Page 1

1718 W. Fullerton Ave

Chicago, IL 60614

Tel: 773-770-1195

Fax: 773-935-5613

www.edgelighting.com

© 2013 Edge Lighting. All Rights Reserved.

info@edgelighting.com

Installation Instructions for Light Channel Trim 1.6

IMPORTANT INFORMATION

- This fixture is wall or ceiling mount.

- This instruction shows a typical installation.

- If modifying channel length, please see “Section

Three: Modifying Channel Length” on Page 4 before

installation.

SAVE THESE INSTRUCTIONS!

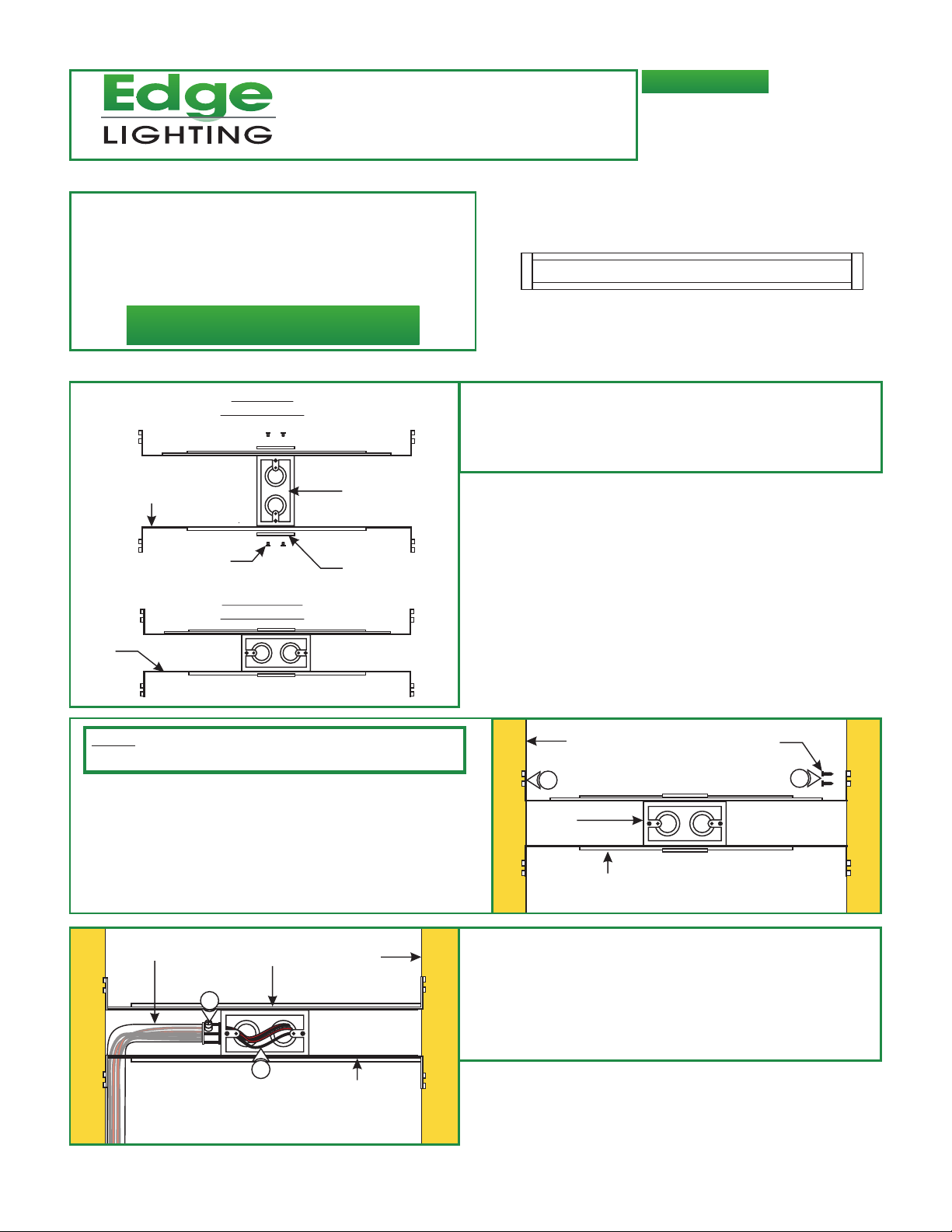

Section One: Installing The Channel

A

ADJUSTABLE

MOUNTING BAR

VERTICAL

ORIENTATION

JUNCTION

BOX

1

: Mount each adjustable mounting bar to one side of the

junction box (mounts to any side of the housing

depending on the orientation of the channel) and secure

them with the mounting brackets and two Phillips screws

provided.

LCT1.6-5WDC-_

904-LCT-1_6_02

PHILLIPS

SCREW

HORIZONTAL

ORIENTATION

JUNCTION

BOX

MOUNTING

BRACKET

NOTE: The adjustable mounting bars mount to studs that are

spaced 13" to 24" apart.

2: Select the location between the two studs for the junction

box to be mounted.

3: Place the adjustable mounting bars between the studs.

4: Make sure the lips on the adjustable mounting bars are

against the studs. Secure the adjustable bars to the studs

with the eight #8 screws.

C

CONDUIT

JUNCTION BOX

5

STUD

B

STUD

3

JUNCTION

BOX

ADJUSTABLE

MOUNTING BAR

#8 SCREW

4

5: Remove a knockout to install the power line conduit.

6: Install the conduit and run the low voltage 24V DC power

wires coming from the remote power supply to the

junction box.

7: Refer to the instruction provided with the power supply

along with the wiring diagram for proper wiring.

6

ADJUSTABLE

MOUNTING BAR

1

Page 2

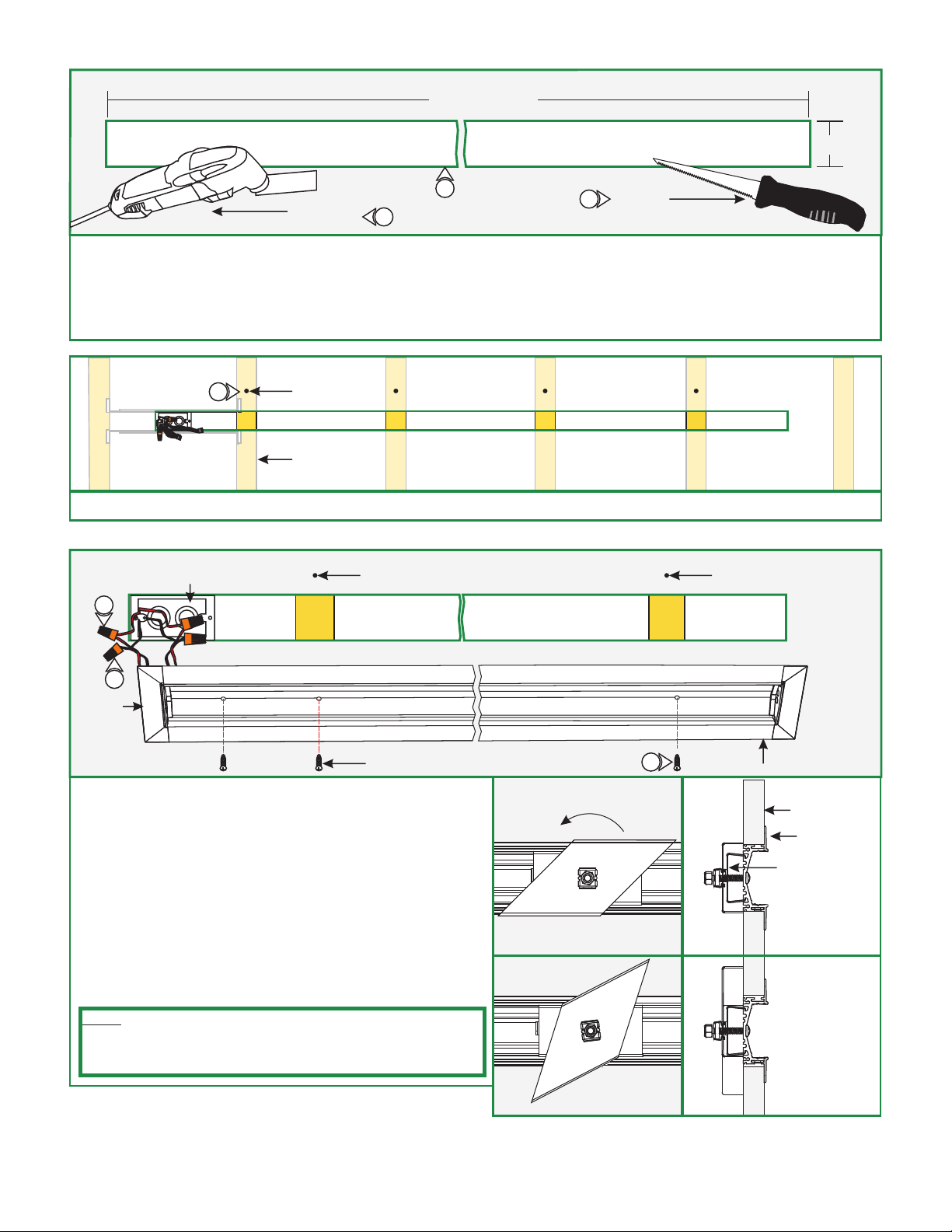

D

LENGTH OF

THE CHANNEL

DRYWALL

2.25"

DREMEL

MULTI-MAX

8

9

9

6" FIXED

JAB SAW

8: Mark the area where the channel will be located on the drywall.

9: Cut out the marked area(s) and install the drywall, using a "Dremel Multi-Max" with the "wood & drywall" cutting bit or a 6"

Fixed Jab Saw.

10: Install & finish drywall.

E

11

11: Mark the location of the studs to the drywall for future reference.

F

12

POWER FEED

JUNCTION BOX

MARKING

STUD

MARKING MARKING

13

ENDCAP

#6 SCREW

12: Connect the red power supply (24VDC+) wires to each red

power wire with a wire nut.

13: Connect the black power supply (24VDC-) wires to each

black power wire with a wire nut.

14: Place the wire nut connections inside junction box.

15: Using the marked locations on the drywall, carefully make a

hole to channel using the provided square drill with counter

sink bit.

16: Secure the channel to the stud and the junction box with the

#6 drywall screws using the provided square recess bit.

NOTE: If channel does not line up with a stud, use the provided

constraint clip kit to install to the drywall. Refer to diagram to the

right for reference. For alternate installation see “Section Two:

Alternate Installation w/Uneven Studs” on Page 4.

BACK

VIEW

TIGHTEN SCREW TO LOCK

CLIP INTO PLACE

16

SIDE

VIEW

CHANNEL

CONSTRAINT

CLIP (CONSISTS

OF A SCREW,

BASE, WING CLIP,

CAGE NUT,

& HEX NUT)

AS SCREW IS

TIGHTENED,

CAGE NUT LOCKS

INTO PLACE

CAUSING

THE WING CLIP TO

SECURE TO

THE DRYWALL.

DRYWALL

CHANNEL

2

Page 3

G

SOFT STRIP

17

18

POWER

CONNECTOR

17: Push the male connector of the Soft Strip into the female connector of the power connector.

18: Carefully remove the backing from the LED soft strip, make sure not to remove the tape from the soft strip. Firmly press down

the adhesive portion of the soft strip onto the channel surface while removing the rest of the backing, making sure there are

no air bubbles that can cause surface irregularities. Ensure the entire length of the channel is covered with Soft Strip to avoid

unlit areas.

H

PAPER

BACKING

CHANNEL

19

END CAP

LED STRIP

CHANNEL

OPTIONAL:

19: Trim excess LED strip at cut point.

20: If channel length has been modified as per the “Section

Three: Modifying Channel Length” section on Page 4,

insert excess LED strip into slot cut between the channel

and end cap.

I

20

LED STRIP

LENS FULLY

SEATED

21: Snap the lens into the channel and make sure it is fully

seated along the length of the channel opening.

LENS NOT

FULLY SEATED

LENS

LENS

CHANNEL

CHANNEL

3

Page 4

Section Two: Alternate Installation w/Uneven Studs

J

1 1

1: Mark the wall where channel mounting holes are located along the channel opening.

K

4 4

3 3

2: Cut 1" thick by 3" long sections of 2x4 to use as support bars.

3: Place the cut support bars through and behind the drywall at the marked mounting hole location.

4: Secure the support bars through drywall using two #6 drywall screws. Continue the installation as per Section One, Step 8.

Section Three: Modifying Channel Length

: If desired fixture length is less than the provided channel

L

CHANNEL

2

END CAP

#4-40

SCREWS

1

length, remove one channel end cap by loosening two #4-40

screws with the provided Torx drive.

2: Cut channel to desired length.

CHANNEL

1

END CAP

#4-40

SCREWS

3 4

3: Slightly grind off (~1/16") of the bottom of the channel. This

will allow excess LED strip to pass through after the end cap

is reinstalled.

4: Reinstall the channel end cap by replacing and tightening the

two #4-40 screws with the provided Torx drive.

4

Loading...

Loading...