Page 1

A PART OF THE APRILAIRE

®

INDOOR AIR COMFORT SYSTEM

AUTOMATED HVAC

THE BEST IN I NDOOR AIR COMFORT

®

Communicating Thermostat

System Installation Manual

Page 2

This manual will guide the installer through the installation, wiring and checkout of an Aprilaire Model 8870 Communicating

Thermostat System. Instructions for the Aprilaire 8840 Series communicating thermostat system are found in a separate

document (DP 10004345). A portion of the command set is found in Appendix 2 in this manual. For a complete command set

with programming suggestions, see the programming manual (DP 10005756). Contact Research Products Corporation for

these documents at 888-782-8638.

COMMUNICATING THERMOSTAT SYSTEM INSTALLATION MANUAL

WARNING

1. 120 volts may cause serious injury from electrical shock. Disconnect electrical power to the HVAC system before

starting installation. This system is a low-voltage system.

2. Improper installation may cause serious injury from electrical shock. This system must be installed by a qualified

contractor in accordance with NEC Standards and applicable local and state codes.

THERE ARE 14 STEPS INVOLVED IN THE INSTALLATION OF A COMPLETE SYSTEM.

Step 1 GET ALL THE COMPONENTS YOU WILL NEED 1

Step 2 DISCONNECT POWER TO ALL HVAC EQUIPMENT AND/OR ZONE CONTROL PANELS 2

Step 3 RUN THE REQUIRED WIRES 3

Step 4 LOCATE AND MOUNT THE AUTOMATION SYSTEM COMPONENTS 4

Step 5 CONNECT THE CONTROL WIRES TO THE HVAC/ZONE SYSTEM AND THERMOSTATS 6

Step 6 CONNECT THE COMMUNICATION AND POWER WIRES TO THE DISTRIBUTION PANEL AND THERMOSTAT 8

Step 7 CONNECT MULTIPLE DISTRIBUTION PANELS 9

Step 8 CONNECT PROTOCOL ADAPTER TO THE DISTRIBUTION PANEL AND HOST COMPUTER OR AUTOMATION SYSTEM 10

Step 9 PROVIDE POWER TO THE DISTRIBUTION PANEL 11

Step 10 TURN ON POWER TO ALL HVAC EQUIPMENT AND TO THE THERMOSTATS 11

Step 11 CHECK-OUT HVAC SYSTEM OPERATION 11

Step 12 ADDRESS THE THERMOSTATS AND SET HIGHEST ADDRESS 12

Step 13 SETUP COMPUTER FOR COMMUNICATION SYSTEM CHECKOUT 13

Step 14 CHECK-OUT COMMUNICATIONS TO THE THERMOSTAT NETWORK 16

Appendix 1 SPECIAL CONSIDERATIONS FOR INSTALLING THE MODEL 8870 WITH THE 8840 SERIES

COMMUNICATING THERMOSTAT 17

Appendix 2 APRILAIRE COMMAND SET 19

EXTRA NETWORK INTERCONNECTION WORKSHEET 21

© Research Products Corp.

Page 3

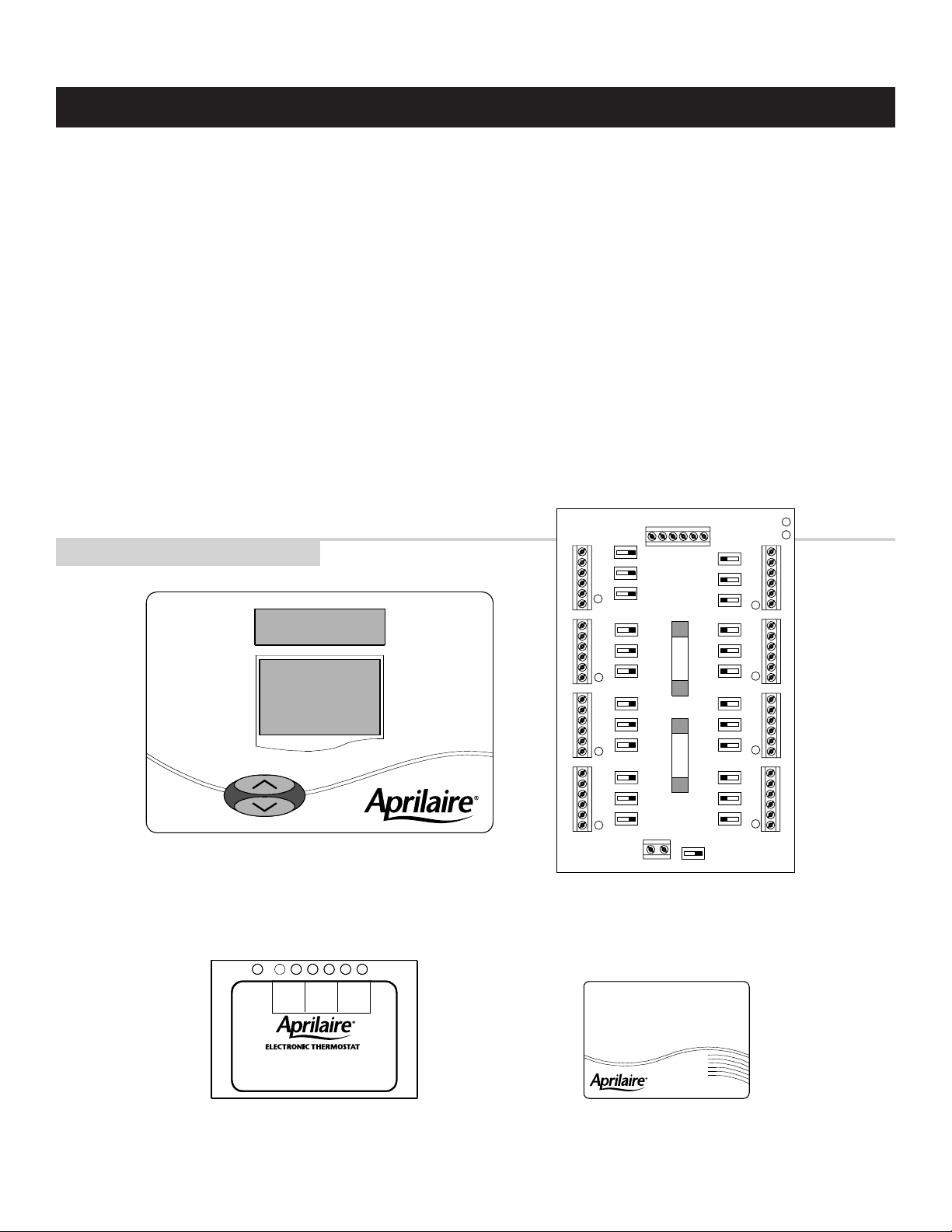

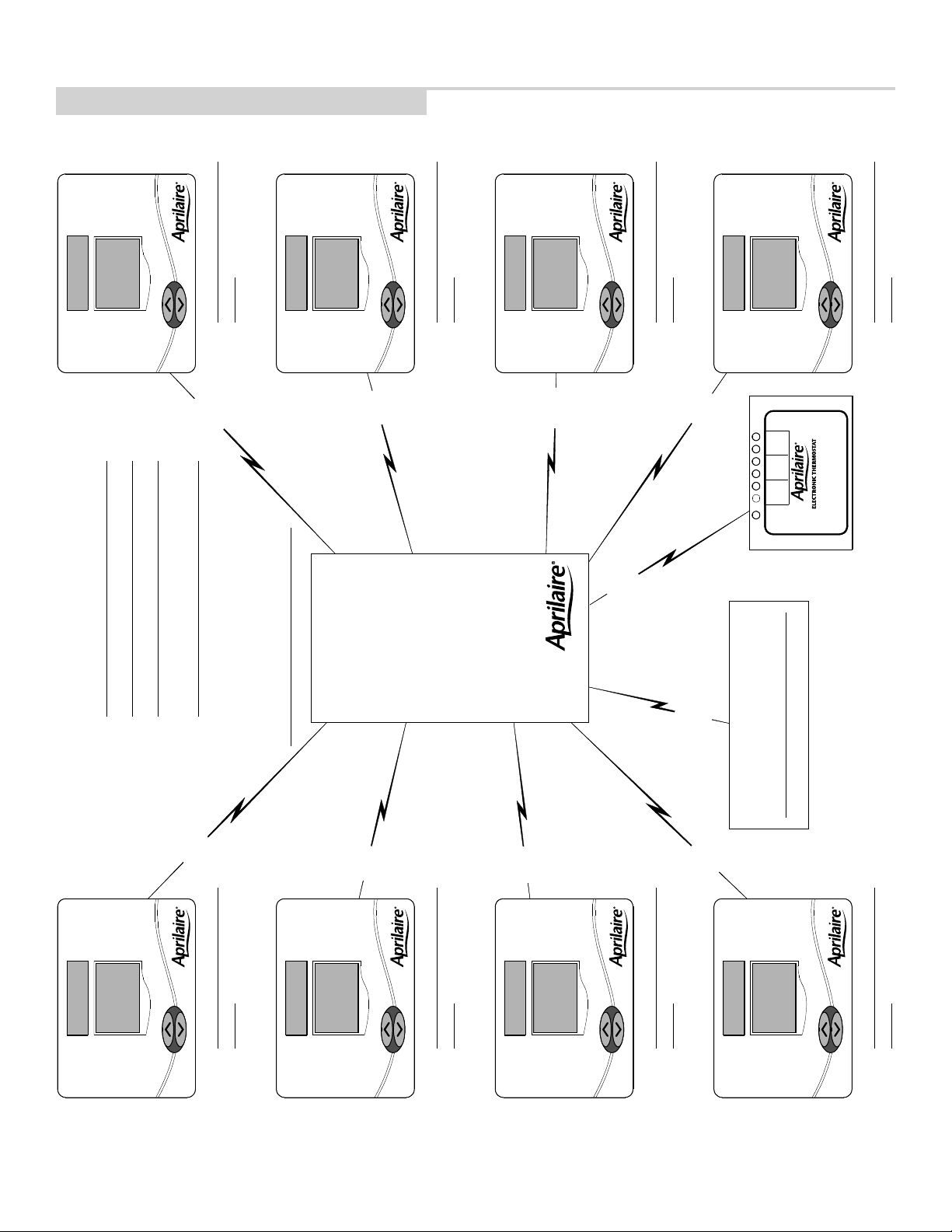

ILLUSTRATION 1 – System Components

Model 8870 Thermostat

RS-422 Communicating Thermostat controls single

or multi-stage heat/cool or heat pump HVAC systems.

Model 8811 Protocol Adapter

Use to convert RS-485 communication signal from Aprilaire

Communication System to RS-232 communication signal

readable by host computer. Supports up to 32 thermostats.

Model 8061 and 8062 Support Modules

Up to four can be connected to a single thermostat

to sense temperature or relative humidity at a

location remote from the thermostat.

Model 8818 Distribution Panel

Switches in the Distribution Panel allow power or

communications to be turned off at each individual

thermostat to make installation and troubleshooting easy.

RX TX

DATA

RS-232

RX TX

ENABLE

RS-485

RX TX

DATA

RS-485

POWER

Model 8811 Protocol Adapter

Power

7.5VAC RS-485 RS-485 RS-232

B+ B- REFA-

RCA+ A- B+ B- R CA+ A- B+ B- R CA+ A- B+ B- R CA+ A- B+ B-

A

B

A+

OFF ON

OFF ON

OFF ON

OFF ON

OFF ON

OFF ON

OFF ON

OFF ON

ON OFF

ON OFF

ON OFF

ON OFF

ON OFF

ON OFF

ON OFF

ON OFF

PWR

PWR

PWR

PWR

PWR

PWR

PWR

PWR

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

MAIN

PWR

ON OFF

RC

24VAC

FUSE SPARE FUSE

RCA+A-B+B-RCA+A-B+B-RCA+A-B+B-RCA+A-B+B-

1

COMPONENTS YOU WILL NEED… (see ILLUSTRATION 1)

• One Aprilaire

®

Model 8870 Communicating Thermostat for each

zone or single zone HVAC system

• One Aprilaire Model 8818 Distribution Panel per eight (8)

thermostats in the system

• One Aprilaire Model 8811 Protocol Adapter per 32 thermostats

or one per Model 8823 system controller

• 4 to 8 conductor thermostat cable depending on equipment

stages (18 – 20 gauge)

• Category 5 communication wire (4-pair twisted cable)

• One 24V AC transformer, ungrounded (part number 8027) per

8818 Distribution Panel

• RS-232 or RS-485 based automation system such as the

Aprilaire Model 8823 System Controller

• OPTIONAL: Aprilaire Model 8061 Temperature Support Module

or Model 8062 Temperature/Humidity Support Module

GET ALL THE COMPONENTS YOU WILL NEED

Step1

TOOLS YOU WILL NEED…

• Small flat head screwdriver for terminal

screws (1/8” wide tip)

• Medium size flat/phillips head screwdriver for

component mounting screws

• Volt/ohm meter

• Computer with available com port (RS-232)

and terminal emulator such as HyperTerminal

(for system checkout)

• Wire strippers

• Small level (use to mount components level,

required for appearance only)

Page 4

2

MODEL 8870 THERMOSTAT

The Model 8870 Thermostat is field configurable to operate

single and multi-stage separate heating and cooling

equipment (such as furnace and air conditioner or roof top

units), or single and multi-stage heat pump systems. A menu

driven set up, using the message center display of the

thermostat, can be used to configure many other features.

Network communication is non-isolated, full duplex RS-485

(RS-422). The ‘A’ terminals are the transmit pair while the ‘B’

terminals are the receive pair. This nomenclature uses the

computer or host as the reference, so transmit refers to the

lines on which the host transmits data to the thermostat

while receive refers to the lines on which the host receives

data from the thermostat. The baud rate is selectable

between 9600 and 19200. Up to 64 uniquely addressed

thermostats may reside on the same thermostat network.

MODEL 8818 DISTRIBUTION PANEL

The Distribution Panel is a switch controlled communication

bus that can be wired to eight (8) Aprilaire Model 8870

thermostats. This allows thermostat communication

(transmit, receive or both) to be turned on and off at one

convenient location which simplifies installation and trouble

shooting. Each thermostat station on the distribution panel

has an on/off switch for power. This allows isolation of any

one thermostat to simplify troubleshooting. Order one

Distribution Panel per eight thermostats.

MODEL 8061 AND MODEL 8062 SUPPORT MODULES

Support modules are used to either monitor or control

temperature or humidity at a location other than the

thermostat. They communicate with the thermostat using a

RS-485 protocol. Up to four support modules may be wired to

a thermostat, with each module able to support two sensors.

The Model 8061 has one onboard temperature sensor and

room for one offboard temperature sensor (sensor #1 &

sensor #2) while the Model 8062 has one onboard

temperature sensor (sensor #1) and one onboard humidity

sensor (sensor #2). All sensors can be configured as either a

control sensor (replaces thermostat temperature sensor as

control variable) or a monitor sensor (read only). An offboard

sensor such as a Model 8051 Flush Mount Sensor can

replace sensor #1 on the Model 8062 or both on the Model

8061. Each support module is addressed and each sensor

value can be accessed through thermostat commands. See

sensor literature for additional information.

FOR EASE OF INSTALLATION AND TROUBLE SHOOTING

DO THE FOLLOWING:

✔ Use Category-5 cable for all communication wiring.

✔ Check and recheck to ensure connection to the proper

terminals before powering up the thermostats. Use wire

color as a guide and be consistent.

✔ Use a Distribution Panel on all systems with more than

one zone. The trouble shooting benefits will outweigh the

cost of the Distribution Panel.

• If the thermostats are wired to a zone control panel, there is generally one set of input terminals supplying power to the

thermostats and dampers. This must be disconnected.

• If the thermostats are wired directly to HVAC equipment, the power must be shut off at the equipment. This can generally be

accomplished by turning off the disconnect switch located near the equipment. If an obvious disconnect switch is

unavailable, you will need to turn the circuit off using the fuse or circuit breaker. Remove the fuse or shut down the circuit

breaker serving the equipment.

DISCONNECT POWER TO ALL HVAC EQUIPMENT AND/OR ZONE CONTROL PANELS

Step 2

CAUTION

Failure to disconnect power could result in damage to the HVAC equipment or thermostats. Leave power disconnected

until all other electrical connections have been made and checked for accuracy.

Page 5

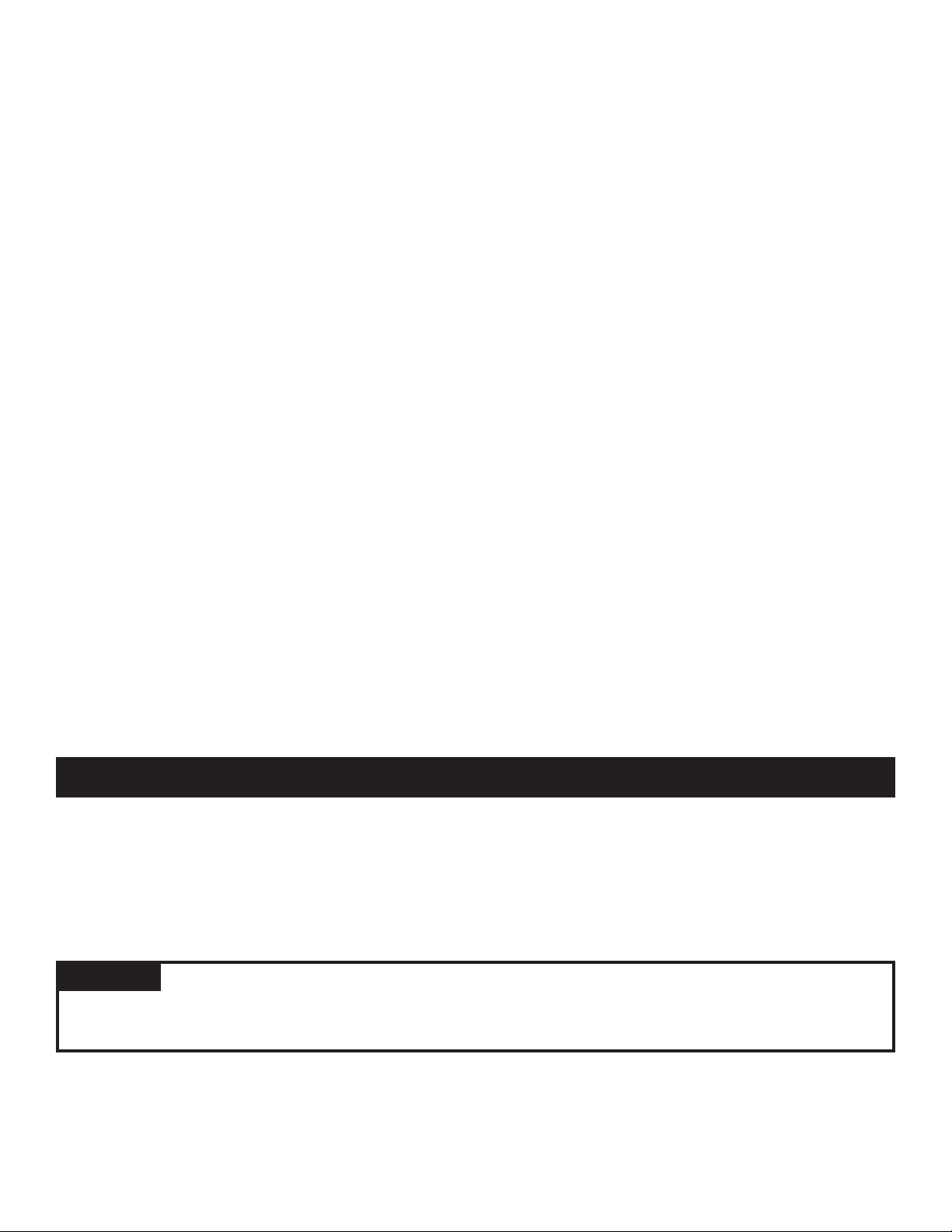

ILLUSTRATION 2 – Run Wire For System

3

RUN THE REQUIRED WIRES

(SEE ILLUSTRATION 2)

Step 3

1. Run thermostat cable from each thermostat to the

appropriate HVAC system or zone control panel. Use 4

through 8-conductor thermostat cable depending on the

type of equipment and number of equipment stages. Run

one more wire than would be required if connecting to a

mechanical thermostat.

❖ If you are using remote temperature or humidity

support modules as part of your installation, now is the

time to run the additional wires for these items. A

separate Category 5 cable must be run from thermostat

to support module.

2. At the HVAC/zone control system, use a piece of tape to

✍

label the location of the thermostat on the cable as you go.

3. Run Category-5, 4-pair twisted cable (8-conductor) from

each thermostat to the Distribution Panel.

4. At the Distribution Panel, use a piece of tape to

✍

label

the location of the thermostat on the cable as you go.

5. Run Category-5 wire from the Distribution Panel to the

Protocol Adapter. If more than one Distribution Panel is

used, run Category-5 wire between each panel.

6. Run two-conductor thermostat cable from the

Model 8027 Transformer to the Distribution Panel. You

can use Category-5 wire, but you must use one pair of

wires per terminal.

ZONE DAMPERS

2-WIRE

THERMOSTAT

CABLE

SINGLE ZONE

HVAC EQUIPMENT

SEE ZONE CONTROL SYSTEM

INSTALLATION LITERATURE

FOR COMPLETE ZONE

SYSTEM WIRING

REQUIREMENTS

INSTALLATION TIP: USE A

PIECE OF TAPE TO

IDENTIFY WHICH

THERMOSTAT EACH CABLE

IS RUN TO

USE 2-WIRE THERMOSTAT

CABLE TO CONNECT OFF-

BOARD SENSORS SUCH AS

THE MODEL 8051 FLUSH

MOUNT SENSOR TO

SUPPORT MODULES.

2-WIRE THERMOSTAT CABLE

MODEL 8027 PLUG-IN

TRANSFORMER

(FOR COMMUNICATION SYSTEM)

THERMOSTAT 1

THERMOSTAT 2

4000 FT.

MAX.

4000 FT. MAX.

POWER

Model 8811 Protocol Adapter

Power

7.5VAC RS-485 RS-485 RS-232

DATA

RS-485

ENABLE

RS-485

DATA

RS-232

RX TX

RX TX

RX TX

ZONE CONTROL SYSTEM

DISTRIBUTION PANEL

4000 FT. MAX.

1000 FT.

MAX.

4000 FT.

MAX.

4000 FT. MAX.

CATEGORY 5 (4-PAIR TWISTED)

COMMUNICATION WIRE

NOTE: TOTAL DISTANCE FROM

PROTOCOL ADAPTER TO THERMOSTAT

NOT TO EXCEED 4,000 FEET

THERMOSTAT CABLE

5 thru 8 CONDUCTOR

SUPPORT MODULE

THERMOSTAT 3

THERMOSTAT 4

Page 6

4

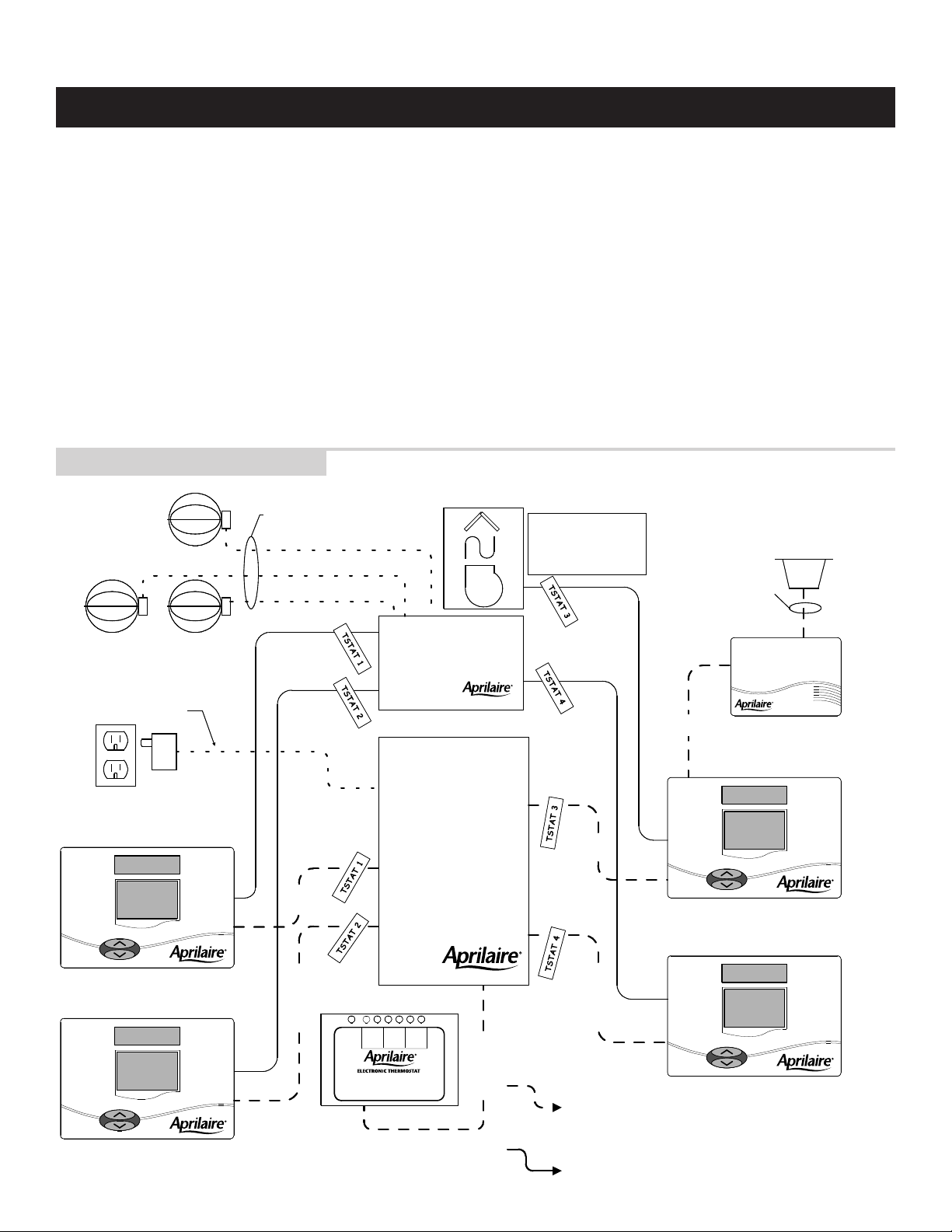

1. Thermostats and sensors are to be located according

installation instructions provided with the units. The

thermostat has four configuration dip switches on the

circuit board that must be set according to the equipment

the thermostat will be controlling. Sensors have six

configuration dip switches that must be properly set.

The installation manuals provided with the products detail

how the switches are to be set.

Review the Network Interconnection Worksheet

(ILLUSTRATION 3) which shows how all the

communication components are connected together

and

✍

write down the location of, or a name for, each

thermostat in the system. This will assist in the software

set-up. Additional copies are available in the back

of this manual.

✍

IMPORTANT!

THE FEW MINUTES SPENT WRITING DOWN

THE INFORMATION SUGGESTED IN THESE STEPS

WILL SAVE A TREMENDOUS AMOUNT OF TIME

DURING THE REST OF THE INSTALLATION.

2. Mount the zone control panel(s) if the HVAC system(s) is

zoned. Refer to the zone control panel installation

instructions.

3. The Aprilaire Distribution Panel must be mounted indoors

in an accessible location such as a closet or utility room.

All thermostats will be wired to the Distribution Panel, so

adequate workspace will be important. There are wire

access holes on the top, bottom, sides and back of the

Distribution Panel.

4. The Model 8811 Aprilaire Protocol Adapter must be

placed within six feet of the host computer or RS-232 port

of the automation system. The Protocol Adapter does not

get fastened down. All the cables and connectors needed

to attach the Protocol Adapter to the computer or

automation system are included with the adapter.

5. The Model 8027 Plug-in Transformer is used to power the

communication system. The transformer is wired to the

Distribution Panel. Locate this transformer in the same

space as the Distribution Panel if possible.

LOCATE AND MOUNT THE AUTOMATION SYSTEM COMPONENTS

Step 4

Page 7

5

ILLUSTRATION 3 – Network Interconnection Worksheet

ADDRESS

LOCATION

WIRE

CAT-5

WIRE

CAT-5

ADDRESS

LOCATION

CAT-5

WIRE

ADDRESS

LOCATION

CAT-5

WIRE

RX TX

RX TX

RX TX

POWER

DATA

ENABLE

DATA

RS-232

RS-485

RS-485

Model 8811 Protocol Adapter

Power

7.5VAC RS-485 RS-485 RS-232

ADDRESS

LOCATION

DISTRIBUTION PANEL LOCATION / NAME

JOB TITLE:

JOB LOCATION:

DATE:

INSTALLING

CONTRACTOR:

Fill Out and Leave with System Software Package

WIRE

CAT-5

CAT-5

WIRE

CAT-5

WIRE

DISTRIBUTION PANEL

CAT-5

WIRE

CAT-5

WIRE

WIRE

CAT-5

TO DISTRIBUTION PANEL

ADDRESS

LOCATION

ADDRESS

LOCATION

ADDRESS

LOCATION

ADDRESS

LOCATION

Page 8

6

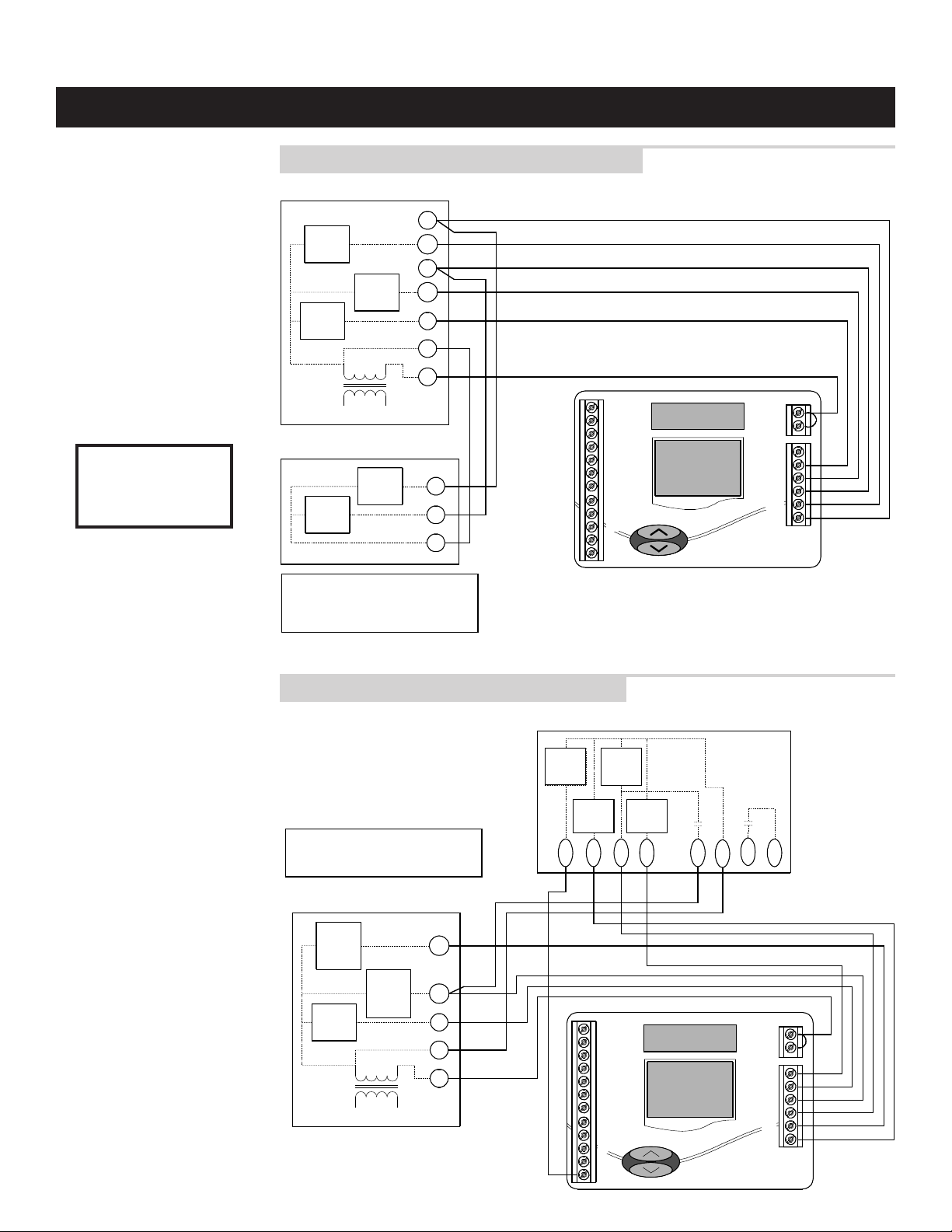

A qualified HVAC technician

should perform this step to

ensure proper termination.

1. Make sure the HVAC

system power is off.

2. The Thermostat

Installation Instructions

show wiring diagrams for

several different HVAC

equipment types. Use

DIAGRAMS 1 & 2 as a

reference only. Use color

coding where possible.

DO NOT TURN ON

THE HVAC SYSTEM

POWER YET!

CONNECT THE CONTROL WIRES TO THE HVAC/ZONE SYSTEM AND THERMOSTATS

Step 5

DIAGRAM 2 – Typical Heat Pump Wiring Schematic

DIAGRAM 1 – Typical Heating / Cool Wiring Schematic

MULTI-STAGE FURNACE

2ND

STAGE

HEAT

FAN

RELAY

2ND STAGE

1ST STAGE

1ST

STAGE

HEAT

24

VAC

L2

120

VAC

COOL

COOL

L1

Y2

W2

Y1

W1

G

C

R

MULTI-STAGE A/C

2ND

1ST

STG

COOL

STG

COOL

Y2

Y1

C

CAUTION!

ENSURE HVAC SYSTEM POWER

IS OFF BEFORE WIRING

USE 18-20 GA. THERMOSTAT CABLE. NUMBER OF CONDUCTORS

REQUIRED DEPENDS ON THE HVAC SYSTEM BEING CONTROLLED

C

R

RSR

RSC

RSB

RSA

REF

BB+

AA+

R.V.-Heat (B)R.V.-Heat (B)

REFER TO THE THERMOSTAT INSTALLATION SHEET FOR

INTERNAL SCHEMATIC, THERMOSTAT CHECK-OUT

PROCEDURES AND OTHER HVAC WIRING DETAILS

RC

RH

R.V.-Cool (O)R.V.-Cool (O)

G

HUM W1

DEH Y1

W2

Y2

OUTDOOR HEAT PUMP UNIT

USE 18-20 GA. THERMOSTAT CABLE. NUMBER

OF CONDUCTORS REQUIRED DEPENDS ON THE

HVAC SYSTEM BEING CONTROLLED

REV

VALV E

HEAT

CAUTION!

ENSURE HVAC SYSTEM POWER

IS OFF BEFORE WIRING

INDOOR BLOWER/HEAT UNIT

2ND

STAGE

AUX.

HEAT

1ST

STAGE

AUX.

FAN

RELAY

REFER TO THE THERMOSTAT INSTALLATION

SHEET FOR INTERNAL SCHEMATIC, THERMOSTAT

CHECK-OUT PROCEDURES AND OTHER HVAC

WIRING DETAILS

HEAT

24

VAC

L2

120

VAC

W2

W1

G

C

R

L1

COMP.

B

1ST

STG

COMP.

2ND

STG

Y2

C

R

RSR

RSC

RSB

RSA

REF

BB+

AA+

R.V.-Heat (B)R.V.-Heat (B)

VALV E

Y1

REV

COOL

C

W1

R.V.-Cool (O)R.V.-Cool (O)

SERVICE

L

RC

RH

HUM W1

DEH Y1

W2

R

G

Y2

DEFROST

O

Page 9

7

COMMUNICATION SYSTEM WIRING

DIAGRAM 3 shows all communication system wiring with terminations. Steps 6 through 8 provide additional

detail for each wiring step.

DIAGRAM 3 – System Communication Wiring

7.5VAC

XFMR

Model 8811 PROTOCOL ADAPTER

RX TX

RX TX

RX TX

POWER

DATA

RS-485

Model 8811 Protocol Adapter

Power

7.5VAC RS-485 RS-485 RS-232

BLU/WHT

ORG/WHT

RED/WHT

BLK/WHT

A

ON OFF

B

PWR

ON OFF

RCA+ A- B+ B- R CA+ A- B+ B- R CA+ A- B+ B- R CA+ A- B+ B-

ENABLE

RS-485

DATA

RS-232

ORG

A+

BLU/WHT

ORG/WHT

ORG

ORG/WHT

BLU

B+ B- REFA-

BLU

CAT-5

DISTRIBUTION PANEL

BLU/WHT

OFF ON

OFF ON

AUTOMATION

SYSTEM

Model 8818

A

B

A

B

PWR

RCA+A-B+B-RCA+A-B+B-RCA+A-B+B-RCA+A-B+B-

Model 8051

FLUSH MOUNT

SENSOR

CABLE

2-WIRE TSTAT

CAT-5

ORG/WHT

CAT-5

GRN

BRN

BLU

ORG

Model 8061 OR 8062 SUPPORT MODULE

BRN

GRN

GRN

BRN

BLU

ORG

BLU/WHT

BLU

ORG

RSR

RSC

RSB

RSA

T1

T2

T3

T4

C

R

RSR

RSC

RSB

RSA

REF

BB+

AA+

R.V.-Heat (B)R.V.-Heat (B)

RC

RH

R.V.-Cool (O)R.V.-Cool (O)

G

HUM W1

DEH Y1

W2

Y2

Model 8870 THERMOSTAT

40VA

XFRMR

A

ON OFF

B

ON OFF

PWR

A

ON OFF

B

ON OFF

PWR

A

ON OFF

B

ON OFF

PWR

24VAC

Model 8027 PLUG-IN

TRANSFORMER

2-WIRE TSTAT

CABLE

A

OFF ON

B

OFF ON

PWR

A

OFF ON

B

OFF ON

PWR

FUSE SPARE FUSE

A

OFF ON

B

OFF ON

PWR

MAIN

PWR

ON OFF

RC

ORG

ORG/WHT

BLU

BLU/WHT

GRN

BRN

ORG

ORG/WHT

BLU

BLU/WHT

GRN

BRN

ORG

ORG/WHT

BLU

BLU/WHT

GRN

BRN

BRN

GRN

BLU/WHT

CAT-5

BLU

ORG/WHT

ORG

BRN

GRN

CAT-5

BLU/WHT

BLU

ORG/WHT

ORG

C

R

RSR

RSC

RSB

RSA

REF

B-

R.V.-Cool (O)R.V.-Cool (O)

HUM W1

DEH Y1

B+

AA+

R.V.-Heat (B)R.V.-Heat (B)

Model 8870 THERMOSTAT

C

R

RSR

RSC

RSB

RSA

REF

BB+

AA+

R.V.-Cool (O)R.V.-Cool (O)

HUM W1

DEH Y1

RC

RH

G

W2

Y2

RC

RH

G

W2

Y2

R.V.-Heat (B)R.V.-Heat (B)

Model 8870 THERMOSTAT

Page 10

-

8

1. MAKE SURE THAT ALL SWITCHES IN THE DISTRIBUTION PANEL ARE OFF!

2. Connect the communication wires. DIAGRAM 4 shows how each thermostat is to be wired to the distribution panel.

• Use the wire colors shown in DIAGRAM 4 to help ensure proper, consistent connections.

3. Connect the REF terminal of each thermostat to the Distribution Panel REF terminals if:

• More than one transformer is used to power the thermostats in the network

• Installation is in an environment that has excessive electromagnetic interference from fluorescent lights, motors, or other

EMI generating devices, such as in an industrial or office setting

CONNECT THE COMMUNICATION AND POWER WIRES TO THE DISTRIBUTION PANEL

AND THERMOSTAT

Step 6

DIAGRAM 4 – Thermostat Communication Wiring

GRN/WHT

B+ B- REFA-

A+

A

ON OFF

B

PWR

ON OFF

A

RCA+ A- B+ B- A+ A

OFF ON

OFF ON

A

B

PWR

A

A

B

RCA+A-B+B-A+A-

COMMUNICATION TERMINAL DEFINITIONS

B+/B- RECEIVE (reference automation system)

A+/A- TRANSMIT (reference automation system)

REF GROUND REFERENCE (see Note)

R THERMOSTAT VOLTAGE (hot)

C THERMOSTAT VOLTAGE (common)

ORG

ORG/WHT

BLU

BLU/WHT

GRN

BRN

See NOTE

ON REF

WIRE

CAT-5

BRN

GRN

GRN/WHT

BLU/WHT

BLU

ORG/WHT

ORG

C

R

RSR

RSC

RSB

RSA

REF

BB+

AA+

R.V.-Heat (B)R.V.-Heat (B)

RC

RH

R.V.-Cool (O)R.V.-Cool (O)

HUM W1

DEH Y1

W2

NOTE ON REFERENCE WIRE

Connect the REF terminals if:

• More than one transformer is used to power the thermostats

in the network

• Installation is in an environment that has excessive electromagnetic

interference from fluorescent lights, motors, or other EMI

generating devices, such as in an industrial or office setting

G

Y2

Page 11

9

1. MAKE SURE THAT ALL SWITCHES IN THE DISTRIBUTION PANEL ARE OFF!

2. If more than one Distribution Panel is used in the thermostat network, the communication lines must be daisy-chained together.

• Use the wire colors shown in DIAGRAM 5 to help ensure proper, consistent connections.

DIAGRAM 5 – Multiple Distribution Panels

CONNECT MULTIPLE DISTRIBUTION PANELS

Step 7

RX TX

RX TX

RX TX

POWER

DATA

RS-485

Model 8811 Protocol Adapter

Power

7.5VAC RS-485 RS-485 RS-232

ORG/WHT

RED/WHT

BLK/WHT

ENABLE

RS-485

BLU/WHT

DATA

RS-232

ORG

BLU/WHT

BLU

ORG/WHT

WHEN CONNECTING MULTIPLE DISTRIBUTION PANELS,

CONNECT THE "REF" TERMINALS FOR EACH

THERMOSTAT TO THE "REF" TERMINAL OF THE

RESPECTIVE DISTRIBUTION PANEL AND CONNECT THE

REF TERMINALS OF EACH DISTRIBUTION PANEL TO

CAT-5

EACH OTHER.

CAT-5

BLU

ORG

A+

A

ON OFF

B

RCA+ A- B+ B-

PWR

ON OFF

ORG/WHT

B+ B- REFA-

BLU/WHT

ORG

ORG/WHT

BLU/WHT

GRN/WHT

OFF ON

OFF ON

BLU

A

B

PWR

BLU

ORG

A

A+

B

A

ON OFF

B

RCA+A-B+B-

RCA+ A- B+ B-

PWR

ON OFF

ORG/WHT

B+ B- REFA-

BLU/WHT

GRN/WHT

OFF ON

OFF ON

A

B

PWR

A

B

RCA+A-B+B-

DISTRIBUTION PANEL #1 DISTRIBUTION PANEL #2

Page 12

10

1. MAKE SURE THAT ALL SWITCHES IN THE DISTRIBUTION PANEL ARE OFF!

2. Use Category-5 wire to connect the main communication terminals on the Distribution Panel with the “Flying Leads” of the

protocol adapter (see DIAGRAM 6).

3. Connect the RS-232 port of the protocol adapter to the computer or automation system. A 6 ft. flat cable with RJ-11

connectors, and an RJ-11 to DB9 transition connector are provided with the protocol adapter.

Some computers use 25-pin connectors on serial ports, which requires a DB25 connector. A DB9 connector fits a 9-pin

port. DB9 to DB25 transitions are available at most computer retail stores.

4. Power up the Protocol Adapter with the plug-in transformer provided. The “Power” LED on the Protocol Adapter along with

the “Enable” LEDs should light up when power is applied.

CONNECT PROTOCOL ADAPTER TO THE DISTRIBUTION PANEL AND HOST COMPUTER

OR AUTOMATION SYSTEM

Step 8

DIAGRAM 6 – Protocol Adapter Wiring

RS-232 input

RX TX

RX TX

RX TX

7.5 VAC

Transformer

provided w/

protocol

adapter

RCA+ A- B+ B-

A

ON OFF

B

ON OFF

PWR

DISTRIBUTION

POWER

DATA

RS-485

ENABLE

RS-485

DATA

RS-232

Model 8811 Protocol Adapter

Power

7.5VAC RS-485 RS-485 RS-232

BLU/WHT

ORG/WHT

RED/WHT

ORG

A+

BLU

ORG/WHT

B+ B- REFA-

BLK/WHT

BLU/WHT

ORG

CAT-5

A

OFF ON

B

OFF ON

PANEL

BLU/WHT

BLU

ORG/WHT

PWR

1 2 3 4 5 6

CONNECTOR

END VIEW

A

B

RCA+A-B+B-

Cable and DB9

connector provided

with protocol

adapter

PROTOCOL ADAPTER PIN-OUTS

WIRE COLOR

ORG/WHT

RED/WHT

LEADS

BLK/WHT

FLYING

BLU/WHT

RJ-11

RS-485

CONNECTORS

1 - CTS: Clear to Send (Outgoing - pulled high)

2 - RTS: Request to Send (Incoming - ignored)

RJ-11

3 - SG: Signal Ground

4 - RD: Receive Data (incoming)

5 - TD: Transmit Data (outgoing)

RS-232

CONNECTOR

6 - TSR: Data-Set-Ready (outgoing - pulled high)

RS-485 CONNECTIONS

Rx+ Tx+ Rx-Tx-

B+

1

2

3

4

5

6

RS-232 CONNECTION

NOT USED

B+

NOT USED

to automation

system or

connect to

computer com

port

SIGNAL

A-

A+

B-

A-

A+

B-

Page 13

11

1. MAKE SURE THAT ALL SWITCHES IN THE DISTRIBUTION PANEL ARE OFF!

2. Use a 2-wire thermostat cable to connect the load terminals of the Model 8027 Plug-in Transformer to the 24V AC terminals

of the Distribution Panel (see DIAGRAM 3).

3. Plug-in the transformer.

4. NO LEDs ON THE DISTRIBUTION PANEL SHOULD BE ON.

1. Turn on power to the HVAC and/or zone control systems.

2. Go to the Distribution Panel and verify that no LEDs on the

Distribution Panel are on. If none are on, proceed to # 3. If

any LED is on, immediately unplug the transformer that

powers the Distribution Panel.

• If any LED is on, it is likely that

the HVAC system transformer is

powering the thermostat.

Go to the thermostats, remove

thermostat from the base and

check the wiring. There must be

no jumper between the RH or RC

and R terminal. The Category 5

cable used to wire

communications and power

should supply the only wires

connected to the thermostat

R and C terminals.

3. Turn on the main power switch

then turn on the power switch to

one of the thermostats (see

ILLUSTRATION 4). The green LED

next to the power switch should

go on, and the corresponding

thermostat display should power

up. DO NOT TURN ON ANY

OTHER SWITCHES.

4. One by one, turn on only the power switches (not the

communication switches) for each thermostat. Verify that

the green LED comes on and that the thermostat display

powers up.

Use the thermostat buttons to verify that the thermostat is controlling the equipment operation. A checkout procedure is

supplied in the installation instructions with the thermostat. This procedure will verify only that the thermostat operates the

equipment. Communication system checkout will be performed next.

PROVIDE POWER TO THE DISTRIBUTION PANEL

Step 9

CHECK-OUT HVAC SYSTEM OPERATION

Step 11

TURN ON POWER TO ALL HVAC EQUIPMENT AND TO THE THERMOSTATS

Step 10

ILLUSTRATION 4 – Power Switches

RCA+ A- B+ B-

PWR

A

ON OFF

B

ON OFF

RCA+ A- B+ B-

A

ON OFF

B

ON OFF

PWR

24VAC

B+ B - R EFA-

A+

OFF ON

OFF ON

FUSE

OFF ON

OFF ON

MAIN

PWR

ON OFF

RC

A

B

PWR

A

B

PWR

A

B

RCA+A-B+B-

Each thermostats

power LED lights when

the “PWR” switch is

turned on

RCA+A-B+B-

Page 14

12

IMPORTANT!

THESE STEPS MUST BE DONE AT EACH THERMOSTAT

FOR COMMUNICATION TO WORK PROPERLY.

1. Press the Mode and Enter buttons simultaneously

through the thermostat. It may take a couple of tries to

get them pressed together.

This will enter the Thermostat Set Up Menu. The first

menu item that will appear on the message center display

is an informational item that indicates that only the

Scroll Up, Scroll Down (two buttons located immediately

to the right of the message center display) and the

Enter buttons are used in thermostat set up. This will

remain on the display for approximately 5 seconds or until

any of the three aforementioned buttons is pressed.

Thermostat Set Up is a series of sub-menus available to

customize the thermostat in various ways. The thermostat

Owners Manual and Installation Manual outline the

thermostat set up features. The following steps will guide

only through the Communications Set Up sub-menu

(see ILLUSTRATION 5).

2. Press the Scroll Down button until the “Communications

Set Up” menu shows on the display.

3. Press the Enter button to select this sub-menu.

4. The first sub-menu item is “Set Thermostat ADDRESS”.

Press the Enter button to select this item.

5. Set the address between 1 and 64 using the Scroll Up

and Scroll Down buttons. (If using Model 8840

thermostats, see Appendix 1.)

• Each thermostat must have a unique address

(i.e. no two thermostats can have the same address)

• Start with address 1 and increment by 1 for each new

address – do not skip an address. This will help to

speed communications.

✍

Write down the address for each thermostat

on the Network Interconnection Worksheet

(see ILLUSTRATION 3).

6. After the address has been selected, press the Enter

button to store the address.

7. Use the Scroll Up and Scroll Down buttons to set the

“Number of Stats On Network” to the highest address

that will be on the thermostat network. This will be equal

to the total number of thermostats on the network, unless

one or more addresses are skipped.

IMPORTANT!

THIS NUMBER MUST BE SET THE SAME

AT EACH THERMOSTAT

8. After setting the number of thermostats on the network

press Enter. The next item will be to “Set BAUD Rate”.

The thermostat defaults to 9600 baud (bits per second).

• If you want to change to 19200 baud operation,

continue with #9.

• If you want to operate at 9600 baud, press the Scroll

Down button to get to the “EXIT” screen for the

Communications Set Up sub-menu and go to #10.

9. Press Enter to set the baud rate. Use the Scroll Up or

Scroll Down button to toggle between 9600 baud and

19200 baud. Press Enter when the baud rate desired is

showing.

10.Press Enter to “EXIT” the Communications Set Up

sub-menu. This will return you to the main menu.

11.Press the Scroll Down button until “EXIT” is displayed.

Press the Enter button. The thermostat will then reset and

return to normal operation.

ADDRESS THE THERMOSTATS AND SET HIGHEST ADDRESS

Step 12

ILLUSTRATION 5 – Setting the Thermostat Address

Page 15

1. Connect the Protocol Adapter RS-232 output to a computer

with Windows ’95, ’98, Windows 2000 or Windows NT.

This may already have been done in Step 7.

2. Turn on the computer.

3. From the Start menu, select PROGRAMS➾

ACCESSORIES➾ COMMUNICATION➾ HYPERTERMINAL

(see ILLUSTRATION 6). HyperTerminal is a terminal

emulator program provided with Windows that will be

used to test the communication system.

SETUP COMPUTER FOR COMMUNICATION SYSTEM CHECKOUT

Step 13

❖ If you now have the HYPERTERMINAL folder available,

skip the next step and go to #6.

4. If the COMMUNICATIONS or HYPERTERMINAL folder is

not present, you will need to add this program to your

Windows setup. From the Start menu, select

SETTINGS➾ CONTROL PANEL, then select (double click)

the Add/Remove Programs icon. Select the Windows

Setup tab, and place a ✔ in the Communications

component box. This will add HyperTerminal to your

Windows setup. Go back to #3 and get into the

HyperTerminal folder as described.

5. Double click the Hypertrm icon. You will then be asked to

name the new connection and select an icon. Type in any

name you want (the shorter the better) and select the

“atom-like” symbol at the end of the Icon list (see

ILLUSTRATION 7). Then click OK.

ILLUSTRATION 6 – Access HyperTerminal

ILLUSTRATION 7 – New Connection

13

Page 16

6. This will bring up a Connect to dialog box. From the pull

down next to “Connect using:”, select the Com port to

which the Protocol Adapter is connected (see

ILLUSTRATION 8). Start with Com port 1 (or the next

lowest available number) if you are unsure which one to

use. Click OK.

7. A COM1 Properties dialog box should appear. Use the

pull-down menus or type in the following for each

selection (see ILLUSTRATION 9):

Bits per second: 9600 (or 19200 if thermostats

are configured for this baud rate)

Data bits: 8

Parity: None

Stop bits: 1

Flow control: none

Click OK.

14

ILLUSTRATION 8 – Select Com Port

ILLUSTRATION 9 – Connection Properties

Page 17

15

8. From the File pull-down menu, select Properties.

This will bring up a Properties dialog box.

9. Select the Settings tab. Make the following selections

(see ILLUSTRATION 10):

Terminal keys

Ctrl+H

Emulation: Auto Detect

Telnet terminal: ANSI

Backscroll buffer lines: 500

10.Then select the ASCII Setup button. This will bring up an

ASCII Setup dialog box. Make the following selections

(see ILLUSTRATION 11):

✔ Echo typed characters locally

✔ Append line feeds to incoming line ends

✔ Wrap lines that exceed terminal width

NOTE:

1. IF USING AN EXISTING HYPERTERMINAL

CONNECTION YOU MAY NEED TO UNCHECK THE

“SEND LINE FEEDS…” BOX.

2. THE MODEL 8870 HAS AN EXPANDED COMMAND

SET. REFER TO DP 10004345 FOR THE MODEL 8840

SERIES COMMAND SET.

11.Click OK to put away both dialog boxes.

12.Verify that you have a connection between the computer

and the Protocol Adapter. Have the Protocol Adapter

within eyesight of the computer keyboard. Type any

character and confirm that the “RS-485, Data, TX” LED

and the “RS-232, Data, RX” LED (see DIAGRAM 6 on

page 10) on the Protocol Adapter flash as you type. The

LEDs flash very quickly.

13.Press Enter to clear the command line.

Note: On Windows ’98 computers, HyperTerminal does

not echo typed characters (doesn’t show them on the

screen as you type) locally. Do not be concerned. This

can be a little confusing, but does not affect the checkout

of the thermostat communication system.

• If you were unable to verify a connection, specify a

different com port. Go to the File pull down menu, and

select Properties. Change the “Connect using:” setting

to a different port by using the pull down menu options.

Start typing and look for the Protocol Adapter LEDs to

flash. Repeat until you have successfully verified

connection between the computer and communication

system, or until you run out of com ports to choose from

in the “Connect using:” pull down. If there is still no

communication you are going to have to consult a

computer professional.

ILLUSTRATION 10 – Terminal Settings

ILLUSTRATION 11 – ASCII Setup

Page 18

1. At the computer type SN? (it does not matter if it is small

or capital letters) then press Enter.

You should get no response because none of the

communication switches to the thermostats have been

turned on yet.

2. Go to the Distribution Panel and turn on the communication

switches for the thermostat with address #1

(see ILLUSTRATION 12).

3. Type SN? and press Enter.

The computer should respond SN1. This indicates that

the thermostat with address #1 is communicating.

• If no response, type in SN? and press Enter again. If it

still does not appear, go to the Distribution Panel make

sure the communication switches for the thermostat

with address #1 are on.

• If the “SN” response contained a number other than one,

the communication switches you turned on were for an

address other than number one. Now is the time to verify

that the thermostat names/locations match the addresses

shown on the Network Interconnection Worksheet

(ILLUSTRATION 3). There is room on the Distribution

Panel label (on the inside cover of the Distribution Panel

enclosure) to write the address and thermostat name

with the corresponding terminal connections.

4. Type SN ID? and press Enter.

The computer should respond SN1 MODEL# 8870 REV:

Vx.x - RPC 2002; where x.x represent the current

firmware revision level. This is done to determine if the

communication is robust. The large amount of data being

transmitted by the thermostat may be corrupted if there is

interference on the communication lines.

• If the response is not exactly as shown, there is a

communication signal problem. The most likely sources

are a loose terminal connection, incorrect wire type,

damaged wire, electrical interference or incorrect

power supply. Look at all the terminal connections and

look at the wire where the insulation was stripped. If the

wire appears kinked, trim the wire and carefully strip the

insulation. Also, make sure the wires connected to the

thermostat “R” and “C” terminals is connected to the

corresponding Distribution Panel “R” and “C” terminals

for that particular thermostat. If this doesn’t help,

connect the “REF” terminal of all the thermostats to the

two “REF” terminals on the Distribution Panel.

5. Go to the Distribution Panel and turn off the

communication switches for address #1 and turn on the

communication switches for address #2.

6. Repeat this process to verify communications to all

thermostats one address at a time. Each time you turn on

the communication switches to a new thermostat, a new

“SN” number should respond. If this is not the case, go to

the thermostats and address them as indicated in Step 12.

7. Finally, go to the Distribution Panel and turn on all the

communication switches.

8. Type SN ID? then press Enter.

All thermostats should respond as shown in #4. Make

sure the number of responses equals the number of

thermostats in your system, and that the responses are

complete and accurate.

9. Once you have successfully completed this procedure

you have verified that proper communication exists

between the computer and all of the thermostats. To test

out all of the functions of the thermostat, use the software

or automation package being installed with this system.

You can check out other thermostat functions using

HyperTerminal: go to the “Aprilaire Command Set”

section on page 19.

CHECK-OUT COMMUNICATIONS TO THE THERMOSTAT NETWORK

Step 14

ILLUSTRATION 12 – Com Switches

16

A+

A

ON OFF

B

RCA+ A- B+ B-

PWR

ON OFF

B+ B- REFA-

A

B

“A” LED flashes when

communications are

transmitted

OFF ON

OFF ON

A

B

PWR

RCA+A-B+B-

“B” LED flashes when

communications are

received

Page 19

.-Cool (O)

If adding a Model 8870 thermostat to a system using 8840

series thermostats (8844, 8846, 8847 or 8848), you must

change the power supply installation, modify the addressing

method and remove terminating resistors from the Model

8811 protocol adapter.

1. A separate power supply is required for Model 8870

thermostats and 8840 series thermostats. This requires

different wiring.

• If using a Model 8800-8808 Communication Panel, see

DIAGRAM 7 for wiring schematic.

• If using a Model 8818 Distribution Panel you must use

the 8840 series thermostat with an 8809 Sub-base to

allow RS-485 communications to be connected directly

to the Distribution Panel. See DIAGRAM 8 for wiring

schematic.

NOTE:

1. IF USING AN EXISTING HYPERTERMINAL

CONNECTION YOU MAY NEED TO UNCHECK THE

“SEND LINE FEEDS…” BOX.

2. THE MODEL 8870 HAS AN EXPANDED COMMAND

SET. REFER TO DP 10004345 FOR THE MODEL 8840

SERIES COMMAND SET.

SPECIAL CONSIDERATIONS FOR INSTALLING THE MODEL 8870 WITH THE

8840 SERIES COMMUNICATING THERMOSTAT

Appendix 1

DIAGRAM 7 – Adding an 8870 Thermostat

17

IMPORTANT!

YOU MUST USE A SEPARATE POWER

SUPPLY FOR 8870 THERMOSTAT(S).

8800-8808 MODEL COMMUNICATION PANELS

CAT-5

BRN

Model 8027

PLUG-IN

TRANSFORMER

2-WIRE TSTAT

CABLE

GRN

485 SERIAL IN

OR BL BK RD

BLU

BLU/

WHT

ORG

ORG/

WHT

ON

OFF

ON

OFF

ON

B4 B8

OFF

ON

OFFONOFF

OR

BK

RD

24V

24Vc

MODEL 8870 THERMOSTAT

BRN

GRN

BLU/WHT

BLU

ORG/WHT

ORG

ON

BL

OFF

ON

2/

YB

OFF

ON

OFF

C

R

RSR

RSC

RSB

RSA

REF

BB+

AA+

R.V.-Heat (B)R.V.-Heat (B)

POWER

24V AC

R.V.-Cool (O)

R.V.-Cool (O)

Communication Card

RC

RH

IMPORTANT!

YOU MUST ADDRESS 8840 SERIES

HUM W1

DEH Y1

W2

G

Y2

THERMOSTATS HIGHER THAN ANY MODEL

8870 THERMOSTAT ON THE NETWORK.

Model 8027

PLUG-IN TRANSFORMER

Y2

24V

24V(c)

W1

Y1

G

R

W2

CLK1

CLK2

RS2

RS1

RS+v

1

2

8840 SERIES THERMOSTAT

CAUTION!

TURN ALL DISTRIBUTION PANEL SWITCHES

OFF BEFORE DOING ANY WIRING.

Page 20

.-Cool (O)

2. IMPORTANT! When addressing the thermostats, the

Model 8870 thermostat(s) must either be the first

addresses on the network, or there must be one address

skipped between 8840 series thermostats. For example, if

one Model 8870 thermostat were to be added to an

existing four 8840 series thermostat network then the 8870

thermostat must be addressed #1 or #6. Change the

existing address #1 to be #5 and add the 8870 as address

#1, or simply add the new thermostat as address #6.

IMPORTANT: Set “Number of Stats On Network” to 32 and

Set BAUD Rate to 9600.

3. Unplug the Model 8811 Protocol Adapter power supply

and RS-232 connection. Remove the four screws securing

the cover to the base. Remove the pin jumpers (shunts)

labeled JP9 (see ILLUSTRATION 13 for relative location).

Replace the shunts on just one of the pins.

DIAGRAM 8

– Adding an 8840 Series Thermostat

ILLUSTRATION 13 – Remove Terminating Resistors

18

MODEL 8870 THERMOSTAT

CAUTION!

TURN ALL DISTRIBUTION PANEL SWITCHES OFF

BEFORE DOING ANY WIRING.

MODEL 8818 DISTRIBUTION PANEL

A

ON OFF

B

PWR

PWR

40VA

XFRMR

A

B

ON OFF

ON OFF

ON OFF

24VAC

2-WIRE TSTAT

RC

CABLE

FUSE

MAIN

PWR

ON OFF

RCA+ A- B+ B- R CA+ A- B+ B-

OFF ON

OFF ON

OFF ON

OFF ON

A

B

PWR

A

B

PWR

40VA

XFRMR

Model 8027 PLUG-IN TRANSFORMERS

CAT-5

ORG

ORG/WHT

BLU

RCA+A-B+B-RCA+A-B+B-

BLU/WHT

GRN

BRN

ORG

ORG/WHT

BLU

BLU/WHT

CABLE

2-WIRE TSTAT

BRN

GRN

MODEL 8809 COMMUNICATING SUB-BASE

BLU

ORG/WHT

CAT-5

ORG

BLU/WHT

BRN

GRN

IMPORTANT!

YOU MUST USE A SEPARATE POWER

SUPPLY FOR 8840 SERIES THERMOSTATS.

ORG

RED

BLK

BLU

BRN

GRN

BLU/WHT

ORG/WHT

ORG

BLU

Communication

Card

C

R

RSR

RSC

RSB

RSA

REF

BB+

AA+

R.V.-Heat (B)R.V.-Heat (B)

RC

RH

R.V.-Cool (O)

R.V.-Cool (O)

G

HUM W1

DEH Y1

W2

Y2

MODEL 8848 SHOWN

CLK1

CLK2

RS2

RED

RS1

RS+v

YEL/BLU

1

2

BLK

24V

24V(c)

IMPORTANT!

YOU MUST ADDRESS 8840 SERIES

THERMOSTATS HIGHER THAN ANY

MODEL 8870 THERMOSTAT ON THE

NETWORK.

Y2

W1

Y1

G

R

W2

PROTOCOL ADAPTER WITH

COVER REMOVED

JP9

Place these 2

jumpers on just

one pin

RJ11 Connectors

Page 21

A full command set and detailed explanation of the

command set is available for those who want to write their

own software. Contact Research Products Corporation at

888-782-8638 to request a copy of DP 10005756.

Upper or lower case letters may be used for all commands.

Invalid characters will immediately invalidate a command,

so the use of backspace or delete is not allowed (applies

mainly when interacting with the thermostat using

HyperTerminal).

All commands will begin with the characters

SN.

Immediately following the SN, without any intervening

spaces (blanks), will be the address

(#) from 1 to 64 of the

Model 8870 Thermostat with which you are communicating.

Single digit addresses may be sent as a two digit address

with a leading zero. Omitting the address, or using a 0 (zero)

in place of a space makes the command global, and all

connected thermostats will respond. Following this initial

command sequence, spaces may be inserted at this point

only, for clarity between commands. The next portion is the

command or variable

[Command]. The table on page 20

describes the basic commands. The next portion

[? or =]

is the action to be performed: “?” corresponds to “state your

value” while “=” corresponds to “set your value”. Spaces

are allowed between the command and the action. The final

portion,

[Value], is used only if a command or variable is

to be set. The value must follow the action with no

intervening spaces. A carriage-return is used as

the terminator for the command string. Line feeds (LF) should

not be sent with commands as this is a recognized ASCII

character and invalidates any command received between

the line feed and the next carriage return.

EXCEPTION: The command SN? or SN0? will respond with

all connected thermostats returning their address.

COMMAND RESPONSE SYNTAX

The Model 8870 will respond by supplying the information

requested or by confirming the completion of an action

command. The response syntax is generally the same as

that used for commands, but no spaces separate command,

action or value. Responses are sent in upper case ASCII

format. Should a command not be recognized, no response

will be forthcoming – there is no ERROR message.

Unless otherwise noted as “Read Only” or “Write Only”, all

commands are “Read and Write”.

Inquiries can be made with all commands (with the

exception of BLTON) to determine the existing value of a

variable. Inquiry is done using the following syntax:

SN [address number, or <blank> or 0 (zero) for global]

“COMMAND” ?; where command is the variable whose

value is desired.

APRILAIRE COMMAND SET

Appendix 2

SN# [Command] [? or =] [Value (use with = only) ] Enter

Enter

19

Page 22

COMMAND DESCRIPTION VALUE

Communication Control Commands

CR Command Response Control Silent / Quiet / Normal

C1 Change of State (COS) – HVAC relays ON/OFF

C2 COS – Temperature ON/OFF

C3 COS – Remote Temperature ON/OFF

C5 COS – Set Points ON/OFF

C6 COS – Network Override ON/OFF

C7 COS – Mode ON/OFF

C8 COS – Fan ON/OFF

HOLD User Hold Status ON / OFF

NAME Location Name <String>

ID Report Model No. and software rev. Read Only

Thermostat Sensing Commands

SCALE Command Temperature Scale F / C (Fahrenheit/Celsius)

TEMP, T Report Thermostat Room Temperature Read Only

HUM Report Thermostat Room Humidity Read Only

(requires humidity control sensor)

RSM Identify all external sensors connected Read Only

to a thermostat’s local communication network

RxSy Report value of any sensor on thermostat’s Read Only

(x = 1-4; y = 1,2) local communication network

OT Report Thermostat Remote “Outdoor” Temperature Read Only

R Report Thermostat Remote “Outdoor” Temperature Read Only

OH Report Thermostat Remote Humidity Read Only

Thermostat HVAC Operational Commands

SH Heat Mode Set Point Two or three digit integer: 40 – 88 for °F; 4 – 31 for °C

SH++ Increment heat set point Integer value which when added to the current heat

set point does not fall outside the SH limits

SH-- Decrement heat set point Integer value which when deducted from the current

heat set point does not fall outside the SH limits

SC Cool Mode Set Point Two or three digit integer: 42 – 90 for °F; 6 – 33 for °C

SC++ Increment cool setpoint Integer value which when added to the current cool

set point does not fall outside the SC limits

SC-- Decrement cool setpoint Integer value which when deducted from the current

cool set point does not fall outside the SC limits

S Current Mode Set Point Two or three digit integer (see next two commands)

SP++ Increment current mode set point Integer value which when added to the current mode

set point does not fall outside the SH and SC limits

SP-- Decrement active setpoint Integer value which when deducted from the current mode

set point does not fall outside the SH and SC limits

MODE, M Thermostat Mode of Operation A /C /H /E/OFF(Auto /Cool /Heat /EMHT/ Off)Humid/Dehum

when operating as a humidity controller

FAN, F Fan Switch Setting A /ON (Auto/ On)

HVAC, H Report HVAC Relay States Read Only

Auxiliary Information Commands

EQUIPCONFIG Reports the setting of the thermostat Read Only

configuration dip switches

BLTON Turns on backlighting for 10 seconds. No Value Required for this Command

20

MODEL 8870 BASIC COMMAND SET

Page 23

21

ADDRESS

JOB TITLE:

JOB LOCATION:

DATE:

CAT-5

INSTALLING

CONTRACTOR:

LOCATION

WIRE

DISTRIBUTION PANEL LOCATION / NAME

CAT-5

WIRE

ADDRESS

LOCATION

Fill Out and Leave with System Software Package

CAT-5

WIRE

DISTRIBUTION PANEL

CAT-5

WIRE

ADDRESS

LOCATION

CAT-5

CAT-5

WIRE

WIRE

TO DISTRIBUTION PANEL

RX TX

RX TX

RX TX

POWER

DATA

ENABLE

DATA

RS-232

RS-485

RS-485

Model 8811 Protocol Adapter

Power

7.5VAC RS-485 RS-485 RS-232

ADDRESS

LOCATION

CAT-5

WIRE

ADDRESS

LOCATION

CAT-5

WIRE

ADDRESS

LOCATION

CAT-5

WIRE

ADDRESS

LOCATION

CAT-5

WIRE

ADDRESS

LOCATION

Page 24

DP 10005754 1.5.4.02

1015 E. WASHINGTON AVE. • MADISON, WI 53703 • PHONE: 888/782-8638 • FAX: 608/257-4357 • www.aprilaire.com

Loading...

Loading...