Page 1

0

INTRODUCTION

We are constantly working on technical

improvement of our products. For this reason,

technical data, equipment and design are subject to

change without notice. All specifications,

illustrations and directions in this SERVICE DATA

are based on the latest products information

available at the time of publication.

CHAIN SAW

CS-3500

SERVICE DATA

1

01-34A-00 CS-3500

CONTENTS

page

1 SERVICE INFORMATION ............................ 2

1-1 Specifications ............................................ 2

1-2 Technical data .......................................... 3

1-3 Torque limits ............................................. 4

1-4 Special repairing materials ....................... 4

1-5 Service limits ............................................. 5

1-6 Special tools ............................................. 6

2. SERVICE HINT

2-1 Assembling clutch...................................... 7

Reference No. 01-34A-00

ISSUED : 199909

INDEX

Page 2

1 SERVICE INFORMATION

1-1 Specifications

Dimensions Length* mm(in) 386 (15.2)

Width* mm(in) 223 (8.78)

Height mm(in) 258 (10.2)

Dry weight* kg(lb) 3.75 (8.27)

Engine Type KIORITZ, air-cooled, two-stroke, single cylinder

Two-piece casting, Ventilated piston

Rotation Clockwise as viewed from the output end

Displacement cm

3

(in3) 34.0 (2.075)

Bore mm(in) 38.0 (1.496)

Stroke mm(in) 30.0 (1.181)

Compression ratio 6.5

Carburettor Type Diaphragm horizontal-draught

Supplier and Model Walbro WT-504

Venturi size-Throttle bore mm(in) 11.11 - 15.85 (7/16 - 5/8)

Ignition Type CDI (Capacitor discharge ignition) system

in a single integrated piece, with electronic timing advancer

Spark plug BPMR7A, RCJ7Y

Starter Type Automatic rewind

Rope diameter x length mm(in) 3.0 x 890 (0.12 x 35.0)

Fuel Type Premixed two-stroke fuel (Refer to operator's manual.)

Tank capacity cm

3

(U.S.fl.oz.) 320 (10.8)

Clutch Type Centrifugal, 3-shoe slide

Guide bar / Saw chain lubrication type Automatic with volume adjuster

Tank capacity, oil cm

3

(U.S.fl.oz.) 180 (6.09)

Sprocket Type Spur

Number of teeth 6

Pitch in 3/8 Low profile

Guide bar Type 30RC50-3/8 35RC50-3/8 40RC50-3/8

Called length cm 30 35 40

Gauge in 0.050

Saw chain Number of drive links 47 53 58

Pitch in 3/8 Low profile

Gauge in 0.050

2

SERVICE INFORMATION CS-3500

*Without guide bar and saw chain

Page 3

3

SERVICE INFORMATIONCS-3500

1-2 Technical data

Engine

Idling speed rpm 2800 - 3200

Operating speed rpm 8000 - 10000

High speed (No load full throttle)* rpm 11500 - 12000

Clutch-in speed rpm 4200 - 4800

Compression pressure kgf/cm

2

(psi) 7.7 (109)

Carburettor

Idle speed screw initial setting turn in 1 3/4

L needle initial setting turns back 1 1/4

H needle initial setting turns back 1 1/8

Test pressure kgf/cm2(psi) 0.5 (7.0)

Metering lever height mm(in) 1.65 (0.065) lower than diaphragm seat

Ignition system

Spark plug gap mm(in) 0.6 - 0.7 (0.024 - 0.028)

Minimum secondary voltage

at 1500 rpm

kV 18

Secondary coil resistance kΩ 1.7 - 2.2

Pole shoe air gaps mm(in) 0.30 - 0.40 (0.012 - 0.016)

Ignition timing °BTDC

at 1500 rpm 26.5

at 3000 rpm 26.5

at 8000 rpm 25

Chain oil discharge volume at 7000 rpm

cm

3

/min(U.S.fl.oz./min) 1.5 - 13 (0.05 - 0.45) adjustable

BTDC: Before top dead center.

*With guide bar and saw chain.

Page 4

1-3 Torque limits

Descriptions Size kgf•cm N•m

Crankcase M 5 70 - 110 7 - 10

Engine mount M 5 70 - 110 7 - 10

Cylinder cover M 4* 10 - 20 1.0 - 1.9

Intake bellows M 5 30 - 45 3.0 - 4.4

Carburettor elbow M 5* 20 - 40 2.0 - 3.9

Clutch hub LM 8 300 - 400 30 - 39

Chain catcher M 5* 20 - 40 2.0 - 3.9

Flywheel M 8 200 - 240 20 - 23

Ignition coil (CDI module) M 5** 30 - 45 3.0 - 4.4

Spark plug M14 130 - 170 13 - 16

Starter pawl M 5** 30 - 45 3.0 - 4.4

Starter case M 4 15 - 25 1.5 - 2.4

Sprocket guard plate M 4* 10 - 20 1.0 - 1.9

Muffler M 5 50 - 75 4.9 - 7.3

Cushion Front handle M 4** 10 - 15 1.0 - 1.4

Engine cover front M 4* 20 - 40 2.0 - 3.9

Engine cover rear M 4 15 - 25 1.5 - 2.4

Auto-oiler M 4 15 - 25 1.5 - 2.4

Throttle latch M10 6 - 10 0.6 - 0.9

Front handle M 5* 15 - 25 1.5 - 2.4

Handle assembly M 4 12 - 18 1.2 - 1.7

M 5 20 - 35 2.0 - 3.4

M 5* 20 - 40 2.0 - 3.9

Guide bar M 6 90 - 110 9 - 10

Regular bolt, nut, M 3 6 - 10 0.6 - 0.9

and screw M 4 15 - 25 1.5 - 2.4

M 5 25 - 45 2.5 - 4.4

M 6 45 - 75 4.5 - 7.3

* Tapping screw

** Apply thread locking sealant

LM: Left-hand thread

Material Location Remarks

Adhesive Ball bearing outer / crankcase Loctite #675, RC #75 or equivalent

Grease Auto-oiler worm

Clutch needle bearing

Cushion, inside Lithium based grease

Oil seal lip

Rewind spring

Chain brake (metal contact part) Molybdenum grease (approx. 1 gram)

Liquid gasket Crankcase seams Loctite #518 or equivalent

Thread locking sealant Ignition coil screws

Starter pawl screws Loctite #222, ThreeBond #1342, #1344

Cushion screws (Front handle) or equivalent

1-4 Special repairing materials

4

SERVICE INFORMATION CS-3500

Page 5

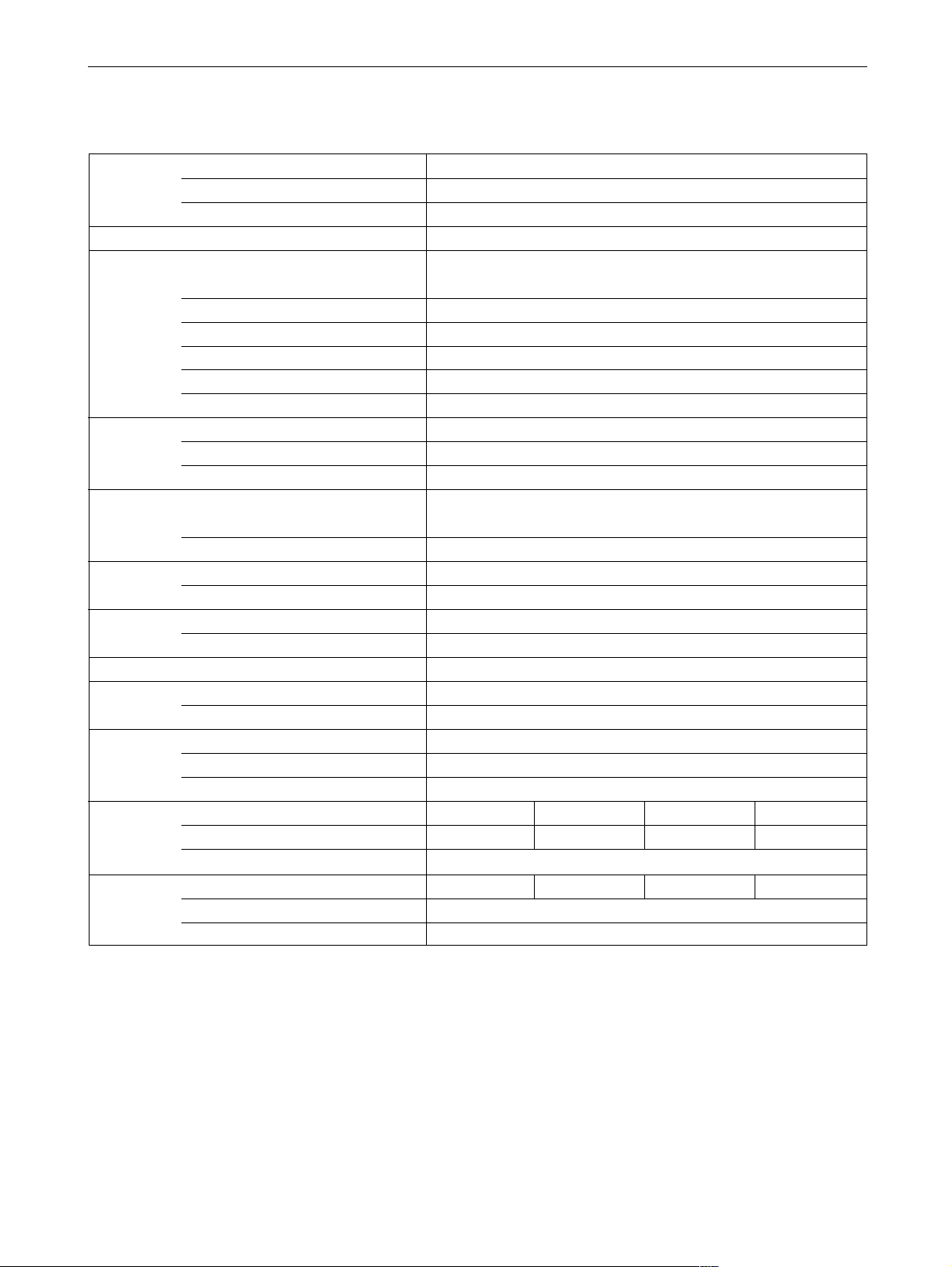

1-5 Service limits

Description mm (in)

A Cylinder bore When plating is worn and aluminum can be seen

B Piston outer diameter Min. 37.90 (1.492)

C Piston pin bore Max. 8.030 (0.3161)

D Piston ring groove Max. 1.6 (0.063)

E Piston ring side clearance Max. 0.1 (0.004)

F Piston pin outer diameter Min. 7.98 (0.3142)

G Piston ring width Min. 1.45 (0.057)

H Piston ring end gap Max. 0.5 (0.02)

K Con-rod small end bore Max. 11.025 (0.4341)

L Crankshaft runout Max. 0.05 (0.002)

M Sprocket bore Max. 13.08 (0.5150)

N Clutch drum bore Max. 61.0 (2.40)

P Sprocket wear limit Max. 0.5 (0.02)

5K177 5K083 5K084 5K081

5K082 5K016 5K025

5K174 5K181 5K097

5K178

5K173

1

23

ABCD

EFGH

KLMP

N

5

SERVICE INFORMATIONCS-3500

Page 6

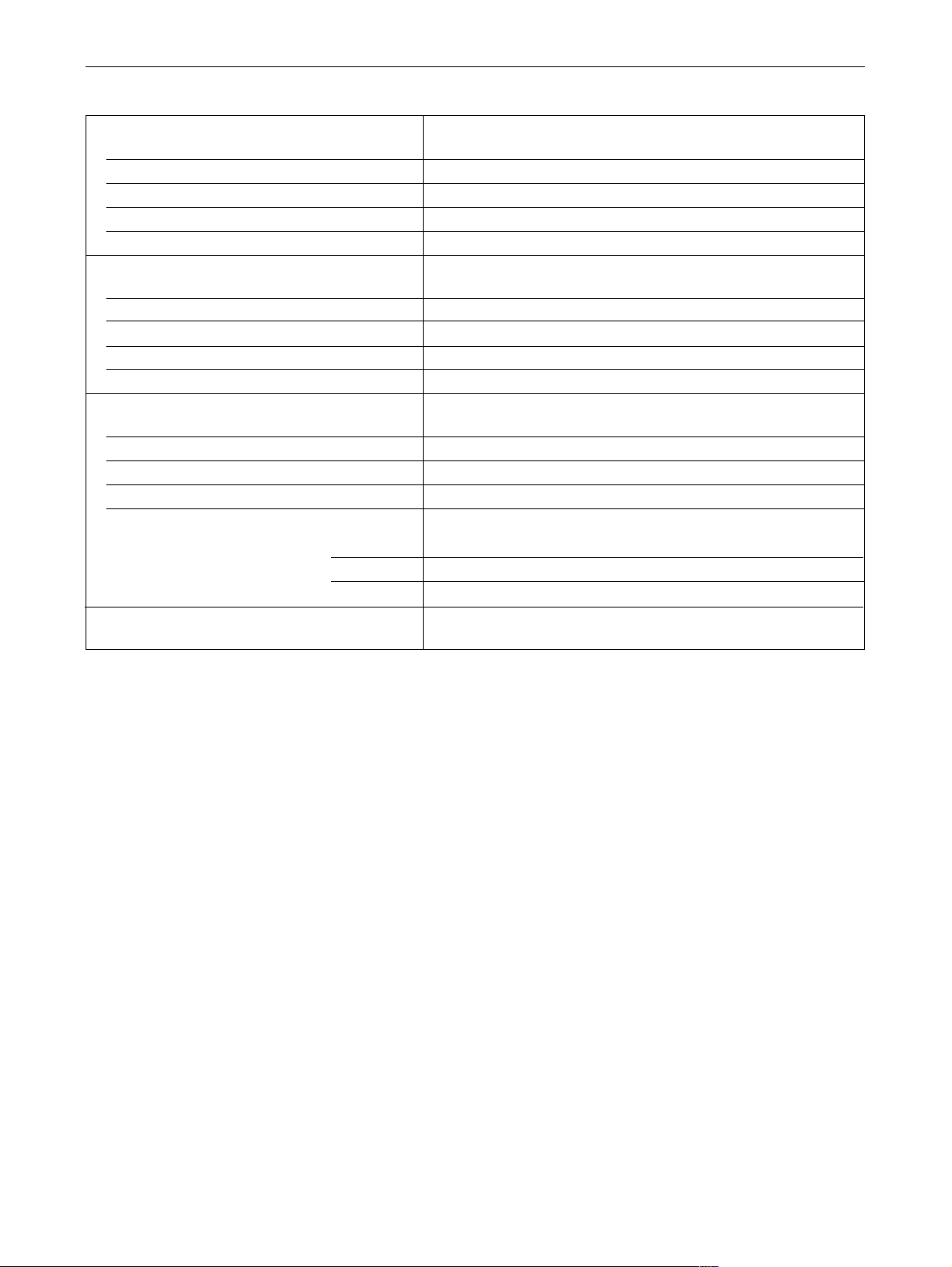

1-6 Special tools

1.35

0.4

1.65

1.5

a

1

5

9

13

2 : a = 4 mm

6

10

14

3

7

11

4

8

12

6

SERVICE INFORMATION CS-3500

Key Part Number Description Used for:

1 Tachometer Adjusting carburettor

2 895610-79920 L-hex. wrench(4 mm) Removing and installing hex. socket bolt (M5)

3 897501-03938 Puller Removing flywheel and auto-oiler

4 897505-16133 Clutch tool Removing and installing clutch assembly

5 897537-30130 Piston stopper Locking crankshaft rotation

6 897563-19830 Metering lever gauge Measuring metering lever height on carburettor

7 897701-02830 Bearing wedge Removing ball bearing from crankshaft

8 897702-30131 Piston pin tool Removing and installing piston pin (Use 8 mm dia. adapter)

9 897603-23030 PTO shaft puller Removing plug on auto-oiler assembly

{Use with bolt (M5-M8) in Puller 897501-03938}

10 897708-19834 Worm remover Removing worm of auto-oiler

11 897708-37532 Worm inserter Installing worm of auto-oiler

12 897724-01361 Spring pin tool Removing and installing spring pin (4 mm or 5/32 in dia.)

13 897726-09130 Oil seal tool Installing ball bearing on crankshaft

14 897800-79931 Spark tester Checking ignition system

15 897803-30130 Pressure tester Testing carburettor and crankcase leakages

16 897826-16131 Pressure plug Plugging intake / exhaust port to test crankcase / cylinder leakages

17 897827-16131 Pressure plate Plugging intake port to test crank case / cylinder leakages

15 16 17

Page 7

2 SERVICE HINT

2-1 Assembling clutch

1. Hook both ends of clutch spring together

and install it into the groove of a clutch shoe.

(Note: The hooks should be located at the

centre of shoe groove.)

2. Install clutch hub and the second shoe.

3. Turn over the assembling clutch and install

2 flat springs.

4. Place the third shoe on top of clutch hub

and clutch spring as shown.

(Note: Shoe groove should be located along

clutch spring.)

5. Using thumbs, push down forward the third

shoe as stretching clutch spring on flat and

solid surface until the shoe is engaged

correctly with clutch hub.

6. Install the last flat spring.

7

SERVICE HINTCS-3500

Loading...

Loading...