Page 1

www.echorobotics.com

DRAFT 05-23-2019

Technical Manual

Robotic Mower

TM-2000

P/N 99922205383

VERSION 1.0

05/28/2019

©2019 ECHO Incorporated. All Rights Reserved.

EN ENGLISH

Page 2

Contents

DRAFT 05-23-2019

Chapter: 1 Important Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Administrative Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

FCC Declarations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

California Proposition 65 . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Chapter: 2 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Chapter: 3 Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Chapter: 4 System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Robot Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

The Charging Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter: 5 How the Robot Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Autonomous Mission State . . . . . . . . . . . . . . . . . . . . . . . . . 6

Inactive Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter: 6 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Station Loop Wire Installation . . . . . . . . . . . . . . . . . . . . . . . 11

Peripheral Wire Installation . . . . . . . . . . . . . . . . . . . . . . . . 11

Peripheral Wire Installation Offsets . . . . . . . . . . . . . . . . . . . . 12

Sites Containing Narrow Straits . . . . . . . . . . . . . . . . . . . . . . 13

Sites With Long Lanes . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Obstacles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Islands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Water Obstacle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Sloped Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Overlaps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Multi-Field Peripheral Wire Installation . . . . . . . . . . . . . . . . . . 18

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Configuration Examples . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Chapter: 7 Using the Robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Safety Measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

The LCD Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

The Actions Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

The Settings Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

i

Page 3

Service Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

DRAFT 05-23-2019

Advanced Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Technician's Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Connecting to Robots . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Chapter: 8 Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . . . 55

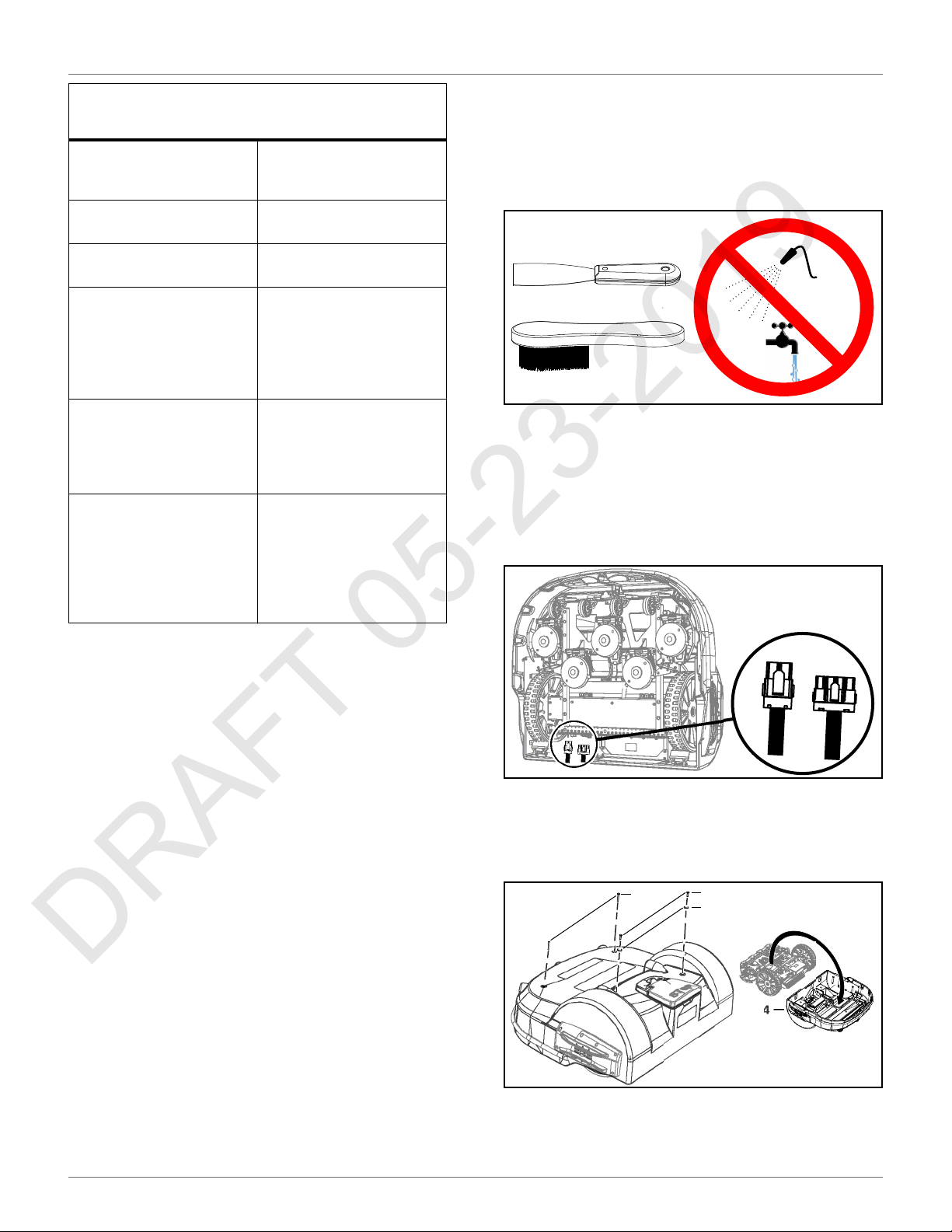

General Inspection and Cleaning . . . . . . . . . . . . . . . . . . . . . 55

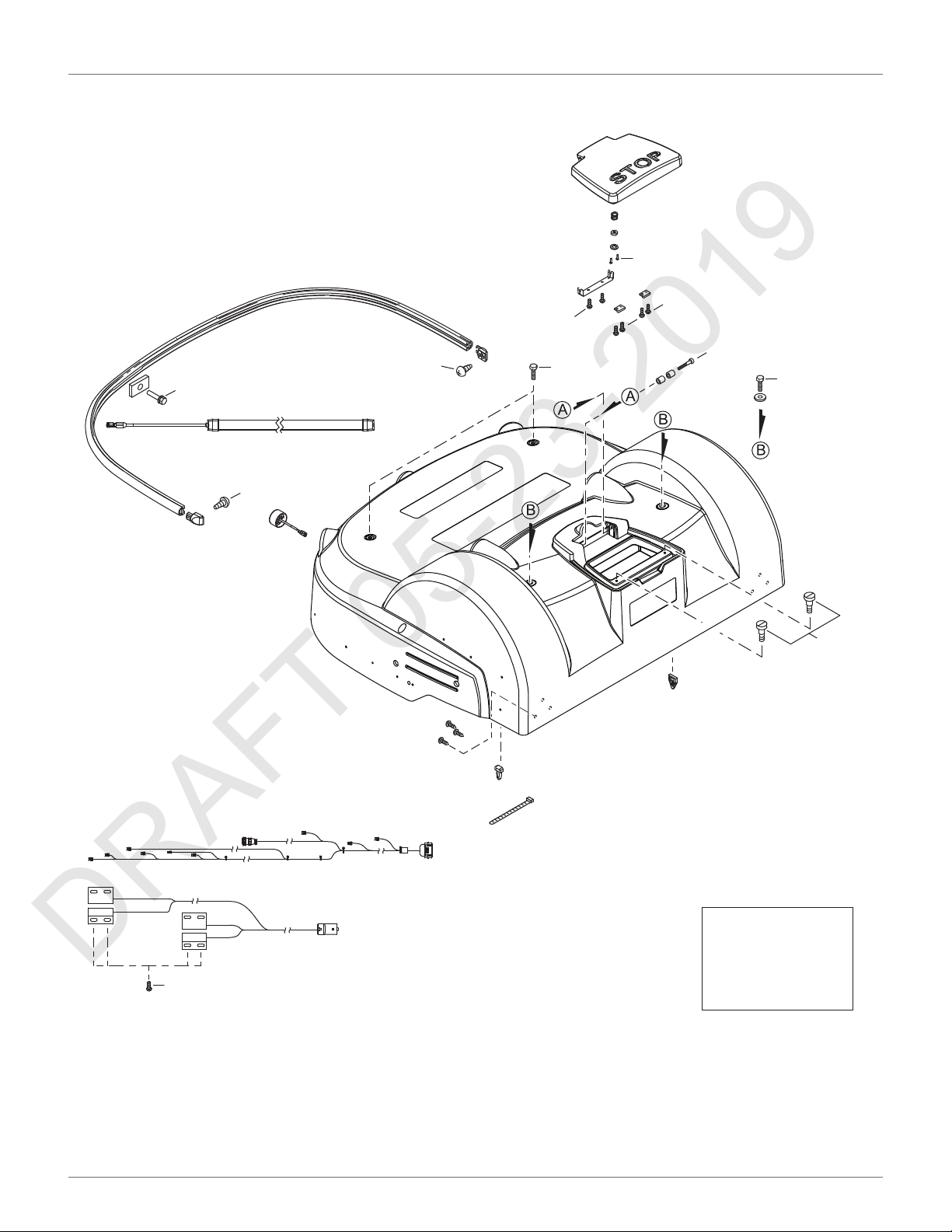

Cover and Electrical Cables . . . . . . . . . . . . . . . . . . . . . . . . . 55

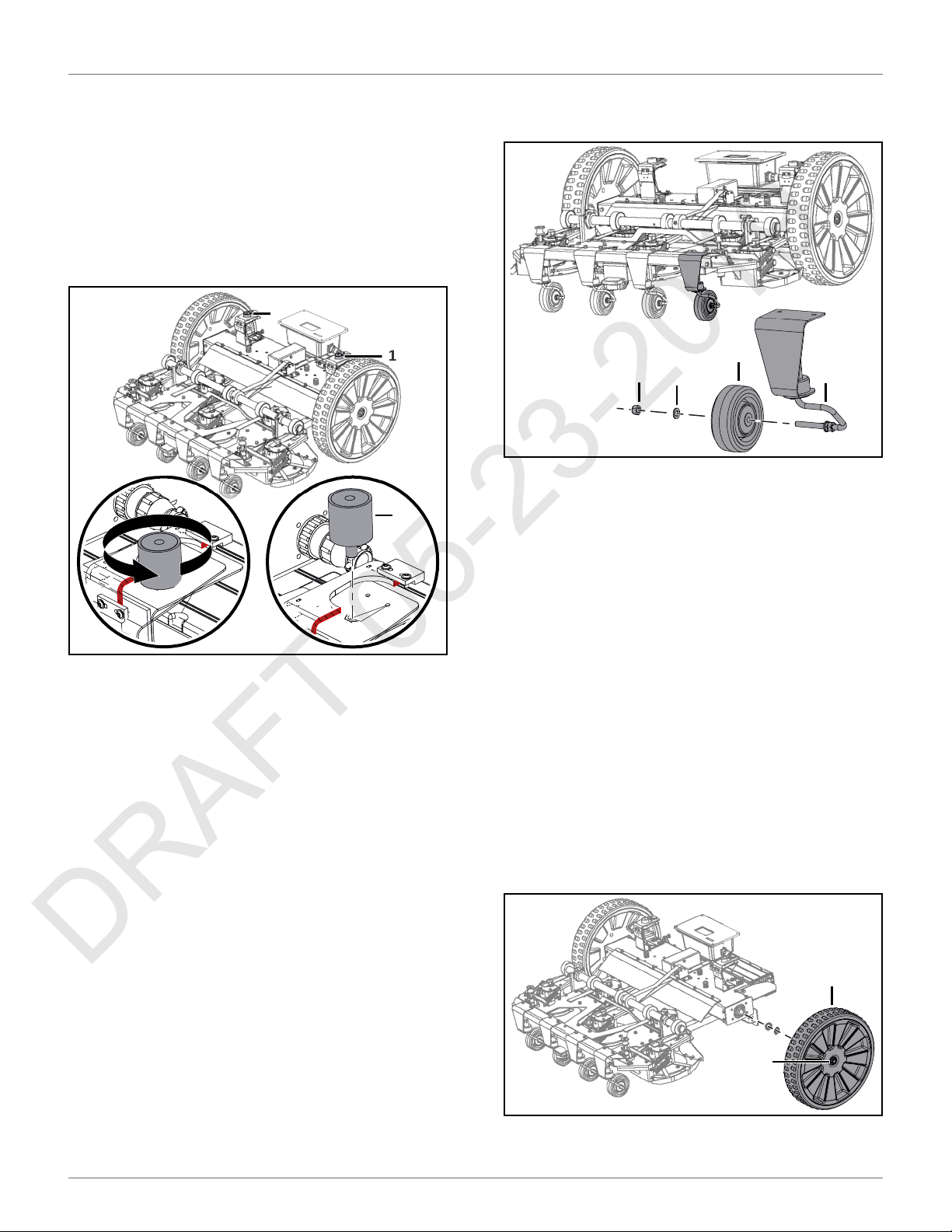

Charge Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Sonar Sensors and Bumper . . . . . . . . . . . . . . . . . . . . . . . . 56

Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Front and Rear Lift Sensors . . . . . . . . . . . . . . . . . . . . . . . . 57

Front Wheel Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Rear Wheels and Rear Wheel Brushes . . . . . . . . . . . . . . . . . . 57

Cutting Height System . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Cutting Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Winter Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Chapter: 9 Service Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Sonar Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Bumper Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Front Lift Cushion Replacement . . . . . . . . . . . . . . . . . . . . . . 59

Rear Lift Cushion Replacement . . . . . . . . . . . . . . . . . . . . . . 60

Front Wheel Replacement . . . . . . . . . . . . . . . . . . . . . . . . . 60

Rear Wheel Replacement . . . . . . . . . . . . . . . . . . . . . . . . . 60

Gear Motor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . 61

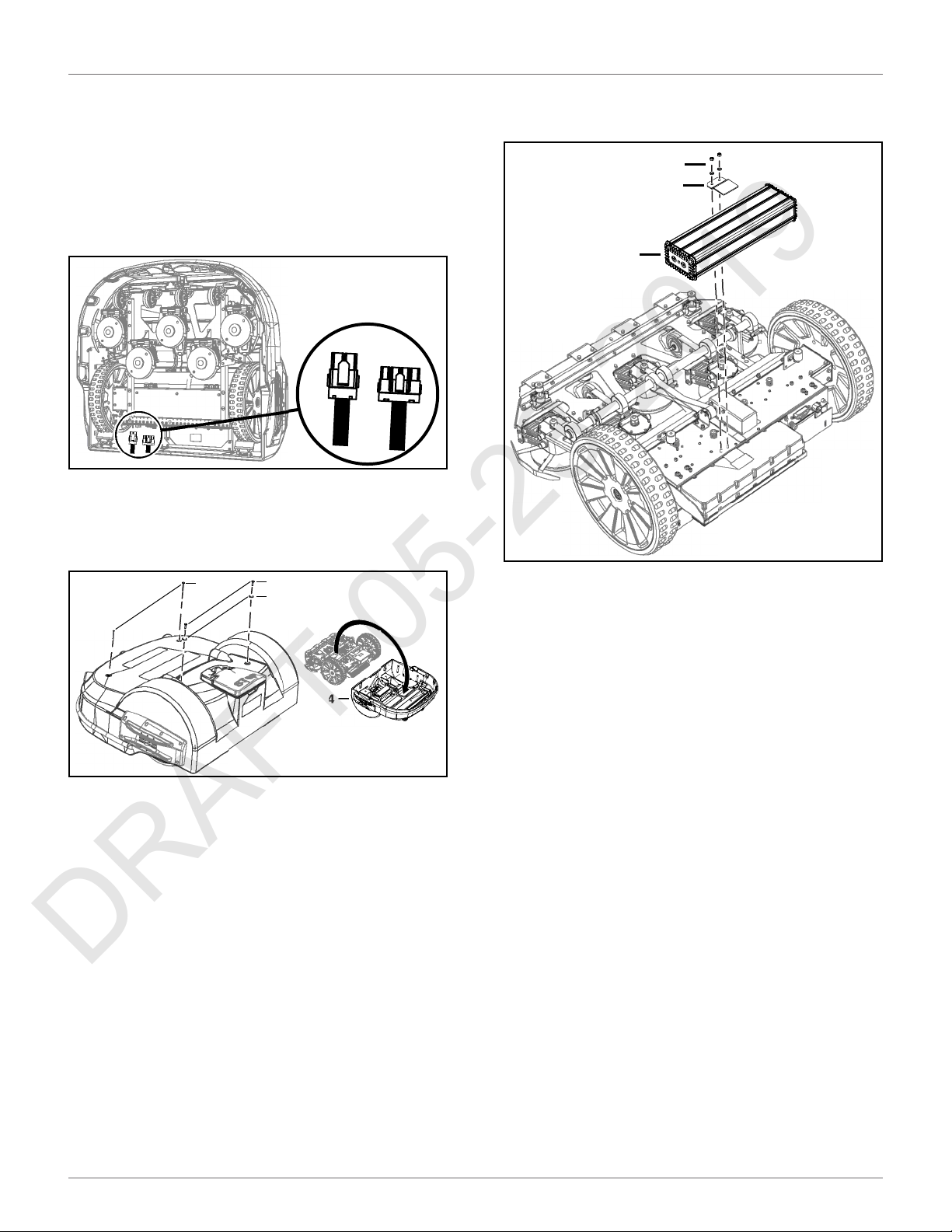

Battery Removal and Installation . . . . . . . . . . . . . . . . . . . . . 62

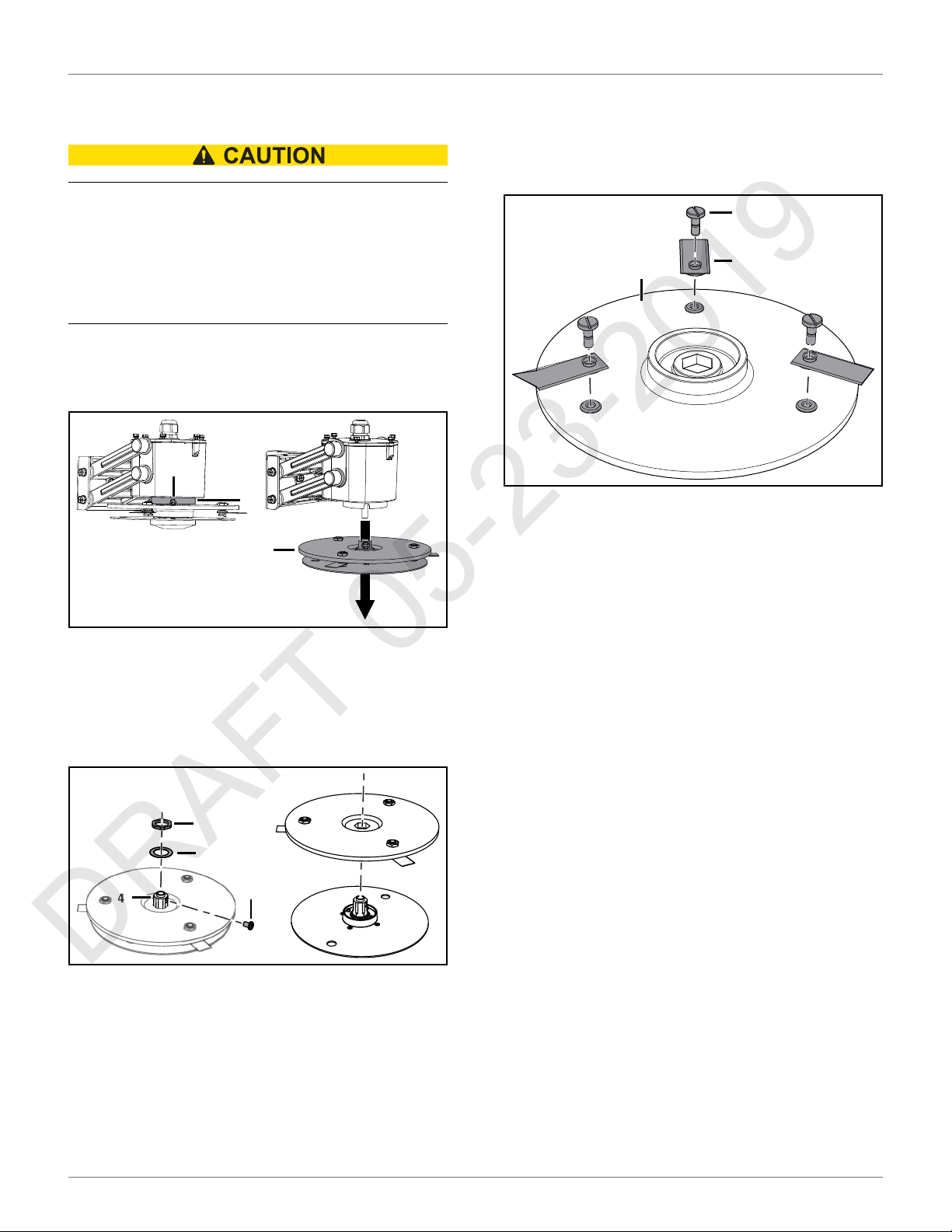

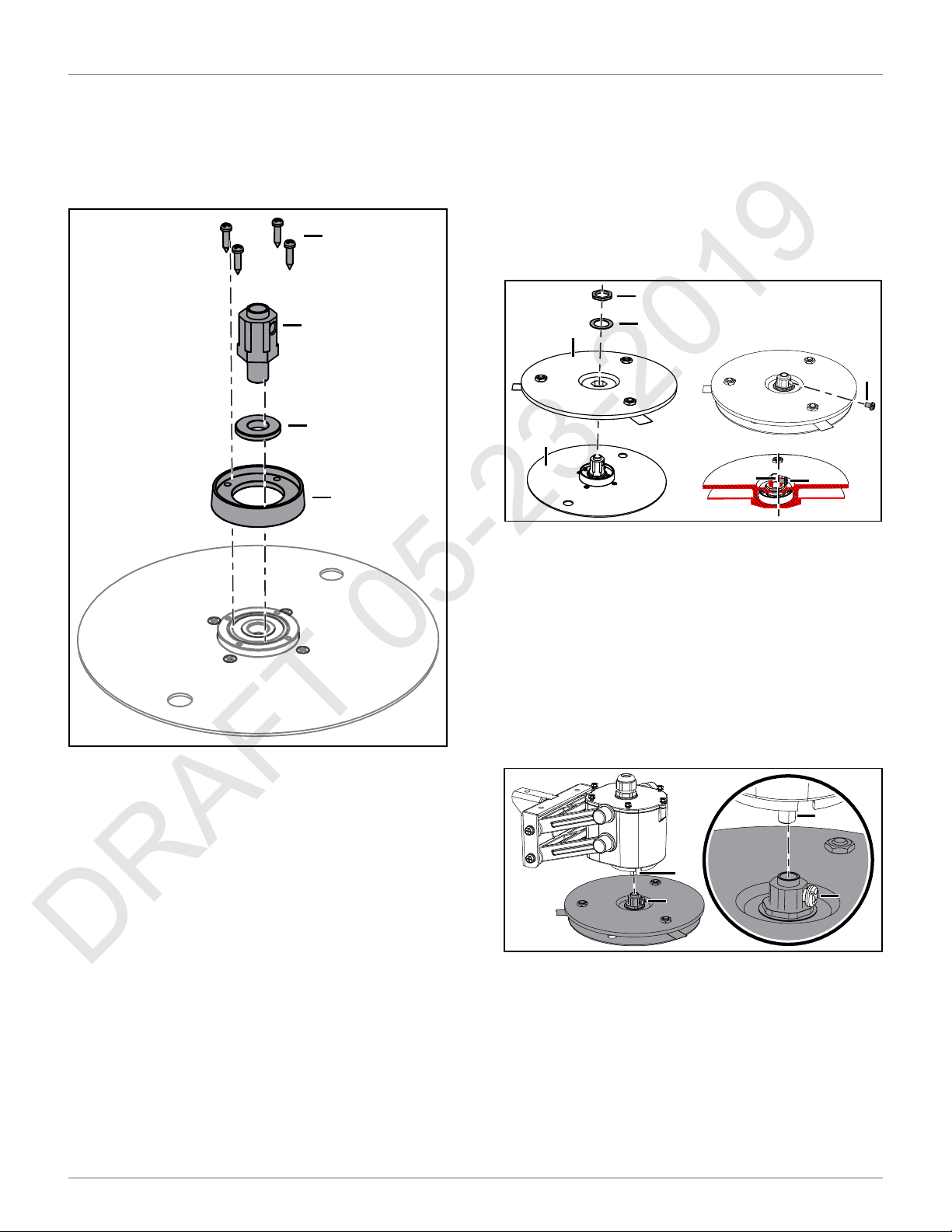

Cutting Disk Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Blade Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Aluminum Anti-friction Disc Replacement . . . . . . . . . . . . . . . . 64

Cutting Head Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . 64

Cutting Motor Service . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

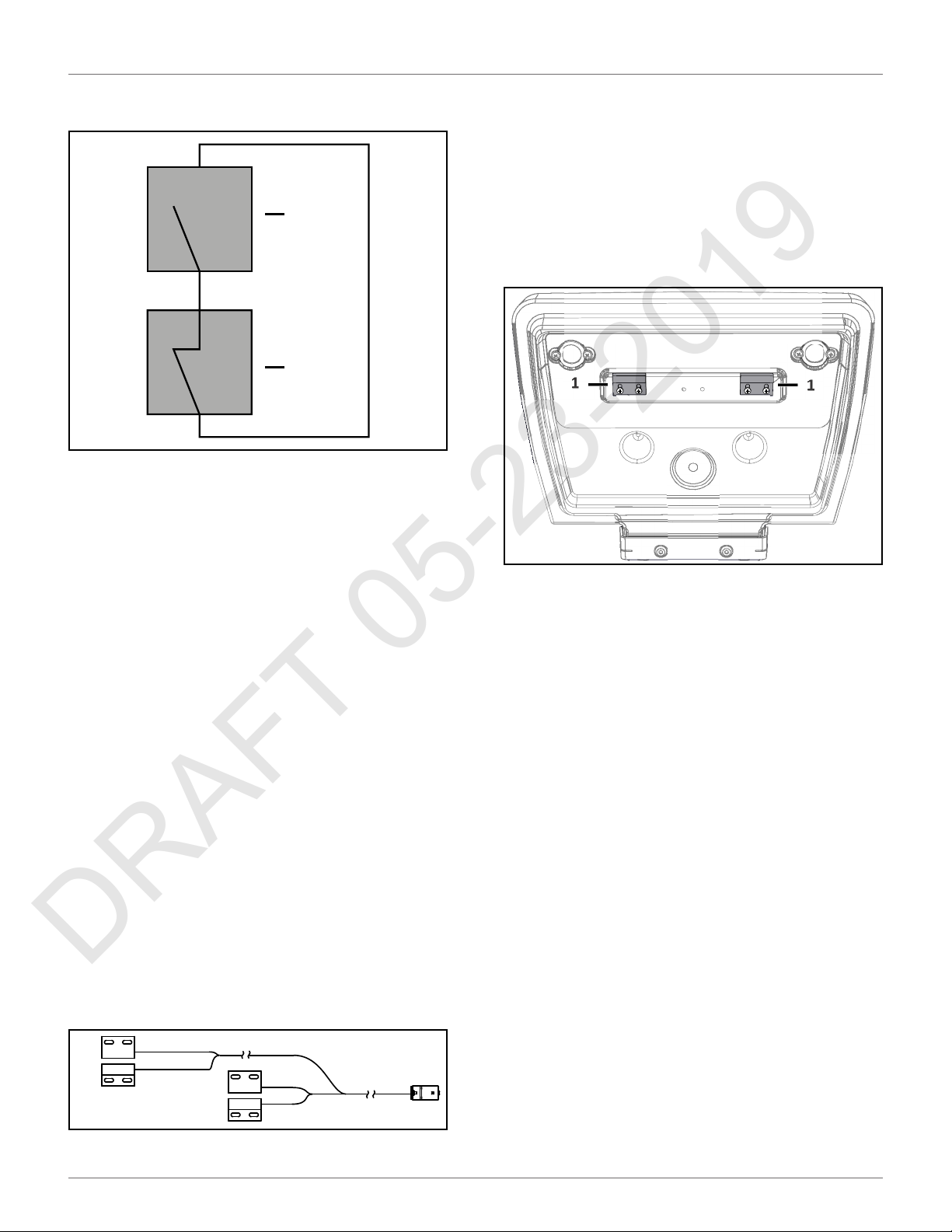

Cutting Motor Cable Replacement . . . . . . . . . . . . . . . . . . . . 65

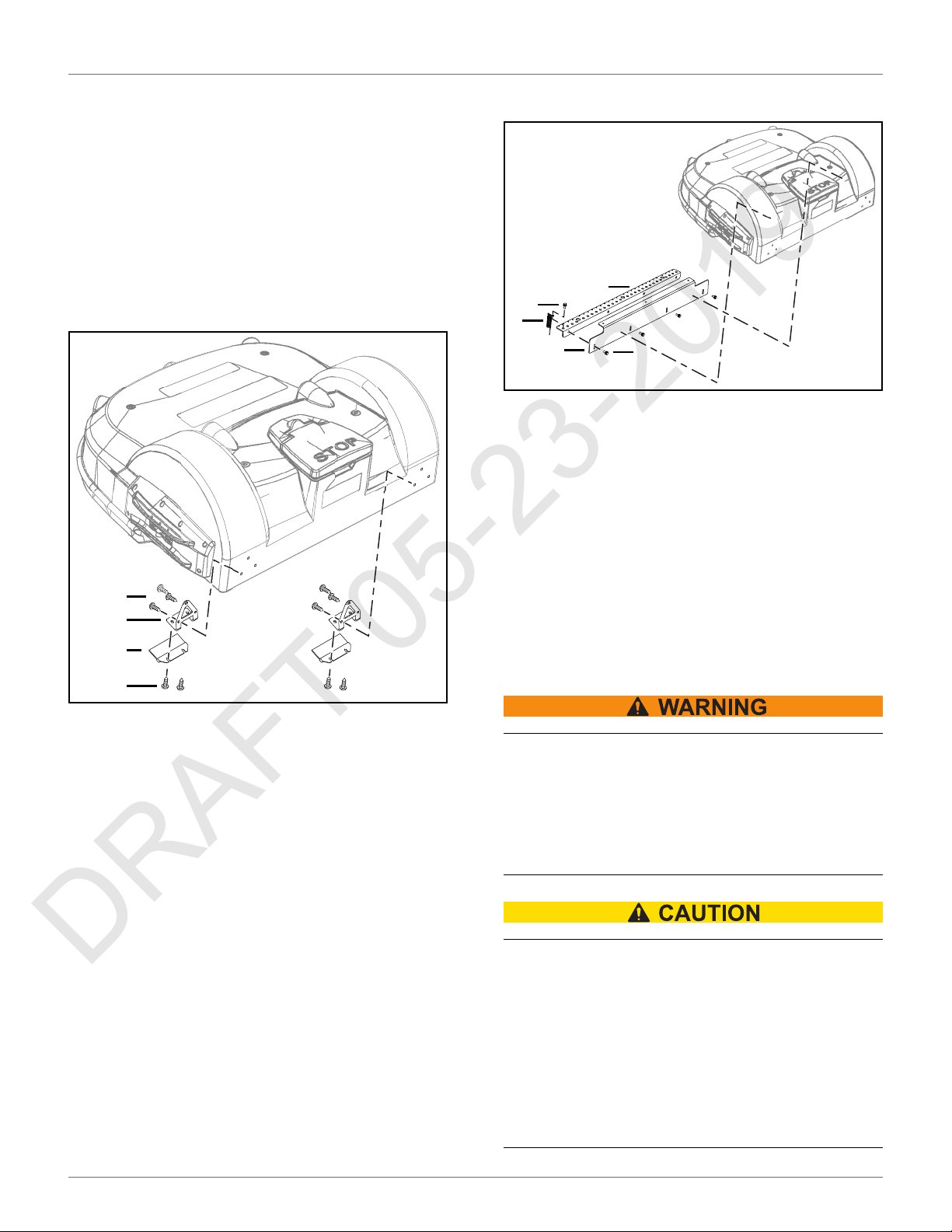

Correcting Stop Button Lid Closure Problems . . . . . . . . . . . . . . 65

Chapter: 10 Robot Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

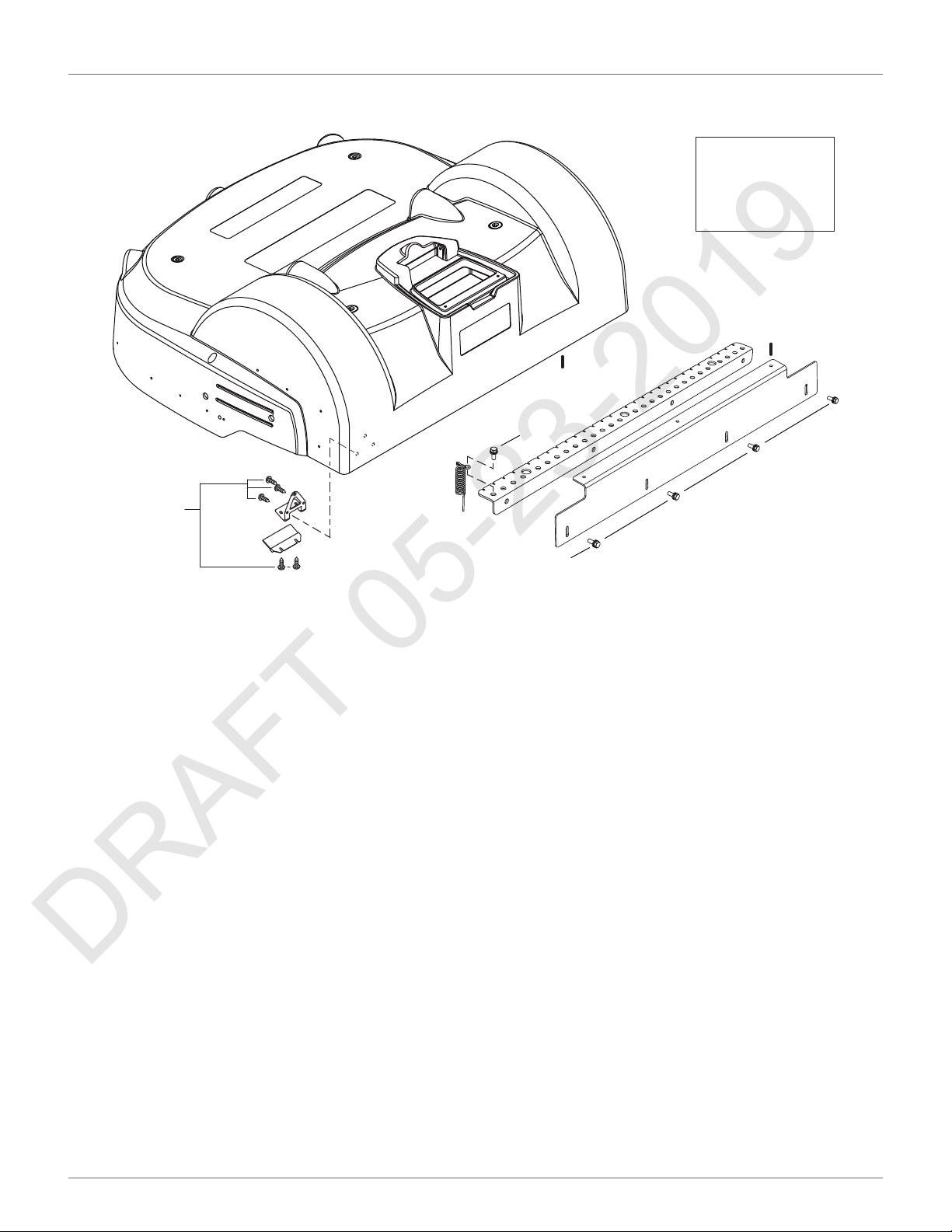

Wheel Brush Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Groomer Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

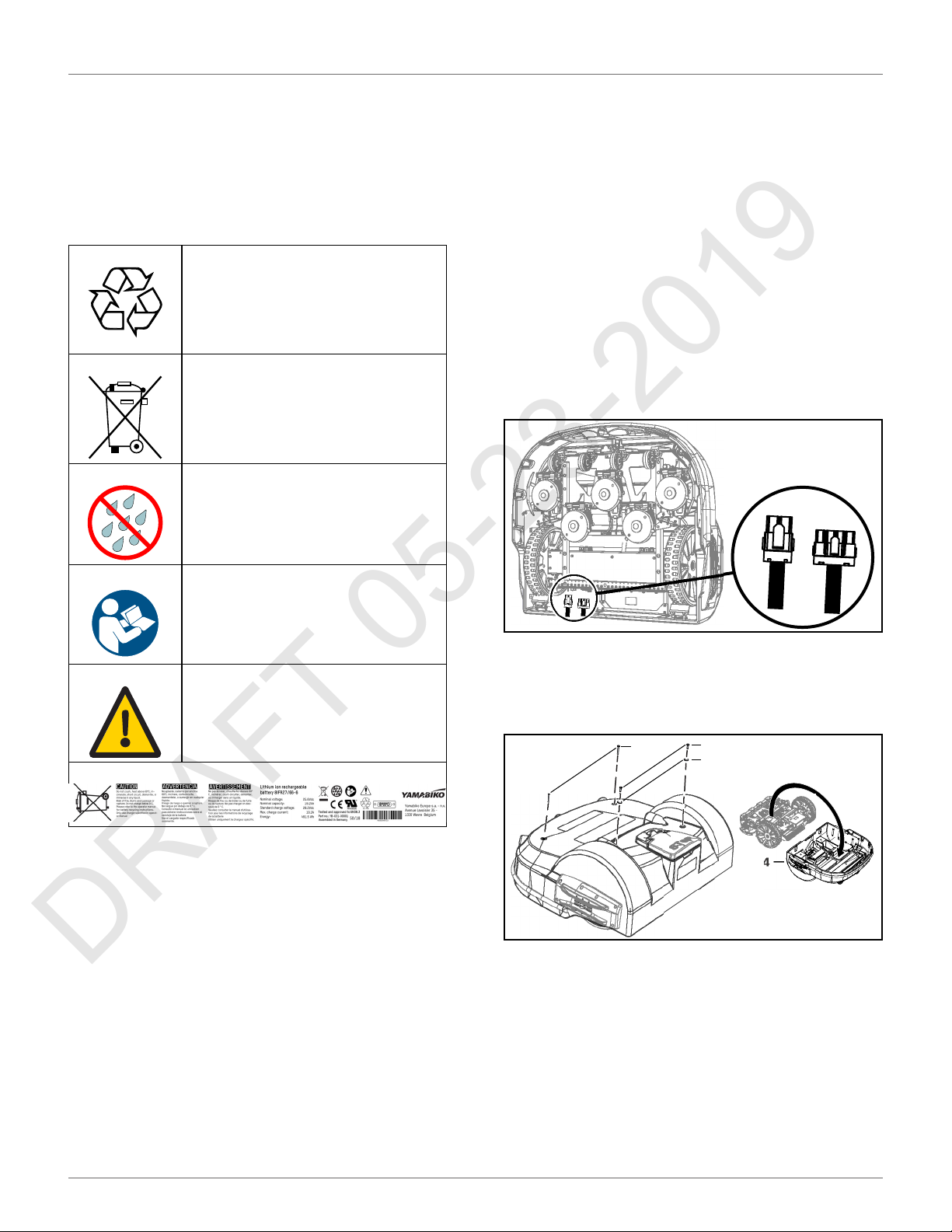

Chapter: 11 Battery Service and Installation . . . . . . . . . . . . . . . . . . . . . 67

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

ii

Page 4

Battery Removal and Installation . . . . . . . . . . . . . . . . . . . . . 68

DRAFT 05-23-2019

Removal and Installation (RP-1200) . . . . . . . . . . . . . . . . . . . . 69

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

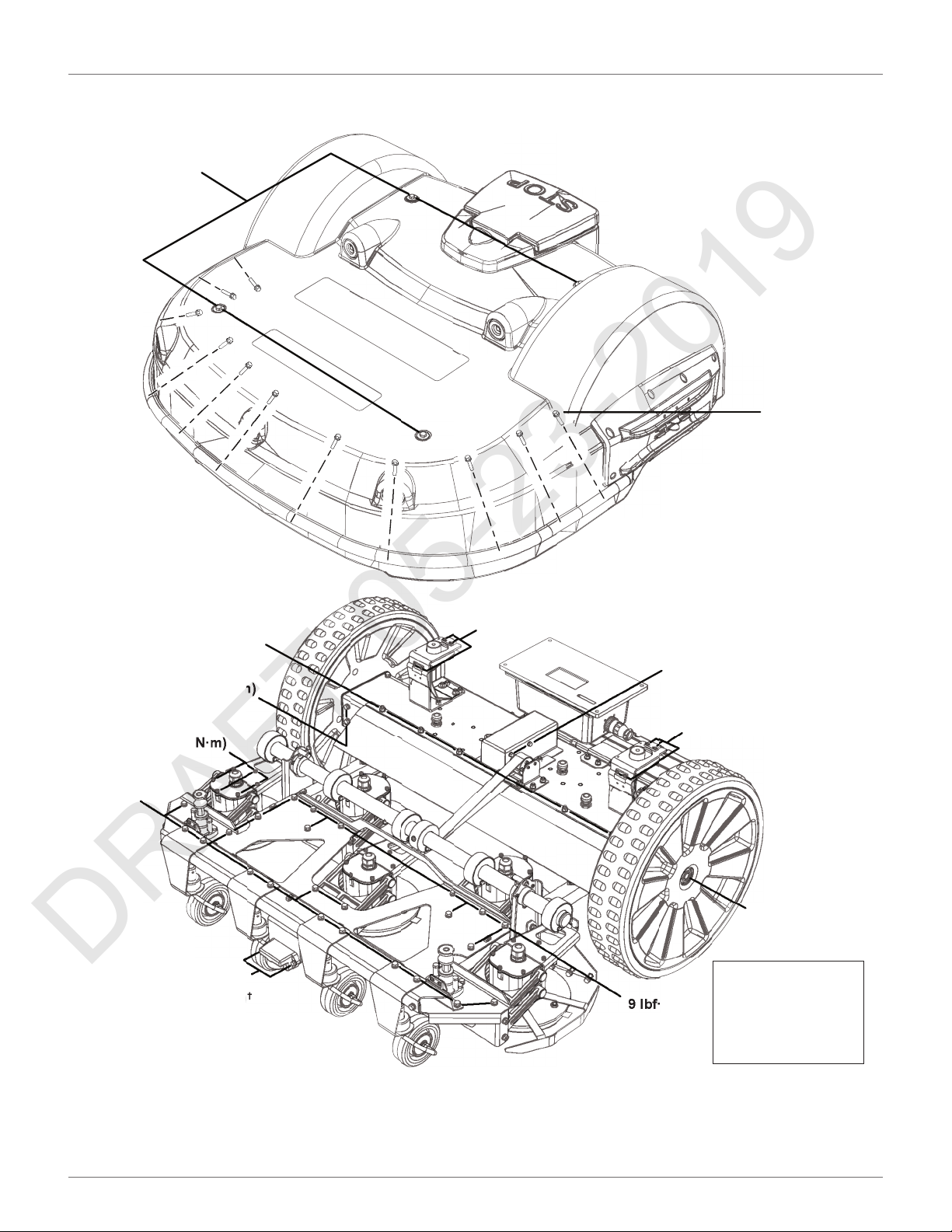

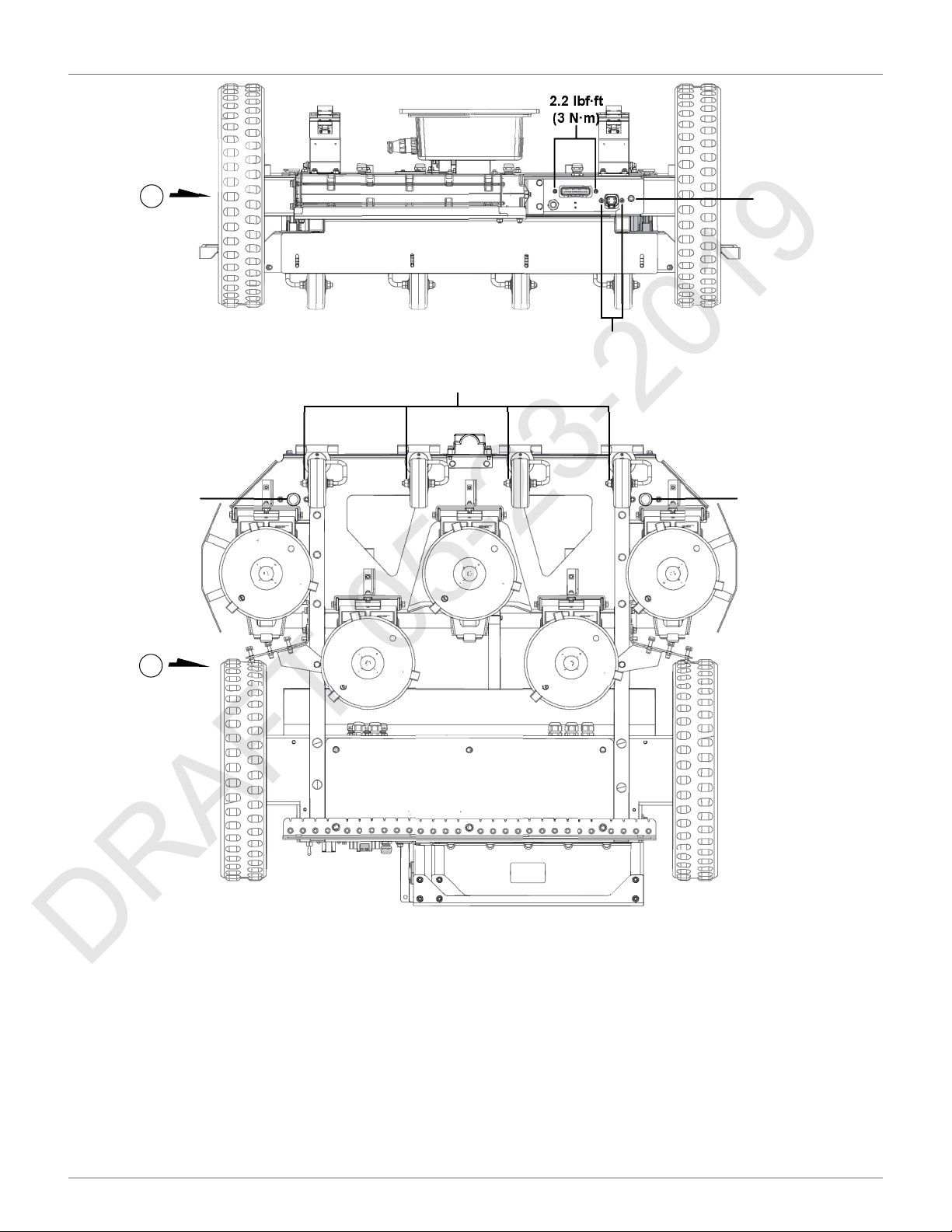

Chapter: 12 Torque References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Mower Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Cutting Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

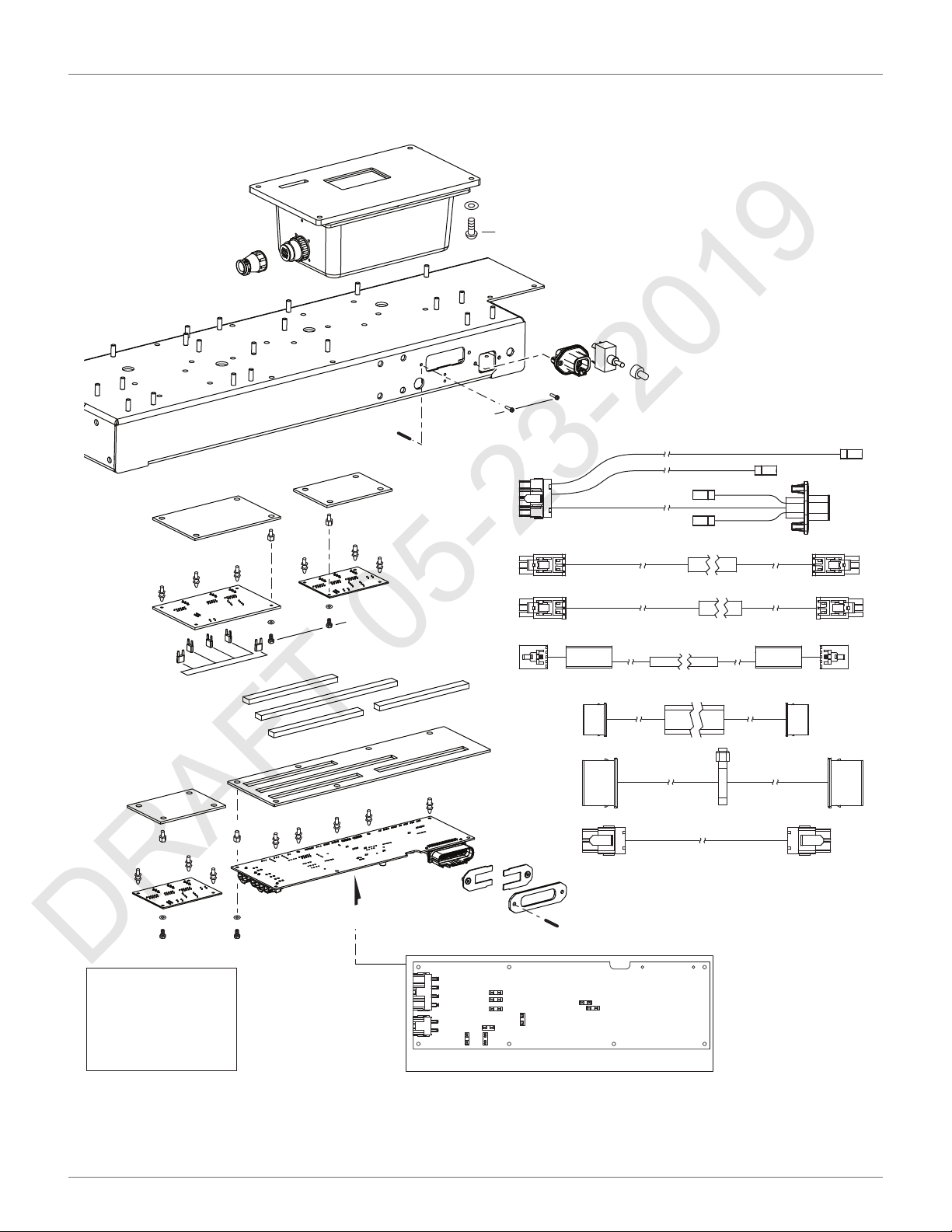

Electrical Box, Battery, and Housing . . . . . . . . . . . . . . . . . . . . 73

Lift Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Wheels, Motor and Gear Box . . . . . . . . . . . . . . . . . . . . . . . 75

Cutting Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Electrical Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

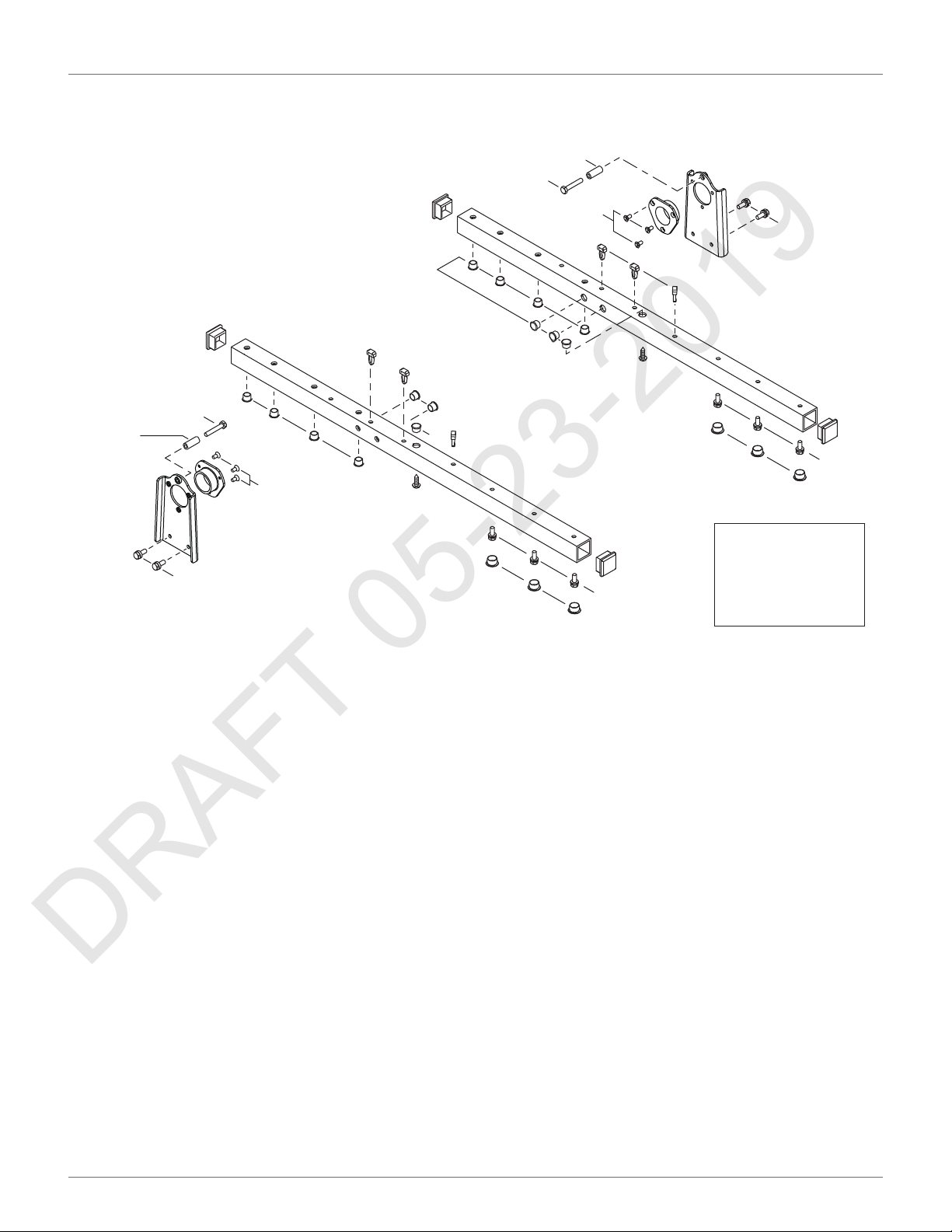

Main Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Main Bars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Cover and Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Gear Motor, Cutting Head, and Front Wheel . . . . . . . . . . . . . . . 83

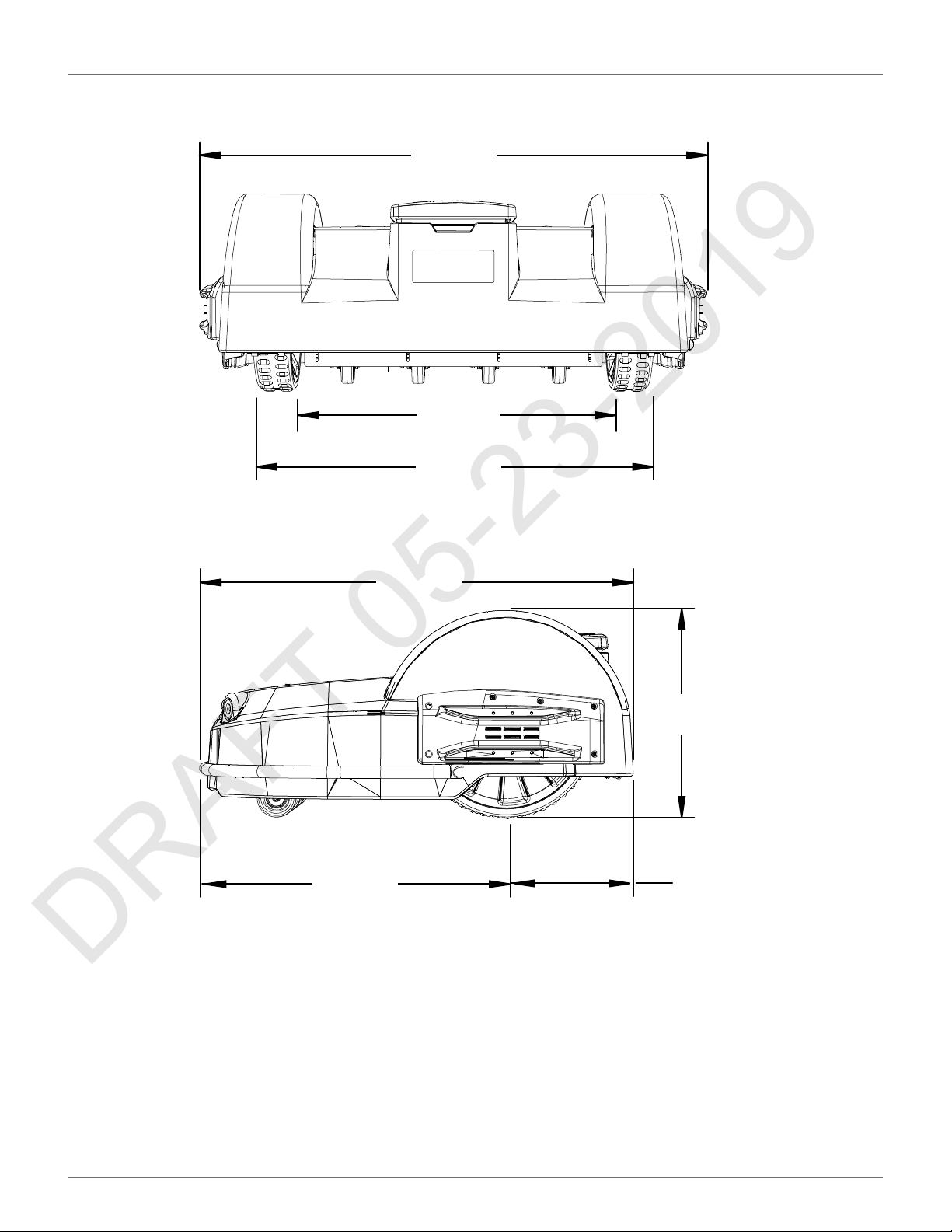

Chapter: 13 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Cutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Weight and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Software and Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . 84

Intelligence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

iii

Page 5

IMPORTANT INFORMATION

DRAFT 05-23-2019

ADMINISTRATIVE SUPPORT

1 Important Information

©2019 ECHO Incorporated. All Rights Reserved.

This manual, or parts thereof, may not be reproduced

in any form, by any method, for any purpose.

ECHO has taken reasonable care in compiling this docu-

ment, however ECHO accepts no liability whatsoever

for any error or omission in the information contained

herein and gives no other warranty or undertaking as

to its accuracy.

ECHO can accept no responsibility for damages,

resulting from the use of the operating software. In

addition, we refer to the conditions of use specified in

the license contract. ECHO reserves the right to amend

this document at any time without prior notice.

ECHO and its affiliates are not liable for damages or

losses related to such security breaches, any unauthorized access, interference, intrusion, leakage and/or

theft of data or information.

This manual contains the original instructions. Information contained in this manual is provided as an indication and is in no way contractual. It can be changed by

ECHO, without the need for prior announcement.

Obtain updated information at: myrobot.echorobotics.com.

The robot has been designed to high safety standards.

Risk is always possible. Read and understand all Safety

and Information Symbols.

This manual refers to Generation 2.0 series of robots

with software version 3.5

user will be required to correct the interference at their

own expense.

1.3 California Proposition 65

Cancer and Reproductive Harm

www.P65Warnings.ca.gov

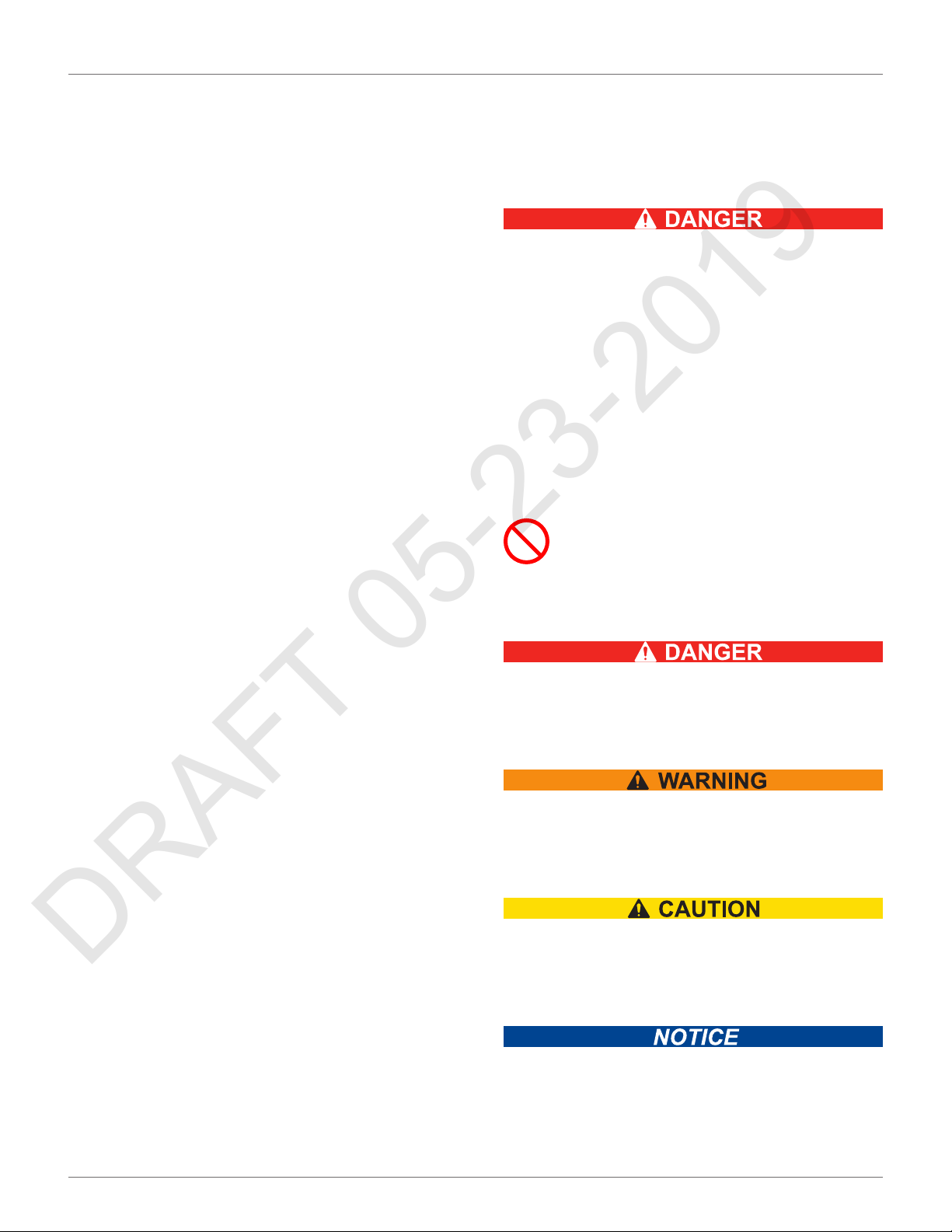

2 Safety Information

Throughout this manual and on the product itself, you

will find safety alerts and helpful, informational

messages preceded by symbols or key words. The

following is an explanation of those symbols and key

words and what they mean to you.

Circle and Slash Symbol:

This symbol means the specific action shown is prohibited. Ignoring this symbol can result in damage to property and serious or fatal injury.

The safety alert symbol accompanied by the word

“DANGER” calls attention to an act or condition which

WILL lead to serious personal injury or death if not

avoided.

1.1 Administrative Support

Send emails to: admin@echorobotics.com.

1.2 FCC Declarations

This equipment has been tested and found to comply

with the limits/or a Class A digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this equipment in a residential area

is likely to cause harmful interference in which case the

The safety alert symbol accompanied by the word

“WARNING” calls attention to an act or condition which

CAN lead to serious personal injury or death if not

avoided.

The safety alert symbol accompanied by the word

“CAUTION” calls attention to an act or condition which

may lead to minor or moderate personal injury if not

avoided.

The enclosed message provides information necessary

for the protection of the unit.

1

Page 6

THEORY OF OPERATION

DRAFT 05-23-2019

SAFETY SYMBOLS

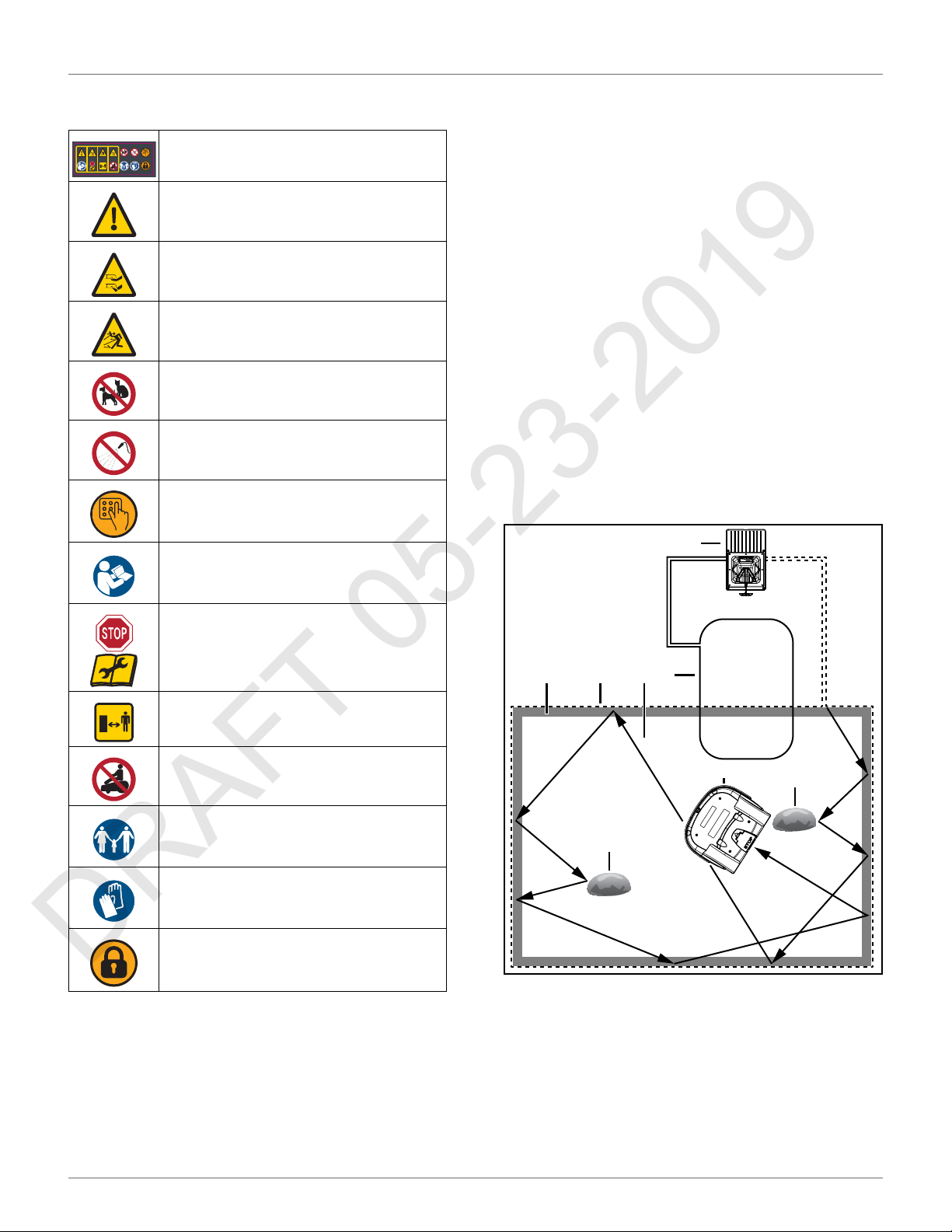

2.1 Safety Symbols

Safety and Information Label

Caution: The robot can be dangerous if

misused.

Never place hands or feet under the

robot while operating.

Beware of projectiles. Keep a safe

distance.

Keep animals away from the robot.

Water cleaning with high pressure jet

systems can cause damage.

The robot is protected by an access

code.

Read the technical manual before using

the robot.

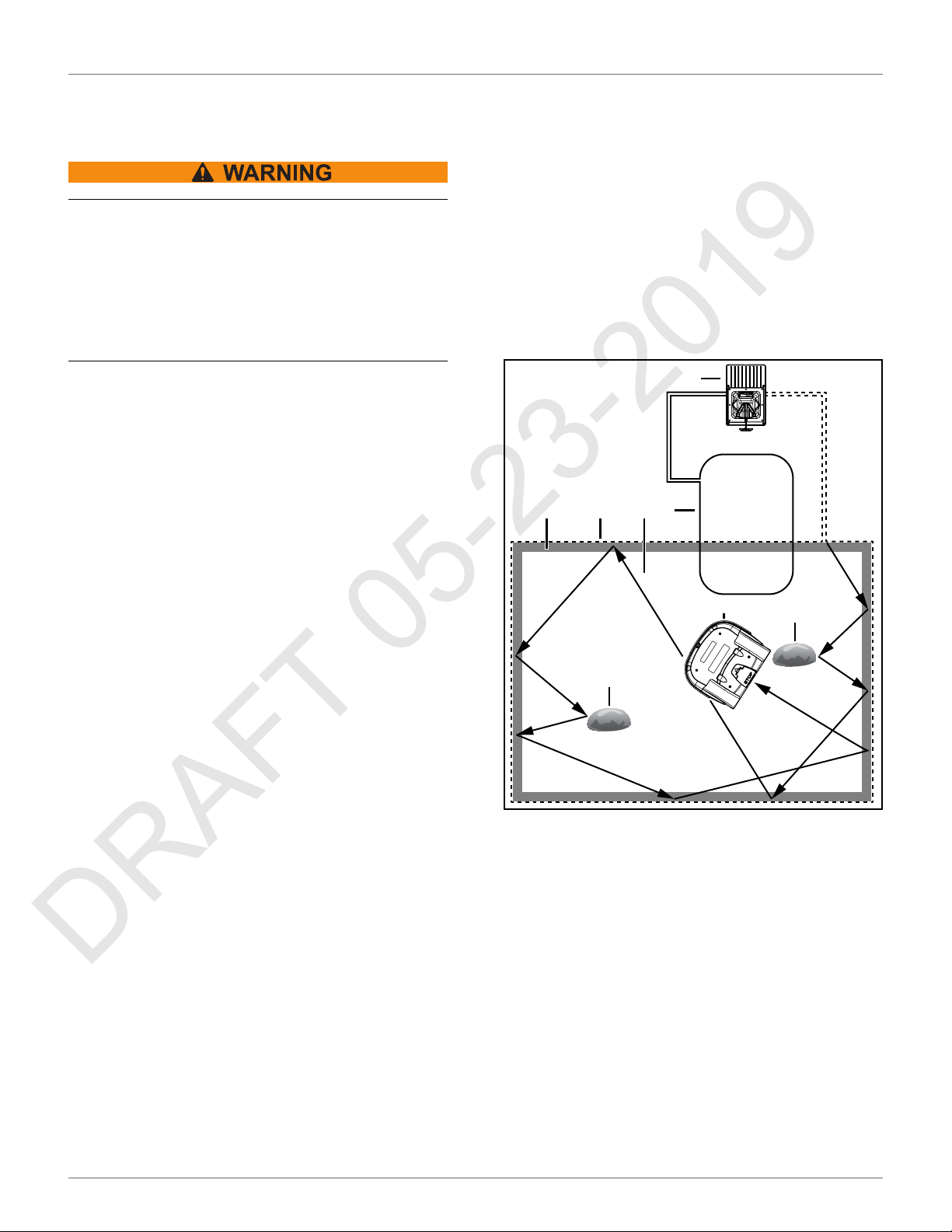

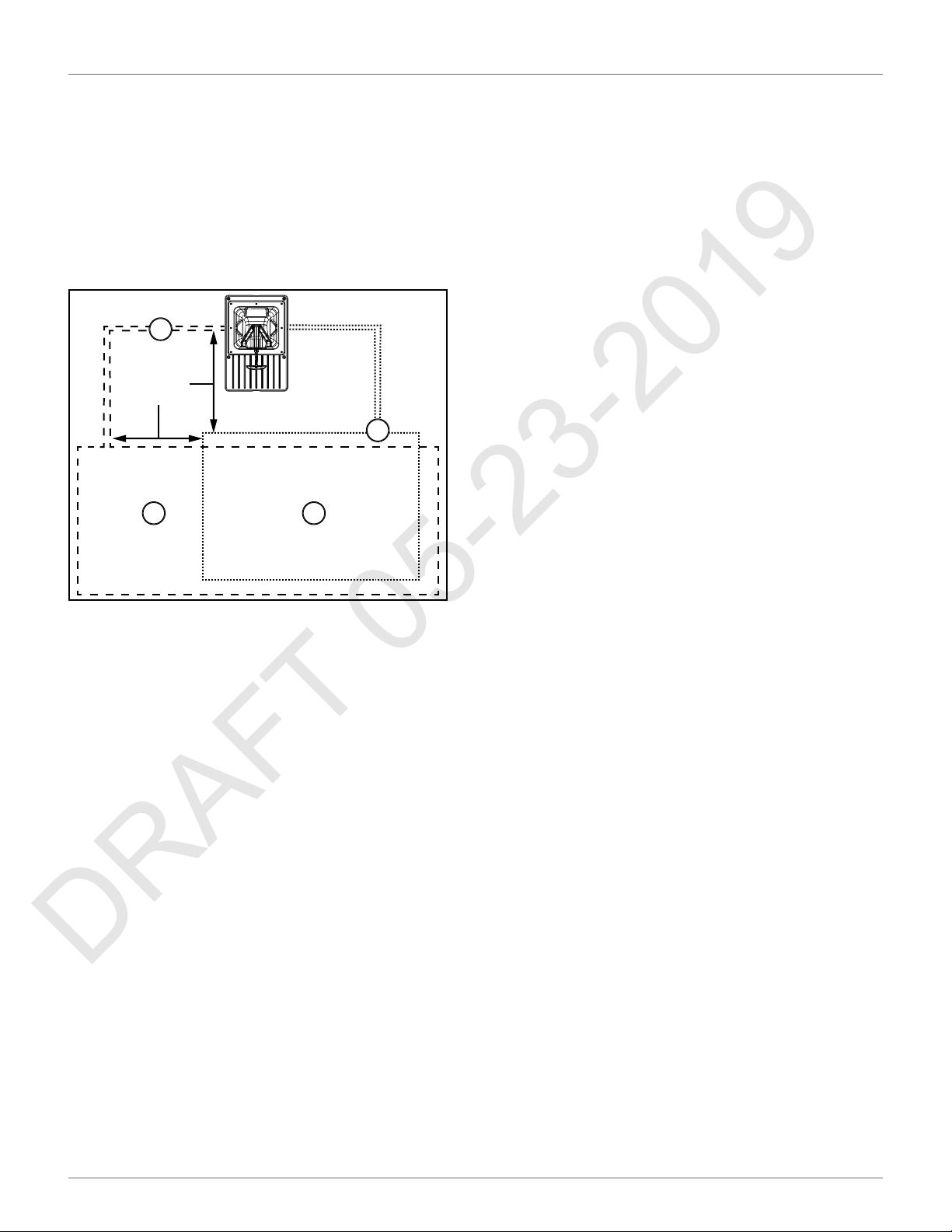

3 Theory of Operation

The robot mows in a random pattern. A peripheral wire

buried in the ground defines the mowing area.

The charging station energizes the peripheral wire. An

electro magnetic field is generated within the mowing

area. The robot senses the magnetic field.

When the robot senses the location of the peripheral

wire, it stops, turns back into the field, and continues

mowing.

The robot is equipped with obstacle detection sensors.

When the robot detects an obstacle it will slow down,

contact the obstacle, then perform a maneuver to

avoid it.

When the battery of the robot needs to be charged, the

robot will stop, move toward the peripheral wire, then

follow a trackborder back to the station loop wire.

When the robot detects the station loop wire, it follows

it to the charging station. The station loop wire guides

the robot into and out of the charging station.

4

Always stop the robot and wait for the

cutting blades to stop before handling

the robot.

Always keep a safe distance from the

robot while handling.

Do not ride the robot.

Keep bystanders away from the robot.

Protective gloves must be worn when

handling the robot, especially the

cutting system.

The robot is equipped with an

anti-theft system.

7 3 2

5

1 – Robot

2 – Mowing area

3 – Peripheral wire

4 – Charging station

5 – Obstacle

6 – Station loop wire

7 – Trackborder

6

1

5

2

Page 7

SYSTEM COMPONENTS

DRAFT 05-23-2019

ROBOT COMPONENTS

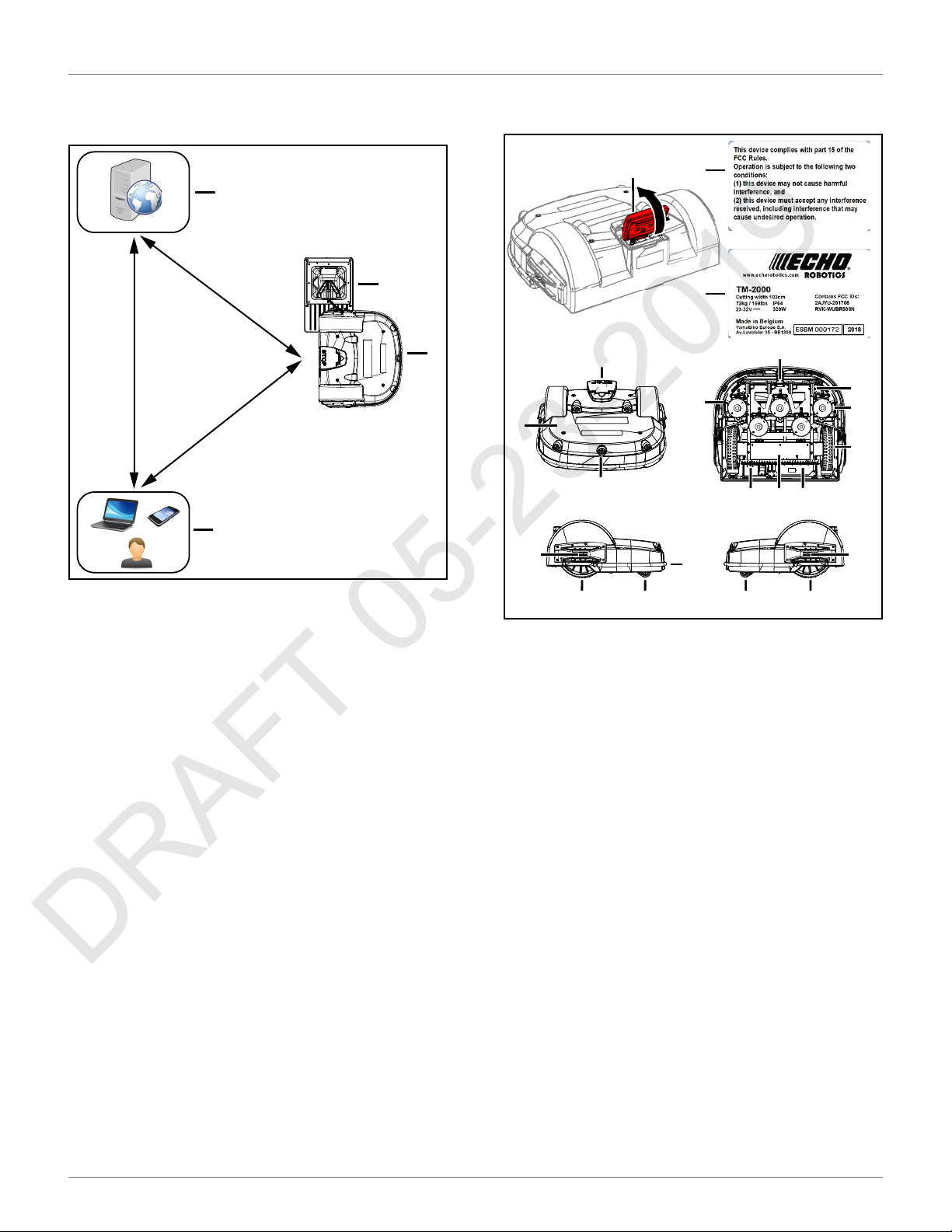

4 System Components

3

1

4

4.1 Robot Components

1

2

4

7

1

5

13

5

2

3

14

6

10

8

151112

7

1 – Charging station

2 – Robot

3 – Internet portal

4 – End user

9

1 – Stop button - Press to stop the robot.

2 – FCC label (lift stop button lid to view)

3 – Serial number label (lift stop button lid to view)

4 – Body

5 – Sonar sensors - Detects object in the path of the robot.

6 – Front wheel

7 – Bumper - A pressure sensor which will cause the robot to

change direction when it touches an obstacle.

8 – Rear wheel

9 – Charge contact- Connects to the charging arm on the charging

station.

10 – Cutting heads - Equipped with three cutting blades.

11 – Li-Ion (Lithium Ion) battery - Supplies power to the robot.

12 – Electrical box - Contains the electronics and the gear drive

motors.

13 – Disc safety guard - A protective guard which inhibits contact

with the cutting heads.

14 – Coil - Detects the magnetic field generated by the peripheral

wires.

15 – Power switch

4

4

9

3

Page 8

SYSTEM COMPONENTS

DRAFT 05-23-2019

ROBOT COMPONENTS

4.1.1 User Interface

Located under the stop button lid.

1 2 3

31 2

4 5

7 9

1 – Numeric buttons - Press to select menu choices and enter

numeric values.

2 – LED screen - Displays the current information.

3 – LED - Indicates the user interface is switched ON.

4 – ON button - Press to turn the user interface ON.

5 – Navigation buttons - Press to highlight menu options.

6 – Back button - Press to exit a menu and return to previous

level.

7 – Accept button - Press to accept an operation or setting.

8 – Service menu button - Press to access the service menu.

9 – Settings menu button - Press to access the settings menu and

define operational settings.

10 – Actions menu button - Press to access the actions menu.

6

8

0

10 9 8 7

X

4.1.2 Cutting Head

1

2

4.1.3 STOP Button

Located on the top of the robot. Press or lift to stop the

robot.

1

4

5

6

1 – Stop button

4.1.4 Obstacle Detection Sensors

Five obstacle detection sonar sensors transmit a sonar

signal of 40 kHz. The sensors allow the robot to detect

and react to obstacles.

Sensors detect obstacles with minimum height of

15.7 in. (400 mm), and a minimum width of 2.0 in.

(50 mm).

When the signal hits an obstacle, it is reflected back to

the sensors. The speed of the robot is reduced to less

than 0.5 mph (0.2 m/s).

ϭ

8

7

6

1 – Bracket unit

2 – Cable gland

3 – Motor case

4 – Blade disc

5 – Anti friction disc

6 – Cutting blade

7 – Lower stay

8 – Upper stay

3

4

ϭ

5

1 – Sensor location

2 – Sensor assembly

When the bumper contacts an object, the robot will

touch the object, stop, move backwards, and by

ϭ

Ϯ

ϭ

ϭ

шϮϬŝŶ

;ϱϬŵŵͿ

шϭϱϳŝŶ

;ϰϬϬŵŵͿ

4

Page 9

SYSTEM COMPONENTS

DRAFT 05-23-2019

ROBOT COMPONENTS

default, turn between 60° and 120°, then continue

moving forward.

4.1.5 Lift Sensors

Each lift sensor is attached to the body and the chassis

of the robot. The two sensors on the front are lift

sensors, the two sensors on the rear are a combination

of lift and body displacement sensors.

If the body is lifted upwards, all functions will stop, and

the robot will remain stationary. If the body is moved

horizontally, the robot will, stop, move backwards, and

by default, turn between 60° and 120°, then continue

moving forward.

1

1

1

1

4.1.6 Coil

Detects the intensity of the magnetic field that is generated by the peripheral wire.

1

1

2

2

2 3

1 – Lift sensor attachment point

2 – Front lift sensor assembly

3 – Rear lift sensor assembly

4.1.7 Tilt / Rollover / and Temperature

Sensors

3

3

These sensors are located on the main circuit board

inside of the electrical box.

The tilt sensor detects the angle of the slope on which

the robot is mowing. If this angle exceeds 30° (58%), an

alarm will be raised and the robot will stop moving.

The rollover sensor detects if the robot has been tipped

upside down, or whether someone is trying to start the

robot when it is upside down.

The temperature sensor measures the ambient

outdoor temperature and will prevent the robot from

operating if this temperature is too low. The minimum

temperature is set as an operating parameter.

5

Page 10

HOW THE ROBOT WORKS

DRAFT 05-23-2019

THE CHARGING STATION

4.2 The Charging Station

2

1

6

8 7

5 How the Robot Works

The robot works in a number of operational states.

Within these states the robot is programmed to

operate in a number of modes.

3

4

5

9

Operational State Description

Autonomous

Mission State

Inactive State

Service State

The robot operates in cycles

in which it mows the grass, or

charges the battery.

The robot can enter an

inactive state if there is a

condition that causes the

Autonomous Mission State to

stop. The robot will return to

the autonomous mission state

when the problem has been

resolved or when a specific

command has been issued.

Initiate this state to access the

Demonstration and

Maintenance Test modes.

1 – Enclosure top

2 – Dust cover

3 – Charging arm

4 – Base

5 – Input panel – Caution label

6 – Serial number location

7 – T-27 Torx® driver

8 – Conduit connector

9 – Tie strap (2X)

5.1 Autonomous Mission State

The robot performs programmed instructions when in

the Autonomous Mission State.

NOTE: Programmed instructions can be over-ridden by

instructions activated from the user interface.

Autonomous

Mission Modes Robot Function

Go zone

Work

Go to charging

station

Charge

Wait in station Remains at the charging station.

Performs a set of maneuvers

before entering the work mode.

Mows the grass in a random

pattern.

Returns to the charging station.

Connects to the charging station

and charges the battery.

6

Page 11

HOW THE ROBOT WORKS

DRAFT 05-23-2019

AUTONOMOUS MISSION STATE

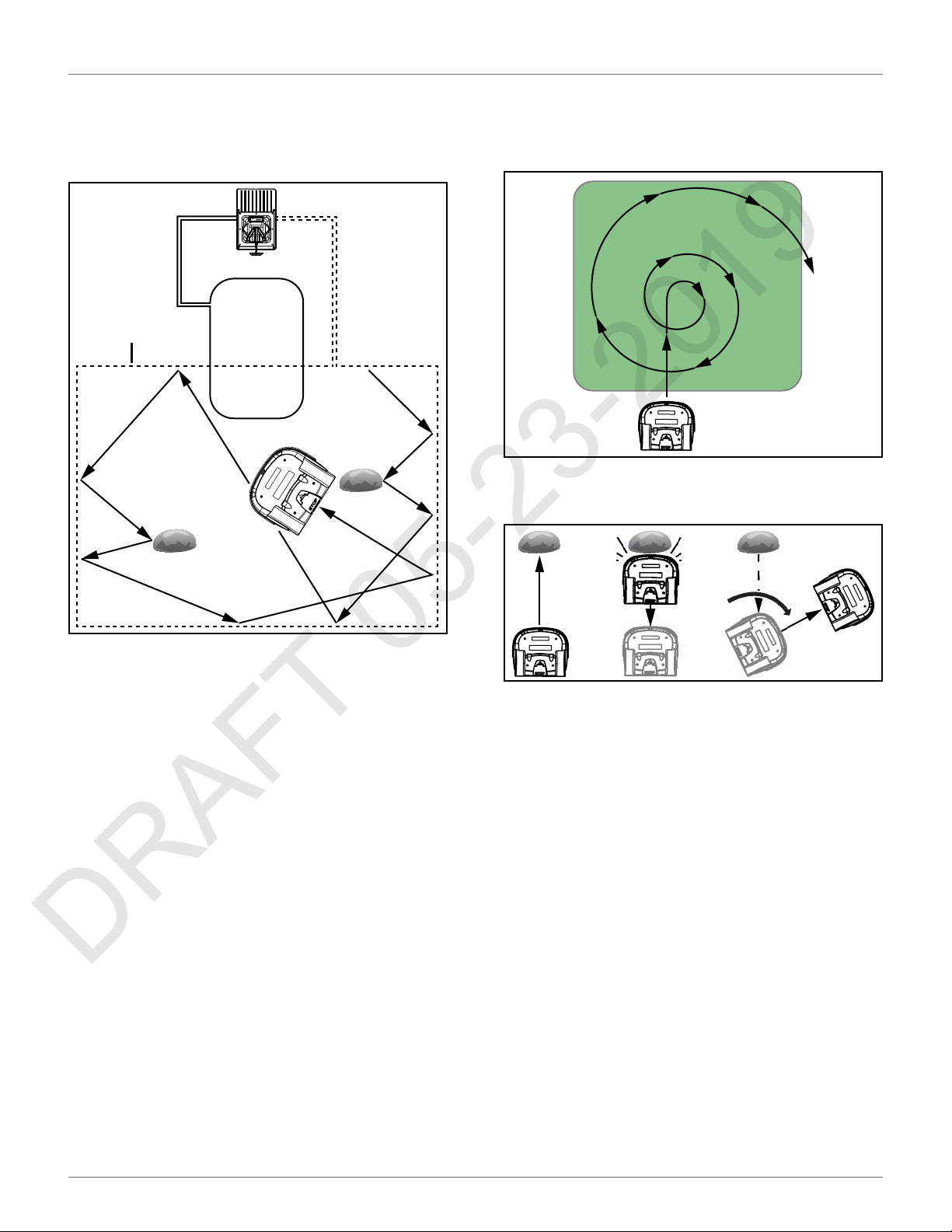

5.1.1 Work Mode

The robot randomly mows the area inside the peripheral wire at a normal mowing speed of 2.2 mph

(1.0 m/s).

1

In an area of long grass the robot will automatically

reduce speed and start mowing in spiral pattern until it

senses that the grass is short. It will then continue in

normal operating mode.

When the robot contacts and obstacle it will maneuver

away from it.

1 – Peripheral wire

When the robot approaches the peripheral wire it

slows down and passes over the wire. The coil senses a

change in phase. This causes the robot to stop, move in

reverse, turn through a defined angle, then continue in

a new direction.

60° - 120°

5.1.2 Go To Charging Station Mode

When working, the robot checks the current conditions

and its programmed instructions. Examples are:

• the battery needs to be charged

• programmed mowing time has ended (for

multi-field installations, this corresponds to the

mowing schedule for the field which the robot is

currently mowing)

• a remote command has been issued

As a result of the condition or programmed instruction,

the robot will return to the charging station and enter

the charge mode.

7

Page 12

HOW THE ROBOT WORKS

DRAFT 05-23-2019

AUTONOMOUS MISSION STATE

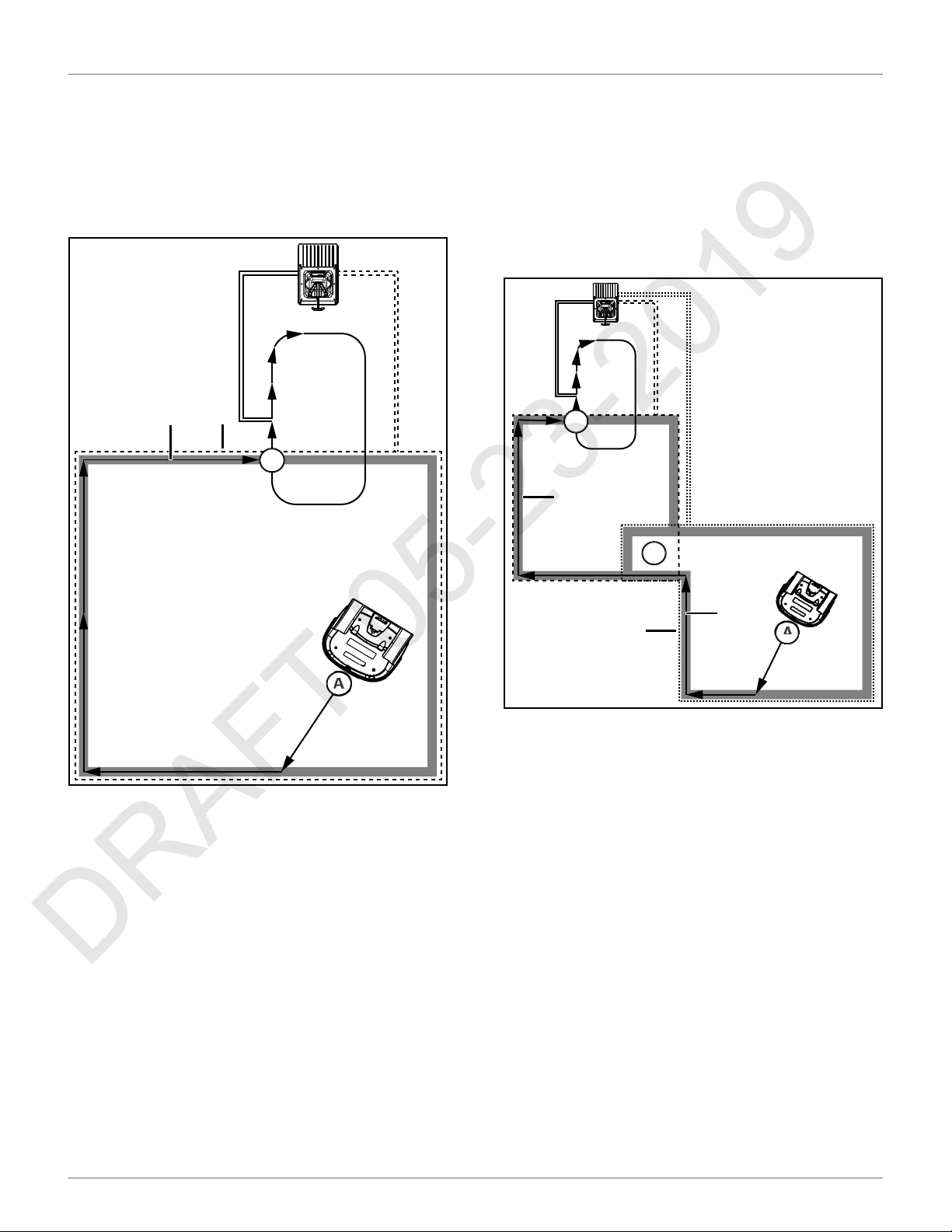

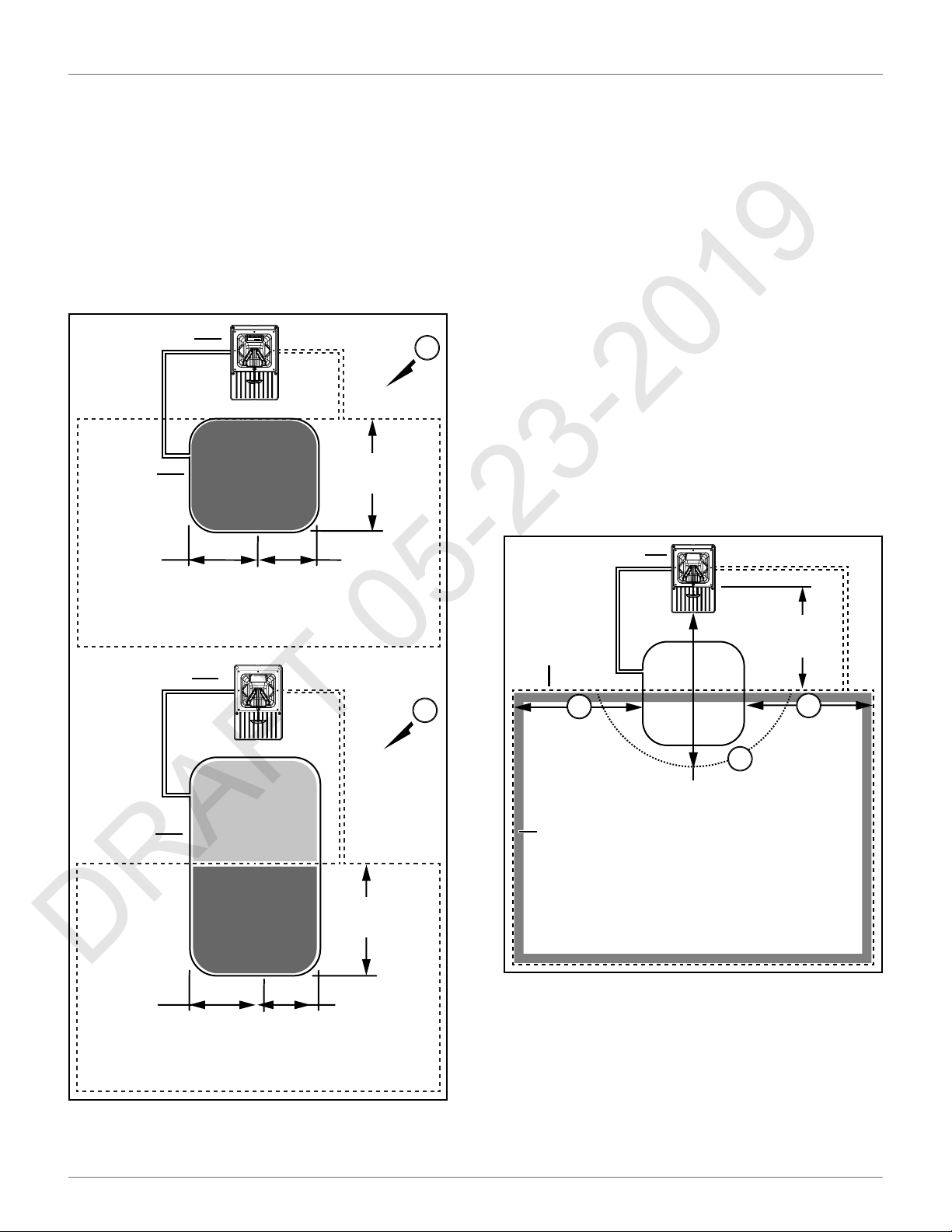

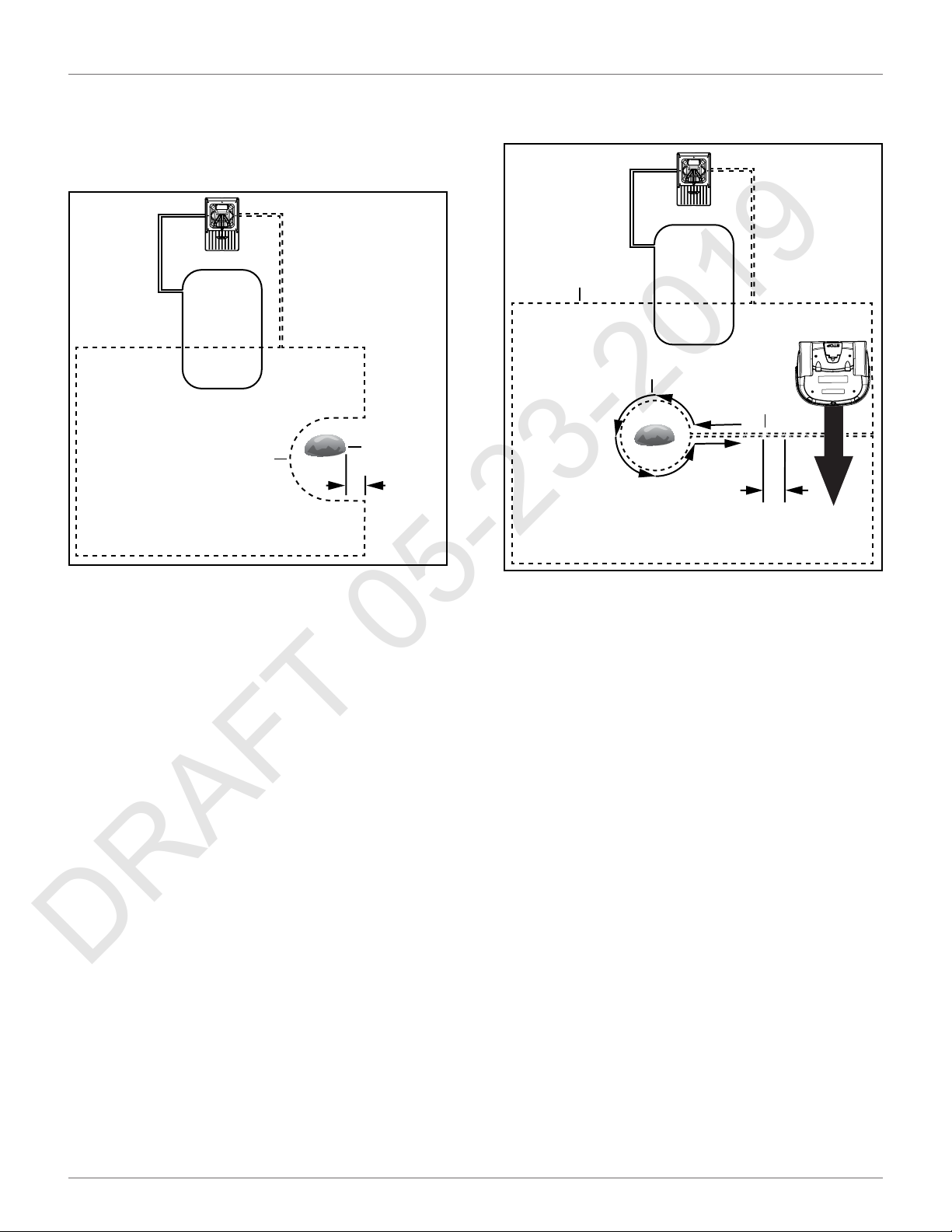

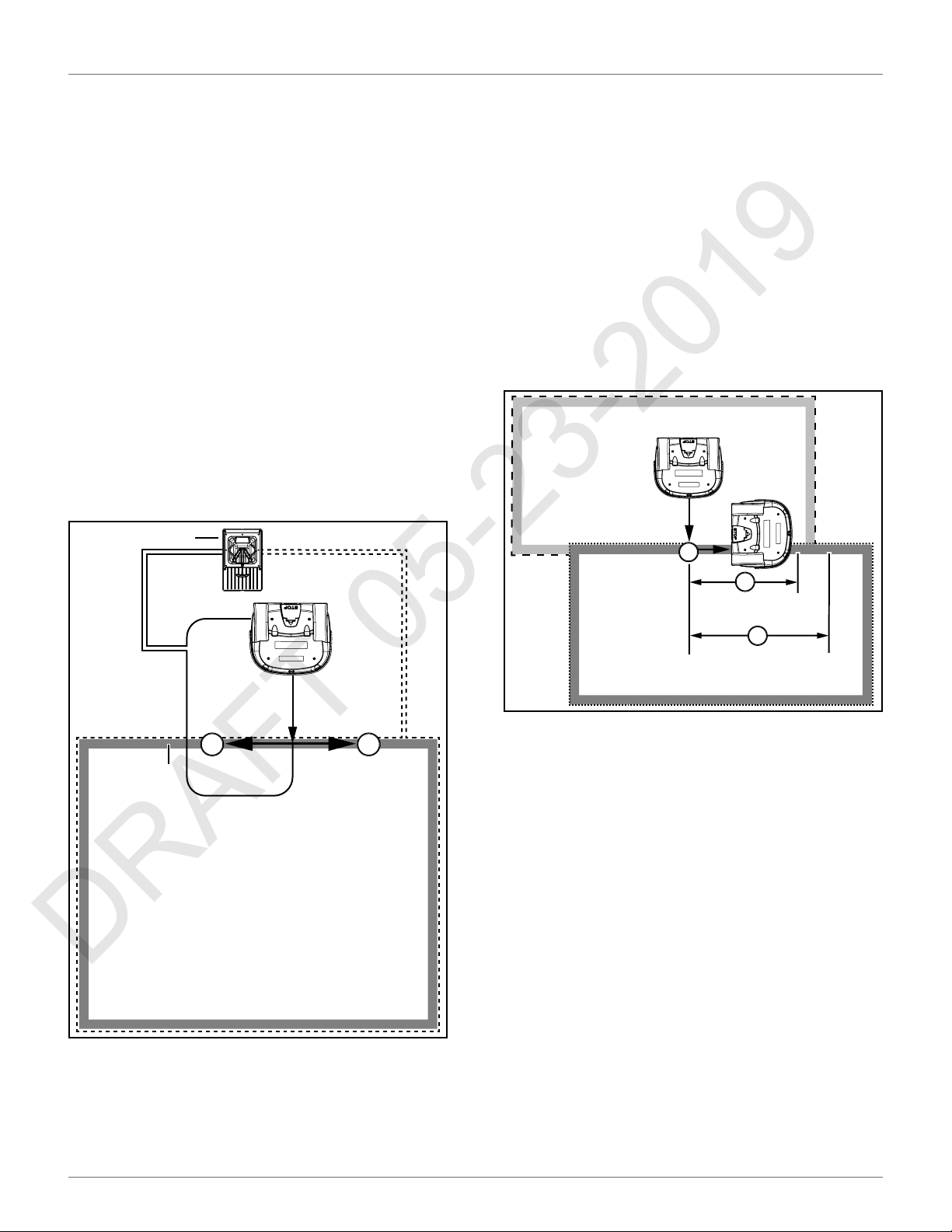

One Field With Station Loop

At Point A, the robot begins a return to the charging

station. It moves to the peripheral wire then follows

the trackborder until it reaches the intersection of the

peripheral and station loop wires (Point B). Then it

follows the station loop wire until it docks at the

charging station.

1

2

B

Two Fields With Station Loop

At Point A, the robot returns to the charging station. It

moves towards the Field 2 peripheral wire and follows

the Field 2 trackborder until it reaches Point B. This is

the area where both fields overlap. It then follows the

Field 1 trackborder until it reaches Point C. This is

where the Field 1 peripheral wire and station loop wire

overlap. Next, the robot follows the station loop wire

until it docks at the charging station.

C

3

1 – Trackborder

2 – Peripheral wire

B

2

1

A

1 – Field 2 / Field 2 peripheral wire

2 – Field 2 trackborder

3 – Field 1 trackborder

A

5.1.3 Charge Mode

In Charge Mode the robot will dock and remain in the

charging station until the battery is fully charged.

The next operations that will be performed depend on

programming and external conditions.

The robot will remain at the charging station if:

• rest periods have been scheduled

• it has been programmed to stay in the station

• the temperature is too low

Otherwise, it will continue with the scheduled mowing

program.

The robot will remain at the charging station once the

battery has been charged until:

8

• the normal program needs to commence

• a specific command is issued

Page 13

HOW THE ROBOT WORKS

DRAFT 05-23-2019

AUTONOMOUS MISSION STATE

5.1.4 Wait In Charging Station Mode

The robot will stay in the charging station once the

battery has been charged until the normal program

needs to commence, or a specific command issued.

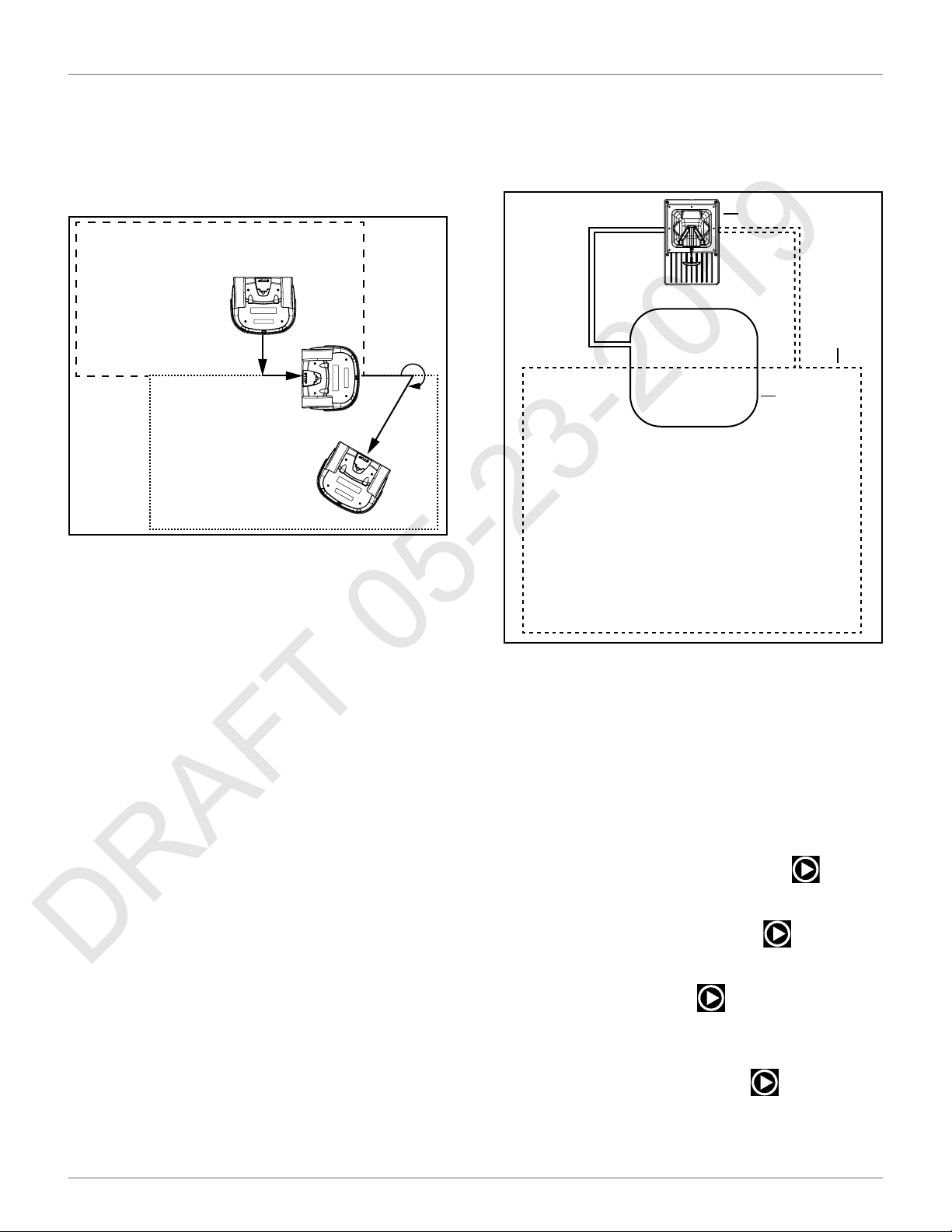

5.1.5 Go Zone Mode

The robot will leave the charging station when the

mowing schedule demands it, or a specific command

has been issued.

Go Zone Mode describes the maneuvers the robot

makes to leave the charging station and start mowing.

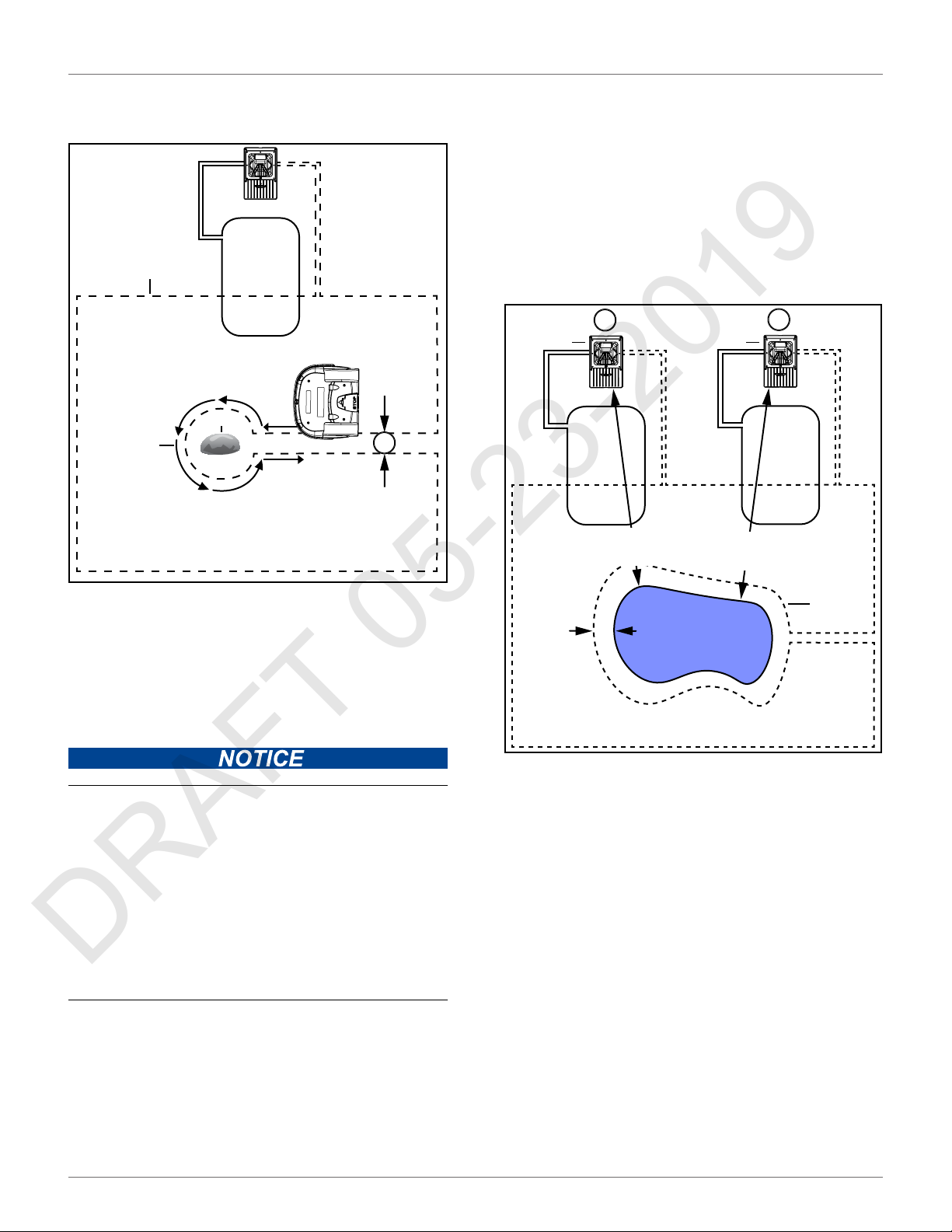

One Field With Station Loop

This configuration contains one peripheral wire and

one station loop wire.

When the robot leaves the charging station it follows

the station loop wire until it reaches Point A. This is a

predefined distance along the field peripheral wire. At

Point A, the robot will follow the trackborder of the

field until it reaches Point B. At Point B, the robot will

turn into the field and start mowing. The distance traveled along the trackborder and the angle at which the

robot turns into the field are specified in the StartZone

parameters for the field to be mowed.

Two Fields With Station Loop

This configuration contains a peripheral wire for each

field and one station loop wire.

Before leaving the charging station the robot will determine which field to start mowing. This will depend on

the defined mowing schedule for each field. If the

schedule dictates that a specific field must be mowed

at this time, the robot will start mowing in that field.

If there are no schedule constraints, the robot will

choose the field based on the percentage values. Over

a period of time the robot ensures that it starts in each

field according the defined proportions.

When the robot leaves the charging station it follows

the station loop wire until it reaches Point A. At Point A,

the robot will turn and follow the trackborder of Field

1, until it reaches Point B. Point B is where the two

fields overlap.

When the robot is in Field 2, it will travel for a certain

distance along the Field 2 trackborder until it reaches

Point C. At Point C, the robot will turn into the field and

start mowing. The distance traveled along the Field 2

trackborder, and the angle at which the robot turns

into Field 2, are specified in the StartZone parameters

for Field 2.

A

A

B

1 – Field 1 trackborder

2 – Field 2 trackborder

1

C

B

2

9

Page 14

INSTALLATION

DRAFT 05-23-2019

INACTIVE MODES

5.1.6 Demonstration Mode

Use this mode to demonstrate the performance of the

robot before installation of the peripheral wire.

OPERATIONAL HAZARD

The robot will ignore the electromagnetic field generated by the peripheral wire when operating in

demonstration mode.

• Do not leave the robot unsupervised when it is

operating in demonstration mode.

5.2 Inactive Modes

The Alarm Mode and Standby Mode will cause the

robot to enter an inactive mode.

5.2.1 Alarm Mode

When the robot encounters a problem it will register

an alarm and enter the inactive mode. When the cause

for the alarm has been corrected, the user can manually clear the alarm and the robot will then enter the

Standby mode. If no intervention takes place, the robot

will turn off and enter the OFF mode.

5.2.4 OFF Mode

The robot will be in the OFF mode when:

• it has been manually switched OFF

• an alarm situation has not been corrected after a

certain period of time

6 Installation

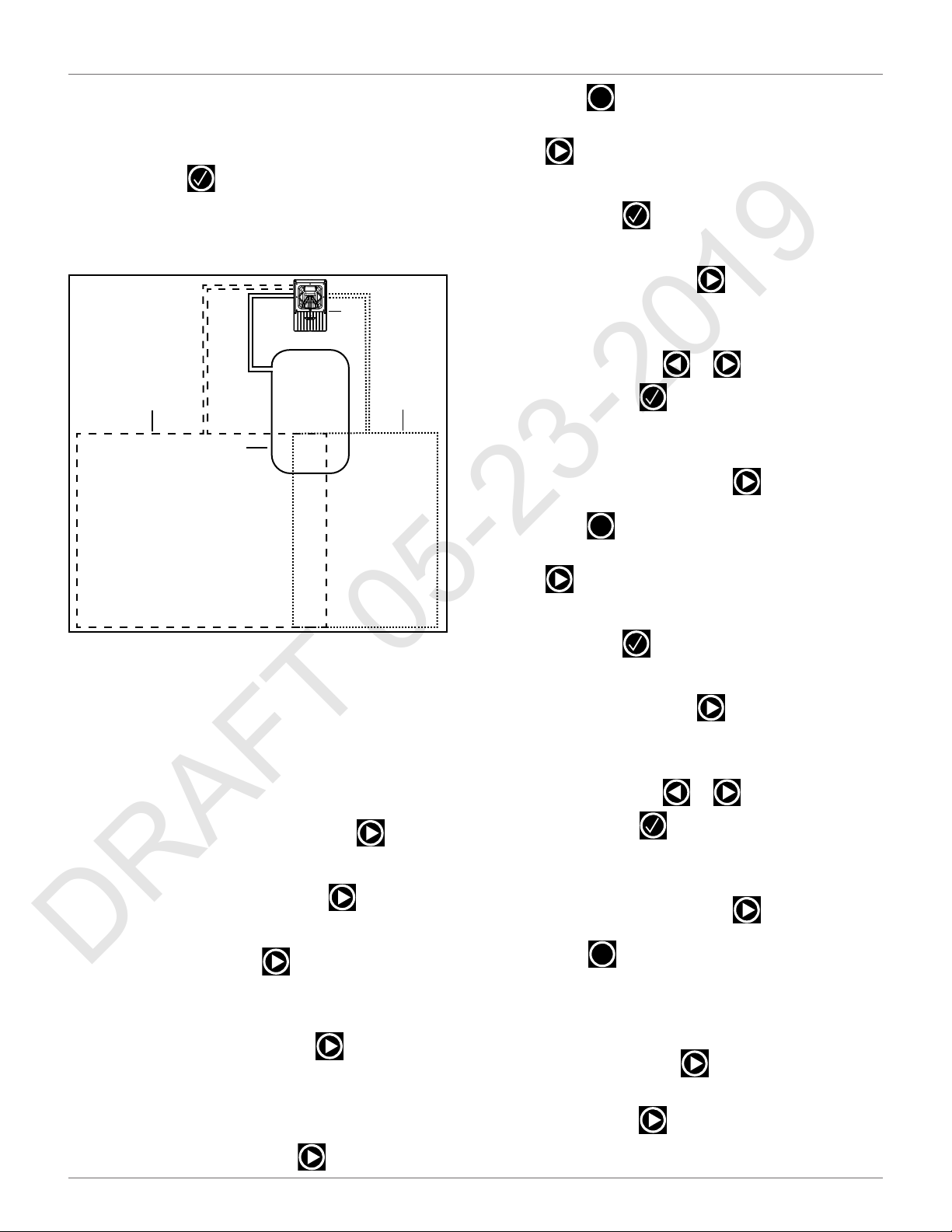

The figure below illustrates the components of a single

field installation.

4

7 3 2

6

1

5

5.2.2 Standby Mode

The robot will enter the Standby mode if:

• the autonomous mission has been stopped due

to an external command

• an alarm situation has been corrected and the

alarm cleared by manual intervention

• it is manually switched ON

The robot will leave the Standby mode when a

command is issued. It will then enter the Self Test

Mode before recommencing any activity.

5.2.3 Self Test Mode

Whenever the robot has been in the Standby Mode it

will perform a self test to check the integrity of the

entire system (including electronics, sensors,

mechanics and software). When the result of the self

test is successful, it will resume the autonomous

working state. If the result of the self test is not

successful, it will register an alarm.

1 – Robot

2 – Mowing area

3 – Peripheral wire

4 – Charging station

5 – Obstacle

6 – Station loop wire

7 – Trackborder

Only install the system on a field with a slope that is less

than or equal to 17°. If the slope is near the peripheral

wire, program the robot to return to the charging

station by descending the slope.

5

10

Page 15

INSTALLATION

DRAFT 05-23-2019

STATION LOOP WIRE INSTALLATION

6.1 Station Loop Wire

Installation

The station loop wire can be installed completely inside

of the field (Figure A), or partially inside of the field

(Figure B). The wire must extend a minimum of

13 ± 1.6 ft. (4.0 ± 0.5 m) into the field.

The distance between the center of the charging

station and the end of the station loop wire is 8.2 ft.

(2.5 m) maximum.

2

1

ϭϯцϭϲŌ

(4 ± 0.5 m)

A

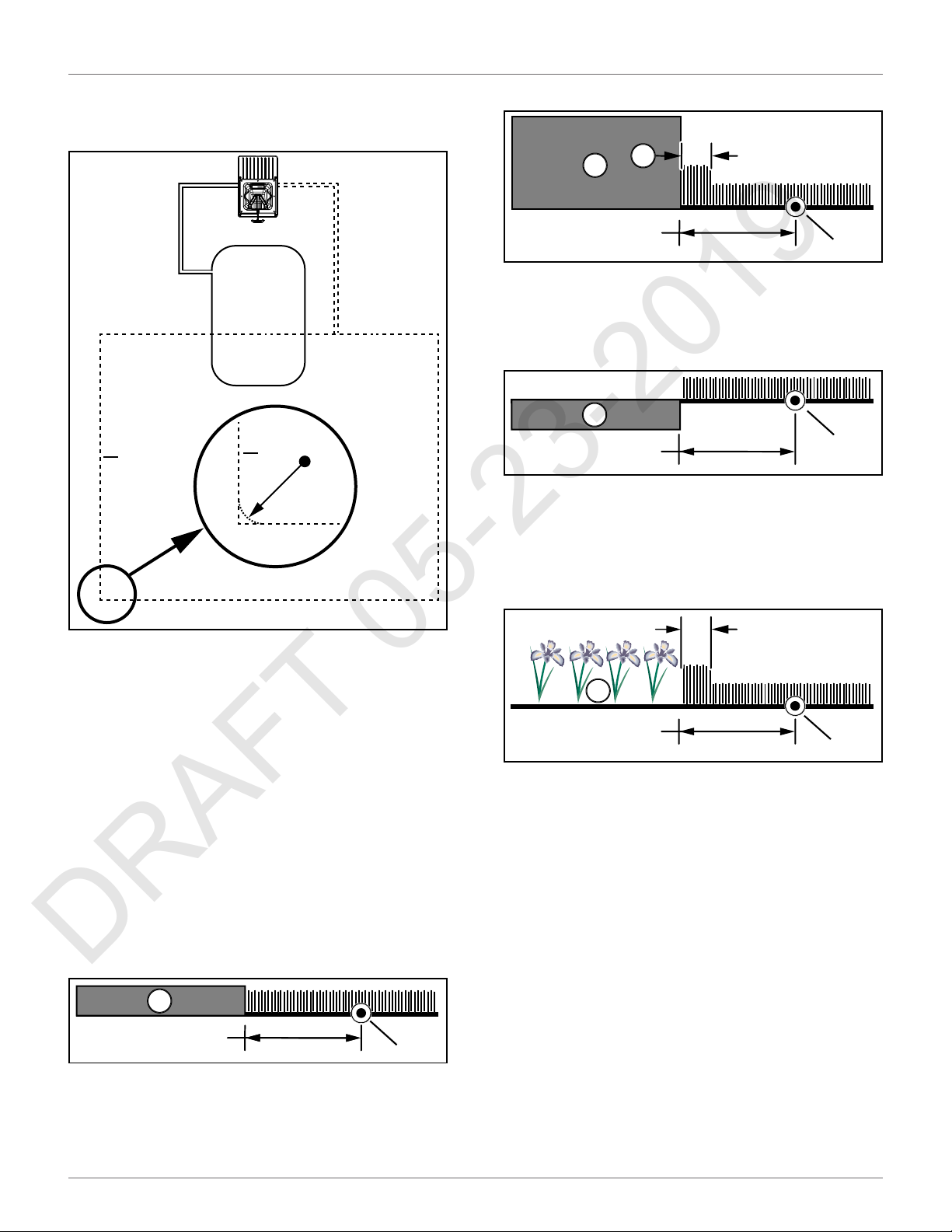

6.2 Peripheral Wire Installation

IMPORTANT: Only use peripheral wire which is

supplied by ECHO Inc.

Each end of a peripheral wire is connected to the

charging station.

Install the peripheral wire in a clockwise direction

around the field. Do not cross or form loops with the

peripheral wire.

Minimum peripheral wire length is 656 ft. (200 m). If

this minimum length is not possible, install an inductor

in series with the peripheral wire. See the ECHO

Robotics Parts Catalog for inductor kit information.

Maximum peripheral wire length is 3937 ft. (1,200 m).

Use a second charging station when:

• total length of the peripheral wire (including

islands and pseudo-islands) exceeds 3,281 ft.

(1,000 m)

• more than five obstacles are on the trackborder

Peripheral wire installation dimensions:

ϴϮŌ

(2.5 m)

ϴϮŌ

(2.5 m)

ϴϮŌ

(2.5 m)

1

2

B

1

ϭϯцϭϲŌ

(4 ± 0.5 m)

ϴϮŌ

(2.5 m)

1 – Peripheral wire

2 – Charging station

3 – Recommended length incoming side

4 – Recommended length outgoing side

5 – Obstacle free zone

6 – Trackborder

3

ϭϲϰŌ

(5.0 m)

6

2

ϯϵϰŌ

(12.0 m)

5

28.3 in.

(720 mm)

4

ϭϲϰŌ

(5.0 m)

1 – Station loop wire

2 – Charging station

11

Page 16

INSTALLATION

DRAFT 05-23-2019

PERIPHERAL WIRE INSTALLATION OFFSETS

Peripheral wire installation angles must be greater

than or equal to 90°, with a radius greater than or equal

to 3.3 ft. (1.0 m).

ϭ

ϭ

шϯϯŌ

;шϭŵͿ

шϵϬΣ

Raised hard landscaping:

1

(750 mm)

1 – Terrace / Path / Wall

2 – Peripheral wire

3 – Area not mowed

Hard landscaping level with grass:

1

(300 mm)

1 – Terrace / Path

2 – Peripheral wire

NOTE: A path that crosses the field to be mowed should

be level with the grass.

Lawn-level planting:

3

29.5 in.

11.8 in.

9.5 in.

(240 mm)

2

2

3.5 in.

(90 mm)

2

1 – Peripheral wire

The peripheral wire needs to take obstacles into

account. Some obstacles can be detected by the sonar

sensors on the robot, others require specific placement

of the peripheral wire, or the use of islands or

pseudo-islands.

6.3 Peripheral Wire Installation

3

1

29.5 in.

(750 mm)

1 – Flower bed

2 – Peripheral wire

3 – Area not mowed

Offsets

NOTE: The dimensional values shown apply when the

“Wire crossing distance” parameter is at the default

setting of 0.2 m.

Rough grass that does not need to be mowed:

1

20 in.

(510 mm)

1 – Rough grass

2 – Peripheral wire

2

12

Page 17

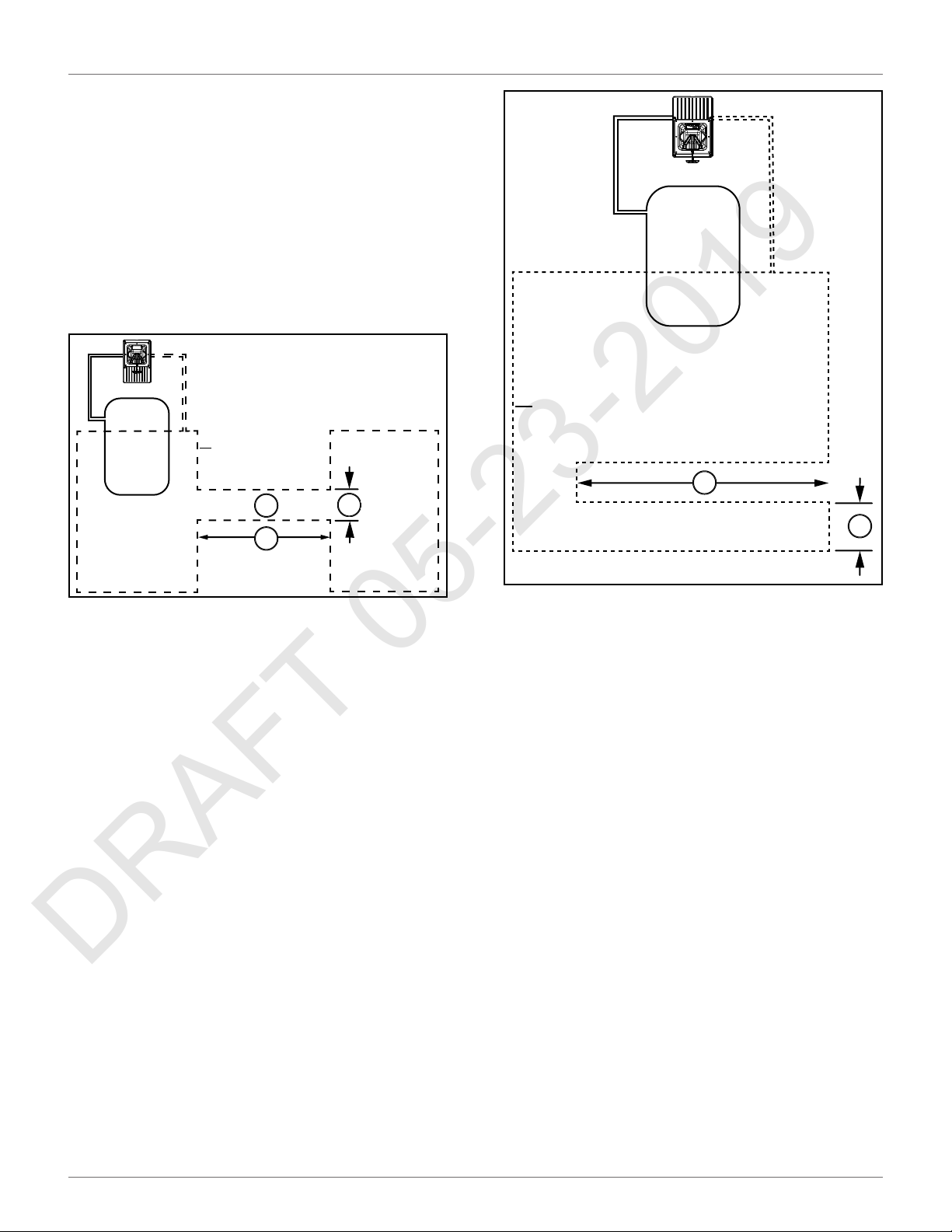

6.4 Sites Containing Narrow

DRAFT 05-23-2019

Straits

These sites require specific installation of the peripheral wire.

The required minimum width of the strait, depends on

the length of the strait. If this minimum width is not

available when the robot is in Zone B, it will not be able

to pass through the strait and return to the charging

station. In this case, installation of an additional

charging station in Zone B is required.

2

3

Zone B

Zone A

1

4

INSTALLATION

SITES CONTAINING NARROW STRAITS

2

1

3

1 – Narrow strait

2 – Peripheral wire

3 – Minimum distance between peripheral wire

4 – Length of strait

The table below presents the minimum distance

between wires required to enable the robot to follow

its trackborder from Zone B through the strait and

return to the charging station in Zone A.

6.5 Sites With Long Lanes

A long lane represents an area where a minimum

distance for the installation of the peripheral wire is

required. If this minimum distance is not met, the robot

may not be able to detect the peripheral wire. If the

peripheral wire is not detected, the robot cannot

return to the charging station to charge its battery.

1 – Lane

2 – Peripheral wire

3 – Minimum distance between peripheral wire

If the length of the lane is less than 49.2 ft. (15 m), then

the minimum distance between the peripheral wire

must be greater than 32.8 ft. (10 m).

6.6 Obstacles

Obstacles are objects that the robot must avoid. Examples are:

• trees, flower beds

• swing sets, climbing frames, trampolines

• sidewalks, walking paths, terraces

• ponds, swimming pools

Some obstacles are detected by the sonar sensors on

the robot. Other obstacles require the installation of

the peripheral wire to create an island, or a

pseudo-island.

If an island is created, the robot will not approach the

obstacle. The robot will move across the peripheral

wire to avoid the obstacle.

If a pseudo-island is created, the robot will approach

the obstacle, and then maneuver around it.

Obstacles Near the Boundary to be Mowed

13

Page 18

INSTALLATION

DRAFT 05-23-2019

ISLANDS

If an obstacle is less than 3.3 ft. (1.0 m) from the

boundary, install the peripheral wire around the

obstacle. If the distance between the obstacle and the

boundary is greater than 3.3 ft. (1.0 m), but less than

16.4 ft. (5.0 m), install a pseudo-island.

2

1

ϯϯŌ

(1.0 m)

• secure with tie straps at 0.4 in. (10 mm) increments

3

2

5

1

x x x x

4

0.4 in.

(10 mm)

1 – Obstacle

2 – Peripheral wire

6.7 Islands

Create an island when an obstacle is more than:

• 16.4 ft. (5.0 m) from the peripheral wire

• 49.2 ft. (15.0 m) from the charging station

• 16.4 ft. (5.0 m) from another island or

pseudo-island

Install the peripheral wire around an obstacle to create

an island. A maximum of five islands can be installed.

Installation requirements for an island:

• counterclockwise direction around an object

• place the approach and return sides of the

peripheral wire directly next to each other (do

not cross or twist the wire)

1 – Obstacle

2 – Direction to install peripheral wire

3 – Peripheral wire

4 – Movement of robot

5 – Tie strap locations

Create a pseudo island when an obstacle is less than:

• 16.4 ft. (5.0 m) from the peripheral wire

• 49.2 ft. (15.0 m) from the charging station

• 16.4 ft. (5.0 m) from another island or

pseudo-island

Install the peripheral wire around an obstacle to create

a pseudo-island.

Installation requirements for a pseudo-island:

• counterclockwise direction around an object

• allow a fixed distance of 15.7 - 23.6 in.

(400 - 600 mm) between the approach and

return sides

14

Page 19

INSTALLATION

DRAFT 05-23-2019

WATER OBSTACLE

• do not cross or twist the approach and return

side of the peripheral wire

3

1

2

15.7 - 23.6 in.

(400 - 600 mm)

4

Install the charging station a minimum of 49.2 ft. (15 m)

from the edge of the water.

Two possible installations for the charging station are

shown in the figure below.

NOTE: The robot should return to the charging station

from the direction away from the water.

If the charging station is located at Point A, program the

robot to return to it in a clockwise direction. If the

charging station is located at Point B, program the

robot to return to it in a counterclockwise direction.

A

2 2

хϰϵϮŌ

(>15.0 m)

хϰϵϮŌ

(>15.0 m)

B

1 – Obstacle

2 – Direction to install peripheral wire (and movement of robot)

3 – Peripheral wire

4 – Fixed distance between approach and return sides

хϱϯŌ

(>1.6 m)

1

6.8 Water Obstacle

1 – Peripheral wire

2 – Charging station

WATER AMPLIFIES THE ELECTROMAGNETIC SIGNAL OF THE PERIPHERAL

WIRE

The robot is attracted towards higher signal levels.

Failure to correctly avoid a water obstacle can result in submersion of the robot.

• Use an island or a pseudo-island to avoid a water obstacle.

Install the peripheral wire a minimum distance of

5.3 ft. (1.6 m) from the edge of the water. Increase this

distance if the ground slopes towards the water, is slippery, or can become wet or flooded.

If meeting the minimum distance of 5.3 ft. (1.6 m) is not

possible, install a physical barrier around the water.

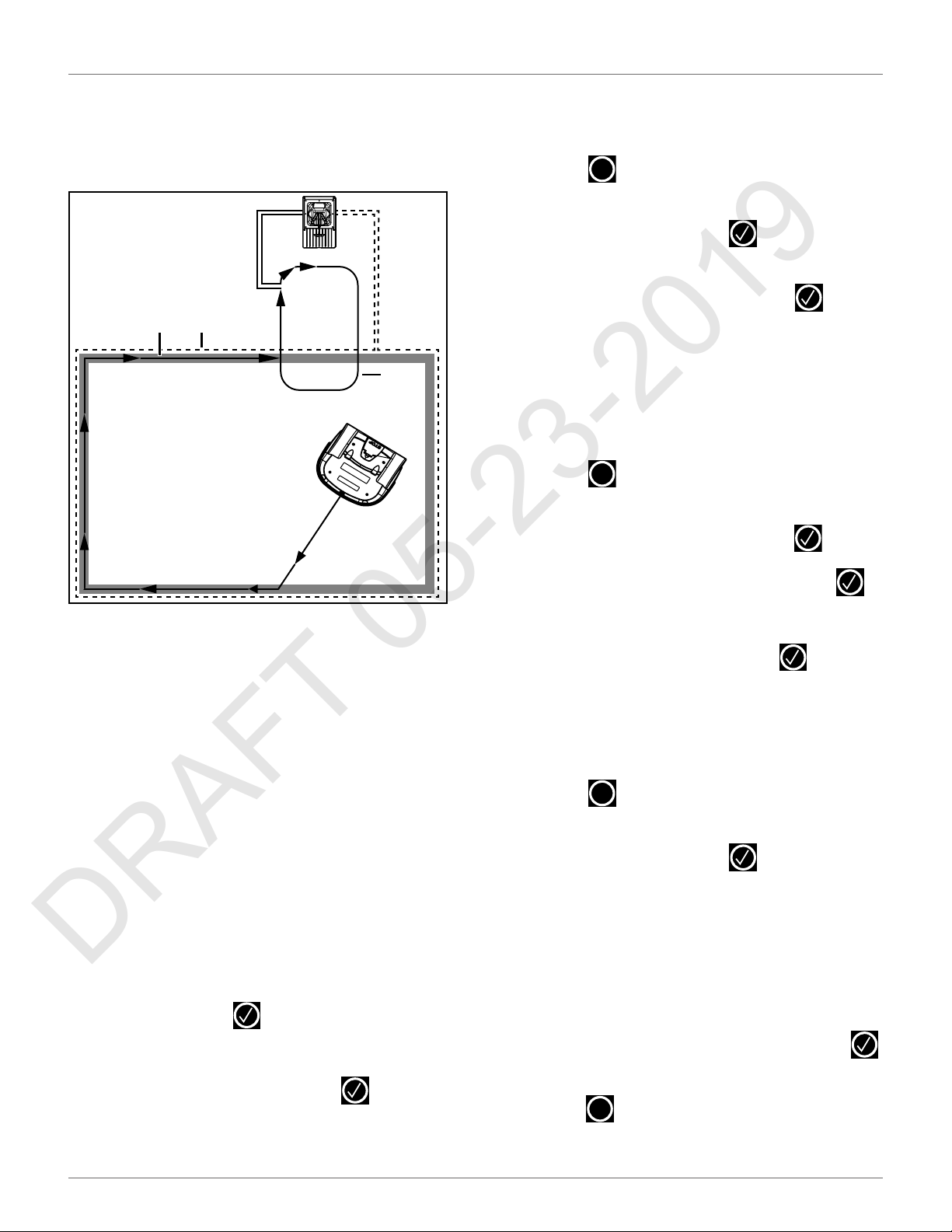

6.9 Sloped Fields

The maximum slope on any part of the field must be

less than or equal to 17°.

If a sloping part of the field is well away from the

peripheral wire, no specific programming of the robot

is required. If the sloping part of the field is near the

peripheral wire, program the robot to return to the

charging station by descending the slope.

This example describes how to configure a station loop

wire to return the robot to the charging station. There

is one wire that defines the area to be mowed; this wire

is named "Field", the additional wire is named "Loop".

The “Field” wire is the peripheral wire. The “Loop” wire

is the station loop wire.

15

Page 20

INSTALLATION

DRAFT 05-23-2019

CONFIGURATION

The "Field" wire is configured for the robot to mow

normally. When it returns to the charging station it will

follow the trackborder until it reaches the "Loop" wire.

It will then follow the “Loop” wire until it reaches the

charging station.

2

3

1

6) Check the value shown at the top of the screen.

This should be positive. If it is not, select Reverse

phase and check the button ON.

7) Press twice to return to the Infrastructure

menu.

8) Select Parcels, then press . Select the parcel

associated with the LOOP wire.

9) Select Return direction, then press . Choose

whether you want the robot to return in a clockwise or counterclockwise direction.

10) Disable the use of the trackborder. Select Use

trackborder and check the button OFF. This

ensures that when the robot is in this field, it will

just follow the wire to reach the station.

11) Press twice to return to the Infrastructure

menu.

X

X

1 – Station loop wire (“Loop”)

2 – Peripheral wire (“Field”)

3 – Trackborder

When installing the wire for the "lawn" loop all the

conditions described must be respected. This includes

the conditions required for multi-fields.

6.10 Configuration

Configuration of this installation is completed through

the through User Interface. The instructions given

below are the minimum set of configuration parameters that must be set for this type of installation.

1) Press and hold 9 on the user interface screen

until the technician's menu appears.

2) Select Infrastructure > Peripheral wires.

3) On the "Wire settings" screen, select Wire

CH{X},then press .

12) Select Create new wire, then press .

13) Select the newly created wire, then press .

14) Rename this field to LAWN.

15) Select Signal channel, then press Assign the

channel number for the large field to be mowed.

16) Check the value shown at the top of the screen.

This should be positive. If it is not, select Reverse

phase and check the button ON.

17) Press twice to return to the Infrastructure

menu.

18) Select Parcels, then press . Select the parcel

associated with the LAWN wire.

19) Set the Return direction to the same as above.

20) Select Use trackborder and check the button ON.

This ensures that when the robot is in this field, it

will follow the trackborder until it reaches the

LOOP field.

X

4) Rename this Wire to LOOP.

5) Select Signal channel, then press . Assign the

channel number for the station loop.

21) Select Neighboring parcels, then press .

Check the button next to the LOOP parcel.

22) Press to exit this menu.

X

16

Page 21

INSTALLATION

DRAFT 05-23-2019

OVERLAPS

23) Select Edit parcels percentage, then press .

Set the value to 100% for the lawn parcel.

24) Press to return to the Infrastructure menu.

25) Select Infrastructure > Stations > Create new

station, then press .

26) A name is generated that you can modify if you

want.

27) Select Connected to parcels, then press .A

list of parcels is presented. Select the parcel

inside the LOOP wire and check the button ON.

28) Select Station inside parcel's wire. Check the

button ON if the station is inside the LOOP wire.

In the example shown above it is outside the

wire.

Connect a total of one station loop and two peripheral

wires to a single charging station.

• Each field is defined by a peripheral wire that

starts and ends at the charging station.

• Each peripheral wire is assigned to a different

signal channel in the charging station.

• The charging station must contain one signal

channel board for every peripheral wire

required.

• The area inside of each peripheral wire is defined

as a field. Each peripheral wire must overlap with

its neighboring one.

• Each pair of wires which overlap must be designated as neighboring fields.

X

The elements of a multiple field installation are shown

in the following figure.

2

2

1 – Station loop wire / Field 1

2 – Peripheral wire 2 / Field 2

3 – Peripheral wire 3 / Field 3

4 – Overlap area

1

4

3

3

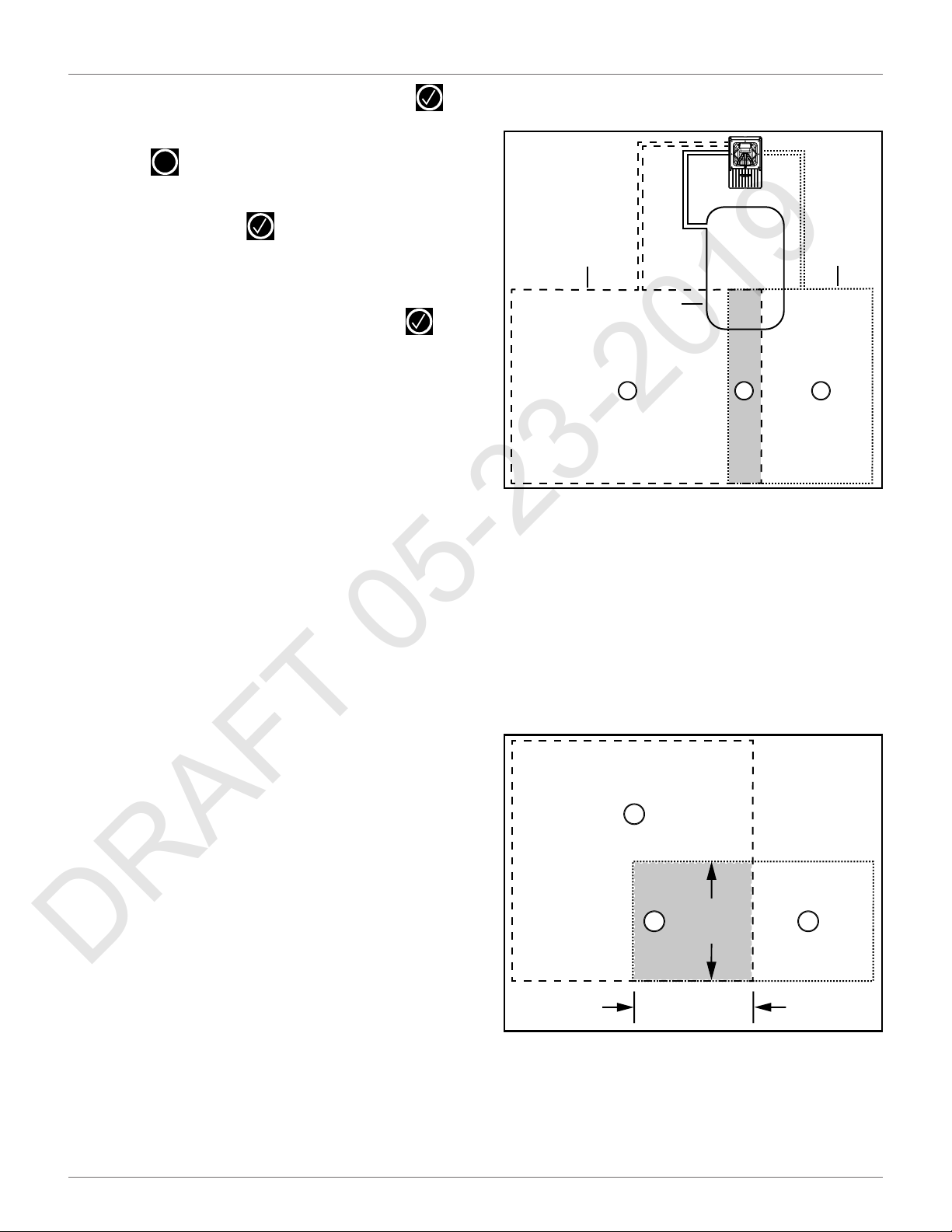

6.11 Overlaps

An overlap is an area that lies within two fields and is

used for the robot to transition from one field to

another. The length and width of the overlap must be

greater than 9.8 ft. (3 m).

Station loop wire 1 / Field 1, is the small wire to which

the charging station is connected. In this example it

overlaps the larger peripheral wires and fields. When in

this field, the robot will not use the trackborder, it will

follow the station loop wire to enter the charging

station.

All three fields are neighbors to each other.

The overlap area is a transition zone used to connect

the main mowing areas of the fields.

The proportion of time that the robot spends mowing

in fields 1 and 2 is determined by the percentage values

assigned to the corresponding fields. For the station

loop field, the percentage can be set to 0.

хϵϴŌ

(> 3.0 m)

1 – Overlap area

2 – Field 1

3 – Field 2

2

хϵϴŌ

1

(> 3.0 m)

3

17

Page 22

INSTALLATION

DRAFT 05-23-2019

MULTI-FIELD PERIPHERAL WIRE INSTALLATION

6.12 Multi-Field Peripheral Wire

Installation

The start and finish sides of the peripheral wire must lie

next to each other when they enter the charging

station. Install the start and finish sides of the peripheral wire for one field around the other field. The

distance between the peripheral wires for each field

must be greater than or equal to 23.6 in. (600 mm).

1

шϮϯϲŝŶ

;шϲϬϬŵŵͿ

Ϯ

ϯ4

7) If the installation is a multi-field installation,

define the start zone parameters for a parcel.

8) Select Infrastructure > Stations.

9) Select Create new station.

10) Select Connected to parcels and connect the

station to the loop parcel.

11) Select Station Inside Parcel's Wire and specify

whether the station is on the inside or the

outside of the station loop wire.

6.13.2 Start Zones

Start zones define where and how the robot starts

mowing.

• A start zone is defined for a parcel.

• Multiple start zones can be defined for the same

wire/parcel.

The Start Zone screen displays the following:

List of defined start zones

1 – Start and finish side of Field 1 peripheral wire

2 – Start and finish side of Field 2 peripheral wire

3 – Field 2

4 – Field 1

6.13 Configuration

Once the peripheral wire(s) and the charging station

have been set in place, the installation needs to be

configured.

Access the User Interface to configure single and

multi-field installations.

6.13.1 General Configuration Procedure

Using a Station Loop

1) Open the technician's menu.

2) Select Infrastructure > Peripheral wires and

create the required number of wires for the

installation.

For each one the line below shows some characteristics

of the zone.

Create new start zone

Enables you to create a new zone with all the properties listed below.

6.13.3 Start Zone Properties

Following from

This option appears if you are defining a start zone for

station with a positioning beacon. It specifies the parcel

in which the start zone is implemented.

For a multi-field installation, you can specify the

specific parcel.

Default means coming from any other parcel.

Coming from

This option appears if you are defining a start zone for

a parcel.

It defines the parcel preceding the one in which the

start zone will be implemented.

3) For each wire assign the channel number and

check the reverse phase.

4) Select Infrastructure > Parcels.

5) Define the properties of the parcel that is associated with each wire.

6) Create new parcels if necessary.

18

Percentage

Allows you to edit the percentages applied to different

parcels.

If only one parcel is defined this value must be set to

100%.

Page 23

INSTALLATION

DRAFT 05-23-2019

CONFIGURATION

Do not edit the percentage until more than one start

zone has been defined.

Edit percentage

Allows you to edit the percentages applied to different

parcels.

If only one parcel is defined this value must be set to

100%.

Do not edit the percentage until more than one start

zone has been defined.

Direction

This specifies the clockwise or counterclockwise direction the robot will take to move along the trackborder

after leaving the charging station.

When the robot leaves the charging station, it follows

the station loop wire for a predefined distance until it

arrives in the trackborder of a mowing field, it then

takes the specified direction.

2

Distance Min. / Distance Max.

This is the distance that the robot will travel along the

trackborder after leaving the station before starting

mowing. A random value between the minimum and

maximum values will be selected.

Distance Min. and Distance Max. are measured from

the point where the robot enters the parcel, if this

differs from the one in which the charging station is

located.

If the start zone is located in a different parcel than the

one containing the charging station, the distances are

measured from the entry point into the parcel (shown

in the figure below).

3

1

2

1 – Distance Min.

5

3

4

2 – Distance Max.

3 – Trackborder

1 – Charging station

2 – Station loop wire

3 – Trackborder

4 – Clockwise direction on trackborder

5 – Counterclockwise direction on trackborder

19

Page 24

INSTALLATION

DRAFT 05-23-2019

CONFIGURATION EXAMPLES

Angle Min. / Angle Max.

This is the angle that the robot will turn through to take

it into the field to start mowing. Minimum and

maximum values are defined and the robot will choose

a random value between the defined limits.

6.14 Configuration Examples

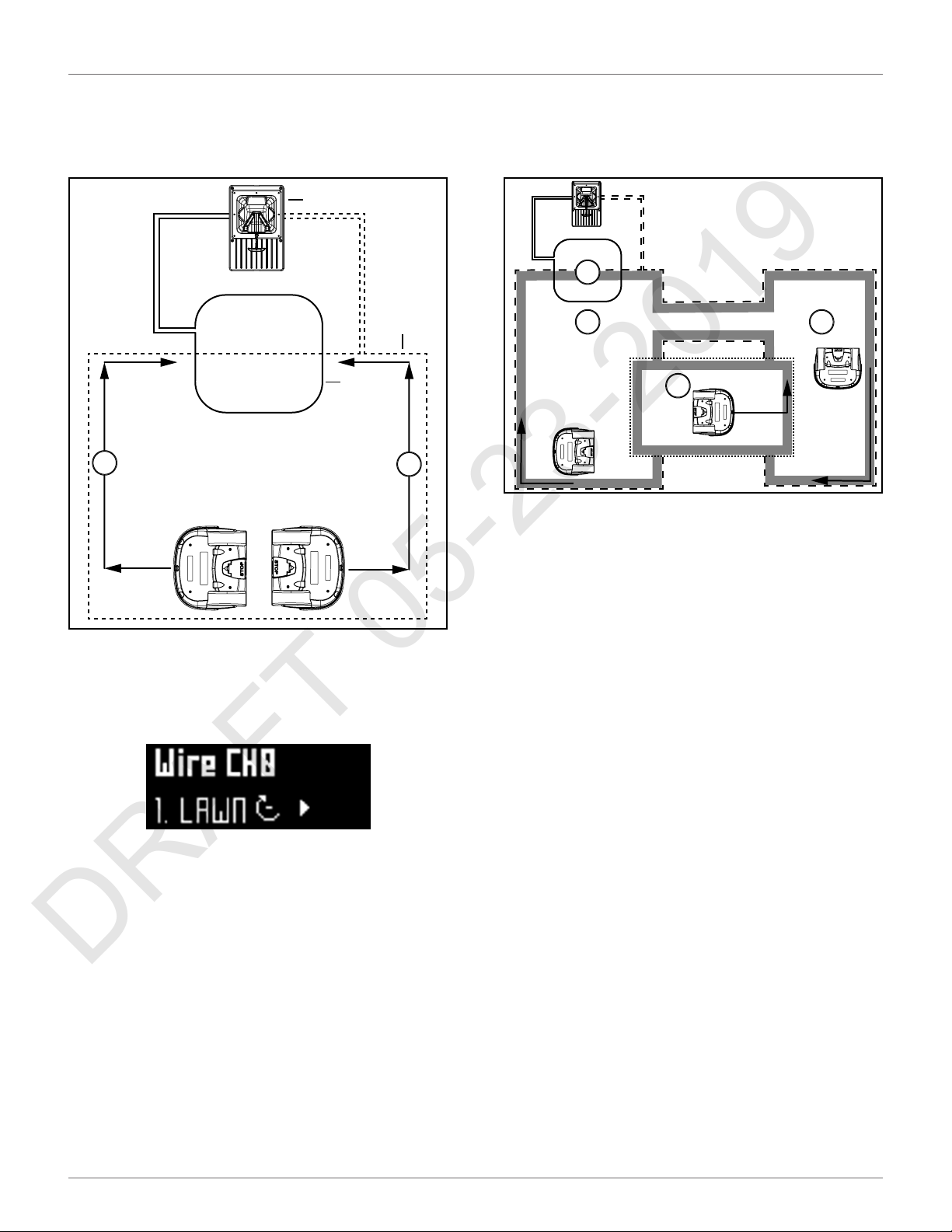

6.14.1 Wire Configuration - One Zone

Installation

1

3

2

Delete StartZone

Allows the start zone to be deleted.

1 – Charging station

2 – Station loop wire

3 – Peripheral wire

Access the User Interface to set the following parameters.

Peripheral Wire Configuration

1) Press and hold 9 on the numeric keypad until the

technician’s menu appears.

2) The TECHNICIAN SETTING menu will display.

Select 1. Infrastructure, then press .

3) The INFRASTRUCTURE menu will display. Select

1. Peripheral wires, then press .

4) The WIRES SETTINGS menu will display. Select 1.

Wire CH0, then press .

5) The WIRE CH0: NO SIGNAL menu will display.

Select the numeric option next to Signal channel,

set the value to 0, then press .

NOTE: The station loop wire will always be set to 0.

20

Page 25

INSTALLATION

DRAFT 05-23-2019

CONFIGURATION EXAMPLES

6) Check the value shown at the top of the screen.

The value should be positive, if it is not, select

Reverse phase, then press .

7) Press once, the WIRES SETTINGS menu will

display. Select 9. Create new wire, then press

8) The VALIDATE screen will display. Select OK,

then press .

9) The WIRES SETTINGS menu will display. Select

Wire CH5, then press .

10) The Wire CH5: No Signal screen will display.

Select the numeric option next to SIGNAL

CHANNEL, press or and set the value to

1, then press .

11) Check the value shown at the top of the screen.

The value should be positive, if it is not, select

Reverse phase, then press .

X

.

6) The FIELD screen will display. Select Use Track-

border, then press .

7) Scroll down to 8. Neighboring parcels, then press

.

8) The NEIGHBORING PARCELS screen will display.

Select LOOP, then press . Select Confirm,

then press .

9) The FIELD screen will display. Press twice to

return to the INFRASTRUCTURE screen.

Station Configuration

Select 3. Stations, then press .

1)

2) Select 9. Create manual station, then press .

3) The VALIDATE screen will display. Select OK,

then press .

4) The Manual Station 1 screen will display. Select

Connected to parcels, then press .

X

12) Press twice to return to the INFRASTRUCTURE screen.

Parcels Configuration

1) From the INFRASTRUCTURE menu, select

Parcels, then press .

2) The PARCELS menu will display. Select 1. Parcel

1, then press .

3) The Parcel 1 menu will display. Parcel 1 will be

highlighted, press . Use , , , or

select V (located in the bottom row), then press

4) Press once to return to the PARCELS screen.

5) Select Parcel 2, then press . Use , ,

renaming, select V (located in the bottom row),

then press .

X

, rename Parcel 1 to LOOP. After renaming,

.

X

, or , rename Parcel 2 to Field. After

5) The VALIDATE screen will display. Select OK,

then press .

6) The Connected Parcels screen will display. The

option for Wire CH0 will be highlighted. Press

to change it to LOOP, then press .

7) Press once to return to the Manual Station

screen.

8) Select Station inside parcel’s wire. Press if

the charging station is inside of the station loop

wire.

9) Press twice to return to the INFRASTRUC-

TURE screen.

10) Press twice, the Waiting for new mission

screen will display.

11) Press once, the SERVICE SETTINGS screen

will display. Select 3. Operations, then press .

12) The OPERATIONS screen will display. Select Edit

X

X

X

parcels percentage, then press .

21

Page 26

INSTALLATION

DRAFT 05-23-2019

CONFIGURATION EXAMPLES

13) The PARCELS PERCENTAGE screen will display.

Select the numeric option next to LOOP, set the

number to O. Select the numeric option next to

FIELD, set the number to100. Select CONFIRM,

then press .

6.14.2 Wire Configuration - Two Zone

Installation

1

3

2

4

7) Press once, the WIRES SETTINGS menu will

display. Select 9. Create new wire, then press

8) The VALIDATE screen will display. Select OK,

then press .

9) The WIRES SETTINGS menu will display. Select

Wire CH5, then press .

10) The Wire CH5: No Signal screen will display.

Select the numeric option next to SIGNAL

CHANNEL, press or and set the value to

1, then press .

11) Check the value shown at the top of the screen.

The value should be positive, if it is not, select

Reverse phase, then press .

12) Press once, the WIRES SETTINGS menu will

display. Select 9. Create new wire, then press

X

.

X

13) The VALIDATE screen will display. Select OK,

1 – Charging station

2 – Station loop wire

3 – Field Zone 1 peripheral wire

4 – Field Zone 2 peripheral wire

Peripheral Wire Configuration

1) Press and hold 9 on the numeric keypad until the

technician’s menu appears.

2) The TECHNICIAN SETTING menu will display.

Select 1. Infrastructure, then press .

3) The INFRASTRUCTURE menu will display. Select

1. Peripheral wires, then press .

4) The WIRES SETTINGS menu will display. Select 1.

Wire CH0, then press .

5) The WIRE CH0: NO SIGNAL menu will display.

Select the numeric option next to Signal channel,

set the value to 0, then press .

NOTE: The station loop wire will always be set to 0.

6) Check the value shown at the top of the screen.

The value should be positive, if it is not, select

then press .

14) The WIRES SETTINGS menu will display. Select

Wire CH5, then press .

15) The Wire CH5: No Signal screen will display.

Select the numeric option next to SIGNAL

CHANNEL, press or and set the value to

2, then press .

16) Check the value shown at the top of the screen.

The value should be positive, if it is not, select

Reverse phase, then press

17) Press twice to return to the INFRASTRUC-

TURE screen.

Parcels Configuration

1) From the INFRASTRUCTURE screen, select

Parcels, then press .

2) The PARCELS menu will display. Select 1. Parcel

1, then press .

X

Reverse phase, then press .

22

Page 27

INSTALLATION

DRAFT 05-23-2019

CONFIGURATION EXAMPLES

3) The Parcel 1 menu will display. Parcel 1 will be

highlighted, press . Use , , , or

, rename Parcel 1 to LOOP. After renaming,

select V (located in the bottom row), then press

.

4) Press once to return to the PARCELS screen.

5) Select Parcel 2, then press . Use , ,

renaming, select V (located in the bottom row),

then press .

6) The FIELD 1screen will display. Select Use Track-

border, then press .

7) Press once to return to the PARCELS screen.

8) Select Parcel 3, then press . Use , ,

renaming, select V (located in the bottom row),

X

, or , rename Parcel 2 to Field 1. After

X

, or , rename Parcel 3 to Field 2. After

Station Configuration

1) Select 3. Stations, then press .

2) Select 9. Create manual station, then press .

3) The VALIDATE screen will display. Select OK,

then press

4) The Manual Station 1 screen will display. Select

Connected to parcels, then press .

5) The VALIDATE screen will display. Select OK,

then press .

6) The Connected Parcels screen will display. The

option for Wire CH0 will be highlighted. Press

to change it to LOOP, then press .

7) Press once to return to the Manual Station

screen.

8) Select Station inside parcel’s wire. Press if

the charging station is inside of the station loop

wire.

X

.

then press .

9) The FIELD 2 screen will display. Select Use Track-

border, then press .

10) Scroll down to 8. Neighboring parcels, then press

.

11) The NEIGHBORING PARCELS screen will display.

Scroll down to select LOOP, then press .

Scroll down to Confirm, then press .

12) Press once to return to the PARCELS screen.

13) Scroll down to Field 1, then press .

14) Scroll down to Neighboring parcels, then press

X

.

9) Press twice to return to the INFRASTRUC-

TURE screen.

10) Press twice, the Waiting for new mission

screen will display.

11) Press once, the SERVICE SETTINGS screen

will display. Select 3. Operations, then press .

12) The OPERATIONS screen will display. Select Edit

parcels percentage, then press .

13) The PARCELS PERCENTAGE screen will display.

Select the numeric option next to LOOP, set the

number to O. Select the numeric option next to

FIELD, set the number to100. Select CONFIRM,

then press .

X

X

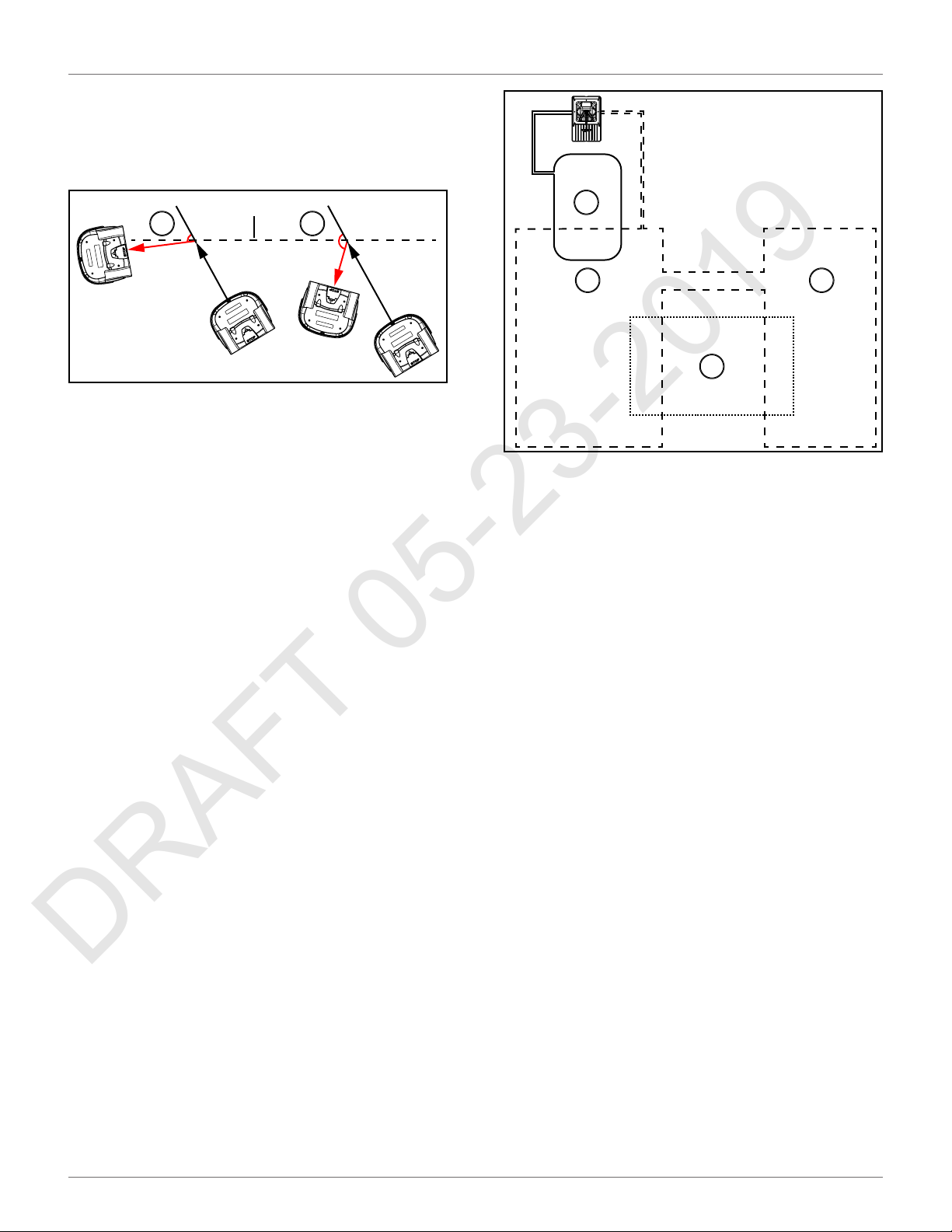

6.14.3 Single Field With Two Start Zones

15) The NEIGHBORING PARCELS screen will display.

Scroll down to select LOOP, then press .

Scroll down to Confirm, then press .

16) The FIELD screen will display. Press twice to

return to the INFRASTRUCTURE screen.

X

This is an example of an installation that might be used

in a large field with two areas. Even though it is set up

as a single field, two start zones are used to ensure that

the robot starts mowing in both areas on a regular

basis.

23

Page 28

INSTALLATION

DRAFT 05-23-2019

CONFIGURATION EXAMPLES

The layout of the installation is shown in the figure

below.

3

1

>16.4 ft.

(>5 m)

2

7) Press once, the WIRES SETTINGS menu will

display. Select 9. Create new wire, then press

8) The VALIDATE screen will display. Select OK,

then press .

9) The WIRES SETTINGS menu will display. Select

Wire CH5, then press .

10) The Wire CH5: No Signal screen will display.

Select the numeric option next to SIGNAL

CHANNEL, press or and set the value to

1, then press .

11) Check the value shown at the top of the screen.

The value should be positive, if it is not, select

Reverse phase, then press .

12) Press twice to return to the INFRASTRUC-

TURE screen.

X

.

X

1 – Start zone 1

2 – Start zone 2

3 – Peripheral wire

Access the User Interface to set the following parameters.

Peripheral Wire Configuration

1) Press and hold 9 on the numeric keypad until the

technician’s menu appears.

2) The TECHNICIAN SETTING menu will display.

Select 1. Infrastructure, then press .

3) The INFRASTRUCTURE menu will display. Select

1. Peripheral wires, then press .

4) The WIRES SETTINGS menu will display. Select 1.

Wire CH0, then press .

5) The WIRE CH0: NO SIGNAL menu will display.

Select the numeric option next to Signal channel,

set the value to 0, then press .

NOTE: The station loop wire will always be set to 0.

6) Check the value shown at the top of the screen.

The value should be positive, if it is not, select

Reverse phase, then press .

Parcels Configuration

1) From the INFRASTRUCTURE menu, select

Parcels, then press .

2) The PARCELS menu will display. Select 1. Parcel

1, then press .

3) The Parcel 1 menu will display. Parcel 1 will be

highlighted, press . Use , , , or

, rename Parcel 1 to LOOP. After renaming,

select V (located in the bottom row), then press

.

4) Press once to return to the PARCELS screen.

5) Select Parcel 2, then press . Use , ,

renaming, select V (located in the bottom row),

then press .

6) The FIELD screen will display. Select Use Track-

border, then press .

7) Scroll down to 8. Neighboring parcels, then press

X

, or , rename Parcel 2 to Field. After

.

24

Page 29

INSTALLATION

DRAFT 05-23-2019

CONFIGURATION EXAMPLES

8) The NEIGHBORING PARCELS screen will display.

Select LOOP, then press . Select Confirm,

then press .

9) The FIELD screen will display. Scroll down to Start

Zones, then press .

10) The Start Zones screen will display. Press

once.

11) The VALIDATE screen will display. Select OK, then

press .

12) The Start Zones screen will display.

For the Coming from parcel option, DEFAULT is

correct.

For the Direction option, CW is correct.

Set the Distance Min. value.

Set the Distance Max. value.

Set the Angle Min. value (between 0° - 180°).

Set the Angle Max. value (between 0° - 180°).

Station Configuration

1) Select 3. Stations, then press .

2) Select 9. Create manual station, then press .

3) The VALIDATE screen will display. Select OK,

then press

4) The Manual Station 1 screen will display. Select

Connected to parcels, then press .

5) The VALIDATE screen will display. Select OK,

then press .

6) The Connected Parcels screen will display. The

option for Wire CH0 will be highlighted. Press

to change it to LOOP, then press .

7) Press once to return to the Manual Station

screen.

X

.

13) Press once. The Start Zones screen will

display. Scroll down to Create new start zone,

then press .

14) The VALIDATE screen will display, select OK, then

press .

15) The Start Zones screen will display.

For the Coming from parcel option, DEFAULT is

correct.

For the Direction option, CW is correct.

Set the Distance Min. value.

Set the Distance Max. value.

Set the Angle Min. value (between 0° - 180°).

Set the Angle Max. value (between 0° - 180°).

16) Scroll to Edit Percentage, then press .

17) The Edit Percentage screen will display. Set the

Start Zone 2 values to 80%. Set the Start Zone 3

value to 20%. Select CONFIRM, then press .

X

8) Select Station inside parcel’s wire. Press if

the charging station is inside of the station loop

wire.

9) Press twice to return to the INFRASTRUC-

TURE screen.

10) Press twice, the Waiting for new mission

screen will display.

11) Press once, the SERVICE SETTINGS screen

will display. Select 3. Operations, then press .

12) The OPERATIONS screen will display. Select Edit

parcels percentage, then press .

13) The PARCELS PERCENTAGE screen will display.

Select the numeric option next to LOOP, set the

number to O. Select the numeric option next to

FIELD, set the number to100. Select CONFIRM,

then press .

X

X

18) The START ZONE screen will display. Press

four times to return to the INFRASTRUCTURE

screen.

X

25

Page 30

USING THE ROBOT

DRAFT 05-23-2019

SAFETY MEASURES

7 Using the Robot

PERSONAL INJURY HAZARD

Contact with the robot during operation can cause

personal injury.

• Press the STOP button before handling the robot.

The operator or user is responsible for accidents or

hazards occurring to other people or their property.

Safety and information symbols are located on the back

of the robot. Follow and understand all Safety and

Information Symbols before using the robot.

Maintain and service the robot on a regular basis.

7.1 Safety Measures

• Remove all non-stationary obstacles from the

area to be mowed before using the robot.

• Never leave the robot on a slope.

• Only use the robot charging station to charge the

robot’s battery. Use of any other charger can

cause damage and loss of warranty coverage.

• Never connect an external electrical element to

the battery cable.

• Never pick up or carry the robot while the motor

is running.

• Do not leave the robot to operate unattended if

there are pets, children or people in the vicinity.

• Never operate the robot if it has defective guards

or shields, or without safety devices.

• Avoid using the robot in bad weather conditions

especially when there is a risk of lightning or

flooding.

7.2 The LCD Screen

1 3 2 4 5

6

7

1 – Name - The name of the robot.

2 – WiFi / Mobile connection - Indicates the robot is connected as

a WiFi client. When blinking, it is trying to connect. When steady,

it is connected.

3 – WiFi access point - Indicates the robot is connected.

4 – GPS - Indicates the robot can detect at least four satellites and

that it knows its current location. If blinking, it indicates the robot

can not detect enough satellites.

5 – Battery charge level - Percentage of battery charge.

6 – Message - Shows the current status of the robot (also displays

error messages).

7 – Time and date (24-hour clock only).

7.3 The Actions Menu

The operations provided in this menu depend on the

current state of the robot when it is in the field and in

the charging station.

7.3.1 Operation In the Field

Perform these operations when the robot is stopped

and not in the charging station.

These operations would be performed if the robot has

been stopped during its normal operation schedule, or

if it has stopped because an alarm has been raised. If an

alarm has been raised, correct the problem before

executing the operations.

Go charge

Return to the charging station, charge the battery and

then resume mowing.

Charge & stay

Return to the charging station and stay there until it a

new instruction is issued.

Mow

Continue the mowing schedule after an interruption.

To execute the operations:

26

Page 31

USING THE ROBOT

DRAFT 05-23-2019

THE SETTINGS MENU

NOTE: If the STOP button cover is not closed withing 10

seconds, the operation is canceled and will need to be

repeated.

1) Open the STOP button lid.

2) Press .

3) Press or to highlight the required

command, then press .

4) Close the STOP button cover.

7.3.2 Operation In the Charging Station

Perform these operations when the robot is in the

charging station.

Use these operations to override the regular operating

schedule.

Mow now

Leave the charging station and continue mowing.

Mow after charge

Remain in the charging station until the battery is

charged and then start mowing.

Stay in station after charge

Stay in the charging station until a new command is

issued.

Mow now on...

Leave the charging station and continue mowing in a

specific parcel. A list of parcel appears in which you can

choose the required one.

7.4 The Settings Menu

Use the options in this menu to control the operation

of the robot.

7.4.1 Schedule

NOTE: The schedule is based on a 24-hour clock.

Use this command to:

• Define the weekly mowing schedule.

• Define a schedule for each day of the week.

• Define mowing periods for each day and each

parcel. Each defined period can be active (implemented) or inactive (ignored).

• Copy a schedule for one day, and for one parcel,

to other days of the week.

• Set the robot to work at all times (which is a

default factory setting).

To define a mowing schedule:

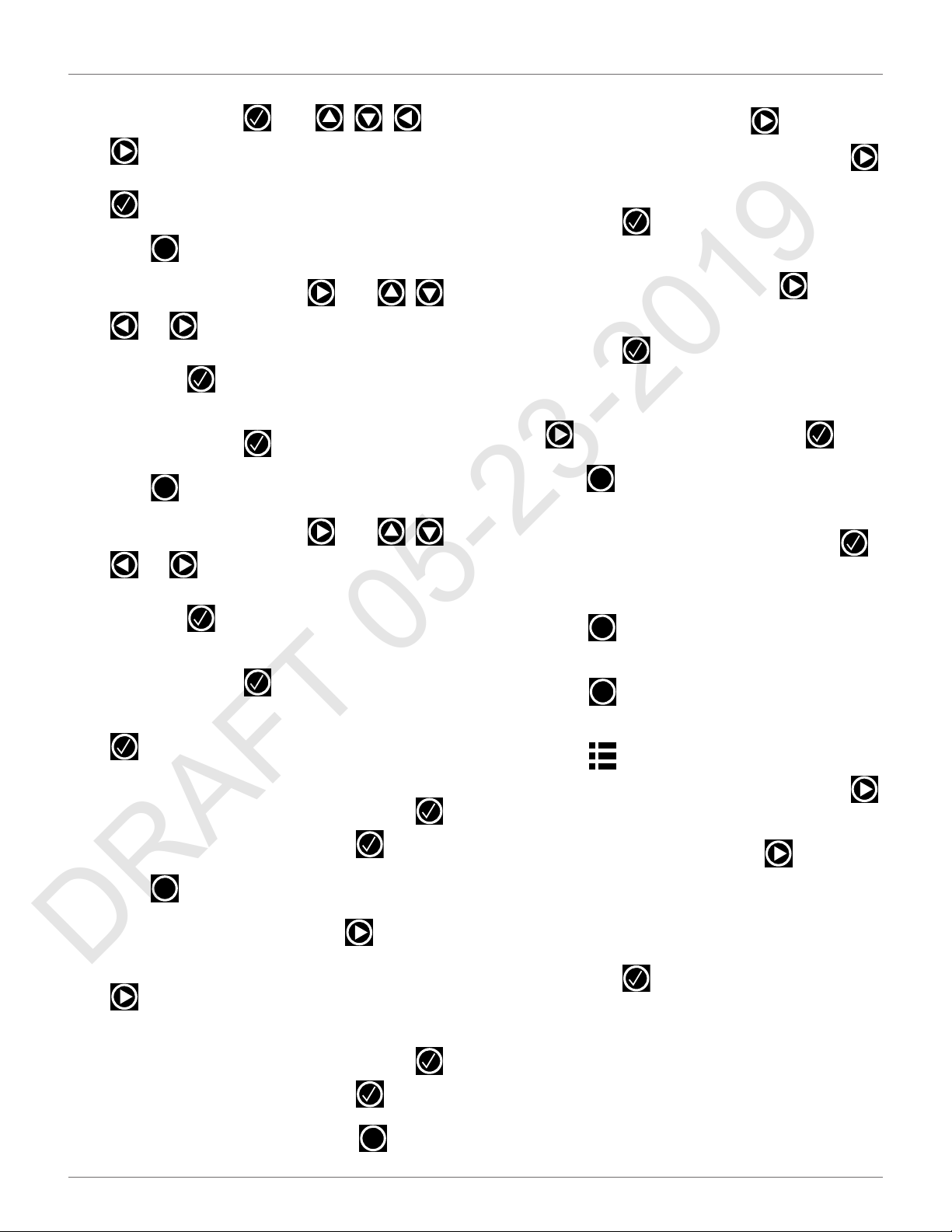

1) Press .

2) Press or to highlight Schedule, then

press . The following screen will appear.

There are two columns for each day because

there are two parcels that have been defined.

This screen shows the current schedule, where

the white blocks represent the time when the

robot will be operating in one parcel. By default,

all the time periods will appear white, meaning

the robot will work continuously.

To execute the operations:

1) Open the STOP button cover.

2) Press .

3) Press or to highlight the required

command, then press .

4) Close the STOP button cover. If the STOP button

cover is not closed within 10 seconds, the operation is canceled and will need to be repeated.

27

Page 32

USING THE ROBOT

DRAFT 05-23-2019

THE SETTINGS MENU

3) Use , , , or to highlight Edit, then

press . The following screen appears:

4) To edit the schedule, highlight the parcel, then

press .

5) Use and to select the required day of

the week, then press .

8) Press to select the active check box, then

press to activate the defined session.

NOTE: In the figure above, Period 1 is active, Period 2 is inactive.

9) Repeat the process for all days and time periods

required. note: The defined schedule can be

copied to another day.

10) Press to return to the “Parcel Schedule”

screen.

11) Use the arrows to select Follow sched. Press

to check the button ON to ensure that the robot

follows the defined schedule. When unchecked,

the robot will ignore the timetable and work

continuously.

To copy the schedule from one day to another:

1) Follow the procedure above to define the

mowing schedule for one day.

2) When all the required periods have been

X

6) Use to select the required period in the day,

then press .

defined, press to highlight Copy, then press

. The following screen will appear:

3) Press the number key that corresponds to the

day to which the schedule is to be copied (more

than one day can be selected).

7) Use the numeric keyboard to enter the start and

end time values where the cursor is flashing,

then press .

28

Page 33

USING THE ROBOT

DRAFT 05-23-2019

THE SETTINGS MENU

4) Press .

5) Highlight Edit.

6) Press .

7) Use the arrow keys to highlight Follow sched.

then press to uncheck the button.

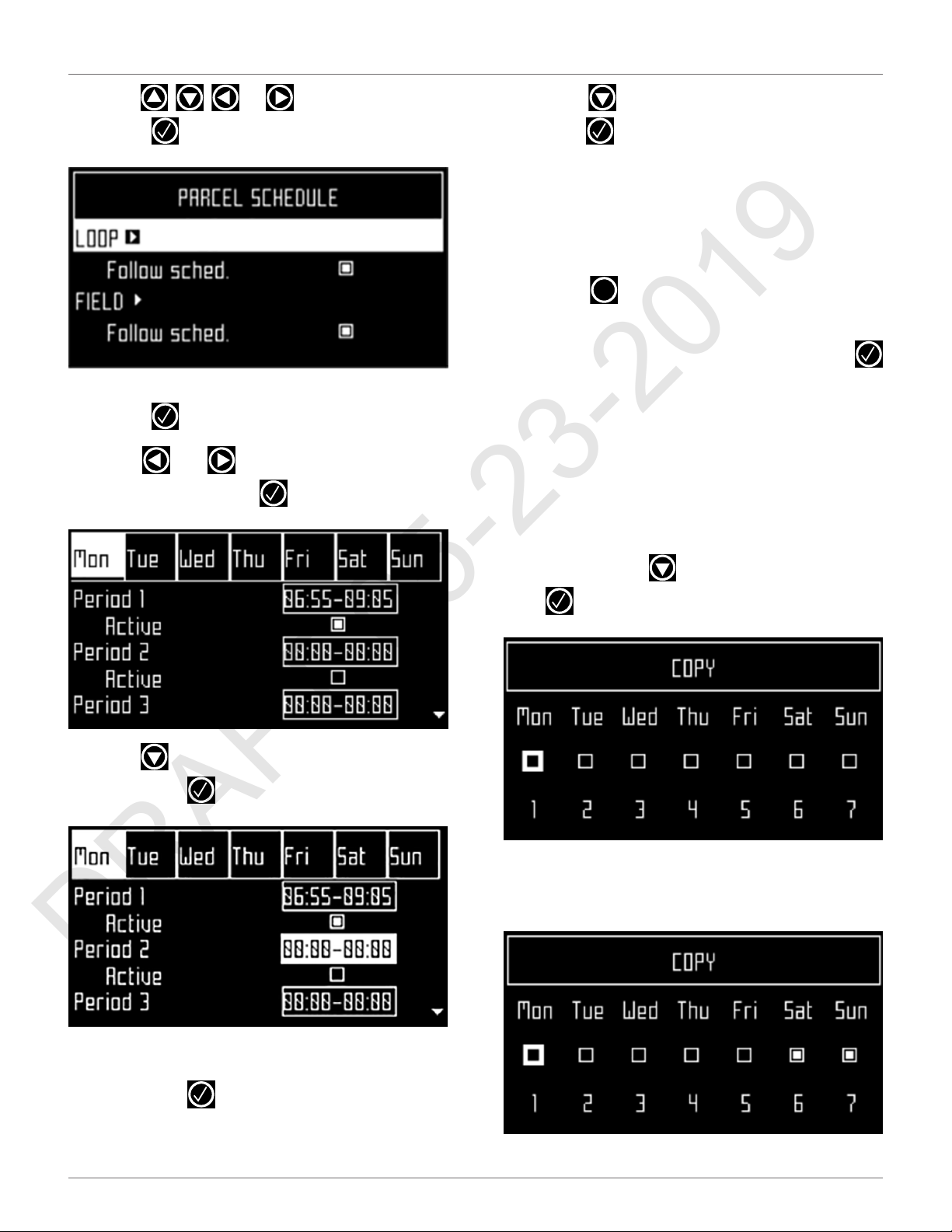

7.4.2 Cutting Heads

The robot is supplied with five cutting heads which,

under normal conditions, should all be used. When

there is a problem with a cutting head, use this menu

to disable it.

To enable or disable specific cutting heads:

1) Press .

2) Press or to highlight Cutting heads, then

press . The following screen appears:

To set the cutting height:

1) Press .

2) Press or to highlight Cutting height,

then press . The following screen appears,

which shows the current cutting height. NOTE: If

this value is negative, a reset of the parameters

has taken place and the cutting height needs to

be re-calibrated.

3) Press to highlight the Set value.

4) Use and to scroll to the required value.

3) Press the number key(s) that corresponds to the

cutting head(s) to enable or disable it. NOTE:

Press 0 on the numeric keypad to select all

cutting heads.

4) Press .

5) Press to return to the main menu.

To enable a disabled cutting head, repeat the procedure above, selecting the disabled head.

X

7.4.3 Cutting Height

Use this command to set the height of the blades.

• lowest cutting height is 0.8 in. (20.0 mm)

• highest cutting height is 4.7 in. (120.0 mm)

The cutting height is adjusted in 0.20 in. (5.0 mm) increments.

5) Press to return to the main menu.

7.4.4 System Locking

Use this command to lock the use of the robot. The

command is useful if the field area is in use during the

time when the robot is scheduled to be mowing. The

robot will remain locked until the system is unlocked.

NOTE: It is also possible to create PIN code which must

be entered before specific commands can be issued.

To lock the system:

1) Press .

2) Press or to highlight System locking,

then press .

3) Highlight OK, then press . The following

screen will appear. Enter the robot’s PIN code to

access the menu again.

X

29

Page 34

USING THE ROBOT

DRAFT 05-23-2019

SERVICE MENU

To unlock the system:

1) Enter the PIN code, then press . The robot will

wait for a new command to be issued.

7.4.5 LCD Settings

To modify the LCD settings:

1) Press and hold for three seconds. The LCD

Setting screen will appear.

2) Press or to change the contrast.

3) Press or to highlight Temperature Auto

Adj. When this option is checked ON, the LCD

contrast is automatically adjusted according to

3) Use and to scroll to the required time

zone.

4) Press to accept the time zone.

5) Press to exit the menu.

To set the language:

1) Press .

2) Press the arrow keys to highlight Regional

parameters, then press .

3) Press to highlight Language.

X

the ambient temperature. Press to check or

uncheck this option.

4) Press the 9 key to invert the black and white

colors.

5) Press the 0 key to revert to the factory settings.

6) Press to exit the menu.

X

7.5 Service Menu

7.5.1 Regional Parameters

Use this menu to set the robot time zone and the

language.

To set the time zone:

1) Press .

2) Press the arrow keys to highlight Regional

parameters, then press .

4) Press .

5) Use and to highlight the required

language.

6) Press to accept the language.

7) Press to exit the menu.

X

7.5.2 Connections

To display the connections screen:

1) Press .

2) The Connections screen will display. Use the

arrow keypad to select an option.

IP address

Select to display the current IP address of the robot,

depending on the mode on which it is operating.

Modes can be mobile, vpn, or WiFi.

Mode

30

Select to set the mode in which the robot is to operate.

Mode selections are:

Page 35

USING THE ROBOT

DRAFT 05-23-2019

SERVICE MENU

• OFF - The robot will not be connected to a

network.

• Client - The robot will connect to the selected

network as a client.

• Access point - The robot will use its inbuilt

modem to generate its own WiFi network to

which you can connect.

Search for networks

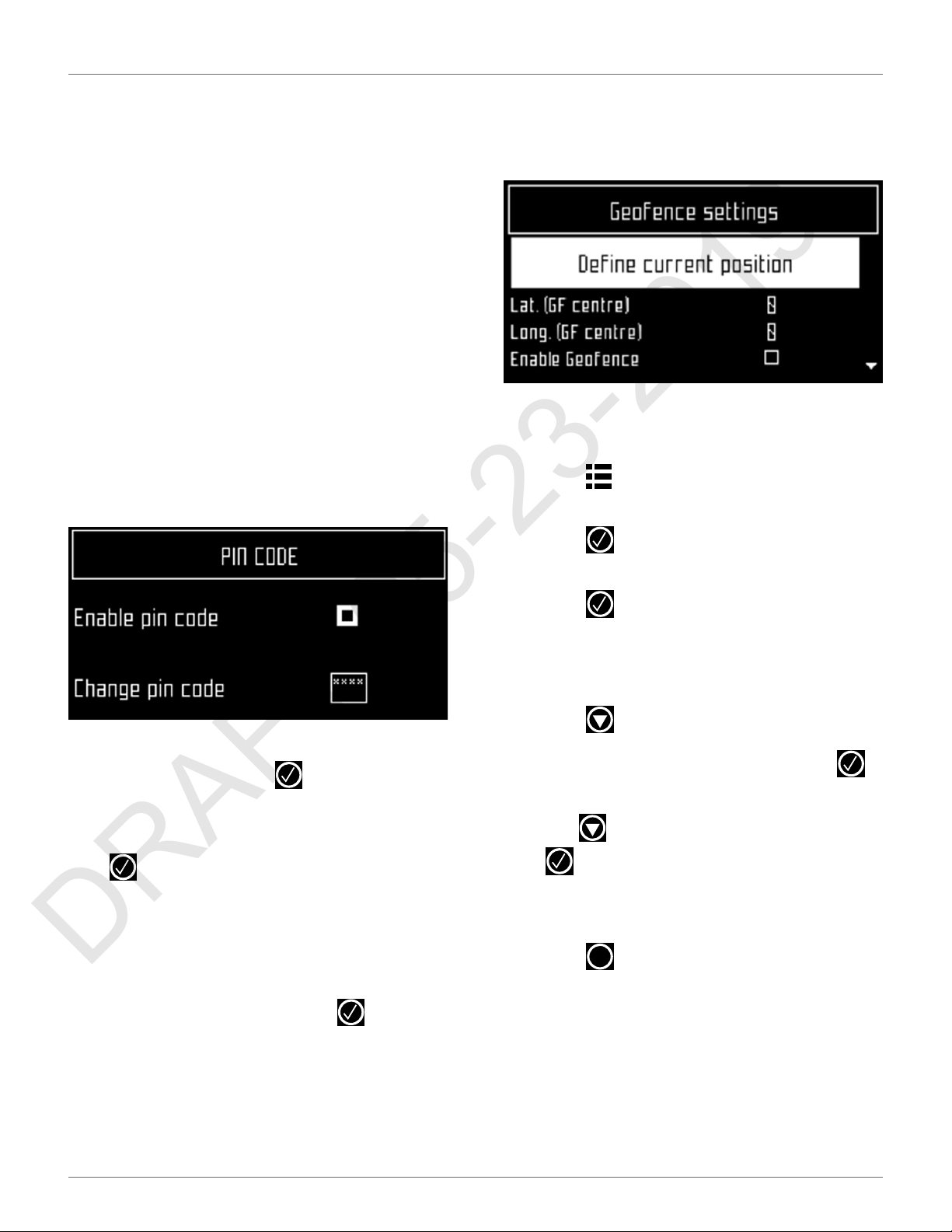

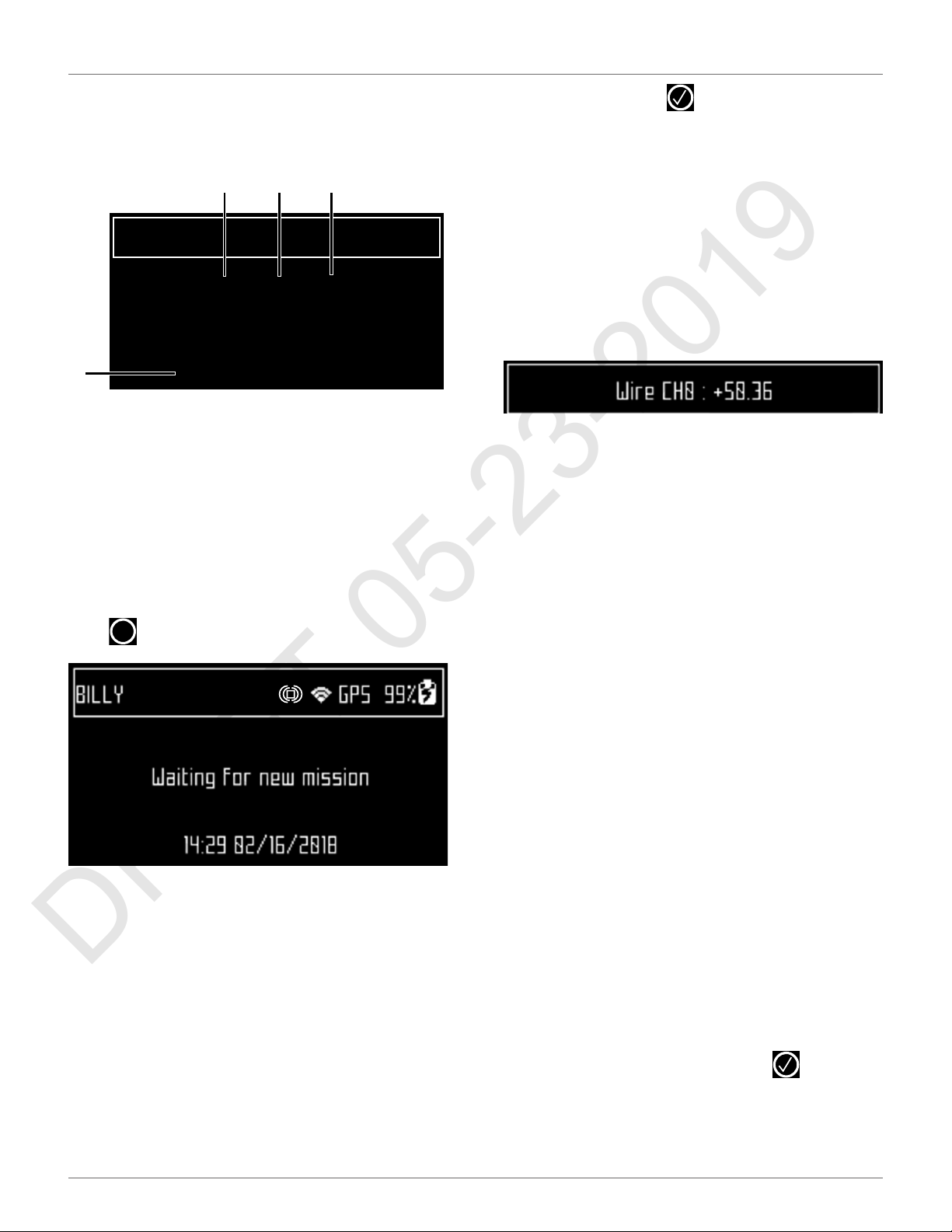

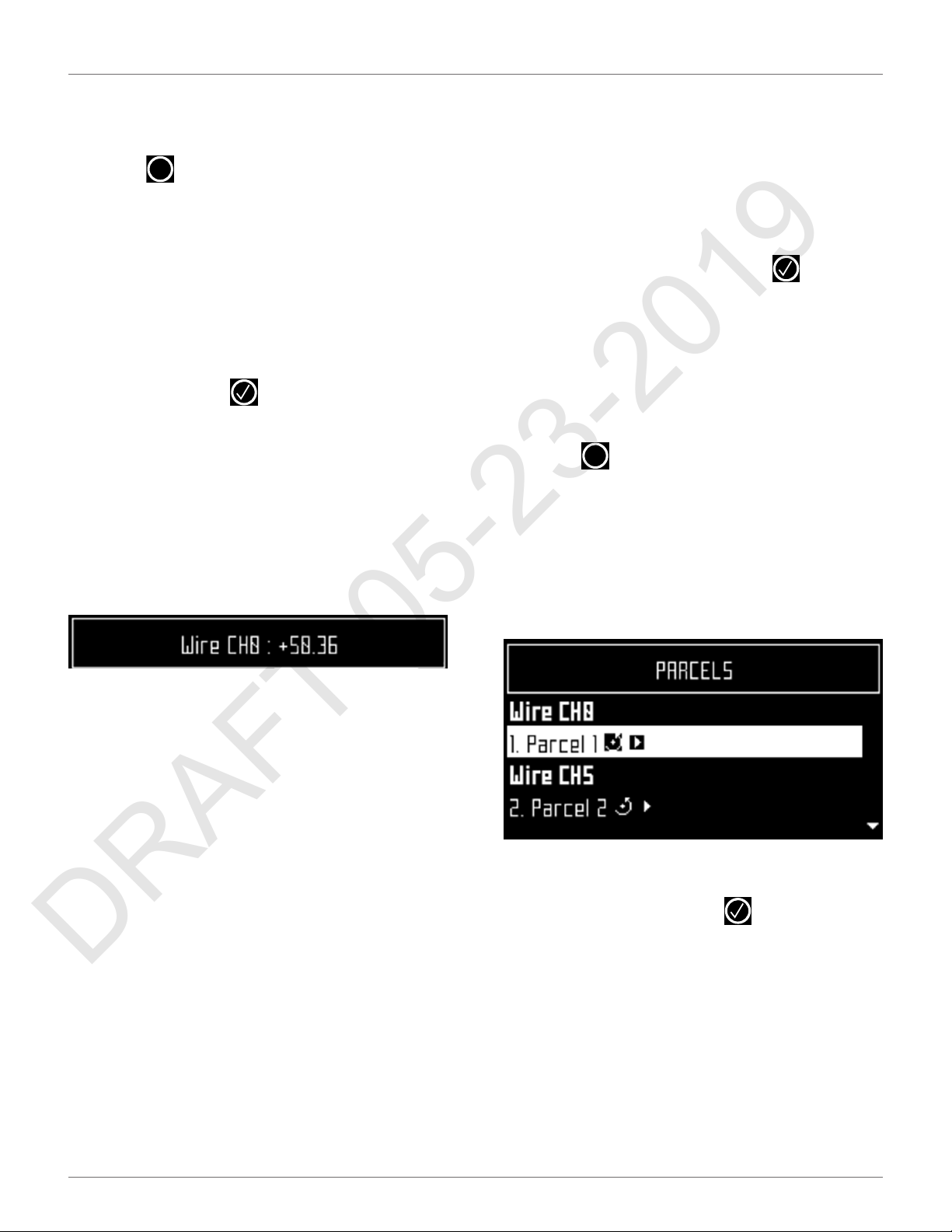

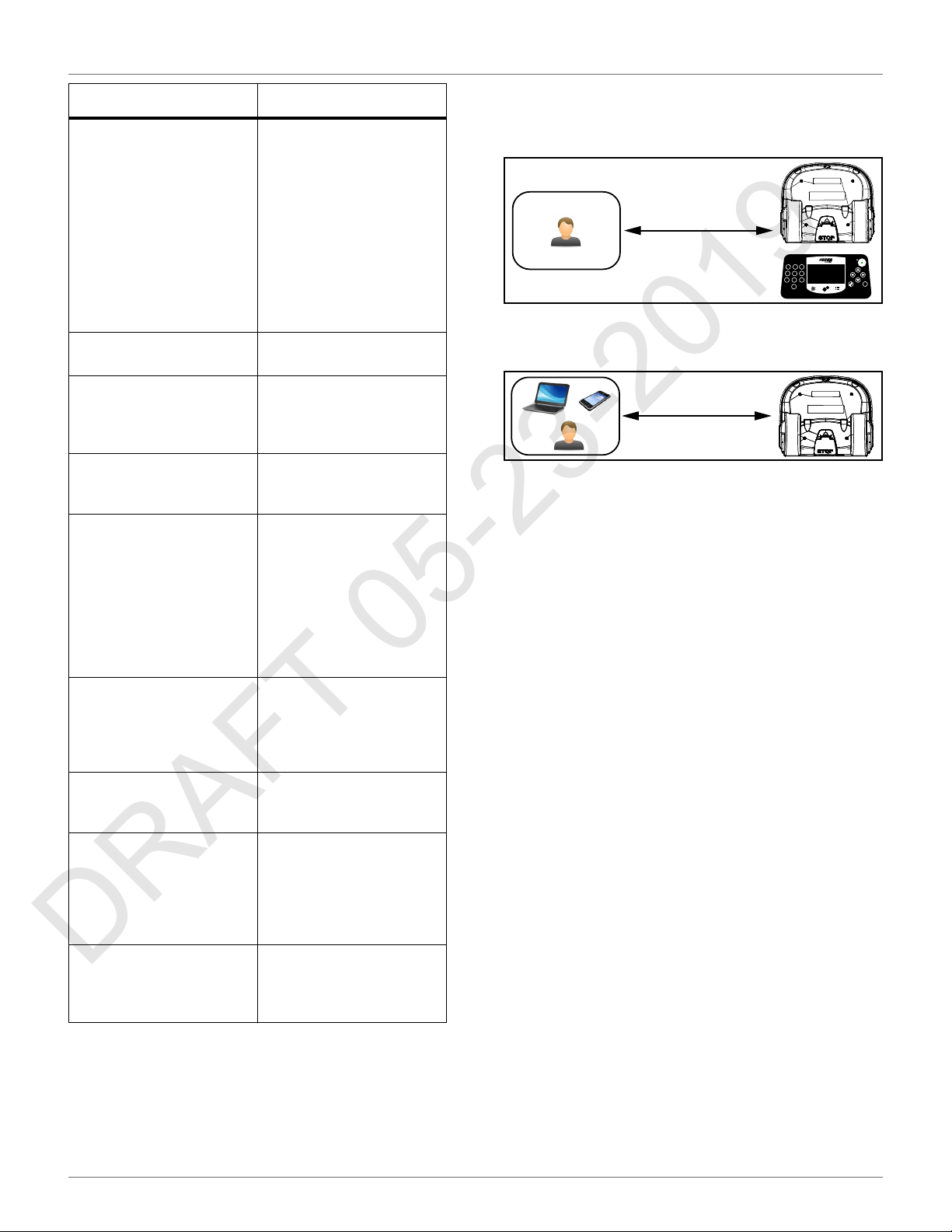

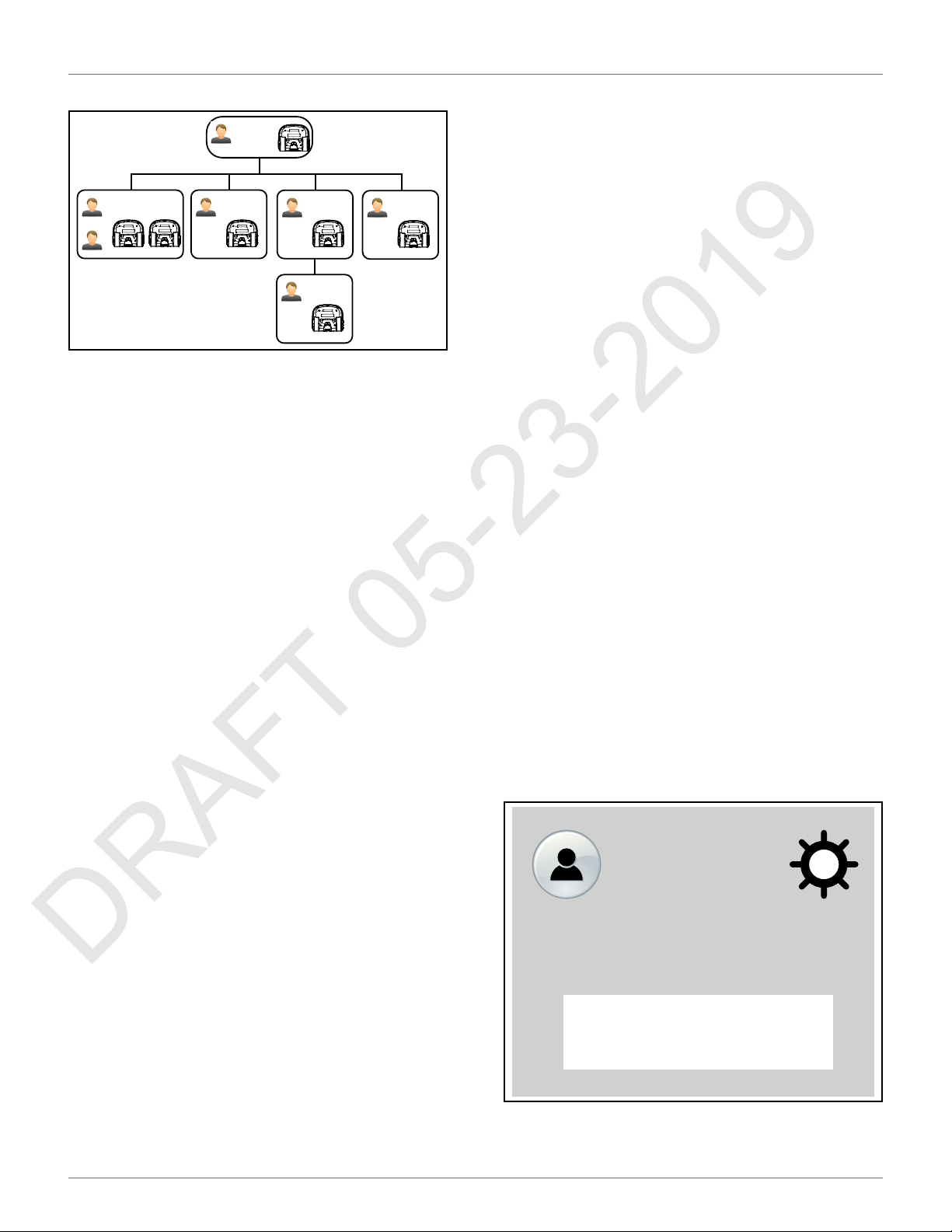

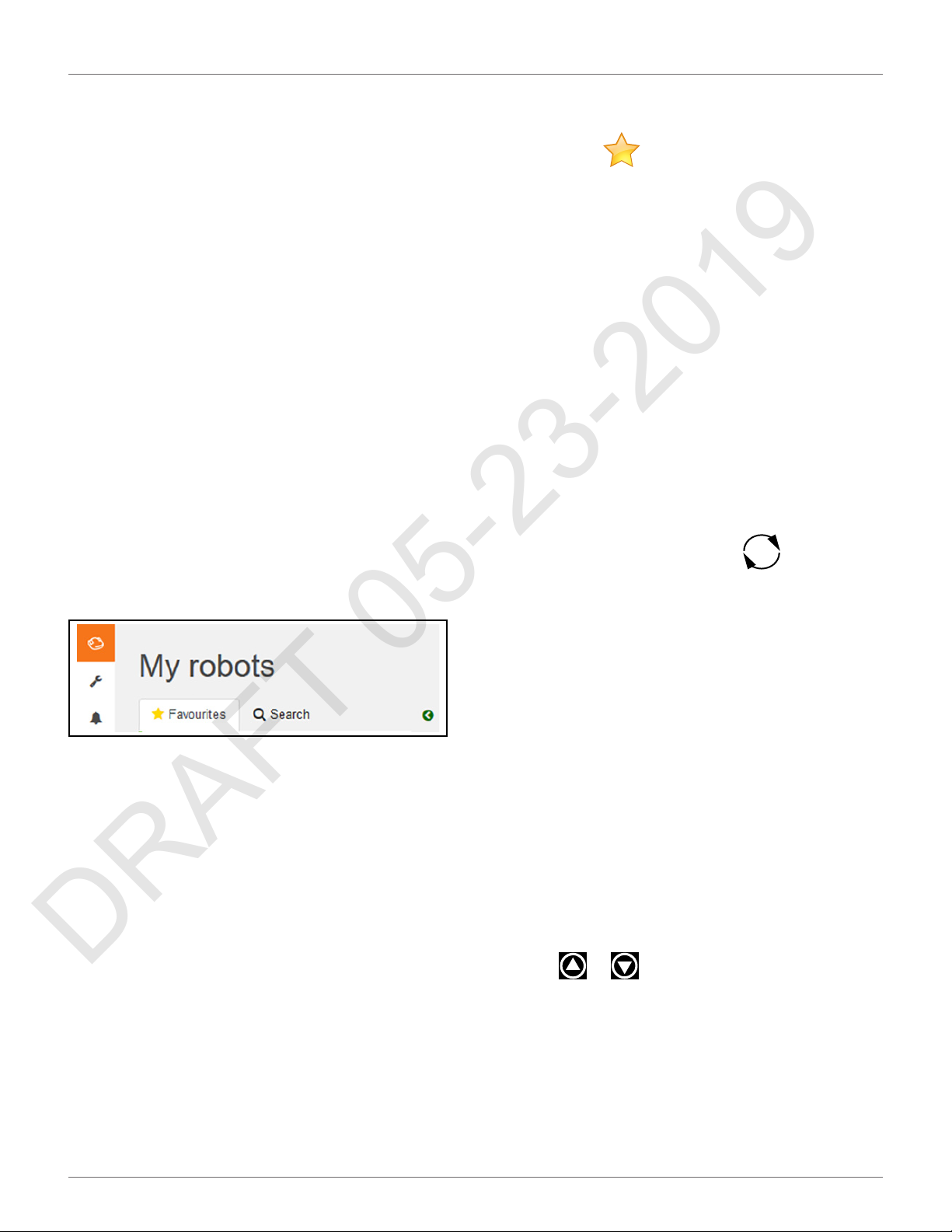

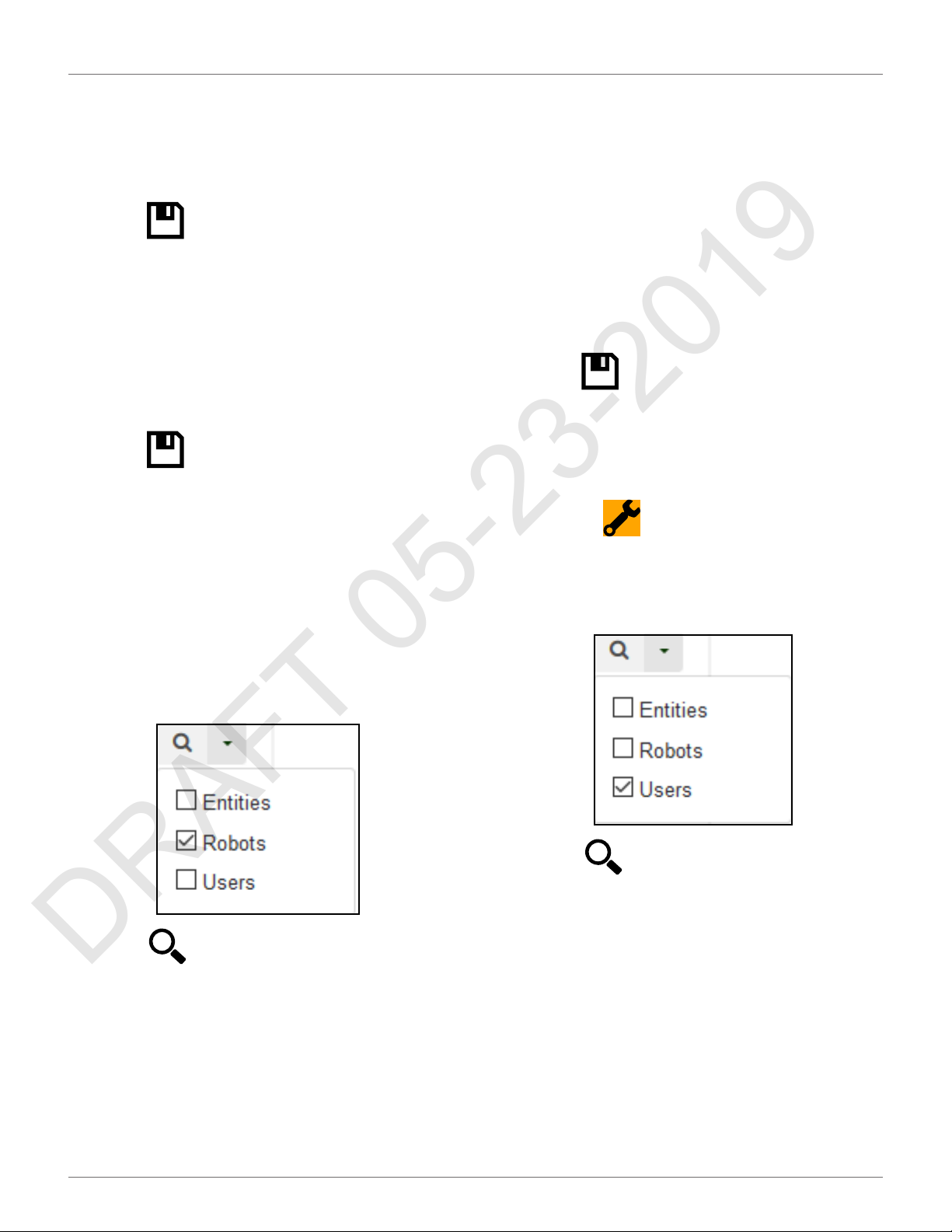

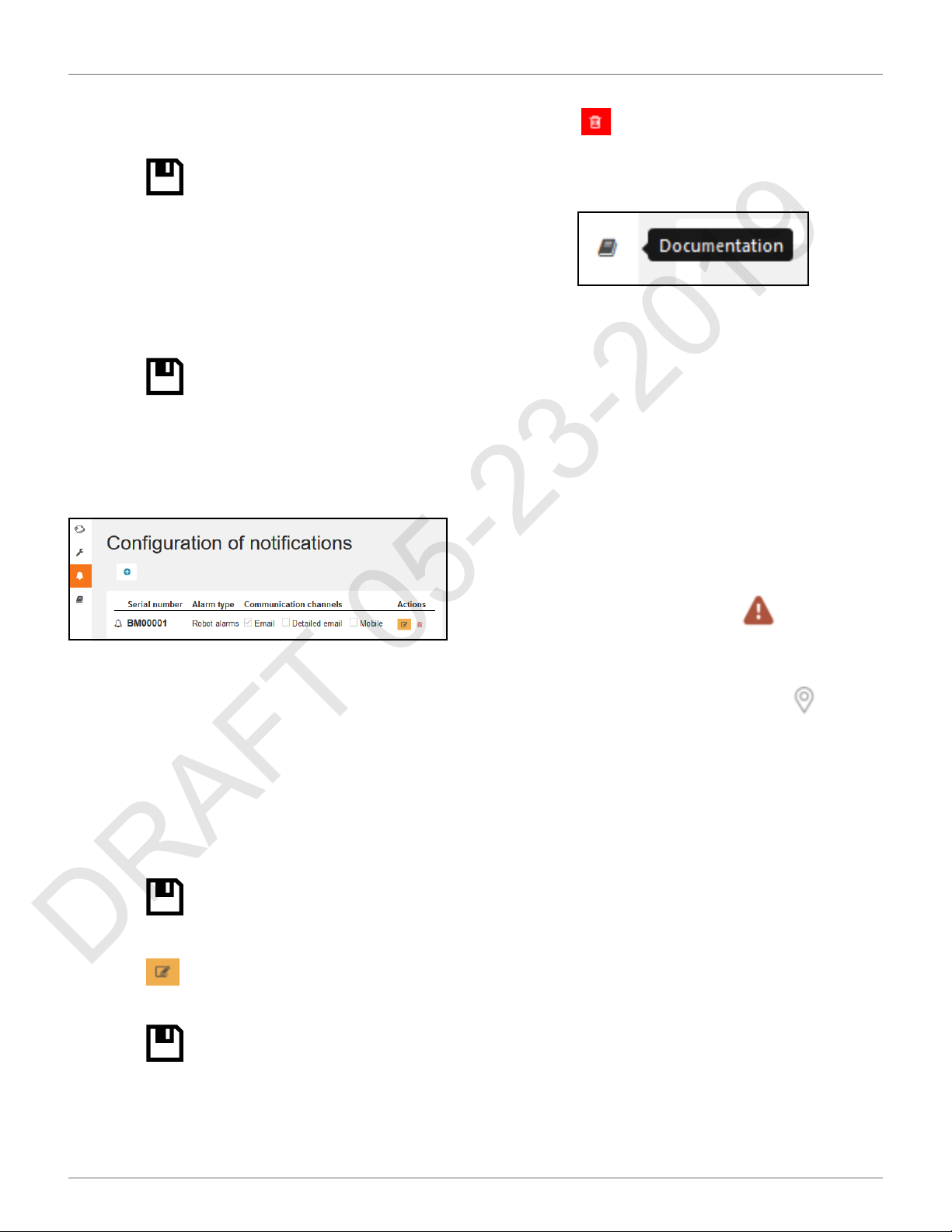

This option appears when the robot is not connected or