Page 1

1718 W. Fullerton Ave

Chicago, IL 60614

Tel: 773-770-1195

Fax: 773-935-5613

www.edgelighting.com

© 2014 Edge Lighting. All Rights Reserved.

info@edgelighting.com

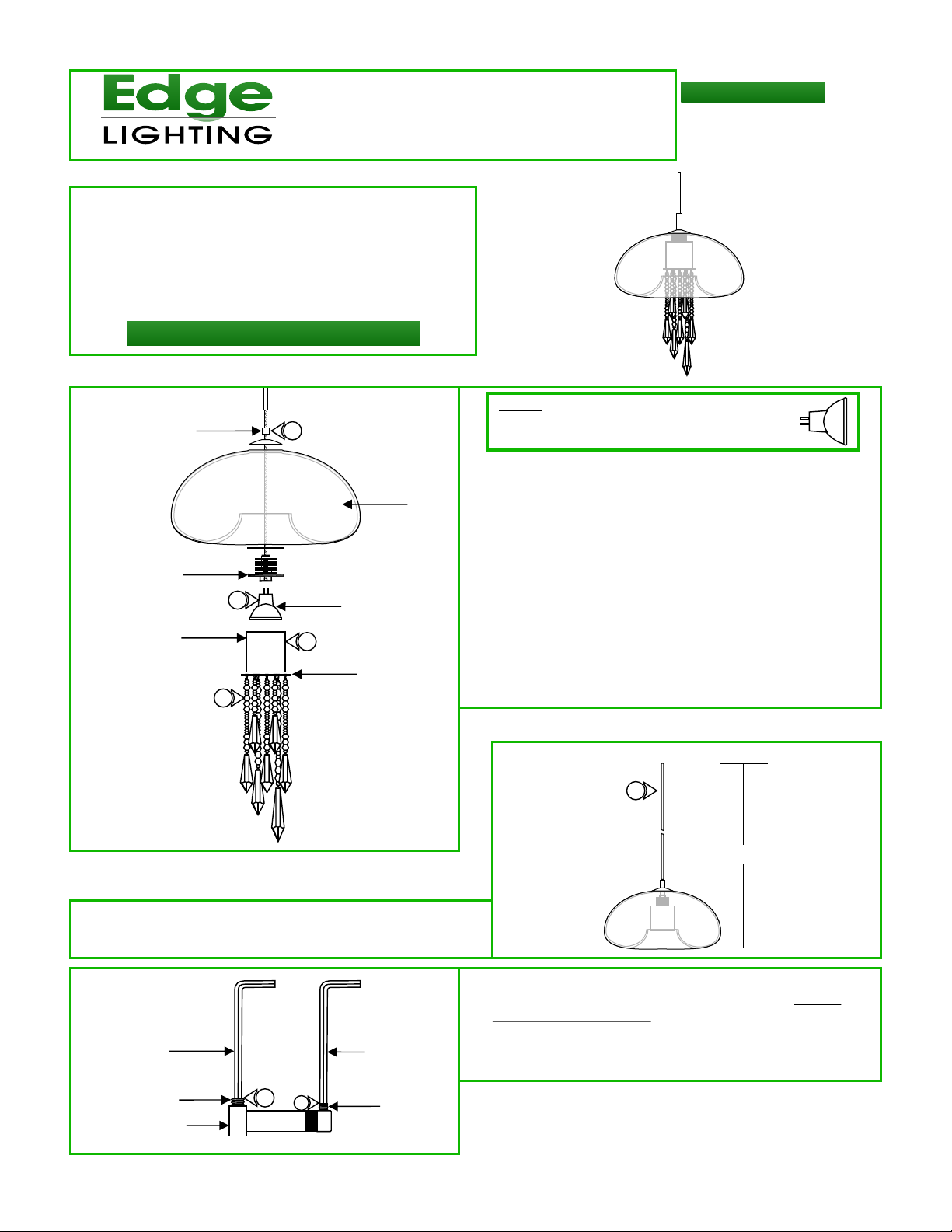

Installation Instructions for Fast Jack Jelly

IMPORTANT SAFETY INSTRUCTIONS

- Use this fixture indoors only.

- This product must be installed by a qualified electrician.

- This product is used with Monorail, Monorail 2 Circuit, and

Fast Jack canopy systems.

- Make sure power to the system is turned OFF before

installing the fixture.

SAVE THESE INSTRUCTIONS!

Install the Lamp

904-FJ-JELLY-01

FJ-JELLY-__-SN-__

A

COLLET

SOCKET

ASSEMBLY

METAL

SHADE

NOTE: Use MAXIMUM 3 Watt 12 VAC MR11

1

GLASS

SHADE

3

4

MR11

BI-PIN

LAMP

2

CRYSTAL

ACCESSORY

(OPTIONAL)

LED lamp or MAXIMUM 20 Watt 12 or 24VAC

MR11 halogen lamp.

1: Loosen the post at the top of the fixture and carefully slide

the socket assembly out of the glass shade.

2: Loosen and remove the metal shade from the socket

assembly.

3: Align the MR11 lamp pins to with the socket holes. Push the

lamp pins completely into socket holes.

4: If necessary, place any optical lenses (or optional crystal

accessory)inside the metal shade before replacing the metal

shade to the socket assembly.

5: Slide the glass shade onto the socket assembly and tighten

the post to secure.

Adjust the Fixture Height

B

1

1: Cut the coaxial cable to the desired height (H) with a sharp

cutter. The overall fixture height is measured from the

bottom of the glass shade to the end of the coaxial cable.

C

2MM ALLEN

WRENCH

M4 SET SCREW

COAXIAL FIXTURE

CONNECTOR

2

3

1.5MM ALLEN

WRENCH

M3 SET

SCREW

H

2: Loosen the M4 set screw on base of the coaxial fixture

connector with the 2mm Allen wrench provided. Do not

remove this set screw.

3: Remove the M3 set screw on tip of the connector with the

1.5mm Allen wrench provided.

1

Page 2

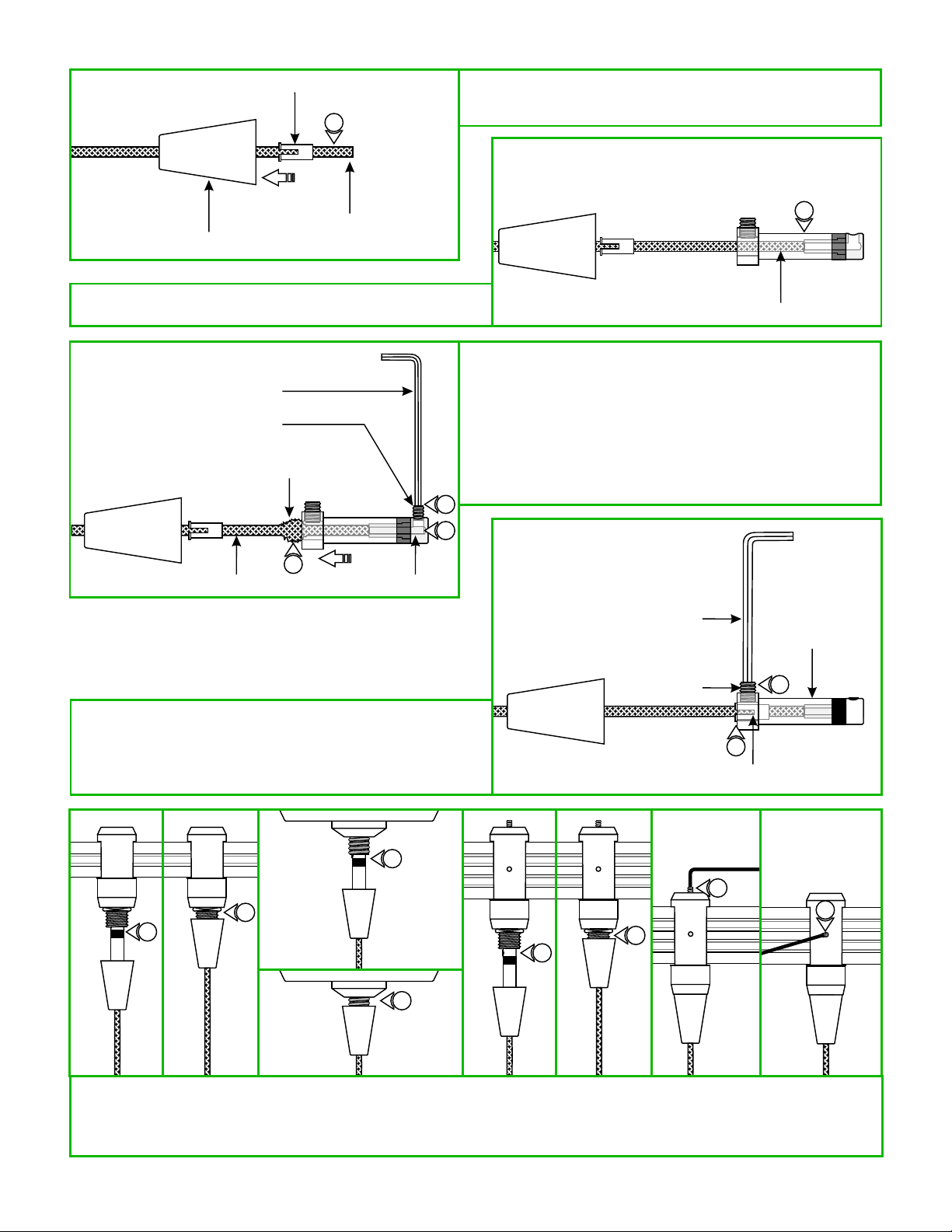

D

CIRCUIT

#1

1

2

N

12

CIRCUIT

#2

1

2

N

12

STRAIN RELIEF TUBE

4

4: Feed the coaxial cable through the conical nipple and flared

side of the strain relief tube. Slide the conical nipple and

strain relief tube down the coaxial cable.

E

COAXIAL CABLE

CONICAL NIPPLE

5: Feed the coaxial cable into the coaxial fixture connector. The

coaxial cable will come to a stop point.

F

1.5MM ALLEN WRENCH

M3 SET SCREW

WRINKLE

7

6

8

OUTER METAL JACK INNER WIRE

5

COAXIAL CABLE

6: Keep feeding the coaxial cable in until the inner wire is

visible in the screw hole of the fixture connector tip. The

outer metal jacket will start to wrinkle.

7: Hold the fixture connector in place. Replace and tighten the

M3 set screw on fixture connector tip with the 1.5mm Allen

wrench.

8: Pull down the outer metal jacket to smooth the wrinkles.

G

2MM ALLEN WRENCH

COAXIAL FIXTURE

CONNECTOR

9: Push the strain relief tube completely into the coaxial

fixture connector. Make sure the slot on the strain relief

tube is not inline with the M4 set screw.

10: Tighten the M4 set screw with the 2mm Allen wrench.

H

11: Use fingers to tighten the Fast Jack fixture connector into the Fast Jack system connector (Monorail, Monorail 2 Circuit, or

canopy connector - Refer to the instructions provided with the system connector or canopy).

12: Refer to the instructions provided with the Monorail 2 Circuit fixture connector to choose Circuit #1 or Circuit #2.

M4 SET SCREW

STRAIN RELIEF TUBE

11

11

11

11

11

11

10

9

2

Loading...

Loading...