Echo Bear Cat 73554 User Manual

OWNER

OPERATOR’S

MANUAL

Models

73525

5" Towable Chipper / Shredder with Discharge Blower

73554

5" PTO Chipper / Shredder with Discharge Blower

Crary Company

A Division of TerraMarc Industries

237 12th St. NW • P.O. Box 849

West Fargo, ND 58078-0849

(701)282-5520 • FAX: (701)282-9522

www.crary.com

Manual P/N 13436-00 Rev. 10/00 Companion to P/N 13437-00

Before you Begin

DEAR BEAR CAT CUSTOMER,

Thank you for purchasing a Crary Bear Cat Chipper Shredder. The Bear Cat Chipper Shredder is designed, tested, and manufactured to give years of dependable performance. To keep your Chipper Shredder operating at peak efficiency, it is necessary to adjust it correctly and make regular inspections. The following pages will assist you in the operation and maintenance of your machine. Please read and understand this manual before operating the chipper.

If you have any questions or comments about this manual, please call us toll-free at 1-800- 247-7335.

If you have any questions or problems with your chipper, please call or write your local factoryauthorized Bear Cat dealer.

PLEASE SEND US YOUR WARRANTY CARD

A warranty card is included in your owner's kit packaged with your chipper shredder. Please take the time to fill in the information requested on the card. When you send your completed card to us, we will register your machine and start your coverage under our limited warranty.

How to Contact Bear Cat

A D D R E S S

Crary Bear Cat

237 NW 12th Street

PO Box 849

West Fargo, ND 58078

P H O N E

800-247-7335

701-282-5520 Fax: 701-282-9522

E M A I L

opesales@crary.com

service@crary.com

H O U R S

M-F, 8 a.m. to 5 p.m. Central Time

EMISSION INFORMATION

WARNING

WARNING

WARNING TO ALL CALIFORNIA AND OTHER STATES OPERATING OUTDOOR POWER EQUIPMENT

Under California Law and under the laws of several other states you are not permitted to operate an internal combustion engine using hydrocarbon fuels on any forest covered, brush covered or grass covered land or on land covered with grain hay or other

flammable agricultural crop, without an engine spark arrester in continuous effective working order.

The engine on your power equipment, like most outdoor power equipment, is an internal combustion engine that burns gasoline, a hydrocarbon fuel. Therefore, your power equipment must be equipped with a spark arrester muffler in continuous effective working order. The spark arrester must be attached to the engine exhaust system in such a manner that flames or heat from the system will not ignite flammable material.

Failure of the owner/operator of the equipment to comply with this regulation is a misdemeanor under California law, and may also be a

violation of other state and or federal regulations, laws, ordinances, or codes. Contact your local fire marshal or forest service for specific information about what regulations apply in your area.

The standard muffler installed on the 25 HP engine is not equipped with a spark arrester. One must be added before use if this machine is intended to be used in an area where a spark arrester is required by law. Contact the local authorities if these laws apply to you. See your authorized engine dealer for spark arrester options.

|

Contents |

|

Section |

Description |

Page |

|

SERIAL NUMBER LOCATION ..................................................................................... |

1 |

|

REPLACEMENT PARTS ............................................................................................. |

1 |

|

THE SAFETY ALERT SYMBOL .................................................................................. |

2 |

|

BEFORE OPERATING ................................................................................................ |

2 |

1 |

SAFETY ...................................................................................................................... |

2 |

|

BEFORE OPERATING ................................................................................................ |

3 |

|

OPERATION SAFETY ................................................................................................. |

3 |

|

PTO SAFETY .............................................................................................................. |

5 |

|

TOWING SAFETY ....................................................................................................... |

5 |

|

BATTERY SAFETY ..................................................................................................... |

6 |

|

MAINTENANCE AND STORAGE SAFETY .................................................................. |

6 |

|

SAFETY DECAL LOCATIONS (MODEL 73525) ........................................................... |

7 |

|

SAFETY DECAL LOCATIONS (MODEL 73554) ........................................................... |

9 |

2 |

ASSEMBLY ............................................................................................................... |

11 |

|

MODEL # 73525 ASSEMBLY INSTRUCTIONS: ......................................................... |

11 |

|

MODEL # 73554 ASSEMBLY INSTRUCTIONS: ......................................................... |

13 |

3 |

FEATURES AND CONTROLS ................................................................................... |

14 |

|

FEATURES AND CONTROLS IDENTIFICATION ........................................................ |

14 |

|

DESCRIPTION OF OPERATION ................................................................................ |

14 |

|

CHIPPING OPERATION ............................................................................................ |

14 |

|

SHREDDING OPERATION ........................................................................................ |

14 |

|

FEATURES AND CONTROLS IDENTIFICATION ........................................................ |

15 |

|

USE OF CONTROLS ................................................................................................. |

16 |

|

FEATURES AND CONTROLS IDENTIFICATION ........................................................ |

17 |

|

DESCRIPTION OF OPERATION ................................................................................ |

17 |

|

CHIPPING OPERATION ............................................................................................ |

17 |

|

SHREDDING OPERATION ........................................................................................ |

17 |

|

FEATURES AND CONTROLS IDENTIFICATION ........................................................ |

18 |

|

USE OF CONTROLS ................................................................................................. |

19 |

4 |

OPERATION ............................................................................................................. |

20 |

|

STARTING TOWABLE MODELS (FILLING THE TANK) ............................................. |

20 |

|

STARTING TOWABLE MODELS ............................................................................... |

20 |

|

STARTING INSTRUCTIONS: PTO MODELS .............................................................. |

21 |

|

CHIPPING GUIDE ..................................................................................................... |

22 |

|

SHREDDING GUIDE ................................................................................................. |

22 |

5 |

SERVICE & MAINTENANCE ..................................................................................... |

23 |

|

MAINTENANCE SCHEDULE ..................................................................................... |

23 |

|

GREASING ............................................................................................................... |

24 |

|

PTO DRIVELINE LUBRICATION ................................................................................ |

26 |

|

SHARPENING CHIPPER BLADES ........................................................................... |

27 |

|

SETTING CHIPPING BLADE CLEARANCE ............................................................... |

28 |

|

REPLACING SHREDDER KIT ................................................................................... |

29 |

|

CLEANING PLUGGED ROTOR ................................................................................. |

29 |

|

REMOVING ROTOR .................................................................................................. |

30 |

|

REPLACING DRIVE BELTS (TOWABLE MODELS) .................................................. |

30 |

|

REPLACING DRIVE BELTS (PTO MODELS) ............................................................ |

31 |

|

TRAILER SERVICE TIPS .......................................................................................... |

31 |

|

ADDITIONAL SERVICE AND MAINTENANCE TIPS .................................................. |

31 |

|

TROUBLESHOOTING................................................................................................ |

32 |

|

SPECIFICATIONS ..................................................................................................... |

34 |

|

BOLT TORQUE REQUIREMENTS ............................................................................. |

36 |

SERIAL NUMBER LOCATION

Always give your dealer the serial number of your Crary Bearcat Chipper Shredder when ordering parts, requesting service or any other information.

The serial number decal for Model # 73525 is located at the top of the machine (See Fig. # 1). The serial number decal for Model # 73554 is located at the left rear of the machine (See Fig. # 2). Please record the Serial number in the space provided below and on the warranty and registration card.

WARNING

WARNING

To prevent personal injury or property damage: Shut off engine, disconnect spark plug wire, remove ignition key, disconnect the PTO driveline from the source providing power or disconnect the driveline from the chipper shredder and make sure that all moving parts have come to a complete stop, before obtaining serial number, servicing, adjusting or repairing.

Fig. 2 Serial number decal location (Model # 73554)

YXXXXX

Fig. # 3 Serial number decal

Fig. 1 Serial number decal location (Model # 73525)

Serial Number ________________________

REPLACEMENT PARTS

Only genuine Bearcat replacement parts should be used to repair the machine. Bearcat replacement parts are available from your Bearcat Dealer. To obtain prompt, efficient service, remember to give the Dealer the correct part description and serial number of the machine.

Please be sure to provide the following information:

1.The SERIAL NUMBER of your Machine.

2.The PART NUMBER of the part.

3.The PART DESCRIPTION.

4.The QUANTITY needed.

Bearcat Chipper Shredder Operator’s Manual |

Page 1 |

1 Safety

Section

THE SAFETY ALERT SYMBOL

This is the safety alert symbol. It is used in this Owner / Operator’s Manual and on your machine to alert you to potential hazards.

Whenever you see this symbol, read and obey the safety message that follows it. Failure to obey the safety message could result in personal injury, death or property damage

DANGER

DANGER

WARNING

WARNING

CAUTION

CAUTION

Indicates an imminently hazardous situation that, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation that, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate injury.

BEFORE OPERATING

1.Read this Owner / Operator’s manual and the separate Engine Owner’s manual carefully before operating this equipment. Be completely familiar with the controls and the proper use of this equipment.

2.Before inspecting or servicing any part of the machine, stop engine, wait for all parts to stop moving, and disconnect spark plug wire.

Remove key or key tool from key switch. Be aware that rotating blades slow down gradually after engine is shut off.

3.Keep safety decals clean and legible. Replace missing or illegible safety decals.

4.Familiarize yourself with all of the safety and operating decals on this equipment and on any of it’s attachments or accessories.

5.Do not allow children or any person unfamiliar with the use of the unit to use this machine.

6.Keep the area of operation clear of all persons, particularly small children. Keep bystanders at least 50 feet (15 meters) away from the area of operation.

7.Do not run this equipment in an enclosed area. Engine exhaust contains carbon monoxide gas, a deadly poison that is odorless, colorless, and tasteless. Do not operate this equipment in or near buildings, windows, or air conditioners.

8.Always use an approved fuel container. Do not remove gas cap or add fuel when engine is running. Add fuel to a cool engine only.

9.Do not fill fuel tank indoors. Keep open flames, sparks, smoking materials, and other sources of combustion away from fuel.

10.Do not operate this machine if you are under the influence of alcohol, medications, or substances that can affect your vision, balance, and judgement. Do not operate if tired or ill. You must be in good health to operate this machine safely.

Page 2 |

Bearcat Chipper Shredder Operator’s Manual |

Safety

BEFORE OPERATING

13.Use only in daylight or good artificial light.

14.Never use without proper guards in place.

15.Wear safety glasses at all times while operating this machine. One pair of safety glasses is provided.

16. Avoid wearing loose fitting clothing. Never operate this machine wearing clothing with drawstrings that could wrap around or get caught in the machine.

17.Check that all screws, nuts, bolts, and other fasteners are properly secured before starting the machine. Check all screws, nuts, bolts, and other fasteners for proper tightness to ensure everything is in proper working condition once every 10 hours of operation.

18.Keep all guards, deflectors, and shields in place and in good working condition.

19.Do not transport or move machine while the machine is running.

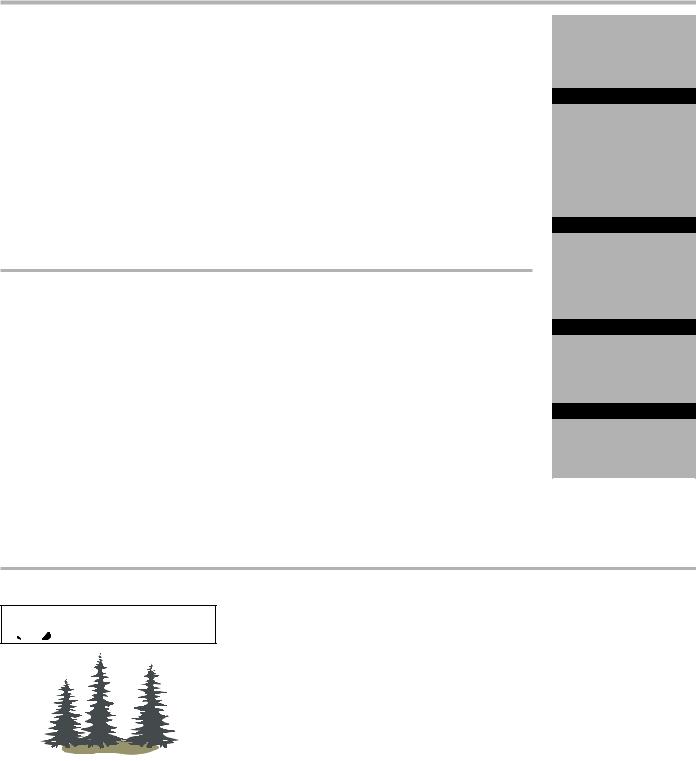

OPERATION SAFETY

1. Do not allow hands, or any part of body or clothing, inside the feeding chamber, discharge chute, or near any moving part.

DANGER

Keep hands, feet and clothing out of inlets and discharge openings while machine is operating to avoid serious personal injury.

WRONG

2.Check the cutting chamber to verify it is empty before starting the machine.

3.Exclude pieces of metal, rocks, bottles, cans, and other foreign objects when feeding chipable material into the machine.

4.Shut off engine immediately if the cutting mechanism strikes any foreign object or the machine starts making an unusual noise or vibrating. Allow the machine to stop completely. After machine stops:

A.Inspect for damage.

B.Replace or repair any damaged parts.

C.Check for and tighten any loose parts.

5.Do not allow processed material to build up in the discharge area; this may prevent proper discharge and can result in kickback of material through the feed opening.

6.Stand clear of the discharge area when operating this machine.

7.Keep your face and body back from the feed opening.

WARNING

WARNING

Material can kickup or shift suddenly and cause serious injury or death.

•Wear eye, and hearing protection.

•Stand to the side of the feed chute.

•Release and stand away from the material after feed roller starts pulling material into chipper or shredder.

8.Do not climb onto chipper shredder feed chutes or frame when operating. Do not overreach. Keep proper balance and footing at all times.

9.Keep the engine clear of debris and other accumulations.

WRONG

Bearcat Chipper Shredder Operator’s Manual |

Page 3 |

Safety

10.Do not tamper with the engine governor settings on the machine; the governor controls the maximum safe operating speed and protects the engine and all moving parts from damage caused by over speed.

11.Setting up your chipping site so you are not endangered by traffic and the public is not endangered by your work is critical for safety. Take great care to provide adequate warning by way of signage and coning, if diverting vehicles or pedestrian traffic is necessary.

12. A well-prepared traffic plan includes parking off the highway whenever possible. Cone the work area as

soon as the vehicle is stopped. Avoid sudden traffic stoppage or lane diversion. Do not allow pedestrians to walk through the work area. Ensure chips or dust do not blow into traffic, parked cars, or pedestrians.

13. Check the bolts on the following for correct torque every 10 hours of operation:

1.Chipper shredder rotor assembly bearings (80 ft lbs).

2.Chipper blades (use 5/16” X 1” Grade 8 bolts) (20 ft lbs).

3.Shredder Knives (36 In lbs).

WARNING

WARNING

Failure to maintain proper fastening torque (20 ft. lbs.) on chipper blade bolts may result in severe damage to the chipper and / or personal injury.

14.Shut off engine and allow machine to stop completely before clearing debris if the machine becomes clogged.

15.On electric start models, disconnect cables from battery before doing any inspection or service.

16.Rotate the discharge tube to face the opposite direction of the towing vehicle before towing. This prevents the discharge tube from projecting over the trailer wheels and striking foreign objects.

Page 4 |

Bearcat Chipper Shredder Operator’s Manual |

Safety

PTO SAFETY

1.Read and follow instructions on PTO safety decals.

2.Stay alert and pay attention when PTO chipper is operating.

3.Keep bystanders, especially children, away from PTO driveline.

4.Connect 3 pt. hitch pins and snap pins, connect PTO driveline, and have leg stand solidly on the ground.

5.Check the driveline to ensure it is attached securely to the tractor.

6. Keep guards and shields in place at all times while operating. Disengage tractor PTO and shut off engine before removing guards or shields.

7.Keep hands, feet, and clothing away from all PTO drive parts.

8.Do not clean, lubricate, or adjust the PTO shaft when it is running.

9.Clothing worn by operator must be fairly tight. Never wear loose fitting jackets, shirts, or pants when working around the PTO. Tie long hair back or put under a cap.

10.Keep hydraulic hoses, electric cords, chains, and other items from contacting the driveline.

11.Make sure the tractor is in neutral or park and PTO is disengaged before starting the tractor.

12.Do not exceed the recommended

540RPM PTO operating speed.

13.When this equipment is stopped for servicing, inspection, storage, or to change an accessory, make sure to disengage PTO and shut off tractor engine.

14.To move the unit: shut off the PTO, lift 3 pt. hitch.

WARNING

WARNING

Recommended tractor PTO horsepower is 15 HP to 45 HP. Use of these units on tractors above 45 PTO horsepower may cause belt and machine damage in overload conditions.

TOWING SAFETY

1.Rotate the discharge tube to face the opposite direction of the towing vehicle before towing. This prevents the discharge tube from projecting over the trailer wheels and striking foreign objects.

2.Connect hitch safety chains. Tighten and secure trailer hitch bolts. Do not attempt to tow the trailer if vehicle is not equipped with a 2” ball.

3.Maximum towing speed is 55 MPH. Inflate tires to manufacturers specs as stated on the tire sidewall. Check

wheel lug bolts periodically to ensure they are tight and secure.

4.Make sure the jack stand on trailer is in the UP position to clear the ground during towing. Place the jack stand on a level surface and secure it in the DOWN position before use.

5.Never allow passengers to ride on the chipper chute while the vehicle is moving, whether the chipper is running or not.

6.Shut off fuel supply to engine when towing.

7. Disconnect spark plug wire when towing.

Bearcat Chipper Shredder Operator’s Manual |

Page 5 |

Safety

BATTERY SAFETY

1. Improper use and care of the battery on electric start models can result in serious personal injury or property damage. Always observe the following safety precautions:

• Poison/Danger - Causes Severe Burns. The battery contains sulfuric acid. Avoid contact with skin, eyes or clothing. Keep out of reach of children.

ANTIDOTE-External Contact: Flush immediately with lots of water.

ANTIDOTE-Internal: Drink large quantities of water or milk. Follow with milk of magnesia, beaten egg or vegetable oil. Call a physician immediately.

ANTIDOTE-Eye Contact: Flush with water for 15 minutes. Get prompt medical attention.

• The battery produces explosive gases. Keep sparks, flame or cigarettes away. Ventilate area when charging battery. Always wear safety goggles when working near battery.

DANGER / POISON

|

|

|

|

|

|

|

|

|

|

FLUSH EYES |

|

|

|

|

|

|

|

|

|

|

IMMEDIATELY |

|

|

|

|

|

|

|

|

|

||

EYES |

|

NO |

|

|

|

SULFURIC |

|

|

|

WITH WATER |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

||||

EXPLOSIVE GASES |

|

|

|

|

ACID |

|

|

|

GET |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|||||

CAN CAUSE |

|

• SPARKS |

|

|

|

CAN CAUSE |

|

|

|

MEDICAL |

|

|

|

|

|

||||||

BLINDNESS OR |

|

• FLAMES |

|

|

|

BLINDNESS OR |

|

|

|

HELP |

|

|

|

|

|

||||||

INJURY |

|

• SMOKING |

|

|

|

SEVERE BURNS |

|

|

|

FAST |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

KEEP OUT OF THE REACH OF CHILDREN. DO NOT TIP. KEEP VENT CAPS TIGHT AND LEVEL.

•The battery contains toxic materials. Do not damage battery case. If case is broken or dam-aged, avoid contact with battery contents. Neutralize acid spills with a baking soda and water solution. Properly dispose of a damaged or worn-out battery. Check with local authorities for proper disposal methods.

•Do not short circuit battery. Severe fumes and fire can result.

•Before working with electrical wires or components: disconnect battery ground (negative) cable first. Disconnect positive cable second. Reverse this order when reconnecting battery cables.

MAINTENANCE AND STORAGE SAFETY

1. Shut off machine and disconnect the spark plug wire when this equipment is stopped for service, inspection, storage, or to change an accessory. Disconnect battery.

NOTE

See engine owners manual or contact the engine manufacturer for engine safety instructions and decals.

2.Replace any missing or unreadable safety decals. Refer to the parts manual for part numbers when ordering safety decals from an area Bear Cat dealer.

3.Store the machine out of reach of children and where fuel vapors will not reach an open flame or spark. Drain the fuel and dispose of it in a safe manner for storage periods of three months or more.

4.Allow machine to cool before storing in a enclosure.

5.Never store this machine with fuel in the fuel tank inside a building where fumes may reach an open flame or spark, or where ignition sources are present such as hot water and space heaters, furnaces, clothes dryers, stoves, electric motors etc.

Page 6 |

Bearcat Chipper Shredder Operator’s Manual |

Safety

SAFETY DECAL LOCATIONS (MODEL 73525)

Familiarize yourself with all of the safety and operational decals on the machine and the associated hazards. Make certain that all safety decals and operational decals on this equipment are kept clean and in good condition. The decals are shown below at reduced sizes. If you need a replacement decal, please refer to the parts catalog for this machine. Decals that need replacement must be applied to their original locations.

P/N 12169 |

P/N 16085 |

WARNING |

|

|

Guards and shields are removed for |

|

|

illustrative purposes only; do not op- |

|

|

erate without guards and shields in |

|

|

place and functioning properly. |

P/N 17423 |

P/N 12174 |

P/N 12175 |

P/N 12172 |

P/N 16558 |

P/N 12173

P/N 12010 |

P/N 12250 |

P/N 17837

Bearcat Chipper Shredder Operator’s Manual |

Page 7 |

Safety

SAFETY DECAL LOCATIONS (MODEL 73525)

Familiarize yourself with all of the safety and operational decals on the machine and the associated hazards. Make certain that all safety decals and operational decals on this equipment are kept clean and in good condition. The decals are shown below at reduced sizes. If you need a replacement decal, please refer to the parts catalog for this machine. Decals that need replacement must be applied to their original locations.

P/N 12173

P/N 16558

P/N 17837

P/N 17846

P/N 12183

P/N 16551

P/N 12175

Page 8 |

Bearcat Chipper Shredder Operator’s Manual |

Safety

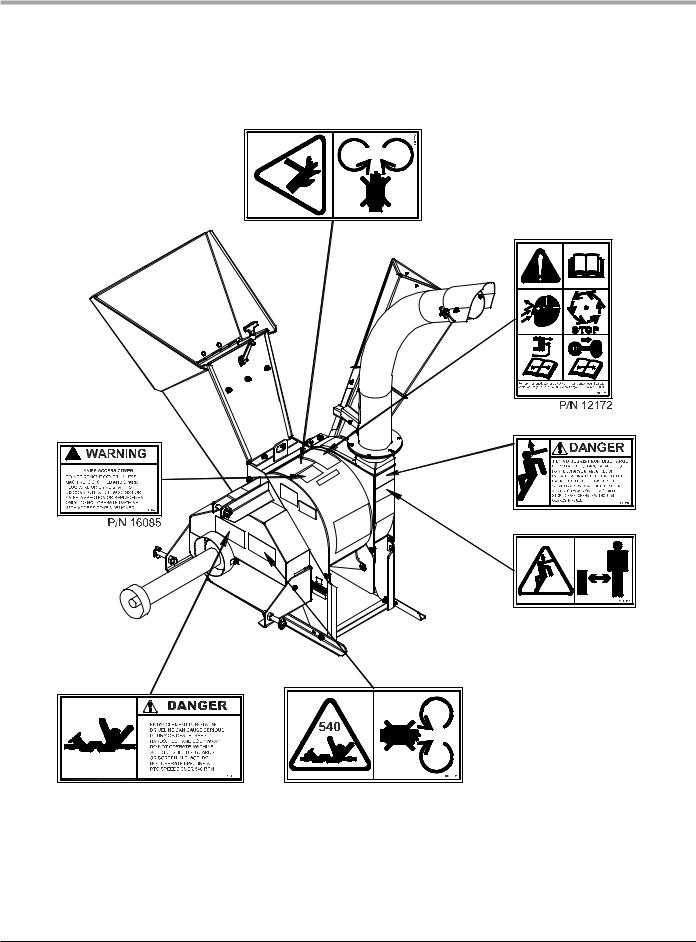

SAFETY DECAL LOCATIONS (MODEL 73554)

Familiarize yourself with all of the safety and operational decals on the machine and the associated hazards. Make certain that all safety decals and operational decals on this equipment are kept clean and in good condition. The decals are shown below at reduced sizes. If you need a replacement decal, please refer to the parts catalog for this machine. Decals that need replacement must be applied to their original locations.

WARNING

Guards and shields are removed for illustrative purposes only; do not operate without guards and shields in place and functioning properly.

P/N 12175 |

DANGER

ROTATING CUTTING BLADES

KEEP HANDS AND FEET OUT OF INLET AND DISCHARGE OPENINGS WHILE MACHINE IS OPERATING TO AVOID SERIOUS PERSONAL INJURY. STOP ENGINE. REMOVE SPARK PLUG WIRE AND ALLOW MACHINE TO COME TO A COMPLETE STOP BEFORE CLEARING OBSTRUCTIONS OR MAKING ADJUSTMENTS.

P/N 12010 |

P/N 12250 |

P/N 17423

P/N 17846

P/N 12174 |

P/N 12173 |

P/N 16558 |

P/N 12175 |

P/N 17837 |

Bearcat Chipper Shredder Operator’s Manual |

Page 9 |

Safety

SAFETY DECAL LOCATIONS (MODEL 73554)

Familiarize yourself with all of the safety and operational decals on the machine and the associated hazards. Make certain that all safety decals and operational decals on this equipment are kept clean and in good condition. The decals are shown below at reduced sizes. If you need a replacement decal, please refer to the parts catalog for this machine. Decals that need replacement must be applied to their original locations.

P/N 12169 |

P/N 16033 |

P/N 12168 |

P/N 16558 |

P/N 12173

Page 10 |

Bearcat Chipper Shredder Operator’s Manual |

Loading...

Loading...