Page 1

Setting

1

2

3

E-2WIRE Analog Class A/B Two-Wire Module

Installation Sheet

Operation

The E-2WIRE module is designed to interface between

conventional two-wire smoke detectors and a control panel. It

monitors the circuit and smoke detectors and signals the

control panel of any trouble or alarm conditions. The module

also regulates and supervises the 24 VDC input power.

The module is configured from the factory to operate as a twowire alarm device that does not require alarm verification. It

can be configured for two-wire alarm verified operation through

front panel programming or the configuration utility. When

using the alarm verification feature of the control panel, do not

mix normally open contact initiating devices with two-wire

conventional smoke detectors.

The module recognizes the CleanMe signal from detectors that

support this feature.

The module device address is set using the two rotary

switches located on the front of the module. One device

address is required.

The device can be set for Class B or Class A operation using

the slide switch located on the front of the module.

Caution: This module cannot be used on a device loop with

isolator modules or isolator bases.

Note: Additional device types are available through front panel

programming or the configuration utility. Refer to applicable

control panel technical reference manual.

Figure 1: Slide switch

LED operation

The module provides a bicolor LED that shows its status.

Normal: Green LED flashes

Alarm/active: Red LED flashes

Installation

WARNING: This module will not operate without electrical

power. As fires frequently cause power interruption, you should

discuss further safeguards with your local fire protection

specialist.

Slide switch operation

The following slide switch settings determine the operation of

the module. Setting the initial slide switch position is generally

performed during module installation. This setting can be

changed while the system is operating, but the change must be

confirmed through front panel programming.

Table 1: Slide switch operation

Operation Device t ype descripti on

Class B

Not used

Class A

© 2013 UTC Fire & Security. All rights reserved. 1 / 4 P/N 3101192 • REV 03 • REB 25JAN13

Class B 2-wire smoke non-verified:

Configures the module to monitor two-wire

conventional smoke detectors (that do not

require alarm verification) and normally

open contact initiating devices on a Class B

circuit.

Class A 2-wire smoke non-verified:

Configures the module to monitor two-wire

conventional smoke detectors (that do not

require alarm verification) and normally

open contact initiating devices on a Class A

circuit.

Note: The module is shipped from the factory as an assembled

unit; it contains no user-serviceable parts and should not be

disassembled.

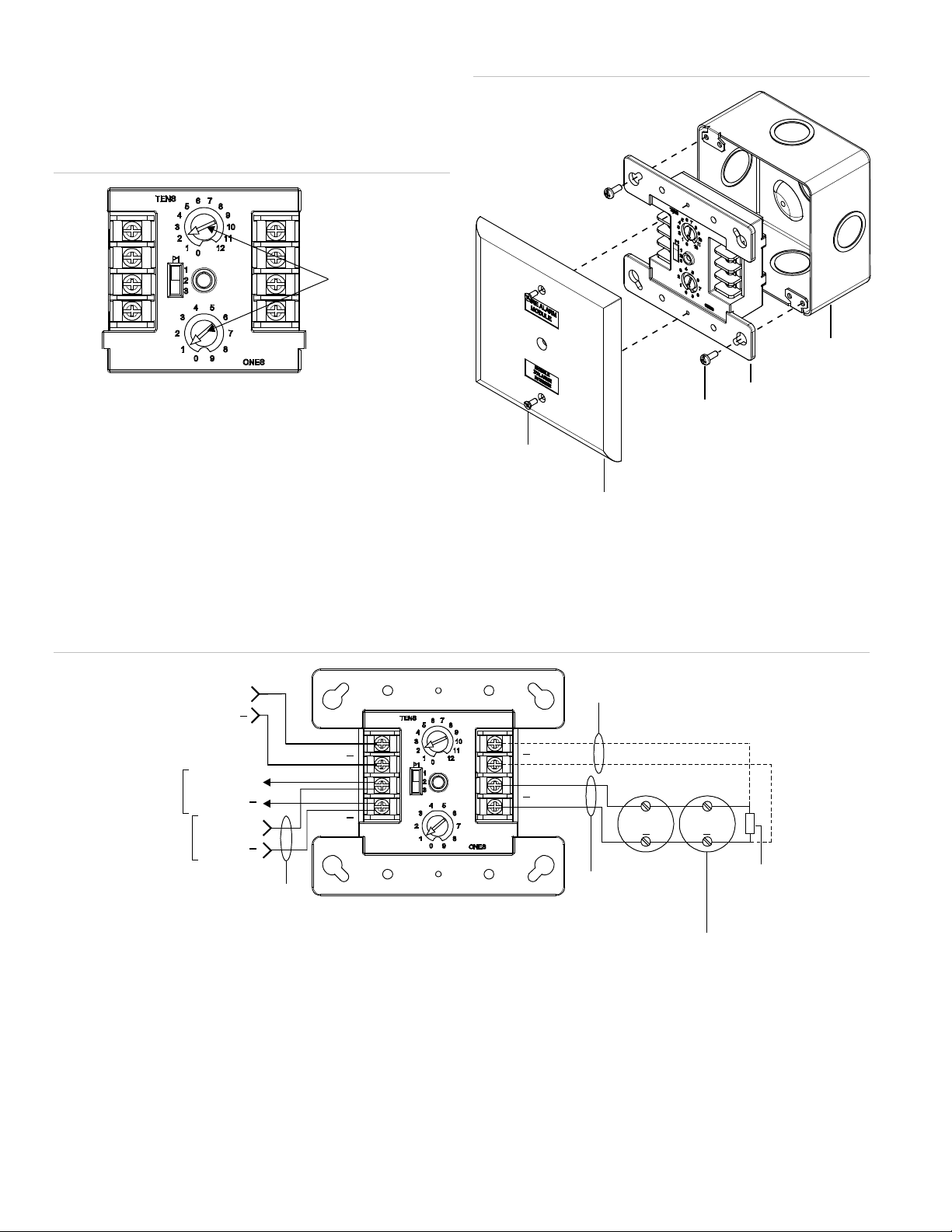

To install the module:

1. Verify that all field wiring is free of opens, shorts, and

ground faults.

2. Make all wiring connections as shown in “Wiring.”

3. Set the module address as follows:

Use a screwdriver to adjust the two rotary switches on the

front of the module. Set the TENS rotary switch (0 through

12) for the 10s and 100s digit and the ONES rotary switch

for the 0 through 9 digit. For example: device address 21,

set TENS rotary switch to 2 and set the ONES rotary

switch to 1.

Refer to “Specification s” for availa ble addr e ss number s.

4. Set slide switch P1 to appropriate setting. Refer to

“Operation.”

Page 2

5. Mount the module on the electrical box using screws

Insert

screwdriver

here

Screw

4-24

screws

Module

Wall plate

Compatible

electrical box

[3]

Style D (Class A)

[1] [2] [4 ]

Style B (Class B)

[1] [2] [4 ]

Typical

initiating

device

TB2 TB1

From

previous

device

To next

device

From control

panel (not

resettable)

24 V +

4.7 k EOLR

Used for

Class B only

Ω

SLC out (+)

SLC out

SLC in

SLC in (+)

SLC

DET. PWR.

(+)

(+)

(+)

(+)

+ +

RETURN

DET.

( )

( )

( )

( )

( )

24 V

( )

provided with the electrical box.

6. Mount the wall plate on the module using #4-24 × 1/2 in.

(13 mm) self-tapping screw s.

Figure 2: Module address

Figure 3: Module installation

Figure 4: Module wiring

Notes

[1] Maximum 25 Ω resistance per wire

[2] Maximum 12 AWG (2.5 sq. mm) wire; minimum 18 AWG (0.75 mm

[3] Refer to the control panel technical referenc e manual for wiring specifications

[4] Maximum 23.8 VDC at 35 mA

2 / 4 P/N 3101192 • REV 03 • REB 25JAN13

Wiring

Wire in accordance with NFPA 72 and CAN/ULC-S524. Be

sure to observe the polarity of the wires as shown in Figure 4.

2

) wire

Page 3

Specifications

Communication line voltage

Current

Ground fault impedance

Control panel input power (not

resettable)

Smoke power current

Smoke detecto

UL compatibility ID

Operating environment

0 to 93% RH, noncondensing at 90°F

Storage temperature range

Compatible electrical boxes

Wire size

Device address

Initiating device circuit (IDC)

Standby

Activated

Standby

Alarm

r current 3 mA

0.0

Temperature

Humidity

EOL resistor value

Max. circuit resistance

Max. circuit capacitance

Maximum 20.6 V peak-to-peak

350 μA

350 μA

5 kΩ

12.4 to 28.3 VDC

17 mA

58 mA

32 to 120°F (0 to 49°C)

(32°C)

–4 to 140°F (–20 to 60°C)

North American 4 inch square ×

2-1/2 in. (64 mm) deep 2 gang box

Standard 4 in. square box 1-1/2 in.

(38 mm) deep

12, 14, 16, or 18 AWG wire (2.5, 1.5,

1.0, or 0.75 mm

AWG are preferred)

01 to 64 (64 point control panel)

01 to 127 (127 point control panel)

4.7 kΩ, (P/N: EOL-4.7)

50 Ω (25 Ω per wire)

0.1 μF

2

) (Sizes 16 and 18

P/N 3101192 • REV 03 • REB 25JAN13 3 / 4

Page 4

4 / 4 P/N 3101192 • REV 03 • REB 25JAN13

Loading...

Loading...