Page 1

OWNER

OPERATORS

MANUAL

For 6" Chipper

Models

74624S 24HP Honda

74628S 28HP Kubota

Crary Company

A Division of TerraMarc Industries

237 12th St. NW • P.O. Box 849

West Fargo, ND 58078-0849

(701)282-5520 • FAX: (701)282-9522

www.bearcatproducts.com

www.terramarc.com

Manual P/N 14688-00

Rev. 08/03

Companion to P/N 14689-00

Page 2

Before you Begin

DEAR BEAR CAT CUSTOMER,

Thank you for purchasing a Crary Bear Cat 6 Inch Chipper. The chipper is designed, tested,

and manufactured to give years of dependable performance. To keep your chipper operating at

peak efficiency, it is necessary to adjust it correctly and make regular inspections. The following

pages will assist you in the operation and maintenance of your machine. Please read and

understand this manual before operating the chipper.

If you have any questions or comments about this manual, please call us toll-free at 1-800-247-

7335.

If you have any questions or problems with your chipper, please call or write your local factoryauthorized Bear Cat dealer.

PLEASE SEND US YOUR WARRANTY CARD

A warranty card is included in your owner's kit packaged with your chipper. Please take the

time to fill in the information requested on the card. When you send your completed card to us,

we will register your machine and start your coverage under our limited warranty.

How to Contact

Bear Cat

A

DDRESS

Crary Bear Cat

237 NW 12th Street

PO Box 849

West Fargo, ND 58078

P

HONE

800-247-7335

701-282-5520

Fax: 701-282-9522

E

MAIL

opesales@crary.com

service@crary.com

H

OURS

M-F, 8 a.m. to 5

p.m. Central Time

Page 3

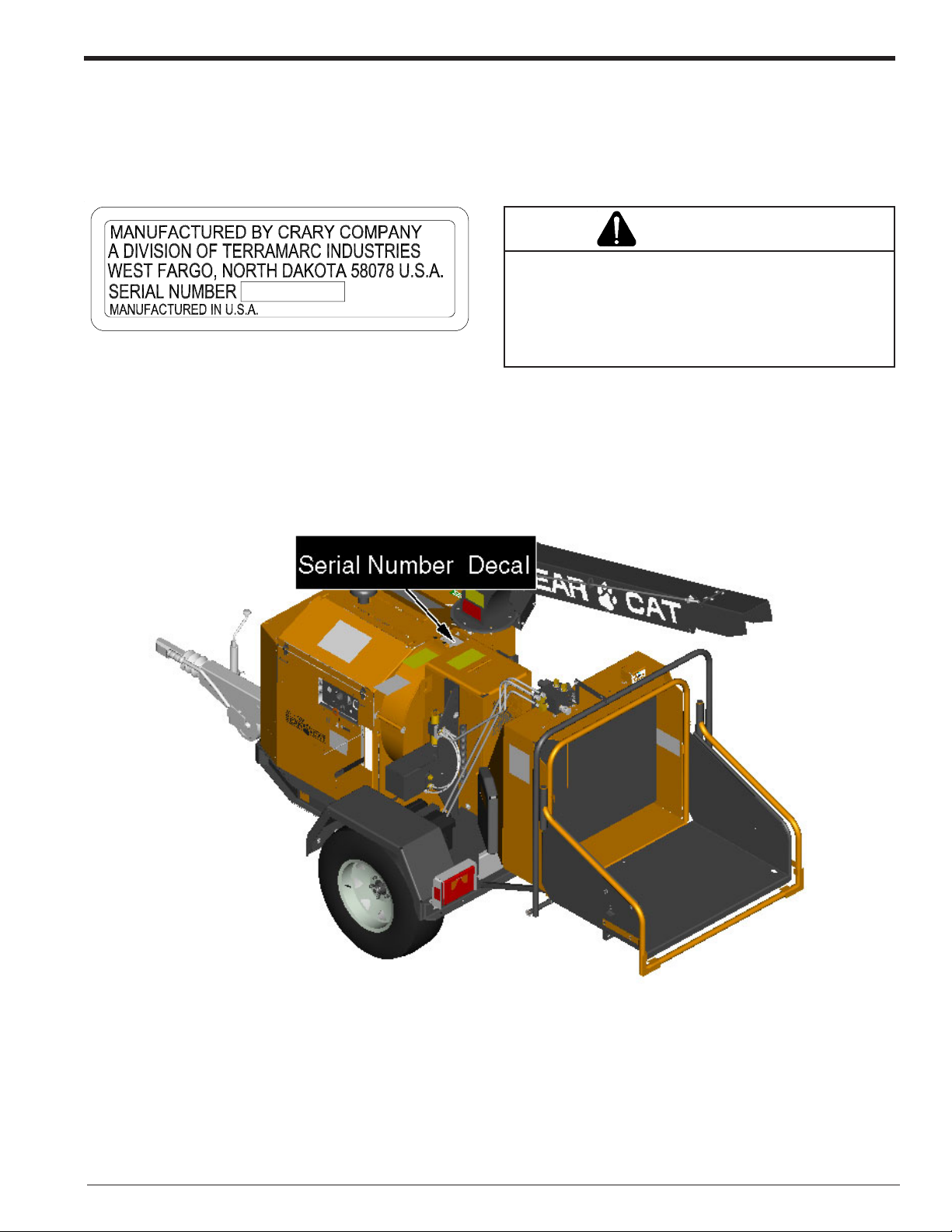

SERIAL NUMBER LOCATION

Always give your authorized Bear Cat dealer the serial number of your Crary Bear Cat chipper when ordering parts, requesting service or any other information. Please record the serial number in the space provided below and on the warranty and

registration card.

WARNING

To prevent personal injury or property damage: Shut

YXXXXX

Fig. # 1 Serial number decal

Serial Number ________________________

off engine, disconnect spark plug wire (if applicable),

make sure that all moving parts have come to a complete

stop, before obtaining serial number, servicing, adjusting

or repairing.

Fig. #2, Serial number decal

6" Chipper Operator’s Manual

I

Page 4

Section Description Page

SAFETY .................................................................................................................................... 1

1.1 THE SAFETY ALERT SYMBOL............................................................................................................. 1

1.2 BEFORE OPERATING .......................................................................................................................... 1

1.3 BEFORE OPERATING .......................................................................................................................... 2

1.4 OPERATION SAFETY ........................................................................................................................... 2

1.5 MAINTENANCE AND STORAGE SAFETY ............................................................................................ 3

1.6 FEED ROLLER SAFETY ....................................................................................................................... 3

1.7 MAINTENANCE AND STORAGE SAFETY ............................................................................................ 3

1.8 SAFETY DECAL LOCATIONS ............................................................................................................... 4

ASSEMBLY .................................................................................................................................... 5

2.1 ADDING MOTOR OIL TO ENGINE (ALL MODELS) ................................................................................ 5

2.2 ADDING HYDRAULIC FLUID ................................................................................................................. 5

2.3 ADDING COOLANT (DIESEL ONLY)...................................................................................................... 6

2.4 ASSEMBLY TORQUE CHART ............................................................................................................... 7

2.5 ATTACH THE TRAILER WHEELS.......................................................................................................... 8

2.6 ATTACHING THE DISCHARGE CHUTE ................................................................................................. 8

2.7 ATTACHING THE HITCH ........................................................................................................................ 9

2.8 INSTALLING THE REAR STABILIZER .................................................................................................... 9

2.9 ATTACHING THE BATTERY .................................................................................................................. 9

Contents

FEATURES AND CONTROLS .......................................................................................................................... 10

3.1 USE OF CONTROLS ........................................................................................................................... 11

OPERATION .................................................................................................................................. 12

4.1 FILLING THE TANK .............................................................................................................................. 13

4.2 STARTING THE GASOLINE CHIPPER ................................................................................................ 13

4.3 STARTING THE DIESEL CHIPPER ...................................................................................................... 14

4.4 HYD FEED CONTROL ......................................................................................................................... 14

4.5 CHIPPING .................................................................................................................................. 15

4.6 DIRECTING CHIPPER CHUTE ............................................................................................................. 16

4.7 FEED ROLLER BOTTLE JACK ............................................................................................................ 16

4.8 STOPPING INSTRUCTIONS ................................................................................................................ 16

4.9 SAFETY BAR OPERATION ................................................................................................................. 17

4.9.1 RESETTING THE CHIPPER ..................................................................................................... 17

4.9.2 LOCKING IN TRAVEL POSITION .............................................................................................. 17

SERVICE & MAINTENANCE ............................................................................................................................ 18

5.1 MAINTENANCE SCHEDULE ............................................................................................................... 18

5.2 REMOVING AND SHARPENING THE CHIPPER BLADES .................................................................. 19

5.3 REPLACING THE CHIPPER DRIVE BELT ........................................................................................... 20

5.4 REPLACING THE HYDRAULIC DRIVE BELT (HONDA ONLY) ............................................................. 21

5.5 GREASING .................................................................................................................................. 22

5.6 ADJUSTING CHIPPER ANVIL ............................................................................................................. 23

5.7 AIR FILTER (DIESEL SHOWN) ............................................................................................................ 23

5.8 CHECKING ANTIFREEZE (DIESEL) .................................................................................................... 23

5.9 HYD RESERVOIR FLUID .................................................................................................................... 24

5.10 HYD OIL FILTER ................................................................................................................................24

5.11 TRAILER SERVICE TIPS ................................................................................................................... 24

5.12 TROUBLESHOOTING ........................................................................................................................ 25

6" Chipper Operator’s ManualII

Page 5

NOTES

Page 6

Chipper Limited Warranty

Crary Bear Cat Chippers are warranted for one year from date of sale for consumer and commercial or

rental operations.

Within the above stated period, Crary Co. will replace any part(s) found to be defective in material and/or

workmanship, after the receipt of the part in our plant. Labor costs to replace these defective parts will be

paid at a Crary established labor rate and time allowed (flat rate) for repair. All transportation charges

incurred in shipping part(s) are the responsibility of the purchaser.

This warranty is void in the case of accidents, failure to perform normal maintenance, or failure to follow

those instructions listed in the service manual. This warranty is also in lieu of all other expressed warranties

and voids any implied warranty as to the merchantability or fitness of the product for a particular purpose

and of any other obligation on the part of Crary Co. Some states do not allow limitations on how long the

implied warranty lasts, so the above limitation may not apply to you.

This warranty applies only to parts or components which are defective, and does not cover necessary

repair due to normal wear, misuse, accidents, or lack of proper maintenance. Components subject to wear

such as wheels, hoses, cables, chipper blades, chipper anvils, etc., are not included in the warranty.

Regular routine maintenance of the unit to keep it in proper operating condition is the

responsibility of the owner.

Engine warranty is not covered by Crary Co. Rather the warranty is covered by the engine manufacturer.

All warranty repair reimbursable under the Crary Co. warranty must be performed by an authorized Bear

Cat service dealer using Bear Cat approved replacement parts. Repair or attempted repair by anyone other

than an authorized Bear Cat service dealer is not reimbursable under the Crary Co. warranty. In addition,

these unauthorized repair attempts may result in additional malfunction, the correction of which is not

covered by warranty.

Crary Co. is not liable for indirect, incidental, or consequential damages in connection with the use of this

product including any cost or expense or providing substitute equipment or service during periods of

malfunction or non-use.

Some states do not allow the exclusion of incidental or consequential damages, so the above exclusion

may not apply to you. This warranty gives you specific legal rights. You may also have other rights which

vary from state to state.

Be sure to note the chipper serial number in any correspondence with Crary Co. or any authorized Bear

Cat dealer.

Crary Company

A Division of TerraMarc Industries

237 12th St. NW • P.O. Box 849

West Fargo, ND 58078-0849

(701)282-5520 • FAX: (701)282-9522

www.bearcatproducts.com

www.terramarc.com

6" Chipper Operator’s Manual

III

Page 7

1

Safety

Section

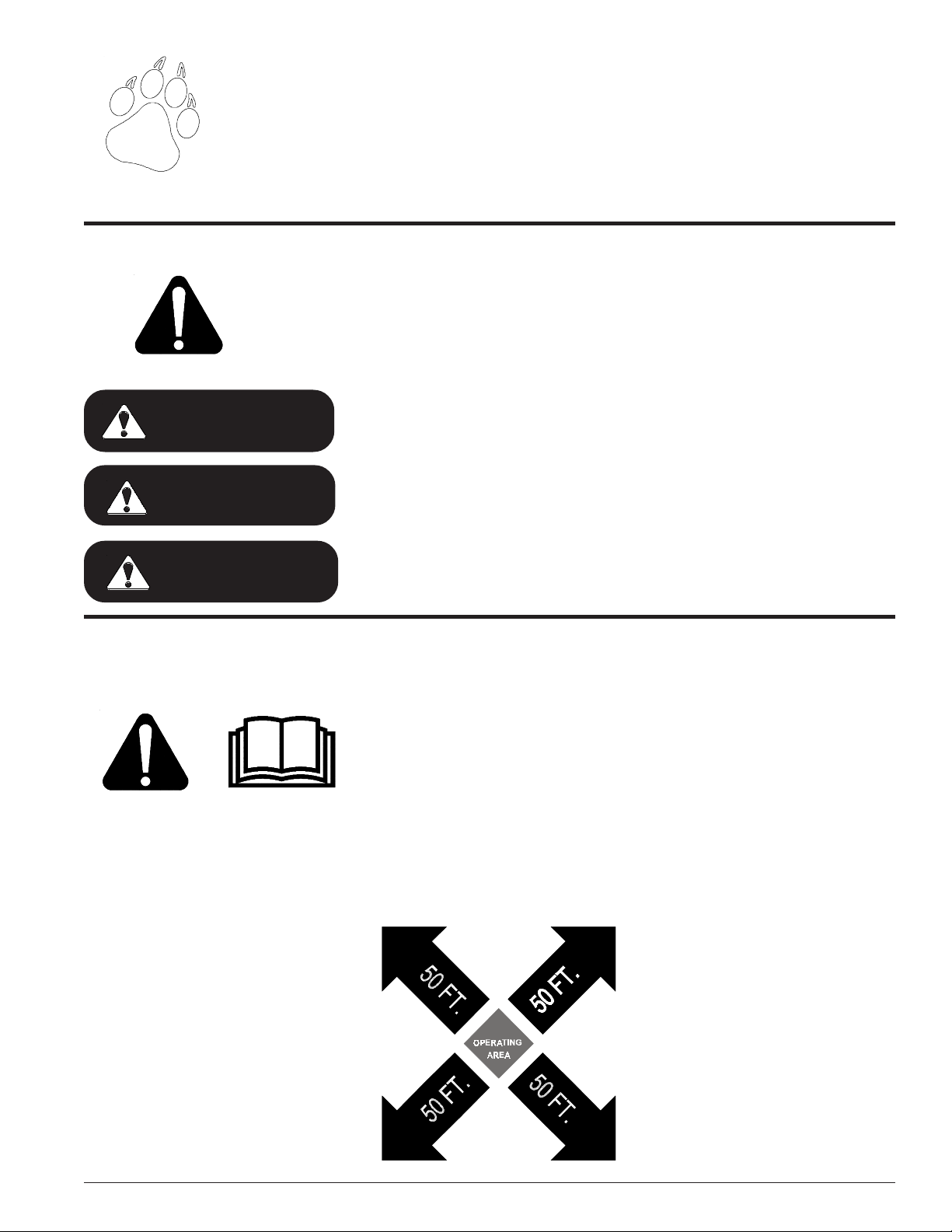

1.1 THE SAFETY ALERT SYMBOL

This manual and your machine uses this symbol to alert you of potential hazards.

When this symbol appears, read and obey the safety message that follows. Failure to obey the

safety message could result in personal injury, death or property damage.

Indicates an imminently hazardous situation that, if not avoided, will result in

DANGER

WARNING

CAUTION

death or serious injury.

Indicates a potentially hazardous situation that, if not avoided, could result in

death or serious injury.

Indicates a potentially hazardous situation that, if not avoided, may result in

minor or moderate injury.

1.2 BEFORE OPERATING

1. Read this Owner / Operator’s

manual carefully before operating

this equipment. Be completely

familiar with the controls and the

proper use of this equipment.

2. To prevent personal injury or death:

Stop chipper and engine.

Make sure that all moving parts

have come to a complete stop,

and disconnect quick couplers

from loader before servicing, adjusting or repairing.

3. Keep safety decals clean and legible. Replace missing or illegible

safety decals.

4. Familiarize yourself with all of the

safety and operating decals on this

equipment and on any of its attachments or accessories.

5. Do not allow children or any person unfamiliar with the unit to use

this machine.

6. Keep the area of operation clear of

all persons, particularly small children. Keep bystanders at least

50 feet (15 meters) away from the

operation area.

7. Do not operate this machine if

under the influence of alcohol,

medications, or substances that

can affect your vision, balance, and

judgement. Do not operate if tired

or ill. Only operate this machine

in good health.

8. Use only in daylight or good artificial light.

9. Never use without proper guards

in place.

10. Wear safety glasses at all times

while operating this machine. Bear

Cat provides one pair of safety

glasses.

11. Wear hearing protection at all times

while operating this machine.

Page 16” Chipper Pro Operator’s Manual

Page 8

1.3 BEFORE OPERATING

Safety

12. Avoid wearing loose fitting clothing. Never operate this machine

wearing clothing with drawstrings

that could wrap around or get

caught in the machine.

1.4 OPERATION SAFETY

DANGER

Keep hands, feet and clothing out of

inlets and discharge openings while

operating the machine to avoid serious personal injury or death.

1. Do not allow hands, or any part of

body or clothing, inside the feeding

chamber, discharge chute, or near

any moving parts.

2. Check the cutting chamber to verify

it is empty before starting the machine.

3. Exclude pieces of metal, rocks,

bottles, cans, and other foreign objects when feeding chipable material into the machine.

4. Shut off machine immediately if the

cutting mechanism strikes any foreign object or the machine starts

making an unusual noise or vibrating. Allow the machine to stop completely. After machine stops:

13. Secure all screws, nuts, bolts, and

other fasteners before starting the

machine. Check once in the first

two hours and every 10 hours thereafter.

14. Keep all guards, deflectors, and

shields in place and in good working condition.

5. Do not allow processed material to

build up in the discharge area; this

may prevent proper discharge and

can result in kickback of material

through the feed opening.

6. Stand clear of the discharge area

when operating this machine.

7. Keep your face and body back from

the feed opening.

8. Do not climb onto chipper feed

chutes or frame when operating. Do

not overreach. Keep proper balance

and footing at all times.

15. While running the machine, do not

transport or move the machine.

WARNING

Material can kickup or shift suddenly

and cause serious injury or death.

• Wear eye and hearing protection.

• Stand to the side of the feed chute.

• Release material and stand to

side of the feed table and chute.

9. When feeding material into feed

roller:

A. Wear eye, face and hearing

protection.

B. Release material and stand to

side of feed table and chute.

WRONG

A. Shut off engine.

B. Remove ignition key.

C. Inspect for damage.

D. Replace or repair any

damaged parts.

E. Check for and tighten any

loose parts.

Page 2 6” Chipper Operator’s Manual

Page 9

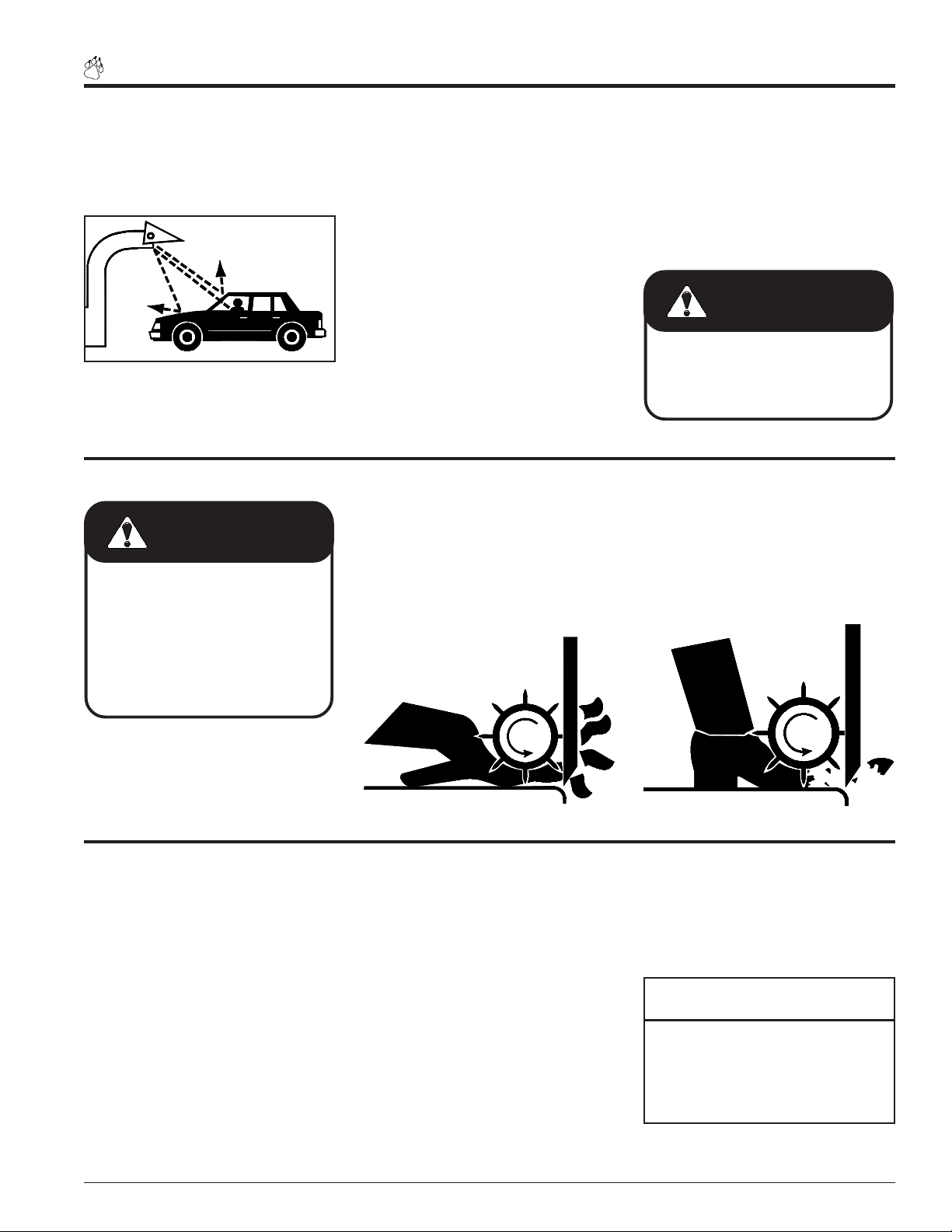

WRONG

Safety

1.5 MAINTENANCE AND STORAGE SAFETY

10. For safety purposes, set up your

chipping site as to not endanger

the public.

WRONG

1.6 FEED ROLLER SAFETY

WARNING

To prevent personal injury or death:

Stop chipper and loader engine.

Make sure that all moving parts

have come to a complete stop, and

disconnect quick couplers from

loader before servicing, adjusting,

or repairing.

11. Rotate the discharge tube to face

the opposite direction of the towing vehicle before towing. This

prevents the discharge tube from

projecting over the trailer wheels

and striking foreign objects.

12. Flying debris can cause serious

injury or death and property damage.

13. Keep bystanders away from discharge chute.

2. Never climb onto chipper feed

chute or table when operating.

3. Do not over reach. Keep proper

balance and footing.

WRONG

14. Position discharge chute away

from bystanders and other property when opening.

15. Check the bolts torque on the

chipper every 10 hours of operation.

WARNING

Failure to maintain proper fastening torque on chipper blade bolts

may result in severe damage to the

chipper and / or personal injury.

4. No riders allowed, keep off the at-

tachment.

1. Feed roller and rotating chipper

can cause serious injury or death.

Keep hands, feet and clothing

away from feed roller chipper

blades.

1.7 MAINTENANCE AND STORAGE SAFETY

1. Shut off machine, remove key, and

disconnect the spark plug wire when

servicing, inspecting or storing this

equipment.

2. Replace any missing or unreadable

safety decals. Refer to the parts

manual for part numbers when ordering safety decals from an area

Bear Cat dealer.

3. Store the machine out of reach of

children and where fuel vapors will

not reach an open flame or spark.

Drain the fuel and dispose of it in a

safe manner for storage periods of

three months or more.

4. Allow machine to cool before storing in an enclosure.

5. Never store this machine with fuel

in the fuel tank inside a building

where fumes may reach an open

flame or spark, or where ignition

sources are present such as furnaces, clothes dryers, stoves, electric motors, hot water and space

heaters, etc.

NOTE

See engine owners manual or contact the engine manufacturer for

engine safety instructions and decals.

Page 36” Chipper Pro Operator’s Manual

Page 10

Safety

1.8 SAFETY DECAL LOCATIONS

Familiarize yourself with all of the safety and operational decals on the machine and the associated hazards. Keep all

safety decals and operational decals on this equipment clean and in good condition. If you need a replacement decal,

please refer to the parts catalog. Apply decals that need replacement to their original locations.

Fig. #3 Safety decal locations

Fig. #4 Safety decal locations

Page 4 6” Chipper Operator’s Manual

Page 11

2

Assembly

Section

Your Chipper may arrive totally or partially assembled. If

your machine arrives partially assembled, perform the steps

in this section.

2.1 ADDING MOTOR OIL TO ENGINE

(ALL MODELS)

1. The machine’s engine ships filled with oil from factory

testing.

2. Refer to the engine owners manual to determine oil type

used.

3. Remove the oil fill plug.

4. Checking as necessary, add oil to the motor until the

dipstick shows the correct reading.

IMPORTANT

Check motor oil before

starting the chipper. Add

if necessary.

3. Fill the inlet line leading from the reservoir to the pump before start-up. Loosen the fitting at the pump on this inlet line

until oil bleeds out.

4. Start the engine and run at the lowest possible RPM.

5. As you purge air from the unit, the oil level in the reservoir

will drop and bubbles may appear in the fluid. Refill the

reservoir as necessary.

6. Run the feed roller in both directions for several minutes

until any remaining air purges from the unit. Refill the reservoir as necessary.

7. Shut down the engine, check for and correct any fluid leaks,

and check the reservoir level. Add fluid if necessary. The

hydraulic gear pump is now ready for operation.

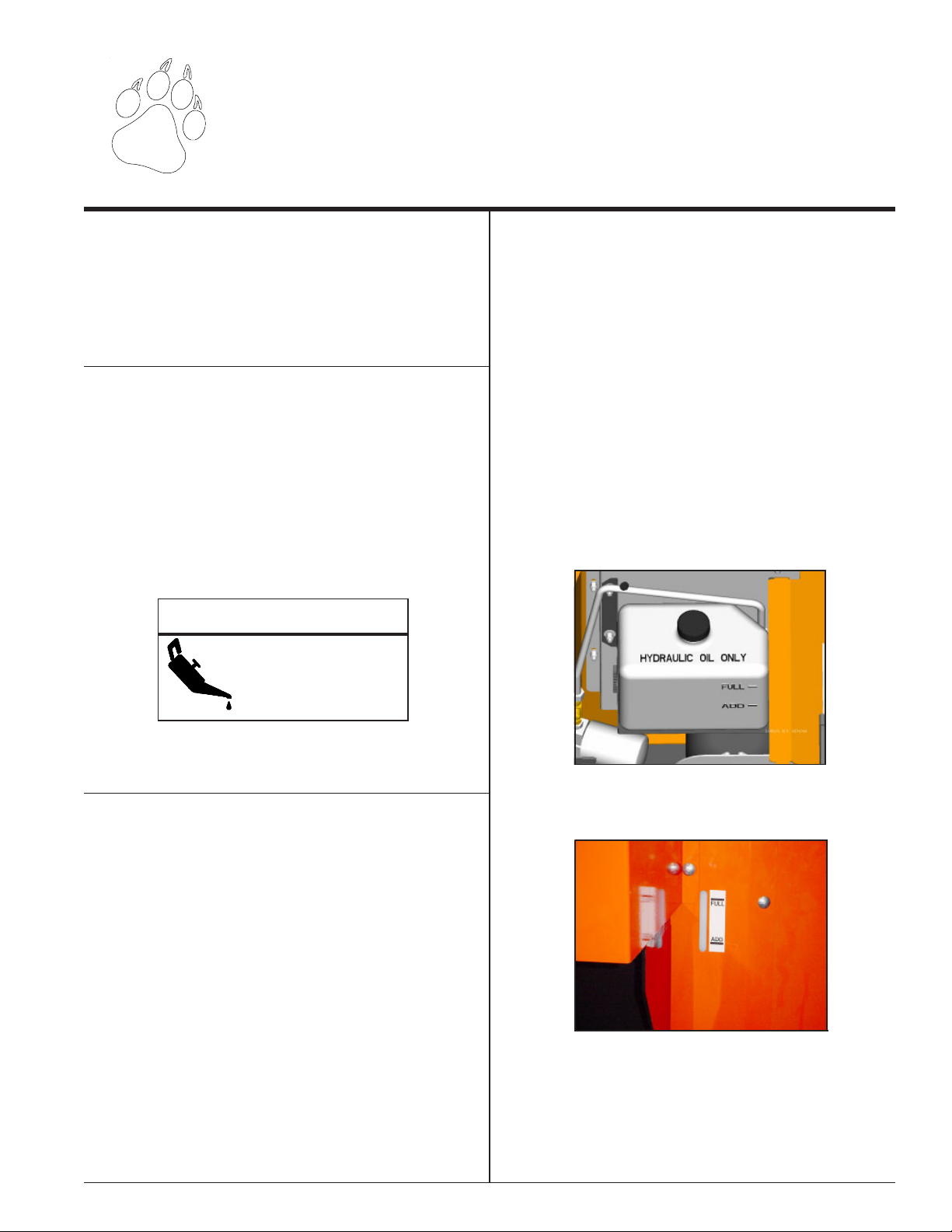

2.2 ADDING HYDRAULIC FLUID

Hydraulic fluid drives the feed roller. The hydraulic pump is

attached to the motor (diesel models) or connected to the

motor with a belt (gasoline models).

The hydraulic pump requires premium hydraulic fluids

containing high quality rust, oxidation, and foam inhibitors.

These include premium turbine oils, API CD engine oils per

SAE J183, M2C33F or G automatic transmission fluids

meeting Allison C-3 or Caterpillar TO-2, and certain specialty

agricultural tractor fluids.

If system has no oil, follow this startup procedure:

1. Clean all system components (reservoir, fittings, etc.)

before starting the hydraulic pump.

2. After filtering the hydraulic fluid, fill the hydraulic reservoir.

Figure #5 Hydraulic reservoir (Honda Engine)

Figure #6 Hyraulic reservoir (Kubota Engine)

Page 56” Chipper Pro Operator’s Manual

Page 12

2.3 ADDING COOLANT

(DIESEL ONLY)

You may need to add coolant before you start the diesel

engine. While operating, check the fluid to ensure the level

sits between the full and the low marks. Add if necessary.

To fill:

1. Remove the top cover.

2. Add a 50/50 mix of water and antifreeze until it reads

slightly below the full line. (The antifreeze should drain

from the tank into the radiator).

3. Wait 10 minutes and check level again. Refill if necessary.

4. After running the machine, recheck the level of antifreeze,

and fill if necessary.

Assembly

Fig. #7 Coolant level

Page 6 6” Chipper Operator’s Manual

Page 13

Assembly

2.4 BOLT TORQUE

CHECKING BOLT TORQUE:

The table shown below is for reference purposes only and its use by anyone is entirely voluntary, unless otherwise noted.

Reliance on its contents for any purpose is at the sole risk of that person. BearCat Co. is not responsible for any loss claim

or damage arising there from. In developing these tables, BearCat has made a determined effort to present the contents

accurately.

SAE - 8SAE - 2ASAE - 5

ENGLISH TORQUE SPECIFICATION

Bolt

Diameter

"A"

1/4" 7.5 5.5 11 8 16 12

5/16"151123173425

3/8" 27 20 41 30 61 45

7/16"413068509570

1/2" 68 50 102 75 149 110

9/16" 97 70 149 110 203 150

5/8" 122 90 203 150 312 230

3/4" 217 160 353 260 515 380

7/8" 230 170 542 400 814 600

1" 298 220 786 580 1220 900

1-1/8" 407 300 1085 800 1736 1280

1-1/4" 570 420 2631 1940 2468 1820

METRIC TORQUE SPECIFICATION

Bolt

Diameter

"A"

M30.50.4 - - - - - M432.2 - - - - - M554 - - - - - M6 6 4.5 11 8.5 17 12 19 14.5

M8 15 11 28 20 40 30 47 35

M102921554080609570

M1250379570140105165120

M14 80 60 150 110 225 165 260 190

M16 125 92 240 175 350 255 400 300

M18 175 125 330 250 475 350 560 410

M20 240 180 475 350 675 500 800 580

M22 330 250 650 475 925 675 1075 800

M24 425 310 825 600 1150 850 1350 1000

M27 625 450 1200 875 1700 1250 2000 1500

SAE 2 SAE 5 SAE 8

N.m Ft-lb N.m Ft-lb N.m Ft-lb

A

4.8 8.8 10.9

N.m Ft-lb N.m Ft-lb N.m Ft-lb N.m Ft-lb

Bolt Torque* (UNC)

Bolt Torque*

12.9

Torque figures indicated above are valid for non-greased or non-oiled threads and heads unless otherwise specified. Therefore, do not grease or

oil bolts or capscrews unless otherwise specified in this manual. When using locking elements, increase torque values by 5%.

* Torque value for bolts and capscrews are identified by their head markings.

Page 76” Chipper Pro Operator’s Manual

Page 14

Assembly

2.5 ATTACH THE TRAILER WHEELS

1. Remove the chipper from its shipping crate. Place the

unit on a level surface before attempting to assemble it.

See the torque on the previous page for tightening torque

of bolts and screws.

2. Raise the trailer several inches from the ground with a

hoist or jack. Support the chipper securely.

3. Lift one wheel to a hub and align the wheel lug holes with

the hub lug bolts. Thread the lug nuts (found in the parts

kit) into the holes and tighten the lug nuts to 75 ft. lbs.

Follow a star pattern when tightening the lug nuts. Repeat this step for the remaining wheel.

2.6 ATTACHING THE DISCHARGE

CHUTE

1. The chute rotator connects to the chipper frame first with

two 3/8 bolts from the owners kit. Install but do not tighten.

Remove the top cover from the chute rotator to expose

the rotator drive sprocket.

2. Attach the discharge chute to the mounting flange on the

chipper frame. The square discharge chute will fit over

the round section of the chipper frame.

3. Place the discharge ring, and discharge retainer around

the base of the mounting flange on the chipper frame.

4. Attach the discharge ring and retainer to the flange with

the provided 3/8” x 1-1/4” bolts and nuts. Tighten to proper

torque.

5. Install the chain around the discharge ring and sprocket

on the inside of the chute rotator. Connect chain with the

connector link.

6. Reassemble the top cover and tighten the 4 bolts.

Fig. #8 Trailer wheels

7. Slide the chute rotator assembly back to remove chain

slack and tighten the two attachment bolts.

8. Torque all fasteners to proper values.

Fig. #9 Discharge chute

Page 8 6” Chipper Operator’s Manual

Page 15

Assembly

2.7 ATTACHING THE HITCH

1. Attach the channel spacer over the square tube.

2. Attach the ball coupler over the channel spacer to the

hitch weldment using the provided 1/2” x 4” bolts and 1/2”

washers and 1/2” nuts. Tighten to proper torque.

3. Slide the hitch weldment into the hole in the frame, back

to the 1/2” mounting holes.

4. Connect the hitch weldment to the frame using the two 1/

2” x 4-1/2” bolts, 1/2” washers and 1/2” nuts. Tighten to

proper torque.

5. Check the tongue jack and safety chains for correct

installation.

2.8 INSTALLING THE REAR STABILIZER

Install the rear stabilizer by sliding the stabilizer into the

corresponding slot on the rear of the chipper frame. Secure

and adjust the stabilizer with the provided snap pin.

Fig. #11 Rear stabilizer

Fig. #10 Trailer hitch

2.9 ATTACHING THE BATTERY

A battery ships with the chipper. Connect the battery cables

to the battery using the two 1/4” bolts and nuts found in the

parts kit. To connect:

1. Route the battery cables to the proper battery terminals,

hooking positive to positive, and negative to negative.

2. Connect cables with 1/4” bolt and nuts. Tighten nuts to

proper torque.

3. Check battery for proper fluid level and fill if necessary.

4. If necessary, charge battery.

Page 96” Chipper Pro Operator’s Manual

Page 16

3

Features and Controls

Section

FEATURES AND CONTROLS IDENTIFICATION

Learn the location of the features and controls on your machine before operating.

Fig. #12 features and controls

Fig. #13 features and controls

DESCRIPTION OF OPERATION

The chipper pulls in wood with the feed roller, chips the wood, and blows the chips out through the adjustable discharge

chute.

Page 10 6” Chipper Operator’s Manual

Page 17

Features & Controls

3.1 USE OF CONTROLS

WARNING

To prevent personal injury or property damage: Shut

off engine, remove key, and make sure that all moving

parts have come to a complete stop, before servicing,

adjusting or repairing.

1. Key: The control panel houses the key on both the diesel and gas engines. Turn the key to the right to activate the electric start. On diesel models turning the key

to the left activates the glow plug. DO NOT START THE

MACHINE WITH THE CHIPPER ENGAGED.

2. Throttle: This controls the speed of the engine. On diesel models adjust the throttle by twisting, or by pushing

the button and pushing or pulling.

3. Choke: Use this to start the gasoline engine when cold.

Move cable to original position as engine warms.

4. Chipper Engagement: To activate slowly push the

handle toward the ground. To disengage the machine

move the handle back up to the original position (See

Fig. #16).

5. Feed Roller Engagement: To engage the feed roller

move the control arm. The cycle of the control arm,

forward to back, is R, F, N, R.

6. Chute Rotor: Directs the discharge of chipped material

horizontally.

Fig. #14 Diesel controls

Fig. #15 Gasoline controls

7. Discharge cap rotor: Directs the discharge of material

vertically.

8. Rear Stabilizer: Prevents the chipper from tipping from

heavy loads when disconnected from the towing vehicle.

9. Bottle Jack: Used to lift feed roller for unplugging.

10. Tongue Jack: Used to adjust the height of the hitch.

11. Fuel Gauge: Shows remaining fuel.

12. Murphy Switch: See starting instructions for diesel

engines. The murphy switch prevents the engine from

running with low oil pressure, or high engine temperature. To start the engine, hold the switch until the oil

pressure appears on the gauge.

Fig. #16 Engagement instructions

Page 116” Chipper Pro Operator’s Manual

Page 18

4

Operation

Section

WARNING

Before operating your machine, be

sure you read and understand all

safety, controls and operation instructions in this Owner/Operators

manual and on your machine.

Failure to follow these instructions

can result in serious injury or property damage.

As with any other piece of outdoor

power equipment, getting the “feel” for

how your machine operates and getting

to know the best techniques for

particular jobs are important to overall

good performance.

Read this section thoroughly before you

start the engine. The instructions given

here will help you become familiar with

your machine and have you operating

efficiently in a short time.

This section covers:

• Filling the tank (Gas and diesel instructions)

• Starting the gasoline chipper

• Starting the diesel chipper

• Hydraulic feed

• Chipping

• Directing the chipper chute

• Feed roller bottle jack

• Stopping Instructions

• Safety Bar Operation

Fig. #17 Chipping

Page 12 6” Chipper Operator’s Manual

Page 19

Operation

4.1 FILLING THE TANK

DANGER

Gasoline is highly flammable and its vapors are explosive. To prevent personal injury or property damage:

Store gasoline only in approved containers, in well ventilated, unoccupied buildings, away from sparks or flames.

Do not fill the fuel tank while the engine is hot or running,

since spilled fuel could ignite if it comes in contact with

hot parts or sparks from ignition. Do not start the engine

near spilled fuel. Never use gasoline as a cleaning agent.

FILLING THE FUEL TANK

Gasoline Type:

For best results use only clean, fresh, unleaded gasoline

with a pump sticker octane rating of 87 or higher. In countries using the Research method, use a 90 octane minimum.

WARNING

Handle fuel with care. It is highly flammable. Always use

an approved container and fill tank outdoors.

CAUTION

Move machine to a clear level area. Do not operate in

the vicinity of bystanders.

4.2 STARTING THE GASOLINE CHIPPER

Make sure the chamber is empty before starting.

1. Reference the Honda Owners Manual.

2. Check engine oil level before starting. Do not overfill or

underfill oil. The Honda engine is equipped with an oil

level sensor and will not allow the engine to start in either

condition.

Gasoline Alcohol blends

Gasohol (up to 10% ethyl alcohol, 90% unleaded gasoline

by volume) is approved as a fuel for Honda engines. Other

gasoline/alcohol blends are not approved.

Gasoline Ether blends

Methyl Tertiary Butyl Ether (MTBE) and unleaded gasoline

blends (up to a maximum of 15% MTBE by volume) are

approved as a fuel for Honda engines. Other gasoline/ether

blends are not approved.

Diesel Fuel:

For best results use only clean, fresh, #2 diesel. Use an

additive for cold weather to prevent the fuel from turning into

a gel.

To Add Fuel:

1. Stop engine, wait for all parts to stop moving, then remove the key. Allow the engine and muffler to cool for at

least three minutes.

2. Clean area around fuel fill cap and remove cap.

3. Place the chipper engagement in the start position.

4. Engage the choke if necessary.

5. Adjust throttle to start/idle position.

6. Turn the key to the right to engage the starter.

7. Release the key after the engine starts.

8. For a Cold Engine — Gradually return the choke from

the choke position to the run position as the engine warms

up.

3. Using a clean funnel, fill fuel tank to 1/2” below bottom of

filler neck to provide space for fuel expansion. Install fuel

fill cap securely and wipe up any spilled diesel.

Page 136” Chipper Pro Operator’s Manual

Page 20

Operation

4.3 STARTING THE DIESEL CHIPPER

WARNING

Allow the machine to come to complete stop before inspection or servicing.

WARNING

Handle fuel with care. Always use an approved container

and fill tank outdoors.

CAUTION

Move machine to a clear, level area. Do not operate in

the vicinity of bystanders.

NOTE

The Murphy switch system will shut the engine off if

the oil pressure is too low or if the engine temperature

is too high. If the engine will not run or shuts off for

these reasons, consult your local dealer.

4.4 HYD FEED CONTROL

1. Reference the Kubota Owners Manual. Before starting,

empty the cutting chamber.

2. Before starting, fill engine with oil to the correct level.

See engine manual for additional starting, operation and

maintenance instructions. Some oil usage is normal.

Check level before each use.

3. Before starting, fill fuel tank with fresh and clean diesel

fuel. For instructions on bleeding the fuel system on initial start up or if fuel runs out, see engine manual.

4. Turn key switch to preheat position (to the left). Hold in

preheat position for several seconds until glow plug indicator light switches off.

5. Place throttle control in the idle position.

6. Disengaged the chipper engagement lever.

7. Push in and hold the Murphy switch push-button. Continue to hold Murphy switch in when cranking engine until engine runs.

8. Activate the starter. Release the switch as soon as the

engine starts. Do not crank over for more than 10 seconds. After starting the engine; hold the Murphy switch

until engine has oil pressure.

Fig. #18 Controller

A pre-programmed hydraulic feed control equips the Bear

Cat chipper. The controller serves a variety of functions

including monitoring chipper rotor RPM, controlling the feed

roller, and providing routine maintenance alerts. The controller

has an on/off feature located below the control panel. If the

controller becomes damaged, the chipper will still run with

the controller shut off, however all of the controller functions

will be disabled. The control arm will control the feed roller.

The controller is positioned under the control panel.

The controller functions are further detailed below:

1. The controller operates the feed roller. The controller monitors the RPMs of the chipper rotor and if it drops below

the preset range the feed roller stops. When the RPMs

reach an acceptable level, the feed roller will reengage.

2. The controller also has a “try again” feature. The controller monitors the hydraulic pressure of the feed roller. If it

senses the level is too high (the feed roller becomes obstructed) the controller will reverse the feed roller , removing the material trying to be chipped. The controller will

then engage the roller into the forward position and try to

feed the material again. If this cycle continues, remove

the obstruction manually. Trim or reposition material if

necessary.

Page 14 6” Chipper Operator’s Manual

Page 21

Operation

4.4 HYD FEED CONTROL (CONT’D)

3. The controller will also flash service alerts when started.

Every 15 hours it will flash (error light blinks 5 times) to

sharpen the chipper blades. Every 100 hours it will flash

(error light blinks 10 times) to change the engine oil. To

reset service alerts, locate light green wire in engine compartment next to the hour meter. Connect green wire to

red wire connector for five seconds.

NOTE: The RPM sensor on the rotor must flash or the

controller won’t work. Clearance between the sensor and

the bolt must be between 1/32” and 3/32”.

4.5 CHIPPING

WARNING

Obtain and wear safety glasses at all times when operating the machine. Do not wear loose fitting clothing.

Use common sense and practice safety to protect yourself from branches, sharp objects and other harmful objects.

5. Never use shovels or forks to push brush. They can go

through the chipper and cause major damage. In addition, metal pieces can come back like shrapnel to injure

or kill.

6. Never push brush into the chute with your feet.

7. Engage the hydraulic feed by moving the control arm.

Pull the arm toward you to engage the hydraulic feed.

Adjust the speed of the feed roller by turning the speed

control knob on the chipper valve assembly.

8. Place limb, butt end first, into the chipper chute until it

contacts the hydraulic feed roller and draws into the chipper blades. The actual feed rate of the limb into the chipper will depend on the type of material fed, and sharpness of the cutting blades.

9. If the feed roller slips, increase the downward pressure on

the roller by moving the eyebolt that connects the spring

to the feed roller.

10. Alternate greener material with dry material to lubricate

the chipping blades for longer life and better performance.

When the chipping blades become dull, they will require

periodic sharpening. Refer to Service and Maintenance,

"Sharpening Chipper Blades."

The Bear Cat chipper chips a variety of materials into a

more readily decomposing or handled condition. Use the

following guidelines to help get started.

Please read and follow all safety instructions in this manual.

Failure to operate the chipper in accordance with the safety

instructions MAY RESULT IN PERSONAL INJURY!

1. Before chipping material, engage the unit to full operating

speed. Adjust engine speed with the throttle. Diesel models have the option of locking the throttle.

2. Select limbs up to 6 inches in diameter. Trim side

branches that do not bend enough to feed into the chipper chute. Hold small diameter branches together in a

bundle and feed in simultaneously.

3. Feed brush from the side of the chute, rather than from

the front. Step aside to avoid being hit by the brush moving into the chipper.

4. Never lean over the chute to push objects into the cutting

device. Use a push stick or brush paddle.

Page 156” Chipper Pro Operator’s Manual

Page 22

4.6 DIRECTING CHIPPER CHUTE

Operation

The chipper chute can lock into 44 different positions using

the chute rotator. The chipper chute will lock before it revolves

over the feed chute area. The discharge cap adjusts how

high and how far the chipped material blows.

To adjust the chute rotor lift up the rotor lock. Turn the chute

rotor until the chute faces the desired position. Let go of the

rotator lock and fine tune the position of the rotor until the

lock snaps in place.

Adjust the discharge cap by turning the discharge crank

cap either clockwise or counterclockwise. Turning the handle

clockwise will raise the position of the discharge cap. Turning

the handle counterclockwise will lower the position of the

discharge cap.

Before entering feed chute for service or removal of material,

place the safety pin in the lock position. This will prevent the

feed roller from dropping and causing injury or death.

Turning the check valve clockwise will engage the pump of

the jack. Once you engage the jack the pumping the handle

will raise the jack. Turning the check valve counterclockwise

will disengage the pump and lower the jack.

Fig. #19 Directing the chute

4.7 FEED ROLLER BOTTLE JACK

Fig. #20 Bottle jack

Use the feed roller bottle jack to raise the feed roller if chipping

material becomes wedged in the feed roller. The jack will

raise the feed roller and remove the tension on the chipped

material.

Figure # 21 Safety Pin in Lock Position

4.8 STOPPING INSTRUCTIONS

WARNING

Allow the machine to come to complete stop before

inspection or servicing.

1. Move throttle to slowest position.

2. Move chipper engagement to the engine start position.

3. Let machine idle for a few seconds.

4. Turn key to off position.

5. Allow machine to come to a complete stop.

Page 16 6” Chipper Operator’s Manual

Page 23

Operation

4.9 SAFETY BAR OPERATION

4.9.1 Resetting the Chipper

The safety bar located around the chute area will stop the

chipper when pushed in. The reset button for this bar sits on

top of the chipper chute. To reset the safety bar, push the

reset button and the machine will start up again. If false trips

occur from a limb, the reset button can be held in to override

the system. Upon start up, safety bar light will be on and will

require the reset button to be pushed in before the feed roller

will operate. When the safety bar has been activated, a red

light will be on signaling that the operator reset button will

need to be pushed before feed roller will function.

4.9.2 Locking in Travel Position

The safety bar will lock into travel position. Place the extension tray in an upright position. Pushing the safety bar down

will lock the safety bar (see Figure # 23). To unlock, lower

the extension tray and push in on the safety bar. This will

release the flange and allow the safety bar to move freely.

Figure # 23 Flange lock

Figure # 22 Safety Bar, Reset Button

Page 176” Chipper Pro Operator’s Manual

Page 24

5

y

p

p

y

Service & Maintenance

Section

5.1 MAINTENANCE SCHEDULE

Check the following items listed in the service and mainte-

WARNING

nance schedule and if necessary, take corrective action.

This schedule is designed for units operating under normal

conditions. If the unit operates in adverse or severe usage

conditions check and service items more frequently.

See engine owners manual for further maintenance and

troubleshooting information.

SERVICE AND MAINTENANCE SCHEDULE

COMPONENT

AIR CLEANER CHECK AND CLEAN (1)

AIR INTAKE CLEAN (1)

ENGINE OIL CHANGE (1)

FUEL FILTER REPLACE

SPARK PLUG

ENGINE OIL CHECK

FUEL TANK FILL

CHIPPER ANVIL

CHIPPER BLADES

ALL INTERNAL AND

EXTERNAL NUTS AND

BOLTS

BELT CONDITION CHECK

BELT TENSION CHECK

GREASE ZERKS LUBE

ENTIRE MACHINE CLEAN

HYD. OIL FILTER REPLACE

WHEEL BEARINGS CHECK AND REPACK

(1) PERFORM MORE FREQUENTLY UNDER EXTREMELY DUSTY CONDITIONS.

(2) PERFORM MORE FREQUENTLY WHEN CHIPPING DRY OR DIRTY WOOD.

As the Chipper Limited Warranty states, failure by the Owner to perform normal maintenance will void the machine's

warrant

NORMAL MAINTENANCE. S

INTERNAL AND EXTERNAL NUTS AND BOLTS is the sole res

cause for Crar

. The aggressive, high-speed nature of chipping REQUIRES THE OWNER TO PERFORM THE ABOVE LISTED

BearCat to deny warranty.

MAINTENANCE

REQUIRED

CHECK CONDITION AND

GAP

CHECK 1/16" TO 1/8"

CLEARANCE AND RETORQUE TO 75 FT. LBS. (2)

CHECK SHARPNESS AND

RETORQUE TO 75 FT. LBS.

(2)

RE-TORQUE PER

ASSEMBLY TORQUE CHART

ecial consideration to maintain and re-torque the CHIPPER ANVIL, CHIPPER BLADES, AND ALL

Refer to Engine

Operator manual

•

To prevent personal injury or property damage: Shut

off engine, disconnect spark plug wire and make sure

that all moving parts have come to a complete stop

before, servicing, adjusting or repairing.

FREQUENCY

EVERY 8

HOURS

EVERY

25

HOURS

EVERY

50

HOURS

•

•

•

onsibility of the Owner. Failure by the Owner to do so shall be

EVERY

200

HOURS

EVERY

YEAR

Page 18 6” Chipper Operator’s Manual

Page 25

Service & Maintenance

5.2 REMOVING AND SHARPENING

THE CHIPPER BLADES

WARNING

To prevent personal injury or property damage: Shut

off engine, remove ignition key and make sure that all

moving parts have come to a complete stop before servicing, adjusting or repairing.

WARNING

The chipping blades are sharp!! Use care when working

on the machine to avoid injury.

To remove the chipping blades for sharpening:

1. Remove the two 3/8 inch retaining bolts holding access

cover to main frame assembly.

2. Tilt access cover over to allow rotor access. The chipper

will not operate with an open cover. Rotate the rotor to

access the bolts holding the blades. To remove the blades,

open the access cover from the top of the feed roller.

3. Remove the two allen head bolts holding the blade itself.

Repeat for all four blades. The four chipping blades have

two edges per blade and can be reversed one time each

before sharpening. Tighten bolts to proper torque and secure access cover.

Sharpening the chipper blades:

Depending on the type of wood fed into the chipper, the

blades will eventually dull, making it difficult to feed material

and produce chips. Check the blades for sharpness every 8

hours.

Regrind the angled edge of the chipping blades to 45 degrees.

(refer to figure below) Grind the blades on a bench grinder or

by a professional. Use some type of fixture to correctly hold

the blade at the proper angle. Be careful when grinding so

that the blade does not become overheated and change

color (This will remove the heat-treated properties). Use short

grinding times and cool with water or some type of liquid

coolant. Try to remove an equal amount off of each blade to

maintain rotor balance. The blades can receive up to

approximately 6 sharpenings depending on the amount of

material removed to restore a razor-sharp edge.

Never sharpen or back grind the flat side of the chipping

blade. This will cause the edge to roll and damage the chipper

blade, resulting in poor chipping performance.Small

imperfections such as nicks, burrs, etc. on the blade may

affect the chipping performance of the machine. Sharpen

the blade to remove imperfections. Replace the blade if

imperfections are too large.

Replace the blade after the allotted sharpening amount dips

below the chipper outlet (See Fig. 25 “A”). If you do not

replace the blade, damage to the machine will occur due to

pieces of wood jamming into the chipping disk and blade.

When completed, replace the chipping blades and tighten

the bolts to 75 ft. lbs. Install all safety screens and guards

and resume chipping.

CHIPPER

SHARPENED

SURFACE

CHIPPING

DISC

A

OUTLET

SHARPENED

SURFACE

Fig. # 24 Exposing the chipper blades

.38

45°

Figure # 26 Imperfections that require replacement

MOUNTING SURFACE

DO NOT GRIND

Fig. # 25 Sharpening the chipper blades

ALLOTTED

SHARPENING AMOUNT

.13

Page 196” Chipper Pro Operator’s Manual

Page 26

5.3 REPLACING THE CHIPPER

DRIVE BELT

Service & Maintenance

Fig. # 27 Idler pulley

Check the condition of the drive belt annually, or after every

25 hours of operation. Replace the belt if cracked, worn,

frayed, or stretched. Only replace it with the original banded

belt type, do not use singe belt types.

To replace the belt:

1. Remove idler pulley. Remove the pulley by loosening the

1/2” mounting hardware.

2. Lift belt idler pulley off of the idler arm weldment.

3. Remove the drive belt from the pulleys and take the old

belt out of the machine.

4. Install new belt on pulleys and lower belt idler. Check

alignment of pulleys and adjust if needed.

5. Reinstall the belt idler pulley to the idler arm weldment

using the 1/2” hardware. Tighten bolt to proper torque.

Fig. # 28 Removing the belt

5. Check belt tension before start-up. If necessary adjust

spring tension.

Page 20 6” Chipper Operator’s Manual

Page 27

Service & Maintenance

5.4 REPLACING THE HYDRAULIC

DRIVE BELT (HONDA ONLY)

Check the condition of the hydraulic drive belt annually, or

after every 25 hours of operation. Replace the belt if cracked,

worn, frayed, or stretched.

To replace:

1. Loosen the mounting bolts shown in Fig. #29.

2. Loosen the nut (not shown) on the back side of the adjusting bolt to relieve tension on the belt. Make sure that

the pump mounting bracket moves and relieves the belt

tension.

3. Remove drive belt according to instructions on prior page.

4. Remove the loosened hydraulic belt from the chipper.

5. Install the new hydraulic belt in the same manner as you

removed the old belt.

6. Replace the drive belt, according to directions on prior

page.

7. Install the hydraulic drive belt onto the two pulleys.

8. Tighten the nuts on the adjusting bolt to move the pump

mounting bracket. Stop when the belt is at the desired

tension.

9. Tighten the mounting bolts on the pump mounting bracket

to the proper torque.

10. Check pulleys for proper alignment and adjust if neces-

sary.

Fig. # 29 Hydraulic pump

Page 216” Chipper Pro Operator’s Manual

Page 28

5.5 GREASING

Grease zerks on the Bear Cat 6” Chipper every 25 hours,

depending upon conditions.

Service & Maintenance

Fig. # 30 Greasing

Fig. # 32 Greasing

Fig. # 33 Greasing

Fig. # 31 Greasing

Page 22 6” Chipper Operator’s Manual

Page 29

Service & Maintenance

5.6 ADJUSTING CHIPPER ANVIL

5.7 AIR FILTER (DIESEL SHOWN)

Fig. # 35 Diesel Air Filter

Both the Kubota diesel and the Honda gas engines used on

the 6” chipper have air filters. Refer to the Kubota and Honda

engine manuals, included with your machine, for specific

instructions on replacing and cleaning these filters.

Fig. # 34 Chipper anvil

The four chipping blades should clear the chipper anvil by 1/

16 inch to 1/8 inch. The chipper anvil is adjustable and

reversible. Use all four sides of the anvil for chipping.

To adjust:

1. Lift rotor access cover and expose rotor.

2. Loosen the three 1/2 inch bolts that hold the chipper anvil

to the frame.

3. Measure the amount of clearance between chipping blade

and chipper anvil from inside of housing.

4. Adjust inward or outward to the desired measurement,

using the adjustment nuts provided.

5. Tighten bolts on chipping block to 75 ft. lbs. and resume

operation.

If damage or uneven wear occurs on chipper anvil edge,

remove the three bolts holding the anvil and use one of the

other three edges. Replace as necessary.

5.8 CHECKING COOLANT (DIESEL)

Fig. # 36 Diesel coolant level

The diesel Kubota is tested before shipping. In order to test

the equipment the fluid levels are filled. However, before

starting the machine, check the coolant level. Add fluid if

the level is low.

To add fluid follow the procedure below:

1. Make sure the coolant isn’t hot.

2. Open the radiator cap pictured in Fig #36.

3. Check level and add if necessary. Use a 50/50 mixture of

antifreeze and water.

Page 236” Chipper Pro Operator’s Manual

Page 30

Service & Maintenance

5.9 HYD RESERVOIR FLUID

Fig. # 37 Hydraulic reservoir (Honda Engine)

The chippers are tested before shipping. In order to test the

equipment the fluid levels are filled. However, check the fluid

levels before initial operation and add if necessary (see the

assembly section). Always check levels before each use.

To check levels look at the side of the hydraulic oil container

and make sure the fluid level falls between the marks. If

necessary add oil.

On the Kubota models the hydraulic tank sits next to the

fuel tank. A cutout exists to check the fluid level.

Premium hydraulic fluids containing high quality rust,

oxidation and foam inhibitors are required. These include

premium turbine oils, API CD engine oils per SAE J183,

M2C33F or G automatic transmission fluids meeting Allison

C-3 or Caterpillar TO-2, and certain specialty agricultural

tractor fluids.

5.10 HYD OIL FILTER

Fig. # 39 Hyd oil filter

Change this filter after the first 50 hours and every 200 hours

thereafter. To change:

1. Using an oil filter wrench turn the filter counterclockwise.

2. Once the filter becomes loose, turn it out the rest of the

way with your hand.

3. Properly discard old filter.

4. Lube the rubber seal on the new filter (P/N 16588) with

clean hydraulic oil.

5. Install the filter onto the threaded pipe. Turn with your

hand until the filter is finger tight.

6. Turn, by hand, another 1/2 turn.

7. Check hydraulic oil level and fill if necessary.

5.11 TRAILER SERVICE TIPS

1. Check wheel bolt torque every 10 hours of towing use.

2. Check air pressure in tires every 10 hours of towing.

3. Check and repack wheel bearings with grease every 12

months.

Figure #38 Hydraulic reservoir (Kubota Engine)

Page 24 6” Chipper Operator’s Manual

4. When towing, always connect the safety chains. Tighten

and secure all trailer hitch bolts.

5. Check trailer lights.

Page 31

p

g

j

g

j

g

g

pp

p

p

g

g

g

g

pty

p

p

g

y

g

Service & Maintenance

5.12 TROUBLESHOOTING

Before performing any of the correction in this troubleshooting chart, refer to the appropriate information contained in this

manual for the correct safety precautions and operating or maintenance procedures. Contact your nearest dealer or the

factory for service problems with the machine.

PROBLEM POSSIBLE CAUSE CORRECTION

Dull chipping blades. Sharpen or replace.

Chipper does not chip. Poor

performance.

Unusual vibration or noise.

Engine runs poorly.

Engine won't start or is hard to start.

Drive belts loose or worn. Re

Too lar

Solid ob

Broken or missin

Solid ob

Chipper blade loose or damaged. Tighten or replace.

En

Loose or missin

Chi

Bad s

Incorrect choke settin

Dirty air filter. Clean or replace.

Stale

Dirt or water in fuel tank. Contact en

Gas tank is em

S

S

Gas line is obstructed. Remove gas line at carburetor and check for

Dirt

Flooded engine. Put throttle control in run position and crank

Dirty or plugged air cleaner. Clean air cleaner and replace.

e of branch. Limit branch size.

ect jammed in the unit. Check and remove.

chipper blade. Replace blade.

ect jammed in the unit. Check and remove obstruction.

ine crankshaft is bent or damaged. See Engine Service Dealer.

bolts on unit. Tighten or replace bolts.

ed or broken chipper blades. Replace chipped or broken blades.

ark plug.Ins

.Chan

asoline. Drain gasoline and add fresh fuel.

. Fill gas tank.

ark plug wire is disconnected. Connect loose wire to spark plug.

ark plug is defective. Replace spark plug.

, stale, water-contaminated gas. Drain tank and fill with fresh gasoline.

lace drive belts, or increase spring tension

ect spark plug and replace if necessary.

e choke setting.

ine service dealer.

obstruction. Drain gas tank and refill with fresh,

asoline.

clean

en

ine several times to clear out excess gas.

Page 256” Chipper Pro Operator’s Manual

Page 32

Page 26 6” Chipper Operator’s Manual

Page 33

Page 276” Chipper Pro Operator’s Manual

Page 34

Manual Improvement Program

If you have a suggestion on how to improve this manual, send it to us. Participants whose ideas are

implemented will receive a free pair of Crary genuine leather gloves.

Send your suggestions to:

Crary Company

C/O Technical Writer

237 NW 12th St. Box 849

West Fargo, ND 78078

Suggestions:

Name:

Address:

Phone Number:

Email (if applicable):

Product purchased:

Manual part number:

Page 28 6” Chipper Operator’s Manual

Page 35

NOTES

Page 36

HEALTH WARNING

GASOLINE, DIESEL, AND

OTHER PETROLEUM PRODUCTS

Harmful or fatal if swallowed.

Long-term exposure to vapors has caused cancer in laboratory animals.

• Avoid prolonged breathing of vapors.

• Keep face away from nozzle and gas tank/container

opening.

• Never siphon by mouth.

Failure to use caution may cause serious injury or illness.

WARNING

CHEMICALS KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS, OR

OTHER REPRODUCTIVE HARM ARE FOUND IN

GASOLINE, DIESEL, CRUDE OIL, AND MANY OTHER

PETROLEUM PRODUCTS AND THEIR VAPORS, OR

RESULT FROM THEIR USE.

READ AND FOLLOW LABEL DIRECTIONS AND USE

CARE WHEN HANDLING OR USING ALL PETROLEUM

PRODUCTS.

ENGINE EXHAUST FROM THIS PRODUCT CONTAINS

CHEMICALS KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS, OR

OTHER REPRODUCTIVE HARM.

Crary Company

A Division of TerraMarc Industries

237 12th St. NW • P.O. Box 849

West Fargo, ND 58078-0849

(701)282-5520 • FAX: (701)282-9522

www.bearcatproducts.com

www.terramarc.com

Manufactured in the

United States of America

by Crary Company

Loading...

Loading...