Page 1

Electric Chain Saw

Operator’s Manual

MODELS:

TABLE OF CONTENTS

Symbol Information ........................................................... 2

Safety Warnings ................................................................. 3

- Before Operating Chain Saw ................................... 3

- Kickback .................................................................. 3

- Pushback and Pull-in ................................................ 4

- Chain Saw Operation ............................................... 4

- Maintenance and Storage of Chain Saw .................. 4

Product Identification ......................................................... 5

Chain Saw Names and Terms............................................. 5

Unpacking .......................................................................... 6

Assembly ............................................................................ 6

Saw Chain Tension Adjustment ......................................... 7

Filling Oil Tank .................................................................. 7

ECS-2000 12" GUIDE BAR

SERIAL NUMBER 200 & UP

ECS-3000 16" GUIDE BAR

SERIAL NUMBER 300 & UP

Operating Chain Saw.......................................................... 7

- Extension Cords ....................................................... 8

- Oiling Chain ............................................................. 8

- Cutting with the Chain Saw ..................................... 8

- Chain Brake.............................................................. 8

- Trimming a Tree ...................................................... 9

- Felling a Tree ........................................................... 9

- Limbing a Tree ....................................................... 10

- Bucking a Log ........................................................ 11

Cleaning and Maintenance ............................................... 12

- Cleaning Saw Body ................................................ 12

- Care of Guide Bar .................................................. 12

- Sharpening Saw Chain ........................................... 12

Storage .............................................................................. 14

Replacement Parts ............................................................ 14

Troubleshooting................................................................ 15

Servicing Information ........................................ Back Cover

WARNING DANGER

Read rules for safe operation and instructions carefully. ECHO provides an Operator’s Manual and a

Safety Manual. Both must be read and understood for proper and safe operation.

Page 2

INFORMATION SYMBOLS

Read Instruction Manual

Do Not Expose to Rain or Use in Wet Conditions

Remove Plug Immediately if Cable is Damaged or

Cut

Hold Chain Saw with Both Hands

Beware of Kickback

Hearing and Eye Protection Must Be Worn

Safety Information Warnings Appears Throughout

This Manual

Pay close attention to them. Below are definitions for the

safety information listed throughout this manual.

WARNING indicates a hazard which can cause severe

personal injury, death, or substantial property damage if

you ignore warning.

CAUTION indicates a hazard which will or can cause

minor personal injury or property damage if you ignore

warning.

!

WARNING ICON G 001

2

102514

Page 3

!

SAFETY WARNINGS

WARNING ICON G 001

Read and understand all Safety Warnings on pages

3 and 4. Improper use of this chain saw can cause

severe injury or death from fire, electrical shock,

body contact with moving chain, or falling wood.

BEFORE OPERATING CHAIN SAW

1. Read and understand this owner’s manual before operating

chain saw.

2. Use chain saw for cutting wood only. Do not use for cutting

any non-wood items.

3. Only well-instructed adults should operate chain saw. Never

allow children to operate chain saw. First-time user should

obtain informed, practical instruction in addition to reading

this manual. Practice cutting logs on a saw horse or cradle.

4. Use only electrical voltage noted on model plate of chain saw.

5. Use only extension cords marked for outdoor use. See page

8 for extension cord requirements.

6. Do not operate chain saw

• while under the influence of alcohol, medication, or drugs

• in rain or in damp or wet areas

• where highly flammable liquids or gases are present

• if saw is damaged, adjusted wrong, or not fully assembled

• if trigger does not turn saw on and off. Chain must stop

moving when you release trigger. Have faulty switch

replaced by authorized service person.

• while tired or in a hurry

• while in tree or on a ladder unless trained to do so

7. Wear snug-fitting clothes when operating chain saw. Do not

wear loose clothing or jewelry. They can get caught in

moving saw chain.

8. Wear the following safety gear when operating chain saw:

• heavy-duty gloves (wear rubber gloves if working oudtoors)

• steel-toed safety footwear with non-skid soles

• eye protection such as safety glasses, goggles, or face screen

• safety hard hat

• ear mufflers or ear plugs

• hair covering to contain long hair

• face or dust mask (if working in dusty areas)

9. Before cutting, always provide the following:

• clear work area

• secure footing

• planned retreat path from falling tree

10.Inspect tree before cutting down. Make sure there are no dead

limbs or branches that may fall on you.

11.To reduce the risk of electric shock, this saw has a polarized

plug (one blade is wider than the other). This plug will fit in

a polarized outlet only one way. If the plug does not fit fully

in the outlet of your extension cord, reverse the plug. If it still

does not fit, a polarized extension cord will be necessary. Do

not change the plug in any way.

KICKBACK

!

WARNING

WARNING ICON G 001

Avoid Kickback. Kickback can cause you to lose

control of chain saw. Kickback can cause severe

injury or death.

102514

This saw has low-kickback chain, reduced-kickback guide bar and

kick guard. These items reduce the chances of kickback. Do not

remove kick guard. The kick guard prevents rotational kickback.

This saw has a chain brake. When kickback occurs, the front hand

guard is moved forward by the back of operator’s left hand. This

stops the saw chain quickly, reducing the chance of serious injury.

Never hold the chain saw by the front hand guard.

Cause Of Kickback

Kickback may occur when nose or tip of guide bar touches an

object while chain is moving. If chain cutter catches on object, a

sudden reverse action will result. The guide bar will kick up and

back towards operator.

Direction

90°

Quadrant

Figure 1 - Kickback Hazard Example. Do Not Let Nose of

Guide Bar Touch Object While Chain is Moving

Kickback may also occur when wood pinches chain at guide bar

nose. A sudden reverse action will also result.

The following steps will reduce the risk of kickback:

• Use both hands to grip saw while saw is running. Use firm

grip. Thumbs and fingers must wrap around saw handles.

• Keep all safety items in place on saw. Make sure they work

properly.

• Do not overreach or cut above shoulder height.

• Keep solid footing and balance.

• Stand slightly to left side of saw. This keeps your body from

being in direct line with chain.

• Do not let guide bar nose touch anything when chain is

moving (see Figure 1).

• Do not remove kick guard.

• Never try cutting through two logs at same time. Only cut one

log at a time.

•

Do not bury guide bar nose or try plunge cut (boring into

wood using guide bar nose).

• Watch for shifting of wood or other forces that may pinch

chain.

• Use extreme caution when re-entering a previous cut.

• Use low-kickback chain and guide bar supplied with this

chain saw. Only replace these parts with chains and guide

bars listed in this manual or on the chain saw.

• Never use dull or loose chain. Keep chain sharp and tensioned

correctly.

3

Do Not Let

Guide Bar Nose

Touch Here

Continued

3

Page 4

SAFETY WARNINGS

Continued

Saw Maintenance and Kickback Safety

Follow maintenance instructions in this manual. Proper cleaning

of saw and chain and guide bar maintenance can reduce chances

of kickback. Inspect and maintain saw after each use. This will

increase the service life of your saw.

sharpening, risk of kickback can increase with each sharpening.

Note:

Even with proper

PUSHBACK AND PULL-IN

WARNING

Avoid pushback and pull-in. These hazards can

cause you to lose control of chain saw. Pushback

or pull-in can cause severe injury.

Cause Of Pushback and Pull-In

Pushback may occur while cutting with top of guide bar. Pushback

will force saw back towards you. Pull-in may occur while cutting

with bottom of guide bar. Pull-in will force saw in towards wood

you are cutting. These hazards can occur if chain is pinched,

caught, or contacts a non-wood object.

The following steps will reduce the risk of pushback or pull-in:

• Use both hands to grip saw while saw is running. Use firm

grip. Thumbs and fingers must wrap around saw handles.

• Do not overreach or cut above shoulder height.

• Keep solid footing and balance.

• Stand slightly to left side of saw. This keeps your body from

being in direct line with chain.

• Have saw running at full speed before starting a cut.

• When cutting, make sure spike of saw is against wood (pullin only). See Product Identification, page 5, to locate spike.

• Never try cutting through two logs at same time. Only cut one

log at a time.

• Watch for shifting of log or other forces that may pinch

chain.

• Use extreme caution when re-entering a previous cut.

• Do not twist saw when removing guide bar from undercut.

• Use wedges made of plastic, wood, or light alloy (never steel or

iron) to hold cut open.

CHAIN SAW OPERATION

1. Stay alert. Use common sense while operating chain saw.

2. Keep work area clean. Cluttered areas invite injuries.

3. Be aware of extension cord while operating chain saw. Be

careful not to trip over cord.

4. Keep children, animals, and bystanders away from chain

saw and extension cord. Only chain saw user should be in

work area.

5. Do not cut down a tree unless you are trained or have expert

help.

6. If two or more persons perform bucking and felling operations at the same time, provide plenty of distance between

operations. Provide distance of at least twice the height of

tree being felled.

7. Secure wood you are cutting by using clamps or chocks.

8. Grip chain saw firmly with both hands. Never operate chain

saw with one hand. Never use hand guard as handle.

9. Keep finger off trigger until ready to make cut.

10. Before starting chain saw, make sure chain is not touching

anything.

11. Avoid body contact with grounded objects such as pipes,

wire fences, and metal posts.

12. Keep all parts of body away from chain when saw is running.

13. Do not force chain saw while cutting. Apply light pressure.

14. Cut small brush and saplings with extreme care. Slender

material may catch in chain and be whipped toward you.

This could also pull you off balance.

15. When cutting limb or tree trunk that is under tension, use

extreme caution. Be alert for wood springing back. When

wood tension is released, limb could spring back and strike

operator causing severe injury or death.

16. Do not activate the chain brake to stop saw. Always release

trigger to stop saw.

17. Carry chain saw from one place to another

• with chain saw unplugged

• by holding front handle (never use front hand guard as

handle)

• with finger off trigger

• with guide bar and chain to rear

• with scabbard in place

MAINTENANCE AND STORAGE OF CHAIN SAW

1. Unplug chain saw from power source

• when not in use

• before moving from one place to another

• before servicing

• before changing accessories or attachments

2. Inspect chain saw before and after each use. Check saw

closely if guard or other part has been damaged. Check for

any damage that may affect operator safety or operation of

saw. Check for alignment or binding of moving parts. Check

that switch turns motor on and off. Check chain brake.

Check for broken or damaged parts. Do not use chain saw if

damage affects safety or operation. Have damage repaired

by authorized service person.

3. Maintain chain saw with care.

• Never expose saw to rain.

• Keep chain sharp, clean, and lubricated.

• Follow steps outlined in this manual to sharpen chain.

• Keep handles dry, clean, and free of oil.

• Keep all screws and nuts tight.

• Inspect power cord often. If damaged, have repaired by

authorized service person.

• Never carry chain saw by power cord.

• Never yank power cord to unplug it.

• Keep power cord from heat, oil, and sharp edges.

• Inspect extension cords often and replace if damaged.

4. When servicing, use only identical replacement parts.

5. Always store chain saw

• in a high or locked place, out of children’s reach

• in a dry place

• in a carrying case or with scabbard over guide bar

Keep this manual for reference. It is your guide to safe and proper

operation of this chain saw.

4

102514

Page 5

PRODUCT IDENTIFICATION

Front Hand

Rear

Handle

Power Cord

Kick Guard

Front

Handle

Motor

Housing

Guard

Saw

Chain

Spike

Rear Hand

Guard

Oil Level Sight Hole

(located on saw body,

hidden by front handle)

Oil Cap

Figure 2 - Electric Chain Saw

Kick Guard

Guide Bar

Nose

Guide Bar

Scabbard

Switch

Lockout

Trigger

CHAIN SAW NAMES AND TERMS

Bucking Process of cutting a felled tree or log into lengths.

Felling Process of cutting down a tree.

Felling Cut Final cut when felling a tree. Make this cut on

opposite side of tree from notching cut.

Front Hand Guard Shield between front handle and guide bar.

Protects left hand while using saw. When kickback occurs, the

front hand guard is moved forward by the back of operator’s left

hand. This stops the saw chain quickly, reducing the chance of

serious injury.

Front Handle Located at front of saw body.

Guide Bar Metal bar that extends from saw body. The guide bar

supports and guides chain.

102514

Guide Bar Nose Tip or end of guide bar.

Kickback Quick backward and upward motion of guide bar.

Kickback may occur when tip of guide bar touches an object while

chain is moving. The guide bar will kick up and back towards

operator.

Kick Guard Covers the nose area of the bar and chain where

kickback reaction is generated. No chain contact in this area. No

rotational kickback.

Limbing Process of cutting limb(s) from a felled tree.

Low-Kickback Chain Chain that reduces chance of kickback

as required by ANSI B175.1.

Normal Cutting Position Stance used while making bucking

and felling cuts.

Notching Cut Notch cut in tree that directs fall of tree.

Oiler Control System for oiling guide bar and chain.

Power Head Chain saw without chain and guide bar. Also

known as saw body.

Pushback (Kickback, Pinch) Rapid pushback of chain saw.

Pushback may occur if chain along top of guide bar is pinched,

caught, or contacts a foreign object.

Rear Handle Handle located at rear of saw body.

Reduced Kickback Guide Bar Guide bar that reduces chance

of kickback.

Replacement Chain Chain that complies with ANSI B175.1

when used with a specific saw. It may not meet ANSI requirements when used with other saws.

Saw Chain (Chain) Loop of chain having cutting teeth for

cutting wood. The motor drives chain. The guide bar supports

chain.

Spiked Bumper (Spike) Pointed teeth at front of saw body

beside guide bar. Keep spiked bumper in contact with wood when

felling or bucking. It helps maintain position of saw while cutting.

Sprocket Toothed wheel that drives chain.

Switch Device that completes or interrupts electrical circuit

to motor of saw.

Switch Linkage This device connects switch to trigger. It

moves switch when you squeeze trigger.

Switch Lockout Device that reduces accidental starting of saw.

Trigger Device that turns saw on and off. Squeezing trigger

turns saw on. Releasing trigger turns saw off.

Trimming (Pruning) Process of cutting limb(s) from a living

tree.

Undercut An upward cut from underside of log or limb. This is

done while in normal cutting position and cutting with top of

guide bar.

5

5

Page 6

UNPACKING

1. Remove all items from carton.

2. Check all items for any shipping damage. If you find any

damage or if any parts are missing, promptly inform

dealer where you bought chain saw.

ASSEMBLY

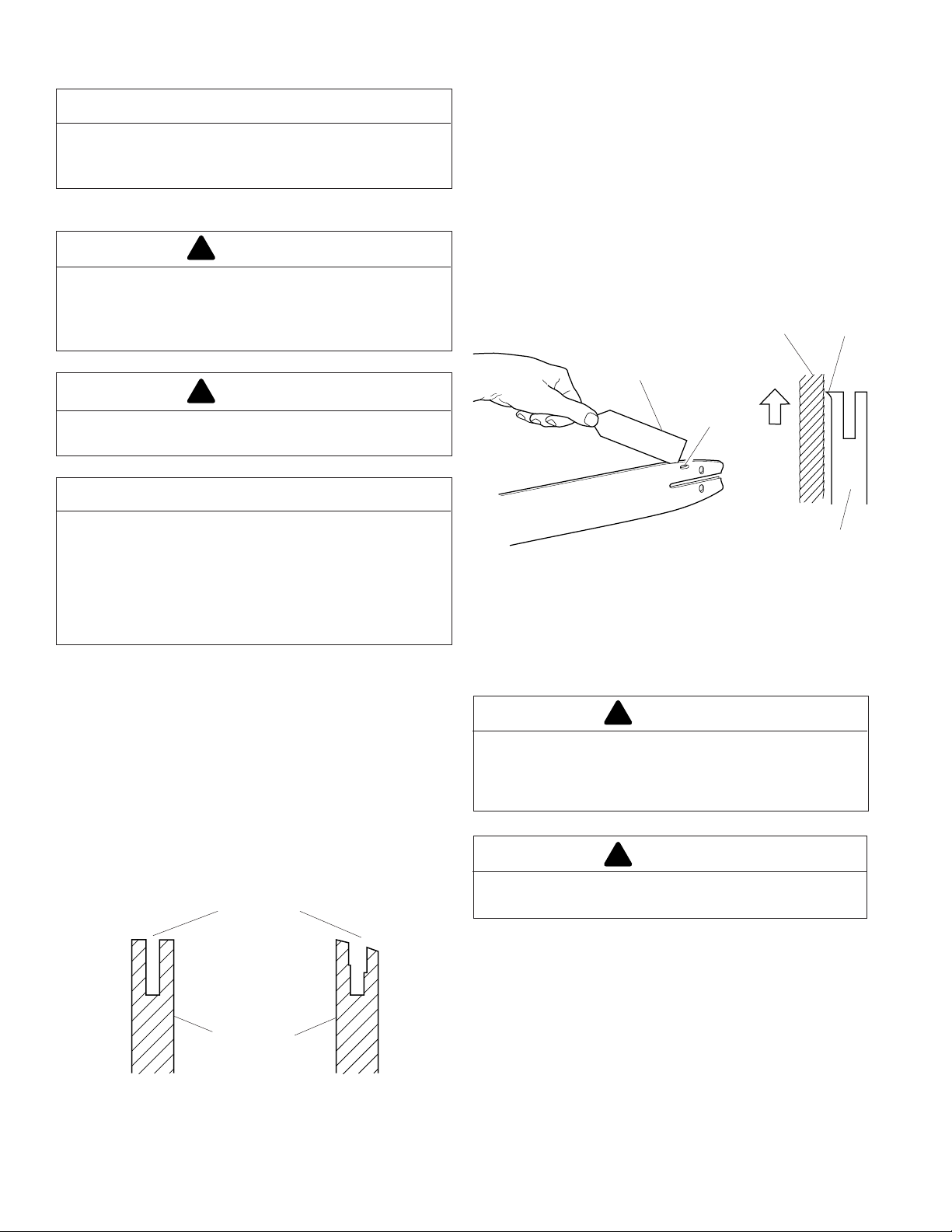

!

WARNING

Cutting edges on chain are sharp. Use protective

gloves when handling chain.

IMPORTANT

Do not clamp chain saw in vise during assembly.

1. Lay chain out flat.

2. Remove guide bar nuts from guide bar bolts (see Figure 3).

3. Turn adjusting screw counterclockwise (see Figure 4).

Continue to turn adjusting screw until adjusting block is to

rear of adjusting plate.

4. Install guide bar onto saw body. Place rear of guide bar

between adjusting plate and sprocket support.

IMPORTANT:

oval adjusting hole on guide bar.

5. Attach guide bar nuts to guide bar bolts.

Tighten guide bar nuts finger tight only. Make sure

adjusting block is in oval adjusting hole on guide bar.

6. Place chain around drive sprocket, then along top groove

of guide bar and around guide bar nose.

cutting edges of chain are facing the right direction.

Position chain so cutting edges on top of guide bar face

guide bar nose (see Figure 3).

Do not place chain on saw backwards. If chain is

backwards, saw will vibrate badly and will not cut.

Make sure to insert adjusting block into

IMPORTANT:

Note:

Make sure

!

CAUTION

Cutting

Towards

Guide

Bar Nose

Drive

Sprocket

Sprocket

Support

Figure 3 - Assembling Guide Bar, Chain, and Hand Guard

Sprocket

Support

Adjusting

Block

Edge

Guide Bar

Bolts

Guide Bar

Nuts

Saw

Chain

Guide

Bar

Adjusting

Hole

Adjusting

Plate

Adjusting

Screw

7. Adjust saw chain tension. Follow steps under Saw

Chain Tension Adjustment, page 7.

8. If saw has 2-piece side cover, attach sprocket cover.

Figure 4 - Part Locations for Assembling Guide Bar

6

102514

Page 7

SAW CHAIN TENSION

ADJUSTMENT

!

WARNING

Unplug chain saw from power source before

adjusting saw chain tension.

!

WARNING

Cutting edges on chain are sharp. Use protective

gloves when handling chain.

!

WARNING

Maintain proper chain tension always. A loose

chain will increase the risk of kickback. A loose

chain may jump out of guide bar groove. This

may injure operator and damage chain. A loose

chain will cause chain, guide bar, and sprocket

to wear rapidly.

Note:

A new chain will stretch. Check new chain after first

few minutes of operation. Allow chain to cool down. Follow

steps below to readjust saw chain tension.

3. Wearing protective gloves, move chain around guide bar.

Chain should move freely. If chain does not move freely,

loosen chain by turning adjusting screw counterclockwise.

4. After chain tension is correct, tighten guide bar nuts firmly.

If not, guide bar will move and loosen chain tension. This

will increase the risk of kickback. This can also damage

saw.

Note:

A new chain will stretch. Check new chain

after first few minutes of operation. Allow chain to cool

down. Readjust chain tension.

Guide Bar

Nuts

Guide Bar

Guide Bar

Gap

Incorrect Tension

Correct

Tension

1. Before adjusting chain, make sure guide bar nuts are only

finger tight (see Figure 3, page 6). Also make sure adjusting block is in oval adjusting hole on guide bar (see Figure

3 and 4, page 6).

2. Turn adjusting screw clockwise until all slack is out of

chain (see Figure 5).

Note:

There should be no gap between side links of chain

and bottom of guide bar (see Figure 6).

Figure 6 - Saw Chain Adjustment

FILLING OIL TANK

1. Remove oil cap.

2. Fill oil tank with Echo bar and chain oil.

3. Replace oil cap at once. Tighten oil cap firmly for good

seal. This will avoid oil seepage from tank.

4. Wipe off excess oil.

Note:

It is normal for oil to seep when saw is not in use.

Empty oil tank after each use to prevent seepage.

OPERATING CHAIN SAW

!

WARNING

Read and understand this owner’s manual

before operating this saw. Make certain you read

and understand all Safety Warnings. Improper

use of this chain saw can cause severe injury or

death from fire, electrical shock, or body contact

with moving chain, or falling wood.

102514

Figure 5 - Turning Adjusting Screw

Continued

7

7

Page 8

OPERATING CHAIN SAW

Continued

EXTENSION CORDS

Use proper extension cord with this chain saw. Use only

extension cords marked for outdoor use. Use an extension

cord no less than 1.5 mm

meters (100 feet). The cord must be marked with suffix W

following the cord type marking.

To reduce the risk of electric shock, this equipment has a

polarized plug (one blade is wider than the other). The plug

will fit in a polarized extension cord only one way. If the plug

does not fit fully in the extension cord, reverse the plug. If it

still does not fit, obtain a polarized extension cord. Do not

change the plug in any way.

Use an extension cord heavy enough to carry the current your

saw will draw. An undersized cord will cause a voltage drop

at the saw, loss of power, and overheating.

Keep cord away from cutting area. Make sure cord does not

catch on branches or logs during cutting. Inspect cords often.

Replace damaged cords.

The extension cord may come undone from the power cord

during use. To avoid this, make a knot with the two cords as

shown in Figure 7 below.

Extension

Cord

2

(14SWG) at distances up to 30

Example

: SJTW

Chain Saw

Power Cord

4. Make sure your footing is firm. Keep feet apart. Divide

your weight evenly on both feet. Stand slightly to left side

of saw. This keeps your body from being in direct line

with chain.

5. When ready to make a cut, press in switch lockout with

right thumb and squeeze trigger (see Figure 9). This will

turn saw on. Releasing trigger will turn saw off. Make sure

saw is running at full speed before starting a cut.

Front Hand

Guard

Switch

Lockout

Trigger

Figure 9 - Front Hand Guard, Switch Lockout,

and Trigger Location

6. When starting a cut, place moving chain against wood.

Hold saw firmly in place to avoid possible bouncing or

skating (sideways movement) of saw.

7. Guide saw using light pressure. Do not force saw. The

motor will overload and can burn out.

8. Remove saw from a cut with saw running at full speed.

Stop saw by releasing trigger. Do not use the chain brake.

Make sure chain has stopped before setting saw down.

9. Practice until you can maintain a steady, even cutting rate.

Figure 7 - Tying Extension Cord and Power Cord in Knot

OILING CHAIN

Always check oil level before using saw. To oil chain, press oil

cap. Oil will feed onto guide bar and chain. Press oil cap at

least once before each cut. Check oil level often by looking at

oil sight level hole. Oil sight level hole is on left side of saw,

between front handle and front hand guard.

Figure 8 - Pressing Oil Cap to Oil Chain

CUTTING WITH THE CHAIN SAW

1. Connect saw to extension cord. Connect extension cord to

power supply.

2. Make sure section of log to be cut is not laying on ground.

This will keep chain from touching ground as it cuts through

log. Touching ground with moving chain will dull chain.

3. Use both hands to grip saw. Always use left hand to grip

front handle and right hand to grip rear handle. Use firm

grip. Thumbs and fingers must wrap around saw handles

(see Figure 9).

CHAIN BRAKE

The chain brake quickly stops the saw chain. Kickback causes

the back of operator’s left hand to contact front hand guard (see

Figure 10). When front hand guard moves forward, the saw chain

stops. This reduces the chance of serious injury during kickback.

When the chain brake activates, release trigger at once.

STOP

Figure 10 - The chain brake quickly stopping the saw chain

To reset chain brake, release trigger and move front hand

guard back into position. You must release trigger first. If not,

the saw will start when you reset the front hand guard.

CAUTION: Do not use the chain brake to stop and start

your saw. Quick repeated stops may cause overheating

of the chain brake. Damage to the chain brake will

occur.

Note:

Test chain brake before each use. Firmly grip saw with

both hands. With saw running, move front hand guard forward

with back of left hand. Keep both hands on the handles. Saw

chain should stop. If chain brake does not work, have saw

repaired by authorized service person.

8

102514

Page 9

OPERATING CHAIN SAW

Continued

TRIMMING A TREE (Pruning)

!

WARNING

Avoid kickback. Kickback can result in severe

injury or death. See

risk of kickback.

Do not operate chain saw while

• in a tree

• on a ladder or any other unstable surface

• in any awkward position

You may lose control of saw causing severe injury.

Do not cut limbs higher than your shoulders.

Kickback

!

WARNING

!

WARNING

, page 3 to avoid

FELLING A TREE (Cutting Down a Tree)

!

WARNING

• Avoid kickback. Kickback can result in severe

injury or death. See

risk of kickback.

• Do not fell a tree without ample skill or expert help.

• Keep children, animals, and bystanders away

from area when felling a tree.

• If two or more persons perform bucking and

felling operations at the same time, provide

ample distance between operations. Provide

distance of at least twice the height of tree

being felled.

When felling a tree, be aware of your

surroundings. Do not endanger any person,

strike utility lines, or cause property damage. If

tree strikes utility lines, contact utility company

at once.

Kickback

!

WARNING

, page 3 to avoid

Trimming a tree is the process of cutting limbs from a living

tree. Make sure your footing is firm. Keep feet apart. Divide

your weight evenly on both feet. Follow directions below to

trim a tree.

1. Make first cut 15 centimeters from tree trunk on underside

of limb. Use top of guide bar to make this cut. Cut 1/3

through diameter of limb (see Figure 11).

2. Move five to ten centimeters farther out on limb. Make

second cut from above limb. Continue cut until you cut

limb off.

3. Make third cut as close to tree trunk as possible on

underside of limb stub. Use top of guide bar to make this

cut. Cut 1/3 through diameter of stub.

4. Make fourth cut directly above third cut. Cut down to meet

third cut. This will remove limb stub.

!

CAUTION

Seek professional help if facing conditions

beyond your ability.

4th Cut - Final

Stub Cut

2nd Cut - Pruning Cut

(to avoid pinching)

!

CAUTION

Seek professional help if facing conditions

beyond your ability.

Felling is the process of cutting down a tree. Make sure your

footing is firm. Keep feet apart. Divide your weight evenly on

both feet. Follow directions below to fell a tree.

Before Felling a Tree

1. Before felling, inspect tree. Make sure there are no dead

limbs or branches that may fall on you. Study natural lean

of tree, location of larger branches, and wind direction.

This will help you judge which way tree will fall.

2. Clear work area around tree.

3. Plan and clear a retreat path before felling. Make retreat

path opposite to planned direction of fall of tree and at 45°

angle (see Figure 12).

Retreat

Path

Direction of Fall

102514

15

cm

5 to 10 cm

1st Cut - Pruning Undercut

(to avoid splintering)

3rd Cut - Stub Undercut

(to avoid splintering)

Figure 11 - Cutting A Limb

45°

Retreat

Path

Figure 12 - Retreat Path From Tree

4. Remove dirt, stones, loose bark, nails, staples, and wire

from tree where you will make felling cuts.

5. Stay on uphill side when felling tree. Tree could roll or

slide downhill after falling.

9

Tree

Continued

9

Page 10

OPERATING CHAIN SAW

Continued

Felling Procedure

Felling Notch

A properly placed felling notch will determine direction tree

will fall. Place felling notch on side of tree in direction you

want tree to fall (see Figure 13). Follow directions below to

create a felling notch.

1. Make lower notch cut as close to ground as possible. Hold

saw so guide bar is horizontal. Cut 1/3 the diameter of tree

trunk (see Figure 13).

lower notch cut first. If you make this cut second, tree can

pinch chain or guide bar.

2. Start upper notch cut the same distance above first cut as

first cut is deep.

Example:

upper notch cut 20 centimeters above it. Cut downward at

45° angle. The upper notch cut should meet end of lower

notch cut (see Figure 13).

3. Remove tree trunk wedge created by notching cuts.

Felling Cut

1. Make felling cut five centimeters higher than lower notch

cut and on opposite side of tree (see Figure 13). Keep

felling cut parallel to lower notch cut.

2. Cut towards notch.

If lower notch cut is 20 centimeters deep, start

Note:

Always make this horizontal

4. When tree begins to fall, quickly

• remove saw from felling cut

• release trigger to turn saw off

• put saw down

• exit area using retreat path

!

WARNING

Be alert for falling overhead limbs. Watch your

footing while exiting area.

LIMBING A TREE

!

WARNING

Avoid kickback. Kickback can result in severe

injury or death. See

risk of kickback.

When cutting limb that is under tension, use

extreme caution. Be alert for wood springing

back. When wood tension is released, limb could

spring back and strike operator causing severe

injury or death.

Kickback

!

WARNING

, page 3 to avoid

!

WARNING

Do not cut all the way through tree. Leave about

five centimeters of tree diameter uncut directly

behind felling notch (see Figure 13). This uncut

portion acts as a hinge. The hinge helps keep

tree from twisting and falling in wrong direction.

Direction of Fall

3rd Cut Felling Cut

5 cm

5 cm

Hinge

2nd Cut Upper

Notch Cut

1st Cut Lower

Notch Cut

!

CAUTION

Seek professional help if facing conditions

beyond your ability.

Limbing is removing branches from a fallen tree. Make sure

your footing is firm. Keep feet apart. Divide your weight

evenly on both feet. Do not remove larger limbs under tree that

support log off ground. Remove each limb with one cut (see

Figure 14). Clear cut limbs from work area often. This will

help maintain a safe work area.

Make sure you start your cut where limb will not pinch saw

during cutting. To avoid pinching, start cut on freely hanging

limbs from above limb. Start cut on limbs under tension from

under limb. If pinch occurs, turn saw off, lift limb, and remove

saw.

Figure 13 - Felling A Tree

3. As felling cut nears hinge, tree should begin to fall.

needed, drive wedges into felling cut to control direction of

fall. If tree settles back and pinches chain, drive wedges into

felling cut to remove saw. Only use wedges made of wood,

plastic, or aluminum. Never use wedge made of steel. This

could cause kickback and damage to chain.

Note:

If

10

Figure 14 - Limbing A Tree

102514

Page 11

OPERATING CHAIN SAW

Continued

BUCKING A LOG

!

WARNING

Avoid kickback. Kickback can result in severe

injury or death. See

risk of kickback.

Kickback

, page 3 to avoid

Log Supported On One End

1. Make first cut on underside of log (see Figure 16). Use top

of guide bar to make this cut. Cut 1/3 through diameter of

log. This cut will keep section from splintering when cut.

2. Make second cut directly above first cut. Cut down to meet

first cut. This cut will keep log from pinching guide bar

and chain.

!

WARNING

• If on slope, make sure log will not roll down

hill. Secure log by using wooden stakes. Drive

wooden stakes into ground on downhill side

of log. Stand on uphill side of log while

cutting. Log may roll after cutting.

• Never try cutting through two logs at same

time. This could increase the risk of kickback.

• While cutting log, never hold log with your

hand, leg, or foot.

• While cutting log, never allow another person

to hold log.

• Turn off and unplug saw before moving from

one place to another.

!

CAUTION

Seek professional help if facing conditions

beyond your ability.

Bucking a log is cutting a log into sections. Make sure your

footing is firm. Keep feet apart. Divide your weight evenly on

both feet. Stand slightly to left of saw. This keeps your body

from being in direct line with chain. When possible, raise log

or section off ground. Do this by using limbs, logs, chocks, etc.

When cutting through log, maintain control by reducing

cutting pressure near end of cut. Do not relax your grip on

chain saw handles. Do not let moving chain touch ground.

Ground will dull moving chain. After cutting through log,

release trigger to turn saw off before moving saw.

2nd Cut

1st Cut

Figure 16 - Bucking Log When Log Is Supported

On One End

Log Supported On Both Ends

1. Make first cut from above log (see Figure 17). Cut 1/3

through diameter of log. This cut will keep section from

splintering when cut.

2. Make second cut on underside of log, directly under first

cut. Use top of guide bar to make this cut. Cut up to meet

first cut. This will keep log from pinching guide bar and

chain.

1st Cut

Follow directions below to buck a log.

Entire Length Of Log On Ground

1. Cut log from top two thirds of the diameter (see Figure

15). Roll log over and complete cut.

Figure 15 - Bucking Log With Entire Length On Ground

102514

2nd Cut

Figure 17 - Bucking Log When Log Is Supported

On Both Ends

11

11

Page 12

CLEANING AND MAINTENANCE

NOTICE

Below are instructions for servicing your chain

saw. Any servicing not mentioned below should

be done by an authorized Echo servicing dealer.

Normal Guide Bar Maintenance

1. Remove guide bar from chain saw.

2. Remove sawdust from guide bar groove periodically. Use

putty knife or wire.

3. Clean oil slots after each day of use.

4. Remove burrs from sides of guide bar. Use flat file to make

side edges square.

CLEANING SAW BODY

!

WARNING

Unplug chain saw from power source before

servicing. Severe injury or death could occur

from electrical shock or body contact with

moving chain.

!

WARNING

Cutting edges on chain are sharp. Use protective

gloves when handling chain.

WARNING

When cleaning saw body,

• do not submerge saw in any liquids

• do not use products that contain ammonia,

chlorine, or abrasives

• do not use chlorinated cleaning solvents,

carbon tetrachloride, kerosene, or gasoline

Replace guide bar when

• bar is bent or cracked

• inside groove of bar is badly worn

Note:

When replacing guide bar, see Replacement Parts, page

14 for proper bar.

Flat File

Cleaning Groove

With Putty Knife

Oil Slot

Figure 19 - Guide Bar Maintenance

Burr

Guide

Bar

Keep saw body clean. Use a soft cloth dampened with a mild

soap and water mixture. Wipe saw body to clean. Let dry

before using saw.

CARE OF GUIDE BAR

Uneven bar wear causes most guide bar problems. Incorrect

sharpening of chain cutter and depth gauge settings often cause

this. When bar wears unevenly, it widens guide bar groove (see

Figure 18). This causes chain clatter and rivet popping. Saw

will not cut straight. Replace guide bar if this occurs.

Inspect guide bar before sharpening chain. A worn or damaged

guide bar is unsafe. A worn or damaged guide bar will damage

chain. It will also make cutting harder.

Guide Bar

Groove

Guide Bar

Normal Guide Bar

Guide Bar With

Uneven Wear

SHARPENING YOUR SAW CHAIN

!

WARNING

Unplug chain saw from power source before

servicing. Severe injury or death could occur

from electrical shock or body contact with

moving chain.

!

WARNING

Cutting edges on chain are sharp. Use protective

gloves when handling chain.

Keep chain sharp. Your saw will cut faster and more safely. A

dull chain will cause undue sprocket, guide bar, chain, and

motor wear. If you must force chain into wood and cutting

creates only sawdust with few large chips, chain is dull.

Items Needed to Sharpen Chain

Purchase these items from your local Echo servicing dealer.

•4 mm round file • Depth gauge tool

• File guide • Vise

• Medium sized flat file

Figure 18 - Guide Bar Cross Section Showing

Uneven Bar Wear

12

102514

Page 13

CLEANING AND MAINTENANCE

Continued

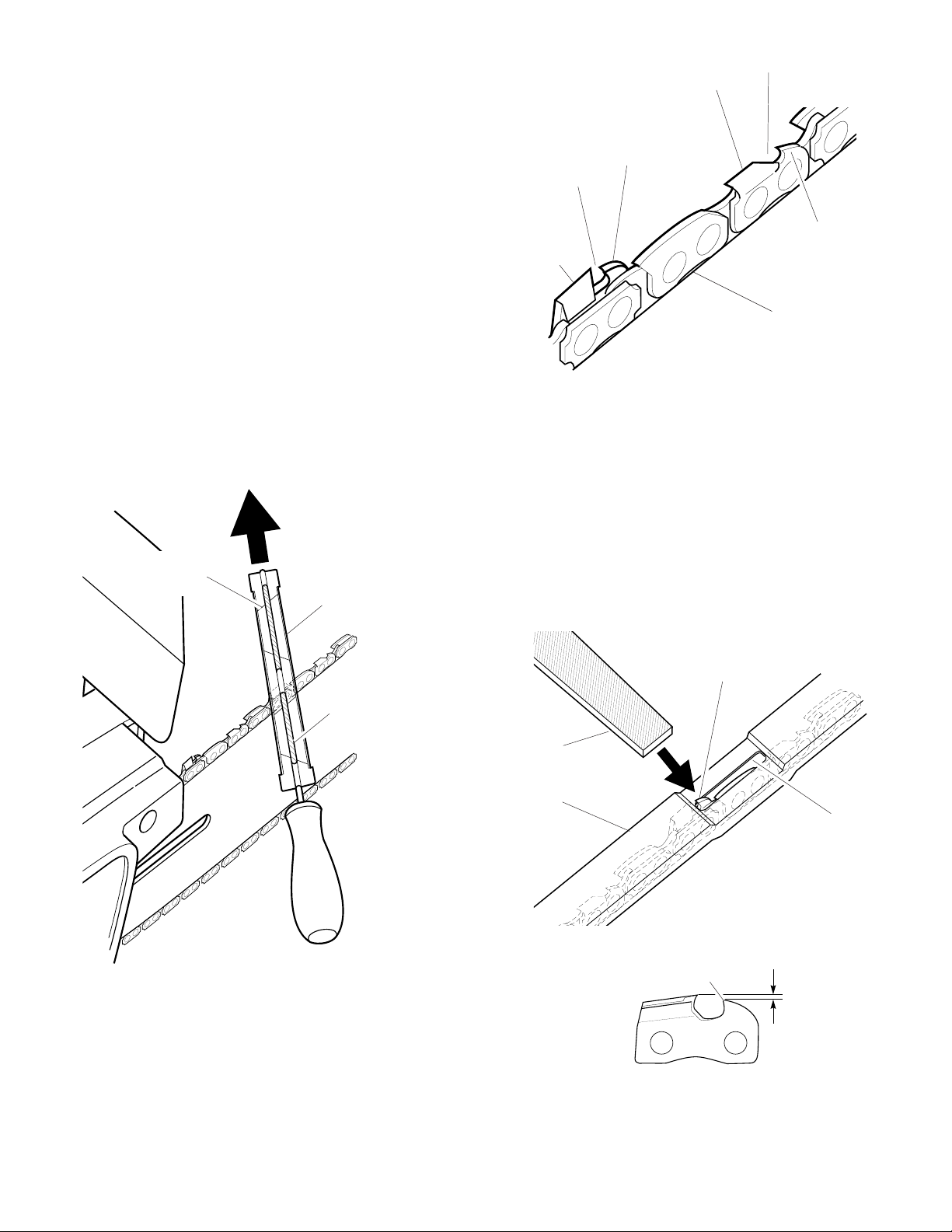

Sharpening Cutters

Use file guide for 30° filing.

1. Adjust chain for proper tension (see Saw Chain Tension

Adjustment, page 7).

2. Clamp guide bar in vise to hold saw steady.

clamp chain.

3. Press four millimeter round file (attached to file guide)

into groove between top plate and depth gauge on chain.

File guide should rest on both top plate and depth gauge

(see Figures 20 and 21).

Note:

File at midpoint of guide

bar.

4. Hold file guide level. Make sure 30° mark on file guide is

parallel to center of guide bar (see Figure 20). This will

insure that you file cutters at 30° angle.

5. File from inside towards outside of cutter until sharp.

Only file in this one direction (see Figure 20).

or three strokes with file should sharpen cutter.

6. After each cutter if sharpened, move chain forward to

sharpen next cutter. File all cutters on one side of chain.

7. Move to other side of chain and repeat process.

Filing

Direction

30° Guide

Mark

File Guide

FILE HOLDER

Note:

Note:

Do not

Two

Left Side

of Chain

Top Plate

(right side of chain)

Depth Gauge

Groove

(left side

of chain)

Groove

Top Plate

(left side

of chain)

Depth Gauge

(right side of chain)

Right Side

of Chain

Figure 21 - Chain Part Locations

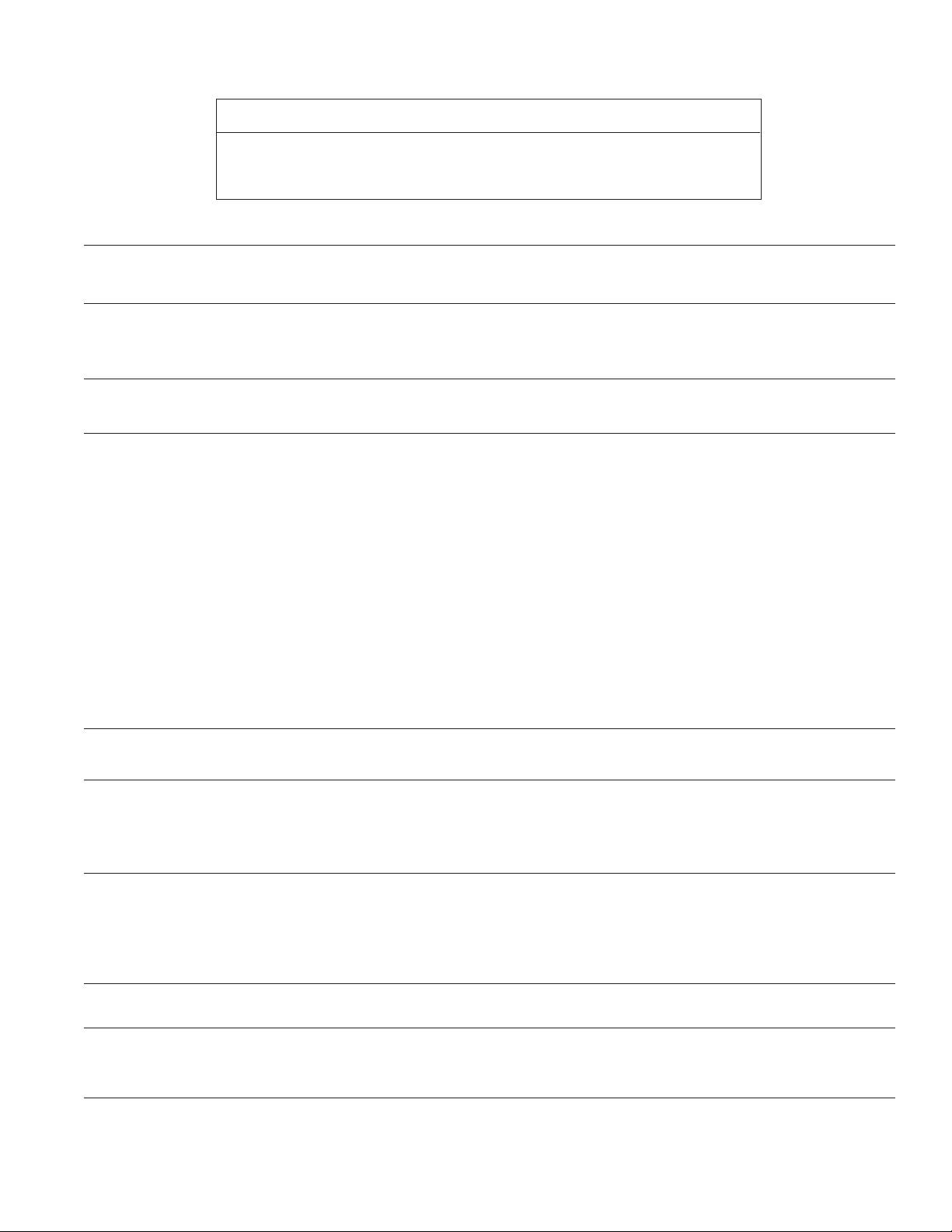

Filing Cutter Depth Gauges

The cutter depth gauge clearance is reduced as cutters are

sharpened. After every second or third sharpening, reset cutter

depth gauges.

1. Place depth gauge tool firmly across top of two cutters.

Make sure depth gauge enters slot in depth gauge tool (see

Figure 22).

2. Use medium flat file. File depth gauge level with depth

gauge tool.

3. Remove depth gauge tool. With flat file, round off front

corner of cutter depth gauge (see Figure 23).

4 mm

Round File

Note: This

illustration

shows file

guide placement and filing

direction for

sharpening

cutters on left

side of chain.

Figure 20 - File and File Guide Placement On Chain

Depth Gauge

Flat File

Depth

Gauge

Tool

Figure 22 - Depth Gauge Tool On Chain

Front Corner

.025"

Figure 23 - Round Off Front Corner Of Depth Gauge

Depth

Gauge

Slot

102514

After several hand filings, have an authorized Echo servicing

dealer sharpen chain. This will insure even filing.

13

13

Continued

Page 14

CLEANING AND MAINTENANCE

Continued

Replacing Saw Chain

Replace chain when cutters are too worn to sharpen. Only use

replacement chain noted in this manual. Always include new

drive sprocket when replacing chain. This will maintain proper

driving of chain.

STORAGE

If storing saw for more than 30 days, follow steps below.

1. Drain oil tank.

2. Remove and clean guide bar and chain. Clean guide bar

and chain by soaking in petroleum based solvent or mild

soap and water mixture.

3. Dry guide bar and chain.

4. Place chain in container filled with oil. This will prevent

rust.

5. Wipe a thin coating of oil over surface of guide bar.

6. Wipe off outside of saw body. Do this with soft cloth

dampened with a mild soap and water mixture.

7. Store chain saw

• in a high or locked place, out of children’s reach

• in a dry place

• in a carrying case (part # 999888-00207) or with

scabbard over guide bar

REPLACEMENT PARTS

!

WARNING

Use only replacement parts described in this

manual. Use of other parts could damage saw or

injure operator.

Purchase these parts from your local dealer.

Part Number Description

120374001 12" guide bar with kick guard

917045 91VG chain, 45 drive links

16037500 16" guide bar with kick guard

917056 91VG chain, 56 drive links

9998880016 Kick guard

14

102514

Page 15

TROUBLESHOOTING

WARNING

Unplug chain saw from power source before servicing. Severe injury

or death could occur from electrical shock or body contact with

moving chain.

OBSERVED FAULT

Saw runs, but does not cut.

Saw does not cut unless heavily forced.

Cutting produces only sawdust with few

large chips.

Saw runs slow. Saw stalls easily.

Motor of saw does not run when you

squeeze trigger.

POSSIBLE CAUSE

Chain assembled backwards on guide

bar.

Chain is dull.

Low power supply voltage.

Switch lockout not pressed in to release

trigger.

Chain brake activated.

Extension cord connections

loose.

Open line fuse or circuit

breaker.

Bad motor brushes.

REMEDY

See Assembly, page 6.

See Sharpening Your Saw Chain,

page 12.

Extension cord wire size too

small. See Extension Cords, page 8.

Press in switch lockout before squeezing trigger.

Release trigger and move front hand

guard back towards rear of saw.

Check cord connections.

Check line fuse or circuit

breaker.

Contact authorized service person.

Motor of saw runs, but chain does not

move.

Chain does not get oil.

Chain comes off guide bar.

Saw smokes.

Saw leaks oil.

Chain brake does not stop saw chain.

Open wiring circuit on saw.

Gear train failure.

Clogged oil slot in guide bar.

Oil is too thick.

Chain is loose.

Guide bar and chain not assembled

right.

Saw damaged. Do not use saw.

Oil cap is not secure.

Brake failure.

Contact authorized service person.

Contact authorized service person.

Remove guide bar and clean oil slot.

Use correct weight of oil. See Filling

Oil Tank, page 7.

Tighten chain. See Saw

Chain Tension Adjustment, page 7.

See Assembly, page 6.

Contact authorized service person.

Tighten oil cap.

Note:

Empty oil tank

when not in use.

Contact authorized service person.

102514

15

15

Page 16

SERVICING INFORMATION

PARTS

Genuine ECHO Parts and Assemblies for your ECHO products are

available only from an Authorized ECHO Dealer. When you do need to

buy parts always have the Model Number and Serial Number of the unit

with you. You can find all three numbers on the engine housing. For future

reference, write them in the space provided below.

Model No. _____________ SN. __________

--

SERVICE --

Service of this product during the warranty period must be performed by

an Authorized ECHO Service Dealer. For the name and address of the

Authorized ECHO Service Dealer nearest you, ask your retailer or call:

1-800-432-ECHO. When presenting your unit for Warranty service/

repairs, proof of purchase is required.

WARRANTY CARD --

This card is our means of registering all original owners of ECHO

equipment. The card plus proof of purchase provides you the assurance

that authorized warranty work will be done. It also provides a direct link

between you and ECHO if we find it necessary to contact you.

DEALER?

Call

1-800-432-ECHO

ADDITIONAL OR REPLACEMENT MANUALS --

Safety Manuals are available, free of charge, from your ECHO dealer

or by contacting Echo Incorporated, 400 Oakwood Road, Lake Zurich, IL

60047

ECHO Incorporated

400 Oakwood Road

Lake Zurich, IL 60047

Operators and Parts Manuals are available for purchase from your

ECHO dealer or directly from ECHO. [See ordering instructions below.]

Technical Publications Orders

ORDERING INSTRUCTIONS

To obtain a Parts Catalog or Operator’s Manual send a check or money order for $2.00 per Parts Catalog or $1.50 per

Operator’ Manual made payable to ECHO, INCORPORATED. State on a sheet of paper model number and serial

number of the ECHO unit you have, part number of the manual (if known), your name and address and mail to address

above.

Available Parts Lists

ECS-2000 PARTS CATALOGS P/N 99922202736

ECS-3000 PARTS CATALOGS P/N 99922202737

ECHO, INCORPORATED

400 OAKWOOD ROAD

LAKE ZURICH, IL 60047

99922202735

03/97

Printed 03/97

102514-01

REV. D

03/97

Loading...

Loading...