Page 1

Instructions

SUBJECT: QUICK SPLIT (PN

75896-00) AND THROTTLE DOWN

(PN 75899-00) KITS

FITS MODELS: ALL LOG

SPLITTERS*

WARNING

Before inspecting or servicing any part of this machine,

shut off power source, remove key, disconnect the

battery cables and make sure all moving parts have

come to a complete stop.

NOTE

If the throttle down kit is installed on model LS21160,

you will first need to install a new Control Assembly.

Contact your local Honda dealer to order part #

16500-ZL8-800.

NOTE

Throttle Down Kit #75899-00 is not designed for use

on LS21 and LS21E Log Splitter models

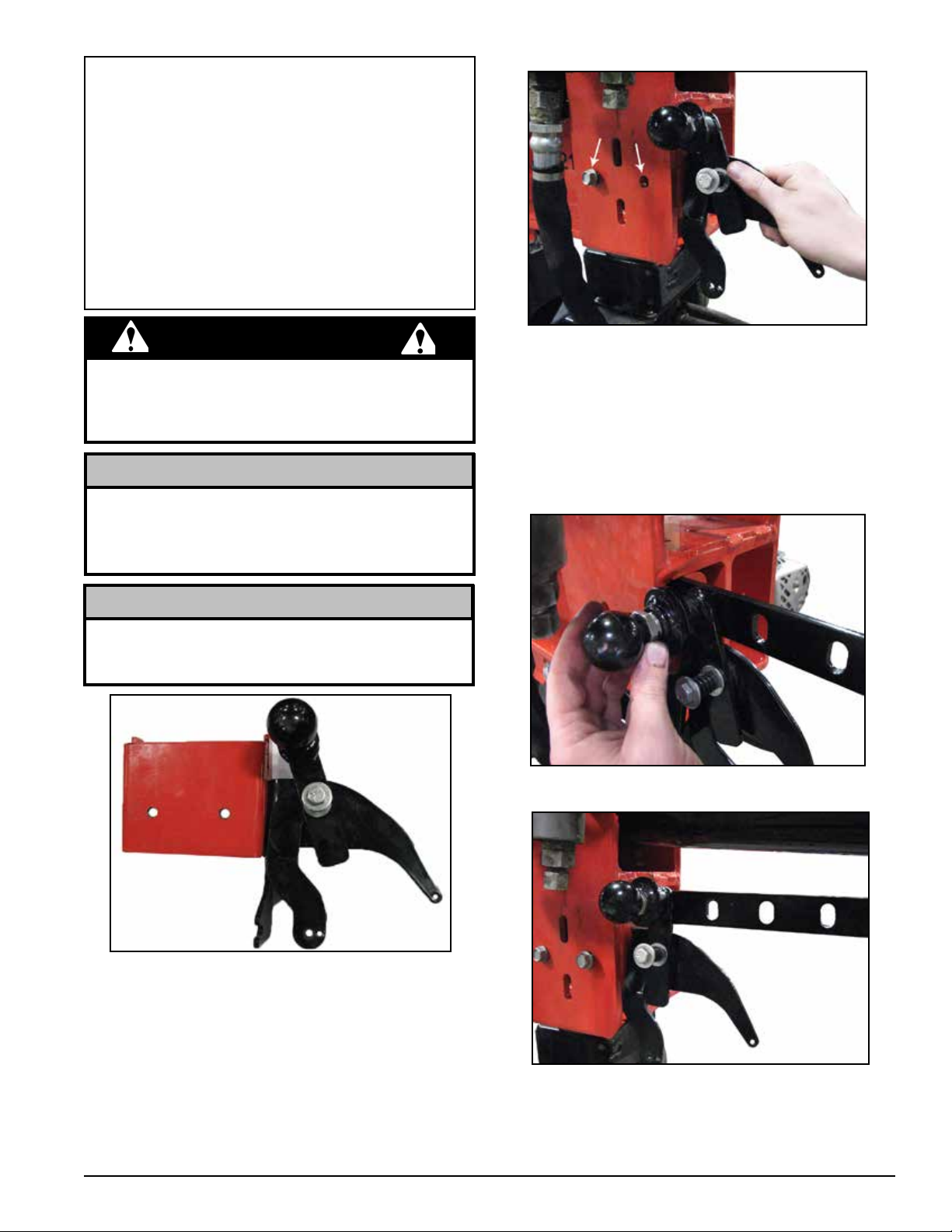

Figure 2. Channel and angle mount assembly

2. Do not completely tighten bolts at this point. Allow

enough movement to assist in completion of

assembly

3. Pull knob on angle mount assembly out to install slider

plate into channel mount as shown in Figures 3 and

4.

Figure 3. Pull knob out to install slider plate

Figure 1. Channel and angle mount assembly

INSTALLATION

1. Install the channel and angle mount assembly on the

right side of the log splitter in the channel with two

3/8 x 3/4" self-tapping hex bolts. IMPORTANT: If your

log splitter does not have the hex bolt holes already

pre-drilled, see Appendix 1 on page 8 for drilling

instructions.

Figure 4. Slider plate installed

PN 36323-00

Rev. 010112

Page 2

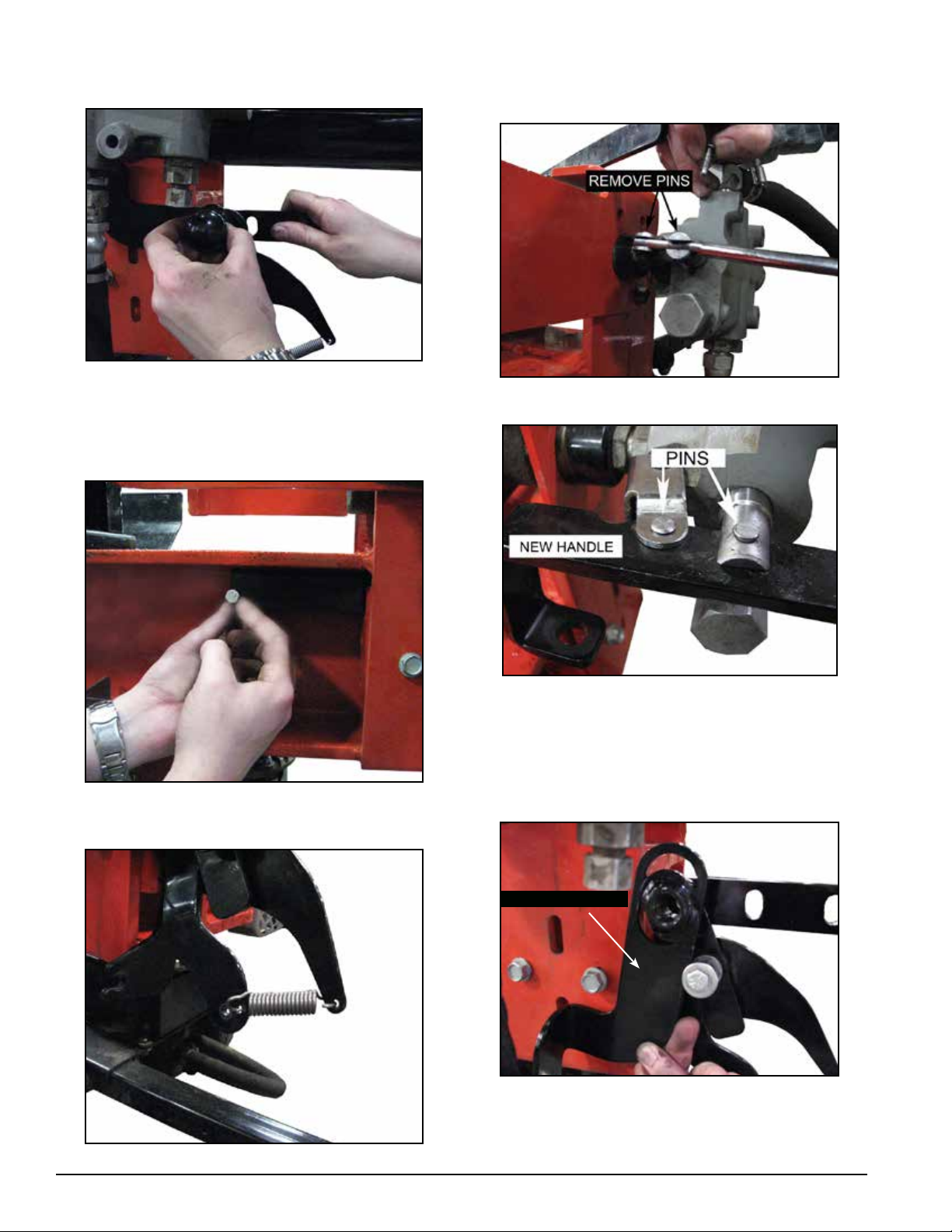

4. Continue to hold knob out and push the slider plate

through the channel and angle mount assembly,

Figure 5. Push slider plate through channel mount

5. Put a 1/4 x 3/4" hex bolt and nylock nut through the

hole on the end of the slider plate as shown in Figure

6.

7. Remove the existing valve handle by removing the

two pins and cottter pins that attach it to the hydraulic

valve.

Figure 8. Pins to be removed on existing handle

Figure 6. Slider plate bolt location

6. Install spring on angle assembly. See Figure 7.

Figure 7. Properly installed spring

2

Figure 9. Pins to be installed on new handle

8. Replace it with the new handle from the kit and reinstall

original pins and cotter pins to secure.

9. Remove knob from angle mount to allow the installation

of the slide angle.

SLIDE ANGLE

Figure 10. Install slide angle with knob removed

10. Reinstall lever knob once slide angle is properly

installed.

Instruction Sheet

Page 3

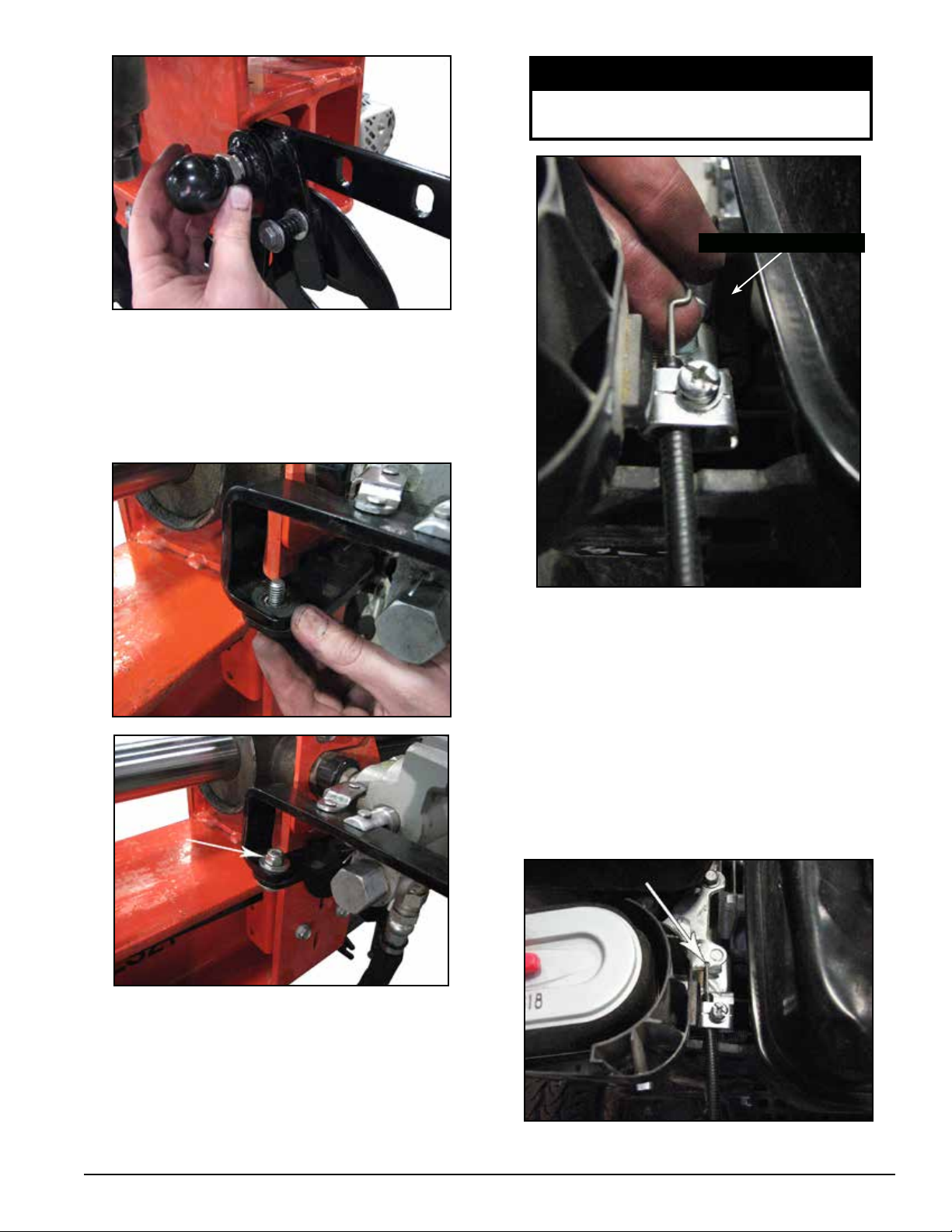

Figure 11. Reinstall lever knob

11. Pivot the end of the newly installed slide angle up and

align it with the end of the new handle. Attach them

using 5/16 x 1" hex head bolt, two washers and one

nylock nut. Tighten nut and bolt to the point that it still

allows proper operation of handle and slide angle.

NOTE

Steps 13 through 22 are not applicable to

Log Splitter models LS21 and LS21E.

CABLE CLAMP

Figures 12 & 12a. Connecting slide angle and new handle

12. At this point, verify that all parts of the assembly

are lined up and operating properly, and completely

tighten the 3/8 x 3/4" self-tapping hex bolts installed

in Step 1.

Figure 13. Throttle cable installed in cable clamp

14. Loosen the cable clamp located next to the throttle

control lever. Place the end of the throttle control cable

through the cable clamp.

15. Make sure several millimeters of cable insulation

are showing and tighten screw until snug. Do not

completely tighten.

16. Insert the "Z" end of the throttle cable into the small

diameter hole on the throttle lever as shown in Figure

13.

13. Remove the top of the air cleaner assembly to allow

better access for attaching the throttle cable end.

Instruction Sheet

Figure 14. "Z" end of cable inserted in throttle arm

3

Page 4

20. Remove the wire stop from the throttle cable by

loosening the bolt.

Figure 17. Coated clamp for routing of throttle cable

21. Attach the cable stop with a screw supplied with the

throttle cable, a #8 washer, and a 3/16" screw to the

lever bottom sheet. Tighten with an Allen head wrench

(the lever bottom must be in the vertical position).

Figure 15. Throttle arm friction nut

17. Loosen the friction nut (Figure 15) on the throttle lever

so the throttle lever moves freely and with very little

resistance. Failure to do this operation will not allow

the throttle cable to move the throttle lever properly or

with the full range of motion.

18. Make sure the throttle is in idle position.

19. Route the throttle cable through the 9/16 coated clamp

and install clamp on the lower right portion of the frame

using 1/4 x 3/4" bolt, washer and nut.

Figure 18. Cable stop mounting location and position

Figure 16. Coated clamp for routing of throttle cable

4

Instruction Sheet

Page 5

23. Remove the existing bottom wedge plate (A) as

shown in Figure 21, by removing the 1/2 nuts and

washers from the three 1/2 x 1-3/4" bolts securing it

to the wedge.

24. Install the new bottom wedge plate (B) that is supplied

in the Quick Split kit by reinstalling the bolts and

hardware, removed in step 23, and tighten securely.

A

Figure 19. Quick Split

22. Hook the spring between the lever bottom sheet and

the mount angle. On the quick split kit adjustment

may be necessary in order to achieve idle and full

throttle. Make adjustments at points (A) and (B) to

attain desired RPM settings. Ensure that the screw at

point (B) is not overtightened to the extent that the

cable stop will no longer pivot.

B

Figure 21. Installation of new cast wedge bottom plate(B)

OPERATION

QUICk SPLIT

1. Set the point to which the anvil will return by pulling the

ball out and adjusting the slider plate.

2. Move handle to split log.

3. After the log is split, push handle back and release. The

anvil will go back to the set point and then stop. The

engine will automatically throttle down.

THROTTLE DOWN

Figure 20. Throttle Down

1. Move handle to split log.

2. After the log is split, push handle back and release. The

anvil will go back to its original location and then stop.

The engine will automatically throttle down.

Instruction Sheet

5

Page 6

QUICk SPLIT kIT PARTS DIAGRAM

24

13

23

12

18

7

7

6

14

8

22

3

21

9

4

2

11

20

10

3

10

13

8

19

17

*Items 2, 6, 11 and 12 are not used in application on Log

Splitter models LS21 and LS21E

QUICk SPLIT kIT (PN 75896-00)

Item Part # Description Qty.

1 12177

2 14048-00 CLAMP, 9/16" COATED 1*

3 15001

4 15030 WASHER, 1/4 FLAT ZP 1

5 15140

6 15209 WASHER, #8 SAE 1*

7 15219

8 15250 WASHER, 5/16 FLAT ZP 5

9 15355 NUT, 1/4 NE NYLOCK ZP 2

10 15356 NUT, 5/16 NE NYLOCK ZP 2

11 15680-00

12 36088-00

6

SPRING, HEAVY DUTY

COMPRESSION

BOLT, 1/4 X 3/4 HEX HD

GR5 ZP

BOLT, 5/16 X 2 HEX HD GR5

ZP

BOLT, 5/16 X 1 HEX HD GR5

NC ZP

SCREW, #8-32 X 3/16 KNR

CUP PT

CABLE, THROTTLE LOG

SPLITTER

1

2

1

1

1*

1*

Instruction Sheet

5

16

15

13 36096-00

14 36387-00

15 75815-12 SHEET, LEVER BOTTOM 1

16 75843-12 ANGLE, MOUNT 1

17 75844-12 WELDMENT, LEVER 1

18 75849-12

19 75851-12

20 75890-12 ANGLE, SLIDE 1

21 75891-12

22 75925-12 CHANNEL, HANDLE 1

23 76015-35

24 77218-12

17320

1

8

BOLT, 3/8 X 3/4 SELF TAP

HEX ZP

SPRING, EXTENSION 1/2 X

2.00 X .075

PLATE, SLIDER QUICK

SPLIT

SPACER, 1/2 OD X 14 GA

X .36

SPACER, 1/2 OD X 14 GA

X .43

CHANNEL, MOUNT QUICK

SPLIT

PLATE, CAST WEDGE

BOTTOM

STRAP, 11 IN BLACK TIE

(NOT SHOWN)

4

1

1

1

1

1

1

1*

Page 7

THROTTLE DOWN kIT PARTS DIAGRAM

12

8

6

17

8

12

18

2

Throttle Down kit #75899-00 is not used on Log Splitter

models LS21 and LS21E

THROTTLE DOWN kIT (PN 75899-00)

Item Part # Description Qty.

1 14048-00 CLAMP, 9/16" COATED 1

2 15001

3 15030 WASHER, 1/4 FLAT ZP 1

4 15209 WASHER, #8 SAE 1

5 15219

6 15250 WASHER, 5/16 FLAT ZP 4

7 15355 NUT, 1/4 NE NYLOCK ZP 1

8 15356 NUT, 5/16 NE NYLOCK ZP 2

9 15436

10 15680-00

BOLT, 1/4 X 3/4 HEX HD GR5

ZP

BOLT, 5/16 X 1 GR5 HEX HD

NC ZP

BOLT, 5/16 X 1-1/4 HEX HD

GR5 NC ZP

SCREW, #8-32 X 3/16 KNR

CUP PT

1

1

1

1

Instruction Sheet

19

1

16

3

15

14

4

10

7

11

11 36088-00

12 36096-00

13 36387-00

14 72985 SPACER, 1/2 X .135 1

15 75843-12 ANGLE, MOUNT 1

16 75845-12 LEVER, THROTTLE 1

17 75850-12

18 75891-12

19 76015-35

17320

CABLE, THROTTLE LOG

SPLITTER

BOLT, 3/8 X 3/4 HEX SELF

TAP ZP

SPRING, EXTENSION 1/2 X

2.00 X .075

PLATE, SLIDER THROTTLE

DOWN

SPACER, 1/2 OD X 14 GA X

.43

CHANNEL, MOUNT QUICK

SPLIT

STRAP, 11 IN BLACK TIE

(NOT SHOWN)

6

9

5

13

1

4

1

1

1

1

1

7

Page 8

APPENDIX 1

DRILLING HOLES IN THE MOUNT PLATE

If your log splitter does not have the two holes in the channel used to complete Step 1, use the dimensions below to drill

two .41" x .50" holes in the mount plate.

Ø .41 x .50

1.25”

2.50”

1.25”

3.25”

ECHO BEAR CAT

Phone: 701.282.5520 • Toll Free: 800.247.7335 • Fax: 701.282.9522

E-mail: service@bearcatproducts.com • sales@bearcatproducts.com

237 NW 12th Street, West Fargo, ND 58078-0849

www.bearcatproducts.com

Loading...

Loading...