Page 1

Protective Signaling Systems

Wiring Practices Manual

Edwards Signaling Products

90 Fieldstone Court, Cheshire, CT 06410-1212

Page 2

Edwards Protective Signaling System Wiring Practices

Figure 1

INTRODUCTION

The installation of fire alarm system wiring is similar in many respects to any

other low voltage system wiring. Because the nature of the system affects life

and property, additional measures are required during installation to insure

the system is operational at all times. The most sophisticated of control

panels will not operate properly if the field wiring is installed incorrectly. It is

the goal of this chapter to explain why correctly installed field wiring is vital in

the operation of a fire alarm system, and how to recognize proper and

improper installations. The process requires four basic steps: SELECT the

proper cable for the application; INSTALL the cable properly; TEST the cable

to make sure it is free of shorts, opens, and ground faults; and TERMINATE

the cable properly.

BASIC CIRCUIT SUPERVISION

There are two types of circuit supervision widely used in fire alarm systems

today. Direct Current (DC) continuity supervision is used extensively on small

systems. Large fire alarm systems use sophisticated electronic multiplex

circuitry and "electronic questions and answers" to supervise field wiring and

devices.

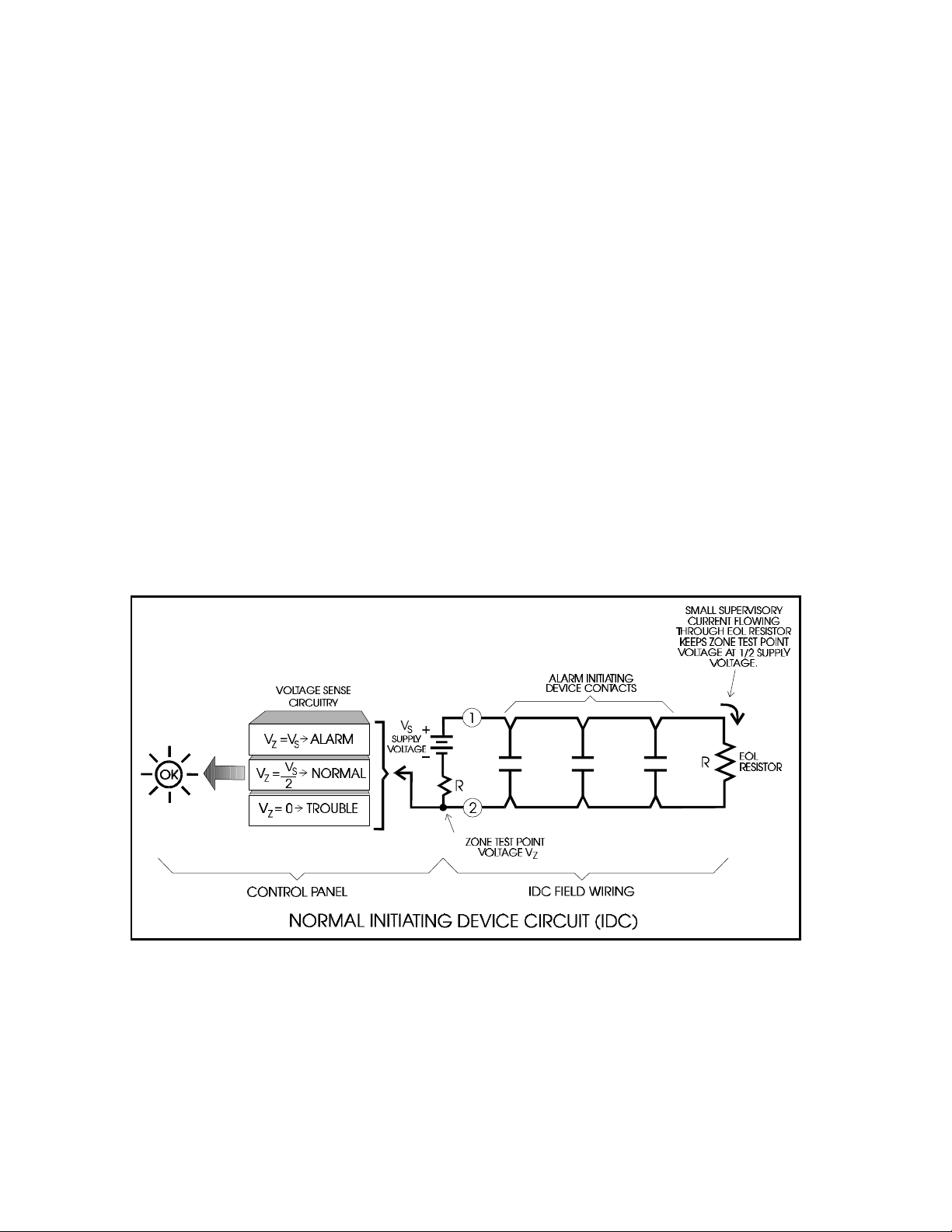

Figure 1 shows a simplified fire alarm panel supervising a single Initiating

Device Circuit or zone using Direct Current (DC) continuity supervision. The

supervisory current from the battery flows through terminal #1, the field

wiring, the EOL resistor, terminal #2 of the control panel through a second

resistor, and returns to the battery. The internal resistor and EOL resistor

have equal resistance values. The voltage at the zone test point VZ is

1

Page 3

measured by voltage sensing circuits. As long as the supervisory current

Figure 2

Figure 3

flows through the EOL resistor, the voltage at VZ is one half the supply

voltage VS, and the voltage sense circuitry generates a normal panel

response.

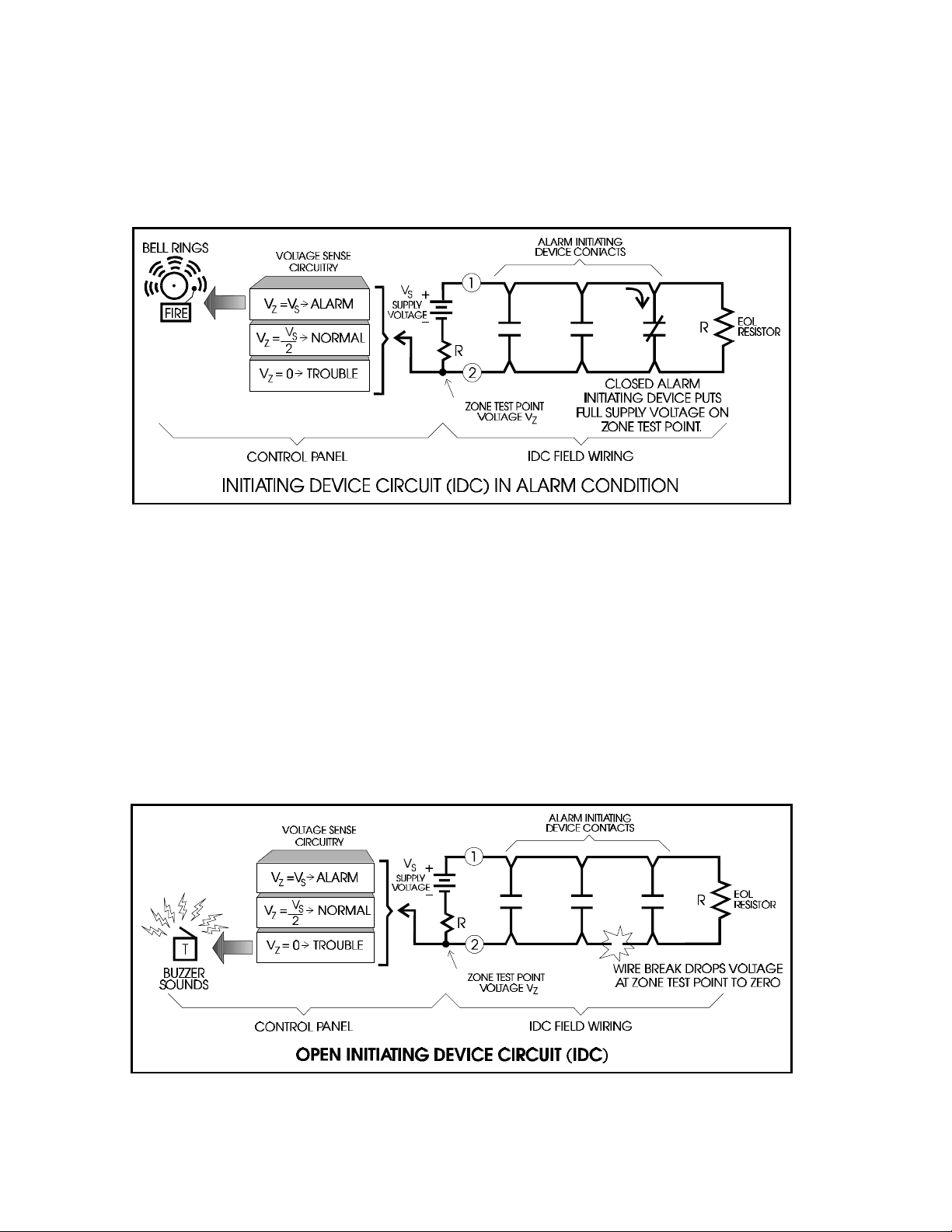

When a smoke detector or pull station operates, it effectively puts a short

across terminals #1 & #2 as shown in Figure 2. This brings the zone test

point voltage VZ up to the supply voltage VS. When the voltage sense circuitry

sees VZ = VS, it generates an alarm response, such as ringing a bell.

Should the field wiring open as shown in Figure 3, the supervisory current no

longer flows through the field wiring and EOL resistor and VZ goes to zero.

When the voltage sense circuitry sees VZ = 0, it generates a trouble

response, such as sounding the trouble buzzer.

2

Page 4

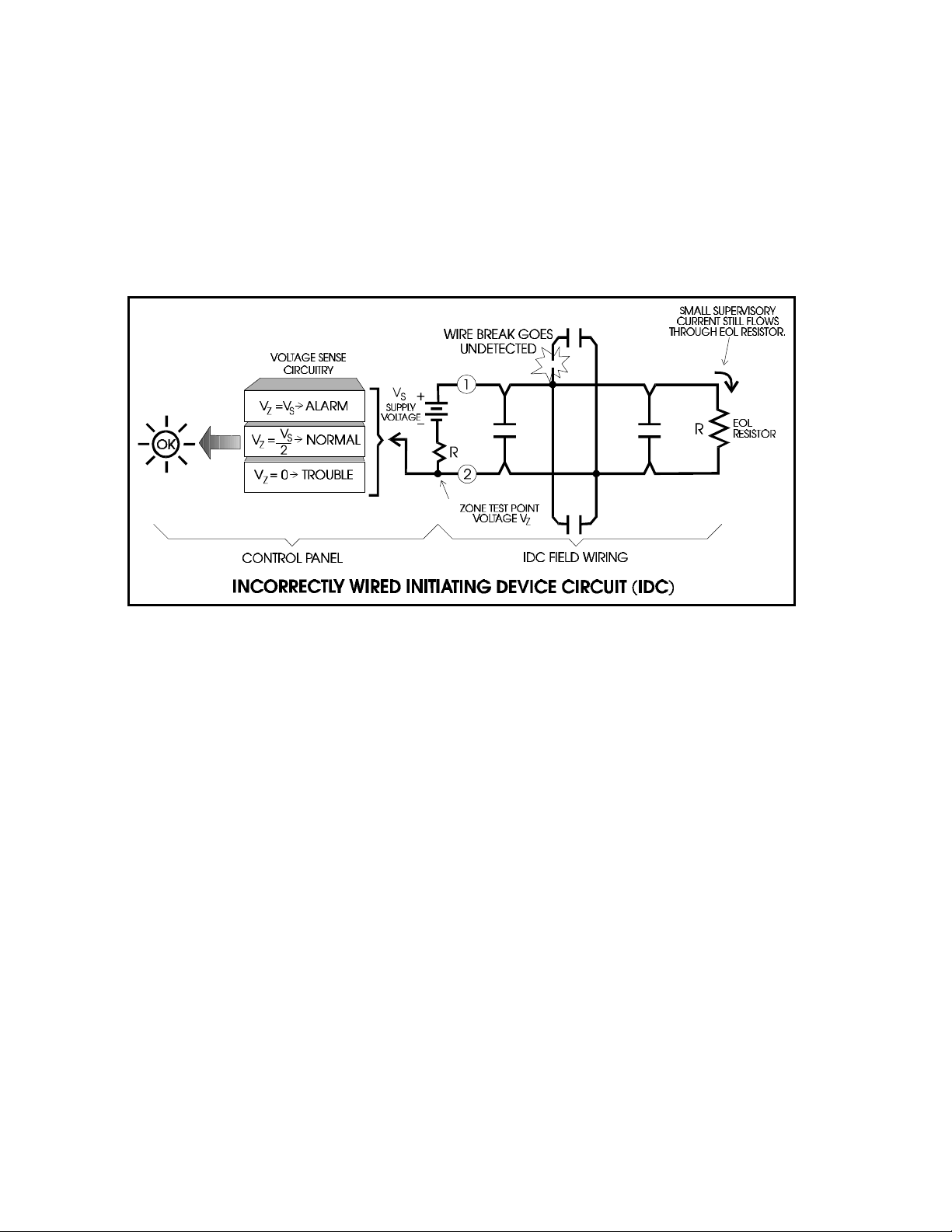

Figure 4 shows an improperly wired Initiating Device Circuit. Because the

supervisory current is not forced to flow through the top and bottom

branches, the break in the top branch doesn't interrupt the supervisory

current, and there is no indication of the trouble. Should the top device detect

a fire, the signal would never reach the control panel. Note that the lower

device would send a fire alarm signal but would not send a trouble signal to

the fire alarm panel, a classic symptom of mis-wiring.

Figure 4

Large multiplex systems use sophisticated electronics that employs a system

of "electronic questions and answers" to verify circuit viability. The control

panel knows the "names" of all the devices that should be connected to it.

After asking a "question" of each name or device on its list, the control panel

must receive an answer from that device only. Failure to receive the proper

answer causes the panel to generate a trouble signal. Because multiplex

systems do not depend on the wiring path for supervision, some multiplex

systems permit limited branch wiring or T-taps.

3

Page 5

CABLE SELECTION:

The majority of fire alarm systems installed today use power limited circuits.

These are low voltage circuits that automatically restrict the electrical current

delivered to the field wiring. Power limited wiring is governed by the National

Electric Code (NEC) Article 760. Field wiring size and distance limits are set

by the fire alarm manufacturer. The manufacturer may also prohibit

combining certain types of circuits in the same conduit. Installation

requirements are set by local, state and national codes. All Power Limited

Fire-Protective Signaling Cable must have its type designation marked on the

cable. NEC Article 760 requires the following insulation types to be used on

conductors installed as power limited wiring:

FPL

Type "FPL" cable may be used for general purpose fire alarm use without

conduit, with the exception of riser, duct, or plenum applications.

FPLP

Limited energy cables installed in environmental air plenum spaces without

conduit must carry a type "FPLP" designation.

FPLR

Limited energy cables installed in vertical riser shafts without conduit must

carry the type "FPLR" or the "FPLP" designation.

Note that the cables used for power limited applications do NOT have the

voltage rating stamped on the cable to avoid misapplication of power limited

cable.

All wiring should use the cables approved by the fire alarm system

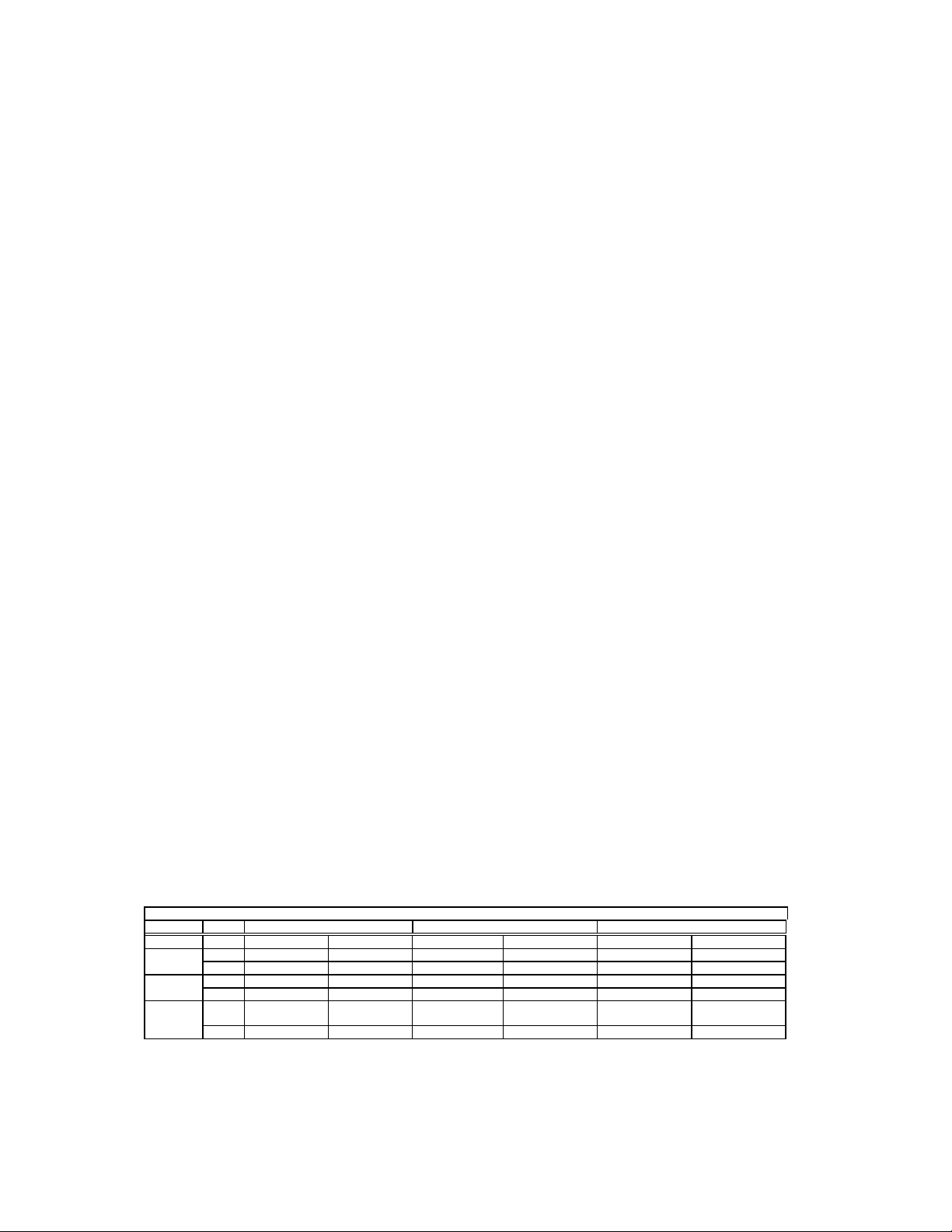

manufacturer. Edwards recommended cables are shown in Table 1.

MFG. TYPE #14 TWISTED PAIR #16 TWISTED PAIR #18 TWISTED PAIR

ATLAS FPL 218-14-1-1TP* 218-14-1-1STP 218-16-1-1TP* 218-16-1-1STP 218-18-1-1TP*] 218-18-1-1STP

BELDEN FPL 9580 9581 9572 9575 9571 9574

WEST

PENN

UNSHIELDED SHIELDED UNSHIELDED SHIELDED UNSHIELDED SHIELDED

FPLP 1762-14-1-2J 1761-16-1-2J 1762-16-1-2J 1761-18-1-2J 1762-18-1-2J

FPLP - 83752 - - - -

FPL 994 995 990 991 D980* D975*

FPLP 60993 60992 60991 60990 60980 60975

TABLE 1 - Edwards APPROVED CABLE MANUFACTURER'S PART NUMBERS

4

Page 6

Fire Alarm systems use a variety of high and low level signals. Table 2 is a listing of cable functions that require

shielding or physical separation in order to eliminate cross-talk and interference when bundled together.

Table 2 - Bundled or single conduit wiring considerations

TRADITIONAL

TRADITIONAL INDICATING

DEVICE CIRCUIT Y Y Y

24 VDC INDICATING APPLIANCE

& CONTROL CIRCUITS

120 Vac CONTROL CIRCUITS

2

2

IDC

Y Y Y Y Y Y Y Y Y Y N

N N N N N Y N N N N N Y

ZAS

IDC

NOTES:

Y = Yes, allowed; N = Not Allowed

All Wiring twisted pair cable unless noted.

1

Twisted-Shielded Cable Required.

2

Twisted Pair Cable not required.

3

Shield recommended on at least one cable.

4

Separate conduit recommended.

RS-232 RS-485 20 mA FIBER

3

Y Y Y Y Y Y

OPTIC

PHONE1LOW LEVEL

2

AUDIO

25 Vrms

1

AUDIO

70 Vrms

4

AUDIO

3

N Y N

24 VDC

CONTROL CIRCUITS

120 Vac CONTROL

2

CIRCUITS

2

5

Page 7

BASIC WIRING PICTORIALS

The supervised wiring configurations commonly used when installing a fire alarm

panel are referred to by function and style. The most common functions are

Initiating Device Circuits (IDC), Indicating Appliance Circuits (IAC). Initiating

device circuits connect the fire alarm panel to the system components that detect

the fire, i.e., smoke detectors, manual pull stations, waterflow switches, etc.

Indicating Appliance Circuits connect the fire alarm panel to the components

which alert building occupants of the fire, i.e., bells, horns, speakers, strobe

lights, etc.

The following illustrations show schematics, wiring connections, riser diagram,

and wire pull, for some commonly used fire alarm circuits.

6

Page 8

Figure 6

7

Page 9

Figure 7

8

Page 10

Figure 8

9

Page 11

Figure 9

10

Page 12

Figure 10

11

Page 13

TEST

Per NFPA Standard 72, Testing Procedures for Local, Auxiliary, Remote Station

and Proprietary Protective Signaling Systems, before the cable conductors are

terminated at the control panel or field devices they should be tested to verify

their suitability for operation. The 72 standard requires that conductors be tested

for: stray voltages, ground faults, short circuit faults, and that conductor

continuity be verified and resistance values measured and recorded. The

measured values should be compared with the manufacturer's requirements, to

ensure compliance.

Failure to perform these simple tests can prolong the system de-bug time, and

in some cases damage expensive equipment.

12

Page 14

TERMINATE

Fire alarm wiring and devices are required to be supervised by the electrical and

fire alarm codes. This verifies the ability of the system to function properly during

a fire. In order for the supervisory circuitry to operate properly, the fire alarm

wiring and device installation must follow a few simple rules.

RULE #1 ALWAYS BREAK A WIRE BEFORE CONNECTING IT TO A

FIRE ALARM DEVICE. NEVER LOOP AN UNBROKEN

WIRE UNDER ANY TERMINAL.

RULE #2 CONNECT ONLY TWO (2) WIRES UNDER EACH WIRE

NUT OR TERMINAL.

13

Loading...

Loading...