Page 1

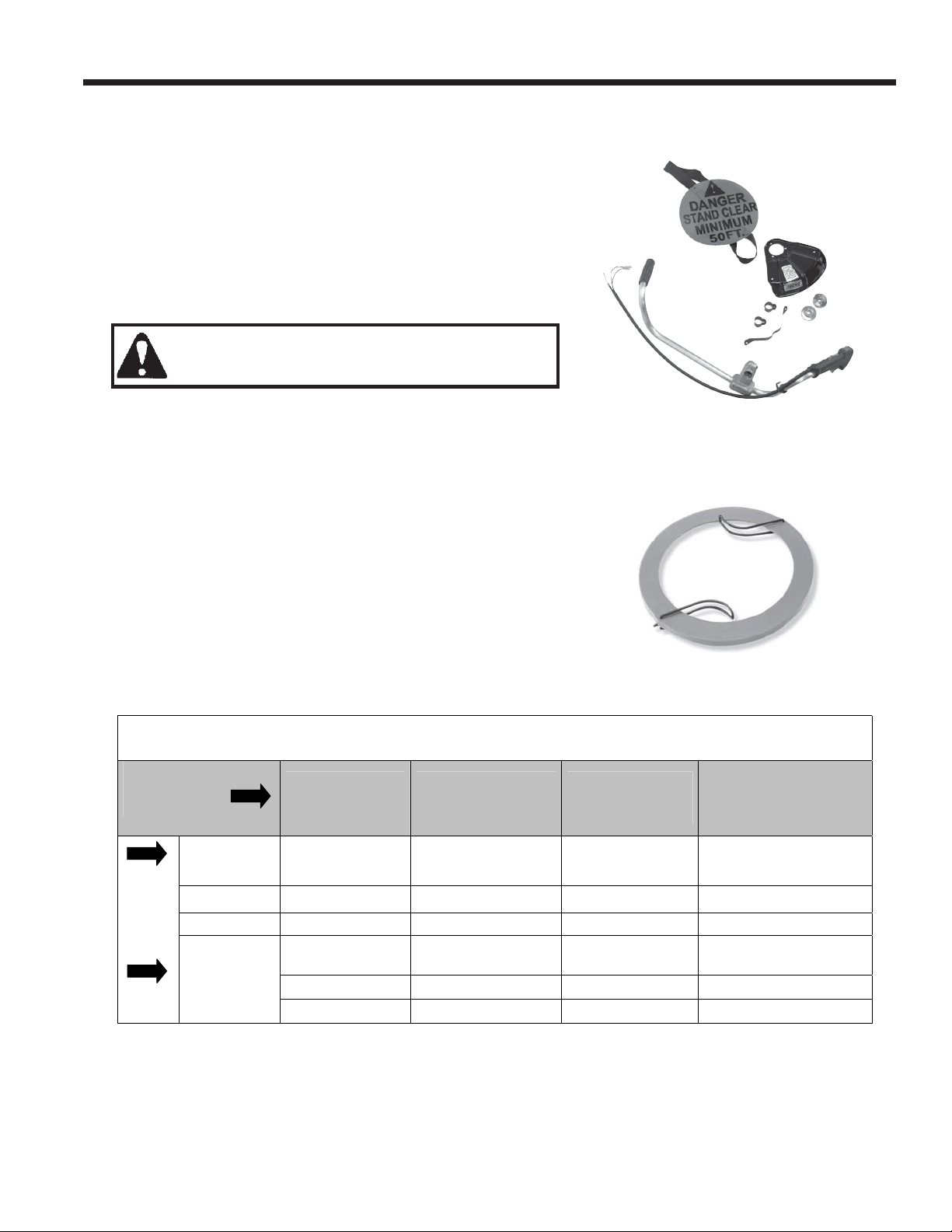

SRM/GT/PAS/SB/PE SAFETY MANUAL

DANGER!

Misuse may result in serious or fatal injuries. You must read, understand, and follow these safety instructions, and the instructions in the

Operator’s Manual, before operating a Model GT Grass Trimmer, SRM

Trimmer-Brushcutter, PAS Pro-Attachment Series Powerhead, SB SplitBoom Trimmer-Brushcutter, or PE Power Edger.

If you operate a model SB Split-Boom or PAS Pro Attachment Series

multi-attachment unit, you must also read, understand, and follow the

instructions in your PAS Attachment Operator’s Manual.

DANGER!

Metal blades are very sharp and can cause severe injuries, even if engine

is off and blades are not moving. Avoid contact with blades. Wear gloves

to protect hands.

To locate your nearest Echo dealer, visit our website at www.echo-usa.com, or call 1-800432-ECHO (3246). Ask how to obtain a FREE Safety Video. Echo’s supplemental Safety

Video provides helpful safety and operating information.

X752000041

X7522270601

09/07

Page 2

INTRODUCTION

W ARNING

This manual describes how to protect yourself and others from hazards related to operation of

a Model GT Grass Trimmer, Model SRM Trimmer-Brushcutter, Model PAS Pro-Attachment

Series unit with attachment, Model SB Split-Boom unit with attachment, and Model PE Power

Edger.

Before assembling, fueling, operating, or servicing your unit, you must read and understand

this Safety Manual, your unit’s Operator’s Manual, and the Operator’s Manual or Installation

Instructions for any attachment or accessory you may be using.

You must understand all safety symbols and warning labels, and obey the safety precautions

provided by these important safety reminders.

You must also be alert at all times, and be physically capable of handling and controlling a

grass trimmer, trimmer-brushcutter, PAS attachment, or Power Edger in a variety of applications. If you are unable to handle the equipment safely, or if you feel that the task you wish to

perform could put you, your property, or others at risk, please call a professional landscape

maintenance company to handle the job.

Echo highly recommends that you obtain and review the supplemental Echo TrimmerBrushcutter Safety Video before using your unit. Contact your Echo dealer for a copy, or for

more information, or call Echo at 1-800-432-ECHO. You may also visit Echo’s website at

www.Echo-USA.com.

TABLE OF CONTENTS

TABLE OF CONTENTS ............................................................................................ 2

SAFETY SYMBOLS AND WARNINGS .....................................................................3

OPERATOR SAFETY................................................................................................7

ASSEMBLY .............................................................................................................12

FUELING .................................................................................................................20

STARTING...............................................................................................................23

STOPPING...............................................................................................................25

OPERATION ............................................................................................................26

MAINTENANCE.......................................................................................................45

STORAGE................................................................................................................47

DEFINITIONS ..........................................................................................................48

2

Page 3

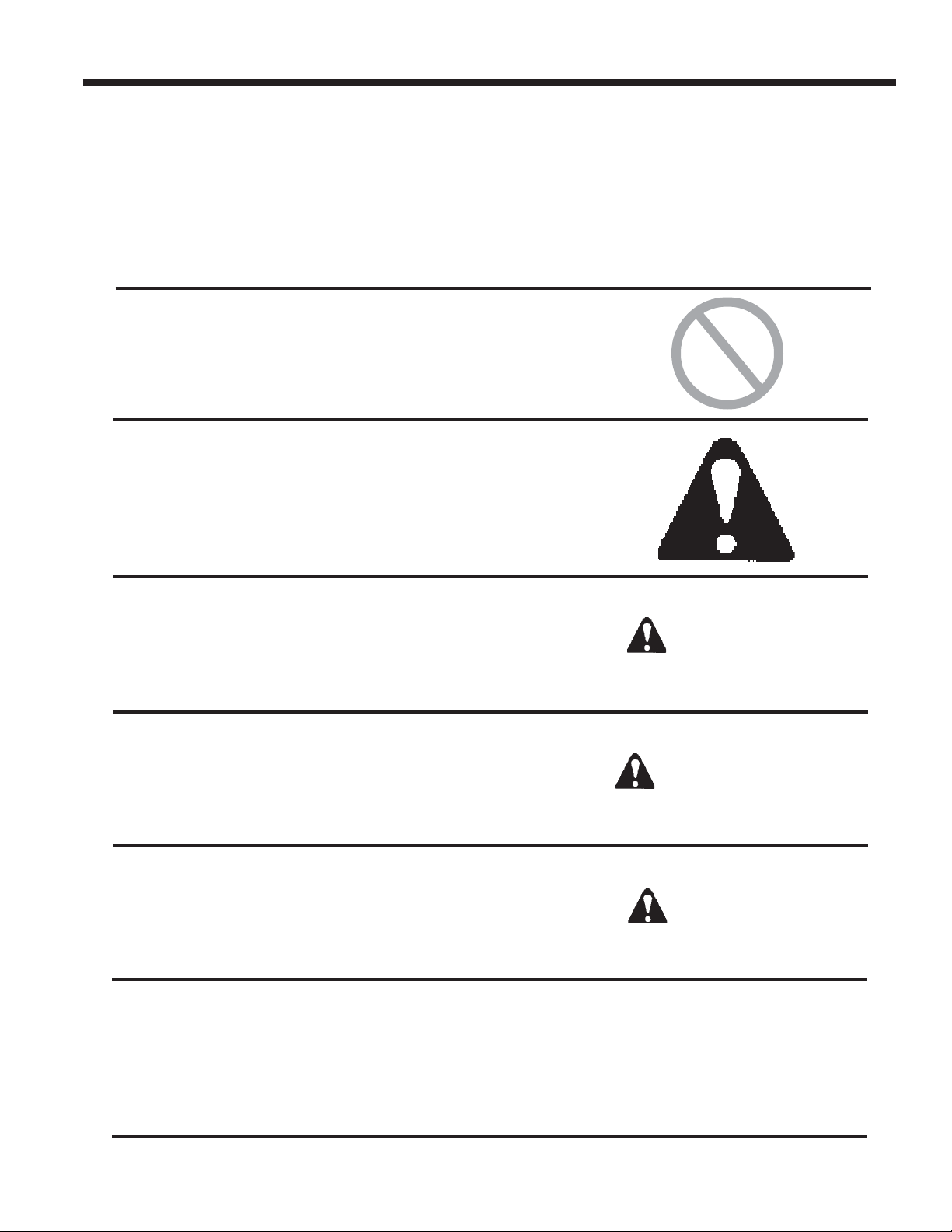

SAFETY SYMBOLS AND WARNINGS

These important safety symbols and warnings are used throughout this manual, and may also

appear in your Operator’s, Attachment, or Installation Instruction Manual. These symbols and

warnings are provided to help make you aware of potential hazards, and the precautions you

must take to protect yourself from injury. You must read and understand this information, and

obey the instructions. These symbols may also appear on safety labels as a visual reminder to

follow these important precautions whenever you are transporting, fueling, operating, servicing,

handling, or storing your unit.

Circle/Slash Prohibition Symbol

This symbol means that the specific action shown is

prohibited. Ignoring these prohibitions can result in

serious or fatal injury.

Safety Alert Symbol

The Safety Alert symbol is used to alert you to potential

personal injury hazards. To avoid serious or fatal

injuries, obey all safety messages that follow this symbol.

Safety Alert Symbol/DANGER Signal Word

The safety alert symbol appearing with the word “Danger!” calls attention to a hazard which will result in death

or serious injury if not avoided.

Safety Alert Symbol/WARNING Signal Word

The safety alert symbol appearing with the word “Warning!” calls attention to a hazard which could result in

death or serious injury if not avoided.

Safety Alert Symbol/CAUTION Signal Word

The safety alert symbol appearing with the word “Caution!” calls attention to a hazard which could result in

minor or moderate injury if not avoided.

NOTICE signal word only. (No safety alert symbol)

The word "NOTICE” calls attention to a situation which

may result in property or equipment damage if the

information that is provided is not followed .

DANGER

WARNING

CAUTION

NOTICE

3

Page 4

SAFETY SYMBOLS AND WARNINGS

Read Operator's and Safety Manuals

Read manuals carefully, and follow rules for safe operation. Failure to do so could result in serious or fatal injury.

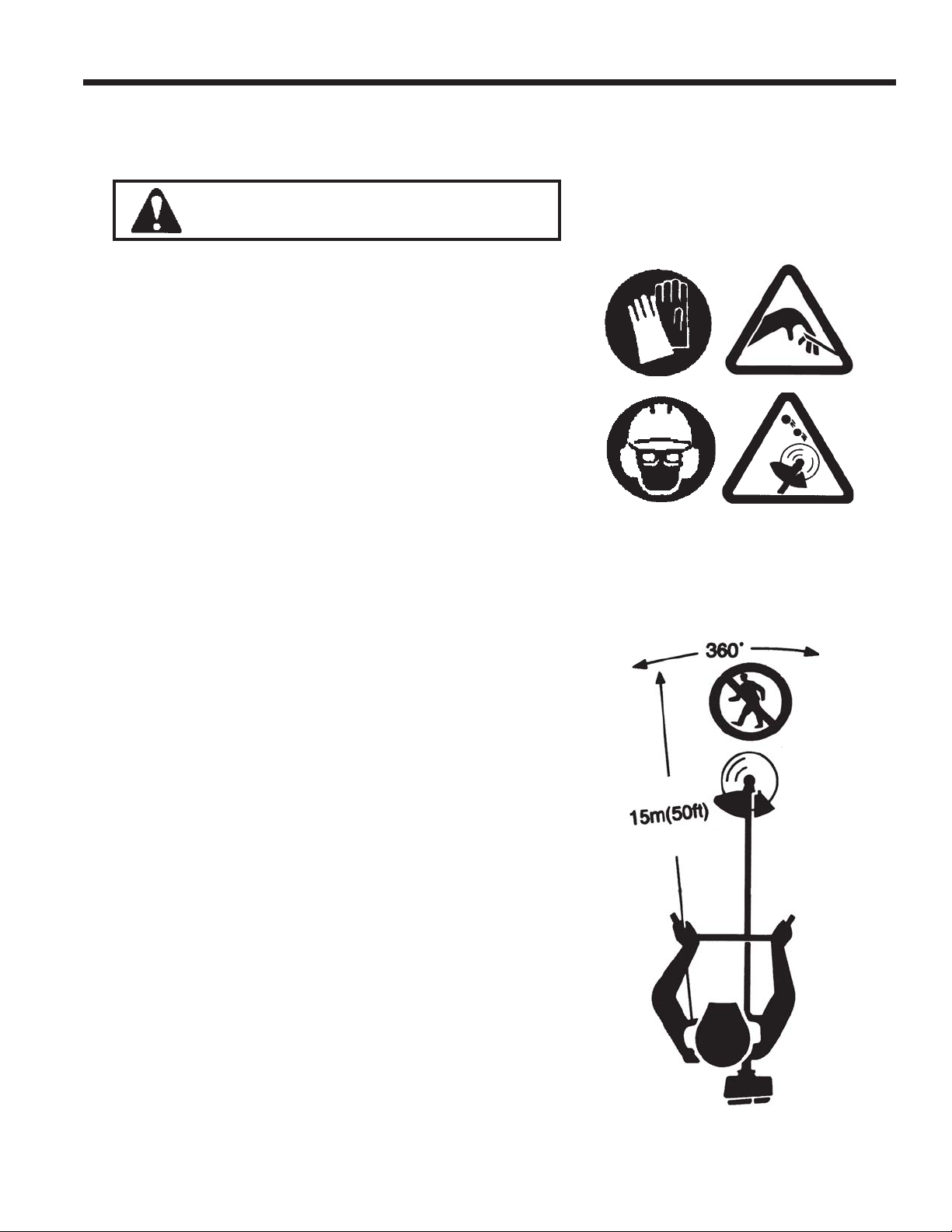

Wear Head, Eye, and Hearing Protection

Wear head, hearing, and eye protection that meet ANSI

requirements.

Wear Hand Protection

Wear heavy duty work gloves to protect hands

Sharp Blades Alert

Contact with blades can result in serious cuts and amputation

Carbon Monoxide Hazard Alert

Do not operate indoors. Breathing carbon monoxide can

cause serious or fatal injuries.

Explosion Hazard Alert

Gasoline vapor can explode if exposed to sparks or open

flame.

Burn Hazard Alert

Contact with hot surfaces can cause serious burns.

Fire Hazard Alert

Risk of fire from gasoline spills or leaks. Wipe up spills

immediately and dispose of wipes in an approved firesafe container.

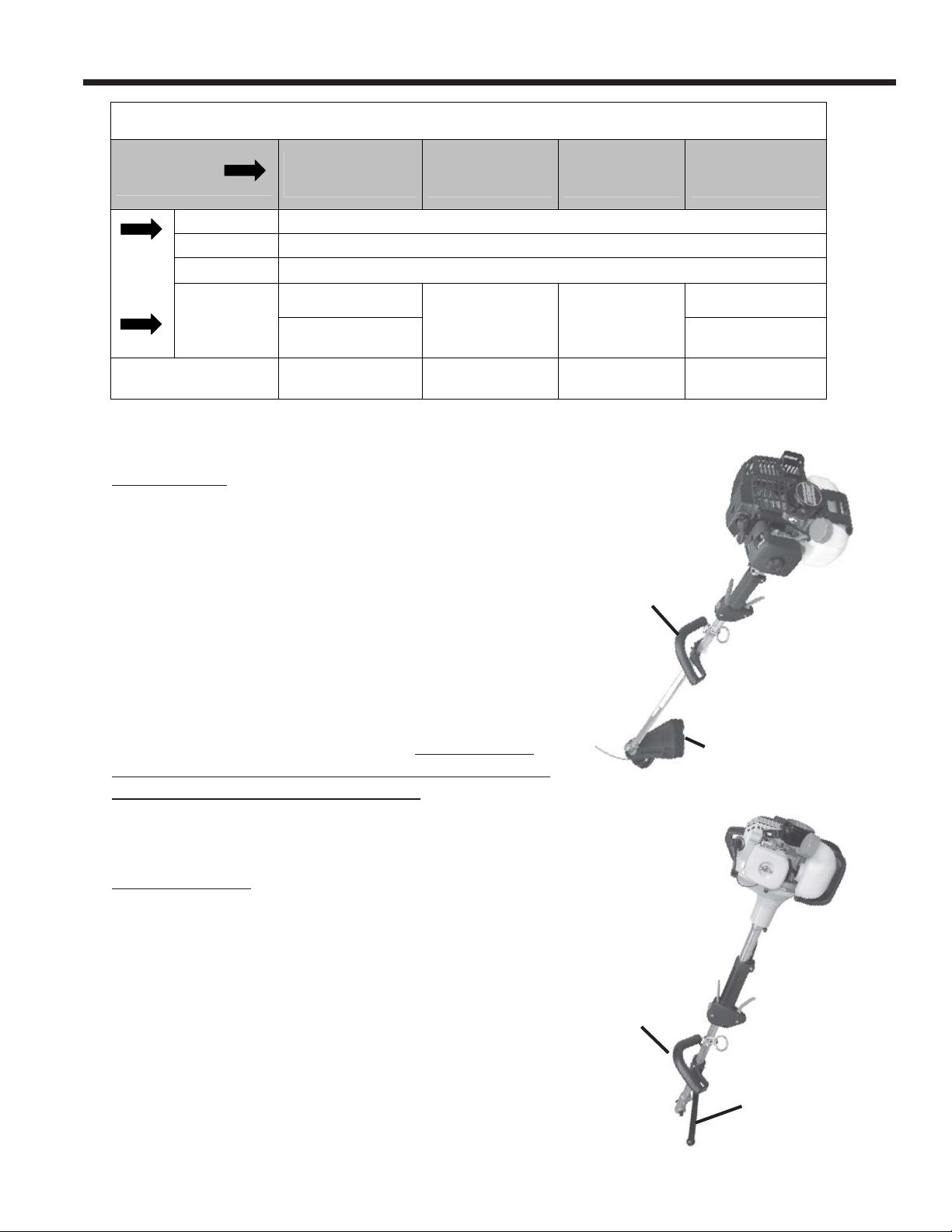

Shock Hazard Alert

Unit not insulated against electrical current. Avoid power

lines.

4

Page 5

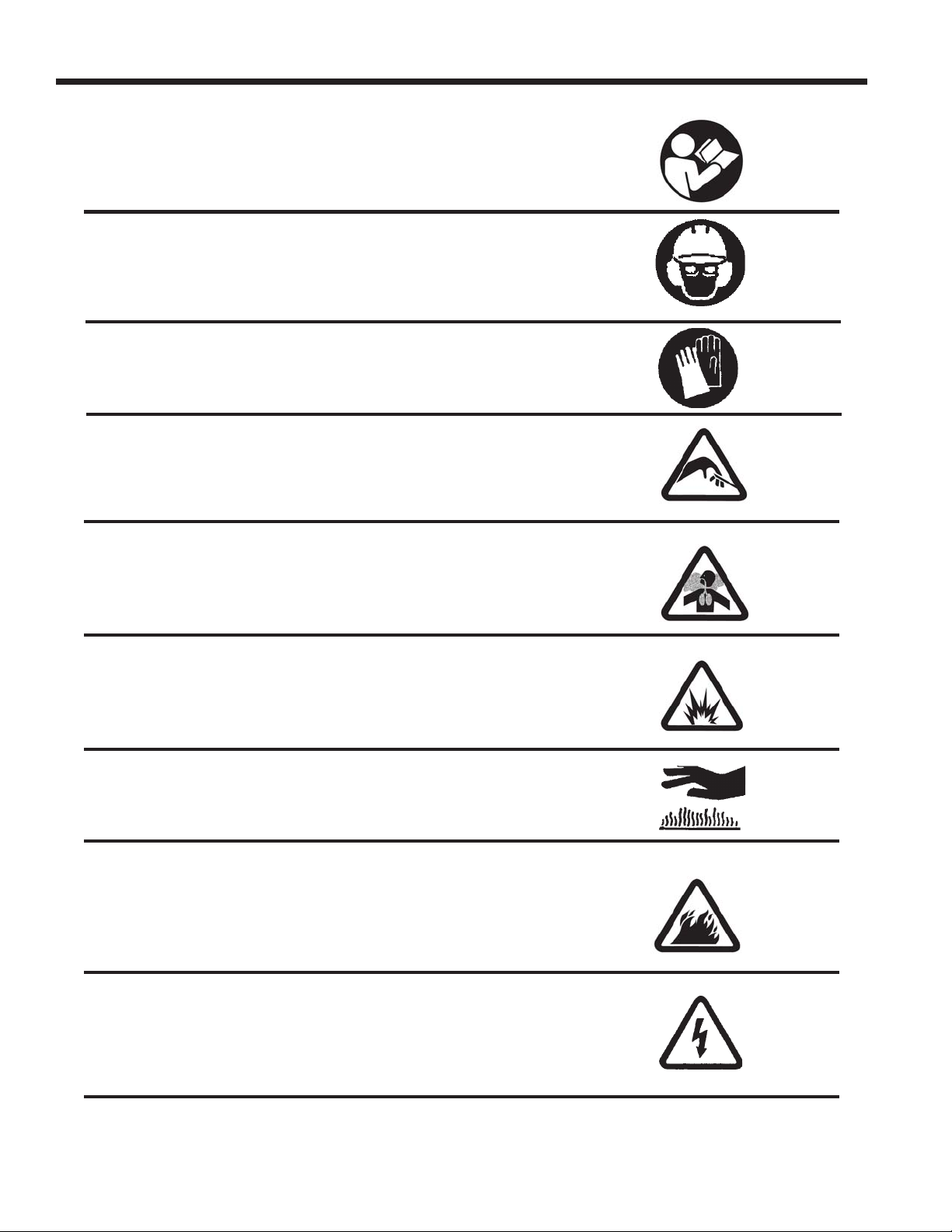

SAFETY SYMBOLS AND WARNINGS

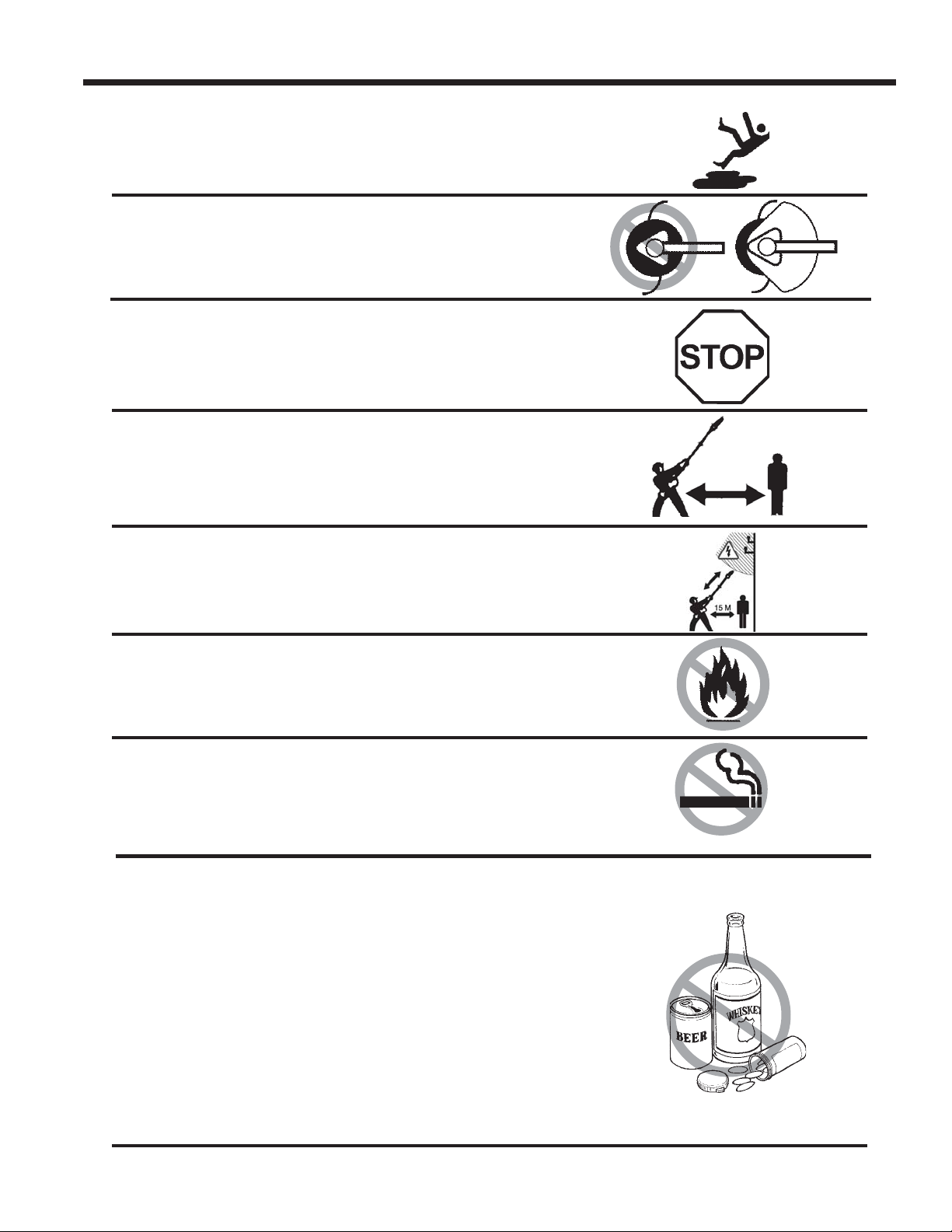

Slip Hazard Alert

Wear slip-resistant footwear to reduce risk of falls.

Operate Only With Debris Shield In Place

Do not operate without correct debris shield.

Stop Symbol

Indicates the “Stop” position for the engine ignition

switch (Stop Switch).

Keep Bystanders 15 m (50 feet) Feet Away

Keep bystanders at least 15 m (50 feet) away when

operating unit.

15 m

15 M

(50 feet)

Do Not Operate Near Electrical Lines

Do not operate closer than 15 m (50 ft.) to electrical

lines.

Flame Prohibition

Do not allow flames or sparks near fuel or fuel vapors.

No Smoking Prohibition

Do not smoke near fuel.

Do Not Operate Equipment While Impaired

Do not operate equipment while under the influence of

alcohol, medication, or any other substance that can

impair judgment, reflexes, vision, or coordination.

Operating a unit while impaired can result in serious

injury to operator and bystanders, or cause damage to

property or equipment.

15 M

5

Page 6

SAFETY SYMBOLS AND WARNINGS

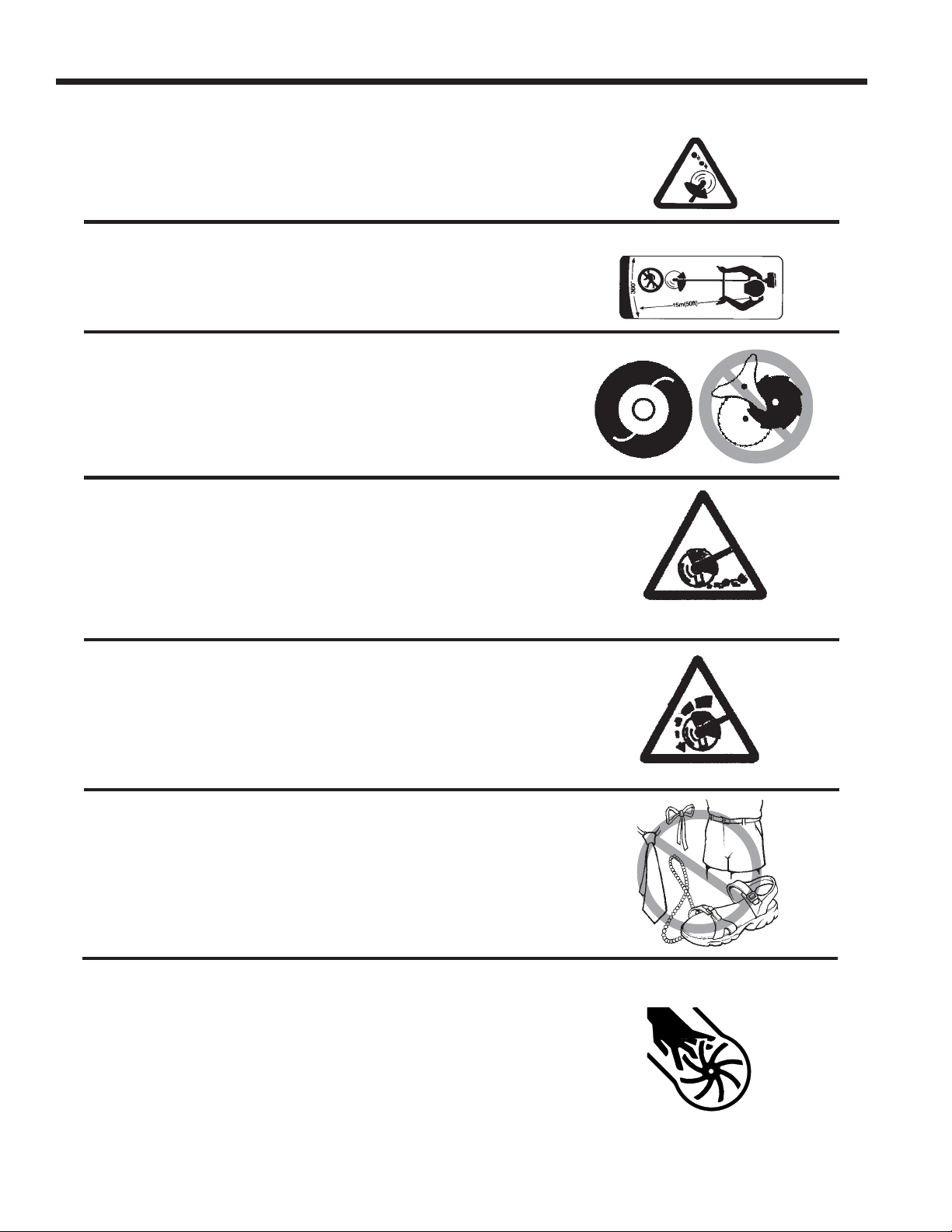

Flying Debris Hazard

Work attachments can throw debris. Flying debris can

cause serious injury.

Danger Zone Alert

Maintain 15 m (50 feet) radius danger zone around

trimmer - brushcutter.

Metal Blade Prohibition (Use Nylon Line Head

Only)

Metal blades cannot be used on unit. Use nylon line

head only.

Edger Debris Alert

Edger debris can affect stable footing. Use extreme

care when walking in edging area.

Edger Blade Alert

Edger Blade is partially exposed during operation.

Keep clear of blade.

Prohibited Clothing

Wear protective clothing and shoes. Loose clothing,

dangling accessories, or open footwear increases risk

of serious injury.

Finger Sever Hazard

Moving parts can amputate fingers or cause severe

injuries. Keep hands, clothing and loose objects away

from all openings.

6

Page 7

OPERATOR SAFETY

DANGER

Echo GT Grass trimmers and SRM trimmer-brush

cutters are powerful, professional-grade tools designed

for applications such as trimming grass and light

weeds, and when properly configured (SRM/PAS/SB /

straight shaft only), cutting brush, woody growth, and

small saplings and trees.

PAS Pro Attachment Series and SB units can be

equipped with a wide variety of lawn and landscaping

attachments for tasks ranging from edging to pruning,

allowing operators to perform an entire range of applications with just one powerhead.

OPERATOR SAFETY

PE Power Edgers provide precise edging action for

maintaining lawn borders in residential and commercial

landscaping. Edgers can also be equipped with an

attachment that quickly cleans out cracks and joints in

sidewalks, driveways, paved areas, and other hard

surfaces.

When used properly, these tools save time, reduce effort, and make difficult landscaping tasks

easy. If handled carelessly or used improperly, they can cause severe injury or death.

Before using this equipment, you must:

• Read and understand this Safety Manual

• Read and understand the Operator’s Manual provided with your unit.

• Read and understand the Manual provided with any blade, attachment, or accessory that

will be used.

• Wear appropriate personal protective equipment and clothing

• Make sure all others who use the equipment have read and understand the manuals before

fueling or operating the tool.

• Clear the work area of bystanders and pets.

• Clear the work area of debris and other work hazards

• Make sure you have safe, unobstructed footing

• Make sure the area to be cut is free of obstacles and hidden hazards

• Safely prepare the fuel/oil mix

• Fuel your unit safely

• Store the fuel and 2-stroke oil containers safely.

7

Page 8

OPERATOR SAFETY

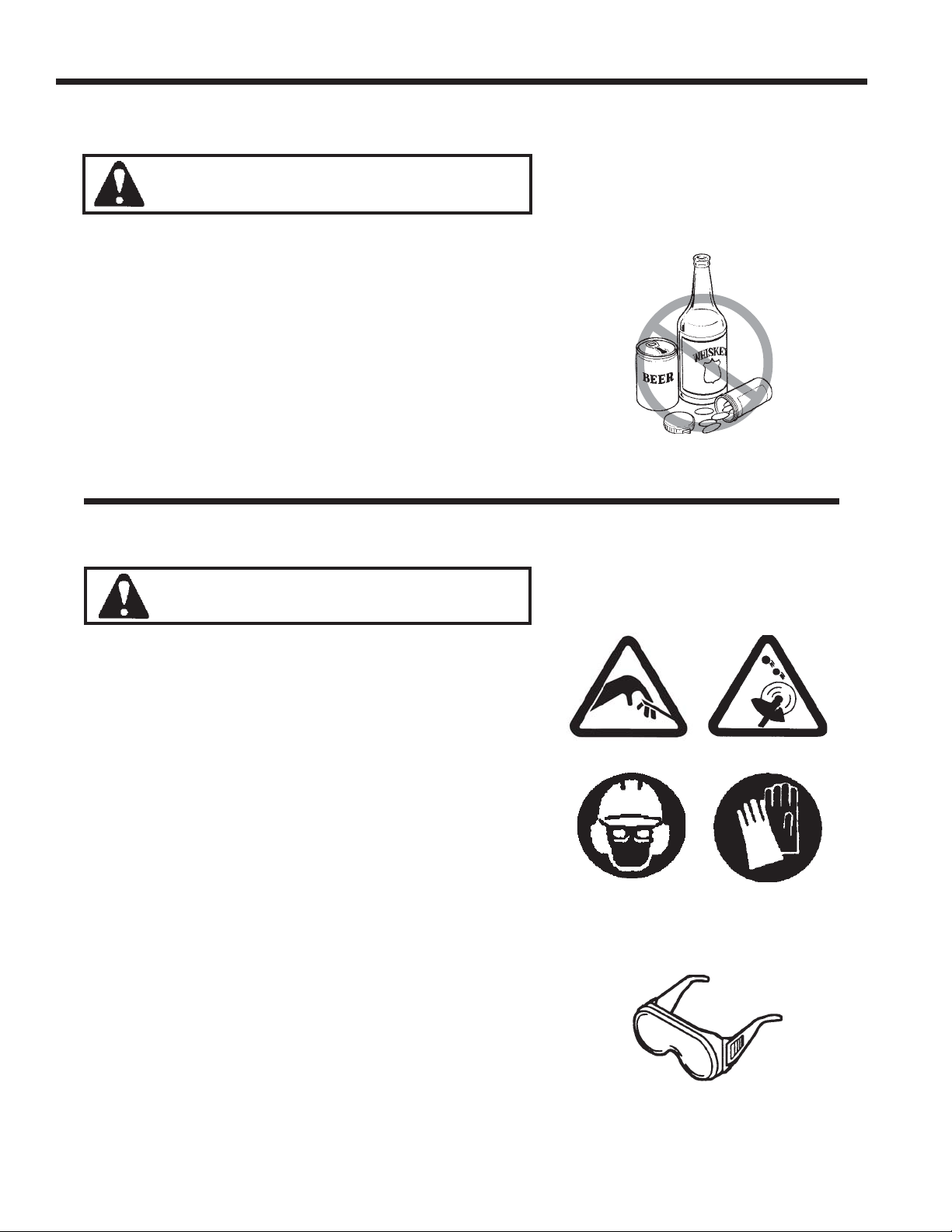

PHYSICAL CONDITION

WARNING

Operating this unit while you are impaired can result in

serious personal injury or death to yourself and others.

Never operate the unit if you are fatigued, or are under

the influence of alcohol, medication, or any other substances that can affect your judgment, reflexes, vision,

or coordination. You must be mentally alert and physically able to operate a trimmer, brushcutter, edger, or

PAS attachment safely. If you are impaired in any way,

or are physically unable to safely operate and control

the unit, do not fuel, start, or attempt to use the unit.

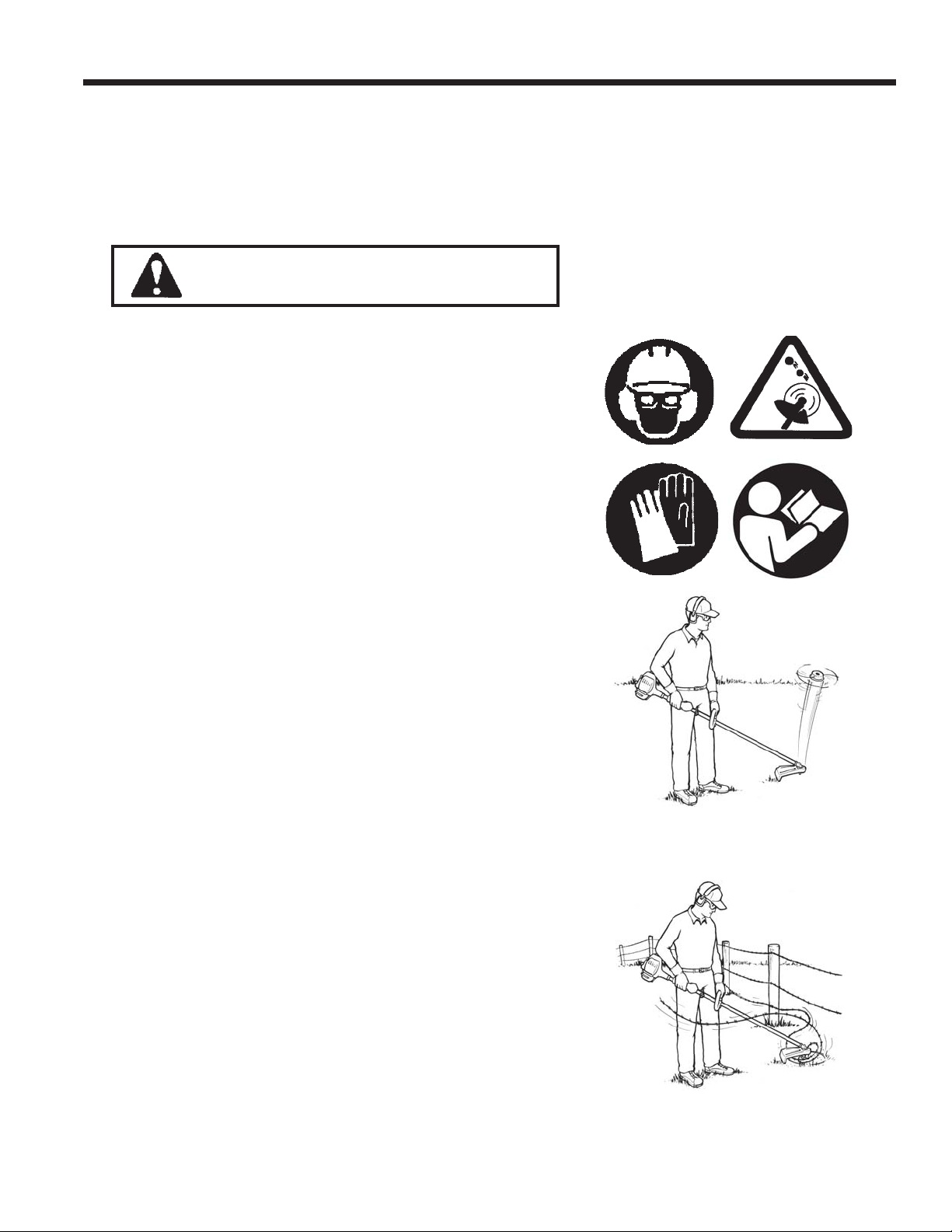

PERSONAL PROTECTIVE EQUIPMENT

WARNING

Operating a trimmer, brushcutter, or other powered

cutting or work attachment may expose you to sharp

blades, powerful cutting action, spinning nylon cutting

line, flying debris, and other work area hazards. These

hazards can cause serious injury to you and others if

you do not take the precautions necessary for safe

operation.

To help protect against risk of injury caused by these

hazards, you must wear appropriate personal protective

equipment:

Eye and Face Protection

Wear eye protection that meets current ANSI Z87.1

requirements. For additional safety, a full-face shield

may be worn over safety glasses or goggles to provide

protection from sharp branches or flying debris.

8

Page 9

OPERATOR SAFETY

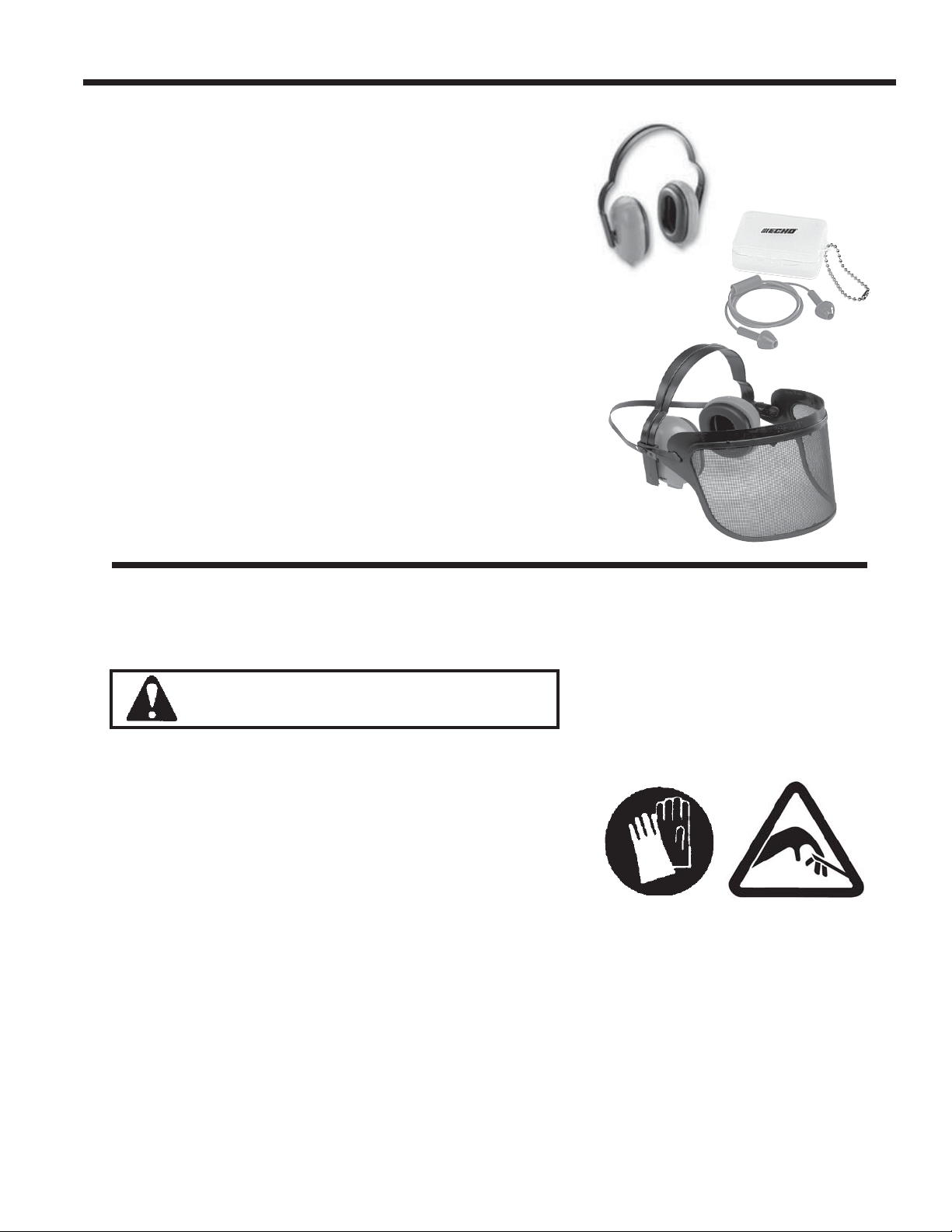

Hearing/Ear Protection

Echo highly recommends wearing ANSI recognized

hearing protection whenever you are operating the unit.

Hearing protection prevents hearing loss caused by

frequent or prolonged exposure to engine noise. Echo

recommends ear plugs, or for constant heavy-duty use,

wear earmuff-style hearing protection.

Combination Face/Hearing Protection

For complete face/hearing protection, the use of combination ear muffs/face shield provides face and hearing

protection all in one unit.

ALWAYS wear safety glasses or goggles under the

face shield, and wear head protection when cutting

overhead using a PAS or SB unit with Power Pruner or

Hedge Clipper Attachments.

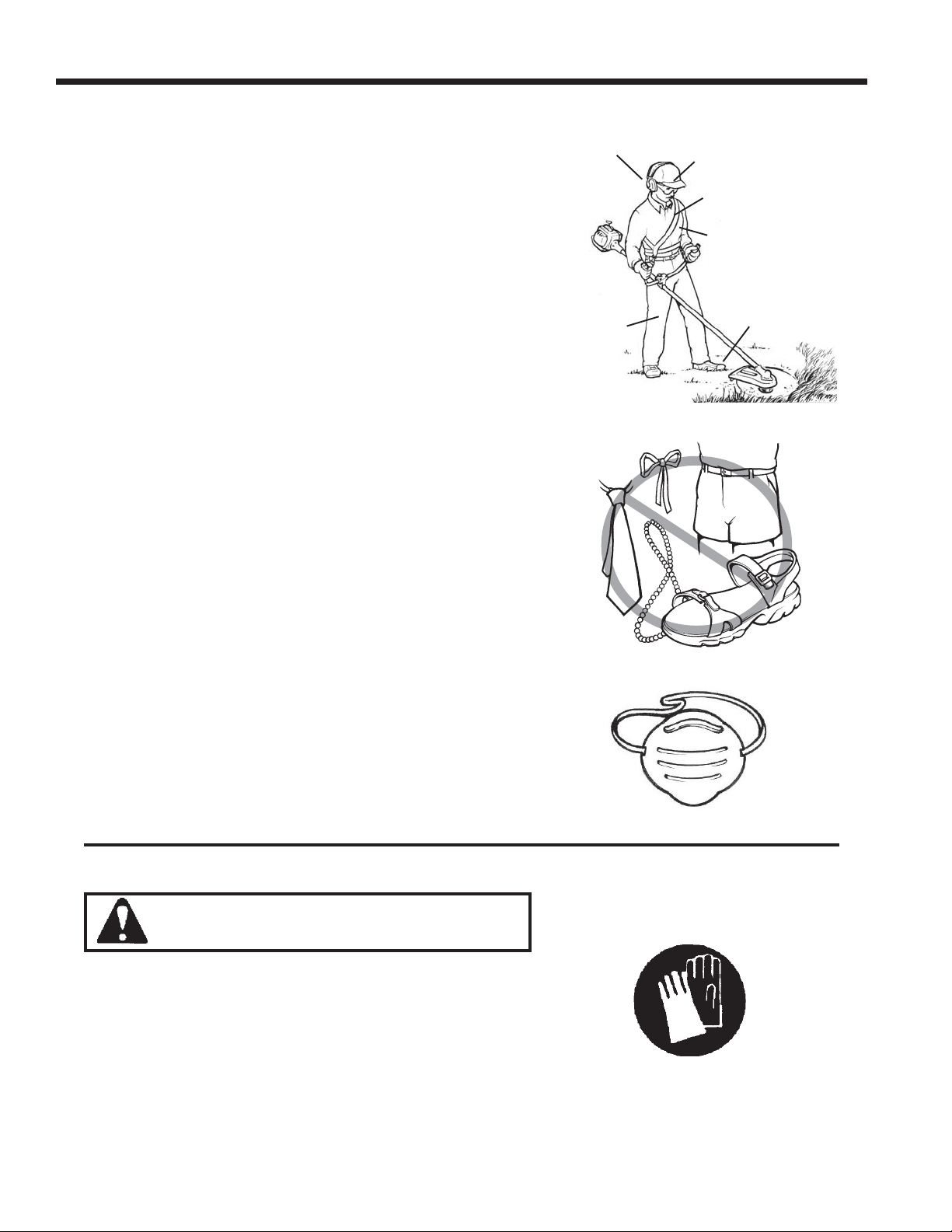

PROTECTIVE CLOTHING

Gloves

WARNING

Sharp Blades/Powerful Cutting Action. Contact with

sharp edges of moving blades and attachments will

cause severe injury or amputation. Keep hands, fingers, and all other body parts away. Work gloves and

other heavy work clothing do not protect against serious

injury if contact is made with moving blades or attachments.

Wear sturdy work gloves to provide protection against

cuts and scratches, and to help reduce the effects of

vibration.

9

Page 10

OPERATOR SAFETY

Leg Protection

Wear long pants to protect legs from cuts and scratches

caused by flying debris.

Foot Protection

Wear sturdy shoes or work boots to provide foot protection. Steel-toe shoes or boots provide extra protection

against dropped or falling objects. Make sure soles are

non-slip for secure footing.

General Clothing Safety

Never wear ties, loose clothing, or clothing with strings,

frills, or dangling straps. Keep clothing buttoned or

zipped, and keep shirt tails tucked in. Never wear

dangling or hanging jewelry such as earrings or necklaces, or any other items that could become entangled

with branches or equipment, and be drawn into the

moving parts of the engine.

HEARING

PROTECTORS

LONG

PANTS

SAFETY

GLASSES

SHOULDER

HARNESS

TRIM-FITTING

CLOTHES

STURDY

SHOES OR

BOOTS

Dust Protection

Operators who are sensitive to wood dust or other

common airborne allergens may need to wear a dust

mask to prevent inhaling these materials while operating unit. Dust masks can provide protection against

sawdust, plant debris, and other plant matter such as

pollen. Make sure the mask does not impair your

vision, and replace the mask as needed to prevent air

restrictions.

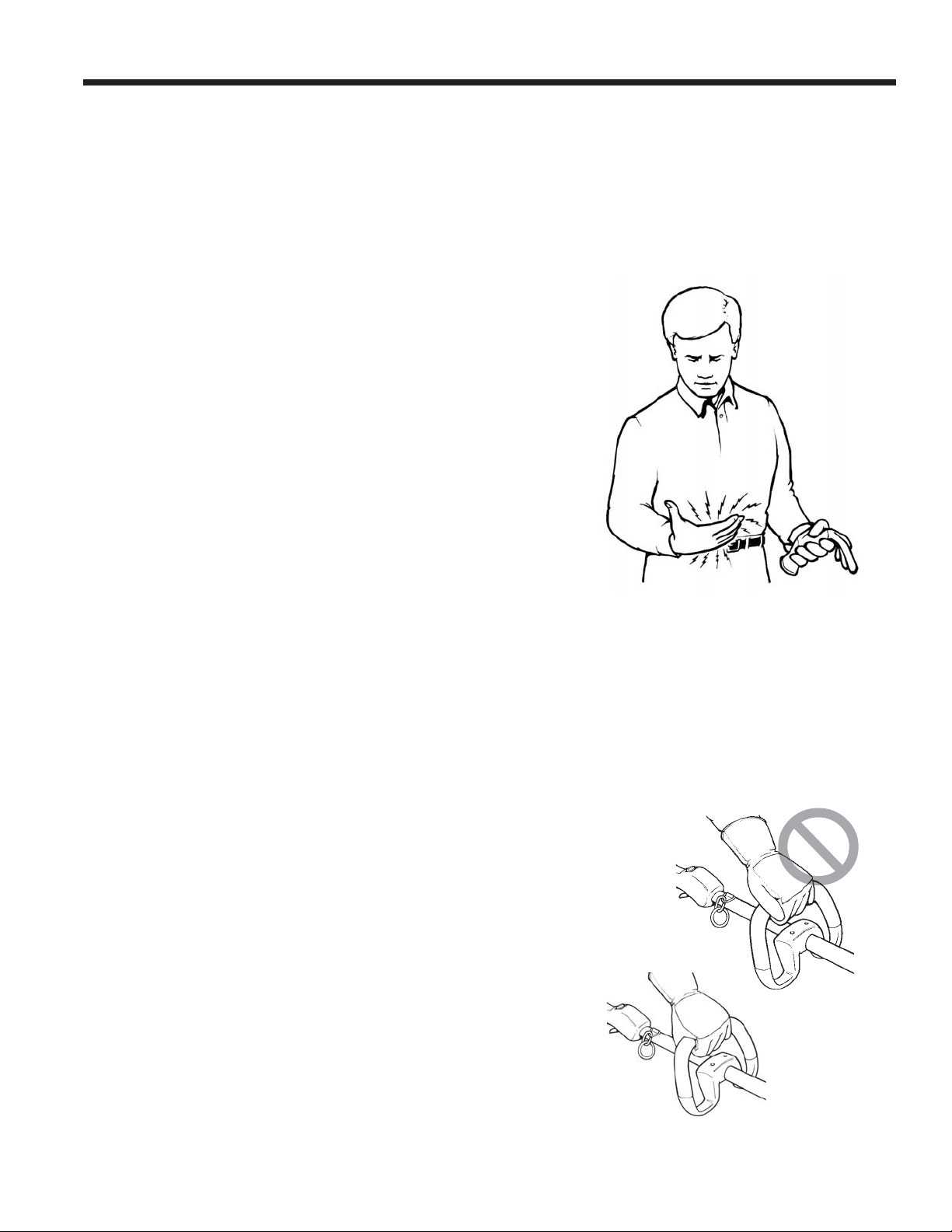

PROTECTION AGAINST COLD OR VIBRATION

CAUTION

Prolonged exposure to cold and/or vibration may result

in injury. Read and follow all safety and operation

instructions to minimize risk of injury. Failure to follow

instructions may result in painful wrist/hand/arm injuries.

Wear sturdy work gloves to help reduce the effects of

cold and vibration, and to help improve your grip.

10

Page 11

OPERATOR SAFETY

Raynaud's Syndrome

A condition known as Raynaud’s Syndrome can occur from exposure to cold and/or vibration.

This condition affects the hands and arms, causing tingling, burning, numbness, and loss of

color in the fingers. The amount of exposure needed to trigger this is unknown, and varies by

individual.

To protect yourself from this condition, take the following precautions:

• Keep your body warm - pay particular attention to

head and neck, hands and wrists, and feet and

ankles.

• Avoid awkward grips on the unit that may cause

stress. Maintain control, but do not hold the unit with

an excessively tight grip.

• Take regular rest breaks.

• Exercise and stretch to strengthen muscles, and to

maintain circulation. Keep exposure to vibration at

a minimum.

• If you experience discomfort, redness, and/or swelling of the fingers, followed by whitening or loss of

feeling, stop using the unit, and contact a doctor.

Repetitive Stress Injuries (RSI)

Overuse of the muscles and tendons of the fingers hands, arms, and shoulders may cause

soreness, swelling, numbness, weakness, and pain in these areas. Repetitive hand/wrist

movement can put you at high risk for developing a Repetitive Stress Injury (RSI), such as

Carpel Tunnel Syndrome (CTS). Carpal Tunnel Syndrome occurs when swelling in the wrist

puts pressure on a nerve, resulting in severe pain.

To protect yourself from these conditions, take the following precautions:

• Avoid using your wrist in a bent or twisted position.

Try to maintain a straight wrist position.

• Avoid using your thumb and index finger to grip

things - use your whole hand.

• Take regular rest breaks.

• Exercise and stretch to strengthen muscles and

maintain circulation.

• Keep exposure to vibration at a minimum.

• Reduce the speed and force of repetitive move-

ments.

• If you experience tingling, numbness, or pain in the

fingers, hands, wrists, or arms, stop using the unit

immediately, and contact a doctor. Early diagnosis

of RSI can help prevent permanent nerve and

muscle damage.

11

Page 12

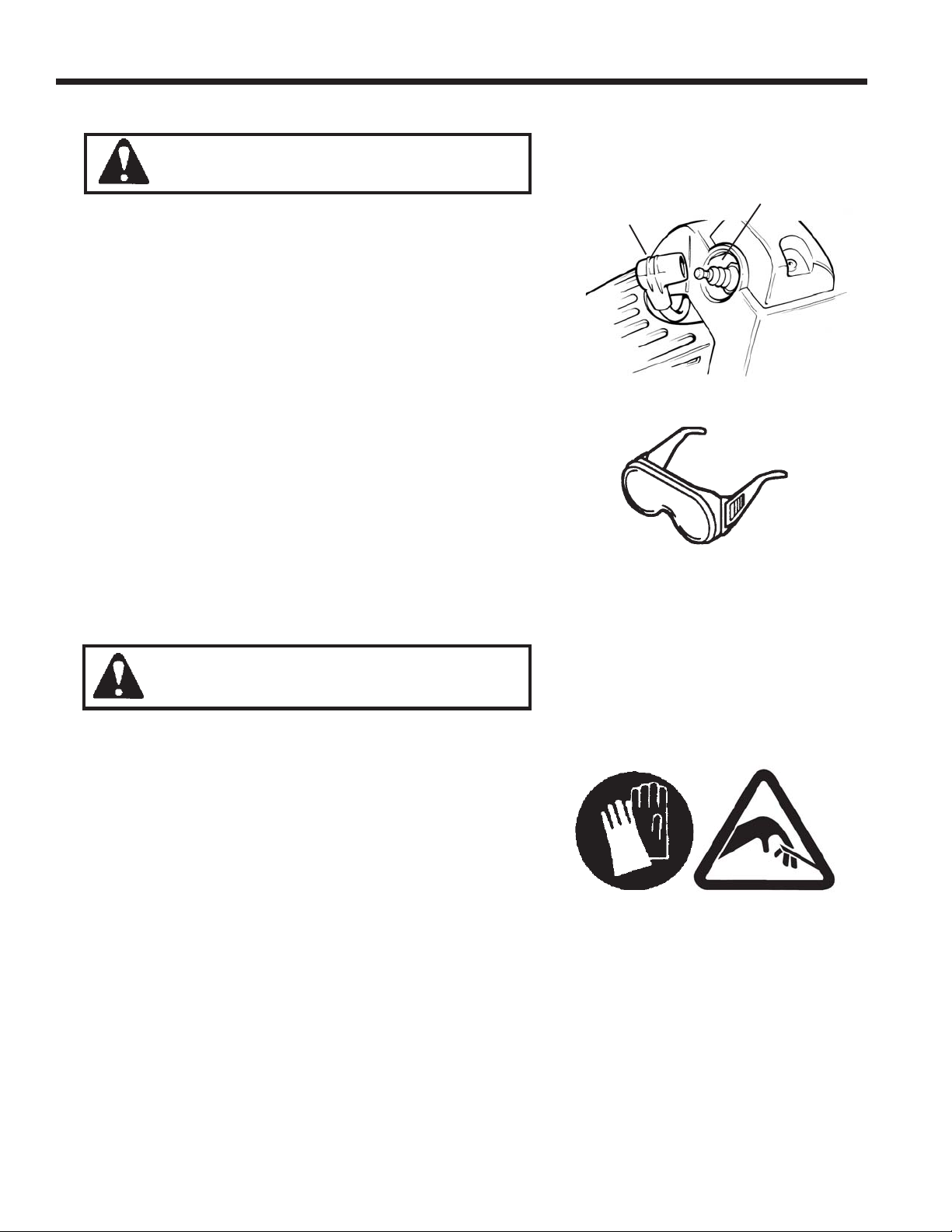

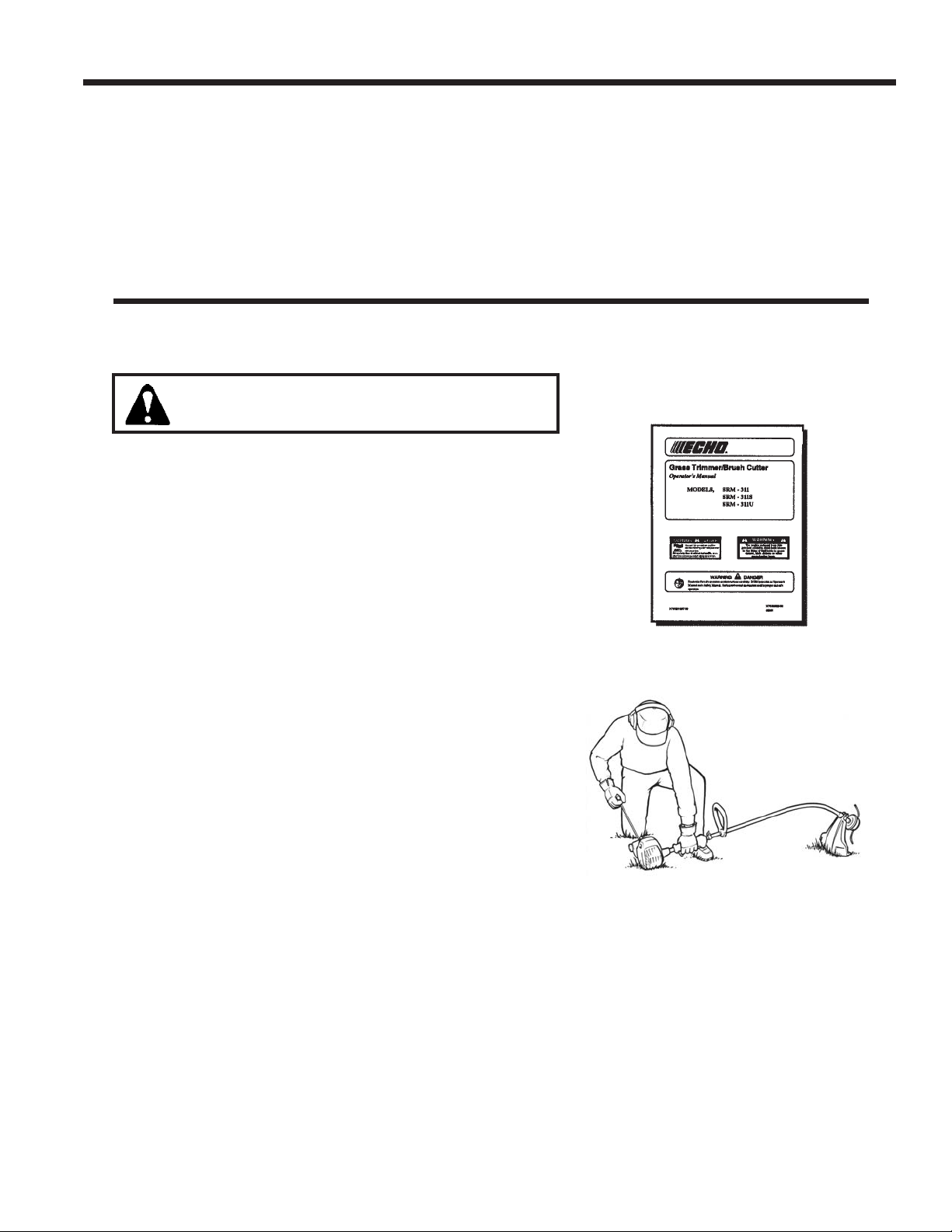

ASSEMBLY

ASSEMBLY

WARNING

Move STOP switch to STOP position and disconnect

spark plug lead at spark plug before assembling unit.

Do not connect spark plug lead to spark plug until unit is

properly assembled, checked, and ready for use.

ALWAYS wear eye protection that meets current

ANSI Z87.1 requirements. Operators that wear prescription glasses must wear appropriate protective

eyewear over glasses. For additional safety, a full-face

shield may be worn over the safety eyewear to provide

complete face protection.

If parts are missing, or if you have a problem installing

parts, contact your Echo Dealer for assistance or call

Echo Consumer Product Support at 1-800-673-1558.

For the Dealer nearest you ask your retailer or call

1-800-432-3246, or visit our website at www.echousa.com

Spark

Plug

Wire

Spark

Plug

DANGER

Metal grass, weed, brush, and clearing blade edges are

extremely sharp. Accidental hand or body contact with

blade edges can result in severe cuts, even if the engine is off and blades are not moving. Always wear

sturdy work gloves when handling blades. Do not allow

blades to contact any part of your body. Work gloves

do not provide protection from contact with moving

blades. Always keeps hands and body away from

moving blades.

NEVER fuel, start, or operate your unit unless it is fully

assembled, all shields and required guards are in

place, and the throttle lock-out lever and trigger are

working properly.

12

Page 13

NEVER install any other type of blade, line head, cutting

attachment, part, or accessory on your trimmer/

brushcutter unless it is approved by Echo for use on

your specific model. Parts and accessories that appear to fit properly may create a safety hazard when the

unit is operated, and could result in serious injury to

operator and bystanders.

ASSEMBLY

ALWAYS use the correct tools for assembly. Using

incorrect or improperly sized tools can result in a sudden slip and serious injuries.

ALWAYS follow the assembly instructions in order, as

shown in the Operator’s Manual. Improper assembly

can result in sudden part failure, and serious injuries.

NEVER use parts that appear to be worn, damaged,

improperly sized, or otherwise incompatible with mating

parts. Contact your dealer or Echo Consumer Support

for assistance if parts do not fit properly.

NEVER modify parts or use parts from other pieces of

equipment to assemble your unit. Use only parts that

are designed to fit your model. Modifying a part to fit

may weaken it, and cause premature failure. Parts from

other models may not work properly, and can create

unsafe operating conditions.

Wiring

Keep feet and

hands away

Position wiring safely to prevent snagging, separation

of connectors, or breakage during operation. Gather

excess wire, and secure with wiring clamp if provided

on unit, or tuck behind the air filter area. Do not place

wiring directly against hot engine components.

Check wiring and connectors for nicks, cuts, exposed

wire, or other damage, and repair or replace as

needed. Exposed wire or connectors can cause

shocks, sparks, and risk of fire or explosion, resulting in

serious injury.

Check wire terminals for secure connections. Loose

connections can cause erratic engine operation, or

prevent Stop switch from stopping engine.

13

Page 14

ASSEMBLY

Debris Shield

WARNING

Plastic Debris Shields are equipped with a sharp cut-off

knife for cutting nylon trimmer line to length during operation. Use extreme care when assembling nylon line

head to gear case to avoid accidental contact with cutoff knife. Wear work gloves when assembling nylon line

head to gear case, and avoid contact with sharp cut-off

knife edges.

Unit Configuration

SRM Debris Shield

Cut-Off Knife

GT Models: If your Model GT curved shaft trimmer is

not fully assembled, you must assemble the unit as

instructed in the Operator’s Manual provided with the

unit. Before using the unit, make sure the plastic debris

shield, trimmer head, and handle are properly attached,

and are securely fastened.

If your GT curved shaft trimmer has been pre-assembled, you must make sure the plastic debris shield,

handle, and trimmer head are properly installed and

securely attached, as shown in the Operator’s Manual

provided with the unit.

DANGER

NEVER install a metal blade on a model GT curved

shaft trimmer. Use of any metal blade on a GT curved

shaft trimmer can result in serious injury to operator and

bystanders. Use only nylon line heads or GT series

Maxi-Cut plastic weed trimmers approved for use on GT

models by Echo. (See Set-up Guide page 15)

GT Debris Shield

Cut-Off

Knife

GT MODEL

Front Handle

GT Debris

Shield

14

Trimmer Head

NO Metal

Blades

Page 15

ASSEMBLY

GT MAXI-CUT BLADE/NYLON LINE HEAD SET-UP GUIDE

TO USE THESE

CUTTING

ATTACHMENTS*

You

must

use

these

parts!

Standard Cutting Line

* All required installation hardware provided with cutting attachment.

GT Series

Maxi-Cut Grass/Weed

Plastic Cutters

Front Handle Loop Handle (STD)

Debris Shield Plastic Shield (STD)

Harness Not Required

Mounting

Hardware*

Diameter

Flat Washer Flat Washer

3/8-24 R.H. Thread

Hex Locknut

N/A .080 Diameter .080 Diameter .095 Diameter

GT Dual Line

ECHOmatic

Line Head

Extra Hardware

Not Required

SRM Models: If your trimmer-brushcutter requires

assembly before it can be used, you must make sure

the unit is properly configured for the type of cutting

attachment you will be using. Follow the instructions in

the Operator’s Manual provided with the unit. You must

install the required cutting attachment, debris shield,

handle, and any other protective devices needed, such

as a harness loop and safety harness. See SRM/PAS/

SB Set-Up Guide Page 17)

GT Single Line

ECHOmatic

Line Head

Extra Hardware

Not Required

SRM MODEL

Front

Handle

2 Line GT

Rapid Loader

Line Head

3/8-24 R.H. Thread

Hex Locknut

If your trimmer-brushcutter has been preassembled, you

must make sure the unit is properly configured for the

type of cutting you will be performing. If the unit is not

properly configured, you must first remove the incorrect

parts, and then install the correct parts, following the

instructions in the Operator’s Manual before using the

trimmer-brushcutter,

PAS/SB Models

Echo Pro Attachment Series (PAS) and Split-Boom

(SB) models are for use only with Echo PAS series

attachments, and must not be used with any other type

or brand of attachment. Select the desired PAS attachment, and assemble the attachment to the powerhead

driveshaft using the coupler. Follow the safety and

operating instructions in the Operator’s Manual provided with the attachment, and General Safety Instructions in this Safety Manual.

Debris Shield

PAS MODEL

Front

Handle

Barrier Bar

15

Page 16

ASSEMBLY

The Echo Pro Attachment Series and Split-Boom models allow the use of a wide range of

attachments to perform various lawn, garden, and landscaping tasks. These attachments

have individual safety and operating rules which must be obeyed for safe operation. You must

read and understand the safety and operating instructions for each attachment before using

the unit. You must also review the general safety instructions for PAS Attachments.

If you change PAS attachments, you must also make sure your front handle is properly configured for the new attachment.

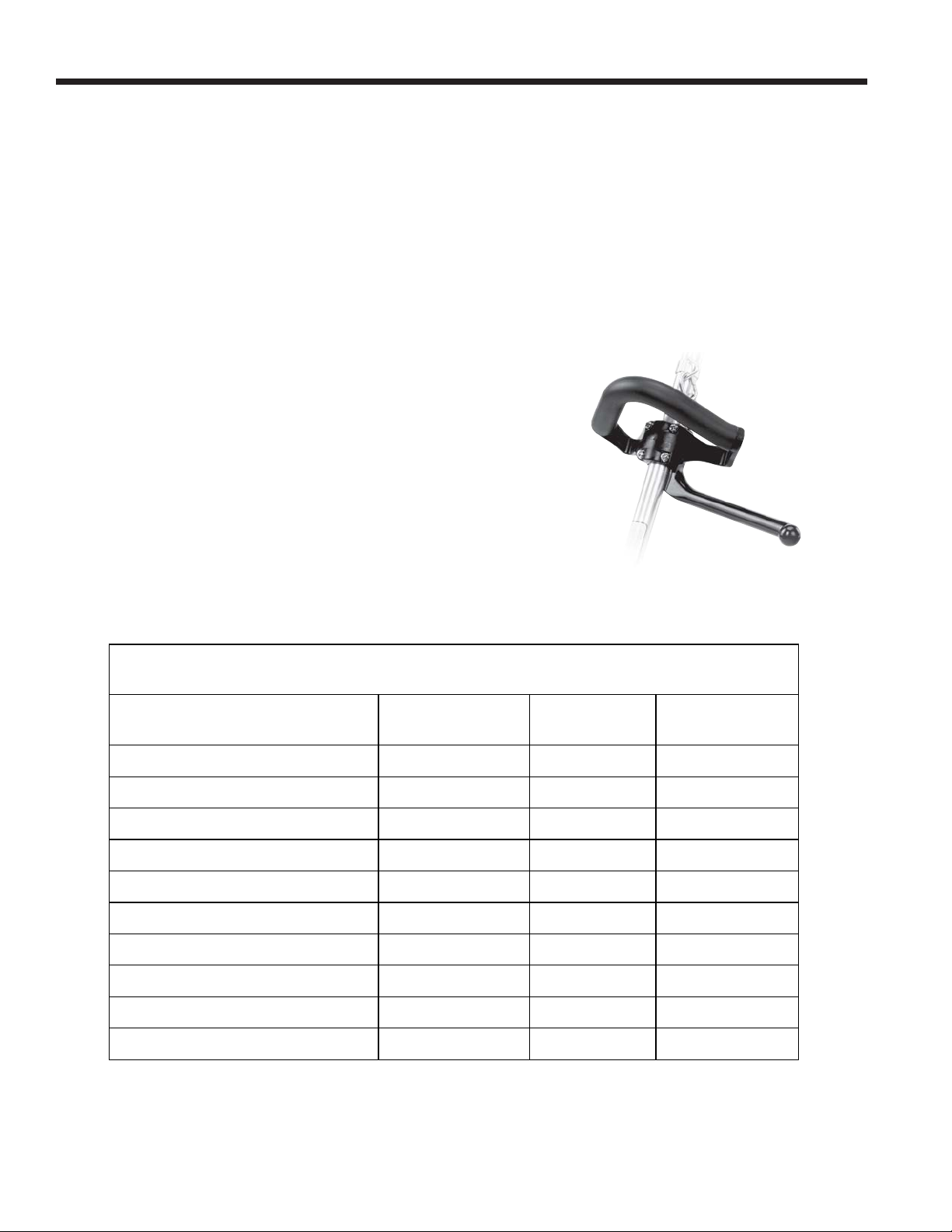

PAS/SB Front Handle Configuration

The required front handle configuration of your PAS/SB

unit may change, depending on the type of PAS attachment being used:

• Use the barrier bar provided with the PAS power

head when instructed in the PAS Attachment

Operator’s Manual.

• Remove the barrier bar when using an attachment

that does not require a barrier. See the PAS/SB

Attachments Barrier Bar Use table for barrier bar

usage information.

BARRIER BAR USE - PAS/SB ATTACHMENTS

PAS ATTACHMENT

Shaft Hedge Clipper X

Tiller-Cultivator X

Power Pruner X

Standard Line Trimmer X

Pro Sweep X

Pro Thatch X

Articulating Hedge Clipper X

Brushcutter1 X

Rapid Loader Line Trimmer X

Pro Paddle X

1 - See SRM/PAS/SB Blade Set-up Guide on Page 17 for blade use requirements

2 - Use J-Handle provided with Pro-Thatch attachment as a barrier

3 - Brushcutter requires U-Handle & Harness

RECOMMENDED OPTIONAL

NOT

RECOMMENDED

2

3

16

Page 17

SRM/PAS/SB Blade Configuration

If you change the cutting attachment on your SRM, PAS,

or SB unit from nylon line head to a blade, you must also

install all of the parts required for blade operation.

These parts vary by type of blade being used, and may

include replacing the front handle with a U-Handle (See

the SRM/PAS/SB Set-Up Guide, Page 17)

ASSEMBLY

DANGER

A trimmer-brushcutter unit equipped with a metal blade

can cause serious injuries if handled improperly.

ALWAYS use extreme care when carrying or handling

the unit to avoid contact with the cutting edges of the

blade. Echo recommends using the optional plastic

blade cover to protect yourself and others from accidental blade contact.

SRM/PAS/SB Blade Set-Up Guide

Use this configuration table as a guide for setting up

your unit with a blade. See the assembly instructions in

your Operator’s Manual or Blade Conversion Kit for

specific information.

SRM/PAS/SB BLADE SET-UP GUIDE*

TO USE

THESE BLADES

Pro Maxi-Cut

Grass/Weed

Plastic Cutters

Rigid Plastic

Tri-Cut

Grass/Weed Blade

U-handle/Blade Kit

Circular Blade Cover

Metal

Tri-Cut/8 Tooth

Grass/Weed Blade

Metal 80T Brush Blade

Metal 22T Clearing Saw Blade

You

must

install

these

parts!

* WARNING! DO NOT INSTALL BLADES ON GT (CURVED SHAFT) MODEL TRIMMERS

** Arbor diameter of Upper Blade Plate must match arbor diameter of metal blades.

*** New cotter pin required each time blade is installed.

**** Brushcutters over 16.5 lbs (7.5 kg) dry weight (weight w/o fuel) require a double shoulder harness

Handle

Debris Shield Metal Shield Metal Shield Metal Shield Metal Shield

Harness Shoulder Harness Shoulder Harness Shoulder Harness Shoulder Harness****

Blade

Mounting

Hardware

Loop Handle, w/or

w/o Barrier Bar

Upper Plate &

Flat Washer

Hex Nut Hex Nut Hex Nut Hex Nut

New Cotter Pin*** New Cotter Pin*** New Cotter Pin*** New Cotter Pin***

Loop Handle

w/Barrier Bar,

or U-Handle

Upper Plate

& Glide Cup

Loop Handle

w/Barrier Bar,

or U-Handle

Upper/Lower

Blade Plates**

U-Handle

Upper/Lower

Blade Plates**

17

Page 18

ASSEMBLY

PE Models

DANGER

Modification, improper assembly, or use of unapproved

blades or attachments, can result in serious injury,

engine failure, and voiding of warranty. Use only Echo

blades and attachments approved for use on PE Series

power edger models.

Assemble unit only as instructed in Operator’s

Manual, using parts provided with unit.

• NEVER modify edger or install blades or attachments not approved by Echo for use on Echo model

PE power edgers.

• NEVER remove debris shield or deflector flap.

• NEVER install grass, weed, clearing, brushcutter, or

any other type of circular metal saw blades or cutting

attachment on an edger.

• ALWAYS use a new split pin each time blade is

installed or replaced.

• ALWAYS remember to remove locking bar, Twrench, and any other tools used to assemble unit or

tighten hardware.

• ALWAYS store assembly tools safely away from the

work area.

Keep Hands/Feet Away

From Edger Blade

PE POWER EDGER

DANGER

Improper use of any trimmer, brushcutter, or PAS/SB

unit and attachment or Power Edger, can cause serious

or fatal injury. Moving edger blades and attachments

can cut through work gloves, protective clothing, and

footwear, and cause serious injuries. Keep hands, feet,

and all other body parts away from spinning blades or

attachments.

You must read, understand, and obey all safety and

operating instructions in this Safety Manual, your unit’s

Operator’s Manual, and in the Operator’s Manual or

Installation Instructions provided with any attachment,

accessory, or parts kit that will be used.

18

PE Debris Shield

Deflector Flap

Page 19

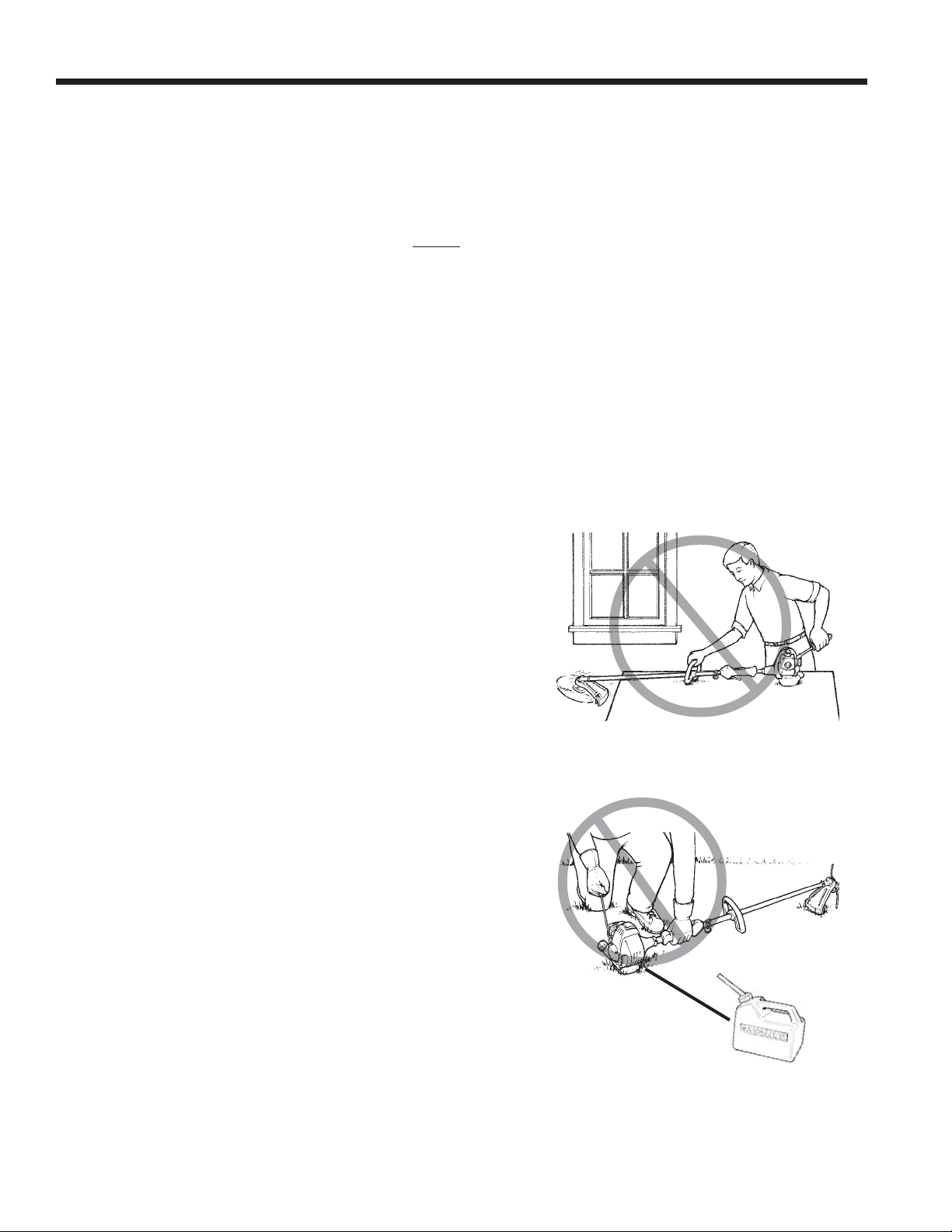

All Front Loop Handle Models

ASSEMBLY

Make sure the front loop handle is positioned beyond

the minimum handle spacing line, as shown on the

handle spacing decal on the drive shaft housing. The

minimum handle spacing line indicates the minimum

distance between the rear handle and front handle, and

helps ensure the operator’s hands are far enough apart

to maintain good control of the unit.

Final Assembly Check List

After assembly, check your unit to make sure guards,

shields, protective devices, and all other parts are

properly and securely assembled and working correctly. See the Operator’s Manual for assembly details

and part locations for your unit.

• Make sure all required hardware has been used

and is properly tightened.

• Make sure throttle lock-out lever resets when re-

leased.

• Make sure throttle trigger does not operate unless

throttle lockout lever is depressed.

• Make sure throttle trigger returns to normal position

when released.

• Make sure stop switch operates properly, moving

feely between STOP and run positions.

• Move STOP switch to stop position.

• Connect spark plug lead.

Minimum Handle

Spacing Line

Minimum

Handle

Spacing

Stop Switch

Throttle Lock-out

Lever

Throttle Trigger

NEVER fuel, start, or operate your unit unless it is fully

assembled, all shields and required guards are in

place, and the throttle lock-out lever and trigger are

working properly.

If parts are damaged, missing, or do not operate properly, or if you have a problem assembling your unit,

contact your Echo Dealer for assistance or call Echo

Consumer Product Support at 1-800-673-1558.

19

Page 20

FUELING

FUELING

DANGER

Explosion/Fire/Burn Hazard. Gasoline is extremely

flammable. Vapors are explosive. Keep at least 50

feet (15 m) away from heat, sparks, open flame, smoking materials, static electricity, and all other sources of

ignition when fueling unit.

Gasoline vapor is heavier than air, and can travel along

the ground to nearby sources of ignition such as electrical motors, pilot lights, and hot or running engines.

Vapors ignited by an ignition source can flash back to

the fuel container, resulting in an explosion, fire, serious

or fatal injuries, and extensive property damage.

Follow these important safety precautions to minimize

risk of explosion or fire:

• ALWAYS use an approved, "no-spill" type fuel

container with tight-fitting caps.

• ALWAYS follow posted safety instructions for filling

fuel containers at filling stations.

• ALWAYS place container to be filled with gasoline

on the ground to prevent static build-up during

filling.

• ALWAYS keep the metal filling pump nozzle in

contact with the fuel container while dispensing fuel

to prevent buildup and discharge of static electricity.

• NEVER fill fuel container on SUV/truck bed or in

trunk of car.

• NEVER smoke near fuel.

• NEVER allow flames or sparks near fuel.

• ALWAYS loosen fuel caps slowly to allow pressure

in tanks and containers to escape

• ALWAYS use extreme care when mixing, storing,

or handling fuel.

Fill Fuel Outdoors

• NEVER remove tank cap or refuel a unit while the

engine is hot or running

20

Open Fuel Cap Slowly

Page 21

• NEVER fill fuel tanks indoors - ALWAYS fill fuel

tanks outdoors over open ground.

• DO NOT overfill fuel tank - ALWAYS allow room in

tank for expansion. Fill tank no more than 95 percent full, or to “Safe Fill Line” if marked on container.

• ALWAYS wipe up spills immediately, and dispose

of fuel soaked wipes safely. Use a fireproof container designed for safe disposal.

• IMMEDIATELY change clothes if fuel spills on

clothing. Wet clothes down with water first to minimize fire risk.

• ALWAYS tighten fuel tank cap securely - check cap

for tightness.

• ALWAYS close fuel container immediately after

refueling.

FUELING

Tighten cap securely

• ALWAYS check fuel system for leaks before using

unit - NEVER start or operate a unit with leaks.

• ALWAYS move at least 3 m (10 ft.) away from

refueling location before starting engine.

• STOP USING UNIT IMMEDIATELY and shut

engine ignition off if you smell the strong odor of

gasoline. Set unit down in a safe location, and allow

to cool before checking for leaks.

• ALWAYS store fuel containers in a well ventilated,

unoccupied building, away from heat, sparks, open

flames, and other sources of ignition.

Fuel Mix

2-Stroke engine oil contains petroleum distillates and

other additives that may be harmful if swallowed.

Heated oil can release vapors that can cause flash fire,

or ignite with explosive force. Read and follow the oil

manufacturer’s instructions, and observe all safety

warnings and precautions for handling flammable

liquids. For more detailed safety and first aid information, visit www.echo-usa.com for a copy of the Material

Safety Data Sheet.

WARNING

3 m

(10 ft.)

Start at least 3 m (10 ft.)

from fueling area.

ECHO Power Blend X

2-Stroke Universal Oil

TM

21

Page 22

FUELING

• KEEP OUT OF REACH OF CHILDREN.

• If swallowed, do not induce vomiting. CALL PHYSI-

CIAN OR A POISON CONTROL CENTER IMMEDIATELY.

• WEAR SAFETY GLASSES when mixing or han-

dling.

• AVOID repeated or prolonged skin contact.

• AVOID inhaling oil mists or vapors.

• ALWAYS wipe up spills promptly - spills may create

a slip hazard if not attended to

••

• NEVER store oil in open or unmarked containers.

••

Also, follow these important safe-handling precautions

to minimize risk of explosion or fire when preparing fuel/

oil mix:

••

• ALWAYS prepare fuel/oil mix in an approved fuel

••

container

••

• ALWAYS follow mixing instructions in Operator’s

••

Manuals.

••

• ALWAYS make sure fuel container caps are tightly

••

secured before shaking container to mix fuel and oil.

••

• ALWAYS store fuel containers in a safe location,

••

with caps and vents sealed tightly.

Wear Safety Glasses when

mixing or handling fuel

Tighten cap before shaking

container

DANGER

Alternative fuels, such as E-20 (20% ethanol), E-85

(85% ethanol) or any fuels not meeting ECHO requirements are NOT approved for use in ECHO 2-stroke

gasoline engines. Use of alternative fuels may cause

performance problems, loss of power, overheating, fuel

vapor lock, and unintended machine operation, including, but not limited to, improper clutch engagement.

Alternative fuels may also cause premature deterioration of fuel lines, gaskets, carburetors and other engine

components.

22

E-20

E-85

Page 23

NEVER use raw (unmixed) fuel, or any high-ethanol fuel

(ethanol content greater than 10%) such as E20 -E85,

in a two-stroke engine.

Fuel containers filled with 2-stroke engine fuel/oil mix

should be identified as containing fuel/oil mix, and

should be stored separately to prevent using raw or high

ethanol gasoline in a two-stroke engine.

STARTING

STARTING

DANGER

The Operator’s Manual for your unit has specific starting

instructions for your model and type of engine. For your

safety and ease of starting, always follow these starting

instructions, and obey the safety rules provided.

The cutting head/work attachment on units that require

starting at wide-open (full) throttle (throttle trigger fully

depressed) will start moving immediately when the

engine starts.

To avoid loss of control and serious injury:

••

• Stabilize unit on ground before pulling starter handle.

••

••

• Stay clear of the cutting head/work attachment.

••

••

• Keep the cutting head/work attachment off the

••

ground and clear of objects that could be struck or

become entangled.

••

• Release the throttle trigger immediately when en-

••

gine starts.

Before starting the unit, make sure you know the location of the unit’s “STOP” switch, and know how to perform an emergency stop in case of a switch malfunction.

(See “Stopping” on page 25.)

Stabilize unit on ground

23

Page 24

STARTING

The cutting head/work attachment (nylon line head,

blade, or PAS/SB attachment) must not move at idle,

otherwise serious personal injury may result. Periodic

carburetor adjustment may be necessary to assure the

cutting head/PAS attachment does not move at idle. If

the cutting head/work attachment moves at idle, readjust carburetor according to “Carburetor Adjustment”

instructions and idle speed specifications provided in

your Operator’s Manual. See your Echo dealer or

contact Echo Consumer Support at 1-800-432-ECHO.

for help if you have any questions.

Follow these important safety rules when starting your

unit:

• DO NOT use unit if cutting head/work attachment

moves while engine is idling (throttle trigger not

depressed). Adjust idle speed as instructed in your

unit’s Operator’s Manual before using unit.

• NEVER start or run your unit indoors or anywhere

else where there is poor air circulation. Indoor

operation produces dangerous levels of Carbon

Monoxide, a colorless and odorless poisonous gas.

Carbon Monoxide (CO) causes nausea and other

flu-like symptoms if breathed. Prolonged exposure

to CO may cause loss of consciousness, brain

damage, or death.

• NEVER start a unit near a gasoline container or

spilled gasoline.

• ALWAYS move at least 3 m (10 ft.) away from

refueling location before starting engine.

• If a protective blade cover is used, ALWAYS re-

move blade cover before starting unit. Keep blade

cover nearby, and place cover back on blade when

unit is off and blade has stopped.

• NEVER start a PAS/HCA (extended shaft, articulat-

ing blade) unit while blade is in folded/locked position. Make cutting angle adjustment first.

Do not operate indoors

3 m

(10 ft.)

Do not start within 3 m (10 ft.) of

fueling location

24

Page 25

• ALWAYS start the unit with power head on the

ground, with cutting head/work attachment off the

ground and clear of debris and all obstructions.

• NEVER “drop start” the unit or attempt to start the

unit while it is resting on blade tips.

• ALWAYS grip the unit firmly when starting to prevent

loss of control when pulling starter handle.

STOPPING

• ALWAYS hold the unit securely on the right side of

your body with both hands. Use left hand on the front

handle and right hand on the rear handle, or use left

and right handgrips on units equipped with UHandle for metal blade use.

• MAINTAIN a secure, two-handed grip at all times

while unit is in use.

• ALWAYS shut unit off immediately if it shakes or

vibrates excessively when started. Tag unit, and

have it checked by an authorized service center

before placing back in use.

STOPPING

The “STOP” switch stops the unit by grounding the

ignition and preventing the spark plug from discharging

a spark. If the STOP switch malfunctions and does not

stop the unit when required, use the choke to stall the

engine to a stop, and have your Echo dealer repair the

switch before using the unit again.

Never drop start unit

Never use one-handed

Use this “Emergency" Stopping sequence only if the

STOP switch malfunctions:

• Release trigger and allow engine to return to idle,

and wait for cutting head/work attachment to stop.

• After the engine has returned to idle and cutting

attachment has stopped, place the unit on a safe,

flat surface, clear of obstructions.

• Keep one hand on the throttle control handle assem-

bly to maintain control of the unit, and move the

choke control lever to the closed, “COLD START”

( ) position to stall the engine.

CHOKE CLOSED

(COLD START POSITION)

25

Page 26

OPERATION

• Hold the unit with a secure, two-handed grip, and

wait for the engine to stall to a complete stop.

• After the engine stops, disconnect the spark plug

lead, and tag the unit to identify it as having a broken

STOP switch.

• Do not restart the unit. Have the unit repaired before

using it again.

OPERATION - GENERAL SAFETY

DANGER

Blade Hazard

Metal blades are extremely sharp, and have powerful

cutting action. Contact with moving blades or cutting

attachments will cause serious injury. Keep hands, feet,

and all other body parts away from moving blades and

cutting attachments at all times. Wear work gloves,

safety glasses, hearing protection, and protective

clothing.

Spark

Plug

Wire

Spark

Plug

Carbon Monoxide Hazard

Engine exhaust contains carbon monoxide, a poisonous gas. Breathing carbon monoxide can cause loss of

consciousness, serious injury, or death. Start and

operate outdoors only.

Spark Hazard

All Echo equipment features spark-arresting mufflers as standard equipment. Spark arrestors

prevent hot, glowing particles of carbon from being discharged from the muffler. Operation

with a damaged, loose, or missing spark arrestor can result in fire.

Hot Exhaust/Burn Hazard

The exhaust produced by gasoline-powered equipment

is hot, and can cause burns or ignite nearby flammable

materials. Never blow engine exhaust against your

body or toward flammable materials. The muffler and

surrounding area become extremely hot during use, and

can cause serious burns if touched.

Finger Sever Hazard

Moving parts can amputate fingers or cause severe

injuries. Keep hands, clothing and loose objects away

from all openings. Always stop engine, disconnect

spark plug, and make sure all moving parts have come

to a complete stop before removing obstructions,

clearing debris, or servicing unit.

26

Page 27

OPERATION

DANGER ZONE

Careless operation, misuse, improper configuration or assembly, or use of unapproved cutting

heads and work attachments can result in serious or fatal injuries to operator and bystanders.

Flying debris can cause serious eye injury, loss of sight, or property damage. You must read,

understand, and follow all safety and operating instructions in this safety manual, in your unit’s

Operator’s Manual, the Attachment Operator’s Manual, and in the Installation Instructions for

any kit or accessory being installed before using this equipment.

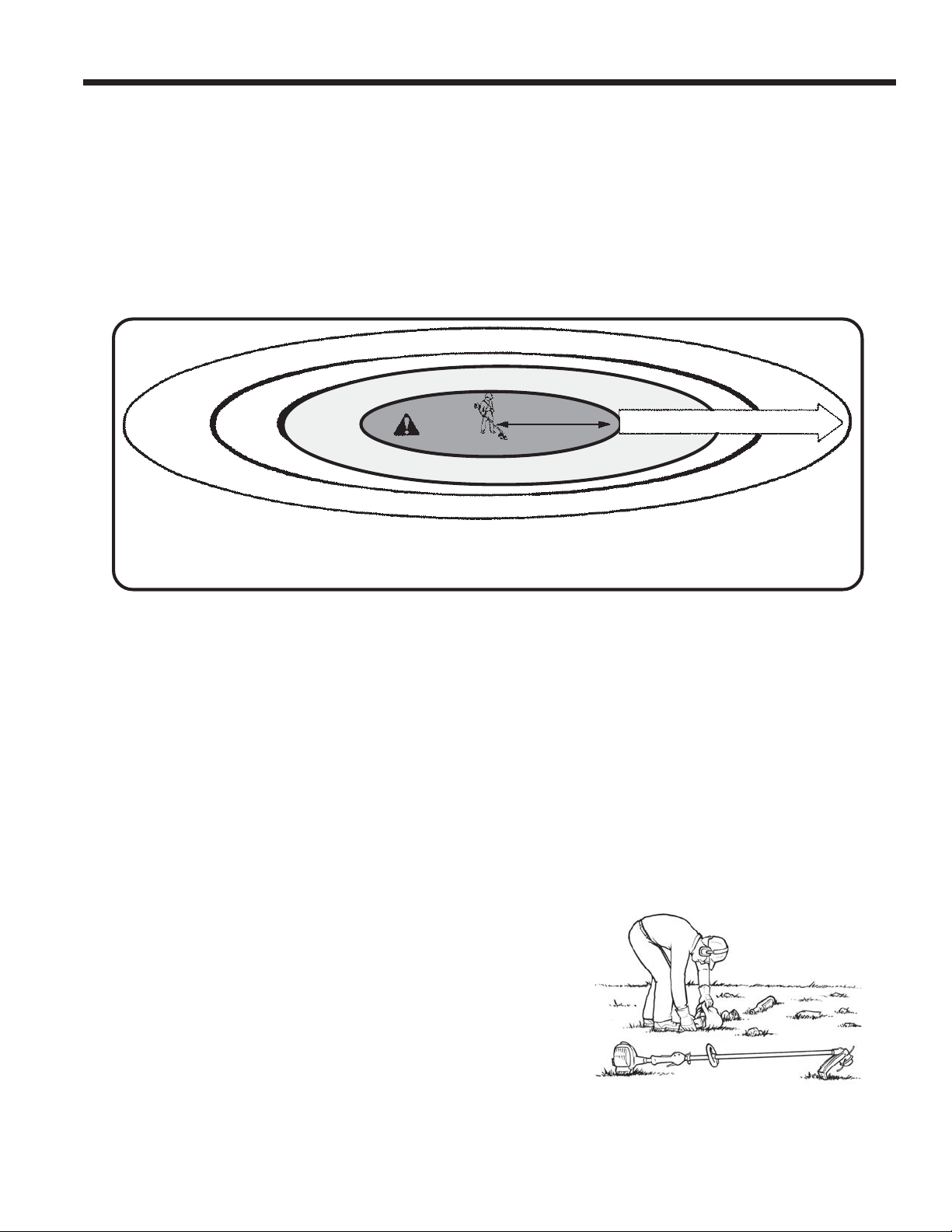

DANGER ZONE

30 METERS

15 METERS

DANGER ZONE

50 FEET

RISK ZONE

100 FEET

NO PERSON EXCEPT OPERATOR IS ALLOWED IN 15 METER RADIUS* DANGER ZONE. EYE,

EAR, FACE, FOOT, LEG AND BODY PROTECTION MUST BE WORN BY OPERATOR. PERSONS

IN ZONE OF RISK BEYOND DANGER ZONE MUST WEAR EYE PROTECTION.

• ALWAYS maintain a minimum safety zone of 50 feet (15 meters) from where you are

working. Don’t allow others to enter the safety zone unless you have shut the unit off and

the cutting/work attachment has completely stopped moving.

• ALWAYS wear appropriate personal protective equipment to protect eyes, face, hearing,

and hands.

• ALWAYS wear protective clothing to minimize risk of cuts, scrapes, and burns, and wear

sturdy shoes or work boots with non-slip soles.

• ALWAYS safety-check equipment carefully before use.

• NEVER operate with missing, broken, or loose parts.

• NEVER operate a unit with a fuel leak of any kind.

• ALWAYS clear the intended cutting/work area of debris such as wire, stones, wood, cans,

broken glass, and other objects which could be thrown, become entangled, or damage the

cutting head/work attachment.

• ALWAYS check for hidden hazards such as sprinkler

heads, metal stakes, or other similar objects that

could break the cutting line or damage the cutting/

work attachment. Stay clear of these hazards when

operating your unit to minimize risk of injury from

flying debris and loss of control, and to prevent

equipment damage.

• ALWAYS check the ground for surface obstacles

and other trip hazards, and be prepared for the

terrain when moving around the work area.

Always clear debris before

using unit

27

Page 28

OPERATION

• ALWAYS use extra care to maintain footing around

sloping, hilly, or slippery ground, and around uneven

surfaces like steps, raised walkways, edging, and

curbs.

• ALWAYS hold the unit firmly with two hands, with

thumbs wrapped around the handles for a secure,

comfortable grip. Left/front handle in left hand and

right/rear handle in right hand.

• ALWAYS cut using a stable stance, with both feet

on the ground.

• NEVER stand on a ladder or other temporary

platform. You can fall or slip, and injure yourself or

others.

• NEVER allow others near the cutting/work area, or

to hold material you are cutting.

• ALWAYS keep both hands on the unit to maintain

control.

• ALWAYS keep the muffler exhaust directed away

from your body.

• NEVER touch the muffler, muffler cover, or surround-

ing area. Allow the unit to cool down before performing any maintenance in the muffler area.

• NEVER allow flammable debris such as dried

leaves and sticks to build up in the exhaust area.

Heat from operation can ignite these materials, and

cause fire.

• ALWAYS keep fingers, hands, and all other body

parts away from the cutting/work attachment and

cutting/work area.

•

NEVER allow anyone to reach into the cutting/work

area for any reason while the unit is running.

• ALWAYS maintain a direct line of sight to the cut-

ting/work attachment and the area where cutting/

work is being performed. Be aware of what lies in

the path of the cutting/work attachment at all times.

• NEVER work in the dark or when visibility of the

work area is poor.

• ALWAYS be alert for changes in operation that

could signal a problem - sudden vibration, unusual

noise, the strong smell of fuel, or poor engine performance, all require immediate attention. Stop the

unit and correct any problems before resuming

cutting.

• NEVER carry unit around the work site while the

blade or attachment is rotating. ALWAYS shut the

engine off and let the blade or attachment stop

before lifting the unit and moving to a new position.

Always use 2 hands to

hold unit

Stop unit immediately if

sudden vibration occurs

28

Page 29

GT GRASS TRIMMER & SRM TRIMMER/

BRUSHCUTTER OPERATION

GT/SRM/PAS Units - Using Nylon Line Heads

OPERATION

Flying Debris

Line heads rotate at high speed - rotating nylon line can

throw debris with sufficient force to cause injury. Keep

bystanders and pets out of the “Danger Zone,” a 50 foot

(15 meter) radius around the unit being operated.

• ALWAYS check area for hidden hazards before

• Make sure line head is securely attached to gear

• Make sure cut-off knife is properly assembled to the

• Make sure debris shield is aligned with drive shaft,

• Keep debris flow directed away from operator to

• Contact with spinning nylon line will cause serious

• Keep cutting line away from wire fences to avoid

W ARNING

starting. Trimmer head or nylon line contact with

hidden hazards (sprinkler heads, metal stakes, etc.)

can result in loss of control of unit, nylon line breakage, and flying pieces of line or other ground debris.

case drive shaft, and, if used to install line head,

locking bar has been removed.

debris shield, and nylon line head is secured.

and is properly secured to the gear case housing.

minimize risk of being struck and injured by flying

debris. Debris flows in direction of line head rotation at point of cutting contact. Change line head

position as needed to change debris flow.

injury. Keep hands, feet, and all other body parts

away from line head.

entanglement with loose or broken wires. Entangled

fence wire can spin around with cutting head at high

speed, and cause serious injuries.

Make sure line head is

securely fastened

Keep cutting head away from

wire fences

29

Page 30

OPERATION

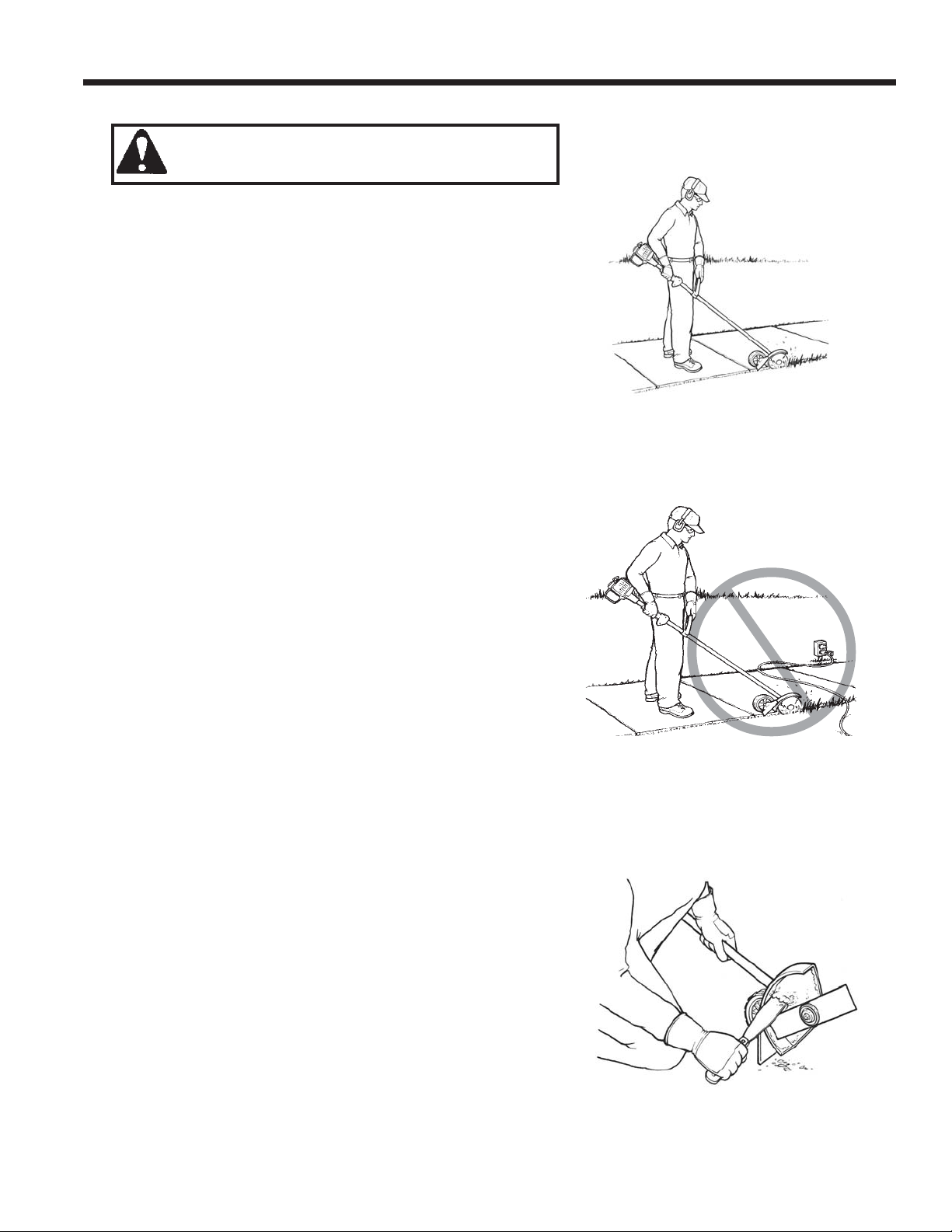

• NEVER operate trimmer with cutting head above

knee height - operation with the cutting head well

above ground level produces a higher debris flow, and

can cause debris to strike you in the face.

• ALWAYS follow instructions provided in Operator’s

Manual or with line head for loading or advancing nylon

line.

• ALWAYS wear gloves when handling or reloading a

line head that has been in use - the gear case and

driveshaft get very hot and can cause burns if touched.

Applications

Nylon line heads may be used for trimming, scything,

edging, and scalping of grass and light weeds.

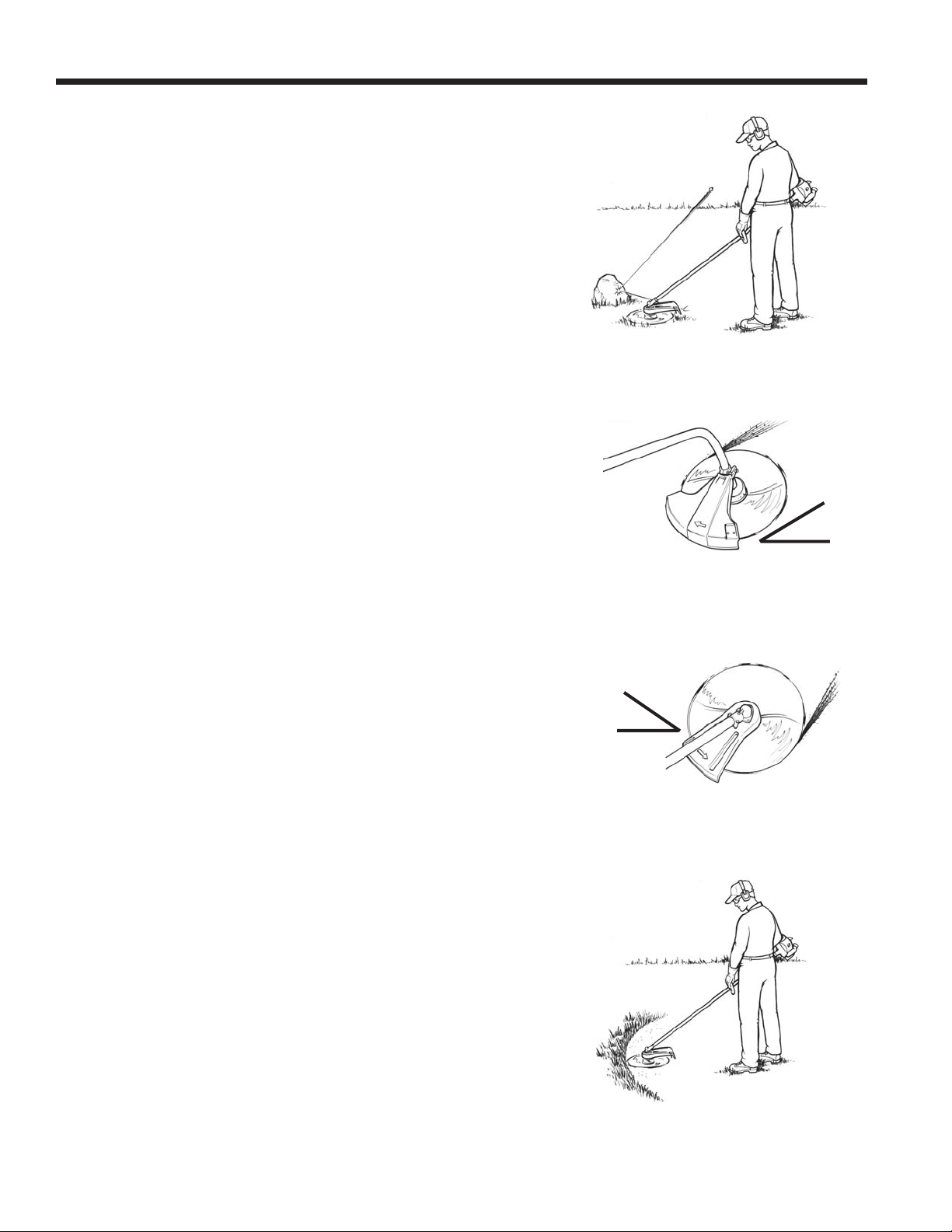

Trimming - Feed the spinning line into the material to be

cut. Tilt the line head to one side to direct cutting debris

away from you:

GT Trimming

Rotation

• Model GT (Curved shaft, clockwise line head rotation)

- Tilt the cutting head down on the left side (air filter

side) while cutting to direct cutting debris away from

operator. Feed the line gradually into the material you

wish to cut, avoiding contact with fences or other

barriers.

• Model SRM/PAS/SB (Straight shaft, counter-clock-

wise line head rotation) - Tilt the cutting head down on

the right side (muffler side) while cutting to direct

cutting debris away from operator. Feed the line

gradually into the material you wish to cut, avoiding

contact with fences or other barriers.

Scything - Swing the cutting head in a level arc, gradually

feeding the line into the material being cut. Move forward

with each arc to cut a swath. Width of cutting swath

depends on arc. Use a larger arc for a wider swath, or a

smaller arc for a narrow swath. Keep line head tilted to

direct cutting debris forward or away from you.

Tilted to the

left

SRM Trimming

Tilted to

the right

Rotation

30

Scything

Page 31

SRM/PAS Brushcutter Operation - Using Metal

Grass/Weed, Brush, & Clearing Blades

DANGER

Sharp Blades/Powerful Cutting Action

Contact with moving blades can cause serious or fatal

injury. Keep hands, feet, and all other body parts away

from blades. Wear all required personal protective

equipment. Misuse, improper assembly or care of

equipment, or failure to follow all safety and operating

instructions, can result in serious injuries to operator

and bystanders.

• Read blade selection, assembly, and sharpening

instructions in operator’s manual before using

trimmer/brushcutter with metal blade.

• Read, understand, and obey all warnings and in-

structions in this safety manual before using trimmer/

brushcutter with metal blade.

• Read, understand, and obey warnings and instruc-

tions on blade and blade packaging.

• Wear sturdy work gloves when handling, installing,

or removing metal blades.

• Keep blades in protective packaging until ready to

install. Store blades safely after removal to prevent

injury from accidental contact.

• Use Blade Protectors to prevent injury and protect

blade teeth during unit transport.

OPERATION

Observe 50’ (15 m) Danger Zone

Spinning blades can throw cutting and ground debris

with sufficient force to cause serious injury. Keep

bystanders and pets out of the “Safety Zone,” a 50 foot

(15 meter) radius around the unit being operated.

• Be alert for bystanders, children, and pets entering

Danger Zone during cutting. Stop unit and clear

work area completely before resuming cutting.

• Moving about while cutting changes Danger Zone

boundaries. Make sure all Danger Zone restrictions

are followed at all times.

31

Page 32

OPERATION

• Make sure the warning sign on the back of the

shoulder harness is properly positioned for easy

viewing by others.

• Wearing hearing protection and engine noise may

prevent you from hearing others about to enter the

Safety Zone. Perform regular visual safety checks

of the area while cutting to help ensure a safe work

area.

Hidden Hazards

Blade contact with exposed or hidden hazards (rocks,

metal posts, metal stakes, sprinkler heads, etc.) can

result in sudden loss of control, and injury from blade

contact or flying debris. Blade damage can result in

breakage, and serious injury caused by flying blade

fragments. Cutting with a dull or damaged blade increases risk of kick out and loss of control.

Standard Harness

• ALWAYS check area for hidden hazards before

starting. Remove hazard, or mark location of hazard

to prevent striking it while using brushcutter.

• ALWAYS use extreme care when cutting near

ground hazards and other obstacles.

• ALWAYS stop unit immediately and check for blade

damage if an object is struck. Do not use blade if

cracked, bent, chipped, or dulled by impact. Replace blade before resuming cutting.

• STOP engine immediately if sudden vibration

occurs, and check blade for damage before using.

Unit Configuration - Blade Use

Blade use requires specific unit configuration. Blade

must be matched to application requirements. See

Blade Configuration Chart (Page 15).

• NEVER use a metal blade with a plastic debris

shield.

• NEVER use a metal blade on a Model GT (Curved

Shaft) Grass Trimmer

• NEVER use an edging blade, circular saw blade, or

any other type of saw blade on an SRM/PAS/SB

unit. Only use brushcutter blades approved for use

by Echo on your model brushcutter.

• NEVER use a dull or damaged blade.

Heavy-Duty Harness

32

Page 33

• ALWAYS use blade only for application for which it

was intended

• ALWAYS use the correct front handle for the type of

blade being used. Echo recommends using a UHandle for all blade use.

REACTION FORCES - Push/Pull - Kickback/

Kickout

During normal use, operating a brushcutter with a

circular metal blade can produce sudden strong reaction forces that are difficult to control. Strong reaction

forces can cause a loss of balance or loss of control of

the unit, resulting in serious injury to operator and bystanders.

Understanding what causes these reactive forces may

help you to avoid them, and can help you to maintain

control of the unit if you experience a sudden reaction

during cutting. Reactive forces occur when the force

being applied by the cutting teeth of a blade meet

resistance, and some of the cutting force is directed

back toward the unit. The greater the cutting force or

the amount of resistance, the greater the reactive force.

OPERATION

PULL

Contact

Point

Push and Pull Forces

Push and pull forces are reactive forces that push the

unit directly toward the operator, or that pull the unit

directly away from the operator. These forces are the

result of cutting on the sides of the blade. The direction

of the force depends on the side of the blade being

used, and the direction of blade rotation at the point of

contact. The reactive force is in the opposite direction

of blade rotation at the contact point, regardless of

where the contact is being made. These types of

reactive forces are also called “Blade Thrust.”

As shown in the illustration, a blade turning counterclockwise will cause the unit to pull away from the

operator if the point of cutting resistance is on the left

side of the blade. If the point of cutting resistance is on

the right side of the blade, the unit will push back toward

the operator. In both examples, the reactive force is in

the opposite direction of blade rotation at the contact

point where resistance occurs.

Contact

Point

PUSH

33

Page 34

OPERATION

Kickout

Kickout is also a reactive force caused by resistance to

cutting, but the direction of blade thrust is lateral (to the

left or right of the blade), instead of forward or back

toward the operator. In most cases, Push, Pull, and

Kickout can be reduced or eliminated by:

• Using the correct blade for the cutting job

• Using properly sharpened blades

• Applying consistent, even force to the blade during

the cut

• Avoiding obstacles and ground hazards

• Using extra care when cutting harder materials such

as extremely dry brush, saplings, and small trees

• Cutting from a stable, secure position

Blade Assembly

Follow the instructions in the Operator’s Manual to

install a blade on your unit.

Kickout

Blade Assembly

Blade Rotation

• ALWAYS wear gloves when handling and assem-

bling blade to unit.

• ALWAYS use correct assembly hardware when

installing blade and debris shield.

• ALWAYS use correct blade arbor size.

• ALWAYS install blade with teeth pointed in direction

of rotation.

• ALWAYS tighten blade hardware securely using

properly sized tools

• ALWAYS use a new cotter pin when installing or

replacing blades.

• ALWAYS check to make sure head locking tool and

hex wrench have been removed from cutting head

after assembly.

Blade Cutting Capacities

Do not exceed recommended blade cutting capacity.

Use a chain saw for larger trees. Exceeding cutting

capacity can cause blade binding in cut, blade damage,

and risk of injury from blade breakage during cutting.

Cutting capacity depends on blade diameter - see

operator’s manual or Echo catalog for more information.

Cotter Pin

Blade

Upper

Blade Plate

Lower Blade

Plate

Lower Blade

Plate

Hex Nut

Cotter

Pin

Metal Debris

Shield

34

Page 35

Blade Applications

Use blades only in recommended applications.

••

• Grass/Weed Blade - Use Grass/Weed blades for

••

cutting thick grasses, weeds, light to medium vegetation, and thick-stalked growth such as reeds and

palm grass.

••

• Brush Blades - Use Brush blades for cutting dried

••

brush, small saplings, and large weeds with thick

stalks.

••

• Clearing Blades - Use Clearing Blades to cut

••

saplings, small trees, and thick, heavy brush.

Blade Cutting Problems

Binding - Blades may bind in the cut if dull or forced.

Binding can damage blade, and result in blade breakage or injury from fragments and flying debris. If a blade

binds in a cut, don’t try to get it out by applying “up and

down” force to pry the cut open. Applying prying force

to the blade can bend the blade, and result in blade

failure and injury.

OPERATION

Grass/Weed

Blade

Brush Blade

Clearing Blade

To free a blade that is bound in the cut, stop the engine, and support the trimmer/brushcutter to keep

stress off the blade. Push the tree away from the entry

point of the cut to open the cut, and pull the blade directly away from the cut in a straight-line motion. Use

caution when releasing the tree to avoid being struck by

spring-back or falling.

Inspect the blade for damage before proceeding.

Sharpen teeth if dull, or replace blade if cracked, bent,

missing teeth, or otherwise damaged. (See "Blade

Sharpening," on next page for important sharpening

information

To prevent binding:

• Keep blades sharp

• Avoid excessive pressure during cuts

• Don’t exceed cutting capacity of blade

• Don’t use blades with damaged or missing cutting

teeth

• Don’t rock blades in cut

Turn

engine off!

Jammed

Open cut to free blade with

engine off

Inspect jammed blade for

damage

35

Page 36

OPERATION

Blade Sharpening

All blades must be kept sharp for best cutting performance. 8 Tooth Grass/Weed blades can be sharpened

using the instructions in the Operator’s Manual. Brush

and Clearing blades require professional sharpening.

Improper sharpening can cause blade failure and result

in severe injury.

PLASTIC/METAL TRI-CUT BLADES

Use blade set-up guide for configuring trimmerbrushcutter to use plastic or metal tri-cut blades.

• Use Plastic tri-cut blades to cut grass and weeds

• Use Metal Tri-cut blades to cut reeds, large weeds,

and light brush

• Read, understand, and obey all trimmer-brushcutter

safety rules before using tri-cut blades.

• NEVER use tri-cut blades to cut heavy brush, sap-

lings, or small trees.

SHARPENING

8-TOOTH

WEED/GRASS

BLADE

30° ANGLE

LEAVE 2MM

RADIUS

UNFILED

SHARP CORNER

GULLET MAY

CRACK

Plastic Tri-Cut Blade SRM Pro Maxi-Cut

GT Maxi-Cut

PE Models

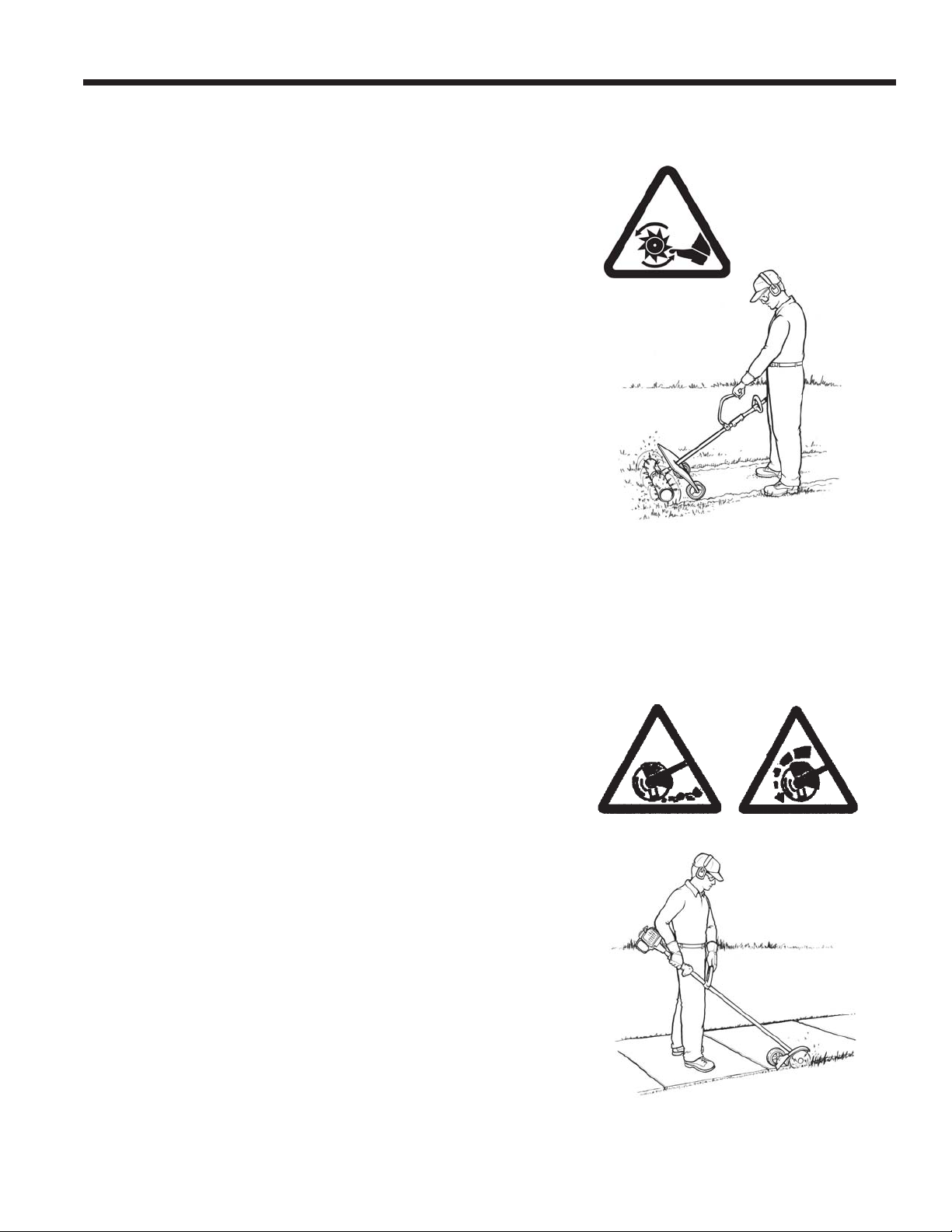

DANGER

Striking concrete or other hard materials with spinning edger blade can cause severe blade

damage or breakage, and serious or fatal injuries from flying fragments. Stop unit immediately

and check blade if an object is struck. Replace blade if broken, cracked, bent, chipped or

otherwise damaged, or if unit began shaking or vibrating after striking the object.

Small stones and other hard debris can be thrown from blade guard, and strike bystanders

and nearby buildings. Keep bystanders a minimum of 50 feet (15 m) away when operating

edger. Always keep flow of edging debris directed away from windows, parked vehicles,

buildings, and bystanders. Always operate edger with unit to right side of body only. Wear

eye protection, work gloves, and protective clothing. Use full face shield when edging in rocky

or debris-filled soil.

36

Page 37

WARNING

Edger operation may scatter ground debris that

can cause unstable or slippery footing, and increase the risk of slips and falls. Always maintain

proper footing and balance while operating edger.

Stop unit if necessary, and remove excessive

debris from work path before continuing.

• ALWAYS maintain control using a secure, wrap-

around, two-handed grip when operating the power

edger. If the edger strikes a buried object, it may

kick up and out of the edging cut forcefully, causing

serious injury.

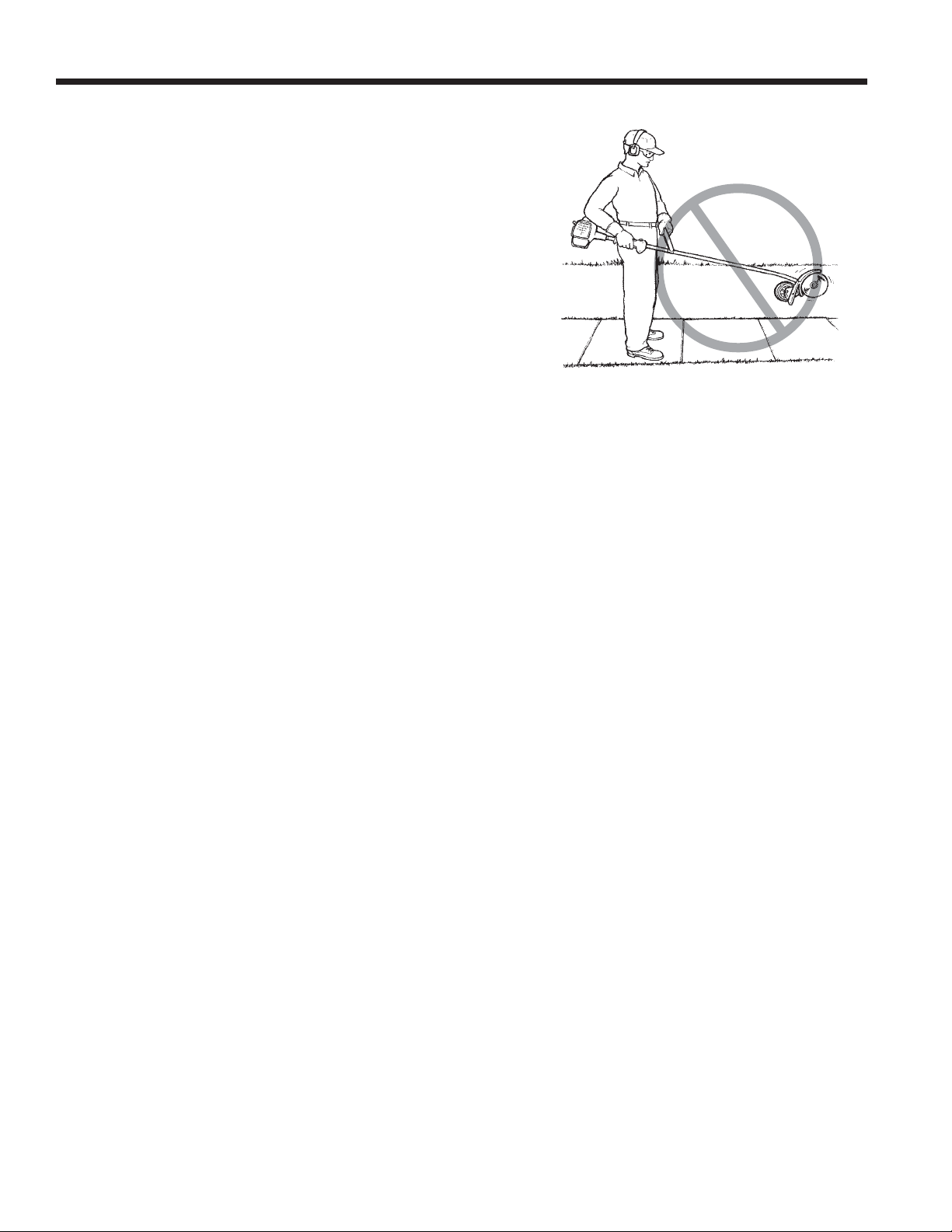

• NEVER operate with unit on left side of operator.

Use only on right side of body to keep operator out

of edger debris flow.

• ALWAYS maintain a stable, balanced stance, and

use extra care when walking on uneven, slippery, or

sloping surfaces.

• ALWAYS use extreme care when walking on wet

surfaces. Wet surfaces reduce traction, and increase the risk of slips and falls.

• ALWAYS be aware of ground and walkway condi-

tions in the work area, and be prepared to maintain

balance and footing when conditions change.

• ALWAYS check edging area for all potential haz-

ards before edging, and remove objects that can be

thrown or cause kick-out.

• NEVER edge where the cut line passes directly

over buried hazards such as sprinkler pipes, electric

wiring, gas lines, or other similar hazards.

• NEVER operate edger in any area where electric

extension cords are on the ground.

• NEVER use edger in gravel, rocky soil, or in areas

with hard ground cover such as decorative rocks.

• NEVER attempt to clear debris build-up from debris

shield by tapping shield against the ground.

ALWAYS shut engine off, wait for blade to stop, and

disconnect spark plug wire. Remove debris with a

small non-scratching scraper. Wear gloves to

protect hands from contact with sharp edges and hot

surfaces.

OPERATION

Edger Operator in Operating

Position

Prohibition - Edger Operation

w/Electric Cord on Ground

ENGINE

OFF

Debris Removal with Scraper

37

Page 38

OPERATION

• ALWAYS use only Echo-approved attachments and

edger blades.

• NEVER operate edger with damaged or missing

debris shield.

• NEVER adjust edger blade height with engine

running. Stop engine, disconnect spark plug lead,

and make adjustments.

• NEVER carry edger around the work site while the

blade or attachment is rotating. ALWAYS shut the

engine off and let the blade or attachment stop

before lifting the edger and moving to a new position.

• ALWAYS avoid contact with engine, muffler area,

and gear case during and immediately after operation. These areas get extremely hot, and touching

them can cause serious burns.

• ALWAYS wear work gloves to protect hands from

sharp edges or hot surfaces.

• NEVER allow edger blade to strike concrete or

other hard surfaces. Blade contact with hard surfaces can dislodge pieces of sidewalk, curb, paved

surfaces, or other hard materials, and cause serious

injury from flying debris.

• NEVER set depth of blade cut deeper than 1/2”

below guide surface. Cutting too deep increases

risk of edger kickout from cut and possible loss of

control of unit.

• ALWAYS keep edger blade vertical during edging -

NEVER operate with blade tilted at an angle.

• ALWAYS operate edger only when conditions

provide good visibility and clear line of sight to

edging cut line.

• ALWAYS release trigger and allow blade to come

to a stop before lifting unit out of the cut.

• ALWAYS release trigger and stop engine if some-

one enters the 50 foot radius danger zone. Wait for

visitor to leave the danger zone area before restarting engine.

• NEVER leave a power edger running while ground

or guide surface debris is being removed. Shut the

engine off, and place the unit in a safe place where it

will not be a trip hazard.

Prohibition - Edger Blade

Spinning Above Knee Level

38

Page 39

PAS ATTACHMENTS

DANGER

Misuse, improper assembly, or use of unapproved

attachments, can result in serious injury, engine failure,

and voiding of warranty. Use only Echo attachments

approved for use on Pro Attachment Series models.

Contact with moving cutting or work attachments can

cause serious injury. Keep clear of moving cutting/work

attachment.

Follow assembly instructions in attachment Operator’s

Manual and PAS power head manual.

OPERATION

• Drive shaft housing and gear case gets hot during

use. ALWAYS wear gloves when handling a unit

that has been in use.

PAS HEDGE CLIPPER ATTACHMENT

DANGER

Hedge clipper blades are very sharp and can

cause severe injuries, even if engine is off and

blades are not moving. Avoid contact with blades.

Wear gloves to protect hands.

••

• ALWAYS grip unit with both hands when operating

••

unit. Left/front handle in left hand and right/rear

handle in right.

••

• ALWAYS wear work gloves to protect hands from

••

sharp edges on blades.

••

• NEVER touch a moving blade or allow it to contact

••

any part of your body.

••

• NEVER feed blades toward your body when cutting

••

- keep blades directed away from yourself at all

times.

39

Page 40

OPERATION

••

• NEVER use unit within 15 meters (50 feet) of any

••

power lines or wires that may be conducting electricity. Contact with wires carrying electrical current can

result in shock or electrocution.

••

• NEVER exceed the cutting capacity of the hedge

••

clippers - forcing the blades to cut materials thicker

than the hedge clipper is designed to handle will

result in jams, blade damage, and poor overall

performance.

••

• ALWAYS use a suitable tool such as a power

••

pruner or chain saw to cut branches larger than the

hedge clipper will allow.

••

• NEVER attempt to cut more than 6 inches from a

••

hedge or shrub in one cutting pass. Use multiple

passes for cleaner, safer cuts, and better control.

••

• ALWAYS stop engine and disconnect spark plug

••

lead before removing a blade obstruction.

••

• NEVER use dull, loose, or damaged blades. Keep

••

blades properly adjusted and lubricated at all times.

••

• NEVER adjust blades when engine is running. Shut

••

engine off, and disconnect spark plug lead from

spark plug.

••

• ALWAYS use correct tools to perform blade adjust-

••

ments. Use long wrenches to keep hands away

from sharp blade edges.

••

• ALWAYS place blade cover on blades when trans-

••

porting or storing unit.

15 M

15 meters

(50 feet)

Blade Cover

PAS HCA ARTICULATING HEDGE CLIPPER

ATTACHMENT

DANGER

Metal blades are very sharp and can cause severe

injuries, even if engine is off and blades are not

moving. Avoid contact with blades. Wear gloves

to protect hands.

••

• ALWAYS read, understand, and obey all hedge

••

clipper warnings, safety rules, and operating instructions before using unit.

••

• ALWAYS shut unit off and make all cutting angle

••

adjustments on the ground.

40

Page 41

••

• ALWAYS use adjustment handle to hold blade

••

assembly when making adjustments.

••

• ALWAYS lock blades securely in position before

••

lifting unit off ground.

••

• ALWAYS check cutting area for hidden wires, fence

••

posts, and other obstacles before starting.

••

• ALWAYS maintain a line of sight to the cutting area.

••

••

• ALWAYS use extreme care when cutting overhead.

••

PAS POWER PRUNER ATTACHMENT

DANGER

OPERATION

Open blades on ground only

with engine stopped.

Saw chain teeth are very sharp and can cause

severe injuries, even if engine is off and chain is

not moving. Avoid contact with saw chain. Wear

gloves to protect hands.

KICKBACK HAZARDS

Contact between the tip of the guide bar nose and

objects such as tree limbs and branches can

cause Kickback. Kickback is a sudden, forceful

reaction that throws the guide bar and saw chain

up and away from the point of contact, and in an

arc back toward the operator.

Kickback can also occur when the moving saw

chain gets pinched in the cut, pushing the unit

straight back toward the operator with a sudden,

forceful reaction.

Kickback can result in loss of balance, loss of unit

control, and serious injury from contact with moving saw chain, or contact between the unit and

surrounding hazards.

Kickback

ROTATIONAL KICKBACK

••

• NEVER operate a Power Pruner Attachment while

••

on a ladder, in a tree, or on slippery or unstable

surfaces.

CHAIN MOVING DOWNWARD AT IMPACT

41

Page 42

OPERATION

••

• ALWAYS make sure that the pruned tree branch or

••

limb can fall safely to the ground after cutting.

••

• NEVER stand under a tree limb or branch during

••

cutting

••

• ALWAYS keep guide bar cover on guide bar until

••

unit is ready to be used.

••

• ALWAYS keep chain properly tensioned

••

••

• NEVER make guide bar/saw chain adjustments

••

while unit is running. Stop engine and disconnect

spark plug lead before tensioning chain.

••

• ALWAYS keep saw chain sharp. Dull chain will

••

cause increased vibration and premature guide bar

and chain failure.

••

• ALWAYS use only to cut wood. Cutting any other

••

type of material can cause increased risk of kickback and damage to saw chain and guide bar.

••

• ALWAYS stop engine immediately and check chain

••

and guide bar for damage if the cutting attachment

strikes an obstacle during cutting.

••

• NEVER use a saw chain with missing or damaged

••

teeth. Excessive vibration and erratic operation can

cause chain failure and serious injury.

Keep chain properly tensioned

PAS PROPADDLE/PROSWEEP ATTACHMENT

Misuse, improper assembly, or use of unapproved

attachments, can result in serious injury, engine failure,