Page 1

1

INTRODUCTION

We are constantly working on technical

improvement of our products. For this reason,

technical data, equipment and design are subject to

change without notice. All specifications,

illustrations and directions in this SERVICE DATA

are based on the latest products information

available at the time of publication.

For further information to service these models,

please refer to ECHO SERVICE MANUAL Ord. No.

402-21.

TRIMMER/BRUSHCUTTER

SRM-3805

SRM-4605

Reference No. 10-37A-00

ISSUED: 199807

SERVICE DATA

1

10-37A-00 SRM-3805, SRM-4605

CONTENTS

page

1 SERVICE INFORMATION ............................. 2

1-1 Specifications ............................................ 2

1-2 Technical data ........................................... 3

1-3 Torque limits .............................................. 4

1-4 Special repairing materials ....................... 4

1-5 Service limits ............................................. 5

1-6 Special tools ............................................. 6

2 SERVICE HINT ............................................. 7

2-1 Gear case construction ............................. 7

INDEX

Page 2

2

SERVICE INFORMATION

SRM-3805

SRM-4605

1 SERVICE INFORMATION

1-1 Specifications

OD: Outer diameter.

ID: Inner diameter.

*Without shoulder harness and cutter head.

**With standard cutter head.

***Install and use U-shaped handle when operating with steel blade.

Model

SRM-3805 (L) SRM-3805 (U) SRM-4605(L) SRM-4605(U)

Dimensions Length* mm(in) 1820 (71.7) 1820 (71.7) 1820 (71.7) 1820 (71.7)

Width mm(in) 360 (14.2) 720 (28.3) 360 (14.2) 720 (28.3)

Height mm(in) 350 (13.8) 455 (17.9) 350 (13.8) 455 (17.9)

Dry weight

**

kg(lb) 8.1 (17.9) 8.7 (19.2) 8.1 (17.9) 8.7 (19.2)

Engine Type KIORITZ, air-cooled, two-stroke, single cylinder

Rotation Counterclockwise as viewed from the output end

Displacement cm

3

(in3) 37.4 (2.284) 45.7 (2.790)

Bore mm(in) 38.0 (1.496) 42.0 (1.654)

Stroke mm(in) 33.0 (1.299) 33.0 (1.299)

Compression ratio 6.3 6.6

Carburetor Type Diaphragm, horizontal-draught

with primer without primer

Model WALBRO WT-297 WALBRO WT-120B

Venturi size-Throttle bore mm(in) 11.11 - 15.85 (0.437 - 0.624) 12.7 - 15.85 (1/2 - 0.624)

Ignition Type Capacitor discharge ignition system

in a single integrated piece

Spark plug Champion RCJ-7Y

Starter Type Automatic rewind

Rope diameter x length mm(in) 3.8 x 950 (0.15 x 37.4)

Fuel Type Premixed two-stroke fuel (Refer to Operator's manual.)

Tank capacity cm

3

(U.S.fl.oz.) 950 (32.1)

Clutch Type Centrifugal, 2-shoe pivot

Handle Type Front Crescent loop U-shaped Crescent loop U-shaped

Rear Integrated --- Integrated ---

control grip control grip

Drive shaft Type Solid

Diameter - Length mm(in) 8 - 1590 (0.31 - 62.6)

Housing OD - ID mm(in) 28 - 24.0 (1.10 - 0.94)

(Main pipe)

Length mm(in) 1530 (60.2)

Gear case Reduction ratio 1.33

Gear tooth Spiral bevel gear

Lubrication Lithium based grease

Cutter Type Nylon line cutter, 8-tooth blade***, 80-tooth blade***, Others

Pilot diameter mm(in) 25.4 (1.0)

Fastener type, size mm Left-hand thread nut, M10 x 1.25 pitch

Cutting rotation Counterclockwise as viewed from top

Page 3

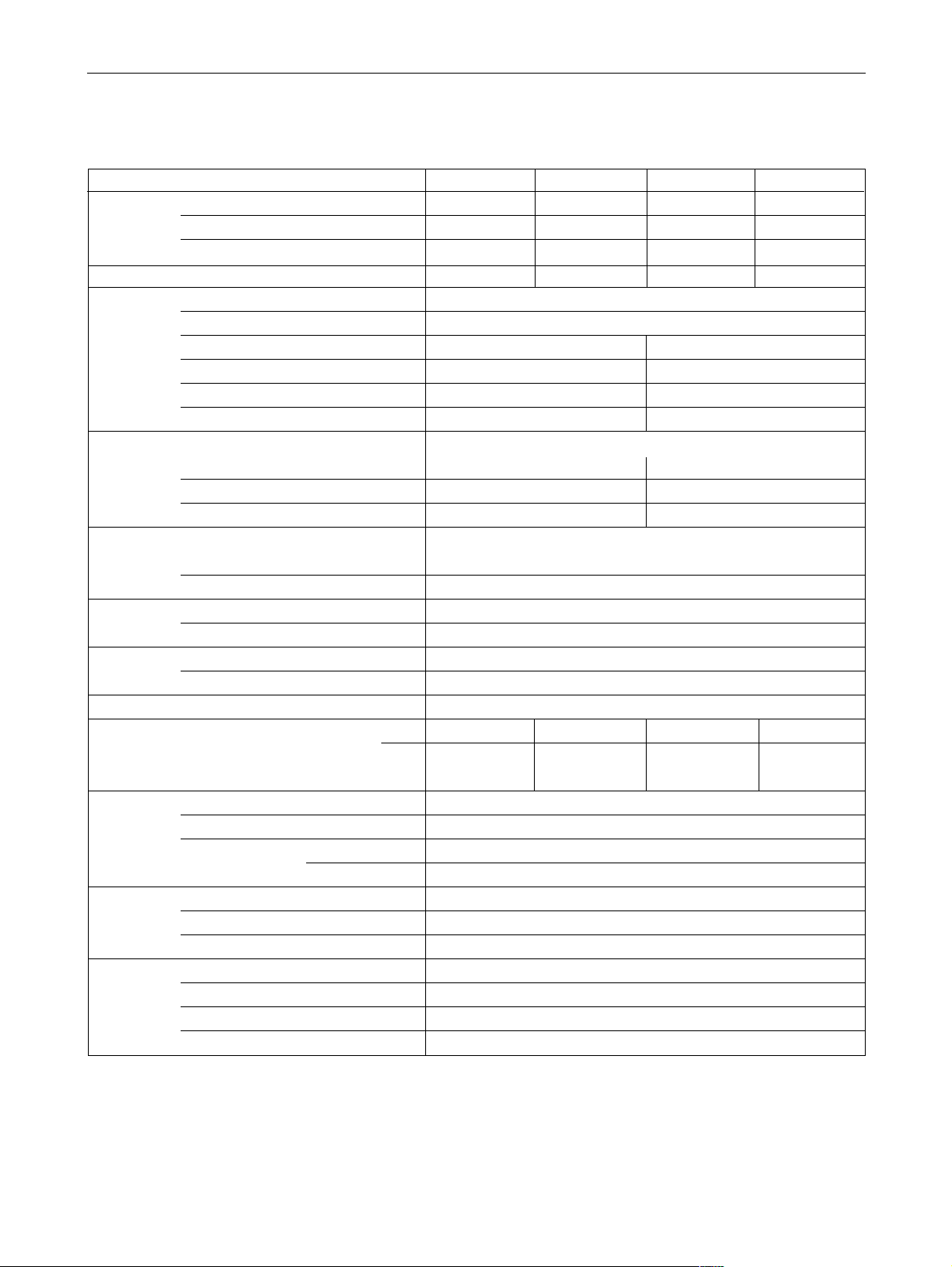

1-2 Technical data

Model SRM-3805 SRM-4605

Engine

Idling speed rpm 2400 - 3000

Operating speed rpm 6000 - 8000

Clutch-in speed rpm 3300 - 3700

Compression pressure, standard kgf/cm

2

(psi) 7.5 (107) 8.0 (114)

Ignition system

Spark plug gap mm(in) 0.6 - 0.7 (0.024 - 0.028)

Minimum secondary voltage

at 1000 rpm

kV 15

Secondary coil resistance kΩ 1.0 - 1.5

Pole shoe air gaps mm(in) 0.3 - 0.4 (0.012 - 0.016)

Ignition timing °BTDC 25

Carburetor

Type Diaphragm horizontal-draught

Supplier Walbro WT-297 Walbro WT-120B

Venturi Size mm(in) 11.11 (0.437) 12.7 (1/2)

Throttle Bore mm(in) 15.85 (0.624) 15.85 (0.624)

Idle speed screw initial setting

turn in

22

H needle initial setting turn back 1 1/2 1 1/4

L needle initial setting turn back 1 1

Test Pressure, minimum kgf/cm

2

(psi) 0.5 (7.0)

Metering lever height mm(in) 1.65 (0.065) lower than diaphragm seat

BTDC: Before top dead center.

H needle: High speed needle.

L needle: Idle needle.

3

SERVICE INFORMATION

SRM-3805

SRM-4605

Page 4

1-3 Torque limits

Descriptions Size kgf•cm in•lbf

Starter Pawl carrier M 8 80 - 100 70 - 85

system Pawl carrier nut M 8 160 - 200 140 - 175

Starter center post M 5 * 25 - 35 22 - 30

Starter case M 4 35 - 50 30 - 45

Ignition Magneto rotor (Flywheel) M10 350 - 400 300 - 350

system Ignition coil (CDI module) M 5 30 - 50 26 - 45

Fan cover M 5 70 - 110 60 - 95

Spark plug M14 130 - 170 110 - 150

Fuel Carburetor insulator M 5 40 - 55 35 - 50

system Carburetor (SRM-3805) M 5 30 - 45 25 - 40

Carburetor (SRM-4605) M 5 35 - 45 30 - 40

Throttle cable nut M 6 25 - 35 22 - 30

Fuel tank bracket , Stand M 5 30 - 45 26 - 40

Clutch Clutch shoe M 8 * 160 - 200 140 - 175

Clutch drum case M 5 70 - 100 60 - 95

Engine Crankcase M 5 70 - 110 60 - 95

Cylinder M 5 70 - 110 60 - 95

Cylinder cover M 5 30 - 45 26 - 40

Top guard M 5 30 - 45 26 - 40

Muffler M 5 60 - 100 52 - 85

Muffler bracket M 5 30 - 45 25 - 40

Muffler cover M 4 14 - 28 12 - 24

Muffler cover (with starter case) M 4 35 - 50 30 - 45

Others Blade fastening nut LM10 280 - 320 245 - 280

Regular bolt, nut, and screw M 3 6 - 10 5 - 9

M 4 15 - 25 13 - 22

M 5 25 - 45 22 - 40

M 6 45 - 75 40 - 65

M 8 110 - 150 95 - 130

M10 210 - 300 180 - 270

LM: Left-hand thread.

* Apply thread locking sealant. (See below.)

Material Location Remarks

Grease Gear case

Rewind spring Lithium based grease

Starter center post

Thread locking sealant Starter center post screw Loctite #222, ThreeBond #1342, or equivalent

Clutch shoe

1-4 Special repairing materials

4

SRM-3805

SRM-4605

SERVICE INFORMATION

Page 5

mm(in)

Description SRM-3805 SRM-4605

A Cylinder bore When plating is worn and aluminum can be seen

B Piston outer diameter Min. 37.90 (1.492) 41.90 (1.65)

C Piston pin bore Max. 10.025 (0.3947) 10.025 (0.3947)

D Piston ring groove Max. 1.3 (0.051) 1.3 (0.051)

E Piston ring side clearance 1st Max. 0.15 (0.006) 0.15 (0.006)

2nd Max. 0.1 (0.004) 0.1 (0.004)

F Piston pin outer diameter Min. 9.98 (0.3929) 9.98 (0.3929)

G Piston ring width Min. 1.15 (0.045) 1.15 (0.045)

H Piston ring end gap Max. 0.5 (0.02) 0.5 (0.02)

K Connecting rod small end bore Max. 14.025 (0.5522) 14.025 (0.5522)

L Crankshaft runout Max. 0.05 (0.002) 0.05 (0.002)

M Clutch drum bore Max. 79.0 (3.11) 79.0 (3.11)

5K223 5K224

5K225 5K016 5K042

5K182 5K222

5K188

0

5

1

23

4

5

6

7

8

5K1895K219 5K220

ABCD

EFGH

KLM

5

SERVICE INFORMATION

SRM-3805

SRM-4605

1-5 Service limits

Page 6

6

SRM-3805

SRM-4605

SERVICE INFORMATION

1-6 Special tools

a

1.5

1

.6

5

1

.3

0.4

c

a

b

1

5

16

2

6

17

3

7

12: c=34 mm

13: c=31 mm

18 20

9

4

8

14

Key Part Number Description Used for:

1 Tachometer Measuring engine speed to adjust carburetor

2 895610-79920 L-hex. wrench(4 mm) Removing and installing hex. socket bolt (M5)

3 897563-19830 Metering lever gauge Measuring metering lever height on carburetor

4 897501-03938 Puller Removing flywheel

5 897603-23030 PTO shaft puller Removing PTO shaft

6 897701-06030 Bearing wedge Removing ball bearings remaining on crankshaft

7 897701-14732 Bearing tool Removing and installing crankcase / clutch drum bearing

8 897702-30131 Piston pin tool Removing and installing piston pin (Use 8 mm dia. adapter)

9 897712-04630 2-pin wrench Removing and installing pawl carrier

10 897714-22830 Oil seal tool Installing drive gear assembly into gear case

11 897714-24330 Oil seal tool Installing drive gear ball bearings

Installing PTO shaft ball bearing

Installing crankcase oil seal (starter side)

12 897718-02830 Bearing tool Installing crankcase ball bearings (clutch side)

13 897718-03930 Bearing tool Installing crankcase ball bearings (starter side)

14 897719-02830 Piston holder Making piston steady to remove and install piston and rings

15 897726-16130 Oil seal tool Installing crankcase oil seal (clutch side)

16 897800-79931 Spark tester Checking ignition system

17 897803-30130 Pressure tester Testing carburetor and crankcase leakages

18 897826-16131 Pressure plug Plugging intake port to test crankcase and cylinder leakages

19 897827-16131 Pressure plate Plugging intake port to test crankcase and cylinder leakages

20 897831-16131 Pressure plug

Plugging exhaust port to test crankcase and cylinder leakages

21 897835-16131 Pressure connector Testing crankcase and cylinder leakages

15

19 21

10:

a = 10 mm

b = 25.5 mm

11:

a = 12 mm

b = 32 mm

Page 7

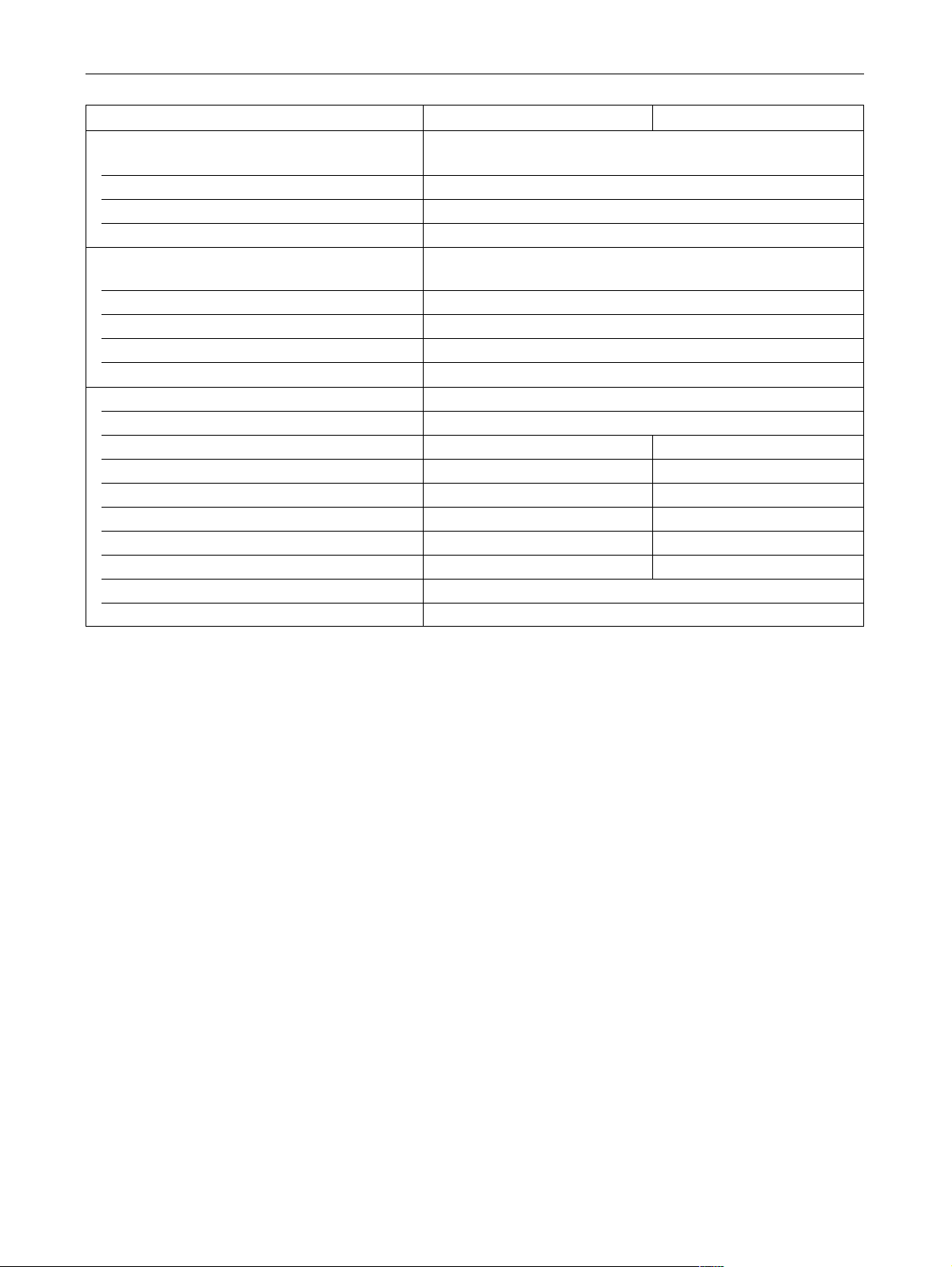

2 SERVICE HINT

2-1 Gear case construction

7

SERVICE INFORMATION

SRM-3805

SRM-4605

Drive gear

Driven gear

PTO shaft

Nut

Adapter plate (L)

Gear case

Adapter plate (U)

Cover plate

Dust seal plate

O-ring

Loading...

Loading...