertical mullions together, line up the mullion halves once the 1/4" gap is

achieved between the mullion halves. See Figure 56 on page 64. Place one clamp at

the bottom of the mullions using wood blocks to protect the extrusions. Tighten the

clamp until the mullion halves begin to snap together. Place another set of wood

blocks and a clamp at the middle of the mullions and tighten it. Then repeat the same

process on the top. Tighten the clamps until the mullion halves are pressed together.

The sight line should be 2". It may be necessary to work from one clamp to the next

several times, or move the clamps, to ensure the mullions are snapped together evenly.

See Figure 59. DO NOT try to hammer the mullion halves together! This will dent,

bend, scratch, or deform the mullions and may cause them to leak. Ensure that the

previous ladder is anchored using the requirements on page 60 before installing the

2nd ladder.

[FIG. 58]

C-CLAMP

OR SIMILA

WOOD BLOCK

8358/8355 SHOWN,

OTHERS SIMILA

8358

8355

2" REF.

[FIG. 59]

June 2012 PART NO. Y017 Page 69 of 90

Page 70

Series 433 Triple Set Installation Instructions

SECTION VIII: Installation

(Includes Offset and Center-Set Glazing)

Step 8) Snapping the Expansion Mullion (Offset Mullion)

To snap the expansion mullion together, line up the mullion halves and gaskets. See

Figure 60. Place one clamp at the bottom of the expansion mullion using wood blocks

to protect the extrusions. Tighten the C-clamp until the expansion mullion halves begin

to snap together. Place another set of wood blocks and a C-clamp at the middle of the

expansion mullion and tighten it. Then repeat the same process on the top. Tighten

the C-clamps until the sight line becomes 2 1/4". It may be necessary to work from one

clamp to the next several times, or move the clamps to ensure the mullions are

snapped together evenly. See Figure 61. DO NOT try to hammer the expansion

mullion together! This will dent, bend, scratch, or deform the expansion mullion and

may cause it to leak. Anchor the head using the requirements shown on page 64

before installing the next ladder. If this is the last ladder, anchor the jambs as required

on page 65 and proceed to the perimeter sealing process, Step 11 on page 72.

C-CLAMP

OR SIMILAR

8394

8395

WOOD BLOCK

8394

8395

2.250"

[FIG. 60]

[FIG. 61]

June 2012 PART NO. Y017 Page 70 of 90

Page 71

Series 433 Triple Set Installation Instructions

SECTION VIII: Installation

(Includes Offset and Center-Set Glazing)

Step 9) Snapping the Expansion Mullion (Center-Set Mullion)

To snap the expansion mullion together, line up the mullion halves and gaskets. See

Figure 62. Place one clamp at the bottom of the expansion mullion using wood blocks

to protect the extrusions. Tighten the C-clamp until the expansion mullion halves begin

to snap together. Place another set of wood blocks and a C-clamp at the middle of the

expansion mullion and tighten it. Then repeat the same process on the top. Tighten

the C-clamps until the sight line becomes 2". It may be necessary to work from one

clamp to the next several times, or move the clamps, to ensure the mullions are

snapped together evenly. See Figure 63. DO NOT try to hammer the expansion

mullion together! This will dent, bend, scratch, or deform the expansion mullion and

may cause it to leak. Anchor the head using the requirements shown on page 64

before installing the next ladder. If this is the last ladder, anchor the jambs as required

on page 65 and proceed to the perimeter sealing process, Step 11 on page 72.

8396

[FIG. 62]

8397

WOOD BLOCK

C-CLAMP

OR SIMILAR

8396

[FIG. 63]

8397

2.000"

June 2012 PART NO. Y017 Page 71 of 90

Page 72

Series 433 Triple Set Installation Instructions

SECTION VIII: Installation

(Includes Offset and Center-Set Glazing)

Step 10) Anchoring the Second Ladder

After the mullion halves are snapped correctly, ensure that the mullions are plumb and

true and anchor the head as shown in Figure 38 on page 64. If this is the last ladder in

a run, ensure that the mullion halves are snapped correctly and install the required

shims between the jamb and condition. Install the head and jamb anchors. Ensure

that the jamb anchors do not separate the last ladder from the previous. It may be

necessary to shim tightly against the condition to prevent this.

Step 11) Perimeter Seal

When the unit is installed and anchored, begin placing caulk rope into the gap between

the perimeter and the frame. Apply a generous amount of silicone type sealant to the

gap between the frame and rough opening. Tool off all excess sealant to ensure a

good seal and to achieve an appropriate appearance. See Figures 64 through 68

below.

4 ½” HEADS

SIMILAR

8366

LB77

LB77

8372

8363 SHOWN

8393 SIMILAR

[FIG. 65]

[FIG. 66]

[FIG. 64]

[FIG. 67] [FIG. 68]

8356

8359

LB90

8359 SYM.

8361

June 2012 PART NO. Y017 Page 72 of 90

Page 73

Series 433 Triple Set Installation Instructions

SECTION IX: Glazing

(Includes Offset and Center-Set Glazing)

IDENTIFICATION OF GLASS POCKETS AND SETTING BLOCKS

INSIDE GLAZED HORIZONTALS

HN92

INSIDE GLAZED SILLS

[FIG. 69]

8363

8365

[FIG. 70]

8366

8364

[FIG. 71]

8372

Customer / Installer Note:

EFCO setting blocks are typically 4" in length with

different depths. If the glazing infill is "NOT BY EFCO"

and glazing sizes are larger than 40 square feet, then

the glazing details must be reviewed by the glazing

manufacturer for proper setting block size.

8367

HN92

8368

HN92

HN32

[FIG. 73]

[FIG. 74]

8375

[FIG. 72]

8362

HN32

8362

HN32

4 ½” SILLS &

HORIZONTALS

SIMILAR

June 2012 PART NO. Y017 Page 73 of 90

Page 74

Series 433 Triple Set Installation Instructions

SECTION IX: Glazing

(Includes Offset and Center-Set Glazing)

IDENTIFICATION OF GLASS POCKETS AND SETTING BLOCKS

OUTSIDE GLAZED HORIZONTALS

[FIG. 75]

8363

8365

HN92

[FIG. 76]

8367

8364

HN92

[FIG. 77]

8368

HN92

[FIG. 78] [FIG. 82]

8386

8365

Customer / Installer Note:

EFCO setting blocks are typically 4" in length with

different depths. If the glazing infill is "NOT BY EFCO"

and glazing sizes are larger than 40 square feet, then

the glazing details must be reviewed by the glazing

manufacturer for proper setting block size.

HN92

8366

8372

8385

8382

OUTSIDE GLAZED SILLS

[FIG. 79]

8362

HN32

HN32

HN32

[FIG. 80]

8362

[FIG. 81]

8384

4 ½” SILLS &

HORIZONTALS

SIMILAR

HN32

8375

June 2012 PART NO. Y017 Page 74 of 90

Page 75

Series 433 Triple Set Installation Instructions

SECTION IX: Glazing

(Includes Offset and Center-Set Glazing)

Step 1) Identification of Glass Pockets

INSIDE AND OUTSIDE GLAZED VERTICALS

Ensure that each vertical DLO has at least one DEEP glass pocket on either side. It is

necessary for the glazing installation that a deep pocket be used to load the glazing

units. These details are shown with the deep glazing pockets shown right justified for

viewing clarity.

[FIG. 83]

[FIG. 88] [FIG. 89] [FIG. 90]

[FIG. 84]

[FIG. 85] [FIG. 86]

DEEP

SHALLOW

[FIG. 87]

8352

8349

8353

8354

8354

8439

8359

DEEP

SHALLOW

DEEP DEEP

SHALLOW

DEEP

8356

DEEP

8357

8361

8355

8358

[FIG. 91] [FIG. 92]

8396

8397

8394

8360

DEEP DEEP DEEP DEEP DEEP