Page 1

Instructions

RESET/OVERRIDE

SUBJECT: Safety Bar Installation Kit

for 6-Inch Chippers With Smart Relay

KIT # 75579-00

MODELS: CH6670H (76624),

CH611DH (76628), CH6993H (76635)

WARNING

Before inspecting or servicing any part of this machine,

shut off power source, remove key, disconnect the

battery cables and make sure all moving parts have

come to a complete stop.

The safety bar gives the operator the ability to immediately

stop the feed roller in a potentially dangerous situation. By

pushing the safety bar, which is located directly under the feed

chute, the operator shuts down the feed roller and no more

material is fed into the chipper. The operator must push the

reset button to restart the feed roller and resume chipping.

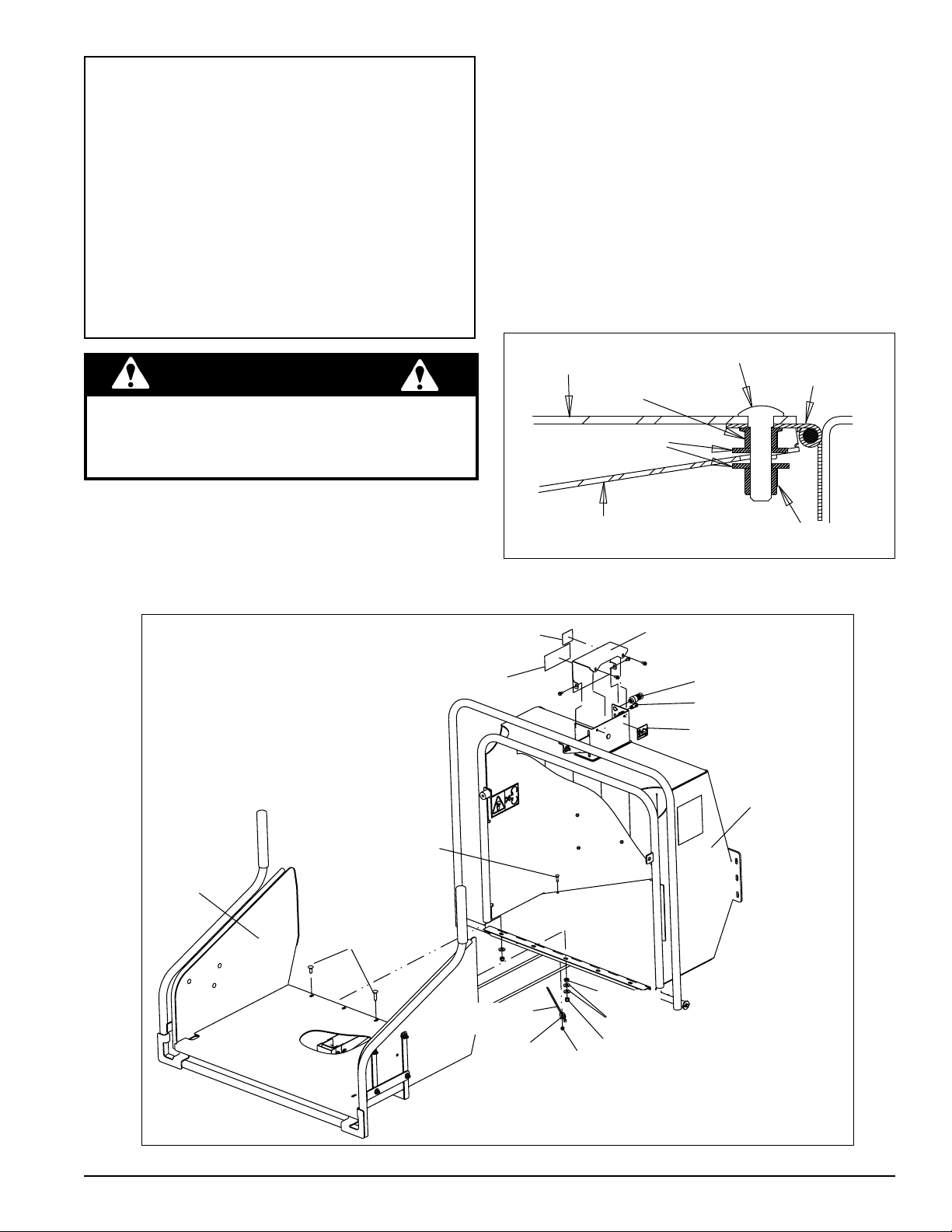

EXTENSION TRAY INSTALLATION

1. Remove existing extension tray.

2. Install extension tray from kit, using existing hardware

except for the middle hole. For this hole, use the flange

nut, two washers, nylock nut, and 1-1/2" bolt as shown

in Fig. 1 to accommodate the kneebar switch shield.

3. Mount the cable mount clamp and tie with the 1/4" nut

and 1" bolt in the existing hole on the left side of the

chute (see Figure 2).

4. Secure the electrical harness from the extension tray with

the clamp mounted in step 3. Use the rest of the nylon ties

to secure the harness to the existing harnesses, leading

it up to the switch box cover.

EXTENSION

TRAY

3/8” FLANGE

NUT

3/8” WASHER

KNEEBAR

SWITCH SHIELD

Figure 1. Install washer and nut between the kneebar switch

shield and extension tray (cross-section drawing)

1-1/2” BOLT

3/8” NYLOCK

NUT

FEED CHUTE

HINGE

EXTENSION

TRAY WITH

SAFETY

BAR

1-1/2”

BOLT

DECAL

MULTILINGUAL

MANUAL DECAL

1”BOLT

NYLON TIE

STRAP

CABLE

MOUNT

CLAMP

SWITCH BOX COVER

RESET/OVERRIDE

SWITCH

LED MOUNT

RESET/OVERRIDE

DECAL

FEED CHUTE

(EXISTING)

3/8” NUT

3/8” WASHER

3/8” NYLOCK NUT

1/4” NUT

Figure 2. Installing new extension tray, LED, switch, and decals

Instruction Sheet

PN 75586-00

Rev. 111108

Page 2

CONNECT WIRES

REMOVE PLUG

1. Remove switch box cover (see Figure 2).

2. Remove knock outs from the switch box using a screw

driver or hammer. These holes will be used for the

reset/override switch and LED.

3. Connect the red and red/black wires from the extension

tray harness to the reset/override switch provided (for

full electrical schematic, see

Figure 5).

4. Connect the red/yellow and

white wires to the LED as

shown in Figure 3.

5. Connect the remaining three

wires from the electrical harness

to wires in the main switch box,

matching wire colors.

6. Push the LED through the

appropriate hole in the switch

box until it snaps into place.

7. Unscrew the nut and button off

RED/YELLOW

Figure 3. LED wiring

WHITE

the reset/override button and install it in the appropriate

hole in the switch box. Screw nut and button back on to

secure reset/override button in place on the switch box.

8. Secure switch box cover in original position with

existing hardware.

9. Add the three decals to the switch box cover as shown

in Figure 2.

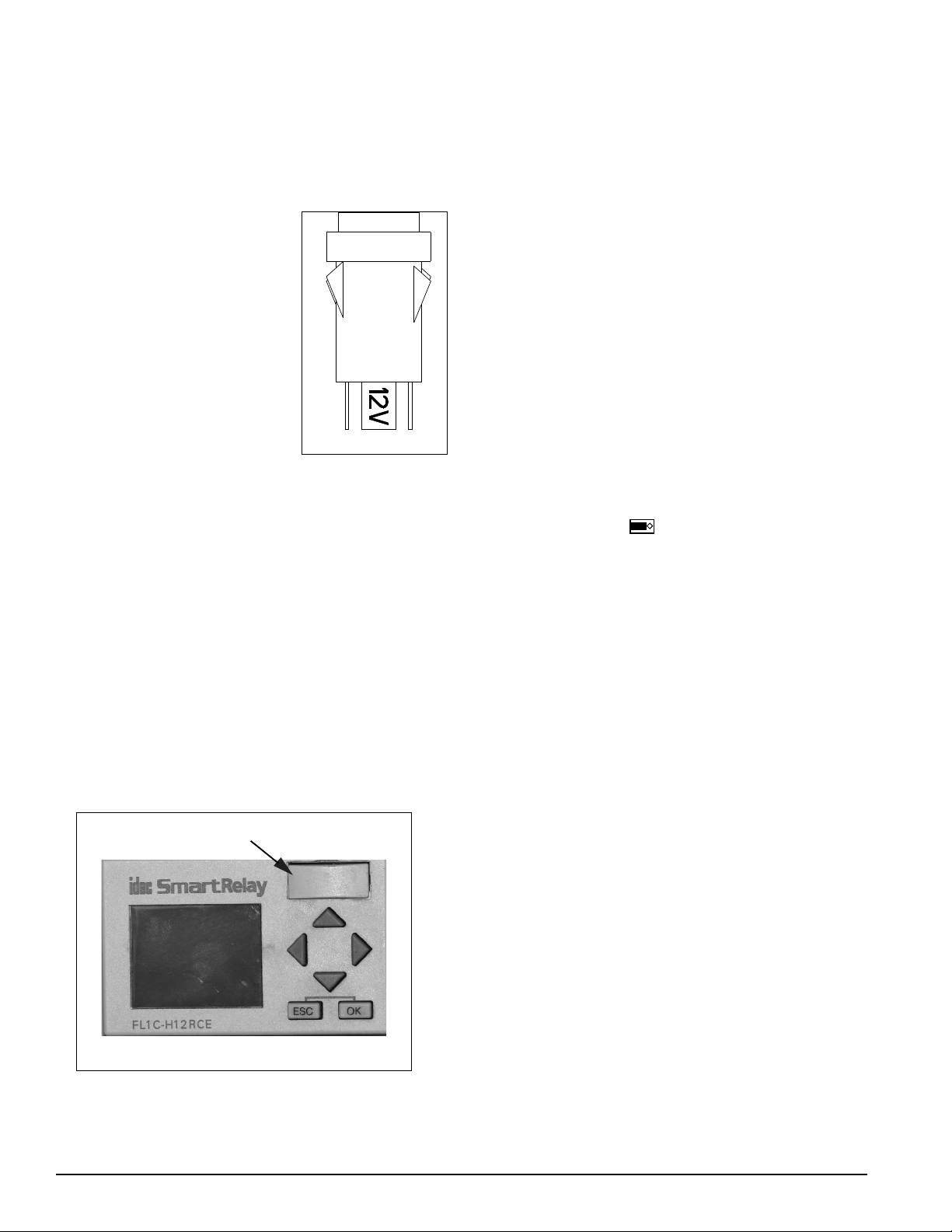

PROGRAM SMART SWITCH

Program the smart switch with the chip provided in the kit.

1. Turn the key to power up the machine but do not start

the engine.

2. Remove the plug from the smart switch with a screw

driver or other sharp object.

4. Push the down arrow. The display should show current

date and time.

5. Push ESC.

6. Scroll to STOP. Push OK.

7. The display should read "Stop Prg." Scroll to "Yes"

and push OK.

8. Scroll to "Program" and push OK

9. Scroll to "Clear Prg" and push OK.

10. At the prompt to clear program, scroll to "Yes" and

push OK.

11. The next screen will ask for a password. Use the

arrows to enter in "BEAR" (up and down arrows to

choose a letter, right and left arrows to move cursor).

Push OK.

12. The current program will be deleted.

13. Push ESC.

14. Scroll to "Card." Push OK

15. Put the new chip in. Two chips are included in the kit,

one for the gas engine model and one for the diesel

model. Pick the appropriate chip for your machine.

16. Scroll to "Card >

." Push OK.

17. Scroll to "Yes." Push OK.

18. At next prompt, scroll to "Start." Push OK.

19. The display should now read "Forward Feed

Stopped."

20. Take the chip out and put the plug back in.

21. Your machine should now be operational.

OPERATION

After the safety bar has been installed, start up the chipper,

engage the feed roller, and check to see if the bar operates

correctly. The feed roller should stop when a minimum of

34 lbs. is applied to the safety bar. Forward feed should

resume when the reset button is pushed.

If a branch causes a false trip of the safety bar during

operation, push in the reset button and hold to override

and reengage the feed roller.

Upon start-up, the red light will be on and the operator must

push the reset button before the feed roller will operate.

Figure 4. Chip location in Smart Relay

3. The Smart Switch display should read "Forward Speed

Stopped."

Instruction Sheet

Page 3

USED ONLY

FOR MODELS

WITH SAFETY

BAR INSTALLED

NOTE:

COLOR CODED WIRES I3, I4, AND Q3 ARE

USED ONLY FOR MODELS WITH A SAFETY

BAR INSTALLED.

SAFETY BAR MODELS ONLY

Figure 5. Electrical schematic for 6 inch chipper with safety bar installed

Instruction Sheet

Page 4

PARTS LIST, KIT #75579-00

PART

NUMBER

14521-00 LED, 12V RED 1/2” SNAP MOUNT 1

14865-00

14942-00 DECAL, MULTILINGUAL MANUAL 1

15031 WASHER, 3/8” FLAT 2

15051 NUT, 3/8” SERR FLANGE 1

15058 BOLT, 3/8” X 1-1/2 CRG 1

15239 BOLT, 1/4” X 1” CRG 2

15355 NUT, 1/4” NYLOCK 2

15388 NUT, 3/8” NYLOCK 1

17320 STRAP, NYLON TIE 9

18549-00 CLAMP, CABLE MOUNT 2

18555-00 DECAL, RESET/OVERRIDE 2

75577-00 ASSEMBLY, EXT. TRAY W/SAFETY BAR 1

75589-00 CHIP, 6 IN GAS RELAY 1

75622-00 CHIP, 6 IN DIESEL RELAY 1

SWITCH, N/O MOMENTARY

PUSHBUTTON

DESCRIPTION QTY

1

ECHO BEAR CAT

www.bearcatproducts.com

237 NW 12th Street, West Fargo, ND 58078-0849

Phone: 701.282.5520 • Toll Free: 888.645.4520 • Fax: 701.282.9522

E-mail: service@bearcatproducts.com • sales@bearcatproducts.com

Loading...

Loading...