Edsyn 971DH-230B, LONER ATMOSCOPE, 971DH-230 User Manual

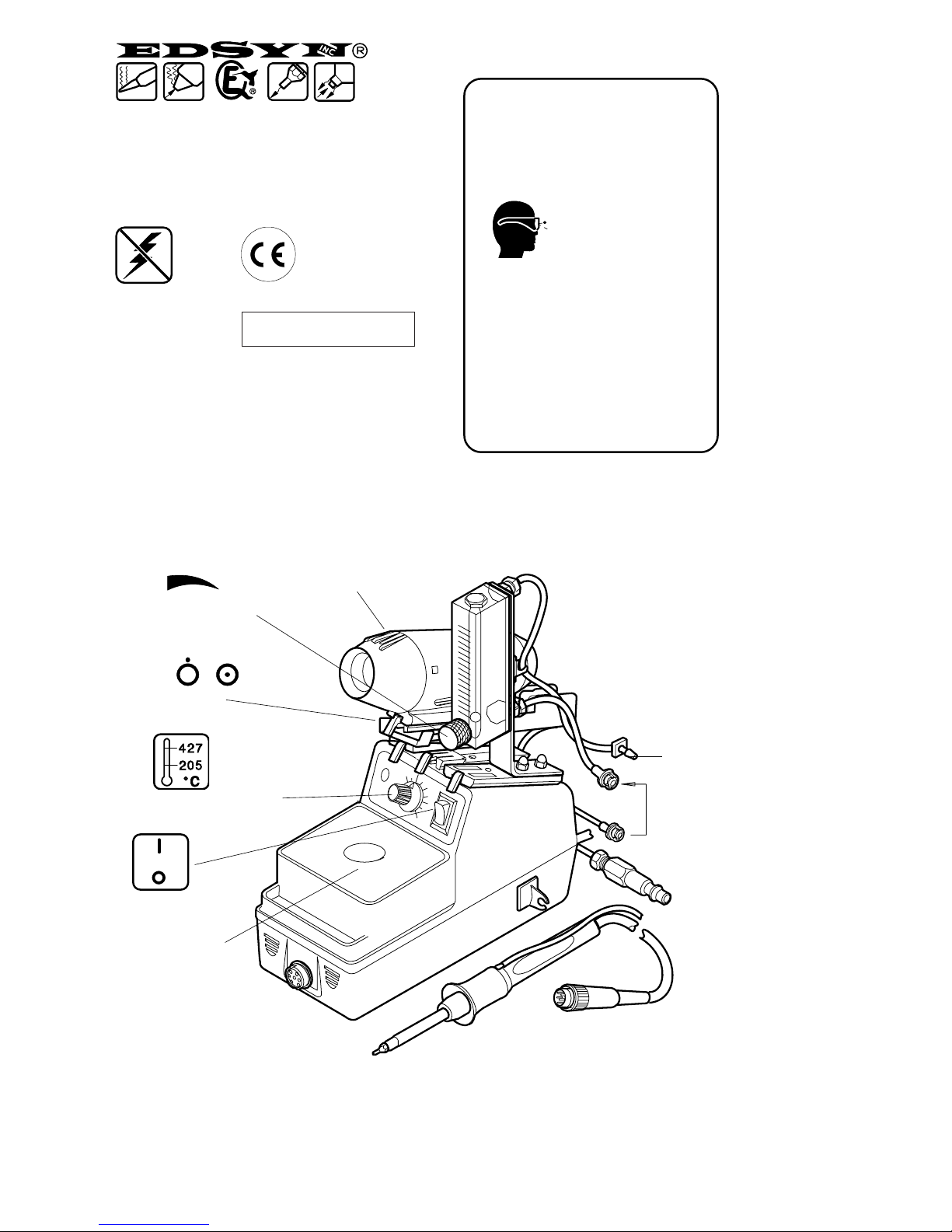

OPERATING REQUIREMENTS:

•230 V, 50 Hz

971DH-230 /B

ATMOSCOPE®

SMD Hot Air Station

24V Tool

Air or nitrogen

input, 5.5 bar max.

(clean & dry)

Connect to tool

Male connector

Female connector

w/ check valve

Power switch

Temperature Control

RS199 Sponge

PD533 Pod

PAS53

Pod Air Switch

PR570

Air Flow Regulator

connect

NOT SHOWN:

External Calibration Pots (left side)

1A fuse (under side)

• Automatic air shut-off

• Easy to use flow regulator

• Modulator assembly

• Easily converted to contact

soldering with NO-FUME system

• ESD safe

• Hot air calibration capability

• Check valve equipped high

pressure hose

LST17-1

Compressed air or non-inflammable gas supply:

approx. 1.4 up to max. 5.5 bar

(approx. 138 up to max. 551 kPa)

(compressed air must be water- and oil-free)

The hot air tool itself must always be

placed in the tool pod when not in use.

To avoid personal injury, a faulty or

damaged power cable must be replaced

by the manufacturer or by an authorized

workshop.

Unplug from power source when

replacing the fuse, 1A.

For indoor use only.

PRECAUTIONARY

MEASURES:

Safety glasses must

be worn when using

the hot air station

WT620

Hot Air Tip

RCS75

CHANGING TIPS

1. Turn Tip counter-clockwise

by using a WT620 Tip

Wrench.

2. Remove and replace with

desired Tip.

You will need:

• MS412 Calibration

System

• TPL09 Set (3 items)

HOT AIR CALIBRATION

It is highly recommended to use new or a very clean thermocouple wires (never been use to calibrate soldering tips)

FOLLOW SET-UP AS ILLUSTRATED

1. With the Hot Air Tip inside the TPL09-1,

place the center of the thermocouple

wire of the SDS100 inside the slot of

TPL09-1 Locator.

2. Turn on power and set Temperature

Control Knob to 205°C.

3. Turn Flow Regulator Knob to 4 - 5 SCFH

(2.4 lpm).

4. Adjust LO-Temp. Calibration Pot so the

Meter will read 205°C.

5. Set Temperature Control Knob to 427°C.

6. Adjust Hi-Temp. Calibration Pot so the

Meter will read 427°C.

Hot Air Tip

TPL09-1

Ceramic

Locator

SDS100

meter

FX635

use a 5/16 wrench to hold the

sleeve if tip is too tight.

PAS53 Pod Air Switch

(Tool Pod not shown)

Flow in standard

cubic feet per hour,

scfh

PR570 Flow Regulator

With tool out of the pod, push in

Tab to lock: Air on (continuous)

With tool in the pod, push in Tab

to lock: Air off (disable)

Tab

Fully clockwise

will shut off the flow.

scfh 5 10 15 20

li/m 2.4 4.7 7.1 9.4

OPERATION

.38 in.

3/8 in

(9.5 mm)

.06 in.

1/16 in.

(1.5 mm)

.25 in.

1/4 in.

(6.4 mm)

.30 in.

5/16 in.

(7.6mm)

.46 in.

15/32 in.

(11.7 mm)

.59 in.

19/32 in.

(14.9 mm)

.65 in.

21/32 in.

(16.5 mm)

.30 in.

5/16 in.

(7.6 mm)

.46 in.

15/32 in.

(11.7 mm)

.59 in.

19/32 in.

(14.9 mm)

.65 in.

21/32 in.

(16 .5 mm)

.02 in.

1/64 in.

(0.6 mm)

.04 in.

3/64 in.

(0.9 mm)

.06 in.

1/16 in.

(1.5 mm)

.03 in.

1/32 in.

(0.8 mm)

.05 in.

3/64 in.

(1.2 mm)

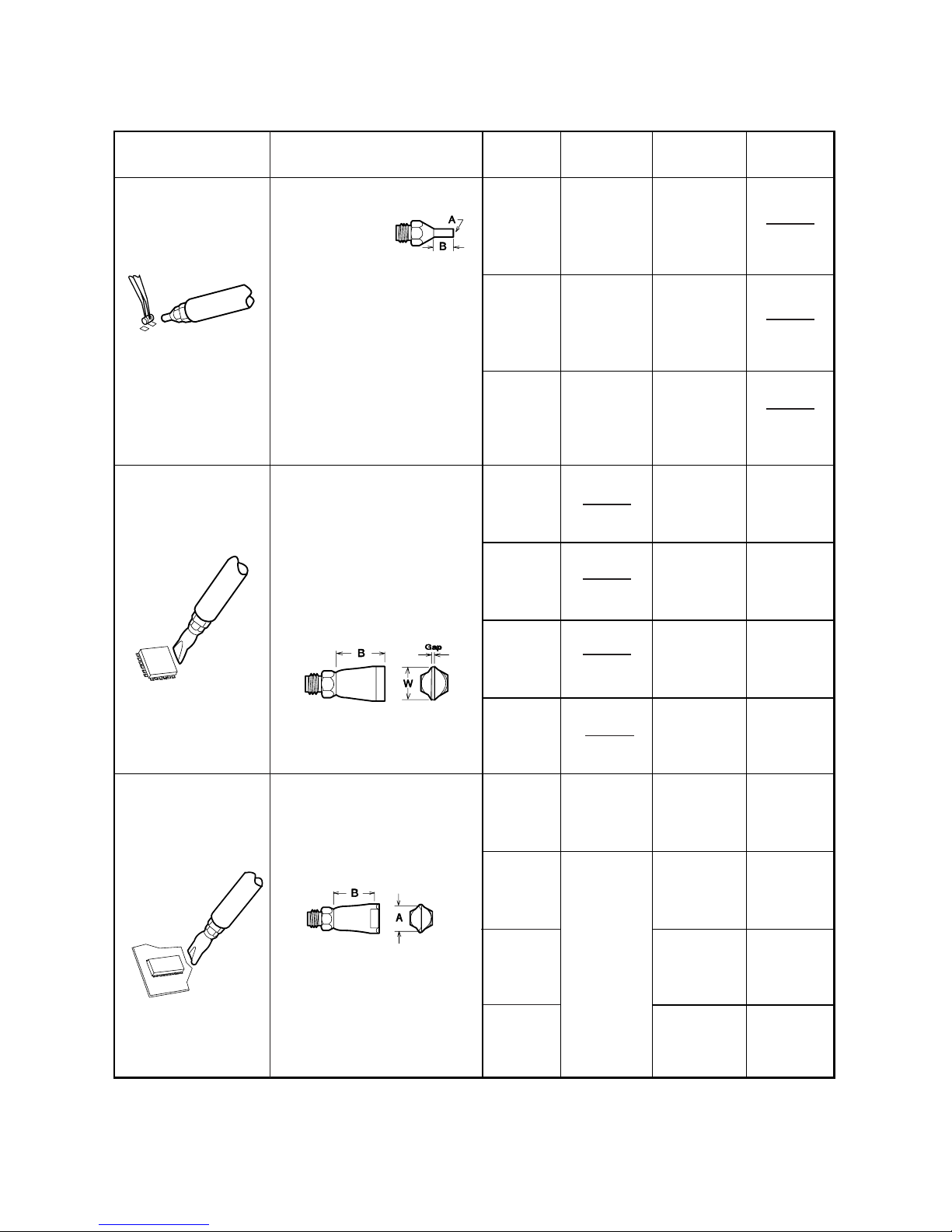

LT427

LT432

LT428

LT426

LT434

LT435

LT436

LT526

LT534

LT535

LT536

.17 in.

3/16 in.

(4.3 mm)

.23 in.

15/64 in.

(5.7 mm)

.35 in.

3/8 in.

(8.9 mm)

.43 in.

7/16 in.

(10.8 mm)

.12 in.

1/8 in.

(3.2 mm)

.20 in.

13/64 in.

(5.1 mm)

.28 in.

17/64 in.

(7.0 mm)

.35 in.

23/64 in.

(8.9 mm)

Description

LW

Application

.020 in

(.5 mm)

Fan Tips

use a wide air

flow enough to

cover one whole

side of the SMD.

Turbo Flow

for large

air flow.

Short Jet Tip

for medium air

Jet Tip

for pin point

air flow.

Dual Flow Tips blow hot

air on both sides of the

SMD, not on the SMD.

Apply AN112 or AN122 ANTI-SEIZE COMPOUND

To Heater and Area of Tip Contact.

AN122 comes in syringe dispenser.

Hole Dia.

Hole

Dia.

Part

No.

SMD Hot Air Tips

See Catalog for SMD Helpers, Pull Wires and other tools used in

aiding SMD removal and placing.

Loading...

Loading...