Page 1

product catalog

Page 2

TABLE

OF

CONTENTS

IRONWORKERS

CHOOSE YOUR IRONWORKER

QUICK REFERENCE GUIDE

25 TON

40 TON

50 TON

55 TON

60 TON

65 TON

75 TON

100 TON

100 TON DELUXE

120 TON

ELITE 110 TON

ELITE 110/65 TON

IRONWORKER ATTACHMENT & ACCESSORY

QUICK REFERENCE GUIDE

.................................................................... 6-7

................................................................... 8-11

................................................................. 12-15

.................................................................16-19

...............................................................20-23

............................................................... 24-27

................................................................28-31

............................................................. 32-35

............................................................40-43

................................................ 44-47

...................................4-5

..........................................36-39

...........................................48-51

.............................. 52-53

POWERLINKTM HYDRAULIC TOOLS

PORTABLE POWER UNIT ................................. 56

10 TON BENDER

20 TON RADIUS ROLLER

20 TON HORIZONTAL PRESS

20 TON SHOP PRESSES

40 TON SHOP PRESSES

60 TON SHOP PRESSES

110 TON SHOP PRESSES

ALLIGATOR SHEARS

HOLE SAW NOTCHER

PUNCH & DIE SETS

PIPE & TUBE BENDER DIES

.................................................... 57

................................. 58

......................... 59

....................................60

..................................... 61

............................. 62-63

............................64-65

................................................ 66

.............................................. 67

.............................................. 68-71

............................ 72-74

2

edwardsironworkers.com

Page 3

YOUR WORK IS YOUR REPUTATION.

That’s why each and every day, you put it all out there for

the world to judge. Never stopping and always looking forward

to your next challenge. You know what it means to work hard

to move the industry ahead one build at a time.

AND SO DO WE.

That is why our focus is a new era of fabrication.

Not only do we have the largest line of Ironworkers but we’ve

TM

invented the PowerLink

System to revolutionize the industry.

BECAUSE WE ARE NEVER

CONTENT WITH THE STATUS QUO.

We push harder and dive deeper to provide our customers the

products and resources they need to rise to their next build.

BECAUSE WE KNOW IT IS NOT ONLY ABOUT THE B UILD…

IT’S ABOUT BUILDING A R EPUTATION .

edwards–made in the usa since 1875

3

Page 4

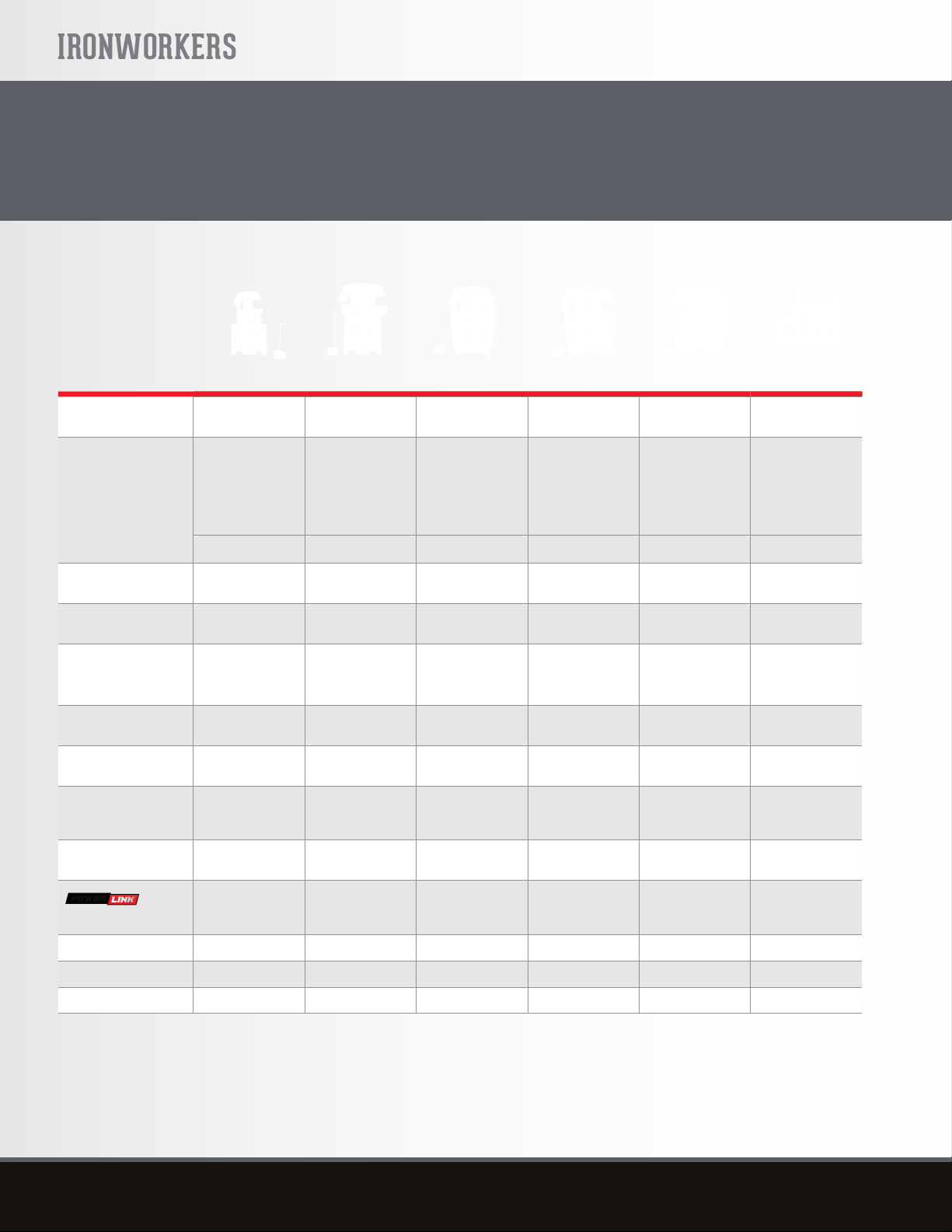

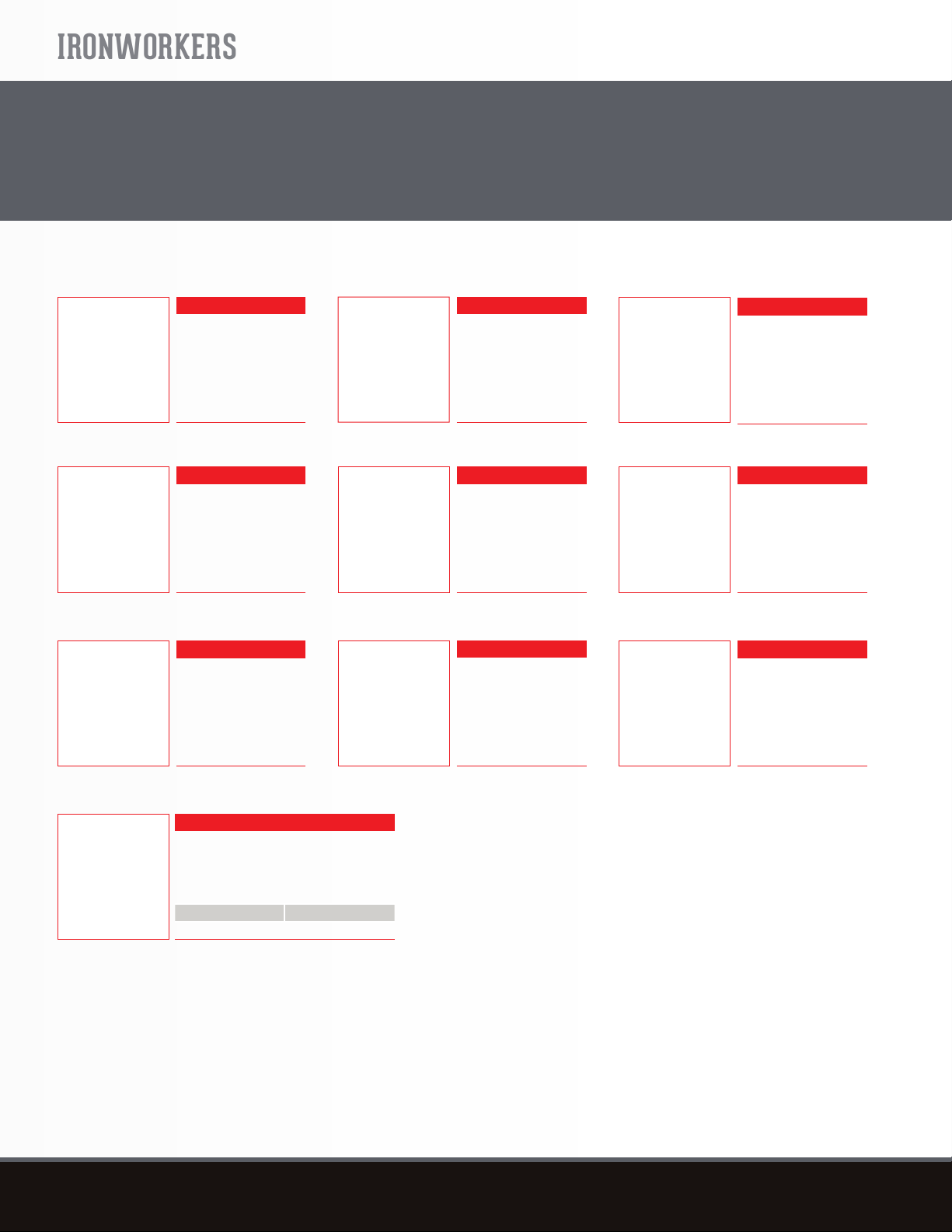

IRONWORKERS

CHOOSE YOUR IRONWORKER

25 TON 40 TON 50 TON 55 TON 60 TON 65 TON

WORKSTATIONS

COUNT

WORKSTATIONS

DESCRIPTION

PUNCH

RATINGS (TONS)

PUNCH MAX

CA PACITY ( IN.)

FLAT BAR S HEAR M AX

CA PACITY ( IN.)

ANGLE SHEAR MAX

CA PACITY ( IN.)

COPER NOTCHER

MAX C APACITY (IN.)

OPTIONAL COPER

NOTCH ER MA X

CA PACITY ( IN.)

MOTOR

2 4 4 4 4

Standard (1)

Punch

Open (1)* Open (1)* — Open (1)* — Open (1)*

25 40 50 55 60

1 diam.

in 5/16 mild steel

—

— 3 x 3 x 1/4

2 x 3 x 1/4 — 2 x 3 x 5/16 — 2-1/2 x 4 x 5/16

—

1 HP

Standard (3)

Punch , Flat Bar

Shear & Angle

Shear

1 diam.

in 1/2 mild steel

3/8 x 10

1/2 x 6

2 x 3 x 5/16

5 HP 5 HP 5 HP 5 HP 5 or 7.5 HP

Standard (4)

Punch , Flat Bar

Shear, Angle

Shear & Coper

Notcher

1 diam.

in 5/8 mild steel

1/2 x 10

3/4 x 4

3 x 3 x 3/8

4 x 4 x 1/4

— 2-1/2 x 4 x 5/16 — —

Standard (3)

Punch , Flat Bar

Shear & Angle

Shear

1-1/16 diam.

in 5/8 mild steel

3/8 x 14

1/2 x 12

3/4 x 4

3 x 3 x 3/8

4 x 4 x 1/4

Standard (4)

Punch , Flat Bar

Shear, Angle

Shear &

Coper Notcher

1 diam.

in 3/4 mild steel

3/8 x 14

1/2 x 12

3/4 x 4

3 x 3 x 1/2

4 x 4 x 3/8

Punch , Flat Bar

Shear & Coper

in 3/4 mild steel

2-1/2 x 5 x 3/8

Standard (4)

Shear, Angle

1-1/16 diam.

5 x 5 x 3/8

5

Notcher

65

3/8 x 24

1/2 x 14

1 x 4

AVAI LA BLE

ATTACHMENTS

ACCESSORIES

PAGE #

ALL IRONWORKERS 40 TON & LARGER AVAILABLE IN THE FOLLOWING POWER CONFIGURATIONS:

1 PHASE, 230 VOLT | 3 PHASE, 208 VOLT | 3 PHASE, 230 VOLT | 3 PHASE, 380 VOLT, 50 HZ | 3 PHASE, 460 VOLT | 3 PHASE, 575 VOLT

* Open Workstation accepts optional Attachments to tailor the Ironworker to your needs

4

No Yes Yes Yes Yes Yes

9 11 9 12 9

7 16 16 17 17

6 - 7 8 - 11 12 - 15 16 - 19 20 - 2 3 24 - 27

edwardsironworkers.com

12

17

Page 5

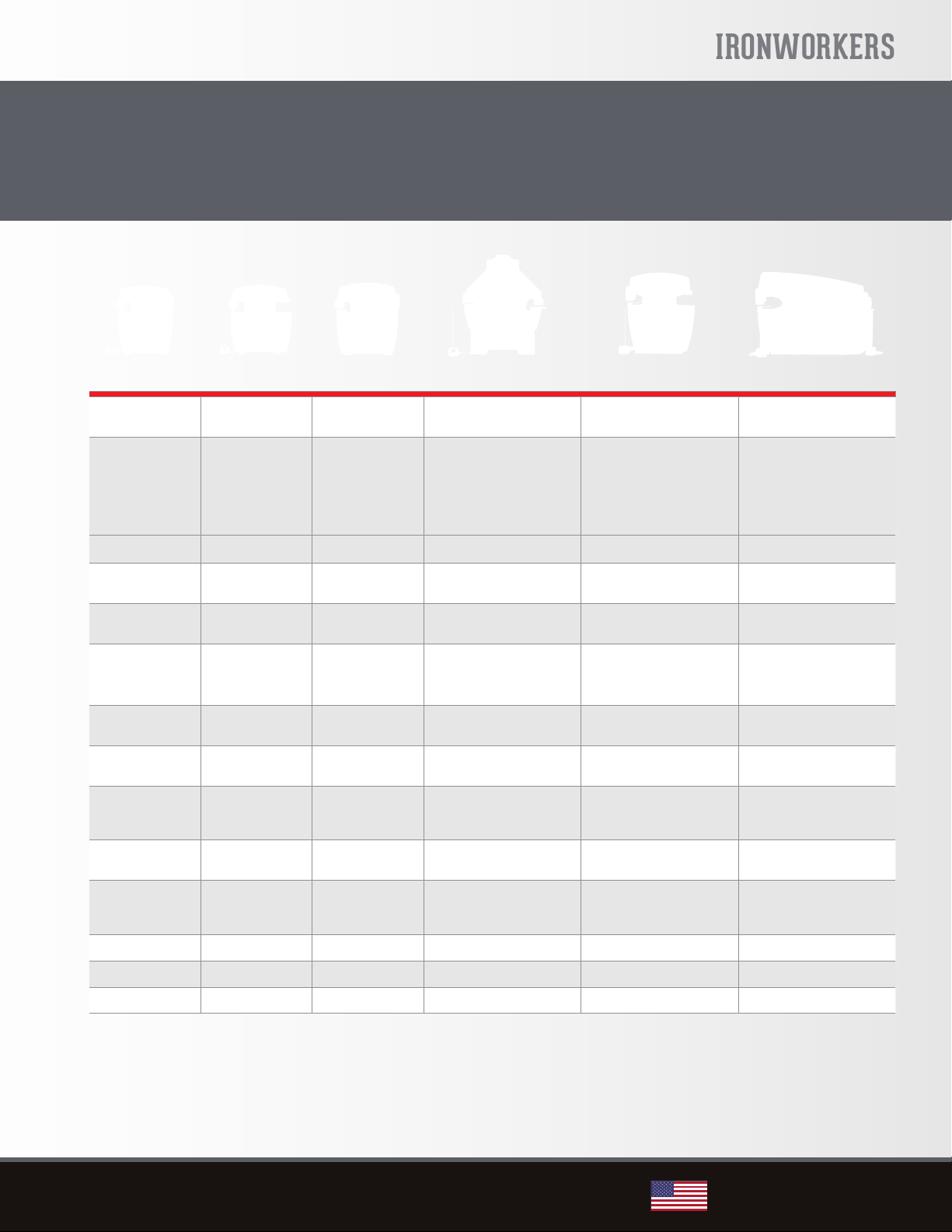

IRONWORKERS

QUICK REFERENCE GUIDE

75 TON 100 TON 100 TON DELUXE 120 TON ELITE 110 ELITE 110/65

4 4 5 5 4 5

Standard (4)

Punch , Flat Bar

Shear, Angle

Shear & Coper

Notcher

— Open (1)* — Open (1)* Open (1)* Open (1)*

75 100 100 120 110 110/6 5

1-1/16 diam.

in 7/8 mild steel

1/2 x 14

3/4 x 10

5 x 5 x 1/2 6 x 6 x 1/2 6 x 6 x 1/2 6 x 6 x 1/2 6 x 6 x 1/2 5 x 5 x 3/8

2-1/2 x 5 x1/2 — 3 x 6 x 1/2 3 x 6 x 1/2 — 2-1/2 x 6 x 3/8

—

5 or 7.5 HP 5 or 7.5 HP 10 HP 10 HP 7.5 H P 7.5 HP

Standard (3)

Punch , Flat Bar

Shear & Angle

Shear

1-1/16 diam.

in 1 mild ste el

3/4 x 14

1 x 10

2-1/2 x 6 x 1/2

Standard (5)

Punch , Flat Bar

Shear, Angle

Shear, Coper

Notcher, & Rod

Shear

1-1/16 diam.

in 1 mild ste el

1/2 x 18

3/4 x 14

1 x 10

— —

Standard (4)

Punch , Flat Bar

Shear, Angle

Shear & Coper

Notcher

1-1/2 diam.

in 1 mild steel

1/2 x 24

1 x 12

Standard (3)

Punch , Flat Bar

Shear & Angle

Shear

1-3/8 diam.

in 1 mild ste el

3/4 x 14

1 x 12

2-1/2 x 6 x 1/2

Standard (4)

Punch , Flat Bar

Shear, Angle

Shear & Coper

Notcher

1-3/8 diam.

in 1 mild ste el

3/8 x 24

1/2 x 14

1 x 4

—

Yes Yes Yes Yes Standard Standard

12 13 10 12 13 12

17 17 16 15 14 14

28 - 31 32 - 35 36 - 39 40 - 43 44 - 47 48 - 51

* Open Workstation accepts optional Attachments to tailor the Ironworker to your needs

edwards–made in the usa since 1875

5

Page 6

IRONWORKERS

WORK

STATIONS

WORK

STATIONS

25 TON

FLEXIBILITY

• Two workstations:

– Standard (1) – Punch

– Open (1) – Customize your Ironworker

with optional Attachments

• 9 interchangeable Attachments available

to tailor the Ironworker to your needs

• 7 optional Accessories available to increase

precision and efficiency

PRODUCTIVITY

• Optimized workstation heights for improved efficiency

SAFETY

• ANSI B11.5-1988(02) Compliant Guarding

• Integrated Lock-out/Tag-out system with E-Stop for

added safety

PERFORMANCE

• Durable, heavy-duty, Made In USA steel construction

• Vertical movement produces even pressure resulting in

precise punching and shearing with minimal distortion

that results in extended tooling life

• Punches are easily changeable, long-lasting and

available from 1/8” to 4” diameters along with square,

oblong, hex, metric, and custom shapes

WORK

STATIONS

SPECIFICATIONS

Punch Rating (tons) 25

Punch Max Capacity (In.) 1 diam. in 5/16 mild steel

Punch Work Height (In.) 38-1/2

Punch Throat Depth (In.) 5-1/2

Punch Stroke (In.) 1

Open Workstation Work Height (In.) 35-3/4

Open Workstation Throat Depth (In.) 5

Motor 1 HP

Amps 14

Hydraulics (GPM) 11

Hydraulics (PSI) 2750

Hydraulic Reservoir (gal.) 3

Product Dimensions (In.) 29 x 23 x 59

Shipping Dimensions (In.) 45 x 51 x 65

Weight (lbs.) 1200

6

6

STOCK # PRODUCT DESCRIPTION

IW25-1P120 25 Ton Ironworker 1 Phase, 120 Volt

IW25-1P230 25 Ton Ironworker 1 Phase, 230 Volt

edwardsironworkers.com

edwardsironworkers.com

Page 7

IRONWORKERS

25 TON

ATTACHMENTS

ATTACHMENTS & ACCESSORIES

STANDARD PUNCH ASSEMBLY

• Accommodates punch &

dies sets from 1/8” to 1-1/16”

diameter

• Can be used as a secondary

Punch Workstation on any

Edwards Ironworker with an

Open Workstation

AC1023-1

*

ANGLE NOTCHER

• Take precise 92° notch

out of mild steel up to 3” x

3” x 1/4”

• Allows for an easy 90° to

create a steel frame

AC0124

*

MULTI SHEAR

• Designed to shear flat bar up

to 1/4” x 6” and angle iron up

to 2” x 2” x 1/4”

• Shears solid round bar 1/4”,

3/8”, 1/2”, 3/4” and 13/16”

square bar

AC1075

OVERSIZE PUNCH ASSEMBLY

• Accommodates punch & die

sets in various shapes and

sizes from 1” up to 1-9/16”

• Replaces Standard Punch

Assembly or can be used

as a secondary Punch

Workstation

AC1027

*

COPER NOTCHER

• Versatile Attachment that

removes anything from a

small nibble to a large notch

out of Flat Bar or Angle Iron

• Integrated alignment slots

on the safety guarding easily

allow for 45° shearing on

Angle Iron to speed up your

fabrication process

AC1012

ROD SHEAR

• Shear solid round rod easily

with the Rod Shear

• Handles 1/4”, 3/8”, 1/2”,

5/8”, 3/4” and 1” solid

round bar

AC1074

241 PUNCH ASSEMBLY

• Accommodates punch & die

sets in various shapes and

sizes from 1” up to 4”

• Punch large holes and slots

in anything from heavy sheet

metal to steel beams

AC1055-1

*

PIPE NOTCHER HOUSING

• Make clean 90° saddle joint

connections quickly and easily

• Compatible with all Edwards

Ironworkers

• Contact Edwards for custom

dies to match your project

• Pipe Notcher Dies sold

separately

*

AC0925

*

7” BRAKE WITH 4-WAY DIE

• Fabricate brackets, frames,

pans and tanks with this Brake

with 4-Way Die

• Includes a standard punch that

allows 1/16”, 1/8”, 3/16” and

1/4” material to be formed to

a 90° angle

AC1033

ACCESSORIES

• 3/8” thick, 12” x 16” table that

adds precision to your Punch

Workstation

• Compartible with both Standard

and Oversized Pedestal Die Tables

• Adjustable fences and handles

quickly and easily guide your

material for perfect repeatable

actions

QUICK CHANGE PUNCH ASSEMBLY

• Increase your efficiency by

saving time and money with

the Quick Change Punch

Assembly.

• Accepts both Standard and

Oversize Punch & Die Sets

GAUGING TABLE KIT

AC0902-1

STRIPPER REDUCING PLATE

• Designed to minimize

distortion on thinner gauge

materials when using 1/2”

punches & dies set or smaller

PRESS BRAKE BACK GAUGE

• Speed up production

on repeatable bends by

providing an adjustable stop

for the various size Brake

Attachments

• A positive stop attachment

that is fitted to the back

of the Ironworker ensures

AC1001

accurate bending

edwards–made in the usa since

AC1914-1

PR135

1875

URETHANE STRIPPER

• Minimize material distortion

when working with light

gauge material

AC1099

PUNCH & DIE STARTER SET

• Includes 8 standard round

punch & die sets selected

to accommodate the most

commonly used bolts

• Sized in 1/8” increments from

3/16” to 1-1/16” with 1/32”

clearance

• See catalog page 68-71 for

additional Punch & Die Sets

*IMAGE NOTE: Guarding removed for clarity

PD1000

7

Page 8

IRONWORKERS

40 TON

WORK

STATIONS

FLEXIBILITY

• Four workstations:

– Standard (3) – Punch, Flat Bar Shear

& Angle Shear

– Open (1) – Customize your Ironworker

with optional Attachments

• 11 interchangeable Attachments available

to tailor the Ironworker to your needs

• 16 optional Accessories available to increase

precision and efficiency

WORK

STATIONS

PRODUCTIVITY

• Compact machine that allows for fast and easy

transitions between fabrication operations: punch,

shear, notch, bend and cope all in one machine.

• Optimized workstation heights for improved efficiency

• Electric foot pedal with integrated jog control

• Adjustable electric stoke control

SPECIFICATIONS

Punch Rating (tons) 40

Punch Max Capacity (in.) 1 diam. in 1/2 mild steel

Punch Work Height (in.) 41-1/2

Punch Throat Depth (in.) 7

Punch Stroke (in.) 1-3/8

Flat Bar Shear Max Capacity (in.)

Flat Bar Shear Work Height (in.) 52-1/2

Flat Bar Shear Max Round Capacity (in.) 1/2 diam.

Flat Bar Shear Max Square Capacity (in.) 1/2

Angle Shear Max Capacity (in.) 3 x 3 x 1/4

Angle Shear Work Height (in.) 52-1/2

Open Workstation Work Height (in.) 35-3/4

Open Workstation Throat Depth (in.) 7-3/4

Opt. Coper Notcher Max Capacity (in.) 2 x 3 x 5/16

Opt. Coper Notcher Work Height (in.) 35-3/4

Motor 5 HP

Amps 23

Hydraulics (GPM) 3-1/2

Hydraulics (PSI) 2750

Hydraulic Reservoir (gal.) 7

Product Dimensions (In.) 32 x 23 x 60-1/2

Shipping Dimensions (In.) 45 x 51 x 67

Weight (lbs.) 1,900

3/8 x 10

1/2 x 6

SAFETY

• ANSI B11.5-1988(02) Compliant Guarding

• ETL Certified Controls

• Integrated Lock-out/Tag-out system with E-Stop for

added safety

PERFORMANCE

• Durable, heavy-duty, Made In USA steel construction

• Vertical movement produces even pressure resulting in

precise punching and shearing with minimal distortion

that results in extended tooling life

• Punches are easily changeable, long-lasting and

available from 1/8” to 4” diameters along with square,

oblong, hex, metric, and custom shapes

• Flat Bar Shear blades are made of precision machined,

high-quality tool steel with 4 cutting edges for

extended life

• Angle Shear blades have 2 corner radii for both thin and

thick material and are made of precision tool steel with

2 cutting edges for extended life

STOCK # PRODUCT DESCRIPTION

IW40-1P230 40 Ton Ironworker 1 Phase, 230 Volt

IW40-3P208 40 Ton Ironworker 3 Phase, 208 Volt

IW40-3P230 40 Ton Ironworker 3 Phase, 230 Volt

IW40-3P380 40 Ton Ironworker Int'l - 3 Phase, 380 Volt, 50 Hz

IW40-3P460 40 Ton Ironworker 3 Phase, 460 Volt

IW40-3P575 40 Ton Ironworker 3 Phase, 575 Volt

PACKAGES

40231010 40 Ton Ironworker 1 Phase, 230 Volt, Coper Notcher

8

edwardsironworkers.com

Page 9

IRONWORKERS

with

40 TON

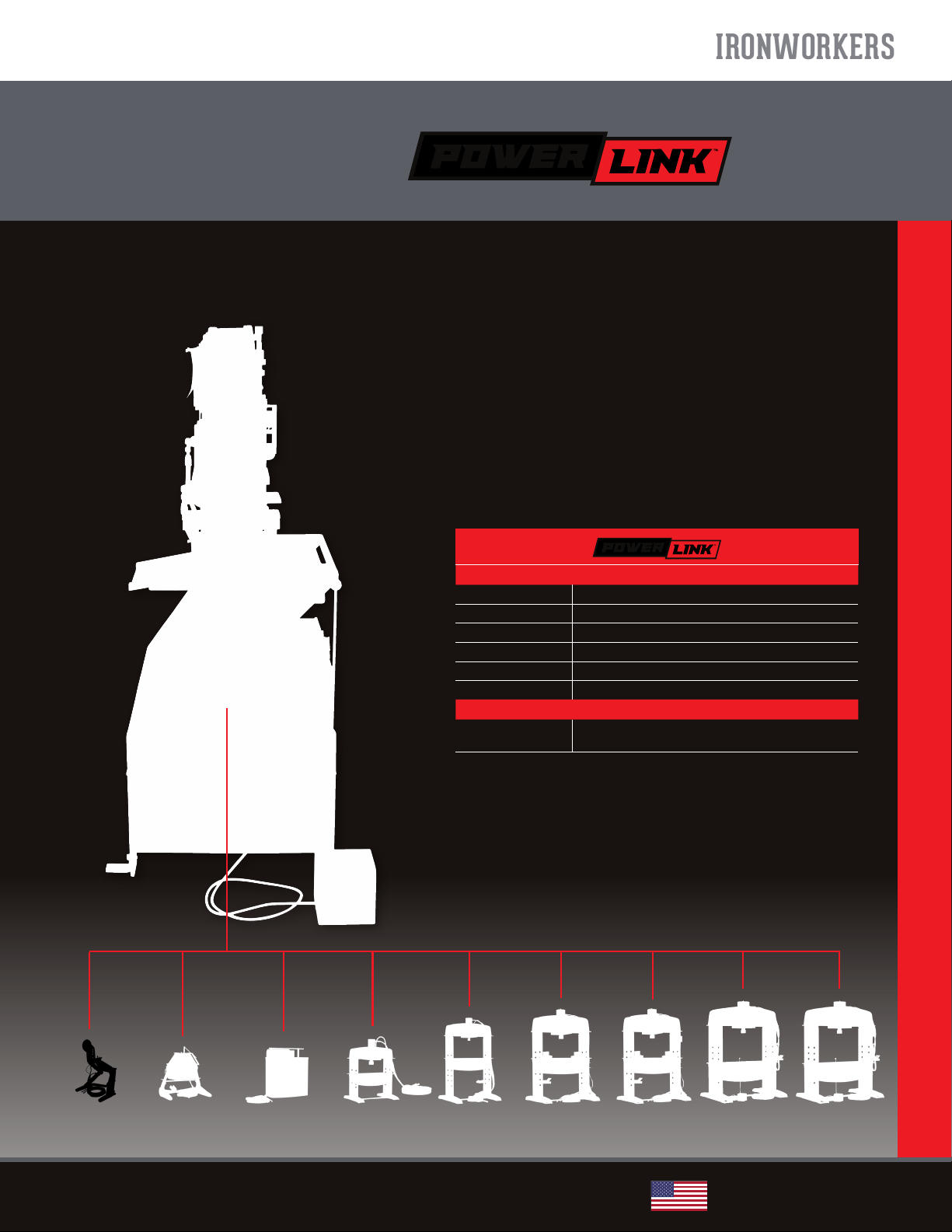

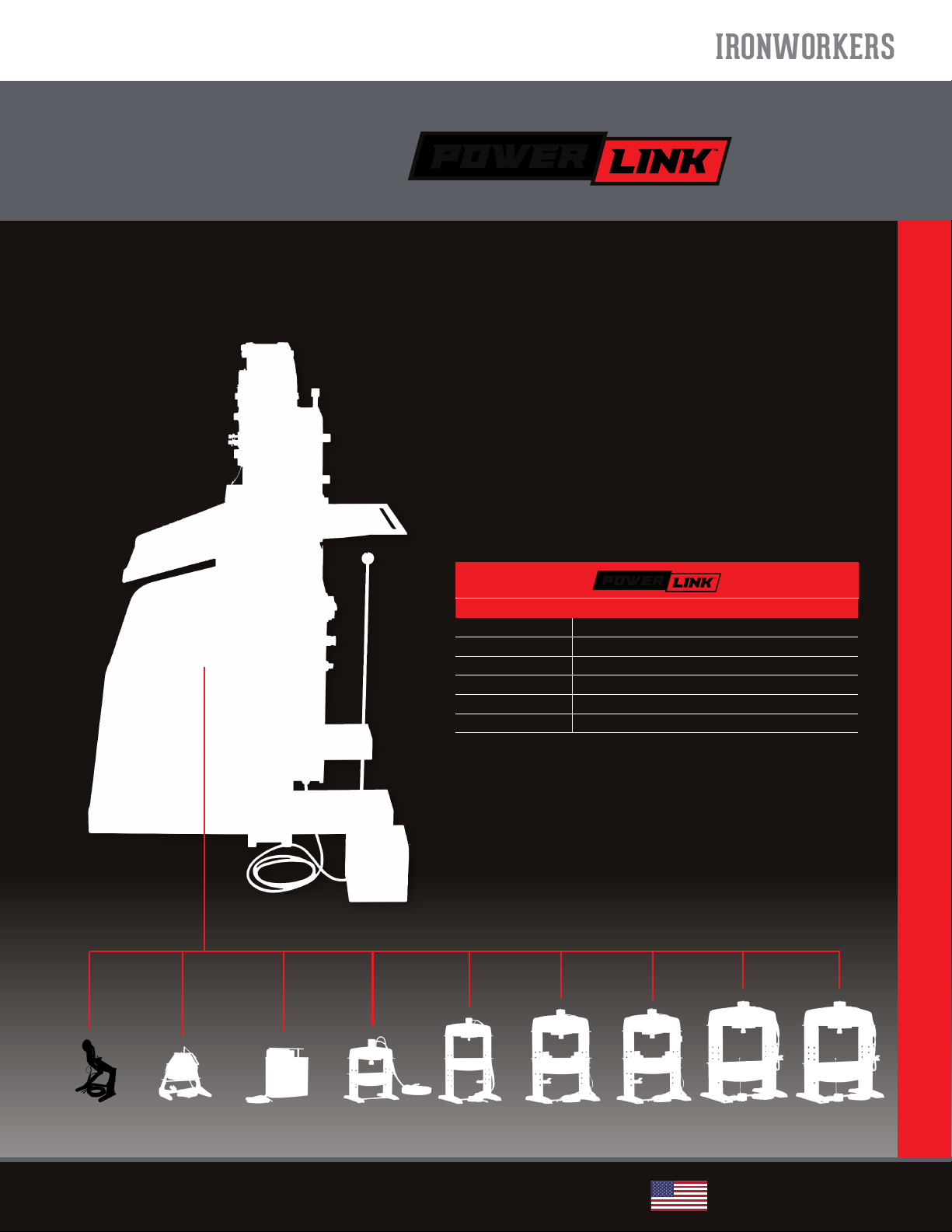

THE EXCLUSIVE EDWARDS POWERLINK™ SYSTEM

TURNS YOUR 55 TON IRONWORKER INTO A POWER

SOURCE FOR OUR EVER INCREASING LINE OF

HYDRAULIC TOOLS.

• Simply PLUG IN & POWER UP any of our Hydraulic Tools

and expand your fabrication capabilities

Our factory installed PowerLink System includes quick

•

connect couplings allowing easy transitions between

Hydraulic Tools

• The Edwards Portable Power Unit is an additional

power source with the PowerLink System

TURN THE PAGE TO VIEW OUR FULL LINE OF ATTACHMENTS & ACCESSORIES FOR THE 40 TON IRONWORKER

STOCK # PRODUCT DESCRIPTION

IW40-1P230-AC400 40 Ton Ironworker 1 Phase, 230 Volt with PowerLink

IW40-3P208-AC400 40 Ton Ironworker 3 Phase, 208 Volt with PowerLink

IW40-3P230-AC400 40 Ton Ironworker 3 Phase, 230 Volt with PowerLink

IW40-3P380-AC400 40 Ton Ironworker Int'l - 3 Ph, 380 V, 50 Hz with PowerLink

IW40-3P460-AC400 40 Ton Ironworker 3 Phase, 460 Volt with PowerLink

IW40-3P575-AC400 40 Ton Ironworker 3 Phase, 575 Volt with PowerLink

PACKAGES

40231510

40 Ton Ironworker 1 Phase, 230 Volt, PowerLink, Coper

Notcher

10 TON

BENDER

20 TON

RADIUS ROLLER

20 TON

HORIZONTAL PRESS

20 TON

SHOP PRESS

40 TON

SHOP PRESS

60 TON

SHOP PRESS

edwards–made in the usa since 1875

60 TON

SHOP PRESS (PLC)

110 TON

SHOP PRESS

110 TON

SHOP PRESS (PLC)

9

Page 10

IRONWORKERS

40 TON

40 TON

ATTACHMENTS

STANDARD PUNCH ASSEMBLY

• Accommodates punch &

dies sets from 1/8” to 1-1/16”

diameter

• Can be used as a secondary

Punch Workstation on any

Edwards Ironworker with an

Open Workstation

AC1023-2

ANGLE NOTCHER

• Take precise 92° notch

out of mild steel up to 3” x

3” x 1/4”

• Allows for an easy 90° to

create a steel frame

TURRET PIPE NOTCHER

• Make clean 90° saddle joint

connections quickly and easily

• Compatible with all Edwards

Ironworkers

• Contact Edwards for custom

dies to match your project

• Pipe Notcher Dies sold

separately

AC0125-1*

AC0925T

OVERSIZE PUNCH ASSEMBLY

• Accommodates punch & die

sets in various shapes and

sizes from 1” up to 1-9/16”

• Replaces Standard Punch

Assembly or can be used

as a secondary Punch

Workstation

*

COPER NOTCHER

• Versatile Attachment that

removes anything from a

small nibble to a large notch

out of Flat Bar or Angle Iron

• Integrated alignment slots

on the safety guarding easily

allow for 45° shearing

MULTI SHEAR

• Designed to shear flat bar up

to 1/4” x 6” and angle iron

up to 2” x 2” x 1/4”

• Shears solid round bar 1/4”,

3/8”, 1/2”, 3/4” and 13/16”

square bar

*

AC1024

*

AC1013*

AC1075*

241 PUNCH ASSEMBLY

• Accommodates punch & die

sets in various shapes and

sizes from 1” up to 4”

• Punch large holes and slots

in anything from heavy sheet

metal to steel beams

AC1055

PIPE NOTCHER HOUSING

• Make clean 90° saddle joint

connections quickly and easily

• Compatible with all Edwards

Ironworkers

• Contact Edwards for custom

dies to match your project

• Pipe Notcher Dies sold

separately

AC0925

ROD SHEAR

• Shear solid round rod easily

with the Rod Shear

• Handles 1/4”, 3/8”, 1/2”,

5/8”, 3/4” and 1” solid

round bar

AC1074

*

*

*

10

BRAKE WITH 4-WAY DIE

• Choose from the sizes listed below to meet your

specific needs

• Fabricate brackets, frames, pans and tanks with

this Brake with 4-Way Die

• Includes a standard punch that allows 1/16”, 1/8”,

3/16” and 1/4” material to be formed to a 90° angle

7" 8"

AC1034

AC1033

*

*

edwardsironworkers.com

*IMAGE NOTE: Guarding removed for clarity

Page 11

IRONWORKERS

40 TON

ACCESSORIES

GAUGING TABLE KIT

• 3/8” thick, 12” x 16” table that

adds precision to your Punch

Workstation

• Compatible with both Standard

and Oversize Pedestal Die Tables

• Adjustable fences and handles

quickly and easily guide your

material for perfect repeatable

actions

AC0900

STRIPPER REDUCING PLATE

• Designed to minimize

distortion on thinner gauge

materials when using 1/2”

punches & dies set or smaller

AC1914-3

AUTO CUT – 48”

• Optimize your productivity on

both the Flat Bar Shear and

Angle Shear Workstations on

your Edwards Ironworker

• The adjustable proximity

sensor automatically cycles

your Ironworker as you feed

in material

AC1010

HEAVY DUTY GAUGING

TABLE KIT

• 1” x 12” x 16” table adds speed

and precision to your Punch

Workstation

• Replaces Standard Pedestal

Die Table

• Adjustable fences and handles

quickly and easily guide your

material for perfect repeatable

actions

AC0903

URETHANE STRIPPER

• Minimize material distortion

when working with light gauge

material

AC1099

BACK GAUGE – 48”

• Speed up production on

repeatable cuts by providing an

adjustable stop for the Flat Bar

Shear and Angle Shear

• A positive stop attachment

that is fitted to the back of the

Ironworker ensures accurate

shearing

AC1009

HEAVY DUTY GAUGING TABLE KIT

FOR OVERSIZED PUNCH ASSEMBLY

• 1” x 12” x 16” table adds speed

and precision to your Punch

Workstation

• Replaces installed Die Table

• Adjustable fences and handles

quickly and easily guide your

material for perfect repeatable

actions

AC0905

QUICK CHANGE PUNCH ASSEMBLY

• Increase your efficiency by

saving time and money with

the Quick Change Punch

Assembly.

• Accepts both Standard and

Oversize Punch & Die Sets

AC1001

PRESS BRAKE BACK GAUGE

• Speed up production

on repeatable bends by

providing an adjustable stop

for the various size Brake

Attachments

• A positive stop attachment

that is fitted to the back

of the Ironworker ensures

accurate bending

PR135

PUNCH & DIE STARTER SET

• Includes 8 standard round

punch & die sets selected

to accommodate the most

commonly used bolts

• Sized in 1/8” increments from

3/16” to 1-1/16” with 1/32”

clearance

• See catalog page 68-71 for

additional Punch & Die Sets

12” & 18” FENCES GUIDES

• Easily adjustable to align

your material, these 12” or 18”

fence guides make precise,

repeatable operations simple.

AC1910 12” Standard Handles

AC1911 18” Standard Handles

AC1912 12” Heavy Duty Handles

AC1913 18” Heavy Duty Handles

ACCESSORY LIGHT

• Super bright LED light with

M12 connections plugs

• Powerful magnetic base

allows users to attach the

light to any Ironworker

surface and move as needed

PD1000

PRODUCTIVITY PACK

Includes 5 Accessories designed

to increase your accuracy and

production speed.

• Accessory light

• 48” Auto Cut

• Fabricator’s Protractor

• 3/8” x 12” x 16” Punch Station table

• Punch & Die Starter Kit

edwards–made in the usa since

AC1000

AC2000

1875

FABRICATOR’S PROTRACTOR

• Includes 8 standard round

punch & die sets selected

to accommodate the most

commonly used bolts

• Sized in 1/8” increments from

3/16” to 1-1/16” with 1/32”

clearance

• See catalog page 66 for

additional Punch & Die Sets

*IMAGE NOTE: Guarding removed for clarity

AC1017

11

Page 12

IRONWORKERS

50 TON

WORK

STATIONS

FLEXIBILITY

• Four workstations:

– Standard (4) – Punch, Flat Bar Shear,

Angle Shear & Coper Notcher

• 9 interchangeable Attachments available

to tailor the Ironworker to your needs

• 16 optional Accessories available to increase precision

and efficiency

WORK

STATIONS

PRODUCTIVITY

• Compact machine that allows for fast and easy

transitions between fabrication operations: punch,

shear, notch, bend and cope all in one machine.

• Optimized workstation heights for improved efficiency

• Electric foot pedal with integrated jog control

• Adjustable electric stoke control

SAFETY

• Bright LED lights increase visibility

• ANSI B11.5-1988(02) Compliant Guarding

• ETL Certified Controls

• Integrated Lock-out/Tag-out system with E-Stop for

added safety

SPECIFICATIONS

Punch Rating (tons) 50

Punch Max Capacity (In.) 1 diam. in 5/8 mild steel

Punch Work Height (In.) 39-9/16

Punch Throat Depth (In.) 7

Punch Stroke (In.) 1-7/8

Flat Bar Shear Max Capacity (In.)

Flat Bar Shear Work Height (In.) 34-1/2

Flat Bar Shear Max Round Capacity (In.) 3/4 diam.

Flat Bar Shear Max Square Capacity (In.) 3/4

Angle Shear Max Capacity (In.)

Angle Shear Work Height (In.) 39-7/8

Coper Notcher Max Capacity (In.) 2 x 3 x 5/16

Coper Notcher Work Height (In.) 39-1/2

Motor 5 HP

Amps 23

Hydraulics (GPM) 3-1/2

Hydraulics (PSI) 2500

Hydraulic Reservoir (gal.) 7

Product Dimensions (In.) 36-3/4 x 36-1/8 x 54-1/2

Shipping Dimensions (In.) 45 x 51 x 62

Weight (lbs.) 2,020

1/2 x 10

3/4 x 4

3 x 3 x 3/8

4 x 4 x 1/4

PERFORMANCE

• Durable, heavy-duty, Made In USA steel construction

• Vertical movement produces even pressure resulting in

precise punching and shearing with minimal distortion

that results in extended tooling life

• Punches are easily changeable, long-lasting and

available from 1/8” to 4” diameters along with square,

oblong, hex, metric, and custom shapes

• Flat Bar Shear blades are made of precision machined,

high-quality tool steel with 4 cutting edges for

extended life

• Angle Shear blades have 2 corner radii for both thin and

thick material and are made of precision tool steel with

2 cutting edges for extended life

STOCK # PRODUCT DESCRIPTION

IW50-1P230 50 Ton Ironworker 1 Phase, 230 Volt

IW50-3P208 50 Ton Ironworker 3 Phase, 208 Volt

IW50-3P230 50 Ton Ironworker 3 Phase, 230 Volt

IW50-3P380 50 Ton Ironworker Int'l - 3 Phase, 380 Volt, 50 Hz

IW50-3P460 50 Ton Ironworker 3 Phase, 460 Volt

IW50-3P575 50 Ton Ironworker 3 Phase, 575 Volt

12

edwardsironworkers.com

Page 13

IRONWORKERS

with

50 TON

THE EXCLUSIVE EDWARDS POWERLINK™ SYSTEM

TURNS YOUR 50 TON IRONWORKER INTO A POWER

SOURCE FOR OUR EVER INCREASING LINE OF

HYDRAULIC TOOLS.

• Simply PLUG IN & POWER UP any of our Hydraulic Tools

and expand your fabrication capabilities

Our factory installed PowerLink System includes quick

•

connect couplings allowing easy transitions between

Hydraulic Tools

• The Edwards Portable Power Unit is an additional

power source with the PowerLink System

TURN THE PAGE TO VIEW OUR FULL LINE OF ATTACHMENTS & ACCESSORIES FOR THE 50 TON IRONWORKER

STOCK # PRODUCT DESCRIPTION

IW50-1P230-AC500 50 Ton Ironworker 1 Phase, 230 Volt with PowerLink

IW50-3P208-AC500 50 Ton Ironworker 3 Phase, 208 Volt with PowerLink

IW50-3P230-AC500 50 Ton Ironworker 3 Phase, 230 Volt with PowerLink

IW50-3P380-AC500 50 Ton Ironworker Int'l - 3 Ph, 380 V, 50 Hz with PowerLink

IW50-3P460-AC500 50 Ton Ironworker 3 Phase, 460 Volt with PowerLink

IW50-3P575-AC500 50 Ton Ironworker 3 Phase, 575 Volt with PowerLink

10 TON

BENDER

20 TON

RADIUS ROLLER

20 TON

HORIZONTAL PRESS

20 TON

SHOP PRESS

40 TON

SHOP PRESS

60 TON

SHOP PRESS

edwards–made in the usa since 1875

60 TON

SHOP PRESS (PLC)

110 TON

SHOP PRESS

110 TON

SHOP PRESS (PLC)

13

Page 14

IRONWORKERS

50 TON

ATTACHMENTS

OVERSIZE PUNCH ASSEMBLY

• Accommodates punch & die

sets in various shapes and

sizes from 1” up to 1-9/16”

• Replaces Standard Punch

Assembly or can be used

as a secondary Punch

Workstation

• Make clean 90° saddle joint

connections quickly and easily

• Compatible with all Edwards

Ironworkers

• Contact Edwards for custom

dies to match your project

• Pipe Notcher Dies sold

separately

• Shear solid round rod easily

with the Rod Shear

• Handles 1/4”, 3/8”, 1/2”,

5/8”, 3/4” and 1” solid

round bar

AC1024

PIPE NOTCHER HOUSING

AC0925

ROD SHEAR

AC1074

*

*

*

241 PUNCH ASSEMBLY

• Accommodates punch & die

sets in various shapes and

sizes from 1” up to 4”

• Punch large holes and slots

in anything from heavy sheet

metal to steel beams

TURRET PIPE NOTCHER

• Make clean 90° saddle joint

connections quickly and easily

• Compatible with all Edwards

Ironworkers

• Contact Edwards for custom

dies to match your project

• Pipe Notcher Dies sold

separately

• Choose from the sizes listed below to meet your

specific needs

• Fabricate brackets, frames, pans and tanks with this

Brake with 4-Way Die

• Includes a standard punch that allows 1/16”, 1/8”,

3/16” and 1/4” material to be formed to a 90° angle

AC1055

*

AC0925T

*

BRAKE WITH 4-WAY DIE

7" 8"

AC1034

AC1033

*

*

ANGLE NOTCHER

• Take precise 92° notch

out of mild steel up to 3” x

3” x 1/4”

• Allows for an easy 90° to

create a steel frame

MULTI SHEAR

• Designed to shear flat bar up

to 1/4” x 6” and angle iron up

to 2” x 2” x 1/4”

• Shears solid round bar 1/4”,

3/8”, 1/2”, 3/4” and 13/16”

square bar

AC0125-1*

AC1075

*

14

*IMAGE NOTE: Guarding removed for clarity

edwardsironworkers.com

Page 15

IRONWORKERS

50 TON

ACCESSORIES

GAUGING TABLE KIT

• 3/8” thick, 12” x 16” table that

adds precision to your Punch

Workstation

• Compatible with both Standard

and Oversize Pedestal Die Tables

• Adjustable fences and handles

quickly and easily guide your

material for perfect repeatable

actions

AC0900

STRIPPER REDUCING PLATE

• Designed to minimize

distortion on thinner gauge

materials when using 1/2”

punches & dies set or smaller

AC1914-3

AUTO CUT – 48”

• Optimize your productivity on

both the Flat Bar Shear and

Angle Shear Workstations on

your Edwards Ironworker

• The adjustable proximity

sensor automatically cycles

your Ironworker as you feed

in material

AC1010

HEAVY DUTY GAUGING

TABLE KIT

• 1” x 12” x 16” table adds speed

and precision to your Punch

Workstation

• Replaces Standard Pedestal

Die Table

• Adjustable fences and handles

quickly and easily guide your

material for perfect repeatable

actions

AC0903

URETHANE STRIPPER

• Minimize material distortion

when working with light gauge

material

AC1099

BACK GAUGE – 48”

• Speed up production on

repeatable cuts by providing an

adjustable stop for the Flat Bar

Shear and Angle Shear

• A positive stop attachment

that is fitted to the back of the

Ironworker ensures accurate

shearing

AC1011

HEAVY DUTY GAUGING TABLE KIT

FOR OVERSIZED PUNCH ASSEMBLY

• 1” x 12” x 16” table adds speed

and precision to your Punch

Workstation

• Replaces installed Die Table

• Adjustable fences and handles

quickly and easily guide your

material for perfect repeatable

actions

AC0905

QUICK CHANGE PUNCH ASSEMBLY

• Increase your efficiency by

saving time and money with

the Quick Change Punch

Assembly.

• Accepts both Standard and

Oversize Punch & Die Sets

AC1001

PRESS BRAKE BACK GAUGE

• Speed up production

on repeatable bends by

providing an adjustable stop

for the various size Brake

Attachments

• A positive stop attachment

that is fitted to the back

of the Ironworker ensures

accurate bending

PR135

PUNCH & DIE STARTER SET

• Includes 8 standard round

punch & die sets selected

to accommodate the most

commonly used bolts

• Sized in 1/8” increments from

3/16” to 1-1/16” with 1/32”

clearance

• See catalog page 68-71 for

additional Punch & Die Sets

12” & 18” FENCES GUIDES

• Easily adjustable to align

your material, these 12” or 18”

fence guides make precise,

repeatable operations simple.

AC1910 12” Standard Handles

AC1911 18” Standard Handles

AC1912 12” Heavy Duty Handles

AC1913 18” Heavy Duty Handles

ACCESSORY LIGHT

• Super bright LED light with

M12 connections plugs

• Powerful magnetic base

allows users to attach the

light to any Ironworker

surface and move as needed

PD1000

PRODUCTIVITY PACK

Includes 5 Accessories designed

to increase your accuracy and

production speed.

• Accessory light

• 48” Auto Cut

• Fabricator’s Protractor

• 3/8” x 12” x 16” Punch Station table

• Punch & Die Starter Kit

edwards–made in the usa since

AC1000

AC2000

1875

FABRICATOR’S PROTRACTOR

• Increase user accuracy on

the Punch and Flat Bar Shear

Workstations

• Designed to guide your

workpiece and gauged at 15°

increments through 180°

AC1017

*IMAGE NOTE: Guarding removed for clarity

15

Page 16

IRONWORKERS

55 TON

WORK

STATIONS

FLEXIBILITY

• Four workstations:

– Standard (3) – Punch, Flat Bar Shear

& Angle Shear

– Open (1) – Customize your Ironworker

with optional Attachments

• 12 interchangeable Attachments available to tailor the

Ironworker to your needs

• 17 optional Accessories available to increase precision

and efficiency

WORK

STATIONS

PRODUCTIVITY

• Compact machine that allows for fast and easy

transitions between fabrication operations: punch,

shear, notch, bend or cope all in one machine.

• Optimized workstation heights for improved efficiency

• Electric foot pedal with integrated jog control

• Adjustable electric stoke control

SPECIFICATIONS

Punch Rating (tons) 55

Punch Max Capacity (In.) 1-1/16 diam. in 5/8 mild steel

Punch Work Height (In.) 36-9/16

Punch Throat Depth (In.) 7-1/2

Punch Stroke (In.) 1-1/4

Flat Bar Shear Max Capacity (In.)

Flat Bar Shear Work Height (In.) 34-1/2

Flat Bar Shear Max Round Capacity (In.) 7/8 diam.

Flat Bar Shear Max Square Capacity (In.) 7/8

Angle Shear Max Capacity (In.)

Angle Shear Work Height (In.) 39-7/8

Open Workstation Work Height (In.) 34-1/2

Open Workstation Throat Depth (In.) 11-3/16

Opt. Coper Notcher Max Capacity (in.) 2-1/2 x 4 x 5/16

Opt. Coper Notcher Work Height (in.) 39-1/2

Motor 5 HP

Amps 23

Hydraulics (GPM) 3-1/2

Hydraulics (PSI) 2500

Hydraulic Reservoir (gal.) 7

Product Dimensions (In.) 36-1/8 x 44-3/8 x 55-1/4

Shipping Dimensions (In.) 45 x 51 x 62

Weight (lbs.) 2,480

3/8 x 14

1/2 x 12

3/4 x 4

3 x 3 x 3/8

4 x 4 x 1/4

SAFETY

• Bright LED lights increase visibility

• ANSI B11.5-1988(02) Compliant Guarding

• ETL Certified Controls

• Integrated Lock-out/Tag-out system with E-Stop

for added safety

PERFORMANCE

• Durable, heavy-duty Made In USA steel construction

• Vertical movement produces even pressure resulting in

precise punching and shearing with minimal distortion

that results in extended tooling life

• Punches are easily changeable, long-lasting and

available from 1/8” to 4” diameters along with square,

oblong, hex, metric, and custom shapes

STOCK # PRODUCT DESCRIPTION

IW55-1P230 55 Ton Ironworker 1 Phase, 230 Volt

IW55-3P208 55 Ton Ironworker 3 Phase, 208 Volt

IW55-3P230 55 Ton Ironworker 3 Phase, 230 Volt

IW55-3P380 55 Ton Ironworker Int'l - 3 Phase, 380 Volt, 50 Hz

IW55-3P460 55 Ton Ironworker 3 Phase, 460 Volt

IW55-3P575 55 Ton Ironworker 3 Phase, 575 Volt

PACKAGES

55231012 55 Ton Ironworker 1 Phase, 230 Volt, Coper Notcher

55203512 55 Ton Ironworker 3 Phase, 208 Volt, Coper Notcher

55233012 55 Ton Ironworker 3 Phase, 230 Volt, Coper Notcher

55231022 55 Ton Ironworker 1 Phase, 230 Volt, 10" Brake

55203022 55 Ton Ironworker 3 Phase, 208 Volt, 10" Brake

55233022 55 Ton Ironworker 3 Phase, 230 Volt, 10" Brake

16

edwardsironworkers.com

Page 17

IRONWORKERS

with

55 TON

THE EXCLUSIVE EDWARDS POWERLINK™ SYSTEM

TURNS YOUR 55 TON IRONWORKER INTO A POWER

SOURCE FOR OUR EVER INCREASING LINE OF

HYDRAULIC TOOLS.

• Simply PLUG IN & POWER UP any of our Hydraulic Tools

and expand your fabrication capabilities

Our factory installed PowerLink System includes quick

•

connect couplings allowing easy transitions between

Hydraulic Tools

• The Edwards Portable Power Unit is an additional

power source with the PowerLink System

TURN THE PAGE TO VIEW OUR FULL LINE OF ATTACHMENTS & ACCESSORIES FOR THE 55 TON IRONWORKER

STOCK # PRODUCT DESCRIPTION

IW55-1P230-AC500 55 Ton Ironworker 1 Phase, 230 Volt with PowerLink

IW55-3P208-AC500 55 Ton Ironworker 3 Phase, 208 Volt with PowerLink

IW55-3P230-AC500 55 Ton Ironworker 3 Phase, 230 Volt with PowerLink

IW55-3P380-AC500 55 Ton Ironworker Int'l - 3 Ph, 380 V, 50 Hz with PowerLink

IW55-3P460-AC500 55 Ton Ironworker 3 Phase, 460 Volt with PowerLink

IW55-3P575-AC500 55 Ton Ironworker 3 Phase, 575 Volt with PowerLink

PACKAGES

55231512 55 Ton Ironworker 1 Ph, 230 V, PowerLink, Coper Notcher

55203512 55 Ton Ironworker 3 Ph, 208 V, PowerLink, Coper Notcher

55233512 55 Ton Ironworker 3 Ph, 230 V, PowerLink, Coper Notcher

55231522 55 Ton Ironworker 1 Ph, 230 V, PowerLink, 10" Brake

55203522 55 Ton Ironworker 3 Ph, 208 V, PowerLink, 10" Brake

55233522 55 Ton Ironworker 3 Ph, 230 V, PowerLink, 10" Brake

10 TON

BENDER

20 TON

RADIUS ROLLER

20 TON

HORIZONTAL PRESS

20 TON

SHOP PRESS

40 TON

SHOP PRESS

60 TON

SHOP PRESS

edwards–made in the usa since 1875

60 TON

SHOP PRESS (PLC)

110 TON

SHOP PRESS

110 TON

SHOP PRESS (PLC)

17

Page 18

IRONWORKERS

55 TON

ATTACHMENTS

STANDARD PUNCH ASSEMBLY

• Accommodates punch &

dies sets from 1/8” to 1-1/16”

diameter

• Can be used as a secondary

Punch Workstation on any

Edwards Ironworker with an

Open Workstation

AC1023-2

ANGLE NOTCHER

• Take precise 92° notch

out of mild steel up to 3” x

3” x 1/4”

• Allows for an easy 90° to

create a steel frame

AC0125-1

TURRET PIPE NOTCHER

• Make clean 90° saddle joint

connections quickly and easily

• Compatible with all Edwards

Ironworkers

• Contact Edwards for custom

dies to match your project

• Pipe Notcher Dies sold

separately

AC0925T

OVERSIZE PUNCH ASSEMBLY

• Accommodates punch & die

sets in various shapes and

sizes from 1” up to 1-9/16”

• Replaces Standard Punch

Assembly or can be used

as a secondary Punch

Workstation

*

AC1024

*

COPER NOTCHER

• Versatile Attachment that

removes anything from a

small nibble to a large notch

out of Flat Bar or Angle Iron

• Integrated alignment slots

on the safety guarding easily

allow for 45° shearing

*

AC1014

*

MULTI SHEAR

• Designed to shear flat bar up

to 1/4” x 6” and angle iron up

to 2” x 2” x 1/4”

• Shears solid round bar 1/4”,

3/8”, 1/2”, 3/4” and 13/16”

square bar

AC1075

*

*

241 PUNCH ASSEMBLY

• Accommodates punch & die

sets in various shapes and

sizes from 1” up to 4”

• Punch large holes and slots

in anything from heavy sheet

metal to steel beams

AC1055

PIPE NOTCHER HOUSING

• Make clean 90° saddle joint

connections quickly and easily

• Compatible with all Edwards

Ironworkers

• Contact Edwards for custom

dies to match your project

• Pipe Notcher Dies sold

separately

AC0925

ROD SHEAR

• Shear solid round rod easily

with the Rod Shear

• Handles 1/4”, 3/8”, 1/2”,

5/8”, 3/4” and 1” solid

round bar

AC1074

*

*

*

18

BRAKE WITH 4-WAY DIE

• Choose from the sizes listed below to meet your specific needs

• Fabricate brackets, frames, pans and tanks with this Brake with

4-Way Die

• Includes a standard punch that allows 1/16”, 1/8”, 3/16” and 1/4”

material to be formed to a 90° angle

7" 8" 10"

AC1033

*

*

AC1051

*

AC1034

edwardsironworkers.com

*IMAGE NOTE: Guarding removed for clarity

Page 19

IRONWORKERS

55 TON

ACCESSORIES

GAUGING TABLE KIT

• 3/8” thick, 12” x 16” table that

adds precision to your Punch

Workstation

• Compatible with both Standard

and Oversize Pedestal Die Tables

• Adjustable fences and handles

quickly and easily guide your

material for perfect repeatable

actions

COPER NOTCHER

GAUGING TABLE KIT

• Provides a larger 3/8” x 121/2” x 15-5/8” size table and

two fences to better align

your material

AC0900

AC0800

QUICK CHANGE PUNCH ASSEMBLY

• Increase your efficiency by

saving time and money with

the Quick Change Punch

Assembly.

• Accepts both Standard and

Oversize Punch & Die Sets

AC1001

HEAVY DUTY GAUGING

TABLE KIT

• 1” x 12” x 16” table adds speed

and precision to your Punch

Workstation

• Replaces Standard Pedestal

Die Table

• Adjustable fences and handles

quickly and easily guide your

material for perfect repeatable

actions

AC0903

STRIPPER REDUCING PLATE

• Designed to minimize

distortion on thinner gauge

materials when using 1/2”

punches & dies set or smaller

AC1914-3

AUTO CUT – 48”

• Optimize your productivity on

both the Flat Bar Shear and

Angle Shear Workstations on

your Edwards Ironworker

• The adjustable proximity

sensor automatically cycles

your Ironworker as you feed

in material

AC1010

HEAVY DUTY GAUGING TABLE KIT

FOR OVERSIZED PUNCH ASSEMBLY

• 1” x 12” x 16” table adds speed

and precision to your Punch

Workstation

• Replaces installed Die Table

• Adjustable fences and handles

quickly and easily guide your

material for perfect repeatable

actions

AC0905

URETHANE STRIPPER

• Minimize material distortion

when working with light gauge

material

AC1099

BACK GAUGE – 48”

• Speed up production on

repeatable cuts by providing an

adjustable stop for the Flat Bar

Shear and Angle Shear

• A positive stop attachment

that is fitted to the back of the

Ironworker ensures accurate

shearing

AC1011

PRESS BRAKE BACK GAUGE

• Speed up production

on repeatable bends by

providing an adjustable stop

for the various size Brake

Attachments

• A positive stop attachment

that is fitted to the back

of the Ironworker ensures

accurate bending

FABRICATOR’S PROTRACTOR

• Increase user accuracy on

the Punch and Flat Bar Shear

Workstations

• Designed to guide your

workpiece and gauged at 15°

increments through 180°

PUNCH & DIE STARTER SET

• Includes 8 standard round

punch & die sets selected

to accommodate the most

commonly used bolts

• Sized in 1/8” increments from

3/16” to 1-1/16” with 1/32”

clearance

• See catalog page 68-71 for

PR135

additional Punch & Die Sets

12” & 18” FENCES GUIDES

• Easily adjustable to align

your material, these 12” or 18”

fence guides make precise,

repeatable operations simple.

AC1910 12” Standard Handles

AC1911 18” Standard Handles

AC1912 12” Heavy Duty Handles

AC1017

AC1913 18” Heavy Duty Handles

edwards–made in the usa since

PD1000

1875

ACCESSORY LIGHT

• Super bright LED light with

M12 connections plugs

• Powerful magnetic base

allows users to attach the

light to any Ironworker

surface and move as needed

AC1000

PRODUCTIVITY PACK

Includes 5 Accessories designed

to increase your accuracy and

production speed.

• Accessory light

• 48” Auto Cut

• Fabricator’s Protractor

• 3/8” x 12” x 16” Punch Station table

• Punch & Die Starter Kit

*IMAGE NOTE: Guarding removed for clarity

AC2000

19

Page 20

IRONWORKERS

60 TON

WORK

STATIONS

SPECIFICATIONS

Punch Rating (tons) 60

Punch Max Capacity (In.) 1 diam. In 3/4 mild steel

Punch Work Height (In.) 36-9/16

Punch Throat Depth (In.) 8-7/8

Punch Stroke (In.) 1-1/4

Flat Bar Shear Max Capacity (In.)

Flat Bar Shear Work Height (In.) 34-1/2

Flat Bar Shear Max Round Capacity (In.) 7/8 diam.

Flat Bar Shear Max Square Capacity (In.) 7/8

Angle Shear Max Capacity (In.)

Angle Shear Work Height (In.) 39-7/8

Coper Notcher Max Capacity (In.) 2-1/2 x 4 x 5/16

Coper Notcher Work Height (In.) 39-1/2

Motor 5 HP

Amps 23

Hydraulics (GPM) 3-1/2

Hydraulics (PSI) 2500

Hydraulic Reservoir (gal.) 7

Product Dimensions (In.) 36-1/8 x 46-1/8 x 56-1/8

Shipping Dimensions (In.) 45 x 51 x 63

Weight (lbs.) 2,550

3/8 x 14

1/2 x 12

3/4 x 4

3 x 3 x 1/2

4 x 4 x 3/8

FLEXIBILITY

• Four workstations:

– Standard (4) – Punch, Flat Bar Shear,

Angle Shear & Coper Notcher

• 9 interchangeable Attachments available

to tailor the Ironworker to your needs

• 17 optional Accessories available to increase precision

and efficiency

WORK

STATIONS

PRODUCTIVITY

• Compact machine that allows for fast and easy

transitions between fabrication operations: punch,

shear, notch, bend and cope all in one machine.

• Optimized workstation heights for improved efficiency

• Electric foot pedal with integrated jog control

• Adjustable electric stoke control

SAFETY

• Bright LED lights increase visibility

• ANSI B11.5-1988(02) Compliant Guarding

• ETL Certified Controls

• Integrated Lock-out/Tag-out system with E-Stop for

added safety

PERFORMANCE

• Durable, heavy-duty, Made In USA steel construction

• Vertical movement produces even pressure resulting in

precise punching and shearing with minimal distortion

that results in extended tooling life

• Punches are easily changeable, long-lasting and

available from 1/8” to 4” diameters along with square,

oblong, hex, metric, and custom shapes

• Flat Bar Shear blades are made of precision machined,

high-quality tool steel with 4 cutting edges for

extended life

• Angle Shear blades have 2 corner radii for both thin and

thick material and are made of precision tool steel with

2 cutting edges for extended life

STOCK # PRODUCT DESCRIPTION

IW60-1P230 60 Ton Ironworker 1 Phase, 230 Volt

IW60-3P208 60 Ton Ironworker 3 Phase, 208 Volt

IW60-3P230 60 Ton Ironworker 3 Phase, 230 Volt

IW60-3P380 60 Ton Ironworker Int'l - 3 Phase, 380 Volt, 50 Hz

IW60-3P460 60 Ton Ironworker 3 Phase, 460 Volt

IW60-3P575 60 Ton Ironworker 3 Phase, 575 Volt

20

edwardsironworkers.com

Page 21

IRONWORKERS

with

60 TON

THE EXCLUSIVE EDWARDS POWERLINK™ SYSTEM

TURNS YOUR 60 TON IRONWORKER INTO A POWER

SOURCE FOR OUR EVER INCREASING LINE OF

HYDRAULIC TOOLS.

• Simply PLUG IN & POWER UP any of our Hydraulic Tools

and expand your fabrication capabilities

Our factory installed PowerLink System includes quick

•

connect couplings allowing easy transitions between

Hydraulic Tools

• The Edwards Portable Power Unit is an additional

power source with the PowerLink System

TURN THE PAGE TO VIEW OUR FULL LINE OF ATTACHMENTS & ACCESSORIES FOR THE 60 TON IRONWORKER

STOCK # PRODUCT DESCRIPTION

IW60-1P230-AC500 60 Ton Ironworker 1 Phase, 230 Volt with PowerLink

IW60-3P208-AC500 60 Ton Ironworker 3 Phase, 208 Volt with PowerLink

IW60-3P230-AC500 60 Ton Ironworker 3 Phase, 230 Volt with PowerLink

IW60-3P380-AC500 60 Ton Ironworker Int'l - 3 Ph, 380 V, 50 Hz with PowerLink

IW60-3P460-AC500 60 Ton Ironworker 3 Phase, 460 Volt with PowerLink

IW60-3P575-AC500 60 Ton Ironworker 3 Phase, 575 Volt with PowerLink

10 TON

BENDER

20 TON

RADIUS ROLLER

20 TON

HORIZONTAL PRESS

20 TON

SHOP PRESS

40 TON

SHOP PRESS

60 TON

SHOP PRESS

edwards–made in the usa since

1875

60 TON

SHOP PRESS (PLC)

110 TON

SHOP PRESS

110 TON

SHOP PRESS (PLC)

21

Page 22

IRONWORKERS

60 TON

ATTACHMENTS

OVERSIZE PUNCH ASSEMBLY

• Accommodates punch & die

sets in various shapes and

sizes from 1” up to 1-9/16”

• Replaces Standard Punch

Assembly or can be used

as a secondary Punch

Workstation

• Make clean 90° saddle joint

• Compatible with all Edwards

• Contact Edwards for custom

• Pipe Notcher Dies sold

• Shear solid round rod easily

• Handles 1/4”, 3/8”, 1/2”,

AC1024

PIPE NOTCHER HOUSING

connections quickly and easily

Ironworkers

dies to match your project

separately

ROD SHEAR

with the Rod Shear

5/8”, 3/4” and 1” solid

round bar

AC0925

AC1074

*

*

*

241 PUNCH ASSEMBLY

• Accommodates punch & die

sets in various shapes and

sizes from 1” up to 4”

• Punch large holes and slots

in anything from heavy sheet

metal to steel beams

TURRET PIPE NOTCHER

• Make clean 90° saddle joint

connections quickly and easily

• Compatible with all Edwards

Ironworkers

• Contact Edwards for custom

dies to match your project

• Pipe Notcher Dies sold

separately

• Choose from the sizes listed below to meet your

specific needs

• Fabricate brackets, frames, pans and tanks with this

Brake with 4-Way Die

• Includes a standard punch that allows 1/16”, 1/8”,

3/16” and 1/4” material to be formed to a 90° angle

AC1055

*

AC0925T

*

BRAKE WITH 4-WAY DIE

7" 8"

AC1034

AC1033

*

*

ANGLE NOTCHER

• Take precise 92° notch

out of mild steel up to 3” x

3” x 1/4”

• Allows for an easy 90° to

create a steel frame

MULTI SHEAR

• Designed to shear flat bar up

to 1/4” x 6” and angle iron up

to 2” x 2” x 1/4”

• Shears solid round bar 1/4”,

3/8”, 1/2”, 3/4” and 13/16”

square bar

AC0125-1

*

AC1075

*

22

*IMAGE NOTE: Guarding removed for clarity

edwardsironworkers.com

Page 23

IRONWORKERS

60 TON

ACCESSORIES

GAUGING TABLE KIT

• 3/8” thick, 12” x 16” table that

adds precision to your Punch

Workstation

• Compatible with both Standard

and Oversize Pedestal Die Tables

• Adjustable fences and handles

quickly and easily guide your

material for perfect repeatable

actions

AC0900

COPER NOTCHER

GAUGING TABLE KIT

• Provides a larger 3/8” x 121/2” x 15-5/8” size table and

two fences to better align

your material

AC0800

QUICK CHANGE PUNCH ASSEMBLY

• Accommodates punch and

Increase your efficiency by

saving time and money with

the Quick Change Punch

Assembly.

• Accepts both Standard and

Oversize Punch & Die Sets

AC1001

HEAVY DUTY GAUGING

TABLE KIT

• 1” x 12” x 16” table adds speed

and precision to your Punch

Workstation

• Replaces Standard Pedestal

Die Table

• Adjustable fences and handles

quickly and easily guide your

material for perfect repeatable

actions

AC0903

STRIPPER REDUCING PLATE

• Designed to minimize

distortion on thinner gauge

materials when using 1/2”

punches & dies set or smaller

AC1914-3

AUTO CUT – 48”

• Optimize your productivity on

both the Flat Bar Shear and

Angle Shear Workstations on

your Edwards Ironworker

• The adjustable proximity

sensor automatically cycles

your Ironworker as you feed

in material

AC1010

HEAVY DUTY GAUGING TABLE KIT

FOR OVERSIZED PUNCH ASSEMBLY

• 1” x 12” x 16” table adds speed

and precision to your Punch

Workstation

• Replaces installed Die Table

• Adjustable fences and handles

quickly and easily guide your

material for perfect repeatable

actions

AC0905

URETHANE STRIPPER

• Minimize material distortion

when working with light gauge

material

AC1099

BACK GAUGE – 48”

• Speed up production on

repeatable cuts by providing an

adjustable stop for the Flat Bar

Shear and Angle Shear

• A positive stop attachment

that is fitted to the back of the

Ironworker ensures accurate

shearing

AC1011

PRESS BRAKE BACK GAUGE

• Speed up production

on repeatable bends by

providing an adjustable stop

for the various size Brake

Attachments

• A positive stop attachment

that is fitted to the back

of the Ironworker ensures

accurate bending

FABRICATOR’S PROTRACTOR

• Increase user accuracy on

the Punch and Flat Bar Shear

Workstations

• Designed to guide your

workpiece and gauged at 15°

increments through 180°

PUNCH & DIE STARTER SET

• Includes 8 standard round

punch & die sets selected

to accommodate the most

commonly used bolts

• Sized in 1/8” increments from

3/16” to 1-1/16” with 1/32”

clearance

• See catalog page 68-71 for

PR135

additional Punch & Die Sets

12” & 18” FENCES GUIDES

• Easily adjustable to align

your material, these 12” or 18”

fence guides make precise,

repeatable operations simple.

AC1910 12” Standard Handles

AC1911 18” Standard Handles

AC1912 12” Heavy Duty Handles

AC1017

AC1913 18” Heavy Duty Handles

edwards–made in the usa since

PD1000

1875

ACCESSORY LIGHT

• Super bright LED light with

M12 connections plugs

• Powerful magnetic base

allows users to attach the

light to any Ironworker

surface and move as needed

AC1000

PRODUCTIVITY PACK

Includes 5 Accessories designed

to increase your accuracy and

production speed.

• Accessory light

• 48” Auto Cut

• Fabricator’s Protractor

• 3/8” x 12” x 16” Punch Station table

• Punch & Die Starter Kit

*IMAGE NOTE: Guarding removed for clarity

AC2000

23

Page 24

IRONWORKERS

65 TON

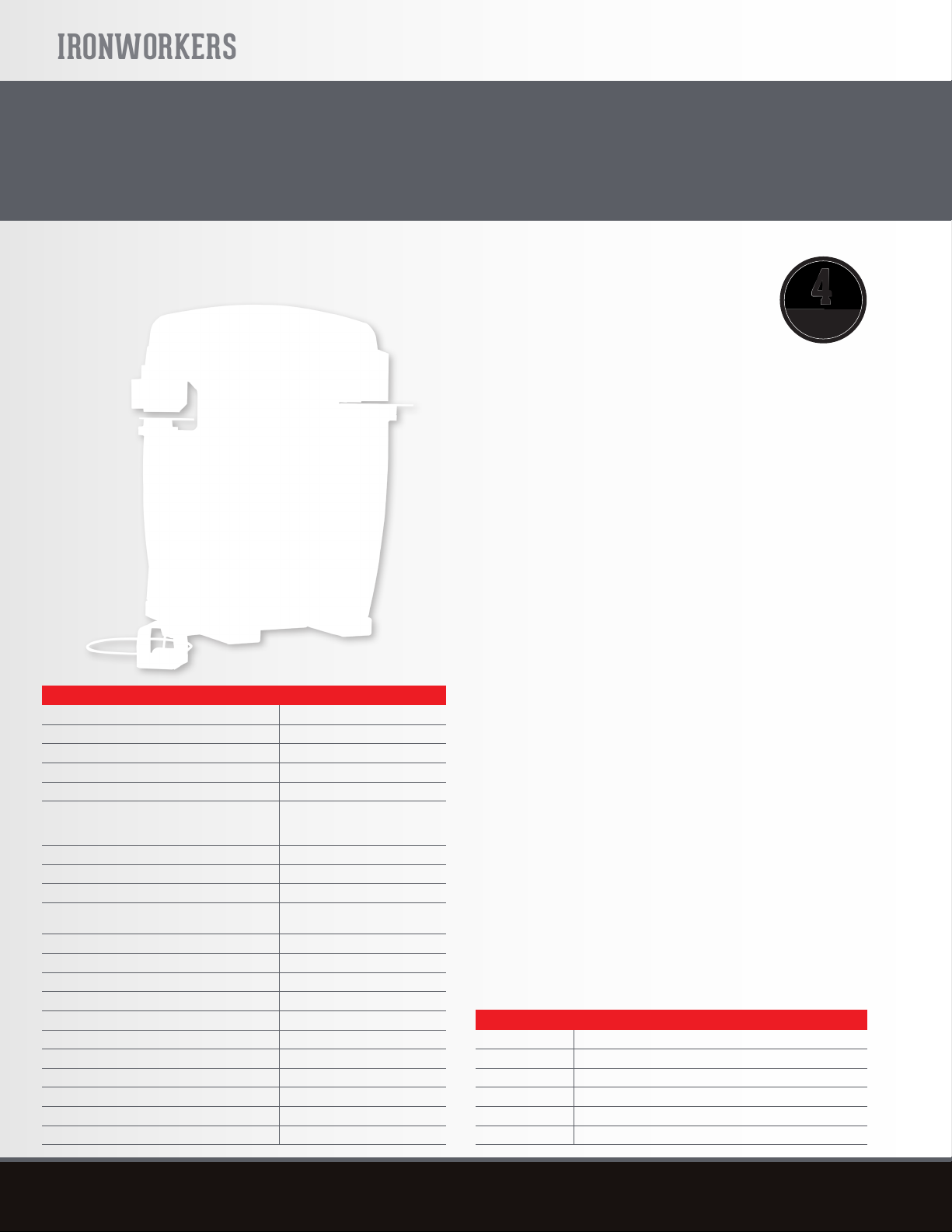

FLEXIBILITY

• Five workstations:

– Standard (4) – Punch, Flat Bar Shear,

Angle Shear & Coper Notcher

– Open (1) – Customize your Ironworker

with with 4 optional Attachments - Brake,

Rod Shear, Multi-Shear or Pipe Notcher

• 12 interchangeable Attachments available to tailor the

Ironworker to your needs

• 17 optional Accessories available to increase precision

and efficiency

WORK

STATIONS

PRODUCTIVITY

• Compact machine that allows for fast and easy

transitions between fabrication operations: punch,

shear, notch, bend and cope all in one machine.

• Optimized workstation heights for improved efficiency

• Electric foot pedal with integrated jog control

• Adjustable electric stoke control

SPECIFICATIONS

Punch Rating (tons) 65

Punch Max Capacity (In.) 1-1/16 diam. in 3/4 mild steel

Punch Work Height (In.) 36-9/16

Punch Throat Depth (In.) 9-3/4

Punch Stroke (In.) 1-13/16

Flat Bar Shear Max Capacity (In.)

Flat Bar Shear Work Height (In.) 34-1/2

Flat Bar Shear Max Round Capacity (In.) 1 diam.

Flat Bar Shear Max Square Capacity (In.) 1

Angle Shear Max Capacity (In.) 5 x 5 x 3/8

Angle Shear Work Height (In.) 43-1/2

Coper Notcher Max Capacity (In.) 2-1/2 x 5 x 3/8

Coper Notcher Work Height (In.) 39-1/2

Open Cavity Height (In.) 8-3/4

Open Cavity Width (In.) 12

Open Cavity Work Height (In.) 43

Motor 5 or 7.5 HP

Amps 23

Hydraulics (GPM) 10-1/2

Hydraulics (PSI) 3500

Hydraulic Reservoir (gal.) 17

Product Dimensions (In.) 45 x 62-1/8 x 57

Shipping Dimensions (In.) 46 x 69 x 63

Weight (lbs.) 4,750

3/8 x 24

1/2 x 14

1 x 4

SAFETY

• Bright LED lights increase visibility

• ANSI B11.5-1988(02) Compliant Guarding

• ETL Certified Controls

• Integrated Lock-out/Tag-out system with E-Stop for

added safety

PERFORMANCE

• Durable, heavy-duty, Made In USA steel construction

• Vertical movement produces even pressure resulting in

precise punching and shearing with minimal distortion

that results in extended tooling life

• Punches are easily changeable, long-lasting and

available from 1/8” to 4” diameters along with square,

oblong, hex, metric, and custom shapes

• Flat Bar Shear blades are made of precision machined,

high-quality tool steel with 4 cutting edges for

extended life

• Angle Shear blades have 2 corner radii for both thin and

thick material and are made of precision tool steel with

2 cutting edges for extended life

STOCK # PRODUCT DESCRIPTION

IW65-1P230 65 Ton Ironworker 1 Phase, 230 Volt

IW65-3P208 65 Ton Ironworker 3 Phase, 208 Volt

IW65-3P230 65 Ton Ironworker 3 Phase, 230 Volt

IW65-3P380 65 Ton Ironworker Int'l - 3 Phase, 380 Volt, 50 Hz

IW65-3P460 65 Ton Ironworker 3 Phase, 460 Volt

IW65-3P575 65 Ton Ironworker 3 Phase, 575 Volt

24

edwardsironworkers.com

Page 25

IRONWORKERS

with

65 TON

THE EXCLUSIVE EDWARDS POWERLINK™ SYSTEM

TURNS YOUR 65 TON IRONWORKER INTO A POWER

SOURCE FOR OUR EVER INCREASING LINE OF

HYDRAULIC TOOLS.

• Simply PLUG IN & POWER UP any of our Hydraulic Tools

and expand your fabrication capabilities

Our factory installed PowerLink System includes quick

•

connect couplings allowing easy transitions between

Hydraulic Tools

• The Edwards Portable Power Unit is an additional

power source with the PowerLink System

TURN THE PAGE TO VIEW OUR FULL LINE OF ATTACHMENTS & ACCESSORIES FOR THE 65 TON IRONWORKER

STOCK # PRODUCT DESCRIPTION

IW65-1P230-AC700 65 Ton Ironworker 1 Phase, 230 Volt with PowerLink

IW65-3P208-AC600 65 Ton Ironworker 3 Phase, 208 Volt with PowerLink

IW65-3P230-AC600 65 Ton Ironworker 3 Phase, 230 Volt with PowerLink

IW65-3P380-AC600 65 Ton Ironworker Int'l - 3 Ph, 380 V, 50 Hz with PowerLink

IW65-3P460-AC600 65 Ton Ironworker 3 Phase, 460 Volt with PowerLink

IW65-3P575-AC600 65 Ton Ironworker 3 Phase, 575 Volt with PowerLink

10 TON

BENDER

20 TON

RADIUS ROLLER

20 TON

HORIZONTAL PRESS

20 TON

SHOP PRESS

40 TON

SHOP PRESS

60 TON

SHOP PRESS

edwards–made in the usa since 1875

60 TON

SHOP PRESS (PLC)

110 TON

SHOP PRESS

110 TON

SHOP PRESS (PLC)

25

Page 26

IRONWORKERS

65 TON

ATTACHMENTS

OVERSIZE PUNCH ASSEMBLY

• Accommodates punch & die

sets in various shapes and

sizes from 1” up to 1-9/16”

• Replaces Standard Punch

Assembly or can be used

as a secondary Punch

Workstation

AC1024

*

PIPE NOTCHER HOUSING

• Make clean 90° saddle joint

connections quickly and easily

• Compatible with all Edwards

Ironworkers

• Contact Edwards for custom

dies to match your project

• Pipe Notcher Dies sold

separately

AC0925

*

MULTI SHEAR

• Designed to shear flat bar up

to 1/4” x 6” and angle iron up

to 2” x 2” x 1/4”

• Shears solid round bar 1/4”,

3/8”, 1/2”, 3/4” and 13/16”

square bar

241 PUNCH ASSEMBLY

• Accommodates punch & die

sets in various shapes and

sizes from 1” up to 4”

• Punch large holes and slots

in anything from heavy sheet

metal to steel beams

PIPE NOTCHER HOUSING

FOR OPEN CAVITY

• Make clean 90° saddle joint

connections quickly and easily

• Compatible with the 65,120, and

110/65 Ton Elite Ironworkers

• Contact Edwards for custom

dies to match your project

• Pipe Notcher Dies sold

separately

AC1055-2

AC0925C

ROD SHEAR

• Shear solid round rod easily

with the Rod Shear

• Handles 1/4”, 3/8”, 1/2”,

5/8”, 3/4” and 1” solid

round bar

ANGLE NOTCHER

• Take precise 92° notch

out of mild steel up to 3” x

3” x 1/4”

• Allows for an easy 90° to

create a steel frame

*

AC0125*

TURRET PIPE NOTCHER

• Make clean 90° saddle joint

connections quickly and easily

• Compatible with all Edwards

Ironworkers

• Contact Edwards for custom

dies to match your project

• Pipe Notcher Dies sold

**

separately

AC0925T

*

26

AC1075

*

BRAKE WITH 4-WAY DIE

• Choose from the sizes listed below to meet your specific needs

• Fabricate brackets, frames, pans and tanks with this Brake with 4-Way Die

• Includes a standard punch that allows 1/16”, 1/8”, 3/16” and 1/4” material to be

formed to a 90° angle

7" 8" 10" 10” OPEN CAVITY

AC1033

*

*

AC1051

*

AC1052

*

AC1034

edwardsironworkers.com

AC1074

*

*IMAGE NOTE: Guarding removed for clarity

Page 27

IRONWORKERS

65 TON

ACCESSORIES

GAUGING TABLE KIT

• 3/8” thick, 12” x 16” table that

adds precision to your Punch

Workstation

• Compatible with both Standard

and Oversize Pedestal Die Tables

• Adjustable fences and handles

quickly and easily guide your

material for perfect repeatable

actions

AC0900

COPER NOTCHER

GAUGING TABLE KIT

• Provides a larger 3/8” x 121/2” x 15-5/8” size table and

two fences to better align

your material

AC0800

QUICK CHANGE PUNCH ASSEMBLY

• Accommodates punch and

Increase your efficiency by

saving time and money with

the Quick Change Punch

Assembly.

• Accepts both Standard and

Oversize Punch & Die Sets

AC1001

HEAVY DUTY GAUGING

TABLE KIT

• 1” x 12” x 16” table adds speed

and precision to your Punch

Workstation

• Replaces Standard Pedestal

Die Table

• Adjustable fences and handles

quickly and easily guide your

material for perfect repeatable

actions

AC0903

STRIPPER REDUCING PLATE

• Designed to minimize

distortion on thinner gauge

materials when using 1/2”

punches & dies set or smaller

AC1914-4

AUTO CUT – 48”

• Optimize your productivity on

both the Flat Bar Shear and

Angle Shear Workstations on

your Edwards Ironworker

• The adjustable proximity

sensor automatically cycles

your Ironworker as you feed

in material

AC1010

HEAVY DUTY GAUGING TABLE KIT

FOR OVERSIZED PUNCH ASSEMBLY

• 1” x 12” x 16” table adds speed

and precision to your Punch

Workstation

• Replaces installed Die Table

• Adjustable fences and handles

quickly and easily guide your

material for perfect repeatable

actions

AC0905

URETHANE STRIPPER

• Minimize material distortion

when working with light gauge

material

AC1099

BACK GAUGE – 48”

• Speed up production on

repeatable cuts by providing an

adjustable stop for the Flat Bar

Shear and Angle Shear

• A positive stop attachment

that is fitted to the back of the

Ironworker ensures accurate

shearing

AC1011

PRESS BRAKE BACK GAUGE

• Speed up production

on repeatable bends by

providing an adjustable stop

for the various size Brake

Attachments

• A positive stop attachment

that is fitted to the back

of the Ironworker ensures

accurate bending

FABRICATOR’S PROTRACTOR

• Increase user accuracy on

the Punch and Flat Bar Shear

Workstations

• Designed to guide your

workpiece and gauged at 15°

increments through 180°

PUNCH & DIE STARTER SET

• Includes 8 standard round

punch & die sets selected

to accommodate the most

commonly used bolts

• Sized in 1/8” increments from

3/16” to 1-1/16” with 1/32”

clearance

• See catalog page 68-71 for

PR135

additional Punch & Die Sets

12” & 18” FENCES GUIDES

• Easily adjustable to align

your material, these 12” or 18”

fence guides make precise,

repeatable operations simple.

AC1910 12” Standard Handles

AC1911 18” Standard Handles

AC1912 12” Heavy Duty Handles

AC1017

AC1913 18” Heavy Duty Handles

edwards–made in the usa since

PD1000

1875

ACCESSORY LIGHT

• Super bright LED light with

M12 connections plugs

• Powerful magnetic base

allows users to attach the

light to any Ironworker

surface and move as needed

AC1000

PRODUCTIVITY PACK

Includes 5 Accessories designed

to increase your accuracy and

production speed.

• Accessory light

• 48” Auto Cut

• Fabricator’s Protractor

• 3/8” x 12” x 16” Punch Station table

• Punch & Die Starter Kit

*IMAGE NOTE: Guarding removed for clarity

AC2000

27

Page 28

IRONWORKERS

75 TON

WORK

STATIONS

FLEXIBILITY

• Four workstations:

– Standard (4) – Punch, Flat Bar Shear,

Angle Shear & Coper Notcher

• 12 interchangeable Attachments available

to tailor the Ironworker to your needs

• 17 optional Accessories available to increase precision

and efficiency

WORK

STATIONS

PRODUCTIVITY

• Compact machine that allows for fast and easy

transitions between fabrication operations: punch,

shear, notch, bend and cope all in one machine.

• Optimized workstation heights for improved efficiency

• Electric foot pedal with integrated jog control

• Adjustable electric stoke control

SAFETY

• Bright LED lights increase visibility

• ANSI B11.5-1988(02) Compliant Guarding

• ETL Certified Controls

• Integrated Lock-out/Tag-out system with E-Stop for

added safety

SPECIFICATIONS

Punch Rating (tons) 75

Punch Max Capacity (In.) 1-1/16 diam. in 7/8 mild steel

Punch Work Height (In.) 39-1/16

Punch Throat Depth (In.) 10

Punch Stroke (In.) 1-13/16

Flat Bar Shear Max Capacity (In.)

Flat Bar Shear Work Height (In.) 37

Flat Bar Shear Max Round Capacity (In.) 1 diam.

Flat Bar Shear Max Square Capacity (In.) 1

Angle Shear Max Capacity (In.) 5 x 5 x 1/2

Angle Shear Work Height (In.) 43-15/16

Coper Notcher Max Capacity (In.) 2-1/2 x 5 x 1/2

Coper Notcher Work Height (In.) 42

Motor 5 or 7.5 HP

Amps 23

Hydraulics (GPM) 10-1/2

Hydraulics (PSI) 3500

Hydraulic Reservoir (gal.) 17

Product Dimensions (In.) 45 x 50 x 60 1/4

Shipping Dimensions (In.) 46 x 69 x 63

Weight (lbs.) 4,100

1/2 x 14

3/4 x 10

PERFORMANCE

• Durable, heavy-duty, Made In USA steel construction

• Vertical movement produces even pressure resulting in

precise punching and shearing with minimal distortion

that results in extended tooling life

• Punches are easily changeable, long-lasting and

available from 1/8” to 4” diameters along with square,

oblong, hex, metric, and custom shapes

• Flat Bar Shear blades are made of precision machined,

high-quality tool steel with 4 cutting edges for

extended life

• Angle Shear blades have 2 corner radii for both thin and

thick material and are made of precision tool steel with

2 cutting edges for extended life

STOCK # PRODUCT DESCRIPTION

IW75-1P230 75 Ton Ironworker 1 Phase, 230 Volt

IW75-3P208 75 Ton Ironworker 3 Phase, 208 Volt

IW75-3P230 75 Ton Ironworker 3 Phase, 230 Volt

IW75-3P380 75 Ton Ironworker Int'l - 3 Phase, 380 Volt, 50 Hz

IW75-3P460 75 Ton Ironworker 3 Phase, 460 Volt

IW75-3P575 75 Ton Ironworker 3 Phase, 575 Volt

28

edwardsironworkers.com

Page 29

IRONWORKERS

with

75 TON

THE EXCLUSIVE EDWARDS POWERLINK™ SYSTEM

TURNS YOUR 75 TON IRONWORKER INTO A POWER

SOURCE FOR OUR EVER INCREASING LINE OF

HYDRAULIC TOOLS.

• Simply PLUG IN & POWER UP any of our Hydraulic Tools

and expand your fabrication capabilities

Our factory installed PowerLink System includes quick

•

connect couplings allowing easy transitions between

Hydraulic Tools

• The Edwards Portable Power Unit is an additional

power source with the PowerLink System

TURN THE PAGE TO VIEW OUR FULL LINE OF ATTACHMENTS & ACCESSORIES FOR THE 75 TON IRONWORKER

STOCK # PRODUCT DESCRIPTION

IW75-1P230-AC700 75 Ton Ironworker 1 Phase, 230 Volt with PowerLink

IW75-3P208-AC600 75 Ton Ironworker 3 Phase, 208 Volt with PowerLink

IW75-3P230-AC600 75 Ton Ironworker 3 Phase, 230 Volt with PowerLink

IW75-3P380-AC600 75 Ton Ironworker Int'l - 3 Ph, 380 V, 50 Hz with PowerLink

IW75-3P460-AC600 75 Ton Ironworker 3 Phase, 460 Volt with PowerLink

IW75-3P575-AC600 75 Ton Ironworker 3 Phase, 575 Volt with PowerLink

10 TON

BENDER

20 TON

RADIUS ROLLER

20 TON

HORIZONTAL PRESS

20 TON

SHOP PRESS

40 TON

SHOP PRESS

60 TON

SHOP PRESS

edwards–made in the usa since 1875

60 TON

SHOP PRESS (PLC)

110 TON

SHOP PRESS

110 TON

SHOP PRESS (PLC)

29

Page 30

IRONWORKERS

75 TON

ATTACHMENTS

OVERSIZE PUNCH ASSEMBLY

• Accommodates punch & die

sets in various shapes and

sizes from 1” up to 1-9/16”

• Replaces Standard Punch

Assembly or can be used

as a secondary Punch

Workstation

• Make clean 90° saddle joint

• Compatible with all Edwards

• Contact Edwards for custom

• Pipe Notcher Dies sold

• Shear solid round rod easily

• Handles 1/4”, 3/8”, 1/2”,

AC1024

PIPE NOTCHER HOUSING

connections quickly and easily

Ironworkers

dies to match your project

separately

ROD SHEAR

with the Rod Shear

5/8”, 3/4” and 1” solid

round bar

AC0925

AC1074

*

*

*

241 PUNCH ASSEMBLY

• Accommodates punch & die

sets in various shapes and

sizes from 1” up to 4”

• Punch large holes and slots

in anything from heavy sheet

metal to steel beams

TURRET PIPE NOTCHER

• Make clean 90° saddle joint

connections quickly and easily

• Compatible with all Edwards

Ironworkers

• Contact Edwards for custom

dies to match your project

• Pipe Notcher Dies sold

separately

• Choose from the sizes listed below to meet your specific needs

• Fabricate brackets, frames, pans and tanks with this Brake with 4-Way Die

• Includes a standard punch that allows 1/16”, 1/8”, 3/16” and 1/4” material to be

formed to a 90° angle

AC1055-2

*

AC0925T

*

BRAKE WITH 4-WAY DIE

• Take precise 92° notch

out of mild steel up to 3” x

3” x 1/4”

• Allows for an easy 90° to

create a steel frame

• Designed to shear flat bar up

to 1/4” x 6” and angle iron up

to 2” x 2” x 1/4”

• Shears solid round bar 1/4”,

3/8”, 1/2”, 3/4” and 13/16”

square bar

7" 8" 10" 12”

AC1034

AC1033

*

*

AC1051

*

AC1035

*

ANGLE NOTCHER

MULTI SHEAR

AC0125*

AC1075

*

30

*IMAGE NOTE: Guarding removed for clarity

edwardsironworkers.com

Page 31

IRONWORKERS

75 TON

ACCESSORIES

GAUGING TABLE KIT

• 3/8” thick, 12” x 16” table that

adds precision to your Punch

Workstation

• Compatible with both Standard

and Oversize Pedestal Die Tables

• Adjustable fences and handles

quickly and easily guide your

material for perfect repeatable

actions

AC0900

COPER NOTCHER

GAUGING TABLE KIT

• Provides a larger 3/8” x 121/2” x 15-5/8” size table and

two fences to better align

your material

AC0800

QUICK CHANGE PUNCH ASSEMBLY

• Accommodates punch and

Increase your efficiency by

saving time and money with

the Quick Change Punch

Assembly.

• Accepts both Standard and

Oversize Punch & Die Sets

AC1001

HEAVY DUTY GAUGING

TABLE KIT

• 1” x 12” x 16” table adds speed

and precision to your Punch

Workstation

• Replaces Standard Pedestal

Die Table

• Adjustable fences and handles

quickly and easily guide your

material for perfect repeatable

actions

AC0903

STRIPPER REDUCING PLATE

• Designed to minimize

distortion on thinner gauge

materials when using 1/2”

punches & dies set or smaller

AC1914-4

AUTO CUT – 48”

• Optimize your productivity on

both the Flat Bar Shear and

Angle Shear Workstations on

your Edwards Ironworker

• The adjustable proximity

sensor automatically cycles

your Ironworker as you feed

in material

AC1010

HEAVY DUTY GAUGING TABLE KIT

FOR OVERSIZED PUNCH ASSEMBLY

• 1” x 12” x 16” table adds speed

and precision to your Punch

Workstation

• Replaces installed Die Table

• Adjustable fences and handles

quickly and easily guide your

material for perfect repeatable

actions

AC0905

URETHANE STRIPPER

• Minimize material distortion

when working with light gauge

material

AC1099

BACK GAUGE – 48”

• Speed up production on

repeatable cuts by providing an

adjustable stop for the Flat Bar

Shear and Angle Shear

• A positive stop attachment

that is fitted to the back of the

Ironworker ensures accurate

shearing

AC1011

PRESS BRAKE BACK GAUGE