Page 1

OPERATOR’S MANUAL

ECHO

ENGINE DRILL

ED-200

WARNING DANGER

READ INSTRUCTIONS CAREFULLY AND

FOLLOW RULES FOR SAFE OPERATION.

FAILURE TO DO SO COULD RESULT IN

SERIOUS INJURY.

ECHO, INCORPORATED

400 Oakwood Road, Lake Zurich, Illinois 60047-1564

Phone : 847-540-8400

X750-004 56 0

X750409-3400

Printed in Japan 0310Ami 857 ES

Page 2

WARNING

Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to the State of

California to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and other masonry

products, and

• Arsenic and chromium from chemically treated lumber.

Your risk from these exposures varies, depending on how often you do

this type of work. To reduce your exposure to these chemicals: work in a

well ventilated area, and work with approved safety equipment, such as

those dust masks that are specially designed to filter out microscopic

particles.

WARNING

The engine exhaust from this

product contains chemicals known

to the State of California to cause

cancer, birth defects or other

reproductive harm.

Page 3

INTRODUCTION

ECHO Engine Drill ED-200 is a lightweight, high

performance, two-stroke engined unit designed for

drilling.

This Manual provides the information necessary for

operation and maintenance.

SAFETY AND SPECIAL INFORMATION

THIS SYMBOL ACCOMPANIED

BY THE WORDS WARNING

AND DANGER CALLS

ATTENTION TO AN ACT OR

CONDITION THAT CAN LEAD

TO SERIOUS PERSONAL

INJURY TO OPERATOR AND

BYSTANDERS.

WARNING DANGER

IMPROPER USE OR CARE OF THIS UNIT, OR

FAILURE TO WEAR PROPER PROTECTION

CAN RESULT IN SERIOUS INJURY. READ

AND UNDERSTAND THE RULES FOR SAFE

OPERATION AND ALL INSTRUCTIONS IN

THIS MANUAL.

IMPORTANT

The enclosed message provides information

necessary for the protection of the unit.

NOTE

This enclosed message provides tips for use,

care and maintenance of the unit.

Throughout this manual and on the product itself,

The circle with the slash symbol

means whatever is shown within

the circle is prohibited.

you will find safety alters and helpful, information

messages preceded by symbols or key words. The

following is an explanation of those symbols and

key words and what they mean to you.

CONTENTS

Introduction .................................................................................................................................................. 1

Safety and Special Information .................................................................................................................... 1

Safety ........................................................................................................................................................... 2

Operating Techniques.................................................................................................................................. 5

Description ................................................................................................................................................... 6

Assembling................................................................................................................................................... 7

Operation ..................................................................................................................................................... 7

Maintenance and Care ................................................................................................................................. 9

Trouble shooting........................................................................................................................................... 10

Maintenance................................................................................................................................................. 11

Storage......................................................................................................................................................... 13

Specifications ............................................................................................................................................... 14

Specifications, descriptions and illustrative material in this literature are as accurate as known at the time of

publication, but are subject to change without notice. Illustrations may include optional equipment and

accessories, and may not include all standard equipment.

1

Page 4

SAFETY

WARNING DANGER

ENGINE DRILL USERS RISK INJURY TO

THEMSELVES AND OTHERS IF THE ENGINE

DRILL IS USED IMPROPERLY, AND/OR

SAFETY PRECAUTIONS ARE NOT

FOLLOWED. PROPER CLOTHING AND

SAFETY GEAR MUST BE WORN WHEN

OPERATING ENGINE DRILL.

OPERATOR SAFETY

• Read this Engine drill Operator’s Manual

carefully. Be sure you understand how to

operate this unit properly before you use it.

• Be familiar with all the controls and the proper

use of the machine.

• Wear proper clothing to protect legs and other

exposed parts of your body.

• Wear non-skid sole shoes. Do not wear opentoed shoes or operate unit while bare footed.

• Wear eye and hearing protection devices.

WARNING DANGER

ALWAYS STOP THE ENGINE WHEN A DRILL

JAM OCCURS. DO NOT ATTEMPT TO

REMOVE AN OBJECT CAUSING A DRILL

JAM IF THE ENGINE IS RUNNING. PHYSICAL

INJURY CAN OCCUR IF A DRILL JAM IS

REMOVED AND THE DRILLS START

MOVING.

• Do all drilling at full throttle speed. Drilling at

less at than full speed can damage the clutch

by allowing it to slip.

WARNING DANGER

USE A FIRM GRIP WITH THUMBS AND

FINGERS ENCIRCLING THE HANDLES. A

FIRM GRIP WILL HELP YOU KEEP CONTROL

OF THE ENGINE DRILL. NEVER OPERATE

THE ENGINE DRILL ONLY ONE HAND OR

BODILY INJURY CAN OCCUR.

• Always carry the engine drill with the engine

stopped and the HOT muffler away from your

body.

• Use caution when handling fuel. Put the caps

back tightly on both the fuel can and the engine

drill fuel tank.

Move at least 3 m (10 feet) from the refueling

point and be sure there is no leakage of fuel

from the fuel tank cap or the fuel system before

starting the engine.

• Operate this gasoline powered engine

equipment in a well-ventilated area only.

• Start the unit on the ground with the throttle set

at idle. Do not start if the drills are obstructed

by the ground or any other object.

• Never allow children to use the machine.

• Do not allow anyone to hold the material you

are drilling.

• Keep a firm grip on the engine drill with both

hands, the right hand on the front handle, the

left hand on the rear handle.

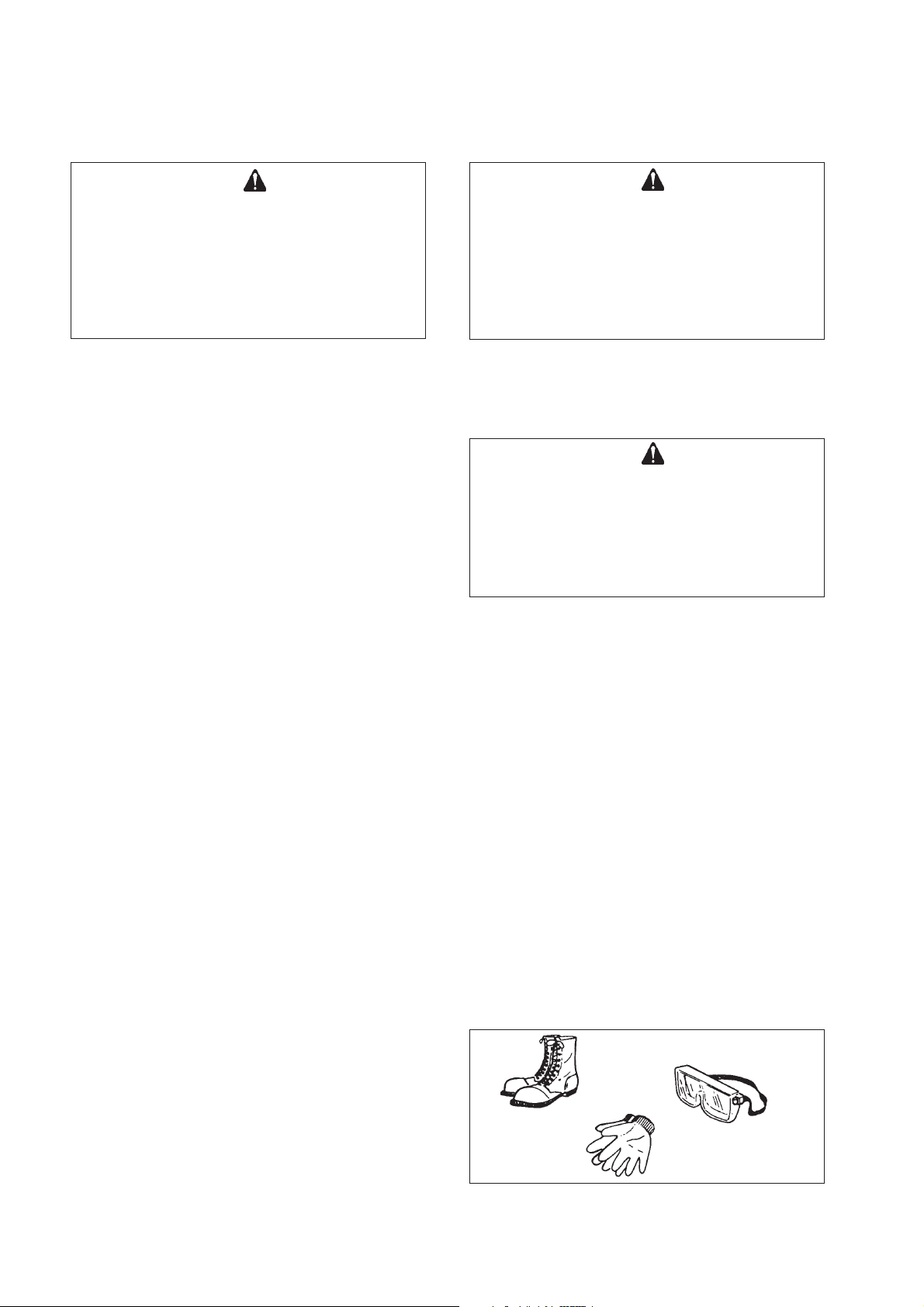

PROTECTIVE EQUIPMENT

• Always wear eye protection goggles that meet

ANSI Z87.1 standards.

• Wear hearing protection.

ECHO recommends that hearing protection be

worn at all times.

• Dress properly! Do not wear loose clothing or

jewellery, they can be caught in moving parts.

Use of sturdy gloves, non-skid footwear, and

safety glasses is recommended.

• While operating the machine always be sure of

a secure position.

2

Page 5

• Wear non-slip, heavy-duty work gloves to

improve your grip on the engine drill handles.

The gloves also help reduce the transmission

of machine vibrations to your hands.

WARNING DANGER

PRECAUTION AGAINST VIBRATION

AND COLD

PROTECTING OTHERS

Spectators, children, fellow workers and animals

must be warned to come no nearer than 4.6 m

(15 feet) while the engine drill is in use.

People working in the area near you should wear

the same protective equipment as the operator.

PHYSICAL CONDITION

Your judgement and dexterity may be impaired if

you are ill or have taken alcohol or other

substances known to affect the way you would

normally function.

IT IS BELIEVED THAT A CONDITION CALLED

RAYNAUD’S PHENOMENON, WHICH

AFFECTS THE FINGERS OF CERTAIN

INDIVIDUALS MAY BE BROUGHT ABOUT BY

EXPOSURE TO VIBRATION AND COLD.

EXPOSURE TO VIBRATION AND COLD MAY

CAUSE TINGLING AND BURNING

SENSATIONS FOLLOWED BY LOSS OF

COLOR AND NUMBNESS IN THE FINGERS.

THE FOLLOWING PRECAUTIONS ARE

STRONGLY RECOMMENDED BECAUSE THE

MINIMUM EXPOSURE WHICH MIGHT

TRIGGER THE AILMENT IS UNKNOWN.

• KEEP YOUR BODY WARM, ESPECIALLY

THE HEAD, NECK, FEET, ANKLES, HANDS

AND WRISTS.

• MAINTAIN GOOD BLOOD CIRCULATION

BY PERFORMING VIGOROUS ARM

EXERCISES DURING FREQUENT WORK

BREAKS AND ALSO BY NOT SMOKING.

• LIMIT THE HOURS OF OPERATION. TRY

TO FILL EACH DAY WITH JOBS WHERE

OPERATING THE ENGINE DRILL OR

OTHER HAND-HELD POWER EQUIPMENT

IS NOT REQUIRED.

Painful or numb fingers?

See your doctor

• IF YOU EXPERIENCE DISCOMFORT,

REDNESS AND SWELLING OF THE

FINGERS FOLLOWED BY WHITENING AND

LOSS OF FEELING, CONSULT YOUR

PHYSICIAN BEFORE FURTHER EXPOSING

YOURSELF TO COLD AND VIBRATION.

3

Page 6

Repetitive Stress Injuries

It is believed that overusing the muscles and

tendons of the fingers, hands, arms and shoulders

may cause soreness, swelling, numbness,

weakness and extreme pain in those areas. Certain

repetitive hand activities may put you at a high risk

for developing a Repetitive Stress Injury (RSI). An

extreme RSI condition is Carpal Tunnel Syndrome

(CTS), which could occur when your wrist swells

and squeezes a vital nerve that runs through the

area. Some believe that prolonged exposure to

vibration may contribute to CTS. CTS can cause

severe pain for months or even years. To reduce

the risk of RSI/CTS, do the following:

• Avoid using your wrist in a bent, extended or

twisted position. Instead try to maintain a

straight wrist position. Also, when grasping,

use your whole hand, not just the thumb and

index finger.

• Take periodic breaks to minimize repetition and

rest your hands.

• Reduce the speed and force with which you do

the repetitive movement.

• Do exercise to strengthen the hand and arm

muscles.

• See a doctor if you feel tingling, numbness or

pain in the fingers, hands, wrists or arms.

The sooner RSI/CTS is diagnosed, the more

likely permanent nerve and muscle damage

can be prevented.

4

Page 7

OPERA TING TECHNIQ UES

• When starting to drill, run the engine at full

throttle.

WARNING DANGER

BEFORE DRILLING, BE SURE TO READ AND

UNDERSTAND THE ENTIRE OPERATOR’S

MANUAL TO AVOID THE CHANCE OF

SERIOUS INJURY.

• Do not force the drills and only move as quickly

as the drills will allow.

• Stop the engine and disconnect from ignition

cable before: - cleaning or when clearing a

blockage; checking, maintenance or working on

the machine.

• Handle fuel with care; it is highly flammable.

Never add fuel to a machine with a running or

hot engine.

• Do not attempt to repair the machine unless

you are qualified to do so.

• When transporting or storing the machine

always remove the drill bit.

• To reduce fire hazard keep engine and

silencer free of debris, leaves or excessive

grease.

• Handle drill with care, contacting with drills

may cause injury.

• Do not operate the machine with a damaged or

excessively worn drill bit.

• Always ensure all handles and guards are fitted

when using the machine. Never attempt to use

an incomplete machine or one fitted with an

unauthorized modification.

5

Page 8

DESCRIPTION

2

1

3

4

14

13

12

11

10

9

8

6

7

5

1. Operator’s manual - Included with unit. Read

before operation and keep for future reference

to learn proper, safe operating techniques.

2. Throttle trigger - Device activated by the

operator’s finger, for controlling the engine

speed.

3. Rear handle - Handle located furthest from the

drill bit.

4. Silencer cover

5. Drill bit - Not included with unit.

6. Chuck

7. Front handle - Handle located on the front

gear case.

8. Fuel tank - Contains fuel and fuel filter.

9. Fuel tank cap - For closing the fuel tank.

10. Air cleaner cover - Covers air filter.

11. Starter handle - Pull handle to start the engine.

12. Throttle trigger lockout - Device that prevents

the accidental operation of the throttle trigger

until manually released.

13. Ignition switch - Device for allowing the

engine to be started and stopped.

14. Spark plug

6

Page 9

Washer

Front handle

(Tighten three points evenly)

Plug

Chuck

Drill bit

ASSEMBLING

FRONT HANDLE

• Insert the front handle to the machine, and turn

clockwise.

(TIGHTEN THE SCREW FIRMLY)

- To operate front handle with right hand,

remove right plug then reverse sides when

installing handle and plug.

DRILL BIT

• Insert the drill bit (not provided with unit) until it

reaches the bottom of the chuck, then back it

out slightly; tighten the chuck laws evenly and

completely.

IMPORTANT

Use drill bits suited for the material being

drilled and for the depth of hole required.

Oil

Gasoline

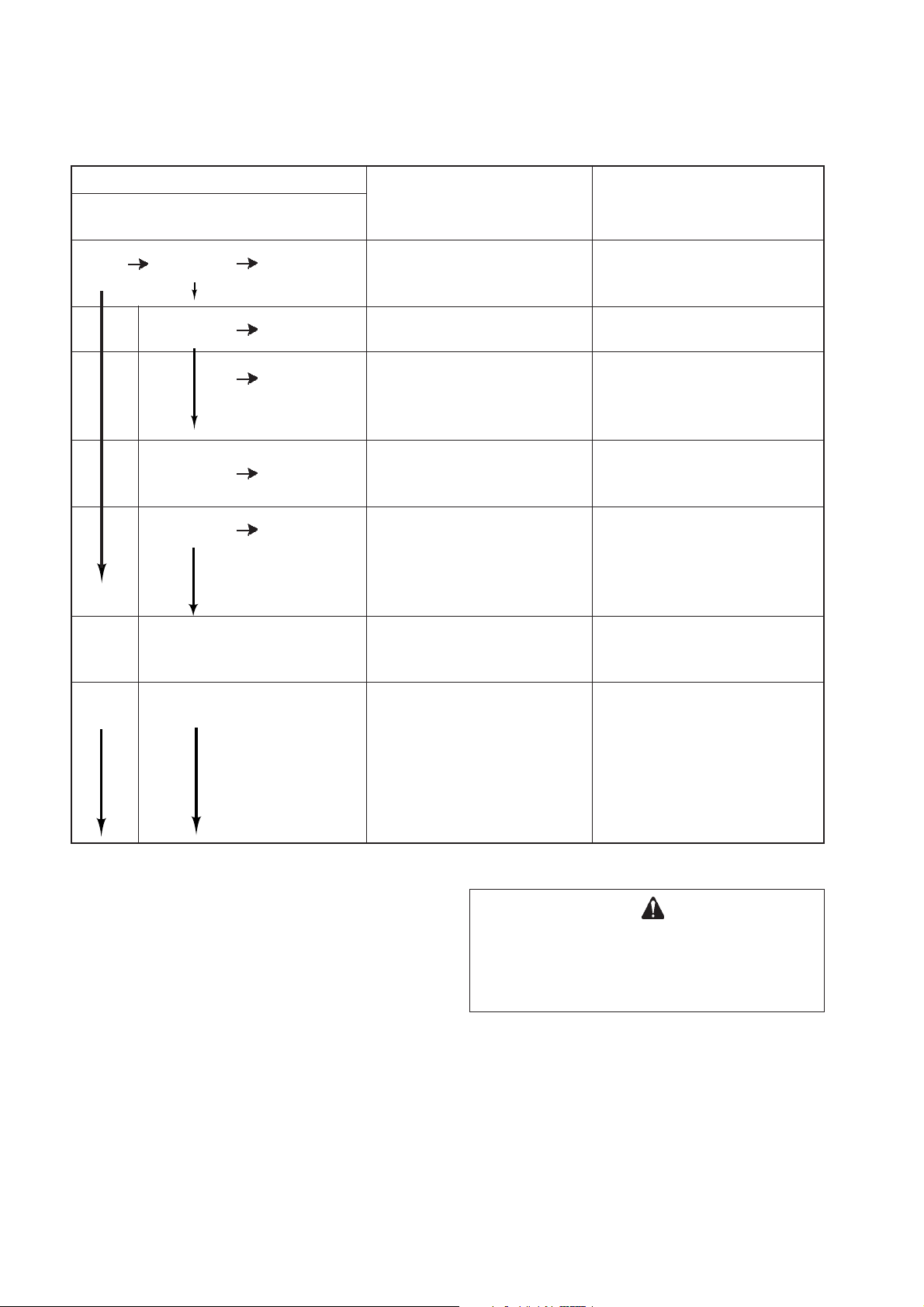

Fuel mix chart (50 : 1)

US METRIC

GAS OIL GAS OIL

GAL. FL.OZ. L mL

1 2.6 4 80

1

50

OPERATION

CHECK UP OF NUTS AND OTHER

HARDWARES

• Check up loose nuts, bolts and screws before

using the unit every day.

FUEL STATEMENT

GASOLINE - Use 89 Octane [(R+M) / 2] gasoline

or gasohol known to be good quality- Gasohol may

contain maximum 10% ethyl (grain) alcohol or 15%

MTBE (methyl tertiary- butyl ether). Gasohol

containing methyl (wood) alcohol is not approved.

OIL - ECHO brand premium two-strokes 50 : 1 oil

is preferred. Mix oil and gasoline/gasohol according

to Instructions on the oil container label.

MIXING - Follow directions on the container.

2 5.1 8 160

5 12.8 20 400

7

Page 10

IMPORTANT

Stored fuel ages. Do not mix more fuel than

you expect to use in thirty (30) days, ninety

(90) days when a fuel stabilizer is added.

Stored two-stroke fuel may separate.

ALWAYS shake fuel container thoroughly

before each use.

STARTING COLD ENGINE

• Stand the engine upright on a level surface.

Throttle trigger

Air cleaner

Purge bulb

Fuel return line

Push

On

Stop

Starter handle

• Place ignition switch in ON (START/RUN)

position.

• Push purge bulb 3 to 4 times (or until fuel is

visible in fuel return line).

• Shift choke lever to close position (START).

• Pull starter handle until the engine fires.

• Shift choke lever to full open position,and if

necessary, start the engine again and allow to

warm up before using.

- The clutch engages at approximately 3,500

r/min. Therefore the drill bit may rotate at fast

idle engine speed.

ST A RTING W ARM ENGINE

• Place ignition switch in ON (START/RUN)

position.

• Pull starter handle until the engine fires.

- Do not use the choke.

RUN

(Open)

START

(Close)

Choke lever

STOPPING ENGINE

• Set throttle trigger in idle position.

• Place ignition switch in STOP position.

NOTE

When engine does not stop, shift choke lever to

close position.

Check and repair ignition switch before starting

the engine again.

8

Page 11

MAINTENANCE AND CARE

AREA MAINTENANCE PAGE BEFORE MONTHLY YEARLY DATE

USE MAINTENANCE

PERFORMED

Air Filter Clean/Replace 11 •

Fuel Filter Inspect/Clean/Replace 11 •

Spark Plug Inspect/Clean/Adjust/

Replace 11 •

Carburetor Adjust 12 •

Cooling System Inspect/Clean 13 •

Silencer Inspect/Tighten/Clean 13 •

Starter Rope Inspect/Replace - •

Drills Inspect/Clean/Lubricate - •

Fuel Leaks Inspect/Repair - •

Screws, Bolts and

Nuts Inspect/Tighten/Replace - •

Fuel Line Inspect - •

IMPORTANT

Time intervals are maximum. Actual use and

your experience will determine the

frequency of required maintenance.

Record dates of monthly and yearly

inspections.

9

Page 12

TROUBLE SHOOTING

Trouble

Engine - starts hard Cause Remedy

- does not start

Engine Fuel at No fuel • Fuel filter clogged • Clean or replace

cranks carburetor at carburetor • Fuel line clogged • Clean

• Carburetor • Ask your ECHO dealer

Fuel at No fuel at • Carburetor • Ask your ECHO dealer

cylinder cylinder

Silencer wet • Fuel mixture is too rich • Open choke

with fuel • Clean/replace air filter

• Adjust carburetor

• Ask your ECHO dealer

Spark at No spark at • Ignition switch off • Turn switch on

end of end of plug • Electrical problem • Ask your ECHO dealer

plug wire wire

Spark at No spark at • Spark gap incorrect • Adjust 0.6 to 0.7 mm

plug plug (0.024 to 0.028 in)

• Covered with carbon • Clean or replace

• Fouled with fuel • Clean or replace

• Spark plug defective • Replace plug

Engine • Internal engine problem • Ask your ECHO dealer

does not

crank

Engine Dies or • Air filter dirty • Clean or replace

runs accelerates poorly • Fuel filter dirty • Clean or replace

• Fuel vent blocked • Clean

• Spark plug • Clean and adjust/replace

• Carburetor • Adjust

• Cooling system blocked • Clean

• Exhaust port/spark arrestor • Clean

screen blocked

WARNING DANGER

ALL ENGINE DRILL SERVICE, OTHER THAN

ITEMS LISTED IN THE OPERATOR’S

MANUAL SHOULD BE PERFORMED BY AN

AUTHORIZED ECHO DEALER.

10

Page 13

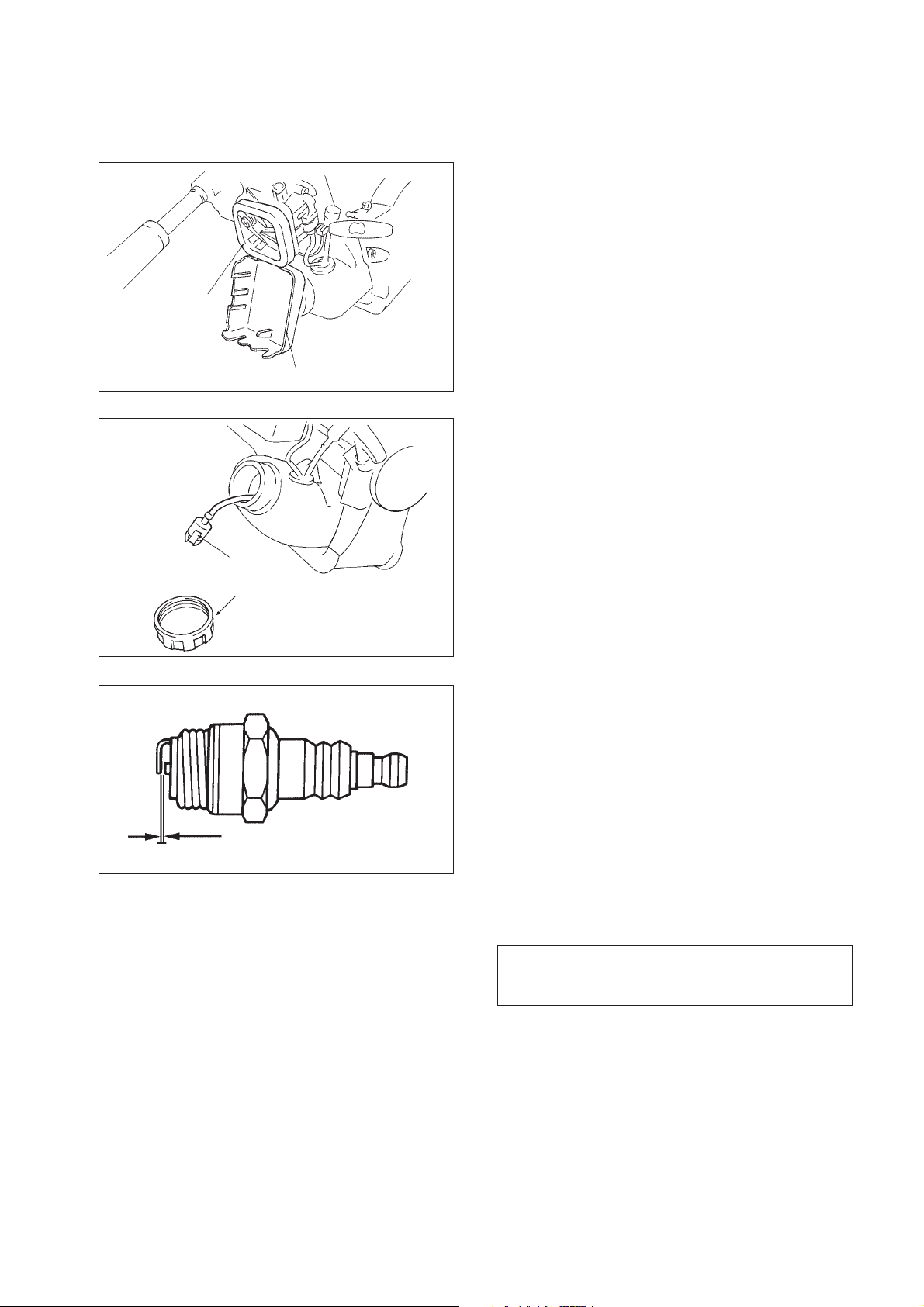

Air filter

Fuel filter

Fuel tank cap

MAINTENANCE

AIR FILTER

• Clean before Use.

- Remove air cleaner cover and pull out air

filter.

- Lightly brush off dust or wash it in water and

detergent.

- Dry completely before putting it back in

place.

Air cleaner cover

FUEL FILTER

• Check periodically.

- Do not allow dust to enter into fuel tank.

- Clogged filter will cause difficulty in starting

engine or poor engine performances.

- Pick up fuel filter through fuel inlet port with a

piece of steel wire or the like.

- When filter is dirty, replace it.

0.6 - 0.7 mm (0.024 - 0.028 in)

SPARK PLUG

• Check periodically.

- The standard spark gap is 0.6 to 0.7 mm

(0.024 to 0.028 in.).

- Correct spark gap if it is wider or narrower

than the standard gap.

- If the electrodes are coated with carbon

deposits replace with a new spark plug.

Do not sandblast to clean.

Remaining sand will damage engine.

• Fastening torque = 15 to 17 N•m

(130 to 145 in•lb)

IMPORTANT

Do not over tighten plug.

11

Page 14

REPLACEMENT OF CHUCK

Replacement of chuck should be done in the

following manner:

1. Remove bolt with hexagonal hole fixed in the

driving axle.

2. Insert accessory hexagonal bar (Part No.

895412-20960) into chuck and fix.

3. Fit 19 mm spanner onto driving axle and keep

it fitted.

4. Fit 10 mm box spanner onto the hexagonal bar

and turn it into direction as indicated by an

arrow to remove chuck.

5. Fit a new chuck in the reversed order of

removing.

(10 mm)

Hexagonal bar

(Part No. 895412-20960)

Spanner (19 mm)Box spanner

ADJUSTING CARBURETOR

(As Required)

GENERAL INFORMATION

The idle speed adjuster screw controls the throttle

opening at the idle position.

IDLE ADJUSTMENT

1. Start engine and allow it to run at high idle until

warm.

2. Turn the idle speed screw clockwise until drill

bit begins to move.

3. Turn idle screw counterclockwise 1 and 1/2 to

2 turn or until the drill bit stops (2,700 to 3,300

r/min).

12

Page 15

CLEANING CYLINDER FINS

(Check Periodically)

NOTE

Clogged fins will cause poor engine cooling.

1. Carefully remove housing and clean dirt and

dust from fins.

2. Reinstall housing.

STORAGE

CLEANING SILENCER AND

EXHAUST PORT

(Check Per iodically)

1. Carefully remove housing halves.

2. Remove and disassemble silencer.

NOTE

Be careful not to scratch the cylinder or piston

when cleaning the cylinder exhaust port.

3. Clean deposits from cylinder exhaust port and

silencer.

LONG TERM STORA GE

(Over 30 Days)

Do not store your unit for a prolonged period of

time (30 days or longer) without performing

protective storage maintenance which includes the

following:

1. Store unit in a dry, dust free place, out of the

reach of children.

2. Place the ignition switch in the STOP position.

3. Remove accumulation of grease, oil, dirt and

debris from exterior of unit.

4. Perform all periodic lubrication and services

that are required.

5. Tighten all the screws and nuts.

WARNING DANGER

DO NOT STORE IN ENCLOSURE WHERE

FUEL FUMES MAY ACCUMULATE OR

REACH AN OPEN FLAME OR SPARK.

6. Drain the fuel tank completely and pull the

recoil starter handle several times to remove

fuel from the carburetor.

7. Remove the spark plug and pour 1/2

tablespoon (1/4 oz) of fresh, clean, 2-stroke

engine oil into the cylinder through the spark

plug hole.

A.Place a clean cloth over the spark plug hole.

B.Pull the recoil starter handle 2 or 3 times to

distribute the oil inside the engine.

C.Observe the piston location through the

spark plug hole. Pull the recoil starter handle

slowly until the piston reaches the top of its

travel and leave it there.

8. Install the spark plug (do not connect ignition

cable.)

9. Lubricate the drill bit with a heavy coat of oil to

prevent rust.

NOTE

For future reference, you should keep this

operator’s manual.

13

Page 16

SPECIFICATIONS

ED-200

Mass without drill bit kg 4.4 (9.7 lbs)

Volume

fuel tank L 0.5 (16.9 US,fl.oz.)

Drill

size mm 32 - 178 (1.25 - 7 inch)

chuck capacity mm 13 (0.5 inch)

speed r/min 430

Mission

reduction ratio 20.5

lubrication grease

External Dimensions

length × width × height mm 395 × 325 × 255

without drill bit (15.5 × 12.8 × 10.0 inch)

Engine

type Air cooled Two stroke single cylinder

engine displacement mL (cm3) 21.2 (1.29 cu. inch)

recommended maximum engine speed r/min 9,000

recommended engine idling speed r/min 2,900

engine speed at beginning of clutch engagement r/min 4,000

carburetor diaphragm type

ignition flywheel magneto - CDI system

spark plug NGK BPM8Y

starter recoil starter

clutch automatic Centrifugal

Fuel

mixing ratio Mixture of gasoline (unleaded, 89 octane

minimum) and specially blended 50 : 1

ECHO two cycle engine oil.

fuel consumption at engine maximum power L/h 0.47 (15.9 US,fl.oz.)

14

Loading...

Loading...