Page 1

ESL 511/518 Series

Smoke Detector

Installation Instructions

U

L

LISTED

Description

The ESL 511/518 Series Smoke Detector is a two-wire

detector designed for use with a 24VDC fire system.

Refer to ESLs Compatibility Index for a complete listing

of compatible control panels. For a copy of the

Compatibility Index, call 1-800-648-7424.

WARNING

!

It is important that you read, understand, and follow

the instructions in this guide. If you have questions,

call Sentrol at 1-800-648-7424.

This document is intended for licensed electricians/

alarm installers. Sentrol cannot provide technical

support to unqualified persons.

Failure to properly install, test, and maintain a

smoke detector system may cause it to fail resulting

in loss of life and/or property.

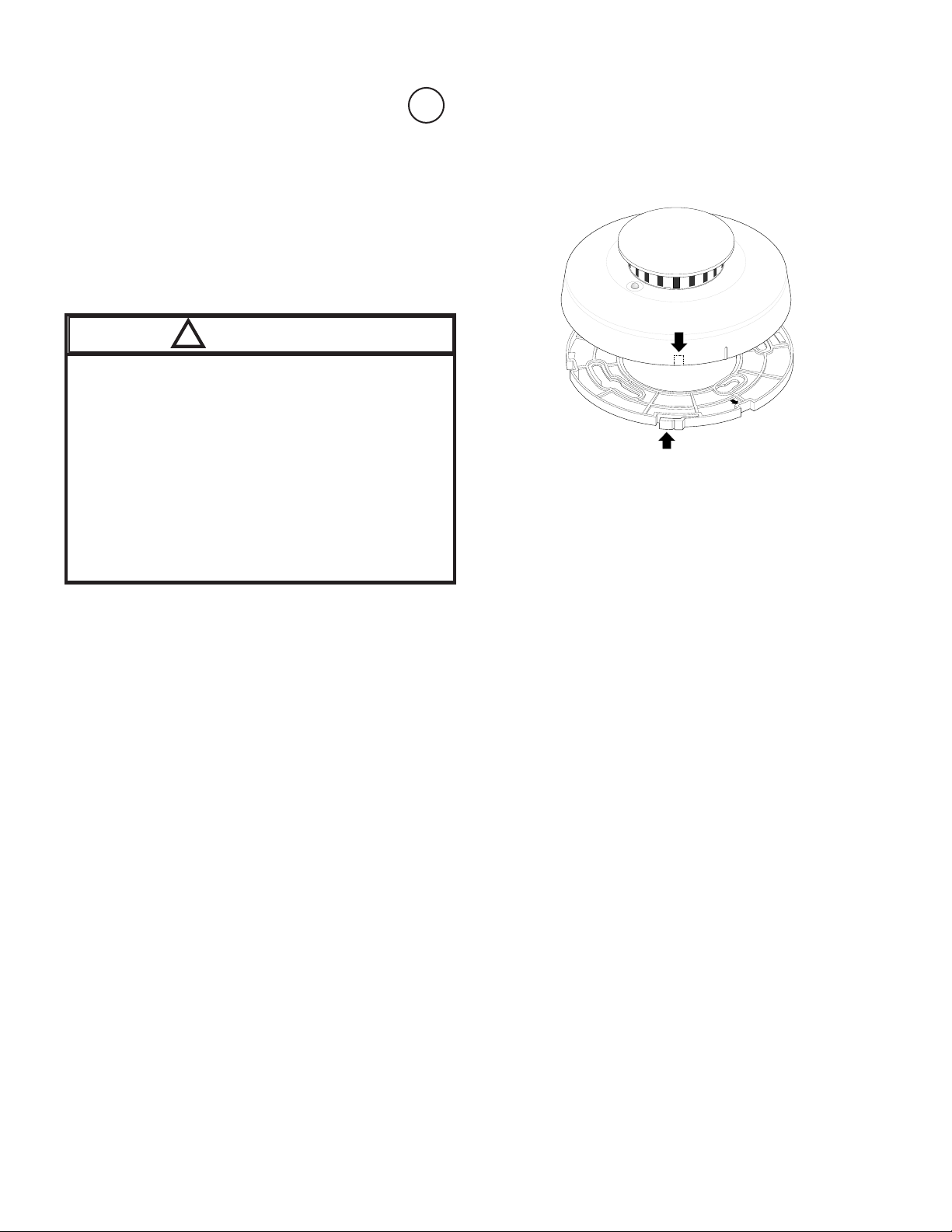

Figure 1 - Detector/Base Lock Knockouts

Locate wall-mounted smoke detectors so the top of the

detector is 4 to 12 inches below the ceiling.

DO NOT locate detectors in or near bathrooms or

kitchens.

The detector provides the following features:

Detector/base lock discourages unauthorized removal of

the detector by requiring a screwdriver to remove the

detector from the base.

Mounting base mounts directly to standard single-gang, 3inch round or 4-inch octagonal electrical boxes. Can also

be mounted directly to walls and ceilings if the local

authority having jurisdiction allows.

Selecting a Location

Selecting a suitable location is critical to the operation of

smoke detectors. This equipment should be installed in

accordance with the National Fire Protection Associations

(NFPA) Standard 72.

Important: Regulations pertaining to detector installation

vary from state to state. For more information, contact

your local fire department or local authority having jurisdiction.

In addition to NFPA 72, use the following location guidelines to optimize performance and reduce the chance of

false alarms from the detector:

Locate ceiling-mounted smoke detectors in the center of

a room or hallway at least 4 inches from any walls or

partitions.

Locate in a suitable environment as follows:

- Temperature between 32°F (0°C) and 100°F (37.8°C)

- Humidity between 0 and 95% non-condensing

Locate away from air conditioners, heating registers and

any other ventilation source that may interfere with

smoke entering the detector.

Mount smoke detectors on a firm permanent surface.

Installing the Detector

All wiring must conform to the National Electric Code

(NEC) and/or local codes having jurisdiction. Use 12 to

24 AWG wire to install the detector.

1. If you are using the detector/base lock, remove the

detector knockout and break off the tab on the mounting

base. See Figure 1.

2. Remove the red plastic dust cover from the detector.

The detector is shipped with a dust cover for protection

on construction sites with dusty environments.

3. Run system wiring to the detector location and mount

electrical boxes if necessary.

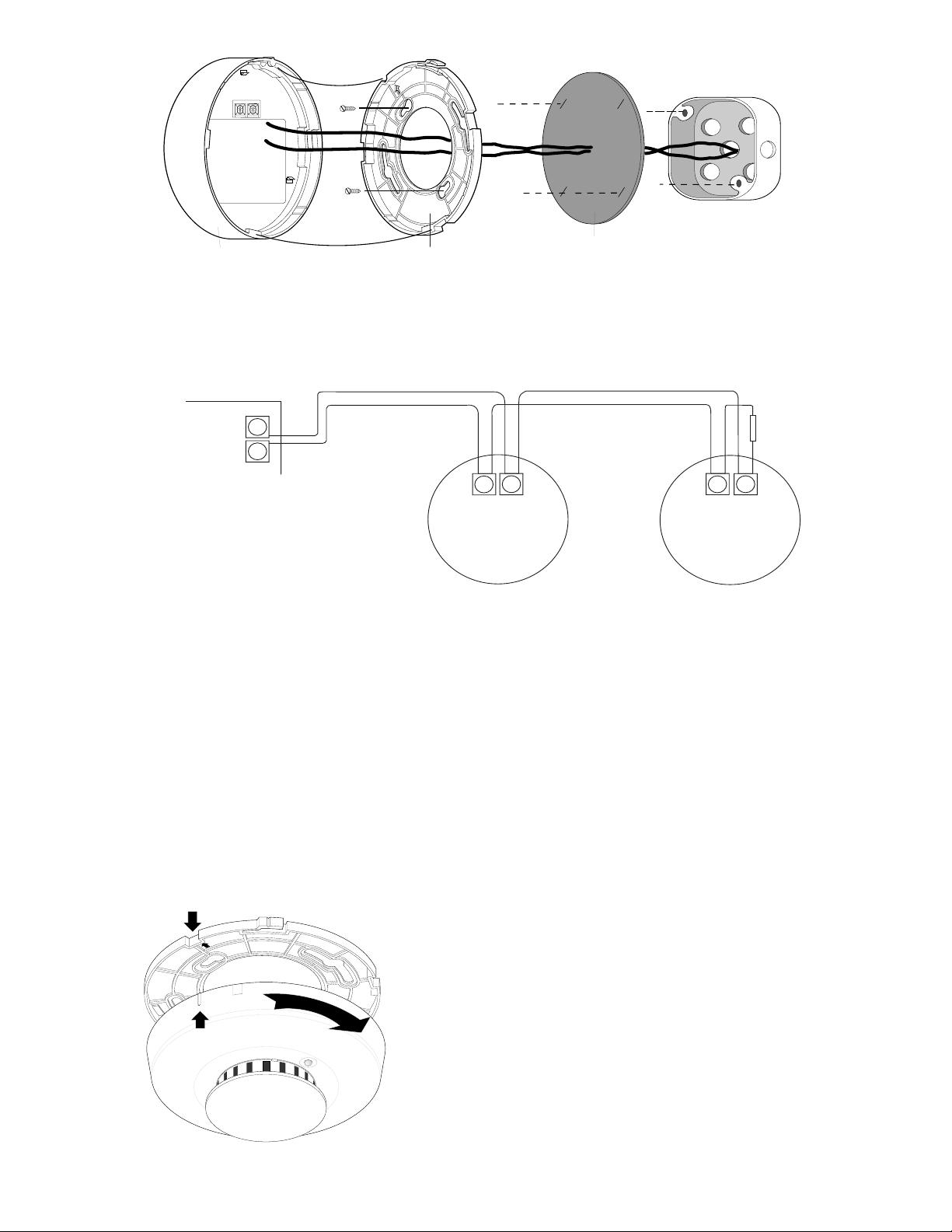

4. Line up and attach the gasket and mounting base to the

electrical box, wall, or ceiling using the screws provided. Use the wall anchors if necessary. See Figure 2.

5. Strip the system wires and connect them to the appropriate terminals on the detector. See Figure 3.

1

Page 2

Detector

UL Listed control panel

Mounting base

Figure 2 - Mounting the Detector

Gasket

2-wire

initiating

circuit

+

_

Figure 3 - Wiring Diagram

6. Attach the detector to the mounting base as follows:

- Line up the raised tab on the side of the detector with

the arrow on the mounting base. See Figure 4.

- Insert the smoke detector into the base and turn

clockwise approximately 15 degrees. It should snap

firmly into place.

7. Apply power.

8. Test the detector. See Smoke Testing the

Detector.

Important: The control panel alarm and all auxiliary

functions should be verified for a complete test of the

system.

EOL

device

_

+

First

detector

_

+

Last

detector

Smoke Testing the Detector

Smoke detectors should be tested in place annually using

smoke or canned aerosol simulated smoke. Follow the

instructions on the canned smoke or use the following

steps to test the detector with smoke:

1. Hold a smoldering punk or cotton wick close to the

smoke entry openings.

2. Gently direct the smoke into the detector for 20 seconds

or until an alarm is indicated.

BE SURE TO PROPERLY EXTINGUISH THE SMOKE

SOURCE AFTER TESTING! The detector LED should

stay on and an alarm should be indicated at the control

panel. Use the system reset switch to reset the detector.

Figure 4- Attaching Detector to Base

Understanding the LED

The LED on the detector indicates the status of the detector

as follows:

Flashing every 9 seconds = Normal operation.

On = Detects smoke, sending an alarm.

Off or flashing once every 1.5 seconds = Trouble or

maintenance is required. Test the detector. See Testing the

Detector Sensitivity.

2

Page 3

Testing the Detector Sensitivity

The detector provides a sensitivity test that allows you to

check the detector sensitivity using a test magnet and the

LED indicator on the detector as follows:

1. Hold the test magnet up to the raised TEST letters on

the top of the detector for 2 seconds. See Figure 5.

Once the test starts, the alarm LED flashes one to nine

times.

2. Count the number of times the LED flashes and use the

following table to determine the status of the detector

sensitivity and what action to take, if any.

sehsalF noitarucsbO

)xorppA(

1A/NelbaecivresnU

3-2A/NtonsirotceteD

4tf/%6.3 nihtiwsirotceteD

5tf/%1.3

6tf/%6.2

7tf/%1.2

9-8A/NootsirotceteD

After the test:

If the sensitivity is within limits and all other tests pass,

the detector goes into alarm and must be reset from the

control panel.

If the sensitivity is not within limits or an unserviceable

hardware fault has been detected, the detector LED

flashes every 1.5 seconds until the detector is serviced.

noitacidnI noitcA

tluaferawdrah

.detceted

.hguoneevitisnes

A/N

ytivitisneslamron

.egnar

.evitisnes

nurerdnatinuteseR

rorreehtfI.tsetytivitisnes

.tinuehtecalper,stsisrep

tinuteseR.tinuehtnaelC

.tsetytivitisnesnurerdna

,stsisreprorreehtfI

.tinuehtecalper

ekomsehttahtyfireV

deppanssirebmahc

Figure 5 - Test Magnet Placement

Attaching and Removing the Detector

To remove the detector from the mounting base, grasp

the detector and turn it counterclockwise approximately 15

degrees. The detector should snap off of the mounting

base.

To remove the detector from the mounting base when

the detector/base lock is used, insert a small screwdriver

.tinunaelC.ylerucesnwod

into the locking tab slot on the side of the base and press in

while simultaneously turning the detector counterclockwise

15 degrees. See Figure 6.

Attach the smoke detector to its mounting base as

follows:

- Line up the raised tab on the side of the detector with the

arrow on the mounting base. See Figure 4.

- Insert the smoke detector into the base and turn

clockwise approximately 15 degrees. It should snap

firmly into place.

Figure 6 - Unlocking the Detector

3

Page 4

Cleaning the Detector

SQUEEZE

HERE

Optical

chamber

Cap

Optical

chamber

base

Clean the detector cover with a dry or damp (water) cloth as

needed to keep it free from dust and dirt.

When necessary, clean the detector interior and replace the

optical chamber as follows:

1. Disconnect the alarm notification appliances, service

release devices and extinguishing systems.

Screwdriver slot

2. Slide a flat-blade screwdriver into the slot on the detector

cap and gently push the handle down to pry the cap up

and off. See Figure 7.

3. Press in on the sides of the optical chamber and pull it up

and away from the detector and discard. See Figure 8.

4. Use a vacuum to remove dust and dirt from the optical

chamber base.

5. Line the new optical chamber up with the optical chamber

base and snap it down into place.

6. Replace the detector cap as follows:

-Line the tabs on the cap with the slots on the detector.

-Insert the cap into the smoke detector and turn

clockwise approximately 15 degrees. It should

snap firmly into place.

7. Test the detector sensitivity (See Testing the Detector

Sensitivity).

8. Reconnect all alarm notification appliances, service

release devices and extinguishing systems.

Important: The control panel alarm and all auxiliary

functions should be verified for a complete test of the

system.

Figure 7 - Removing the Detector Cap

Detector

Cap

Maintaining the Detector

The 511/518 Series smoke detectors are designed for

easy field service and maintenance. When installed and

used properly, they require minimal maintenance.

The smoke detector should be tested weekly. See

Testing the Detector Sensitivity and Smoke Testing the

Detector.

Figure 8 - Removing the Optical Chamber

4

Page 5

WARNING

!

Smoke detectors MAY NOT provide early warning

for fires resulting from explosions, smoking in bed

or other furniture, ignition of flammable liquids,

vapors and gases, or children playing with matches

or lighters.

Limited Warranty

ESL is a brand name of Sentrol. The manufacturer warrants this smoke detector to be free from defects in material

and workmanship under conditions of normal use for a

term of 3 years from the date of manufacture.

During the warranty period, if a Sentrol product or any of

its components becomes defective, it will be repaired or

replaced without charge.

Out-of-warranty units will be repaired at the discretion of

the manufacturer, if not, a card will be forwarded to the

customer suggesting a replacement unit and the cost of that

unit.

This warranty does not apply to units which have been

subject to environmental damage, abuse, misuse, negligence or accident, or to which any modifications, alterations or repairs have been made or attempted.

This warranty is extended only to the original purchaser of

the smoke detector and may be enforced only by such

person. During the warranty period, if the detector or any

warranted components thereof becomes defective, at the

manufacturers discretion, it will be replaced or repaired

without charge if returned in accordance with the following

instructions:

TIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE LIMITED IN DURATION

FOR A PERIOD OF 3 YEARS FROM THE DATE OF

MANUFACTURE. UNDER NO CIRCUMSTANCES

SHALL MANUFACTURER BE LIABLE TO THE PURCHASER OR ANY OTHER PERSON FOR INCIDENTAL

OR CONSEQUENTIAL DAMAGES OF ANY NATURE,

INCLUDING WITHOUT LIMITATION DAMAGES FOR

PERSONAL INJURY OR DAMAGES TO PROPERTY,

AND HOWEVER OCCASIONED, WHETHER ALLEGED AS RESULTING FROM BREACH OF WARRANTY BY MANUFACTURER, THE NEGLIGENCE OF

MANUFACTURER OR OTHERWISE.

MANUFACTURERS LIABILITY WILL IN NO EVENT

EXCEED THE PURCHASE PRICE OF THE PRODUCT.

SOME STATES DO NOT ALLOW LIMITATIONS ON

HOW LONG AN IMPLIED WARRANTY LASTS, OR

THE EXCLUSION OR LIMITATION OF INCIDENTAL

OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATIONS AND EXCLUSIONS MAY NOT APPLY

TO YOU. UNLESS A LONGER PERIOD IS REQUIRED

BY APPLICABLE LAW, ANY ACTION AGAINST

MANUFACTURER IN CONNECTION WITH THIS

SMOKE DETECTOR MUST BE COMMENCED

WITHIN ONE YEAR AFTER THE CAUSE OF ACTION

HAS OCCURRED.

No agent, employee or representative of the Manufacturer

nor any other person is authorized to modify this warranty

in any respect. Repair or replacement as stated above is the

exclusive remedy of the purchase hereunder. This warranty

gives you specific legal rights and you also have other

rights which vary from state to state.

Obtain a Return Authorization Number by calling 1-800648-7422 or 503-692-4052, then carefully pack it in a well

padded and insulated carton and return, postal charges

prepaid to:

Customer Service

Sentrol

12345 SW Leveton Drive

Tualatin, OR 97062-9938

A note should be included advising the nature of the

malfunction. Care must be exercised in the proper packing

of detectors returned under this warranty as Sentrol will not

be responsible for warranty repairs to equipment damaged

because of improper packing.

THE ABOVE WARRANTY IS IN LIEU OF ALL OTHER

EXPRESS WARRANTIES, AND IMPLIED WARRAN-

5

Page 6

Specifications

Voltage................24VDC (8.5 - 33VDC), polarity sensitive

Maximum standby current ......................................... 70uA

Maximum alarm current ........................................... 70mA

Minimum reset time......................................................1 sec

Photoelectric sensitivity...........................3.1% +0.5% -1%

Operating temperature .........................32°-100°F (0°-37.8°C)

Operating humidity......................... 0-95% non-condensing

Color ...........................................................................white

Packaging........................................ 10 detectors per carton

Detector dimensions....................... 5" x 2" (12 cm x 5 cm)

Base dimensions ................4.75" x 0.3" (12.5 cm x 0.8 cm)

Drift compensation adjustment ........................ 1%/ft. max.

Heat detector specifications:

Rate of rise............15°F/min>105°F (8.3°C/min>40.6°C)

Field wiring size.................................................12-24AWG

Listings:

511C/511AFT.......................................................UL 268

518C/518AFT...........................................................ULC

UL Compatibility identifier..........................................S10A

Product Ordering

ledoM noitpircseD

C115.detsil,LUrotcetedcirtceletohp,eriw-2

TFA115 .detsilLU,rosnestaeh/wrotcetedcirtceletohp,eriw-2

C815.detsilCLU,rotcetedcirtceletohp,eriw-2

TFA815 .detsilCLU,rosnestaeh/wrotcetedcirtceletohp,eriw-2

seirosseccA

104.gnitnuomeloprofllehscitsalpanitengamtseT

002-MS

1TXE-MS

112.)01fotes(srebmahclacitpotnemecalpeR

naCani!ekomS

naCani!ekomS

ebutnoisnetxe

.

.gnitsetlanoitcnufrofekomsdennac

ESL

a product of sentrol

SENTROL

12345 SW Leveton Dr., Tualatin, OR 97062

Tel.: 503.692.4052 Fax: 503.691.7566

http://www.sentrol.com

U.S. & Canada: 800.547.2556

Technical Service: 800.648.7424

FaxBack: 1.800.483.2495

6

Sentrol reserves the right

to change specifications

without notice.

© 2000 Sentrol

1032551 RevA 02/00

Loading...

Loading...