Page 1

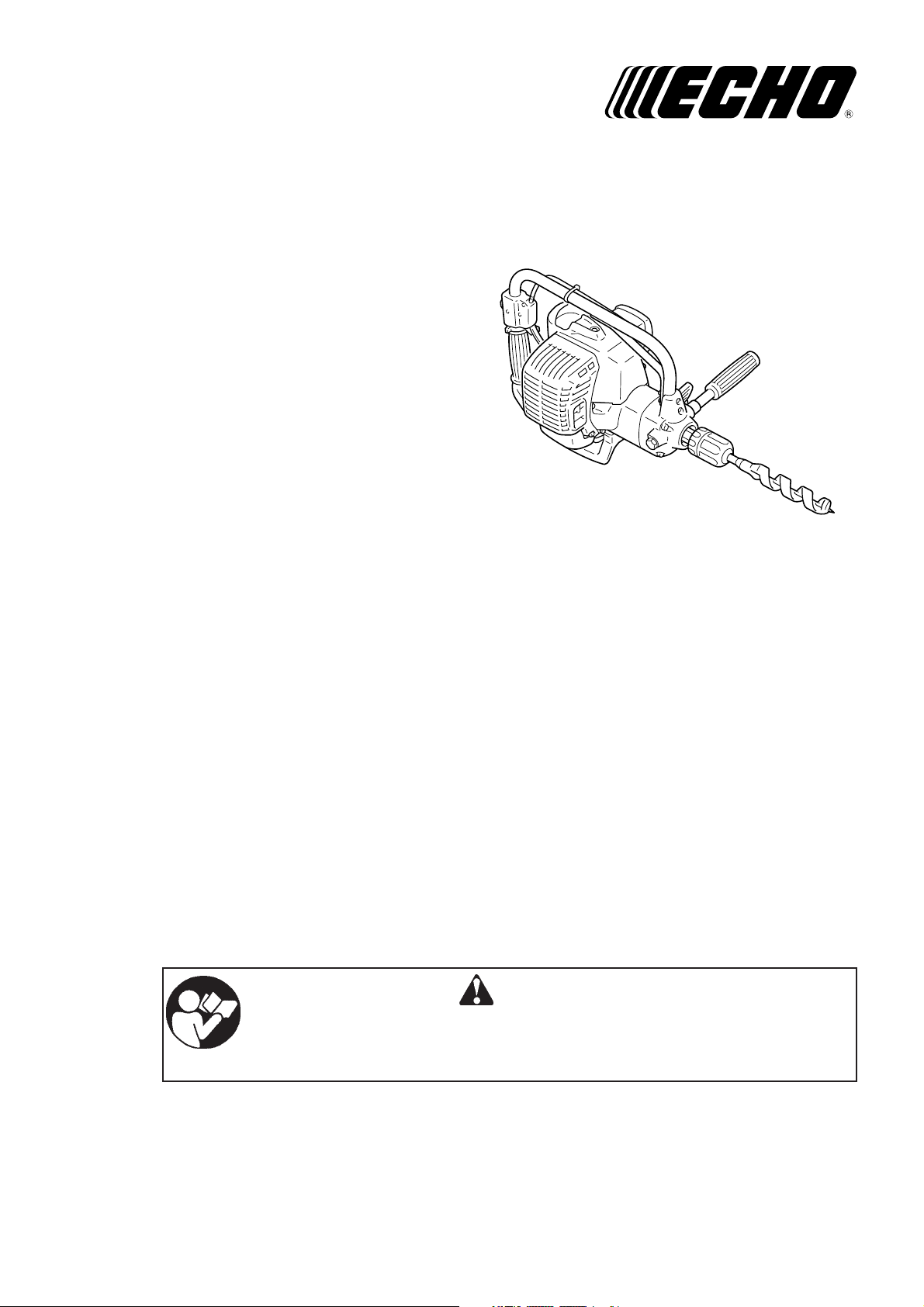

OPERATOR’S MANUAL

ENGINE DRILL

WARNING

READ INSTRUCTIONS CAREFULLY AND FOLLOW RULES FOR

SAFE OPERATION.

FAILURE TO DO SO COULD RESULT IN SERIOUS INJURY.

ECHO POWER EQUIPMENT(CANADA)

501 Newbold Street, London, Ontario Canada N6E 1K4

EDR-260

X750-005 04 5

X750409-3705

Printed in Japan 0907mh 1091 ES

Page 2

This spark ignition system complies with Canadian ICES-002.

Copyright © 2002 All Rights Reserved.

Page 3

INTRODUCTION

ECHO Engine Drill EDR-260 is a lightweight, high

performance, two-stroke engined unit designed for

drilling.

This Manual provides the information necessary

for operation and maintenance.

SAFETY AND SPECIAL INFORMATION

WARNING

IMPROPER USE OR CARE OF THIS UNIT, OR

FAILURE TO WEAR PROPER PROTECTION

CAN RESULT IN SERIOUS INJURY.

READ AND UNDERSTAND THE RULES FOR

SAFE OPERATION AND ALL INSTRUCTIONS

IN THIS MANUAL.

DANGER

The safety alert symbol accompanied by the

word “DANGER” calls attention to an act or

condition which WILL lead to serious

personal injury or death if not avoided.

WARNING

The safety alert symbol accompanied by the

word “WARNING” calls attention to an act or

condition which CAN lead to serious

personal injury or death if not avoided.

NOTE

This enclosed message provides tips for use,

care and maintenance of the unit.

IMPORTANT

The enclosed message provides information

necessary for the protection of the unit.

CIRCLE AND SLASH SYMBOL

This symbol means the specific action

shown is prohibited. Ignoring these

prohibitions can result in serious or

fatal injury.

CAUTION

The safety alert symbol accompanied by the

word “CAUTION” calls attention to an act or

condition which may lead to minor or

moderate personal injury if not avoided.

Throughout this manual and on the product itself,

you will find safety alters and helpful, information

messages preceded by symbols or key words.

The following is an explanation of those symbols

and key words and what they mean to you.

WARNING

Moving parts can amputate fingers or cause severe injuries. Keep hands, clothing and loose

objects away from all openings.

• ALWAYS stop engine, disconnect spark plug, and make sure all moving parts have come to a

complete stop before removing obstructions, clearing debris, or servicing unit.

• DO NOT start or operate unit unless all guards and protective covers are properly assembled

to unit.

• NEVER reach into any opening while the engine is running. Moving parts may not be visible

through openings.

WARNING

Check fuel system for leaks due to fuel tank damage, especially if the unit is dropped. If damage

or leaks are found, do not use unit, otherwise serious personal injury or property damage may

occur. Have unit repaired by an authorized servicing dealer before using.

1

Page 4

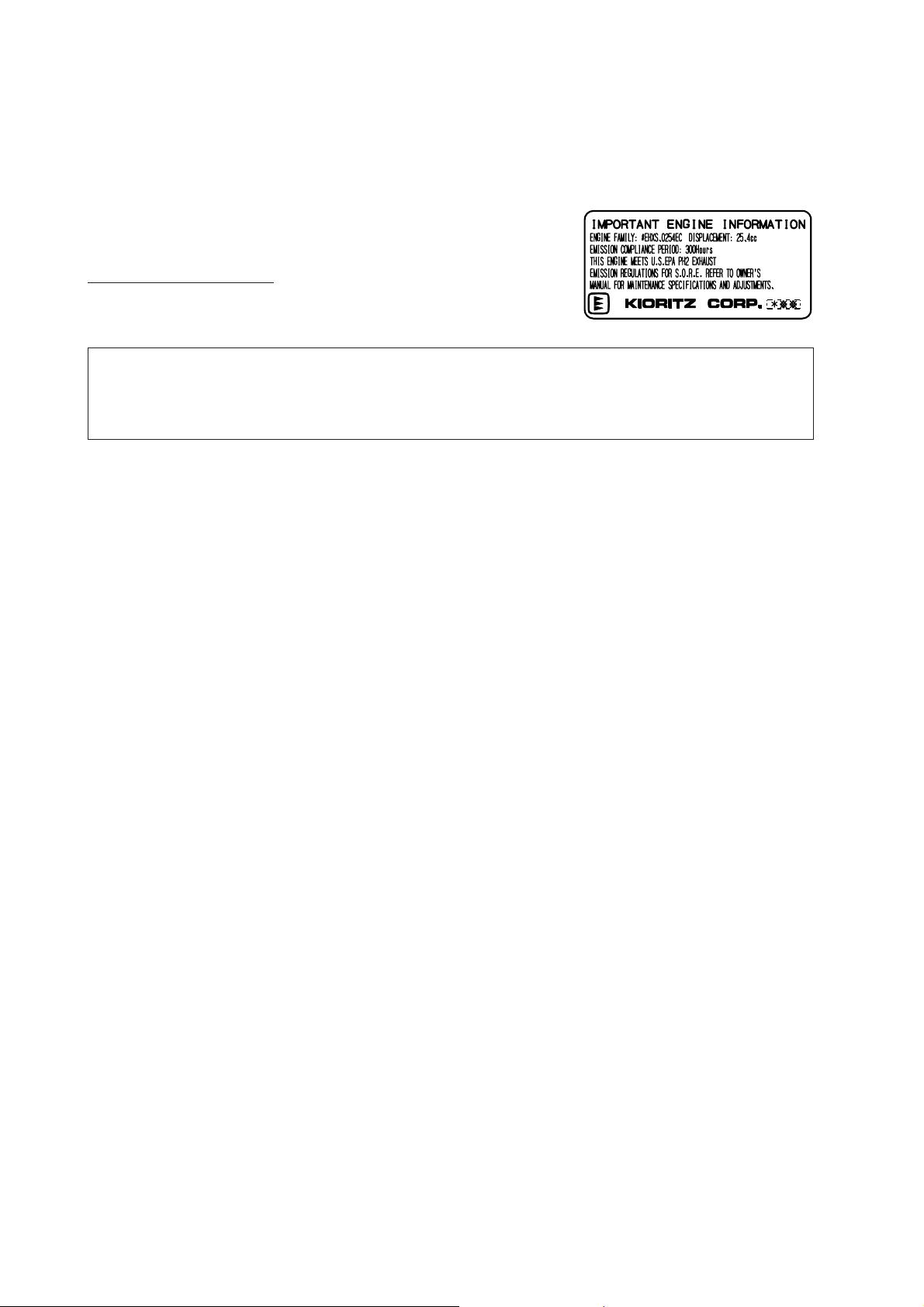

EMISSION CONTROL (EXHAUST & EVAPORATIVE)

EPA Phase 2 / C.A.R.B. TIER III

The emission control system for the engine is EM/TWC (Engine Modification and 3-way Catalyst) and for

the fuel tank the Control System is EVAP (Evaporative Emissions) or N (for Nylon Tank). Evaporative

emission may be applicable to California models only.

An Emission Control Label is located on the engine.

(This is an EXAMPLE ONLY, information on label

varies by engine FAMILY).

PRODUCT EMISSION DURABILITY (EMISSION COMPLIANCE PERIOD)

The 300 hour emission compliance period is the time span selected by the manufacturer certifying

the engine emissions output meets applicable emissions regulations, provided that approved

maintenance procedures are followed as listed in the Maintenance Section of this manual.

CONTENTS

Introduction ............................................................................................................................................. 1

Safety and Special Information ............................................................................................................... 1

Safety ...................................................................................................................................................... 3

Operating Techniques ............................................................................................................................. 5

Description .............................................................................................................................................. 6

Assembling .............................................................................................................................................. 7

Operation ................................................................................................................................................ 7

Maintenance and Care ............................................................................................................................ 12

Trouble shooting...................................................................................................................................... 13

Maintenance ............................................................................................................................................ 14

Storage .................................................................................................................................................... 17

Specifications .......................................................................................................................................... 18

Specifications, descriptions and illustrative material in this literature are as accurate as known at the time

of publication, but are subject to change without notice. Illustrations may include optional equipment and

accessories, and may not include all standard equipment.

2

Page 5

SAFETY

WARNING

ENGINE DRILL USERS RISK INJURY TO

THEMSELVES AND OTHERS IF THE ENGINE

DRILL IS USED IMPROPERLY, AND/OR

SAFETY PRECAUTIONS ARE NOT

FOLLOWED. PROPER CLOTHING AND

SAFETY GEAR MUST BE WORN WHEN

OPERATING ENGINE DRILL.

OPERATOR SAFETY

• Read this Engine drill Operator’s Manual

carefully. Be sure you understand how to

operate this unit properly before you use it.

• Be familiar with all the controls and the proper

use of the machine.

• Wear proper clothing to protect legs and other

exposed parts of your body.

• Wear non-skid sole shoes. Do not wear opentoed shoes or operate unit while bare footed.

• Wear eye and hearing protection devices.

WARNING

ALWAYS STOP THE ENGINE WHEN A DRILL

JAM OCCURS. DO NOT ATTEMPT TO

REMOVE AN OBJECT CAUSING A DRILL

JAM IF THE ENGINE IS RUNNING. PHYSICAL

INJURY CAN OCCUR IF A DRILL JAM IS

REMOVED AND THE DRILLS START

MOVING.

• Do all drilling at full throttle speed. Drilling at

less at than full speed can damage the clutch

by allowing it to slip.

WARNING

USE A FIRM GRIP WITH THUMBS AND

FINGERS ENCIRCLING THE HANDLES. A

FIRM GRIP WILL HELP YOU KEEP

CONTROL OF THE ENGINE DRILL. NEVER

OPERATE THE ENGINE DRILL ONLY ONE

HAND OR BODILY INJURY CAN OCCUR.

• Always carry the engine drill with the engine

stopped and the HOT muffler away from your

body.

• Use caution when handling fuel. Put the caps

back tightly on both the fuel can and the

engine drill fuel tank.

Move at least 3 m (10 feet) from the re-fueling

point and be sure there is no leakage of fuel

from the fuel tank cap or the fuel system before

starting the engine.

• Operate this gasoline powered engine

equipment in a well-ventilated area only.

• Start the unit on the ground with the throttle set

at idle. Do not start if the drills are obstructed

by the ground or any other object.

• Never allow children to use the machine.

• Do not allow anyone to hold the material you

are drilling.

• Keep a firm grip on the engine drill with both

hands, one hand on the front handle, the other

hand on the rear handle.

PROTECTIVE EQUIPMENT

• Always wear eye protection goggles that meet

ANSI Z87.1 standards.

• Wear hearing protection.

ECHO recommends that hearing protection be

worn at all times.

• Dress properly! Do not wear loose clothing or

jewellery, they can be caught in moving parts.

Use of sturdy gloves, non-skid footwear, and

safety glasses is recommended.

• While operating the machine always be sure of

a secure position.

3

Page 6

• Wear non-slip, heavy-duty work gloves to

improve your grip on the engine drill handles.

The gloves also help reduce the transmission

of machine vibrations to your hands.

WARNING

PRECAUTION AGAINST VIBRATION

AND COLD

PROTECTING OTHERS

Spectators, children, fellow workers and animals

must be warned to come no nearer than 4.6 m (15

feet) while the engine drill is in use.

People working in the area near you should wear

the same protective equipment as the operator.

PHYSICAL CONDITION

Your judgement and dexterity may be impaired if

you are ill or have taken alcohol or other

substances known to affect the way you would

normally function.

IT IS BELIEVED THAT A CONDITION

CALLED RAYNAUD’S PHENOMENON,

WHICH AFFECTS THE FINGERS OF

CERTAIN INDIVIDUALS MAY BE BROUGHT

ABOUT BY EXPOSURE TO VIBRATION AND

COLD. EXPOSURE TO VIBRATION AND

COLD MAY CAUSE TINGLING AND

BURNING SENSATIONS FOLLOWED BY

LOSS OF COLOR AND NUMBNESS IN THE

FINGERS. THE FOLLOWING PRECAUTIONS

ARE STRONGLY RECOMMENDED BECAUSE

THE MINIMUM EXPOSURE WHICH MIGHT

TRIGGER THE AILMENT IS UNKNOWN.

• KEEP YOUR BODY WARM, ESPECIALLY

THE HEAD, NECK, FEET, ANKLES, HANDS

AND WRISTS.

• MAINTAIN GOOD BLOOD CIRCULATION

BY PERFORMING VIGOROUS ARM

EXERCISES DURING FREQUENT WORK

BREAKS AND ALSO BY NOT SMOKING.

• LIMIT THE HOURS OF OPERATION. TRY

TO FILL EACH DAY WITH JOBS WHERE

OPERATING THE ENGINE DRILL OR

OTHER HAND-HELD POWER EQUIPMENT

IS NOT REQUIRED.

Painful or numb fingers?

See your doctor

• IF YOU EXPERIENCE DISCOMFORT,

REDNESS AND SWELLING OF THE

FINGERS FOLLOWED BY WHITENING AND

LOSS OF FEELING, CONSULT YOUR

PHYSICIAN BEFORE FURTHER EXPOSING

YOURSELF TO COLD AND VIBRATION.

4

Page 7

Repetitive Stress Injuries

It is believed that over-using the muscles and

tendons of the fingers, hands, arms and shoulders

may cause soreness, swelling, numbness,

weakness and extreme pain in those areas.

Certain repetitive hand activities may put you at a

high risk for developing a Repetitive Stress Injury

(RSI). An extreme RSI condition is Carpal Tunnel

Syndrome (CTS), which could occur when your

wrist swells and squeezes a vital nerve that runs

through the area. Some believe that prolonged

exposure to vibration may contribute to CTS.

CTS can cause severe pain for months or even

years. To reduce the risk of RSI/CTS, do the

following:

• Avoid using your wrist in a bent, extended or

twisted position. Instead try to maintain a

straight wrist position. Also, when grasping,

use your whole hand, not just the thumb

and index finger.

• Take periodic breaks to minimize repetition

and rest your hands.

OPERATING TECHNIQUES

• When starting to drill, run the engine at full

throttle.

WARNING

BEFORE DRILLING, BE SURE TO READ AND

UNDERSTAND THE ENTIRE OPERATOR’S

MANUAL TO AVOID THE CHANCE OF

SERIOUS INJURY.

• Do not force the drills and only move as

quickly as the drills will allow.

• Stop the engine and disconnect from ignition

cable before: - cleaning or when clearing a

blockage; checking, maintenance or working

on the machine.

• Handle fuel with care; it is highly flammable.

Never add fuel to a machine with a running or

hot engine.

• Reduce the speed and force with which you do

the repetitive movement.

• Do exercise to strengthen the hand and arm

muscles.

• See a doctor if you feel tingling, numbness or

pain in the fingers, hands, wrists or arms.

The sooner RSI/CTS is diagnosed, the more

likely permanent nerve and muscle damage

can be prevented.

• Do not attempt to repair the machine unless

you are qualified to do so.

• Do not operate the machine with a damaged or

excessively worn drill bit.

• Always ensure all handles and guards are

fitted when using the machine. Never attempt

to use an incomplete machine or one fitted with

an unauthorized modification.

• When transporting or storing the machine

always remove the drill bit.

• To reduce fire hazard keep engine and silencer

free of debris, leaves or excessive grease.

• Handle drill with care, contacting with drills

may cause injury.

5

Page 8

DESCRIPTION

2

3

4

Part Number X505-002310

Part Number X505-002570

Part Number X505-002310

Part Number X505-002570

1

15

5

6

7

8

14

13

12

11

10

9

* If a decal cannot be read, a new one can be

ordered from your ECHO dealer.

1. Operator’s manual - Included with unit. Read

before operation and keep for future reference

to learn proper, safe operating techniques.

2. Throttle trigger - Device activated by the

operator’s finger, for controlling the engine

speed.

3. Rear handle - Handle located furthest from the

drill bit.

4. Silencer cover

5. Drill bit - Not included with unit.

6. Chuck

7. Front handle - Handle located on the front

gear case.

8. Shift lever

9. Fuel tank - Contains fuel and fuel filter.

10. Fuel tank cap - For closing the fuel tank.

11. Air cleaner cover - Covers air filter.

12. Starter handle - Pull handle to start the

engine.

13. Throttle trigger lockout - Device that

prevents the accidental operation of the throttle

trigger until manually released.

14. Ignition switch - Device for allowing the

engine to be started and stopped.

15. Spark plug

6

Page 9

Washer

Front handle

Chuck

ASSEMBLING

FRONT HANDLE

• Insert the front handle to the machine, and turn

clockwise. (TIGHTEN THE SCREW FIRMLY)

- To operate front handle with right hand,

remove right plug then reverse sides when

installing handle and plug.

DRILL BIT

• Loosen the chuck and insert the drill bit (not

provided with unit). Then tighten the chuck by

turning it clockwise.

Drill bit

Plug

IMPORTANT

Use drill bits suited for the material being

drilled and for the depth of hole required.

OPERATION

WARNING

Moving parts can amputate fingers or cause severe injuries. Keep hands, clothing and loose

objects away from all openings. Always stop engine, disconnect spark plug, and make sure all

moving parts have come to a complete stop before removing obstructions, clearing debris, or

servicing unit.

WARNING

Engine exhaust IS HOT, and contains Carbon Monoxide (CO), a poison gas. Breathing CO can

cause unconsciousness,serious injury, or death. Exhaust can cause serious burns. ALWAYS

blow exhaust away from your face and body.

7

Page 10

WARNING

ALTERNATIVE FUELS, SUCH AS E-20 (20 %

ETHANOL), E-85 (85 % ETHANOL) OR ANY

FUELS NOT MEETING ABOVE

REQUIREMENTS ARE NOT APPROVED FOR

USE IN ECHO 2-STROKE GASOLINE

ENGINES.

USE OF ALTERNATIVE FUELS MAY CAUSE

PERFORMANCE PROBLEMS, LOSS OF

POWER, OVERHEATING, FUEL VAPOR

LOCK, AND UNINTENDED MACHINE

OPERATION, INCLUDING, BUT NOT LIMITED

TO, IMPROPER CLUTCH ENGAGEMENT.

ALTERNATIVE FUELS MAY ALSO CAUSE

PREMATURE DETERIORATION OF FUEL

LINES, GASKETS, CARBURETOR AND

OTHER ENGINE COMPONENTS.

Fuel Mix Chart 50 : 1

US. METRIC

Gasoline Oil Gasoline Oil

Gallons US. fl. oz. L mL

1 2.6 4 80

2 5.2 8 160

5 12.8 20 400

CHECK UP OF NUTS AND OTHER

HARDWARES

• Check up loose nuts, bolts and screws before

using the unit every day.

FUEL STATEMENT

GASOLINE - Use 89 Octane [(R+M)/2] (mid grade

or higher) gasoline or gasohol known to be good

quality.

Gasohol may contain up to 10 % Ethyl (grain)

alcohol or 15 % MTBE (methyl tertiary-butyl ether).

Gasohol containing methyl (wood) alcohol is NOT

approved.

Two-Stroke Oil - A two-stroke engine oil meeting

ISO-L-EGD (ISO/CD 13738) and J.A.S.O. FC/FD

Standards must be used. ECHO brand premium

Power Blend X™ Universal 2-Stroke Oil meets these

standards. Engine problems due to inadequate

lubrication caused by failure to use an ISO-L-EGD

(ISO/CD 13738) and J.A.S.O. FC/FD certified oil,

such as ECHO premium Power Blend X™, will void

the two-stroke engine warranty.

IMPORTANT

• ECHO premium Power Blend X™ Universal

2-Stroke Oil may be mixed at 50 : 1 ratio for

application in all ECHO engines sold in the

past regardless of ratio specified in those

manuals.

• Use of unmixed, improperly mixed, or fuel

older than 90 days, (stale fuel), may cause

hard starting, poor performance, or severe

engine damage and void the product

warranty. Read and follow instructions in

the Storage section of this manual.

8

Page 11

DANGER

FUEL IS VERY FLAMMABLE. USE EXTREME

CARE WHEN MIXING, STORING OR

HANDLING OR SERIOUS PERSONAL

INJURY MAY RESULT.

• USE AN APPROVED FUEL CONTAINER.

• DO NOT SMOKE NEAR FUEL.

• DO NOT ALLOW FLAMES OR SPARKS

NEAR FUEL.

• FUEL TANKS/CANS MAY BE UNDER

PRESSURE.

ALWAYS LOOSEN FUEL CAPS SLOWLY

ALLOWING PRESSURE TO EQUALIZE.

• NEVER REFUEL A UNIT WHEN THE

ENGINE IS HOT!

• NEVER REFUEL A UNIT WITH THE

ENGINE RUNNING.

• DO NOT FILL FUEL TANKS INDOORS.

ALWAYS FILL FUEL TANKS OUTDOORS

OVER BARE GROUND.

• DO NOT OVERFILL FUEL TANK. IT IS NOT

PERMITTED TO FILL FUEL ABOVE THE

SHOULDER LEVEL OF FUEL TANK. WIPE

UP SPILLS IMMEDIATELY.

• SECURELY TIGHTEN FUEL CAP AFTER

REFUELING.

• INSPECT FOR FUEL LEAKAGE.

IF FUEL LEAKAGE IS FOUND, DO NOT

START OR OPERATE UNIT UNTIL

LEAKAGE IS REPAIRED.

• MOVE AT LEAST 3 M (10 FEET) FROM

REFUELING LOCATION BEFORE

STARTING THE ENGINE.

HANDLING FUEL

MIXING INSTRUCTIONS -

1. Fill an approved fuel container with half of the

required amount of gasoline.

2. Add the proper amount of two-stroke oil to

gasoline.

3. Close container and shake to mix oil with

gasoline.

4. Add remaining gasoline, close fuel container,

and remix.

IMPORTANT

• Spilled fuel is a leading cause of

hydrocarbon emissions. Some states may

require the use of automatic fuel shut-off

containers to reduce fuel spillage.

• Stored fuel ages.

Do not mix more fuel than you expect to

use in thirty (30) days, ninety (90) days

when a fuel stabilizer is added.

• Stored two-stroke fuel may separate.

ALWAYS shake fuel container thoroughly

before each use.

AFTER USE -

DO NOT store a unit with fuel in its tank. Leaks can

occur. Return unused fuel to an approved fuel

storage container.

STORAGE -

Fuel storage laws vary by locality. Contact your

local government for the laws affecting your area.

As a precaution, store fuel in an approved, airtight

container. Store in a well-ventilated, unoccupied

building, away from sparks and flames.

Shoulder level

Fuel tank

9

Page 12

ON

Ignition switch

STOP

STARTING COLD ENGINE

WARNING

WHEN ENGINE IS STARTED, CONFIRM IF

THERE IS NOT ANY ABNORMAL VIBRATION

OR SOUND. IF THERE IS ABNORMAL

VIBRATION OR SOUND, ASK YOUR DEALER

TO REPAIR.

• Stand the engine upright on a level surface.

• Place ignition switch in ON (START/RUN)

position.

• Push purge bulb 3 to 4 times (or until fuel is

visible in fuel return line).

• Shift choke lever to close position (START).

Throttle trigger

Purge bulb

Push

Throttle trigger lockout

Starter handle

Fuel return line

START

(Close)

• Pull starter handle until the engine fires.

• Shift choke lever to full open position, and if

necessary, start the engine again and allow to

warm up before using.

- The clutch engages at approximately 3500

r/min. Therefore the drill bit may rotate at

fast idle engine speed.

STARTING WARM ENGINE

• Place ignition switch in ON (START/RUN)

position.

• Pull starter handle until the engine fires.

- Do not use the choke.

STOPPING ENGINE

• Set throttle trigger in idle position.

• Place ignition switch in STOP position.

Choke lever

RUN

(Open)

NOTE

When engine does not stop, shift choke lever to

close position.

Check and repair ignition switch before starting

the engine again.

10

Page 13

Shift lever

Counter

clockwise

(CCW)

Clockwise

(CW)

REVERSE ROTATION

• This model is equipped with reverse rotation

mechanism.

• When drilling, set shift lever down to clockwise

(CW) rotation position.

• If bit is locked due to deep penetration during

drilling operation, set shift lever up to

counterclockwise (CCW) rotation position and

operate reversed for easy pulling-out.

• When changing direction of drill rotation,

operate as follows:

- Return engine to idle.

- Engine shift lever to CW or CCW position

with a slight acceleration of the throttle

trigger.

To properly lock the gears in the gear case.

- Do not operate shift lever forcibly when

changing rotation direction.

WARNING

• WHEN THE DRILL CAN NOT PULL OUT

FROM THE WOOD, DO NOT TRY TO PULL

OUT THE DRILL BY FORCE.

• WHEN CHANGING THE BIT, ENSURE TO

STOP THE ENGINE.

• AFTER A JOB, BIT AND GEAR CASING

MAY BE HEATED, DO NOT TOUCH THEM

WITH BARE HANDS.

NOTE

Do not shift from forward to reverse (or viceversa) while the chuck is turning.

Failure to do so may cause unit damage.

Always release throttle and allow the unit to

return to idle before shifting.

Do not stand close to drill or chuck with your

body or clothes while operation.

When drilling, ensure that no power cable or

other obstacle exist.

11

Page 14

MAINTENANCE AND CARE

COMPONENT / SYSTEM

Air Filter Inspect/Clean

Choke Shutter Inspect/Clean

Fuel Filter Inspect/Replace

Fuel Cap Gasket Inspect/Replace

Fuel System Inspect/Replace

Spark Plug Inspect/Clean/Replace

Cooling System Inspect/Clean

Muffler Spark Arrestor Inspect/Clean/Replace

Cylinder Exhaust Port Inspect/Clean/Decarbon

Recoil Starter Rope Inspect/Clean

Screws/Nuts/Bolts Inspect/Tighten/Replace

MAINTENANCE PROCEDURE LETTER CODES:

IMPORTANT NOTE

frequency of required maintenance.

MAINTENANCE PROCEDURE NOTES:

(1) Low evaporative fuel tanks DO NOT require regular maintenance to maintain emission integrity.

* All recommendations to replace are based on the finding of damage or wear during inspection.

- Time intervals shown are maximum. Actual use and your experience will determine the

MAINTENANCE

PROCEDURE

REQ'D

SKILL

LEVEL

1I / C * R *

1I / C

1 I * I / R *

1I *R

1 I (1) * I (1) *

1 I / C / R *

2I / C

2 I / C / R *

2I / C

1I / C *

1I *

I = INSPECT, R = REPLACE, C = CLEAN

DAILY OR

BEFORE USE

EVERY

REFUEL

3 MONTHS

OR 90

HOURS

YEARLY

600 HOURS

IMPORTANT

Time intervals are maximum. Actual use and

your experience will determine the frequency

of required maintenance.

Record dates of monthly and yearly

inspections.

12

Page 15

TROUBLE SHOOTING

Trouble

Engine - hard to start Cause Remedy

- does not start

Engine Fuel at No fuel • Fuel filter clogged • Clean or replace

cranks carburetor at carburetor • Fuel line clogged • Clean

• Carburetor • Ask your ECHO dealer

Fuel at No fuel at • Carburetor • Ask your ECHO dealer

cylinder cylinder

Silencer wet • Fuel mixture is too rich • Open choke

with fuel • Clean/replace air filter

• Adjust carburetor

• Ask your ECHO dealer

Spark at No spark at • Ignition switch off • Turn switch on

end of end of plug • Electrical problem • Ask your ECHO dealer

plug wire wire

Spark at No spark at • Spark gap incorrect • Adjust 0.6 to 0.7 mm

plug plug (0.024 to 0.028 in)

• Covered with carbon • Clean or replace

• Fouled with fuel • Clean or replace

• Spark plug defective • Replace plug

Engine • Internal engine problem • Ask your ECHO dealer

does not

crank

Engine Dies or • Air filter dirty • Clean or replace

runs accelerates poorly • Fuel filter dirty • Clean or replace

• Fuel vent blocked • Clean

• Spark plug • Clean and adjust/replace

• Carburetor • Adjust

• Cooling system blocked • Clean

• Exhaust port/spark • Clean

arrester screen blocked

WARNING

• ALL ENGINE DRILL SERVICE OPERATIONS, OTHER THAN ITEMS LISTED IN THE

OPERATOR’S MANUAL, SHOULD BE PERFORMED BY AN AUTHORIZED ECHO DEALER.

• FUEL VAPORS ARE EXTREMELY FLAMMABLE AND MAY CAUSE FIRE AND/OR

EXPLOSION. NEVER TEST FOR IGNITION SPARK BY GROUNDING SPARK PLUG NEAR

CYLINDER PLUG HOLE, OTHERWISE SERIOUS PERSONAL INJURY MAY RESULT.

13

Page 16

Air filter

Air cleaner cover

MAINTENANCE

AIR FILTER

• Clean before use.

- Remove air cleaner cover and pull out air

filter.

- Lightly brush off dust or wash it in water and

detergent.

- Dry completely before putting it back in

place.

FUEL FILTER

• Check periodically.

- Do not allow dust to enter into fuel tank.

- Clogged filter will cause difficulty in starting

engine or poor engine performances.

- Pick up fuel filter through fuel inlet port with

a piece of steel wire or the like.

- When filter is dirty, replace it.

Fuel filterFuel tank cap

0.6 - 0.7 mm (0.024 - 0.028 in)

CHECK FUEL SYSTEM

• Check before every use.

• After refueling, make sure fuel does not leak or

exude from around fuel pipe, fuel grommet or

fuel tank cap.

• In case of fuel leakage or exudation there is a

danger of fire. Stop using the machine

immediately and request your dealer to inspect

or replace.

SPARK PLUG

• Check periodically.

- The standard spark gap is 0.6 to 0.7 mm

(0.024 to 0.028 in).

- Correct spark gap if it is wider or narrower

than the standard gap.

- If the electrodes are coated with carbon

deposits replace with a new spark plug.

Do not sandblast to clean.

Remaining sand will damage engine.

• Fastening torque = 15 to 17 N • m

(130 to 145 in • lb).

IMPORTANT

Do not over tighten plug.

14

Page 17

Box spanner

(10 mm)

REPLACEMENT OF CHUCK

Replacement of chuck should be done in the

following manner:

1. Fit 19 mm spanner onto driving axle and keep

it fitted.

2. Remove bolt with hexagonal hole fixed in the

driving axle.

3. Insert accessory hexagonal bar (Part Number

895412-20960) into chuck and fix.

Spanner (19 mm)

4. Fit 10 mm box spanner onto the hexagonal bar

and turn it into direction as indicated by an

arrow to remove chuck.

5. Fit a new chuck in the reversed order of

removing.

Spanner (19 mm)

Hexagonal bar

(Part Number 895412-20960)

Idle speed adjustment screw

ADJUSTING CARBURETOR

(As Required)

GENERAL INFORMATION

The idle speed adjuster screw controls the throttle

opening at the idle position.

IDLE ADJUSTMENT

1. Start engine and allow it to run at high idle until

warm.

2. Turn the idle speed screw clockwise until drill

bit begins to move.

3. Turn idle screw counterclockwise 1 and 1/2 to 2

turn or until the drill bit stops (2700 to 3300

r/min).

NOTE

When there is some trouble with the carburetor,

contact your dealer.

15

Page 18

Cylinder fins

Silencer cover

CLEANING CYLINDER FINS

(Check Periodically)

NOTE

Clogged fins will cause poor engine cooling.

1. Carefully remove housing and clean dirt and

dust from fins.

2. Reinstall housing.

CLEANING SILENCER AND

EXHAUST PORT

(Check Periodically)

1. Carefully remove housing halves.

2. Remove and disassemble silencer.

NOTE

Be careful not to scratch the cylinder or piston

when cleaning the cylinder exhaust port.

Silencer

3. Clean deposits from cylinder exhaust port and

silencer.

Exhaust Port Cleaning

Level 2.

Tools required: 4 mm Hex Wrench, Wood or

plastic scraper

Parts Required:As needed: Heat Shield

A

B

1. Remove spark plug lead from spark plug, and

remove engine cover (2 screws).

2. Place piston at top dead center. Remove

muffler (A) and heat shield (B).

3. Use a wood or plastic scraping tool to clean

deposits from cylinder exhaust port.

IMPORTANT

Never use a metal tool to scrape carbon from

the exhaust port.

Do not scratch the cylinder or piston when

cleaning the exhaust port. Do not allow

carbon particles to enter the cylinder.

4. Inspect heat shield, and replace if damaged.

5. Install heat shield and muffler.

16

Page 19

6. Tighten muffler mounting bolts (or nuts) to 8095 in•lbf (90-110 kgf•cm).

7. Start engine, and warm to operating temperature.

8. Stop engine, and re-tighten mounting bolts (or

nuts) to specifications.

9. Install engine cover and attach spark plug lead.

STORAGE

LONG TERM STORAGE

(Over 30 Days)

Do not store your unit for a prolonged period of

time (30 days or longer) without performing

protective storage maintenance which includes the

following:

1. Store unit in a dry, dust free place, out of the

reach of children and other unauthorized

persons.

2. Place ignition switch in STOP position.

3. Remove accumulation of grease, oil, dirt and

debris from exterior of unit.

4. Perform all periodic lubrication and services

that are required.

5. Tighten all the screws, bolts and nuts.

WARNING

DO NOT STORE IN AN ENCLOSURE WHERE

FUEL FUMES MAY ACCUMULATE OR

REACH AN OPEN FLAME OR SPARK.

6. Drain the fuel tank completely and pull the

recoil starter handle several times to remove

fuel from the carburetor.

7. Remove the spark plug and pour 1/2

tablespoon (1/4 oz) of fresh, clean, 2-stroke

engine oil into the cylinder through the spark

plug hole.

A. Place a clean cloth over the spark plug hole.

B. Pull the recoil starter handle 2 or 3 times to

distribute the oil inside the engine.

C. Observe the piston location through the

spark plug hole. Pull the recoil starter handle

slowly until the piston reaches the top of its

travel and leave it there.

8. Install the spark plug (do not connect ignition

cable).

9. Lubricate the drill bit with a heavy coat of oil to

prevent rust.

NOTE

For future reference, you should keep this

operator’s manual.

17

Page 20

SPECIFICATIONS

EDR-260

Mass without drill bit kg 5.18 (11.42 lb)

Volume

fuel tank L 0.58 (19.6 US fl. oz.)

Drill

size mm 32 - 178 (1.25 - 7 inch)

chuck capacity mm 13 (0.5 inch)

speed r/min 610

Mission

reduction ratio 17.1 (regular side)

19.0 (reverse side)

lubrication grease

External Dimensions

length × width × height mm 450 × 340 × 290

without drill bit (17.72 × 13.39 × 11.42 inch)

Engine

type Air cooled Two stroke single cylinder

engine displacement mL(cm³) 25.4 (1.55 cu. inch)

recommended maximum engine speed r/min 10500

recommended engine idling speed r/min 2800

engine speed at beginning of clutch engagement r/min 3600

carburetor diaphragm type

ignition flywheel magneto - CDI system

spark plug NGK BPMR8Y

starter recoil starter

clutch automatic centrifugal

Fuel

mixture ratio 50:1 ratio with ECHO Power Blend X™ ,

ISO-L-EGD (ISO/CD 13738) and JASO

M345-FC/FD two-stroke, air-cooled engine

oil.

gasoline Use 89 octane unleaded. Do not use fuel

containing methyl alcohol, more than 10%

ethyl alcohol or 15% MTBE. Do not use

alternative fuels such as E-20 or E-85.

fuel consumption at engine maximum power L/h 0.62 (20.97 US fl. oz.)

18

Loading...

Loading...