Page 1

www.edwardssignaling.com

P/N 1030523 • REV D • REB 20MAR13

Integrity Series

Description

The INT-04 Series Emergency-Stop (E-Stop) Safety Relays are designed for use as part

of a safety circuit in emergency-stop or safety floor mat sensing applications. Each is

a safety relay that uses positive-guided relays, configured for self-checking, to inhibit

machine restart in case of internal component failure.

The INT-04 relay can also monitor contacts on external relays for controlling primary

machine control elements or expansion block relays (INT-05 or INT-06).

TUV Notes:

1. Relay conforms to Pollution Degree II, meets EN1760-1:1998, and must be installed

in an IP54-type enclosure.

2. The wire insulation of connected devices must be rated for 250VAC. The relay meets

basic insulation requirements only.

3. Input devices must meet requirements of EN60947-5-1.

4. The relay must be connected to a primary disconnect device that meets the

requirements of EN60947-3.

5. System total response time must not exceed 200ms.

6. Controller meets IP20 and must be connected to safety category 4 mat or

sensing device.

7. Test system before operation and after machine maintenance. Controller does not

require maintenance.

8. The complete system should be tested weekly. If a fault occurs, contact

Sentrol Industrial.

Dimensions

2.17"

5.5cm

2.95"

7.5cm

4.53"

11.5cm

0.26"

0.66cm

1.48"

3.75cm

2.46"

6.25cm

Slot for 35mm

DIN rail mount

Emergency-Stop Safety Relay

INT-04-024

INT-04

INT-04-120

Installation

1. Mount the relay on a 35mm DIN rail or panel. See

2. Connect the wiring for the switches and relay. See

operation, DO NOT jumper terminal 1 to terminal 2. Use a momentary button.) For

floor mat applications, connect the two floor mat loops from terminal X1 to X2 and

from Y1 to Y2.

Caution! The relay is available in either a 24 VDC, 120 VAC, or 230 VAC model.

Make sure you are using the correct model before you apply power.

3. Use one of the following methods to energize the relay:

• For E-stop installations, close all E-stop button contacts and monitored contacts,

and then press the START button.

• For floor mat installations, press the START button without an object on the mat.

Note: Use only outputs A, B, C, and D for safety outputs. The auxiliary outputs E, F,

and G may fail in an unsafe condition and should only be used for signaling.

E-Stop Relay

When installed as an E-stop relay, the device monitors both contacts on the E-stop

buttons to ensure both have opened and closed to allow machine restart. Multiple

contacts can be wired in series. Upon failure of either contact, the relay turns off and

prevents a restart.

Safety Floor Mat Relay

When installed as a Safety Floor Mat relay, the INT-04 monitors both loops of a safety

floor mat. The safety outputs of the INT-04 turn off when an operator steps on the mat.

The relay incorporates loop break detection to turn off if one of the loops breaks or

becomes disconnected.

INT-04 __________

Dimensions

Wiring Diagrams

.

. (For proper

Page 2

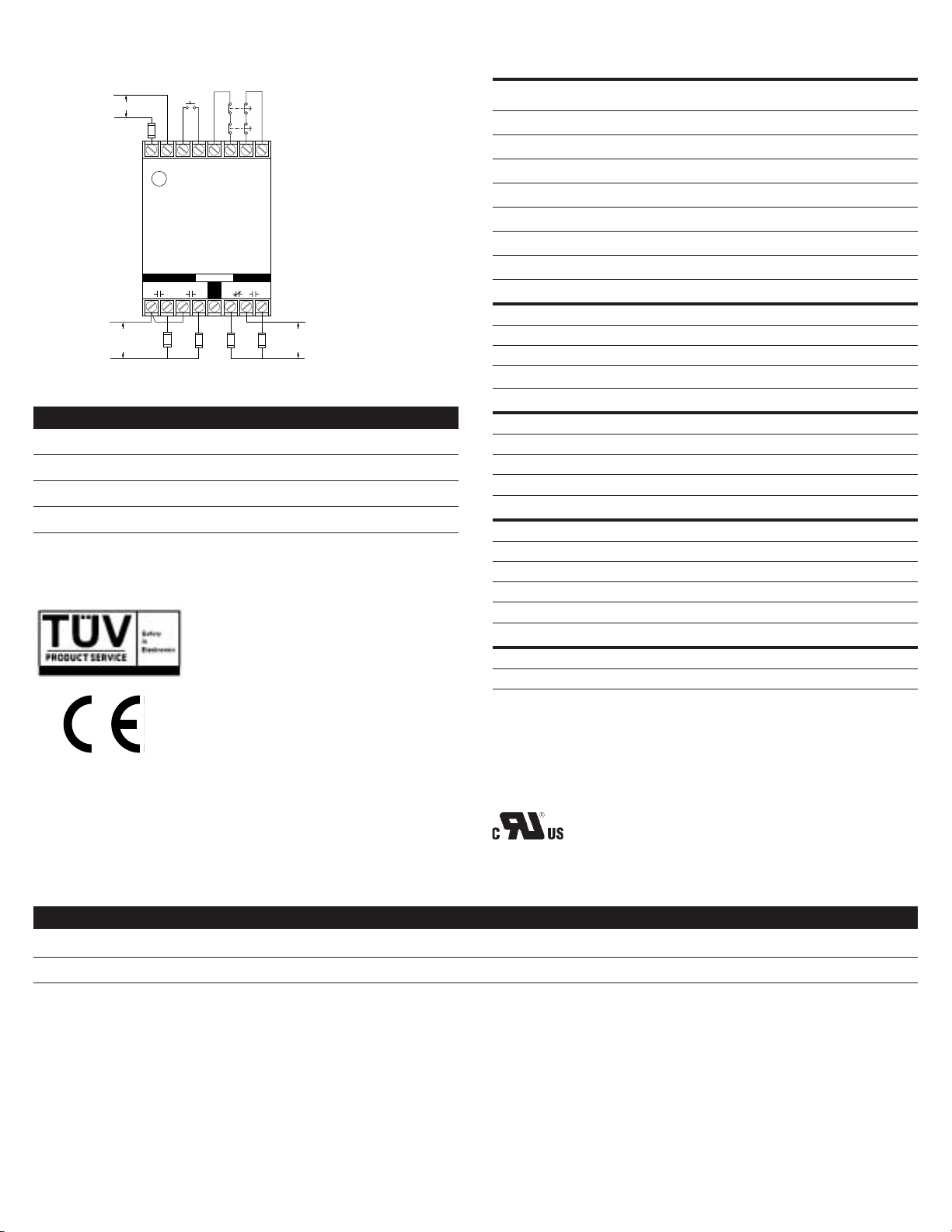

Typical Wiring Diagram

General Specifications

120 VAC

230 VAC

60 VDC

FUSE

RESET

L1 L2 1 2 X1 X2 Y1 Y2

–

+

Emergency Stop Relay

INT-04

SAFE AUX.

A

BCD

LOADS

N.O.

OUTPUTS

EFG

INT04WIR

120 VAC

30 VDC

Auxillary Contacts

POWER RESET (1, 2) E-STOPS E, F F, G

Off Open or Closed Open or Closed Closed Open

On Open Open or Closed Closed Open

On Open or Closed Open Closed Open

On Closed Closed Open Closed

Reset “Open” is prior to initiating a cycle.

Reset “Closed” can be momentary to maintained.

European Directives

Machinery Directive (98/37/EEC)

Low Voltage Directive (73/23/EEC), LVD

Specific European Standards

EN60204-1 Safety of electrical equipment of industrial

machines: 1993

EN954-1 Risk Assessment Category 4

depending on wiring method, See diagrams: 1997

EN50081-2 Electromagnetic Emissions: 1995

EN50082-2 Electromagnetic Immunity: 1995

Declaration of Conformity

available upon request.

IEC 664-1 Insulation requirements: 1992

IEC 68, part 2-1, 2-2, 2-3, 2-6, 2-14, 2-27, 2-30.

EN1760-1:1998

Listings TUV, UL E122942

Weight INT-04-24 9oz

INT-04-120 15oz

Field wiring size 12 gauge max.

Environmental rating Pollution Degree II

Controller rating IP20

Temperature range 32°F to 149°F (-0°C to 65°C)

Relative humidity 30 to 95% non-condensing

Power Supply (+,- or L1, L2)

INT-04-024 24VDC +/-15%

Required fuse 1/4A (250V, 5x20mm, F/T)

INT-04-120 120VAC +10%, -20%, 5VA, 50/60Hz

Required Fuse 80mA (250V, 5x20mm, F/T)

Control Inputs (X1, X2 & Y1, Y2 terminals)

Open-circuit voltage 24VDC

Closed-circuit current 24mA

Max. contact resistance 30 Ohms

Simultaneity 500ms typical

Safe Outputs (A, B & C, D terminals)

Voltage 230VAC/60VDC

Current 4A (resistive) each output

Response time ON: <100msOFF: <100ms

Required Fuse 4A (250V, 5x20mm, F/T)

Life Expectancy 100,000 cycles

Signaling Outputs (E, F, and G terminals)

Voltage: 120VAC/30VDC

Current: 1A (resistive)

File E 122942

Ordering/Electrical Specifications

PART NUMBER POWER INPUT INPUT FUSE REQUIRED

INT-04-024 24VDC +/-15%, 100mA Fast acting 1/4mA (250V, 5 x 20mm, F/T)

INT-04-120 120VAC +10% -20%, 5VA, 50/60Hz Fast acting 80mA (250V, 5 x 20mm, F/T)

Loading...

Loading...