Page 1

Instruction Manual

EXPT Pumping Station

B723-00-880

Issue B Original

Description Item Number

EXPT Pumping Station B723-00-000

Page 2

Page 3

B723-00-880 Issue B

Contents

Section Page

1 Introduction ........................................................................................1

1.1 Scope and definitions .................................................................................................... 1

1.2 Description................................................................................................................. 2

1.2.1 Overview...................................................................................................................2

1.2.2 General description of the EXPT pumping station major components ........................................... 2

1.2.3 Electrical protection ..................................................................................................... 2

1.2.4 Accessories ................................................................................................................2

2 Technical data .....................................................................................5

2.1 General..................................................................................................................... 5

2.2 Electrical data ............................................................................................................ 6

2.3 Legislation and standards ............................................................................................... 7

2.4 Operating and storage data............................................................................................. 7

2.5 Fuse ratings................................................................................................................ 7

2.6 Earth stud.................................................................................................................. 8

2.7 Electrical connections ................................................................................................... 8

2.8 Connections ............................................................................................................... 8

Contents

3 Installation ....................................................................................... 11

3.1 Safety......................................................................................................................11

3.2 Unpack and inspect .....................................................................................................11

3.3 Locate the EXPT pumping station.....................................................................................12

3.4 Fill the rotary pump with oil...........................................................................................13

3.5 XDS scroll pump silencer ...............................................................................................13

3.6 Fit accessories (optional)...............................................................................................13

3.7 Connect the EXPT pumping station to your vacuum system ......................................................14

3.8 Connect to your exhaust extraction system.........................................................................14

3.9 Connect the electrical supply .........................................................................................14

3.10 Additional earth bonding...............................................................................................14

3.11 Configure the EXPT pumping station .................................................................................14

3.12 Commission the installation............................................................................................16

3.13 Connecting an active gauge............................................................................................16

3.14 Connecting the logic interface ........................................................................................16

3.15 Connecting the serial interface .......................................................................................17

4 Operation......................................................................................... 19

4.1 Use of the backing pump controls ....................................................................................19

4.2 Start-up ...................................................................................................................19

4.3 Shut-down ................................................................................................................19

5 Maintenance...................................................................................... 21

5.1 Safety......................................................................................................................21

5.2 Maintenance plan........................................................................................................21

5.3 Inspect the hoses, pipelines and connections.......................................................................22

5.4 Trouble-shooting.........................................................................................................22

6 Storage and disposal ......................................... ..... ..... ..... ..... ..... ..... ..... 23

6.1 Storage ....................................................................................................................23

6.2 Disposal ...................................................................................................................23

ITR 21466

© Edwards Limited 2008. All rights reserved. Page i

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 4

B723-00-880 Issue B

Contents

7 Spares and accessories ......................................................................... 25

7.1 Introduction ..............................................................................................................25

7.2 Spares .....................................................................................................................25

7.3 Accessories ...............................................................................................................25

7.3.1 BX bakeout band.........................................................................................................25

Index............................................................................................... 27

Illustrations

Figure Page

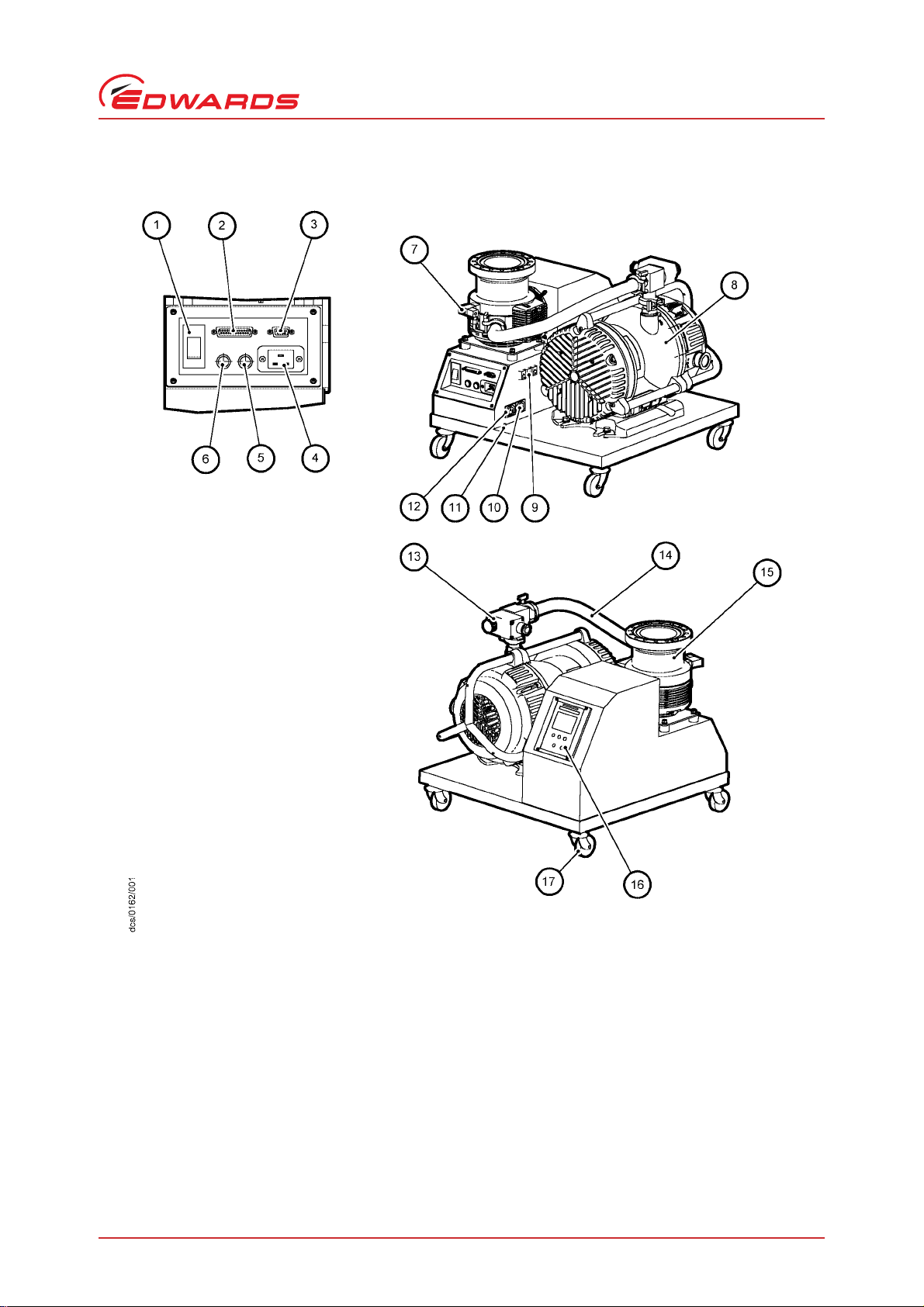

1 Components of the EXPT pumping station (typical system shown)............................................... 3

2 Equipment dimensions (mm) (XDD1 and EXT75DX shown) ......................................................... 9

3 Position the lifting slings/lifting hooks...............................................................................13

4 Turbomolecular pump start delay with XDD1 diaphragm pump..................................................15

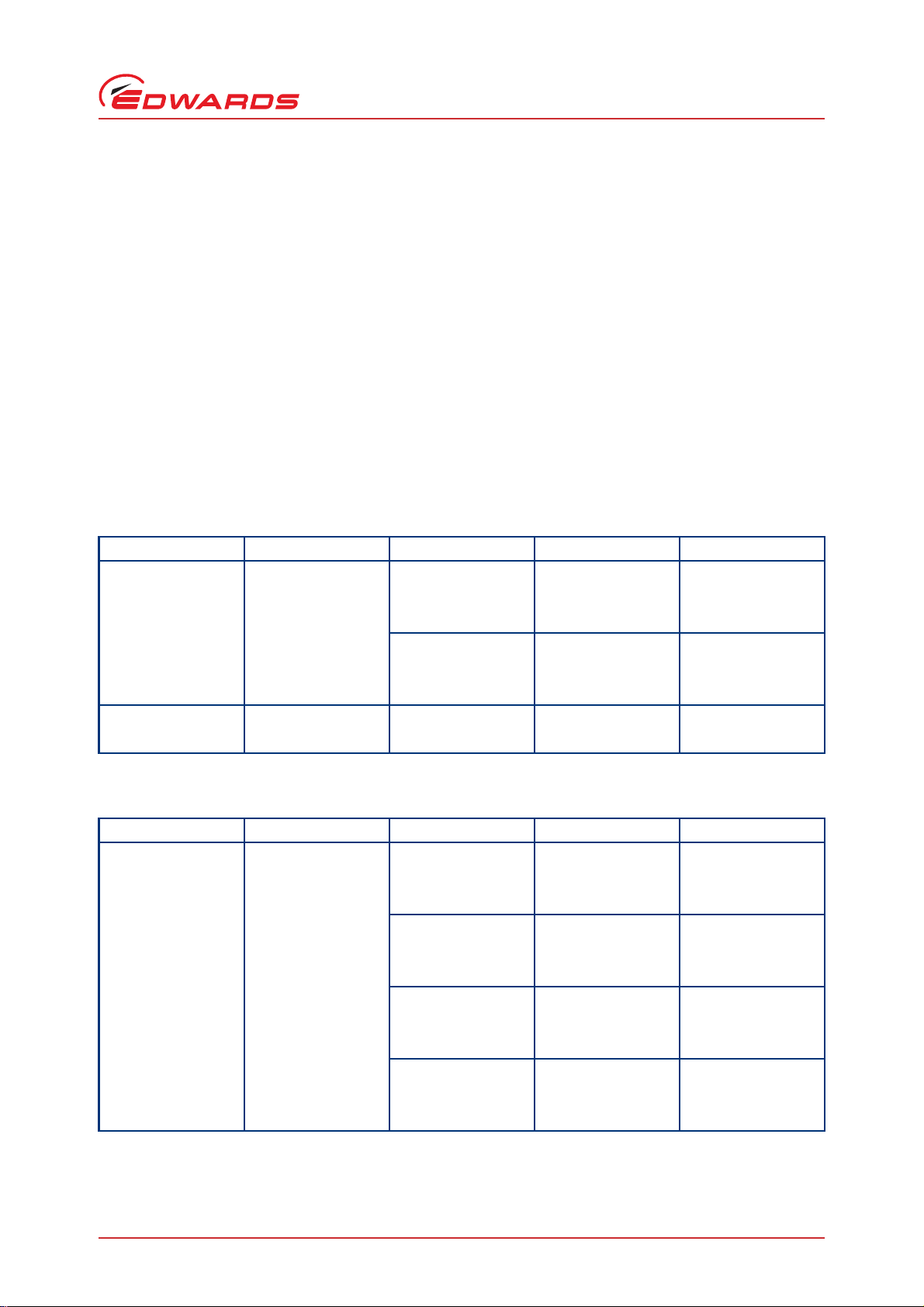

Tables

Table Page

1 EXPT1 pumping station mass............................................................................................ 5

2 EXPT2 pumping station mass............................................................................................ 5

3 Electrical data ............................................................................................................ 6

4 Operating and storage data............................................................................................. 7

5 Fuse ratings................................................................................................................ 7

6 Earth stud.................................................................................................................. 8

7 Electrical connections ................................................................................................... 8

8 Connections ............................................................................................................... 8

9 Checklist of components ...............................................................................................11

Supplementary publications

Publication title Publication number

XDD1 115/230 Diaphragm Pump A746-01-885

Turbo Instrument Controller (TIC) D397-10-880

EXT75DX Turbomolecular Pump B722-40-880

XDS Scroll Pump A726-01-880

Low Voltage EXT Compound Molecular Pumps EXT70H / 255H 24 V B722-20-880

EXDC Turbomolecular Pump Drive Modules D396-45-880

RV Rotary Vane Pumps A652-01-880

E2M Rotary Vane Pumps A371-22-880

EXPT Pumping Station Instruction Manual (quick guide) B723-00-860

CD ROM Instruction Manual B723-00-879

Page ii © Edwards Limited 2008. All ri ghts reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 5

B723-00-880 Issue B

Associated publications

Publication title Publication number

EXT Pump Accessories B580-65-880

Contents

© Edwards Limited 2008. All rights reserved. Page iii

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 6

B723-00-880 Issue B

This page has been intentionally left blank.

Page iv © Edwards Limited 2008 . All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 7

B723-00-880 Issue B

CAUTION

WARNING

1Introduction

1.1 Scope and definitions

This manual provides installation, operation and maintenance instructions for the Edwards EXPT Pumping Station.

You must use the EXPT Pumping Station as specified in this manual.

Read this manual before you install and operate the EXPT Pumping Station. Important safety information is

highlighted as WARNING and CAUTION instructions; you must obey these instructions. The use of WARNINGS and

CAUTIONS is defined below.

Warnings are given where failure to observe the instruction could result in injury or death to

people.

Cautions are given where failure to observe the instruction could result in damage to the equipment, associated

equipment and process.

Introduction

A full list of Supplementary Publications is provided at the end of the Contents list of this manual. A number of these

Supplementary Publications will be supplied with your EXPT Pumping Station. The Supplementary Publications

supplied will be the instruction manuals for the components in your EXPT Pumping Station.

The Supplementary Publications you receive also contain WARNING and CAUTION instructions. When you install and

operate the EXPT Pumping Station, you must refer to these Supplementary Publications and obey all of the WARNING

and CAUTION instructions which they contain.

The units used throughout this manual conform to the SI international system of units of measurement.

The following IEC warning labels appear on the product and in the manual.

Warning – refer to accompanying documentation.

Warning – risk of electric shock.

Warning – hot surfaces.

© Edwards Limited 2008. All rights reserved. Page 1

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 8

B723-00-880 Issue B

Introduction

1.2 Description

1.2.1 Overview

The EXPT Pumping Station is a fully automatic pumping system which is suitable for a wide range of applications. The

system is capable of utilising an extensive range of standard Edwards backing pumps, turbomolecular pumps and

controllers from a single compact unit. The open system configuration allows easy maintenance of the main pumping

components.

The function of the controller depends on your system configuration and will control the backing pump and

turbomolecular pump plus optional accessories. For systems with turbo and instrument controllers, up to three active

gauges may be used using the convenient gauge interface incorporated into the system housing. Both controllers are

provided with a large clear graphic display and easy-to-use control interface via a touch sensitive keypad. The system

incorporates an RS232/485 interface for control and data monitoring on a remote PC and a logic interface for

interface with associated system hardware.

Both systems are base mounted and come in two sizes. The EXP T1 base uses rob ust rubber feet as standard, castors

are optional. The EXPT2 base uses castors as standard to allow ease of transportation.

1.2.2 General description of the EXPT pumping station major components

For the general description of the major components used on the EXPT Pumping Station, click on the appropriate

instruction manual reference against each product type.

Diaphragm pump XDD1 (A746-01-885)

Rotary vane pumps E2M0.7 / E2M1.5 (A371-22-880 Section 1.2)

RV3 / RV5 / RV8 / RV12 (A652-01-880 Section 1.2)

Turbomolecular pumps EXT70H / EXT255H 24 V (B722-20-880 Section 1.2)

EXT75DX / EXT255DX (B722-40-880 Section 1.2)

Scroll pumps XDS5 / XDS10 (A726-01-880 Section 1.2)

TIC controller Turbo controller (D397-12-880 Section 1.2)

Turbo instrument controller (D397-22-880 Section 1.2)

1.2.3 Electrical protection

The EXPT Pumping Station has a double-pole thermal circuit breaker which provides short circuit protection. The

backing pump and TIC Controller both have overload protection.

1.2.4 Accessories

A wide range of standard accessories is available for the major components of the EXPT Pumping Station; refer to

Section 7.

Page 2 © Edwards Limited 2008. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 9

Figure 1 - Components of the EXPT pumping station (typical system shown)

13.Backing line valve

14.Flexible bellows

15.Turbomolecular pump

16.TIC controller

17.Castors (standard on EXP T2

systems)

1. Mains ON/OFF

2. Logic interface

3. Serial communications port

4. Mains input

5. Heater fuse

6. Backing pump fuse

7. TAV vent valve

8. Backing pump

9. Vacuum gauge inputs

10.Backing pump supply

11.Earth stud

12.Heater supply (turbomolecular

pump remote use only)

B723-00-880 Issue B

Introduction

© Edwards Limited 2008. All rights reserved. Page 3

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 10

B723-00-880 Issue B

This page has been intentionally left blank.

Page 4 © Edwards Limited 2008. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 11

B723-00-880 Issue B

2Technical data

Note: The operating, storage conditions and performance of the EXPT Pumping Station depends on the major

components fitted to the EXPT Pumping Station; refer to the technical data in the appropriate

supplementary publications.

2.1 General

Dimensions Refer to Figure 2

Mass Refer to Tables 1 and 2

Electrical data Refer to Table 3

Degree of protection (to IEC34-5: 1981) IP20

Initial force required to push the EXPT pumping station*

(for systems with castors)

* Measured under ideal conditions and will increase on uneven floor surfaces, slopes etc.

Table 1 - EXPT1 pumping station mass

EXT pump TIC controller Backing pump Inlet flange Mass (kg)

XDD1

70H / 75DX TIC (100W)

E2M0.7/1.5

255H / 255DX TIC (200W) XDD1

3.5 kgf max.

NW40 22.9

DN63ISO-K 23

DN63CF 24.9

NW40 26.4

DN63ISO-K 26.5

DN63CF 28.4

DN100 ISO-K 25.5

DN100CF 27.75

Technical data

Table 2 - EXPT2 pumping station mass

EXT pump TIC controller Backing pump Inlet flange Mass (kg)

NW40 38

RV3 / 5

RV8 / 12

70H / 75DX TIC (100W)

XDS5

XDS10

DN63ISO-K 38.1

DN63CF 40

NW40 42.7

DN63ISO-K 42.8

DN63CF 44.7

NW40 39.4

DN63ISO-K 39.5

DN63CF 41.4

NW40 40.9

DN63ISO-K 41

DN63CF 42.9

© Edwards Limited 2008. All rights reserved. Page 5

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 12

B723-00-880 Issue B

Technical data

Table 2 - EXPT2 pumping station mass (continued)

EXT pump TIC controller Backing pump Inlet flange Mass (kg)

RV3 / 5

RV8 / 12

255H / 255DX TIC (200W)

XDS5

XDS10

2.2 Electrical data

Table 3 lists the electrical requirements for the different EXPT Pumping Stations.

Table 3 - Electrical data

DN100 ISO-K 40.6

DN100CF 42.85

DN100 ISO-K 45.3

DN100CF 47.55

DN100 ISO-K 42

DN100CF 44.25

DN100 ISO-K 43.5

DN100CF 45.75

Backing pump

XDD1

E2M0.7

E2M1.5

RV3 / 5

TIC

controller

100W 0.355

200W

100W

200W

100W

200W

100W

200W

Supply voltage

50/60Hz

100 4.67

110-120 4.04

220-240 2.07

100 6.02

220-240 2.57

110-120 4.34 8.14

220-240 2.27 4.07

110-120 5.44 9.24

220-240 2.77 4.57

110-120 5.54 14.44

220-240 2.67 6.77

110-120 6.64 15.54

220-240 3.17 7.27

100 8.15 33.94

220-240 3.67 16.87

100 9.5 43.1

220-240 4.17 17.37

Full load Start *

Current (A)

Maximum power

kW

0.49110-120 5.14

0.365

0.5

0.435

0.57

0.575110-120 7.04 20.875

0.71110-120 8.14 35.04

Page 6 © Edwards Limited 2008. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 13

Table 3 - Electrical data (continued)

B723-00-880 Issue B

Technical data

Backing pump

RV8/12

XDS5/10

Note: * If the EXPT Pumping Station uses a rotary vane pump, the system may draw up to the start current value

shown in Table 3. You must use a slow blow fuse to prevent unnecessary fuse failures, the start current

could typically last for several seconds and generally occurs when the rotary vane pump oil is cold.

TIC

controller

100W

200W

100W

200W

Supply voltage

50/60Hz

100 10.35 36.44

220-240 5.27 19.27

100 11.7 45.6

220-240 5.77 19.77

100 10.75

220-240 4.87

100 12.1

220-240 5.37

Full load Start *

Current (A)

Maximum power

kW

0.825110-120 10.24 22.375

0.96110-120 11.34 37.54

0.575110-120 9.64

0.71110-120 10.74

2.3 Legislation and standards

The legislation and standards with which the EXPT Pumping Station complies are listed in full on the Declaration of

Conformity shown on the front inside cover of this manual.

2.4 Operating and storage data

Table 4 - Operating and storage data

General items Reference data

Ambient operating temperature range 0 °C to 35 °C

Ambient storage temperature range -30 °C to 70 °C

Maximum ambient operating humidity Max 90% RH non cond at 40 °C

Maximum operating altitude 3000 m max.

2.5 Fuse ratings

Table 5 - Fuse ratings

General items Reference data

BX bakeout band fuse (Heater)

90 to 132 V a.c. electrical supply 1 A, type F 20 mm

180 to 264 V a.c. electrical supply 0.5 A, type F 20 mm

Backing pump

Refer to backing pump documentation 10 A, type T 20 mm (maximum)

© Edwards Limited 2008. All rights reserved. Page 7

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 14

B723-00-880 Issue B

Technical data

2.6 Earth stud

Table 6 - Earth stud

General items Reference data

Earth stud M5

2.7 Electrical connections

Table 7 - Electrical connections

General items Reference data

Electrical supply (refer to Figure 1, item 4)

Inlet plug type CEE/IEC 320 (16A)

Backing pump (refer to Figure 1, item 10)

Outlet socket type CEE/IEC 320

Max power 600 W

Bakeout band (refer to Figure 1, item 12)

Outlet socket type CEE/IEC 320

Max power 150 W

2.8 Connections

Note: The connectors listed in Table 8 offer the same functionality as the connectors on the TIC Controller. Refer

to the TIC instruction manual for full details for these connectors.

Table 8 - Connections

General items Reference data

Active gauge connectors

Connector type FCC/RJ45, 8-way

Power supply 24 V d.c.

Logic interface

Connector type 25-way sub-miniature ‘D’ type socket

Power supply 24 V d.c.

Serial communications

Connector type 9-way sub-miniature ‘D’ type socket

Page 8 © Edwards Limited 2008. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 15

Figure 2 - Equipment dimensions (mm) (XDD1 and EXT75DX shown)

Position Base or pump description Dimension

A

EXT70H

B

EXT75DX

EXT255H/

EXT255DX

EXPT1 380.0

EXPT2 500.0

ISO63/CF63 415.0

NW40 422.0

ISO63 415.0

NW40 427.0

CF63 434.0

ISO100 450.1

CF100 450.1

B723-00-880 Issue B

Technical data

© Edwards Limited 2008. All rights reserved. Page 9

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 16

B723-00-880 Issue B

This page has been intentionally left blank.

Page 10 © Edwards Limited 2008. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 17

B723-00-880 Issue B

WARNING

3 Installation

3.1 Safety

Obey the safety instructions given below and take note of appropriate precautions. If you do not,

you can cause injury to people and damage to equipment.

z When you refer to a manual supplied as a Supplementary Publication, you must obey all of the W ARNING and

CAUTION instructions in the manual.

z A suitably trained and supervised technician must install the EXPT Pumping Station.

z Check that all the required parts are available and of the correct type before you start work.

z Ensure that the installation technician is familiar with the safety procedures which relate to the products

pumped. Wear the appropriate safety-clothing when you come into contact with contaminated components.

z Isolate the other components in your system from the electrical supply so that they cannot be operated

accidentally.

Installation

z Do not reuse ‘O’ rings and Co-Seals if they are damaged.

z Dispose of components, grease and oil safely (refer to Section 6).

z Take care to protect sealing-faces from damage.

z Leak-test the system after installation and seal any leaks found.

3.2 Unpack and inspect

Remove the outer cover and all packing materials, remove the protective covers from the inlet and outlet ports,

inspect the system for any damage. If the EXPT Pumping Station is damaged, notify your supplier and the carrier in

writing within three days; state your order number and invoice number. Retain all packing materials for inspection.

Do not use the EXPT Pumping Station if it is damaged. Check that your package contains the items listed in Table 9.

If any item is missing, notify your supplier within three days.

If the EXPT Pumping Station is not to be used immediately, replace the protective covers. Store the EXPT Pumping

Station in suitable conditions as described in Section 6.1.

Table 9 - Checklist of components

Qty Description Check (✓)

1 EXPT Pumping Station

1 Instruction Manual Package

1 Logic Interface Interlock D-Connector

1TMP Flange Inlet Seal

1 Rotary Pump Oil (RV/E2M pumps only)

1 XDS Silencer (optional on systems with XDS pumps)

❏

❏

❏

❏

❏

❏

© Edwards Limited 2008. All rights reserved. Page 11

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 18

B723-00-880 Issue B

CAUTION

CAUTION

CAUTION

WARNING

WARNING

Installation

3.3 Locate the EXPT pumping station

Heavy objects can cause muscle strain or back injury. It is advisable to use suitable lifting

equipment when moving the EXPT Pumping Station.

(Applicable for systems with base castors) For your safety, both front castors must be locked when

the system is in operation. If you do not and the turbomolecular pump seizes, movement of the

system may damage equipment and injure people.

When lifting the EXPT Pumping Station, do not attempt to support the mass of the system from the backing

pump.

When lifting the EXPT Pumping Station, always use slings with sufficient length to prevent damage of the system

components.

Before attempting to lift the EXPT Pumping Station, move the system (on its pallet) close to the operating position.

Ensure that you provide a firm level base before removing the system from its pallet. It is advisable to always use

mechanical lifting equipment when moving the heavier EXPT2 systems. Use slings around the base of the system from

front to back, make sure each sling is routed between the castors or feet and the base guides to prevent slippage.

Alternatively use straps with lifting hooks. Refer to Figure 3 which shows where to locate the slings or lifting hooks.

When locating the EXPT Pumping Station, care should be taken not to restrict the ventilation grid located under

the base of the system. Failing to observe this may result in over heating of the controller and the

turbomolecular pump.

Page 12 © Edwards Limited 2008. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 19

Figure 3 - Position the lifting slings/lifting hooks

B723-00-880 Issue B

Installation

3.4 Fill the rotary pump with oil

If the EXPT Pumping Station uses a EM or RV series rotary or rotary vane pump you must fill it w ith the correct quantity

of oil (supplied with the equipment) before you operate the equipment, as described in the pump Instruction Manual.

3.5 XDS scroll pump silencer

The silencer is used to reduce exhaust noise during pump down and gas ballast operations. This part may be ordered

and supplied (not fitted) with the system or can be ordered as an optional extra. To fit the silencer, follow the

instructions in manual A505-97-880.

3.6 Fit accessories (optional)

If you wish to fit accessories to the EXPT Pu mping Station, fit them now, before you start to install the EXPT Pum ping

Station into your vacuum system. Install accessories as described in the instruction manuals supplied with the

accessories. Refer to Section 7 for further information on the accessories available and for specific fitting instructions

to fit the accessories to the EXPT Pumping Station.

Note: The use of water coolers and BX bake-out bands on the EXPT Pumping Station is not permitted. If you wish

to fit these accessories, it is advisable to install the turbomolecular pump away from the EXPT Pumping

Station. For further details regarding turbomolecular pump remote mounting please contact Edwards UK.

© Edwards Limited 2008. All rights reserved. Page 13

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 20

B723-00-880 Issue B

WARNING

WARNING

WARNING

Installation

3.7 Connect the EXPT pumping station to your vacuum system

If you install your vacuum system directly onto the EXPT Pumping Station, the centre of gravity of

the mass must be above and within 300 mm of the centre line.

Note: If the vacuum system is to be supported by the EXPT Pumping Station, the mass of the vacuum system must

not be greater than the maximum mass which can be supported by the turbomolecular pump (refer to the

EXT Pump Instruction Manual). Use the co-seal or copper gasket (supplied with the equipment) with a

suitable clamp to secure to the vacuum system. Alternatively you may wish t o use a pipeline to connect the

vacuum system to the inlet of the turbomolecular pump. Refer to the EXT Pump Instruction Manual for

further details.

3.8 Connect to your exhaust extraction system

Note: For further information, refer to the instruction manual which corresponds to the backing pump fitted to

your EXPT Pumping Station.

3.9 Connect the electrical supply

Ensure that the electrical installation of the EXPT Pumping Station conforms with your local and

national safety requirements. It must be connected to a suitably fused and protected electrical

supply and a suitable earth point.

Ensure the mains cord is routed so as not to cause a trip hazard.

Check that your electrical supply is suitable for this equipment. Refer to Table 3 for the electrical requirements for

this equipment. The EXPT Pumping Station is supplied with an electrical cable which includes a moulded

IEC connector fitted at one end, the other end of the cable will be fitted with a moulded plug suitable for connection

to the local electrical supply.

3.10 Additional earth bonding

The electrical supply cable normally provides protective earthing for electrical safety. If this is not the case, or if

additional earth bonding is required, the earth stud located on the base at the rear of the EXPT Pumping Station

should be connected to your vacuum system.

3.11 Configure the EXPT pumping station

As supplied, the TIC Controller has been reconfigured for the TIC Pumping Station to suit most vacuum applications

and will:

When the TIC System ON is selected:

z Switch on both the backing pump and the turbomolecular pump *.

z Close the TAV vent valve.

z Open the backing valve.

Page 14 © Edwards Limited 2008. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 21

B723-00-880 Issue B

When the TIC System OFF is selected:

z Switch off both the backing pump and the turbomolecular pump.

z Close the backing valve.

EXDC pump controllers:

z Open the TAV vent valve fully after the turbomolecular pump has slowed to 50% of its rotational speed.

DX pump controllers:

z Open the T AV vent valve (controlled venting) from 100–50% rotational speed, and then open fully from 50% of

full rotational speed.

Note: The TAV vent valve and LCPVEK backing valve are optional extras.

Note: The TIC Controller factory settings have been changed to provide a standard operation for the EXPT

Pumping Station, if you replace the TIC Controller you should reconfigure the set up options to suit your

application, refer to the TIC instruction manual for further details.

Note: * If your EXPT Pumping Station uses an XDD1 diaphragm pump, the turbomolecular pump drive will be

delayed for two minutes while the backing pump reduces the pressure to a suitable level, this is typical for

a five litre volume and will prevent the turbomolecular pump from running under high pressure for a

prolonged period. This delay is adjustable (refer to the TIC instruction manual) and is recommended for

system volumes >2 litres, refer to Figure 4 to estimate the turbomolecular start delay if you know your

system volume.

Installation

Figure 4 - Turbomolecular pump start delay with XDD1 diaphragm pump

© Edwards Limited 2008. All rights reserved. Page 15

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 22

B723-00-880 Issue B

CAUTION

CAUTION

CAUTION

WARNING

Installation

3.12 Commission the installation

Do not operate the system with the exhaust pipeline blocked. For example, if your EXPT Pumping

Station uses a rotary vane pump, oil mist may be discharged from the oil mist filter and cause injury

to people.

After you have installed the EXPT Pumping Station, use the following procedure to test the system.

1. Make sure that all the electrical connections are secure.

2. Switch on the electrical supply and your exhaust-extraction system (if available).

3. Turn ON the EXPT Pumping Station using the ON/OFF switch positioned on the rear panel. To start-up the

equipment, refer to the TIC instruction manual. Check that the equipment operates as described in

Section 3.11.

4. Inspect the vacuum, exhaust and pipeline connections and check that there are no leaks. Sea l if any leaks are

found.

5. Wait until the turbomolecular pump has reached full speed, then select OFF on the front panel of the TIC

Controller again; check that both pumps stop.

3.13 Connecting an active gauge

Do not connect Barocel capacitance manometers to the TIC Pumping Station gauge connectors. Doing so will

result in damage to the gauge and will invalidate the warranty.

Up to three compatible active gauges can be fitted to the gauge connectors on the rear inside of the EXPT Pumping

Station housing, refer to Figure 1. Connect the gauges using Edwards active gauge cables to each of the three sockets,

the number indicated above each socket corresponds to the same gauge number shown on the TIC Controller display.

This option is only available if the EXPT Pumping Station uses a TIC turbo and instrument controller.

Note: Only one AIGX gauge can be connected to the TIC Pumping Station gauge connectors at a time.

3.14 Connecting the logic interface

Do not earth the logic interface 0 V lines (pins 7, 10, 12, and 13). If you do, you will provide an earth return

path for any electrical fault in the pump-motor and this could damage your Controller or your control

equipment.

Do not connect voltages greater than 24 V to the logic interface.

The logic interface provides a number of signals that can be used for monitoring the status of your vacuum system,

and for controlling certain aspects of its operation. These signals can be broadly divided into three groups, control

inputs, control outputs and status outputs.

The EXPT Pumping Station is supplied with an interlock D-connector connected into the logic interface a t the rear of

the equipment. If you do not intend to connect the logic interface to your system you must use the interlock

D-connector, failing to do so will disable a number of control outputs which operate the EXPT system.

Page 16 © Edwards Limited 2008. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 23

B723-00-880 Issue B

Note: The user logic interface on the rear panel offers the same functionality as the logic interface on the TIC

Controller. Refer to the TIC instruction manual for further details of this connector.

3.15 Connecting the serial interface

The TIC has two serial communications protocols built in, RS232 and RS485. RS232 is the simple st interface and can

be used to allow a host PC to control the TIC. RS485 allows a host PC to control a small network of TICs.

Note: The user serial interface on the rear panel offers the same functionality as the serial interface on the TIC

Controller. Refer to the TIC instruction manual for further details of this connector.

Installation

© Edwards Limited 2008. All rights reserved. Page 17

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 24

B723-00-880 Issue B

This page has been intentionally left blank.

Page 18 © Edwards Limited 2008. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 25

B723-00-880 Issue B

4 Operation

4.1 Use of the backing pump controls

If the backing pump has a mode selector and or ga s-ballast control, refer to the ap propriate backing pump instruction

manual to optimise the performance of the pump for your application.

4.2 Start-up

Use the following procedure to start the EXPT Pumping Station. If you wish to reconfigure the operation of the EXPT

Pumping Station to suit an application, refer to the TIC instruction manual.

1. Switch on the electrical supply to the EXPT Pumping Station and your exhaust-extraction system (if available).

2. Turn ON the EXPT Pumping Station using the ON/OFF switch positioned on the rear panel.

3. To operate the equipment components, refer to the TIC instruction manual for full operation.

4.3 Shut-down

Operation

Use the following procedure to shut down the EXPT Pumping Station.

1. Refer to the TIC Controller instruction manual to stop the turbomolecular pump (TMP) and backing pump

operation.

2. Switch off the ON/OFF rocker switch located on the equipment rear panel.

3. Remove the electrical mains supply from the equipment.

© Edwards Limited 2008. All rights reserved. Page 19

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 26

B723-00-880 Issue B

This page has been intentionally left blank.

Page 20 © Edwards Limited 2008. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 27

B723-00-880 Issue B

WARNING

5Maintenance

5.1 Safety

Obey the safety instructions given below and take note of appropriate precautions. If you do not,

you can cause injury to people and damage to equipment.

z When you refer to a manual supplied as a Supplementary Publication, you must obey all of the W ARNING and

CAUTION instructions in the manual.

z A suitably trained and supervised technician must maintain the EXPT Pumping Station.

z Allow the pumps to cool to a safe temperature before you start maintenance work.

z Check that all the required parts are available and of the correct type before you start work.

z Ensure that the maintenance technician is familiar with the safety procedures which relate to the products

pumped. Wear the appropriate safety-clothing when you come into contact with contaminated components.

Dismantle and clean contaminated components in a fume-cupboard.

Maintenance

z Isolate the EXPT Pumping Station and other components in the system from the electrical supp ly so that they

cannot be operated accidentally.

z Do not reuse ‘O’ rings and Co-Seals if they are damaged.

z Dispose of components, grease and oil safely (refer to Section 6).

z Protect sealing -faces from damage.

z Do not touch or inhale the thermal breakdown products of fluoroelastomer seals. These breakdown products

are very dangerous and may be present if the EXPT Pumping Station has been heated to 260 °C and above.

z Leak-test the system after maintenance and seal any leaks found if you have discon nected any vacuum or

exhaust pipeline connections.

5.2 Maintenance plan

The following documents list the minimum maintenance operations necessary to maintain the EXPT Pumping Station

in normal use.

More frequent maintenance may be necessary if the EXPT Pumping Station has been used to pump corrosive or

abrasive gases and vapours. If necessary, adjust the maintenance plan according to your experience.

EXT pumps

Turbomolecular pumps EXT70H / EXT255H 24 V (B722-20-880)

EXT75DX / EXT255DX (B722-40-880)

Backing pumps

Diaphragm pump XDD1 (A746-01-885)

Rotary vane pumps E2M0.7 / E2M1.5 (A371-22-880)

RV3 / RV5 / RV8 / RV12 (A652-01-880)

Scroll pumps XDS5 / XDS10 (A726-01-880)

© Edwards Limited 2008. All rights reserved. Page 21

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 28

B723-00-880 Issue B

Maintenance

5.3 Inspect the hoses, pipelines and connections

1. If the turbomolecular pump on your EXPT Pumping Station is water-cooled:

z Inspect all of the cooling-water connections and check that they are secure. Tighten any loose connections.

z Inspect all cooling-water hoses, pipelines and connections and check that they are not corroded or damaged

and that they do not leak. Replace or repair any corroded or damaged component and seal any leaks found.

2. Inspect all of the electrical connections and check that they are secure. Tighten any loose connections.

3. Inspect all of the electrical cables and check that they are not damaged and have not overheated. Replace or

repair any damaged or overheated cable.

4. Inspect all of the vacuum and exhaust connections and check that they are secure. Tighten any loose

connections.

5. Inspect all of the vacuum and exhaust pipelines and check that they are not corroded or damaged and that they

do not leak. Replace or repair any corroded or damaged component and seal any leaks found.

5.4 Trouble-shooting

For trouble-shooting instructions on the EXPT Pumping Station, refer to the following documents:

EXT pumps

Turbomolecular pumps EXT70H / EXT255H 24 V (B722-20-880)

EXT75DX / EXT255DX (B722-40-880)

Backing pumps

Diaphragm pump XDD1 (A746-01-885)

Rotary vane pumps E2M0.7 / E2M1.5 (A371-22-880)

RV3 / RV5 / RV8 / RV12 (A652-01-880)

Scroll pumps XDS5 / XDS10 (A726-01-880)

TIC controller

TIC controller Turbo controller (D397-12-880)

Turbo instrument controller (D397-22-880)

Page 22 © Edwards Limited 2008. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 29

B723-00-880 Issue B

6 Storage and disposal

Note: We recommend that you avoid long-term storage of the EXPT Pumping Station. If you will store the EXPT

Pumping Station for several months, refer to the storage instructions in the relevant instruction manual.

6.1 Storage

Use the following procedure to store the EXPT Pumping Station:

1. Shut down the EXPT Pumping Station as described in Section 4.3.

2. Isolate the EXPT Pumping Station from the electrical supply and disconnect it from the vacuum system.

3. Drain the oil from the backing pump (rotary vane pumps only) as described in the instruction manual for the

pump. Refer to the following documents:

Rotary vane pumps E2M0.7 / E2M1.5 (A371-22-880)

RV3 / RV5 / RV8 / RV12 (A652-01-880)

4. Place protective covers over the inlet and outlet-flanges.

5. For the fastest pump-down after the EXPT Pumping Station is re-installed, seal the turbomolecular pump inside

a plastic bag together with a suitable desiccant.

Storage and disposal

6. Store the EXPT Pumping Station in cool, dry conditions until required for use.

6.2 Disposal

Dispose of the EXPT Pumping Station and any components safely in accordance with all local and national safety and

environmental requirements.

Particular care must be taken with components which have been contaminated with dangerous process substances.

© Edwards Limited 2008. All rights reserved. Page 23

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 30

B723-00-880 Issue B

This page has been intentionally left blank.

Page 24 © Edwards Limited 2008. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 31

B723-00-880 Issue B

7 Spares and accessories

7.1 Introduction

Edwards products, spares and accessories are available from Edwards compani es in Belgium, Brazil, Canada, France,

Germany, Hong Kong, Italy, Japan, Korea, Switzerland, United Kingdom, U.S.A and a worldwide network of

distributors. The majority of these centres employ Service Engineers who have undergone comprehensive Edwards

training courses.

Order spare parts and accessories from your nearest Edwards company or distributor. When you order, state for each

part required:

z Model and Item Number of your equipment

z Serial number (if any)

z Item Number and description of the part.

Fit accessories as described in the Supplementary Publications and in the instruction manual supplied with the

accessory.

Spares and accessories

7.2 Spares

The spares available for use with the EXPT Pumping Station (including replacement component parts) are listed in

the instruction manuals supplied as Supplementary Publications.

7.3 Accessories

For accessories on the EXPT Pumping Station, refer to the following documents:

EXT pumps

Turbomolecular pumps EXT70H / EXT255H 24 V (B722-20-880)

EXT75DX / EXT255DX (B722-40-880)

Backing pumps

Diaphragm pump XDD1 (A746-01-885)

Rotary vane pumps E2M0.7 / E2M1.5 (A371-22-880)

RV3 / RV5 / RV8 / RV12 (A652-01-880)

Scroll pumps XDS5 / XDS10 (A726-01-880)

TIC controller

TIC controller Turbo controller (D397-12-880)

Turbo instrument controller (D397-22-880)

7.3.1 BX bakeout band

The BX bakeout band should only be used on turbomolecular pumps intended to be used remotely away from the

EXPT Pumping Station. For further details please contact Edwards UK.

© Edwards Limited 2008. All rights reserved. Page 25

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 32

B723-00-880 Issue B

This page has been intentionally left blank.

Page 26 © Edwards Limited 2008. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 33

Index

B723-00-880 Issue B

Index

A

Accessories ............................................2, 25

Additional earth bonding ...............................14

B

BX bakeout band ......................................... 25

C

Checklist of components ............................... 11

Commission the installation

Configure the EXPT pumping station

Connect the electrical supply ......................... 14

Connect the EXPT pumping station to your

vacuum system

Connect to your exhaust extraction system ......... 14

Connecting an active gauge ............................ 16

Connecting the logic interface

Connecting the serial interface ....................... 17

Connections ................................................8

........................................... 14

............................ 16

................. 14

........................ 16

D

Description .................................................2

Disposal ................................................... 23

M

Maintenance .............................................. 21

Maintenance plan ........................................ 21

O

Operating and storage data ..............................7

Operation ................................................. 19

Overview

....................................................2

S

Safety ..................................................... 11

Shut-down ................................................ 19

..................................................... 25

Spares

Start-up

Storage .................................................... 23

................................................... 19

T

Technical data .............................................5

Trouble-shooting ........................................ 22

U

Unpack and inspect ..................................... 11

Use of the backing pump controls .................... 19

E

Earth stud ...................................................8

Electrical connections ....................................8

Electrical data

Electrical protection ......................................2

.............................................6

F

Fill the rotary pump with oil ........................... 13

Fit accessories (optional) ............................... 13

Fuse ratings

.................................................7

G

General description of the EXPT pumping station

major components

.........................................2

I

Inspect the hoses, pipelines and connections ....... 22

Installation ................................................ 11

Introduction

................................................1

L

Legislation and standards ................................7

Locate the EXPT pumping station

..................... 12

X

XDS scroll pump silencer ............................... 13

© Edwards Limited 2008. All rights reserved. Page 27

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 34

B723-00-880 Issue B

This page has been intentionally left blank.

Page 28 © Edwards Limited 2008. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Loading...

Loading...