Page 1

Series 406 storefront

Installation Instructions

Part NO. Y016

February 2013

Page 2

SECTION

TABLE OF CONTENTS

I GENERAL NOTES

II PARTS IDENTIFICATION

III FABRICATION

A) SCREW SPLINE FABRICATION

1) TEMPLATE for SCREW SPLINE

2) DJ17 DRILL GUIDE

B) SHEAR BLOCKS at SCREW SPLINE DOOR JAMB

1) TEMPLATE for SHEAR BLOCKS

2) DJ16 DRILL GUIDE

3) TEMPLATE for TRANSOM BAR SHEAR BLOCK (K978)

4) TEMPLATE for TRANSOM BAR w/ C.O.C. SHEAR BLOCK (K996)

5) DJ16 DRILL GUIDE for TRANSOM BAR SHEAR BLOCK

6) DJ16 DRILL GUIDE for TRANSOM BAR w/ C.O.C. SHEAR BLOCK

C) SHEAR BLOCK FABRICATION - FRAMES

1) DJ18 DRILL GUIDE at INTERMEDIATE HORIZONTAL

2) DJ18 DRILL GUIDE at TRANSOM HEAD

D) SNAP-IN GLAZING POCKET & SCREW APPLIED GLAZING

1) SNAP-IN GLAZING POCKET END PREP

2) SCREW APPLIED GLAZING END PREPS

IV ASSEMBLY & INSTALLATION

A) DOOR FRAME ASSEMBLY

B) DOOR FRAME INSTALLATION

C) SILL FLASHING INSTALLATION

D) SCREW SPLINE FRAMES & SIDE LITE TO DOOR JAMB ASSEMBLY

E) WATER DEFLECTOR INSTALLATION

PAGE 1

PAGE 2-3

PAGE 4

PAGE 5

PAGE 6

PAGE 7

PAGE 8

PAGE 9

PAGE 10

PAGE 11

PAGE 12

PAGE 13

PAGE 14

PAGE 15

PAGE 16

PAGE 16

PAGE 17-22

PAGE 23-24

PAGE 25-29

PAGE 30-31

PAGE 32

V GLAZING

A) GLASS SIZE FORMULAS

B) GLASS INSTALLATION

C) ANTIWALK BLOCK INSTALLATION

NOTE: Please reference EFCO's "Understanding Condensation" brochure which can be obtained through your EFCO representative.

Condensation will form on any surface when unfavorable conditions (interior temperature and relative humidity and exterior

temperature) are present. When the formation of excessive condensation is a concern, it is highly recommended that a design

professional is utilized to perform an analysis of the shop drawings to recommend the best installation methods. Please contact

EFCO representative for information on EFCO's Thermal Analysis Services.

Many current installation practices lead to an increase in the possibility of the formation of condensation. Though not all

inclusive, the list of examples below illustrates conditions under which condensation is likely to occur:

1. Bridging system thermal break with non-thermally broken metal flashing or lintels that are exposed to the

exterior.

2. System exposure to cold air cavities.

3. Interior relative humidity levels not maintained at recommended levels, see EFCO's "Understanding

Condensation" brochure.

4. Inadequate separation between system and surrounding condition at perimeter.

5. Product combinations during the shop drawing stage that result in bridging thermal breaks of one or all products

involved.

PAGE 33

PAGE 34-37

PAGE 38-39

Minimizing Conden sation

Page 3

SECTION I - GENERAL NOTES

SERIES 406

2" x 6 1/2" - 1" GLAZING (THERMAL)

Check shop drawings, installation instructions, and glazing instructions

1)

to become thoroughly familiar with the project. The shop drawings

take precedence for extrusions and details on the project.

THESE INSTALLATION INSTRUCTIONS ARE OF A GENERAL NATURE

AND COVER THE MOST COMMON CONDITIONS AND SITUATIONS.

REFERENCE THE STANDARD STOREFRONT INSTALLATION INSTRUCTIONS

FOR COVERAGE OF ITEMS COMMON TO STOREFRONT SYSTEMS.

2)

Check all of the materials upon arrival and be sure you have

everything required to begin installation.

PAGE 1

See Section II "PARTS IDENTIFICATION", also particular parts from

the standard 403 - 2" x 4 1/2" can be used with this deep system.

All work should start from bench marks and/or column center lines

3)

as established by the architectural drawings and the general contractor.

Check construction for compliance with the contract documents.

4)

NOTE:

Sealants must be compatible with all surfaces. Consult with the sealant

manufacturer for recommendations regarding compatibility and adhesion.

5)

All materials are to be installed plumb, level, and true.

Protect materials after erection. Cement, plaster, alkaline solutions,

6)

and acid based materials can be harmful to the finish.

Masonry runoff may leach harmful acids onto the storefront.

This situation must also be taken into consideration at installation.

7)

Clean aluminum surfaces with a mild detergent and water. No

abrasive agent shall be used.

REFERENCE THESE OTHER MANUALS:

STOREFRONT INSTALLATION INSTRUCTIONS

SYSTEMS 401, 402, and 403

DORMA RTS 88 CONCEALED OVERHEAD CLOSERS

INTERNATIONAL 200 CONCEALED OVERHEAD CLOSERS

DOOR, DOOR GLASS, and HARDWARE

406 STOREFRONT

Y001

Y013

Y014

Y015

DPS 12/2002

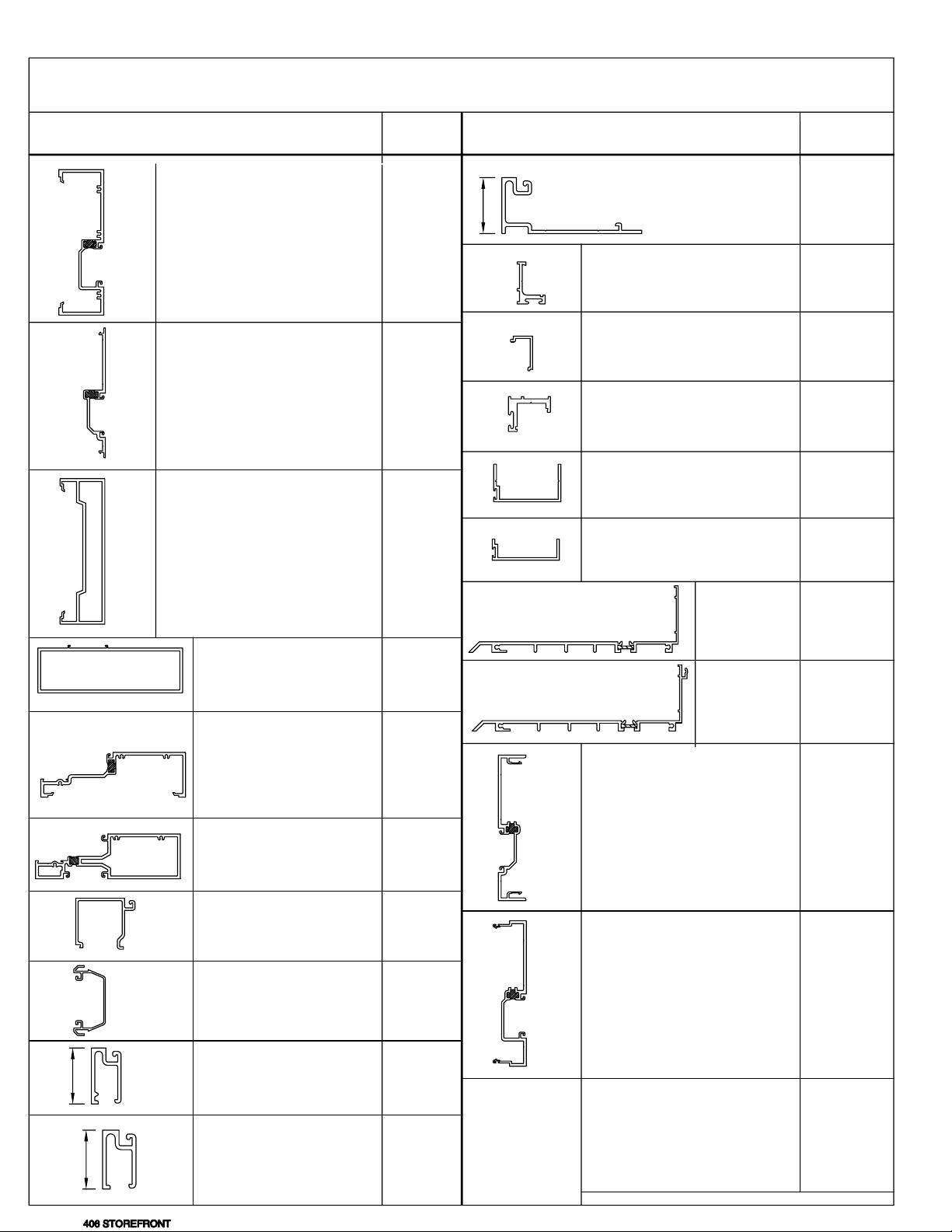

Page 4

PAGE 2

SECTION II

DESCRIPTION

HEAD or JAMB

2" X 6 1/2" DEEP

USE w/ 9358

VERTICAL/HORIZONTAL

GLAZING ADAPTOR

2" X 6 1/2" DEEP

USE WITH

9357, 9359, & 8402

SCREW SPLINE

DOOR JAMB

2" X 6 1/2" DEEP

USE w/ 9358

COC TRANSOM BAR

2" X 6 1/2" DEEP

USE 9123 STOPS

2 pc. OPEN BACK

HORIZONTAL / SILL

2" X 6 1/2" DEEP

USE w/ 9358, USE 9229 STOP

(SHEAR BLOCKS

APPLICABLE AT SILL ONLY)

TUBULAR HORIZONTAL

2" X 6 1/2" DEEP

USE 9229 STOP

PARTS IDENTIFICA TION.

PART

NO.

1"

9359

9358

8402

8400

9357

8401

DESCRIPTION

APPLIED FIXED SASH

USED w/ 9133 STOP

FOR TRANSOM LITES OVER 4 FT.

AT JAMBS

SCREW APPLIED

JAMB DOOR S TOP

USE w/ 9155 & W138

SCREW APPLIED

DOOR STOP COVER

USE w/ 9154 & W138

5/8" DOOR STOP

AT HEADER

USE w/ 9155 & W138

C.O.C. DOOR STOP

AT HEADER

USE W138 WEATHERING

LCN C.O.C. DOOR STOP

AT HEADER

USE W138 WEATHERING

STD. SILL

FLASHING

SILL

FLASHING

WITH

STOOL CLI P

MALE EXPANSION

MULLION HALF

USE w/ 4461

PART

NO.

9250

9154

9155

4437

9914

9933

1G83

1G86

4462

15

HORIZONTAL GLAZING

STOP, USE WITH

9357 & 8401

TRANSOM JAMB

GLAZING POCKE T

w/ 8402 JAMB

48" CUT OUT MAX .

TRANSOM BAR

1"

"

/

16

GLAZING STOP

1" GLAZING

USE w/ 8400

REMOVABLE STOP

USE w/ 9250 fo r

1" APPLIED GLAZING

FOR TRANSOM LITES OVER

4' AT JAMBS

9229

8403

9123

9133

FEMALE EXPANSION

MULLION HALF

USE w/ 4462

PARTS ON THIS PAGE ARE NOT TO SCALE

4461

MDM 04/2006

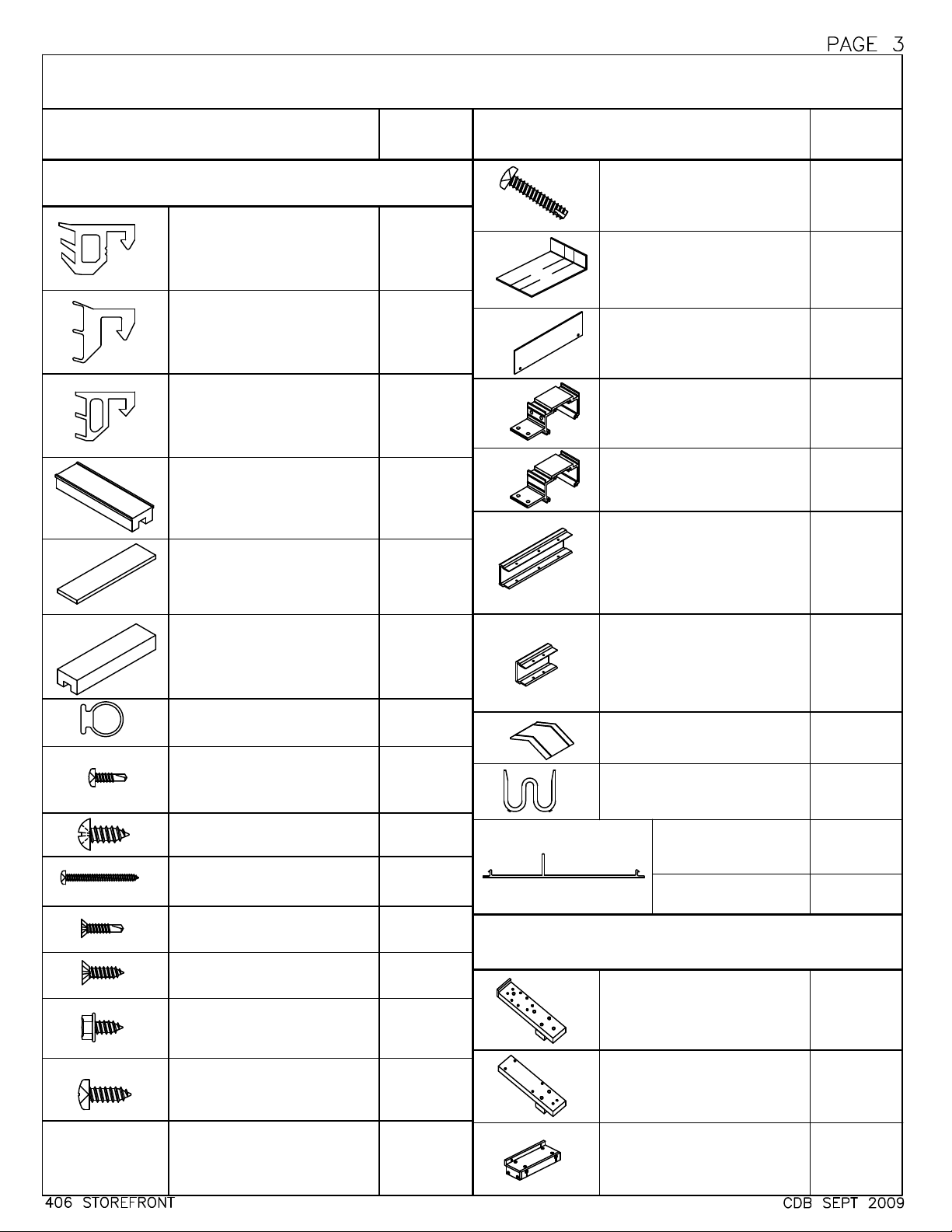

Page 5

SECTION II

DESCRIPTION

PARTS IDENTIFICATION

PART

NO.

DESCRIPTION

cont.

PART

NO.

ACCESSORIES

GLAZING GASKET for

UNDERSIZED GLASS

3/4" INFILL @ 1" POCKET

GLAZING GASKET for

OVERSIZED GLASS

1 1/8" INFILL @ 1" POCKET

STANDARD GLAZING

GASKET

1" INFILL @ 1" POCKET

EXTERIOR GLAZED

SETTING BLOCK

at SILL & HORIZ.

USE w/ 9357 & 8401

INTERIOR GLAZED

SETTING BLOCK

at HORIZ. INTERMEDIATE

USE w/ 8401

TRANSOM BAR

SETTING BLOCK

1" GLAZING

USE w/ 8400

STANDARD WEATHER

SEAL @ DOOR STOPS

APPLIED DOOR STOP

ATTACHMENT SCREW

USE w/ 9154 & 9155

HORIZ. to

SHEAR BLOCK

SHEAR BLOCK

to VERT.

DOOR HEAD ER

TO SHEAR BLOCK

TRANSOM HEAD

TO SHEAR BLOCK

TRANSOM BAR

SHEAR BLOCK

to VERT.

SILL FLASHING

END CAP

ATTACHMENT SCREW

W165

W166

W164

HN32

HN92

HNA3

W138

STT6

STB9

S100

STK4

S101

STV2

STC7

FRAME SPLINE

ATTACHMENT SCREW

#10 x 1" SL-HW-SMS

SILL FLASHING

SPLICE JOINT PKG.

USE WITH 1G83 & 1G86

(1) FV34, (1) WM96

SILL FLASHING

END CAP PKG.

USE WITH 1G83 & 1G86

(1) FV35, (2) SFP6

HEAD & HORIZONTAL

SHEAR BLOCK PKG.

USE w/ 9359 & 8401

(1) FV 36,(2 ) STB9 , (4) S100, (2) S101

SILL SHEAR BLOCK PKG.

USE w/ 9357

(1) FU49, (1) STB9, (4) S100

TRANSOM BAR

SHEAR BLOCK PKG.

OPP. COC @ SINGLE DR

USE w/ 8400

(1) FV33, (3) STV2, (4) STK4

TRANSOM BAR

SHEAR BLOCK PKG.

USE W/ COC 'F' CLIP or FT16

ANGLE CLIP at CLOSER END

(1) FU31, (2) STV2, (4) STK4

WATER DEFL ECTOR @

INT. HORIZONTAL

5/8" ANTIWALK BLOCK

at DEEP POCKET ONLY

PLASTIC

CAULK BACKER

10 FT. LENGTHS

3" CUT LENGTHS

USED AT FASTENERS

S129

K979

K980

K977

KN65

K978

K996

HWD1

HN52

LB78

FV16

SYSTEM DRILL JIGS

SHEAR BLOCK

DRILL JIG

SCREW SPLINE

DRILL JIG

SHEAR BLOCK

DRILL FIXTURE

(HORIZONTALS to

SHEAR BLOCKS)

DJ16

DJ17

DJ18

Page 6

PAGE 4

SECTION III FABRICATION

A - SCREW SPLINE FABRICATION

The screw spline system is a fabrication and erection method that

permits the preassembly of single units in the shop or at the job site.

These units are then erected by mating the male mullion with the

female mullion counterpart.

When an entrance is required, screw spline joinery may be used with

the screw spline door jambs only.

NOTE)

STEP 1)

NOTE: Allow minimum 1/2" shim and caulk space around the perimeter.

NOTE: Allow extra clearances, if necessary, to accommodate building

NOTE: Consult A.D.A. requirements to verify compliance.

STEP 2)

NOTE: Verticals must run through.

NOTE: The screw spline door jamb runs to the floor and is cut longer

DUE TO THE SCREW TENSIONS REQUIRED FOR CORRECT

INSTALLATION, IT IS NECESSARY TO 'WAX' THE FRAME

ASSEMBLY SCREWS TO PREVENT GALLING AND BREAKAGE.

MEASURE THE OPENING TO DETERMINE THE CUT LENGTH

OF THE FRAME COMPONENTS.

tolerances and building movement.

CUT THE VERTICALS TO FRAME SIZE.

If the opening has an entrance, see the appropriate frame and

door fabrication installation sheets.

than other verticals. The glazing adaptor will be cut to the

STEP 3)

NOTE: Drill jigs are available.

STEP 4)

406 STOREFRONT

standard jamb and vertical intermediate length.

DRILL THE HOLES FOR ASSEMBLY SCREWS ON

VERTICAL MEMBERS. (See Fig. # 1 page 5).

See page 3 of the parts identification section.

CUT THE HORIZONTAL MEMBERS TO DAY LITE OPENINGS.

(BETWEEN VERTICAL MULLIONS)

CUT THE HORIZONTAL GLASS STOPS TO DAYLITE OPENINGS

MINUS 1/32". (D.L.O. - 1/32")

MDM 04/2008

Page 7

2 PC.

VERTICAL

SECTION III FABRICATION

A - SCREW SPLINE FABRICATION

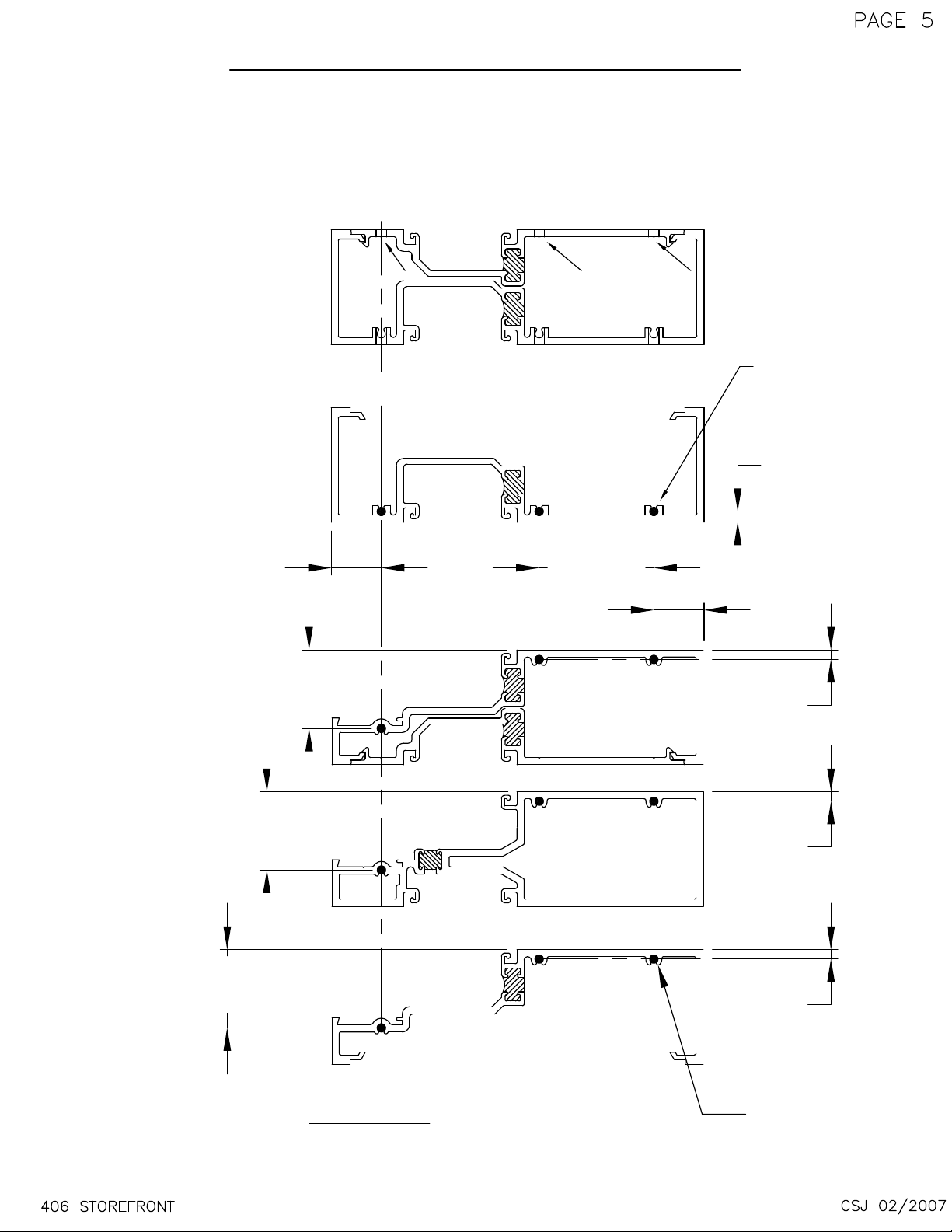

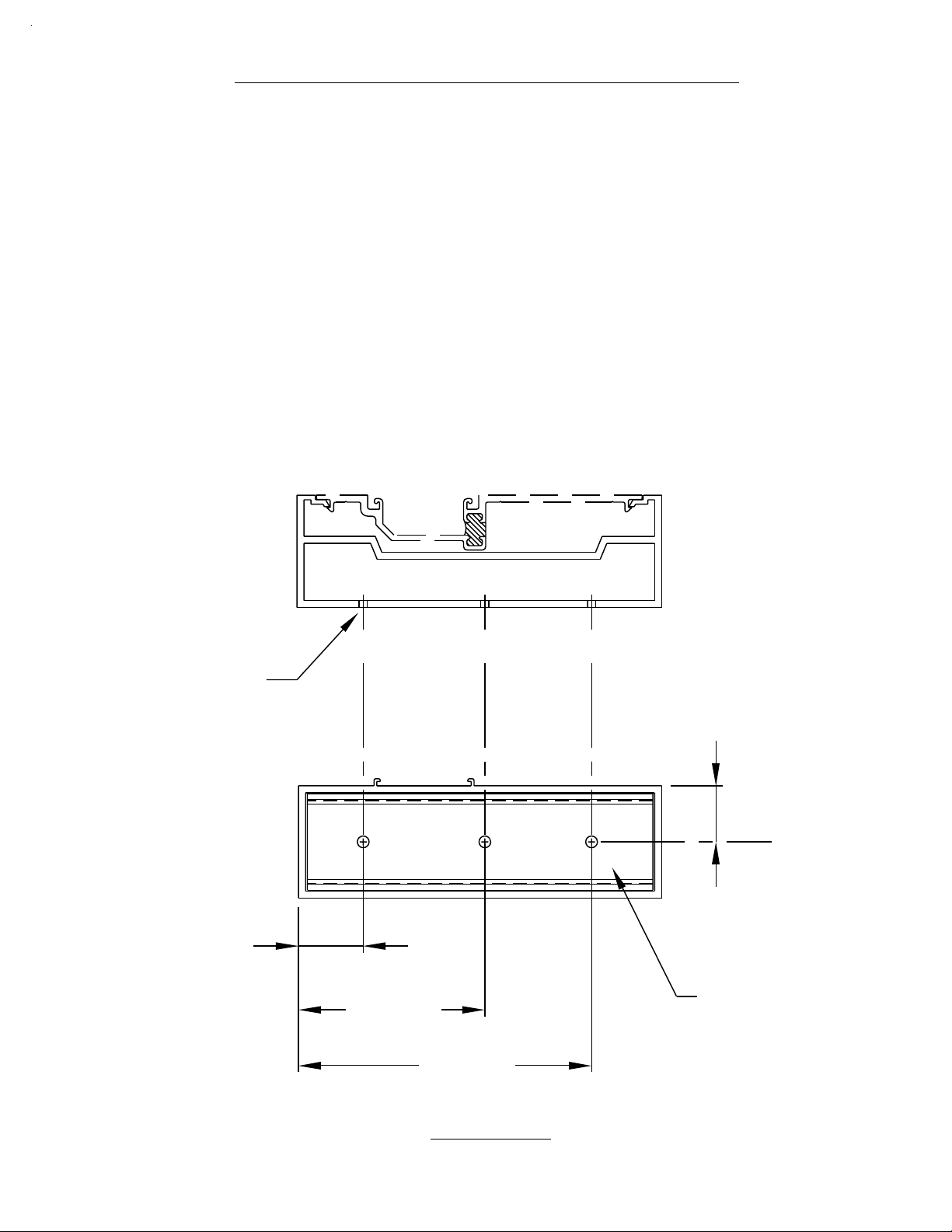

1) TEMPLATE FOR O. G. SCREW SPLINE

( INVERT FOR I NSIDE GLAZE )

9358

9359

# 7 Drill (.201 dia.)

C

C

L

L

C

L

(3) PLACES TYP.

S129 FASTENERS

(CONT.)

O.G. HEAD

2 PC.

O.G. HORIZONTAL

TUBULAR

O.G. HORIZONTAL

I.G. SILL

.875

I.G. HORIZONTAL

1.367

I.G. HORIZONTAL

1.367

9359

2.000

9357

9358

8401

.188

HEAD

ONLY

.875

.168

.168

9357

1.367

O.G. SILL

I.G. HEAD

FIG. # 1

USE BLOCKED OUT HOLE LOCATIONS FOR O.G. SCREW SPLINE APPLICATIONS

INVERT PATTERN FOR INSIDE GLAZE APPLICATIONS

DRILL JIGS ARE ALSO AVAILABLE

.168

#7 Drill (.201 dia.)

(3) PLACES TYP.

S129 FASTENERS

Page 8

SECTION III FABRICATION

A - SCREW SPLINE FABRICATION

2) DJ17 DRILL GUIDE

FOR SCREW SPLINE APPLICATI O N

NOTE: The drill jig is reversible

for left and right positions.

(CONT.)

Use the top edge of the

drill guide to locate the

hole pattern for the screw

2"

6

0

4

F

Insert this lug into the glazing

pocket, then drill the screw

spline assembly holes as

indicated.

splines.

# 7 Drill (.201 dia.),

(3) holes are located

per horizontal end.

Refer to the horizontal

extrusion being used to

determine the correct holes

to drill for the application

at head, intermediate,

or sill.

2"

TYP. VERTICAL

FIG. #2

TOP OF HORIZONTAL

R

O

LO

F

D

HE

S

NI

I

F

O

T

Page 9

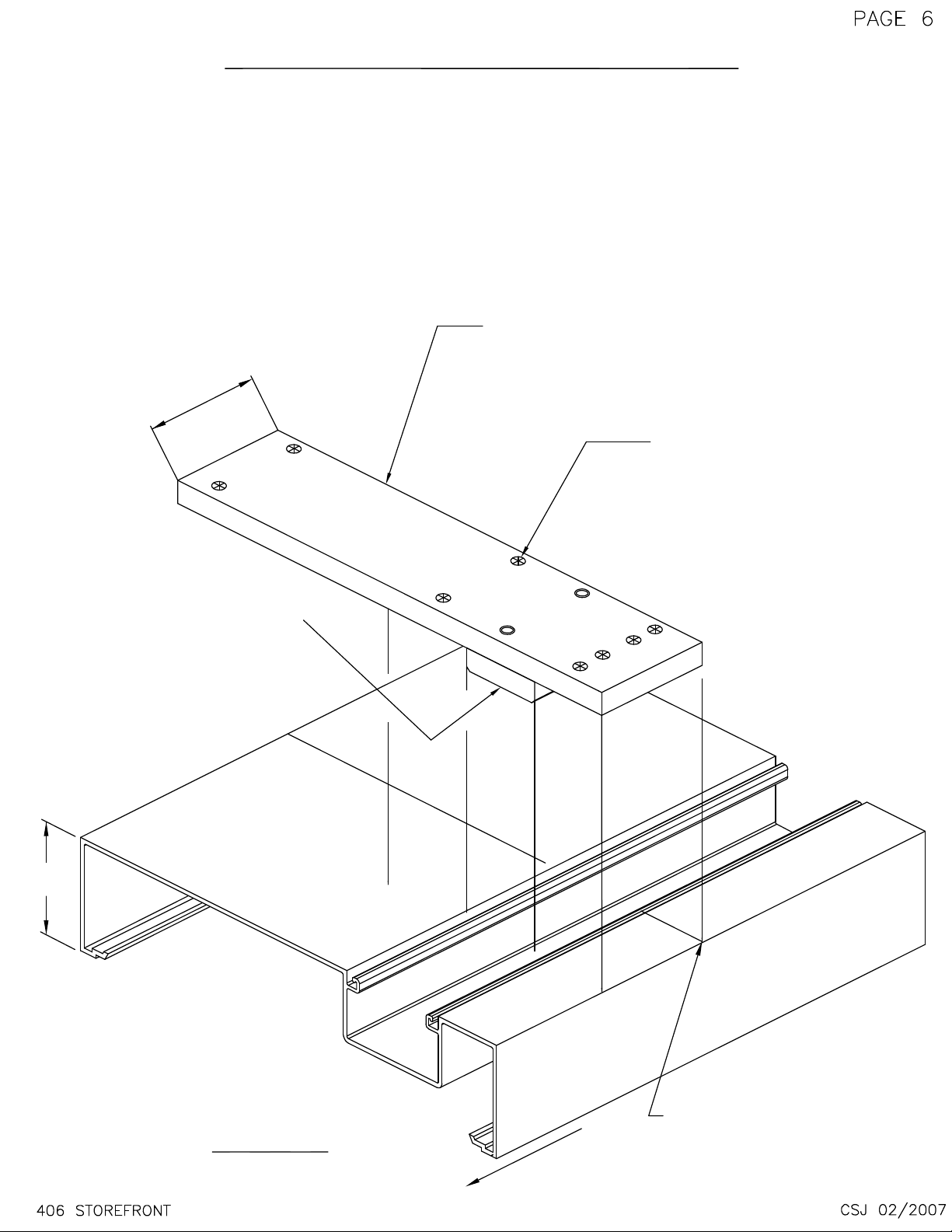

PAGE 7

SECTION III FABRICATION

B - SHEAR BLOCKS AT SCREW

SPLINE DOOR JAMB

Because the screw spline door jamb is actually a tubular member,

it will be necessary to shear block the transom bar, the transom

head, and any intermediate horizontal that is being incorporated in

the transom area.

STEP 1)

NOTE: Consult A.D.A. requirements to verify door opening

STEP 2)

NOTE: Door jambs run to the floor and are cut longer than other

STEP 3)

MEASURE THE OPENINGS AND SUBTRACT THE VERTICAL

MEMBER'S SIGHT LINES TO DETERMINE THE HORIZONTAL

FRAME CUT LE NGTHS.

Horizontals and transom bar cut length = D.L.O.

Horizontal glass stop cut length = D.L.O. - 1/32".

Transom bar glass stop cut length = D.L.O. - 25/32"

width compliance.

CUT THE DOOR JAMBS T O RO UG H OP EN I N G MINUS 1/4".

verticals.

DRILL TH E HO L E S F O R T H E SHEAR BLOCK S C REWS ON

THE DOOR JAMBS AS SHOWN ON PAGES 8 THROUGH 13.

STEP 4)

NOTE: Drill jigs are available.

STEP 5)

406 STOREFRONT

PROCEED TO SECTION III C FOR HORIZONTAL TO SHEAR

BLOCK PREPS, AS SH OWN ON PAGES 14 AND 15.

(See page 3 of the parts identification section.

PLEASE REFER TO DOOR, DOOR GLASS, AND

HARDWARE MANUAL (PART #Y01 5), FOR THE DOOR

HINGING PREPS, STRIKE PREPS, AND THRESHOLD PREPS.

THESE PREPS SHOULD BE DONE TO THE DOOR JAMBS

AT THIS TIME FOR EASE OF ASSEMBLY.

CSJ 12/2006

Page 10

SECTION III FABRICATION

PAGE 8

B - SHEAR BLOCKS AT SCREW

SPLINE DOOR JAMB

1) TEMPLATE FOR O.G. SHEAR BLOCKS

HEAD & HORIZONTAL SHEAR BLOCK TO S.S. DOOR JAMB

CAUTION:

Door jambs must run to the floor and are cut longer than other verticals.

Shear blocks are not applicable with 2 pc. horizontal intermediates.

NOTE: (2) pc. horizontal (9357/9358) cannot be shear block assembled.

DOOR JAMB

INVERT #8401 HORIZONTAL FOR I.G. TRANSOM

9358

8402

# 26 Drill (.147 dia.)

(4) PLACES

S100 FASTENERS

C

C

LL

C

C

L

L

1.118

(CONT.)

O.G. HEAD

TUBULAR

O.G. HORIZONTAL

I.G. HEAD

9359

K977

SHEAR BLOCK

PACKAGE

1.300

.340

1.525

2.000

.861

.340

1.525

8401

406 STOREFRONT

FIG. # 3

USE BLOCKED OUT HOLE LOCATIONS FOR O.G. SHEAR BLOCK APPLICATIONS

OUTSIDE GLAZED AS SHOWN, INVERT PATTERN FOR INSIDE GLAZE APPLICATIONS

DRILL JIGS ARE ALSO AVAILABLE

DPS 12/2002

Page 11

SECTION III FABRICATION

PAGE 9

B - SHEAR BLOCKS AT SCREW

SPLINE DOOR JAMB

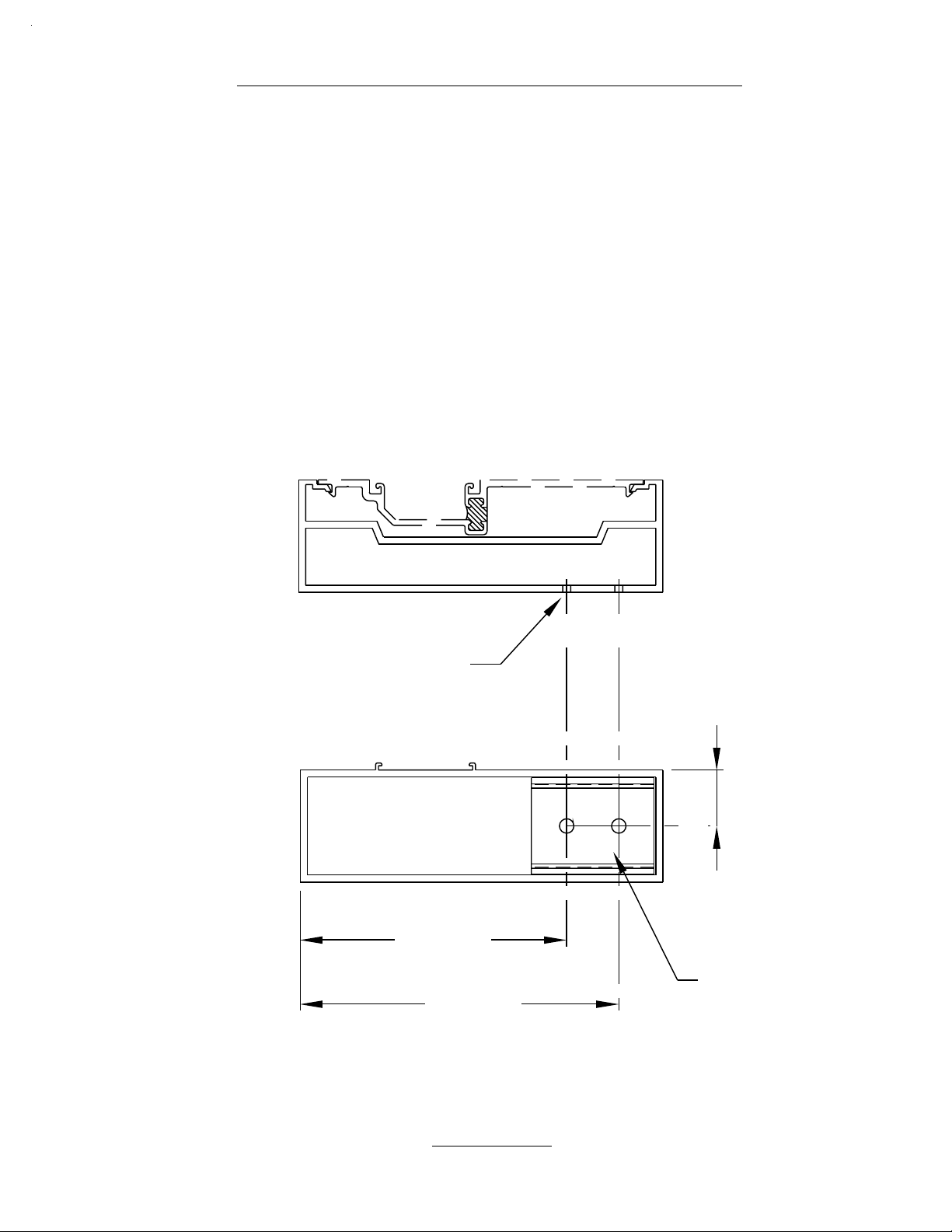

2) DJ16 DRILL GUIDE

FOR TRANSOM - HEAD AND HORIZONTAL

INTERMEDIATE SHEAR BLOCK APPLICATION

NOTE: The drill jig is reversible

for left and right positions.

2"

F406

Insert this lug into the glazing

pocket, then drill the shear

Use the top edge of the

drill guide to locate the

hole pattern for the shear

blocks.

(CONT.)

# 26 Drill (.147 dia.),

(4) holes are located

per horizontal end.

Refer to the horizontal

extrusion being used to

determine the correct holes

to drill for the application

at head (#9359) or intermediate

horizontal (#8401).

2"

block attachment holes as

indicated.

TYPICAL VERTICAL MEMBER

406 STOREFRONT

TOP OF HORIZONTAL

FIG. #4

TO FINISHED FLOOR

DPS 12/2002

Page 12

SECTION III FABRICATION

PAGE 10

B - SHEAR BLOCKS AT SCREW

(CONT.)

SPLINE DOOR JAMB

3) TEMPLATE FOR TRANSOM BAR SHEAR BLOCK

TO S.S. DOOR JAMB

OPPOSITE A C.O.C. AT A SINGLE DOOR

ALL OTHER STD. 402 DOOR FRAME PREPS WILL APPLY

NOTE:

DOOR JAMB

FOR C.O.C.'S, PIVOTS, AND OTHER HINGING.

9358

#4 Drill (.209 dia.)

(3) Places

STV2 FASTENERS

8400

TRANSOM

BAR

1.150

C

L

3.320

8402

C

L

C

L

8400

1.000

C

FV33

K978

K978

SHEAR BLOCK

PACKAGE

L

406 STOREFRONT

5.220

FIG. # 5

DRILL JIGS ARE ALSO AVAILABLE

DPS 12/2002

Page 13

SECTION III FABRICATION

PAGE 11

B - SHEAR BLOCKS AT SCREW

(CONT.)

SPLINE DOOR JAMB

4) TEMPLATE FOR TRANSOM BAR SHEAR BLOCK

TO S.S. DOOR JAMB

WITH C.O.C. 'F' CLIP OR FT16 ANGLE CLIP

ALL OTHER STD. 402 DOOR FRAME PREPS WILL APPLY

NOTE:

DOOR JAMB

FOR C.O.C.'S, PIVOTS, AND OTHER HINGING.

9358

8400

TRANSOM

BAR

#4 Drill (.209 dia.)

(2) Places

STV2 FASTENERS

C.O.C 'F' CLIP

or FT16 ANGLE

- HERE -

4.750

5.687

8402

CC

L

L

8400

1.000

C

L

K996

SHEAR BLOCK

PACKAGE

406 STOREFRONT

SEE Y013 DORMA C.O.C. INSTALLATION INSTRUCTIONS FOR

DIMENSIONS AND APPLICATIONS FOR THE CLOSER

FIG. # 6

DRILL JIGS ARE ALSO AVAILABLE

DPS 12/2002

Page 14

SECTION III FABRICATION

PAGE 12

B - SHEAR BLOCKS AT SCREW

SPLINE DOOR JAMB

5) DJ16 DRILL GUIDE

TRANSOM BAR SHEAR BLOCK TO DOOR JAMB

OPPOSITE A C.O.C. AT A SINGLE DOOR

NOTE: The drill jig is reversible

for left and right positions.

#4 Drill (.209 dia.),

# 26 Drill (.147 dia.),

(4) holes are located

per shear block.

Use # K977 shear block pkg.

2"

(CONT.)

Use the top edge of the

drill guide to locate the

hole pattern for the shear

blocks.

(3) holes are located

on center, per transom bar end.

This prep is opposite a C.O.C.

at a single door.

Use #K978 shear block pkg.

Locate this block to

the interior edge of

the door jamb.

FIG. #7

406 STOREFRONT

LOCATE TOP EDGE OF

DRILL JIG AT THE

TOP OF THE T-BAR

TO FINISHED FLOOR

DPS 12/2002

Page 15

SECTION III FABRICATION

PAGE 13

B - SHEAR BLOCKS AT SCREW

SPLINE DOOR JAMB

6) DJ16 DRILL GUIDE

TRANSOM BAR SHEAR BLOCK TO DOOR JAMB

WITH A C.O.C - SINGLE OR PAIRS OF DOORS

NOTE: The drill jig is reversible

for left and right positions.

#4 Drill (.209 dia.),

# 26 Drill (.147 dia.),

(4) holes are located

per shear block.

Use # K977 shear block pkg.

2"

(CONT.)

Use the top edge of the

drill guide to locate the

hole pattern for the shear

blocks.

(2) holes are located

on center, per transom bar end.

This prep is in conjunction with

the C.O.C. 'F' clip or FT16 angle.

Use #K996 shear block pkg.

Locate this block to

the interior edge of

the door jamb.

FIG. #8

406 STOREFRONT

LOCATE TOP EDGE OF

DRILL JIG AT THE

TOP OF THE T-BAR

TO FINISHED FLOOR

DPS 12/2002

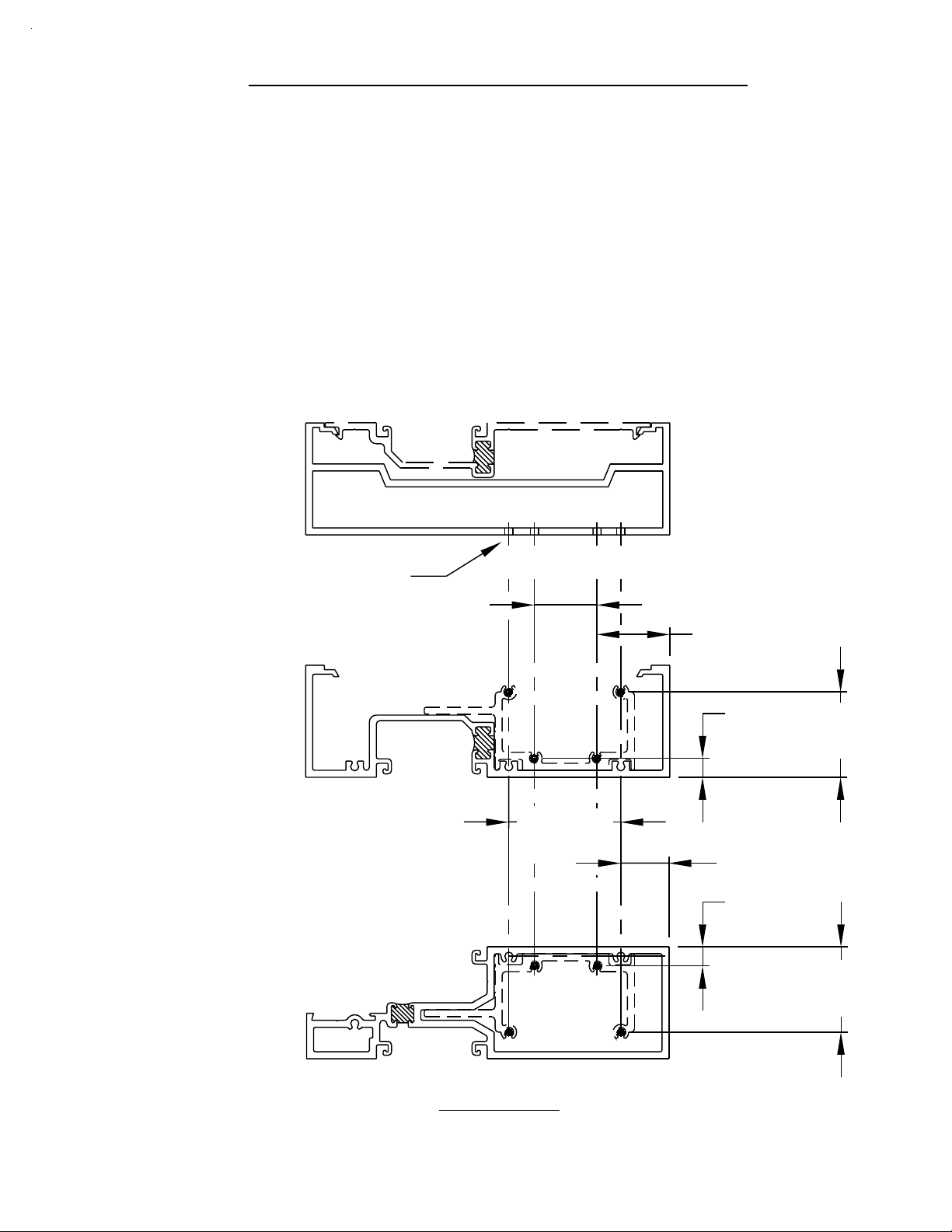

Page 16

SECTION III FABRICATION

C- SHEAR BLOCK FABRICATION - FRAMES

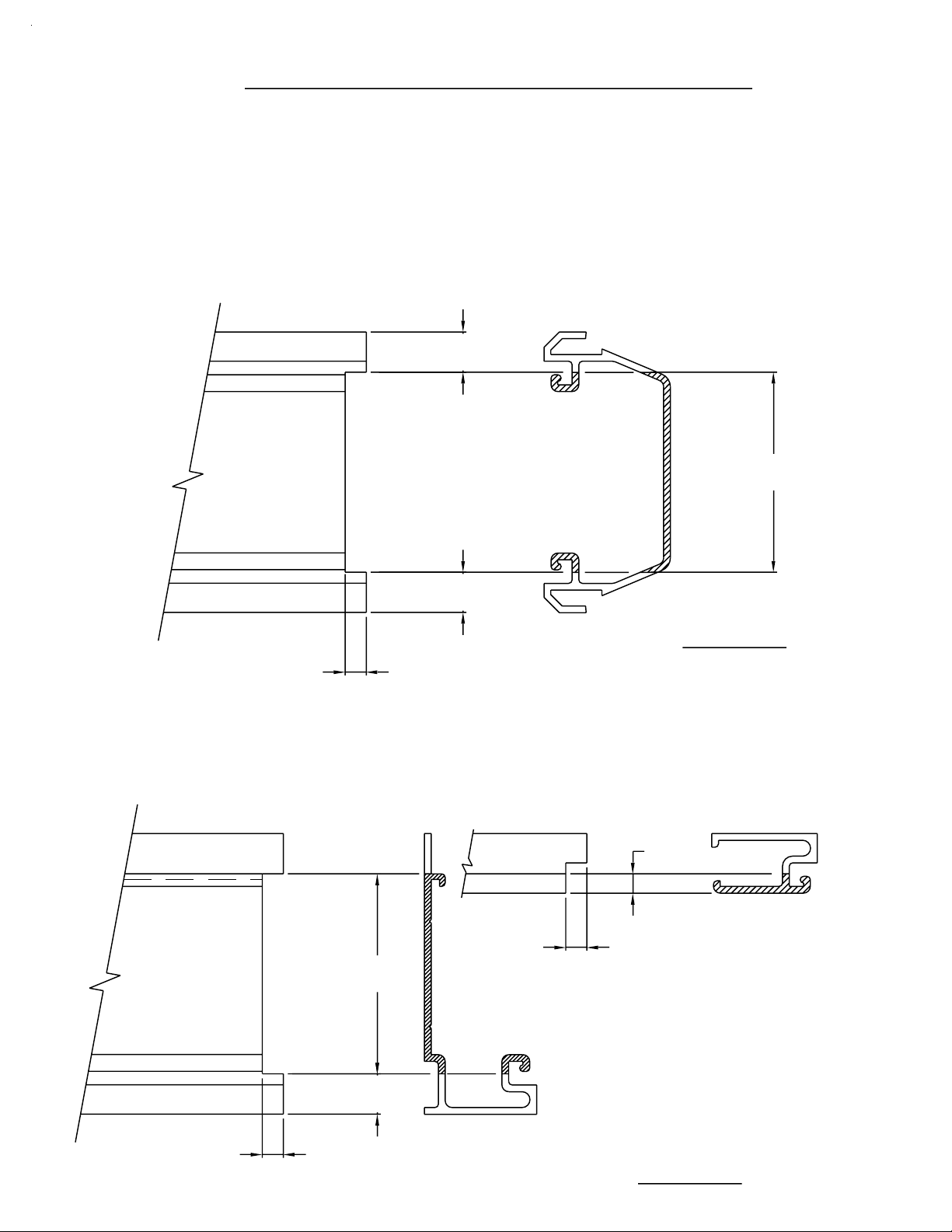

1) DJ18 DRILL GUIDE APPLICATION

AT TUBULAR INTERMEDIATE HORIZONTAL

AND OPEN BACK SILL

LOCATE ON

GUIDE TRACK

HORIZONTAL AND SILL END

PREP FOR ATTACHMENT TO

.567

2.656

.221 DIA.

DRILL

SHEAR BLOCKS

PAGE 14

1.000

K977 FOR 8401 HORIZ./SILL

KN65 FOR 9357 SILL

DJ18

Fig. #9

Drill as indicated thru one

wall using #2 drill (.221 Dia).

#8401 AT HORIZONTAL

406 STOREFRONT

.221 DIA.

DRILL

DJ18

Fig. # 10

DPS 4/2004

Page 17

PAGE 15

SECTION III FABRICATION

C- SHEAR BLOCK FABRICATION - FRAMES

(CONT.)

2) DJ18 DRILL GUIDE APPLICATION

AT OPEN BACK TRANSOM HEAD

TRANSOM HEAD END PREP FOR ATTACHMENT TO SHEAR BLOCKS

C

L

.875

REF.

C

L

2.656

.221 DIA.

DRILL

1.000

2.656

.221 DIA.

DRILL

EXTERIOR

Fig. # 11

.221 DIA.

DRILL

DJ18

#9359 AT TRANSOM HEAD

Drill as indicated thru one

wall using #2 drill (.221 Dia)

406 STOREFRONT

EXTERIOR

.221 DIA.

DRILL

DJ18

Fig. # 12

DPS 12/2002

Page 18

SECTION III FABRICATION

D - SNAP-IN GLAZING POCKET &

SCREW APPLIED GLAZING

1) SNAP-IN GLAZING POCKET END PREP

.358

PAGE 16

#8403

THIS END

TO TRANSOM BAR

1.780

.358

Fig. # 13

CUT LENGTH =

VERTICAL D.L.O. - 1/32"

.188

NOTE:

NOTCH THROUGH GLAZING TRACKS AND

BACK WALL OF PART AS SHOWN.

2) SCREW APPLIED GLAZING END PREPS

.173

#9133

406 STOREFRONT

.188

1.781

THIS END

TO TRANSOM BAR

.358

.188

CUT LENGTHS =

VERTICAL D.L.O. - 1/32"

#9250

Fig. # 14

DPS 12/2002

Page 19

PAGE 17

SECTION IV ASSEMBLY & INSTALLATION

A - DOOR FRAME ASSEMBLY

NOTE: If an entrance frame is required, it must be installed first.

Attach the transom bar to the jamb with the #K978 shear block

or the K996 and the 'F' clip or angle bracket (#FT16) for a C.O.C.

Be sure the snap-in glazing pocket has been notched to clear the

glazing stop tracks on the top of the transom bar.

Please see page 16 for this end prep.

HEAD SHEAR

BLOCK PREP

See #Y013 for Dorma C.O.C. Installation Instructions.

See #Y014 for International C.O.C. Installation Instructions.

8402 DOOR JAMB

If the jambs are not factory prepped, please

see page 18 for transom jamb glazing pocket cut out.

K978 PKG.

K996 SIM.

Apply sealant to the

end of the transom bar

before attaching it to

the shear block.

8400

TRANSOM BAR

406 STOREFRONT

THIS ASSEMBLY IS

OPPOSITE A C.O.C.

AT A SINGLE DOOR.

SEE PAGE 23

Factory prep shown.

Fig. # 15

DPS 12/2002

Page 20

PAGE 18

SECTION IV ASSEMBLY & INSTALLATION

A - DOOR FRAME ASSEMBLY

(CONT.)

NOTE: If an entrance frame is required, it must be installed first.

The transom jamb glazing pocket will snap into the cut out cavity.

The glazing pocket will flush with the top of the transom bar or with

the top of the horizontal intermediate, if used.

HEAD SHEAR

BLOCK PREP

The cut out must not

exceed 48" in length.

See page 20 for lengths

greater than 48".

1.188

3.313

TOP OF

TRANSOM BAR

8402 DOOR JAMB

8403 TRANSOM JAMB

GLAZING POCKET

See page 16 for end prep.

SEE PAGE 23

FOR THIS PREP

406 STOREFRONT

Fig. # 16

DPS 12/2002

Page 21

PAGE 19

SECTION IV ASSEMBLY & INSTALLATION

A - DOOR FRAME ASSEMBLY

#8403

#K977

#K978

EXPLODED VIEW

(CONT.)

#9359

#8402 DOOR JAMB

FACTORY PREP SHOWN

Fig. # 17

#8400

#9954/#9955 DOOR STOP

THIS ASSEMBLY IS

OPPOSITE A C.O.C.

AT A SINGLE DOOR.

406 STOREFRONT

DPS 12/2002

Page 22

PAGE 20

SECTION IV ASSEMBLY & INSTALLATION

A - DOOR FRAME ASSEMBLY

FOR TRANSOM D.L.O. OVER 48" USE #9250 AND #9133

APPLIED GLAZING AT JAMB APPLIED STOPS RUN THROUGH

AT TRANSOM BAR GLAZING STOPS.

CUT LENGTH = VERTICAL D.LO. - 1/32".

EXPLODED VIEW

SEALANT IN

CAVITY

#K9250 / #9133

See page 16 for end prep.

APPLY SEALANT TO

ALL HORIZONTAL ENDS

#K977

BEFORE ASSEMBLY

(CONT.)

#8402 DOOR JAMB

FACTORY PREP SHOWN

#9359

#K978

#8400

#9954/#9955 DOOR STOP

406 STOREFRONT

Fig. # 18

THIS ASSEMBLY IS

OPPOSITE A C.O.C.

AT A SINGLE DOOR.

DPS 12/2002

Page 23

PAGE 21

SECTION IV ASSEMBLY & INSTALLATION

A - DOOR FRAME ASSEMBLY

DORMA RTS 88 w/ BUTT HINGES,

GEARED HINGES &

#8403

DUAL ACTING

#K977

EXPLODED VIEW

(CONT.)

#9359

F CLIP

(BY DORMA)

F045

#8402 DOOR JAMB

FACTORY PREP SHOWN

#K996

#8400

#9954/#9955 DOOR STOP

406 STOREFRONT

Fig. # 19

REFER TO Y013 DORMA RTS 88

INSTALLATION INSTRUCTIONS

DPS 12/2002

Page 24

PAGE 22

SECTION IV ASSEMBLY & INSTALLATION

A - DOOR FRAME ASSEMBLY

DORMA RTS 88 w/ OFFSET PIVOTS

#8403

#K977

#9359

(CONT.)

FT16

F045

#8402 DOOR JAMB

FACTORY PREP SHOWN

#K996

#8400

#9954/#9955 DOOR STOP

406 STOREFRONT

REFER TO Y013 DORMA RTS 88

INSTALLATION INSTRUCTIONS

Fig. # 20

DPS 12/2002

Page 25

PAGE 23

SECTION IV ASSEMBLY & INSTALLATION

B - DOOR FRAME INSTALLATION

NOTE: If an entrance frame is required, it must be installed first.

STEP 1)

STEP 2)

STEP 3)

STEP 4)

CORRECTLY LOCATE THE ENTRANCE FRAME IN THE OPENING.

APPLY A BEAD OF SEALANT AROUND THE INTERIOR PORTION OF

THE JAMB TO SET THE MEMBER INTO. THEN MARRY THE SIDE LITE

SEALANT OR CONDITION SEALANT INTO THE BEAD OS SEALANT TO

BE APPLIED UNDER THE THRESHOLD. THE CONCEPT IS TO HAVE A

CONTINUOUS BEAD OF SEALANT AT THE INTERIOR, CONNECTED

FROM THE SILL FLASHING/CONDITION THROUGH THE DOOR JAMB

AND CONTINUING UNDER THE THRESHOLD TO THE OPPOSITE JAMB

AND SO ON.

SET THE ASSEMBLED DOOR FRAME IN THE OPENING,

PLUMB AND LEVEL.

ANCHOR THE DOOR FRAME AS INDICATED BELOW AND IN

FIG. #22 THROUGH FIG. #25 ON PAGE 24.

#9357/1G83

SIDE LITE SILL

& FLASHING

NOTE:

The door jamb runs to the

floor and is cut longer

than any other vertical

member.

K-124/K-125 Threshold Clip & Screws

@ Offset Pivots & Butt Hinges

K-153/K-154 Threshold Clip & Screws

@ Concealed Rod Panic

THRESHOLD

(9950)

#8402

Continuous bead

of sealant to tie into

underside of sill.

Fig. # 21

406 STOREFRONT

DPS 12/2002

Page 26

PAGE 24

SECTION IV ASSEMBLY & INSTALLATION

B - DOOR FRAME INSTALLATION

At the open back head and jamb, EFCO

recommends using full lengths of caulk

backer (LB7 8) or use 3" pieces (FV16) and

locate them at the frame and door frame

anchors. This is to prevent collapsing the

glazing pocket s or distorting the door jamb.

9359 frame jamb & 9357 frame sill require

LB78/FV16 similar.

Fig. # 22

#8402 SHOWN

LB78/FV16

(CONT.)

LB78/FV16

#9359

Anchor through the transom head/frame head

glazing pocket with flat head screws located

6" from the ends and 16" on center,

maximum spacing.

Fig. # 23

Anchor through the S.S. jamb at

the door stop centerline with flat head

screws located 6" from the ends and

16" on center, maximum spacing.

EXTERIOR

INTERIOR

Fig. # 25

#8400

Fig. # 24

Anchor through the transom bar at

the door stop centerline with flat head

screws located 6" from the ends and

16" on center, maximum spacing.

Attach through the threshold

with flat head screws

located 6" from the ends and

15" on center, typical spacing.

Continuous bead of sealant at

the back of the threshold and sides of

the jambs and tied into mullion sealant

at the condition.

NOTE: These are general anchor locations. It may be necessary to use 9358 as the

perimeter filler if structural loads require a greater shear strength at the anchor locations.

All projects should be reviewed by a structural engineer for exact anchoring requirements

Page 27

PAGE 25

SECTION IV ASSEMBLY & INSTALLATION

C - SILL FLASHING INSTALLATION

STEP 1)

Sealant

INSTALL THE SILL FLASHING CONTINUOUSLY BETWEEN

THE MASONRY JAMBS OR BETWEEN THE DOOR FRAME

AND THE MASONRY JAMB. SEE FIGURES BELOW.

Anchor the sill flashing 6" from verticals

and 24" O.C. Before the fastener is

Sealant

inserted, force sealant into the hole

to ensure that the hole through the sill

flashing is sealed.

Sill flashing optio ns:

THERMAL

1G83 - STANDARD

{

1G86 - w/ STOOLS

Sealant

Shim the flashing

until it is level and

set it in a continuous

bead of sealant.

FIG. #26

NOTE:

Seal over the heads of all

flashing attachment screws.

Seal the ends of the flashing with a

"skinning", nonhardening type of

sealant (i.e., silicone).

ALL THERMAL STRUT SILL FLASHING THAT COULD

ENCOUNTER MOISTURE MIGRATION MUST HAVE THE

THERMAL STRUT SEALED OVER WITH SILICONE.

Apply a continuous bead of sealant

across the top of the thermal strut

when using thermal flashing.

1G83 SHOWN,

1G86 SIMILAR.

FIG. #27

8731

9738

Page 28

PAGE 26

SECTION IV ASSEMBLY & INSTALLATION

STEP 2)

C - SILL FLASHING INSTALLATION

INSTALL THE SILL FL ASHING IN A CONTINUOUS BEAD OF

SEALANT BETWEEN THE MASONRY JAMB AND THE DOOR

FRAME. THE BEAD OF SEALANT WILL TIE INTO THE SEALANT

THAT FILLS THE CAVITY IN THE DOOR JAMB AND TIES INTO THE

BEAD OF SEALANT THAT THE THRESHOLD IS SET INTO. SEAL

THE END OF THE SILL FLASHING TO THE DOOR JAMB

THOROUGHLY. FILL THE HOLLOW AREA OF THE DOO R JAMB

WITH SEALANT LEVEL WITH THE SILL FLASHING TO DIVERT ANY

WATER ONTO THE SILL FLASHING. SEE FIGURE BELOW.

SEAL FLASHING

(CONT.)

APPLY SEALANT JUST

BEFORE SETTING THE

SILL MEMBER

TO JAMB

Fill this cavity with

sealant, level with the

sill flashing.

SEAL THIS AREA OF THE

SILL FLASHING

SEAL OVER THERMAL STRUT

CONTINUOUS BEAD

OF SEALANT TO THE

MASONRY JAMB

OPTIONAL SEALANT

FIG. #28

Page 29

PAGE 27

SECTION IV ASSEMBLY & INSTALLATION

C - SILL FLASHING INSTALLATION

VIEW OF JAMB AT CONDITION

#9359

#9358 CONTINUOUS SHOWN

OR LB78/FV16 VINYL NOT SHOWN

#9357

The sill flashing must be sealed to the condition

and the jamb member set in a bead of sealant

to ensure a water tight seal.

SEALANT

(CONT.)

FIG. #29

STEP 3)

INCORPORATING THE SILL FLASHING END CAPS WILL COMPLEMENT

THE SEALING PROCEDURE. THE END CAPS MUST BE SEALED TO THE

CONDITION AND THE SEALANT MUST TIE-IN WITH THE JAMB BLOCKING

AND THE PERIMETER SEALS. THE END CAP EDGES MUST ALSO BE

CONCEALED WITH THE SEALANT TO PRESENT A NEAT CLEAN

INSTALLATION. THIS MAY CAUSE THE CAULK JOINT AT THE JAMB TO

INCREASE IN THICKNESS, IF THE CONDITION IN IRREGULAR.

406 STOREFRONT

K980

DPS 12/2002

Page 30

SECTION IV ASSEMBLY & INSTALLA TION

STEP 4)

C - SILL FLASHING INSTALLATION

(CONT.)

SILL FLASHING CUT LENGTH = ROUGH OPENING MINUS 1/2" WITH END

CAPS. END CAPS WOULD BE INCORPORATED IF THE SILL FLASHING

COULD NOT BE SEALED TO THE CONDITION COMPLETELY. AN EXAMPLE

WOULD BE, IF THE JAMB CONDITION IS LESS THAN THE SILL FLASHING

DEPTH OR IF THERE IS A VOID IN THE CONDITION.

Sealant

K980

Sealant

for # 1G83

& # 1G86

FIG. #30

STEP 5)

Anchor sill flashing

6" from verticals and

24" O.C. and seal

over all screw heads.

Set sill flashing splice in a bed

of sealant around the perimeter

of the splice.

SPLICE THE FLASHING EVERY 20'-0" AS SHOWN IN FIG. #31 BELOW. USE

K979 FOR S406 HIGH PERFORMANCE FLASHING. IT IS NOT ADV I S E D TO

LOCATE THE SPLICE JOINT DIRECTLY AT A VERTICAL INTERMEDIATE.

ALLOW 6" MINIMUM SPACING FROM THE VERTICALS. FOR MITERED

CORNERS, SEE PAGE 29.

Reapply sealant across the splice

when in place to ensure the

bead of sealant is continuous.

FIG. #31

Bond breaker tape

1" wide centered on

back of splice.

K979

.050 aluminum

formed sleeve

After the splice is in place, apply

the cosmetic seal to the

3

/

8

"

Use backer rod and

silicone to fill the joint

in the sill flashing.

interior gap vertically.

Page 31

PAGE 29

SECTION IV ASSEMBLY & INSTALLATION

STEP 6)

1 1/2"

C - SILL FLASHING INSTALLATION

(CONT.)

IF A CORNER IS REQUIRED, MITER THE FLASHING TO THE

REQUIRED ANGLE AND THEN INSTALL AS SHOWN IN THE FIGURES

BELOW. LOCATE FASTENERS 3" AWAY FROM ANY CORNER AND 1

1/2" FROM THE EDGE OF THE SILL FLASHING SPLICE.

Cover the heads of all

6" MIN.

1 1/2"

K979

attachment screws

with sealant.

SEALANT

12" MIN.

TO SPLICE JOINT

TYP.

3/8"

12" MIN.

TO SPLICE JOINT

3"

TYP.

FIG. #32

# 1G83 sill flashing shown,

SEALANT

3"

Cover the heads of all

attachment screws with sealant.

# 1G86 is similar.

FIG. #33

406 STOREFRONT

# 1G83

DPS 12/2002

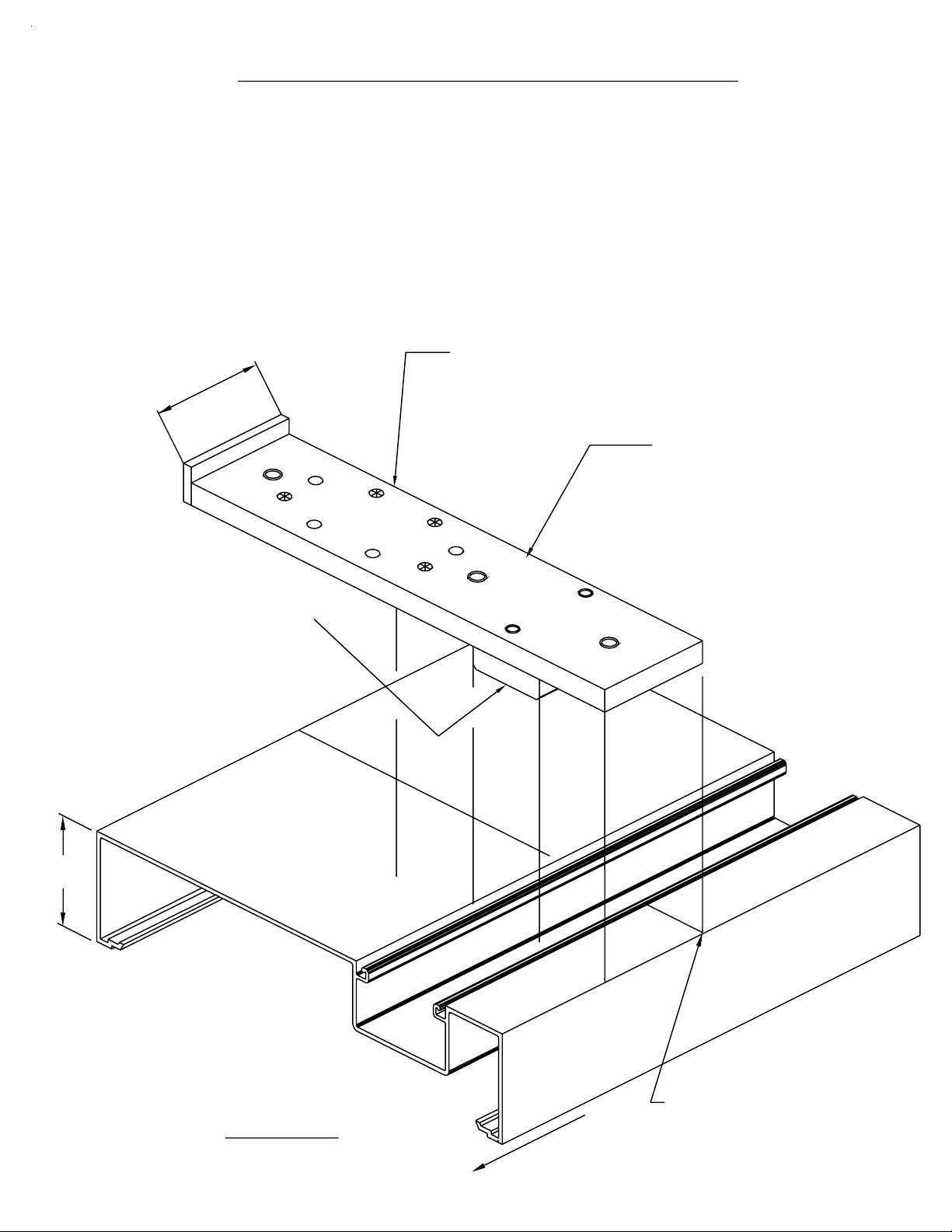

Page 32

PAGE 30

SECTION IV ASSEMBLY & INSTALLATION

D - SCREW SPLINE FRAME & SIDE LITE TO

DOOR JAMB ASSEMBLY

#9359 JAMB

NOT SHOWN

FOR CLARIT Y

LB78/FV16 PERIMETER

FILLERS NO T SHO W N

FOR CLARITY.

(REQUIRE D @ HE AD , J A MB

& SILL)

#8401 HORIZ. SHOWN

#9357/#9358 SIMILAR

#9359 HEAD

APPLY SEALANT TO

THE ENDS OF ALL

HORIZONT ALS BEFOR E

ASSEMBLY.

#9358 SHOWN at

DOOR JAMB

WAX ALL SCREW S

S129

ASSEMBLY SCREWS

S129

APPLY SEALANT TO

SNAP AREA AT TH E

INTERIOR AND

EXTERIOR.

#9357 SILL

SILL FLASHING

NOT SHOWN

S129

FIG. #34

WAX ALL SCREW S

NOTE: THE SILL FLASHING ENDS AT A DOOR JAMB.

THE SILL FLASHING RUNS THRU AT JAMBS

AND VERTICAL I NT ER M E DIATES.

NOTE: Use full lengths of LB78 perimeter adaptor at the head and jambs as a caulk backer

and to keep from collapsing the glazing pocket. Use 3" lengths of LB78 perimeter adaptor

S129

(FV16) at the sill member and locate them at the fastener, to keep the anchors or weight of

the glazing material from collapsing the glazing pocket.

Page 33

PAGE 31

SECTION IV ASSEMBLY & INSTALLATION

D - SCREW SPLINE FRAME & SIDE LITE TO

DOOR JAMB ASSEMBLY

EXPLODED VIEW

(CONT.)

NOTE: #9358 GLAZING ADAPTOR

IS THE SAME LENGTH AS THE

STANDARD #9359 JAMB.

NOTE:

Make sure the bead of sealant under the threshold is continuous

through the door jamb and married into the bead of sealant that the

sill flashing is set into.

406 STOREFRONT

FIG. #35

DPS 12/2002

Page 34

PAGE 32

SECTION IV ASSEMBLY & INSTALLATION

E - WATER DEFLECTOR INSTALLATION

Water deflectors are used at the ends of all horizontal intermediates to prevent

any accumulated moisture in the glazing pocket from dropping on the top edge

of the 1" glass unit below.

HWD1 WATER DEFLECTOR

#9359/#9358

Apply a thin coat of silicone sealant to the end of

the horizontal. Set the HWD1 into the sealant

and allow to cure prior to installing glass.

Seal the horizontal to the vertical at

the inside face of the glazing pocket.

#8401

Seal over the attachment screws,

FIG. #36

406 STOREFRONT

This end extends into

the vertical glazing pocket

and over the lower glass

unit's corner.

if shear block, and across the

horizontal joint for shear block or

screw spline

TYP. VERTICAL

HWD1 WATER DEFLECTOR

TYP. HORIZONTAL

GLASS UNIT BELOW

FIG. #37

DPS 12/2002

Page 35

SECTION V GLAZING

A - GLASS SIZE FORMULAS

System 406 (2" sight line) = D.L.O. + 7/8" (HORIZONTAL)

System 406 (2" sight line) = D.L.O. + 7/8" (VERTICAL)

TRANSOM LITE

9358/8402/8403

2.000

D.L.O.

PAGE 33

9359

2.000

2.000

.375

1.000

D.L.O.

9250/9133

D.L.O.

9358/9359

.375

1.000

2.000

2.000

2.000

8401

D.L.O.

1.000

2.000

8400

Fig. # 39

2.000

406 STOREFRONT

D.L.O.

Fig. # 38

2.000

DPS 12/2002

Page 36

SECTION V GLAZING

B - GLASS INSTALLATION

STEP 1) GASKET INSTALLATION FOR OUTSIDE GLAZE.

A) Apply sealant to the ends of all horizontals to seal the intersections

at the verticals. At all 4 corners of the D.L.O., apply sealant in the gasket race

1" away from the intersection of the vertical and horizontal members.

See detail # 40 below.

B) Cut the interior and exterior push-in gasket to an approximate length of

D.L.O. x 1.02 (DLO PLUS 2%).

C) Install the interior glazing gasket. NOTE: The vertical gaskets run through.

D) Start at the ends an d wo rk toward the center , fi rm ly pushing the

gasket in place.

DO NOT STRETCH THE GA SK ET O R IT WILL RETURN TO ITS ORIGINAL

FORM, CREATING GAPS AT THE GASKET INTERSECTIONS.

E) Clean the glaz in g ga skets with denat ur ed alcohol at the intersection area.

Apply a small amount of sealant at the interse ct area to marr y the ver tical

and horizontal glazing gaskets. Tool all sealant to present a neat,

clean appear ance.

NOTE:

These steps are included in the test lab procedure and are requirements

to achieve th e te st rep or t results for air an d wa te r infiltration.

#9359/#9358

1"

1"

SEALANT IN INTERIOR GASKET RACE

1" FROM INTERSECTION

TYPICAL ALL 4 CORNERS OF DLO.

GASKET RACE

Sealant

W164

#8401

SEAL UNDER THE GASKET TRACK

OF THE HORIZ. & MARRY SEALANT

INTO VERTICAL GASKET TRACK &

HWDI @ INT. HORIZ. ONLY.

Fig. # 40

Page 37

SECTION V GLAZING

B - GLASS INSTALLATION

STEP 1) GASKET INSTALLATION FOR OUTSIDE GLAZE

TRANSOM BAR GLAZING STOP SEAL.

PAGE 35

(CONT.)

#8402 DOOR JAMB

w/ #9358 GLAZING

ADAPTOR

Seal the interior glass stop leg to

the transom bar and seal the end

joint to the jamb and transom bar

completely.

Exterior glass stop shown in place,

remove to set the glass unit.

Do not seal the exterior glass stop,

this will allow weepage.

#8403 SNAP-IN

GLAZING POCKET

(48" MAX.)

APPLY SEALANT IN GASKET RACE

1" FROM INTERSECTION

TYPICAL ALL 4 CORNERS OF D.L.O..

# 9123 GLASS STOP

CUT LENGTH = D.LO. - 13/32".

#8400

NOTE:

IF SCREW APPLIED GLAZING STOPS ARE USED VERTICALLY INSTEAD OF

THE SNAP-IN GLAZING POCKET, THE SEALING SCENARIO WILL BE THE

SAME. BE SURE TO SET THE GLAZING BASE IN A BEAD OF SEALANT

BEFORE ATTACHING IT TO THE DOOR JAMB.

406 STOREFRONT

Fig. # 41

RAM 4/2004

Page 38

SECTION V GLAZING

PAGE 36

B - GLASS INSTALLATION

(CONT.)

STEP 2) GLASS INSTALLATION

A) Position the glass unit in front of the opening to be glazed. Lift the unit

to just clear the sill stop area, and then shift the glass into the deep pocket.

B) Swing the opposite edge of the glass around to align with the glazing

pocket.

C) Shift the glass into the shallow pocket until there is equal glass bite

on both edges of the glass.

NOTE:

If using antiwalk blocks,

refer to page 38.

C

A

B

406 STOREFRONT

Fig. # 42

DPS 12/2002

Page 39

SECTION V GLAZING

7

B - GLASS INSTALLATION

STEP 2) GLASS INSTALLATION

D) Lift the glass into the he ad member's glazing pocket.

E) Insert the setting blocks under the glass at the proper locations, typically

1/4 points of the D.L.O. Then lower the glass onto the setting blocks.

F) Snap on the remo vable glass stop and install the exterior glazing gasket.

PAGE 3

LB78 full length/FV16 3" clip

D

E

F

9359

9357

FV16 3" clip

1G83

Fig. # 43

Page 40

SECTION V GLAZING

C - ANTIWALK BLOCK INSTALLATION

STEP 1) ANTIWALK BLOCK INSTALLATION

A) Install the interior gasket following the

steps on page 34.

B) Position the glass as described in the

steps on pages 36 and 37.

C) Stretch the antiwalk block as shown

in Fig. 44 below, and insert it from the

exterior at midlite and deep pocket

side only.

PAGE 38

D) Recenter the glass unit to maintain

equal glass bite all around.

E) Install the exterior gasket.

HN52

ANTIWALK BLOCK

406 STOREFRONT

FIG. # 44

DPS 12/2002

Page 41

SECTION V GLAZING

PAGE 39

C - ANTIWALK BLOCK INSTALLATION

STEP 2) ANTIWALK BLOCK DEGLAZING

A) Remove the interior and exterior glazing gaskets.

B) Push the glass back to the interior side.

C) Remove the antiwalk block with a sharp

hook shaft tool from the exterior side.

(CONT.)

406 STOREFRONT

ANTIWALK BLOCK

REMOVE FROM THIS SIDE

GASKETS REMOVED

EXTERIOR

FIG. # 45

DPS 12/2002

Loading...

Loading...